Page 1

Operating Instructions

Troubleshooting: TCRU/ORU

For safe and correct use, be sure to read Safety Information before using

the machine.

Page 2

Page 3

TABLE OF CONTENTS

Introduction......................................................................................................................................................... 6

How to Read This Manual................................................................................................................................. 7

Symbols...........................................................................................................................................................7

Disclaimer........................................................................................................................................................7

Notes...............................................................................................................................................................7

1. Before You Begin

About This Manual............................................................................................................................................. 9

Guide to Components......................................................................................................................................10

About the Display for Options.........................................................................................................................11

Before you change a setting............................................................................................................................12

About Printing Surfaces....................................................................................................................................13

2. Troubleshooting Service Call Problems (SC Codes)

What Are SC Codes?...................................................................................................................................... 15

If an SC code appears:............................................................................................................................... 15

SC Code List..................................................................................................................................................... 16

3. Troubleshooting Image Quality Problems

Toner Spotting/Staining.................................................................................................................................. 17

Paper Is Spotted with Toner........................................................................................................................ 17

Black Spots...................................................................................................................................................18

Streaks (1).................................................................................................................................................... 19

Streaks (2).................................................................................................................................................... 21

Streaks (3).................................................................................................................................................... 22

Streaks (4).................................................................................................................................................... 22

Two 13-mm Long Vertical Streaks..............................................................................................................23

Two 14-mm Wide Streaks.......................................................................................................................... 25

Stained Paper Edges................................................................................................................................... 27

Stained Background.................................................................................................................................... 27

Ghosting....................................................................................................................................................... 28

Scratched Images and Stained Paper Edges............................................................................................ 29

Toner Scatter.....................................................................................................................................................31

Toner Scatter (1).......................................................................................................................................... 31

Toner Scatter (2).......................................................................................................................................... 32

Toner Scatter (3).......................................................................................................................................... 34

1

Page 4

Color Loss......................................................................................................................................................... 37

White Spots.................................................................................................................................................. 37

Blister-like White Spots................................................................................................................................38

Mottling.........................................................................................................................................................39

Density Problems.............................................................................................................................................. 42

Uneven Image Density................................................................................................................................ 42

Uneven Density from Top to Bottom........................................................................................................... 45

Fainter Leading Edge...................................................................................................................................46

Fainter Trailing Edge....................................................................................................................................48

Uneven Density within 90 mm (3.5 in.) of the Trailing Edge....................................................................49

Periodic Density Fluctuation........................................................................................................................ 51

Entire Image Faint........................................................................................................................................ 52

Color Is Too Dense...................................................................................................................................... 53

Broken Thin Lines..........................................................................................................................................54

Blurred Images............................................................................................................................................. 55

Dropouts (Character Voids)........................................................................................................................56

Afterimages.................................................................................................................................................. 58

White Streaks............................................................................................................................................... 59

Shock jitter: When the paper is inserted.................................................................................................... 60

Gloss Problems.................................................................................................................................................63

Vertical Glossy Lines....................................................................................................................................63

Insufficient Gloss.......................................................................................................................................... 64

Fusing Problems................................................................................................................................................65

Insufficient Toner Fusing...............................................................................................................................65

Improving Image Quality When Using Different Types of Paper............................................................ 66

4. Troubleshooting Paper Delivery Problems

Frequent Paper Misfeeds.................................................................................................................................69

Wrapped Around the Upper Fixing Side Separation Plate..................................................................... 70

Messages Reporting Paper Misfeeds.............................................................................................................73

If (J049) Appears.........................................................................................................................................73

If (J050) Appears.........................................................................................................................................75

If (J080) Appears.........................................................................................................................................77

If (J082) Appears.........................................................................................................................................78

2

Page 5

If (J099/J424/J425/J439/J440) Appears........................................................................................... 80

If (J430/J431/J445/J446/J460/J461) Appears................................................................................81

If (J085/J086/J087) Appears When Using Coated Paper...................................................................82

Paper Skew.......................................................................................................................................................83

Wrong Detection of Skew............................................................................................................................... 84

Double Feeding................................................................................................................................................85

Wrong Detection of Double Feeding............................................................................................................. 88

Paper Misfeeding.............................................................................................................................................89

Paper Feed Problems Affecting Image Quality..............................................................................................93

The Image Is Positioned Incorrectly............................................................................................................93

Image Scaling Error on the Side 1 of Paper..............................................................................................94

Image Scaling Error on the Side 2 of Paper..............................................................................................95

Paper Edges Are Soiled (1)........................................................................................................................ 96

Paper Edges Are Soiled (2)........................................................................................................................ 96

Paper Edges Are Soiled (3)........................................................................................................................ 98

Scratches, Streaks, or Vertical Creases Appear on the Image................................................................99

Decurling Results in Scratches, Streaks, or Creases............................................................................... 100

The Leading/Trailing Edge Margin Is Long............................................................................................102

Curling........................................................................................................................................................103

Ear-fold.......................................................................................................................................................104

Cleaning the Paper Feed Path...................................................................................................................... 106

Cleaning Paper Trays 1-3........................................................................................................................ 107

Cleaning the Paper Feed Path for Paper Trays 1-3................................................................................108

Cleaning the Paper Feed Path in the Drawer..........................................................................................110

Cleaning the Paper Feed Path in the Wide LCT......................................................................................122

Cleaning the Paper Feed Path in the LCT................................................................................................ 124

Cleaning the Paper Feed Path in the Multi Bypass Tray........................................................................ 125

Cleaning the Paper Feed Rollers and Paper Feed Belt in the Interposer.............................................. 125

Cleaning the Rollers and Guide Boards in the Finisher..........................................................................128

5. Post-Processing Option Troubleshooting

Finisher SR5090/Booklet Finisher SR5100................................................................................................135

Delivered Sheets Are Not Stacked Properly...........................................................................................135

Large Delivered Sheets Are Not Stacked Properly................................................................................ 136

3

Page 6

Trailing edge of stapled sheets close to the paper exit.......................................................................... 138

Sheets cannot be stapled properly.......................................................................................................... 139

Finisher SR5110/Booklet Finisher SR5120................................................................................................141

Delivered Sheets Are Not Stacked Properly...........................................................................................141

Large Delivered Sheets Are Not Stacked Properly................................................................................ 142

Trailing edge of stapled sheets close to the paper exit.......................................................................... 144

Sheets cannot be stapled properly.......................................................................................................... 146

The Edge Is Rolled.....................................................................................................................................146

Carbonless Sheets Are Not Stacked In an Aligned Manner.................................................................148

Stitching missing, incorrect stitching position, ear-fold, or misaligned occurs......................................151

Paper is stained..........................................................................................................................................151

Paper jam occurs on thin coated paper of Paper Weight 2 or less...................................................... 152

Scratches on the edge of the stapled paper occur.................................................................................153

Paper jam occurs while saddle stitching..................................................................................................153

Multi-Folding Unit.......................................................................................................................................... 155

Inaccurate Folding (Folding Deviation)...................................................................................................155

Folding Deviation...................................................................................................................................... 156

Folds soiled by multi-sheet folding...........................................................................................................161

Edges of letter fold bent............................................................................................................................ 162

Z-Folding is Not Performed Properly.......................................................................................................164

Folded Sheets Are Not Stacked Properly................................................................................................165

High Capacity Stacker.................................................................................................................................. 167

Delivered Sheets Are Severely Curled.................................................................................................... 167

The Machine Wrongly Detects That the Tray Is Full............................................................................... 169

The Paper Press Leaves an Impression on the Paper..............................................................................170

Paper Pressed Down Insufficiently........................................................................................................... 171

Paper of Paper Weight 1 does not align correctly.................................................................................171

Interposer........................................................................................................................................................173

Paper jam due to paper misfeeding or double feeding occurs.............................................................173

Vertical lines and scratches occur at random positions..........................................................................175

6. Improving Throughput

Reducing the Waiting Time Prior to Printing................................................................................................ 177

4

Page 7

Improving Throughput When Printing on Coated Paper with a Thickness Equivalent to Paper Weight 7 or

Higher.............................................................................................................................................................178

Reducing the Waiting Time When Different Types of Paper are Used..................................................... 180

Reducing the Time the Machine Takes to Return from Standby Mode..................................................... 182

5

Page 8

Introduction

This manual contains detailed instructions and notes on the operation and use of this machine. For your

safety and benefit, read this manual carefully before using the machine. Keep this manual in a handy

place for quick reference.

6

Page 9

How to Read This Manual

Symbols

This manual uses the following symbols:

Indicates points to pay attention to when using functions. This symbol indicates points that may result in

the product or service becoming unusable or result in the loss of data if the instructions are not obeyed.

Be sure to read these explanations.

Indicates supplementary explanations of the product's functions and instructions on resolving user errors.

Indicates where you can find further relevant information.

[ ]

Indicates the names of keys or buttons on the product or display.

Disclaimer

Contents of this manual are subject to change without prior notice.

In no event will the company be liable for direct, indirect, special, incidental, or consequential damages

as a result of handling or operating the machine.

Notes

The manufacturer shall not be responsible for any damage or expense that might result from the use of

parts other than genuine parts from the manufacturer with your office products.

For good output quality, the manufacturer recommends that you use genuine toner from the

manufacturer.

Some illustrations in this manual might be slightly different from the machine.

Certain options might not be available in some countries. For details, please contact your local dealer.

Depending on which country you are in, certain units may be optional. For details, please contact your

local dealer.

Two kinds of size notation are employed in this manual.

7

Page 10

8

Page 11

1. Before You Begin

About This Manual

If the machine will not print, does not print as expected, or exhibits any other problem, find the problem

in this manual and troubleshoot accordingly.

• Before you replace any unit:

• To prevent electrical shock, turn off the printer controller on the machine control panel,

switch off the main power switch then the AC power switch, and then disconnect the

machine from the power supply.

• Allow the machine to cool for at least 30 minutes before replacing a part.

9

Page 12

1

2

3

1

2

5

4

6

3

ECH004

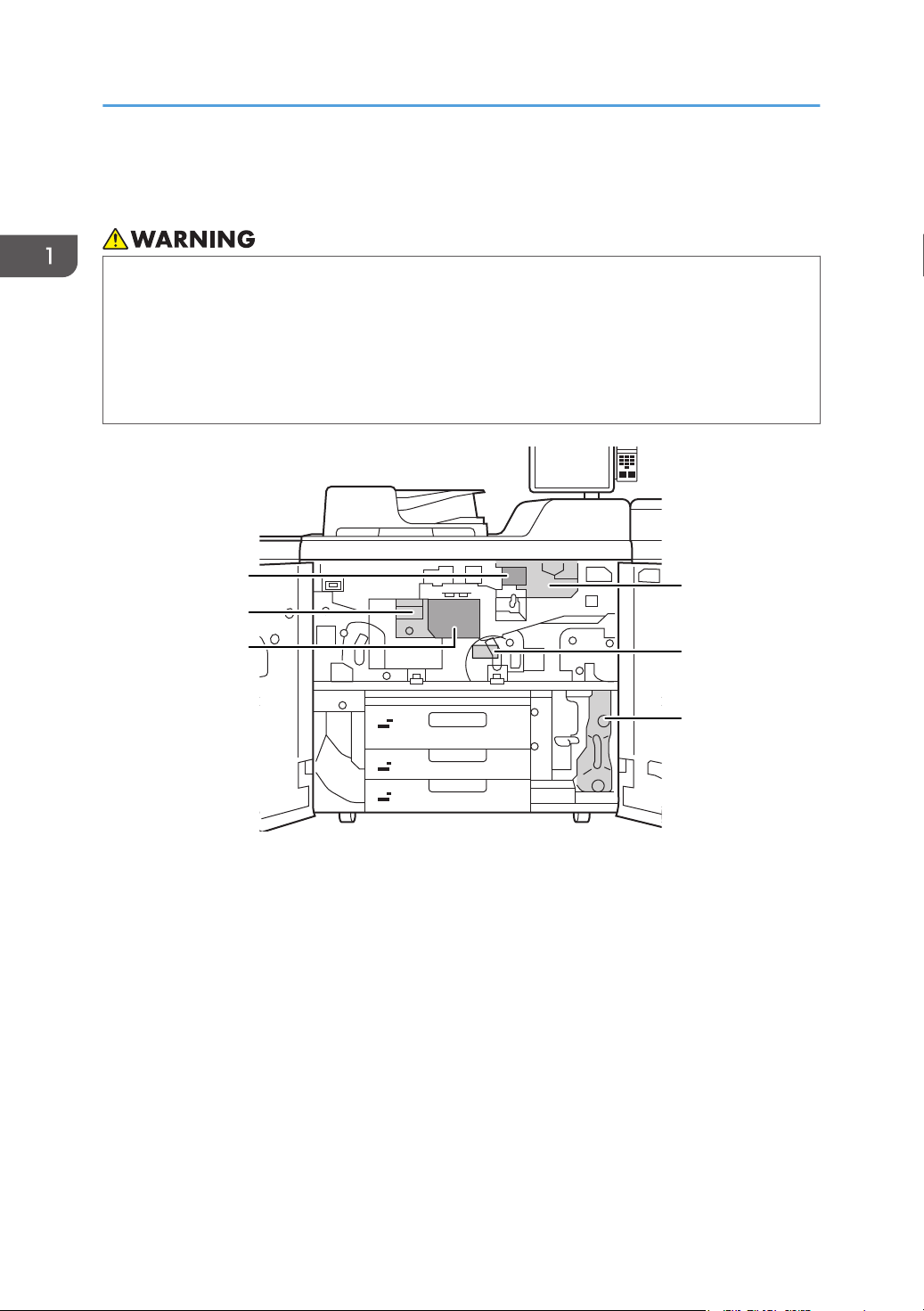

1. Before You Begin

Guide to Components

• Do not remove any covers or screws other than those explicitly mentioned in this manual. Inside

this machine are high voltage components that are an electric shock hazard and laser

components that could cause blindness. Contact your sales or service representative if any of the

machine's internal components require maintenance, adjustment, or repair.

