Page 1

This manual contains detailed instructions and notes on the

operation and use of this product. For your safety and benefit,

read this manual carefully before using the product.

Original instructions

Appendix

Troubleshooting

Maintenance

Extended Functions

Basic Operations

Before Use

6.

5.

4.

3.

2.

1.

Operation Manual

Page 2

TABLE OF CONTENTS

Information ...........................................................................v

Introduction ...................................................................... v

Legal Prohibition .............................................................. v

CAUTION ............................................................................ vi

DISCLAIMER OF WARRANTY .......................................vi

FCC Statement (USA) .....................................................vi

Note to users in the state of California (USA) ..................vi

User Information on Electrical & Electronic Equipment ...vi

Note for the Battery and/or Accumulator Symbol

(For EU countries only) ...................................................vii

Warning on Class A Product ..........................................vii

DECLARATION OF CONFORMITY ..............................viii

Safety Precautions .............................................................. ix

Symbols ...........................................................................ix

Safety interlock ...............................................................xv

Warning labels ................................................................... xvi

Chapter 1

Before Use

Moving This Machine ........................................................1-2

Where to Install This Machine .......................................... 1-2

Working Environmental Temperature ............................... 1-2

Moving This Machine ........................................................1-2

Names of Parts and Functions ..........................................1-3

Front Side of the Machine ................................................ 1-3

Rear Side and Right Side of the Machine ........................ 1-4

Operation Panel ................................................................1-5

Signs on the power switch ................................................ 1-5

Heater ............................................................................... 1-6

Media sensor .................................................................... 1-6

Carriage ............................................................................ 1-7

Cutter blade and slot for cutting ........................................ 1-7

Connector of Temperature sensor/ Drying heater/

Take-up device .................................................................1-8

Capping station ................................................................. 1-8

Pinch rollers and Feed rollers ...........................................1-9

Connecting Cables ..........................................................1-10

Connecting USB2.0 Interface Cable ............................... 1-10

Connecting the power cable ...........................................1-11

Inserting ink cartridge ......................................................1-12

How to assemble ink cartridge ....................................... 1-12

About the ink that can be used with this machine .......... 1-14

Setting orders of ink cartridges ....................................... 1-15

Caution in handling of ink cartridges .............................. 1-17

Media ...............................................................................1-18

Usable sizes of media .................................................... 1-18

Caution in handling of medias ........................................ 1-18

About antistatic sheet ......................................................1-19

i

Page 3

Chapter 2

Basic Operations

Workflow ........................................................................... 2-2

Turning the Power ON/OFF .............................................. 2-3

Turning the Power ON ......................................................2-3

Turning the Power OFF ....................................................2-4

Setting a Media ................................................................. 2-5

Adjusting the Head Height ................................................2-5

Note for media setting .......................................................2-7

Setting a roll media ...........................................................2-8

Take-up device ...............................................................2-13

Setting leaf media ...........................................................2-14

Changing the printing origin ............................................2-16

Preparing for the Heaters ............................................... 2-17

Changing the Temperature Settings for the Heaters ......2-17

Checking the Heater Temperature .................................2-18

Changing the Temperature Settings for the

Drying Heater ..................................................................2-18

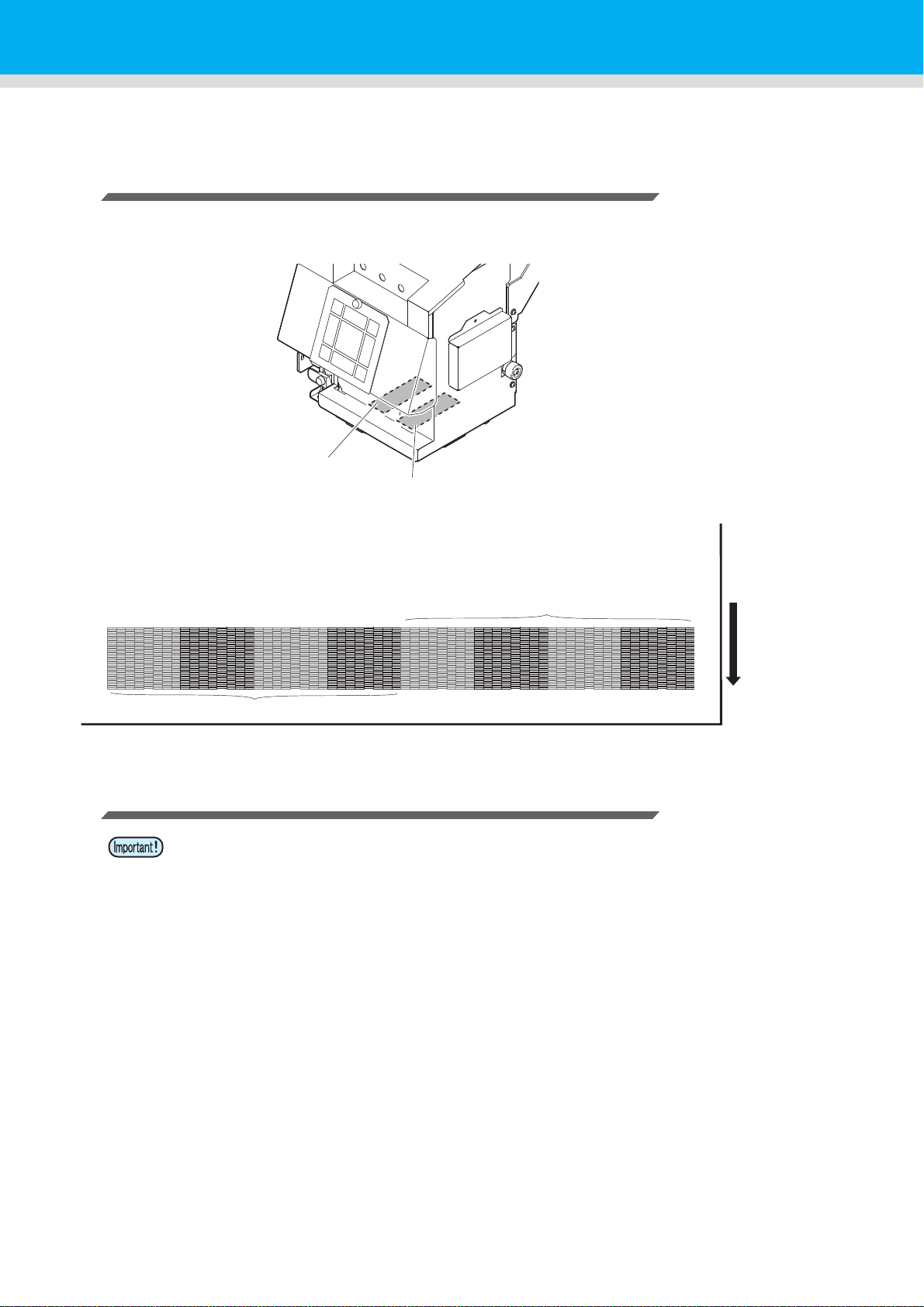

Test Feeding ................................................................... 2-19

Test Printing .................................................................... 2-20

Test Printing ....................................................................2-21

Head Cleaning ................................................................ 2-22

About head cleaning .......................................................2-22

Perform head cleaning depending on the test printing

result ...............................................................................2-22

Set the media feeding ..................................................... 2-23

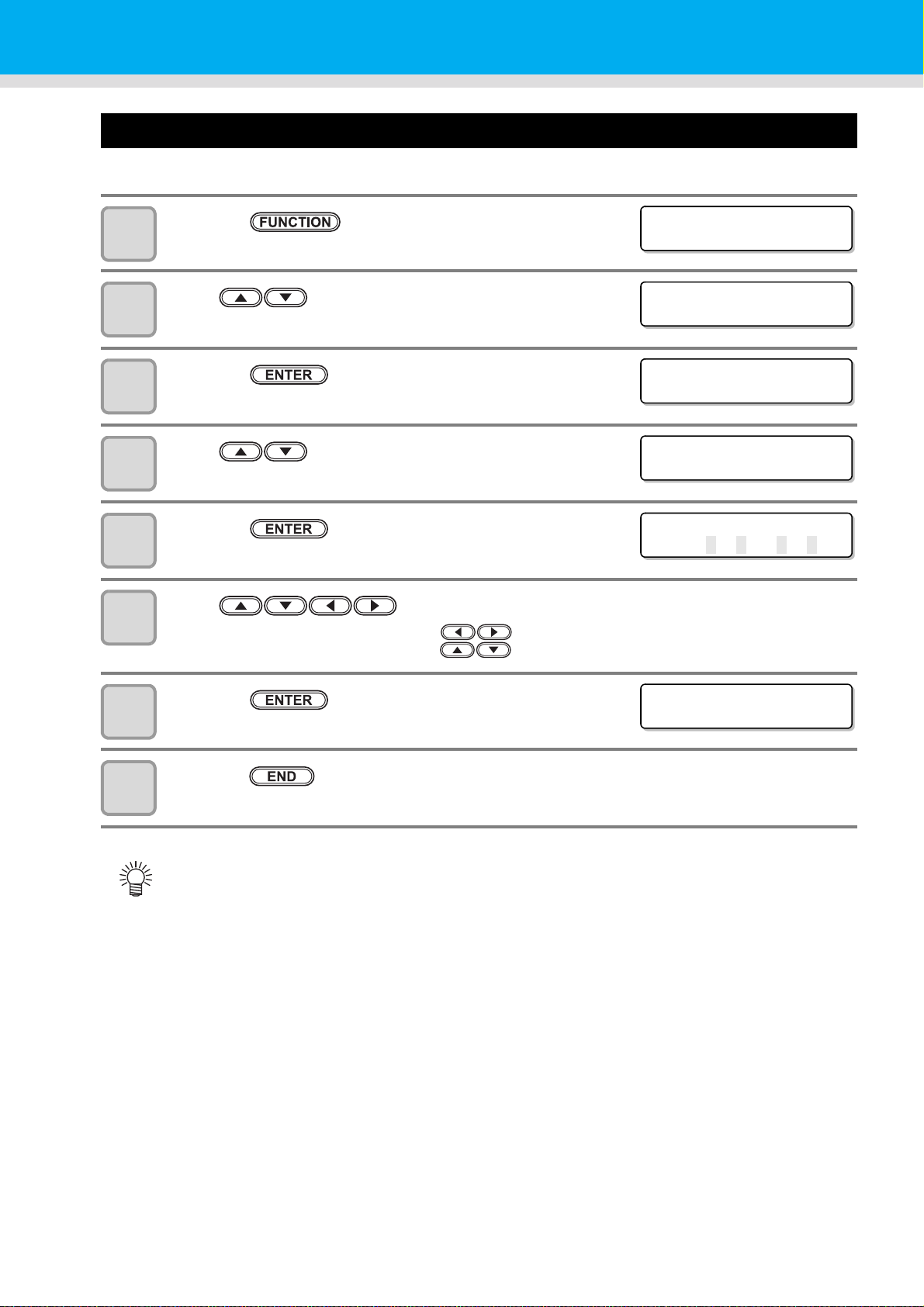

Setting Feed Correction ..................................................2-23

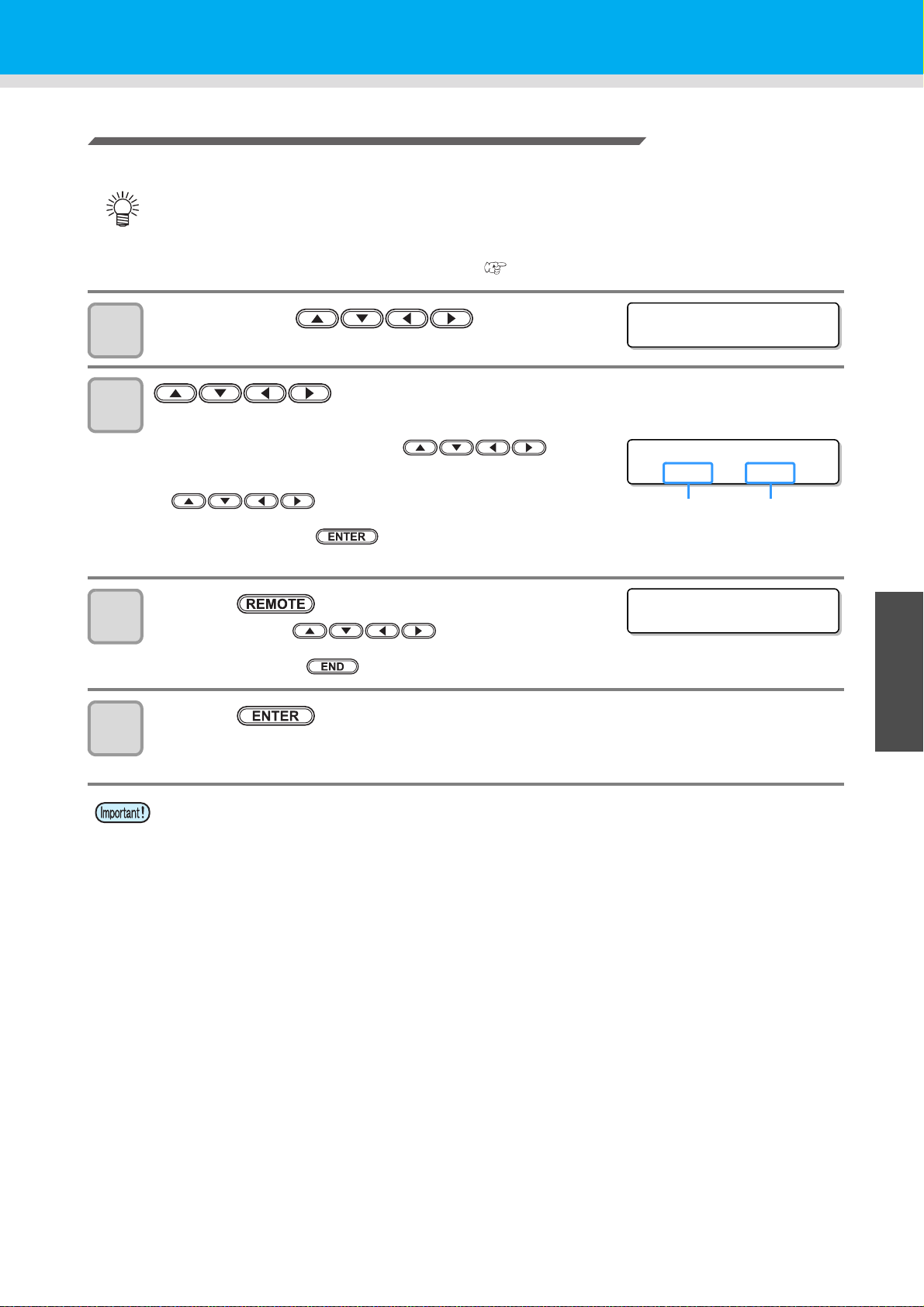

Correct the ink drop position for bidirectional printing ..... 2-25

Printing Data ................................................................... 2-27

Checking the Status of Ink Cartridges ............................2-27

Checking the Status of Waste Ink Bottle ........................2-27

Starting a Printing Operation ..........................................2-28

Stopping a printing operation halfway ............................. 2-29

Deleting Received Data (Data Clear) .............................2-29

Behavior after printing has been completed ...................2-29

Cutting a media ...............................................................2-30

When [NEAR END] error occurs while printing ............... 2-30

When [INK END] error occurs while printing ................... 2-30

When a waste ink bottle confirmation message

appears while printing .....................................................2-31

Chapter 3

Extended Functions

List of Functions ................................................................ 3-2

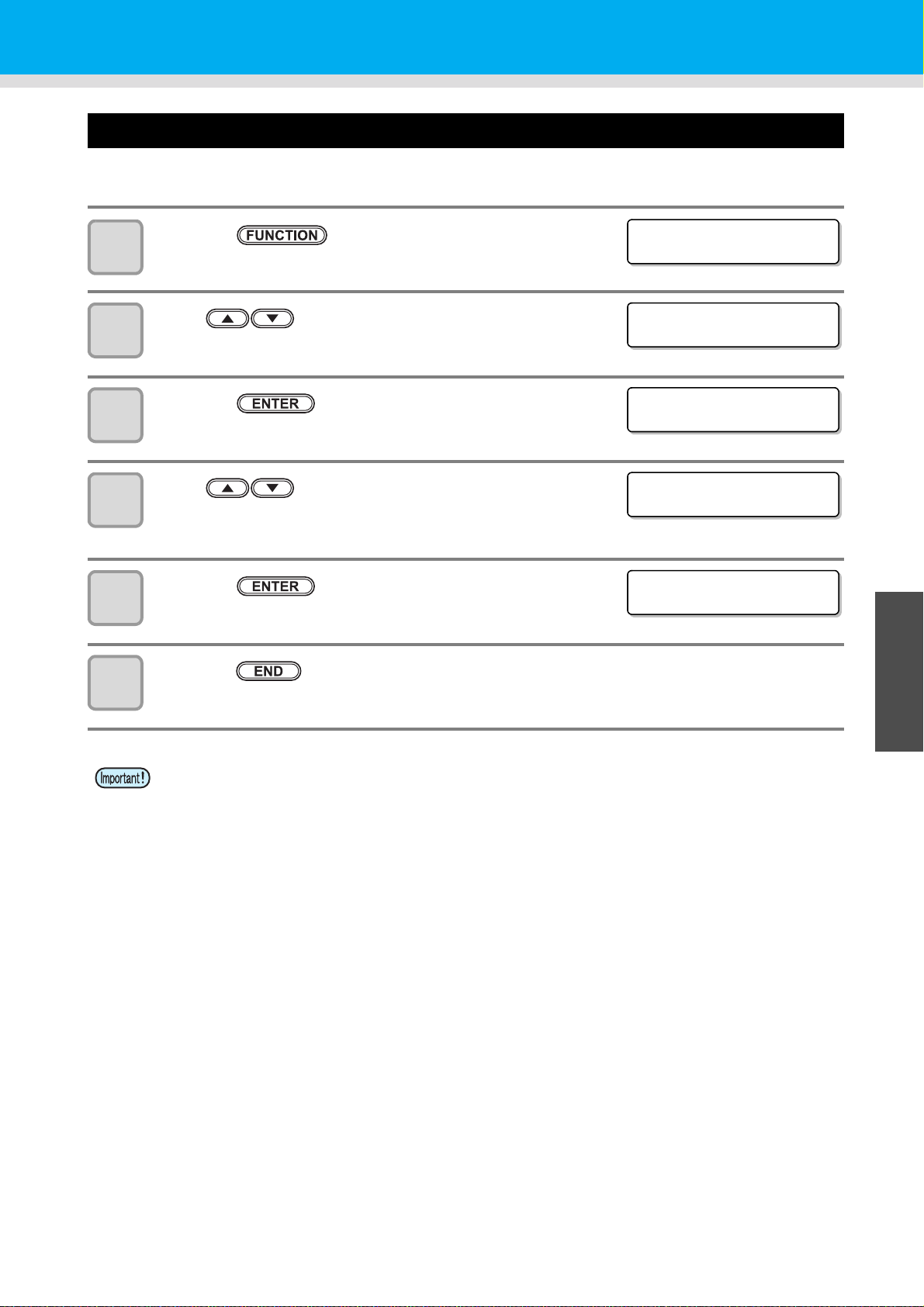

Setting Logical Seek ......................................................... 3-3

Setting Drying Time .......................................................... 3-4

Setting Margins ................................................................. 3-5

