Page 1

JP730

Page 2

Page 3

Introduction

This manual describes detailed instructions on the operation and notes about the use of this machine.

To get maximum versatility from this machine all operators are requested to read this manual carefully

and follow the instructions. Please keep this manual in a handy place near the machine.

Please read the Safety Information before using this machine. It contains important information related

to USER SAFETY and PREVENTING EQUIPMENT PROBLEMS.

Notes:

Some illustrations in this manual might be slightly different from the machine.

Certain options might not be available in some countries. For details, please contact your local dealer.

The model names of the machines do not appear in the following pages. Check the type of your machine before reading this manual.

• LG drum: Not Available

• B4 drum: 6123cp

Certain types might not be available in some countries. For details, please contact your local dealer.

Two kinds of size notation are employed in this manual. With this machine refer to the metric version.

For good print quality, the supplier recommends that you use genuine masters and ink from the supplier.

The supplier shall not be responsible for any damage or expense that might result from the use of parts

other than genuine parts from the supplier with your office products.

Power Source

220 – 240V, 50/60Hz, 1.3A or more

Please be sure to connect the power cord to a power source as above. For details about power source,

see p.67 “Power Connection”.

For safety, please read this manual carefully before you use this product and keep it handy for future

reference.

Page 4

Declaration of Conformity

“The Product complies with the requirements of the EMC Directive 89/336/EEC and its amending directives and the Low Voltage Directive 73/23/EEC and its amending directives.”

In accordance with IEC 60417, this machine uses the following symbols for the main switch:

aaaa means POWER ON.

bbbb means POWER OFF.

Copyright © 2002

Page 5

TABLE OF CONTENTS

Safety Information .................................................................................................1

Safety During Operation.............................................................................................1

How to Read this Manual ......................................................................................3

What You Can Do with this Machine....................................................................4

Machine Exterior....................................................................................................6

Machine Interior .....................................................................................................7

Control Panel..........................................................................................................8

Keys ...........................................................................................................................8

Indicators....................................................................................................................9

1. Operation

Printing Paper ......................................................................................................11

Originals ...............................................................................................................12

Printing Preparations ..........................................................................................13

Loading Paper..........................................................................................................13

Preparing the Paper Delivery Tray...........................................................................14

Standard Printing.................................................................................................15

After Printing........................................................................................................17

Adjusting the Print Image Position....................................................................18

Shifting the Print Image Position Forwards or Backwards .......................................18

Shifting the Print Image Position to the Right or Left ...............................................19

Adjusting the Print Image Density .....................................................................20

Before Making a Master...........................................................................................20

After Making a Master..............................................................................................20

Changing the Printing Speed..............................................................................21

Stopping the Machine during the Multi-print Run ............................................22

When You Want to Stop the Machine during the Multi-print Run and Print the Next Original

When You Want to Change the Number of Prints Entered or Check the Completed Prints

Preset Reduce/Enlarge—Reducing and Enlarging Using Preset Ratios........ 23

Printing on Different Types of Paper Thickness...............................................25

Feed Roller Pressure Lever .....................................................................................25

Separation Pressure Lever ......................................................................................26

Selecting Original Type.......................................................................................27

Auto Cycle—Processing a Master and Making Prints in One Step................. 28

Combine—Combining Two Originals onto One Print ......................................29

...22

...22

2. Optional Functions

Colour Printing Using the Optional Colour Drum.............................................33

Making Colour Prints................................................................................................33

Changing the Colour Drum Unit...............................................................................34

Printing in Two Colours............................................................................................35

i

Page 6

3. Replenishing Supplies

Loading Paper into the Paper Feed Tray...........................................................37

Replenishing Paper..................................................................................................37

Changing the Paper Size .........................................................................................38

When the Add Ink Indicator (jjjj) Lights .............................................................39

Master Roll Replacement .................................................................................... 41

4. Troubleshooting

If Your Machine does not Operate as You Want...............................................43

xxxx Clearing Misfeeds ...........................................................................................45

When “x” and “P” light up .......................................................................................46

When “x”, “B” and “A” light up...............................................................................47

When “x” and “B” light up .......................................................................................48

When “x” and “C” light up.......................................................................................50

When “x” and “D” light up.......................................................................................52

When “x” and “E” light up .......................................................................................53

When the Open Cover/Unit Indicator (MMMM) Lights..............................................55

When the Master Eject Indicator (kkkk) Lights .....................................................57

Poor Printing ........................................................................................................58

Dirt on the Back Side of Paper.................................................................................58

Dirt on the Front Side of Paper (Black Line/Stain) ...................................................60

White Prints or Incomplete Prints.............................................................................61

5. Remarks

Operation Notes...................................................................................................63

General Cautions .....................................................................................................63

Print Paper ...............................................................................................................65

Originals...................................................................................................................65

Where to Put Your Machine................................................................................66

Environmental Conditions ........................................................................................66

Power Connection....................................................................................................67

Access to Machine ...................................................................................................67

Maintaining Your Machine ..................................................................................68

Document Feeder ....................................................................................................68

Paper Feed Roller (paper feed tray) ........................................................................68

Combination Chart...............................................................................................69

6. Specifications

Main Frame...........................................................................................................71

Consumables .......................................................................................................74

INDEX......................................................................................................... 75

ii

Page 7

Safety Information

R

R

When using this machine, the following safety precautions should always be followed.

Safety During Operation

In this manual, the following important symbols are used:

WARNING:

CAUTION:

Indicates a potentially hazardous situation which, if instructions

are not followed, could result in death or serious injury.

Indicates a potentially hazardous situation which, if instructions are not

followed, may result in minor or moderate injury or damage to property.

R WARNING:

• Connect the power cord directly into a wall outlet and never use an extension cord.

•

Disconnect the power plug (by pulling the plug, not the cable) if the

power cable or plug becomes frayed or otherwise damaged.

• To avoid hazardous electric shock, do not remove any covers or

screws other than those specified in this manual.

• Turn off the power and disconnect the power plug (by pulling the plug,

not the cable) if any of the following occurs:

• You spill something into the machine.

• You suspect that your machine needs service or repair.

• The external housing of your machine has been damaged.

1

Page 8

R CAUTION:

• Protect the machine from dampness or wet weather, such as rain, snow.

• Unplug the power cord from the wall outlet before you move the machine.

While moving the machine, you should take care that the power cord will not

be damaged under the machine.

• When you disconnect the power plug from the wall outlet, always pull the

plug (not the cable).

• Do not allow paper clips, staples, or other small metallic objects to fall inside

the machine.

• For environmental reasons, do not dispose of the machine or expended

supply waste at household waste collection points. Disposal can take place

at an authorized dealer.

• Be careful not to cut yourself on any sharp edges when you reach inside the

machine to remove misfed sheets of paper or masters.

• Our products are engineered to meet high standards of quality and functionality, and we recommend that you use only the expendable supplies available at an authorized dealer.

2

Page 9

How to Read this Manual

R

R

Symbols

In this manual, the following symbols are used:

WARNING:

This symbol indicates a potentially hazardous situation that might result in

death or serious injury when you misuse the machine without following the instructions under this symbol. Be sure to read the instructions, all of which are described in the Safety Information section.

CAUTION:

This symbol indicates a potentially hazardous situation that might result in minor or moderate injury or property damage that does not involve personal injury

when you misuse the machine without following the instructions under this

symbol. Be sure to read the instructions, all of which are described in the Safety

Information section.

* The statements above are notes for your safety.

Important

If this instruction is not followed, paper might be misfed, originals might be

damaged, or data might be lost. Be sure to read this.

Preparation

This symbol indicates the prior knowledge or preparations required before operating the machine.

Note

This symbol indicates precautions for operation, or actions to take after misoperation.

Limitation

This symbol indicates numerical limits, functions that cannot be used together,

or conditions in which a particular function cannot be used.

Reference

This symbol indicates a reference.

[]

Keys that appear on the machine's display panel.

{}

Keys built into the machine's control panel.

3

Page 10

What You Can Do with this Machine

Below is a quick summary of this machine's features and where to look in this

manual for more information.

❖❖❖❖ Standard Printing

See p.15 “Standard Printing”.

❖❖❖❖ Adjusting the Print Image Position

See p.18 “Adjusting the Print Image Position”.

❖❖❖❖ Adjusting the Print Image Density

See p.20 “Adjusting the Print Image Density”.

❖❖❖❖ Changing the Print Speed

See p.21 “Changing the Printing Speed”.

❖❖❖❖ Reducing and Enlarging Using Preset Ratios

See p.23 “Preset Reduce/Enlarge—Reducing and Enlarging Using Preset Ratios”.

GRREDU0E

❖❖❖❖ Printing on Thick or Thin Paper

See p.25 “Printing on Different Types of Paper Thickness”.

❖❖❖❖ Selecting Original Type

See p.27 “Selecting Original Type”.

❖❖❖❖ Printing from Several Originals at Once

See p.28 “Auto Cycle—Processing a Master and Making Prints in One Step”.

4

GRENLA0E

Page 11

❖❖❖❖ Combining Originals onto One Print

See p.29 “Combine—Combining Two Originals onto One Print”.

BA AB

ZCTX040E

❖❖❖❖ Making Colour Prints

See p.33 “Making Colour Prints”.

❖❖❖❖ Printing in Two Colours

See p.35 “Printing in Two Colours”.

5

Page 12

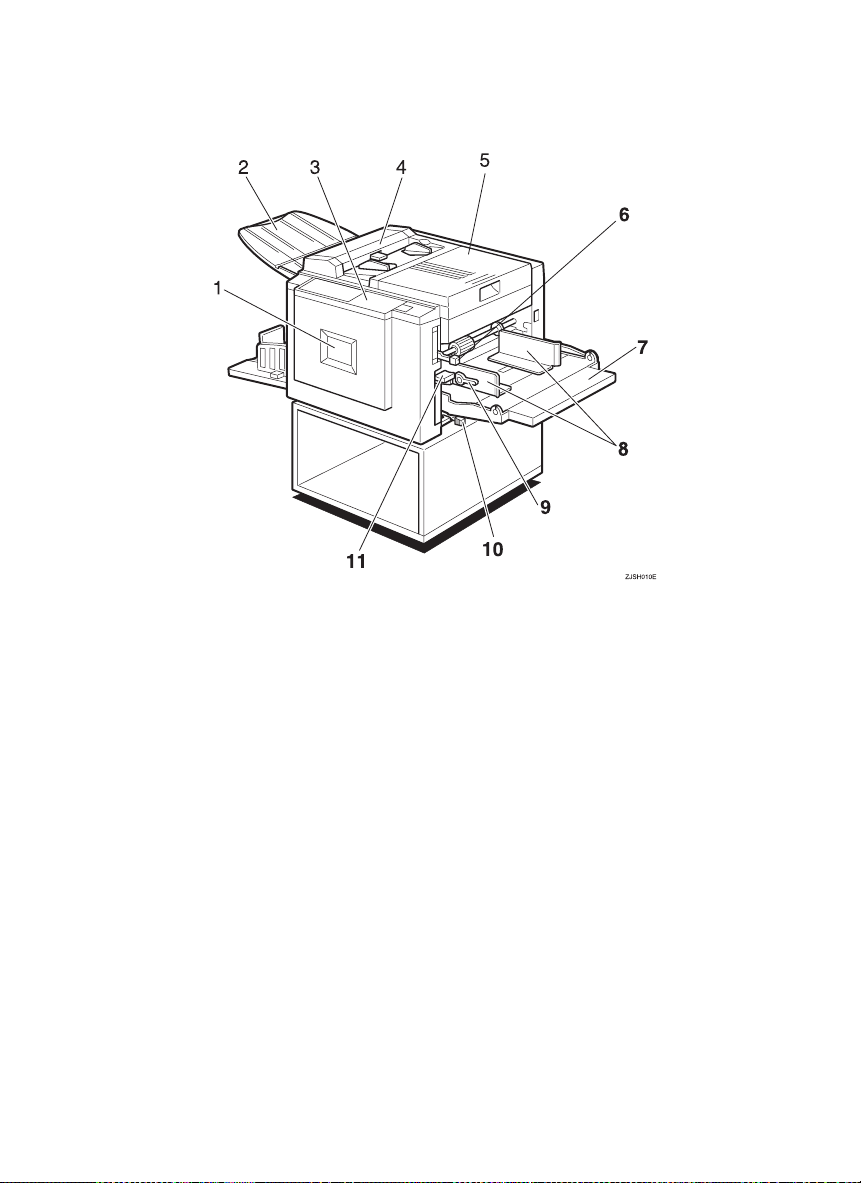

Machine Exterior

1.

Front door

Open for access to the inside of the machine.

2.

Original delivery tray

The scanned original is delivered here.

3.

Control panel

Operator controls and indicators are located here. See p.8 “Control Panel”.

4.

Document feeder cover

Open this cover to clean the document

feeder.

5.

Right side cover

Open to replace the master roll or to clear

a master misfeed.

6

6.

Feed roller pressure lever

Use to adjust the contact pressure of the

paper feed roller according to the paper

thickness.

7.

Paper feed tray

Set paper on this tray for printing.

8.

Paper feed side plates

Use to prevent paper skew.

9.

Paper feed side plate lock levers

Use to lock or unlock the paper feed side

plates.

10.

Separation pressure lever

Use to prevent double-feed.

11.

Paper feed tray adjustment lever

Use to move the paper feed tray up or

down.

Page 13

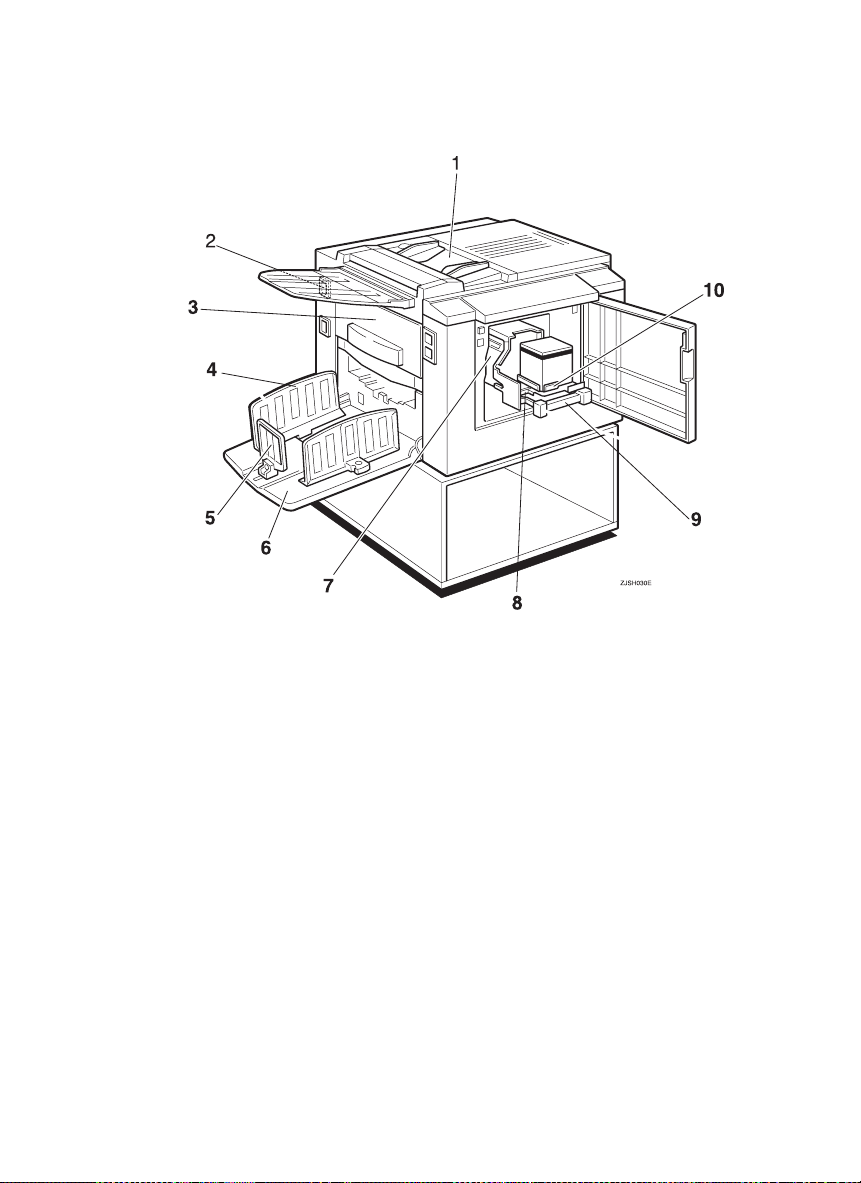

Machine Interior

1.