• Do not attempt to disassemble or modify this machine. Doing so risks burns and electric shock.

Note again that exposure to the laser components inside this machine risks blindness.

1. Developer Outlet/Inlet

2. Fusing Unit

3. Cleaning Unit for Intermediate Transfer Belt

4. Development Unit

5. Paper Transfer Unit

6. Waste Toner Bottle

10

Page 13

About the Display for Options

About the Display for Options

This machine displays all of the adjustment items in the Adjustment Settings for Operators menu and

advanced settings for custom paper regardless of whether or not the items are for options. Note that any

modifications to the option settings do not take effect unless the applicable options are installed on this

machine.

• For details about the options available for this machine, see "Guide to Functions of the Machine's

Options", Preparation.

11

Page 14

1. Before You Begin

Before you change a setting

• When changing the current settings, make a note of their present values before changing them.

• If the problem persists even though the setting has been changed, restore the value noted.

• Operating the machine with the changed setting may cause problems, such as inferior printed

images.

12

Page 15

DSM008

DSM009

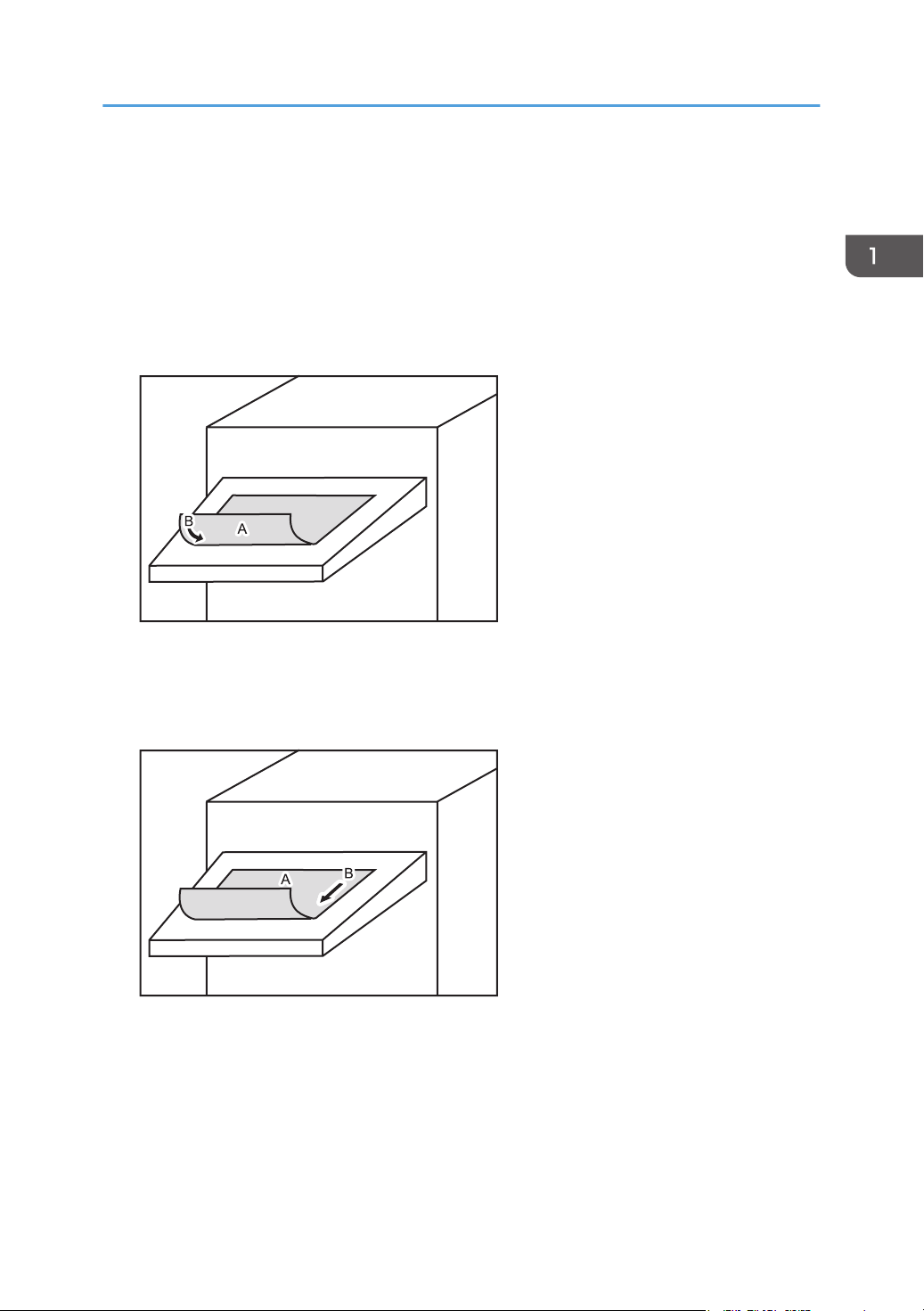

About Printing Surfaces

About Printing Surfaces

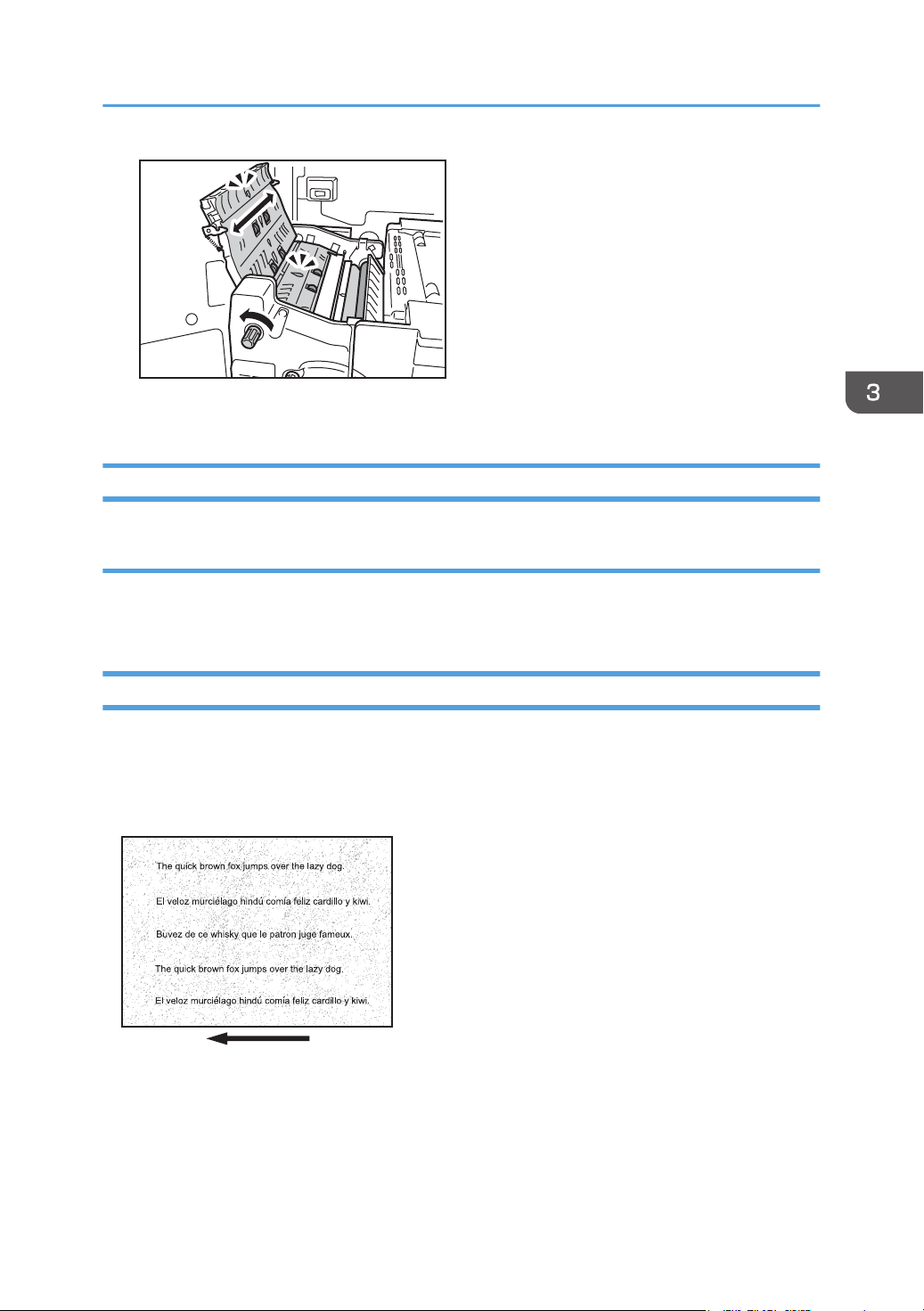

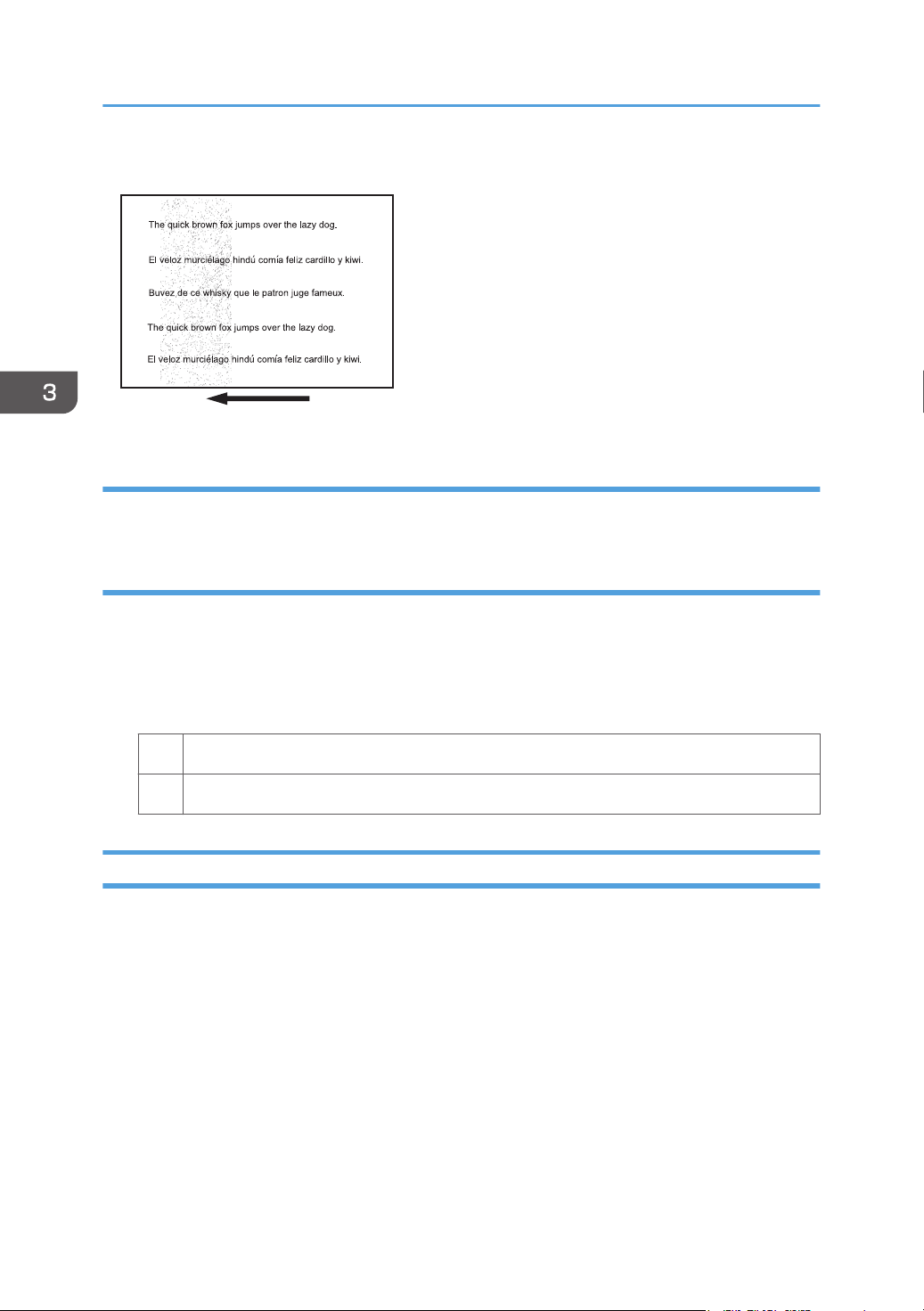

Depending on the setting, printed copies are fed as follows:

Side 1 is the surface of the paper printed during one-sided printing, or the surface of the first print during

duplex printing.

