Page 1

FINISHER

(Machine Code:A379)

Page 2

23 April 1993 OVERALL MACHINE INFORMATION

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size: Maximum: 11" x 17"/A3

Minimum: 51/2" x 81/2"/A5 sideways

Paper Weight: Standard copying/Stack mode

14 ~ 42 lb/52 ~ 157 g/m

Staple mode

17 ~ 20 lb/64 ~ 80 g/ m

Paper Capacity: 1,500 sheets:

81/2" x 11"/A4 or smaller size (20 lb/80 g/m2)

1,000 sheets:

81/2" x 14"/B4 or larger size (20 lb/80 g/m2)

Stapler Capacity: 81/2" x 11"/A4 or smaller size (20 lb/80 g/m2):

from 2 to 50 sheets

81/2" x 14"/B4 or large size (20 lb/80 g/m2):

from 2 to 30 sheets

2

2

Staple Replenishmen t: Cartridge exchange (5,00 0 pie ces/ cartridge)

Power Source: DC 24 V (from copier)

Power Consumption: 44.4 W (average)

Weight: 34.2 kg (75.4 lb)

Finisher

1

Page 3

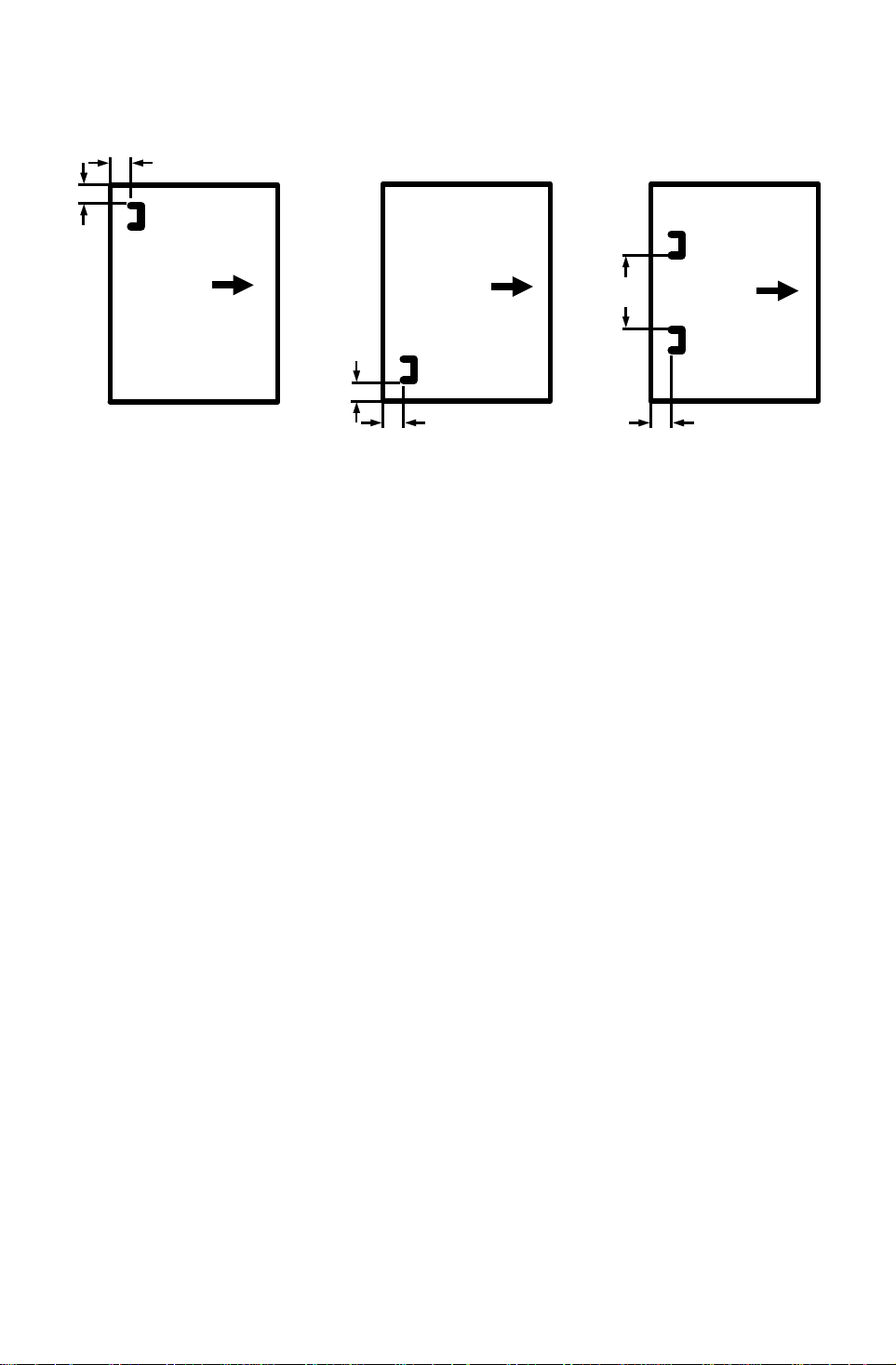

b

(2 staples)

OVERALL MACHINE INFORMATION 23 April 1993

Stapling Position:

(1 staple)

a

b

b

aa

a = 0.24" ± 0.12" (6 ± 3 mm)

b = 0.24" ± 0.12" (6 ± 3 mm)

a = 0.24" ± 0.12" (6 ± 3 mm)

b = 0.24" ± 0.12" (6 ± 3 mm)

a = 0.24" ± 0.12" (6 ± 3 mm)

b = 5.20" ± 0.12" (13.2 ± 3 mm)

Dimensions: 26.4" x 20.2" x 37.4"

(671 mm x 514 mm x 950 mm)