Document feeder

Place the original in the document feeder

one sheet at a time.

2.

Main switch

Use to turn the power on or off.

3.

Master eject box

Used masters are stored here.

4.

Paper delivery side plates

Use to align the prints on the paper delivery tray.

5.

Paper delivery end plate

Use to align the leading edge of prints.

6.

Paper delivery tray

Completed prints are delivered here.

7.

Drum unit

The master is wrapped around this unit.

8.

Ink holder lock lever

Release this lever in order to pull out the

ink holder.

9.

Drum unit lock lever

Lift to unlock and pull out the drum unit.

10.

Ink holder

Set the ink cartridge in this holder.

7

Page 14

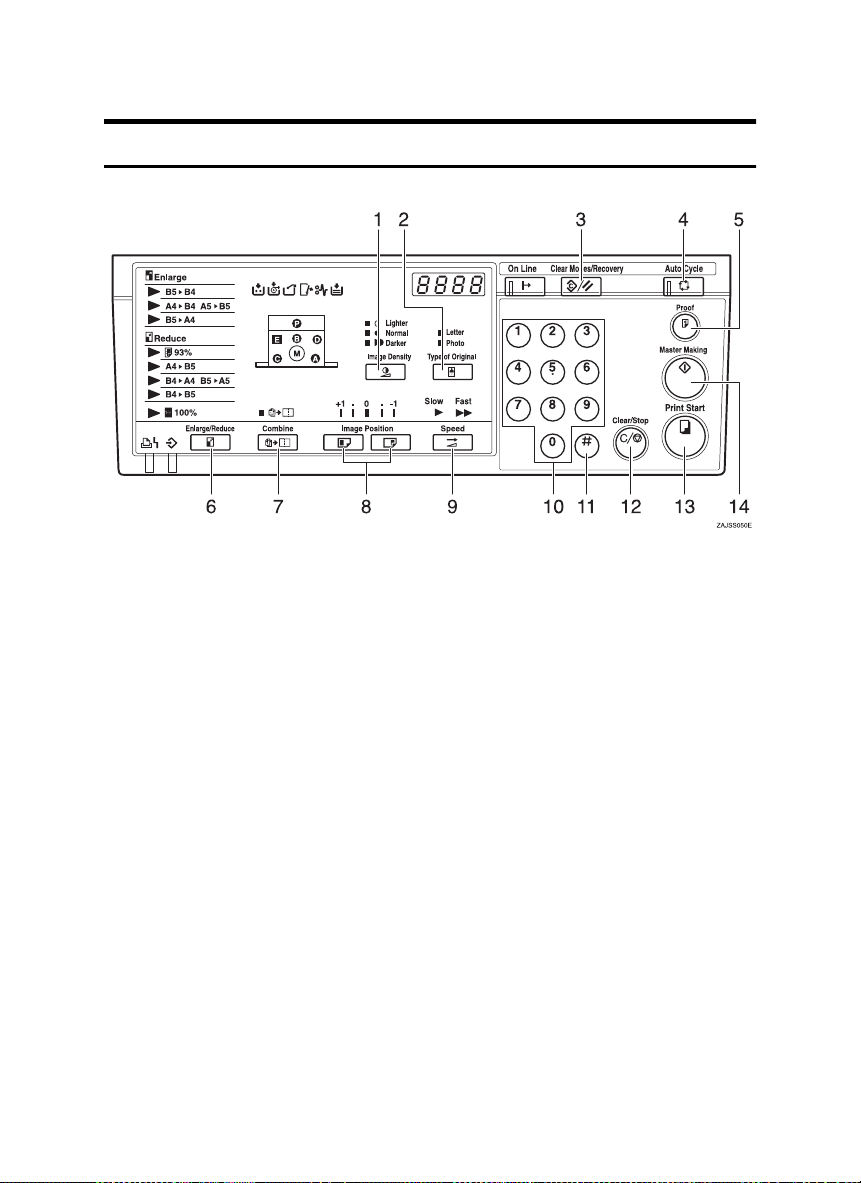

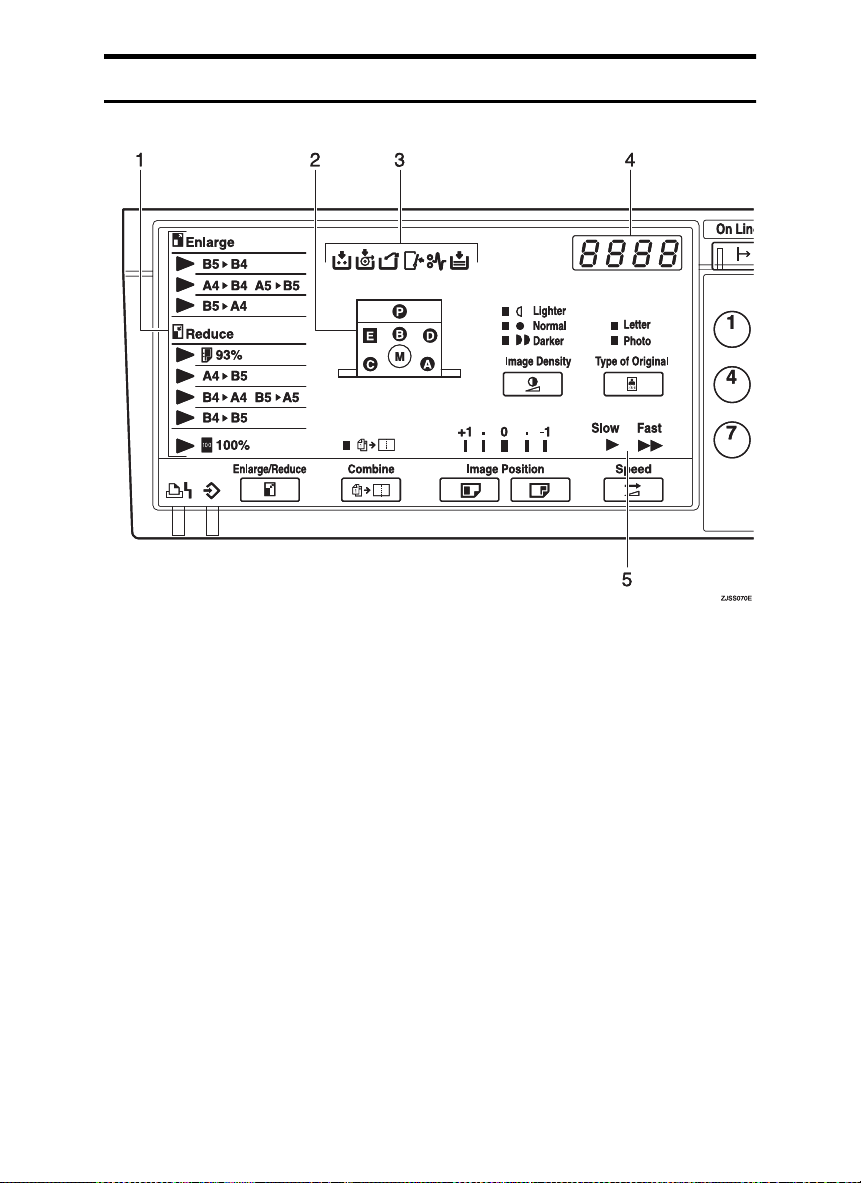

Control Panel

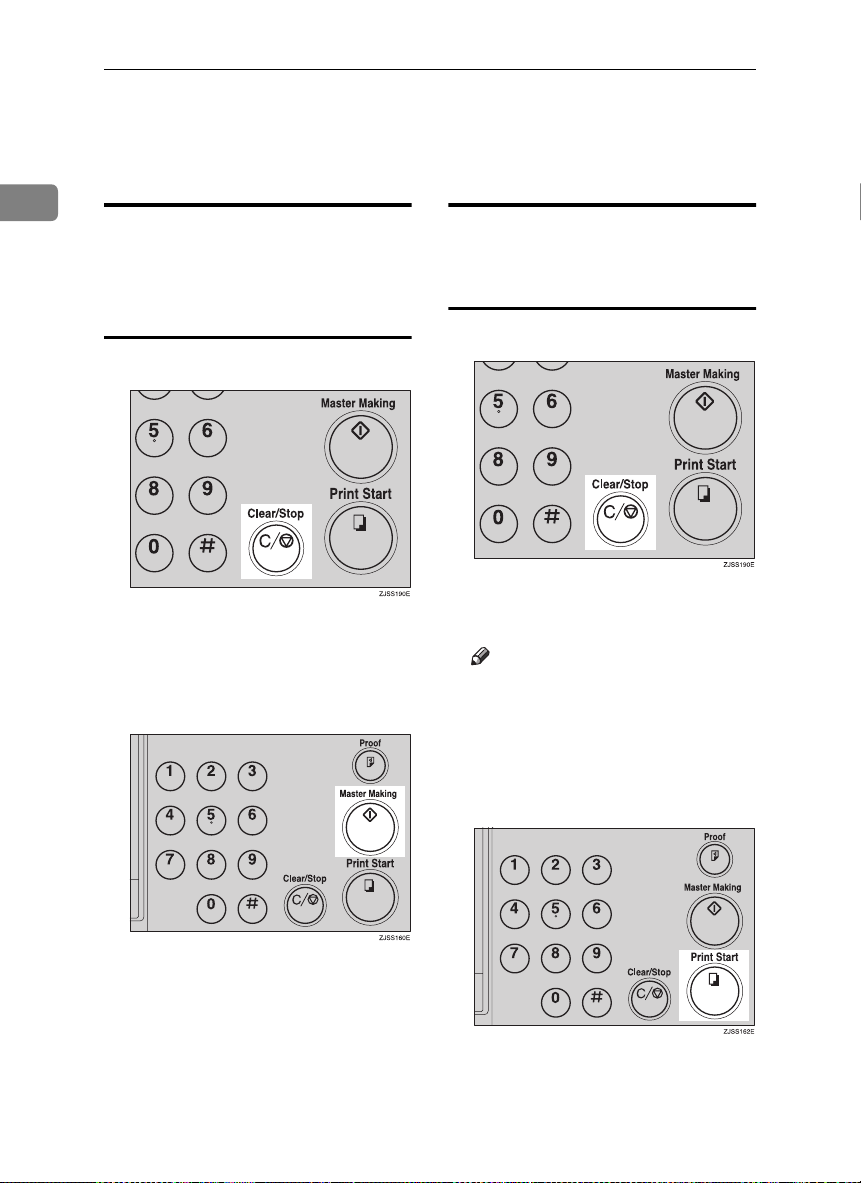

Keys

1.

{{{{Image Density}}}} key

Press to make prints darker or lighter. See

p.20 “Adjusting the Print Image Density”.

2.

{{{{Type of Original}}}} key

Press to select Letter or Photo mode. See

p.27 “Selecting Original Type”.

3.

{{{{Clear Modes/Recovery}}}} key

• Clear Modes

Press to clear the previously entered

job settings.

• Recovery

Press to reset the error indicators after

clearing a misfeed. See p.45 “x Clearing Misfeeds”.

4.

{{{{Auto Cycle}}}} key

Press to process the master and make

prints automatically. See p.28 “Auto Cycle—Processing a Master and Making

Prints in One Step”.

5. {

{Proof}}}} key

{{

Press to make proof prints.

6.

{{{{Enlarge/Reduce}}}} key

Press to enlarge or reduce the image. See

p.23 “Preset Reduce/Enlarge—Reducing

and Enlarging Using Preset Ratios”.

8

7.

{{{{Combine}}}} key

Press to combine originals onto one print.

See p.29 “Combine—Combining Two

Originals onto One Print”.

8.

{{{{Image Position}}}} keys

Press to shift the image forwards or backwards. See p.18 “Adjusting the Print Image Position”.

9.

{{{{Speed}}}} key

Pres s to selec t Fast or Slow f or you r prin ting speed. See p.21 “Changing the Printing Speed”.

10.

Number keys

Press to enter the desired number of

prints and data for selected modes.

11.

{{{{qqqq}}}} key

Press to enter data in selected modes.

12.

{{{{Clear/Stop}}}} key

Press to cancel a number you have entered or to stop printing.

13.

{{{{Print Start}}}} key

Press to start printing.

14. {

{Master Making}}}} key

{{

Press to make a master.

Page 15

Indicators

1.

Magnification indicators

Show the preset magnification ratio selected. See p.23 “Preset Reduce/Enlarge—Reducing and Enlarging Using

Preset Ratios”.

2.

Machine indicators

Show the jammed area with the x indicator. See p.45 “x Clearing Misfeeds”.

Show the cover/unit that is opened with

the M indicator. See p.55 “When the

Open Cover/Unit Indicator (M) Lights”.

3.

Error indicators

Show errors and machine status.

j: Add Ink indicator

See p.39 “When the Add Ink Indicator

(j) Lights”.

C: Master End indicator

See p.41 “Master Roll Replacement”.

k: Master Eject indicator

See p.57 “When the Master Eject Indica-

tor (k) Lights”.

M: Open Cover/Unit indicator

See p.55 “When the Open Cover/Unit In-

dicator (M) Lights”.

x: Misfeed indicator

See p.45 “x Clearing Misfeeds”.

B: Load Paper indicator

See p.37 “Loading Paper into the Paper

Feed Tray”.

4.

Counter

Displays the number of prints entered.

While printing, it shows the number of

prints remaining.

5.

Speed indicators

Shows the printing speed selected.

9

Page 16

10

Page 17

1. Operation

Printing Paper

The following types of print paper are not recommended for this machine.

• Paper smaller than 90 mm × 140 mm, 3.6" × 5.6"

• Paper larger than 275 mm × 395 mm, 10.8" ×15.6"

• Paper heavier than 127.9 g/m

• Paper lighter than 35 g/m

• Roughly-cut paper

• Paper of different thickness in the same stack

• Buckled or curled paper

• Low stiffness paper

Correct curls in the paper before setting it in the machine. When you cannot correct the paper curl, stack the paper with the curl face down. Otherwise the paper

might wrap around the drum or stains might appear.

Store paper where it will not curl or absorb moisture. Use paper soon after it is

unpacked.

Only use paper where the leading edge has two right angle corners, as shown

below.

2

2

, 9.3 lb

, 34.0 lb

GRPRIN0E

11

Page 18

Operation

Originals

Note

1

❒ Originals that can be set in the document feeder are as follows:

• Maximum size: 275 × 395 mm, 10.8" × 15.6"

• Minimum size: 90 × 140 mm, 3.6" × 5.6"

• Maximum weight: 127.9 g/m

• Minimum weight: 40.7 g/m

❒ If you are printing from originals that have bold letters or solid images at the

leading edges, you may get prints with dirty edges. In this case, insert the

widest margin first, or raise the printing speed.

❒ The first 5 mm, 0.2" of the leading edge cannot be printed. Make sure the lead-

ing edge margin is at least 5 mm, 0.2".

Original Print

❒ a: 5 mm, 0.2"

2

, 34.0 lb

2

, 10.8 lb

a

12

Page 19

Printing Preparations

Loading Paper

Lower the paper feed tray adjust-

AAAA

ment lever.

Release the paper feed side plate

BBBB

lock levers and adjust the side

plates to match the paper size.

Printing Preparations

Load paper into the paper feed

CCCC

tray.

Note

❒ Correct the paper curl before

setting the paper. If you cannot

do so, stack the paper with the

curl face down as shown.

1

1: Paper Feed Side Plate Lock Levers

13

Page 20

Operation

Make sure that the paper feed

DDDD

side plates touch the paper lightly. Shift the lock levers back to

their original positions.

1

Shift the tray adjustment lever to

EEEE

the paper feeding position.

Note

❒ Before you start printing, the

paper feed tray must be aligned

with the feeding position. If not,

a paper misfeed might occur.

Preparing the Paper Delivery

Tray

Adjust the paper delivery side

AAAA

plates to match the paper size.

Adjust the paper delivery end

BBBB

plate to match the paper size.

14

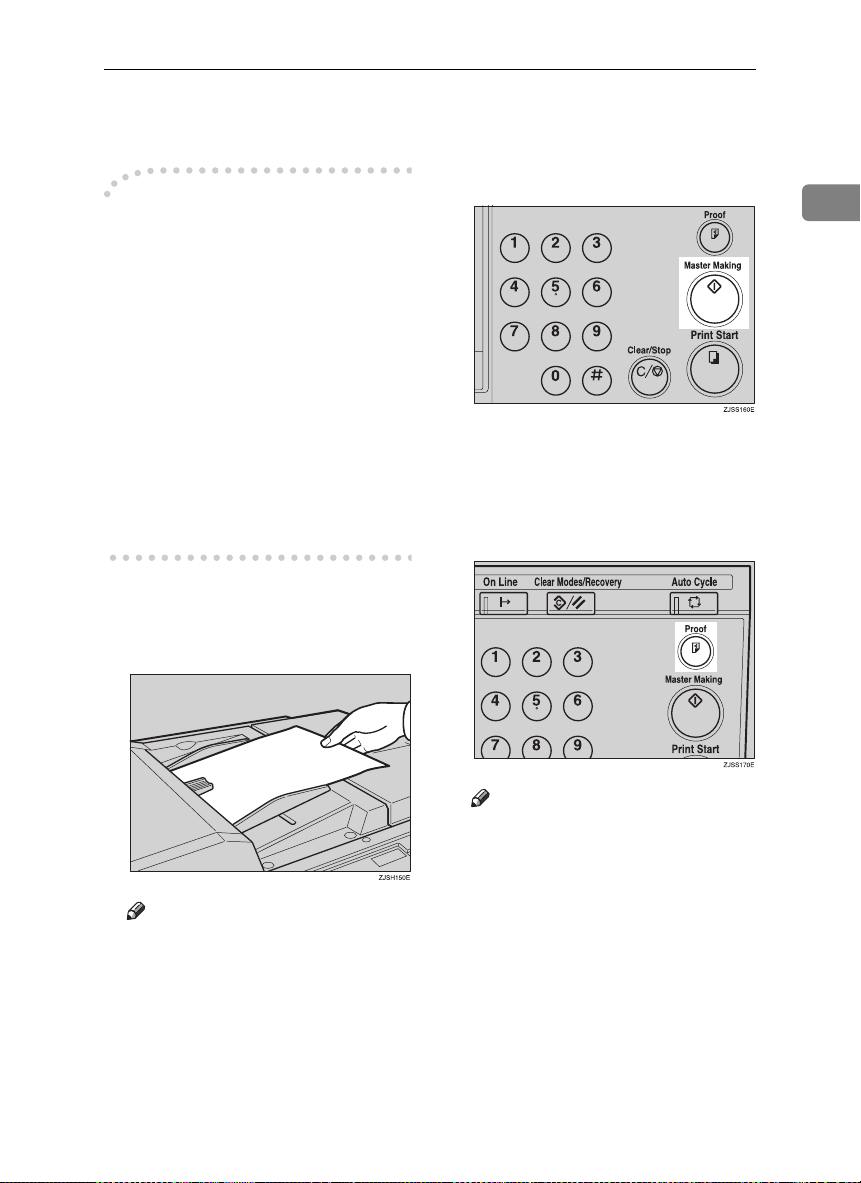

Turn on the main switch.

CCCC

Page 21

Standard Printing

----Printing

In this manual, the word, “printing”

is used as opposed to “copying” in order to distinguish between the process that your machine uses to make

prints, and the process used by a

standard copier machine.

A standard copier scans in the original for each copy set made. This machine, however, scans in your original

once and makes multiple prints from

this master.

This chapter describes the basic printing operations that your machine is

capable of.

Place the original face down in

AAAA

the document feeder. Adjust the

original side guides to match the

size of the original.

Standard Printing

Press the {{{{Master Making}}}} key.

BBBB

A trial print is delivered to the paper delivery tray.

Press the {{{{Proof}}}} key and check

CCCC

the image density and image position on the proof print.

1

Note

❒ You can only place one original

at a time.

Note

❒ If the image position is not cor-

rect, adjust it using the {{{{Image

Position}}}} keys. See p.18 “Adjust-

ing the Print Image Position”.

❒ If the image density is too dark

or too light, adjust the image

density using the {{{{Image Densi-

ty}}}} key. See p.20 “Adjusting the

Print Image Density”.

15

Page 22

Operation

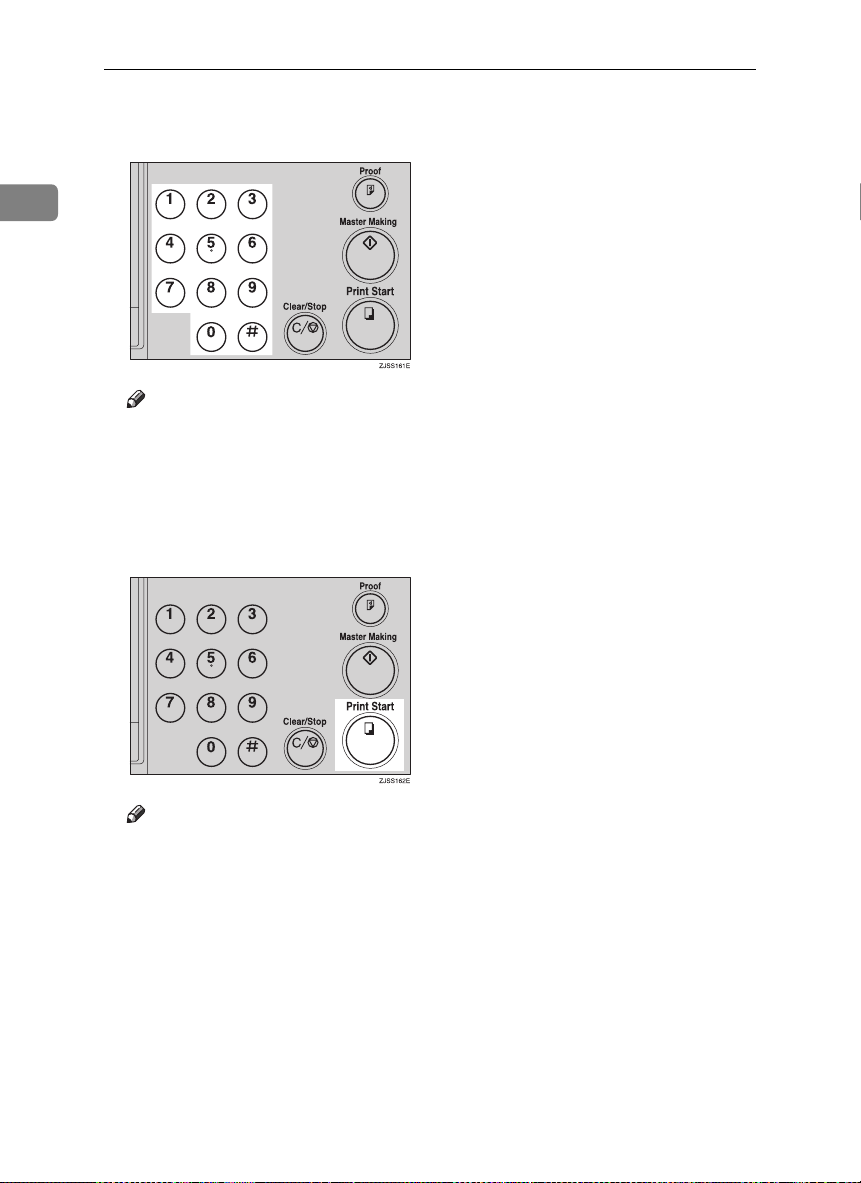

Enter the number of prints re-

DDDD

quired with the number keys.

1

Note

❒ Up to 9999 prints can be entered

at a time.

❒ To change the number entered,

press the {{{{Clear/Stop}}}} key and

enter the new number.

Press the {{{{Print Start}}}} key.

EEEE

16

Note

❒ After printing is completed, the

same number of prints is automatically set for the next job.

❒ To stop the machine during the

multi-print run, press the

{{{{Clear/Stop}}}} key.

❒ To return the machine to the in-

itial condition after printing,

press the {{{{Clear Modes/Recovery}}}}

key.

Page 23

After Printing

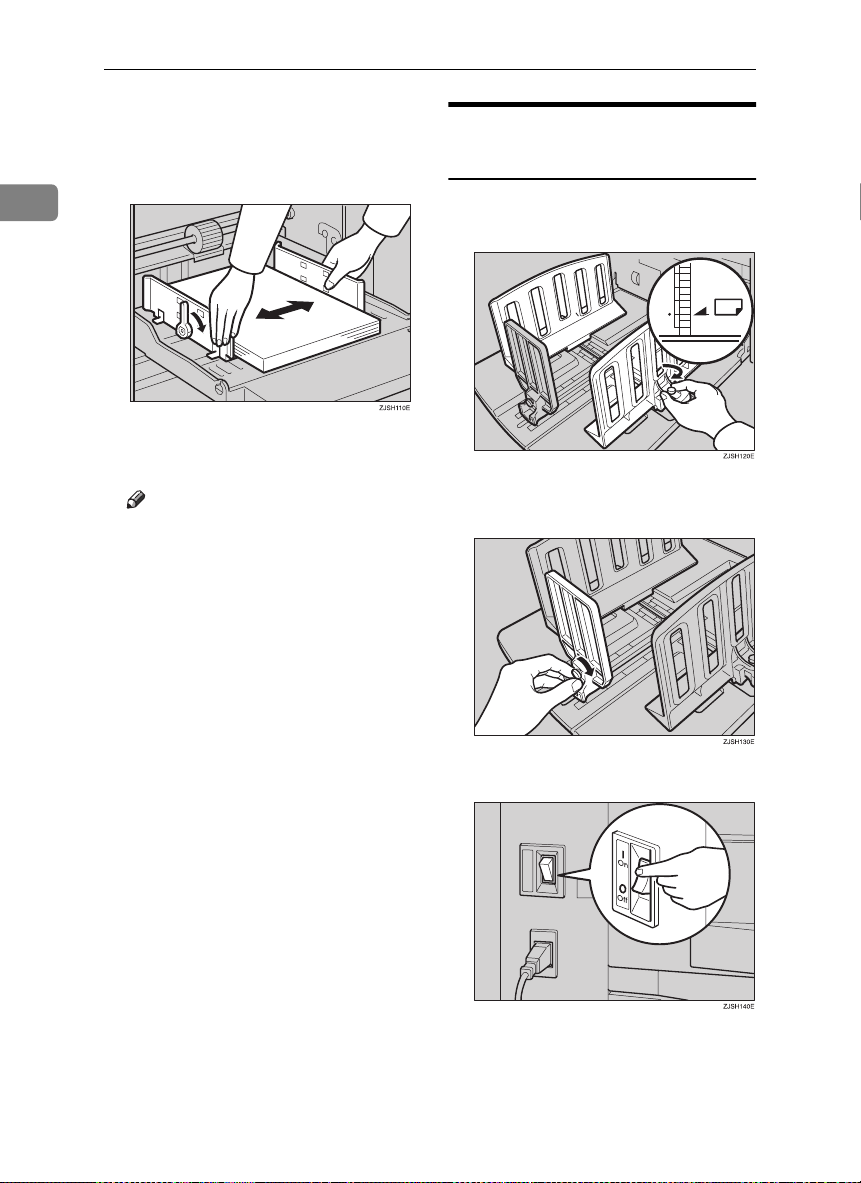

Lower the paper feed tray adjust-

AAAA

ment lever and remove the paper

from the paper feed tray.

Remove the prints from the paper

BBBB

delivery tray.

Turn off the main switch.