Side 2 is the surface of the paper printed on the back side of Side 1 during duplex printing.

Single-sided printing: Printed side face down

A. Side 1

B. Paper feed direction of Side 1

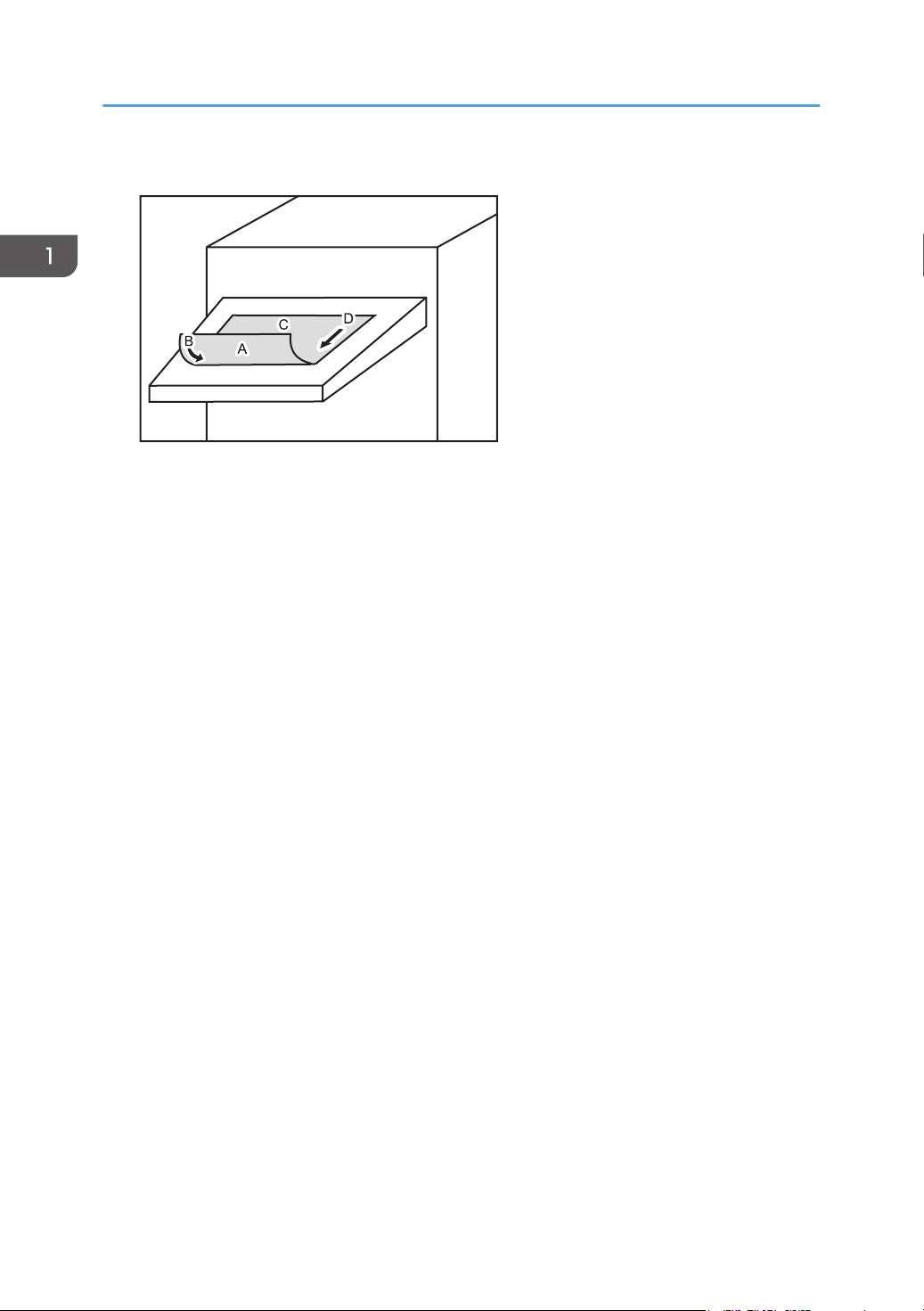

Single-sided printing: Printed side face up

A. Side 1

B. Paper feed direction of Side 1

13

Page 16

DSM010

1. Before You Begin

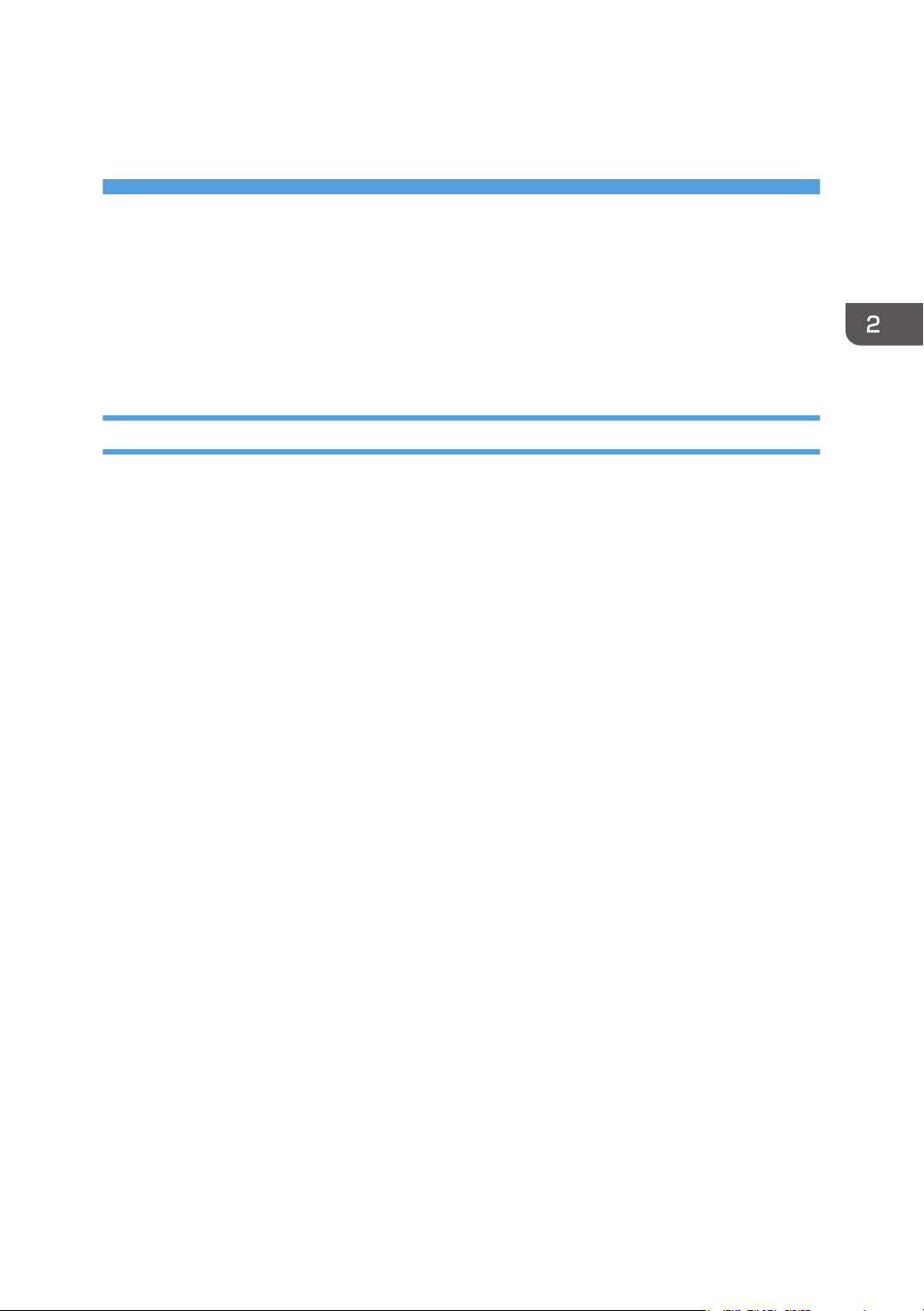

Duplex printing

A. Side 1

B. Paper feed direction of Side 1

C. Side 2

D. Paper feed direction of Side 2

14

Page 17

2. Troubleshooting Service Call Problems (SC Codes)

What Are SC Codes?

If an error occurs during operation, the machine displays an SC code ("SCnnn", where "nnn" is a threedigit number). The machine stops and cannot be used when an SC code is displayed.

If an SC code appears:

1. Write down the SC number.

2. Turn off the main power switch.

3. Wait a few moments, then turn the machine on again.

In most cases, cycling the machine off and on will restore it to full operation.

4. If the SC code reappears, check it against the SC code table. For details, see page 16

"SC Code List".

Check for the SC code in the table.

If the SC code is listed in the table, carry out the recommended procedure.

If the SC code is not listed in the table, contact your service representative.

15

Page 18

2. Troubleshooting Service Call Problems (SC Codes)

SC Code List

This table contains a list of selected SC codes. If the SC code that is displayed on the control panel is

listed in this table, carry out the recommended procedure. If the SC Code is not listed in this table,

contact your service representative.

• If the error persists after replacing the unit, contact your service representative.

Code Error Procedure

332-01 Toner supply motor 1 error (left bottle) Check that toner supply motor 1 operates

properly.

332-05 Toner supply motor 2 error (right bottle) Check that toner supply motor 2 operates

properly.

336-01 Developer imperfect setting (K) Check the developer.

410-01 Remaining potential: Vr detection error (K) Replace the photoconductor unit.

411-01 Charge potential: Vd adjustment error (K) Replace the charge unit.

412-01 Exposure potential: Vpl adjustment error (K) Replace the charge unit.

16

Page 19

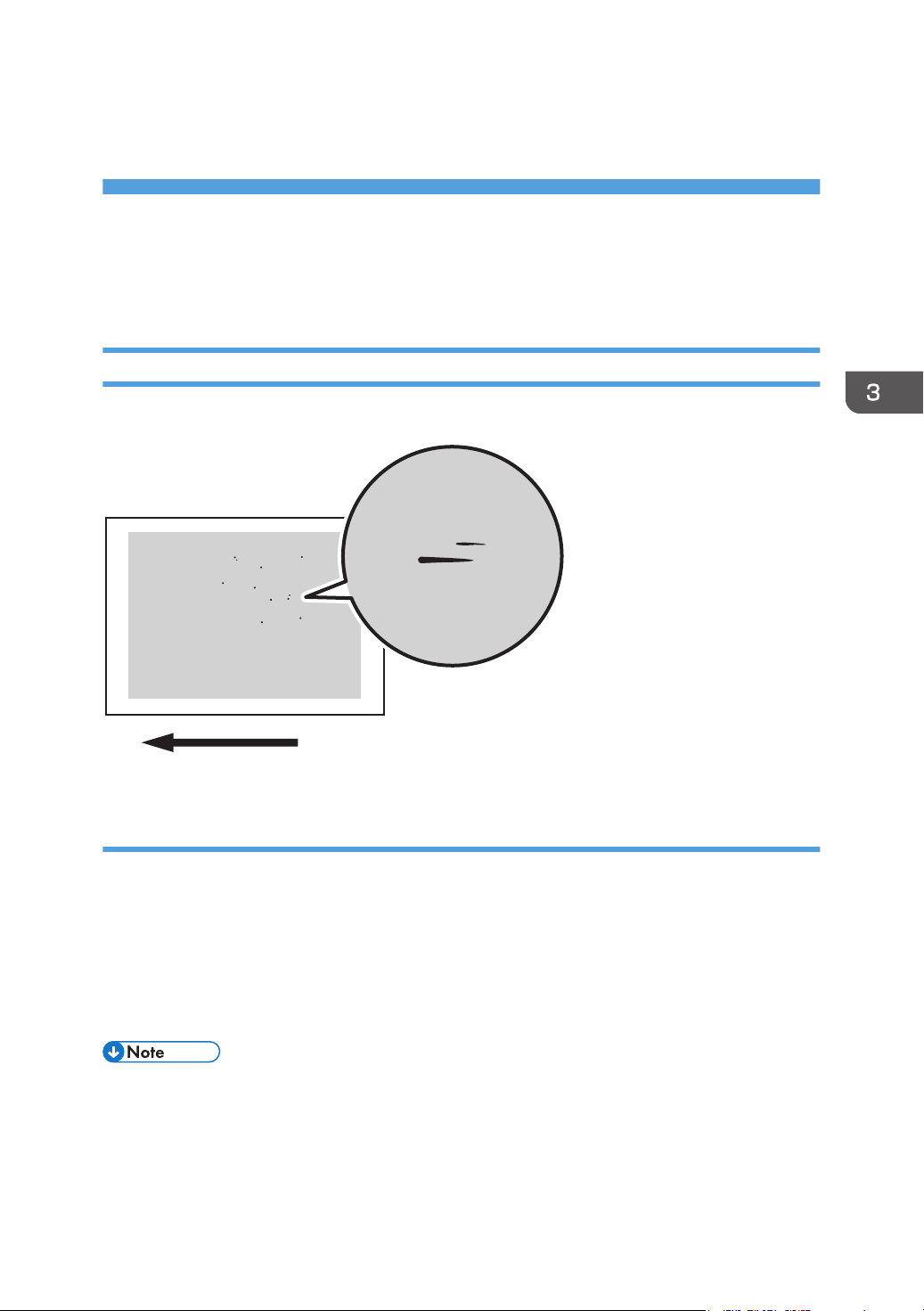

3. Troubleshooting Image Quality

CEZ538

Problems

Toner Spotting/Staining

Paper Is Spotted with Toner

Paper is soiled with toner spots of 0.5–1 mm (0.02–0.04 inches) in diameter.