Weight: 75.2 lb/34.2 kg

2

Page 4

12

23 April 1993 OVERALL MACHINE INFORMATION

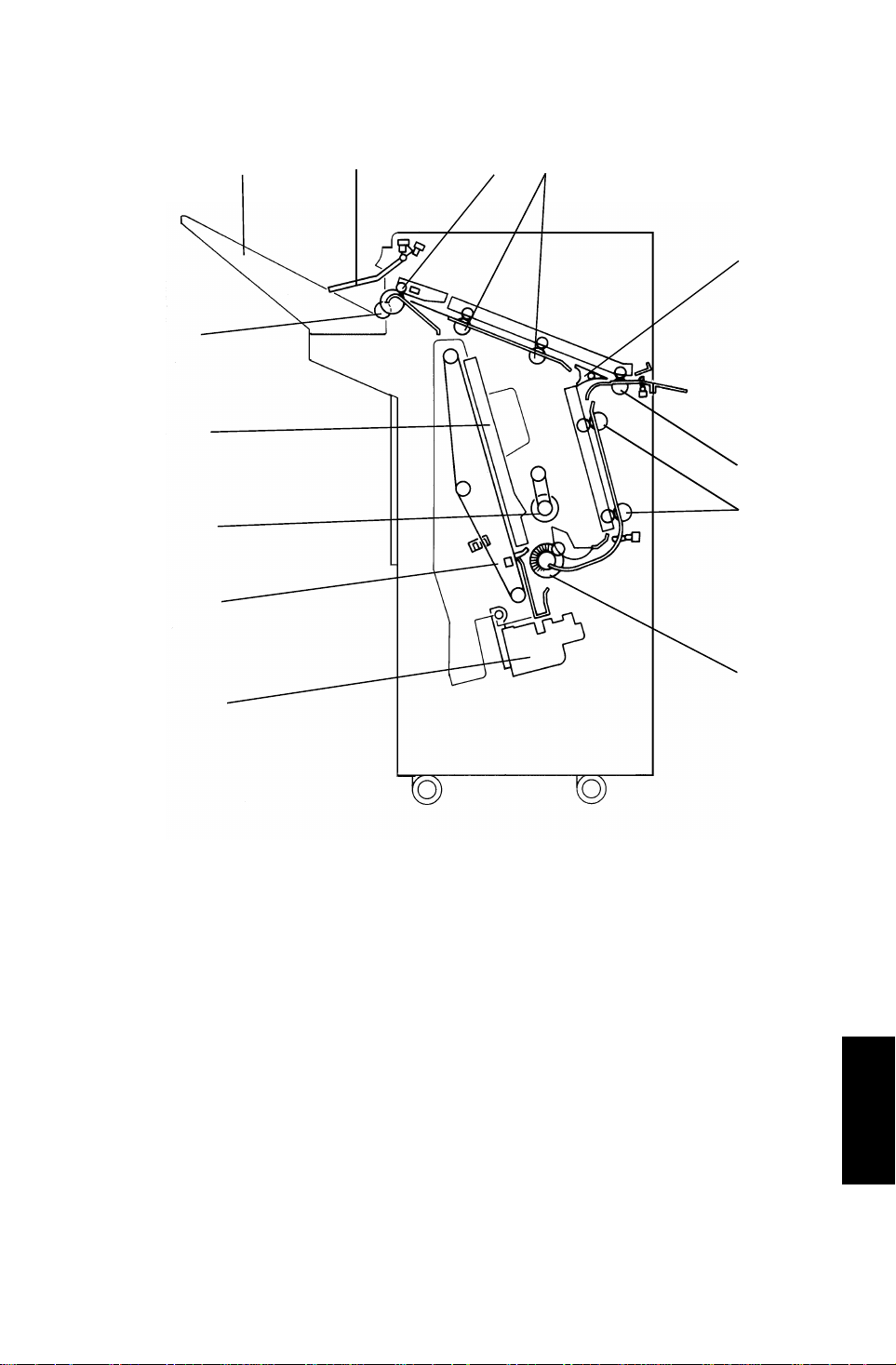

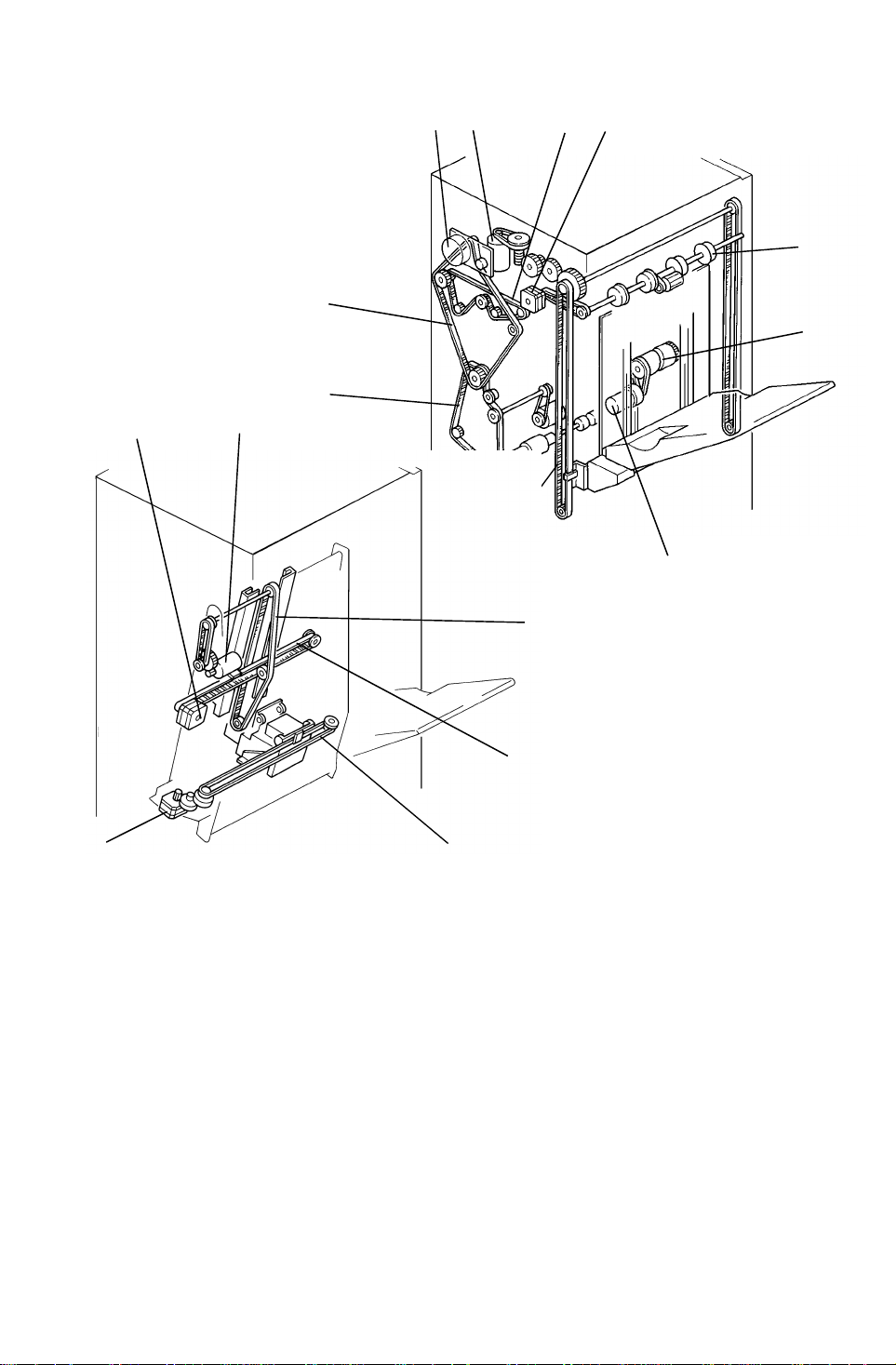

1.2 MECHANICAL COMPONENT LAYOUT

2

1

13

11

3

4

10

9

5

6

8

7

1. Stack Height Sensor Feeler

2. Shift Tray

3. Shift Tray Positioning Roller

4. Jogger Unit

5. Positioning Roller

6. Stack Feed-out Belt

7. Stapler Unit

8. Alignment Brush Roller

9. Lower Transport Rollers

10. Entrance Rollers

11. Junction Gate

12. Upper Transport Rollers

13. Exit Rollers

Finisher

3

Page 5

OVERALL MACHINE INFORMATION 23 April 1993

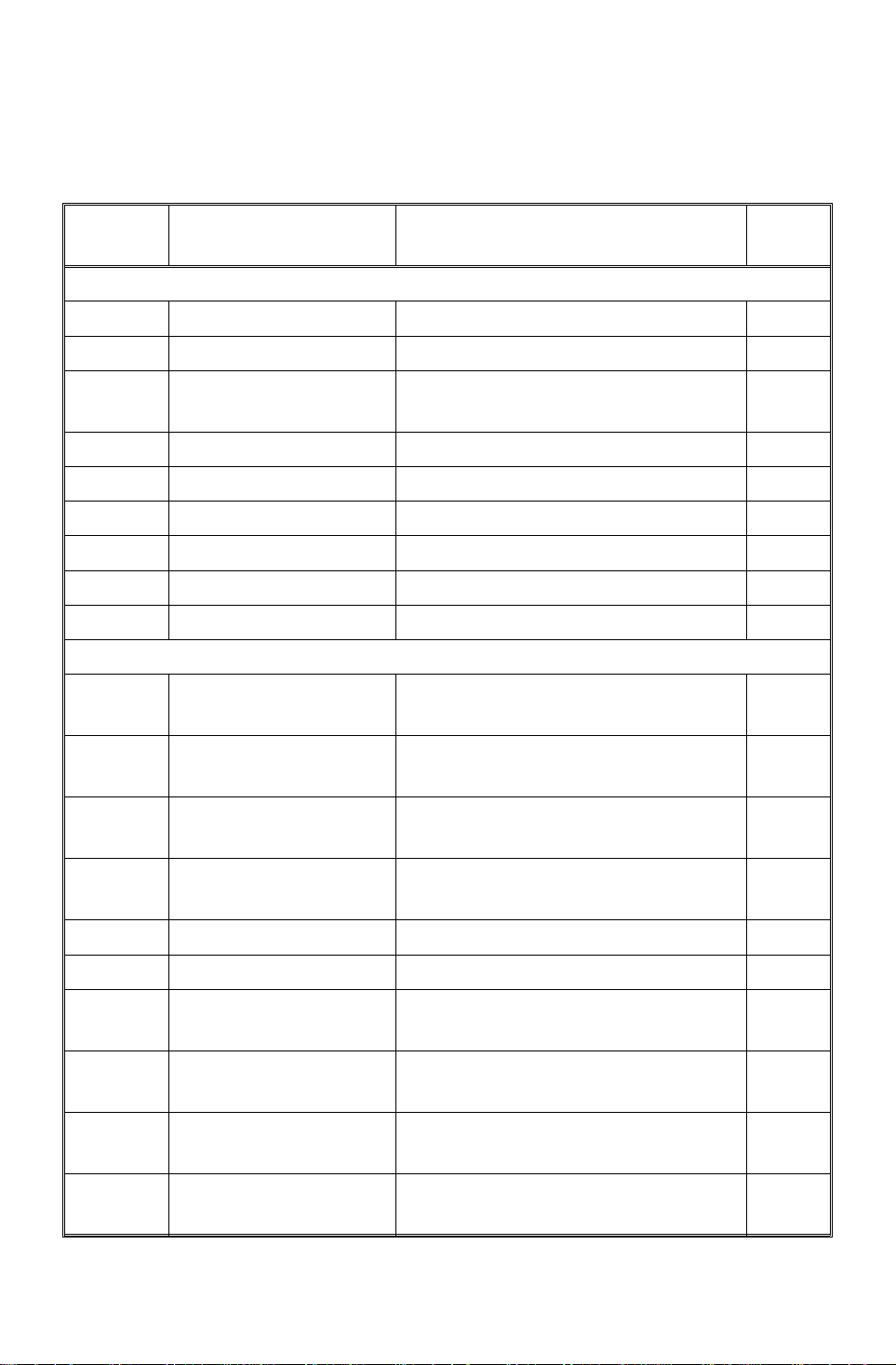

1.3 ELECTRICAL COMPONE NT DES CRI PTI O N

Refer to the electrical compone nt layou t on the reverse side of the Poin t to

Point (water proof paper) ind ex nu mbe rs.

Symbol Name Function

Motors

M1 Transport Drive Drives transport rollers. 23

M2 Shift Tray Lift Moves the shift tray up or down. 24

M3 Exit Drive Drives the exit and shif t tra y

positioning rollers.

M4 Stack Feed-out Drives the stack feed-out belt. 5

M5 Jogger Moves the jogger fen ces. 17

M6 Stapler Drive Moves the stapler unit . 14

M7 Shift Moves the shift tray side to side. 8

M8 Staple Drives the staple hammer. 12

Sensors