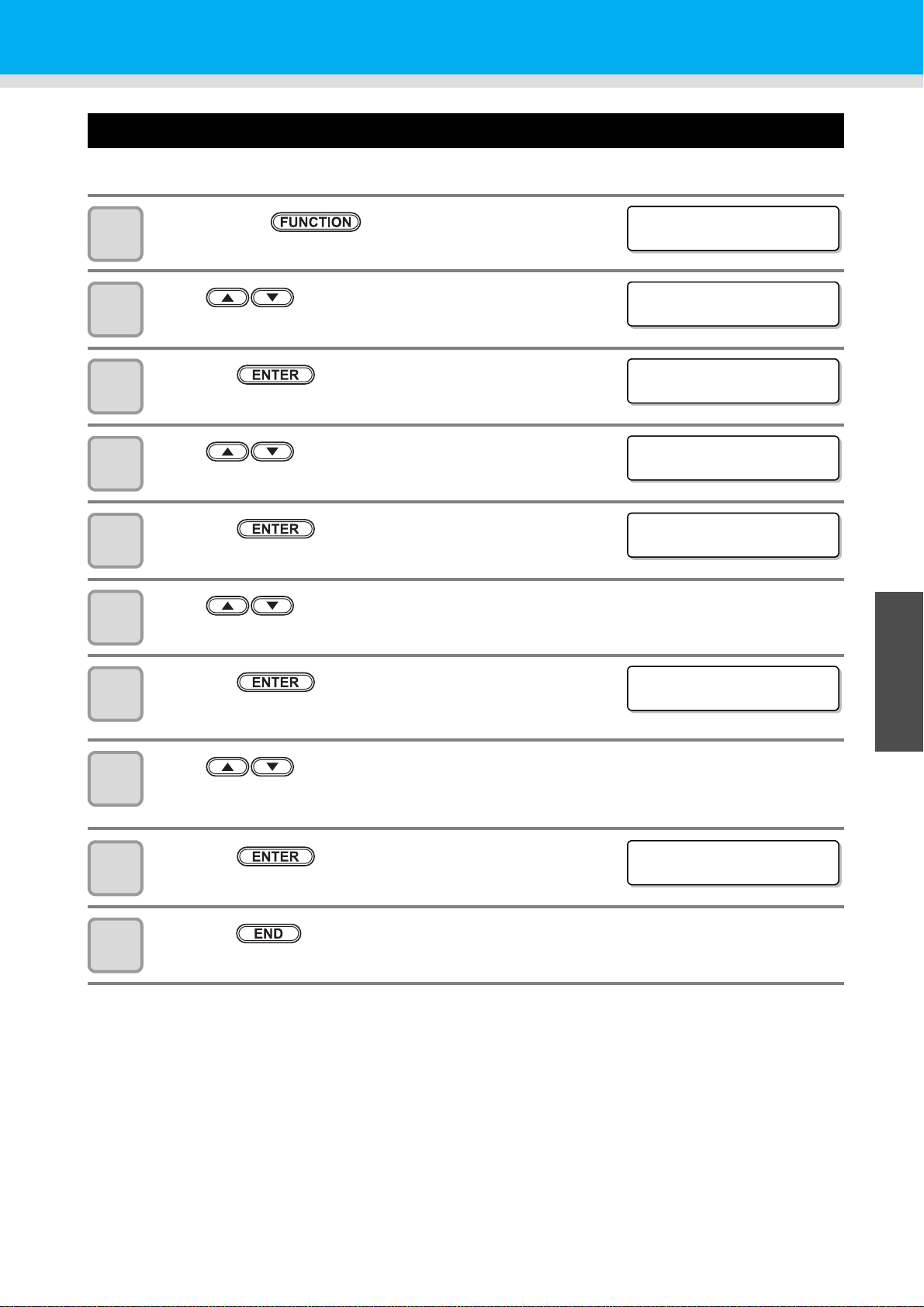

Perform setting to reduce stripes between passes ........... 3-6

Setting Auto Cleaning ....................................................... 3-7

ii

Page 4

Setting nozzle face cleaning time ......................................3-8

Other Settings ...................................................................3-9

Machine Settings .............................................................3-10

Setting a AUTO Power-off ..............................................3-11

Setting the Display of Media Residual ............................ 3-12

Setting Time ................................................................... 3-14

Setting Units ................................................................... 3-15

Setting a KEY BUZZER .................................................. 3-16

Setting a LANGUAGE .................................................... 3-17

Initializing the Settings .....................................................3-18

Confirming Machine Information .....................................3-19

Displaying the Information ..............................................3-19

Check such as the machine version information ............ 3-21

Displaying the Information of this machine ..................... 3-21

Chapter 4

Maintenance

Maintenance ......................................................................4-2

Precautions for Maintenance ............................................ 4-2

About Cleaning Fluid ........................................................4-2

Cleaning the Exterior Surfaces ......................................... 4-3

Cleaning the Media Transfer Surface ............................... 4-3

Cleaning of after heater cover and pre heater cover ........ 4-3

Cleaning the Media Sensor .............................................. 4-4

Cleaning the Media Holder ...............................................4-4

Maintaining the Capping Station .......................................4-5

Cleaning the Wiper and Cap ............................................ 4-5

Washing the Ink Discharge Passage (DISWAY WASH) .. 4-8

When the Machine Is Not Used for a Long Time

(CUSTODY WASH) .......................................................... 4-9

Cleaning the Head and the Area around It (every day) ...4-13

Replacing method of absorber kit ....................................4-15

When Nozzle Clogging Cannot Be Solved ......................4-17

Washing of Head nozzle ................................................. 4-17

Washing nozzle surface .................................................4-20

Alternative nozzles for printing, when nozzles missing

can not be improved .......................................................4-22

Automatic Maintenance Function ....................................4-25

Setting the Refreshing Intervals ..................................... 4-25

Setting the Cleaning Intervals .........................................4-26

Setting the Cleaning Intervals .........................................4-27

Replacing consumables ..................................................4-28

Replacing the wiper ........................................................4-28

If a Waste Ink Bottle Confirmation Message Appears .... 4-29

Replacing the Cutter Blade .............................................4-32

Replacing the white ink filter ........................................... 4-34

When white ink filter becomes required to be replaced ..4-34

iii

Page 5

Chapter 5

Troubleshooting

Troubleshooting ................................................................ 5-2

Power does not turn on .....................................................5-2

The machine does not start printing .................................5-2

Media get jammed / media is soiled .................................5-3

[HEAT] or [CONSTANT] LED does not light up ................5-4

Image quality is poor .........................................................5-4

Nozzle is clogged ..............................................................5-5

Ink cartridge warning appears ..........................................5-5

When Error 618 to 61b occur ............................................5-6

When nozzle missing occurs due to ink mixture or

aeration .............................................................................5-7

Regular maintenance of white ink .....................................5-9

When media heaves up at feeding .................................5-10

When the feeding media is loosened and reached to the

floor .................................................................................5-10

Warning / Error Messages .............................................. 5-11

Warning messages .........................................................5-11

Error messages ..............................................................5-14

Chapter 6

Appendix

Specifications .................................................................... 6-2

Sheet for inquiry ................................................................ 6-5

Function Flowchart ........................................................... 6-6

Machine specifications ......................................................6-2

Ink specifications ..............................................................6-3

List of consumables ..........................................................6-4

iv

Page 6

Information

Introduction

Read this manual carefully before you use this machine and keep it handy for future reference. For safe and

correct use, be sure to read the Safety Precautions in this manual before using the machine.

Legal Prohibition

Do not copy or print any item for which reproduction is prohibited by law.

Copying or printing the following items is generally prohibited by local law:

bank notes, revenue stamps, bonds, stock certificates, bank drafts, checks, passports, driver's licenses.

The preceding list is meant as a guide only and is not inclusive. We assume no responsibility for its

completeness or accuracy. If you have any questions concerning the legality of copying or printing certain

items, consult with your legal advisor.

v

Page 7

CAUTION

DISCLAIMER OF WARRANTY

Contents of this manual are subject to change without prior notice.

To the maximum extent permitted by applicable laws, in no event will the manufacturer be liable for any

damages whatsoever arising out of failures of this machine, losses of the registered data, or the use of this

product and operation manuals provided with it. Make sure that you always copy or have backups of the data

registered in this machine. Documents or data might be erased due to your operational errors or malfunctions

of the machine. In no event will the manufacturer be responsible for any documents created by you using this

machine oranyresults from the data executed by you.

FCC Statement (USA)

Note:

This equipment has been tested and found to comply with the limits for a Class A digital devices, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference in which case the user will be required to correct the interference at

his own expense.

Caution:

Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment.

Note to users in the state of California (USA)

Perchlorate Material - special handling may apply. See: www.dtsc.ca.gov/hazardouswaste/perchlorate

User Information on Electrical & Electronic Equipment

Users in the countries where this symbol shown in this section has been specified in national

law on collection and treatment of E-waste

Our Products contain high quality components and are designed to facilitate recycling.

Our products or product packaging are marked with the symbol below.

1

2

3

4

The symbol indicates that the product must not be treated as municipal waste. It must be disposed of

separately via the appropriate return and collection systems available. By following these instructions you

ensure that this product is treated correctly and help to reduce potential impacts on the environment and

human health, which could otherwise result from inappropriate handling. Recycling of products helps to

conserve natural resources and protect the environment.

For more detailed information on collection and recycling systems for this product, please contact the shop

where you purchased it, your local dealer or sales/service representatives.

All Other Users

If you wish to discard this product, please contact your local authorities, the shop where you bought this

product, your local dealer or sales/service representatives.

vi

5

6

Page 8

For Users in India

This product complies with the "India E-waste Rule 2011" and prohibits use of lead, mercury, hexavalent

chromium, polybrominated biphenyls or polybrominated diphenyl ethers in concentrations exceeding 0.1

weight % and 0.01 weight % for cadmium, except for the exemptions set in Schedule 2 of the Rule.

For Turkey only

complies with EEE regulation:

The system including supply and parts complies with Directive

Note for the Battery and/or Accumulator Symbol (For EU countries only)

In accordance with the Battery Directive 2006/66/EC Article 20 Information for end-users Annex II, the above

symbol is printed on batteries and accumulators.

This symbol means that in the European Union, used batteries and accumulators should be disposed of

separately from your household waste.

In the EU, there are separate collection systems for not only used electrical and electronic products but also

batteries and accumulators.

Please dispose of them correctly at your local community waste collection/recycling centre.

Warning on Class A Product

Warning:

This is a Class A product. In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

vii

Page 9

CAUTION

DECLARATION OF CONFORMITY

We, RICOH CO., Ltd. at address 3-6, Naka-magome 1-Chome, Ohta-Ku, Tokyo 143-8555, Japan declare

under our sole responsibility that the product consisting of the following;

Product Name : Inkjet Printer

Model Name : Pro L4160, Pro L4130

to which this declaration relates is in conformity with the following standards.

EN 60950-1:2006+A11:2009+A1:2010+A12:2011

EN ISO 12100:2010

EN 60204-1:2006+A1:2009

EN 55022:2010 ClassA

EN 55024:2010

EN 61000-3-2:2006+A2:2009

EN 61000-3-3:2008

EN 62311:2008

EN 50581:2012

following the provisions of

EMC Directive 2004/108/EC

Low Voltage Directive 2006/95/EC

Machinery Directive 2006/42/EC

RoHS Directive 2011/65/EU

1

CE Mark is affixed in 2013

Place : Tokyo, Japan

Date : September 26, 2013

Importer:

Ricoh Europe PLC

20 Triton Street, London, NW1 3BF, U.K.

2

3

4

viii

5

6

Page 10

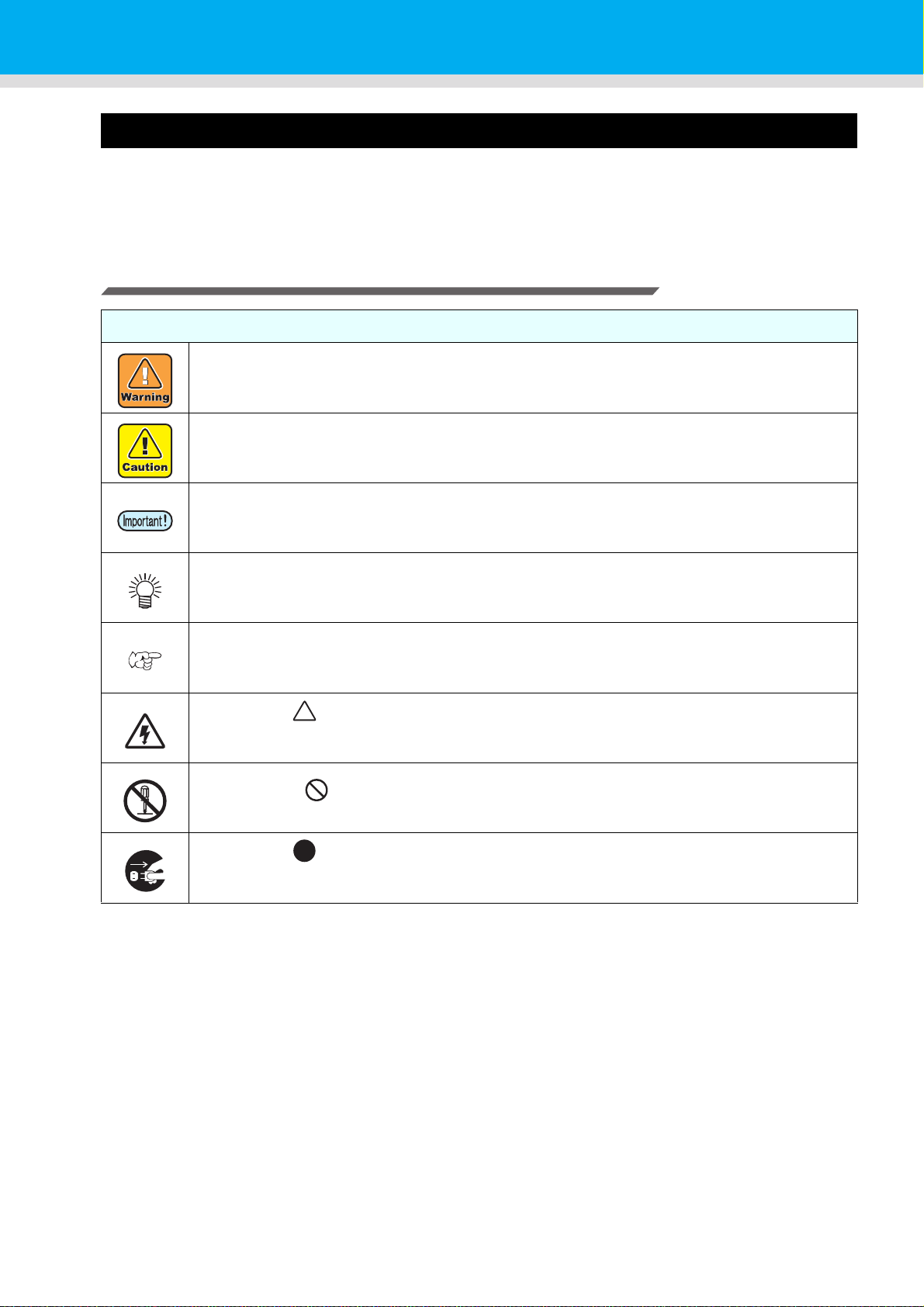

Safety Precautions

Symbols

Symbols are used in this Operation Manual for safe operation and for prevention of damage to the machine.

The indicated sign is different depending on the content of caution.

Symbols and their meanings are given below. Please follow these instructions as you read this manual.

Examples of symbols

Meaning

Failure to observe the instructions given with this symbol can result in death or serious injuries

to personnel. Be sure to read it carefully and use it properly.

Failure to observe the instructions given with this symbol can result in injuries to personnel or

damage to property.

Important notes in use of this machine are given with this symbol. Understand the notes

thoroughly to operate the machine properly.

Useful information is given with this symbol. Refer to the information to operate the machine

properly.

Indicates the reference page for related contents.

The symbol " " indicates that the instructions must be observed as strictly as the CAUTION

instructions (including DANGER and WARNING instructions). A sign representing a precaution

(the sign shown at left warns of hazardous voltage) is shown in the triangle.

The symbol " " indicates that the action shown is prohibited. A sign representing a

prohibited action (the sign shown at left prohibits disassembly) is shown in or around the circle.

The symbol " " indicates that the action shown must be taken without fail or the instructions

must be observed without fail. A sign representing a particular instruction (the sign shown at left

instructs to unplug the cable from the wall outlet) is shown in the circle.

ix

Page 11

Safety Precautions

Warning for Use

WARNING

• The set of power cables provided with this machine is for use with this machine only, and cannot be

used with other electrical devices. Do not use any power cables other than the ones provided with the

machine. Failure to observe those instructions may result in fire or electric shocks.

• Take care not to damage, break or work upon the power cable. If a heavy material is placed on the

power cable, or if it is heated or pulled, the power cable can break, thus resulting in fire or electric

shocks.

• Do not use this machine in an environment where humidity is high or the machine may get wet. Using

the machine under such environment may result in fire or electric shock, or cause malfunction.

• Use of the machine under an abnormal condition where it produces smoke or strange smell can result

in fire or electric shocks. If such an abnormality is found, be sure to turn off the power switch

immediately and unplug the cable from the wall outlet. Check first that the machine no longer

produces smoke, and then contact your distributor or a sales office of RICOH for repair.

• Never repair your machine by yourself since it is very dangerous for you to do so.

• Never disassemble or remodel the main unit of the machine or the ink cartridge. Disassembly or

remodeling can result in an electric shock or breakdown of the machine.

• Take care that no dust or dirt sticks to Media Transfer Surface heaters. Dust and dirt sticking heaters

can cause fire.

• Do not use extension cords. Doing so may result in fire or electric shocks.

• Keep the power plug prong clear of any foreign object such as a piece of metal. Failure to do so may

result in a fire or electric shocks.

• Do not plug too may leads into a single socket. Doing so may result in fire or electric shocks.

• Do not use the machine if the power cord or plug is damaged. Using the machine with damaged power

cord may result in fire or electric shocks. Contact your service representative for replacement cord.

• Do not handle the power plug with wet hands. Doing so may result in electric shocks.

• Grasp by holding the plug itself when removing the power plug from wall outlet, and never hold by the

cord. Holding and pulling the cord may damage the cord, leading to fire or electric shocks.

Hazardous Moving Parts

• Keep Fingers and Other Body Parts Away

• If a foreign object such as a small piece of metal or a liquid such as water gets inside the machine, turn

off the machine and unplug the power cord immediately, then consult your service representative.

Continuing to use the machine without proper maintenance or repair may result in fire or electric

shocks.

• Do not use a flammable spray or solvent inside or around the machine. Doing so may result in fire or

electric shocks.

• Do not place a vase, flower pot, water glass, container with liquid such as water or chemicals inside, or

small metallic object near or on top of this machine. Liquid or foreign object may get inside the

machine, leading to fire or electric shocks.

1

2

3

4

5

6

x

Page 12

CAUTION

Handling of the power cable Power supply

• Connect to a socket-outlet with determinate

polarity.

• For Inlet 1 and 2, be sure to supply power

from the outlet of the same voltage.

• for PLUGGABLE EQUIPMENT, the socketoutlet shall be installed near the equipment

and shall be easily accessible.

• Unplug the cord from the wall outlet and

remove dust from the power plug

periodically, at least once a year. Failure to

do so may result in fire or electric shocks.

• Do not use the machine unless it is

connected to a power supply that satisfies

the displayed voltage condition.

• Check the voltage of the wall outlet and the

capacity of the circuit breaker before you

plug the power cords. Plug each power cord

to different outlet that has independent

circuit breaker. If you plug more than one

power cord to wall outlets that share the

same circuit breaker, the power may be cut

off by the breaker.

Heater

• Do not spill liquid on the Media Transfer

Surface as this may cause failure of the

heater or firing.

• Do not touch Media Transfer Surface heaters

with bare hand while it is hot; otherwise, you

can get burned.

Note on maintenance

• When cleaning the ink-station or the heads, make sure to wear the attached goggles and gloves.

• The gloves supplied with the machine are disposable. When all the gloves are expended, purchase an

equivalent product on the market.

Handling of ink

• Leave the breaker turned ON.

• Do not turn off the main power switch on the

right side of this machine.

• Keep ink away from an open flame. Also

keep the room well ventilated when you use

or handle ink.