Cause:

Toner fragments have slipped through the cleaning web, which cleans the pressure roller, and readhered to paper.

This may occur if:

• Printing on both sides of paper

• Printing on uncoated (especially rough-textured) paper

• Printing a single-dot halftone image

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

17

Page 20

3. Troubleshooting Image Quality Problems

Solution:

Increasing the temperature when using thin paper with a thickness equivalent to Paper Weight 0 or 1

may cause paper curling, resulting in paper jams at the fusing unit. Carry out steps from Step 6 when

using thin paper with a thickness equivalent to Paper Weight 0 or 1.

1. In [Advanced Settings] for the custom paper in use, select 1206: [Fusing Temperature],

and then increase the temperature by 5 degrees in [Heat Roller Temp].

2. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

3. Increase the temperature an additional 5 degrees in [Heat Roller Temp].

4. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

5. Have changes to the settings resulted in glossy lines or paper misfeed?

Yes Decrease the temperature by 10 degrees, and then go to the next step.

No Go to the next step.

6. In [Advanced Settings] for the custom paper in use, select 1209: [Fusing Cleaning], and

then set [Cleaning Interval] to 0.01.

7. Print the image. Is the problem resolved?

Yes Finished!

No No further improvement is likely. Contact your service representative.

• Decreasing the value in [Cleaning Interval] will shorten the replacement cycle of the cleaning web.

Black Spots

Black spots appear at 314 mm (12.4 inches) intervals.

18

Page 21

CZC307

314 mm (12.4 in.)

Cause:

The drum is scratched or stained.

Toner Spotting/Staining

Solution:

1. Detach the photoconductor unit and check the drum surface. Is the surface scratched?

Yes Replace the photoconductor unit.

No Contact your service representative.

2. If the problem persists, contact your service representative.

• For details about replacing the photoconductor unit, see Replacement Guide.

Streaks (1)

Streaks parallel to the paper feed direction appear.

19

Page 22

CZC346

3. Troubleshooting Image Quality Problems

Cause:

• The charger is stained.

• The cleaning unit for PCU has worn out.

• The drum surface is scratched.

Solution:

1. In the [Main Unit: Maintenance] group on the [Adjustment Settings for Operators] menu,

select 0522: [Execute Charger Cleaning] and execute [Charger Cleaning].

2. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

3. Detach the charge unit and check its surface. Is the surface stained?

Yes Contact your service representative.

No Go to the next step.

4. Detach the photoconductor unit and check the drum surface. Is the surface stained or

scratched?

Stained: Replace the cleaning unit for PCU.

Scratched: Replace the photoconductor unit.

Neither: Contact your service representative.

20

5. If the problem persists even though you have replaced the cleaning unit for PCU or

photoconductor unit, contact your service representative.

Page 23

CWH401

Toner Spotting/Staining

• For details about replacing the charge unit, cleaning unit for PCU and photoconductor unit, see

Replacement Guide.

Streaks (2)

Extended, blurred streaks parallel to the paper feed direction appear. The streaks also appear

randomly in the margins.

Cause:

If the temperature or humidity is low, remaining toner might be missed by the cleaning blade of the

cleaning unit for intermediate transfer belt or transfer unit, causing streaks to appear sporadically.

Solution:

1. Is the printed side affected by the problem?

Yes Go to the next step.

No Contact your service representative.

2. Replace the cleaning unit for intermediate transfer belt.

3. If the problem persists even though you have replaced the cleaning unit for intermediate

transfer belt, contact your service representative.

• For details about replacing the cleaning unit for intermediate transfer belt, see Replacement Guide.

21

Page 24

CEZ542

3. Troubleshooting Image Quality Problems

Streaks (3)

Streaks appear in solid-filled areas.

Cause:

If the toner contains small clumps, they disintegrate in the development unit, producing streaks.

This problem may occur if the machine is left unattended for a long period or the toner bottle is kept out

of its moisture-proof bag for a long period.

Solution:

1. Print 350 full-page, solid-fill A3 or DLT sheets.

2. Print the image. Is the problem resolved?

Yes Finished!

No Replace the toner bottle.

3. Print 350 full-page, solid-fill A3 or DLT sheets.

4. If the problem persists, contact your service representative.

Streaks (4)

Irregular black streaks appear, running parallel to the feed direction.

This occurs on both sides regardless of whether printing one-sided or duplex.

22

Page 25

DTH009

Toner Spotting/Staining

These are not toner streaks. You can remove them by rubbing them with an eraser or similar.

Cause:

If the machine remains in standby mode without paper or toner in it for a long time, friction between the

pressure roller and the cleaning web may cause dust to accumulate, resulting in streaks.

This may occur when either of the following conditions is met:

• The Low Power Mode Timer function in System Settings, which specifies the length of time before

switching to low-power mode, is set to a long time.

• Paper with excessive dust is used.

• The printing amount each month is small (less than approx. 30,000 pages).

Solution:

1. Set the Low Power Mode Timer function in System Settings to the initial value of 15

minutes.

2. If the problem persists, contact your service representative.

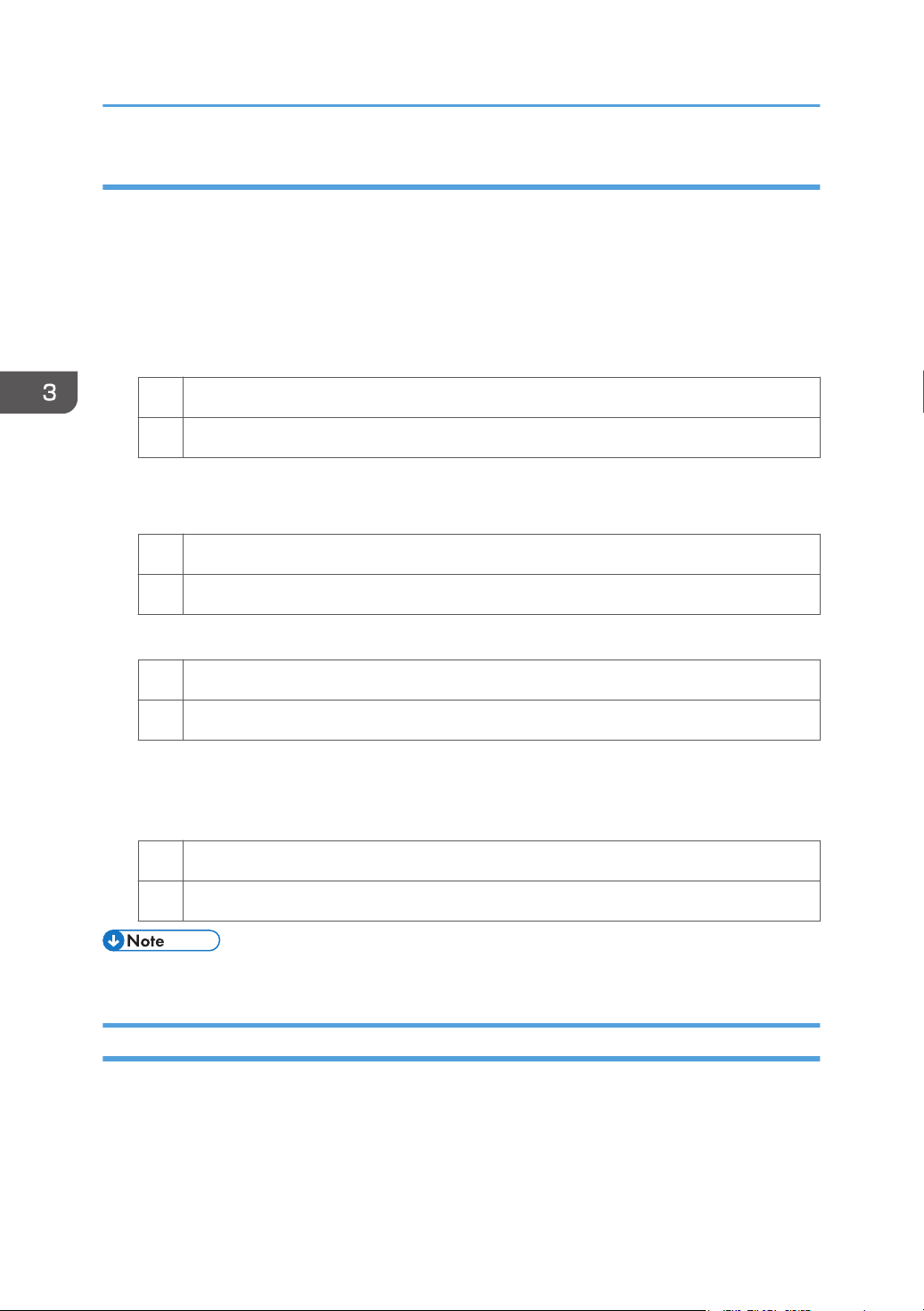

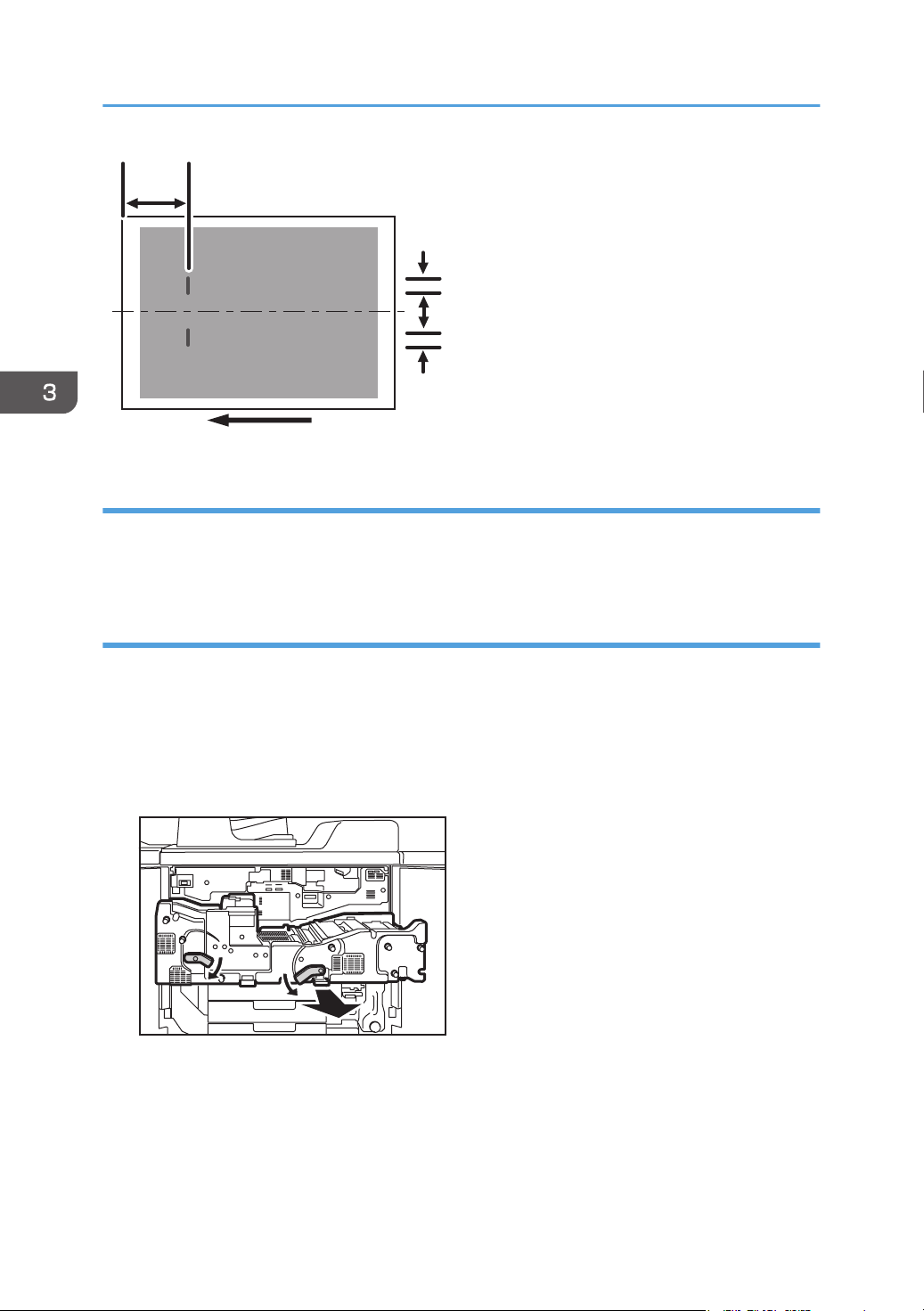

Two 13-mm Long Vertical Streaks

Two 13-mm long vertical streaks appear within 50 mm (2.0 inches) from the leading edge.

