Page 1

Technical Bulletin No. RTB-014

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 1 of 6

PREPARED BY: S. MANO

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

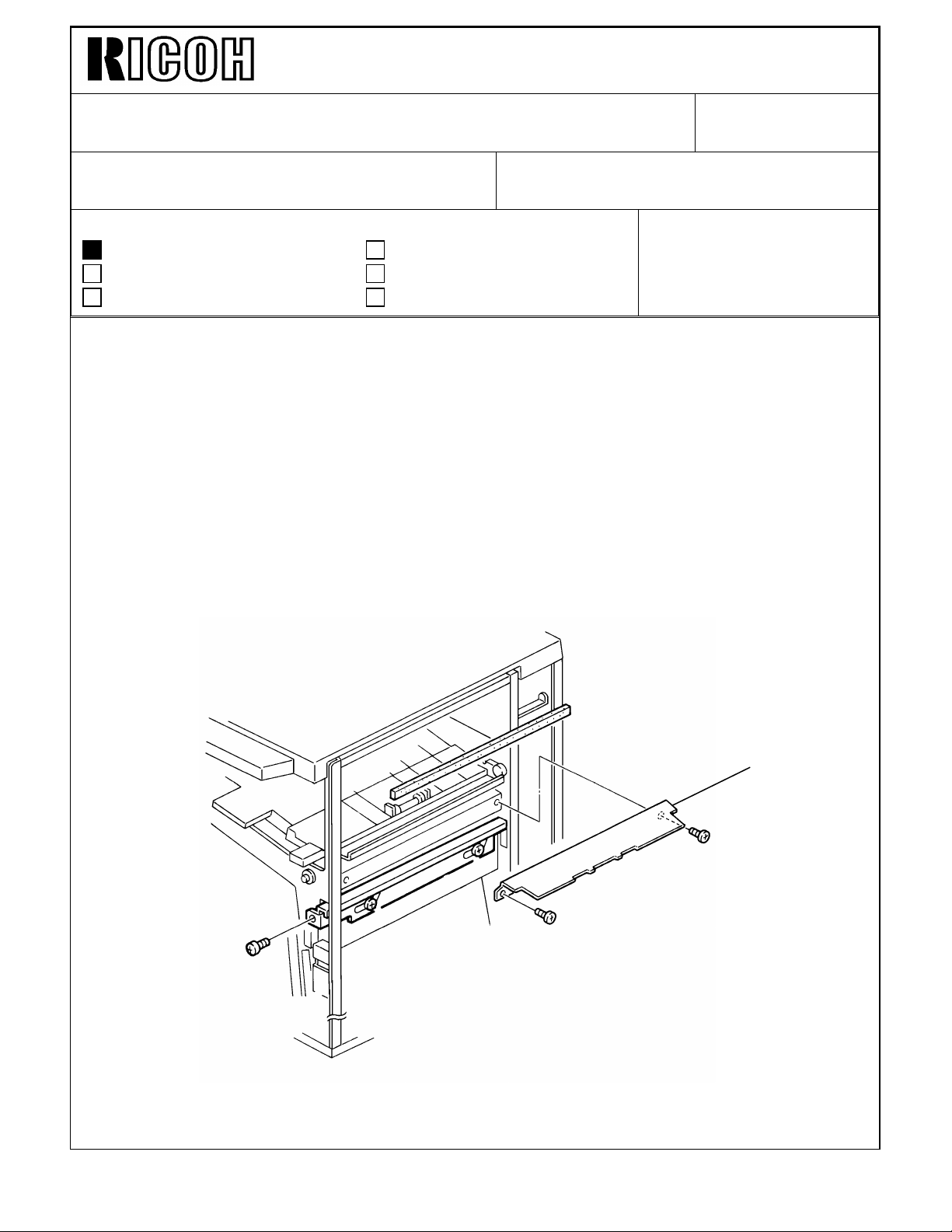

It has been reported that several sorter stapler (A377) entrance guide become deformed.

(This is introduced in F400/F410 RTB No.13, please refer to it for details)

Since the F400 finisher has the same type of guide plate, the entrance guide plate [A] is

separated from the finisher and kept in the accessory bag.

This is implemented from the first February 1994 production machine.