• If you get ink in your eyes, immediately wash

your eyes with a lot of clean water for at least

15 minutes. In doing so, also wash eyes to

rinse ink away completely. Then, consult a

doctor as soon as possible.

• If anyone drinks ink by mistake, keep him or

her quiet and see a doctor immediately. Do

not allow him or her to swallow the vomit.

After that, contact the Poison Control Center.

• If you inhale a lot of vapor and feel bad,

immediately move to a location of fresh air

and then keep yourself warm and quiet.

Then, consult a doctor as soon as possible.

• Store ink cartridges in a place that is out of

the reach of children.

• Black and white cause serious eye irritation,

suspected of damaging fertility or the

unborn child, causes damage to the lungs

through prolonged or repeated exposure.

Please use protective equipment in order to

avoid exposure to liquid.

• Orange, green, cyan, magenta and yellow

cause serious eye irritation, suspected of

damaging fertility or the unborn child. Please

use protective equipment in order to avoid

exposure to liquid.

xi

• Do not to touch the sharp edge of the blade when replacing the cutter. Touching the sharp edge may

result in injury.

• Turn off the machine and unplug the power cord from the wall outlet for safety when moving the

machine.

Page 13

Notes on Handling the Machine

• Do not use the machine in a confined or poorly ventilated room.

• Keep the room well ventilated when using the machine.

• Do not use the machine under humid or dusty environment. Doing so may result in fire or electric

shocks.

• Do not place the machine on unstable or inclined surface. The machine may fall or topple over and

cause a damage or injury.

• There is a cutter inside the machine for cutting print media. Do not touch any other parts other than

the ones described in this manual when loading or replacing paper, or removing jammed paper.

Otherwise, it may cause an injury.

• Be careful not to get your fingers get caught inside the machine and injured when replacing print

paper.

• The dust collected inside the machine may result in fire or cause malfunction. If the machine has not

been cleaned for a long period of time, contact your service representative for cleaning the machine.

For the cleaning charge, consult your sales or service representative.

• Consult our service office in your area before moving this machine.

Safety Precautions

CAUTION

1

2

3

4

xii

5

6

Page 14

CAUTIONS and NOTES

Warning

Handling of ink cartridges Front cover and lever

• The safety evaluation of this machine assumes that

the ink recommended by this company is used. For

safe usage of this machine, use the ink recommend

by this company

• Never refill the ink pack and white ink cartridge with

ink. Refilled ink cartridge can cause a trouble.

Remember that RICOH assumes no responsibility for

any damage caused by the use of the ink cartridge

replenished with ink.

• If the ink cartridge is moved from a cold place to a

warm place, leave it in the room temperature for three

hours or more before using it.

• Open the ink cartridge just before installing it in the

machine. If it is opened and left for an extended

period of time, normal printing performance of the

machine may not be ensured.

• Make sure to store ink cartridges in a cool and dark

place.

• Store ink cartridges and waste ink bottle in a place

that is out of the reach of children.

• Be sure to thoroughly consume the ink in the ink

cartridge, once it is opened, within three months. If an

extended period of time has passed away after

opening the cartridge tank, printing quality would be

poor.

• Neither pound the Eco-cartridge nor shake it violently,

as doing so can cause leakage of ink.

• Do not touch or stain the contacts of the ink cartridge,

as doing so may cause damage to the print circuit

board.

• Consult your sales or service representative for

proper disposal of ink cartridge, ink pack, and waste

ink. Otherwise, commission an industrial waste

disposal company.

• Never open the front cover or raise the lever during

printing. Opening the cover or raising the lever will

abort printing.

Handling of media

• Use media recommended by RICOH to ensure

reliable, high-quality printing.

• Set the heater temperature to meet the characteristics

of the media.

Set the temperature of the Pre-heater, Print heater and

Post-heater according to the type and characteristics

of the media used. Automatic temperature setting can

be made on the operation panel by setting the profile

on the dedicated RIP. For setting on the RIP, refer to

the instruction manual for your RIP.

• Pay attention to the expansion and contraction of the

media.

Do not use media immediately after unpacking. The

media can be affected by the room temperature and

humidity, and thus it may expand and contract.The

media have to be left in the atmosphere in which they

are to be used for 30 minutes or more after unpacked.

• Do not use curled media.

The use of curled media can not only cause a media

jam but also affect print quality.

Straighten the sheet of media, if significantly curled,

before using it for printing. If a regular-sized coated

sheet of media is rolled and stored, the coated side

has to face outside.

• Do not leave the media with the heater ON for a long

time.

Protection of media from dust

• Store media in a bag. Wiping off dust accumulated on

media will adversely affect the media due to static

electricity.

• When leaving the workshop after the working hours,

do not leave any media on the roll hanger. If any

media is left on the roll hanger, it can get dusty.

Warning

Notes on maintenance

• It is strongly recommended to use the machine in a room that is not dusty.

• Keep the front cover closed even when the machine is not printing. If not, dust can accumulate on the nozzles

in the heads.

• Dust in the heads can also cause drops of ink to fall suddenly down on the media during printing. In such a

case, be sure to clean up the heads. (P.4-13 “Cleaning the Head and the Area around It (every day)”)

• When cleaning the ink-station or the heads, make sure to wear the attached gloves.

• Perform wiping (removal of dust and paper powder) of the capping station and wiper frequently.

Periodic replacement parts

• Some parts of this machine must be replaced with a new one periodically by service personnel. Be sure to

make a contract with your distributor or dealer for After sale service to ensure a long life of your machine.

Disposition of this machine

• Consult your sales or service representative for proper disposal of this machine. Otherwise, commission an

industrial waste disposal company.

xiii

Page 15

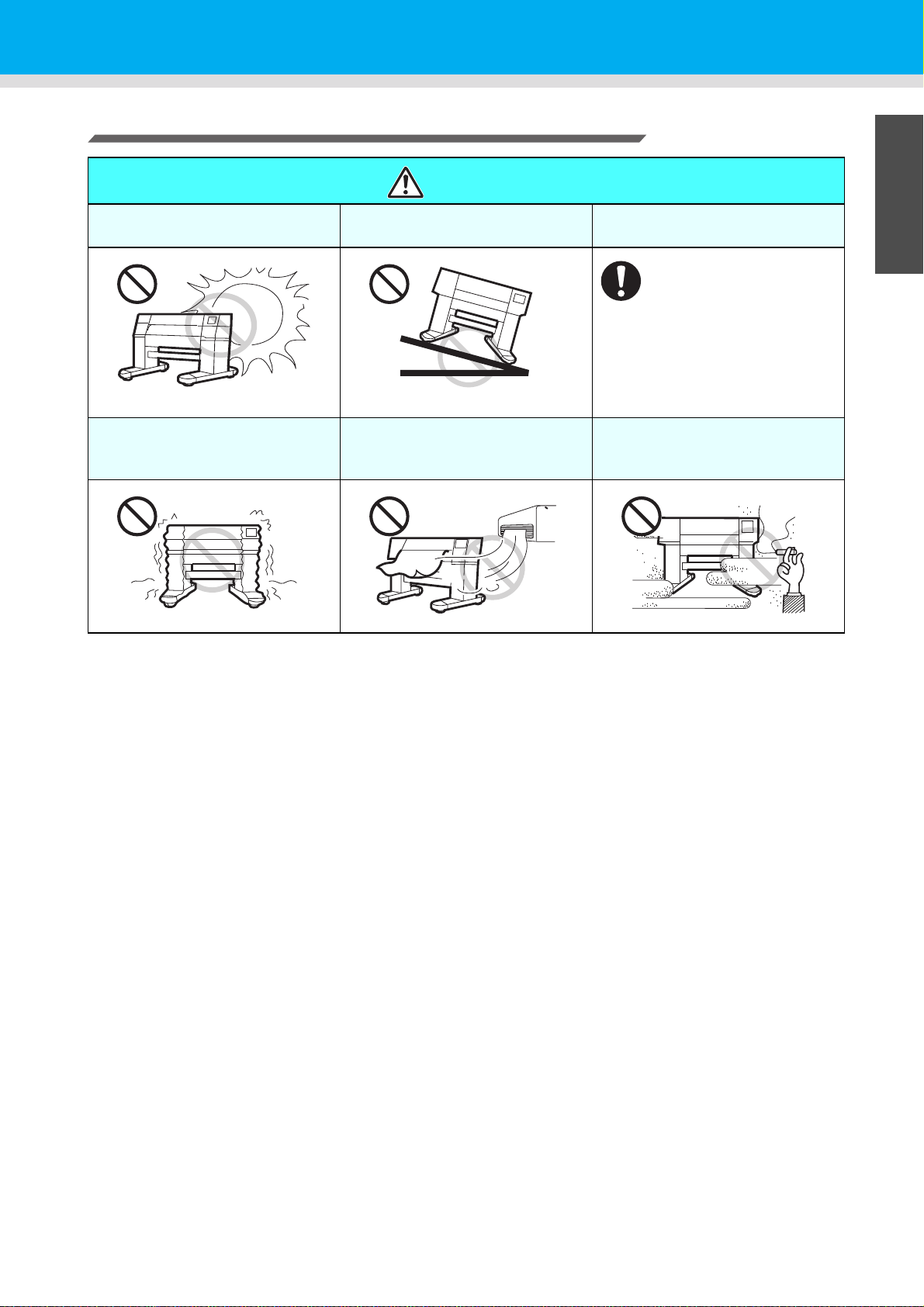

Cautions on Installation

Safety Precautions

CAUTION

A place exposed to direct

sunlight

A place that vibrates

On an inclined surface

A place exposed to direct air

flow from an air conditioner or

the like.

A place where temperature or

humidity varies significantly

• Use the machine under the

following environmental

conditions:

• Operating environment:

20 to 30 °C

(68 to 95 °F)

35 to 65 % (Rh)

1

Around a place where fire is

used

2

3

4

5

xiv

6

Page 16

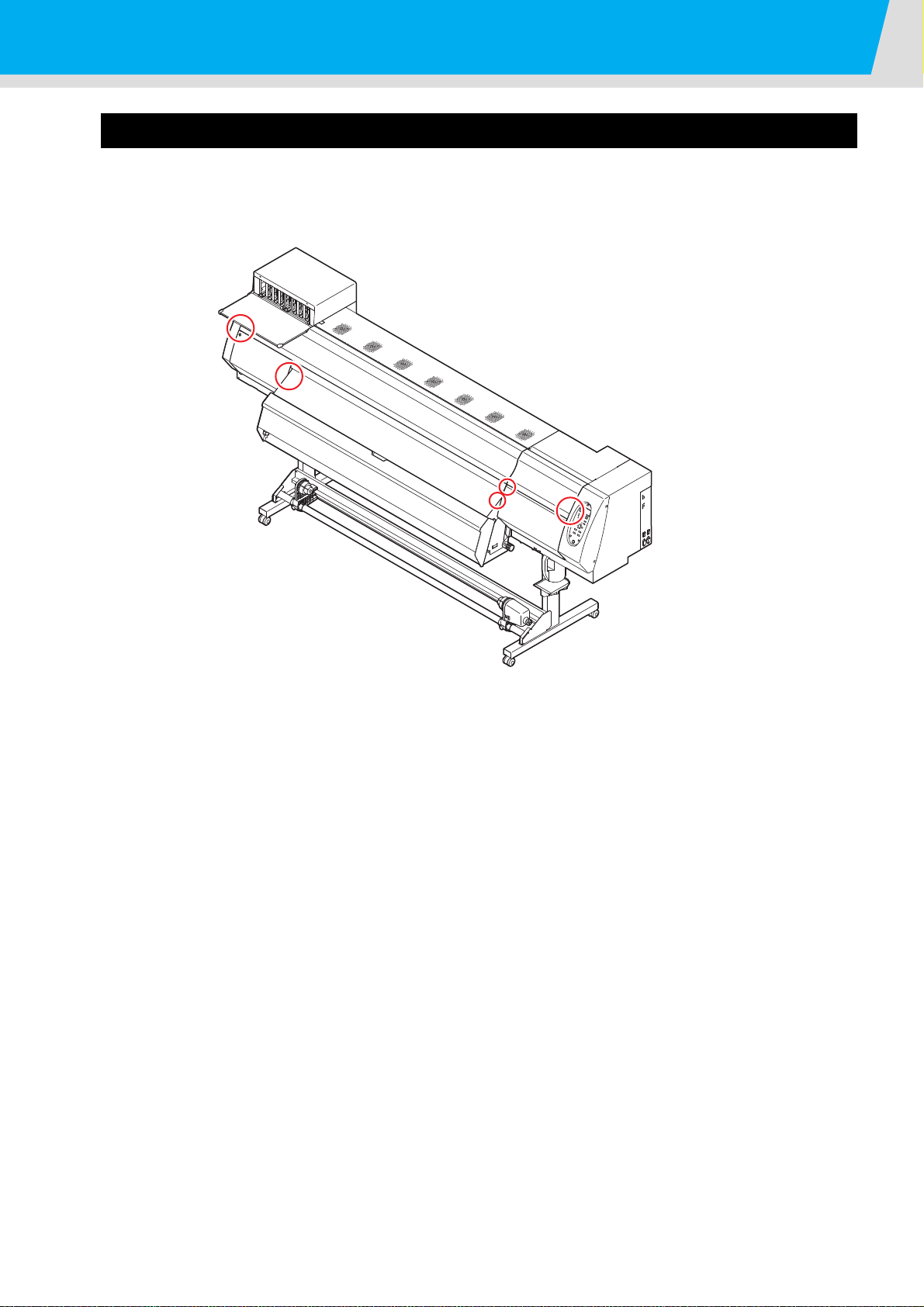

Safety Precautions

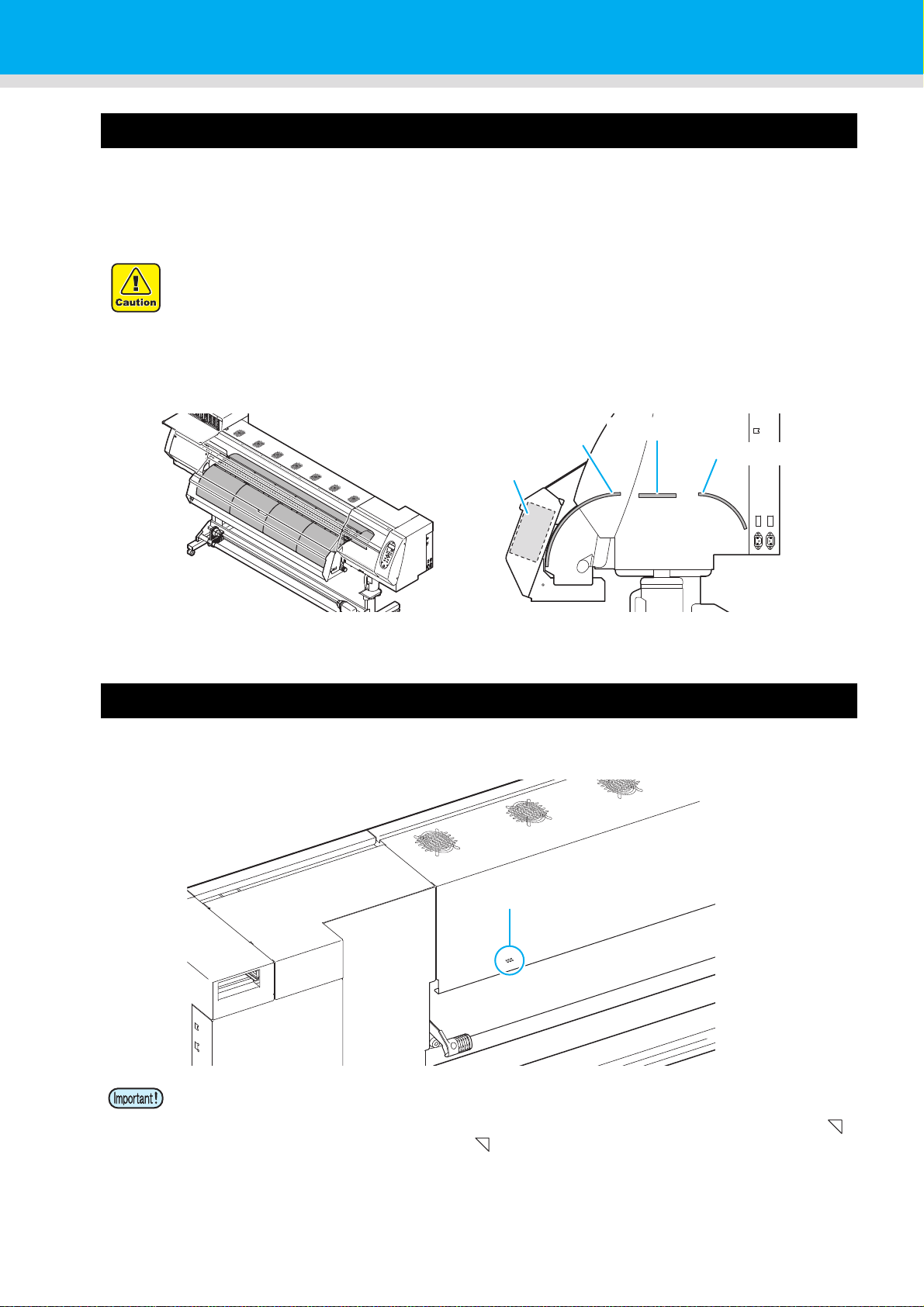

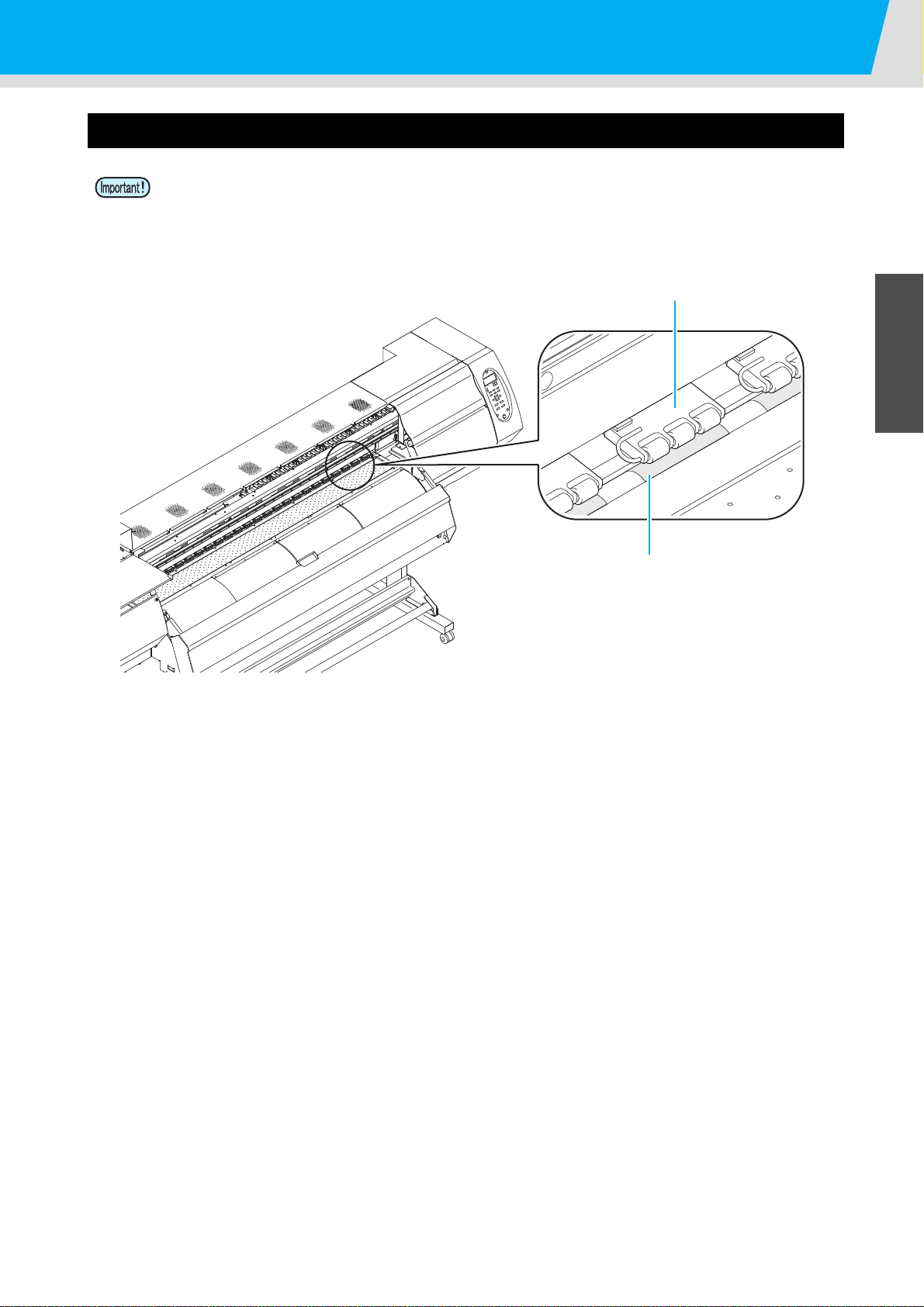

Safety interlock

This machine is equipped with interlocks to terminate the operation for your safety when the cover opens

during printing etc. (red circle parts in the figure below).