S1 Entrance Detects copy pap er entering into

the finisher.

S2 Jogger Unit Entrance Detects copy paper ente ring into

the jogger unit.

Index

No.

22

25

18

S3 Jogger Unit Paper Detects copy paper in the jogger

unit.

S4 Stack Feed-out BeltHPDetects the home positio n of the

stack feed-out belt.

S5 Jogger HP Detects the jogger home position. 16

S6 Exit Detects misfeeds in exit area. 3

S7 Stack Height 1 Detects copy pap er sta ck height

in staple mode.

S8 Stack Height 2 Detects copy pap er sta ck height

in sort/stack mode.

S9 Shift Tray Lower Limit Detects the lower limit of the shift

tray position.

S10 Stapler Hammer HP Detects the staple hammer home

position.

4

6

15

2

1

13

11

Page 6

23 April 1993 OVERALL MACHINE INFORMATION

Symbol Name Function

S11 Shift Tray Half-Turn Detects shift tray side-to-side

position.

S12 Stapler Unit HP Detects the stapler unit home

position.

S13 Staple End Detects staples in the cartrid ge 10

Switches

SW1 Front Door Safety

(Switch)

SW2 Shift Tray Upper

Limit (Switch)

Cuts dc power when the front

door is opened.

Detects the upper limit of the shift

tray position.

Solenoids

SOL1 Positioning Roller Lowers the positioning roller in

the jogger unit.

SOL2 Junction Gate Drives the junction gate. 21

Index

No.