23

Page 26

50 mm

(2.0 in.)

13 mm

(0.5 in.)

13 mm

(0.5 in.)

67 mm

(2.6 in.)

CZC313

CZC300

3. Troubleshooting Image Quality Problems

Cause:

The invert exit drive rollers or invert exit idle rollers in the drawer are soiled.

This may occur if sheets are delivered face down after one-sided printing.

Solution:

Clean the rollers, sensors, and guide boards in the drawer.

1. Make sure that the system is turned off and the machine power cord is disconnected from

the power source.

2. Open the front covers.

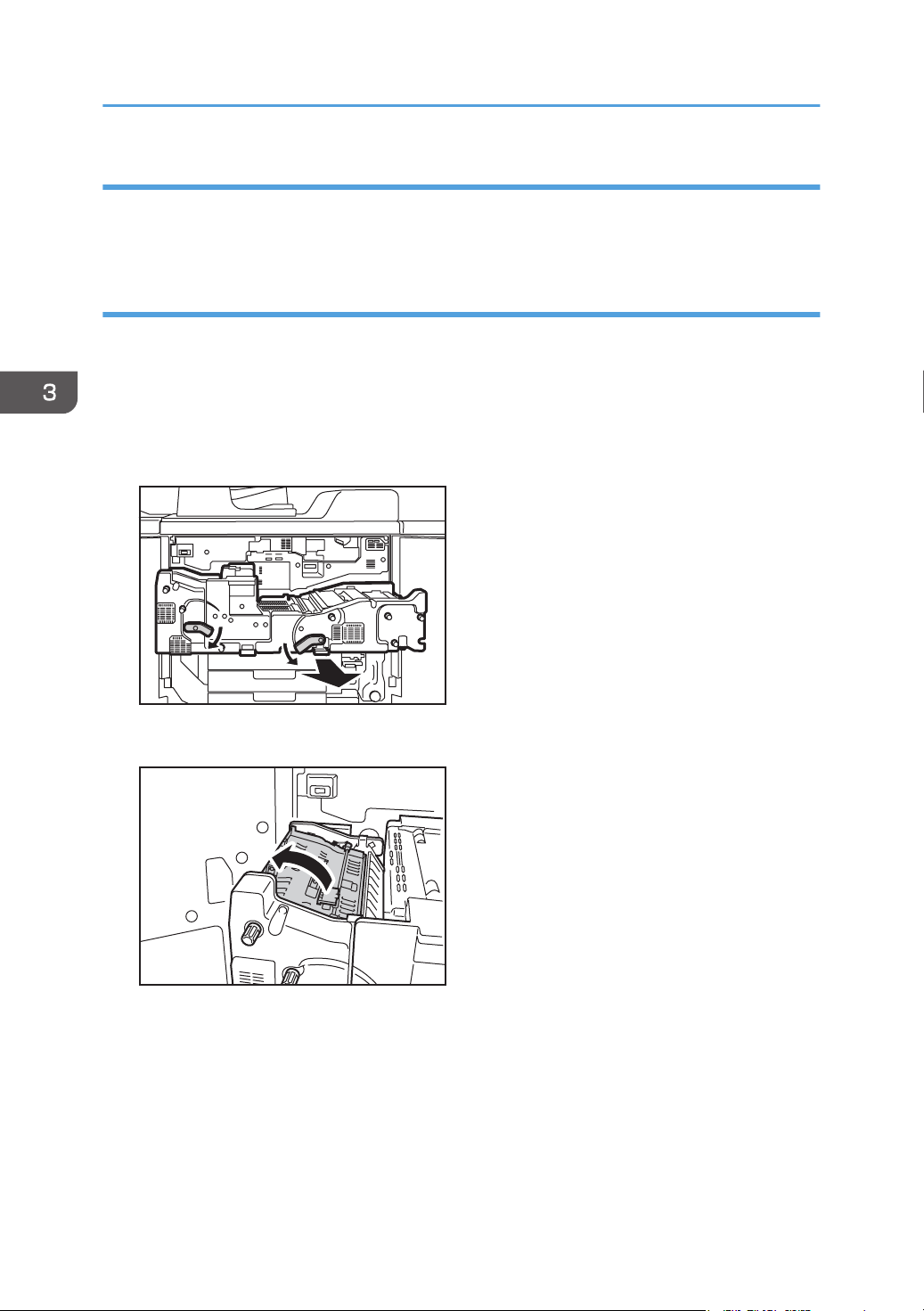

3. Lower the levers C1 and C2, and then pull the drawer out completely until it stops.

24

Page 27

4. Pull down and open the cover D4.

CZC301

CZC302

14 mm

(0.5 in.)

14 mm

(0.5 in.)

64 mm

(2.5 in.)

CZC314

5. Clean the rollers, sensors, and guide boards.

For details about cleaning the parts, see page 106 "Cleaning the Paper Feed Path".

Toner Spotting/Staining

6. After cleaning, restore the machine so that it resumes operation.

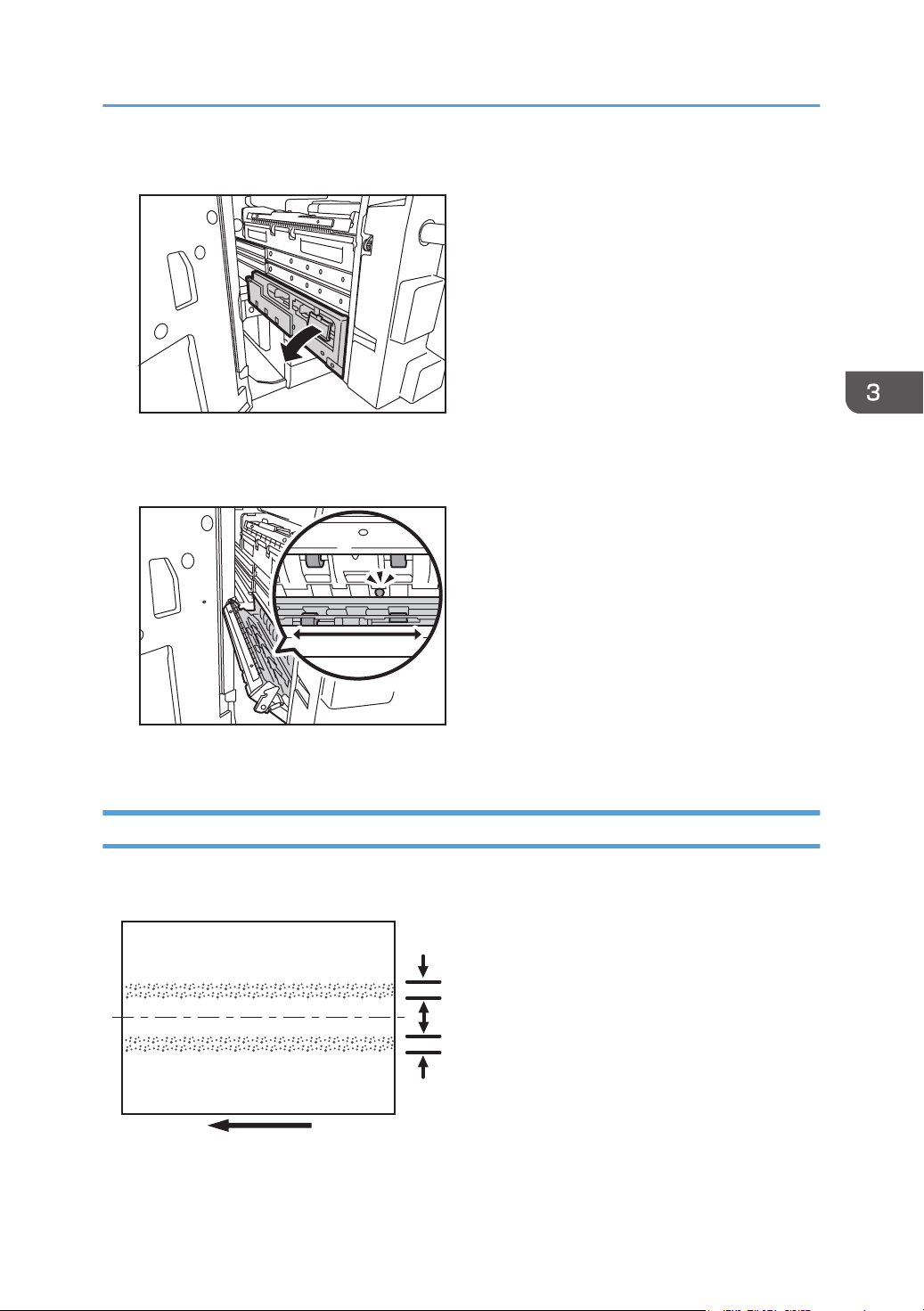

Two 14-mm Wide Streaks

Two 14-mm wide streaks parallel to the paper feed direction appear.

25

Page 28

CZC300

CZC341

3. Troubleshooting Image Quality Problems

Cause:

The exit drive rollers, exit idle rollers, exit relay drive rollers, or exit relay idle rollers in the drawer are

soiled.

Solution:

Clean the rollers, sensors, and guide boards in the drawer.

1. Make sure that the system is turned off and the machine power cord is disconnected from

the power source.

2. Open the front covers.

3. Lower the levers C1 and C2, and then pull the drawer out completely until it stops.

26

4. Pull up and open the cover D3.

5. Clean the rollers while turning the knob D1. Clean the sensors and guide boards also.

For details about cleaning the parts, see page 106 "Cleaning the Paper Feed Path".

Page 29

CZC342

CEZ543

Toner Spotting/Staining

6. After cleaning, restore the machine so that it resumes operation.

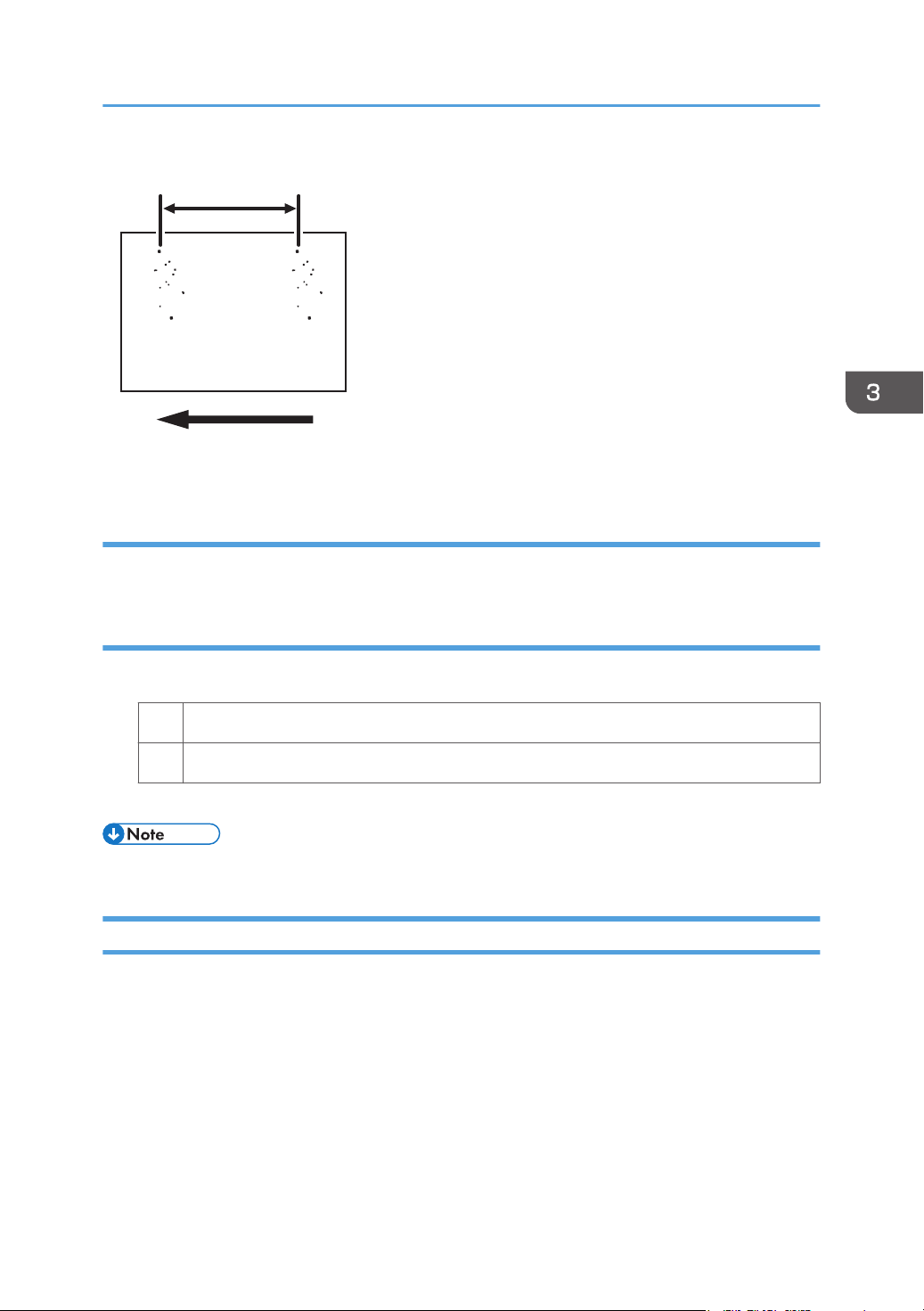

Stained Paper Edges

Solution:

1. If the paper edges are stained, carry out the procedure in page 65 "Insufficient Toner

Fusing".