xv

Page 17

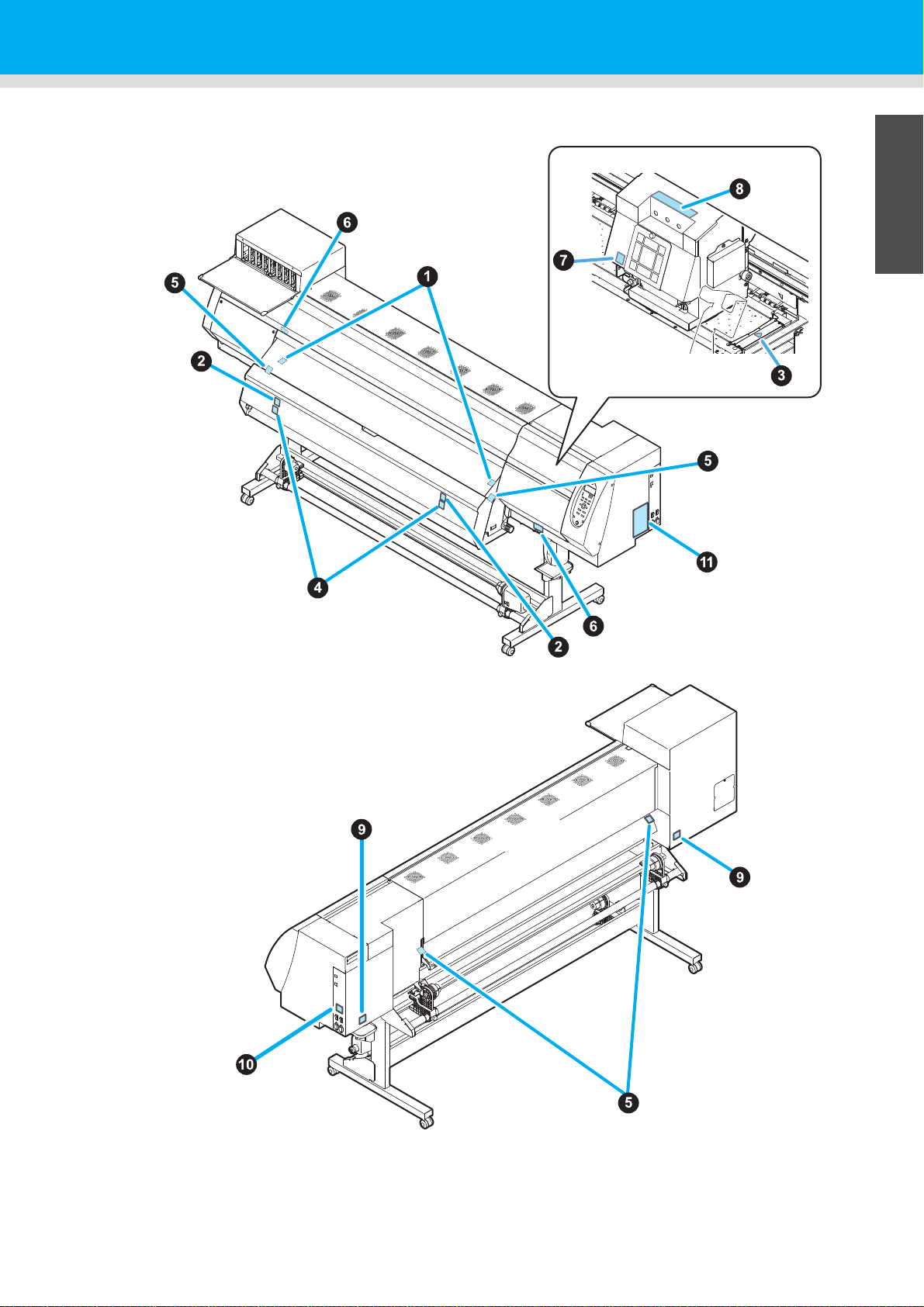

Warning labels

When the front cover is open

Stuck on right and left media

press

Warning labels are stuck on the machine. Be sure to fully understand the warning given on the labels.

1

2

3

4

xvi

5

6

Page 18

No.

2

5

5234

7

8

78

9

-

10

910

CAN ICES-3 (A)/NMB-3(A)C AN I CE S -3 (A )/ N MB -3 (A )

COLORC O LO R INKJETI N KJ E T PRINTERP R IN T E R

Pro L4130P ro L 4 13 0

PLUG1P LU G1 100-240V1 00 -2 40 V ~,~ , 12A-8A,1 2A -8 A, 50/60Hz,5 0/ 60 H z, forf or powerpo we r suppliessu pp l ie s heaterh ea te r

PLUG2P LU G2 100-120V/220-240V1 00 -1 20 V /2 20 -2 40 V ~,~ , 12A/8A,1 2A /8 A, 50/60Hz,5 0/ 60 H z, forf or hetaershe ta er s

weightwe ig h t ofo f machinem ac hi ne 235kg23 5 kg

RICOHR I C OH COMPANY,C O MP A N Y, LTDL T D

3-63 -6 NakamagomeN a ka m a go m e 1-chome,1- c h om e , Ohtaku,O h t ak u , Tokyo,T ok y o , 143-85551 4 3 -8 5 5 5 JapanJ ap a n

IntertekI n t e r t e k

CAN ICES-3 (A)/NMB-3(A)C AN I CE S -3 (A )/ N MB -3 (A )

COLORC O LO R INKJETI N KJ E T PRINTERP R IN T E R

Pro L4160P ro L 4 16 0

PLUG1P LU G1 100-240V1 00 -2 40 V ~,~ , 12A-8A,1 2A -8 A, 50/60Hz,5 0/ 60 H z, forf or powerpo we r suppliessu pp l ie s heaterh ea te r

PLUG2P LU G2 100-120V/220-240V1 00 -1 20 V /2 20 -2 40 V ~,~ , 12A/8A,1 2A /8 A, 50/60Hz,5 0/ 60 H z, forf or hetaershe ta er s

weightwe ig h t ofo f machinem ac hi ne 235kg23 5 kg

RICOHR I C OH COMPANY,C O MP A N Y, LTDL T D

3-63 -6 NakamagomeN a ka m a go m e 1-chome,1- c h om e , Ohtaku,O h t ak u , Tokyo,T ok y o , 143-85551 4 3 -8 5 5 5 JapanJ ap a n

IntertekI n t e r t e k

1

6

Warning labels

Always follow the procedure described in this manual

when loading and replacing paper, removing jammed

paper, cleaning the media transfer surface, and performing any other operations inside the machine. Otherwise, the carriage may hit or catch your hand and

cause injury.

There are hot surfaces inside the machine. Do not

touch any parts other than the ones described in this

manual when removing jammed paper. Otherwise,

burn injury may result.

Always wear the goggle and gloves provided with this

machine to prevent your skin to come in contact with

the cleaning fluid when cleaning the ink station and

print head.

There is a cutter inside the machine for cutting print

media. Do not touch any parts other than the ones

described in this manual when loading and replacing

paper, removing jammed paper, and cleaning the

media transfer surface.

11

Electrical power is supplied to this machine via multiple power cables. To completely disconnect all supply

of power to the machine, all power cables?must be

disconnected..

(Pro L4130) (Pro L4160)

xvii

Page 19

Chapter 1

Before Use

This chapter

describes the items required to understand before use, such as the name of each part of

the machine or the installation procedures.

Moving This Machine ....................................1-2

Where to Install This Machine ..................... 1-2

Working Environmental Temperature ......... 1-2

Moving This Machine .................................. 1-2

Names of Parts and Functions ......................1-3

Front Side of the Machine ........................... 1-3

Rear Side and Right Side of the Machine ... 1-4

Operation Panel .......................................... 1-5

Signs on the power switch .......................... 1-5

Heater ......................................................... 1-6

Media sensor ............................................... 1-6

Carriage ...................................................... 1-7

Cutter blade and slot for cutting .................. 1-7

Connector of Temperature sensor/

Drying heater/ Take-up device .................... 1-8

Capping station ........................................... 1-8

Pinch rollers and Feed rollers ..................... 1-9

Connecting Cables ......................................1-10

Connecting USB2.0 Interface Cable ..........1-10

Connecting the power cable ......................1-11

Inserting ink cartridge ..................................1-12

How to assemble ink cartridge ...................1-12

About the ink that can be used with this

machine .....................................................1-14

Setting orders of ink cartridges ..................1-15

Caution in handling of ink cartridges ..........1-17

Media ..........................................................1-18

Usable sizes of media ................................1-18

Caution in handling of medias ...................1-18

About antistatic sheet ..................................1-19

Page 20

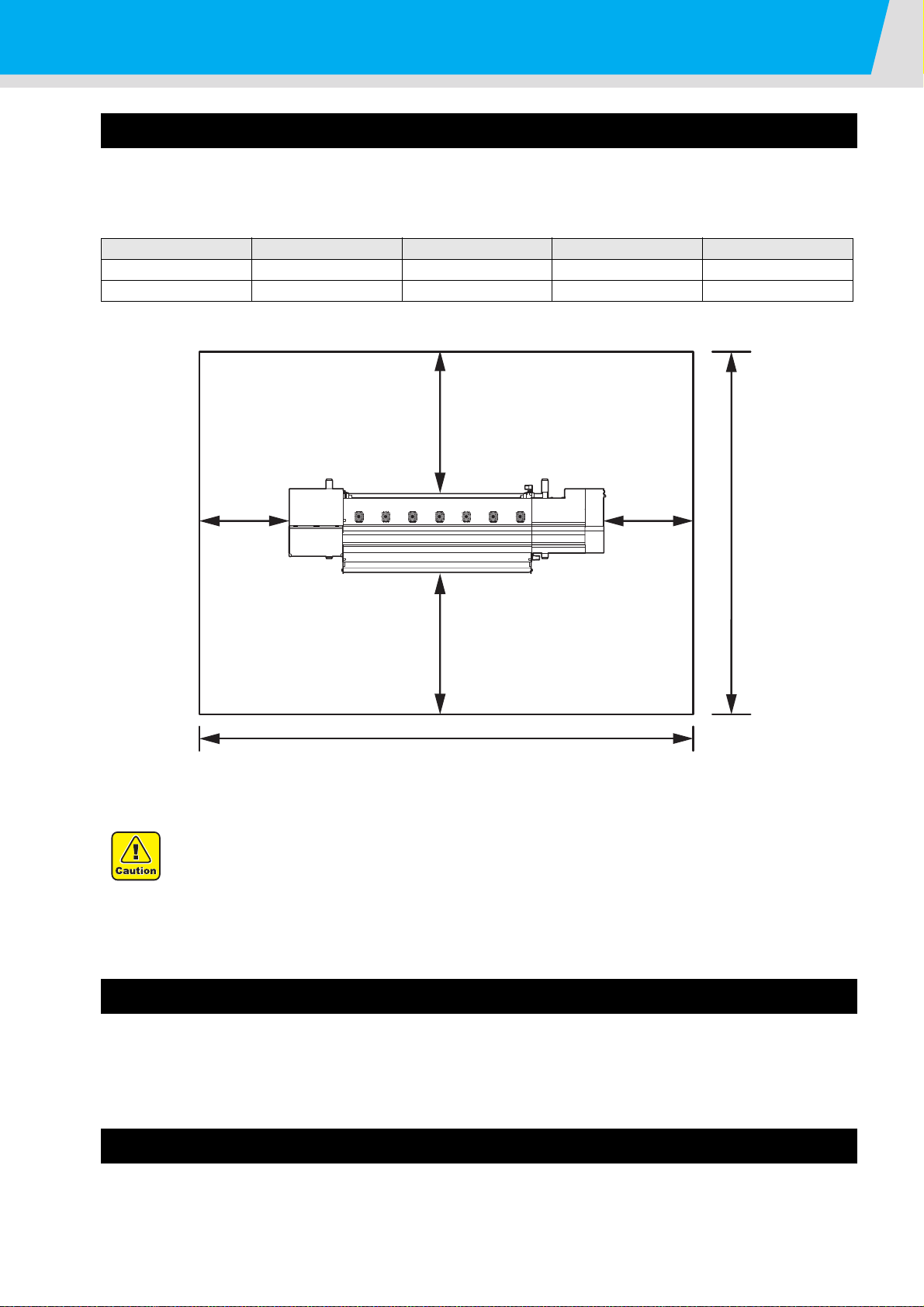

Moving This Machine

Pro L4130: 3634 mm or more

Pro L4160: 3879 mm or more

500 mm

or more

500 mm

or more

1000 mm or more

1000 mm or more

2854 mm

or more

Where to Install This Machine

Secure a suitable installation space before assembling this machine.

The place of installation must have enough space for not only this machine itself, but also for the printing

operation.

Model Width Depth Height Gross weight

Pro L4130 2634mm 854mm 1435mm 216kg

Pro L4160 2879mm 854mm 1435mm 231kg

• When you usually use photographic fixer, do not install this machine in a room filled with

vapor of photographic fixer. If you install this machine in such a room, ink adhering to the

head hardens and it may cause image quality defect that cannot be improved even if you

perform head cleaning many times and may cause nozzle clogging.

• Besides photographic fixer, if you leave this machine in an environment where acidic vapor

(acetic acid, muriatic acid, etc.) is generated, the same phenomenon occurs.

Working Environmental Temperature

Use this machine in an environment of 20 to 30°C to ensure reliable printing.

The heater temperature may not reach the set value, depending on the ambient temperature.

Moving This Machine

Consult our service office in your area before moving this machine.

1-2

Page 21

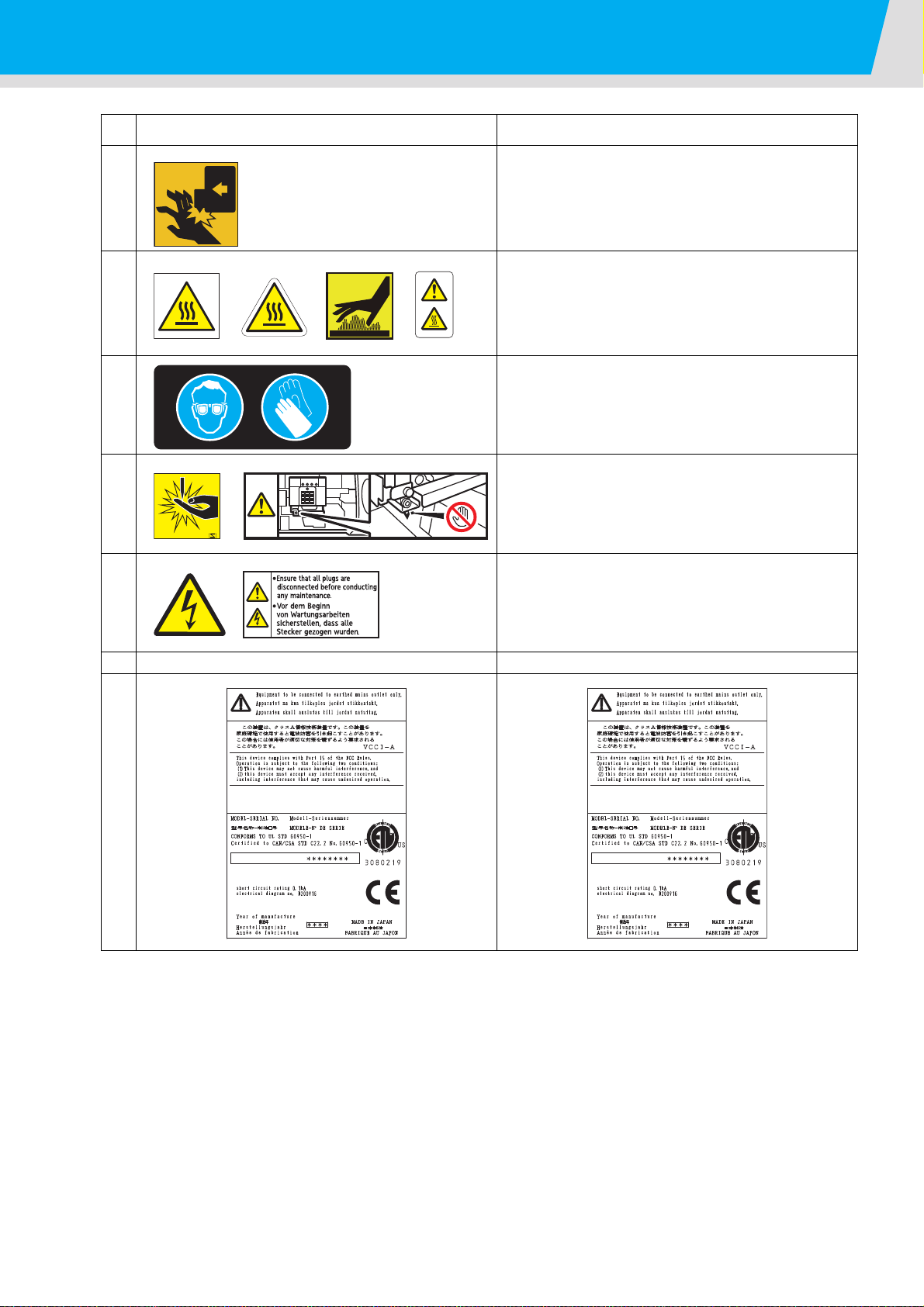

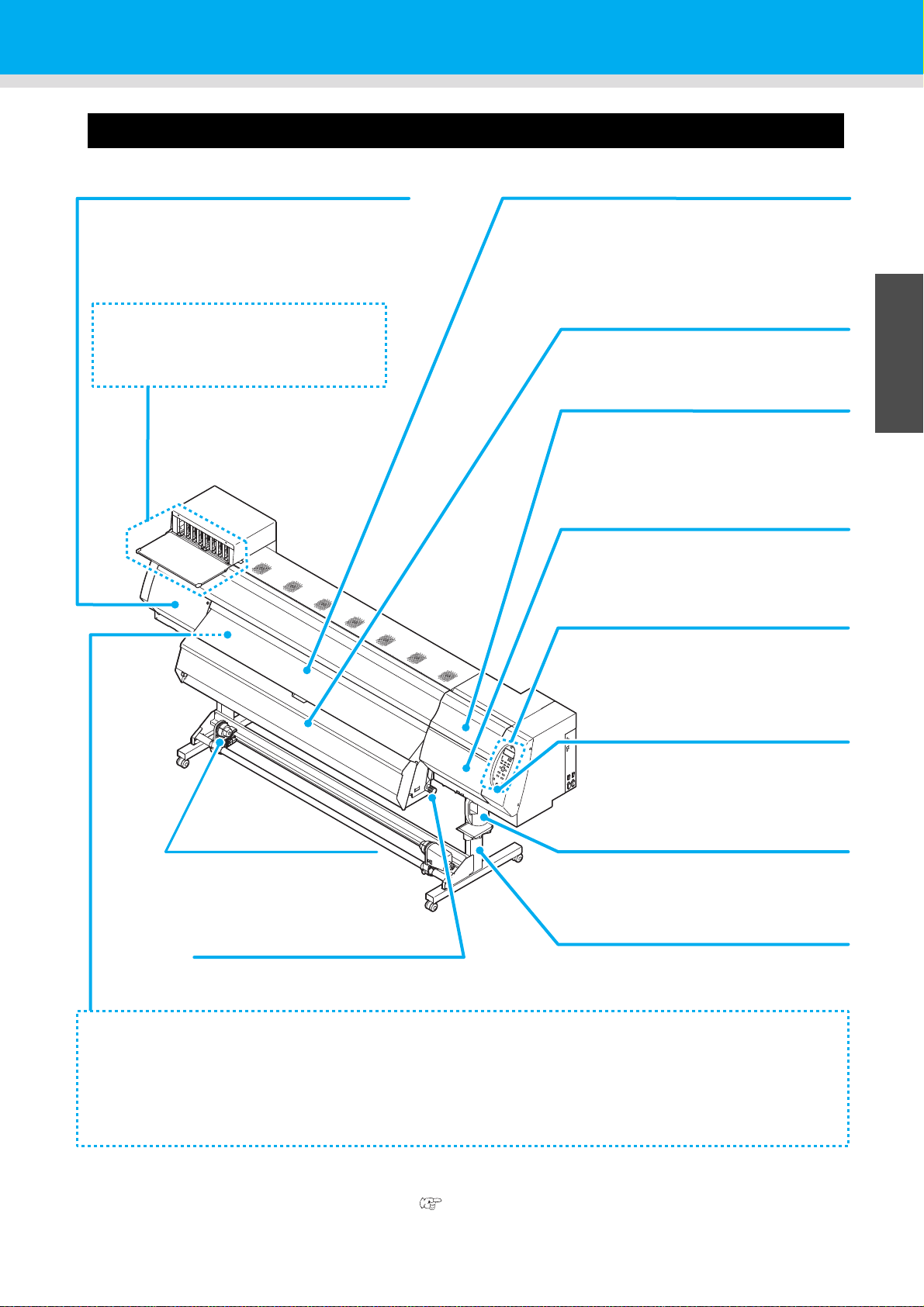

Names of Parts and Functions

Front cover

Open the cover in setting of medias, taking of measures

against jamming of medias or in maintenance inside the

station.

