Ricoh Pro C5210s, Pro C5200s, Pro 5210S Operating Instructions Manual

Operating Instructions

Adjustment Item Menu Guide: TCRU/ORU

For safe and correct use, be sure to read the Safety Information in "Read This First" before using the machine.

TABLE OF CONTENTS

Introduction......................................................................................................................................................... 3

How to Read This Manual................................................................................................................................. 4

Symbols...........................................................................................................................................................4

Disclaimer........................................................................................................................................................4

Notes...............................................................................................................................................................4

Manuals for This Machine................................................................................................................................. 5

Paper Feed Direction of Printed Copies (Side 1/Side 2)............................................................................... 6

1. Adjustment Settings for Skilled Operators

Displaying the [Adjustment Settings for Skilled Operators] Button.................................................................9

Accessing Adjustment Settings for Skilled Operators....................................................................................12

Layout of Adjustment Settings for Skilled Operators..................................................................................... 14

Features of the Displayed Items and Setting Operations..............................................................................15

Notes on How Adjustment Settings are Applied to Printed Copies............................................................. 17

2. Details of Menu Items in Adjustment Settings for Skilled Operators

Menu Items and Functions...............................................................................................................................19

Setting Values................................................................................................................................................... 27

[Machine: Image Position].......................................................................................................................... 27

[Machine: Image Quality]...........................................................................................................................33

[Machine: Paper Feed/ Output]................................................................................................................ 39

[Machine: Maintenance]............................................................................................................................ 42

[Preprocessing: LCT].................................................................................................................................... 46

[Finishing: Finisher].......................................................................................................................................47

[Finishing: Fold]............................................................................................................................................ 81

3. Custom Paper Settings for Administrators

Accessing Advanced Settings......................................................................................................................... 91

Access Using the Control Panel.................................................................................................................. 91

Access Using Web Image Monitor............................................................................................................ 93

Description of Paper Icons...............................................................................................................................95

Deleting Saved Custom Paper Profiles........................................................................................................... 96

Paper Presets in "Advanced Settings".............................................................................................................99

Displaying the Paper Profile Version.......................................................................................................... 99

Backing up and Restoring Custom Paper Profiles....................................................................................... 100

Backing up Custom Paper Profiles Saved in the Saved Paper Library..................................................100

1

Backing up Custom Paper Profiles Registered Under the [Edit] Setting................................................ 100

Backing up and Restoring Custom Paper Profiles Using the External Controller's Control Panel.......101

4. Details of Menu Items in Advanced Settings

Menu Items and Functions............................................................................................................................ 103

Setting Values.................................................................................................................................................112

Paper Feed Adjustment............................................................................................................................. 112

Paper Delivery Adjustment........................................................................................................................113

Image Position/Scaling Adjustment.........................................................................................................113

Line Speed Adjustment..............................................................................................................................119

Toner Adhesion Adjustment......................................................................................................................128

Transfer Adjustment................................................................................................................................... 129

Fuser Adjustment........................................................................................................................................141

Decurler Adjustment.................................................................................................................................. 149

Finishing Position Adjustment....................................................................................................................149

2

Introduction

This manual contains detailed instructions and notes on the operation and use of this machine. For your

safety and benefit, read this manual carefully before using the machine. Keep this manual in a handy

place for quick reference.

3

How to Read This Manual

Symbols

This manual uses the following symbols:

Indicates points to pay attention to when using the machine, and explanations of likely causes of paper

misfeeds, damage to originals, or loss of data. Be sure to read these explanations.

Indicates supplementary explanations of the machine’s functions, and instructions on resolving user

errors.

This symbol is located at the end of sections. It indicates where you can find further relevant information.

[ ]

Indicates the names of keys on the machine's display or control panels.

Disclaimer

Contents of this manual are subject to change without prior notice.

In no event will the company be liable for direct, indirect, special, incidental, or consequential damages

as a result of handling or operating the machine.

Notes

The manufacturer shall not be responsible for any damage or expense that might result from the use of

parts other than genuine parts from the manufacturer with your office products.

For good output quality, the manufacturer recommends that you use genuine toner from the

manufacturer.

Some illustrations in this manual might be slightly different from the machine.

Certain options might not be available in some countries. For details, please contact your local dealer.

Depending on which country you are in, certain units may be optional. For details, please contact your

local dealer.

Two kinds of size notation are employed in this manual. With this machine refer to the inch version.

4

Manuals for This Machine

The following manuals are for skilled operators only.

Adjustment Item Menu Guide

This manual explains the items in Adjustment Settings for Skilled Operators and the advanced

settings for custom paper adjustment in "System Settings".

Replacement Guide

This manual explains how to replace the machine's components.

Troubleshooting

This manual explains how to troubleshoot problems related to image quality, paper delivery, and

other aspects of machine operation.

5

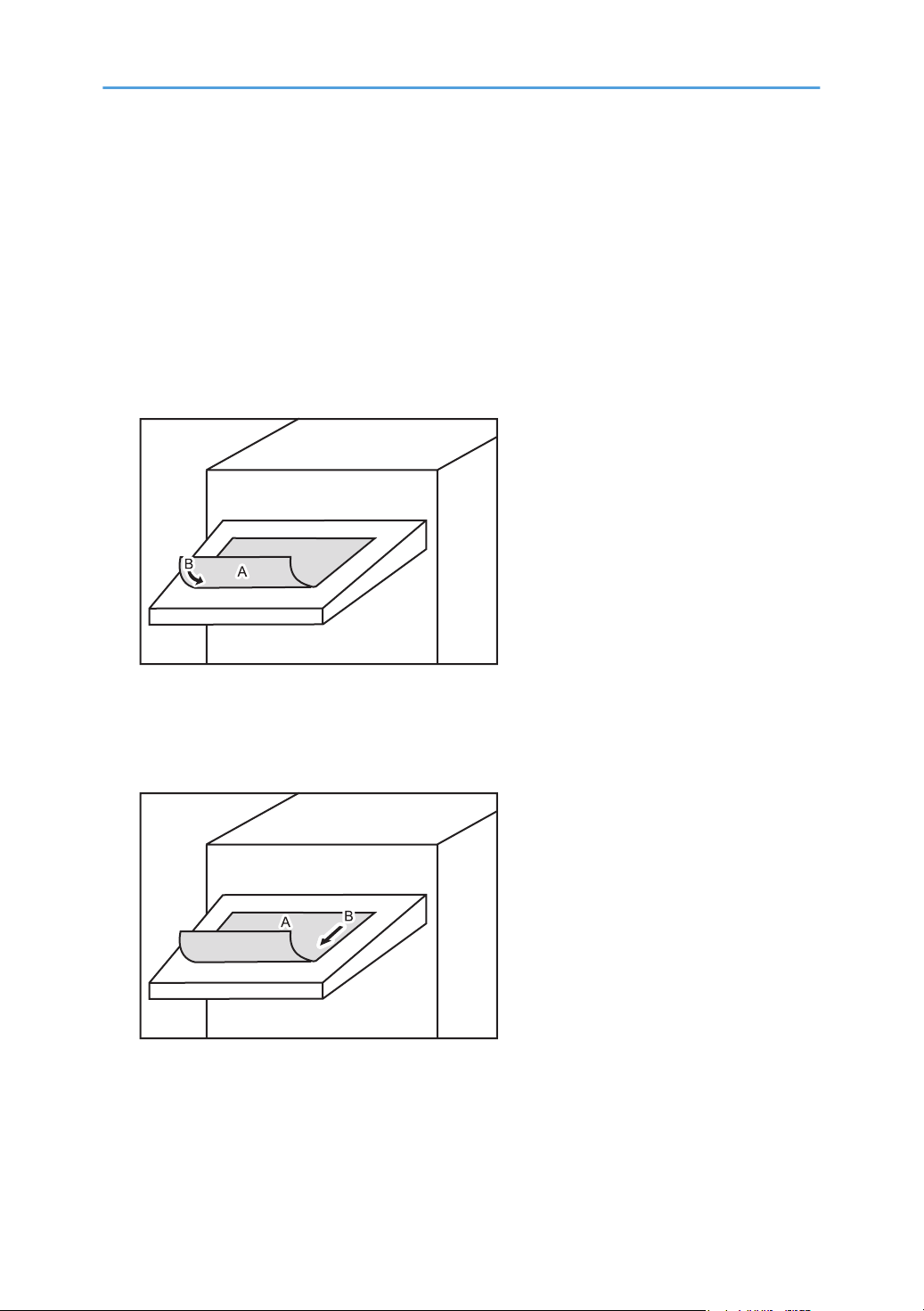

Paper Feed Direction of Printed Copies (Side

DSM008

DSM009

1/Side 2)

Depending on the setting, printed copies are fed as follows:

Side 1 is the surface of the paper printed during one-sided printing, or the surface of the first print during

duplex printing.

Side 2 is the surface of the paper printed on the back side of Side 1 during duplex printing.