Stained Background

Random "powdered" dots appear, creating a dirty background.

The background may be partially or completely stained.

Completely stained background

27

Page 30

CEZ544

3. Troubleshooting Image Quality Problems

Partially stained background

Cause:

This may occur because of wearing of the developer, drum unit, or charger.

Solution:

1. If a message prompting replacement of a unit has appeared, replace the unit.

2. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0202: [Adjust Image Density] and execute [Adjust Image Density].

3. Print the image. Is the problem resolved?

Yes Finished!

No Contact your service representative.

Ghosting

A ghost image of an image to be printed appears at a distance of 314 mm (12.4 in.) to the side of the

intended image.

28

Page 31

314 mm (12.4 in.)

R

R

R

R

R

R

CZC308

Toner Spotting/Staining

Cause:

The image transfer current is transmitted to the drum, where a potential difference occurs between a

developed area and non-developed area and causes the intended image to be reproduced.

This may occur if:

• Solid filled images or bold characters are printed in black on a halftone background

• Printing is done at low temperature or humidity

• Many screening lines are used

Solution:

1. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0202: [Adjust Image Density] and execute [Adjust Image Density].

2. Print the image. Is the problem resolved?

Yes Finished!

No Contact your service representative.

Scratched Images and Stained Paper Edges

Scratched images or soiled paper edges appear.

29

Page 32

CNT008

3. Troubleshooting Image Quality Problems

Cause:

When a relatively stiff, thick paper is delivered, the entrance guide board for the transfer unit is warped

toward the intermediate transfer belt due to the stiffness of the paper. The edge of the entrance guide

board comes into contact with the toner on the belt to cause images to be scratched and paper edges to

be soiled.

This may occur if:

• Paper with a thickness equivalent to Paper Weight 7 is used

• Paper with its grain parallel to the paper feed direction is used. For example, A3/DLT long grain

paper is delivered, A4/LT short grain paper is delivered from its long edge, or A4/LT long grain

paper is delivered from its short edge.

• Paper is stored at low temperature or humidity

Solution:

Change the direction of paper grain for paper delivery.

• When storing paper at low humidity, wrap the paper in coated paper or a plastic sheet.

30

Page 33

Toner Scatter

CEZ545

Toner Scatter (1)

Toner is scattered around a solid-fill print.

Toner Scatter

Cause:

This may occur if printed at low temperature or humidity.

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

Solution:

The solution depends on which side of the paper the problem occurs on.

• If the problem occurs on side 1 of the paper, perform the solution described in (a).

• If the problem occurs on side 2 of the paper, perform the solution described in (b).

• If the problem occurs on both sides, perform the solutions described in (a), and then (b).

(a) If the problem occurs on side 1

1. Adjust the setting for the side 1 of the paper. In [Advanced Settings] for the custom paper

in use, select [Machine: Image Quality] and increase the absolute value of [Side 1] by 5%

in 1203: [Paper Transfer Output].

Example: If the present current is −40 A, change it to −42 A.

31

Page 34

CZC309

5 mm (0.2 in.)

3. Troubleshooting Image Quality Problems

2. Print the image. Is the problem resolved?

Yes Finished! If the problem also occurs on side 2 of the paper, perform the solution described

in "(b) If the problem occurs on side 2".

No Increase the absolute value of the negative current by another 5%.

3. Repeat Step 2. If the problem persists, contact your service representative.

(b) If the problem occurs on side 2

1. Adjust the setting for the side 2 of the paper. In [Advanced Settings] for the custom paper

in use, select [Machine: Image Quality] and increase the absolute value of [Side 2] by 5%

in 1203: [Paper Transfer Output].

Example: If the present current is −40 A, change it to −42 A.

2. Print the image. Is the problem resolved?

Yes Finished!

No Increase the absolute value of the negative current by another 5%.

3. Repeat Step 2. If the problem persists, contact your service representative.

Toner Scatter (2)

Parts of a line that is 5 mm (0.2 inches) or less from an image exhibit splatter.

32

Page 35

Toner Scatter

Cause:

Air contained between images is compressed and blows off parts of a line.

This may occur if:

• Printing is done at high temperature or humidity

• Using coated or other slippery paper

• Printing line images at less than 5 mm (0.2 inches) intervals

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

Solution:

The solution depends on the area in which the line splatter occurs. If the splatter occurs 15 mm (0.6

inches) or less from the leading edge, follow Procedure (a) on the following page; otherwise, follow

Procedure (b) on the following page.

a) Line splatter that is 15 mm (0.6 inches) or less from the leading edge

Increase the leading edge margin to more than 15 mm (0.6 inches) using one of the following

procedures:

1. Select [Machine: Image Position] in [Advanced Settings] for the custom paper in use and

specify the following for 1101: [Image Position].

• On side 1 of the paper: Adjust to [ ] direction with [With Feed] of [Image Position: Side

1].

• On side 2 of the paper: Adjust to [ ] direction with [With Feed] of [Image Position: Side

2].

2. Adjusting the mask width at the leading edge

Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use, and then

specify [Leading Edge] in 1210: [Erase Margin].

3. Adjusting the file's leading edge margin

Increase the leading edge margin in the print settings for the image to be printed.

For details about adjusting the shift image and adjusting the mask width at the leading edge,

see Adjustment Item Menu Guide.

If you cannot increase the leading edge margin to more than 15 mm (0.6 inches), contact

your service representative.

b) Line splatter that is in an area more than 15 mm (0.6 inches) from the leading edge

1. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use, select

1202: [Image Transfer Output].

33

Page 36

3. Troubleshooting Image Quality Problems

2. Check the present value. Is it the upper limit?

Yes Go to Step 5.

No Go to the next step.

3. Increase the absolute value of the current by 5 A in [Image Transfer Output].

4. Print the image. Is the problem resolved?

Yes Finished!

No Increase the value by 5 A. If the problem persists even though you have increased

the value to the upper limit (150 A), go to the next step.

5. Do you mind if image density is low?

Yes Contact your service representative.

No Go to the next step.

6. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use, select

1201: [Max Image Density].

7. Check the present value. Is it the lower limit?

Yes Contact your service representative.

No Decrease the value by 1 in [Max Image Density].

8. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 5 to 7. If the problem persists even though you have decreased the

value to the lower limit, contact your service representative.

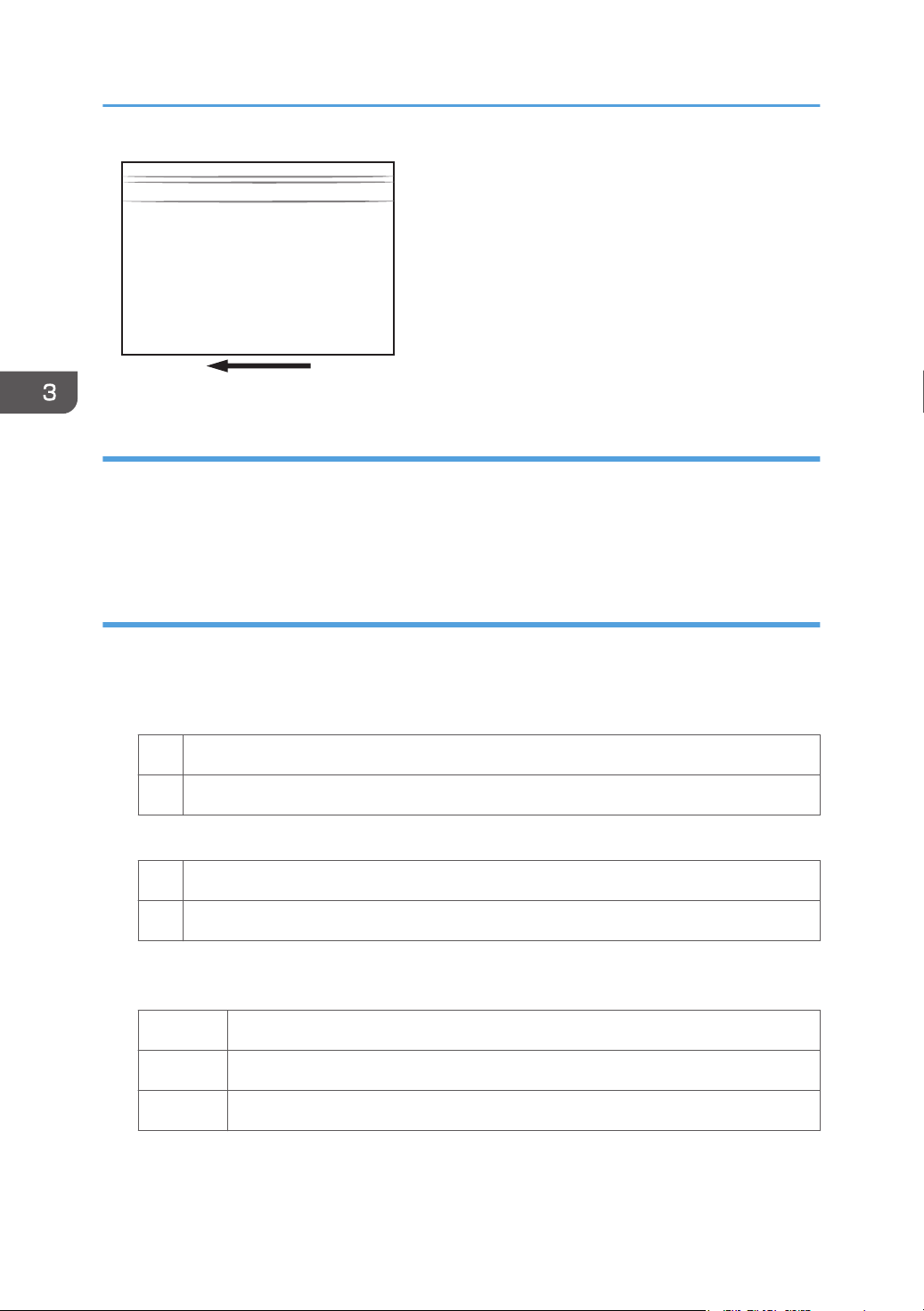

Toner Scatter (3)

Parts of a line or character exhibit splatter. This may occur in a line or character that is 8 to 13 mm (0.3

to 0.5 inches) from the trailing edge and 20 mm (0.8 inches) or less from the left edge facing the paper

feed direction.

34

Page 37

8-13 mm (0.3-0.5 in.)

20 mm (0.8 in.)

CNT009

Toner Scatter

Cause:

A shock jitter occurs when the trailing edge of the paper leaves the paper guide during paper transfer

and causes toner scattering.

This may occur if paper with a thickness equivalent to Paper Weight 4 or higher is used.

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

• Changing the transfer current may produce either or both of the following side effects:

• Reduction in toner yields

• Occurrence of banding (streaks)

Solution:

1. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use,

select 1202: [Image Transfer Output].

2. Check the present value. Is it lower than 100 A?

Yes Carry out all of the following:

(1) Increase the value by 5 A in 1202: [Image Transfer Output].

(2) Set [Trailing Edge] of 1204: [Paper Transfer Output Correction: Paper Edge] to

"200%".

(3) Set [Trailing Edge Length] of 1204: [Paper Transfer Output Correction: Paper Edge] to

"30 mm".

No No further improvement is likely. Contact your service representative.

35

Page 38

3. Troubleshooting Image Quality Problems

3. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 1 to 3. If the problem persists even though you have increased the value to

100 A, contact your service representative.

36

Page 39

Color Loss

CEZ549

White Spots

White spots of 0.2–0.3 mm (0.008–0.01 inches) in diameter appear.

Color Loss

Cause:

This may occur if printed at low temperature or humidity.

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

• If you reduce the paper transfer current to eliminate white spots, copies may become too faint.

Solution:

The solution depends on which side of the paper the problem occurs on.

• If the problem occurs on side 1 of the paper, perform the solution described in (a).

• If the problem occurs on side 2 of the paper, perform the solution described in (b).

• If the problem occurs on both sides, perform the solutions described in (a), and then (b).

