Ricoh priport vt3600 Operating Instructions Manual

PRIPORT VT3600

Operating Instructions

-——~— —..——.

For good print quality, Ricoh recommends that you use genuine Ricoh master

and ink.

#

1

I

Ricoh shall not be responsible for any damage or expense that may result from

the use of parts other than genuine Ricoh parts in your Ricoh office product.

,

Power Source: 120V , 60Hz , more than 4.1A

Please make sure to connect the power cord to a power source as above. For

s about power connection, see page 6.

Power Comsuption: Master Making : 374W

Printing : 372W

I

Note: Some of the illustrations may be slightly different from your machine,

@ Copyright 1994

Ricoh Co., Ltd.

_—.—

——------

..—..——————

Safety During Operation

INTRODUCTION

INTRODUCTION

This manual contains detailed instructions on the operation and care of this

machine. To get the maximum versatility from this machine, all operators should

read and follow the instructions in this manual. Please keep this manual in a

handy place near the machine.

SAFETY INFORMATION

When using your machine, the following safety precautions should always be

followed.

Safety During Operation

In this manual, all safety messages are identified by

“Caution”. These words mean the following:

the words “WARNING” and

WARNING:

Important information to alert you to a situation

injury and damage to your property if instructions

Caution:

Important information on how to

avoid a situation that might cause

-

WARNING -

prevent damage to

minor injuty.

that might cause

are not followed.

your equipment, or how to

serious

IJ Do not modify or replace any parts other than the ones specified in this

manual.

Since some parts of the machine are supplied with high voltage, touch

CJ

on/y the parts specified in this manual.

IJ Do not operate the machine without covers. You might get your fingers

caught in the machine, or the machine might be damaged because of

something, such as dust, getting inside it.

IJ Since some parts of the machine are sharp and might cause injury,

touch only the parts

Caution –

–

I_JWhile copying, do not

CIWhile copying, do not

specified in this manual.

turn off the main switch.

open the door.

i

SAFETY INFORMATION

General Safety Information

IJ While copying, do not unplug the power cord.

~ While copying, do not move the machine.

CJKeep corrosive liquids, such as acid, off the machine.

CJDo not allow paper clips, staples, or other small objects to fall inside the

machine.

#Open and close the door and covers softly.

fJ Do not put anything except originals or command sheets on the machine.

n Do not spill liquid on the machine.

~ When you open or close the door or cover, don’t let go of them.

~ When you open or close the platen cover or optional document feeder, be

careful not to pinch your fingers between the platen cover or document feeder

and the back cover.

IJ If you clean rubber parts with benzine, wipe them with a dry cloth afterwards.

General Safety Information

~ Always turn the machine off when you have finished printing for the day.

u When the machine will

not be used for long periods, disconnect the power

cord.

CI If the machine must be transported by vehicle, please contact your service

representative.

..

.

Chapter I

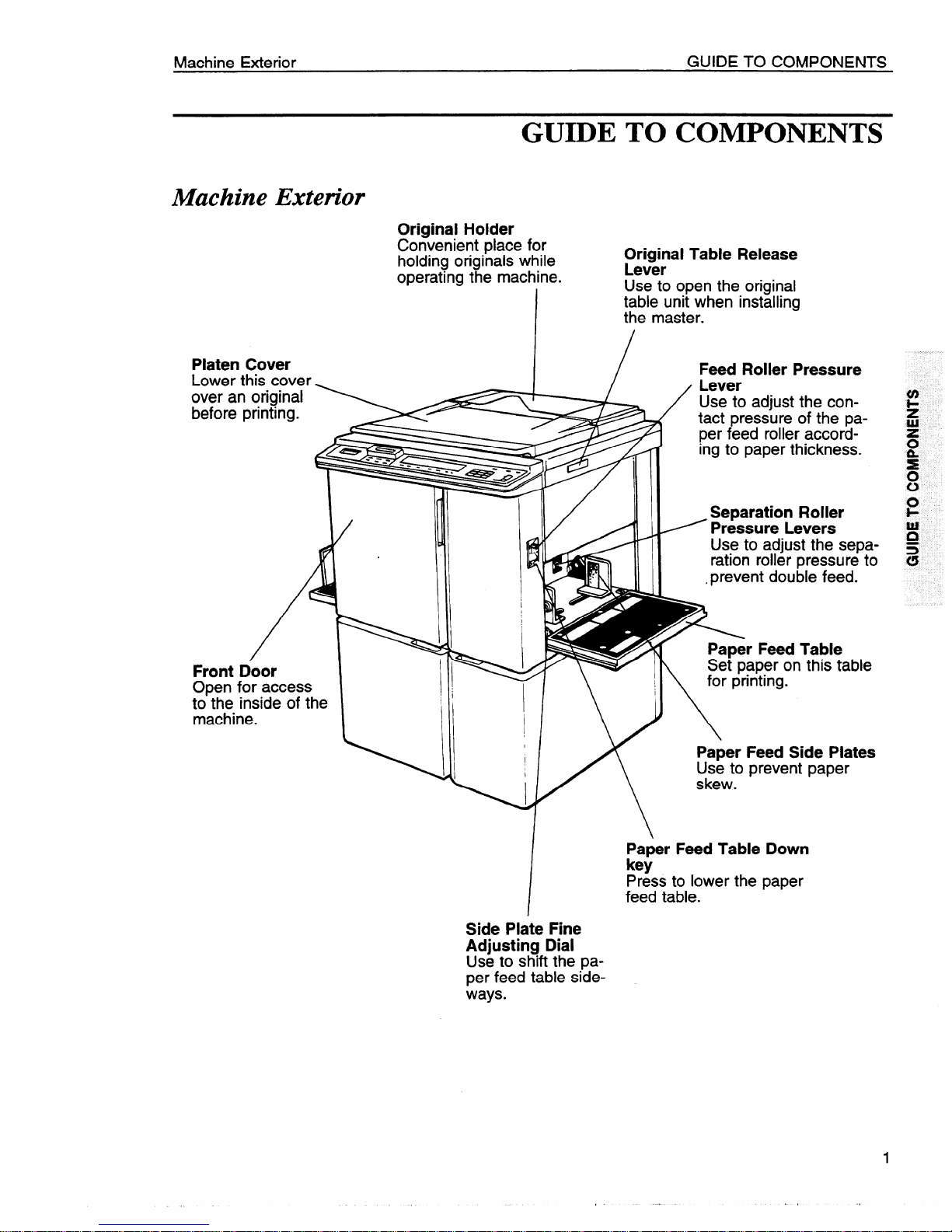

Machine Exterior

GUIDE TO COMPONENTS

GUIDE TO COMPONENTS

Machine Exterior

Original Holder

Convenient place for

holding originals

while

Original Table Release

operating the machine.

Lever

I

Use to open the original

table unit when installing

the master.

Platen Cover

Lower this cover

over an original

before printing.

Front Door

Open for access

too::i$eside of the

.

I

Feed Roller Pressure

/

Lever

Use to adjust the con-

tact pressure of the pa-

per feed roller according to paper thickness.

Separation Roller

= Pressure Levers

Use to adjust the separation roller pressure to

,prevent double feed.

r Feed Table

aper on this table

..

W \ !1 \ ‘orpr’nt’ng”

\

1

I

Paper Feed Side Plates

Use to prevent paper

skew.

/

Paper Feed Table Down

key

Press to lower the paper

feed table.

Side Plate Fine

Adjusting Dial

Use to shift the paper feed table sideways.

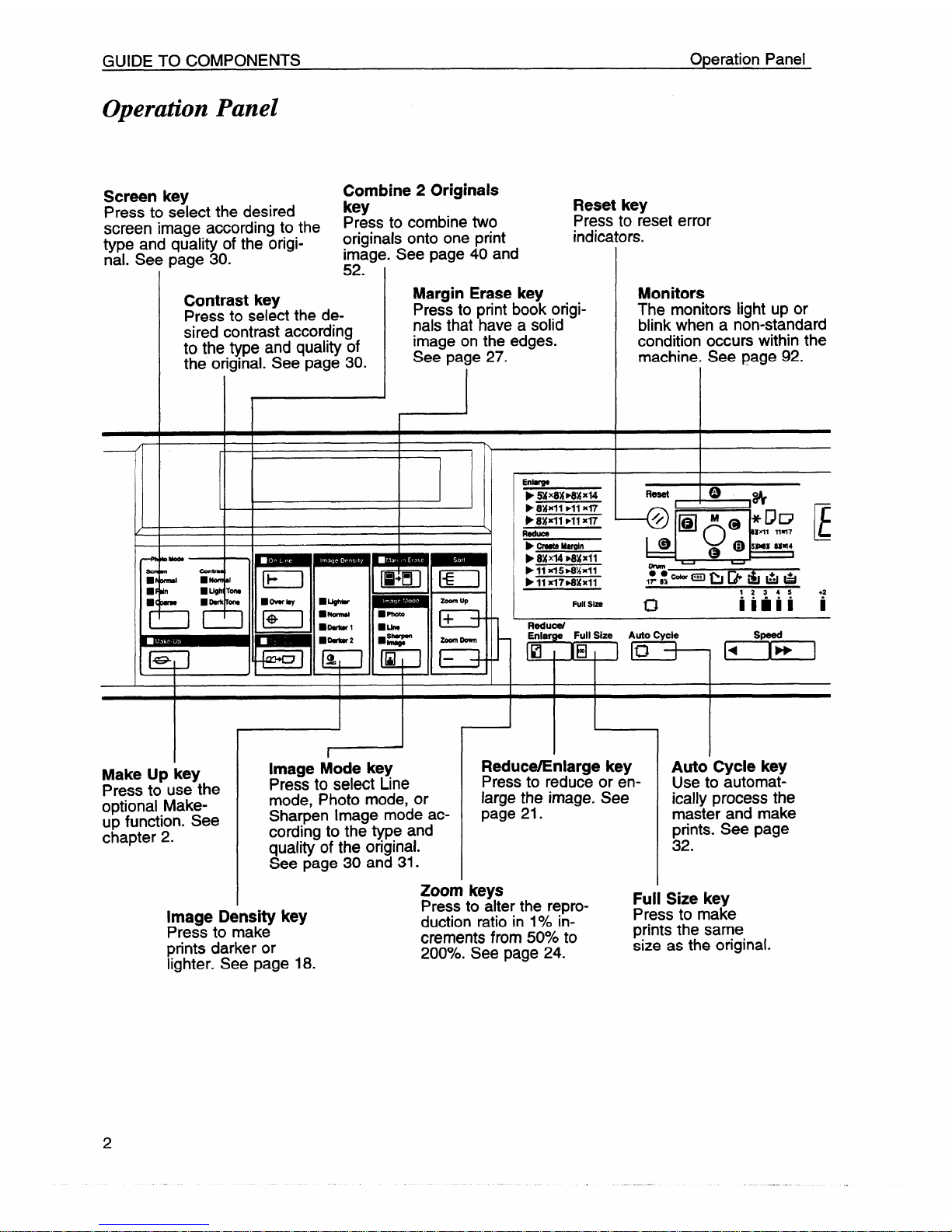

GUIDE TO COMPONENTS Operation Panel

Operation Panel

Screen key

Combine 2 Originals

Press to select the desired

key

Reset key

screen image according to the

Press to combine two

Press to reset error

type and quality of the origi-

originals onto one print

indicators.

nal. See page 30.

image. See page

40 and

co

ad.

Contrast key

Press to select the desired contrast according

to the type and quality of

the original. See page 30.

Margin Erase key

Press to print book originals that have a solid

image on the edges.

See page 27.