CCCC

After Printing

1

17

Page 24

Operation

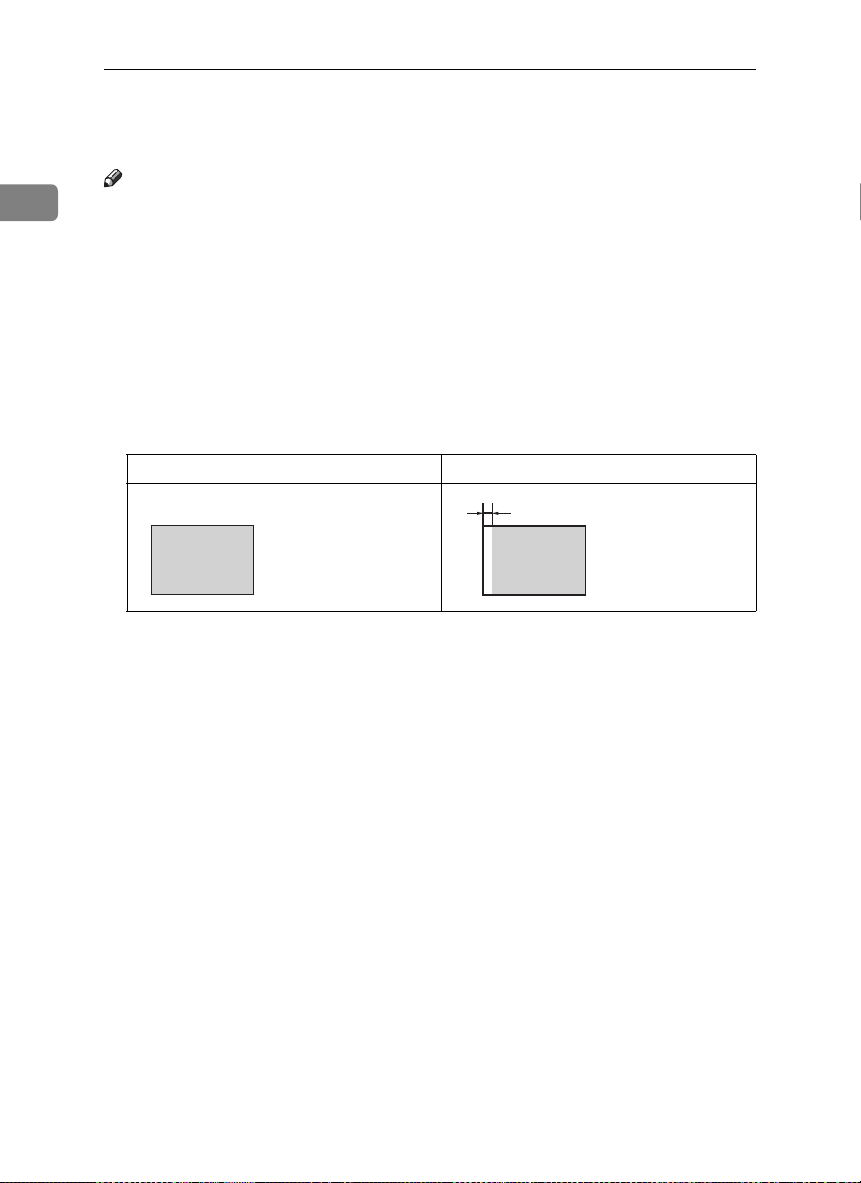

Adjusting the Print Image Position

After master making, you can adjust

1

the print image position to suit your

needs. There are two ways to do this:

❖❖❖❖ Shifting the Image Position Forwards

or Backwards

Adjust the image position using

the {{{{Image Position}}}} keys.

❖❖❖❖ Shifting the Image Position to the

Right or Left

Adjust the image position by shifting the paper in the paper feed

tray.

Shifting the Print Image Position

Forwards or Backwards

GRFORW0E

* Paper feed direction

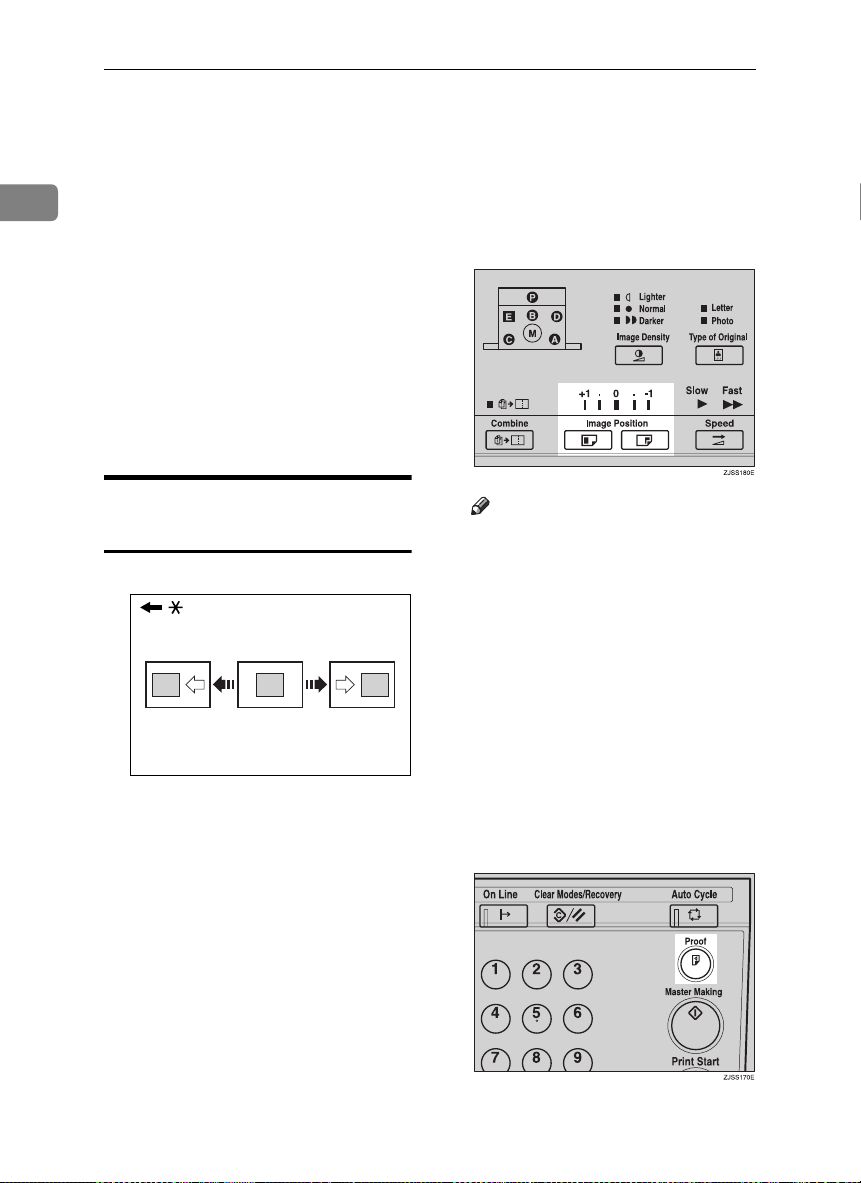

Press the left {{{{Image Position}}}} key

AAAA

to move the image forwards, and

the right key to move it backwards.

Note

❒ When you shift the image for-

wards, leave a margin (more

than 5 mm, 0.2") at the leading

edge. If there is no margin, paper might wrap around the

drum and cause a misfeed.

❒ The right or left {{{{Image Position}}}}

keys shift the image about 1

mm, 0.04" each time they are

pressed. However, the indicator

will only register a change

when the image position is

shifted about 5 mm, 0.2".

Press the {{{{Proof}}}} key to check the

BBBB

image position.

18

Page 25

Shifting the Print Image

Position to the Right or Left

* Paper feed direction

Lower the paper feed tray adjust-

AAAA

ment lever and unlock the paper

feed side plates.

❖❖❖❖ Shifting the image to the right

Shift the paper towards the

front of the machine.

GRLEFT0E

Adjusting the Print Image Position

❖❖❖❖ Shifting the image to the left

Shift the paper towards the back

of the machine.

Note

❒ The image position can be shift-

ed up to about 10 mm, 0.4" each

way.

Lock the paper delivery side

BBBB

plates and shift the tray adjustment lever back to the paper feeding position.

Press the {{{{Proof}}}} key to check the

CCCC

image position.

1

19

Page 26

Operation

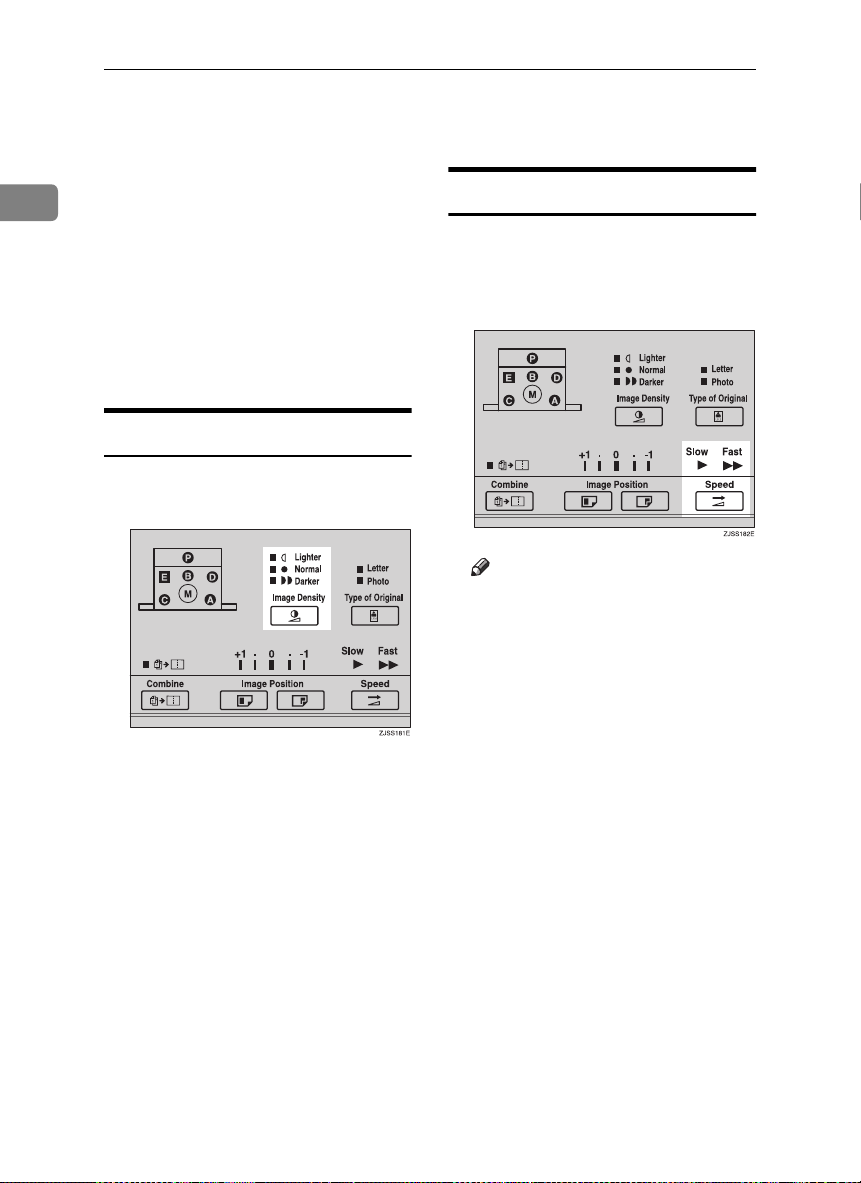

Adjusting the Print Image Density

You can adjust the print image densi-

1

ty to suit your needs. There are two

ways to do this:

❖❖❖❖ Before Making a Master

Adjust the image density using the

{{{{Image Density}}}} key.

❖❖❖❖ After Making a Master

Adjust the image density using the

{{{{Speed}}}} key.

Before Making a Master

Use the {{{{Image Density}}}} key before

AAAA

pressing the {{{{Master Making}}}} key.

After Making a Master

Press the {{{{Speed}}}} key to decrease

AAAA

the printing speed. Press it again

to bring the printing speed back

to Fast.

Note

❒ The faster the printing speed be-

comes, the lighter the printing

density is. If you want darker

prints, decrease the printing

speed.

20

Page 27

Changing the Printing Speed

Use the {{{{Speed }}}} key to adjust the

speed of the machine to suit the image density and paper type.

Press the {{{{Speed}}}} key to select the

AAAA

printing speed.

Note

❒ The following speeds are avail-

able:

• Fast:

90 sheets/minute

• Slow:

60 sheets/minute

❒ The default is 90 sheets/minute.

❒ The faster the printing speed be-

comes, the lighter the printing

density is, and vice versa.

❒ Select the slower speed when

you are printing on very thick

or very thin paper.

Changing the Printing Speed

1

21

Page 28

Operation

Stopping the Machine during the Multi-print Run

1

When You Want to Stop the

Machine during the Multi-print

Run and Print the Next

Original

Press the {{{{Clear/Stop}}}} key.

AAAA

Place the new original in the doc-

BBBB

ument feeder.

Enter the number of prints and

CCCC

press the {{{{Master Making}}}} key.

When You Want to Change the

Number of Prints Entered or

Check the Completed Prints

Press the {{{{Clear/Stop}}}} key.

AAAA

Change the number of prints or

BBBB

check the completed prints.

Note

❒ When you change the number

of prints, you can re-enter the

number with the number keys

after pressing the {{{{Clear/Stop}}}}

key.

22

Press the {{{{Print Start}}}} key.

CCCC

Page 29

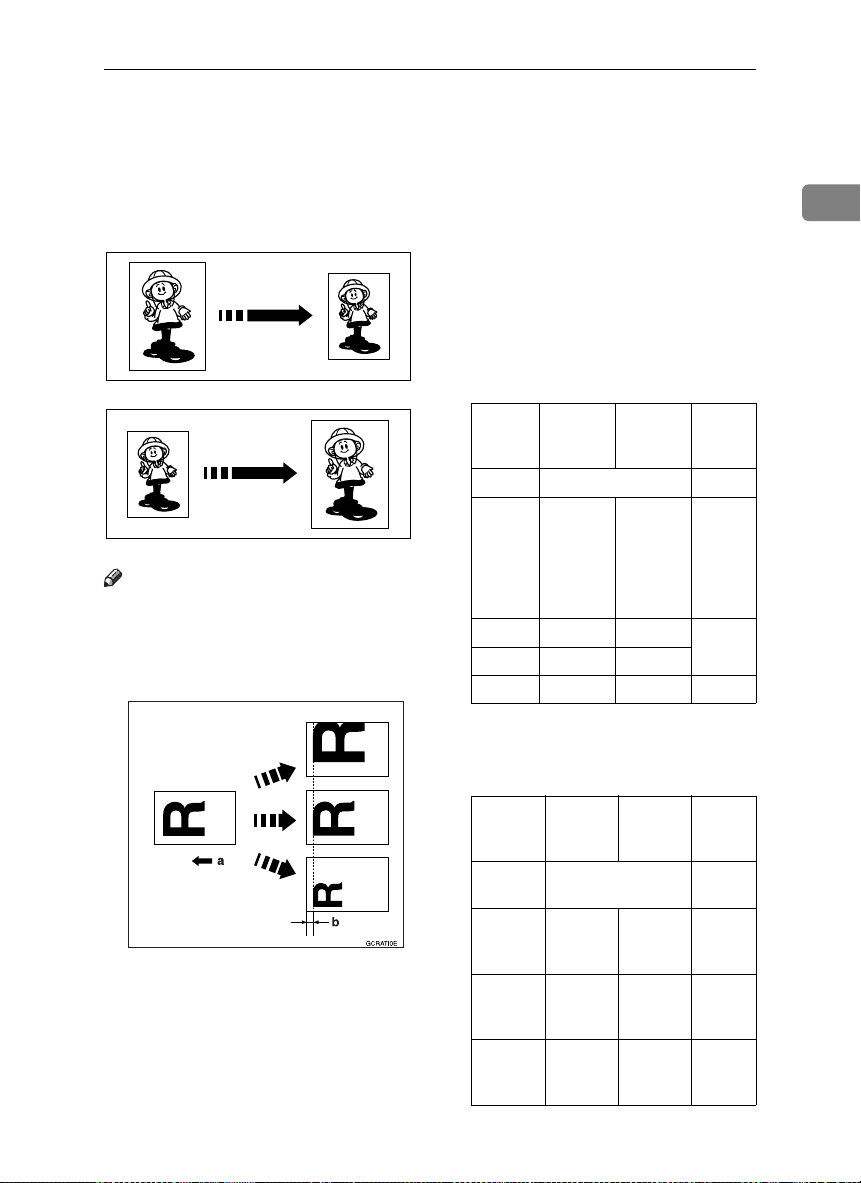

Preset Reduce/Enlarge—Reducing and Enlarging Using Preset Ratios

Preset Reduce/Enlarge—Reducing and

Enlarging Using Preset Ratios

You can select a preset ratio for printing.