(a) If the problem occurs on side 1

1. Adjust the setting for the side 1 of the paper. Select [Machine: Image Quality] in

[Advanced Settings] for the custom paper in use, decrease the absolute value of [Side 1]

by 5 A in 1203: [Paper Transfer Output].

Example: If the present current is −100 A, change it to −95 A.

37

Page 40

3. Troubleshooting Image Quality Problems

2. Print the image. Is the problem resolved?

Yes Finished! If the problem also occurs on side 2 of the paper, perform the solution described

in "(b) If the problem occurs on side 2".

No Decrease the absolute value of the negative current by another 5 A.

3. Repeat Step 2. If the image is lighter in density but the problem persists, reset the current

to the original value and go to Step 4.

4. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use,

decrease the absolute value by 5 A in 1202: [Image Transfer Output].

Example: If the present current is 80 A, change it to 75 A.

5. Print the image. Is the problem resolved?

Yes Finished!

No Decrease the absolute value of the negative current by another 5 A.

6. Repeat Step 5. If the image is lighter in density but the problem persists, contact your

service representative.

(b) If the problem occurs on side 2

1. Adjust the setting for the side 2 of the paper. Select [Machine: Image Quality] in

[Advanced Settings] for the custom paper in use, decrease the absolute value of [Side 2]

by 5 A in 1203: [Paper Transfer Output].

Example: If the present current is −100 A, change it to −95 A.

2. Print the image. Is the problem resolved?

Yes Finished!

No Decrease the absolute value of the negative current by another 5 A.

3. Repeat Step 2. If the image is lighter in density but the problem persists, contact your

service representative.

Blister-like White Spots

White spots 0.3–0.5 mm (0.01–0.02 inches) in diameter surrounded by denser spots (blister-like white

spots) appear.

38

Page 41

CEZ602

Color Loss

Cause:

This may occur if a solid image is printed on coated paper, if a solid image is printed during duplex

printing, or if printing is done at low temperature.

Solution:

If blister-like white spots appear, carry out the procedure in page 65 "Insufficient Toner Fusing".

Mottling

Mottling occurs in solid-filled areas.

Normal

39

Page 42

3. Troubleshooting Image Quality Problems

Mottled

Cause:

The transfer electric field on the concave portion of paper is weakened to cause a decrease in

transcription.

This may occur if:

• Using paper with a rough surface

• Continuously printing an image that consumes little toner

• Printing is done at high temperature or humidity

Solution:

Before you perform the solution procedure, make sure that the use rate of the replacement parts does

not exceed 100%. To check this, select 0516: [Display Parts Life Counter] of the [Main Unit:

Maintenance] group in [Adjustment Settings for Operators].

For details about checking the counter, see Adjustment Item Menu Guide.

If the [Display Parts Life Counter] has exceeded 100%, replace the corresponding part.

For details about replacing the parts, see Replacement Guide.

1. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0202: [Adjust Image Density] and execute [Adjust Image Density].

2. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

3. Print 100 full-page, solid-fill A4 or LT sheets. Is the problem resolved?

Yes Finished!

No Reload with new paper.

40

Page 43

4. Print the image. Is the problem resolved?

Yes Finished!

No Replace the paper with smoother paper.

5. If the problem persists, contact your service representative.

Color Loss

41

Page 44

cez552

cez553

3. Troubleshooting Image Quality Problems

Density Problems

Uneven Image Density

The density is uneven.

Solution:

The solution depends on the type of unevenness.

Carry out the appropriate procedure from those in the following table:

(A) The density is uneven across the entire image.

Affected area Solution

The density from

top to bottom is

uneven.

The sides are

fainter or denser.

1. In the [Main Unit: Image

Quality] group on the

[Adjustment Settings for

Operators] menu, select

0202: [Adjust Image

Density] and execute

[Adjust Image Density].

2. If the problem persists, see

page 45 "Uneven

Density from Top to

Bottom".

1. In the [Main Unit: Image

Quality] group on the

[Adjustment Settings for

Operators] menu, select

0202: [Adjust Image

Density] and execute

[Adjust Image Density].

2. If the problem persists,

contact your service

representative.

42

Page 45

Affected area Solution

cez554

cez555

cez556

Density Problems

The top and

bottom are fainter

or denser.

(B) The density is uneven in a part of the image.

Affected area Solution

The leading edge

is fainter.

1. In the [Main Unit: Image

Quality] group on the

[Adjustment Settings for

Operators] menu, select

0202: [Adjust Image

Density] and execute

[Adjust Image Density].

2. If the problem persists,

contact your service

representative.

1. In the [Main Unit: Image

Quality] group on the

[Adjustment Settings for

Operators] menu, select

0202: [Adjust Image

Density] and execute

[Adjust Image Density].

The trailing edge

is fainter.

2. If the problem persists, see

page 46 "Fainter

Leading Edge".

1. In the [Main Unit: Image

Quality] group on the

[Adjustment Settings for

Operators] menu, select

0202: [Adjust Image

Density] and execute

[Adjust Image Density].

2. If the problem persists, see

page 48 "Fainter

Trailing Edge".

43

Page 46

cez558

cez559

CWH402

3. Troubleshooting Image Quality Problems

Affected area Solution

The center is

fainter or denser

Wavy

unevenness

1. In the [Main Unit: Image

Quality] group on the

[Adjustment Settings for

Operators] menu, select

0202: [Adjust Image

Density] and execute

[Adjust Image Density].

2. If the problem persists,

contact your service

representative.

1. In the [Main Unit: Image

Quality] group on the

[Adjustment Settings for

Operators] menu, select

0202: [Adjust Image

Density] and execute

[Adjust Image Density].

2. If the problem persists,

contact your service

representative.

(C) The density is uneven in the direction perpendicular to the paper feed direction at regular

intervals.

Affected area Solution

Periodic vertical

density fluctuation

1. In the [Main Unit: Image

Quality] group on the

[Adjustment Settings for

Operators] menu, select

0202: [Adjust Image

Density] and execute

[Adjust Image Density].

2. If the problem persists, see

page 51 "Periodic

Density Fluctuation".

44

Page 47

Uneven Density from Top to Bottom

CEZ561

The density is uneven from top to bottom.

Density Problems

• You can adjust the density of halftone images, but not that of solid fills.

Cause:

This may occur at high temperature or humidity.

Solution:

1. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0206: [Density Difference: Across Feed].

Decreasing the value makes the area above the center denser and that below fainter.

Increasing the value makes the area above the center fainter and that below denser.

2. Turn off the power and the main power switch, and then turn the main power switch back

on.

The setting specified in step 1 will be in effect.

3. Print the image. Is the problem resolved?

Yes Finished!

No Replace the charge unit and photoconductor unit.

4. If unit replacement does not resolve the problem, contact your service representative.

45

Page 48

CEZ562

3. Troubleshooting Image Quality Problems

• For details about replacing the charge unit and photoconductor unit, see Replacement Guide.

Fainter Leading Edge

The leading edge is fainter.

Cause:

At low temperature or when using thin coated paper, this may occur if the paper transfer current is

insufficient.

At high temperature, this may occur if the paper transfer current is excessive.

• This solution only works when the thickness of the paper is equivalent to Paper Weight 4 or higher.

Do not try this as a solution when using paper with a thickness equivalent to Paper Weight 3 or

lower, as it may cause paper misfeeding.

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

Solution:

Be sure to perform Step "(a) Increase the current value" first, and then Step "(b) Decrease the current

value".

46

Page 49

Density Problems

(a) Increase the current value

1. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use, and

then record the set values of [Leading Edge] and [Leading Edge Length] in 1204: [Paper

Transfer Output Correction: Paper Edge].

2. For [Leading Edge Length], is the set value the upper limit?

Yes Go to Step 7.

No Increase the set value by 5 percentage points.

3. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

4. For [Leading Edge], is the set value lower than 200?

Yes Increase the set value by 10 percentage points.

No Reset [Leading Edge] to the initial value and repeat the steps from Step 2.

5. Print the image. Is the problem resolved?

Yes Finished!

No Repeat the steps from Step 4.

6. If the problem is not resolved by repeating the steps from Step 4 to increase the value of

[Leading Edge] to "200", reset it to the value noted in Step 1 and go to Step "(b) Decrease

the current value".

7. For [Leading Edge], is the set value lower than 200?

Yes Increase the set value by 10 percentage points.

No Switch to a different paper type.

8. Print the image. Is the problem resolved?

Yes Finished!

No Repeat the steps from Step 7.

9. If the problem is not resolved by repeating the steps from Step 7 to increase the value of

[Leading Edge] to "200", reset it to the value noted in Step 1 and go to Step "(b) Decrease

the current value".

47

Page 50

CEZ563

3. Troubleshooting Image Quality Problems

(b) Decrease the current value

1. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use and

decrease [Leading Edge] of 1204: [Paper Transfer Output Correction: Paper Edge] by

10%.

2. Print the image. Is the problem resolved?

Yes Finished!

No Decrease the value by a further 10 percentage points.

3. Repeat Step 2. If the problem is not resolved by decreasing the value by a total of 50

percentage points, reset it to the value noted in Step "(a) Increase the current value" and

contact your service representative.

Fainter Trailing Edge

The trailing edge is fainter.

Cause:

This may occur because of insufficient or excessive paper transfer current when using paper weighing

approximately 160 g/m2 (60 lb. Cover) or heavier at low temperature or humidity.

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

48

Page 51

Density Problems

Solution:

1. Measure in millimeters how far the fainter area extends from the trailing edge.

2. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use,

select 1204: [Paper Transfer Output Correction: Paper Edge] and configure the following

setting.

In [Trailing Edge Length], enter the value you measured in Step 1 plus an additional 10 mm.

3. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use and

record the set values of [Trailing Edge] in 1204: [Paper Transfer Output Correction: Paper

Edge].

4. Increase the scaling factor in the above setting by 10 percentage points.

5. Print the image. Is the problem resolved?

Yes Finished!

No Increase the scaling factor by 5 percentage points.

6. Repeat Step 5. If the problem persists even though you have increased the scaling factor

by 50 percentage points, restore the value noted in Step 3 and go to the next step.

7. Decrease the scaling factor in the above setting by 10 percentage points.

8. Print the image. Is the problem resolved?

Yes Finished!

No Decrease the scaling factor by 5 percentage points.

9. Repeat Step 8. If the problem persists even though you have decreased the scaling factor

by 50 percentage points, restore the value noted in Step 3 and contact your service

representative.

Uneven Density within 90 mm (3.5 in.) of the Trailing Edge

Printing in the area extending approximately 90 mm (3.5 inches) from the trailing edge is fainter or

denser.

49

Page 52

90 mm

(3.5 in.)

90 mm

(3.5 in.)

CEZ564

3. Troubleshooting Image Quality Problems

Cause:

This may occur if:

• Printing is done at low temperature or humidity

• Printing a single-dot halftone image

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

Solution:

The solution depends on whether the area within 90 mm (3.5 inches) of the trailing edge is denser or

fainter.

<If the area within 90 mm (3.5 inches) of the trailing edge is fainter>

1. Select [Machine: Paper Feed / Output] in [Advanced Settings] for the custom paper in use

and check the set values of [Transfer Timing Roller] in 1351: [Motor Speed]. Is it the upper

limit value?

Yes Contact your service representative.

No Go to the next step.

2. Increase the value in [Transfer Timing Roller] by 0.1 percentage point.

3. Print the image. Is the problem resolved?

Yes Finished!

50

Page 53

CWH407

Density Problems

No Repeat Steps 2 and 3. If the problem persists even though you have increased the value to

+1.0%, contact your service representative.

<If the area within 90 mm (3.5 inches) of the trailing edge is denser>

1. Select [Machine: Paper Feed / Output] in [Advanced Settings] for the custom paper in use

and check the set values of [Transfer Timing Roller] in 1351: [Motor Speed]. Is it the lower

limit value?

Yes Contact your service representative.

No Go to the next step.

2. Decrease the value in [Transfer Timing Roller] by 0.1 percentage point.

3. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 2 and 3. If the problem persists even though you have decreased the value

to -1.0%, contact your service representative.

Periodic Density Fluctuation

The vertical density fluctuates periodically.

51

Page 54

CEZ585

3. Troubleshooting Image Quality Problems

Solution:

Before you perform the solution procedure, make sure that the environmental conditions where you are

using the machine meet those recommended for use. For details on the environmental conditions for use,

see "Where to Put Your Machine", Maintenance and Management.

The solution depends on the interval.

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

Interval Solution

Approximately 12-18 mm (0.5-0.7 inches) Contact your service representative.

Approximately 60 mm (2.4 inches) Select [Machine: Paper Feed / Output] in [Advanced

Settings] for the custom paper in use and adjust the

set value of [Transfer Timing Roller] in 1351: [Motor

Speed] according to the paper type and thickness.

If the problem persists, contact your service

representative.

Approximately 95 mm (3.7 inches) Contact your service representative.

Approximately 314 mm (12.4 inches) Replace the photoconductor unit. If the problem

persists, contact your service representative.

• For details about replacing the photoconductor unit, see Replacement Guide.