I

I

I

I

Enhrge

p

wx8xmAJd4

p 8XXll ➤11 x~

➤ 84Jfll ➤11 X17

Reduce

➤ Create M8rgln

➤ 8XX14 ➤8XX11

P 11 X15*%X11

➤ 11 X17 MMX11

Full Slzo

Monitors

The monitors light up or

blink when a non-standard

condition occurs within the

machine. See page 92.

E

+2

i

w

El

db

I

Make Up key

Press to use the

optional Makeup function. See

chapter 2.

r

I

Image Mode key

Press to select Line

mode, Photo mode, or

Sharpen Image mode according to the type and

aualitv of the original.

I

See page 30 and 31.

Image Density key

Press to make

prints darker or

lighter. See page 18.

I

1

Reduce/Enlarge key

Press to reduce or enlarge the image. See

page 21.

Auto Cycle key

Use to automatically process the

master and make

prints. See page

32.

Size key

Zoom keys

Press to alter the repro-

Full

duction ratio in 1940in-

Press to make

crements from

50’%0to

prints the same

200?40.See page 24.

size as the original.

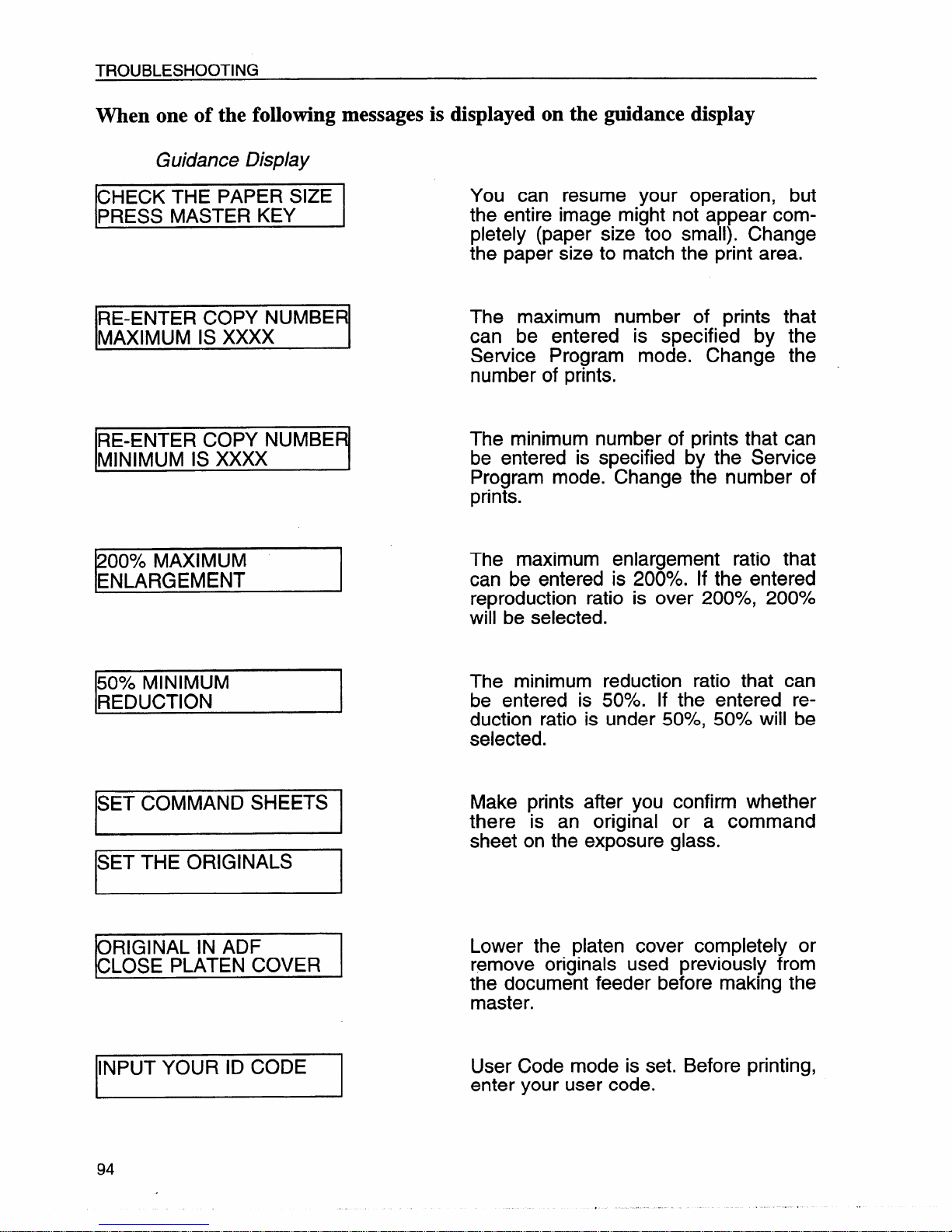

TROUBLESHOOTING

When one of the following messages is displayed on the guidance display

Guidance Display

CHECK THE PAPER SIZE

PRESS MASTER KEY

RE-ENTER COPY NUMBER

MAXIMUM IS XXXX

IRE-ENTER

cow NumERl

lMINIMUM IS xxxx

I

200% MAXIMUM

ENLARGEMENT

50?40 MINIMUM

REDUCTION

ISET COMMAND SHEETS I

SET THE ORIGINALS

ORIGINAL IN ADF

CLOSE PLATEN COVER

I

INPUT YOUR ID CODE

94

You can resume your operation, but

the entire image might not appear completely (paper size too small). Change

the paper size to match the print area.

The maximum number of prints that

can be entered is specified by the

Service Program mode. Change the

number of prints.

The minimum number of prints that can

be entered is specified by the Service

Program mode. Change the number of

prints.

The maximum enlargement ratio that

can be entered is 200940. If the entered

reproduction ratio is over 200?4, 200%

will be selected.

The minimum reduction ratio that can

be entered is 50?40. If the entered reduction ratio is under 50?4, 50?40will be

selected.

Make prints after you confirm whether

there is an original or a command

sheet on the exposure glass.

Lower the platen cover completely or

remove originals used previously from

the document feeder before making the

master.

User Code mode is set. Before printing,

enter your user code.

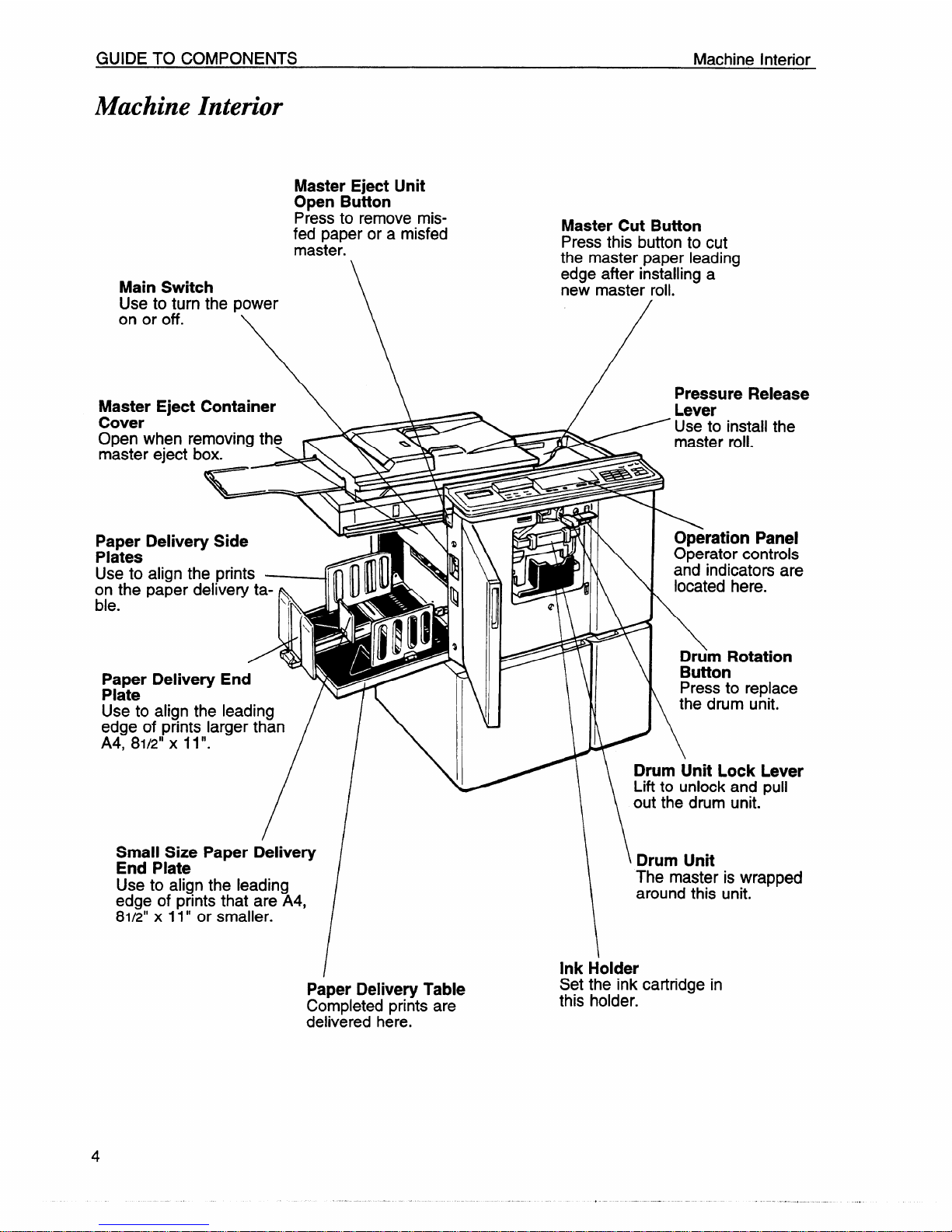

GUIDE TO COMPONENTS

Machine Interior

Machine Interior

Master Eject Unit

Open Button

Main Switch

P~essto remove misfed paper or a misfed

master.

\

Use to turn the power

on or off.

\\

Master Cut Button

Press this button to cut

the master paper leading

edge after installing a

new master roil.

*’

Master Eject Container

Cover

Open when removing the

master eject box.

Paper Delivery Side

Plates

Use to align the prints

4

on the paper delivery ta-

ll

70!

ble.

\r

IN

Pressure Release

Lever

Use to install the

master roll.

111’d’

Operation Panel

T&

Operator controls

!JI”k‘N

and indicators are

located here.

\

/

Drum Rotation

Paper Delivery End

m> q ‘$ ‘ \

Button

Plate

Press to replace

Use to align the leading

the drum unit.

edge of prints larger than

A4, 81/2” x 11”.

//

~\

‘

Drum Unit Lock Lever

Lift to unlock and pull

out the drum unit.

Small Size Paper Delivery

End Plate

Use to align the leading

edge of prints that are A4,

81/2” x 11” or smaller.

/ ,njo,?,nzrapped

Paper Delivery Table

Set the ink cartridge in

Completed prints are

this holder.

delivered here.

INSTALLATION REQUIREMENTS

Power Connection

Power Connection

IJ Connect the power cord to an appropriate power source (as described inside

of the front cover).

n Make sure the plug is firmly inserted in the outlet.

CI

Avoid multiwiring.

~ Do

not pinch the power cord.

