Page 1

J2SS-C3

(Machine Code: B047/B048)

Service Manual

– Insert Version –

The B047/B048 machines are based on the A163/A251/A252 copiers.

Only the differences from the base copier are described in the following pages.

Therefore, this documentation should be treated as an insert version of the base

copier’s service manual. It should always be utilized together with the base

copier’s service manual.

Page 2

INSERTION PROCEDURE OF SERVICE MANUAL

1. Replace the book spine tag with the new one.

2. Insert the B047/B048 service manual a fter the A1 63/A 25 1/A252 manual.

Page 3

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the peripherals are supplied

with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

6. The copier is not attached to the table. Pushing the copier too hard may

cause it to drop onto the floor. While moving the copier, push the table.

7. When the main switch is turned on, the machine will suddenly start turning to

perform the developer initialization. Keep hands away from any mechanical

and electrical components during this period.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

Page 4

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may ignite

suddenly when exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductors according to

local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Page 5

TABLE OF CONTENTS

This manual describes new items for the J2SS-C3 (B 04 7/B048).

Please refer to the J2SS Mark II (A251/A252) manual for the descriptions marked

with “*” in page column.

1. OVERALL MACHINE INFORMATION........................................ 1-1

1.1 SPECIFICATIONS.....................................................................................1-1

1.2 PAPER PATH............................................................................................1-3

1.3 DRUM PROCESSES ............................................................................... *

1.4 MECHANICAL COMPONENTS................................................................1-4

1.5 DRIVE LAYOUT....................................................................................... *

1.6 ELECTRICAL COMPONENTS..................................................................1-6

2. DETAILED SECTION DESCRIPTIONS ...................................... 2-1

2.1 DRUM....................................................................................................... *

2.1.1 DRUM CHARACTERISTICS........................................................... *

2.1.2 DRUM DRIVE.................................................................................. *

2.2 CHARGE.................................................................................................. *

2.2.1 OVERVIEW..................................................................................... *

2.2.2 CHARGE CORONA CIRCUIT......................................................... *

2.2.3 CORONA UNIT VENTILATION....................................................... *

2.3 EXPOSURE...............................................................................................2-1

2.3.1 OVERVIEW..................................................................................... *

2.3.2 PAPER AND ORIGINAL FEED (B048 ONLY)..................................2-1

Basic Operation (Manual Feed)........................................................... *

Original Jam Check Timing.................................................................. *

Drive Mechanism................................................................................. *

Original Positioning...............................................................................2-1

Scanning ...............................................................................................2-2

Start Key Enable...................................................................................2-3

2.3.3 FL REGULATOR CONTROL........................................................... *

2.3.4 MANUAL ID CONTROL................................................................... *

Manual ID Control................................................................................ *

2.4 DEVELOPMENT.......................................................................................2-4

2.4.1 OVERVIEW..................................................................................... *

2.4.2 DRIVE MECHANISM....................................................................... *

2.4.3 CROSS-MIXING.............................................................................. *

2.4.4 TONER DENSITY CONTROL..........................................................2-4

Toner Near End Condition................................................................... *

Recovery from Toner End Condition.....................................................2-5

Toner Density Sensor.......................................................................... *

2.4.5 DEVELOPMENT BIAS.................................................................... *

Basic Concept...................................................................................... *

Manual Image Density Bias................................................................. *

2.4.6 TONER SUPPLY............................................................................. *

2.5 IMAGE TRANSFER AND PAPER SEPARATION.................................... *

i

Page 6

2.5.1 PRE-TRANSFER LAMP (PTL)........................................................ *

2.5.2 IMAGE TRANSFER......................................................................... *

2.5.3 PAPER SEPARATION.................................................................... *

2.5.4 PICK-OFF MECHANISM................................................................. *

2.5.5 T/S CORONA CIRCUIT ................................................................... *

2.6 CLEANING............................................................................................... *

2.6.1 OVERVIEW..................................................................................... *

2.6.2 USED TONER COLLECTION..........................................................2-6

2.7 QUENCHING............................................................................................ *

2.8 FUSING AND PAPER EXIT......................................................................2-7

2.8.1 OVERVIEW......................................................................................2-7

2.8.2 DRIVE MECHANISM....................................................................... *

Fusing Unit Drive................................................................................. *

2.8.3 TEMPERATURE CONTROL............................................................2-8

Fusing Circuit Operation...................................................................... *

Overheat Protection............................................................................. *

Hot Roller Temperature Control............................................................2-8

2.8.4 TEMPERATURE CONTROL........................................................... *

The Ready Condition........................................................................... *

Fusing Unit Operating Modes.............................................................. *

2.8.5 ENERGY SAVER FUNCTION......................................................... *

2.8.6 FUSING ENTRANCE GUIDE HEIGHT............................................ *

2.9 OTHERS .................................................................................................. *

2.9.1 ROLL CUTTING RAIL ..................................................................... *

2.10 ENERGY STAR COMPLIANT MACHINES

(ALL THE DESTINATION)......................................................................2-9

3. INSTALLATION ........................................................................... 3-1

3.1 INSTALLATION REQUIREMENTS...........................................................3-1

3.1.1 ENVIRONMENT...............................................................................3-1

3.1.2 MINIMUM SPACE REQUIREMENTS...............................................3-2

3.1.3 MACHINE LEVEL.............................................................................3-2

3.1.4 POWER SOURCE............................................................................3-3

3.2 INSTALLATION PROCEDURE.................................................................3-4

3.2.1 COPIER............................................................................................3-4

Accessory Check.................................................................................. 3-4

B048 copier only (step 21)..................................................................3-12

B047 copier only (step 22 and 23)......................................................3-12

Both copiers (step 24 and 25).............................................................3-12

3.2.2 TABLE (B439) ................................................................................3-13

Accessory Check................................................................................ 3-13

3.2.3 COPY tray (B440)........................................................................... 3-15

Accessory Check................................................................................ 3-15

3.2.4 ROLL FEEDER1 and 2 (B435/b436)..............................................3-19

Accessory Check................................................................................ 3-19

3.2.5 Roll Cutting Rail (B437)..................................................................3-28

ii

Page 7

4. SERVICE TABLES...................................................................... 4-1

4.1 PREVENTIVE MAINTENANCE SCHEDULE........................................... *

4.1.1 PM TABLE....................................................................................... *

4.1.2 REGULAR PM PROCEDURE......................................................... *

4.2 SERVICE TABLES................................................................................... *

4.2.1 TEST POINTS................................................................................. *

Main Board .......................................................................................... *

Charge/Bias/Grid Power Pack............................................................. *

4.2.2 VARIABLE RESISTORS................................................................. *

Charge/Bias/Grid Power Pack............................................................. *

T&S Power Pack.................................................................................. *

4.3 SERVICE TOOLS......................................................................................4-1

4.3.1 SERVICE PROGRAM MODE...........................................................4-1

Service Program Mode Access Procedure.......................................... *

Service Program Mode Table...............................................................4-1

4.3.2 INPUT/OUTPUT CHECK MODE....................................................4-23

Input/Output Check Mode Access Procedure...................................... *

Input Check Mode Table.....................................................................4-23

Output Check Mode Table..................................................................4-23

4.3.3 POWER ON INITIAL SETTING MODE........................................... *

4.4 JAM CODE LIST.....................................................................................4-25

4.4.1 ACCESS PROCEDURE.................................................................. *

4.4.2 JAM CODE TABLE.........................................................................4-25

Fixed Paper Size Pattern Data (SP No. 22)........................................4-27