Single-sided printing: Printed side face down

A. Side 1

B. Paper feed direction of Side 1

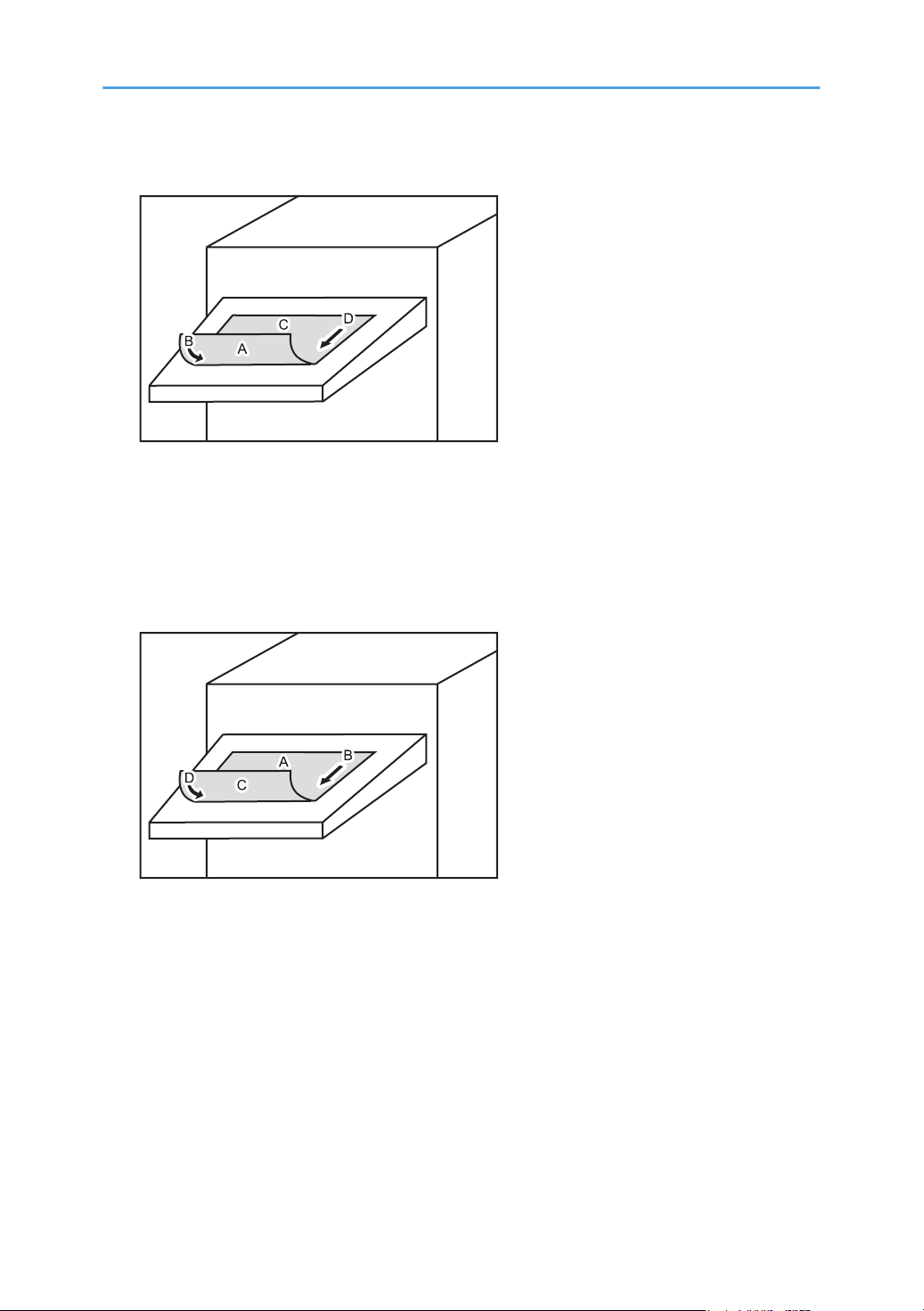

Single-sided printing: Printed side face up

A. Side 1

B. Paper feed direction of Side 1

6

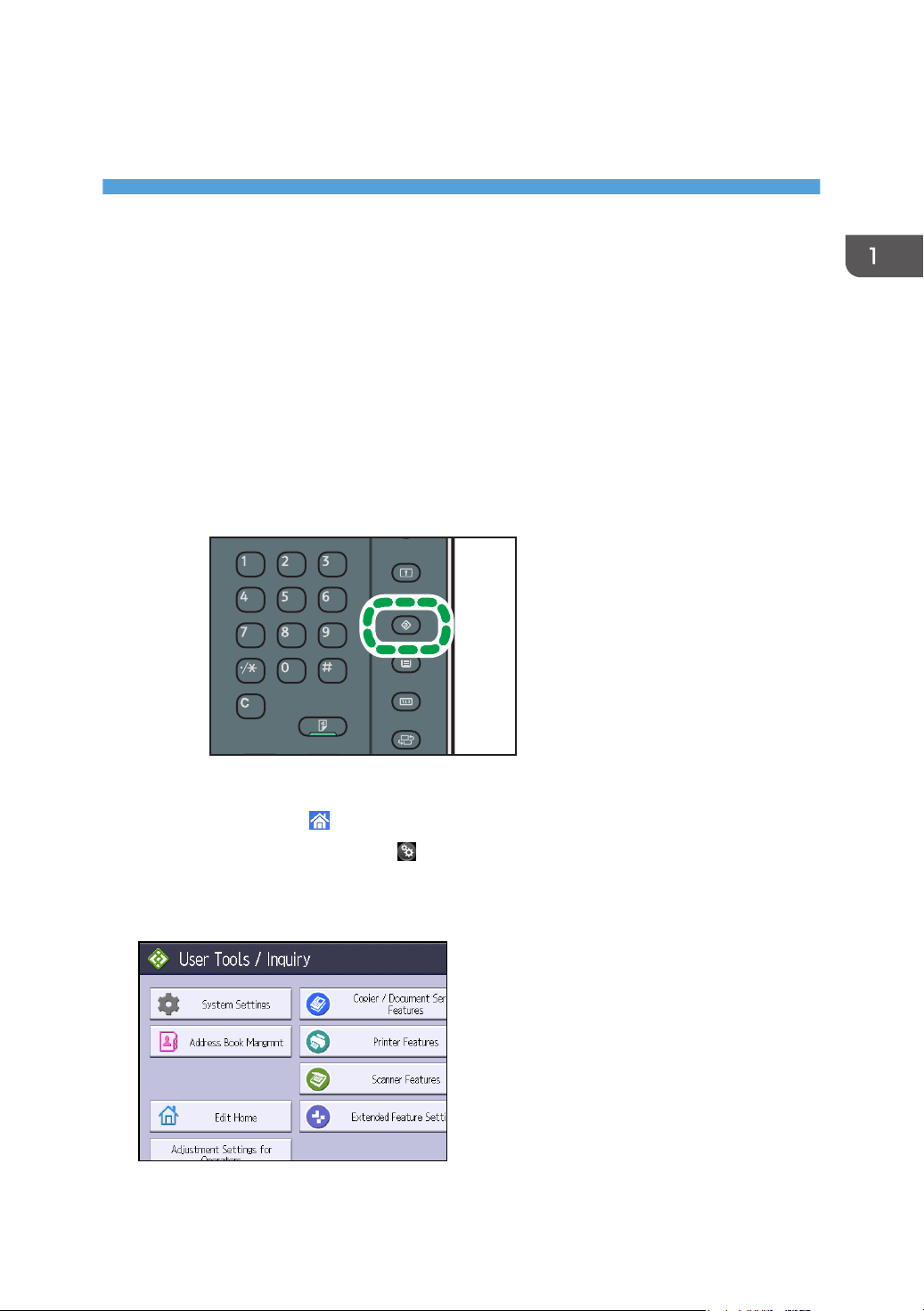

Duplex printing: Printed side face down

DSM010

DWM001

A. Side 1

B. Paper feed direction of Side 1

C. Side 2

D. Paper feed direction of Side 2

Duplex printing: Printed side face up

A. Side 1

B. Paper feed direction of Side 1

C. Side 2

D. Paper feed direction of Side 2

7

8

1. Adjustment Settings for Skilled

CUV110

Operators

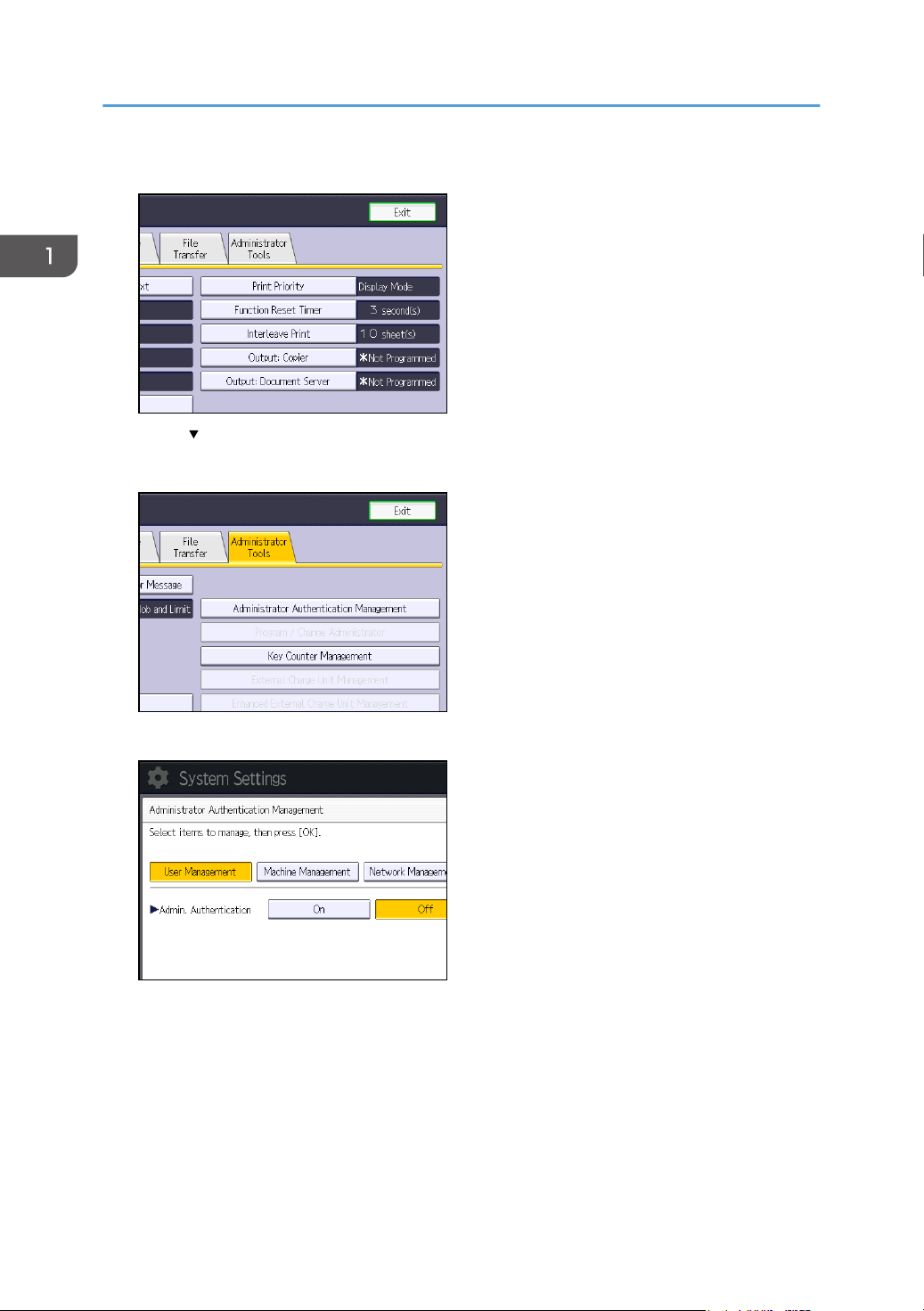

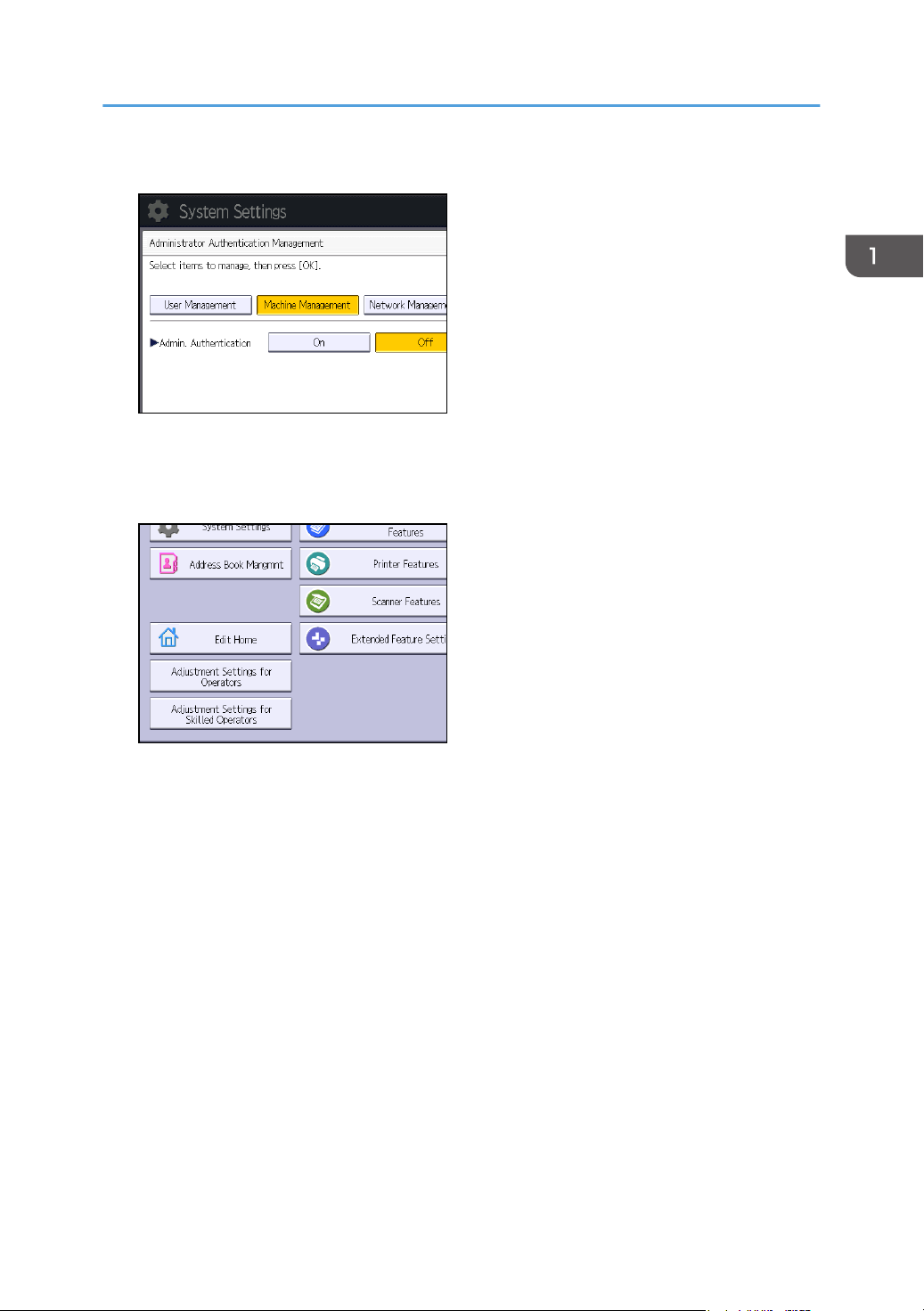

Displaying the [Adjustment Settings for Skilled Operators] Button

To use the Adjustment Settings for Skilled Operators, you must first configure your machine's

Administrator Authentication Management setting.

1. Display the initial settings screen.

• When using the standard operation panel

1. Press the [User Tools] key.

• When using the Smart Operation Panel (For mainly Europe and North America)

1. Press [Home] ( ) at the bottom of the screen in the center.

2. Press the [User Tools] icon ( ) on the [Home] screen.

3. Press [Machine Features].

2. Press [System Settings].

9

1. Adjustment Settings for Skilled Operators

3. Press [Administrator Tools].

4. Press [ Next].

5. Press [Administrator Authentication Management].

10

6. Press [Machine Management].

Displaying the [Adjustment Settings for Skilled Operators] Button