CI Make sure that the wall-outlet is near the machine and easily accessible,

Printing Paper OPERATION

OPERATION

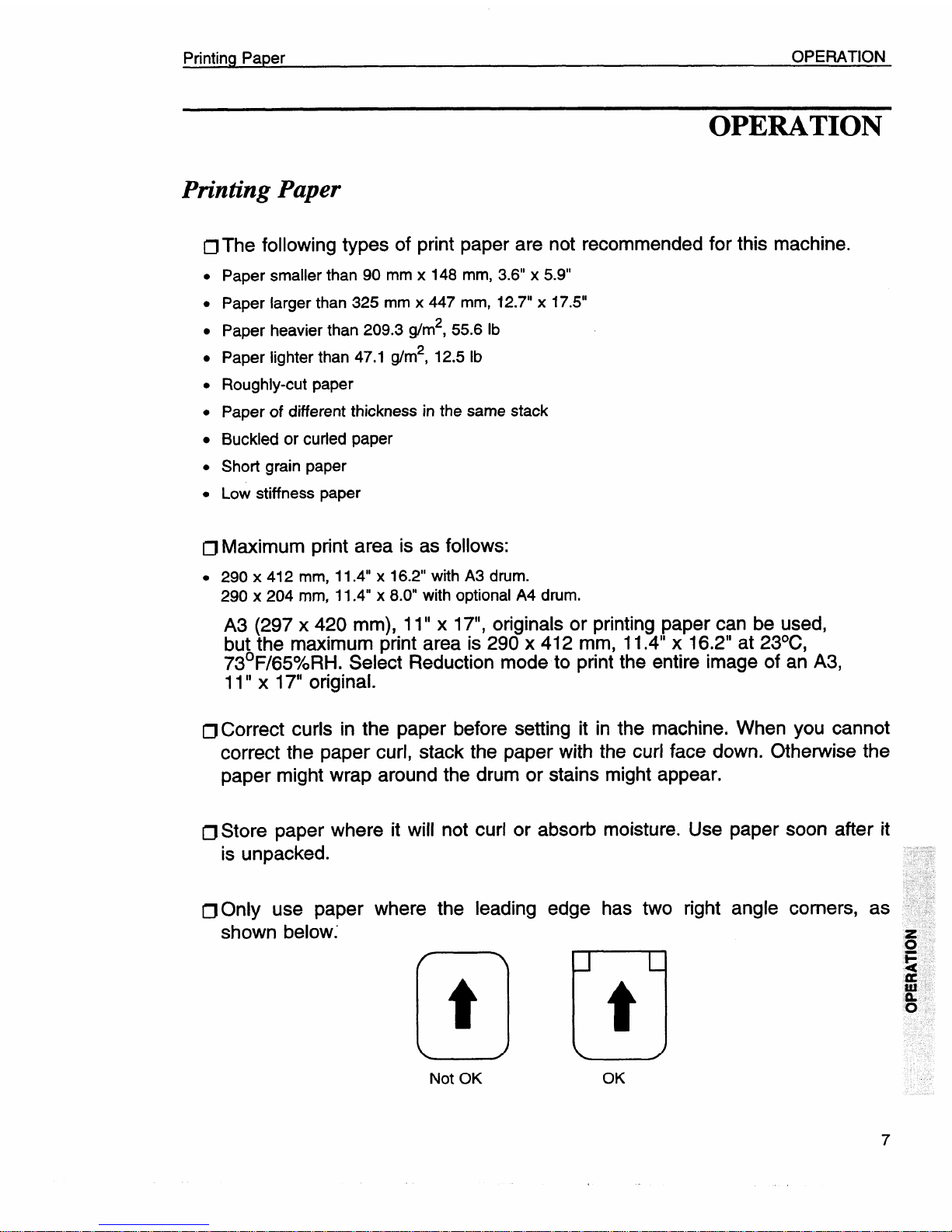

Printing Paper

fJ

The following types of print paper are not recommended for this machine.

●

●

●

●

●

●

●

●

●

Paper smaller than 90 mm x 148 mm, 3.6” x 5.9”

Paper larger than 325 mm x 447 mm, 12.7” x 17.5”

Paper heavier than 209.3 g/m2, 55.6 lb

Paper lighter than 47.1 g/m2, 12.5 lb

Roughly-cut paper

Paper of different thickness in the same stack

Buckled or curled paper

Short grain paper

Low stiffness paper

n Maximum print area is as follows:

.

290 x412 mm, 11.4” x 16.2” with A3 drum.

290 x 204 mm, 11.4” x 8.0” with optional A4 drum.

A3 (297 x 420 mm), 11” x 17“, originals or printing paper can be used,

but the maximum print area is 290 x412 mm, 11.4” x 16.2” at 23°C,

73°F/65YoRH. Select Reduction mode to print the entire image of an A3,

11” x 17“ original.

IJ Correct curls in the paper before setting it in the machine. When you cannot

correct the paper curl, stack the paper with the curl face down. Otherwise the

paper might wrap around the drum or stains might appear.

IJ Store paper where it will not curl or absorb moisture. Use paper soon after it

is unpacked.

n Only use paper

shown below;

where the leading

Not OK

edge has two

El

t

OK

right angle comers,

OPERATION

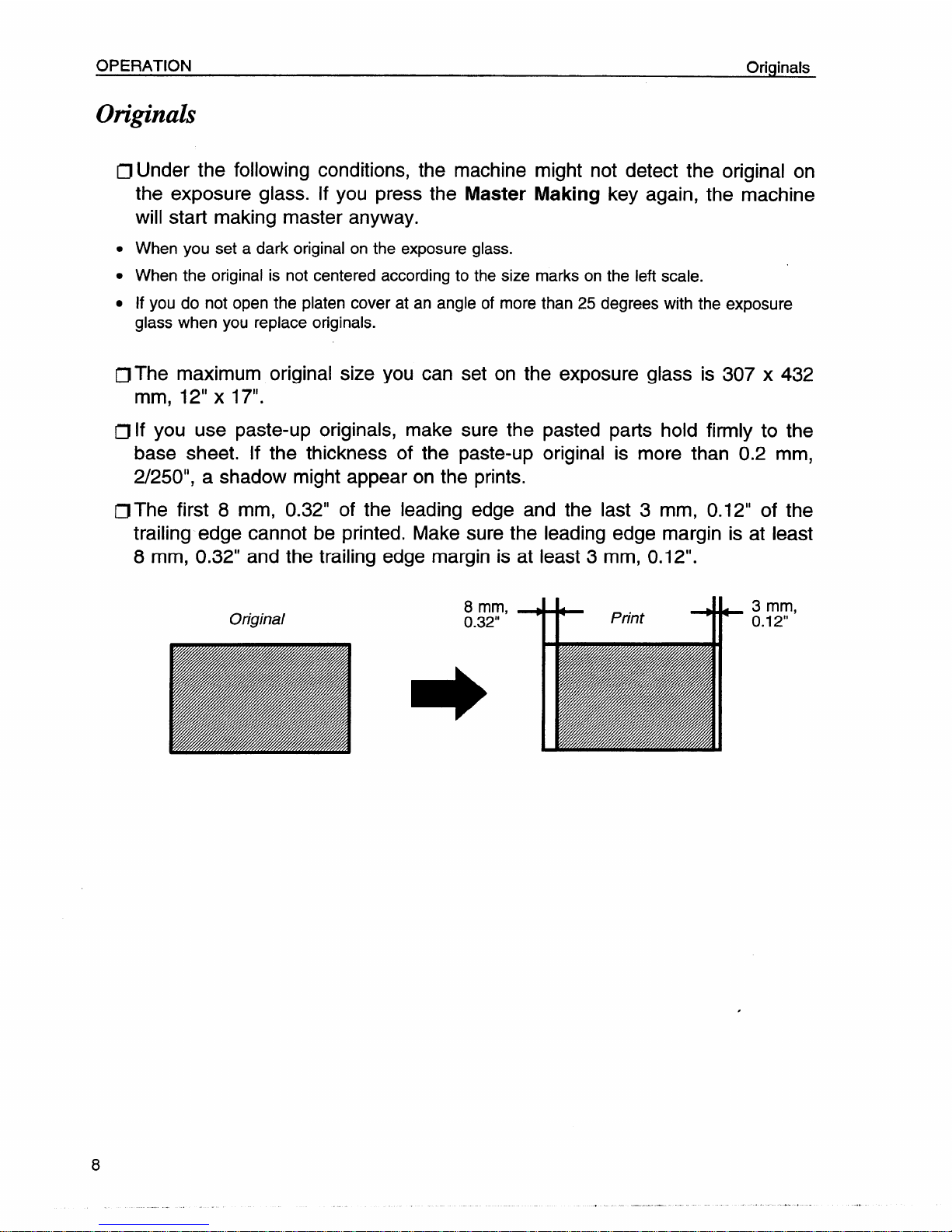

Originals

Originals

~

Under the following conditions, the machine might not detect the original on

●

●

●

the exposure glass. If you press the Master Making key again, the machine

will start making master anyway.

When you set a dark original on the exposure glass.

When the original is not centered according to the size marks on the left scale.

If you do not open the platen cover at an angle of more than 25 degrees with the exposure

glass when you replace originals.

n

The maximum original size you can set on the exposure glass is 307 x 432

mm, 12” x 17”.

~ If you use paste-up originals, make sure the pasted parts hold firmly to the

base sheet. If the thickness of the paste-up original is more than 0.2

mm,

2/250”,

a shadow might appear on the prints.

IJ The first 8 mm, 0.32” of the leading edge and the last 3 mm, 0.12“ of the

trailing edge cannot be printed. Make sure the leading edge margin is

8 mm, 0.32” and the trailing edge margin is at least 3 mm, 0.1 2“.

Original

8 mm,

0.32”

*

Print

*

at least

3 mm,

0.12”

Preparation For Printing

OPERATION

Preparation For Printing

. See page 61 when you load paper in the

Loading paper

optional

paper cassette.

P~

w

:s .....

.. .

. .+

.:: .

. ..

..

)

m

Q

● B4

-00

e

-- . *3

D

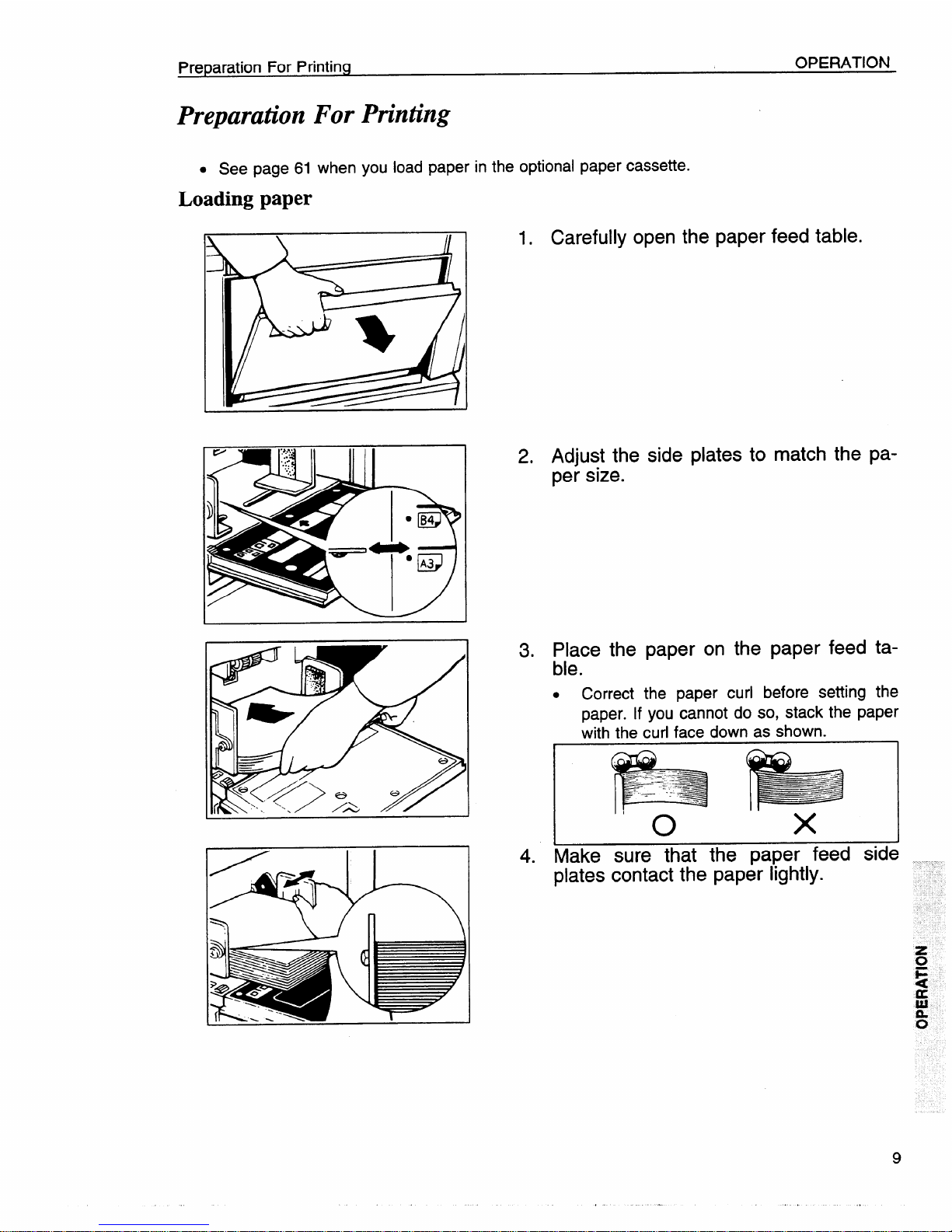

1. Carefully open the paper feed table.

2. Adjust the side plates to match the paper size.

3. Place the paper on the paper feed ta-

ble.