Whenever transporting the sorter stapler after taking out of the carton box, separate the

guide plate from the finisher. Reset it just before you dock the finisher to the copier.

The installation procedure (accessory) has also been modified. Please refer to the

following pages. Step #13 has been added. The other steps are the same as before.

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL:

F410 FINISHER

[A]

Page 2

Technical Bulletin No. RTB-014

[F]

[D]

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 2 of 6

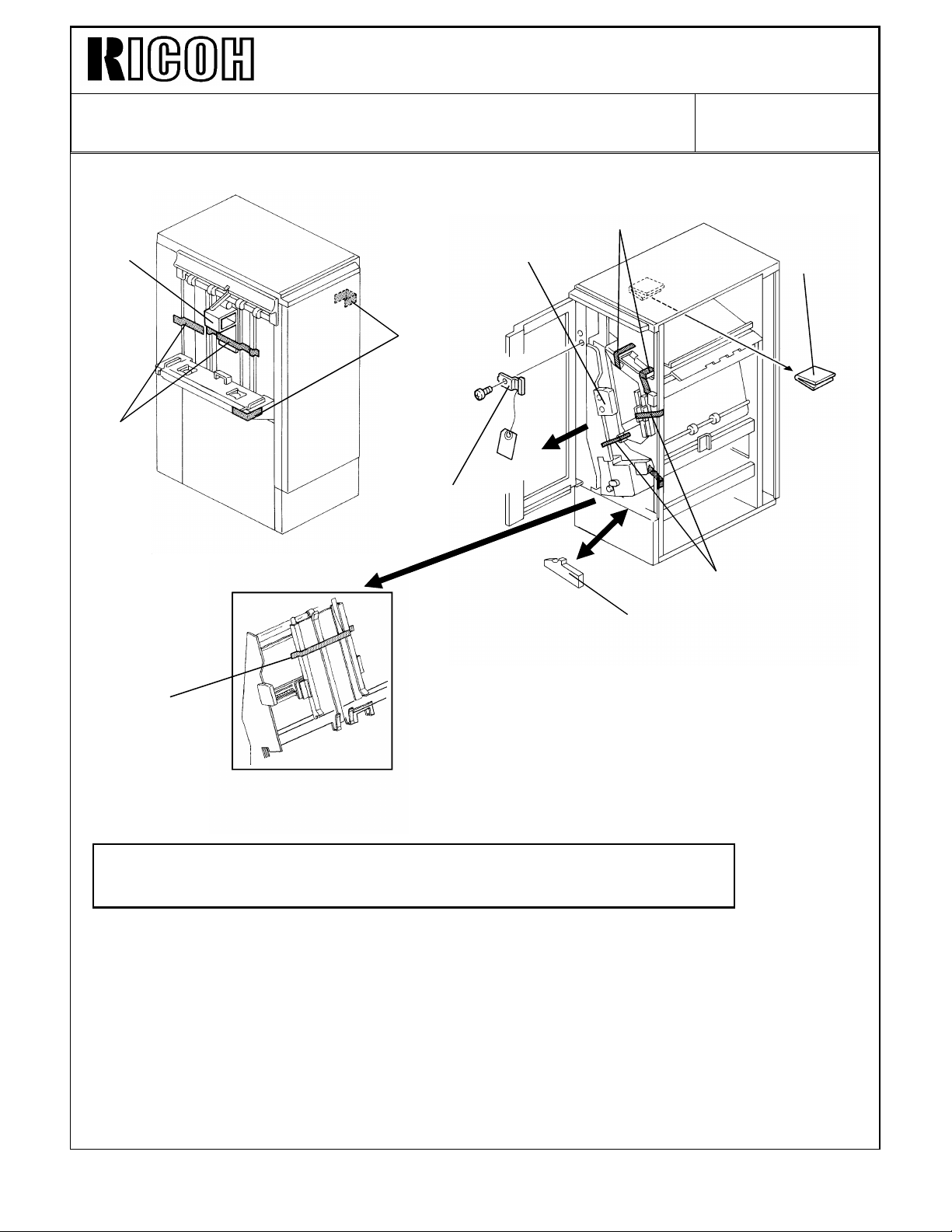

INSTALLATION PROCEDURE

[B]

[A]

[C]

[D]

[A]

[E]

[C]

[G]

CAUTION: Unplug the copier power cord before starting the following

procedure.