7

9

26

4

19

PCBs

PCB1 Main Control Controls overall finisher o peration. 20

Finisher

5

Page 7

142

OVERALL MACHINE INFORMATION 23 April 1993

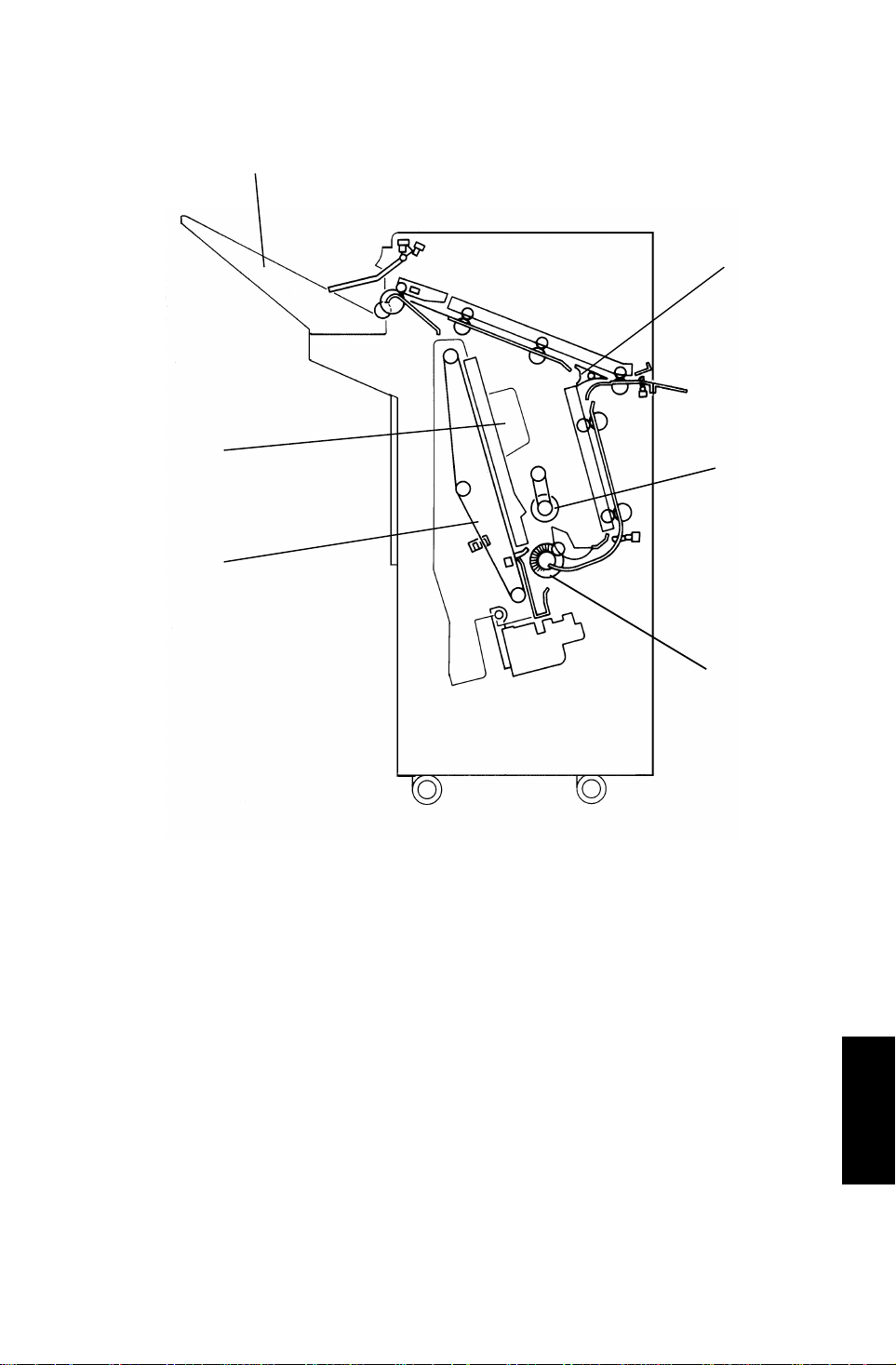

1.4 DRIVE LAYOUT

5

6

12

11

3

10

9

87

16

13

1. Exit Drive Motor

2. Upper Transport Drive Belt

3. Shift Tray Lift Motor

4. Transport Drive Motor

5. Transport Drive Belt

6. Lower Transport Drive Motor

7. Shift Tray Lift Belt

8. Shift Motor

15

14

9. Shift Cam

10. Exit Roller

11. Stack Feed-out Motor

12. Jogger Motor

13. Stapler Drive Motor

14. Stapler Drive Belt

15. Jogger Drive Belt

16. Stack Feed-out Belt

6

Page 8

23 April 1993 OVERALL MACHINE INFORMATION

1.5 BASIC OPERATI ON

[B]

[A]

[F]

[D]

[C]

[E]

After the copy is complet ed , the paper is directed to the finisher. If the

sort/stack mode is selecte d, the junction gate [A] directs the paper upwards

to transport it to the shif t tra y [B] . In the se mod es, the shift tray is shifted from

side to side to stagger a nd sepa rat e set s of copies. The amount of shift is

approximately 30 mm.

When the staple mode is selected, the junctio n gate direct s the paper below

to transport the paper to the jo gger un it [C] . Ea ch time a copy is delivered to

the jogger unit, the position ing ro ller [D] , th e alignment brush roller [E], and

the jogger fences [F] square the stack of copies. Af ter the final copy of the set

is squared, the set is stapled, and then delivered to th e shift tray.

7

Finisher

Page 9

SECTIONAL DESCRIPTIONS 23 April 1993

2. SECTIONAL DESCRIPTIONS

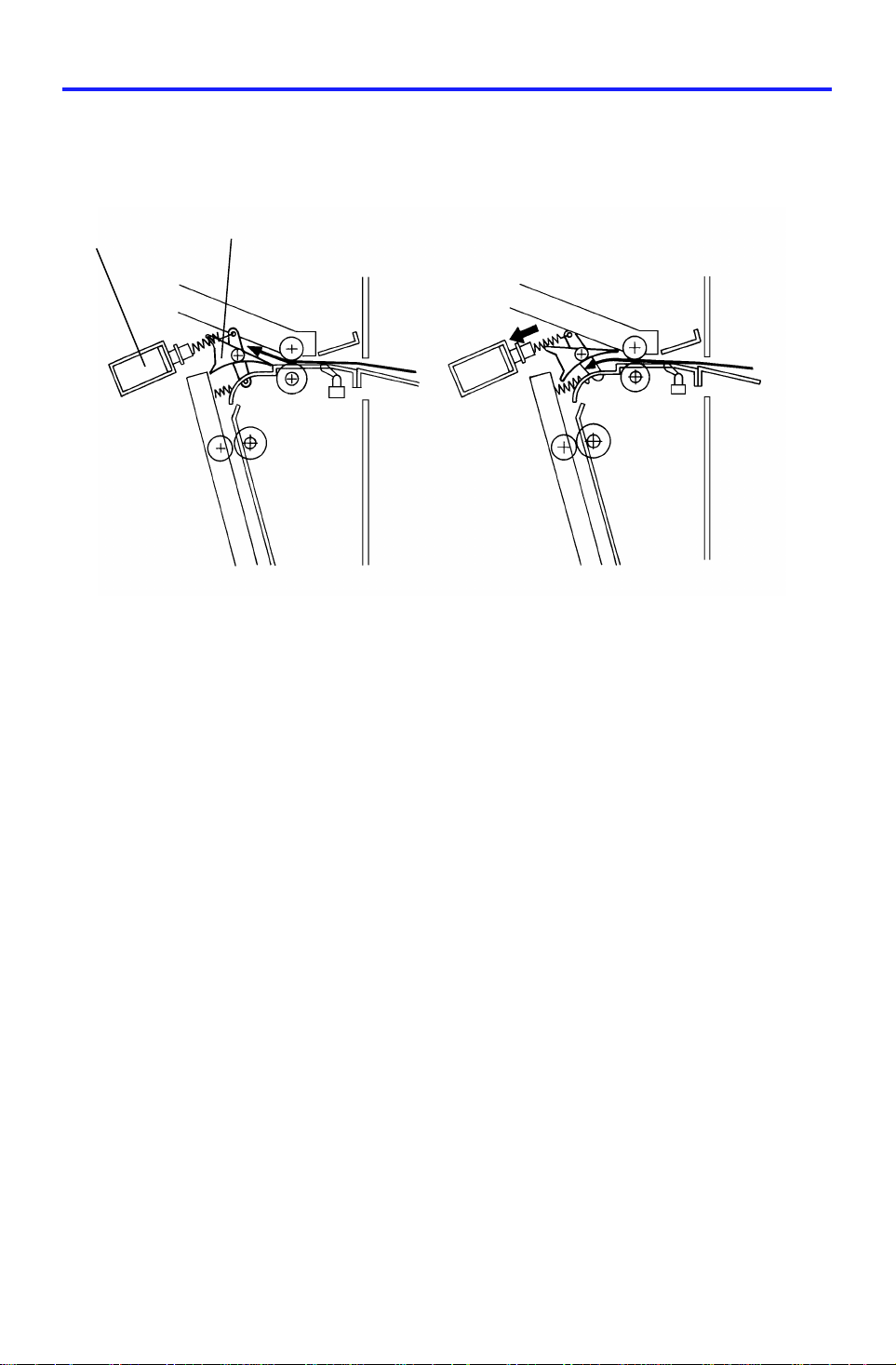

2.1 PAPER DELIVE RY S WI TCHI NG

[B]

[A]

Depending on the sele cte d finishing mode, the copie s are directed up or

down by the junction gate [A], is controlled by a solenoid.

(1) When the exit sensor of the copie r is activat ed while in staple mode, the

solenoid [B] is energ ized . Then, the junction gate dire cts the copies down

to transport them to the jogger unit.

(2) When the exit sensor of the copie r is activat ed while in the sort/stack

mode, the solenoid sta ys o ff . The ju nct ion gate directs the copies up to

deliver them to the shift tra y.

8

Page 10

[D]

[B]

23 April 1993 SECTIONAL DESCRIPTIONS

2.2 SHIFT TRAY UP/DOWN MECHANI S M

[H]

[I]

[E]

[F]

[A]

[J]

[C]

[G]

The vertical position of the shift tray [A] is controlle d by the shif t tra y lif t mot or

(dc motor) [B] through gears and timing belts [C]. Whe n the main switch is

turned on, the tray position is initialized to the upper posit ion . The tray’s

uppermost position is detected when the shift tray pushes up the actuator [D]

to deactuate the stack he ight sensor 1 [E].

While copying, the actua to r [ D] is grad ua lly raised as the copy stack grows. In

the sort/stack mode, when stack height sensor 2 [F ] rema ins actuated for 4

seconds, the shift tray lift moto r [B] rota te s, lowering the tray unit for 50 ms.

In staple mode, when the stack height sensor 1 re main s dea ctuated for 4

seconds, the motor rotate s, lowering the tray until the sensor [E] is actu at ed .

When the tray reaches its lower limit position, the lower limit sen sor [G] is

actuated by the actuator [H], and copy operation stops.

After the copy proce ss is finished and the machine stop s, th e tray is raised to

its upper most position 4 seconds after the copies are removed.

A mechanical safety switch [I] is inst alle d to preve nt the drive gears from

being damaged if the sensor doe s not work. Whe n th e shift tray pushes up

the shift tray positioning roller [J], the shift tray lift motor stops.

Finisher

9

Page 11

SECTIONAL DESCRIPTIONS 23 April 1993

2.3 SHIFT TRAY SIDE-TO -SIDE SHIFT MECHANISM

[B][C]

[A]

[E]

[D]

[F]

[G]

[H]

In the sort/stack mode, the shift tray [A] moves from side to side to stagger

and separate sets of copies.

The horizontal position of th e shif t tray is controlled by the shift motor (d c

motor) [B] and the shift cam (helical cam) [C]. After one set of originals is

copied and delivered to the shift tray, the shift moto r [B] start s rota tin g, driving

the shift cam through the timing belt. The pin [D] fixed to the shift tray base

plate [E] is position ed in the groo ve on the shift cam, creating the side-to -side

movement required to sta gger copies.

When the shift cam rotates 180 degrees (when the tray is fully shifted.), the

plate [F] on the shift cam pushes the actu at or [G] of the shift tray half-turn

sensor [H] and the shift motor sto ps. The next set of copies is then delivered.

The motor rotates rep ea tin g the same process and moving the tray ba ck to

the previous position.

10

Page 12

[F]

23 April 1993 SECTIONAL DESCRIPTIONS

2.4 STAPLE UNIT PAPE R PO SITI ONING

[C]

[B]

[F]

[E]

[A]

[H]

[G]

[C]

[D]

In the staple mode, copies are vertica lly a nd horizo nt ally alig ne d in the jog ge r

unit before being stapled.

For horizontal paper alignment, the jogger mot or [A ] moves both the front and

the rear jogger fences [B ] to align the copies.

For vertical paper alignment, the positio nin g rolle r [C] and the alig nme nt

brush roller [D] push the copy again st th e stack stopper [E].

After the trailing edge of the copy pa sses th e jogge r unit entrance sensor [F],

the positioning roller sole noid [G] is energized for 280 ms pushing th e

positioning roller into con ta ct with the paper. The po sitio nin g rolle r ro tate s to

push the paper back and align the trailin g edge of the pape r against the stack

stopper. Both the position ing roller and the alignment brush roller are driven

by the transport drive motor through the timin g belt [H] .

11

Finisher

Page 13

SECTIONAL DESCRIPTIONS 23 April 1993

2.5 JOGGER MOVEMENT

7 mm 2 mm

[A] [B]

(2)(1) (3)

When the Start key is pressed, the copier sends the paper size information to

the finisher. In accordance wit h th at data, the jogger motor (stepper mot or)

starts rotating to position the front and rear jogg er fe nces [A] 7 mm away from

the selected paper’s edges. (1)

After the trailing edge of the copy pa sses th e jogge r unit entrance sensor,

each jogger fence moves inwa rd 5 mm. The y st op 3 mm away from the paper

edges. (2)

Just after the positioning ro ller pushes the copy back, each jogger fence

moves inward 2 mm more so that the leaf spring [B] on the rear jogg er fe nce

pushes the copy side edge slightly.

After a copy is stacked in the jogg er tray, the jogger fences move back 7 m m

from the copy edge for the next copy.

12

Page 14

[C]

[G]

23 April 1993 SECTIONAL DESCRIPTIONS

2.6 STAPLER

[B]

[E]

[A]

[F]

[D]

The staple hammer [A] is driven by the staple motor [B] via gea rs [C], two

eccentric cams [D], and two links [E] .

When the aligned copies are brought to the staple position by the positioning

roller, alignment brush rolle r, an d jog ge r fen ces, the stapler motor starts

rotating. When the cams complete one rotation, the stapler home position

sensor [F] turns on detecting the end of the staple ope rat ion. The stapler

motor then stops.