Default Settings for Each Destination (SP#-1)....................................4-28

4.5 SPECIAL TOOLS AND LUBRICANTS..................................................... *

4.6 SERVICE REMARKS..............................................................................4-29

4.6.1 DRUM UNIT .................................................................................... *

Drum.................................................................................................... *

4.6.2 CHARGE CORONA......................................................................... *

4.6.3 OPTICS........................................................................................... *

4.6.4 DEVELOPMENT ............................................................................. *

4.6.5 TRANSFER AND SEPARATION..................................................... *

4.6.6 CLEANING UNIT............................................................................. *

4.6.7 FUSING UNIT.................................................................................. *

4.6.8 ORIGINAL FEED............................................................................. *

4.6.9 PAPER FEED.................................................................................. *

4.6.10 ROLL FEEDER.............................................................................. *

4.6.11 OTHERS........................................................................................ *

4.6.12 AC DRIVE BOARD.......................................................................4-29

Service Remark for 220 ~ 240 V Version............................................4-29

Service Remarks for 120 V Version....................................................4-30

5. REPLACEMENT AND ADJUSTMENT........................................ 5-1

5.1 EXTERIOR COVERS............................................................................... *

5.1.1 LEFT SIDE COVER REMOVAL...................................................... *

Left Upper Cover ................................................................................. *

Left Lower Cover.................................................................................. *

iii

Page 8

5.1.2 RIGHT SIDE COVER REMOVAL .................................................... *

Right Upper Cover............................................................................... *

Right Lower Front, Right Lower Middle, and Right Lower

Rear Covers......................................................................................... *

5.1.3 REAR COVER REMOVAL .............................................................. *

Rear Cover .......................................................................................... *

5.2 OPTICS.................................................................................................... *

5.2.1 ORIGINAL FEED UNIT REMOVAL (A252 ONLY)........................... *

5.2.2 EXPOSURE GLASS REMOVAL (A252 ONLY)............................... *

5.2.3 EXPOSURE LAMP REMOVAL (A252 ONLY)................................. *

5.2.4 FIBER OPTICS ARRAY REMOVAL (A252 ONLY).......................... *

5.2.5 LIGHT SENSOR REPLACEMENT (A252 ONLY)............................ *

5.2.6 SYNCHRO-CUT LENGTH ADJUSTMENT (A252 ONLY)............... *

5.3 DEVELOPMENT...................................................................................... *

5.3.1 DEVELOPMENT UNIT REMOVAL.................................................. *

5.3.2 DEVELOPER REMOVAL................................................................ *

5.3.3 TONER DENSITY SENSOR REPLACEMENT................................ *

5.3.4 PTL REPLACEMENT...................................................................... *

5.3.5 DEVELOPMENT BIAS VOLTAGE ADJUSTMENT ......................... *

Bias Voltage for Image Area................................................................ *

Bias Voltage for Non-image Area ........................................................ *

5.4 DRUM UNIT ..............................................................................................5-1

5.4.1 DRUM UNIT REMOVAL................................................................. *

5.4.2 DRUM REPLACEMENT...................................................................5-1

5.4.3 CLEANING BLADE REPLACEMENT.............................................. *

5.4.4 CHARGE CORONA UNIT REMOVAL............................................. *

5.4.5 CHARGE CORONA WIRE REPLACEMENT .................................. *

5.4.6 PICK-OFF PAWL UNIT REMOVAL................................................. *

5.4.7 GRID VOLTAGE ADJUSTMENT..................................................... *

5.4.8 DRUM CURRENT ADJUSTMENT .................................................. *

Charge Current Adjustment................................................................. *

Transfer Current Adjustment................................................................ *

Separation Current Adjustment............................................................ *

5.5 FUSING.....................................................................................................5-2

5.5.1 FUSING UNIT REMOVAL............................................................... *

5.5.2 HOT ROLLER REPLACEMENT...................................................... *

5.5.3 PRESSURE ROLLER REPLACEMENT.......................................... *

5.5.4 PRESSURE ROLLER THERMISTOR REPLACEMENT................. *

5.5.5 PRESSURE ROLLER STRIPPER UNIT REPLACEMENT.............. *

5.5.6 HOT ROLLER STRIPPER UNIT REPLACEMENT.......................... *

5.5.7 HOT ROLLER THERMISTOR REPLACEMENT ..............................5-2

5.5.8 FUSING THERMOFUSE REPLACEMENT......................................5-2

5.5.9 FUSING TEMPERATURE ADJUSTMENT.......................................5-3

5.6 T & S CORONA UNIT .............................................................................. *

5.6.1 T & S CORONA UNIT REMOVAL................................................... *

5.6.2 TRANSFER AND SEPARATION CORONA WIRE

REPLACEMENT.............................................................................. *

Preparation.......................................................................................... *

Separation Corona Wire Replacement................................................ *

iv

Page 9

Transfer Corona Wire Replacement .................................................... *

5.7 OTHERS .................................................................................................. *

5.7.1 OZONE FILTER REPLACEMENT................................................... *

5.7.2 ANTICONDENSATION HEATER INSTALLATION.......................... *

5.8 COPY QUALITY ADJUSTMENT...............................................................5-4

5.8.1 LIGHT SENSOR ADJUSTMENT..................................................... *

5.8.2 IMAGE BIAS ADJUSTMENT........................................................... *

5.8.3 TONER DENSITY ADJUSTMENT................................................... *

5.8.4 REGISTRATION ADJUSTMENT......................................................5-4

6. TROUBLESHOOTING ................................................................ 6-1

6.1 COPY QUALITY TROUBLESHOOTING.................................................. *

6.1.1 LOW IMAGE DENSITY................................................................... *

6.1.2 UNEVEN COPY IMAGE.................................................................. *

6.1.3 DIRTY BACKGROUND................................................................... *

6.1.4 BLACK LINE OR BAND................................................................... *

6.1.5 ENTIRELY BLANK COPY............................................................... *

6.1.6 PAPER CREASING......................................................................... *

6.2 SERVICE CALL CONDITIONS................................................................. 6-1

6.2.1 SC CODE DESCRIPTIONS .............................................................6-1

SC Code E-1: Exposure Lamp Abnormal.............................................6-1

SC Code E-2: Fusing Thermofuse Open..............................................6-1

SC Code E-3: Hot Roller Thermistor Open...........................................6-1

SC Code E-4: Hot Roller Thermistor Short...........................................6-2

SC Code E-5: Pressure Roller Thermistor Open..................................6-2

SC Code E-6: Pressure Roller Thermistor Short..................................6-2

SC Code E-7: Fusing Overheat............................................................6-2

SC Code E-8: Fusing Warm-up Error...................................................6-3

SC Code E-9: Toner Density Sensor Abnormal....................................6-3

SC Code E-10: Main Motor Abnormal...................................................6-3

SC Code E-11: Toner Density Sensor Adjustment Error......................6-3

SC Code E-13: Total Counter Abnormal...............................................6-4

SC Code E-14: Zero Cross Signal Detection Abnormal........................6-4

SC Code E-15: Main Switch Abnormal................................................. 6-4

SC Code E-17: Unstable Fusing Temperature .....................................6-4

SC Code E-18: Fusing Lamp Continuous Light....................................6-4

6.3 BLOWN FUSE TABLE ..............................................................................6-5

6.3.1 POWER SUPPLY UNIT....................................................................6-5

Europe Version.....................................................................................6-5

U.S.A. Version......................................................................................6-5

AC Drive Board.....................................................................................6-5