.

Correct the paper curl before setting the

paper. If you cannot do so, stack the paper

with the curl face down as shown.

&q

4.

Make sure that the paper feed side

plates contact the paper lightly.

z

u

F

4

&

a.

o

OPERATION

Preparation For Printing

Setting up the paper delivery table

I WI I

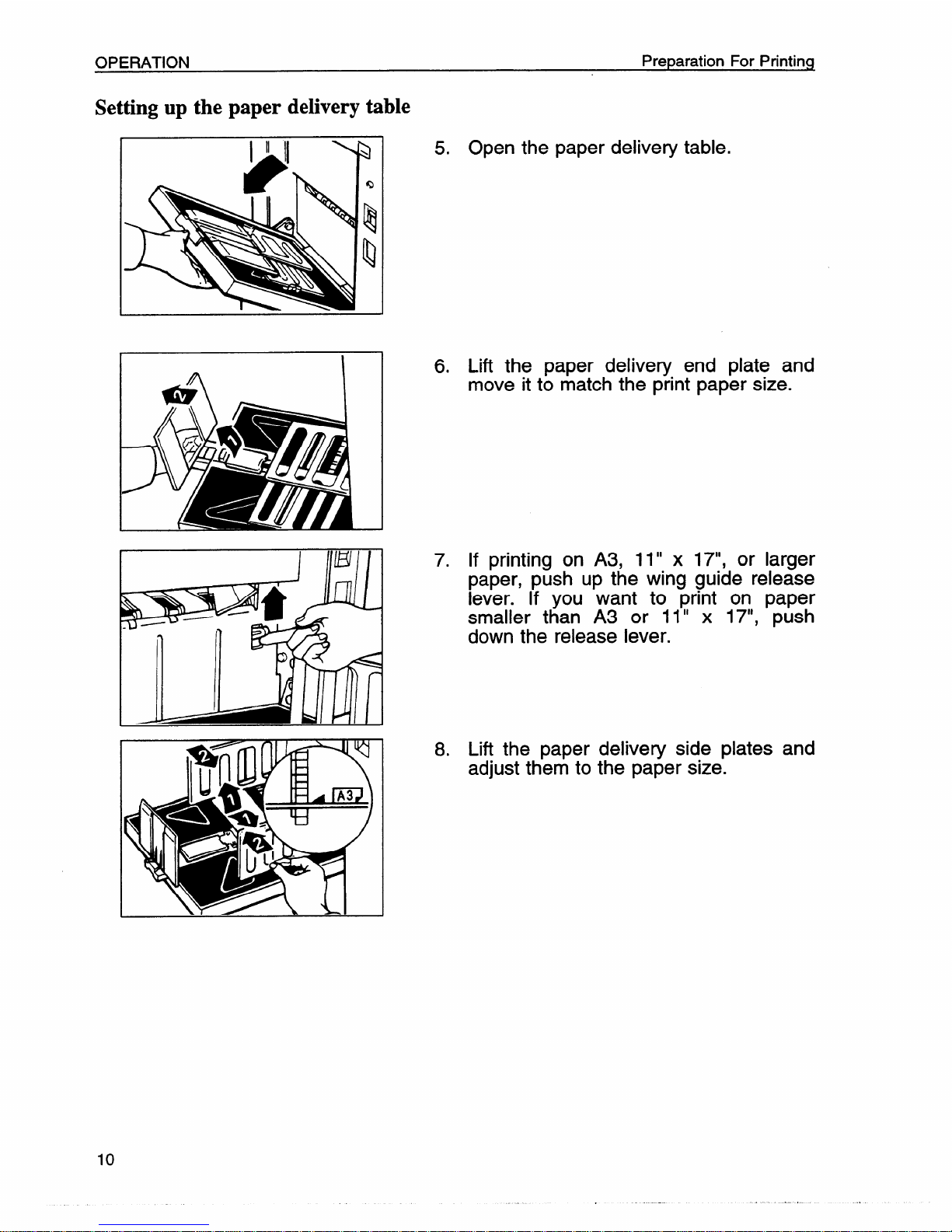

5. Open the paper delivery table.

6. Lift the paper delivery end plate and

move it to match the print paper size.

7. If printing on A3, 11” x 17“, or larger

paper, push up the wing guide release

lever. If you want to print on paper

smaller than A3 or 11” x 17“, push

down the release lever.

8. Lift the paper delivery side plates and

adjust them to the paper size.

Preparation For Printing

OPERATION

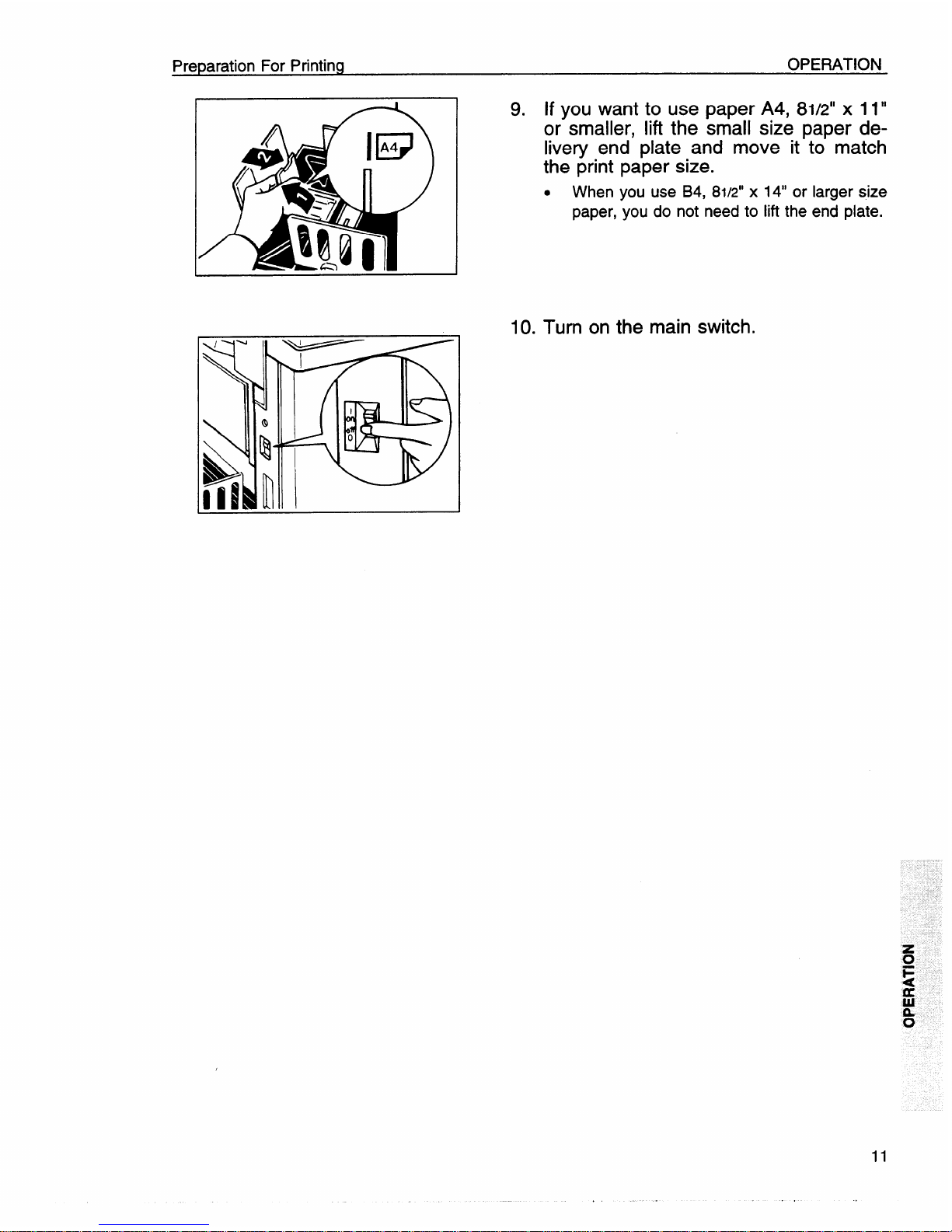

9. If you want to use paper A4, 8112”x 11”

or smaller, lift the small size paper de-

livery end plate and move it to match

the print

.

When

paper,

paper size.

you use B4, 8112”x 14“ or

you do not need to lift the

larger size

end plate.