7. Select [On] for "Admin. Authentication".

8. Press [OK].

9. Press [Exit].

The [Adjustment Settings for Skilled Operators] button appears.

11

1. Adjustment Settings for Skilled Operators

Accessing Adjustment Settings for Skilled Operators

1. Press [Adjustment Settings for Skilled Operators].

2. Press [Login].

12

3. Enter your login user name, and then press [OK].

If you are logging on as the administrator for the first time, enter "admin".

4. Enter your login password, and then press [OK].

The Adjustment Settings for Skilled Operators appears.

Accessing Adjustment Settings for Skilled Operators

13

321

CWH201

1. Adjustment Settings for Skilled Operators

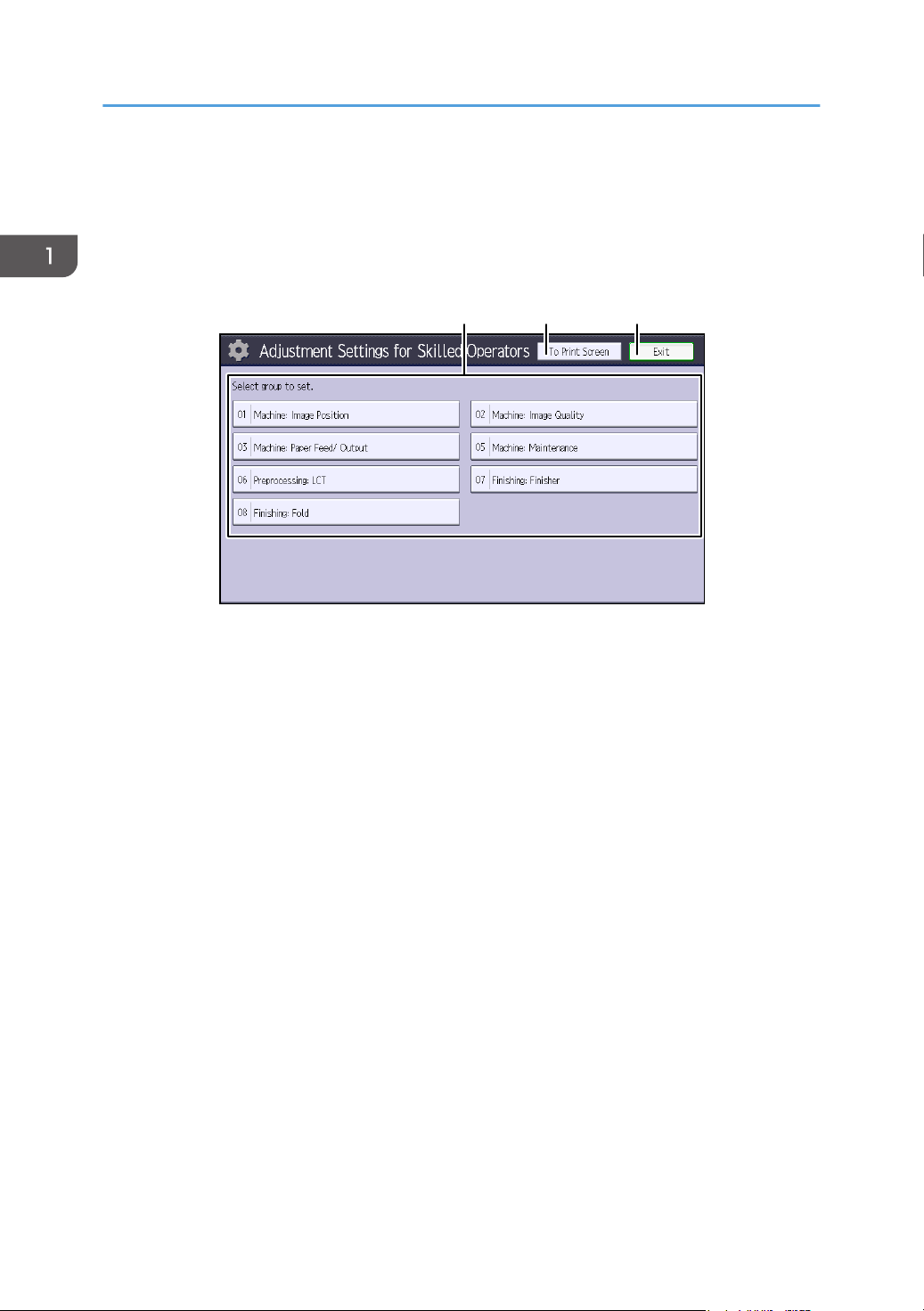

Layout of Adjustment Settings for Skilled Operators

This section explains how to use Adjustment Settings for Skilled Operators.

1. Adjustment items are displayed in this area. Select the setting you want to specify or change.

2. Press this button to display the print screen. You can use this screen to view the changes you have

made.

3. Press this button to close Adjustment Settings for Skilled Operators.

14

Features of the Displayed Items and Setting Operations

Features of the Displayed Items and Setting

Operations

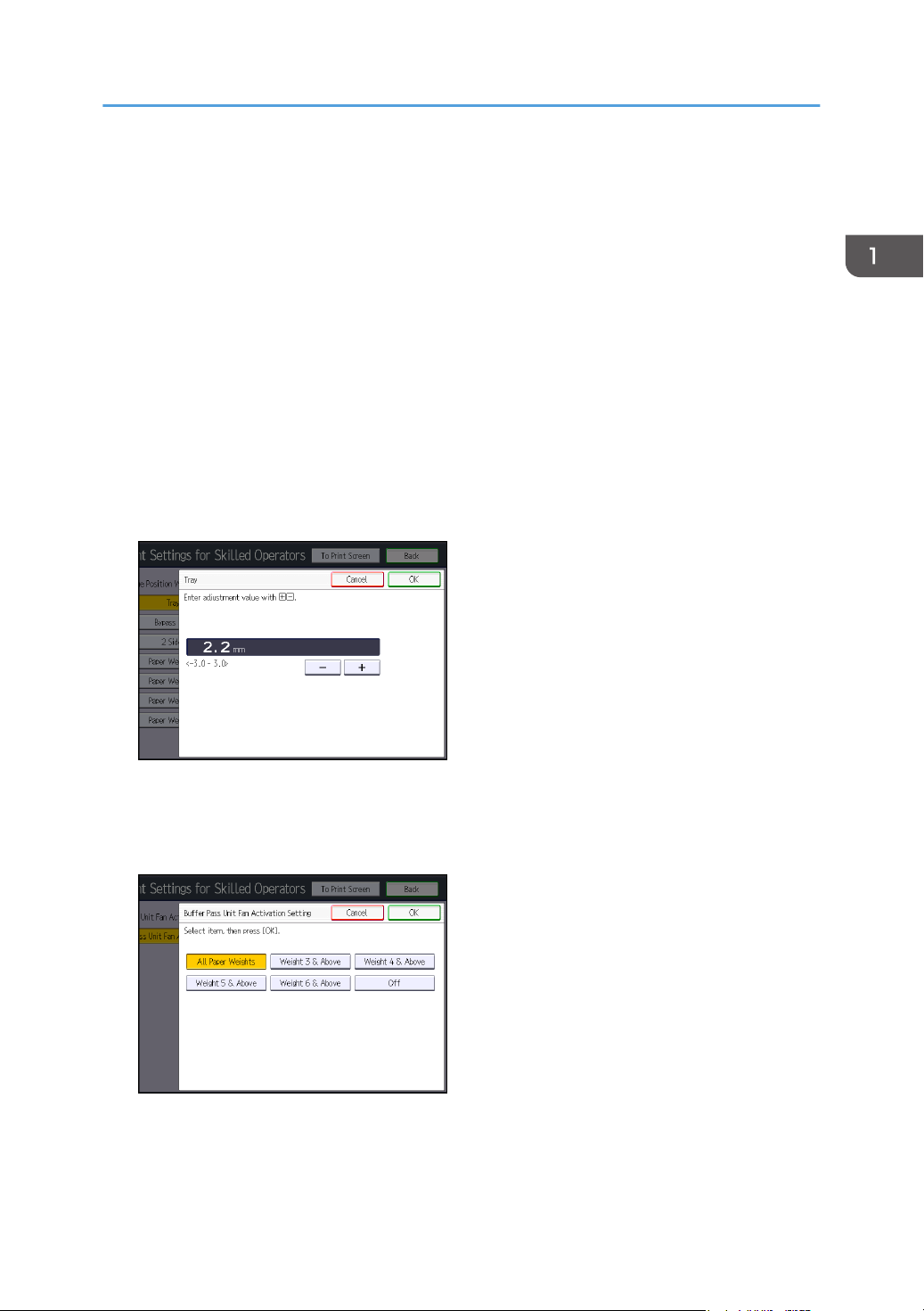

The following operations are available for each adjustment item:

• Value setting

• Item setting

• Executing

• Display only

Value setting

Press [+] to increase the value, or [-] to decrease. You can also use the number keys to enter

numbers.

Select [OK] to apply the new setting.

Item setting

Select the item you require.

Select [OK] to apply the new setting.

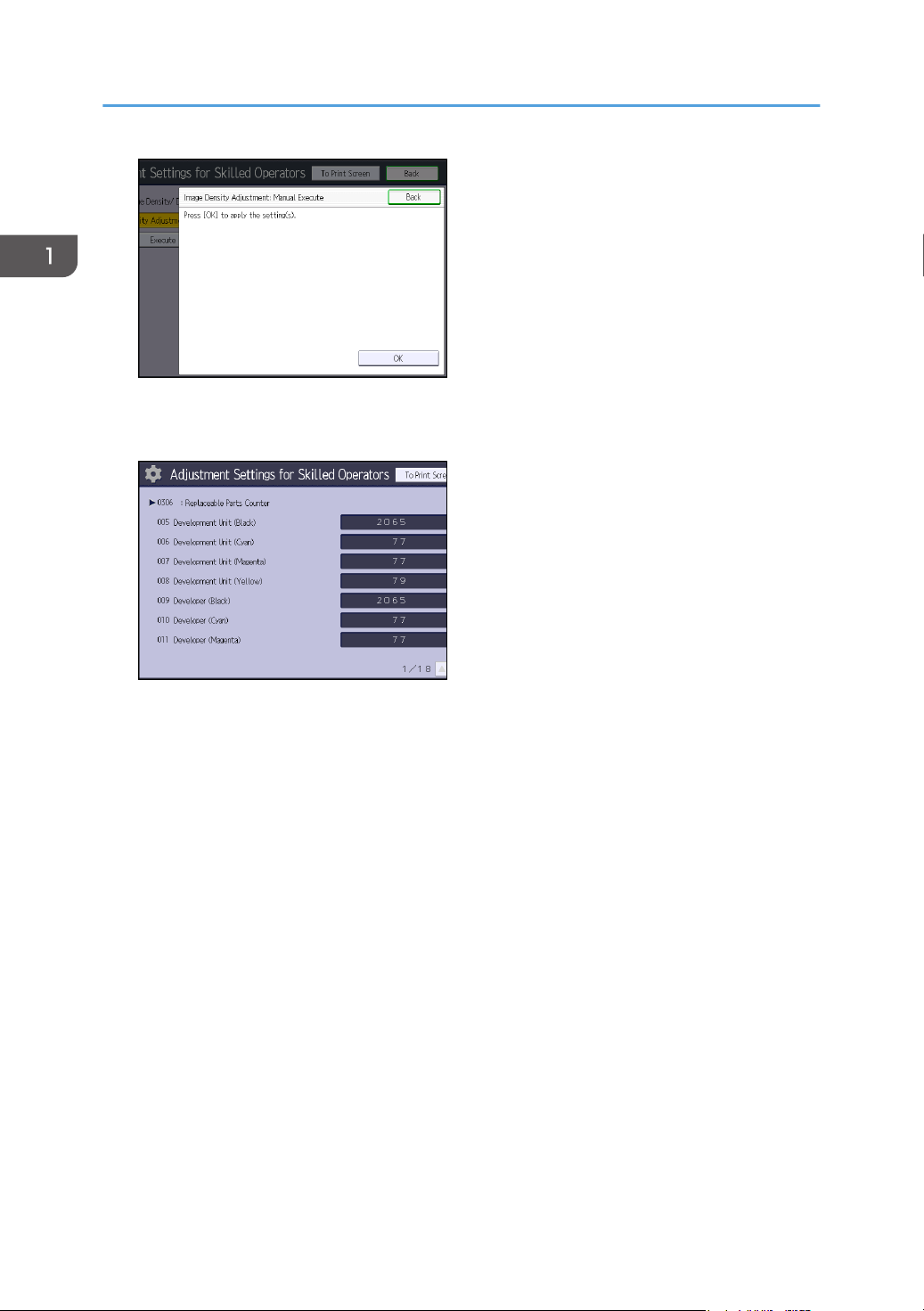

Executing

Press [OK] to perform a selected function.

15

1. Adjustment Settings for Skilled Operators

Display only

You can check the setting for the selected item.

16

Notes on How Adjustment Settings are Applied to Printed Copies

Notes on How Adjustment Settings are Applied

to Printed Copies

The adjustment settings are applied to printed copies according to the settings specified for each paper

tray, paper size, and paper weight.

Depending on the adjustment setting, the same settings specified under different categories may be

applied to printed copies concurrently.

• Settings for each paper tray

• Settings for each paper weight

• Settings for each paper size

Settings for each paper tray

These adjustment settings can be specified for each paper tray.

The settings are applied only to printed copies fed from each paper tray.

Settings for each paper weight

These adjustment settings can be specified for each paper weight.

The settings are applied only to printed copies of each paper weight.

Settings for each paper size

These adjustment settings can be specified for each paper size.

17

1. Adjustment Settings for Skilled Operators

The settings are applied only to printed copies of each paper size.

• For information about the paper tray, paper thickness, and tray paper size settings that can be

specified for a particular function, see the manual for the relevant function.

18

2. Details of Menu Items in Adjustment Settings for Skilled Operators

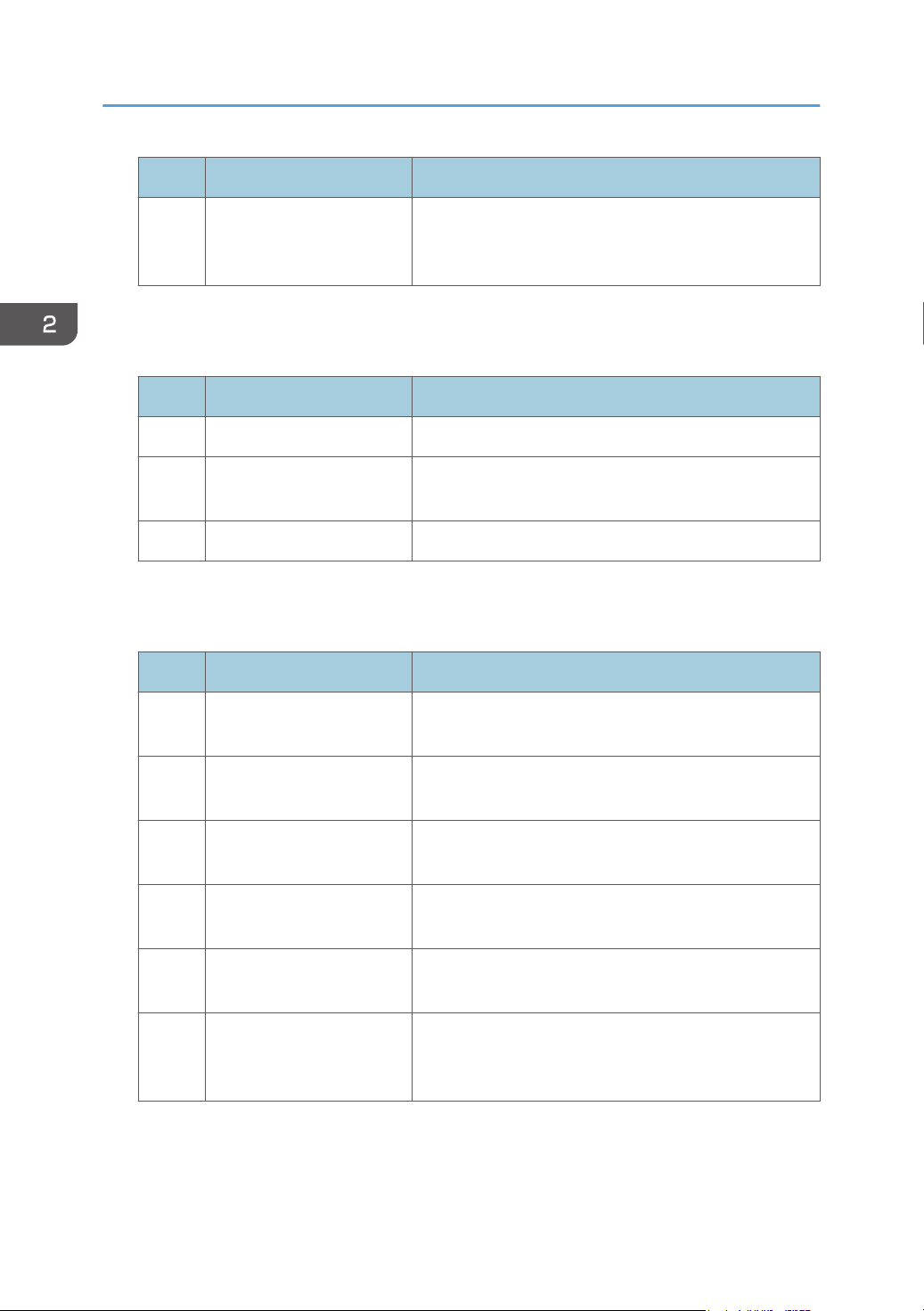

Menu Items and Functions

[Machine: Image Position]

For details about the following items, see page 27 "[Machine: Image Position]".

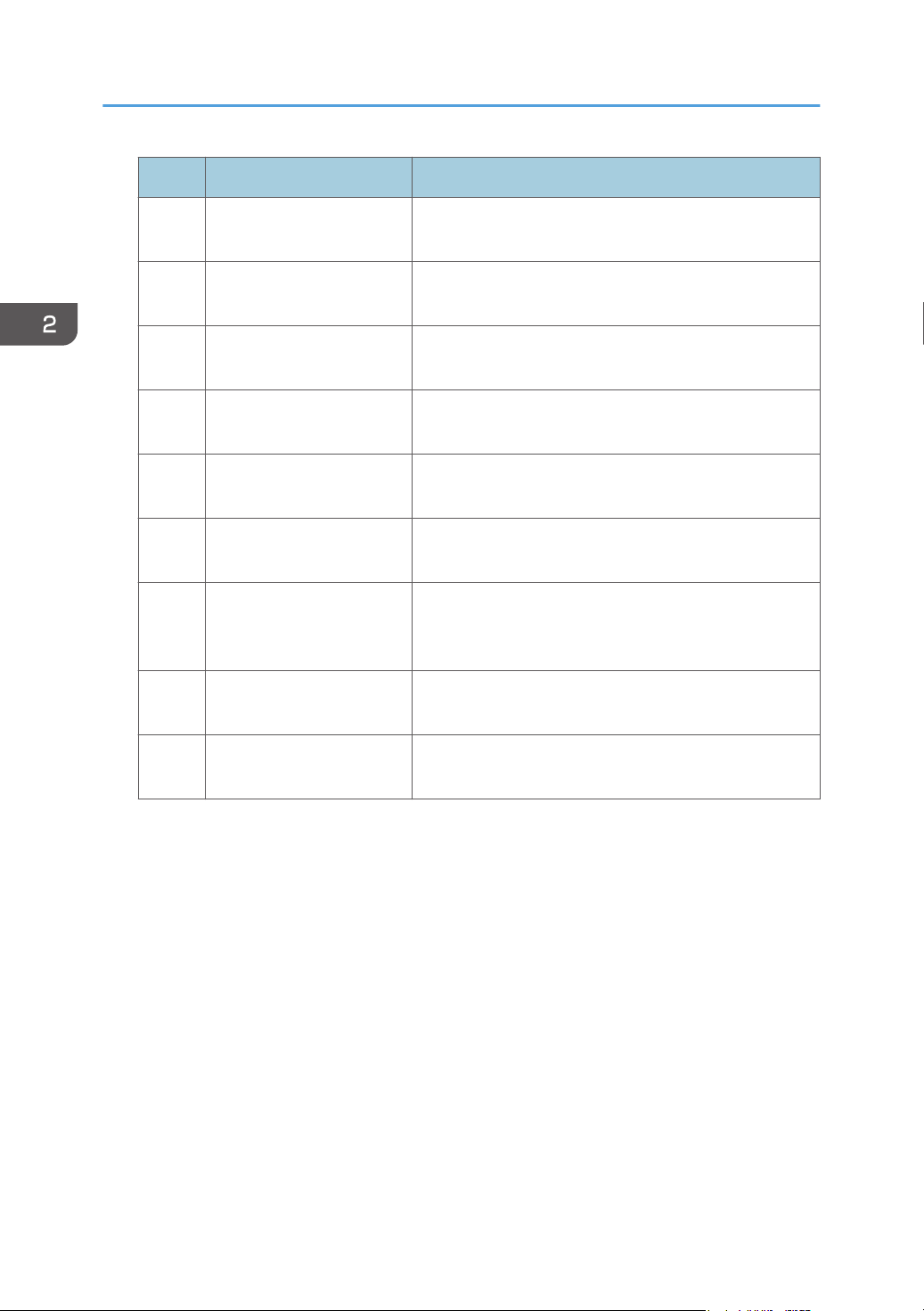

No. Item Description

0101 [Image Position: With

Feed]

0102 [Image Position: Across

Feed]

0107 [Erase Margin: Leading

Edge/Trailing Edge]

[Machine: Image Quality]

For details about the following items, see page 33 "[Machine: Image Quality]".

No. Item Description

0201 [Adjust Image Density/

DEMS]

0202 [Image Density Adjustment

Execute Interval]

0203 [Maximum Image Density] Specify the adhesion of toner to the drum surface and

Adjust the horizontal position of the print image.

Adjust the vertical position of the print image.

Adjust the mask width at the leading edge, trailing edge,

left edge, or right edge of the image.

Execute image density control manually.

DEMS can reduce the variations in thickness that occur in

the intervals between the photoconductor and

development sleeve operations.

Specify the number of sheets the machine prints in full

color before it automatically adjusts image density.

intermediate transfer belt when image density adjustment

is executed.

0204 [Line Width] Adjust the intensity of the laser for transferring image

data to the drum.

0205 [Density Difference: Across

Feed]

Adjust the image density difference between the top and

bottom of the image.

19

2. Details of Menu Items in Adjustment Settings for Skilled Operators

No. Item Description

0207 [Fusing Temperature on

Standby]

0208 [Auto Color Selection

Setting]

Adjust the set fusing temperature according to the

machine status.

Specify the number of sheets the machine prints in full

color mode before switching to black-and-white mode

when printing a job which involves full color printing

followed by black-and-white printing.

0209 [Photoconductor Special

Mode]

Increase the amount of lubricant applied to the

photoconductor.

0210 [Smooth Fusing Belt] Polish the fusing belt to eliminate the scratches caused by

paper edges.

0211 [Fusing Ability by Feed

Speed]

0212 [Slope for Envelope Nip

Width]

Specify appropriately to improve transferability to thick

paper.

Adjust the slope for nip width between the fusing belt

and the pressure roller when an envelope is being fed.

0213 [PCU Potential] Adjust the current supplied to the photoconductor unit at

high temperature and humidity.

0214 [Fusing Belt Smoothing

Setting: Uneven Gloss]

Specify whether or not to automatically execute [For

Uneven Gloss (Short Time)] for smooth fusing belt.

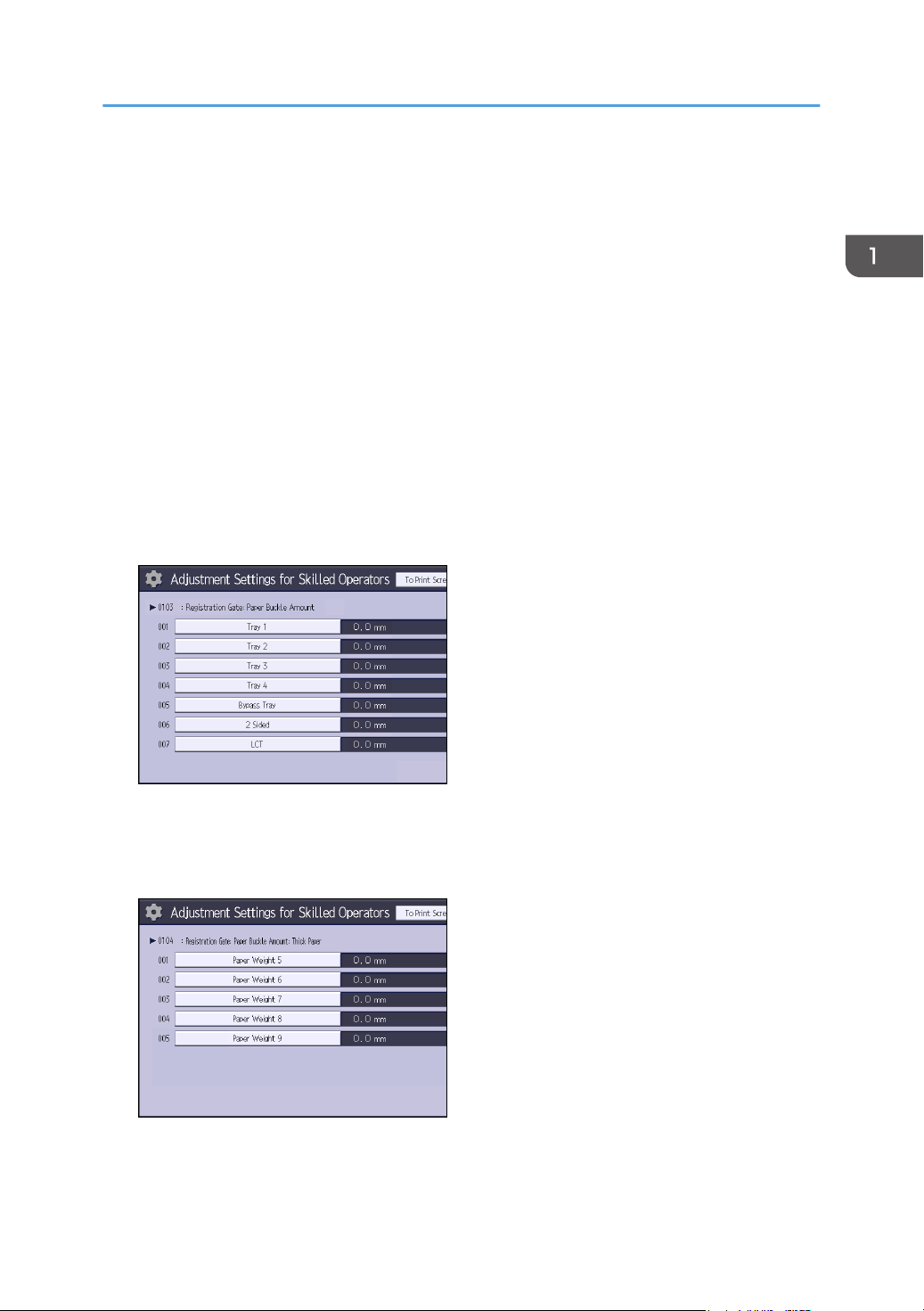

[Machine: Paper Feed/ Output]

For details about the following items, see page 39 "[Machine: Paper Feed/ Output]".

No. Item Description

0103 [Registration Gate: Paper

Buckle Amount]

0104 [Registration Gate: Paper

Buckle Amount: Thick

Paper]

0106 [Criteria for Paper Weight] Adjust the criteria used to determine the paper weight.

0130 [Perpendicularity

Adjustment]

20

Adjust the allowable amount of buckle when the edge of

the paper is pressed against the registration unit.

Adjust the allowable amount of buckle for paper of

Paper Weight 5 to 9 when the edge of the paper is

pressed against the registration unit.

Adjust the vertical skew of the image.

No. Item Description

Menu Items and Functions

0140 [Buffer Pass Unit Fan

Select when the buffer pass unit fan is to operate.

Activation Setting]

[Machine: Maintenance]

For details about the following items, see page 42 "[Machine: Maintenance]".

No. Item Description

0301 [Execute Cleaning Initial

Setting]

0302 [Execute Process Initial

Initialize the cleaning unit for the photoconductor unit

(PCU).

Initialize print settings at once.

Setting]

0303 [ITB Manual Lubrication] Lubricate the intermediate transfer belt.

0304 [Tighten Fuser Cleaning

Tighten the cleaning web after replacing it.

Unit at Replacement]

0305 [Reset Replaceable Parts

Counter Reset the counter for replaceable parts.

Counter]

0306 [Replaceable Parts

Display the counters for replaceable units.

Counter]

0307 [Target Value for

Replaceable Part]

0308 [Execute Charge Roller

Cleaning]

0309 [Execute Developer

Refreshing]

0310 [Counter Settings for Fuser

Unit Replacement]

0702 [Temperature / Humidity

outside the Machine]

0703 [Back Up / Restore Custom

Paper Data]

Display the values at which replaceable units must be

replaced.

Clean the charge roller unit.

Replenish the developer manually.

Replace part of the developer in the development unit.

Display the counter for the fuser unit replacement.

Display the external temperature and humidity.

Back up and restore custom paper profiles.