Entire Image Faint

The entire image is fainter than normal.

52

Page 55

CEZ568

Density Problems

Cause:

This may occur if:

• Continuously printing an image that consumes little toner

• The machine has not been used for a long time

• The machine is located somewhere very humid and has not been used for a while

Solution:

1. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0202: [Adjust Image Density] and execute [Adjust Image Density].

2. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

3. Increase the value by 1 in 0204: [Maximum Image Density].

4. Select 0202: [Adjust Image Density] and execute [Adjust Image Density].

5. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 3 to 5. If the problem persists even though you have increased the value to

5, contact your service representative.

Color Is Too Dense

The entire image is denser than normal.

53

Page 56

3. Troubleshooting Image Quality Problems

Cause:

This may occur if:

• Continuously printing an image that consumes much toner

• The machine has not been used for a long time

• The machine is located somewhere very humid and has not been used for a while

Solution:

1. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0202: [Adjust Image Density] and execute [Adjust Image Density].

2. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

3. Decrease the value by 1 in 0204: [Maximum Image Density].

4. Select 0202: [Adjust Image Density] and execute [Adjust Image Density].

5. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 3 to 5. If the problem persists even though you have decreased the value to

-5, contact your service representative.

Broken Thin Lines

Thin lines (1 dot lines in 1200 dpi images) break.

54

Page 57

CEZ569

Density Problems

Cause:

Oblique (approximately 45°) thin lines or thin lines printed in faint colors are likely to contain breaks.

Solution:

1. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0202: [Adjust Image Density] and execute [Adjust Image Density].

2. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

3. Increase the value by 1 in 0205: [Line Width].

4. Select 0202: [Adjust Image Density] and execute [Adjust Image Density].

5. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 3 to 5. If the problem persists even though you have increased the value to

5, contact your service representative.

Blurred Images

Lens-shaped blurred images appear at 314 mm (12.4 inches) intervals.

55

Page 58

314 mm (12.4 in.) 314 mm (12.4 in.)

CZC310

3. Troubleshooting Image Quality Problems

Cause:

If the machine is left unattended for a long period in an environment where temperature and humidity

are high, corona products on the drum absorb moisture to prevent a buildup or removal of static

electricity on the drum.

Solution:

1. In the [Main Unit: Maintenance] group on the [Adjustment Settings for Operators] menu,

select 0502: [Execute Photoconductor Refreshing] and execute [Photoconductor

Refreshing].

2. Print the image. Is the problem resolved?

Yes Finished!

No Contact your service representative.

Dropouts (Character Voids)

Dropouts (character voids) occur when characters or lines are printed.

56

Page 59

CNT003

Cause:

This may occur if:

• Continuously printing an image that consumes much toner

Density Problems

• The machine has not been used for a long time

• The machine is located somewhere very humid and has not been used for a while

Solution:

1. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0202: [Adjust Image Density] and execute [Adjust Image Density].

2. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

3. Decrease the value by 1 in 0204: [Maximum Image Density].

4. Select 0202: [Adjust Image Density] and execute [Adjust Image Density].

5. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 3 to 5. If the problem persists even though you have decreased the value to

-5, contact your service representative.

57

Page 60

CZC311

3. Troubleshooting Image Quality Problems

Afterimages

An afterimage of the image printed just before the intended image appears.

Cause:

This may occur when the image record on the intermediate transfer belt has largely changed. For

example, this may occur when a solid-fill image is printed after horizontal lines are printed continuously.

A potential difference occurs between an image portion and non-image portion on the intermediate

transfer belt as a result of continuous printing of horizontal lines, causing the horizontal lines to become

obvious on the next solid-fill image.

This may occur if:

• Printing is done at high temperature or humidity

• Printing on thin coated paper (Paper Weight 3 or lower) or on transparent film

• Printing an extremely different type of image

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

Solution:

1. In the [Main Unit: Image Quality] group on the [Adjustment Settings for Operators] menu,

select 0202: [Adjust Image Density] and execute [Adjust Image Density].

2. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

58

Page 61

CZC312

Density Problems

3. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use and

decrease the value of [Side 1] or [Side 2] in 1203: [Paper Transfer Output] by 10 A.

Example: -200 A to -190 A

4. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 3 and 4. If the problem persists even though you have decreased the value

to -100 A, contact your service representative.

White Streaks

White streaks perpendicular to the paper feed direction appear.

Cause:

A separating discharge occurs between the intermediate transfer belt and paper edge during paper

transfer, which causes a streak-like electric charge on the intermediate transfer belt. This residual electric

charge may cause white streaks during image transfer.

This may occur at low temperature or humidity.

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

Solution:

1. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use,

select [Trailing Edge Length in 1204: Paper Transfer Output Correction: Paper Edge].

59

Page 62

270 mm

(106.3 in.)

ECG078

3. Troubleshooting Image Quality Problems

2. Check the present value. Is it the upper limit?

Yes Go to Step 5.

No Go to the next step.

3. Increase the value by 5 mm in [Trailing Edge Length].

4. Print the image. Is the problem resolved?

Yes Finished!

No Go to the next step.

5. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use,

select [Trailing Edge in 1204: Paper Transfer Output Correction: Paper Edge].

6. Check the present value. Is it the lower limit?

Yes Reset the value back to the factory-default settings and perform steps from Step 1 again.

No Decrease the value by 20% in [Trailing Edge].

7. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 5 to 7. If the problem persists even though you have decreased the value to

the lower limit, contact your service representative.

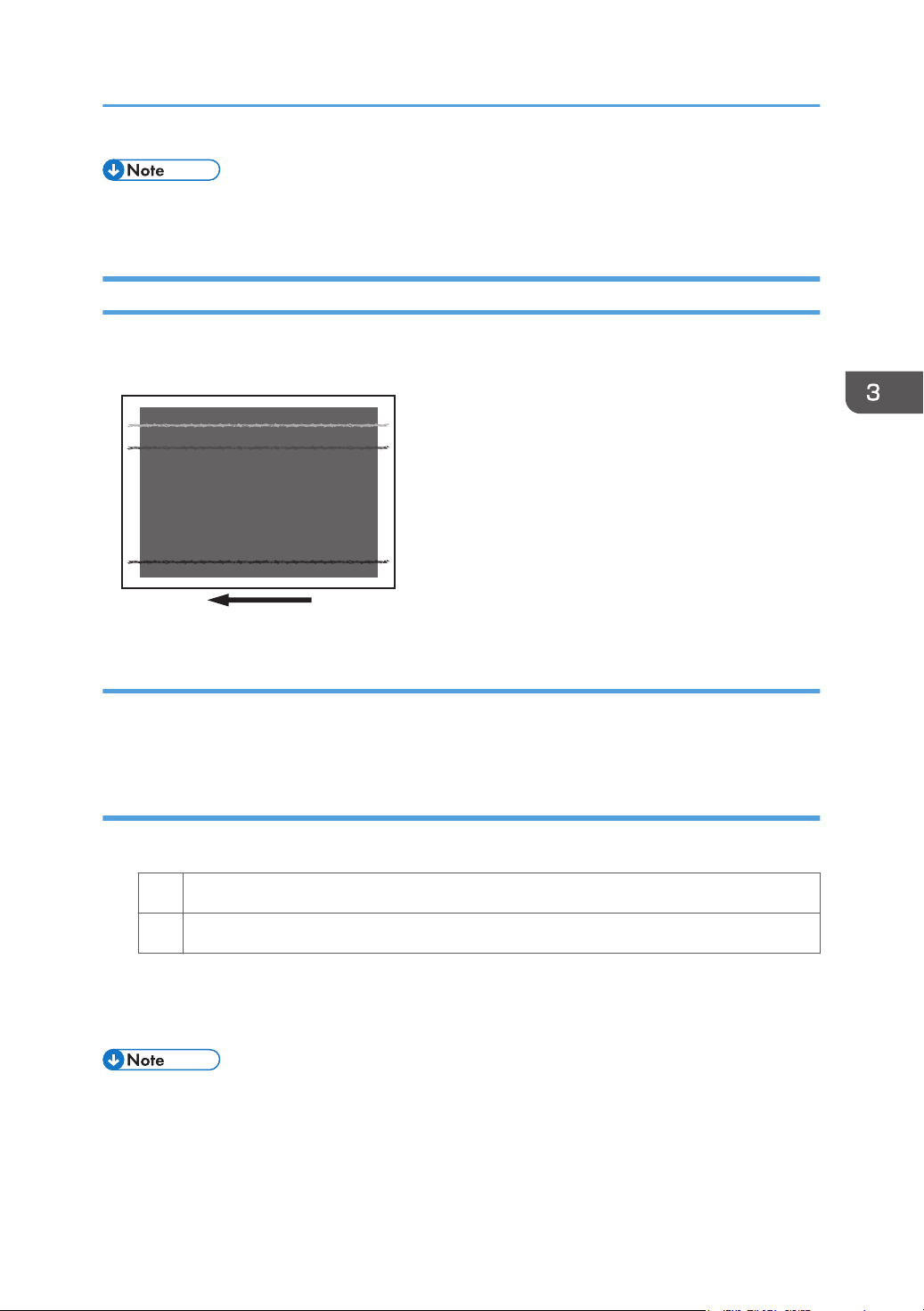

Shock jitter: When the paper is inserted

Horizontal black streaks occur at the position 270 mm from the leading edge of the paper due to the

shock when the paper is inserted.

60

Page 63

Density Problems

Cause:

Horizontal black streaks might occur at the position 270 mm from the leading edge of the paper due to

the shock when the paper is inserted being transmitted to the paper transfer part.

This may occur if:

• When printing on a paper with length longer than 270 mm

• Thick paper is used

• Printing a halftone image

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

Solution:

1. Can you change the paper length to 270 mm or less?

Yes Go to the next step.

No Go to Step 3.

2. Print a paper with length of 270 mm or less. Is the problem resolved?

Yes Finished!

No Contact your service representative.

3. Select [Machine: Paper Feed / Output] in [Advanced Settings] for the custom paper in use

and check the set value of [Fusing Belt] in 1351: [Motor Speed].

4. Decrease the value by 0.1% in [Fusing Belt].

5. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 4 to 6. If the problem persists even though you have lowered the setting

value to -0.4%, go to step 7.

6. Select [Machine: Paper Feed / Output] in [Advanced Settings] for the custom paper in use

and check the set value of [Process Speed Setting] in 1351: [Motor Speed].

7. Decrease the value of [Process Speed Setting]. Is it okay that productivity will be

reduced?

Yes Go to the next step.

61

Page 64

3. Troubleshooting Image Quality Problems

No Contact your service representative.

8. Decrease the value by one level in [Process Speed Setting].

9. Print the image. Is the problem resolved?

Yes Finished!

No Repeat Steps 8 to 10. If the problem persists even though you have decreased the value

to [Low], contact your service representative.

62

Page 65

Gloss Problems

DTH012

251 mm

(10 inches)

251 mm

(10 inches)

Vertical Glossy Lines

Glossy lines perpendicular to the paper feed direction appear.

Gloss Problems

Cause:

Glossy lines perpendicular to the paper feed direction may appear 251 mm (10 inches) from the

boundary of the margin and the solid image (in the paper feed direction).

Solution:

1. Print the image on twenty sheets. Do glossy lines appear on the tenth sheet and later

sheets?

Yes Go to the next step.

No You cannot resolve the problem with this procedure. Contact your service representative.

2. Select [Machine: Image Quality] in [Advanced Settings] for the custom paper in use,

select 1206: [Fusing Temperature] and decrease the value in [Heat Roller Temp] by 5

degrees.

63

Page 66

3. Troubleshooting Image Quality Problems

3. Print the image on twenty sheets. Do glossy lines appear on the tenth sheet and later

sheets?

Yes Repeat Step 2 and 3. If the problem persists even though the setting has reached its

minimum value, contact your service representative. If the problem is resolved, go to the

next step.

No Go to the next step.

4. Check the toner fusion. Is it satisfactory?

Yes Finished!

No Restore the previous setting and contact your service representative.

Insufficient Gloss

The image is not glossy enough.

Solution:

If the gloss of the image is not glossy enough, carry out the procedures in Procedure 1, "Changing the

fusing temperature" and Procedure 2, "Changing the process speed" of page 65 "Insufficient Toner

Fusing".

64

Page 67

Fusing Problems

Fusing Problems

Insufficient Toner Fusing

This section explains how to resolve the problem of insufficient toner fusing on printed copies.

• To adjust the following settings, pre-register the type of paper in use as a custom paper. For details

about registering custom papers, see "Registering a Custom Paper", Preparation.

• Changing the fusing temperature or changing the process speed may produce one or more of the

following side effects:

• Paper curling

• Paper misfeeding

• Blisters

• Glossy lines

• Change of gloss

• If one or more of the above side effects occurs, adjust the fusing temperature and process speed by

decreasing the fusing temperature and increasing the process speed.

• Check the toner fusibility as follows:

• The printed image does not come off.

• The toner does not come off even if it is lightly rubbed by a nail.

• The toner does not come off even if it is rubbed by the cloth for cleaning the exposure glass.

Solution: