Page 1

MODEL K3

RICOH FAX 5510L

SERVICE MANUAL

14 June, 2002

Subject to change

Page 2

!IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the machine and peripherals,

make sure that the machine power cord is unplugged.

2. The wall outlet should be near the machine and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

4. The inside and the metal parts of the fusing unit become extremely hot while

the printer is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner is non-toxic, but if you get it in your eyes by accident, it may cause

temporary eye discomfort. Try to remove with eye drops or flush with water as

first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. Do not incinerate toner cartridge. Toner dust may ignite suddenly when

exposed to an open flame.

2. Dispose of used toner cassette in accordance with local regulations. (It is

non-toxic supply.)

3. Dispose of replaced parts in accordance with local regulations.

LITHIUM BATTERIES (MEMORY B ACK-UP)

The danger of explosion exists if a battery of this type is incorrectly replaced.

Replace only with the same or an equivalent type recommended by the

manufacturer. Discard used batteries in accordance with the manufacture’s

instructions.

SAFE AND ECOLOGICAL DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

if exposed to an open flame.

2. Dispose of used toner, developer, and organic Photoconductor in

accordance with local regulations. (These are nontoxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Page 3

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!WARNING

Use of controls not specified in this manual, or performance of

adjustments or procedures not specified in this manual, may result in

hazardous radiation exposure.

!WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can cause

serious damage to eyes.

CAUTION MARKING:

H310DECAL.WMF

Page 4

i

TABLE OF CONTENTS

1. INSTALLATION...........................................................................1-1

1.1 MAINFRAME............................................................................................ 1-1

1.2 INSTALLING BASE UNIT/CABINET/SPACER......................................... 1-4

1.3 INSTALLING OPTIONAL UNITS.............................................................. 1-6

1.3.1 PAPER FEED UNIT TYPE 510........................................................ 1-6

1.3.2 BYPASS FEEDER TYPE 510.......................................................... 1-7

1.3.3 ISDN G4 INTERFACE UNIT TYPE 510........................................... 1-9

1.3.4 G3 INTERFACE UNIT TYPE510................................................... 1-12

1.3.5 FAX ON DEMAND TYPE 510........................................................ 1-15

1.3.6 FUNCTION UPGRADE UNIT TYPE 510....................................... 1-17

1.3.7 COUNTER TYPE 510.................................................................... 1-18

1.3.8 FEATURE EXPANDER TYPE 300 40M ........................................ 1-19

2. PREVENTIVE MAIN TENANCE................................................... 2-1

2.1 SPECIAL TOOLS AND LUBRICANTS ............................................... 2-1

2.2 PM TABLE................................................................................................ 2-1

3. REPLACEMENT A ND ADJUSTMEN T........................................ 3-1

3.1 EXTERNAL COVERS............................................................................... 3-1

3.1.1 REMOVING THE ADF FRONT AND REAR COVERS.................... 3-1

3.1.2 REMOVING THE UPPER GUIDE PLATE....................................... 3-1

3.1.3 REMOVING THE REAR COVER..................................................... 3-2

3.1.4 REMOVING THE OPERATION PANEL AND FRONT COVER....... 3-3

3.2 ADF/SCANNER SECTIONS ..................................................................... 3-4

3.2.1 REPLACING THE PICK-UP ROLLER (PART OF THE ADF

MAINTENANCE KIT)....................................................................... 3-4

3.2.2 REPLACING THE FEED ROLLER (PART OF THE ADF

MAINTENANCE KIT)....................................................................... 3-4

3.2.3 REPLACING THE REVERSE ROLLER AND TORQUE LIMITER

(PART OF THE ADF MAINTENANCE KIT)..................................... 3-5

3.2.4 REPLACING THE R0 ROLLER....................................................... 3-6

3.2.5 REPLACING THE R1, R2 AND DOCUMENT EXIT ROLLERS ....... 3-7

3.2.6 REPLACING THE CIS (CONTACT IMAGE SENSOR) (SCANNER)3-9

3.2.7 REMOVING THE STAMP UNIT..................................................... 3-10

3.2.8 ADJUSTING THE SCANNING TOP MARGIN............................... 3-10

3.3 LASER UNIT........................................................................................... 3-11

3.3.1 REPLACING THE LASER SYNCHRONIZATION DETECTOR AND

LD UNITS ...................................................................................... 3-11

3.3.2 REPLACING THE POLYGON MOTOR......................................... 3-12

3.3.3 ADJUSTING THE PRINTING SIDE-TO-SIDE REGISTRATION.... 3-13

Page 5

ii

3.4 AIO CARTRIDGE ................................................................................... 3-14

3.4.1 REPLACING THE AIO CARTRIDGE............................................. 3-14

3.4.2 REPLACING THE TRANSFER ROLLER (PART OF THE FUSING

MAINTENANCE KIT)..................................................................... 3-15

3.4.3 REPLACING THE POWER PACK................................................. 3-16

3.5 PAPER FEED AND REGISTRATION..................................................... 3-17

3.5.1 REPLACING THE PAPER FEED ROLLER ................................... 3-17

3.5.2 REPLACING THE REGISTRATION ROLLER............................... 3-18

3.5.3 ADJUSTING THE PRINTING TOP MARGIN................................. 3-19

3.6 SENSORS.............................................................................................. 3-20

3.6.1 REPLACING THE ADF/MDF SENSORS AND SWITCHES .......... 3-20

3.6.2 REPLACING THE PAPER-END LED BOARD AND PAPER SIZE

SENSOR SWITCH................................................................................... 3-22

3.6.3 REPLACING THE PAPER NEAR END SENSOR......................... 3-23

3.6.4 REPLACING THE UPPER LIMIT AND PAPER END SENSORS.. 3-23

3.6.5 REPLACING THE AIO CARTRIDGE SENSOR............................. 3-24

3.6.6 REPLACING THE PAPER EXIT SENSOR.................................... 3-25

3.6.7 REPLACING THE TONER END SENSOR.................................... 3-26

3.6.8 REPLACING THE REGISTRATION SENSOR .............................. 3-27

3.7 FUSING UNIT......................................................................................... 3-28

3.7.1 REPLACING THE FUSING UNIT (PART OF THE FUSING

MAINTENANCE KIT)..................................................................... 3-28

3.7.2 DISASSEMBLING THE FUSING UNIT.......................................... 3-29

3.7.3 REPLACING THE PRESSURE ROLLER ...................................... 3-30

3.7.4 REPLACING THE HOT ROLLER, FUSING LAMP, AND

THERMOFUSE.............................................................................. 3-31

3.7.5 REPLACING THE THERMISTOR................................................. 3-32

3.7.6 REPLACING THE HOT ROLLER STRIPPERS............................. 3-33

3.8 PCBS...................................................................................................... 3-34

3.8.1 REPLACING THE PSU.................................................................. 3-34

3.8.2 REPLACING THE OPIF/NCU/FCU................................................ 3-35

1. OPIF board...................................................................................... 3-35

2. FCU and MBU boards...................................................................... 3-36

3. NCU board....................................................................................... 3-37

3.8.3 REPLACING THE LCD CONTROLLER AND LCD BOARD.......... 3-38

3.8.4 REPLACING THE POWER PACK................................................. 3-39

3.8.5 REPLACING THE COOLING FAN................................................ 3-40

3.9 BYPASS FEEDER UNIT......................................................................... 3-41

3.9.1 DISASSEMBLING THE BYPASS FEEDER UNITS....................... 3-41

3.9.2 REPLACING THE CLUTCH AND PAPER FEED ROLLER........... 3-42

3.9.3 REPLACING THE PAPER SIZE DETECTION SWITCH............... 3-43

3.9.4 REPLACING THE CONNECTOR AND PAPER END SENSOR.... 3-44

3.10 DATA OR FIRMWARE DOWNLOAD/UPLOAD.................................... 3-45

3.10.1 DATA COPY BETWEEN THE IC CARD AND MACHINE............ 3-46

4. TROUBLESHOOTIN G.................................................................4-1

4.1 COPY QUALITY TROUBLESHOOTING.................................................. 4-1

4.1.1 BLANK COPIES............................................................................... 4-2

4.1.2 BLACK COPIES............................................................................... 4-2

Page 6

iii

4.1.3 DIRTY BACKGROUND ................................................................... 4-3

4.1.4 UNEVEN IMAGE DENSITY............................................................. 4-4

4.1.5 VERTICAL BLACK LINES............................................................... 4-5

4.1.6 HORIZONTAL BLACK LINES.......................................................... 4-6

4.1.7 VERTICAL WHITE LINES................................................................ 4-7

4.1.8 HORIZONTAL WHITE LINES.......................................................... 4-8

4.1.9 BLACK DOTS/SPOTS..................................................................... 4-9

4.1.10 WHITE SPOTS IN BLACK IMAGE AREAS ................................. 4-10

4.1.11 FAINT COPIES............................................................................ 4-11

4.1.12 VERTICAL BLACK BAND............................................................ 4-13

4.1.13 UNFUSED COPIES..................................................................... 4-13

4.1.14 GHOST IMAGE............................................................................ 4-14

4.1.15 TONER ON THE BACK OF THE PRINTER PAPER ................... 4-14

4.1.16 INCORRECTLY ALIGNED OUTPUT (DATA SHIFTED TO THE

RIGHT OR LEFT)........................................................................ 4-15

4.1.17 INCORRECTLY ALIGNED OUTPUT (IMAGE SHIFTED

VERTICALLY)/REDUCED IMAGE .............................................. 4-15

4.2 MECHANICAL PROBLEMS................................................................... 4-16

4.2.1 ADF/SCANNER............................................................................. 4-16

4.2.2 PRINTER....................................................................................... 4-18

4.3 SERVICE CALL CONDITIONS............................................................... 4-21

4.4 ERROR CODES..................................................................................... 4-22

4.5 MODEM STATUS CODES IN V.34 PROTOCOL DUMP........................ 4-32

4.5.1 CALLING SIDE.............................................................................. 4-32

Phase 1 (V.8)..................................................................................... 4-32

Phase 2 (Line Probing)...................................................................... 4-32

Phase 3 (Equalizer Training).............................................................. 4-33

Phase 4 and 5 (Control Channel)....................................................... 4-33

Phase 6 (Primary Channel)................................................................ 4-33

Control Channel (Post Message - Sh)................................................ 4-34

Control Channel (Post Message - PPh)............................................. 4-34

Control Channel Recovery (AC)......................................................... 4-34

V.34 End............................................................................................ 4-35

4.5.2 CALLED SIDE................................................................................ 4-35

Phase 1 (V.8)..................................................................................... 4-35

Phase 2 (Line Probing)...................................................................... 4-35

Phase 3 (Equalizer Training).............................................................. 4-36

Phase 4 and 5 (Control Channel)....................................................... 4-36

Phase 6 (Primary Channel)................................................................ 4-37

Control Channel (Post Message - Sh)................................................ 4-37

Control Channel (Post Message – PPh)............................................ 4-38

Control Channel Recovery (AC)......................................................... 4-38

V.34 End............................................................................................ 4-38

4.6 ERROR CODES FOR THE ISDN OPTION............................................ 4-39

4.6.1 D-CHANNEL LAYER MANAGEMENT........................................... 4-40

4.6.2 D-CHANNEL, LAYER 1................................................................. 4-40

4.6.3 D-CHANNEL LINK LAYER............................................................ 4-40

4.6.4 D-CHANNEL NETWORK LAYER.................................................. 4-41

4.6.5 B-CHANNEL LINK LAYER............................................................. 4-41

Page 7

i

v

4.6.6 B-CHANNEL NETWORK LAYER.................................................. 4-42

4.6.7 TRANSPORT LAYER.................................................................... 4-42

4.6.8 SESSION LAYER.......................................................................... 4-43

4.6.9 DOCUMENT LAYER ..................................................................... 4-44

4.6.10 PRESENTATION LAYER............................................................ 4-44

4.7 ISDN TEST FUNCTION.......................................................................... 4-45

4.7.1 LEDS ............................................................................................. 4-45

4.7.2 BACK-TO-BACK TEST ................................................................... 4-46

5. SERVICE TABLES AND PROCEDURES ...................................5-1

5.1 SERVICE LEVEL FUNCTIONS................................................................ 5-1

5.1.1 BIT SWITCH PROGRAMMING (FUNCTION 01)............................. 5-1

5.1.2 SYSTEM PARAMETER LIST (FUNCTION 02)................................ 5-2

5.1.3 ERROR CODE DISPLAY (FUNCTION 03)...................................... 5-2

5.1.4 SERVICE MONITOR REPORT (FUNCTION 04)............................. 5-2

5.1.5 GROUP 3 PROTOCOL DUMP (FUNCTION 05)............................. 5-2

5.1.6 RAM DISPLAY/REWRITE/MEMORY DUMP (FUNCTION 06)........ 5-3

5.1.7 COUNTER DISPLAY/REWRITE (FUNCTION 07)........................... 5-3

5.1.8 NCU PARAMETERS (FUNCTION 08)............................................. 5-4

5.1.9 MODEM TEST (FUNCTION 08)...................................................... 5-4

5.1.10 DTMF TONE TEST (FUNCTION 08)............................................. 5-5

5.1.11 V.8 MODEM TEST (FUNCTION 08).............................................. 5-5

5.1.12 V.34 MODEM TEST (FUNCTION 08) ............................................ 5-6

5.1.13 OPERATION PANEL TEST (FUNCTION 09)................................ 5-6

5.1.14 LAMP TEST (B/W) (FUNCTION 10).............................................. 5-6

5.1.15 ADF TEST (FUNCTION 10)........................................................... 5-7

5.1.16 LAMP TUNING (FUNCTION 10).................................................... 5-7

5.1.17 LAMP TEST (COLOR) (FUNCTION 10)........................................ 5-8

5.1.18 PRINTER TEST PATTERNS (FUNCTION 11).............................. 5-8

5.1.19 PRINTER FREE RUN (FUNCTION 11)......................................... 5-8

5.1.20 RAM TEST (FUNCTION 12).......................................................... 5-9

5.1.21 DATA COPY (FUNCTION 12)....................................................... 5-9

5.1.22 SERVICE STATION FAX NUMBER (FUNCTION 13)................... 5-9

5.1.23 SERIAL NUMBER (FUNCTION 14)............................................. 5-10

5.1.24 40 MB FLASH MEMORY INITIALIZATION (FUNCTION 16)....... 5-10

5.1.25 40 MB FLASH MEMORY FORMATTING (FUNCTION 16).......... 5-11

5.1.26 40 MB FLASH MEMORY TEST (FUNCTION 16)........................ 5-11

5.1.27 G4 INTERNAL SWITCH PROGRAMMING (FUNCTION 17)....... 5-12

5.1.28 G4 PARAMETER SWITCH PROGRAMMING (FUNCTION 17).. 5-12

5.1.29 PRINTING G4 MEMORY DUMP (FUNCTION 17)....................... 5-13

5.1.30 PRINTING G4 PROTOCOL DUMP LIST (FUNCTION 17).......... 5-13

5.1.31 OPTIONAL G3 BIT SWITCHES (FUNCTION 18)........................ 5-14

5.1.32 OPTIONAL SG3 BOARD RAM DUMP (FUNCTION 18).............. 5-14

5.1.33 OPTIONAL SG3 BOARD NCU PARAME TERS (FUNCTION 18) 5-15

5.1.34 OPTIONAL SG3 BOARD MODEM TEST (FUNCTION 18)......... 5-15

5.1.35 OPTIONAL SG3 BOARD DTMF TONE TEST (FUNCTION 18).. 5-16

5.1.36 OPTIONAL SG3 BOARD V.8 MODEM TEST (FUNCTION 18)... 5-17

5.1.37 OPTIONAL SG3 BOARD V.34 MODEM TEST (FUNCTION 18). 5-17

5.1.38 LAN SW SETTING (FUNCTION 20)............................................ 5-18

Page 8

v

5.1.39 LAN LINK CHECK (FUNCTION 20)............................................. 5-18

5.1.40 LAN LOOP BACK TEST (FUNCTION 20)................................... 5-19

5.1.41 LAN LOG DUMP (FUNCTION 20)............................................... 5-19

5.1.42 LAN PING TEST (FUNCTION 20)............................................... 5-19

5.1.43 JPEG TEST (FUNCTION 21)....................................................... 5-20

5.1.44 IP-FAX IPG3 BIT SWITCHES (FUNCTION 22)........................... 5-20

5.1.45 IP-FAX PORT SETTING (FUNCTION 22)................................... 5-20

5.1.46 ROM VERSION (FUNCTION 23)................................................. 5-21

5.1.47 SENSOR INPUT (FUNCTION 24)............................................... 5-21

5.2 BIT SWITCHES...................................................................................... 5-24

5.2.1 SYSTEM SWITCHES.................................................................... 5-24

5.2.2 SCANNER SWITCHES ................................................................. 5-39

5.2.3 PRINTER SWITCHES................................................................... 5-40

5.2.4 COMMUNICATION SWITCHES.................................................... 5-43

5.2.5 G3 SWITCHES.............................................................................. 5-53

5.2.6 G3-2 SWITCHES........................................................................... 5-61

5.2.7 G4 INTERNAL SWITCHES............................................................ 5-67

5.2.8 G4 PARAMETER SWITCHES....................................................... 5-74

5.3 NCU PARAMETERS .............................................................................. 5-77

5.4 DEDICATED TRANSMISSION PARAMETERS ..................................... 5-85

5.4.1 PROGRAMMING PROCEDURE................................................... 5-85

5.4.2 PARAMETERS.............................................................................. 5-86

5.5 SERVICE RAM ADDRESSES................................................................ 5-90

5.6 SERVICE RAM ADDRESSES: ADF AND SCANNER .......................... 5-110

5.7 SERVICE RAM ADDRESSES: PRINTER ENGINE (PLOTTER).......... 5-112

5.7.1 ADJUSTING THE PRINTING SIDE-TO-SIDE REGISTRATION.. 5-112

5.7.2 ADJUSTING THE PRINTING TOP MARGIN............................... 5-113

6. DETAILED SECTION DESCRIPTIONS.......................................6-1

6.1 ADF/SCANNER........................................................................................ 6-1

6.1.1 OVERVIEW...................................................................................... 6-1

6.1.2 DETAILED DESCRIPTIONS............................................................ 6-2

Document Detection............................................................................. 6-2

Document Pick-up................................................................................ 6-3

Document Feed.................................................................................... 6-4

Stamping.............................................................................................. 6-5

Returning to Ready Status................................................................... 6-6

Image Scanning................................................................................... 6-7

Jam Detection...................................................................................... 6-8

6.2 PRINTER.................................................................................................. 6-9

6.2.1 OVERVIEW...................................................................................... 6-9

6.2.2 LASER EXPOSURE...................................................................... 6-10

Overview............................................................................................ 6-10

Optical Path........................................................................................ 6-10

Auto Power Control (APC)................................................................. 6-11

LD Safety........................................................................................... 6-12

LD Unit Service Call Condition........................................................... 6-12

6.2.3 AIO CARTRIDGE........................................................................... 6-13

Overview............................................................................................ 6-13

Page 9

vi

Drive................................................................................................... 6-14

Drum Charge...................................................................................... 6-15

Development...................................................................................... 6-16

Drum Cleaning................................................................................... 6-18

Service Call Conditions for the Development Section........................ 6-18

6.2.4 TRANSFER AND PAPER SEPARATION...................................... 6-19

Overview............................................................................................ 6-19

Transfer Roller Cleaning.................................................................... 6-20

Service Call Conditions for the Transfer Section................................ 6-20

6.2.5 PAPER FEED................................................................................ 6-21

Overview............................................................................................ 6-21

Paper Size Detection ......................................................................... 6-23

Bottom Plate Lift, Upper Limit Detection and Paper End Detection.... 6-24

Paper Near-end Detection.................................................................. 6-25

Paper Feed........................................................................................ 6-25

By-pass Tray...................................................................................... 6-26

6.2.6 FUSING......................................................................................... 6-28

Overview............................................................................................ 6-28

Fusing................................................................................................ 6-30

Fusing Unit Drive................................................................................ 6-30

Fusing Pressure Roller, Separation, Exit........................................... 6-31

Fusing Drive Release......................................................................... 6-31

Fusing Temperature Control .............................................................. 6-32

Cooling Fan Control........................................................................... 6-33

Fusing Unit Service Call Conditions................................................... 6-34

6.3 OPTIONAL PAPER FEED UNITS.......................................................... 6-35

6.3.1 OVERVIEW.................................................................................... 6-35

6.3.2 MECHANISMS............................................................................... 6-36

Paper Size Detection ......................................................................... 6-36

Bottom Plate Lift, Upper Limit Detection and Paper End Detection.... 6-37

Paper Near-end Detection.................................................................. 6-38

Paper Feed........................................................................................ 6-39

Jam Detection.................................................................................... 6-39

6.4 PCBS...................................................................................................... 6-40

6.4.1 FCU ............................................................................................... 6-40

6.4.2 OPIF (OPTION INTERFACE BOARD) .......................................... 6-45

6.4.3 NCU............................................................................................... 6-46

6.4.4 PSU ............................................................................................... 6-46

6.4.5 NICF (NETWORK INTERFACE CARD FOR FACSIMILE)............ 6-47

6.4.6 SG3-D BOARD.............................................................................. 6-49

6.4.7 SIG4 BOARD................................................................................. 6-50

6.5 SYSTEM FEATURES............................................................................. 6-51

6.5.1 VERTICAL BLACK LINE CORRECTION....................................... 6-51

Overview............................................................................................ 6-51

Count Detection Parameters List ....................................................... 6-52

Settings for Vertical Black Line Detection.......................................... 6-53

Vertical Black Line Warning Message................................................ 6-53

Page 10

vii

6.5.2 BLANK PAGE DETECTION........................................................... 6-54

Blank Page Detection Operation........................................................ 6-54

Blank Page Detection Switch Settings ............................................... 6-54

6.5.3 ENERGY SAVER MODE............................................................... 6-55

Overview............................................................................................ 6-55

Setting the Energy Saver Mode Timer............................................... 6-56

How the Energy Saver Mode Operates.............................................. 6-57

Important Points About Energy Saver and Standby........................... 6-60

6.5.4 ERASE ALL REGISTERED SETTINGS ........................................ 6-61

6.5.5 RECEIVING FROM A FAX INFORMATION SERVICE.................. 6-62

6.5.6 DUAL ACCESS.............................................................................. 6-63

Dual Access Jobs and Resources...................................................... 6-63

Additional Dual Access Limitations.................................................... 6-64

Simultaneous Broadcasting................................................................6-65

6.5.7 OPERATION LOG......................................................................... 6-66

Memory Dump List............................................................................. 6-66

6.5.8 SENDING COLOR DOCUMENTS ................................................. 6-68

6.5.9 SCAN RESOLUTION..................................................................... 6-69

SPECIFICATIONS.................................................................... SPEC-1

1.1 SPECIFICATIONS.......................................................................SPEC-1

1.2 FEATURES..................................................................................SPEC-3

1.2.1 FEATURES LIST......................................................................SPEC-3

1.2.2 CAPABILITIES OF PROGRAMMABLE ITEMS ........................SPEC-6

1.3 COMPONENT LAYOUT..............................................................SPEC-7

1.3.1 MECHANICAL COMPONENTS................................................SPEC-7

1.3.2 ELECTRICAL COMPONENTS.................................................SPEC-8

PCBs.............................................................................................SPEC-9

Motors.........................................................................................SPEC-10

Sensors.......................................................................................SPEC-10

Interlock Switch...........................................................................SPEC-11

Others.........................................................................................SPEC-11

1.3.3 DRIVE LAYOUT......................................................................SPEC-12

Components................................................................................SPEC-12

1.4 POWER DISTRIBUTION...........................................................SPEC-13

1.4.1 DISTRIBUTION DIAGRAM.....................................................SPEC-13

1.4.2 MEMORY BACK-UP CIRCUIT ................................................ SPEC-14

Page 11

14 June, 2002 MAINFRAME

1-1

Installation

1. INSTALLATION

!CAUTION

Do the following before installing an optional unit:

1. Print out all messages stored in the memory.

2. Print out the lists of user-programmed items and the system parameter list.

3. Turn off the main switch, and disconnect the power plug.

1.1 MAINFRAME

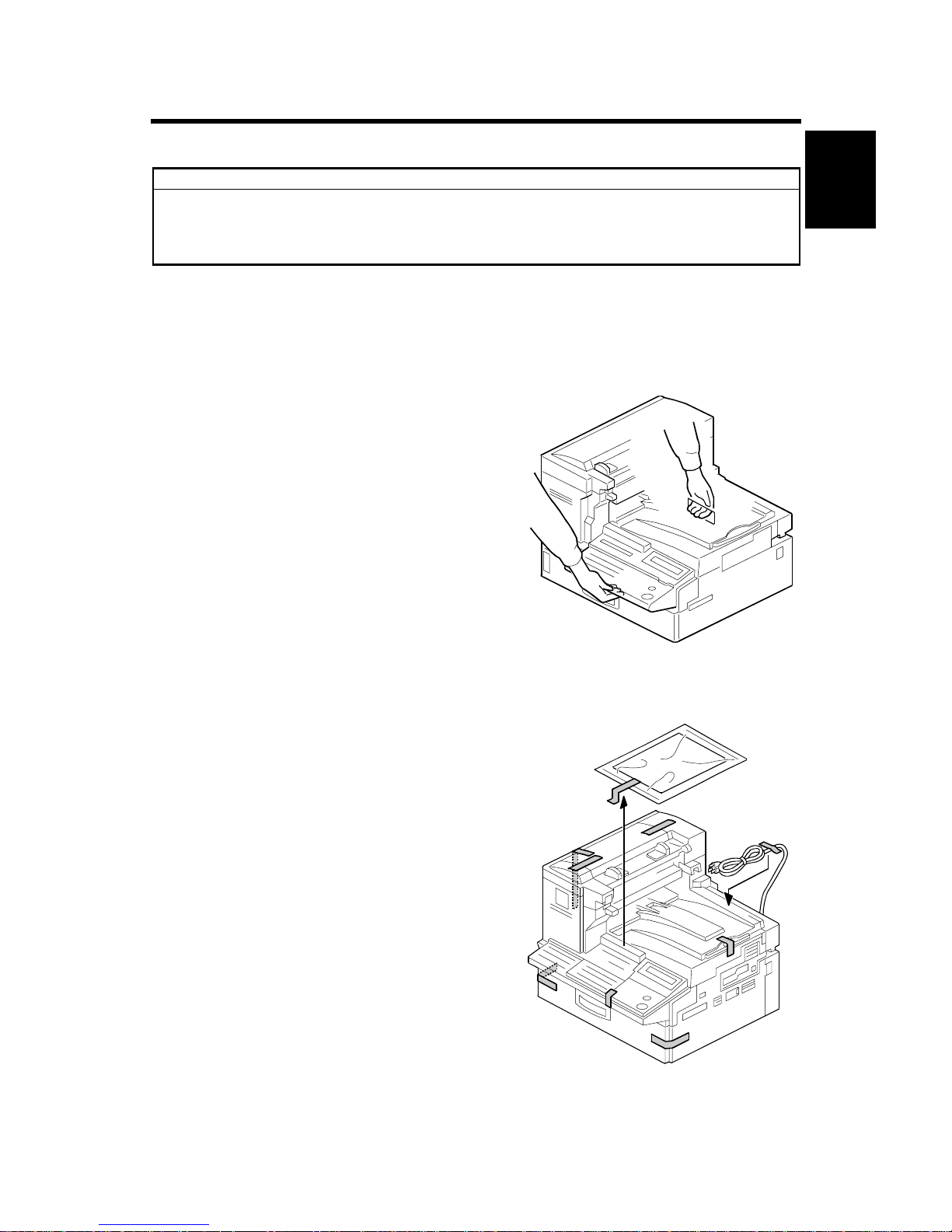

1. Remove the mainframe from the box.

2. Remove the shipping tape.

H310I939.WMF

H310I001.WMF

Page 12

MAINFRAME 14 June, 2002

1-2

3. Remove the shock absorber [A] and sheet

[B].

4. Remove the shock absorbers and

shipping tape from the paper trays.

5. Attach the document exit tray and

document tray.

6. Open the ADF unit and attach the handset

bracket [C].

7. Open the left cover and remove the AIO cartridge.

8. Shake the AIO cartridge left to right then

back and forth about 7-8 times (total).

Then, remove the toner ribbon seal.

9. Reinstall the AIO cartridge.

10. Load the desired paper in the paper trays,

and set up the paper size dials

accordingly

11. Turn the machine ON, then follow the

display to program the following items:

Date/time, PSTN line type (tone/pulse

dial), own name, fax header, fax number.

12. Program the machine serial number in

Service mode, then exit Service mode.

H310I002.WMF

H310I940.WMF

H310I991.WMF

[A]

[B]

[C]

Page 13

14 June, 2002 MAINFRAME

1-3

Installation

13. Remove the backing from the brand

plaque [A] and avoid touching the

adhesive surface. Place the brand

plaque in the depression on the ADF

front cover. Taking care that the brand

plaque is orientated correctly and

aligned straight. Once in place, apply

even pressure beginning at the center

of the brand plaque moving toward the

outer edges. This will insure that it is

well adhered to the surface.

H310I059.WMF

[A]

Page 14

INSTALLING BASE UNIT/CABINET/SPACER 14 June, 2002

1-4

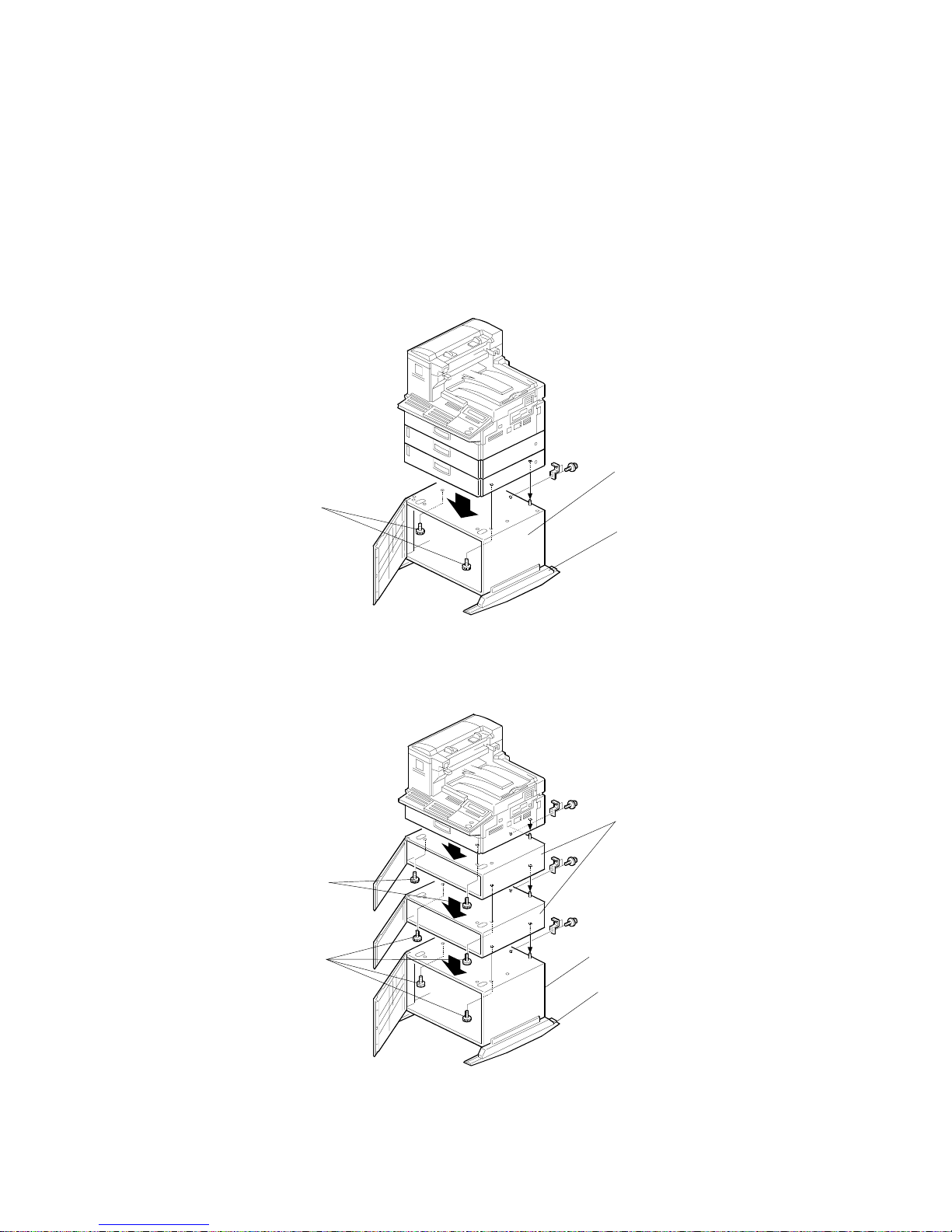

1.2 INSTALLING BASE UNIT/CABINET/SPACER

To ensure proper machine stability, be sure to attach the Cabinet Type 510 when

installing 2 PFUs/Spacer Type 510, or the Base Unit Type 51 0 when installing 3 or

more PFUs/Spacer Type 510 (both of which have Support Boards attached).