ROLL FEEDER UNIT (B435/B436)

1. OVERALL MACHINE INFORMATION.................................B436-1

1.1 SPECIFICATIONS.............................................................................. B436-1

1.2 ELECTRICAL COMPONENT DESCRIPTIONS................................. B436-2

v

Page 10

2. DETAILED SECTION DESCRIPTIONS ................................B436-3

2.1 MECHANICAL OPERATION.............................................................. B436-3

2.1.1 BASIC OPERATION.................................................................. B436-3

2.1.2 ROLL EDITION DETECTION.................................................... B436-5

2.1.3 DRIVE MECHANISM................................................................. B436-5

2.1.4 CUTTER OPERATION.............................................................. B436-6

3. REPLACEMENT A ND ADJUSTMENT..................................B436-7

3.1 CUTTER UNIT REPLACEMENT........................................................ B436-7

3.2 ROLL FEED LEADING EDGE SENSOR REPLACEMENT................ B436-8

3.3 ROLL FEED UNIT REMOVAL............................................................ B436-9

3.4 ROLL FEED CLUTCH REPLACEMENT.......................................... B436-10

3.5 ROLL FEED MOTOR REPLACEMENT ........................................... B436-11

3.6 ROLL END SENSOR REPLACEMENT............................................ B436-12

3.7 CUT LENGTH ADJUSTMENT.......................................................... B436-13

Preset Cut : Adjustment standards: ±3 mm (for Length Shorter

than 420 mm) ±5 mm (for 420 to 1,189 mm) ±11 mm

(3,000 mm) .................................................................................. B436-13

3.8 SIDE REGISTRATION ADJUSTMENT ............................................. B436-14

vi

Page 11

11 May, 2001 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Configuration: Table top

Copy Process: Electrostatic transfer system

Original Feed: Sheet feed

Original Size: Maximum: 914 x 3,000 (36" x 118")mm

Minimum: A4 (8

Copy Size: Same as “Original Size”

Copying Speed: 4 cpm (A1/D sideways)

First Copy: 21 seconds (A1/D sideways): B047 copier

25 seconds (A1/D sideways): B048 copier

Warm-up Time:

Multi-Copy: B047: Single copies only,

Automatic Reset: 2 minutes after copying has finished (can be set to

Photoconductor: Organic photoconductor drum

Within 3 minutes (Room temperature 23°C)

B048: Up to 10 copies

1, 3, 4, or 5 minutes or to no auto reset)

" x 11") lengthwise

1/2

Overall

Information

Drum Charge: Scorotron corona wire and grid (Negative Charge)

Reproduction Ratio:

Exposure System: Slit exposure via fiber optic array

Exposure Lamp: Fluorescent lamp (26 W)

Development: Dual-component dry toner system

Toner Replenishment: Cartridge system (750 g toner/cartridge)

Toner Consumption: 1,860 A1 or D copies per cartridge (6% original)

Development Bias: Negative

Toner Density Control: Direct toner density detection using an induction

Image Density Adjustment: Development bias control + exposure control

Paper Separation: Dual wire AC corona and pick-off pawls

Cleaning: Cleaning blade

Paper Feeding: Manual feed (roll feeder optional)

Image Fusing: Teflon heat roller (upper) and a silicone rubber

1 : 1 (±0.5%)

sensor

pressure roller (lower)

Fusing Lamp: Halogen lamp

(115 V: 1,200 W, 230 V: 1,200 W)

1-1

Page 12

SPECIFICATIONS 11 May, 2001

Self-diagnostic Codes: 16 codes, displayed on the copy counter

Power Source: 115 V/60 Hz, 12 A

220 ~ 240V/50, 60 Hz, 7A

Power Consumption: Maximum: 1.4 kW

Warm-up: 1.3 kW

Ready: 0.04 to 1.3 kW

Copy cycle:1.4 kW

Dimensions (W x D x H): B047: 1,080 x 570 x 490 mm

42.5" x 22.4" x 19.3"

B048: 1,080 x 623 x 480 mm

42.5" x 24.5" x 18.9"

Weight: B047: 79 kg, 174.0 lbs

B048: 80 kg, 176.0 lbs

Optional Equipment and Machine Configuration

Configuration

Main frame Optional equipment

Roll feeder (B435: 1 roll, B436: 2 rolls) —

B047 copier

B048 copier

Roll cutting rail (B437) —

Table (B439) —

Side guides (B438) —

Roll feeder (B435: 1 roll, B436: 2 rolls) Copy tray (B440)

Side guide (B438) —

Additional equipment

NOTE: 1) Roll cutting rail cannot be installed on the B048 copier.

2) Key counters cannot be installed on these copiers.

3) The B048 requires a roll feeder (either 1 roll or 2 rolls). While the roll

feeders are shipped separately, they are not really optional. One must

be installed for the B048 to function properly. .

Other Optional Equipment

• Roll Holder Unit (B394)

• Drum anti-condensation heater

Specifications are subject to change without notice.

1-2

Page 13

11 May, 2001 PAPER PATH

1.2 PAPER PATH

- B047 copier -

- B048 copier -

Overall

Information

A

B

C

B047V102.WMF

E

D

E

A

B

D

C

B048V102.WMF

A: Original Path

B: Manual Feed Path

C: Roll Feeder Path

D: Paper Exit

E: Original Path: Rear Feeder

There are two versions of this machine. The B047 is the basic version. It can only

make one copy at a time. The B048 is the multi-print version. It can make multiple

copies of an original (scanning and copying an original multiple times).

Both versions can be equipped with either a single or a double paper roll.

1-3

Page 14

MECHANICAL COMPONENTS 11 May, 2001

1.4 MECHANICAL COMPONENTS

14

13

19

18

17

16

15

20 21 22 1 2

3

4

5

6

7

8

9

10

11

1. 1st Original Feed Roller

2. 1st Press Rollers

3. Copy Tray

4. Exit Rollers

5. Fusing Exit Rollers

6. Hot Roller

7. Pressure Roller

8. Gas Spring

9. OPC Drum

10. T/S Corona Unit

11. Main Drive Unit

12

B047V101.WMF

12. Roll Feed Unit (1 roll or 2 rolls)

13. Roll Paper

14. Paper Registration Rollers

15. Manual Feed Table

16. Development Unit

17. Toner Cartridge

18. 2nd Original Feed Roller

19. Original Table

20. 2nd Original Press Roller

21. Exposure Lamp

22. Fiber Optic Array

1-4

Page 15

11 May, 2001 MECHANICAL COMPONENTS

27

28 29

26

25

23

Overall

Information

23. Original Guide

24. Optional Copy Tray

25. Original Entrance Roller

26. Original Entrance Press Roller

24

B048V101.WMF

27. Original Roller Feed Motor

28. Original Rear Press Roller

29. Original Rear Roller

1-5

Page 16

ELECTRICAL COMPONENTS 11 May, 2001

1.6 ELECTRICAL COMPONENTS

Refer to the electrical component layout on the reverse side of the Point to Point

index (Water proof paper).