GRREDU0E

GRENLA0E

Note

❒ The centre and the leading edge of

the print image do not shift when a

print image is made with this function.

❒ You can select a ratio regardless of

the size of an original or printing

paper. With some ratios, parts of

the image might not be printed or

margins will appear on prints.

❒ Prints can be reduced or enlarged

as follows:

❖❖❖❖ Reduction (Metric version)

Indicator

93%

A4VB5 A4 B5 JIS

B4VA4 B4 JIS A4 82%

B5VA5 B5 JIS A5

B4VB5 B4 JIS B5 JIS 71%

*1

Original

Size

*1

Print

Size

(Japanese Industrial

Standard)

Reduction

Ratio

93%

87%

Select this ratio when you make

prints with a lot of edge margins.

❖❖❖❖ Reduction (Inch version)

1

a: Paper Feed Direction

b: Constant

❒ You can select one of 7 preset ratios

(3 enlargement ratios, 4 reduction

ratios).

Indicator

Create

Margin

81/2" ×

14"

×

11"

11" ×

15"

×

11"

11" ×

17"

×

11"

*1

V

V

V

81/2"

81/2"

81/2"

Original Size

*1

81/2" ×

14"

11" × 15" 81/2" ×

11" × 17" 81/2" ×

Print

Size

81/2" ×

11"

11"

11"

Select this ratio when you make

prints with a lot of edge margins.

Reduction

Ratio

93%

77%

74%

65%

23

Page 30

Operation

❖❖❖❖ Enlargement (Metric version)

Indicator

1

B5VB4 B5 JIS B4 JIS 141%

A4VB4 A4 B4 JIS 122%

A5VB5 A5 B5 JIS

B5VA4 B5 JIS A4 115%

Original

Size

Print

Size

Enlargement

Ratio

Place the original in the docu-

CCCC

ment feeder and specify the

number of prints.

Press the {{{{Master Making}}}} key.

DDDD

❖❖❖❖ Enlargement (Inch version)

Indicator

51/2" ×

1

8

/2"V81/2"

×

14"

51/2" ×

1

/2"V81/2"

8

×

11"

1

8

/2" ×

14"V11"

×

17"

Original Size

51/2" ×

1

8

/2"

51/2" ×

1

/2"

8

81/2" ×

14"

Print

Size

1

/2" ×

8

14"

1

8

/2" ×

11"

11" × 17" 121%

Enlargement

Ratio

155%

129%

Check the image position on the

EEEE

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {{{{Image

Position}}}} key (see p.18 “Shifting

the Print Image Position Forwards or Backwards”) or by

moving the position of the paper (see p.19 “Shifting the Print

Select the desired reduction or en-

AAAA

largement ratio using the {{{{En-

Image Position to the Right or

Left”).

large/Reduce}}}} key.

Press the {{{{Print Start}}}} key.

FFFF

24

Make sure that the original and

BBBB

the print paper are of the correct

size.

Page 31

Printing on Different Types of Paper Thickness

Printing on Different Types of Paper

Thickness

Depending on the thickness of the paper that you are printing on, you need

to perform the following steps.

Feed Roller Pressure Lever

Shift the feed roller pressure le-

AAAA

ver to the Thick or Standard paper

position.

Note

❒ Shift the lever according to the

paper weights as shown in the

following table.

Metric

version

Thick 81.6–127.9

Stand

ard

2

g/m

35–81.5 g/m29.3–21.6 lb.

Inch version

21.7–34.0 lb.

Make sure that the paper feed

BBBB

side plates touch the paper lightly.

When you have finished printing,

CCCC

shift the feed roller pressure lever

back to the Standard paper position.

1

❒ If the feed roller pressure lever

is at the Standard paper position, and paper misfeeds occur

even though you are using paper within the specified range,

move the lever to the Thick paper position.

25

Page 32

Operation

Separation Pressure Lever

To prevent double-feed, adjust

AAAA

1

the paper separation pressure using the separation pressure lever.

Note

❒ Paper separation pressure can

be adjusted according to the paper weights as shown in the following table.

Posi-

Metric

tion

version

1 Use this position if the lead-

ing edge of the paper is

curled, or when the paper

does not feed properly at Position 2.

*1

35–47.0

2

3 47.1–81.5

4 Use this position when a

5 Use this position if double-

*1

This position can also be used if

2

g/m

, 81.6–

127.9 g/m

2

g/m

double-feed occurs.

feeds persist even after the

lever has been shifted to Position 4.

the leading edge of the paper is

curled, or when the paper does

not feed properly.

Inch version

9.3 – 12.5 lb.,

21.7–34.0 lb.

2

12.6–21.6 lb.

26

Page 33

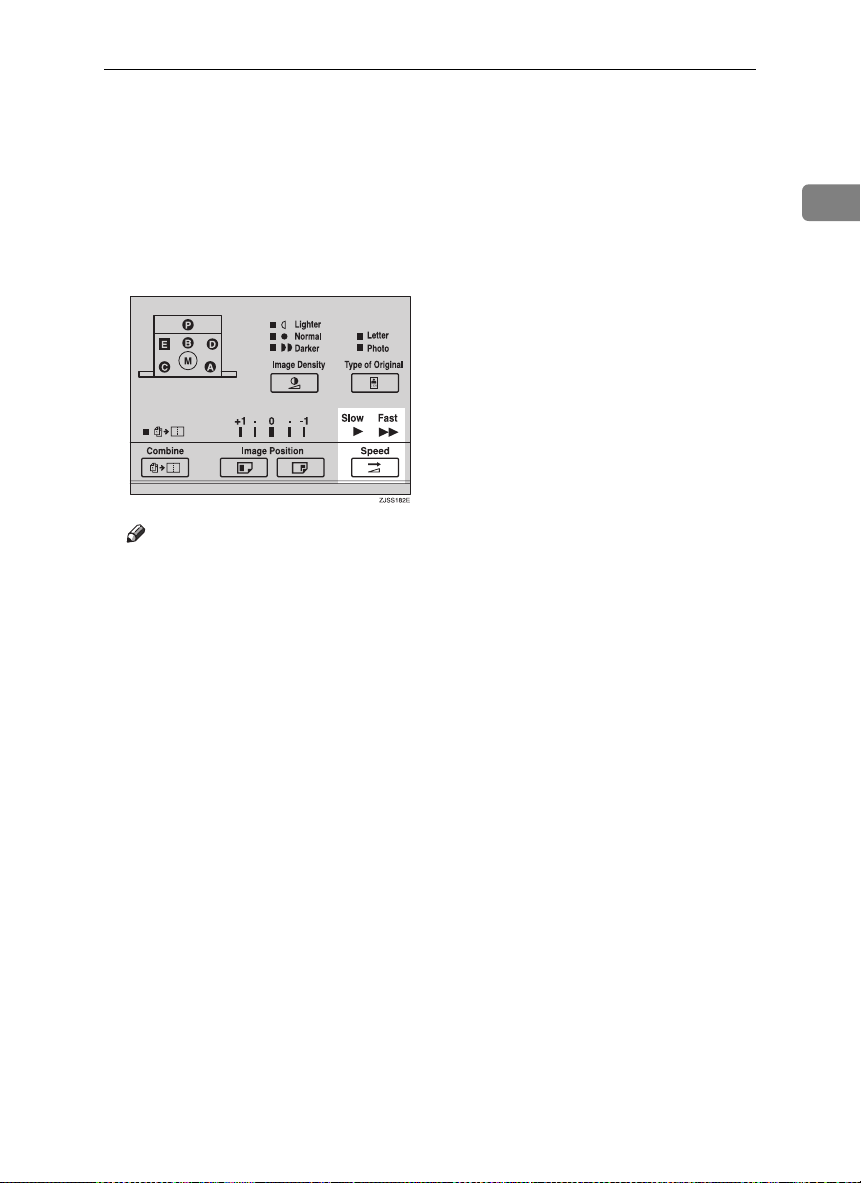

Selecting Original Type

Selecting Original Type

Select one of the following two types

to suit your originals:

❖❖❖❖ Photo mode

Delicate tones of photographs and

pictures can be reproduced with

this mode.

❖❖❖❖ Letter mode

Select this mode when your originals contain only letters (no pictures).

Note

❒ Moire patterns might occur when

screened originals are printed.

❒ When using Photo mode to print

originals with both letters and

photographs, the letters will appear lighter.

Press the {{{{Type of Original}}}} key to

AAAA

select either Letter or Photo mode.

Press the {{{{Image Density}}}} key to ad-

BBBB

just the image density.

Place the original in the docu-

CCCC

ment feeder.

Press the {{{{Master Making}}}} key.

DDDD

1

Check the image position on the

EEEE

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {{{{Image

Position}}}} key (see p.18 “Shifting

the Print Image Position Forwards or Backwards”) or by

moving the position of the paper (see p.19 “Shifting the Print

Image Position to the Right or

Left”).

Make your prints.

FFFF

27

Page 34

Operation

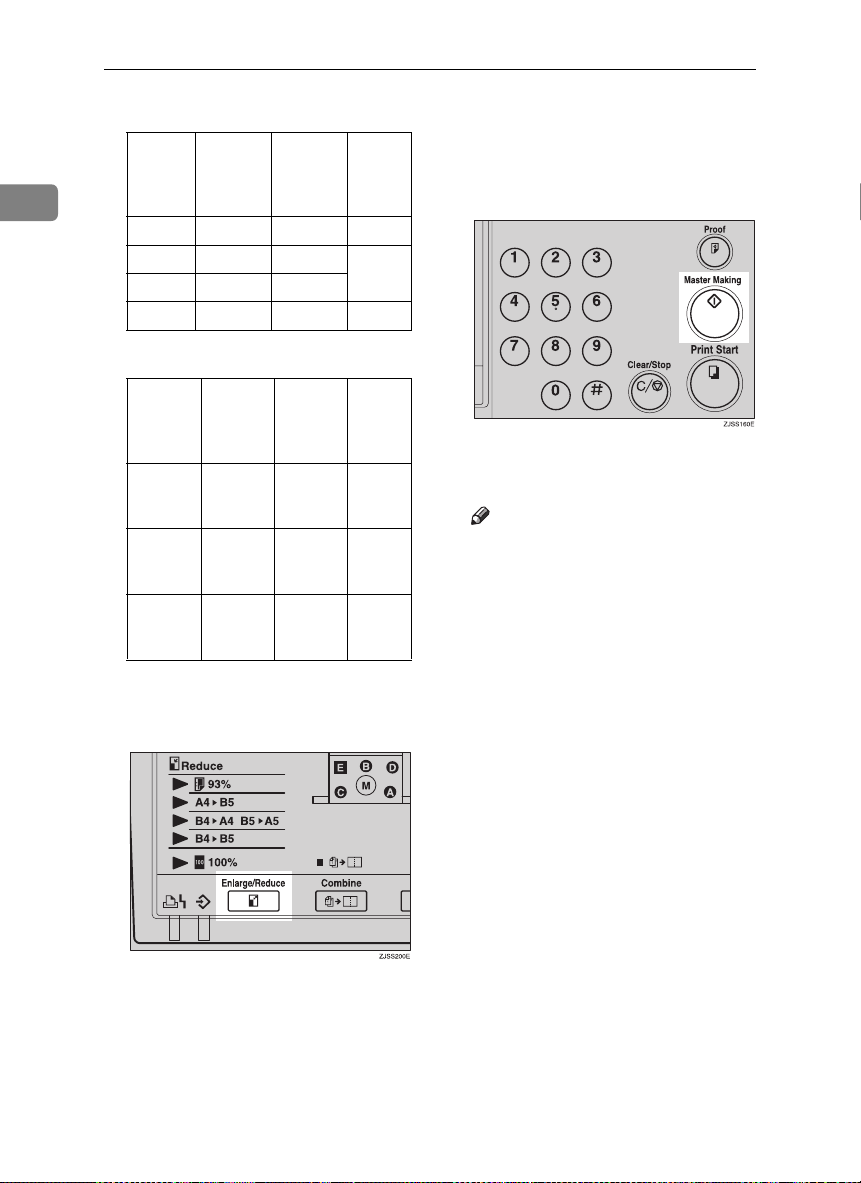

Auto Cycle—Processing a Master and Making Prints in One Step

1

Use the {{{{Auto Cycle}}}} key to process

masters and make prints in one step.

Place the original in the docu-

AAAA

ment feeder.

Press the {{{{Auto Cycle}}}} key.

BBBB

Enter the number of prints re-

CCCC

quired with the number keys.

Press the {{{{Master Making}}}} key.