Even when the power switch is off, keep this cover and

the other covers closed.

Operation panel

This panel has the operation keys required for

operating the machine and the LCDs for

displaying setting items, etc.

Clamp lever (front)

Moves the pinch rollers up and down to hold or

release the media.

Power switch

*1

Turns on/off the power to the machine.

Waste ink bottle

Waste ink gathers in this bottle.

Stand

Supports the main body of the machine. It is

provided with casters that are used to move

this machine.

Left maintenance cover

Open the cover in maintenance.

Even when the power switch is off, keep all covers

closed.

Media Transfer Surface

Print media is retained and transferred along the media transfer surface by vacuum. Three heaters are installed inside

the media transfer surface.

Print heater/ Post-heater

Fixes and dries the ink on the currently produced print. (Located inside the Media Transfer Surface)

Electrostatic sheet

Prevents the media from sticking to the Media Transfer Surface due to static.

Ink cartridge setting section

Set the ink cartridge for each color.

*1 : The power switch under the operation panel lights in green when the power is turned on. The ink clogging

prevention function is periodically operated even when the power switch is OFF if the main power switch

keeps being ON. (Auto maintenance function) P.1-4

Take-up device

Take up the output drawn with a

roll medium automatically.

Drying heater

The dryer blows warm air on the

printed paper to fix and dry ink.

Maintenance cover (upper right)

Open this cover when performing

maintenance on the print head and the

surrounding parts.

Maintenance cover (lower right)

Open this cover when performing

maintenance on the print head and the

surrounding parts.

Front Side of the Machine

1

Before Use

3

4

5

6

1-3

Page 22

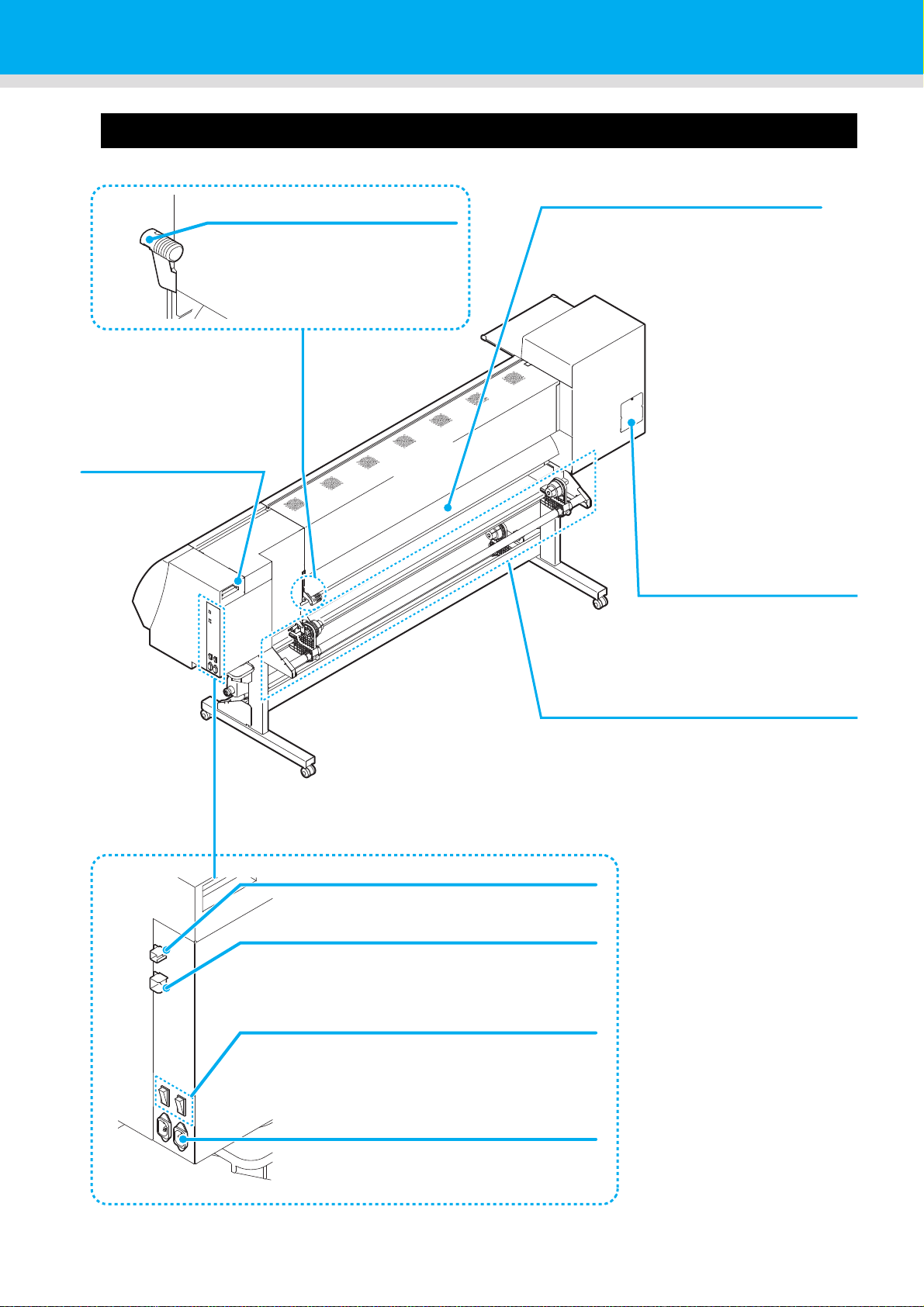

Rear Side and Right Side of the Machine

Pre-heater

Preheats the media before printing.

(Located inside the Media Transfer

Surface)

AC inlet

Connect the power cable to the AC inlet.

Clamp lever (rear)

Interlocks with the clamp lever in the

font of this machine.

LAN connector

Do not use this LAN port. It is for use by the

qualified service technicians only.

Main power switch

Turns on/off the main power for this machine.

Leave the main power turned on to prevent ink

clogging.

Cleaning solution cartridge

Set a Washings cartridge

that is recommended

by this company.

Roll holders

Putting this into the paper core (right and left) of

a narrow roll medium (less than 1.6m), hold the

medium. It supports the paper core of 2 inch

and 3 inch.

USB 2.0 connector

This is USB2.0 interface connector.

W filter maintenance cover

Cover for white filter

maintenance.

1-4

Page 23

Names of Parts and Functions

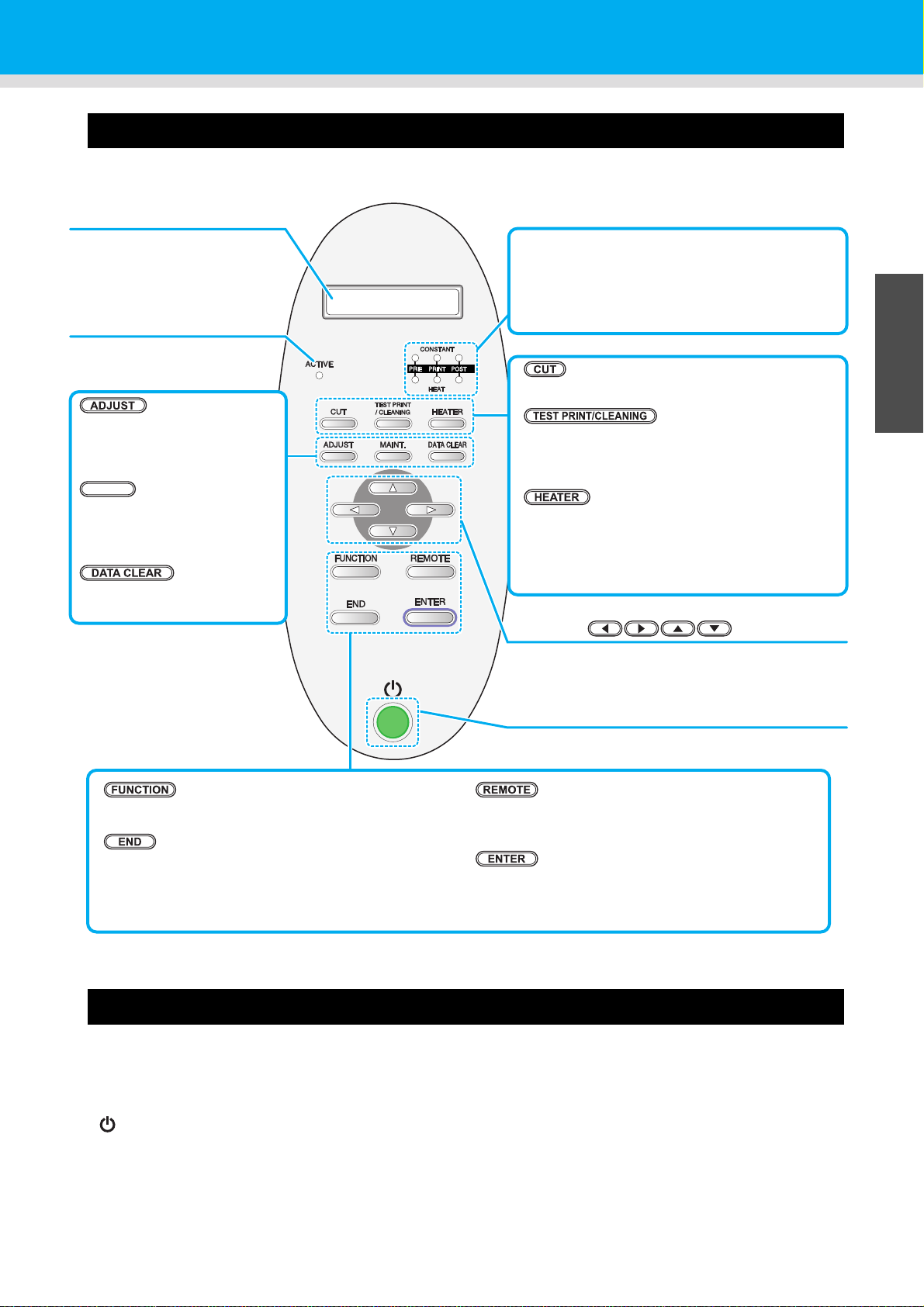

JOG key

Use these keys to shift the carriage or the media in

[LOCAL]. Also use them to select an item of printing

conditions.

key

Use this key to display function setting menu.

key

Cancels the last input value or returns the setting menu

to the immediate higher level of the hierarchy.

Display

Displays the status of the

machine, set items and errors.

ACTIVE lamp

It lights when the power

supply is turned on.

key

Use this key to switch between [REMOTE] and

[LOCAL].

key

Registers the last input value as the setting value or

goes to the immediate lower level of the hierarchy.

key

Use this key on cutting .

key

Draws test patterns to check if there are any

drawing failures such as ink clogging.

Or executes Head cleaning at ink clogging.

key

Use this key to set the temperatures of the Preheater, Print heater, Post-heater and Drying heater

or check the current temperature of the Media

Transfer Surface.

key

Performs the adjusting function

such as “Drop.POScorrect” and

“Feed COMP.”

key

Performs the maintenance

function such as station

maintenance.

key

Deletes the data that have been

received.

MAINT.

CONSTANT lamp

Lights in green when the heater temperature

reaches the set temperature.

HEAT lamp

Lights in orange during heating up of the heater.

Power switch

Turns on/off the power to the machine.

Operation Panel

Use the operation panel to make settings for printing or operate this machine.

1

Before Use

Signs on the power switch

3

4

The meaning of the signs on the machine's power switch are as follows:

・|:Power is on

・○:Power is off

・:Standby

5

6

1-5

Page 24

Heater

Post-heater

Print heater

Drying-heater

Pre-heater

Media sensor

Pre-heater/Print heater/Post-heater are equipped on the Media Transfer Surface.

The Pre-heater is used for pre-heating of the media prior to printing to prevent rapid changes in temperature.

The Print-heater improves the image quality in printing.The Post-heater and drying-heater dries ink after

printing.

• While the heater is on, the Media Transfer Surface is very hot.When the front cover is to be

opened or media is to be replaced, lower the heater temperatures and wait until the Media

Transfer Surface temperature drops;otherwise, you can get burned.

• When the media is to be replaced with a thin one, lower the heater temperatures and wait until

the Media Transfer Surface temperature drops adequately.Setting a thin sheet of media while

the Media Transfer Surface is hot may cause the media to stick to the Media Transfer Surface

or cause wrinkling or curling of the media.

Media sensor

The media sensor detects the presence of the media and the media length.

This machine has a media sensors on the Media Transfer Surface (in the rear).

• When setting a medium, be sure to cover the medium sensors located on the rear of the Media

Transfer Surface. The media cannot be detected unless it is placed over the sensor.

• In case that you use 210mm-wide media, media cannot be detected if it is set in accordance with .

Set media approximately 15mm inner than .

1-6

Page 25

Carriage

Carriage

Cutter unit

slot for cutting

Cutter blade

The carriage is provided with the heads for printing, the cutter unit

for cutting off the sheet of media, etc.

A lever is also provided to adjust the height of Head in 3 stages

according to the thickness of media. ( P.2-5)

Names of Parts and Functions

1

Cutter blade and slot for cutting

The carriage is provided with a cutter unit for cutting off the media that has been printed on.

The cutter cuts off the sheet of media along the slot for cutting on the Media Transfer Surface.

The cutter blade is consumables. If it gets dull, replace it with new one. (P.4-32)

• The blade is sharp. Be careful not to hurt yourself or anyone else.

Before Use

3

4

5

6

1-7

Page 26

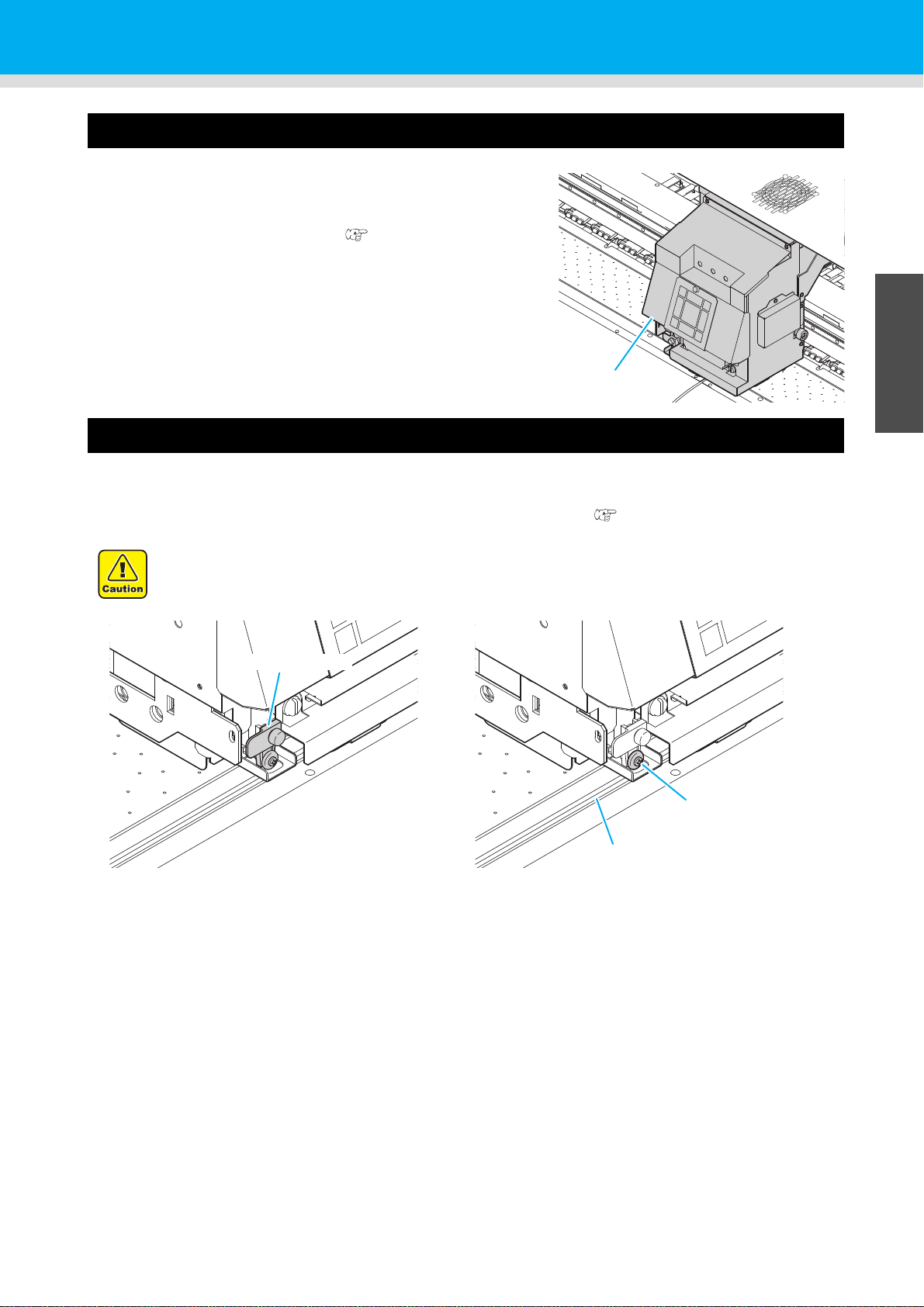

Connector of Temperature sensor/ Drying heater/ Take-up device

Drying heater (blue)

Temperature sensor (red)

Take-up device (black)

Connector of Temperature sensor/ Drying heater/ Take-up device

If an error related to the Temperature sensor/ Drying heater/ Take-up device occurs, refer to the Chapter 5 and

check the connector.

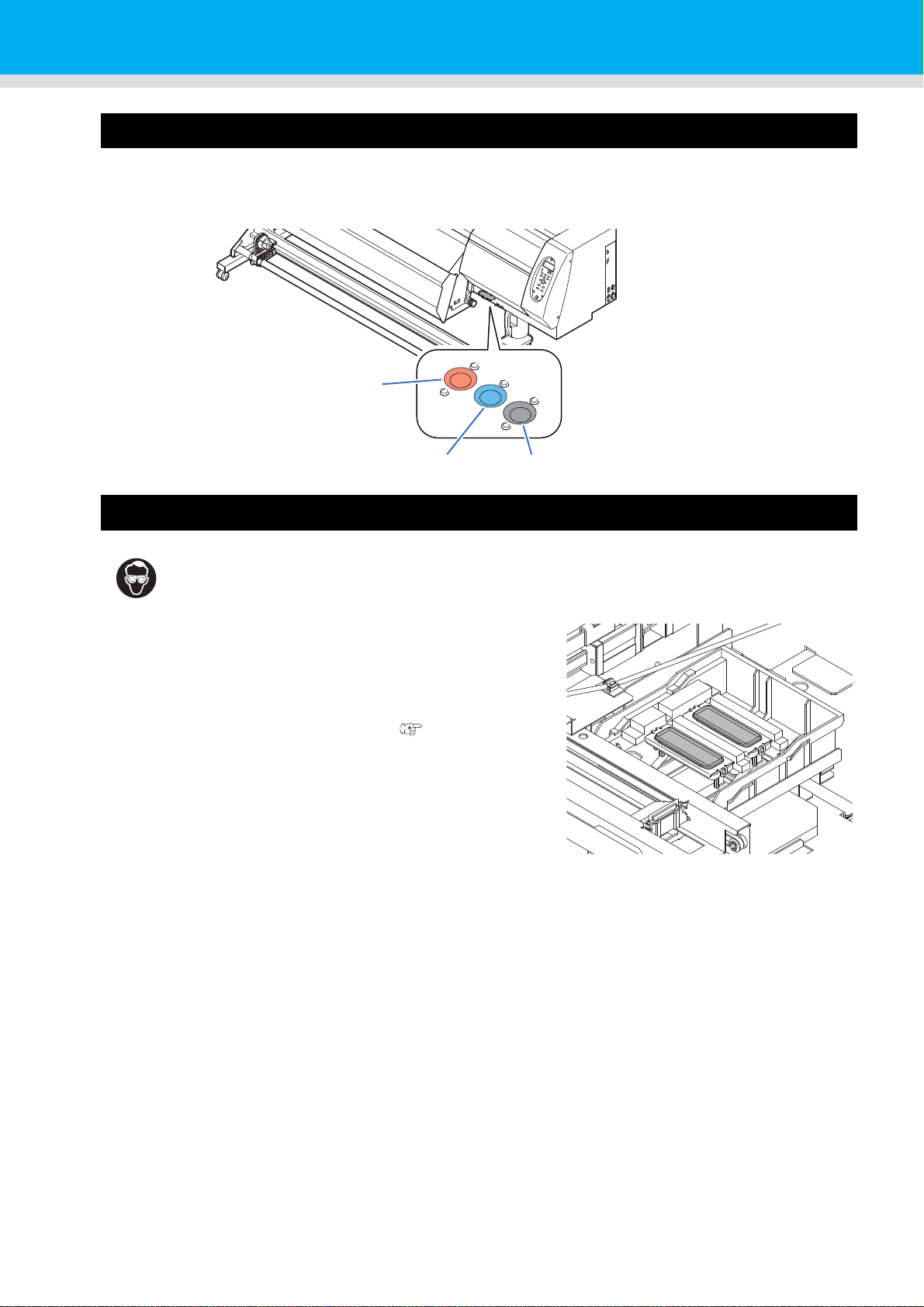

Capping station

• Be sure to wear the attached goggles in cleaning within the capping station to protect your

eyes against ink. Otherwise, you may get ink in your eyes.

The capping station consists of the ink caps, the wiper for cleaning

the heads, etc.

The ink caps prevent the nozzles in the heads from drying up.

The wiper cleans the nozzles in the heads.

The wiper is consumable.If the wiper is deformed or the media is

stained, replace the wiper with a new one. ( P.4-28)

1-8

Page 27

Names of Parts and Functions

Feed roller

Pinch roller

Pinch rollers and Feed rollers

• Keep the pinch rollers lifted up when this machine is not in use. If the pinch rollers are left lowered for

an extended period of time, they can be deformed and fail to securely retain the media.

This machine retains the media with the pinch rollers and feed rollers. During printing operation, the feed rollers

feed the media forward.

1

Before Use

3

4

5

6

1-9

Page 28

Connecting Cables

USB cable

USB 2.0 repeater cable

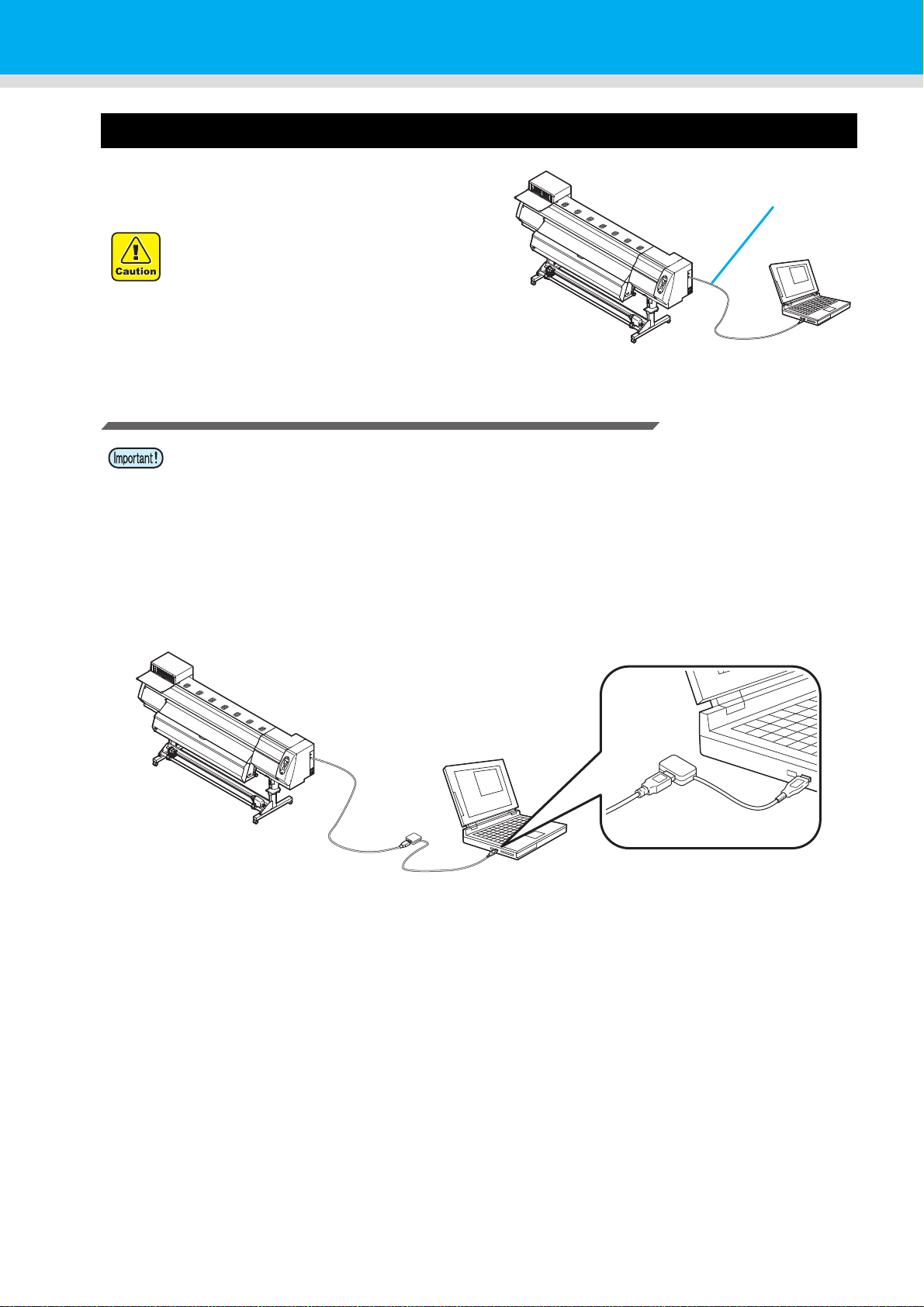

Connecting USB2.0 Interface Cable

Connect the PC and this machine with the USB2.0

interface cable.

• Your RIP must be compatible with USB

2.0.

• When you connect USB cable, do not

touch the connector contact point with

your bare hand. Static may be generated

and it may break the PCB of this machine.

Notes on USB 2.0 Interface

• Your RIP must be compatible with USB 2.0.

z When two or more Pro L4160/L4130 machines are connected to one personal computer

When two or more Pro L4160/L4130 machines are connected to one personal computer, the personal

computer may not recognize all the Pro L4160/L4130 machines normally.

Reconnect the unrecognized Pro L4160/L4130 machine to another USB port, if available, and check to see if it

is recognized.If the Pro L4160/L4130 machine is not recognized by the newly connected USB port, use USB

2.0 repeater cables available on the market.

z Notes on peripheral devices in USB high speed mode

When a peripheral device (USB memory or USB HDD) to be operated in USB high speed mode is connected to

the same personal computer that a Pro L4160/L4130 machine is connected to, the USB device may not be

recognized.

When Pro L4160/L4130 is connected to the personal computer to which an external HDD is connected via

USB, the speed of data output to Pro L4160/L4130 may drop.That can cause the head unit to stop temporarily

at the right or left end during printing.

1-10

Page 29

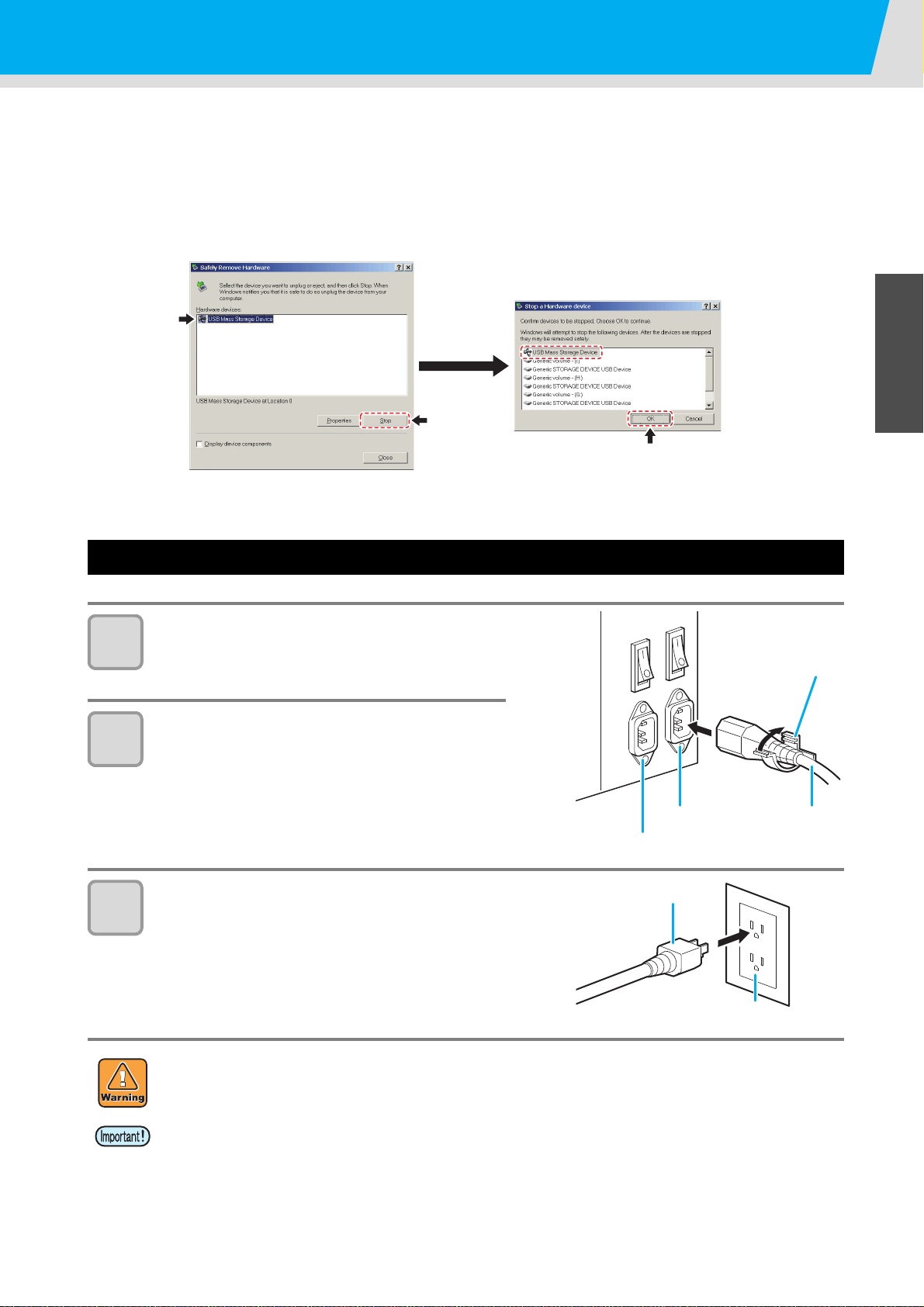

Connecting Cables

Inlet 1 Power cable

Cable band

Inlet 2

Power plug

Socket

z Removing USB memory

If a USB memory module is inserted in the personal computer to which a Pro L4160/L4130 machine is

connected, click "Stop" in the "Safely Remove Hardware" window by following the instructions given there first

and then remove the module.

Leaving a USB memory module inserted can cause [ERROR 201 COMMAND ERROR].

Copy the data onto the hard disk before outputting it for printing.

1

Before Use

Connecting the power cable

Insert the power cable into an inlet of the

1

2

machine.

Secure a cable band.

• Secure the cable with the cable band attached to this

machine.

Insert the power plug into a plug socket.

3

3

4

• Do not use any power cables other than the attached power cable.

• For Inlet 1 and 2, be sure to supply power from the outlet of the same voltage.

• Be sure to connect the power cable to the outlet near this machine, and make sure that the power

cable can be easily removed.

• Connect the power cable to the grounded outlet.Otherwise, it may result in fire or an electric shock.

• Check the voltage of the wall outlet and the capacity of the circuit breaker before you plug the power cords.

Plug each power cord to different outlet that has independent circuit breaker. If you plug more than one

power cord to wall outlets that share the same circuit breaker, the power may be cut off by the breaker.

5

6

1-11

Page 30

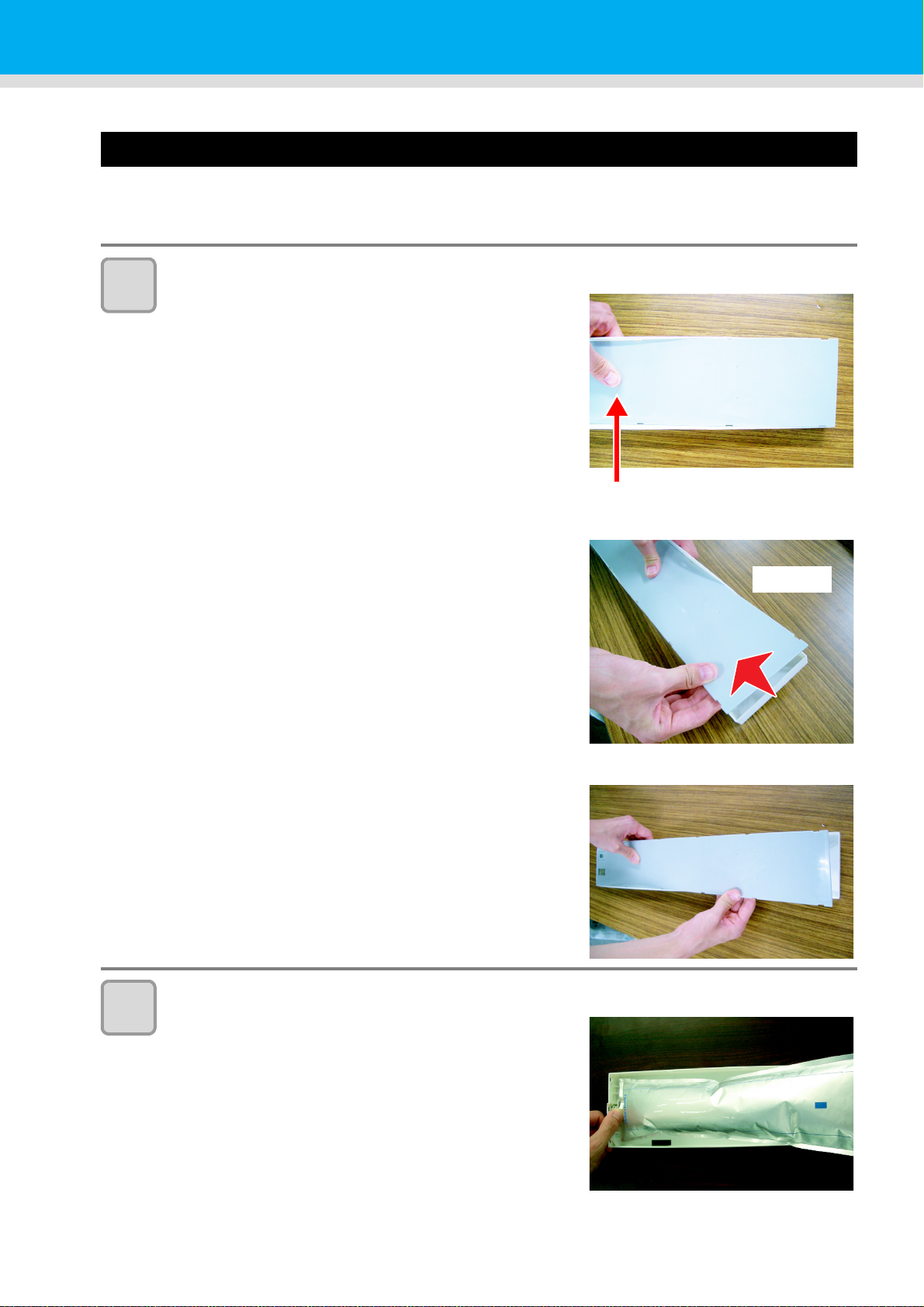

Inserting ink cartridge

Press the center part with your finger.

Raise.

Insert an ink cartridges.