1. Remove the strips of tape [A] and the cushion [B].

2. Open the front door and remove the strips of tape [C] and cushions [D].

3. Remove a clamp [E] (1 screw).

4. Slide out the staple unit [F].

5. Remove a strip of tape [G].

Page 3

Technical Bulletin No. RTB-014

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 3 of 6

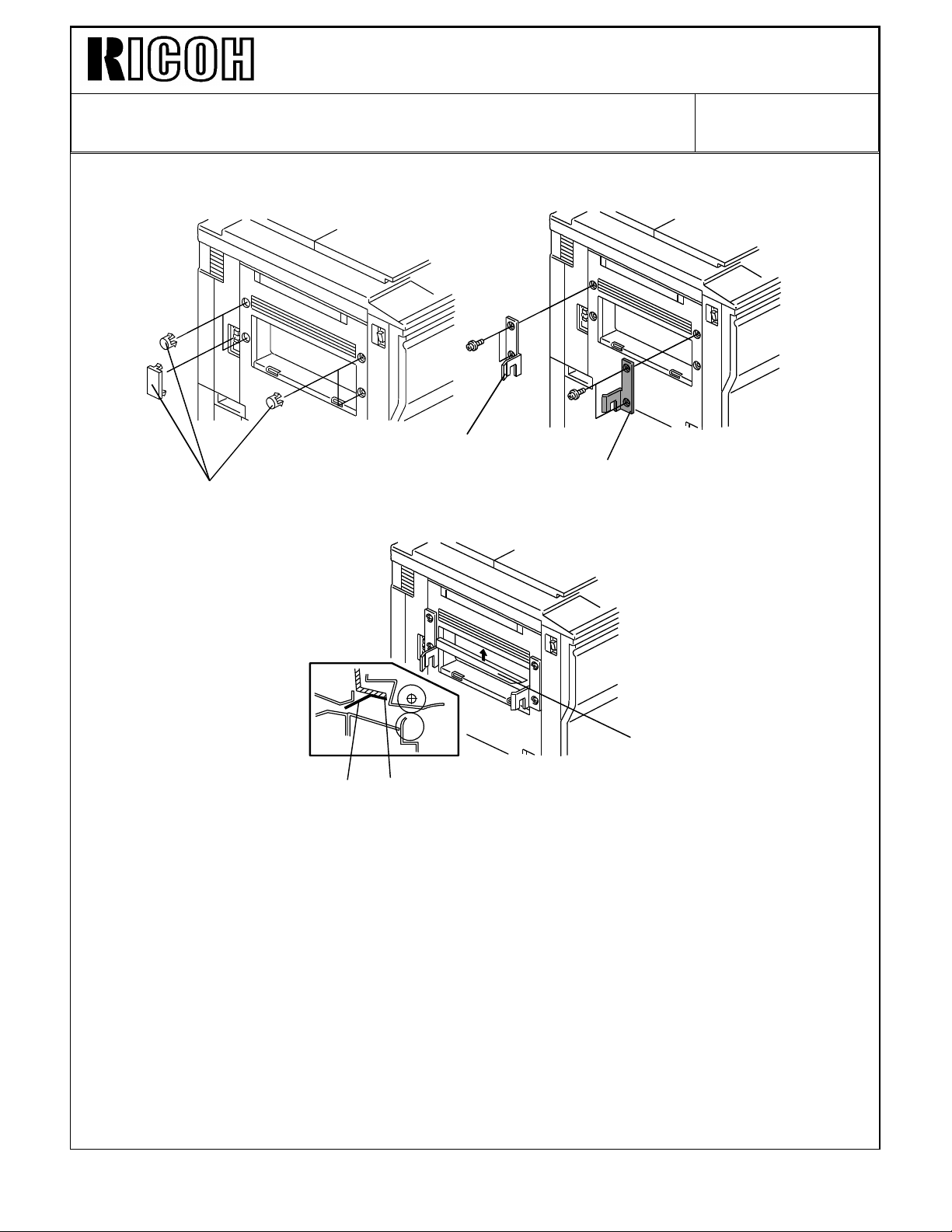

[C]

[B]

[A]

[D]

[E]

[D]

6. Remove five plastic caps [A] on the copier’s left cover.

7. Install the front connecting bracket [B] (2 screws– M4 x 12) and the rear connecting

bracket [C] (2 screws– M4 x 12) on the copier.