DDDD

28

Page 35

Combine—Combining Two Originals onto One Print

Combine—Combining Two Originals onto

One Print

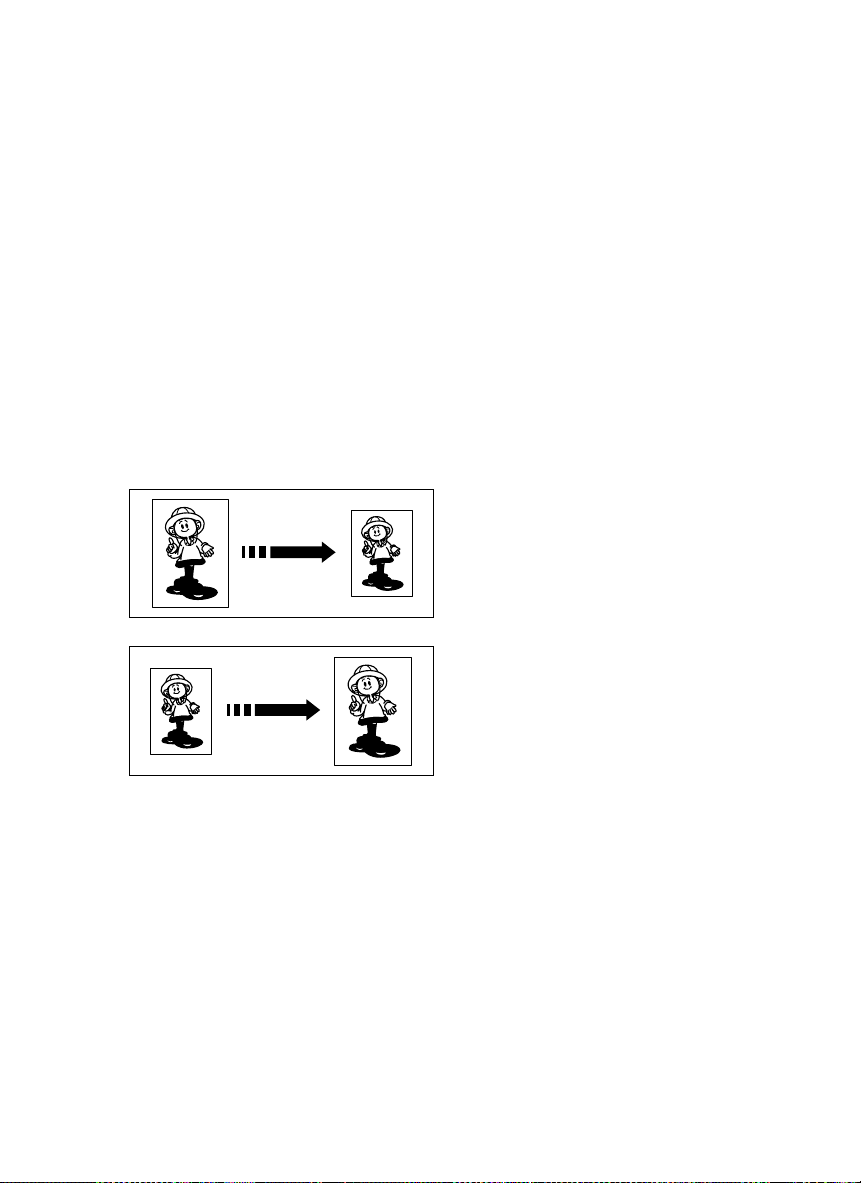

You can print two separate originals

on a single sheet of paper. The following diagrams show the available paper lists and orientations.

12 3

BA AB

ZCTX010E

1: B5 JISK, A5K, B6 JISK or A6K.

2: B5 JISK, A5K, B6 JISK or A6K.

3: B4 JISL, A4L, B5 JISL or A5L.

Note

❒ The following tables list the repro-

duction ratios used.

❖❖❖❖ Metric version

Original Size

B5

A5KB6

JIS

K

B4

100%122

JIS

L

A4L82%

*2

B5

71%

*1

JIS

Paper Size

L

A5L-- 71%

*1

For a reduction ratio of 71%, use

*5

%

100%115

87%

*3

*1

the {{{{Enlarge/Reduce}}}} key to select

“B4VB5”.

*2

For a reduction ratio of 82%, use

the {{{{Enlarge/Reduce}}}} key to select

“B4VA4 B5VA5”.

A6

K

JIS

K

141

--

*6

%

141

*4

%

%

100%122

%

82%

100

*2

%

*6

*5

*3

For a reduction ratio of 87%, use

the {{{{Enlarge/Reduce}}}} key to select

“A4VB5”.

*4

For an enlargement ratio of 115%,

use the {{{{Enlarge/Reduce}}}} key to select “B5VA4”.

*5

For an enlargement ratio of 122%,

use the {{{{Enlarge/Reduce}}}} key to select “A4VB4 A5VB5”.

*6

For an enlargement ratio of 141%,

use the {{{{Enlarge/Reduce}}}} key to select “B5VB4”.

❖❖❖❖ Inch version

Original Size

1

/2" × 81/2"

5

1

Paper

Size

*1

For a reduction ratio of 65%, use

8

11"

5

8

/2" ×

L

1

/2" ×

1

/2"

the {{{{Enlarge/Reduce}}}} key to select

“11" × 17"V8

L

1

/2" × 11" “.

100%

65%

K

*1

❒ If the master length of the first

original is longer than 243mm, 9.5"

or shorter than 70 mm, 2.8", Combine mode is disabled.

❒ Any image closer than 5 mm, 0.2"

to the leading edge of an original

will not be printed. When the image is too close to the leading edge,

use copies of the originals with the

image shifted at least 5 mm, 0.2"

from the leading edge.

❒ You can select different image set-

tings for the first and second original.

❒ Make sure that the paper feed side

plates touch the paper lightly

when using the Combine function.

If they do not, the two original images will not appear at the proper

position on the prints.

1

29

Page 36

Operation

Press the {{{{Combine}}}} key.

AAAA

1

Place the first original face down

BBBB

in the document feeder.

Note

❒ The first original will be printed

on the leading part of the print.

Specify the reproduction ratio and

CCCC

check that the correct paper size is

loaded.

Press the {{{{Master Making}}}} key.

DDDD

The beeper sounds after the first

EEEE

original has been stored. Place the

second original face down in the

document feeder.

Note

❒ If you wish to select a different

reproduction ratio for the second original, you need to enter

the new settings before the

beeping stops.

Press the {{{{Master Making}}}} key.

FFFF

Check the image position on the

GGGG

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {{{{Image

Position}}}} key (see p.18 “Shifting

the Print Image Position Forwards or Backwards”) or by

moving the position of the paper (see p.19 “Shifting the Print

Image Position to the Right or

Left”).

30

Page 37

Enter the number of prints with

HHHH

the number keys.

Press the {{{{Print Start}}}} key to make

IIII

your prints.

Combine—Combining Two Originals onto One Print

1

31

Page 38

Operation

1

32

Page 39

2. Optional Functions

Colour Printing Using the Optional Colour Drum

In addition to the standard black

drum, colour drum units (red, blue,

green, brown, yellow, purple, navy,

maroon, orange, and teal) are also

available as options. To make colour

prints, a separate drum unit is needed

for each colour.

GRCOPR0E

Making Colour Prints

Check that the machine is loaded

AAAA

with a drum unit of the correct

colour.

Reference

For how to change the colour

drum unit, see p.34 “Changing

the Colour Drum Unit”.

Place the original in the docu-

BBBB

ment feeder and press the {{{{Master

Making}}}} key.

Check the image position on the

CCCC

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {{{{Image

Position}}}} key (see p.18 “Shifting

the Print Image Position Forwards or Backwards”) or by

moving the position of the paper (see p.19 “Shifting the Print

Image Position to the Right or

Left”).

Make your prints.

DDDD

33

Page 40

Optional Functions

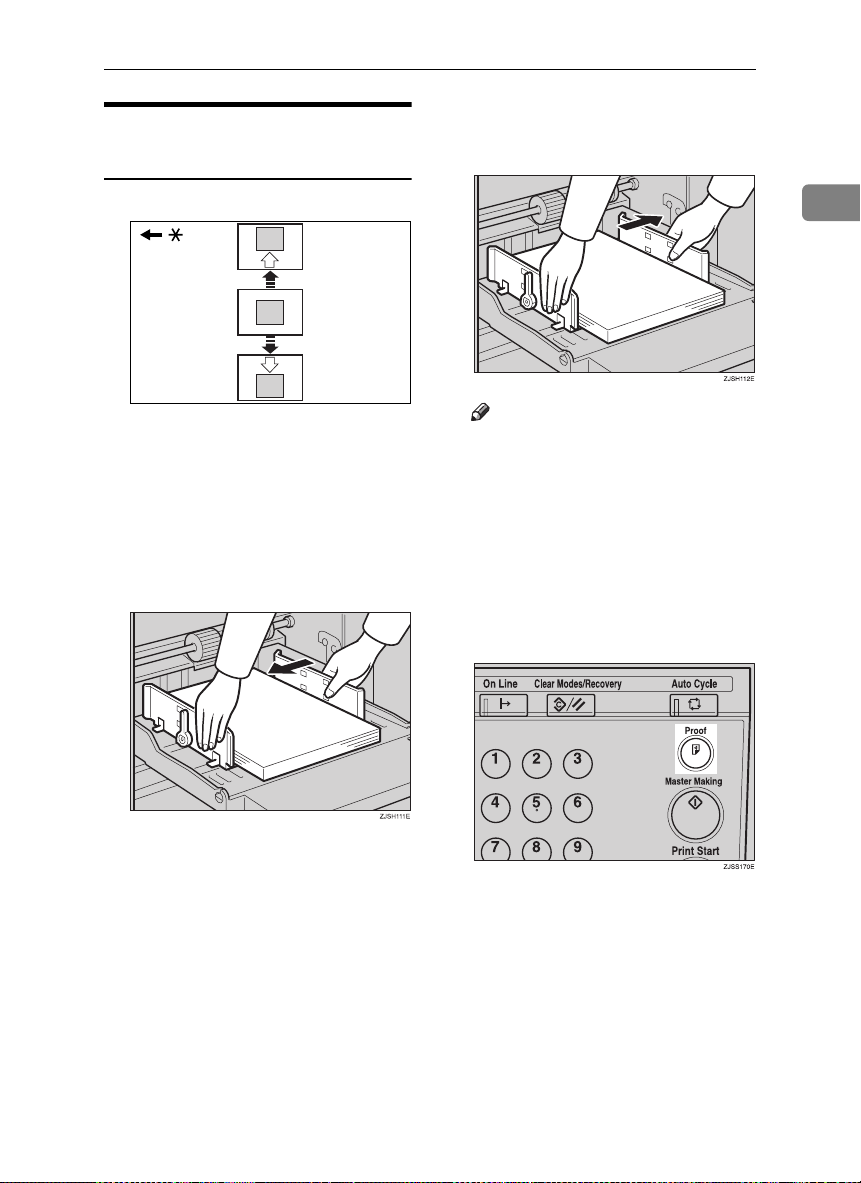

Hold the rail on the drum and

Changing the Colour Drum

Unit

Open the front door.

AAAA

DDDD

slide out the drum while pulling

the release towards you.

2

Remove the drum unit from the

EEEE

machine while holding the upper

Lift the drum handle to unlock

BBBB

the drum.

drum stay.

34

Slowly pull the drum out.

CCCC

Note

❒ If you cannot pull out the drum

unit, turn off the main switch

and then try again.

Note

❒ Be careful not to let the drum

unit fall.

Set the colour drum unit on the

FFFF

guide rail.

TSLH01PE

Page 41

Slide in the drum unit until it

GGGG

locks in position.

Lower the drum unit lock lever.

HHHH

Colour Printing Using the Optional Colour Drum

Printing in Two Colours

After printing in one colour, you can

print in another colour on the same

side of the print.

Important

❒ Allow the prints to dry for a while

before printing the second colour.

❒ If the prints are still wet when you

print on them again, the paper feed

roller might become dirty. In this

case, wipe off the roller with a

cloth.

Note

❒ You cannot print in two colours at

a time.

Prepare two originals. Place the

AAAA

first original in the document

feeder.

2

Close the front door.

IIII

Note

❒ Make sure that the Cover Open

indicator (M) turns off.

R

P

Press the {{{{Master Making}}}} key.

BBBB

R

P

GRCOLO0E

35

Page 42

Optional Functions

Check the image position on the

CCCC

trial or proof print.

Note

❒ If the image position is not cor-

rect, adjust it using the {{{{Image

Position}}}} key (see p.18 “Shifting

2

the Print Image Position Forwards or Backwards”) or by

moving the position of the paper (see p.19 “Shifting the Print

Image Position to the Right or

Left”).

Enter the number of prints with

DDDD

the number keys.

Press the {{{{Print Start}}}} key.

EEEE

Remove the prints from the paper

FFFF

delivery tray and re-load them

into the paper feed tray, as shown

in the illustration.

Change the drum unit. See p.34

GGGG

“Changing the Colour Drum

Unit”.

36

Place the second original and

HHHH

press the {{{{Master Making}}}} key.

Check the image position.

IIII

Press the {{{{Print Start}}}} key.

JJJJ

Page 43

3. Replenishing Supplies

Loading Paper into the Paper Feed Tray

The Load Paper indicator (B) and the

machine indicator “A” lights when

the paper feed tray runs out of paper.

Replenishing Paper

Press the {{{{Clear/Stop}}}} key.

AAAA

Note

❒ This step is necessary only if

you want to pause a print run to

replenish paper.

Lower the paper feed tray adjust-

BBBB

ment lever.

Load paper into the paper feed

CCCC

tray.

Note

❒ Correct paper curl before set-

ting the paper.

Shift the tray adjustment lever to

DDDD

the paper feeding position.

Note

❒ Before you start printing, the

paper feed tray must be aligned

with the feeding position. If not,

a paper misfeed might occur.

Press the {{{{Print Start}}}} key to

EEEE

resume printing.

Note

❒ The top sheet of paper might re-

main between the feed rollers.

In this case, remove the top

sheet.