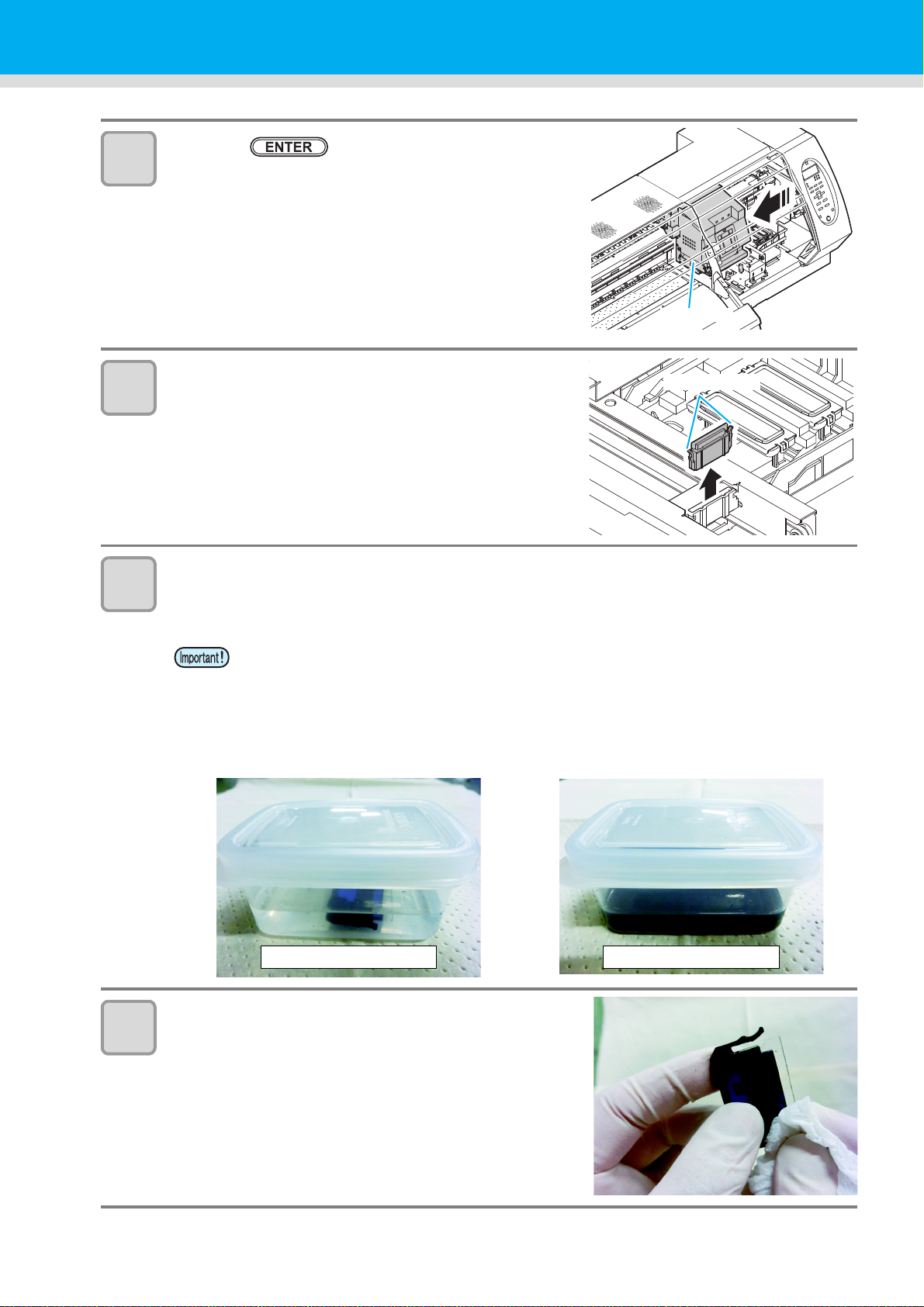

How to assemble ink cartridge

Before setting the ink cartridge, it is required to set the ink pack on the eco cartridge.

By following the next procedures, assemble the ink cartridge.

Open the cover of the eco cartridge.

1

(1) Press the center part of the cover with your finger.

• The claw on the side without attaching part of IC chip

comes off.

2

(2) Raise the cover as described in the photo.

• At this time, the claw on the IC chip side does not

come off.

Do not raise the cover forcedly so that you may not

damage the claw.

(3) Remove the remaining claw while pressing the cover

as indicated in the photo, and remove the cover.

Set the ink pack on the eco case.

(1) Turn the side with double coated tape downward and

insert the stopper.

• After inserting the stopper, push it firmly with your

finger.

1-12

Page 31

3

Good example

The corner of the case

matches the ink pack

corner.

The ink pack has

gone too far

downward.

The ink pack goes slack in

spots.

Bad example

No gap shall be found.

There is a gap.

The ins and the outs is

reverse.

The back and the forth is

reverse.

Inserting ink cartridge

(2) Peel the seal of double coated tape.

Firmly fix the ink pack on the eco case with

double coated tape so that it may not move.

• Fix the ink pack after pulling it so that the ink pack may not

go slack.

1

Before Use

• Fix the ink pack so that it may not be biased in the eco case.

4

5

Attach the cover.

• Hang the claw on the IC ship side and then insert the cover

into the case.

Attach the IC chip.

• Attach the IC chip as indicated in the photo.

• Attach it so that there is no gap in the part indicated with an

arrow.

Bad example of attaching IC chip

3

4

5

6

1-13

Page 32

About the ink that can be used with this machine

SHAKE WH I TE I NK

CARTRIDGES [ ENT ]

A part

(the place to stick a needle)

B part

(the slot on the bottom)

Cover with paper towel firmly

and shake ink slowly

Repeat this

A part

The following three types of ink sets can be used with this machine: 4 color, 6 color, and 6 color+white versions

• 4-color version: 2 each of Cyan, Magenta, Yellow and Black ink cartridges are used.

• 6-color version: 1 each of Yellow, Orange, Green, and Black, 2 each of Cyan and Magenta ink cartridges are

used.

• 6-color+white version: 1 each of Cyan, Magenta, Yellow, Orange, Green and Black, and 2 White ink

cartridges are used.

White ink is fed from an ink cartridge, but the inks for Cyan, Magenta, Yellow, Orange, Green and Black are

supplied from an ink-pack. Set the inks in the eco case before you set the ink cartridge. Also, the white ink is

contained in a eco cartridge that is shorter in length than the cartridge of Cyan, Magenta, Yellow, Orange,

Green and Black inks.

Slowly shake the white ink cartridge more than twenty times right and left.

1

• To prevent ink from leaking when you shake the Eco-cartridge, wear gloves and firmly cover the A part

of the upper surface of the cartridge and the B part of the bottom surface of the Eco-cartridge with paper

towels. Then, shake it more than twenty times right and left so that ink flows inside the cartridge.

• If you shake it too strong, the pack inside may be damaged and it may cause ink

leakage. Therefore, perform this carefully.

• If the remaining amount of ink is less, ink in the Eco-cartridge cannot be beaten enough.

Tilt the cartridge until it becomes vertical.

• When you use white ink:

When 24 hours have passed with the power supply

is ON, or, when the power supply is ON, the

message is displayed.

As the component of white ink is easy to settle out, it is necessary to shake it

periodically.

1-14

Page 33

2

The front side

4 colors model M

M

C

C

YYKK

6 colors model Inks M M C C Or G Y K

6 colors+W model MOrC G Y K WW

Inserting ink cartridge

Insert the ink cartridge.

• Insert the ink cartridge lengthwise with the surface having

IC chips pointing to the left side.

Setting orders of ink cartridges

The orders of ink cartridges set in the ink station differ depending on the ink set you use.

• Set the ink cartridge according to the cartridge label under the ink station.

1

Before Use

3

4

5

6

1-15

Page 34

Changing an ink cartridge

Ink cartridge lamps

Perform as follows when [INK END] or [INK NEAR END] is displayed on the display.

z When [INK END] is displayed

(1) Pull out an ink cartridge to be replaced.

(2) Insert a new ink cartridge, paying attention to the direction of IC chip.

z When [INK NEAR END] is displayed

There is a little of ink left. It is recommended to replace the ink cartridge soon since ink may become empty in

printing while printing is continuously enabled.

When you press the key in LOCAL, you can check the Eco-cartridge to be replaced in the local

guidance.

( P.3-21)

• When you changed the ink pack, be sure to change the IC chip, too.

For Ink cartridge lamps

The condition of the ink cartridges set in the machine is confirmable with lamps located over the ink cartridges.

Condition of Lamp Description

No error

There is less ink in the ink cartridge (Near

End), or ink has expired. It will become

unusable soon.

There is no ink in the ink cartridge, or the ink

cartridge cannot be used due to other ink

error. ( P.5-5)

As ink has expired, the ink cartridge cannot

be used.

No error

Indicates that ink is supplied.

When you use four-color ink set, this

machine first supplies ink from the ink

cartridge whose ink expires soon.

Upper row

Red lamp

Lower row

Green lamp

OFF

Blinking

ON

Quick

blinking

OFF

ON

About ink expiration date

The ink cartridge has its expiration date.

You can use the Eco-cartridge in two months after the expiration date indicated on it, however, you cannot use

it when three months have passed from the expiration date.

As LED will blink quickly to inform you of it, replace the Eco-cartridge.

Ex.) When the expiration date is April 2014

May 2014: Usable

June 2014: Usable (LED blinks)

July 2014: Unusable (LED blinks quickly)

About cartridge ink end and ink near end

When ink near end (less ink) occurs, LED “red” blinks to inform you of it. It is recommended to replace it as

soon as possible.

When ink end (no ink) occurs, LED “red” is lit to inform you of it. Replace the ink cartridge.

1-16

Page 35

Caution in handling of ink cartridges

• If you get ink in your eyes, immediately wash your eyes with a lot of clean running water for at

least 15 minutes. In doing so, also wash the eyess to rinse ink away completely. Then, consult

a doctor as soon as possible.

• Depending on how the machine is used, the [INK END] message may be displayed even if the

[INK NEAR END] message is not yet displayed. The remaining amount of ink in a cartridge is

calculated based on the printed data and the estimated amount of ink used by maintenance

processes, and may not show the actual amount of ink in the cartridge.

• Use genuine ink cartridges for this machine. This machine functions by recognizing the

genuine ink cartridges. In case of troubles caused by modified ink cartridges or the like, it shall

be out of the warranty even within the warranty period.

• If the ink cartridge is moved from a cold place to a warm place, leave it in the room temperature

for three hours or more before using it.

• Make sure to store ink cartridges in a cool and dark place.

• Store ink cartridges and waste ink bottle in a place that is out of the reach of children.

• Request an industrial waste processor for processing of the ink cartridges that are no longer

required.

• Do not shake ink cartridges violently. This may result in ink leakage from the Eco-cartridges.

• Do not refill the ink in the ink-pack and white ink cartridge. This may result in troubles.

RICOH will not bear any responsibility for any damage caused by the use of the ink cartridges

refilled with ink.

• Do not touch or stain the contacts of the ink cartridge. This may cause damages on printed

circuit boards.

• Do not disassemble the white ink cartridge.

Inserting ink cartridge

1

Before Use

3

4

5

1-17

6

Page 36

Media

Usable media sizes and notes for handling are described.

Usable sizes of media

Model Pro L4130 Pro L4160

Type of Recommended media

Maximum width

Minimum width

Maximum printing width

Thickness 0.3mm or less

Roll outside diameter

Roll weight

Roll inside diameter 3 or 2 inches

Side printed Side facing outward

Roll media

Roll end treatment

Thin coat paper/PET/Tarpaulin/Weatherproof PVC/Polyester cloth/

Cotton

1371mm 1620mm

210mm

1361mm 1610mm

φ180mm and less

25kg and less (for small-size media holder, 25kg and less)

The roll end is gently fixed to the core with weak-adhesive tape or weak

glue for easy removal.

*1

*1. Some media have bad drying characteristics. Please check this beforehand.

Caution in handling of medias

Pay attention to the followings for handling of medias.

• When handling media, wear the gloves.

If you touch the media with your bare hand, the media may be stained due to fingerprints or oil of your

finger. Be careful about it.

• Do not leave the media with the heater ON for a long time.

Waviness may occur on the media and it may cause media clogging.

When the pinch roller is at the lower position, even if it is for a short time, impression produced by the

pinch roller is left depending on the media material. Perform test feeding

media status.

• Use media recommended by RIOCH to ensure reliable, high-quality printing.

Set the heater temperature to meet the characteristics of the media.

• Set the temperature of the Pre-heater, Print heater and Post-heater according to the type and

characteristics of the media used.

Automatic temperature setting can be made on the operation panel by setting the profile on the

dedicated RIP. For setting on the RIP, refer to the instruction manual for your RIP.

• Pay attention to the expansion and contraction of the media.

Do not use media immediately after unpacking. The media can be affected by the room temperature

and humidity, and thus it may expand and contract.

The media have to be left in the atmosphere in which they are to be used for 30 minutes or more after

unpacked.

• Do not use curled media.

This may result in paper jamming.

If a regular-sized coated sheet of media is rolled and stored, the coated side has to face outside.

• Be careful to dusts on the edge face of the medium.

Some rolls have dusts contained in the package gathered on the edge surface of the roll. If you use as

it is, the drawing quality may be degraded due to nozzle missing or ink drops. Be sure to set the roll

after removing dusts adhering on the edge face of the roll.

• Use a media wider than 450 mm when performing the ink drop position correction for bidirectional

printing. Correcting the ink drop position for bidirectional printing cannot be performed on narrower

media. Use unidirectional printing in such a case. Also, select [STRONG] in the [VACUUM] setting if the

media is not securely adhered to the media transfer surface when using a media such as narrow media.

(P.2-19) to check the

1-18

Page 37

About antistatic sheet

Sheet

spring

Pro L4130: three antistatic sheets, Pro L4160: four antistatic sheets are attached in this machine.

The electrostatic sheet is used to prevent the media from clinging due to static.

Use this when static or deflection of the media on the post heater occurs and affects the media feeding.

z Fix the electrostatic sheet

Hang the claw of the antistatic sheet on the groove of the Media Transfer Surface.

1

Before Use

z Remove the electrostatic sheet

Remove it in the reverse procedures of assembling, and use with it hanging on the attached sheet spring.

3

4

5

6

1-19

Page 38

About antistatic sheet

Sheet

holder

If you removed the antistatic sheet, attach the sheet holder on the Media Transfer Surface (Pro L4130: three

positions / Pro L4160:four positions).

If you do not attach the sheet holder, the heater temperature drops and drying may become not enough.

1-20

Page 39

Chapter 2

Basic Operations

This chapter

describes procedures and setting methods for ink and media preparation, and printing.

Workflow .......................................................2-2

Turning the Power ON/OFF ..........................2-3

Turning the Power ON ................................ 2-3

Turning the Power OFF ............................... 2-4

Setting a Media .............................................2-5

Adjusting the Head Height .......................... 2-5

Note for media setting ................................. 2-7

Setting a roll media ..................................... 2-8

Take-up device .......................................... 2-13

Setting leaf media ..................................... 2-14

Changing the printing origin ...................... 2-16

Preparing for the Heaters ............................2-17

Changing the Temperature Settings for the

Heaters ...................................................... 2-17

Checking the Heater Temperature ............ 2-18

Changing the Temperature Settings for

the Drying Heater ...................................... 2-18

Test Feeding ...............................................2-19

Test Printing ................................................2-20

Test Printing .............................................. 2-21

Head Cleaning ............................................ 2-22

About head cleaning ................................. 2-22

Perform head cleaning depending on the

test printing result ......................................2-22

Set the media feeding .................................2-23

Setting Feed Correction .............................2-23

Correct the ink drop position for bidirectional

printing ........................................................2-25

Printing Data ...............................................2-27

Checking the Status of Ink Cartridges .......2-27

Checking the Status of Waste Ink Bottle ...2-27

Starting a Printing Operation .....................2-28

Stopping a printing operation halfway ........ 2-29

Deleting Received Data (Data Clear) ........2-29

Behavior after printing has been

completed ..................................................2-29

Cutting a media ..........................................2-30

When [NEAR END] error occurs while

printing .......................................................2-30

When [INK END] error occurs while

printing .......................................................2-30

When a waste ink bottle confirmation

message appears while printing ................2-31

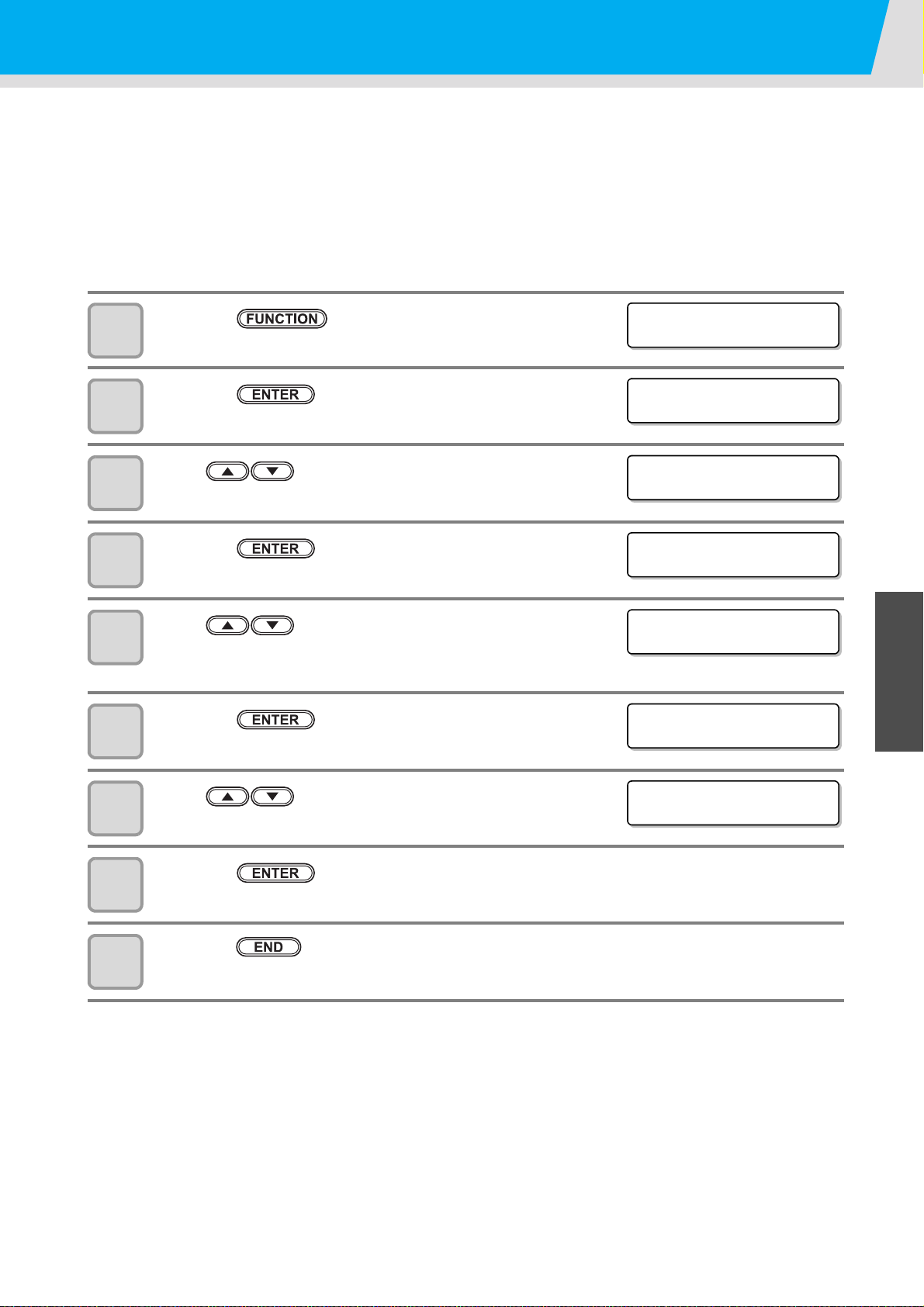

Page 40

Workflow

1

Turning the Power ON/OFF

2

3

Setting a Media

4

Preparing for the Heaters

5

Test Printing

Set the media feeding

Referring to “Turning the Power ON/OFF”

( P.2-3).

Referring to “Setting a Media” ( P.2-5).

Referring to “Preparing for the Heaters”

(P.2-17).

Referring to “Test Printing” ( P.2-20).

Referring to “Set the media feeding” ( P.2-23).

6

7

Correct the ink drop position for

bidirectional printing

Printing Data

Referring to “Correct the ink drop position for

bidirectional printing” ( P.2-25).

Referring to “Printing Data” ( P.2-27).