There is a reflecting pho to sen sor [G] in the staple unit to detect the staple

end condition.

Finisher

13

Page 15

SECTIONAL DESCRIPTIONS 23 April 1993

2.7 STAPLER UNIT SIDE- TO-SIDE MOVEMENT

[A]

[B]

[C]

Customers can select one of the followin g th ree diff ere nt stap le mod es:

Staple 1: Top left

Staple 2: Bottom left

Staple 3: Top/Bottom left

The stapler drive motor [A ] (ste pp er mot or) move s the stap ler unit [B] from

side to side. When the Start key is pressed, the stapler moves from its home

position to the staple position.

If staple mode 3 is selected, the stap ler un it move s to th e fro nt stap le po sitio n

first, then moves to the rear stap le po sitio n. Howeve r, for the next copy set, it

staples in the reverse order; that is, at the rear side first and th en at th e front.

After the job is complet ed , the stapler unit moves back to its ho me position.

(The stapler unit home position sensor [C] is actuated.)

14

Page 16

23 April 1993 SECTIONAL DESCRIPTIONS

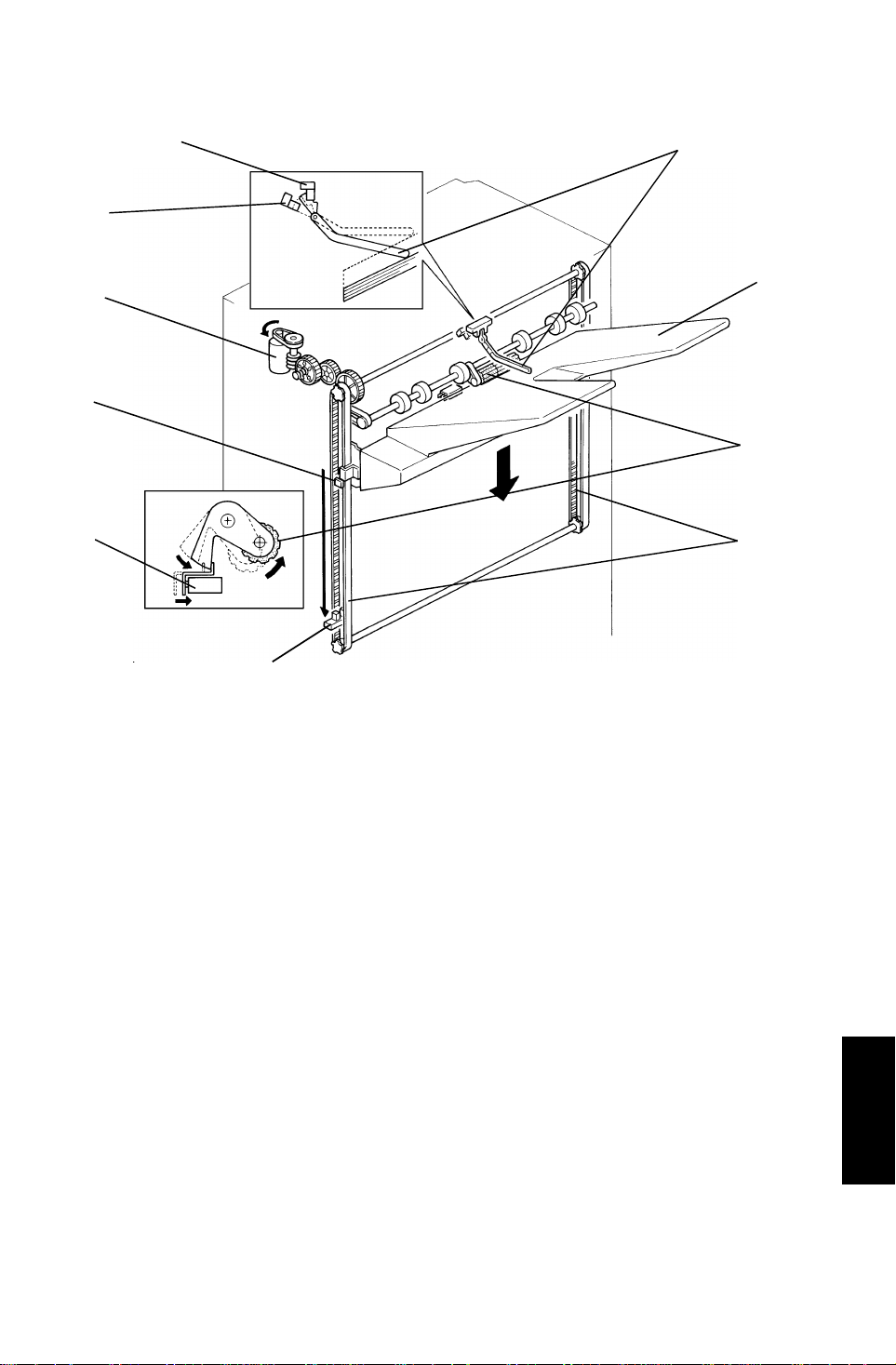

2.8 FEED-OUT TO SHI FT TRAY

[E]

[A]

[B]

[D]

[C]

[B]

After being stapled, the stack feed-out motor [A] starts rotating. The pawl [B]

on the lift belt [C] transports the set of st apled copies up, and feeds it to the

shift tray. Approximate ly 0.6 secon d after the stack feed-out mot or sta rts, the

motor stops for 400 ms. At this moment , th e exit ro llers cat ch th e sta ple d

copies to feed them out to th e shift tray. Then the motor rot ates again until

the pawl actuates its home position sensor [D].

The exit drive motor starts rotating to drive the exit rolle rs [E] when the first

copy activates the entrance sensor. The exit drive motor speed is reduced

just before each copy paper is comple tely fed out. This is to ensure an even

copy stack.

Finisher

15

Page 17

INSTALLATION 23 April 1993

3. INSTALLATION

3.1 ACCESSORY CHECK

Check the accessories in the box acco rdin g to the following list.

Description Q’ty

1. Installation Procedure.............................................................1

2. Front Connecting Bracket.......................................................1

3. Rear Connectin g Bracket .................... .. .......... .. .......... .. .........1

4. Staple Cartridge......................................................................1

5. Entrance Gu ide.............. .. .......... .. .......... .. .......... .. ...................1

6. Shift Tray ................................................................................1

7. NECR (for -17 machine only).................................................1

8. Cushion – 5 x 10 x 345............ .................... .. .......... .. .......... .. .1

9. Cushion – 5 x 10 x 125............ .................... .. .......... .. .......... .. .1

10. Cushion – 5 x 10 x 637............ .. .......... .. .................... .. .......... .1

11. Philips Truss Head Screw – M4 x 8 ............ .. .... .... .. .... .. .... .... .4

12. Philips Pan Head Screw – M4 x 12............... .. .. .... .. .. .. .. .. .. .... .4

13. Philips Screw with Flat Washer – M4 x 8...................... .... .. .. .2

14. Envelope – NECR (for -17 mach ine only)........... .. .............. .. .1

16

Page 18

[C]

[C]

23 April 1993 INSTALLATION

3.2 INSTALLATION PROCEDURE

[B]

[A]

[G]

[E]

[A]

[F]

[D]

[D]

CAUTION: Unplug the copier power cord before starti ng the follow ing

procedure.