10. Turn on the main switch.

OPERATION

Standard Printing

Standard Printing

1

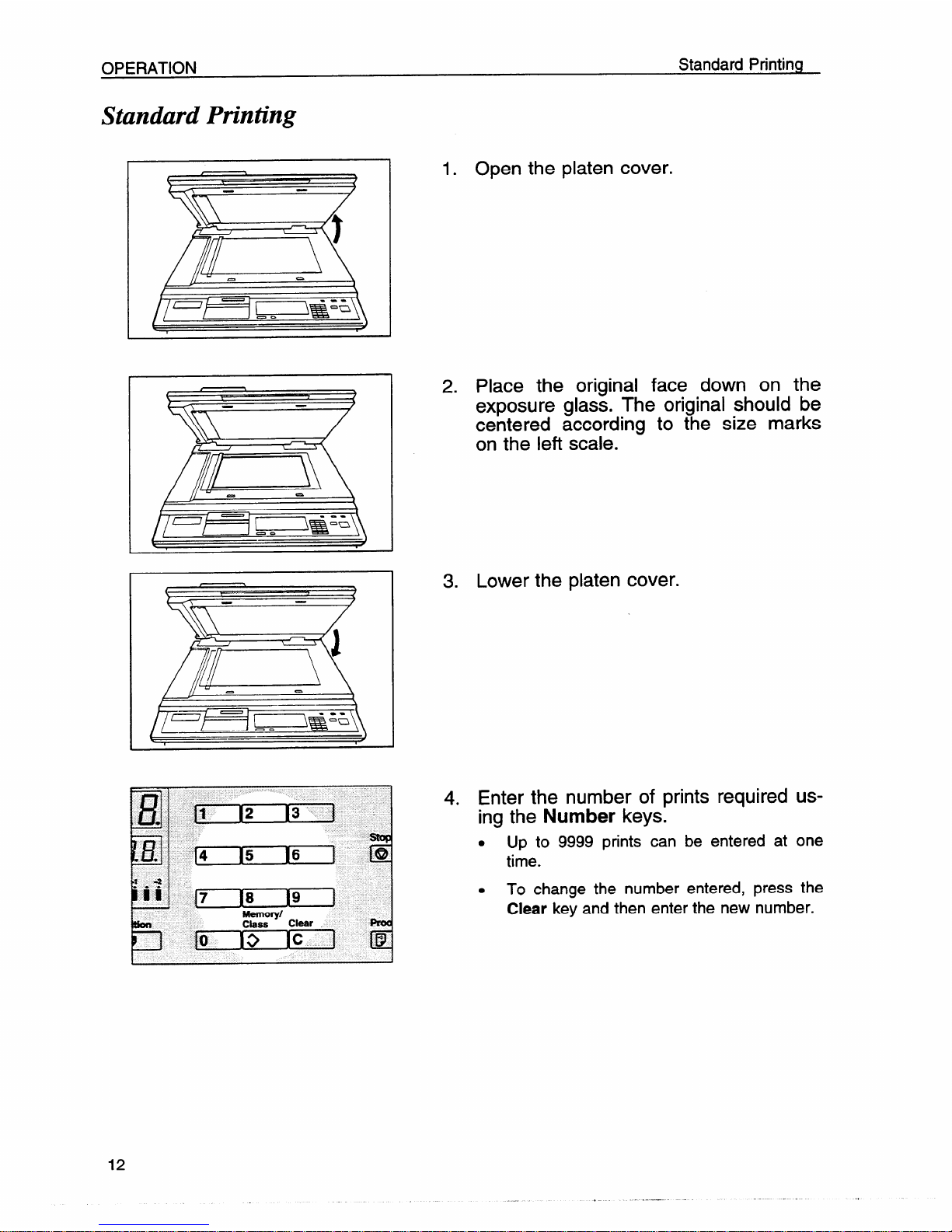

1. Open the platen cover.

2. Place the original face down on the

exposure

glass. The original should be

centered according to the size marks

on the left scale.

3.

Lower the platen cover.

4. Enter the number of prints required using the Number keys.

. Up to 9999 prints can be entered at one

time.

. To change the number entered, press the

Clear key and then enter the new number.

Standard Printing

OPERATION

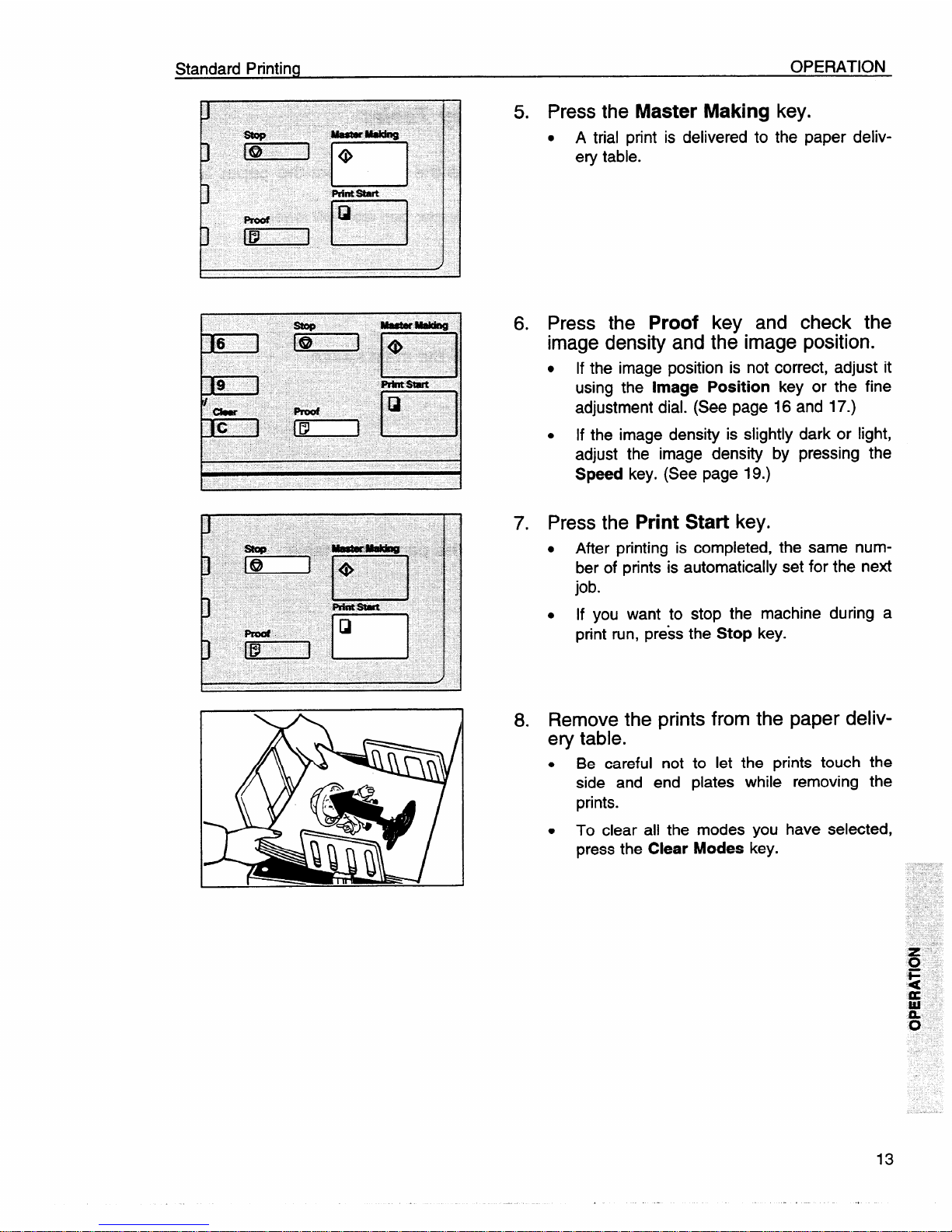

5. Press the Master Making key.

. A trial print is delivered to the paper deliv-

ery table.

6. Press the Proof key and check the

image density and the image position.

● Ifthe image position is not correct, adjust it

using the

Image Position key or the fine

adjustment dial. (See page 16 and 17.)

. If the image density is slightly dark or light,

adjust the image density by pressing the

Speed key. (See page 19.)

7. Press the Print Start key.

● After printing is completed, the same num-

ber of prints is automatically set for the next

job.

. If

you want to stop the machine during a

print run, press the

Stop key.

8. Remove the prints from the paper delivery table.

. Be careful not to let the prints touch the

side and end plates while removing the

prints.

. To clear all the modes you have selected,

press the

Clear Modes key.

13

,,

OPERATION

Restoring Paper Feed And Paper Delivery Tables

Restoring Paper Feed And Paper Delivery Tables

1. Remove the paper from the paper feed

table.

.

The paper feed table will lower.

2. Turn off the main switch.

3. Close the paper feed table.

4. Push the small size paper delivery

plate to the left, then lower it, if necessary.

5. Move the side plates to the sides, then

lower them.

.

Make sure that the side plates do not touch

the small size paper delivery end plate.