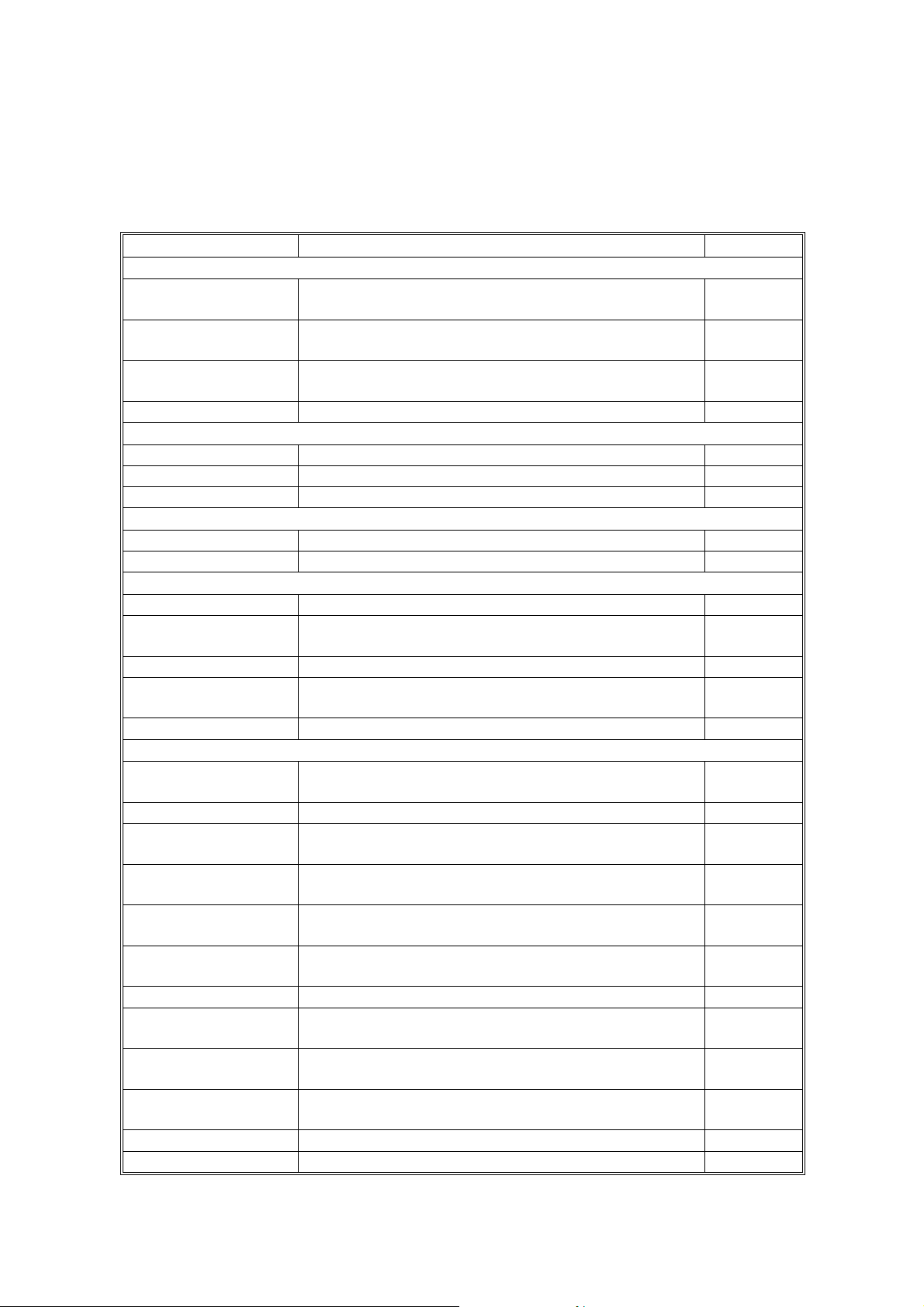

Name Function Index. No.

Motors

Main Drives all mechanical components except the fans

(DC Motor).

Exhaust Fan Removes the ozone built up around the drum

section to the ozone filter (DC Motor).

Original Feed

(B048 only)

Magnetic Clutches

Registration Drives the registration rollers. 30

Toner Supply Turns on to supply toner to the development unit. 31

Solenoids

Pick-off Pawl Moves the pick-off pawls against the drum. 6

Drives the original feed motor (DC Motor).

32

5

45

Switches

Main Supplies power to the copier. 17

Original & Paper

Feed Safety

Fusing Exit Safety Cuts AC power when the fusing exit unit is opened. 12

Used Toner Cover “Door Open” is displayed on the operation panel

Sensors

Door Open Indicates “Door Open” on the operation panel and

Toner Density Detects the density of toner in the developer. 26

Original Registration Activates when the leading edge of the original

Light Measures the intensity of the exposure lamp’s

Entrance Feed Activates when copy paper is inserted (jam

Registration

Exit Detects jams through the fusing exit unit. 7

Original Entrance

(B048 only)

Original Rear

(B048 only)

Exit Cover Open Indicates “Door Open” in the operation panel and

Toner Overflow Detects whether the used toner tank is full or not. 46

Cuts AC power when the original or paper feed unit

are opened.

when the used toner cover is open.

prevents operation.

passes the front of the exposure glass.

output.

detector).

Activates when copy paper arrives at the

registration rollers (jam detector).

Measures the original length and detects jams. 43

Detects original jams. 44

prevents operation.

18

48

29

4

27

24

25

47

1-6

Page 17

11 May, 2001 ELECTRICAL COMPONENTS

Name Function Index. No.

Printed Circuit Boards

Main Controls all copier functions both directly and

through other PCBs.

22

PSU Converts t h e voltag e from AC to DC voltage. 21

AC Drive Provides AC power to the fusing lamp and PSU. 15

FL Regulator Stabilizes power to the exposure lamp. 23

Operation Panel Controls the operation panel display. 10

Lamps

Exposure Provides light to reflect the original’s image onto

the drum (fluorescent lamp).

2

Fusing Provides heat to the fusing unit. 3

Pre-Transfer (PTL) Reduces the charge on the drum surface prior to

image transfer.

Quenching (QL) Neutralizes any charge remaining on the drum

surface after cleaning.

20

1

Power Packs

Charge/Bias/

Grid Power Pack

Transfer/Separation Provides high voltage power for the transfer corona

Provides high voltage power for the charge corona,

charge grid, and development bias.

and separation.

19

16

Overall

Information

Thermistors

Hot Roller Monitors the hot roller’s surface temperature. 8

Pressure Roller Monitors the pressure roller’s surface temperature. 11

Thermofuses

Fusing Protects the fusing unit against overheating. 9

Heaters

Anti-condensation Keeps m oistur e from forming inside the copier

(option).

13

Others

Total Counter Keeps track of the total length of copies made

(Europe) or the total copies made (U.S.A.).

Circuit Breaker

Guards against voltage surges in the input power.

(Europe, Asia)/

28

14

Fuse (U.S.A.)

1-7

Page 18

11 May, 2001 EXPOSURE

2. DETAILED SECTION DESCRIPTIONS

2.3 EXPOSURE

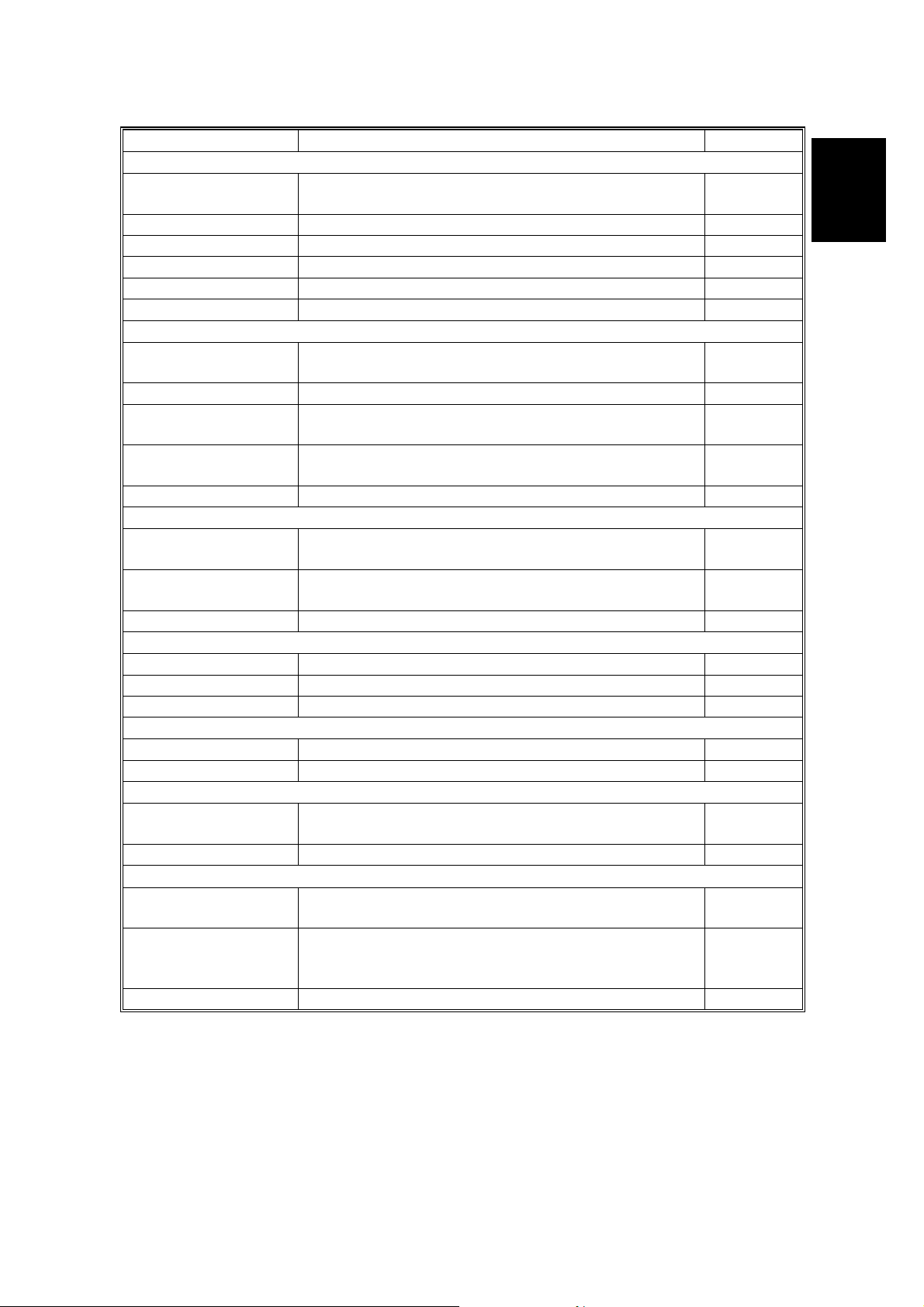

2.3.2 PAPER AND ORIGINAL FEED (B048 ONLY)

[E]

[C]

[G]

[D]

[L]

26 mm

[F]

[H]

10 mm

[I]

J: Original Rear Roller

K: Original Rear Sensor

L: Fiber Optics Array

[B]

[J]

[K]

[A]

Detailed

Descriptions

[M]

B047D500.WMF

B047D501.WMF

NOTE: For clarity’s sake, the following description will ref er to the paper’s edges

as edge [A] (furthest edge from the operator) and edge [B] (closest to the

operator).

Original Positioning

In the B048 copier, edge [A] of the original is placed onto the original table. This

activates the original entrance sensor [C].

The main motor turns the original entrance rollers [D]. The quenching lamp,

development bias and PTL also turn on.

For proper feeding (especially for a thin original), the original entrance rollers rotate

backwards (feeding towards the operator) for 300 ms. This ensures that the original

is gripped firmly by both of the original entrance rollers [D], feeding it evenly.

2-1

Page 19

EXPOSURE 11 May, 2001

4 seconds after the sensor is activated, the original feed motor starts rotating. This

delay gives the user time to align edge [A] against the original entrance rollers [D].

This helps prevent skew.

The original is fed through the machine to the scanning start position [E]. This

machine scans the original backwards, starting with edge [B] and scanning towards

edge [A]. The original is now ready to scan.

Scanning

The original is scanned, moving back towards the operator.

When edge [ A] activates the original registration sensor [F], the roll paper feed

motor turns on. Copy paper begins to feed, and the registration clutch is activated.

When edge [B] reaches the original feed start posi tion [E] (26 mm ahead of the

original registration sensor [F]), the original feed motor stops to wait for the copy

paper.

In the copy section, the registration clutch turns off once the copy paper’s leading

edge is 10 mm past the registration sensor [H]. The voltage is now applied to the

charge coro na.

The original feed motor begins rotating towards the operator again at 60 mm/s, and

the original is delivered to the exposure glass. Light from the exposure lamp [M] is

reflected off the paper to the fiber optics array [L].

Once the original’s edge [B] passes the original entrance sensor, the registration

clutch and roll paper feed motor turn on agai n. The pap er feed res ume s and the

copy paper is transported to the drum [I].

To measure the original length for cutting, the copier’s CPU measures the time

from when the original registration sensor detects edge [A] until the original

entrance sensor detects edge [B].

The copy paper length is measured by counting the number of steps as the roll

paper feed motor (a stepper motor) turns. Just before the paper is cut, the feed

motor speed doubles. This creates a buckle at the trailing edge of the copy paper.

The feed motor then stops as the cutter unit cuts the paper. Copying, however,

continues. The buckle provides the necessary slack while cutting.

When making duplicate copies, the original feed motor pauses, then changes

directions again, and the original is fed back to the scanning position 200 mm/s.

Once previous paper exits out of the roll feeder, the roll paper feed starts as well,

and the process repeats.

After all copies are made, the original is delivered to the original table. If original

hold mode is enabled (SP16), the original will stop with edge [A] caught by the

original entrance rollers. The original can be fed out by pressing the ! key. If

original hold mode is not enabled, the original feeds out completely, and is not

caught.

2-2

Page 20

11 May, 2001 EXPOSURE

Start Key Enable

When the start key enabled (SP34) is set, the start key acts as a starting trigger. In

this mode, when the original activates the original registration sensor, edge [B] is

delivered to the original registration sensor position. Everything pauses until the

user presses the start key. Original feed and paper feed then resume.