2-2

Page 41

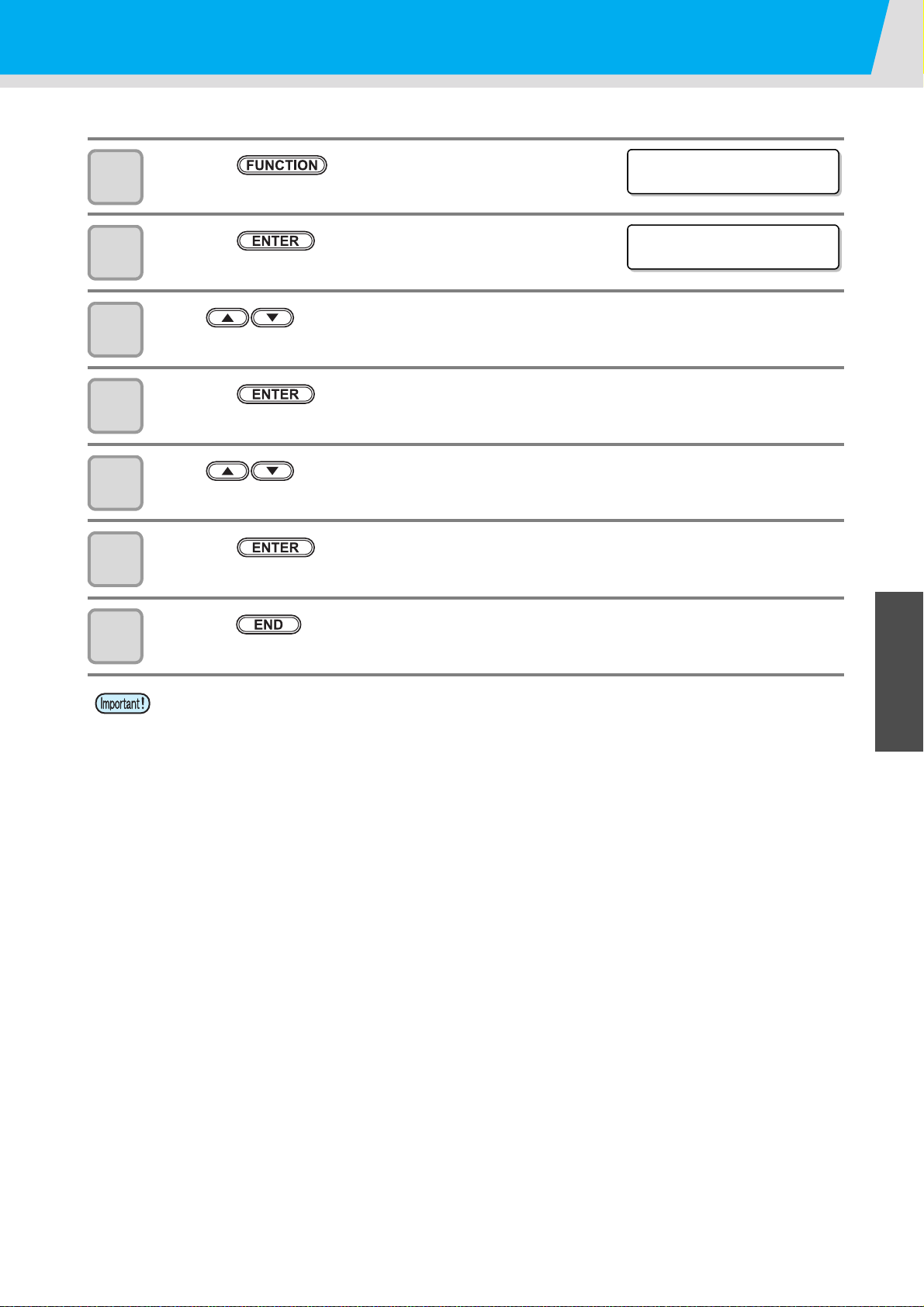

Turning the Power ON/OFF

Main power

switch

Power switch

Start -up

Ve r 1 . 00

<LOCAL>

Turning the Power ON

This machine is provided with the following two power switches:

Main power switch:Two switches are located on the side of this machine.Keep this switch ON all the time.

Power switch : Normally, use this switch to turn the power ON/OFF.

The power switch lights in green when the power is ON.

Turn the main power switch ON.

1

2

• Set the two main power switches located on the side of this

machine to the “I” side.

Turn the power switch ON.

• Push the power switch located on the operation panel.

1

3

4

• The firmware version is displayed when the power is turned ON.

2

• The machine performs its initial operation.

Basic Operations

The machine enters LOCAL.

Turn ON the power of the connected PC.

• Turn the power ON after the front cover and maintenance cover are closed.

• Use the machine with always turning “ON” the main power. The function preventing nozzle clogging

operates automatically to protect the head of the nozzle.

• The head nozzle may result in nozzle clogging if the main power switch is left OFF for a long time.

4

5

6

2-3

Page 42

Turning the Power ON/OFF

Power switch

Turning the Power OFF

When having ended the operation of the machine, turn the power OFF by pressing the power switch located on

the front side.

Check the following items when turning the power OFF.

• If the machine is receiving data from the PC or if there is any data that has not been output yet

• If the head has returned to the capping station

• If any error has occurred ( P.5-14 “Error messages”

Turn OFF the power of the connected PC.

)

1

Press the power switch to turn the power OFF.

2

• Do not turn OFF the main power switch located on the side

of the machine.

• To use this machine again, light the green lamp by pressing

the power switch.

Cautions about Turning the Power OFF

Q Do not turn the main power switch OFF.

When the main power switch is ON, the power periodically turns ON and the nozzle clogging prevention

function (flushing function) operate.

When the main power switch has been turned OFF, the auto maintenance functions, such as flushing, do

not operate, and this may cause nozzle clogging.

Q Keep the front cover and the maintenance cover closed.

If the cover is opened, the auto maintenance function such as the flushing function does not work.

Q Turn the power OFF after having checked the position of the head.

If the power is turned OFF in a state where the head has not returned to the capping station, the head

dries, which may cause nozzle clogging.

In this case, turn the power ON again and check that the head has returned to the capping station, and

then turn the power OFF.

Q Do not turn the power OFF during printing.

The head may not return to the capping station.

Q After having turned the power switch OFF, turn the main power switch OFF.

When turning the main power switch off for moving the machine or for solving the error or the like, press

the power switch on the front of the machine, check the display is turned off on the operation panel, and

then turn the main power switch off.

2-4

Page 43

Setting a Media

Carriage

Screw

Lever

This machine can be used with a roll media and leaf media.

For usable medias, refer to P.1-18 “Usable sizes of media”.

Adjusting the Head Height

Adjust the head height according to the thickness of the media you use.

• Turn OFF heater and perform this after temperature dropped.

• Adjust the head height prior to setting the media.If the head height is adjusted after the media is set,

this may cause a media jamming, deterioration of the print quality or head damage.

• The range of the initial head height is adjustable by 3 levels according to the purpose of use.

• The range of the printing height of Pro L4160/L4130 is from L (1.8 mm), M (2.3 mm), H range (2.8

mm). (Set to L range 1.5 mm at shipping)

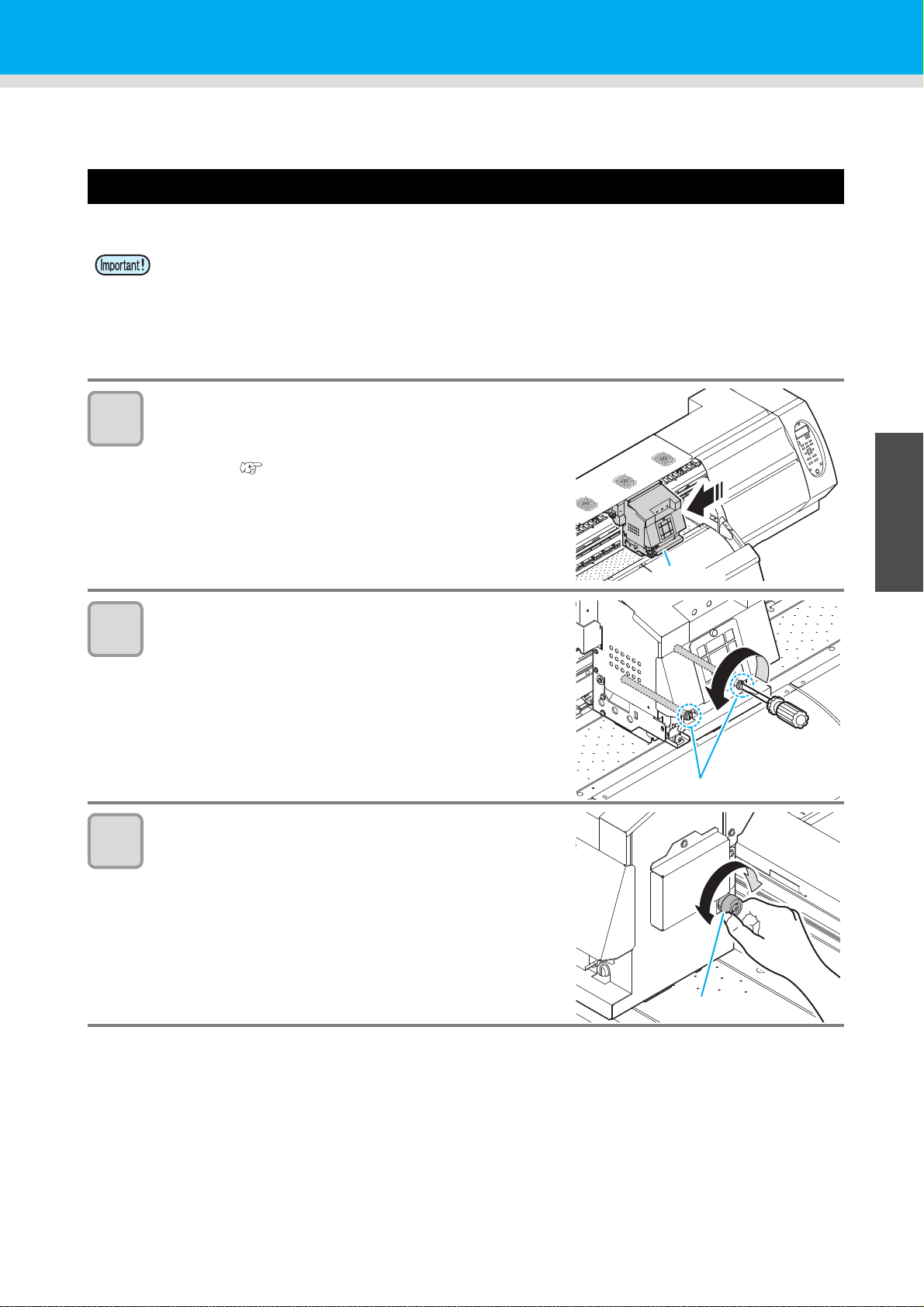

1

2

3

Move the carriage to the Media Transfer Surface.

• When the device is turned ON

:Execute [STATION - CARRIAGE OUT] of the Maintenance

functions.( P.4-5 Step1,2)

• When the device is turned off :

Open the front cover, then move the carriage by hand.

Loosen two screws located at the front.

• Loosen the screws, rotating each by one turn of a flat-blade

screwdriver.

Loosen two screws located at the front.

• The print head moves upward when you turn this lever to

the right (clockwise).

• The print head moves downward when you turn this lever to

the left (counter-clockwise).

1

2

Basic Operations

4

5

6

2-5

Page 44

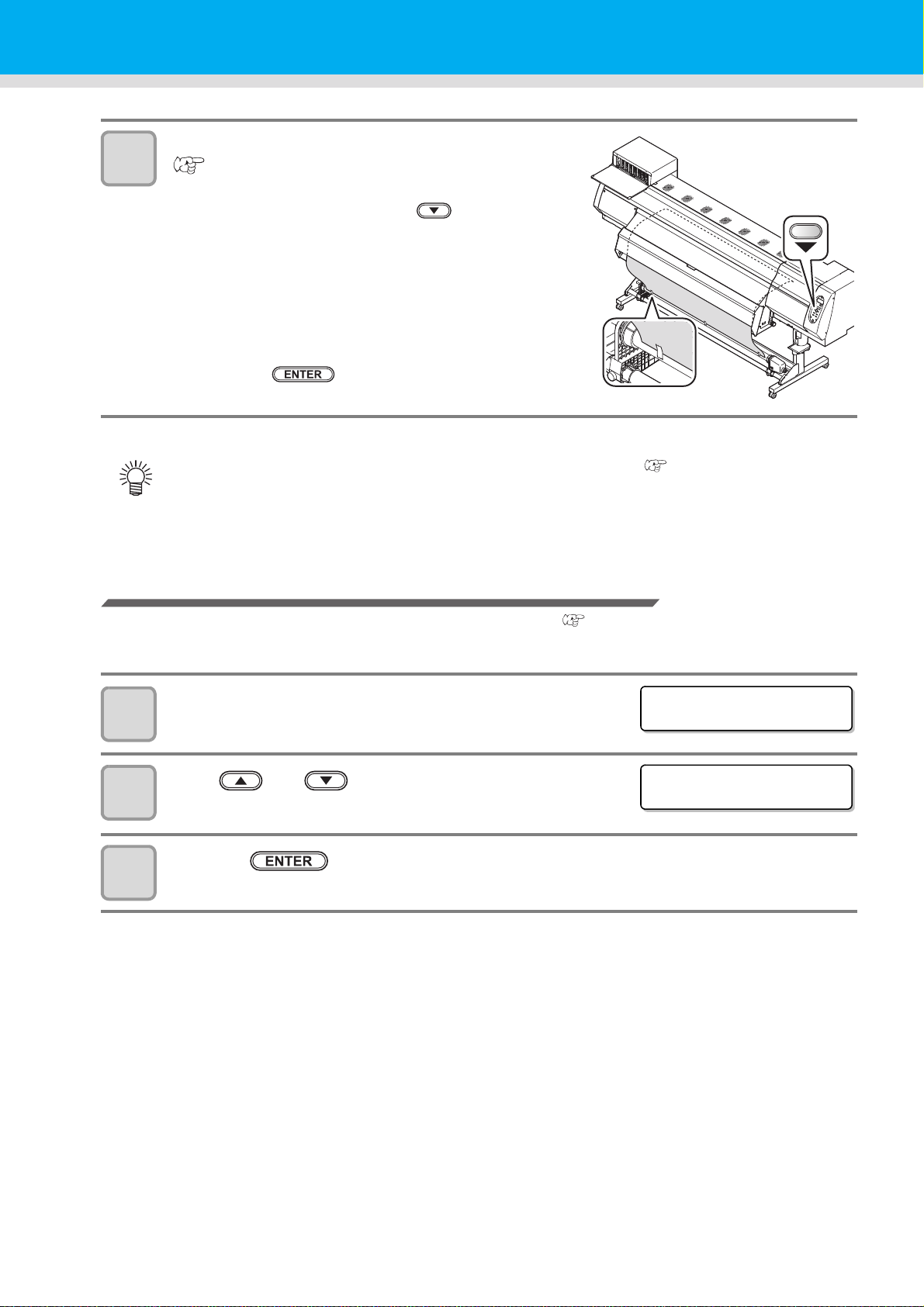

4

Fix the carriage.

STAT I ON

COMPL E T ED [ EN T ]

5

Fix the carriage.

• Fastening the screw in front, you can fix the carriage.

• Fasten the screw securely.

Return the carriage to the station position.

• When the power supply is off, return the carriage to the

station manually.

• When the power supply is on, press the key if the

screen below is displayed.

6

Close the front cover.

2-6

Page 45

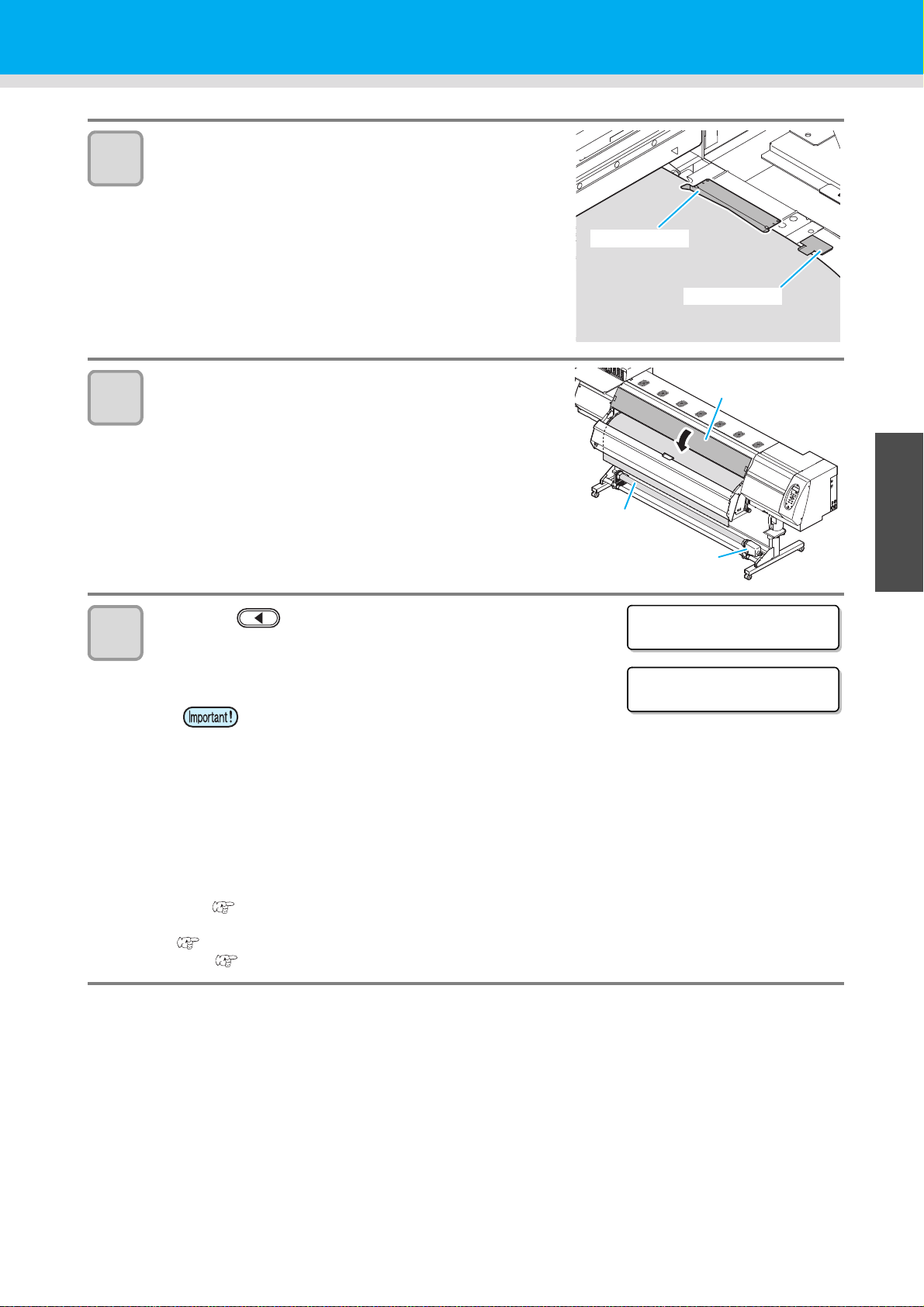

Note for media setting

OK

NoGood

Roll stopper arm

Roll

holder

Device

side

Roll stopper

Roll stopper arm

Roll stopper

Roll

holder

Device

side

When setting media, read the following notes carefully.

• Take care not to drop the media on a foot or so when the media is set. It may cause an

injury due to the media.

• There is a cutter inside the machine for cutting the print media. Do not touch any

parts other than the ones described in this manual when loading and replacing paper,

removing jammed paper, and cleaning the media transfer surface.

• Be careful not to get your fingers caught inside the machine and injured when replacing paper.

• Be careful not to get your fingers caught inside the machine when opening and closing the cover of the paper feed section.

• Hold the roll paper horizontally with both of your hands. When the roll paper is set in

the paper holder, the paper may fall off from the folder and cause injury if you hold

the holder vertically.

• The roll stopper arm works with the clamp lever. Do not push the clamp lever down

while roll stopper is caught between the roll stopper arm and this machine. The roll

stopper arm might be broken and roll stopper function

Setting a Media

*1

might be disabled.

1

*1. The function that once pulled out a certain amount of media, media pullout is temporarily locked.

2

Basic Operations

4

5

6

2-7

Page 46

Setting a roll media

Roll holder

fixing screw

Roll holder

Roll holder

Basis