Restoring Paper Feed And Paper Delivery Tables

OPERATION

I

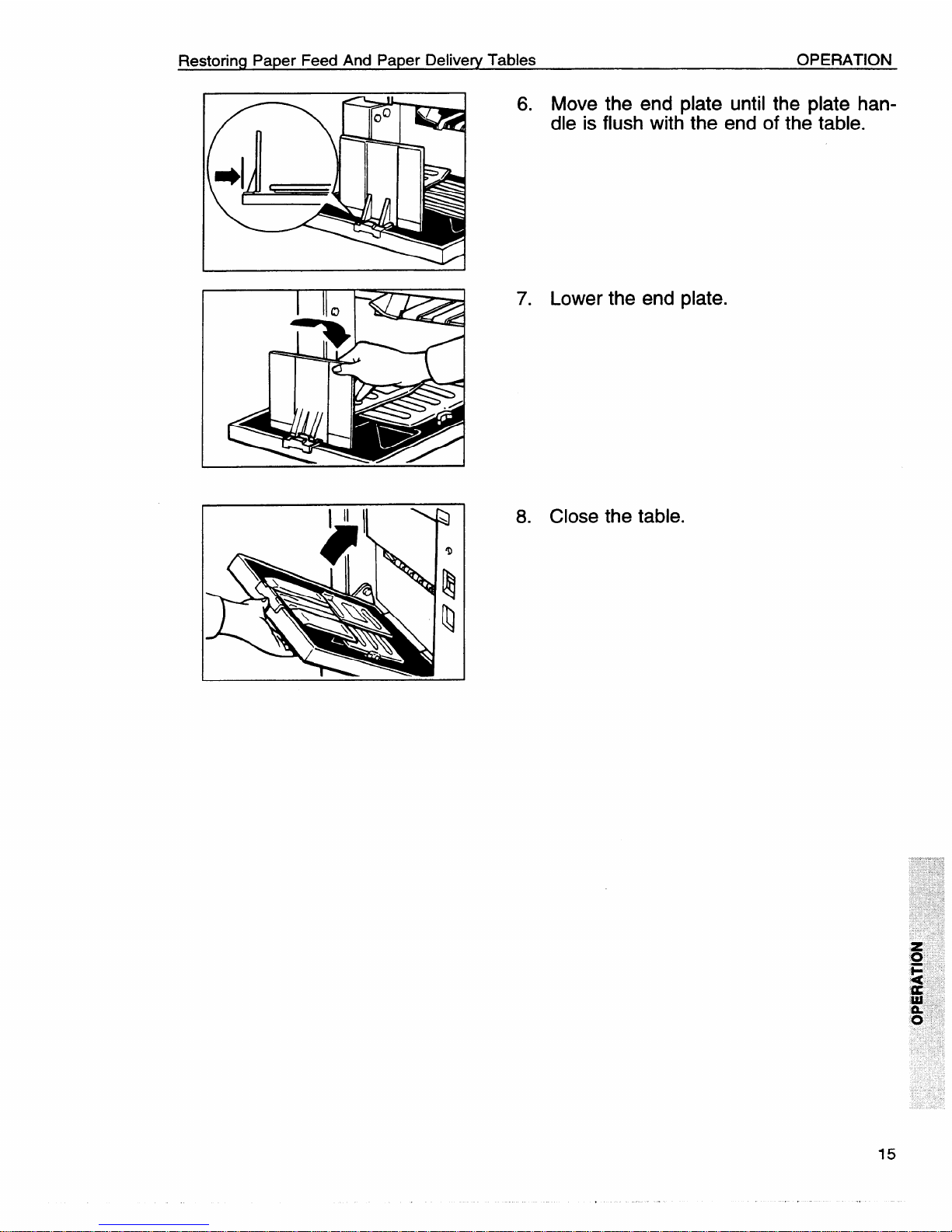

6. Move the end plate until the plate handle is flush with the end of the table.

7. Lower the end plate.

8. Close the table.

OPERATION

Adjusting The Image Position

A&usting

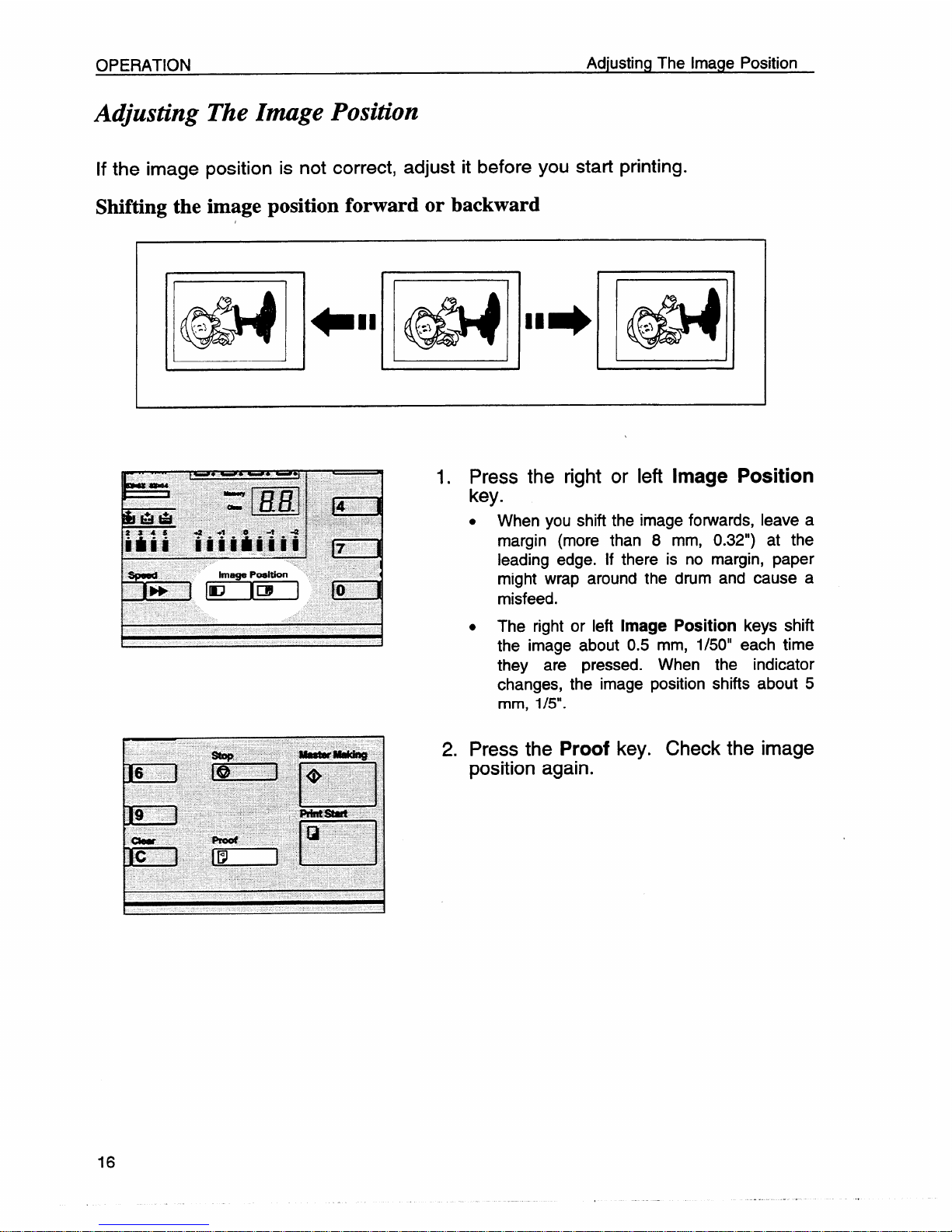

If the image

Shifting the

The Image Position

position is not correct, adjust it before you start printing.

image position forward or backward

1. Press the right or left Image Position

key.

. When you shift the image forwards, leave a

margin (more than 8 mm, 0.32”) at the

leading edge. If there is no margin, paper

might wrap around the drum and cause a

misfeed.

. The right or left

Image Position keys shift

the image about 0.5 mm, 1/50” each time

they are pressed.

When the indicator

changes, the image position shifts about 5

mm, 1/5”.

2. Press the Proof key. Check the image

position again.

Adjusting The Image Position

Shifting the image to the right or left

OPERATION

I

Shiiting the image to the right

@J+.+@

11111111111

L

Shifting the image to the left

IP-49

11111111111

d

1. Turn the adjusting dial as

illustrations.

. The image position can be shifted up to

10 mm, 2/5” each way. Each division on

the scale is 2 mm, 0.08”.

1

in the

Adjust the paper delivery side plates to

2.

the print paper position.

Press the

3.

Proof key. Check

position.

OPERATION

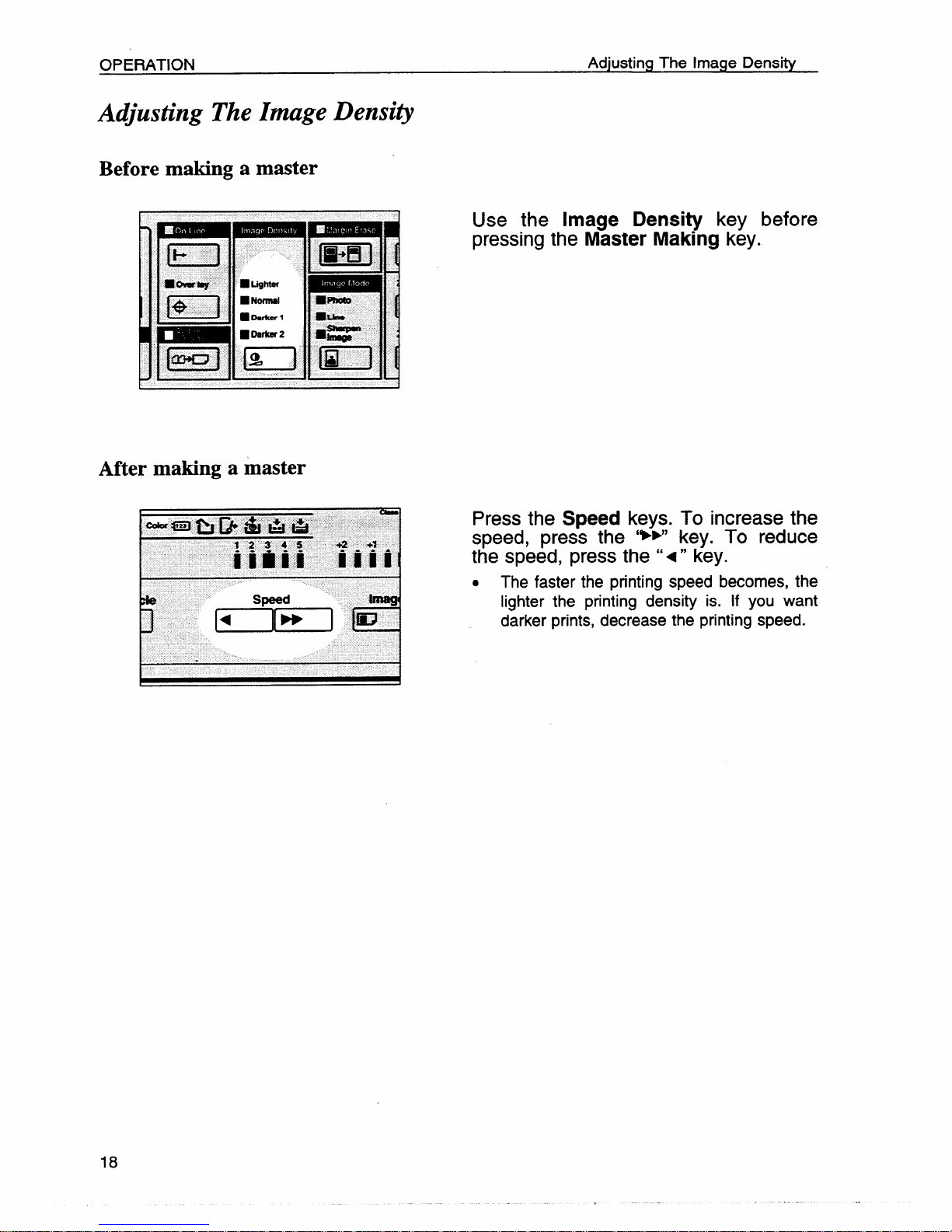

Adjusting The Image Density

Before making a master

Adjusting The Image Density

B

ti

mvawe

13E2 ::R’, :s”

IziEEl [’1 gz’-l

iDDnl

u

■ LigMtn

gDarkw2

After making a master

Use the Image Density key before

pressing the

m

n

a=

Press the

Master Making key.

Speed keys. To increase the

speed, press the ‘*~” key. To reduce

the speed, press the “4” key.

. The faster the printing speed becomes, the

lighter the printing density is. If you want

darker prints, decrease the printing speed.

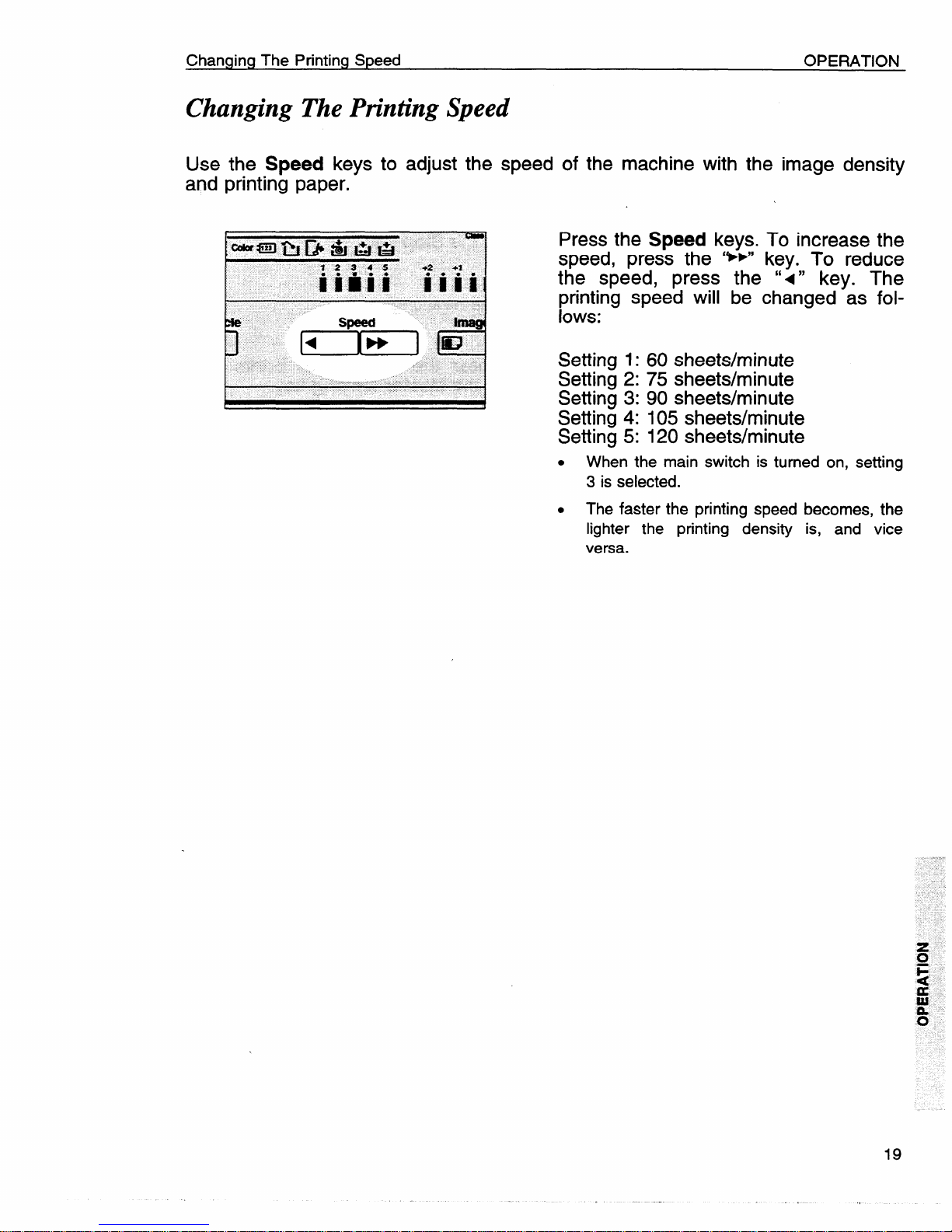

Changing The Printing Speed

Changing The Printing Speed

OPERATION

Use the Speed keys

and printing paper.

to adjust the speed of the machine with the image density

Press the

Speed keys. To increase the

speed, press the ‘**” key. To reduce

the speed, press the “<” key. The

printing speed will be changed as follows:

Setting 1:60 sheets/minute

Setting 2:75 sheets/minute

Setting 3:90 sheets/minute

Setting 4:105 sheets/minute

Setting 5:120 sheets/minute

. When the main switch is turned on, setting

3 is selected.