1. Remove the strips of tap e [A ] an d th e cushion [B].

2. Open the front doo r and remove the strips of tape [C] and cushio ns [D].

3. Remove the clamp [E] (1 screw).

4. Slide out the staple unit [F] .

5. Remove the strip of tape [G].

17

Finisher

Page 19

INSTALLATION 23 April 1993

[C]

[B]

[A]

[D]

[D] [E]

6. Remove five plastic caps [A] on th e cop ier’s left cover.

7. Install the fro nt conn ecting bracket [B] (2 screws– M4 x 12) and the rear

connecting bracket [C] (2 screws– M4 x 12) on the copier.

8. Stick the entrance guide mylar [D] on the cop ier exit area as shown .

NOTE: Align the edge [E] of the cover and the mylar.

18

Page 20

[F]

23 April 1993 INSTALLATION

[J]

[G]

[C]

[D]

[M]

[A]

[B]

[H]

[E]

[I]

[M]

[K]

[L]

9. Secure the pro te ctive earth wire [A]* (1 screw with sprin g washer) and the

wire [B] (1 screw with spring washer).

*NOTE:For all models other than those intended for North America, the

green wire is meant to be used as a functional earth and should

be connected as shown.

10. Connect the fiber optics connector [C] and the 4P connector [D].

11. Open the front door of the finisher and remove the screw [E] fixing the

locking lever [F], then lower th e locking lever.

12. Stick the cushions [G] (mid dle ), [H] (short), [I] (long) as shown.

NOTE: Stick the cushion [G] on the metal stay (not on the co ver).

Align the upper edg e of the cu shio n [H] with the edge of the

stay [J].

Align the lower edge of the cushion [I] with the edge of the

stay [K].

13. Align and press the finisher against the copier and fix them by raising the

locking lever [F].

NOTE: At this time, confirm that the mylar [L] is located betwe en the

guides [M].

14. Secure the locking leve r (1 screw).

19

Finisher

Page 21

INSTALLATION 23 April 1993

[A]

[D]

[B]

[C]

15. Install the shift tra y [A] with 4 screws – M4 x 8 (re move tape [B ]).

16. Adjust the heigh t of the copier by using the leveling foot [C] so that the

difference in level betwe en the copie r [ D] and the finisher will be

30 ± 1 mm.

20

Page 22

23 April 1993 INSTALLATION

[B]

[A]

17. Remove the green plastic clip [A ] fro m t he st aple cartridge, and install the

cartridge in the stapler.

NOTE: When installing the staple cartridge, make su re th at all the staple

sheets [B] are in the init ial po sitio n.

18. Plug in the copier.

19. Turn on the main switch of the copier and test th e operation of the finisher.

NOTE: The copier recognizes automatically that the finisher is installed.

The stapler will not be stapling for the first 10 or so copies until

the first staple comes to th e pro pe r position from the cartridge.

21

Finisher

Page 23

SERVICE TABLES 23 April 1993

4. SERVICE TABLES

4.1 TEST POINT TABLE (Main Board)

Number Function

TP3 GND

4.2 FUSE TABLE

Number Rated Current Location

Fuse 1 5A Main PCB

4.3 LED TABLE

LED No. ON Status

LED1 Motor speed is too high.*

LED3 Motor speed is too low.*

*NOTE:While each motor is adjusted, if the motor speed is normal, LED

1 and LED 3 light. If the motor speed is too high, only LED 1

lights. If the motor spe ed is too low, only LED 3 lights.

There is no LED 2.

4.4 DIP SW TABLE

4.4.1 Factory Setting

DIP SW101 DIP SW102

12341234

00000000

4.4.2 Motor Test Mode

DIP SW101 DIP SW102

12341234

11011000Stack Feed-out Motor

After setting DIP SW101, turn on switch 1 of DIP SW102 to start

the stack feed-out mot or, turn off the DIP SW102 to sto p the motor.

Motor

22

Page 24

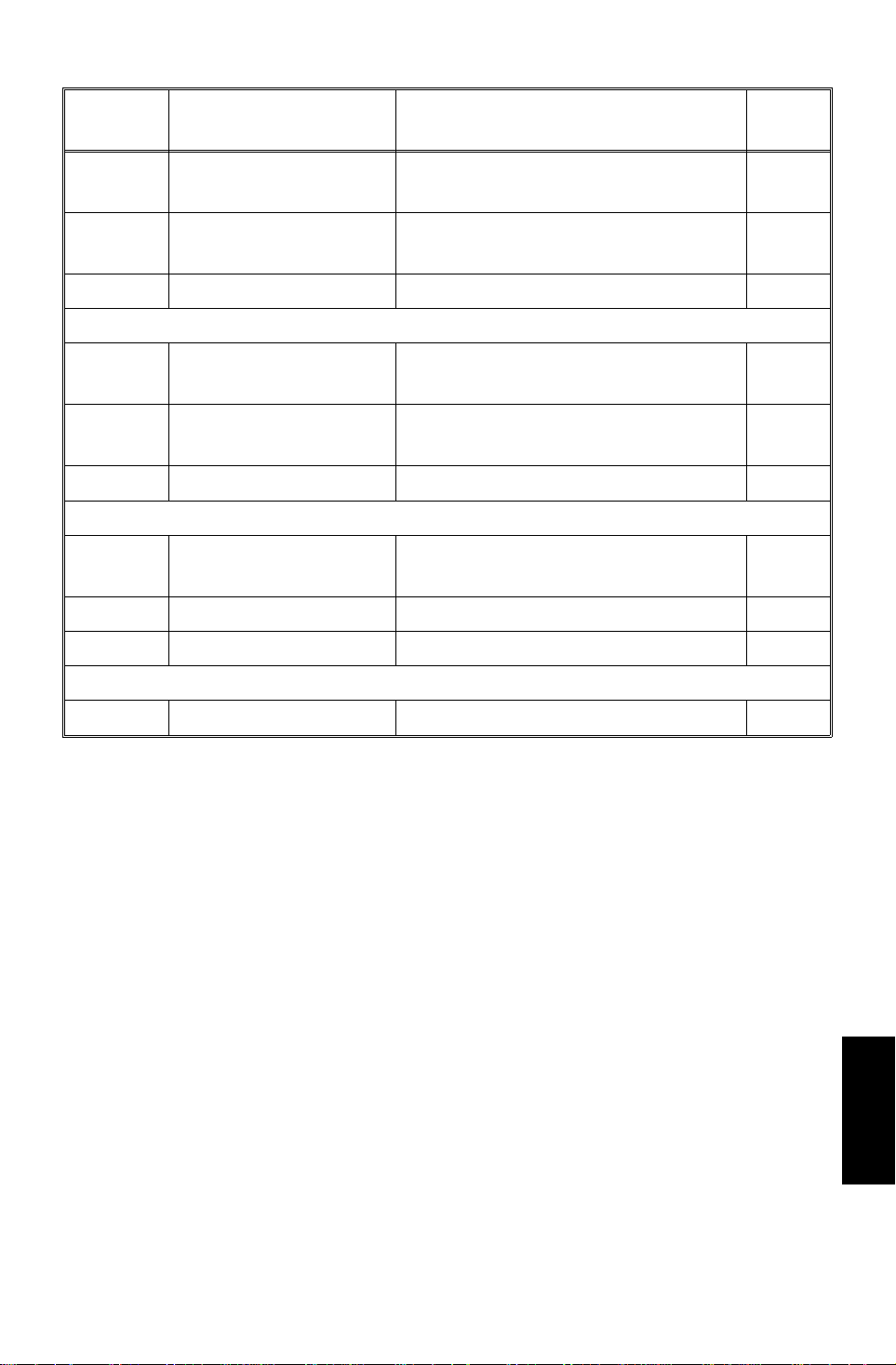

23 April 1993 SERVICE TABLES

4.4.3 Free Run Test Mode Without Paper

DIP SW101 DIP SW102

Function

12341234

11101000Shift Tray Mode

11100100Staple mode - (1)