21

2. Details of Menu Items in Adjustment Settings for Skilled Operators

No. Item Description

0704 [Switch Print Screen] Switch to the print screen if you want to output an

alignment pattern to check image misalignment with the

color controller connected.

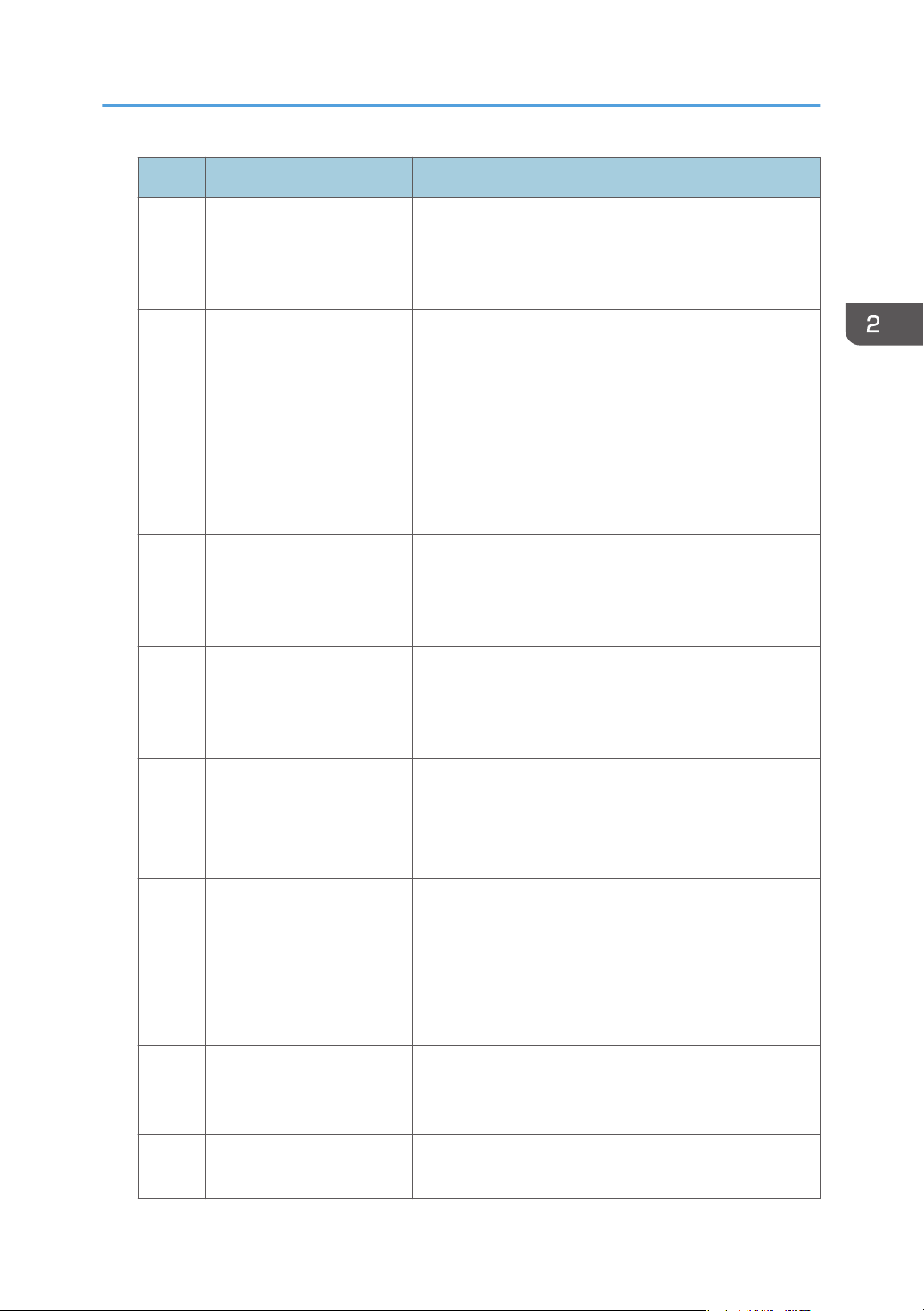

[Preprocessing: LCT]

For details about the following items, see page 46 "[Preprocessing: LCT]".

No. Item Description

0108 [Wide LCT: Fan Level] Adjust the airflow of the wide LCT for fanning the sheets.

0109 [Wide LCT: Fan Timer] Adjust the duration of the airflow of the wide LCT for

fanning the sheets.

0110 [Pickup Assist] Specify the paper feed roller movement.

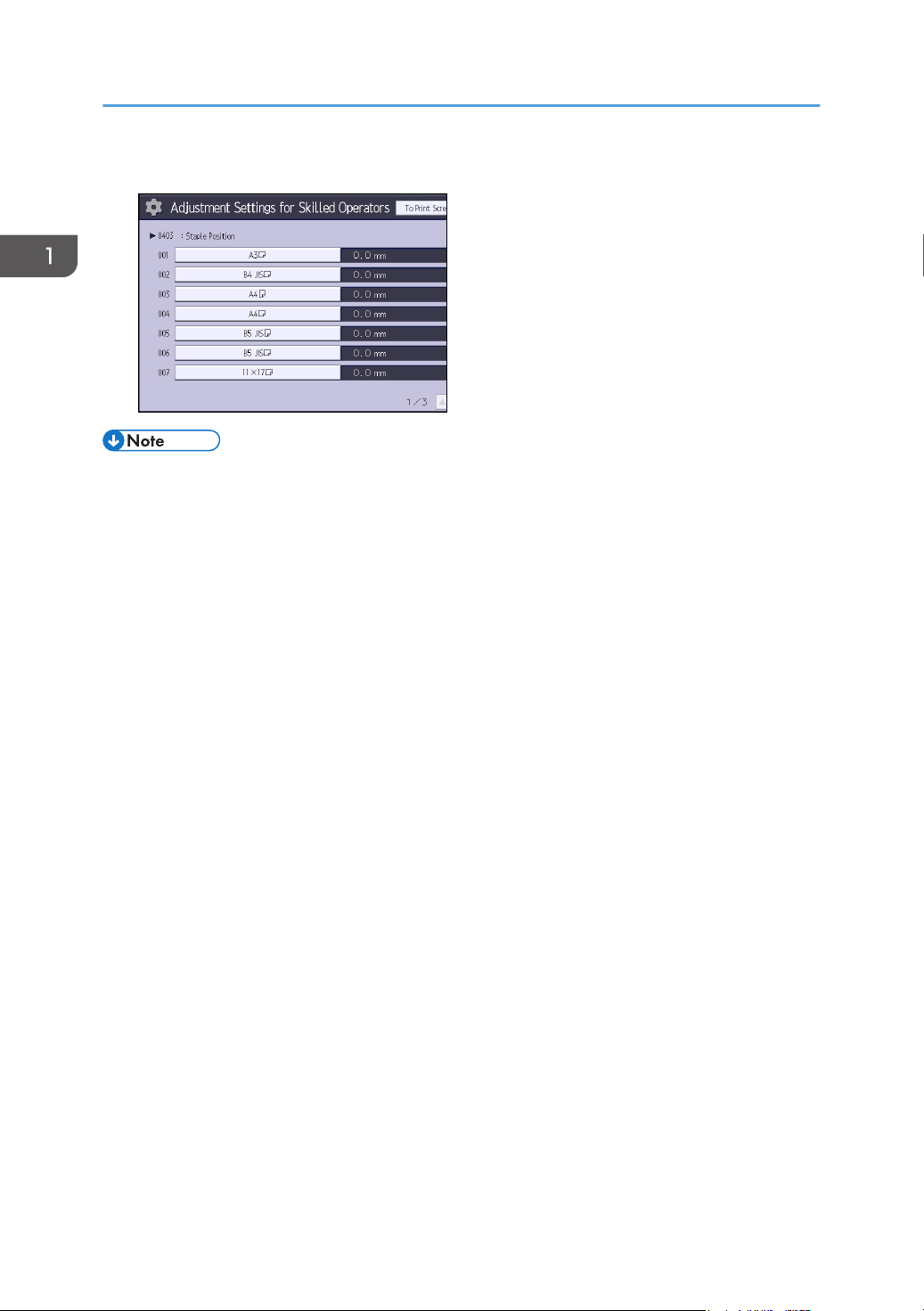

[Finishing: Finisher]

For details about the following items, see page 47 "[Finishing: Finisher]".

No. Item Description

0401 [Punch Position: With Feed] Adjust the horizontal position of the punch holes when

using Finisher SR4120 or Finisher SR4130.

0402 [Punch Position: Across

Feed]

Adjust the vertical position of the punch holes when using

Finisher SR4120 or Finisher SR4130.

0403 [Staple Position] Adjust the vertical position of the staples when using

Finisher SR4120 or Finisher SR4130.

0404 [Staple Position for Booklet] Adjust the horizontal position of the booklet staples when

using Finisher SR4130.

0405 [Folding Position for

Booklet]

Adjust the horizontal folding position when using Finisher

SR4130.

0406 [Folding Speed for Booklet] Adjust the speed of center folding by the SR4130

finisher. By reducing the folding speed, you can make

folds crisper.

22

Menu Items and Functions

No. Item Description

0407 [Correct Punch Skew] Adjust skew correction for punching in order to reduce

punch skew due to difference in size, thickness, and

paper curl when using Finisher SR4120 or Finisher

SR4130.

0408 [Punch Skew Correction] Disable punch skew correction function if jams or

edgefolding problems occur particularly when punching

lightweight paper using Finisher SR4120 or Finisher

SR4130.

0409 [Paper Alignment in Shift

Tray: Across Feed]

0410 [Paper Alignment for

Stapling: Across Feed]

0411 [Paper Alignment for

Booklet: Across Feed]

0412 [Paper Tapping for Extra

Feed for Stapling]

0413 [Claw Shift for Center

Folding]

Adjust the width of the paper alignment jogger in the shift

tray in order to reduce vertical variation in paper

alignment due to difference in size, thickness, and paper

curl when using Finisher SR4120 or Finisher SR4130.

Adjust the width of the staple jogger for edge stapling in

order to reduce vertical variation in paper alignment due

to difference in size, thickness, and paper curl when

using Finisher SR4120 or Finisher SR4130.

Adjust the width of the staple jogger for booklets in order

to reduce vertical variation in paper alignment due to

difference in size, thickness, and paper curl when using

Finisher SR4130.

Adjust the paper tapping for extra paper feed to the

paper guide for stapling.

Adjust this setting if the paper delivered to the paper

guide for stapling overshoots or stops short of the guide.

Adjust the paper alignment in the paper feed direction

for center folding.

Adjust this setting if the paper alignment in the paper

feed direction is inaccurate because of inconsistent

paper size and paper curling when using certain types of

paper.

0801 [Staple Position: Across

Feed 1]

0802 [Staple Position: Across

Feed 2]

Adjust the vertical position of the staple (applied at an

edge) when using Finisher SR5070 or Booklet Finisher

SR5080.

Adjust the vertical position of the staples (dual) when

using Finisher SR5070 or Booklet Finisher SR5080.