. The faster the printing speed

lighter the printing density

versa.

becomes, the

is, and vice

OPERATION

Stopping The Machine During A Printing Run

Stopping The Machine During A Printing Run

When you want to stop the machine during a print run and print the next

original

1. Press the Stop key.

2. Set the new original.

3. Re-enter

press the

the number of prints and

Master Making key.

When you want to change the number of prints entered or to check the completed prints

1. Press the Stop key.

2. Change the number

the completed prints.

.

When you change the number of prints,

you can re-enter the number using the

Number keys after pressing the Stop key.

Press the Print Start key.

3.

of prints or check

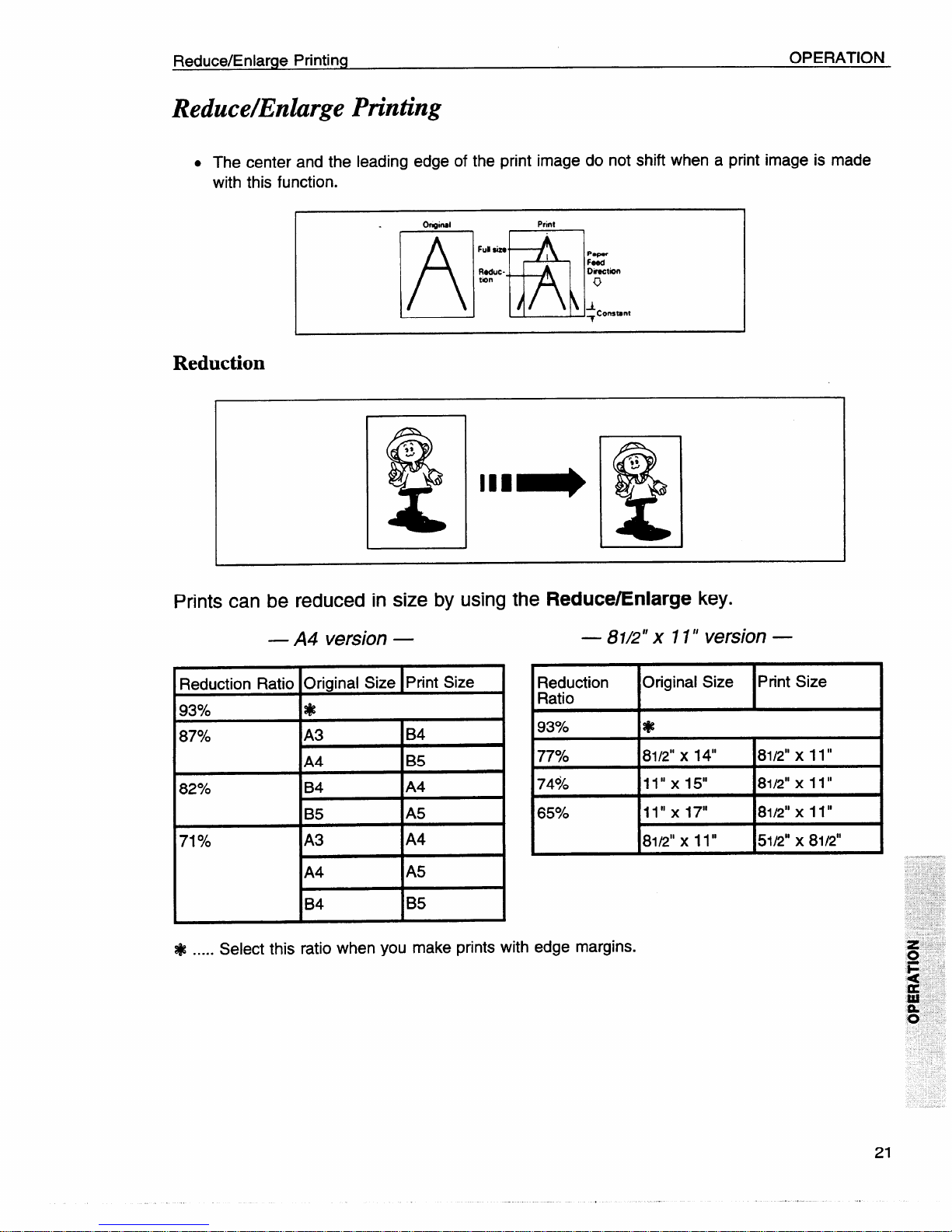

Reduce/Enlarge Printing

Reduce/Enlarge Printing

OPERATION

● The

with

center and the

this function.

leading

edge of the print image do lot shift when a print image is made

Print

t

A

Full siz,

Ro8uctm

R

P8fmr

Feed

Chmction

0

-L

Consmnt

~

Reduction

Prints can be reduced in size by using the Reduce/Enlarge key.

— A4 version —

Reduction Ratio

93%

87940

I

i?--E--

82%

71%fO

Select this ratio when you make prints with edge margins.

.....

*

B4

A4

B4

IA4

A5

I

IB5

— 81/2” x 11” version —

Reduction Original Size

Ratio

93%

7770

7490 11’’ XI5° 8112”x 11”

65?40

*

X 14“

81/2”

11” x 17” 8112”x 11”

L

8112”x 11” 51/2” x 81/2t’

Print Size

81/2” X 11“

Reduce/Enlarge Printing

1. Select the desired reduction ratio using

the

Reduce/Enlarge key.

2. Make sure that the original and the

print paper are the correct size.

3. Follow the standard printing procedure.

(See page 12.)

Reduce/Enlarge Printing

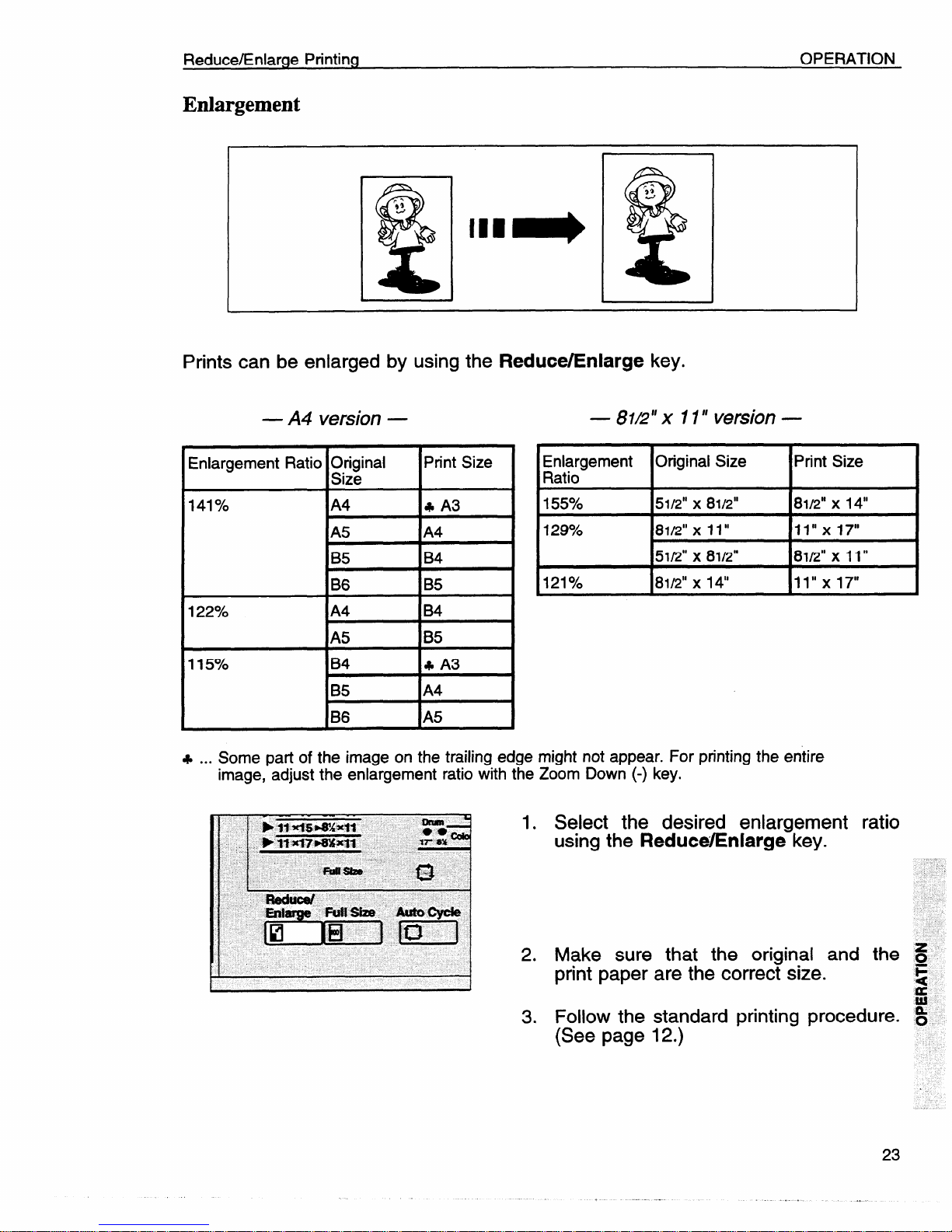

Enlargement

Prints can be enlarged by using the Reduce/Enlarge key.

OPERATION

— A4 version —

Enlargement Ratio O&inal

I

141Yo

122%-0

115?40

...

Some patt of the image on the trailing ed! Ie might not appear. For printing the entire

+

image, -adjust the enlargement ratio

IA4

tA5 1A4

B5

B6

A4

A5

IB4

IB5

IB6

Print Size

I

B4

B5

B4

B5

k A3

IA4

]e Zoom Down (-) key.

with 1

— 81L?”x 11” version —

~a~igement Original Size

155?40 51/2” x 8112”

129% 81/2”

121?40 81/2” x 14“

x 11” 11’’ XI7°

51/2” x 81/2”

1. Select the desired enlargement ratio

using the

ReduceEnlarge key.

Print Size

8112”x 14“

8112”x 11”

11’’ X17°

2. Make sure that the original and the S

print paper are the correct size.

3. Follow the standard printing procedure. ~

(See page 12.)