8. Stick the entrance guide mylar [D] on the copier exit area as shown.

NOTE: Align the edge [E] of the cover and the mylar.

Page 4

Technical Bulletin No. RTB-014

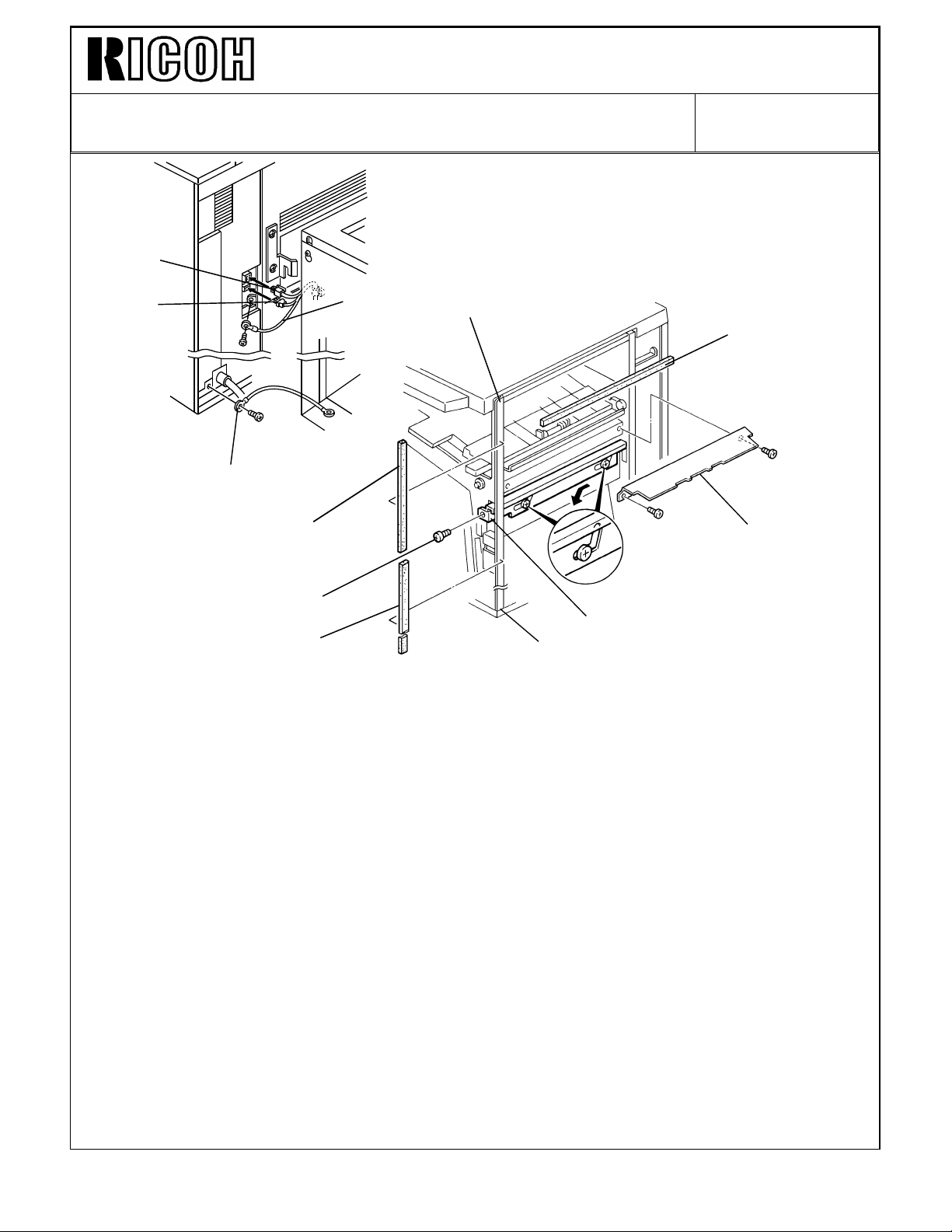

[F]

[K]

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 4 of 6

[C]

[I]

[A]

[J]

[G]

[L]

[D]

[B]

[H]

[E]

9. Secure the protective earth wire [A]* (1 screw with spring washer) and the wire [B] (1

screw with spring washer).