37

Page 44

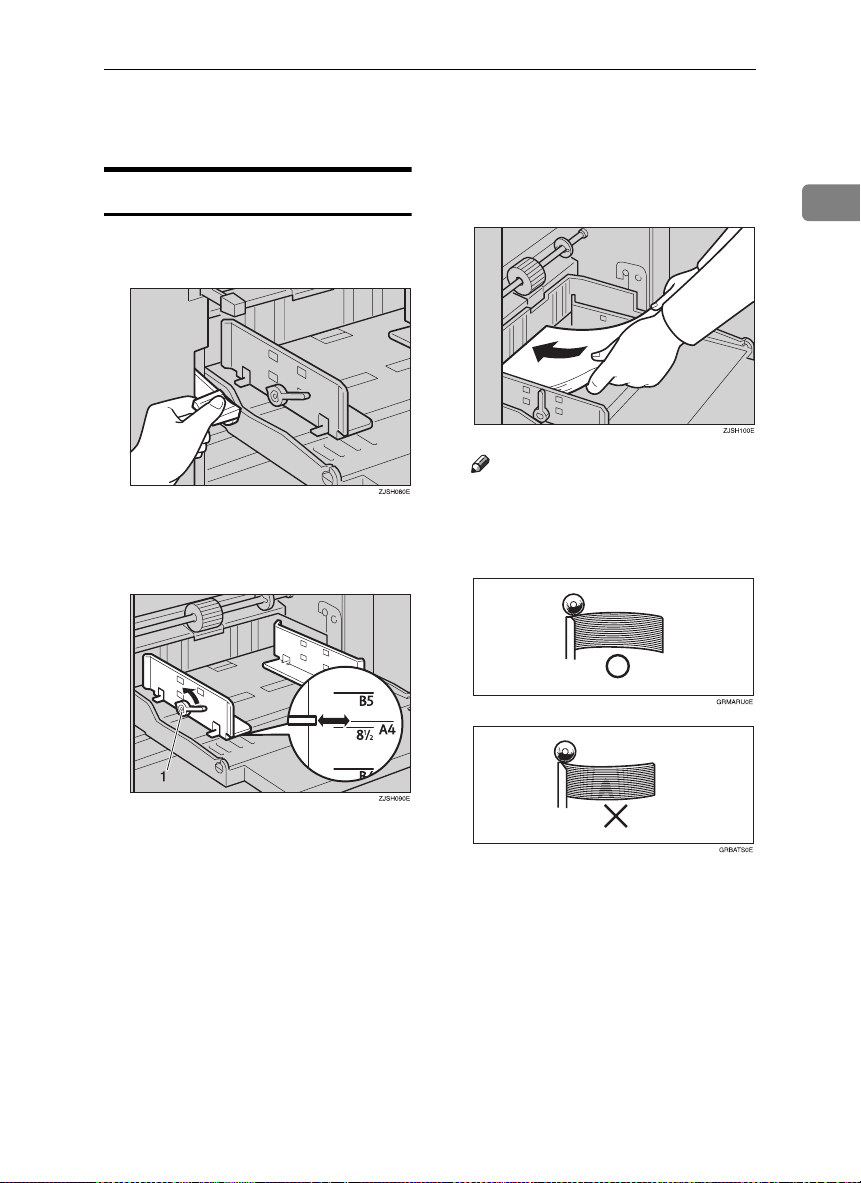

Replenishing Supplies

Load paper into the paper feed

Changing the Paper Size

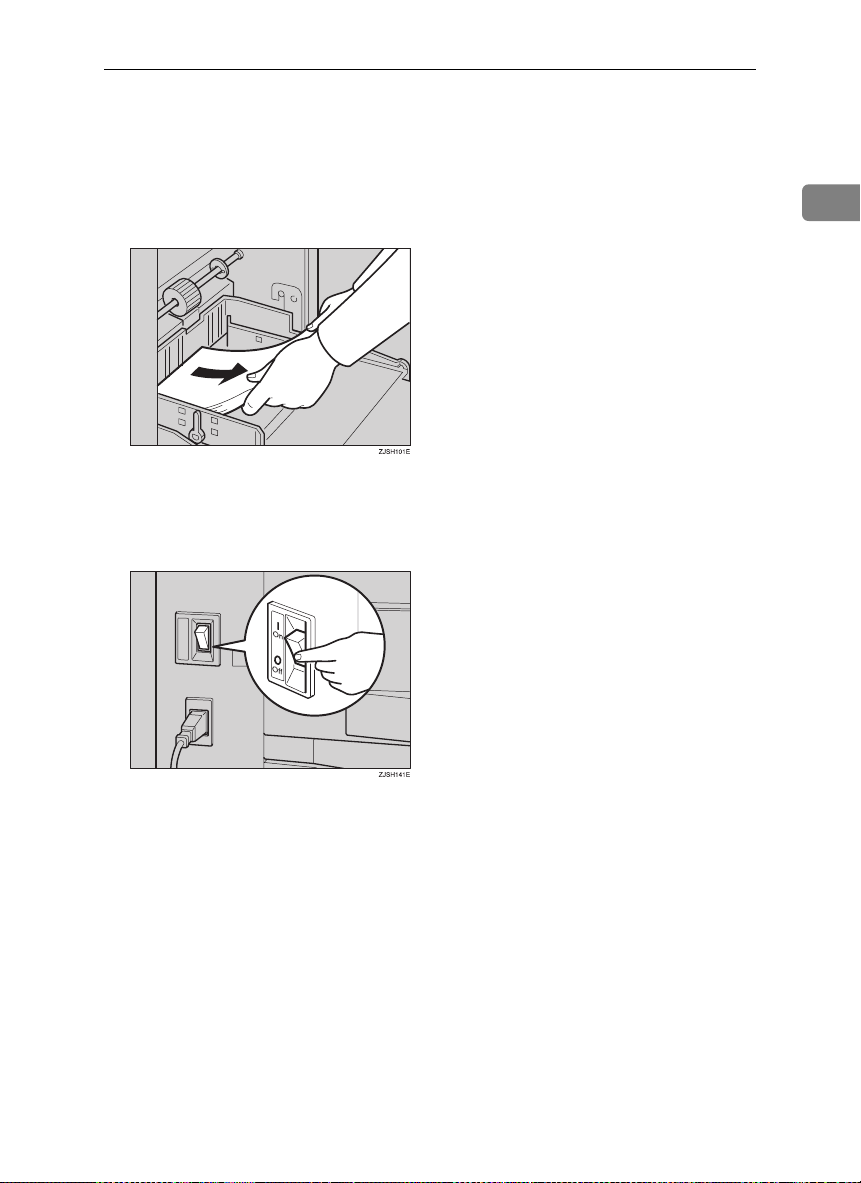

Lower the paper feed tray adjust-

AAAA

ment lever. Remove the paper

from the paper feed tray.

CCCC

tray.

3

Note

❒ Correct any paper curl before

setting the paper.

Release the paper feed side plate

BBBB

lock levers. Adjust the paper feed

side plates to match the new paper size.

❒ Make sure that the side plates

touch the paper lightly.

❒ Shift the lock levers back to their

original positions.

Adjust the side plates and the end

DDDD

plate of the paper delivery tray.

38

1: Paper Feed Side Plate Lock Levers

Page 45

When the Add Ink Indicator (j) Lights

R

R

R

R

When the Add Ink Indicator (

The Add Ink indicator (j) lights up when it is time to supply ink.

CAUTION:

• If ink comes into contact with your eyes, rinse immediately in running water.

For other symptoms, consult a doctor.

CAUTION:

• Keep the ink or ink container out of reach of children.

CAUTION:

• If ink is ingested, induce vomiting by drinking a strong saline solution. Consult a doctor immediately.

CAUTION:

• Our products are engineered to meet high standards of quality and functionality, and we recommend that you use only the expendable supplies available at an authorized dealer.

Open the front door.

AAAA

jjjj

) Lights

3

Release the ink holder lock lever and pull out the ink holder. Remove the

BBBB

used ink cartridge.

39

Page 46

Replenishing Supplies

Remove the cap of the new ink cartridge.

CCCC

3

Insert the new cartridge into the ink holder.

DDDD

Note

❒ Always supply ink of the same colour.

❒ Make sure that the part indicated by the arrow mark is firmly inserted into

the guide.

TSLT012E

40

TSLT011E

Slide the ink holder back in until it clicks into place.

EEEE

Close the front door.

FFFF

The machine will start idling to supply ink to the drum.

Note

❒ It will stop when the correct amount of ink reaches the drum.

Page 47

Master Roll Replacement

Master Roll Replacement

The Master End indicator (C) lights

up when it is time to replace the master roll.

Open the right side cover.

AAAA

Open the plotter cover.

BBBB

TSLH02EE

Note

❒ When the Master End indicator

lights up, it is necessary to replace the master roll even if

some master remains on the old

roll.

Make sure that the new master

DDDD

roll is positioned as shown in the

illustration.

Set the paper edge of the master

EEEE

roll as shown.

3

TSLH01XE

Remove the used master roll and

CCCC

pull out both spools. Then, insert

both spools into a new master

roll.

TSLH01UE

Note

❒ Rotate the spools backward to

take up any slack in the master.

TSLT010E

41

Page 48

Replenishing Supplies

Close the plotter cover using both

FFFF

hands until it clicks into place.

3

Close the right side cover.

GGGG

TSLH023E

42

Page 49

4. Troubleshooting

R

If Your Machine does not Operate as You Want

If a malfunction or a misfeed occurs within the machine, the following indicators

will light.

❖❖❖❖ When the misfeed indicator (xxxx) lights with the machine indicators

Indicator Page

x

and “P” p.46 “When “x” and “P” light up”

x

, B and “A” p.47 “When “x”, “B” and “A” light up”

x

and “B” p.48 “When “x” and “B” light up”

x

and “C” p.50 “When “x” and “C” light up”

x

and “D” p.52 “When “x” and “D” light up”

x

and “E” p.53 “When “x” and “E” light up”

CAUTION:

• Be careful not to cut yourself on any sharp edges when you reach inside the

machine to remove misfed sheets of paper or masters.

Note

❒ To prevent misfeeds, do not leave any torn scraps of paper within the ma-

chine.

❒ When clearing misfeeds, do not turn off the main switch. If you do so, your

copy settings are cleared.

❒ If misfeeds occur repeatedly, contact your service representative.

43

Page 50

Troubleshooting

❖❖❖❖ When the open cover/unit indicator (MMMM) lights up

Indicator Meaning Page

M

Close the front door or the right side

M

and “M” Set the drum.

M

and “D” Close the plotter cover.

M

and “E” Close the master eject box.

cover.

p.55 “When the Open Cover/Unit Indicator (M) Lights”

❖❖❖❖ When the supply/exchange indicators light up

Indicator Meaning Page

B

and “A” Load more paper. p.37 “Loading Paper into the Paper Feed

4

j

C

k

Load new ink cartridge. p.39 “When the Add Ink Indicator (j)

Load new master roll. p.41 “Master Roll Replacement”.

Empty master eject box. p.57 “When the Master Eject Indicator

Tray”.

Lights”.

(k) Lights”.

----When a service code (E-XX) is displayed

Turn the main switch off and on. If a service code appears again, contact your

service representative.

Note

❒ If a service code appears on the display after you turn the main switch off and

on a few times, do not continue turning it on and off. Leave the machine off.

❒ E04 might be displayed when you make masters continuously using the orig-

inals that have solid images. In the case, turn off the main switch and wait for

a while.

44

Page 51

xxxx

Clearing Misfeeds

x Clearing Misfeeds

The machine indicator shows the area where jams occur.

Important

❒ When clearing misfeeds, do not turn off the main switch. If you do, your print

settings are cleared.

----After clearing misfeeds

Press the {{{{Clear Modes/Recovery}}}} key to reset the error indicators.

4

45

Page 52

Troubleshooting

When “xxxx” and “P” light up

An original misfeed occurs in the document feeder.

Open the cover of the document feeder.

AAAA

4

Pull out the original gently.

BBBB

Close the cover of the document feeder.

CCCC

----To prevent original misfeeds:

• Originals heavier than 127.9 g/m2, 34.0 lb

• Originals lighter than 40 g/m

• Carbon coated originals

• Damaged originals

• Originals with glue on them

• Originals perforated for ring binders

• Book originals

• Originals smaller than 90 mm × 140 mm, 3.6" × 5.6"

• Originals larger than 275 mm × 395 mm, 10.8" × 15.6"

• Folded, curled, creased originals

46

2

, 10.8 lb

Page 53

x Clearing Misfeeds

R

• Bound, stapled, or clipped originals

• OHP transparencies

• Translucent paper

• Pasted originals

Note

❒ The first 5 mm, 0.2" of the leading edge cannot be printed. Make sure the lead-

ing edge margin is at least 5 mm, 0.2".

Original Print

a

❒ a: 5 mm, 0.2"

❒ Remove staples or clips of originals. Fan originals that have had staples or

clips removed.

When “xxxx”, “BBBB” and “A” light up

A paper misfeed occurs in the paper feed section.

CAUTION:

• Be careful not to cut yourself on any sharp edges when you reach inside the

machine to remove misfed sheets of paper or masters.

4

Lower the paper feed tray adjustment lever.

AAAA

Slowly but firmly pull out the paper.

BBBB

47

Page 54

Troubleshooting

When “xxxx” and “B” light up

The master or paper is wrapped around the drum, or a paper misfeed occurs inside the machine.

Pull out the drum unit.

AAAA

4

Remove the misfed paper.

BBBB

Re-insert the drum unit until the drum unit locks into position and put the

CCCC

lever back in place.

Close the front door.

DDDD

----To prevent paper misfeeds:

If the paper is curled or the originals leading edge margin is too narrow, the following action is necessary.

48

Page 55

x Clearing Misfeeds

• When you use curled paper, correct the curl as shown.

GRCURL0E

• If you cannot correct the paper curl, stack the paper with the curl face down

as shown.

4

• When the leading edge margin of the original is less than 5 mm, 0.2" or there

is a solid image on the leading edge, insert the original with the widest margin first or make a leading edge margin by making a copy.

GRLEAD0E

49

Page 56

Troubleshooting

R

When “xxxx” and “C” light up

A paper misfeed occurs in the paper delivery section.

CAUTION:

• Be careful not to cut yourself on any sharp edges when you reach inside the

machine to remove misfed sheets of paper or masters.

Remove the misfed paper.

AAAA

4

If the paper is completely wrapped around the drum, pull out the drum

BBBB

unit and remove the misfed paper from the drum.

50

TSLH02BE

Re-install the drum unit locks in position and put the lever back in place.

CCCC

Note

❒ If you followed step B or C, close the front door.

Page 57

x Clearing Misfeeds

----To prevent paper misfeeds:

If the paper is curled or the original's leading edge margin is too narrow, the following action is necessary.

• When you use curled paper, correct the curl as shown.

GRCURL0E

• If you cannot correct the paper curl, stack the paper with the curl face down

as shown.

4

51

Page 58

Troubleshooting

• When the leading edge margin of the original is less than 5 mm, 0.2" or there

is a solid image on the leading edge, insert the original with the widest margin first or make a leading edge margin by making a copy.

4

GRLEAD0E

When “xxxx” and “D” light up

Open the right side cover.

AAAA

Open the plotter cover, and then remove the misfed master.

BBBB

52

TSLH02EE

Page 59

x Clearing Misfeeds

If you could not remove the misfed master in steps BBBB and CCCC, take out the

CCCC

drum and remove the misfed master from the inside.

Close the right side cover.

DDDD

When “xxxx” and “E” light up

Check where the misfed master is. Remove the misfed master as follows:

AAAA

When a master misfeed occurs in the master eject section

A Pull out the master eject box.

4

B Remove the misfed master.

Note

❒

Be careful not to stain your hands with ink when you touch used masters.

53

Page 60

Troubleshooting

C Return the master eject box to its original position.

Note

❒ Set the drum unit and close the front door.

When a master misfeed occurs on the drum

A Lift the lever to unlock the drum unit and pull out the unit.

4

Reference

For how to remove the drum unit, see p.34 “Changing the Colour Drum

Unit”.

B Remove the master from the drum.

54

1

22

C Re-insert the drum unit until the drum unit locks in position and put the

lever back in place.

TSLH031E

Page 61

When the Open Cover/Unit Indicator (M) Lights

When the Open Cover/Unit Indicator (

MMMM

Lights

MMake sure that the following door/units are closed.

The machine indicator shows the place where the door/units are not closed.

❖❖❖❖ Right Side Cover

Close the right side cover firmly until it locks into position.

)

4

❖❖❖❖ Front Door

Close the front door completely.

55

Page 62

Troubleshooting

❖❖❖❖ Drum Unit

Set the drum unit completely until it locks in position.

4

56

Page 63

When the Master Eject Indicator (k) Lights

When the Master Eject Indicator (

The Master Eject indicator (k) lights when it is time to empty master eject box

or when you need to set the master eject box.

Take out the master eject box and remove the used masters.

AAAA

Note

❒ Spread an old newspaper, then turn the master eject box upside down on

it to remove the used masters. Then, throw away the masters.

Push the master eject box back in until it clicks into position.

BBBB

kkkk

) Lights

4

57

Page 64

Troubleshooting

Poor Printing

Dirt on the Back Side of Paper

GRDIRT0E

4

Note

❒ When you use paper smaller than the original, select the proper reduction ra-

tio. Otherwise, you might get dirty background prints.

❒ When you use postcards and the like, the background might be dirty because

postcards do not absorb ink well.

❒ You might get prints with dirty background when printing at low speed and

under high temperature.

Turn off the main switch.

AAAA

58

Pull out the drum unit.

BBBB

Page 65

Poor Printing

Reference

See p.34 “Changing the Colour Drum Unit”for the details.

Clean the pressure roller with a clean cloth.

CCCC

With a clean cloth, remove any ink that has accumulated on the trailing

DDDD

edge of the drum unit.

4

TSLH02CE

Insert the drum unit until it locks in position, then lower the drum unit

EEEE

lock lever.

Close the front door.

FFFF

59

Page 66

Troubleshooting

Turn on the main switch.

GGGG

4

Dirt on the Front Side of Paper (Black Line/Stain)

GRBLAC1E

Note

❒ When black lines or stains still appear on prints even if you clean the above,

contact your service representative.

❒ If there is no margin or if there is a solid image area near the leading edge of

the original, make a margin of at least 5 mm, 0.2" at the leading edge. Otherwise, the paper exit pawl might become dirty and cause black lines on prints.

❒ Check the document feeder and clean it if dirty. (See p.68 “Document Feed-

er”.)

60

Page 67

Poor Printing

White Prints or Incomplete Prints

GRWHIT0E

• Make sure that the paper feed side plates touch the paper lightly. Put back the

lock levers.

When you get white or incomplete prints even when you have checked the

above, perform the following procedure.

4

Pull out the drum unit.

AAAA

Reference

See p.34 “Changing the Colour Drum Unit”for the details.

61

Page 68

Troubleshooting

Remove the master from the drum.

BBBB

1

22

Remove paper that is stuck to the drum.

CCCC

TSLH031E

4

TSLH02BE

Insert the drum unit until it locks in position, then lower the drum unit

DDDD

lock lever.

62

Close the front door.

EEEE

Page 69

5. Remarks

Operation Notes

General Cautions

• While printing, do not turn off the main switch.

• While printing, do not open the door or covers.

• While printing, do not unplug the power cord.

• While printing, do not move the machine.

• Keep corrosive liquids, such as acid, off the machine.

• Open and close the door and covers softly.

• Do not put anything except originals on the machine.

• Do not spill liquid on the machine.

• When opening or closing the door or covers, keep hold of them so they do not

fall.

• When removing the drum unit from the machine, be careful not to let the

drum unit fall.

• Do not modify or replace any parts other than the ones specified in this manual.

• Do not operate the machine without covers. You might get your fingers

caught in the machine, or the machine might be damaged because, for example, dust or the like might get inside.

• Since some parts of the machine are sharp and might cause injury, touch only

the parts specified in this manual.

• If you clean rubber parts with alcohol, wipe them with a dry cloth afterwards.

• Always turn the machine off when you have finished printing for the day.

• If the machine must be transported by vehicle, please contact your service

representative.

• Always make trial prints to check the image position because the image position of the trial print might not correspond with that of the original.

• If image registration is not consistent, slow down the printing speed.

• When doing bicoloured or multicoloured printing, leave the printed paper

for a while before the next printing in order to let the ink dry on the printed

paper. If this is not done, feed roller marks will appear on the print image.

• If the machine has not been used for a long period, the ink may dry up causing image density to decrease. In such a case, select the slower printing speed

and make extra prints until the image density recovers.

63

Page 70

Remarks

• When the machine is used in low temperature conditions, the image density

might decrease. In this case, select the slower printing speed.

• Press the {{{{Proof}}}} key to perform a test print as the first few prints might be

light.

• The outer portion of the image might not be printed under low temperature.

In this case, either select the slower printing speed, or increase the room temperature.

• The paper exit pawl might come in contact with the printing paper and cause

black lines on the prints. In this case, increase the printing speed or make a

new master with a lighter image density.

• If you cannot pull out the drum, close the front cover again to rotate the drum.

Pull out the drum after it stopped at the position.

• The leading edge of the prints might become stained if the edge touches the

image of prints on the paper delivery tray.

• The ink of the print on the paper delivery tray might stick to the back side of

5

the next print.

• When the machine is on and the power source is less than 90% of the specified

amount, printing quality will decrease. Therefore, make sure the supply from

your electrical outlet is at least 90% of the required amount.

• As various kinds and qualities of paper exist, some paper might be wrapped

around the drum or cause misfeeds.

• If your hands are stained with ink:

• Avoid prolonged or repeated contact with skin.

• Cleanse skin thoroughly after contact, before breaks and meals, and at the

end of the work period.

• Ink is readily removed from skin with waterless hand cleaners followed by

washing with soap and water.

• Also, be careful not to get any ink on your clothing while emptying the master

eject box or while loading a new ink cartridge.

• The image density varies according to the printing speed and the room temperature. To achieve the desired image density, adjust the printing speed or

increase the room temperature.

• When you make a lot of prints from a small image, ink might ooze out from

the edges of the master, especially under high temperature and when printing in two or more colours. In this case, make a new master.

• Use ink made within one year. Ink stored for a long period of time tends to

dry up gradually and result in lower image density.

• While making a master, do not leave the document feeder cover open.

• When you use originals with light lettering, edges of the letters might be

printed clearly and the inside of the letters might be light. In this case, increase the image density.

64

Page 71

Operation Notes

• When marks on the printing paper occur, clean the paper feed roller. See p.68

“Paper Feed Roller (paper feed tray)”.

• If you make a print before the ink on the first print dries, the ink may adhere

to the paper feed roller and soil the print. Before printing on the reverse side

of a printed sheet or overprinting on a printed sheet, be sure that the ink on

the first print is adequately dry. See p.68 “Paper Feed Roller (paper feed

tray)”.

Print Paper

• When the paper is curled, stack the paper with the curl face down, otherwise

the paper might wrap around the drum or stains might appear.

• Postcards and the like do not absorb ink well. Offset images might appear on

the rear side of subsequent prints. Solid image originals will cause offset image prints.

Originals

• If there is no margin or if there is a solid image area near the leading edge of

the original, make at least a 5 mm, 0.2", margin at the leading edge; otherwise,

the paper might wrap around the drum or the paper exit pawl might become

dirty and cause black lines on prints.

• If you use originals that have bold letters or solid images at the leading edges,

you might get prints with dirty edges. In this case, insert the widest margin

first, or increase the printing speed.

5

65

Page 72

Remarks

R

R

R

Where to Put Your Machine

Your machine's location should be carefully chosen because environmental conditions greatly affect its performance.

Environmental Conditions

Optimum environmental conditions

CAUTION:

• Keep the machine away from humidity and dust. Otherwise a fire or an electric shock might occur.

• Do not place the machine on an unstable or tilted surface. If it topples over,

an injury might occur.

5

CAUTION:

• If you use the machine in a confined space, make sure there is a continuous

air turnover.

CAUTION:

• After you move the machine, use the caster fixture to fix it in place. Otherwise the machine might move or come down to cause an injury.

• Temperature: 10 – 30°C, 50 – 86°F

• Humidity: 20 – 90%RH

• A strong and level base (a sturdy desk and cabinet etc.)

• The machine must be level within 5 mm, 0.2" both front to rear and left to

right.

• Make sure to locate this machine in a large well ventilated room that has an

air turnover of more than 30 m

3

/hr/person.

Environments to avoid

• Locations exposed to direct sunlight or strong light (more than 1500 lux).

• Locations directly exposed to cool air from an air conditioner or heated air

from a heater. (Sudden temperature changes might cause condensation within the machine.)

• Places where the machine might be subjected to frequent strong vibration.

• Dusty areas.

• Areas with corrosive gases.

66

Page 73

Where to Put Your Machine

R

R

R

Power Connection

WARNING:

• Connect the machine only to the power source described on the inside

front cover of this manual. Connect the power cord directly into a wall

outlet and do not use an extension cord.

• Do not damage, break or make any modifications to the power cord.

Do not place heavy objects on it. Do not pull it hard nor bend it more

than necessary. These actions could cause an electric shock or fire.

CAUTION:

• Unplug the power cord from the wall outlet before you move the machine.

While moving the machine, you should take care that the power cord will not

be damaged under the machine.

CAUTION:

• When you disconnect the power plug from the wall outlet, always pull the

plug (not the cable).

❖❖❖❖ Main Frame

• Make sure the plug is firmly inserted in the outlet.

Access to Machine

5

Place the machine near the power source, providing clearance as shown.

❖❖❖❖ Main Frame

1

2

4

3

GRINST0E

1.

More than 20 cm, 8.0"

2.

More than 60 cm, 23.7"

3.

More than 60 cm, 23.7"

4.

More than 60 cm, 23.7"

67

Page 74

Remarks

Maintaining Your Machine

To maintain high print quality, clean

the following parts and units regularly.

Document Feeder

Lift the document feeder cover.

AAAA

Clean the two areas indicated be-

BBBB

low using a damp cloth and then

wipe with a dry cloth.

Paper Feed Roller (paper feed

tray)

Wipe off the paper dust on the pa-

AAAA

per feed roller with a damp cloth,

then wipe it with a dry cloth.

5

Note

❒ If you do not clean the paper

feed roller, paper misfeeds tend

to occur.

Note

❒ If you do not clean the docu-

ment feeder, marks on the feeder will be printed.

68

Page 75

Combination Chart

This combination chart shows which modes can be used together.

❍

×

1 Enlarge/Reduce --

2Auto Cycle

3Combine

4 Type of Original

5Image Density

6 On-Line

means that these modes can be used together.

means that these modes cannot be used together.

123456

❍❍ ❍ ❍ ×

❍

--

❍❍

❍❍❍

❍❍❍❍

× ❍ ×××

❍❍❍❍

❍❍×

--

--

Combination Chart

❍ ×

×

--

--

5

69

Page 76

Remarks

5

70

Page 77

6. Specifications

Main Frame

❖❖❖❖ Configuration:

Desk top

❖❖❖❖ Printing Process:

Full automatic one drum stencil system

❖❖❖❖ Original Type:

Sheet

❖❖❖❖ Original Size:

Maximum 275 mm × 395 mm, 10.8" × 15.6"

❖❖❖❖ Pixel Density:

300 × 300 dpi

❖❖❖❖ Image Mode:

Photo mode

Letter mode

❖❖❖❖ Reduction Ratios:

• Inch version:

93%, 77%, 74%, 65%

• Metric version:

93%, 87%, 82%, 71%

❖❖❖❖ Enlargement Ratios:

• Inch version:

155%, 129%, 121%

• Metric version:

141%, 122%, 115%

❖❖❖❖ Printing Area:

• LG drum:

210 mm × 355 mm, 8.2" × 14.0"

• B4 drum:

250 mm × 355 mm, 9.8" × 14.0"

❖❖❖❖ Print Paper Size:

Maximum 275 mm × 395 mm, 10.8" × 15.6"

Minimum 90 mm × 140 mm, 3.6" × 5.6"

71

Page 78

Specifications

❖❖❖❖ Leading Edge Margin:

5 mm ± 3 mm, 0.2" ± 0.12"

❖❖❖❖ Print Paper Weight:

35 g/m2 to 127.9 g/m2, 9.3 lb to 34 lb

❖❖❖❖ Print Speed:

60 – 90 cpm (2 steps)

❖❖❖❖ First Copy Time (Master Process Time):

Less than 45.0 seconds (A4L, 81/2" × 14"L)

❖❖❖❖ Second Copy Time (First Print Time):

Less than 47.0 seconds (A4L, 81/2 " × 14"L)

❖❖❖❖ Colour Printing:

Drum unit replacement system (black, red, blue, green, brown, yellow, purple, navy, maroon, orange and teal)

❖❖❖❖ Image Position Adjustment:

• Vertical:

6

More than ± 10 mm, ± 0.39"

• Side:

10 mm, 0.39" (for either side)

❖❖❖❖ Paper Feed Tray Capacity:

500 sheets (80 g/m2, 20 lb)

❖❖❖❖ Paper Delivery Tray Capacity:

500 sheets (80 g/m2, 20 lb)

❖❖❖❖ Master Eject Box Capacity:

30 masters

❖❖❖❖ Dimensions (W ×××× D ×××× H):

*1

Stored

Set up 1,332 mm, 52.5" 663 mm, 26.1" 519 mm, 20.5"

*1

With both the paper feed tray and the paper delivery tray detached.

❖❖❖❖ Weight:

• Main Frame: 54 kg, 119.1 lb

72

Width Depth Height

582 mm, 23.0" 663 mm, 26.1" 519 mm, 20.5"

Page 79

Main Frame

❖❖❖❖ Noise Emission *1:

Sound Power Level

Printing Speed Noise Emission

During printing 60 cpm 77 dB(A)

90 cpm 80 dB(A)

Stand-by -- 32 dB(A)

Sound Pressure Level*2

Printing Speed Noise Emission

During printing 60 cpm 64 dB(A)

90 cpm 68 dB(A)

Stand-by -- 23 dB(A)

*1 These noise emission levels are actual values measured in accordance with

ISO 7779.

*2 Sound pressure level 2 is measured from the position of the operator.

❖❖❖❖ Power Source:

See the inside front cover of this manual.

❖❖❖❖ Power Consumption:

Master Making Less than 0.175 kW

Printing Less than 0.175 kW

6

❖❖❖❖ Optional Equipment:

• Colour Drum

B4 drum

LG drum

73

Page 80

Specifications

Consumables

Name Size Remarks

Master for LG drum Length: 50 m, 164ft/roll

Width: 240 mm, 9.5"

1 roll/pack

Master for B4 drum Length: 50 m, 164ft/roll

Width: 280 mm, 11.0"

1 roll/pack

Ink-Black 500ml/pack, 5 packs/case Environmental conditions: – 5

Ink-Red 600ml/pack, 5 packs/case

Ink-Blue 600ml/pack, 5 packs/case

Ink-Green 600ml/pack, 5 packs/case

Ink-Brown 600ml/pack, 5 packs/case

Ink-Yellow 600ml/pack, 5 packs/case

Ink-Purple 600ml/pack, 5 packs/case

6

Ink-Navy 600ml/pack, 5 packs/case

Ink-Maroon 600ml/pack, 5 packs/case

Ink-Orange 600ml/pack, 5 packs/case

Ink-Teal 600ml/pack, 5 packs/case

100 masters can be made per

roll

100 masters can be made per

roll

to 40°C, 10 to 95%RH

Note

❒ Specifications are subject to change without notice.

74

Page 81

INDEX

A

Access to machine, 67

Adjusting the Print Image Density

Adjusting the Print Image Position

After clearing misfeeds

After Printing

Auto Cycle

{Auto Cycle}}}} key

,

, 17

28

, 45

, 8, 28

C

Changing the Colour Drum Unit, 34

Changing the Paper Size

Changing the Printing Speed

Clearing Misfeeds

{Clear Modes/Recovery}}}} key

{Clear/Stop}}}} key

Colour Printing

Combination Chart

Combine

{Combine}}}} key

Consumables

Control panel

Counter

, 8, 22

,

, 29

, 8, 29

, 74

, 6, 8

, 9

, 45

33

, 69

, 38

,

, 21

8

D

Dirt on the Back Side of Paper, 58

Dirt on the Front Side of Paper

(Black Line/Stain)

Document Feeder