Detailed

Descriptions

2-3

Page 21

DEVELOPMENT 11 May, 2001

2.4 DEVELOPMENT

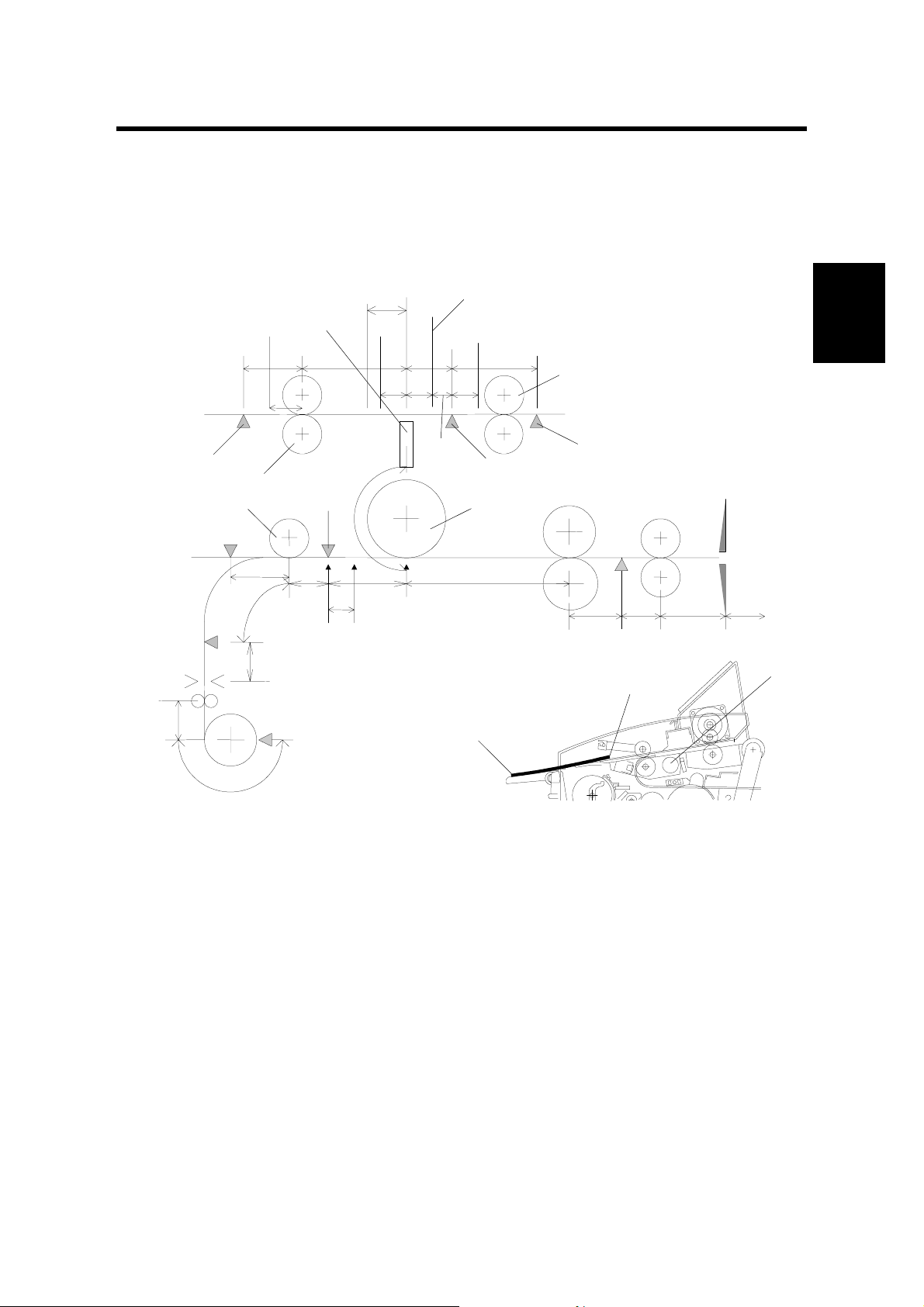

2.4.4 TONER DENSITY CONTROL

The toner supply amount ratio is determined by the following conditions.

N

L

H

TS

Level

0

1

2

3

4

5

0

1

2

3

4

5

0

1

2

3

4

5

201 ~ 250

sheets

(120 ~ 150 m)

<

2.25 ≤ V

2.70

<

2.70 ≤ V

3.15

<

3.15 ≤ V

3.60

<

3.60 ≤ V

3.90

3.90 ≤ V

<

3.25 ≤ V

3.50

<

3.50 ≤ V

3.80

<

3.80 ≤ V

4.00

<

4.00 ≤ V

4.35

4.35 ≤ V

<

2.00 ≤ V

2.40

<

2.40 ≤ V

2.80

<

2.80 ≤ V

3.20

<

3.20 ≤ V

3.60

3.60 ≤ V

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

<

<

<

<

TS

<

<

<

<

TS

<

<

<

<

TS

(30 ~ 60 m)

<

3.50 ≤ V

<

3.80 ≤ V

<

4.10 ≤ V

<

4.20 ≤ V

<

4.30 ≤ V

<

4.33 ≤ V

<

4.36 ≤ V

<

4.40 ≤ V

<

3.00 ≤ V

<

3.50 ≤ V

<

4.00 ≤ V

<

4.20 ≤ V

51 ~ 100

sheets

3.80

4.10

4.20

4.35

4.35 ≤ V

4.33

4.36

4.40

4.43

4.43 ≤ V

3.50

4.00

4.20

4.30

4.30 ≤ V

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

TS

0 ~ 50 sheets

(~ 30 m)

TS

V

< 4.00 VTS < 3.50 VTS < 3.00 VTS < 2.50 VTS < 2.25 VTS < 2.00

4.00 ≤ V

TS

4.10

4.10 ≤ V

TS

4.20

4.20 ≤ V

TS

4.30

4.30 ≤ V

TS

4.40

4.40 ≤ V

TS

V

4.35 ≤ V

TS

< 4.35 VTS < 4.30 VTS < 4.25 VTS < 3.75 VTS < 3.25 VTS < 2.75

TS

4.38

4.38 ≤ V

TS

4.40

4.40 ≤ V

TS

4.42

4.42 ≤ V

TS

4.45

4.45 ≤ V

TS

V

4.00 ≤ V

TS

< 4.00 VTS < 3.00 VTS < 2.50 VTS < 2.25 VTS < 2.00 VTS < 1.80

TS

4.10

4.10 ≤ V

TS

4.20

4.20 ≤ V

TS

4.30

4.30 ≤ V

TS

4.40

4.40 ≤ V

TS

(60 ~ 90 m)

<

3.00 ≤ V

<

3.50 ≤ V

<

4.00 ≤ V

<

4.20 ≤ V

<

4.25 ≤ V

<

4.30 ≤ V

<

4.33 ≤ V

<

4.36 ≤ V

<

2.50 ≤ V

<

3.00 ≤ V

<

3.50 ≤ V

<

4.00 ≤ V

101 ~ 150

sheets

TS

3.50

TS

4.00

TS

4.20

TS

4.30

4.30 ≤ V

TS

4.30

TS

4.33

TS

4.36

TS

4.40

4.40 ≤ V

TS

3.00

TS

3.50

TS

4.00

TS

4.25

4.25 ≤ V

(90 ~ 120 m)

<

2.50 ≤ V

<

3.00 ≤ V

<

3.50 ≤ V

<

4.00 ≤ V

TS

<

3.75 ≤ V

<

4.00 ≤ V

<

4.10 ≤ V

<

4.20 ≤ V

TS

<

2.25 ≤ V

<

2.70 ≤ V

<

3.15 ≤ V

<

3.60 ≤ V

TS

151 ~ 200

sheets

TS

3.00

TS

3.50

TS

4.00

TS

4.25

4.25 ≤ V

TS

4.00

TS

4.10

TS

4.20

TS

4.38

4.38 ≤ V

TS

2.70

TS

3.15

TS

3.60

TS

3.90

3.90 ≤ V

TS

TS

TS

251 sheets ~

(150 m ~)