NOTE*: For all models other than those intended for North America, the green wire is

intended as a functional earth and should be connected as shown.

10. Connect the 4P connector [C] and the fiber optic connector [D].

11. Open the front door of the finisher and remove the screw [E] fixing the locking lever [F],

then lower the locking lever.

12. Stick the cushions [G] (middle) [H] (short) [I] (long) as shown.

NOTE: Stick the cushion [G] on the metal stay (not on the cover).

Align the upper edge of the cushion [H] with the edge of the stay [J].

Align the lower edge of the cushion [I] with the edge of the stay [K].

13. Install the entrance guide plate [L] (2 screws -M4 x 6).

Page 5

Technical Bulletin No. RTB-014

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 5 of 6

[D]

[E]

[G]

[C]

[B]

[A]

[F]

14. Align and press the finisher against the copier and fix them by raising the locking lever

[A].

NOTE: At this time, confirm that the myler [B] locates between the guides [C].

15. Secure the locking lever [A] (1 screw).

16. Install the shift tray [D] with 4 screws – M4 x 8.

(Remove tape [E].)

17. Adjust the height of the copier by using the leveling feet [F] so that the difference in

level [G] between the copier and the finisher will be 30 ± 1 mm.

Page 6

Technical Bulletin No. RTB-014

SUBJECT: FINISHER ENTRANCE GUIDE DATE:Jan. 31, ’93

PAGE: 6 of 6

[B]

[A]

18. Remove the green plastic clip [A] from the staple cartridge, and install the cartridge in

the stapler.

NOTE: When installing the staple cartridge. Make sure that all the staple sheets [B]

are in the initial position.

19. Plug in the copier.

20. Turn on the main switch of the copier and test the operation of the finisher.

NOTE: The copier recognizes automatically that the finisher is installed.

The stapler will not staple for the first 10 or so copies until the first staple

comes to the proper position.

Page 7

Page 1 of Finisher

[A]

• Incorrect

Paper size Minimum: 5 1/2" x 8 1/2" / A5 sideways

Weight: 34.2 kg (75.4lb )

• Correct

Paper size Minimum: 5 1/2" x 8 1/2" / A6 lengthwise

Weight: 35 kg (77.2lb)

Page 8

Technical Bulletin No. RTB-017

SUBJECT: MANUAL CORRECTIONS DATE: Jan. 31,’94

PAGE: 13 of 13

Page 2 of Finisher Staple position (2 staple)

• Incorrect

b=5.20" ± 0.12" (13.2 ± 3 mm)

• Correct

b=5.20" ± 0.8" (132 ± 2 mm)

Page 25 of Finisher Step #6

• Incorrect

6. Remove the rear cover [G] (5 screws).

• Correct

6. Remove the rear cover [G] (6 screws).

Page 29 of Finisher Illustration

• Incorrect

Page 29 of Finisher Standard of item #1

[C]

[D]

• Correct

[C]

• Incorrect

Standard: 6mm deflection at 50 ± 20g pressure

• Correct

Standard: 6mm deflection at 180 ± 100g pressure

Page 9

Technical Bulletin No. RTB-027

SUBJECT: SC733 DATE:Mar. 15 ’94

PAGE: 1 of 3

PREPARED BY: S. MANO

CHECKED BY: S. Hamano

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Revision of service manual

Information only

Other

FROM: 2nd Technical Support Section

MODEL: Finisher for F410

< POSSIBLE CAUSE - 1>

If the paper level actuator [A] is out of the position (See the illustration on page 2 of 3), the

machine may sense that the shift tray [B] has not arrived at the proper level even though

the shift tray [B] is at the maximum position (the stack height sensor 2 [C] is not actuated).

The fail safe mechanism (there is a safety switch [D] to detect the shift tray overrun

condition) stops the shift tray lift motor from trying to raise the shift tray any more.