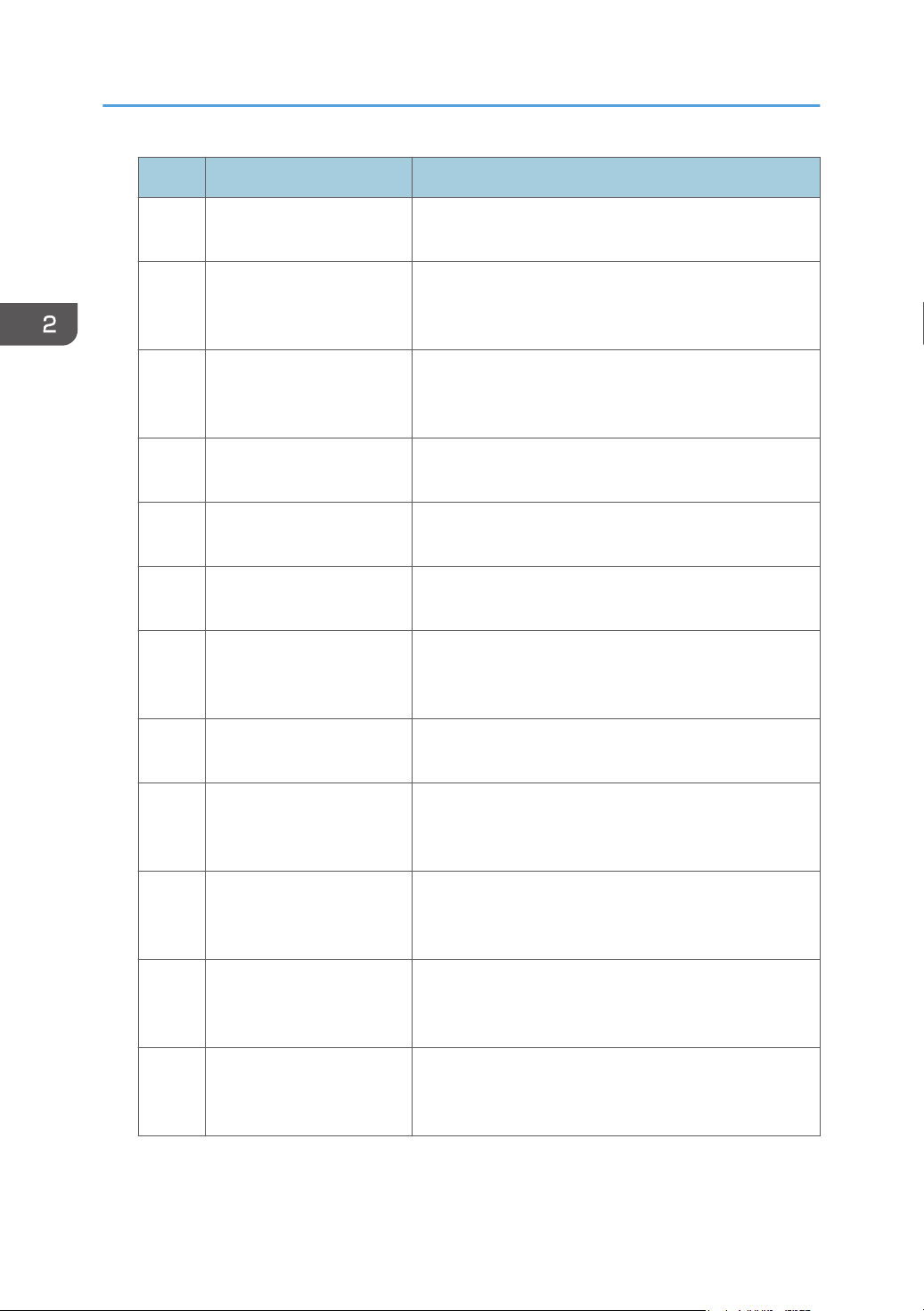

23

2. Details of Menu Items in Adjustment Settings for Skilled Operators

No. Item Description

0803 [Staple Position: With

Feed]

0804 [Paper Alignment for

Stapling: Across Feed]

Adjust the horizontal position of the staples when using

Finisher SR5070 or Booklet Finisher SR5080.

Adjust the width of the staple jogger for edge stapling

when using Finisher SR5070 or Booklet Finisher

SR5080.

0805 [Paper Alignment for

Stapling: With Feed]

Adjust the travel distance of the paper edge stopper for

edge stapling when using Finisher SR5070 or Booklet

Finisher SR5080.

0806 [Number of Sheet Align for

Stapling]

0807 [Punch Position: Across

Feed]

Specify the number of sheets the staple unit aligns at a

time for stapling.

Adjust the vertical position of the punch holes when using

Finisher SR5070 or Booklet Finisher SR5080.

0808 [Punch Position: With Feed] Adjust the horizontal position of the punch holes when

using Finisher SR5070 or Booklet Finisher SR5080.

0809 [Correct Punch Skew] Specify whether or not to enable punch skew correction

when using Finisher SR5070 or Booklet Finisher

SR5080.

24

0810 [Punch Skew Correction] Adjust the amount of skew correction for punching when

using Finisher SR5070 or Booklet Finisher SR5080.

0811 [Paper Alignment in Shift

Tray Setting]

Specify the accuracy of printed paper alignment when

applying shift-sorting with Finisher SR5070 or Booklet

Finisher SR5080.

0812 [Paper Alignment in Shift

Tray: Across Feed]

Adjust the width of the paper alignment jogger in the shift

tray when using Finisher SR5070 or Booklet Finisher

SR5080.

0813 [Output Tray Descending

Position]

Specify the descending position for the finisher shift tray

when paper is delivered to it using Finisher SR5070 or

Booklet Finisher SR5080.

0814 [Exit Guide Close Timing:

Booklet Fin]

Specify when to close the exit guide after paper is

delivered to the finisher shift tray of Finisher SR5070 or

Booklet Finisher SR5080.

No. Item Description

Menu Items and Functions

0815 [Output Trail Edge Press

Setting]

Specify whether or not to press down the trailing edge of

the paper when it is delivered to the finisher shift tray of

Finisher SR5070 or Booklet Finisher SR5080.

0816 [Output Fan Setting] Specify how the shift tray fan moves when using Finisher

SR5070 or Booklet Finisher SR5080.

0817 [Output Fan Level] Adjust the airflow of the shift tray for fanning the sheets

when using Finisher SR5070 or Booklet Finisher

SR5080.

0818 [Staple Position for Booklet] Adjust the horizontal position of the booklet staples when

using Booklet Finisher SR5080.

0819 [Folding Position for

Booklet]

0820 [Paper Alignment for

Booklet: Across Feed]

Adjust the horizontal position of the folding when using

Booklet Finisher SR5080.

Adjust the width of the staple jogger for booklets when

using Booklet Finisher SR5080.

0821 [Folding Speed for Booklet] Specify the number of booklet folds to be performed

when using Booklet Finisher SR5080.

0822 [Paper Alignment for

Booklet: With Feed]

Adjust the travel distance of the paper edge stopper for

booklets when using Booklet Finisher SR5080.

0823 [Z-fold Skew Correction] Specify how to correct skew (occurring during paper

transport) when Z-folding with the folding unit.

0824 [Correct Z-fold Skew] Adjust the length of sheets moved for Z-fold skew

correction.

0825 [Correct Z-fold Skew:

Reverse]

0826 [Maximum No. Stacked

Sheets in Output Tray]

Adjust how much the registration roller rotates in reverse

for Z-fold skew correction.

Specify the amount of paper stacked in Finisher SR5070

or Booklet Finisher SR5080.

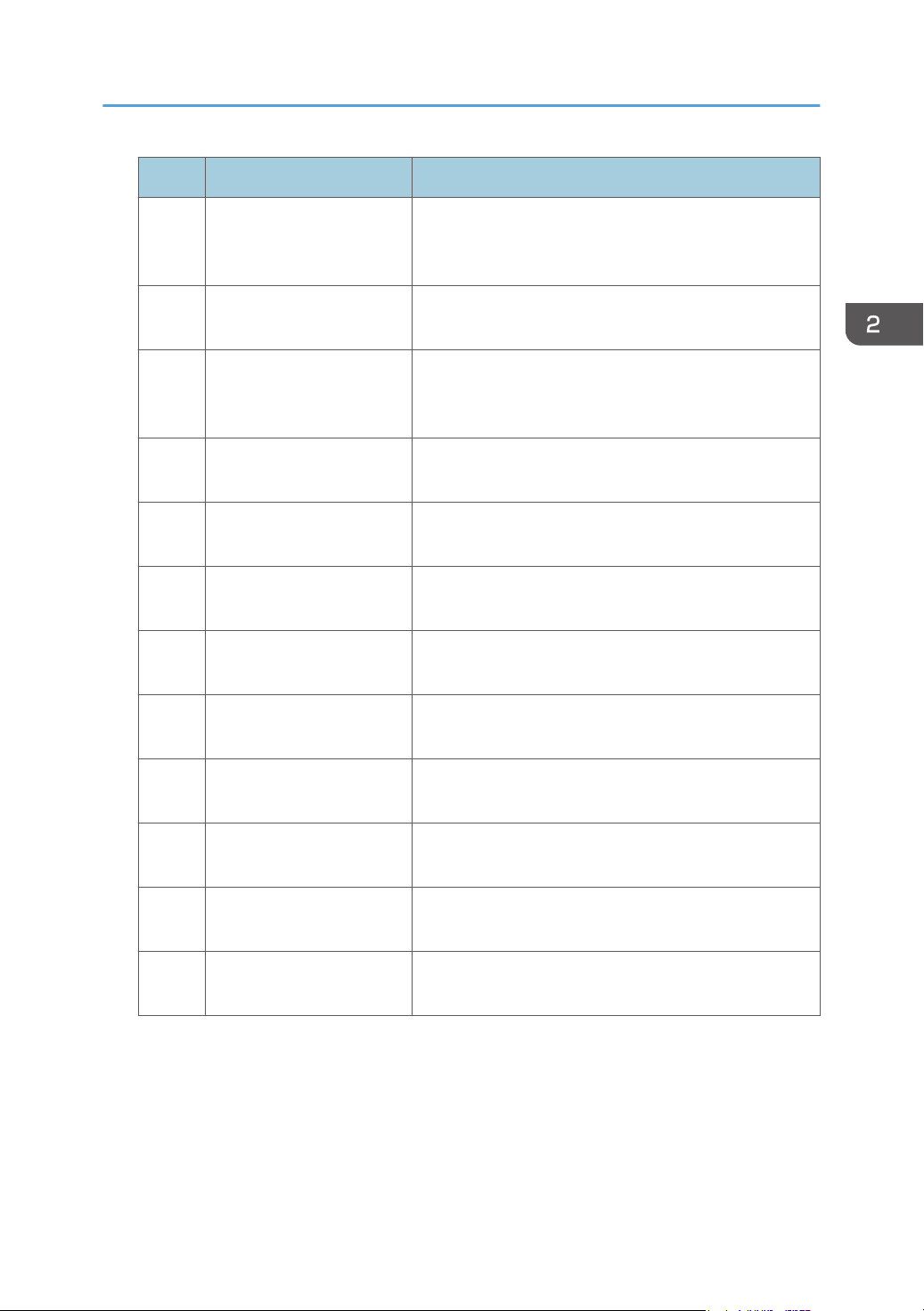

[Finishing: Fold]

For details about the following items, see page 81 "[Finishing: Fold]".