TS

2.00 ≤ V

<

2.40

TS

2.40 ≤ V

<

2.80

TS

2.80 ≤ V

<

3.20

TS

3.20 ≤ V

<

3.60

TS

TS

<

3.60 ≤ V

2.75 ≤ V

3.20

TS

3.20 ≤ V

<

3.60

TS

3.60 ≤ V

<

3.90

TS

3.90 ≤ V

<

4.30

TS

TS

<

4.30 ≤ V

1.80 ≤ V

2.00

TS

2.00 ≤ V

<

2.50

TS

2.50 ≤ V

<

3.00

TS

3.00 ≤ V

<

3.50

3.50 ≤ V

TS

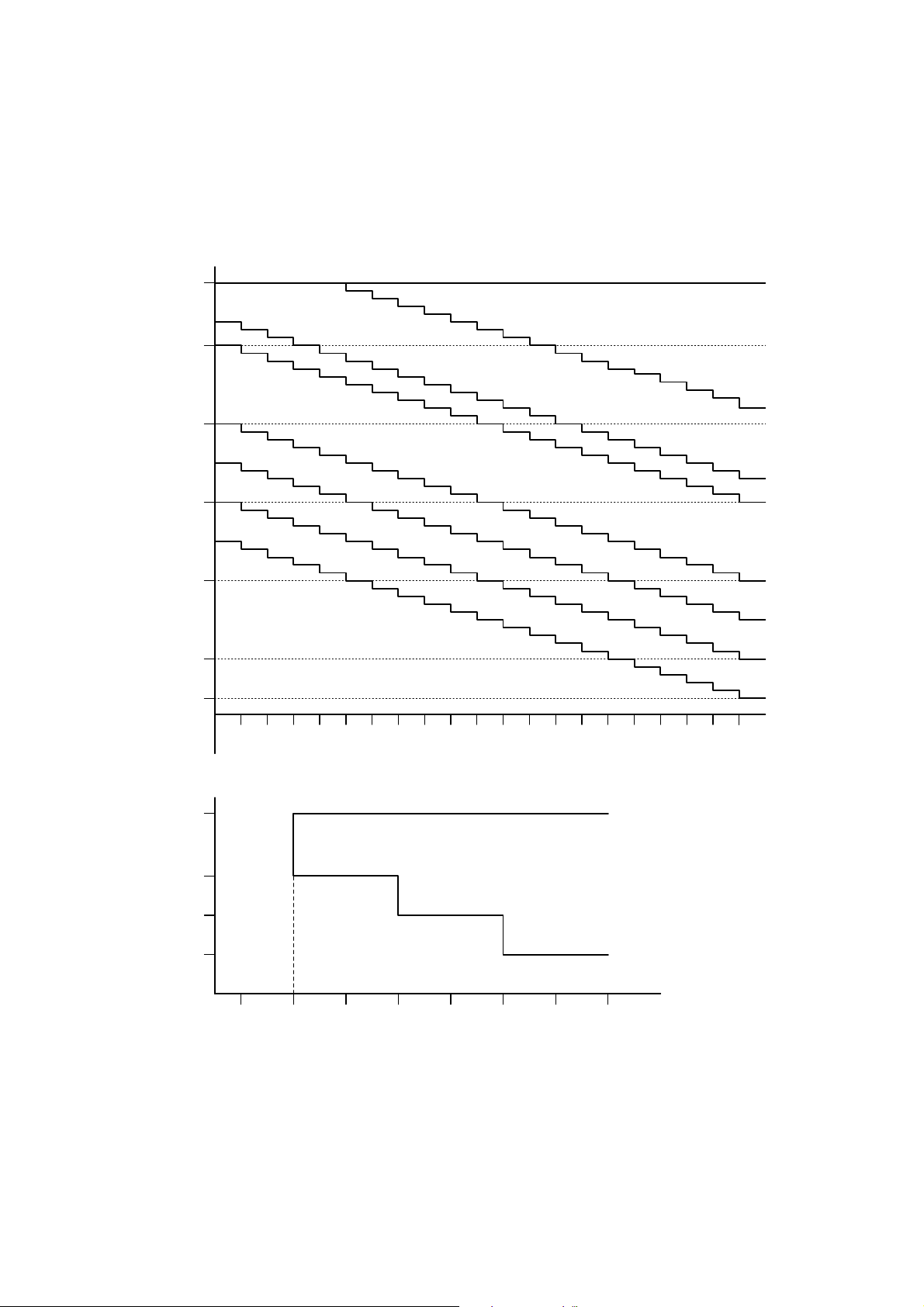

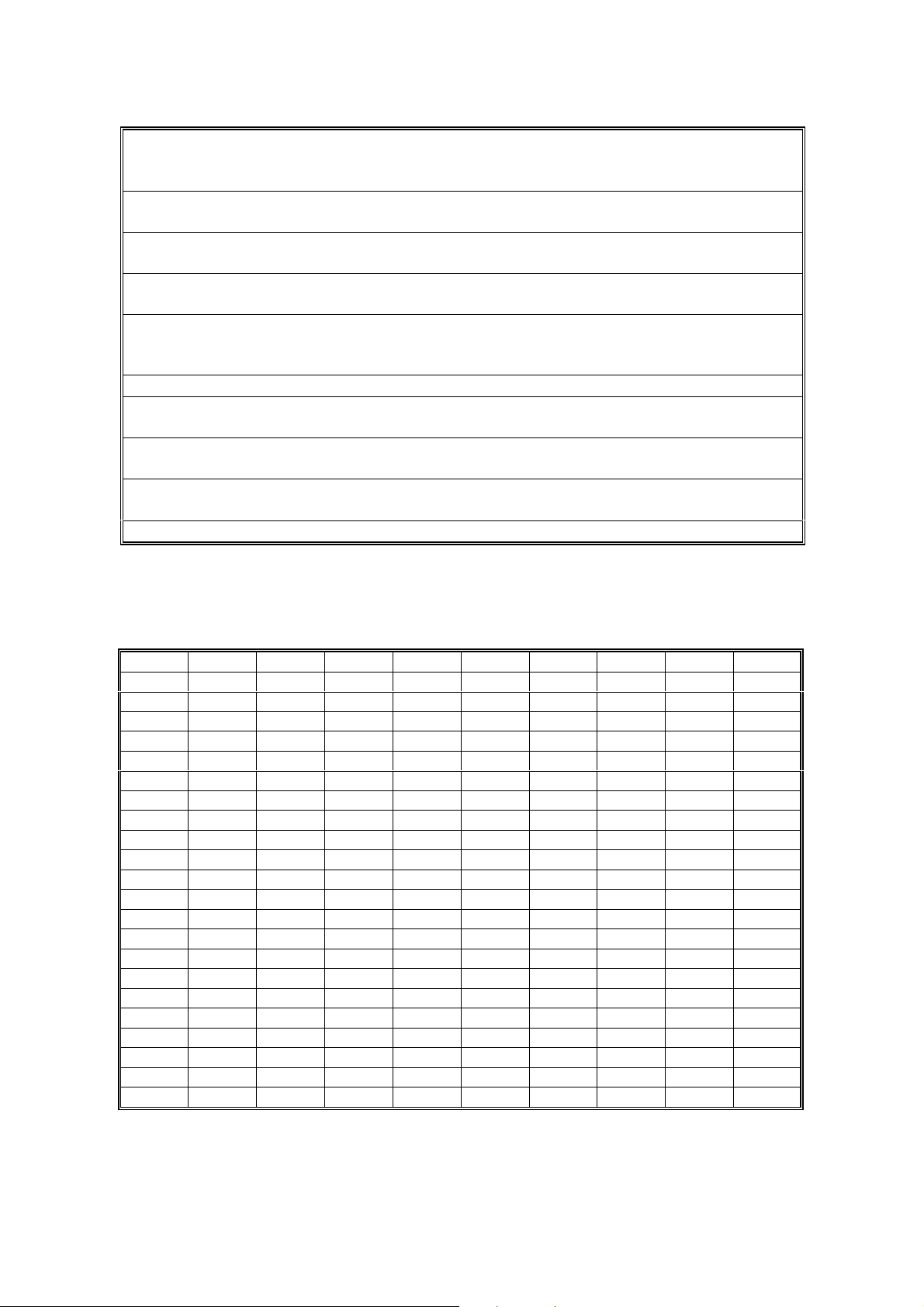

TS Level (Toner Supply Ratio)

0: No supply 1: 7.5% 2: 7.5% 3: 7.5% 4: 15% 5: 100%

Toner density control table has been changed for B047/B048 copiers.