F

s

OPERATION

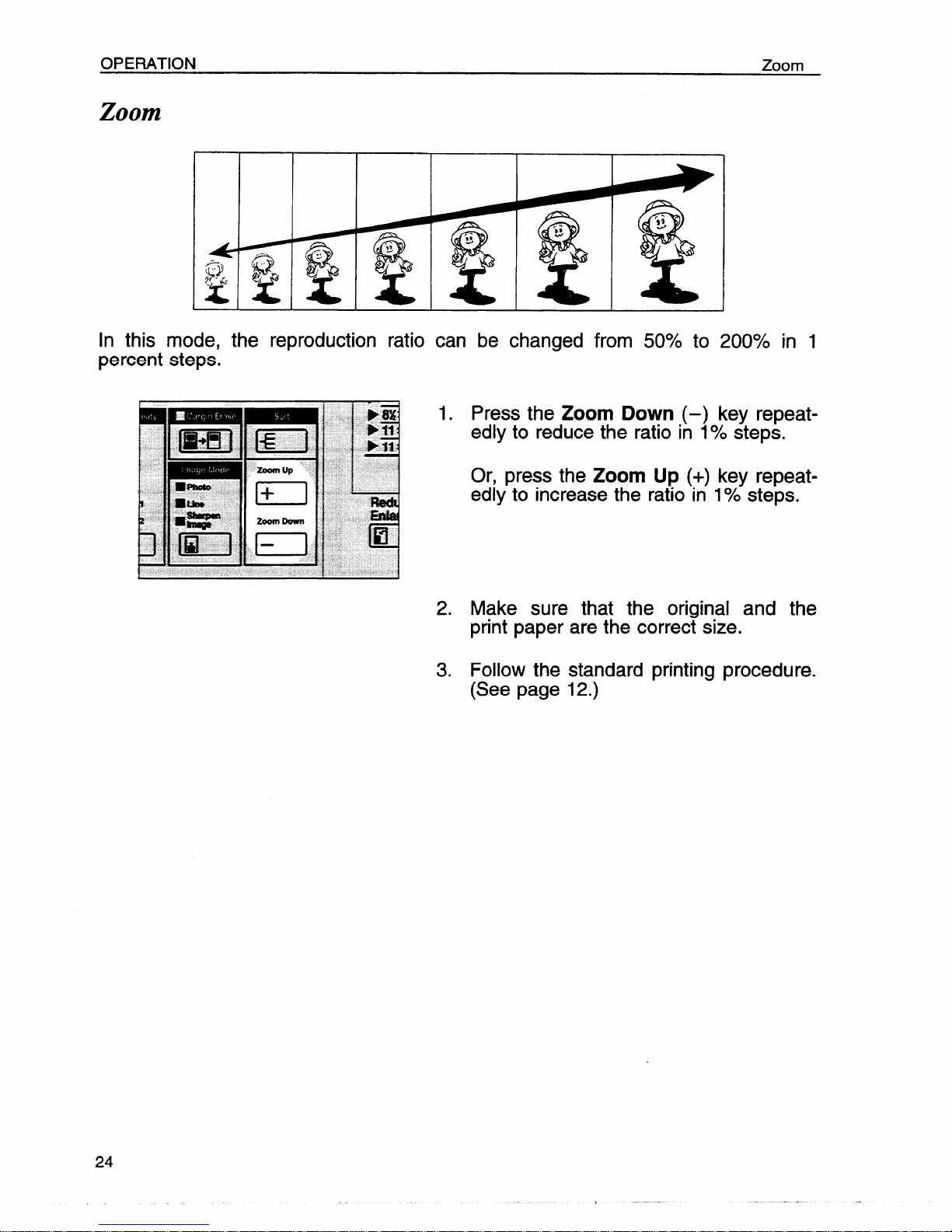

Zoom

Zoom

In this mode, the reproduction ratio can be changed from 50% to 200’XO in 1

percent steps.

1. Press the Zoom Down

edly to reduce the ratio

Or, press the

Zoom Up (+)

edly to increase the ratio in

(–) key repeat-

in 10/0steps.

key repeat-

1?40steps.

2.3.Make sure that the original and the

print paper are the correct size.

Follow the standard printing procedure.

(See page 12.)

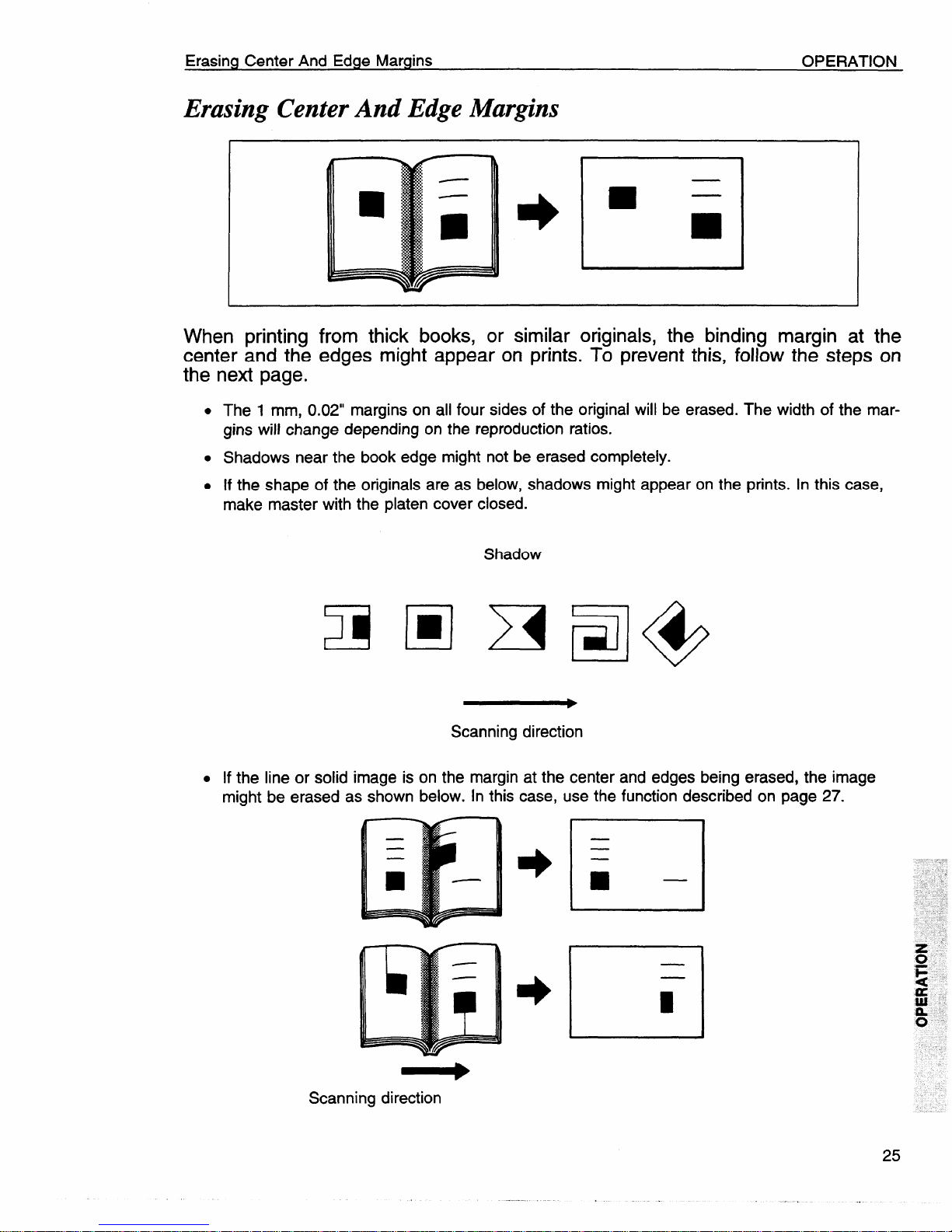

Erasing Center And Edge Margins

OPERATION

Erasing Center And Edge Margins

I

When printing from thick books, or similar originals, the binding margin at the

center and the edges might appear on prints. To prevent this, follow the steps on

the next page.

.

The 1 mm, 0.02” margins on all four sides of the original will be erased. The width of the margins will change depending on the reproduction ratios.

. Shadows near the book edge might not be erased completely.

. If the shape of the originals are as

make master with the platen cover

L

. If the line or solid image is on the margin at the center and edges being erased, the image

might be erased as shown below. In this case, use the function described on page 27.

1

J

below, shadows might appear on the prints. In this case,

closed.

Shadow

J

~F=l@

Scanning direction

t 1

b

—

El

Scanning direction

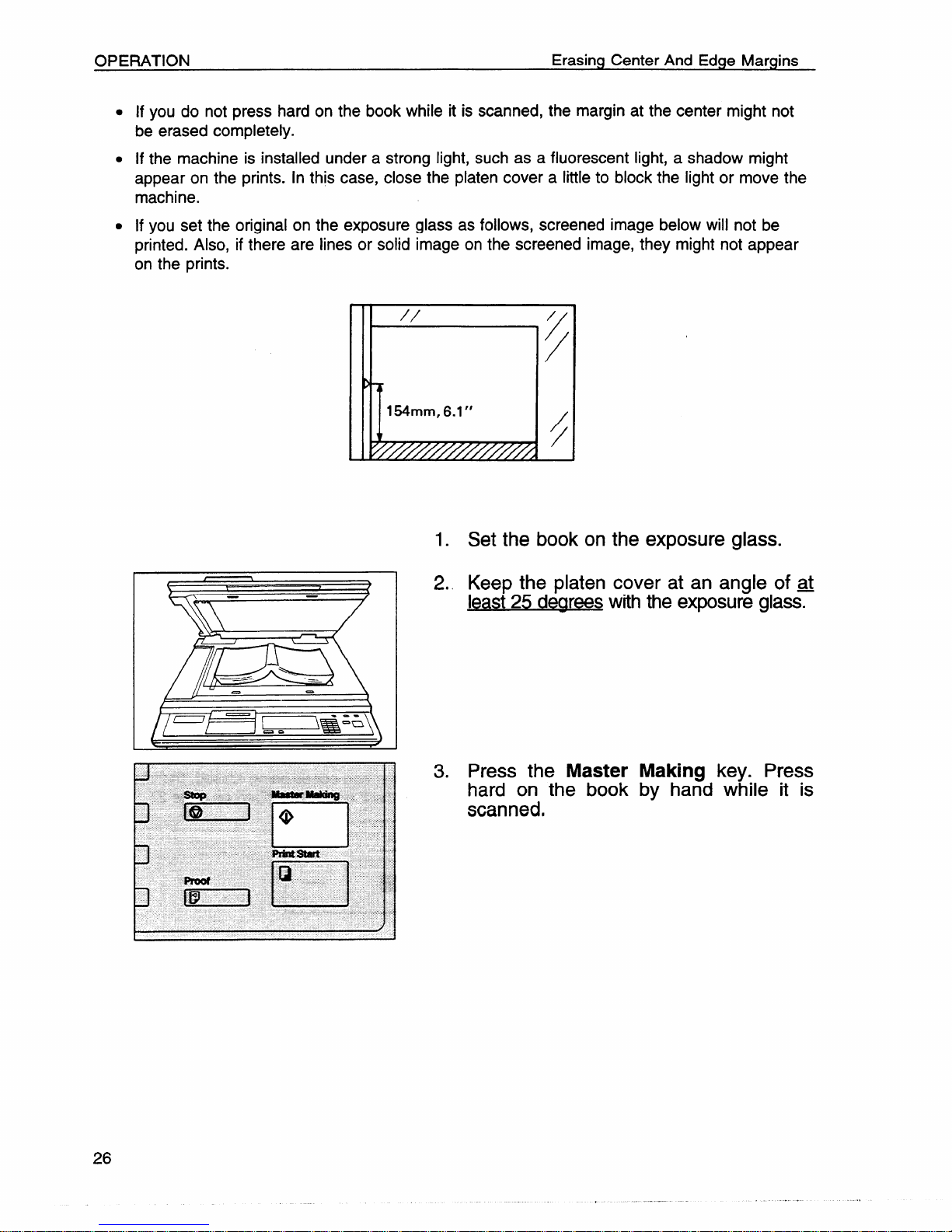

OPERATION

●

If you do not press hard on the book while it is scanned, the margin at the center might not

Erasing Center And Edge Margins

be erased completely.

●

If the machine is installed under a strong light, such as a fluorescent light, a shadow might

appear on the prints. In this case, close the platen cover a little to block the light or move the

machine.

●

If you set the original on the exposure glass as follows, screened image below will not be

printed. Also, if there are lines or solid image on the screened image, they might not appear

on the prints.

I

1.

Set the book on the exposure glass.

Keep the platen cover at an angle of ~

2.

least 25 dearees

Press the

3.

with the exposure glass.

Master Making key. Press

hard on the book by hand while it is

scanned,

Loading...

Loading...