Please refer to the following examples:

Example 1: Mainframe, PFU X 2 and Cabinet Type 510

Example 2: Mainframe, Spacer Type 510 X 2 and Cabinet Type 510

H310I056.WMF

H310I057.WMF

Cabinet Type 510

M4 screws

Support Board

Cabinet Type 510

Support Board

M3 screws

M4 screws

Spacer Type 510

Page 15

14 June, 2002 INSTALLING BASE UNIT/CABINET/SPACER

1-5

Installation

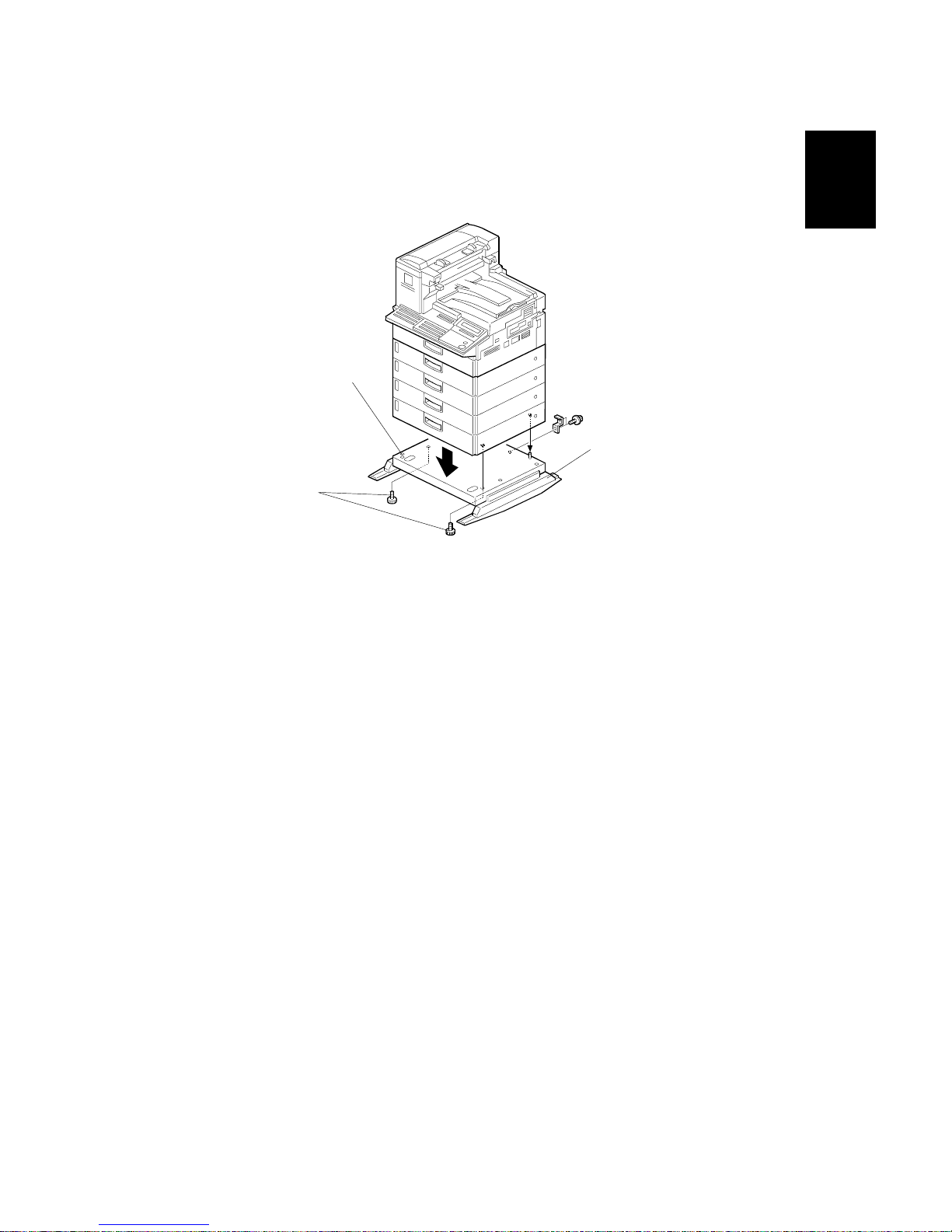

Example 3: Mainframe, PFU X 4 and Base Unit Type 510

NOTE: As shown in the illustrations above, when attaching any of the units directly

under the mainframe, use the two forward parallel screw-holes. For all

other attachments, use the two diagonally positioned screw holes.

H310I058.WMF

Base Unit Type 510

Support Board

M3 screws

Page 16

INSTALLING OPTIONAL UNITS 14 June, 2002

1-6

1.3 INSTALLING OPTIONAL UNITS

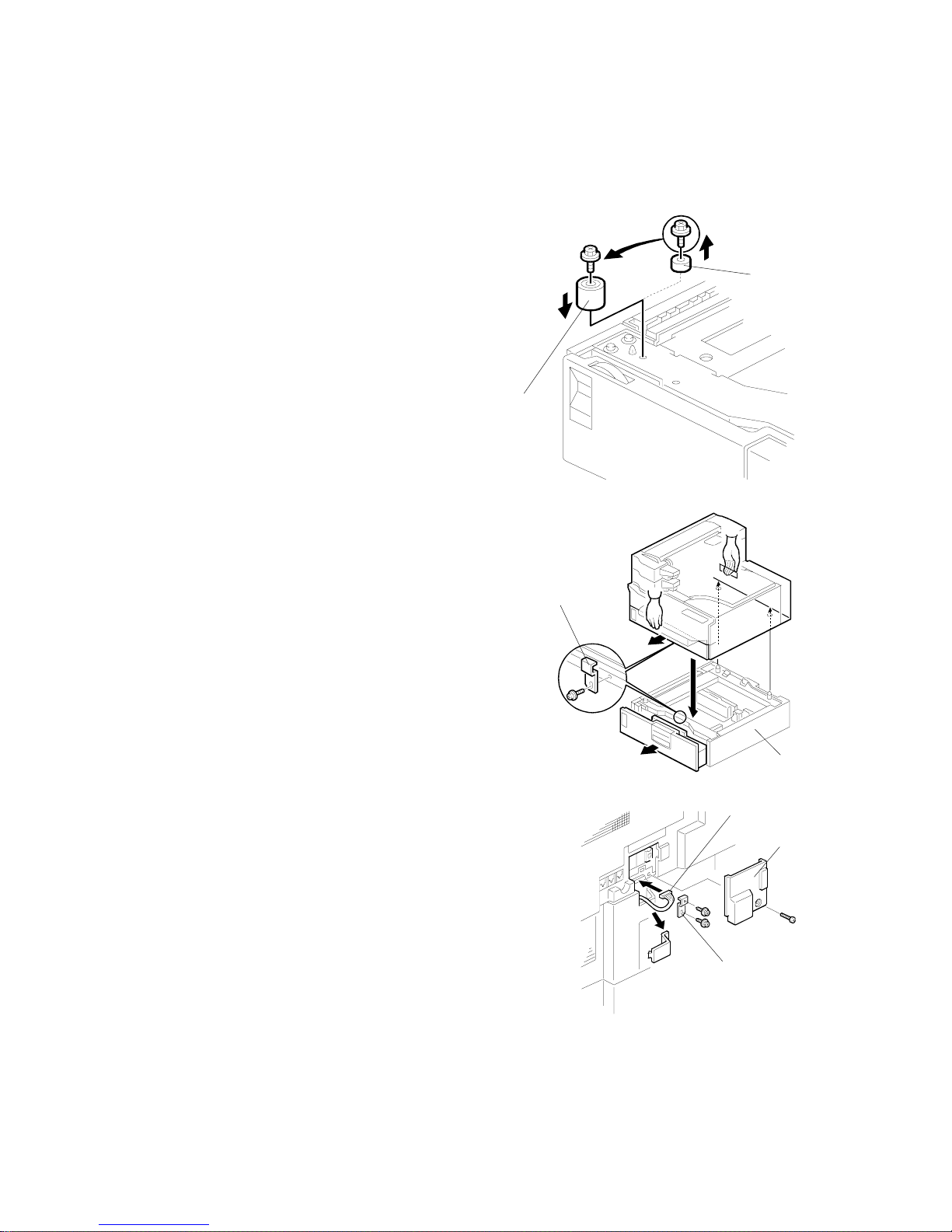

1.3.1 PAPER FEED UNIT TYPE 510

1. When installing optional Paper Fe ed Units 2,

3 or 4 (i.e. ones not attached directly under

the mainframe), it is necessary to replace the

large leg [A] with the small leg [B] enclosed

with the unit.

NOTE: Remove the 2 tie-wraps securing the

paper feed rollers (located under the

red tag).

2. Place the mainframe and any attached PFUs

on top of the Paper Feed Unit [C], then

secure the two with the bracket [D] (1 screw)

on the front of the machine

NOTE: If the existing mainframe and PFU

assembly is too heavy, disassemble

them and install them one by one on

top of the new optional PFU.

3. Remove the connector cover [E] (1 screw)

and secure the new PFU to the mainframe

(or PFU) above it with the bracket [F] (2 screws).

Then, connect the harness [G] to the machine

and reattach the connector cover.

4. Plug in the machine and turn on the main power

switch.

5. Print the System Parameter List from inside

Service mode, then make sure that

“CASSETTE” is listed as an option. Then exit

Service mode.

6. Add some paper and make some test prints

using the newly installed PFU.

H206I601.WMF

H206I602.WMF

H206I603.WMF

[B]

[A]

[C]

[D]

[E]

[F]

[G]

Page 17

14 June, 2002 INSTALLING OPTIONAL UNITS

1-7

Installation

1.3.2 BYPASS FEEDER TYPE 510

1. Remove the rear cover [A] (7 screws) and

small cut-out [B] as shown.

2. Open the large cover. Then, remove the 2

screws [C] as shown to release the small

cover.

3. Attach the 2 magnet catches [D], 2 small

brackets [E] and 2 cushions [F]. Then attach

the knob [G] (2 screws) to the small cover as

shown.

H207I029.WMF

H207I030.WMF

H207I031.WMF

[A]

[B]

[C]

[G]

[F]

[E]

[D]

Page 18

INSTALLING OPTIONAL UNITS 14 June, 2002

1-8

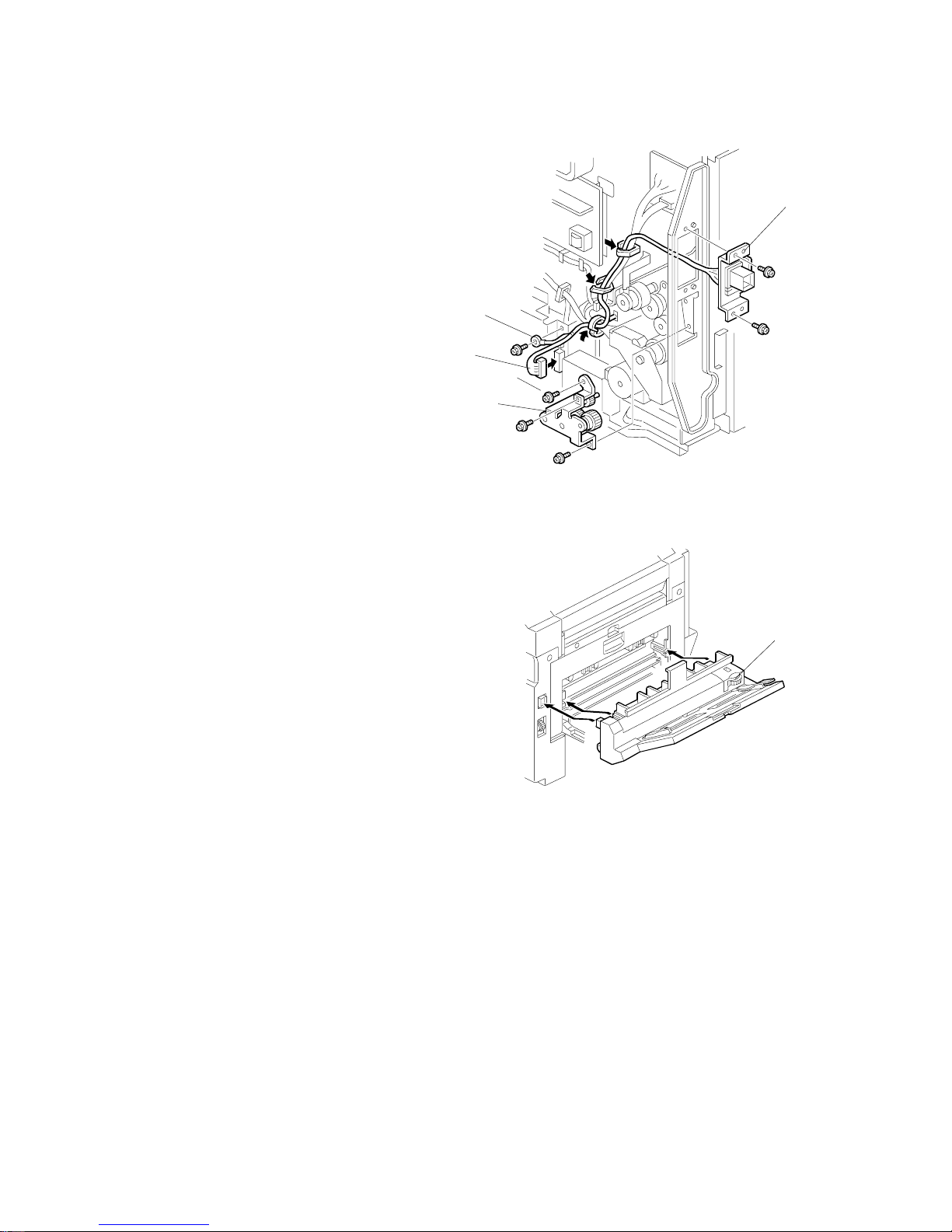

4. Attach the gear assembly [H] to the

back of the machine. Then, attach the

connector [I] and lead the bypass

feeder harness through the 3 clamps

as shown. Finally, connect the end of

the harness [J] and secure the

grounding wire [K] to the mainframe.

5. Reattach the rear cover.

6. Attach the bypass feeder [L] to the

machine.

7. Plug in the machine and turn on the main power switch.

8. Print the System Parameter List from inside Service mode, then make sure that

“BY-PASS” is listed as an option. Then, exit Service mode.

9. Add some paper and make some test prints using the newly installed Bypass

Feeder.

H207I032.WMF

H207I033.WMF

[H]

[I]

[J]

[K]

[L]

Page 19

14 June, 2002 INSTALLING OPTIONAL UNITS

1-9

Installation

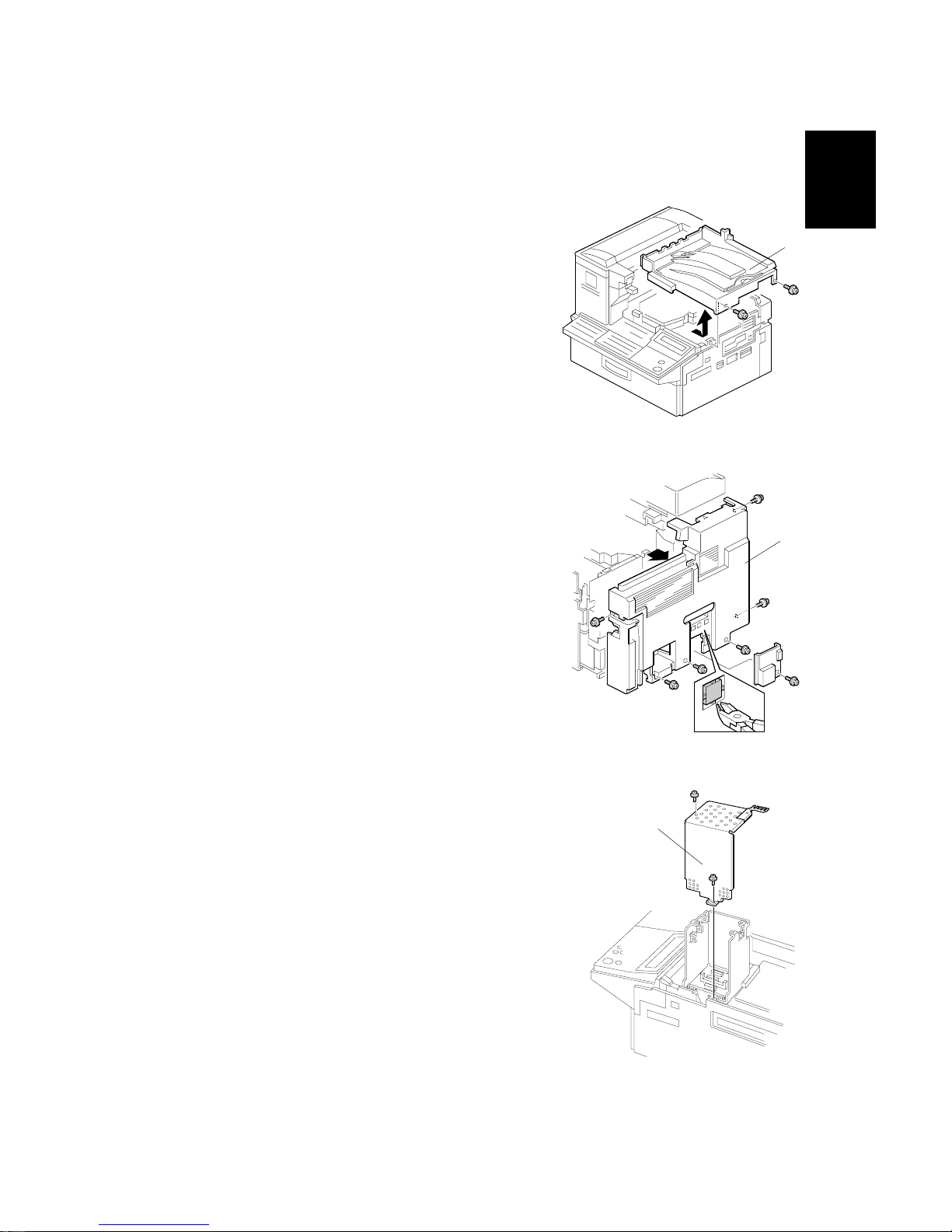

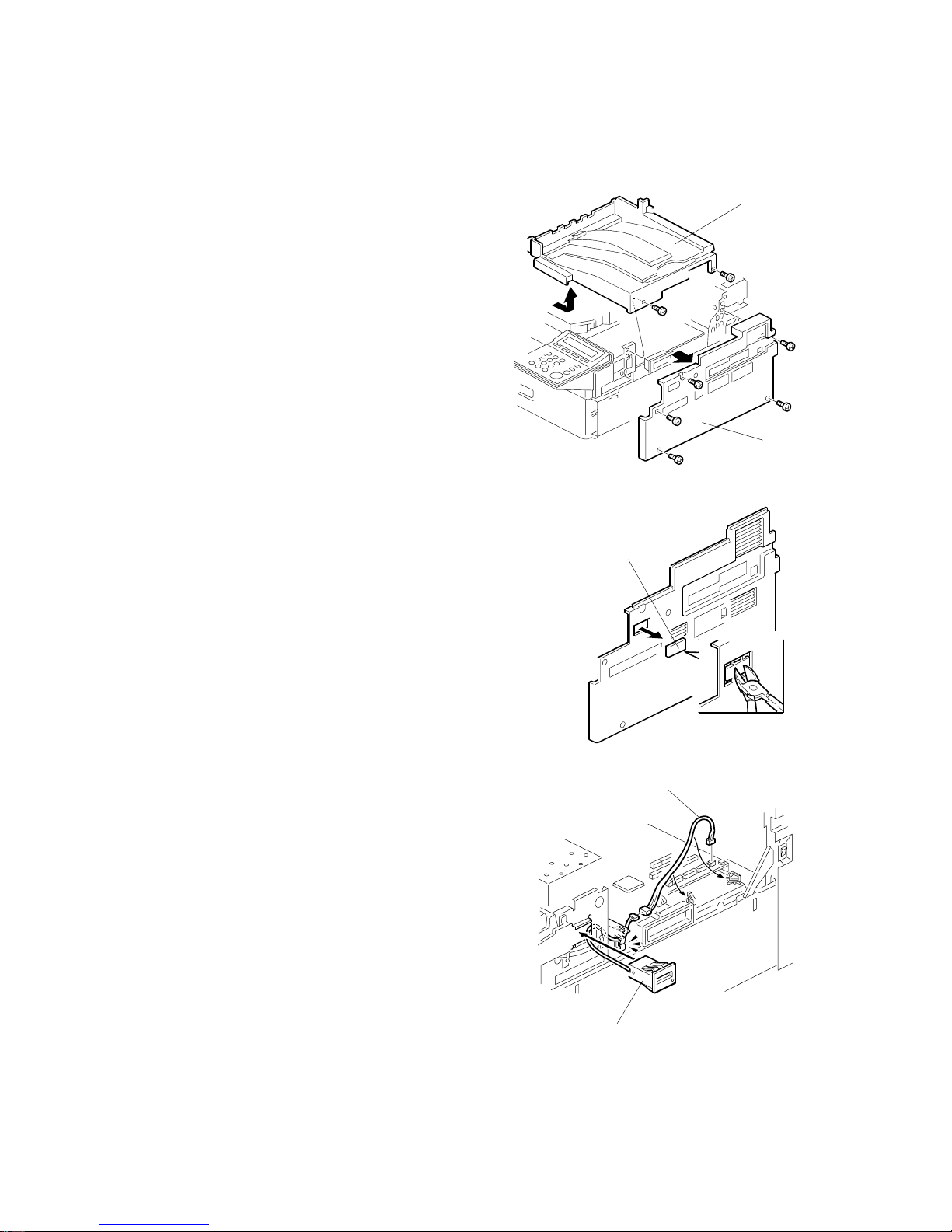

1.3.3 ISDN G4 INTERFACE UNIT TYPE 510

1. Remove the upper cover [A] (2 screws).

2. Remove the rear cover (7 screws) [B] and cut

away the ISDN small cover as shown.

3. Remove the bracket cover [C] (4 screws) as shown.

H208I006.WMF

H208I013.WMF

H208I523.WMF

[C]

[B]

[A]

Page 20

INSTALLING OPTIONAL UNITS 14 June, 2002

1-10

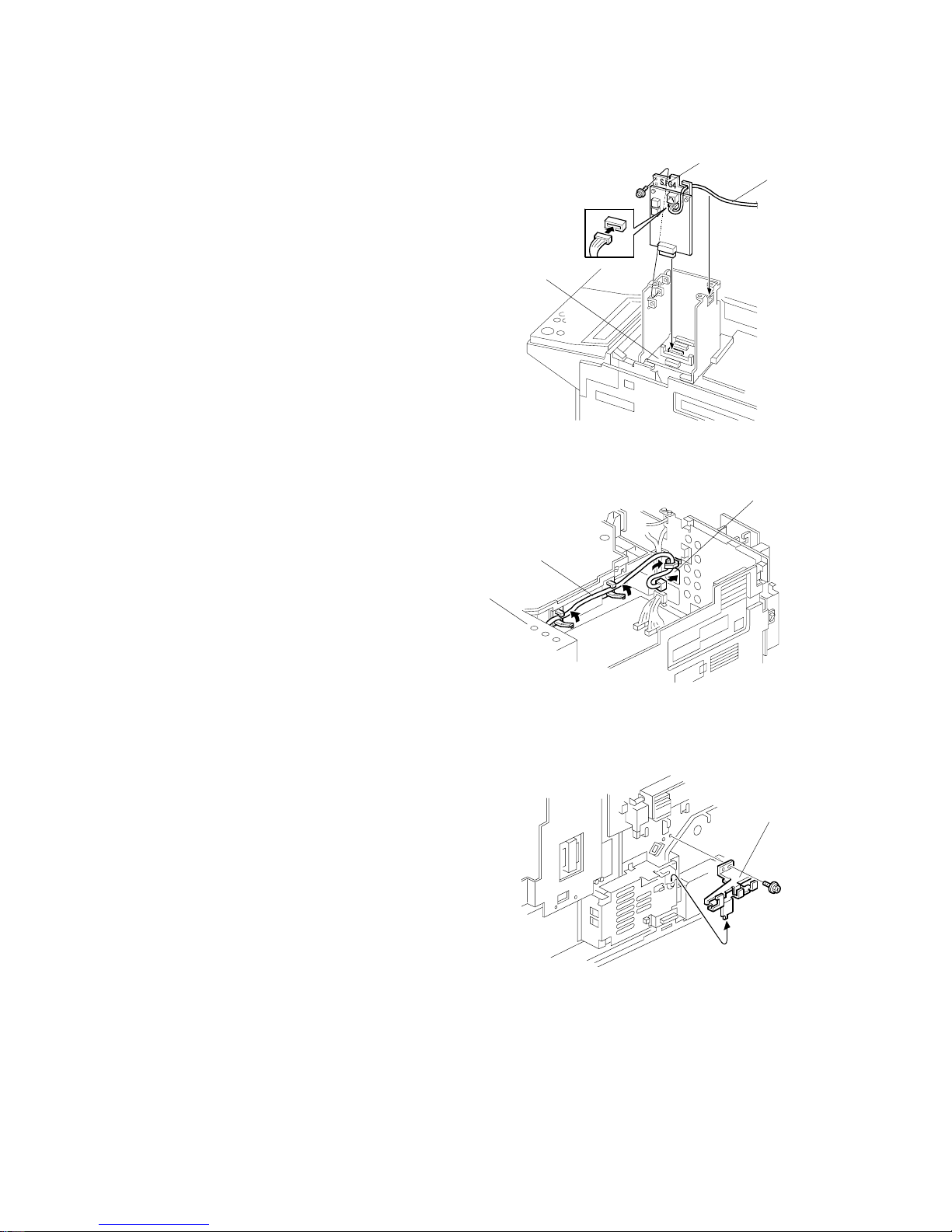

4. Connect the harness [D] to the SiG4 board

[E] and insert the board into the SiG4

connector on the OPIF board [F].

5. Reattach the bracket cover [C], then lead

the harness [D] through the 3 clamps and

the hole [G] in the rear bracket as shown.

6. Remove the bracket assembly [H] from

rear side of the machine as shown.

H208I019.WMF

H208I020.WMF

H208I040.WMF

[D]

[F]

[D]

[H]

[E]

[C]

[G]

Page 21

14 June, 2002 INSTALLING OPTIONAL UNITS

1-11

Installation

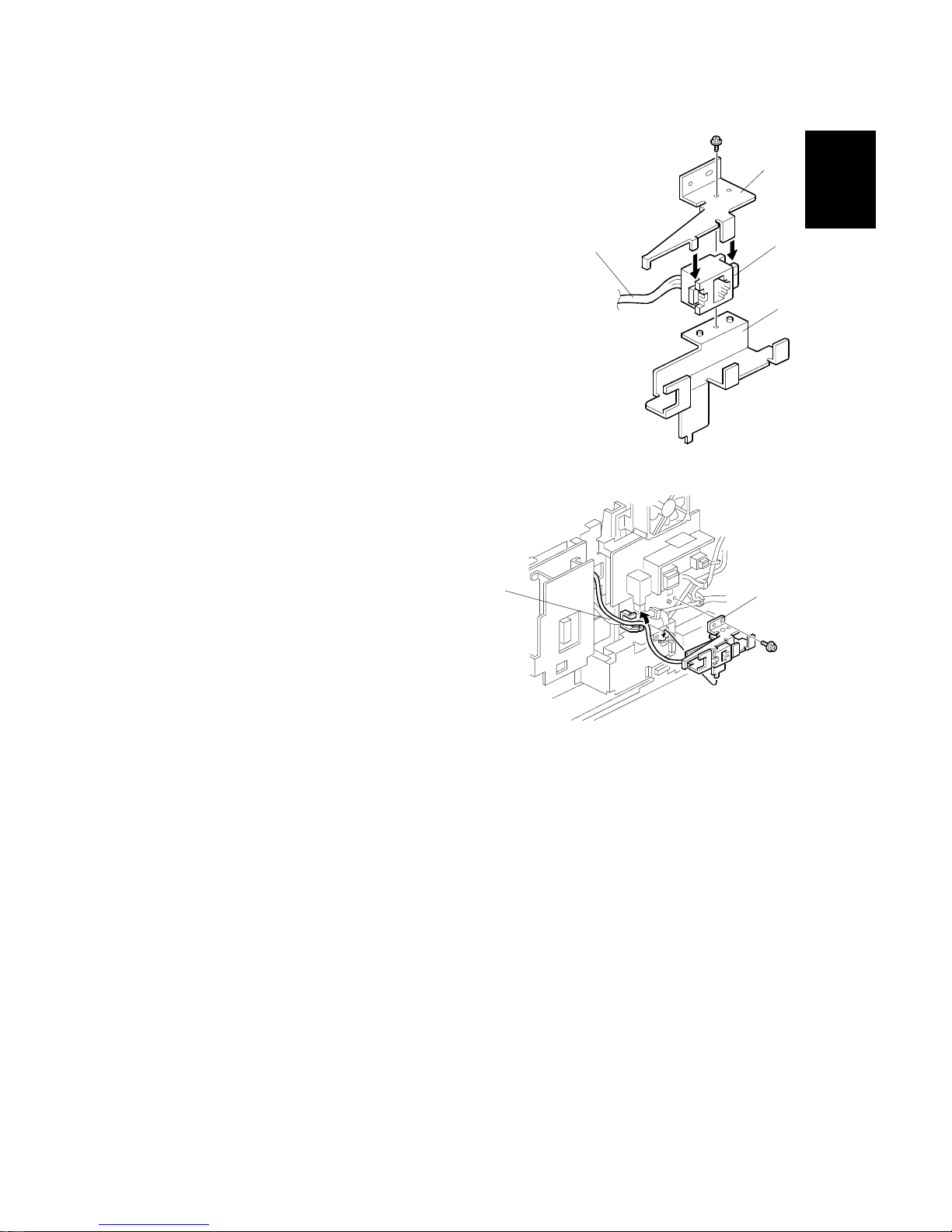

7. Attach the bracket [I] to the connector [J] on the

harness [D] from the unit kit. Then, attach them to

bracket [K] as shown.

8. Clamp the harness [D] from Step 7 as

shown, then attach the bracket assembly [L]

to the machine (1 screw).

9. Reattach the rear and upper covers.

14. Plug in the machine and turn on the main power switch.

15. Enter Service mode and set bit 2 of communication switch 16 to “1”.

16. Exit Service mode and turn off the machine, then turn the machine back on.

17. Print the System Parameter List from inside Service mode, and make sure that

“G4” is listed as an option. Then exit Service mode.

10. Set up and program the items required for ISDN communications:

To connect to the US National ISDN network, it is necessary to also input the

SPID (Service Profile ID Number).

H208I021.WMF

H208I022.WMF

[D]

[I]

[J]

[D]

[K]

[L]

Page 22

INSTALLING OPTIONAL UNITS 14 June, 2002

1-12

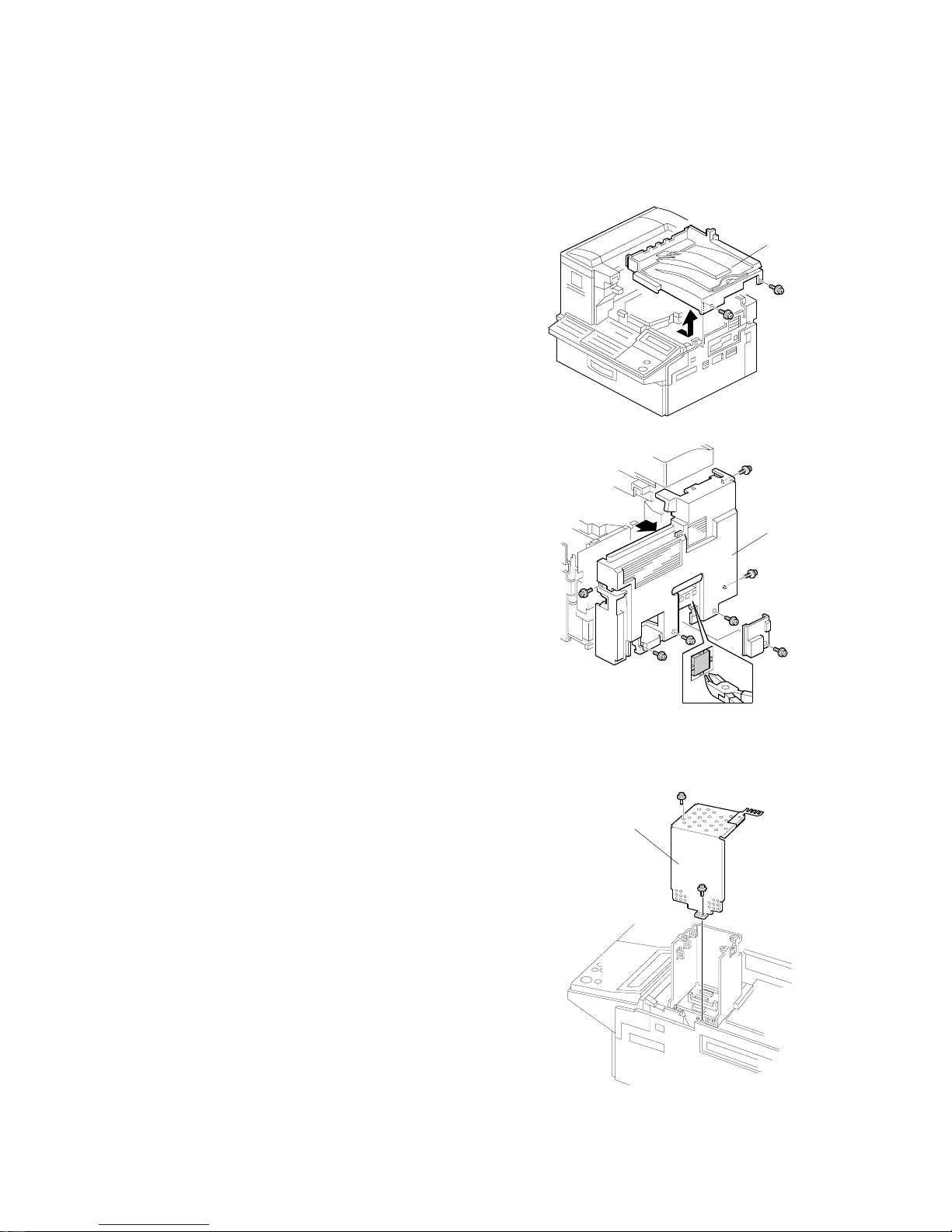

1.3.4 G3 INTERFACE UNIT TYPE510

1. Remove the upper cover [A] (2 screws).

2. Remove the rear cover (7 screws) [B] and cut

away the LINE2 small cover as shown.

3. Remove the bracket cover [C] (4 screws) as

shown.

H209I006.WMF

H209I013.WMF

H209I523.WMF

[C]

[A]

[B]

Page 23

14 June, 2002 INSTALLING OPTIONAL UNITS

1-13

Installation

4. Connect the harness [D] to the SG3 board

[E] and insert the board into the SG3

connector on the OPIF board [F].

5. Reattach the bracket cover [C], then

lead the harness [D] through the 2

clamps as shown.

6. Remove the bracket assembly [G] from

rear side of the machine as shown.

H209I014.WMF

H209I015.WMF

H209I040.WMF

[D]

[F]

[D]

[G]

[E]

[C]

Page 24

INSTALLING OPTIONAL UNITS 14 June, 2002

1-14

7. Attach the connector [H] of the harness [I] to

the bracket [J] and secure the bracket [K] (1

screw).

8. Lead the harness [I] from Step 7 through

the clamp and hole in the bracket as

shown. Then, attach the bracket

assembly [L] to the rear side of the

machine (1 screw).

9. Attach the NCU board [M] to the machine as

shown (2 screws), then connect the 2

harnesses [N] to the NCU board.

10. Replace the rear and upper covers.

11. Plug in the machine and turn on the main

power switch.

12. Enter Service mode and set bit 1 of

communication switch 16 to “1”.

13. Exit Service mode and turn off the machine,

then turn the machine back on.

14. Print the System Parameter List from inside

Service mode, and make sure that “G3” is

listed as an option. Then exit Service mode.

15. Set up and program the items required for PSTN-2 communication.

H209I016.WMF

H209I017.WMF

H209I018.WMF

[H]

[J]

[I]

[L]

[I]

[K]

[M]

[N]

Page 25

14 June, 2002 INSTALLING OPTIONAL UNITS

1-15

Installation

1.3.5 FAX ON DEMAND TYPE 510

1. Remove the right cover [A] (5 screws) and

small cut-out as shown.

2. Attach the FOD unit [B] (1 screw) to the

right side of the machine. Then, lead the

harness through the clamps and connect it

to CN53 [C] on the FCU board.

H213I026.WMF

H213I055.WMF

[A]

[B]

[C]

Page 26

INSTALLING OPTIONAL UNITS 14 June, 2002

1-16

3. Reattach the right cover and insert the IC

card [D] as shown. Then affix the “MIC”

decal [E] on the right cover.

4. Plug in the machine and turn on the main power switch.

5. Print the System Parameter List from inside Service mode, then make sure that

“FOD” is listed as an option. Then exit Service mode.

6. Remind the user to connect the microphone from the FOD kit whenever using

Fax On Demand.

H213I028.WMF

[D]

[E]

Page 27

14 June, 2002 INSTALLING OPTIONAL UNITS

1-17

Installation

1.3.6 FUNCTION UPGRADE UNIT TYPE 510

1. Remove the upper cover [A] (2 screws).

2. Remove the bracket cover [B] (4 screws) as

shown.

3. Insert the Function Upgrade Unit [C]

into CN3 on the OPIF board [D].

4. Replace the bracket cover and upper

cover.

5. Plug in the machine and turn on the

main power switch.

6. Print the System Parameter List from

inside Service mode, and make sure

that “FUNCTION BOARD” is listed as

an option. Then exit Service mode.

H214I006.WMF

H214I523.WMF

H214I041.WMF

[B]

[D]

[A]

[C]

Page 28

INSTALLING OPTIONAL UNITS 14 June, 2002

1-18

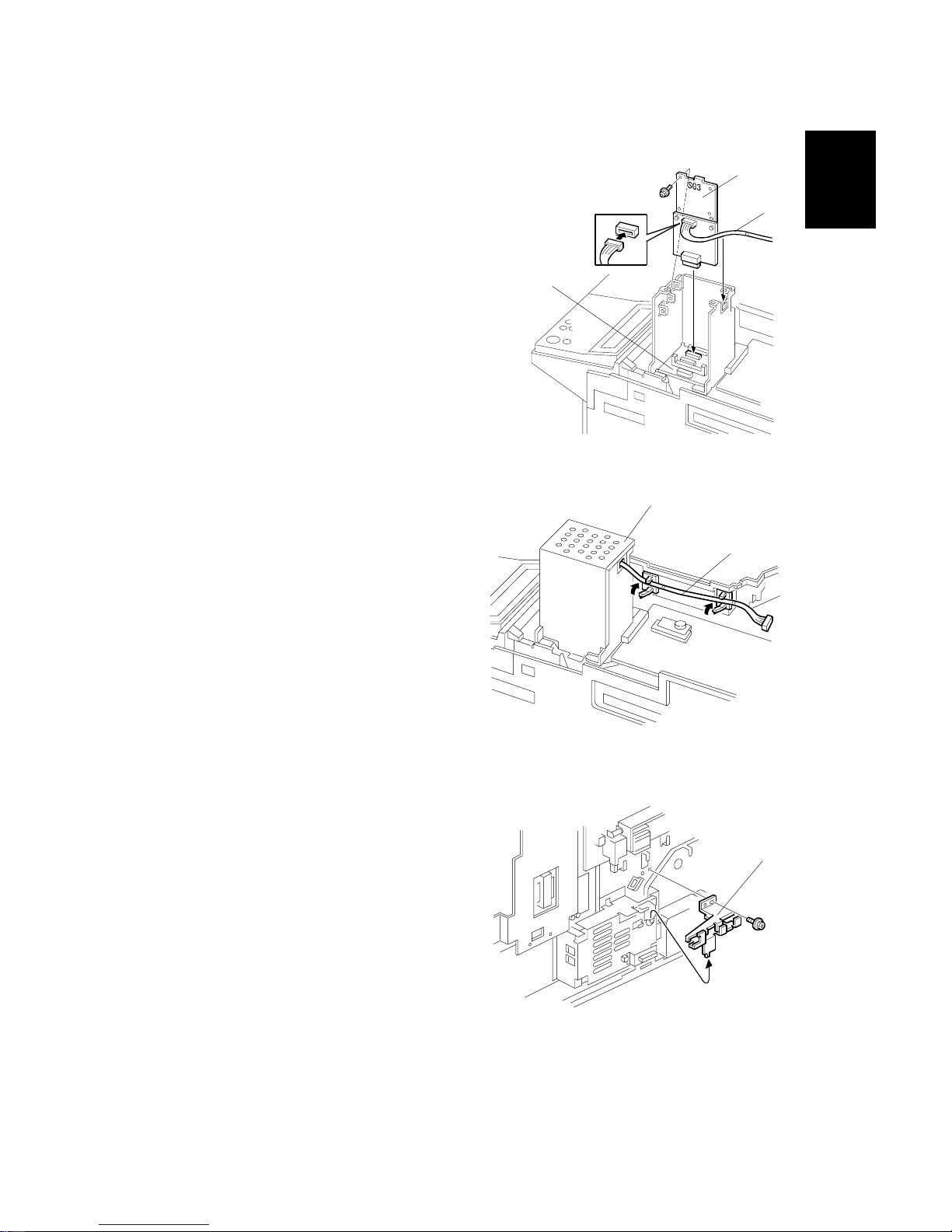

1.3.7 COUNTER TYPE 510

1. Remove the top cover [A] (2 screws)

and right cover [B] (5 screws).

2. Cut away the small cover [C].

3. Attach the counter [D] on the machine,

then connect relay harness [E] (contained

in the kit) to the counter harness.

4. Connect the relay harness [E] to CN52 on

the FCU board, then clamp the harness.

5. Replace the top and the right covers.

6. Make some copies and check whether or

not the counter is working correctly. If it is

not, check the connection of the FCUcounter harness.

H230I003.WMF

H230I501.WMF

H230I530.WMF

[A]

[B]

[C]

[D]

[E]

Page 29

14 June, 2002 INSTALLING OPTIONAL UNITS

1-19

Installation

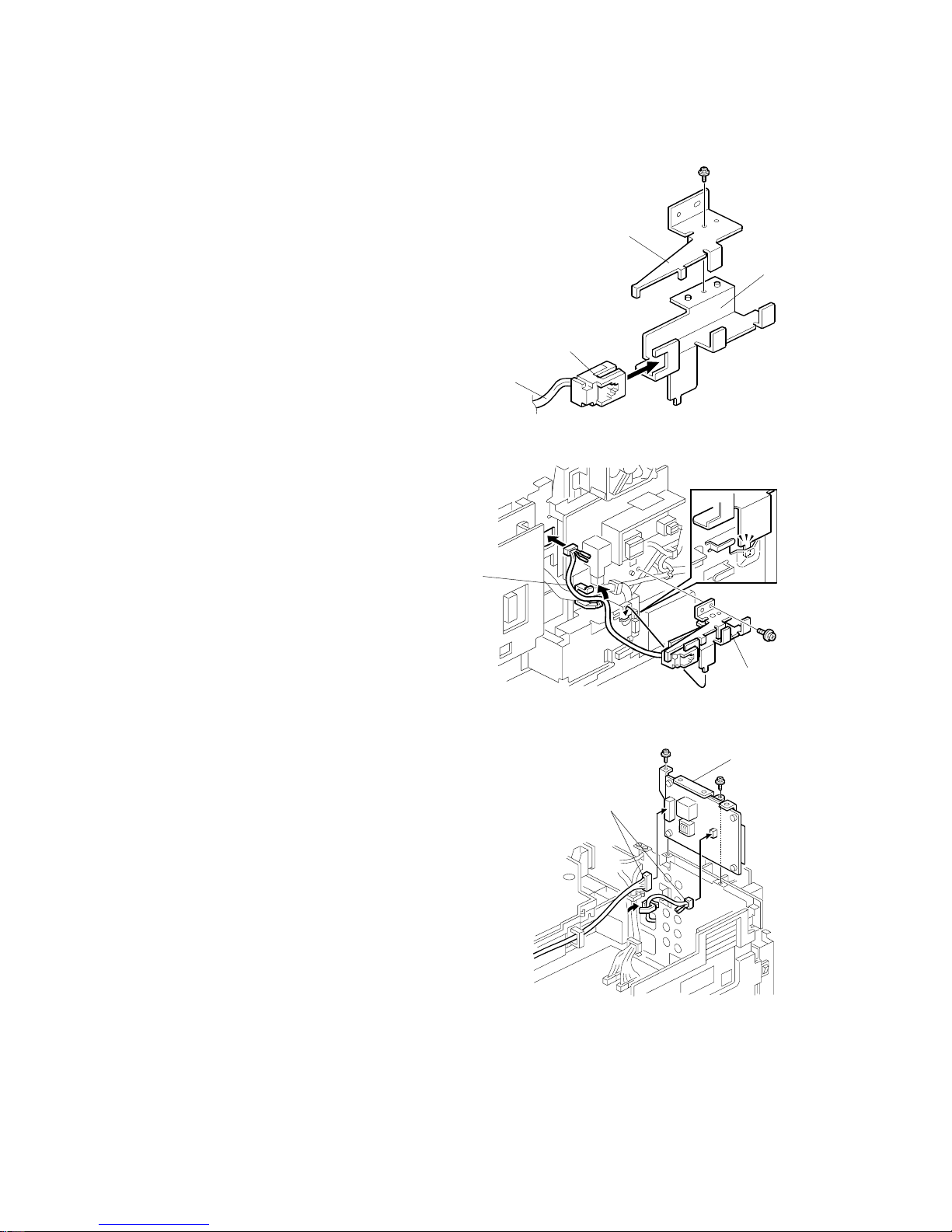

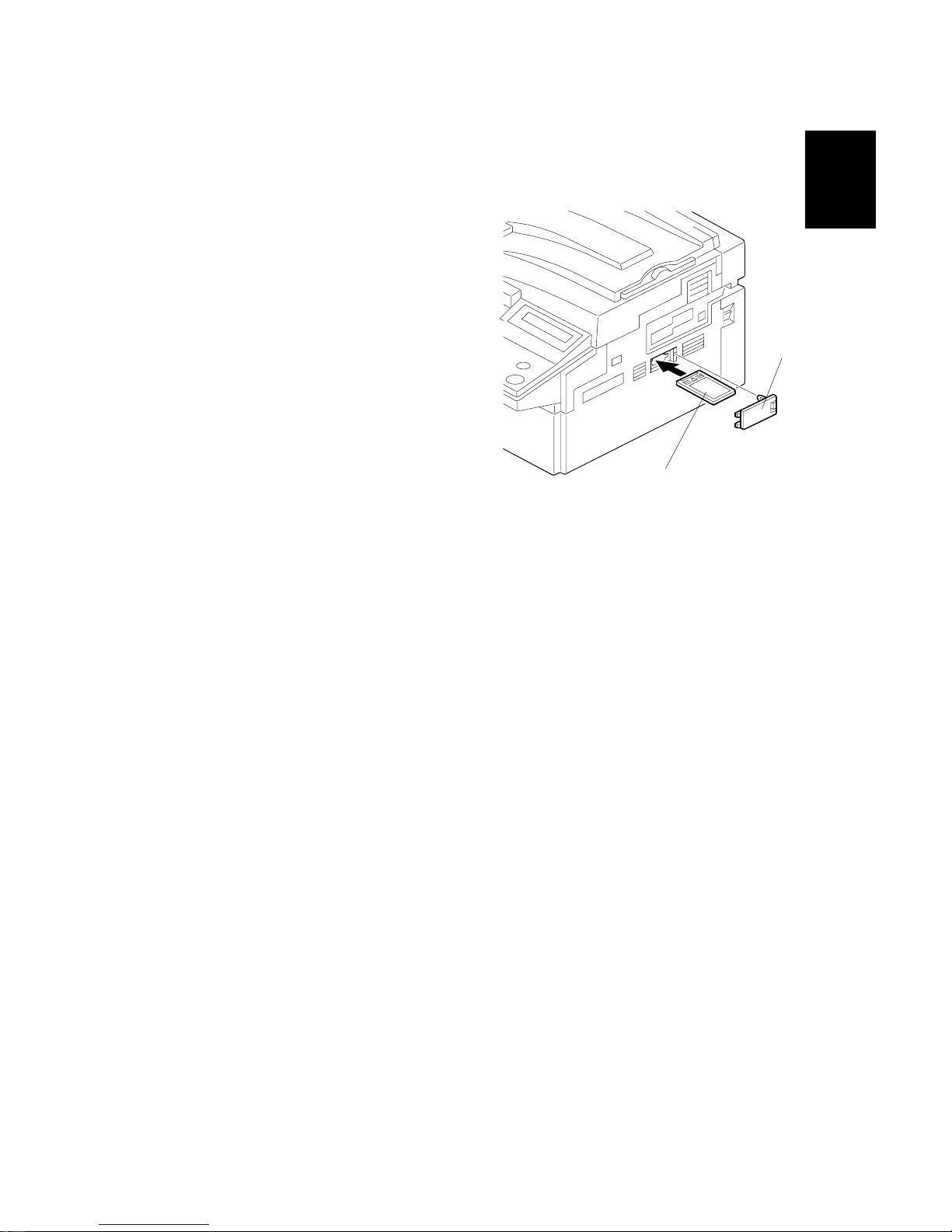

1.3.8 FEATURE EXPANDER TYPE 300 40M

1. Remove the small cover [A] on the right

cover.

2. Insert the 40MB memory card [B] into

the machine.

3. Reattach the small cover.

4. Print the System Parameter List from inside Service mode, then make sure that

“40MB” is listed as an option. Then exit Service mode.

H215I003.WMF

[A]

[B]

Page 30

14 June, 2002 SPECIAL TOOLS AND LUBRICANTS

2-1

Preventive

Maintenance

2. PREVENTIVE MAINTENANCE

2.1 SPECIAL TOOLS AND LUBRICANTS

• Flash memory card -4M (P/N: N8036701)

• Flash/SRAM data copy tool (P/N: A1939353/H5159100)

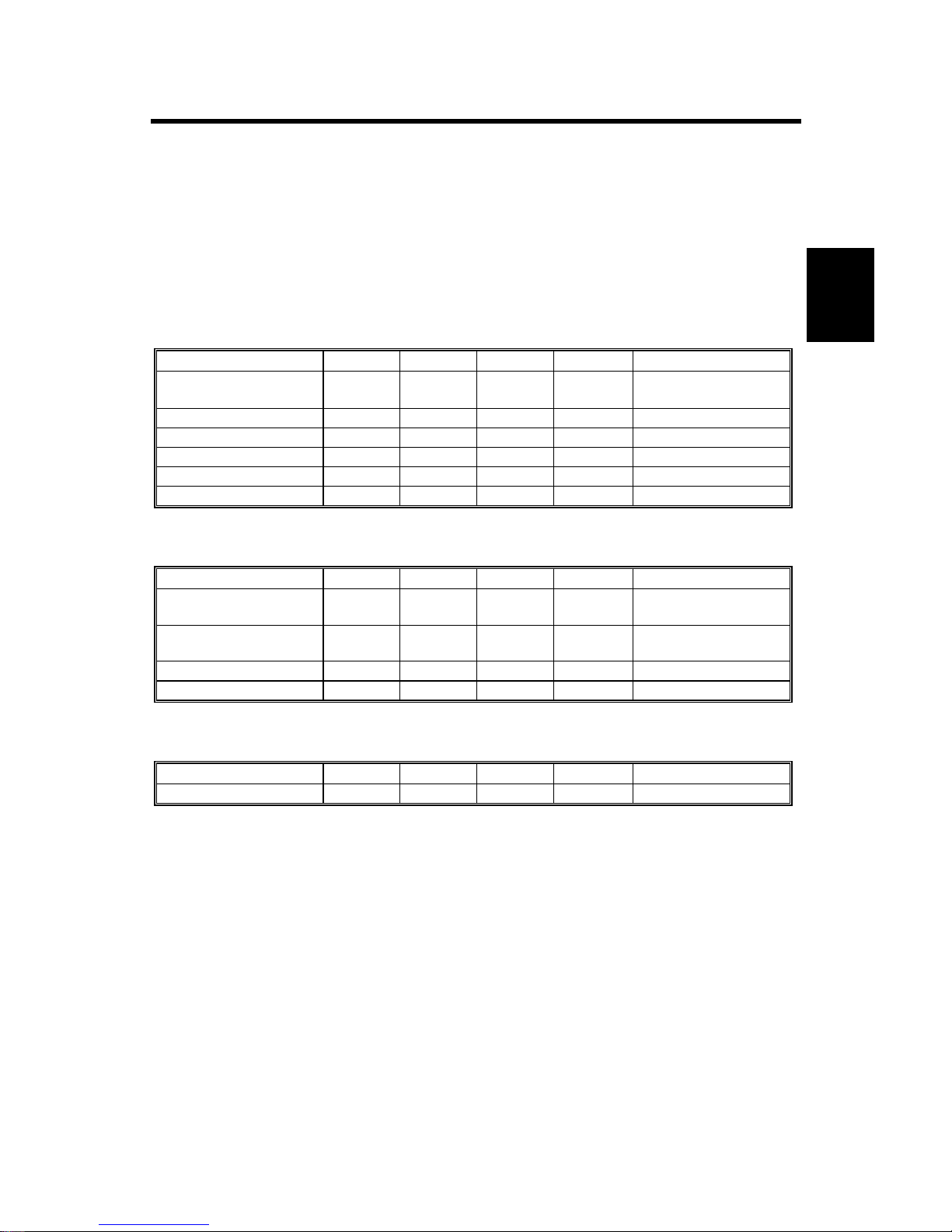

2.2 PM TABLE

Scanner/ADF

Item 30K 60K 120K 180K Notes

Pick-Up Roller Ass’y

(Including Feed Roller)

R (user) R (user) R (user) R (user) ADF Maintenance Kit

Reverse Roller R (user) R (user) R (user) R (user) ADF Maintenance Kit

Exposure Glass C (user) C (user) C (user) C (user) Soft cloth and water

R0, R1 and R2 Rollers C (user) C (user) C (user) C (user) Soft cloth and water

Pressure Roller C (user) C (user) C (user) C (user) Soft cloth and water

White Shading Plate C (user) C (user) C (user) C (user) Soft cloth and water

Printer

Item 30K 60K 120 180K Notes

Fusing Unit - R (user) R (user) R (user)

Fusing Maintenance

Kit

Transfer Roller - R (user) R (user) R (user)

Fusing Maintenance

Kit

Paper Feed Roller - - - R (FST)

Registration Roller - C (user) C (user) C (user) Soft cloth and water

Paper Feed Unit (Optional)

Item 30K 60K 120K 180K Notes

Feed Roller - - - R (FST)

FST: Field Service Technician

C: Clean, R: Replace

NOTE: After replacing a maintenance kit, make sure to reset the appropriate PM

counter through the Key Operator Tools menu (User Tools – Key Operator

Tools – System Settings – Reset PM Counter).

Page 31

14 June, 2002 EXTERNAL COVERS

3-1

Replacement

Adjustment

3. REPLACEMENT AND ADJUSTMENT

3.1 EXTERNAL COVERS

3.1.1 REMOVING THE ADF FRONT AND REAR COVERS

1. Open the ADF upper cover [A].

2. Remove the ADF front cover [B] (! x 2).

3. Remove the pick-up roller unit [C] by sliding the unit toward the back (toward

the spring-loaded end).

4. Remove the ADF rear cover [D] (! x 1).

3.1.2 REMOVING THE UPPER GUIDE PLATE

1. Remove the upper guide plate [A] (! x 4).

H310R001.WMF

H310R002.WMF

[A]

[B]

[C]

[D]

[A]

Page 32

EXTERNAL COVERS 14 June, 2002

3-2

3.1.3 REMOVING THE REAR COVER

1. Remove the optional connector cover [A] (! x 1).

2. Remove the rear cover [B] (! x 6).

H310R006.WMF

[A]

[B]

Page 33

14 June, 2002 EXTERNAL COVERS

3-3

Replacement

Adjustment

3.1.4 REMOVING THE OPERATION PANEL AND FRONT COVER

1. Remove the upper cover [A] (! x 2).

2. Remove the right cover [B] (! x 5).

3. Remove the front upper cover [C] (! x 2).

4. Remove the operation panel [D] (! x 3, " x 1).

5. Pull out the cassette [E].

6. Remove the front lower cover [F] (! x 5).

H310R003.WMF

H310R004.WMF

H310R005.WMF

[A]

[B]

[C]

[D]

[E]

[F]

Page 34

ADF/SCANNER SECTIONS 14 June, 2002

3-4

3.2 ADF/SCANNER SECTIONS

3.2.1 REPLACING THE PICK-UP ROLLER (PART OF THE ADF

MAINTENANCE KIT)

1. Open the ADF upper cover [A].

2. Remove the pick-up roller unit [B].

NOTE: Slide the unit toward the rear (toward the spring-loaded end). The front

bushings will detach and the unit can then be removed.

NOTE: If you install all parts in the ADF maintenance kit at the same time, be sure

to reset the PM counter (ADF).

3.2.2 REPLACING THE FEED ROLLER (PART OF THE ADF

MAINTENANCE KIT)

First, do the first two steps of the pick-up roller replacement procedure above.

1. Release the pick-up roller stopper [C] and pull the shaft toward the end with the

E-clip [D]. This will allow the pick-up roller to be removed.

2. Remove the three E-clips from the feed roller [E].

3. Release the roller clutch stoppers [F], pull out the shaft [G], and remove the

feed roller.

NOTE: If you install all parts in the ADF maintenance kit at the same time, be sure

to reset the PM counter (ADF).

H310R001.WMF

H310R025.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G]

Page 35

14 June, 2002 ADF/SCANNER SECTIONS

3-5

Replacement

Adjustment

3.2.3 REPLACING THE REVERSE ROLLER AND TORQUE

LIMITER (PART OF THE ADF MAINTENANCE KIT)

1. Remove the separation roller cover [A].

2. Remove the clip [B] and replace the reverse roller [C] and torque limiter [D].

NOTE: If you install all parts in the ADF maintenance kit at the same time, be sure

to reset the PM counter (ADF).

H310R050.WMF

H310R051.WMF

[A]

[B]

[C]

[D]

Page 36

ADF/SCANNER SECTIONS 14 June, 2002

3-6

3.2.4 REPLACING THE R0 ROLLER

1. Remove the ADF rear cover (☛ 3.1.1).

2. Remove the ADF front cover (☛ 3.1.1).

3. Remove the upper guide plate [A] (! x 4).

4. Remove the belt tension roller with spring plate [B] (! x 1).

5. Remove the belt [C].

6. Release the pawl that holds the pulley [D], and remove the pulley.

7. Slide the R0 roller [E] toward the rear and lift the roller out.

H310R002.WMF

H310R950.WMF

[A]

[B]

[C]

[D]

[E]

Page 37

14 June, 2002 ADF/SCANNER SECTIONS

3-7

Replacement

Adjustment

3.2.5 REPLACING THE R1, R2 AND DOCUMENT EXIT ROLLERS

1. Remove the ADF rear cover (☛ 3.1.1).

2. Remove the ADF front cover (☛ 3.1.1).

3. Remove the rear cover (☛ 3.1.3).

4. Remove the ADF lower cover [A] (! x 1).

5. Remove the belt [B].

6. Remove the scanner motor bracket and scanner motor [C] (! x 3).

H310R959.WMF

[A]

[B]

[C]

Page 38

ADF/SCANNER SECTIONS 14 June, 2002

3-8

7. Remove the white plate [D]. This is done by first sliding the plate toward the

front of the machine, then releasing and removing the rear pawl.

8. Remove the screw [E] that fastens the grounding strip.

9. Remove the guide plate [F] (! x 5).

10. Remove the gears [G], [H], [I], and [J] (first remove the gear pawls).

11. Remove the clips and bushings, followed by the R1 [K] and R2 [L] rollers, and

the exit roller [M].

H310R029.WMF

H310R953.WMF

[G]

[H]

[I]

[J]

[K]

[L]

[M]

[D]

[E]

[F]

Page 39

14 June, 2002 ADF/SCANNER SECTIONS

3-9

Replacement

Adjustment

3.2.6 REPLACING THE CIS (CONTACT IMAGE SENSOR)

(SCANNER)

1. With the ADF open, remove the R1 roller guide [A] (! x 2) and exit guide [B] (!

x 2).

2. Remove the CIS [C] (! x 2, " x 1).

H310R007.WMF

H310R008.WMF

[A]

[B]

[C]

Page 40

ADF/SCANNER SECTIONS 14 June, 2002

3-10

3.2.7 REMOVING THE STAMP UNIT

1. With the ADF open, remove the exit guide (! x 2) (☛ 3.2.6).

2. Replace the stamp unit (! x 1).

NOTE: When removing the stamp unit, ensure that ink does not leak out of it.

3.2.8 ADJUSTING THE SCANNING TOP MARGIN

To adjust the scanner home position, change the following RAM data. When the

value is increased (with respect to the default value), the image on the printed copy

moves down the page.

ADF scanning:

Address: 4049C4 to 4049C5 default value: 004FH Unit: 0.1 mm

Adjustable range: 0000 to 009EH

MDF scanning

Address: 4049C6 to 4049C7 default value: 004FH Unit: 0.1 mm

Adjustable range: 0000 to 009EH

H310R009.WMF

Page 41

14 June, 2002 LASER UNIT

3-11

Replacement

Adjustment

3.3 LASER UNIT

!

WARNING

Before attempting any of the procedures in this secti on, turn off the main

switch, unplug the machine, and remove the AIO cartridge. Laser beams

can seriously damage your eyes.

3.3.1 REPLACING THE LASER SYNCHRONIZATION DETECTOR

AND LD UNITS

1. Remove the exit guide (☛ 3.2.6).

2. Remove two brackets [A] (! x 1 each).

3. Remove the upper cover (☛ 3.1.4).

4. Remove the bracket [B] (! x 1).

5. Remove the LD unit [C] (! x 5, " x 3).

Loosen the two screws in the back of the machine by inserting a screwdriver

through the two openings.

DECAL6.WMF

H310R010.WMF

H310R011.WMF

[A]

[B]

[C]

Page 42

LASER UNIT 14 June, 2002

3-12

6. Remove the laser synchronization detector [A] (! x 1).

7. Remove the LD unit [B] (! x 1).

3.3.2 REPLACING THE POLYGON MOTOR

1. Remove the laser unit cover (! x 5).

2. Remove the polygon motor [A] (! x 4, " x 1).

H310R954.WMF

H310R955.WMF

[A]

[B]

[A]

Page 43

14 June, 2002 LASER UNIT

3-13

Replacement

Adjustment

3.3.3 ADJUSTING THE PRINTING SIDE-TO-SIDE REGISTRATION

Adjust the laser beam main scan start position when the offset is large. The

procedure is as follows:

1. Make copies using the mainframe cassette, bypass feeder, and optional paper

feed units and check the amount that the image is shifted.

2. Adjust by changing the contents of the following addresses:

Source Address Default Unit

Main Frame 402466 0002H 0.5 mm

1st Optional Unit 402468 0000H 0.5 mm

2nd Optional Unit 40246A 0000H 0.5 mm

3rd Optional Unit 40246C 0000H 0.5 mm

4th Optional Unit 40246E 0000H 0.5 mm

By-pass Feeder 402470 0004H 0.5 mm

3. To move the start position to the right, increase the value.

To move the start position to the left, decrease the value.

For example:

• To move the start position to the right 2 mm (with respect to the default

value):

0002H + (2 / 0.5) H = 0006H

• To move the start position to the left 1 mm (with respect to the default value):

0002H - (1 / 0.5) H = 0000H

Page 44

AIO CARTRIDGE 14 June, 2002

3-14

3.4 AIO CARTRIDGE

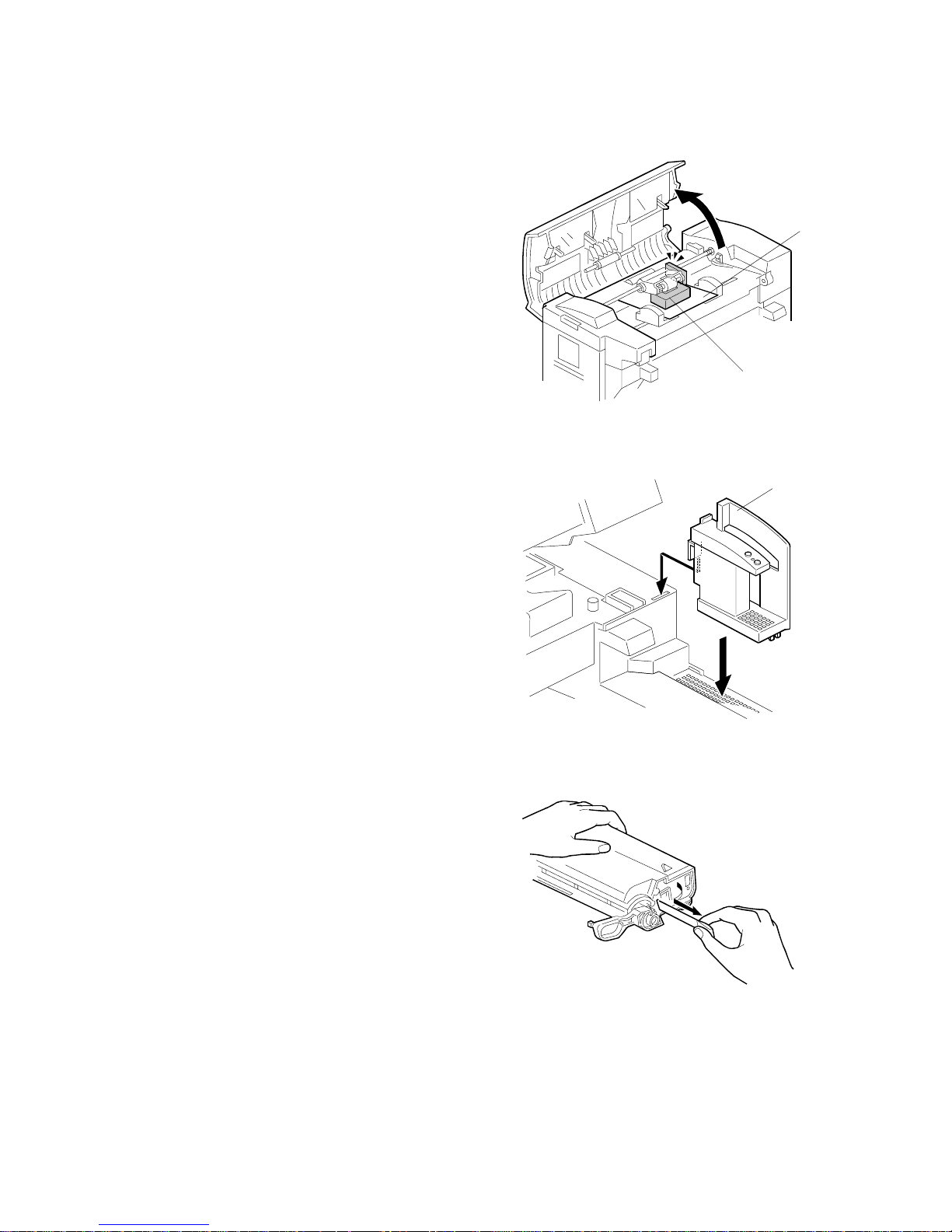

3.4.1 REPLACING THE AIO CARTRIDGE

1. Open the (mainframe) left cover [A].

2. Tilt the AIO cartridge [B] upward slightly (to prevent it from touching other parts)

and remove the unit from the machine.

H310R956.WMF

[A]

[B]

Page 45

14 June, 2002 AIO CARTRIDGE

3-15

Replacement

Adjustment

3.4.2 REPLACING THE TRANSFER ROLLER (PART OF THE

FUSING MAINTENANCE KIT)

1. Open the transfer roller cover [A] as shown in the illu stration (note the direction

of the arrow).

2. While holding both ends of the roller (by the green gears on each end), lift and

remove the roller [B].

NOTE: 1) Do not touch the surface of the roller. Oils from the skin stuck on the

roller surface may result in roller failure.

2) If you install all parts in the fusing maintenance kit at the same time,

be sure to clear the PM counter (Fusing Unit).

H310R966.WMF

[A]

[B]

Page 46

AIO CARTRIDGE 14 June, 2002

3-16

3.4.3 REPLACING THE POWER PACK

1. Remove the rear cover. (☛ 3.1.4)

2. Remove the power pack [A] (! x 2 , " x 4).

!CAUTION

When removing the power pack, make sure to first turn off the main power

and unplug the power cord. This is done to eliminate the risk of electrical

shock.

H310R957.WMF

[A]

Page 47

14 June, 2002 PAPER FEED AND REGISTRATION

3-17

Replacement

Adjustment

3.5 PAPER FEED AND REGISTRATION

3.5.1 REPLACING THE PAPER FEED ROLLER

1. Open the left cover [A].

2. Remove the guide plate [B] (! x 2).

3. Remove the paper feed rollers [C] (# x 2).

H310R036.WMF

H310R026.WMF

[C]

[A]

[B]

Page 48

PAPER FEED AND REGISTRATION 14 June, 2002

3-18

3.5.2 REPLACING THE REGISTRATION ROLLER

1. Remove the rear cover. (☛ 3.1.3.)

2. Loosen the screws for the paper feed drive bracket [A].

3. Release the small pawl on the tip of the clutch [B] and remove the clutch.

4. Release and rotate the collar [C], then remove it along with the bushing.

5. Open the left side cover.

6. Remove the registration guide plate [D].

7. Remove the clip [E] (rear side).

8. Slide the registration roller toward the rear (left in the illustration). Once the

front side is freed, pull it up toward you and remove the roller.

H310R021.WMF

[A]

[B]

[C]

[D]

[E]

Page 49

14 June, 2002 PAPER FEED AND REGISTRATION

3-19

Replacement

Adjustment

3.5.3 ADJUSTING THE PRINTING TOP MARGIN

Adjust the start position at the top of the page when the offset is large. The

procedure is as follows:

1. Make copies using the mainframe cassette, bypass feeder, and optional paper

feed units and check the amount that the image is shifted.

2. Adjust by changing the contents of the following addresses:

Source Address Default Unit

Main Frame 40245A FFFEH 0.5 mm

1st Optional Unit 40245C FFFCH 0.5 mm

2nd Optional Unit 40245E FFFCH 0.5 mm

3rd Optional Unit 402460 FFFCH 0.5 mm

4th Optional Unit 402462 FFFCH 0.5 mm

By-pass Feeder 402464 FFFCH 0.5 mm

3. To lower the start position, increase the default value.

To raise the start position, reduce the default value.

For example:

• To lower the start position by 2 mm (with respect to the default value):

0000H + (2 / 0.5) H = 0004H

Page 50

SENSORS 14 June, 2002

3-20

3.6 SENSORS

3.6.1 REPLACING THE ADF/MDF SENSORS AND SWITCHES

1. Open the ADF upper cover. (☛ 3.1.1.)

2. Remove the ADF front cover (! x 2).

3. Remove the pickup-roller unit.

4. Remove the ADF rear cover (! x 1).

5. Remove the upper guide plate (! x 4). (☛ 3.1.2.)

6. Release the pawls of the S1 [A], B4 [B], A3 [C] sensors (at the connector sides)

and remove the sensors (" x 1 each).

7. Release and remove the pawl located on the rear face of the ADF upper cover

switch [D] (" x 1).

H310R903.WMF

[A]

[B]

[C]

[D]

Page 51

14 June, 2002 SENSORS

3-21

Replacement

Adjustment

8. Remove the sensor bracket [A] (! x 1).

9. Remove the S2 sensor [B] (" x 1).

10. Remove the ADF lower cover (! x 1). (☛ 3.2.5.)

11. Remove the ADF unit switch [C] (" x 1).

12. Remove the rear cover (☛ 3.1.3).

13. Open the ADF unit.

14. Remove the ADF lower guide plate [D] (! x 4).

15. Release the MDF S1 [E], B4 [F], A3 [G] sensor pawls and remove the sensors

(" x 1 each).

NOTE: If the rear cover is not rem oved, damage will result when opening the

ADF.

H310R022-2.WMF

H310R904.WMF

[A]

[B]

[C]

[D]

[E]

[F]

[G]

Page 52

SENSORS 14 June, 2002

3-22

3.6.2 REPLACING THE PAPER-END LED BOARD AND PAPER

SIZE SENSOR SWITCH

1. Pull the paper feed tray.

2. Remove the cover [A] (! x1).

3. Remove the paper end LED board [B] (" x 1).

4. Remove the paper size sensor switch [C] (" x 1).

H310R911.WMF

[A]

[B]

[C]

Page 53

14 June, 2002 SENSORS

3-23

Replacement

Adjustment

3.6.3 REPLACING THE PAPER NEAR END SENSOR

1. Remove the paper feed tray (! x 2).

2. Remove the guide plate (! x 2)

3. Remove the paper near end sensor [A] (" x 1)

3.6.4 REPLACING THE UPPER LIMIT AND PAPER END SENSORS

1. Remove the paper feed tray (! x 2).

2. Remove the connectors attached to the upper limit sensor [A] and paper end

sensor [B].

3. Remove the screw that holds the sensor bracket [C] in place, and remove the

bracket by pulling downward.

4. Remove the sensors from the bracket.

H310R915.WMF

H310R914.WMF

[A]

[A]

[B]

[C]

Page 54

SENSORS 14 June, 2002

3-24

3.6.5 REPLACING THE AIO CARTRIDGE SENSOR

1. Remove the upper cover (! x 2). (☛ 3.1.4)

2. Remove the right cover (☛ 3.1.4).

3. Remove the screw that fastens the AIO cartridge sensor bracket [A].

4. Remove the AIO cartridge sensor [B] from the bracket (" x 1).

NOTE: This procedure is easier to perform if the AIO cartridge is first removed.

Be sure to put the AIO cartridge sensor back in the original position.

H310R907.WMF

[A]

[B]

Page 55

14 June, 2002 SENSORS

3-25

Replacement

Adjustment

3.6.6 REPLACING THE PAPER EXIT SENSOR

1. Remove the upper cover (! x 2). (☛ 3.1.4)

2. Remove the front upper cover (☛ 3.1.4)

3. Remove the connectors of the paper exit sensor.

4. While holding up the actuator [A] of the paper exit sensor, release the front

pawl and remove the paper exit sensor [B].

H310R905.WMF

[A]

[B]

Page 56

SENSORS 14 June, 2002

3-26

3.6.7 REPLACING THE TONER END SENSOR

1. Open the left cover [A].

2. Remove the AIO cartridge [B].

3. Remove the pawls on both sides of the toner end sensor [C] and remove the

sensor (" x 1).

H310R956.WMF

H310R958.WMF

[A]

[B]

[C]

Page 57

14 June, 2002 SENSORS

3-27

Replacement

Adjustment

3.6.8 REPLACING THE REGISTRATION SENSOR

1. Open the left cover.

2. Lift up the registration guide.

3. While the registration guide is held up, remove the sensor cover by releasing

the pawl of the registration sensor cover [A].

4. Release the pawl of the registration sensor and remove the sensor [B] from the

cover (" x 1).

H310R022.WMF

[A]

[B]

Page 58

FUSING UNIT 14 June, 2002

3-28

3.7 FUSING UNIT

3.7.1 REPLACING THE FUSING UNIT (PART OF THE FUSING

MAINTENANCE KIT)

1. Open the left cover [A].

2. Remove the stopper screw (green) located below the rear side lever [B]

(brown).

3. Push down levers [B].

4. Remove the fusing unit [C].

!CAUTION

1. Since the temperature of the fusing unit is very high, exercise caution

to avoid being burned.

2. If you install all parts in the fusing maintenance kit at the same time, be

sure to clear the PM counter (Fusing Unit).

H310R952.WMF

[A]

[B]

[C]

Page 59

14 June, 2002 FUSING UNIT

3-29

Replacement

Adjustment

3.7.2 DISASSEMBLING THE FUSING UNIT

1. Remove the fusing unit cover [A] (! x 2).

2. Remove two springs [B] and two support plates [C] (! x 2).

3. Disassemble the fusing unit (! x 2).

H310R013.WMF

H310R015.WMF

[A]

[A]

[B]

[C]

[B]

[C]

Page 60

FUSING UNIT 14 June, 2002

3-30

3.7.3 REPLACING THE PRESSURE ROLLER

1. Remove the two bushings [A], two metal levers [B] and the two levers [C].

2. Remove the pressure roller.

NOTE: The marked end of the roller [D] must be at the front side of the machine.

H310R017.WMF

H310R018.WMF

[A]

[B]

[C]

[D]

[B]

[A]

[C]

Page 61

14 June, 2002 FUSING UNIT

3-31

Replacement

Adjustment

3.7.4 REPLACING THE HOT ROLLER, FUSING LAMP, AND

THERMOFUSE

1. Remove the hot roller stripper springs and the grounding plate [A] (! x 1).

2. Remove the fusing lamp [B] (! x 2), bushings, and hot roller [C].

3. Remove the thermofuse [D] (! x 4).

H310R019.WMF

[A]

[B]

[C]

[D]

Page 62

FUSING UNIT 14 June, 2002

3-32

3.7.5 REPLACING THE THERMISTOR

1. Remove the cable terminal [A] (! x 3).

2. Remove the thermistor [B] (! x 1).

H310R028.WMF

[A]

[B]

Page 63

14 June, 2002 FUSING UNIT

3-33

Replacement

Adjustment

3.7.6 REPLACING THE HOT ROLLER STRIPPERS

1. Disconnect the springs [A].

2. Remove the two outer exit rollers [B].

3. Release the stoppers [C] and remove the hot roller strippers [D].

H310R020.WMF

[A]

[B]

[C]

[D]

Page 64

PCBS 14 June, 2002

3-34

3.8 PCBS

3.8.1 REPLACING THE PSU

1. Remove the rear cover. (☛ 3.1.3)

2. Lift the PSU [B] out of the machine (! x 5, " x 4, 1 grounding wire [A]).

!CAUTION

When removing the PSU, make sure to first turn off the main power and

unplug the power cord. This is done to eliminate the risk of electrical

shock.

H310R951.WMF

[A]

[B]

Page 65

14 June, 2002 PCBS

3-35

Replacement

Adjustment

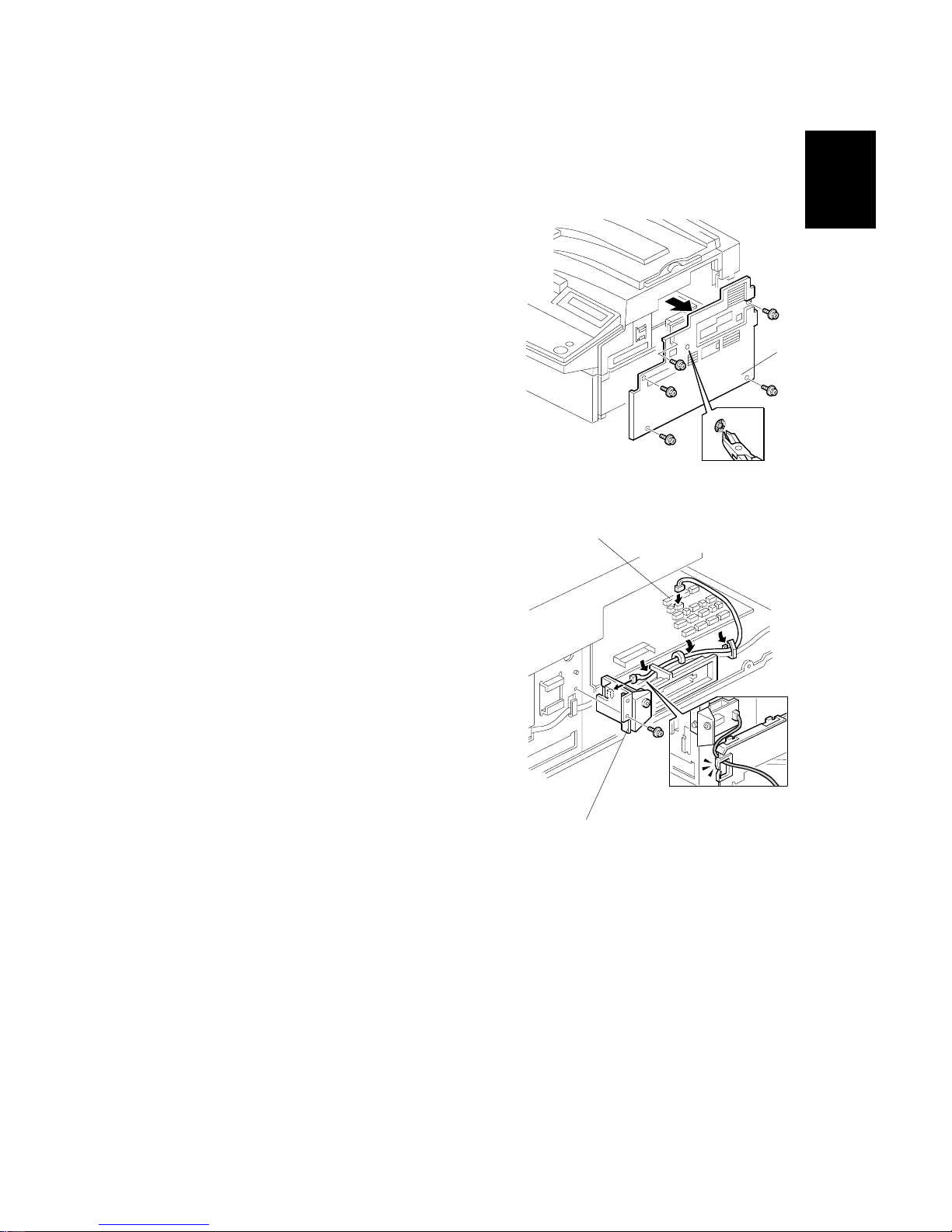

3.8.2 REPLACING THE OPIF/NCU/FCU

1. OPIF board

1. Remove the upper cover (☛ 3.1.4).

2. Remove the bracket cover [A] (! x 4).

3. Remove the bracket [B] (! x 4).

4. Remove the OPIF board [C] (! x 2).

H310R960.WMF

H310R961.WMF

H310R962.WMF

[A]

[B]

[C]

Page 66

PCBS 14 June, 2002

3-36

2. FCU and MBU boards

!CAUTION

Make sure to first turn off the main power and unplug the power cord. This

is done to eliminate the risk of electrical shock.

1. Remove the upper cover (☛ 3.1.4).

2. Disconnect the harnesses.

3. Remove the FCU board [A] (! x 4).

4. Remove the MBU board [B] from the old FCU and connect it to the new FCU.

If you have to replace the MBU, first try to upload the RAM data from the MBU to

an IC card, then try to download it to the new card after reassembling the machine.

Make sure that the battery switch on the MBU is at the ON position.

H310R023.WMF

[A]

[B]

Page 67

14 June, 2002 PCBS

3-37

Replacement

Adjustment

3. NCU board

!CAUTION

Make sure to first turn off the main power and unplug the power cord. This

is done to eliminate the risk of electrical shock.

1. Remove the rear cover (☛ 3.1.3).

2. Remove the relay connector bracket [A] (! x 1).

3. Remove the NCU board unit [B] (! x 3, " x 3).

H310R963.WMF

H310R964.WMF

[A]

[B]

Page 68

PCBS 14 June, 2002

3-38

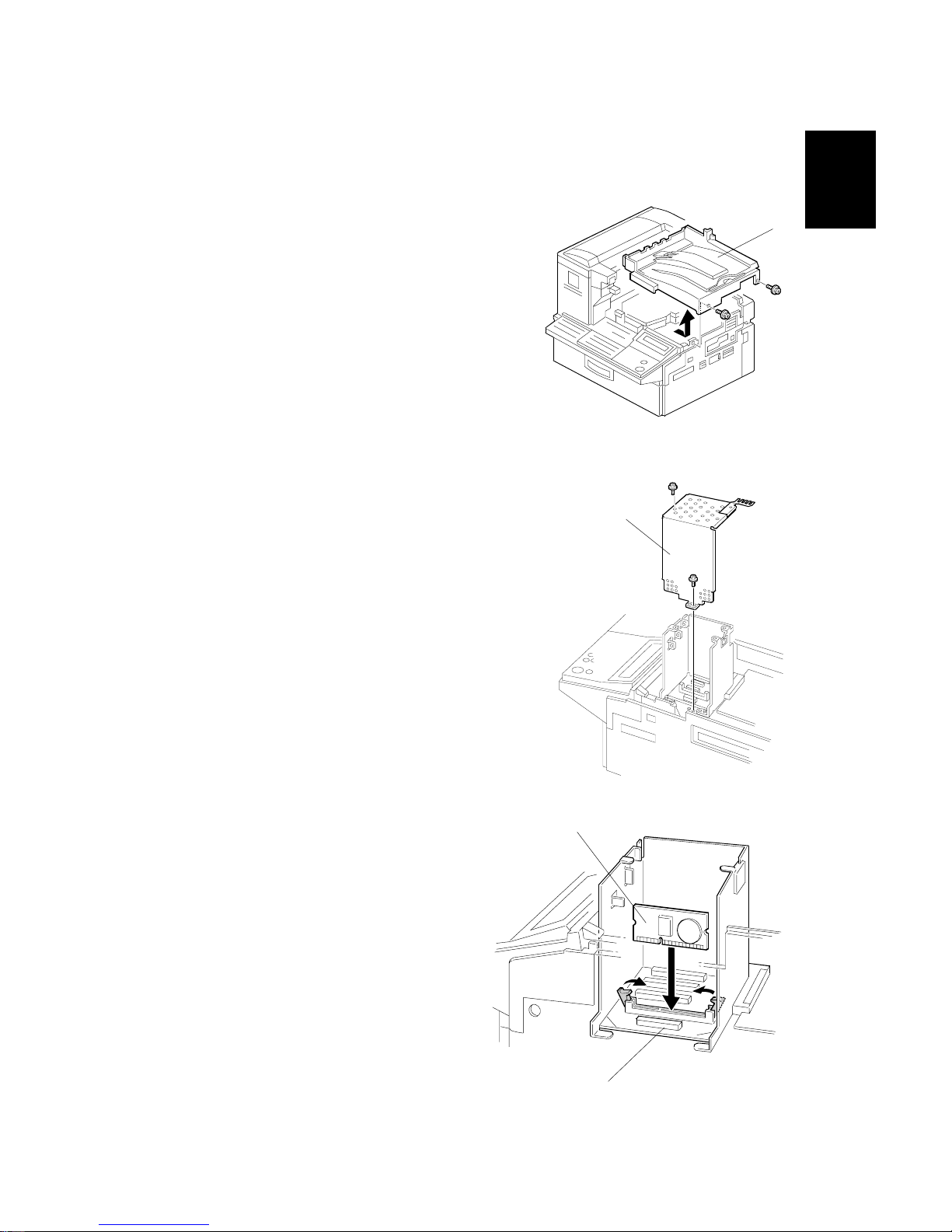

3.8.3 REPLACING THE LCD CONTROLLER AND LCD BOARD

1. Remove the upper cover (☛ 3.1.4).

2. Remove the operation panel (☛ 3.1.4).

3. Remove the LCD controller board [A] (! x 23).

4. Remove the LCD board [B] (! x 4, " x 2).

H310R012.WMF

[A]

[B]

Page 69

14 June, 2002 PCBS

3-39

Replacement

Adjustment

3.8.4 REPLACING THE POWER PACK

1 Remove the rear cover (☛ 3.1.3)

2 Remove the power pack [A] (! x 2, " x 4)

H310R957.WMF

[A]

Page 70

PCBS 14 June, 2002

3-40

3.8.5 REPLACING THE COOLING FAN

1. Replace the rear cover (☛ 3.1.3)

2. Remove the cooling fan [A] (! x 2, " x 1)

NOTE: The decal on the surface of the fan [B] must be at the rear side of the

machine.

H310R024.WMF

[A]

[B]

Page 71

14 June, 2002 BYPASS FEEDER UNIT

3-41

Replacement

Adjustment

3.9 BYPASS FEEDER UNIT

3.9.1 DIS ASSEMBLING THE BYPASS FEEDER UNITS

1. Remove the unit [A] (! x 2, " x 1, 1 grounding wire)

H310R030.WMF

[A]

Page 72

BYPASS FEEDER UNIT 14 June, 2002

3-42

3.9.2 REPLACING THE CLUTCH AND PAPER FEED ROLLER

1 Remove the spring and three clips.

2 Remove the clutch [A].

3 Remove the paper feed roller [B].

H310R035.WMF

H310R034.WMF

[A]

[B]

Page 73

14 June, 2002 BYPASS FEEDER UNIT

3-43

Replacement

Adjustment

3.9.3 REPLACING THE PAPER SIZE DETECTION SWITCH

1 Remove the bypass cover [A] (! x 3)

2 Remove the dial cover [B].

3 Remove the pin [C] and dial [D].

4 Remove the switch [E] (" x 1).

H310R032.WMF

[A]

[B]

[C]

[D]

[E]

Page 74

BYPASS FEEDER UNIT 14 June, 2002

3-44

3.9.4 REPLACING THE CONNECTOR AND PAPER END SENSOR

1 Disconnect the harness (" x 2).

2 Remove the connector [A].

3 Disconnect the harness (" x 1).

4 Remove the paper end sensor [B].

H310R033.WMF

H310R031.WMF

[A]

[B]

Page 75

14 June, 2002 DATA OR FIRMWARE DOWNLOAD/UPLOAD

3-45

Replacement

Adjustment

3.10 DATA OR FIRMWARE DOWNLOAD/UPLOAD

!

CAUTION

1. Make sure to turn the power off before in serting the IC card.

2. If the optional 40MB memory card (feature expander or fax on demand)

is installed, make sure to re-install it before turning the power on in

Step 7 below. Otherwise, programmed data may be lost.

If copying the firmware onto an IC card beforehand with MCE (Memory Card

Explorer),.please confirm that the start address and firmware file are as follows:

Firmware Start address Firmware file type

MBU (FCU) 0H *. bin

SG3

SiG4

NIC-F

JPEG

200000H *. rdt / *. mdt

Page 76

DATA OR FIRMWARE DOWNLOAD/UPLOAD 14 June, 2002

3-46

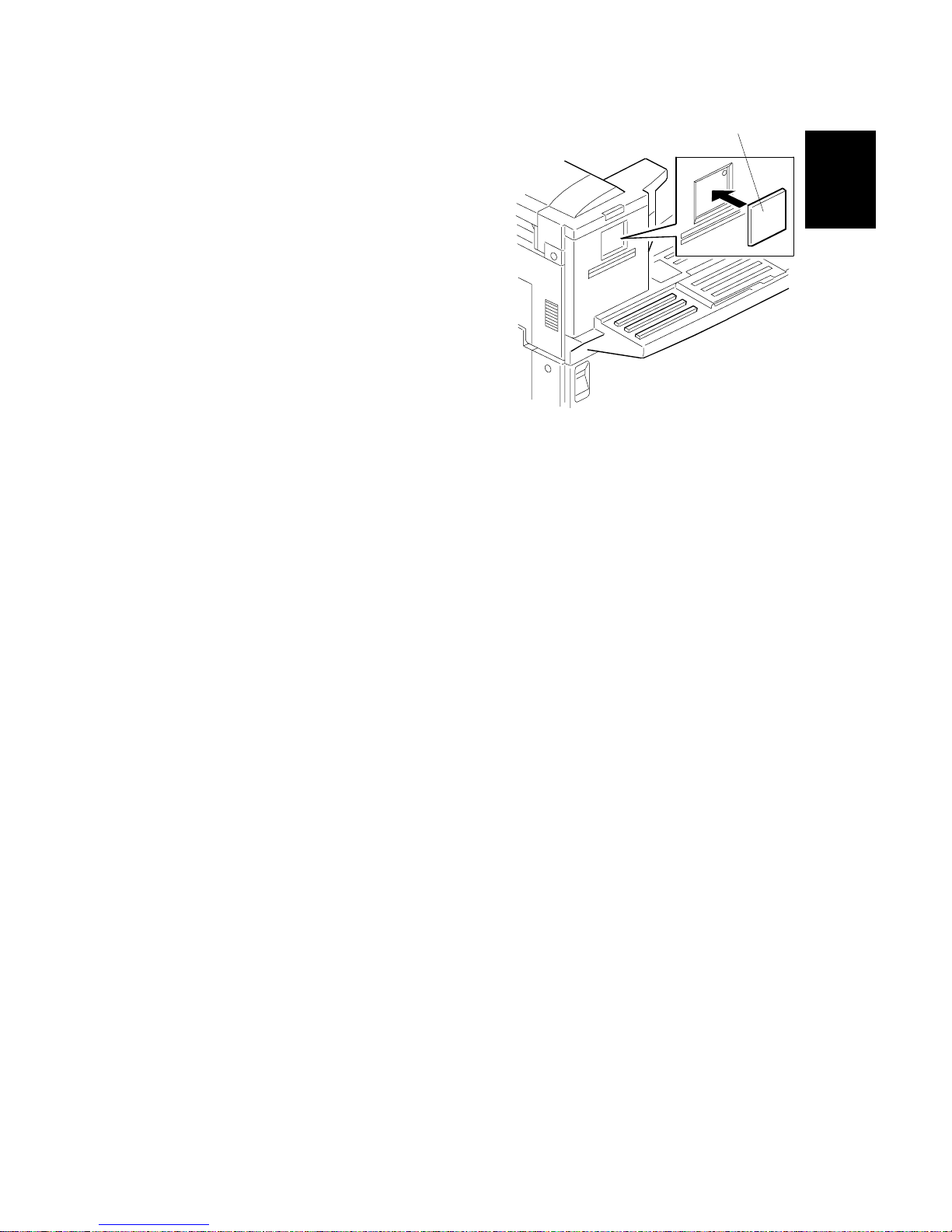

3.10.1 DATA COPY BETWEEN THE IC CARD AND MACHINE

Use the following procedure to copy data between the IC card and mainframe.

1. Turn the main power OFF. Then, insert the IC card into the IC card slot on right

side of the machine.

NOTE: The IC card should be oriented with the “A” side facing up, as shown.

2. Turn the main power ON.

If the menu does not appear, enter

service mode and use service function

12

3. Select the appropriate item.

NOTE: To copy optional firmware,

scroll down using the “DOWN”

key.

4. Press Start.

5. If “OK” is displayed, exit the function and turn the power OFF.

If “NG!!” is displayed, repeat from step 1.

6. Remove the IC card, re-insert the 40MB memory card (if present) and reattach

the small cover.

7. After uploading firmware: Turn the main power back ON and check the ROM

version in Service mode (Function 23).

H310R965.WMF

H310R501.BMP

H310R502.BMP

Page 77

14 June, 2002 COPY QUALITY TROUBLESHOOTING

4-1

Trouble-

shooting

4. TROUBLESHOOTING

4.1 COPY QUALITY TROUBLESHOOTING

If there is a copy quality problem that cannot be solved easily, try using the

following troubleshooting procedures, while referring to the point-to-point diagram.

The procedures may not be exhaustive, but they may help you to find the problem.

First, distinguish whether the problem is caused by the remote terminal or by your

machine. If your machine causes the problem, determine whether it is due to a

scanner or printer problem.

Is the print image

OK?

OK

NG

Is the image

received by fax

OK?

OK

Is the print image

OK?

OK

NGNG

Make a copy

Print a test pattern

Check the remote

terminal

Check the symptom again Check the scanner

Check the printer

H310T501.WMF

Page 78

COPY QUALITY TROUBLESHOOTING 14 June, 2002

4-2

4.1.1 BLANK COPIES

Possible Cause (Printer)

• Poor drum sensitivity.

• Laser optic components are out of position.

• The proper bias voltages are not applied to the development roller.

• The proper current is not applied to the transfer roller.

Action:

1. Print a test pattern, and open the cover in the middle of printing.

2. Check to see if there is toner adhered to the drum surface.

If there is, do the following. If not, go to step 3.

• Check to see if the cartridge is correctly installed.

• Check to see if the transfer roller is correctly positioned.

3. Check if there is toner on the surface of the development roller.

If there is, do the following. If not, go to step 4.

• Check to see if the laser optic components are properly positioned.

4. Check to see if the cartridge is empty. If it is, replace the cartridge.

If not, do the following.

• Check the connection between the FCU (CN15) and the toner end sensor

• Replace the toner end sensor.

4.1.2 BLACK COPIES

Possible Cause (Scanner)

• The contact image sensor.

Action:

1. Check the connection between the FCU (CN21) and the contact image sensor.

2. Replace the contact image sensor.

Possible Cause (Printer)

• The charge is incorrectly applied.

Action:

1. Check the connections between the power pack, the charge voltage terminals,

and the cartridge.

• If they are OK, go to step 2.

• If not, fix the connections.

2. Check the connections behind the power pack.

Page 79

14 June, 2002 COPY QUALITY TROUBLESHOOTING

4-3

Trouble-

shooting

4.1.3 DIRTY BACKGROUND

Possible Cause (Scanner)

• Scanner shading correction error

Action:

1. Clean the shading white plate.

2. Replace the contact image sensor if necessary.

Possible Cause (Printer)

• Poor drum sensitivity.

• The charge is incorrectly applied.

• The hot roller is dirty.

Action:

1. Try replacing the cartridge.

2. Check to see if the hot roller surface is dirty.

• If it is, clean the roller.

• If not, go to step 3.

3. Check to see if all the charge bias terminals and the cartridge.

• If they are, check or replace the power pack.

• If not, fix the connections.

H310T502.WMF

H310T503.WMF

Page 80

COPY QUALITY TROUBLESHOOTING 14 June, 2002

4-4

4.1.4 UNEVEN IMAGE DENSITY

Possible Cause (Scanner)

• Dirty exposure glass

• Partial scanner lamp defect

Action

• Clean the exposure glass of the contact image sensor.

• Replace the contact image sensor.

Possible Cause (Printer)

• Poor drum sensitivity.

• Dirty laser optic components.

• A deformed toner doctor blade.

• Uneven toner supply in the toner hopper.

Action:

1. Print a solid black test pattern, and open the cover in the middle of printing.

2. If the image is lighter in the center of the image, the toner may be low. Replace

the cartridge. If it is not, go to step 3.

3. Check to see if the toner is evenly distributed on the drum.

• If it is not, check the cartridge and the laser optic components.

• If it is, check if there is any dirt on the transfer roller surface.

H310T503.WMF

H310T504.WMF

Page 81

14 June, 2002 COPY QUALITY TROUBLESHOOTING

4-5

Trouble-

shooting

4.1.5 VERTICAL BLACK LINES

Possible Cause (Scanner)

• Dirt or dust on the exposure glass and/or optical mirror(s).

• Dirty white plate in the ADF.

• Defective contact image sensor.

Action:

1. Clean the exposure glass and the shading white plate.

2. Replace the contact image sensor

Possible Cause (Printer)

• Damaged cleaning blade.

• Dirty hot roller stripper(s).

Action:

1. Replace the cartridge.

2. Clean the hot roller strippers.

H310T503.WMF

H310T505.WMF

Page 82

COPY QUALITY TROUBLESHOOTING 14 June, 2002

4-6

4.1.6 HORIZONTAL BLACK LINES

Possible Cause (Printer)

• The drum surface is scratched or damaged.

Action:

1. Check to see if the surface of the drum is damaged.

• Change the cartridge if it is damaged.

H310T507.WMF

H310T506.WMF

Page 83

14 June, 2002 COPY QUALITY TROUBLESHOOTING

4-7

Trouble-

shooting

4.1.7 VERTICAL WHITE LINES

Possible Cause (Scanner)

• Dirty white plate in the ADF.

• Defective contact image sensor.

Action:

1. Clean the exposure glass and the shading white plate.

2. Replace the contact image sensor.

•

Possible Cause (Printer)

• The laser optic components are dirty.

• The hot roller stripper scrapes off toner from the print paper.

• Damaged cleaning blade.