[E]

[C]

[A]

[B]

[D]

Under this condition, the machine indicates the "R2" jam indication. If the front door of the

finisher is opened and closed and if the paper level actuator is still out of position, the

machine indicates SC733.

Page 10

Technical Bulletin No. RTB-027

SUBJECT: SC733 DATE: Mar. 15 ’94

PAGE: 2 of 3

The paper level actuator may be out of the position under the following situation:

1) The customer places something (for example, book, copies, etc.) [A] on the shift tray, it

pushes the actuator out of the position.

[A]

2) When the copy sets are delivered on the shift tray, the customer removes the copies. If

the operator reaches for the copies from just in front of the operation panel the operator

will not be able to see the actuator. It is possible for the operator to push the actuator

out of position when removing the copies.

< countermeasure>

1. Instruct the customer to return the actuator to the correct position (so that the actuator

becomes straight) and turn off then on the main switch.

2. The shift tray level actuator shape has been changed so that it cannot be bent easily.

This modification will be implemented from April 1994 production.

We will issue a Modification Bulletin as soon as the cut-in serial number becomes available.

Page 11

Technical Bulletin No. RTB-027

SUBJECT: SC733 DATE: Mar. 15 ’94

PAGE: 3 of 3

< POSSIBLE CAUSE - 2>

If there is obstacle (for example, desk, chair, dust box etc.) below the shift tray and it

prevents the shift tray from being lowered. The stack height sensor-1 [E] (See the

illustration in page 1 of 3) cannot be actuated. In this case, SC733 occurs.

< countermeasure>

Instruct the customer to remove the obstacle below the shift tray and then turn off then on

the main switch.

Page 12

Technical Bulletin No. RTB- 046

SUBJECT: SOFTWARE MODIFICATION DATE: Dec. 31, ’94

PAGE: 3 of 7

2. "B" version ROMs

From the following serial numbers, the EPROMs (A0965151A and A0965153A) on the

main board have been updated to version "B".

NOTE: We will re-issue this RTB as soon as the cut-in serial number becomes

available.

Code Serial Number

A095-10 5204

A095-15 264

A095-17 A3354

A095-22 5234

A095-26 3D5

A095-27 A3354

A095-29 A3354

A096-10 5244

A096-15 284

A096-17 A3364

A096-22 5274

A096-26 3D6

A096-27 A3364

A096-29 A3364

A097-10

A097-15

A097-17

A097-22

A097-26

A097-27

A097-29

Caution: Whenever replacing from the old main ROMs to the new version ROMs in

the field, this modification is necessary.

The following are corrected by this software change:

2-1. Machine enters the screen saver mode during auto counting

If the time to enter the screen saver mode (this time can be changed by using User tools)

comes during the auto count mode, the machine enters the screen saver mode. After

counting all originals, the machine indicates the original jam condition.

Page 13

Technical Bulletin No. RTB- 046

SUBJECT:SOFTWARE MODIFICATION DATE: Dec. 31, ’94

PAGE: 4 of 7

2-2. Operating time indication is incorrect

During operation, the time remaining before the end of the copy job is indicated by

animation on the touch panel screen.

During the duplex mode by using RDH and Finisher, the indicated time was incorrect.

<Countermeasure>

For the single side original to duplex copy mode, it is impossible to calculate the time due

to a highly complex operation using the alternate feed system. Therefore, in this mode,

the operating time is not indicated.

For the duplex original to duplex copy mode, the accuracy of the indicated operation time

has been improved.

2-3. RDH and Finisher, copy set limitation (maximum: 50 sets)

When using the RDH and Finisher, the selectable copy set for sort mode should be "999"

(In the sort mode, due to the alternate feed operation, the paper stocked in the duplex tray

is always less than 50 sheets). However, it was limited to 50. If a larger number was

entered, it was canceled and "50" was displayed.

2-4. RDH and Finisher, Copier misfeed caused by the original misfeed

When an original exit jam occurs in the RDH, it should not cause a copier misfeed (the

copier should exit all sheets in the copier then stop) but actually a misfeed also occurs in

the copier. This symptom occurs depending on the copy tray selected and the size of the

copy paper. (The combination of the longer paper path and shorter paper length tends to

create this symptom.)

Loading...

Loading...