11100010Staple mode - (2)

11100001Staple mode - (3)

Free run test mode starts when SW101 on the main board is

pressed, and stop when the push SW102 is pressed.

If in shift tray mode, the fin ishe r wo rks as if 10 set s of 5 LT pape rs

are being sorted. The shift tray is lowered for each of the 2 sets an d th en

returns to its home posit ion to repeat the same operat ion.

If in staple mode, the fin ishe r works a s if 5 sets of 5 LT papers are bein g

stapled and delivered . The ma chin e is t hen initialized and repeats the

same operation.

4.4.4 Off Line Test Mode

DIP SW101

Mode

DIP SW102

1 2 3 4 1 2 Copy Q’ty 3 4 Paper Size

1 1 0 0 Shift Tray Mode 0 0 2 sheets 0 0

1001

0110

0101

Staple Mode

(1)

Staple Mode

(2)

Staple Mode

(3)

1 0 10 sheets 1 0

0 1 30 sheets 0 1

1 1 50 sheets 1 1

A4

Sideways

A4 Length -

wise

LT

Sideways

LT Length-

wise

Off line test mode starts when SW101 on the main board is presse d, and

stops when SW102 is pressed.

The operation of the finisher can be checked without the main copier.

Finisher

23

Page 25

SERVICE TABLES 23 April 1993

4.4.5 Shift Tray Rise Mode

DIP101 DIP102

12341234

10000000

0: OFF 1: ON

In this mode, the shift tray moves to its uppermost positio n if the copy paper

stacked on the tray is removed while st aple mode copying.

When the stapling copy mode is used with the shif t tray rise mode, the shift

tray moves up and down slightly fo r each stapled copy set delivered to th e

tray.

[A]

OFF

ON

NOTE: In the stapling copy mode (unlike the sort copy mod e), the machine

cannot detect if the copy st ack on the tray is remove d. This is

because the stack heig ht sensor 1 [A] is always ON while in this

copy mode. To counter th is, whe n the shift tray rise mode is selecte d

by turning on DIP switch 101-1 on the finisher main control board ,

the shift tray slightly mo ves up just when the stapled copy is

delivered. At this time, if the stack he igh t sensor 1 turns off, this

means that the tray is in the proper po sitio n. The tra y mo ves down

soon and returns to the original position (unt il the sensor turns on

again). If the sensor remain s ON, th is mean s tha t th e tra y position is

too low. The tray continu ously mo ves up unt il the senso r turns off

then moves down until the sen sor tu rns on . In this mode the shift tray

motor frequently raises or lowers the shift tra y to monitor the paper

height.

To reduce the load to the shift tray motor, this mode is not enabled

as the factory setting.

24

Page 26

[E]

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

5. REPLACEMENTS AND ADJUSTMENTS

5.1 EXTERIOR REMOVAL

[H]

[I]

[G]

[A]

[B]

[C]

[D]

[J]

1. Remove the left upper cover [A] (2 screws).

2. Remove the upper cover [B] (3 screws).

3. Remove the upper door bracket [C] (1 screw) and remove the front door

[D].

4. Remove the lower front cover [E ] (2 screws).

5. Remove the front shif t cove r [ F] (2 screws).

6. Remove the rear cover [G] (5 screws).

7. Remove the shift tray [H] (4 screws).

8. Remove the front an d rear tray cover [I] (1 screws at th e fro nt, 2 screws

at the rear).

9. Remove the left cover [J] (4 screws).

[I]

[F]

Finisher

25

Page 27

REPLACEMENTS AND ADJUSTMENTS 23 April 1993

5.2 ALIGNMENT BRUSH ROLLER REPLACE MENT

[A]

[H]

[B]

[D]

[I]

[J]

[I]

[H]

[C]

[E]

[F]

[G]

[F]

1. Remove the rear cover.

2. Remove the main board [A] (15 connectors, 1 optics cable).

3. Remove the tension bracke t [B ] (1 screw an d 1 sprin g).

4. Remove the E-rings [C], slide ou t th e pu lleys [D] , an d remo ve 2 E-rings

[E] , then remove 2 bushings [F].

[E]

5. Remove the alignmen t bru sh rolle r a ssemb ly [G] .

6. Remove the 2 E-ring [H] and remo ve th e brush rollers [I].

NOTE: Do not lose the link keys [J].

26

Page 28

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

5.3 SENSOR REPLACEME NT

[E]

[C]

[D][A]

Stack Height Sensors

1. Remove the upper cover.

2. Remove the stack height sensor actuator [A] (1 screw).

3. Remove the bracket [B ] (1 screw, 2 connectors).

4. Replace stack height sensor 1 [C] and stack height sensor 2 [D].

NOTE: When reinstalling the bracket [B], align the edge of the bracket

with the stay [E].

[B]

Finisher

27

Page 29

REPLACEMENTS AND ADJUSTMENTS 23 April 1993

5.4 POSITING ROLLER REP LACEME NT

[A]

1. Open the front door and slid e out the jogger unit.

2. Remove the position ing roller [A ] (1 clip).

28

Page 30

[D]

23 April 1993 REPLACEMENTS AND ADJUSTMENTS

5.5 BELT TENSION ADJUSTMENT

[B]

[C]

[A]

[A, B]

[a, b]

[C]

[c]

1. Remove the rear cover and ad just the belt

[A] tension with tigh tener [a].

Remove the left upper cover, the upper

cover, the front door, and the front shift cover

and the front supporting cover (2 screws).

Adjust the belt [B] with tightener [b].

Standard: 6 mm deflection at 50 ± 20 g

pressure.

2. Open the front door an d slide out the jogg er

unit. Adjust the belt [C] ten sion with

tightener [c].

Finisher

Standard: 8 mm deflection at 100 ± 30 g

pressure.

29

Page 31

REPLACEMENTS AND ADJUSTMENTS 23 April 1993

[D]

[d]

150 ± 40 g

3. Open the front doo r and slid e ou t th e jogger unit. Adjust the belt [D ]

tension with tight en er [d ].

Standard: 8 mm deflection at 150 ± 40 g pressure.

30

Loading...

Loading...