When using custom paper, settings for [Z-fold Position 1] or [Z-fold Position 2] in the [Advanced

Settings] for custom paper are prioritized.

25

2. Details of Menu Items in Adjustment Settings for Skilled Operators

No. Item Description

0601 [Half Fold Position: Multi-

sheet Fold]

0602 [Letter Fold-out Position 1:

Multi-sheet Fold]

0603 [Letter Fold-out Position 2:

Multi-sheet Fold]

0604 [Letter Fold-in Position 1:

Multi-sheet Fold]

0605 [Letter Fold-in Position 2:

Multi-sheet Fold]

0606 [Folding Unit Tray Full

Detection]

0607 [Number of Sheets Folded

after Full Detection]

Adjust the fold position of half folded sheets when using

the multi-folding unit.

Adjust the fold position for the bottom segment of letter

fold-out sheets when using the multi-folding unit.

Adjust the overall fold size of letters fold-out sheets when

using the multi-folding unit.

Adjust the fold position of the bottom segment of letter

fold-in sheets when using the multi-folding unit.

Adjust the fold position of letters fold-in sheets when

using the multi-folding unit.

Specify whether or not to automatically detect when the

folding unit tray becomes full.

Specify the number of sheets the machine prints when it

detects that the folding unit tray is full before displaying a

warning message.

0608 [Z-fold Position 1] Adjust the width of the bottom end segment of Z-folded

sheets when using the multi-folding unit.

26

0609 [Z-fold Position 2] Adjust the overall fold size of Z-fold sheets when using

the multi-folding unit.

Setting Values

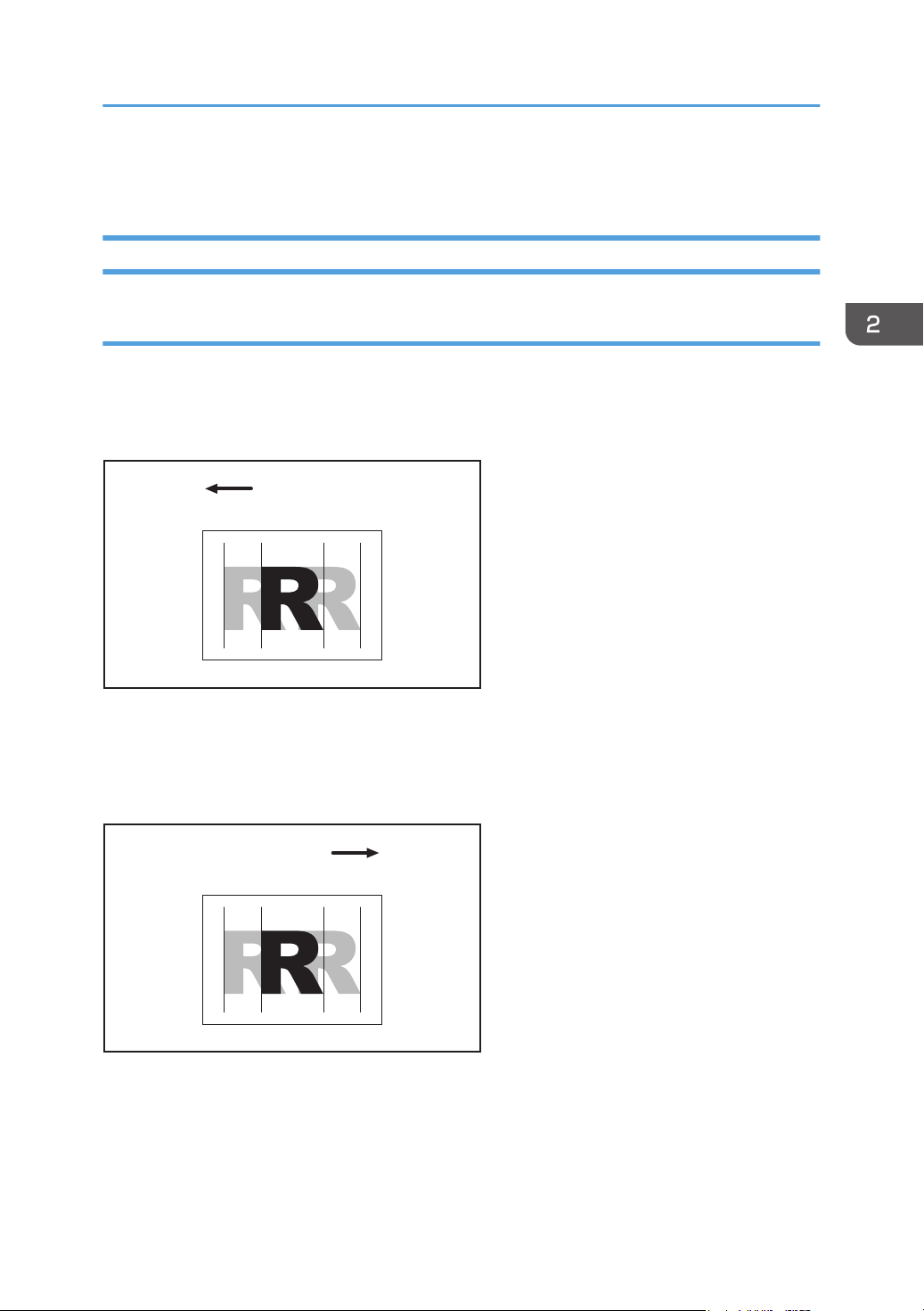

(Leading Edge) (Trailing Edge)

Left

To p

Bottom

Right

Paper feed direction

(+)(-)

Default

CEZ012

(Leading edge)(Trailing edge)

Left Right

Paper feed direction

(+)

(-)

Default

CEZ013

To p

Bottom

[Machine: Image Position]

0101: [Image Position: With Feed]

Adjust the horizontal position of the print image.

You can make this adjustment to Side 1 on an individual tray basis, but not to Side 2.

Side 1

Setting Values

Press [+] to shift the image to the right (trailing edge).

Press [−] to shift the image the left (leading edge).

Side 2

Press [+] to shift the image to the left (trailing edge).

Press [−] to shift the image to the right (leading edge).

27

2. Details of Menu Items in Adjustment Settings for Skilled Operators

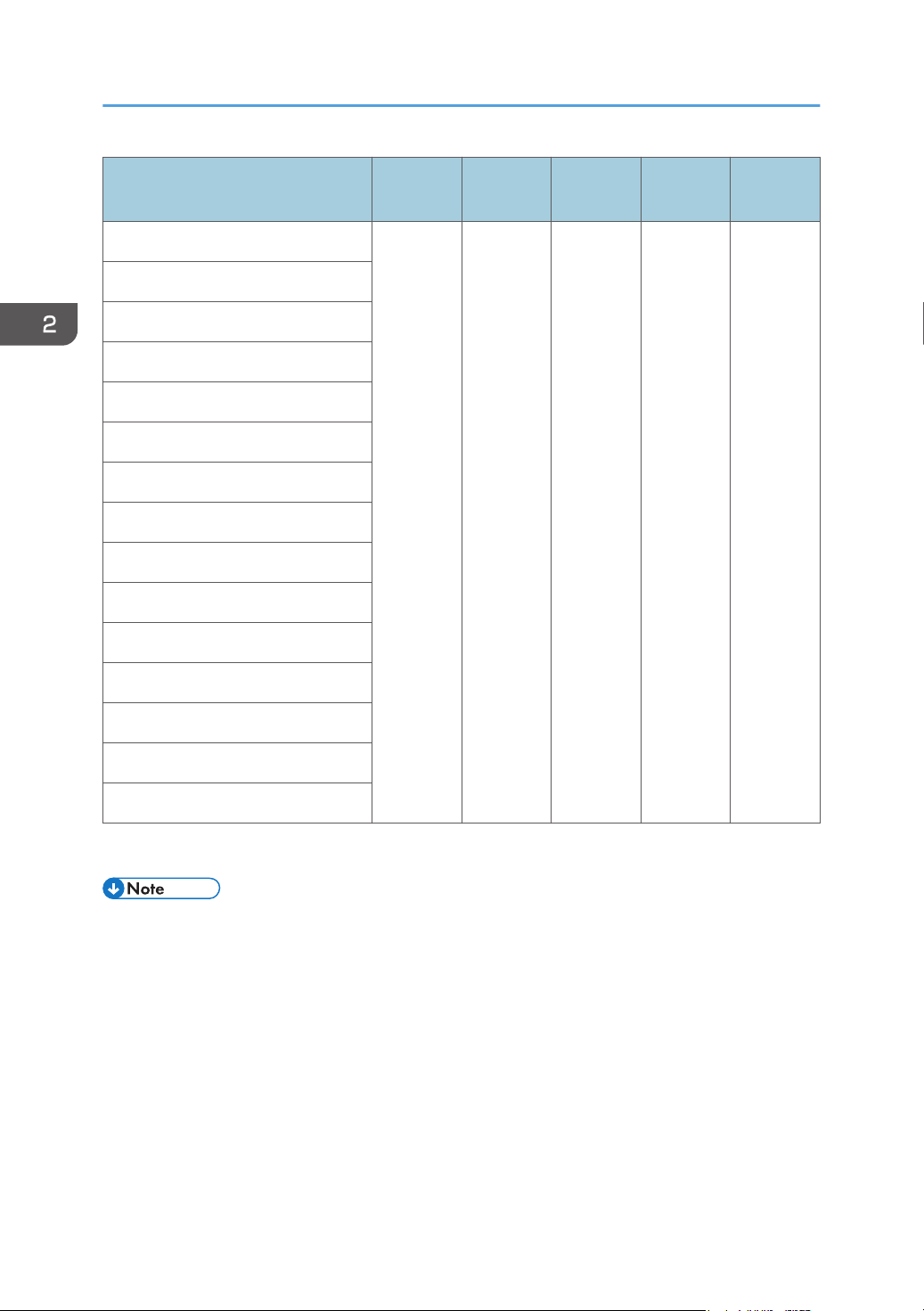

Setting Items

[Tray 1]

[Tray 2]

[Tray 3]

[Bypass Tray]

[2 Sided]

[LCT]

[Paper Weight 1]

[Paper Weight 2]

[Paper Weight 3]

[Paper Weight 4]

[Paper Weight 5]

[Paper Weight 6]

Default

Value

*1

Max.

Value

Min.

Value

Step Unit

9.0 -9.0 0.1 mm

[Paper Weight 7]

[Paper Weight 8]

[Paper Weight 9]

The factory-set value is preset.

*1

• If paper is delivered face-down, turn it over in the paper feed direction and check the image

position.

• If the leading-edge margin on Side 1 of the paper is too narrow, paper jams may occur.

• If the trailing-edge margin on Side 1 of the paper is too narrow, paper jams may occur when

printing on the back side of paper during duplex printing.

28

Loading...

Loading...