2-4

Page 22

11 May, 2001 DEVELOPMENT

Recovery from Toner End Condition

After replacing the toner cartridge (opening and closing the original feed unit), the

main motor rotates the development unit for 60 seconds. During the first 30

seconds, toner is supplied at 100% of the supply amount until TS level reaches 3.

The main motor continues to rotate the development unit for another 30 seconds.

Then copies can be made.

If the TS level does not reach 3, the CPU stops the machine and displays the toner

end condition. This prevents the operator from resetting the toner end condition by

simply opening and closing original feed unit.

Detailed

Descriptions

2-5

Page 23

CLEANING 11 May, 2001

2.6 CLEANING

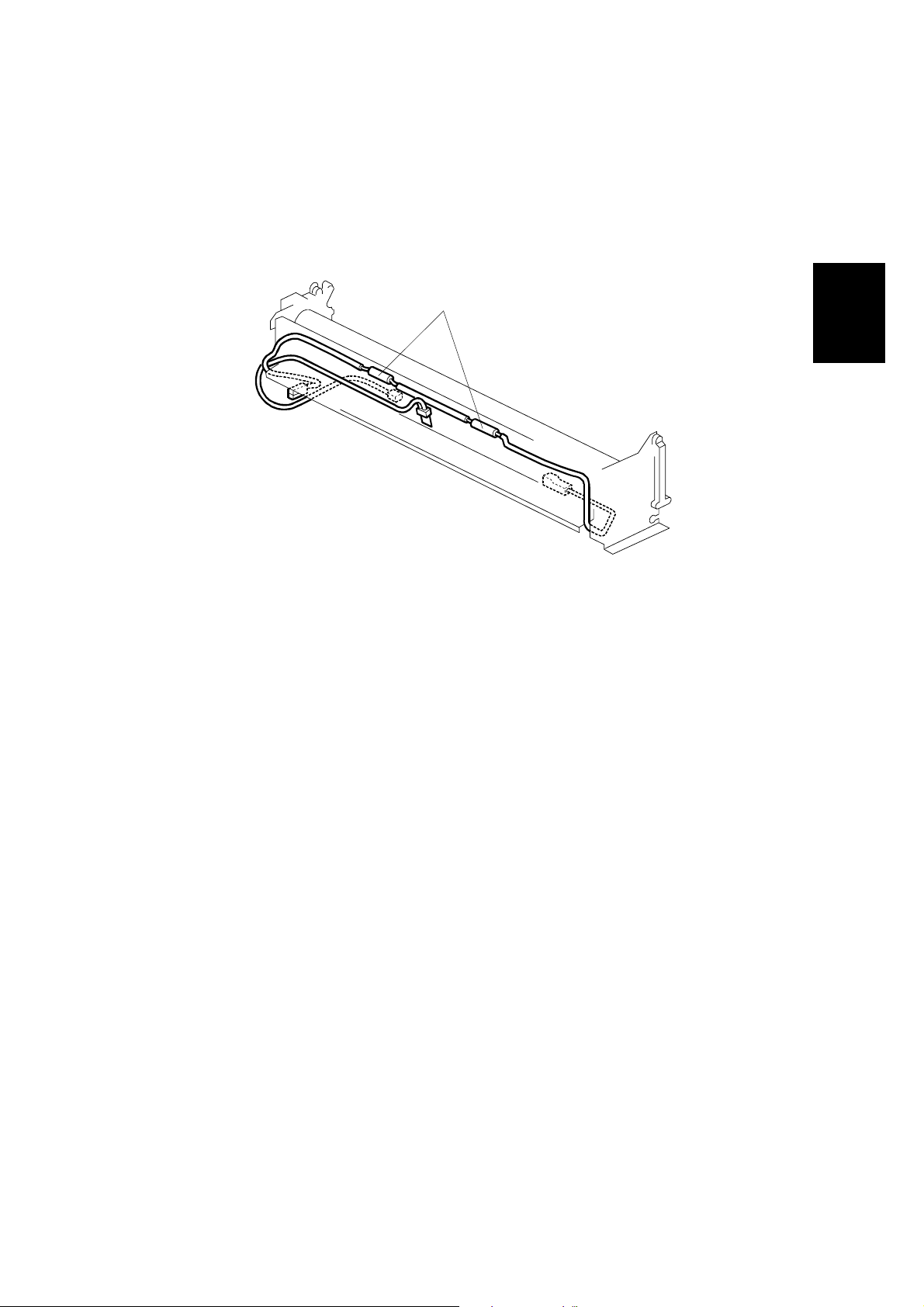

2.6.2 USED TONER COLLECTION

[A]

[B]

B047D101.WMF

B047/B048 copiers have a used toner overflow sensor [A] and a used toner cover

switch [B].

When the used toner overflow sensor detects that the used toner tank is full, the

overflow indicator begins blinking on the operation panel. 30 more meters (A1/D

size: 50 copies, SP51) can be copied. After that, the used toner overflow indicator

stays ON, and the machine will not operate.

The used toner cover switch detects when the used toner cover is open. “Door

open” is displayed on the operation panel, and the start key is disabled.

2-6

Page 24

11 May, 2001 FUSING AND PAPER EXIT

2.8 FUSING AND PAPER EXIT

2.8.1 OVERVIEW

[A]

Detailed

Descriptions

B047D102.WMF

Two thermofuses [A] (184°C, 192°C) keep the fusing unit from overheati ng .

Two thin-film thermistors measure the hot roller and pressure roller’s temperature.

The hot roller is a thin-shell, Teflon coated roller. The thinne r roller allows a much-

shorter warm-up time. However, extra care should be taken while working around

the hot roller. It is very easy to damage.

Like the A163/A251/A252 copiers, if the fusing temperature is lower than 60°C

when the main switch is turned on, the machine assumes that it has not been used

recently, and the main motor must rotate to generate the necessary triboelectric

charge on the toner and developer.

In the A163/A251/A252 copiers, the main motor begins rotating immediately.

However, the B047/B048 copiers have a thin shell hot roller and a contact

thermistor. When cold, the thermistor is hard and might damage the roller. The

machine waits until the hot roller temperature reaches 80°C. At that temperature

the thermistor softens and the hot roller can rotate safely.

Except for the differences listed above, the B047/B048 copiers are identical to the

A251 and A252 copiers. Please refer to A163/A251/A252 copier service manual for

additional details.

2-7

Page 25

FUSING AND PAPER EXIT 11 May, 2001

2.8.3 TEMPERATURE CONTROL

Hot Roller Temperature Control

Hot Roller Temp. (°C)

198

190

180

170

160

150

142

Mode 8

Mode 7

Mode 6

Mode 5

Mode 4

Mode 3

Mode 2

Mode 1

~60

63 66 69 72 75 78 81 84 87 90 93 96 99 102105108111 114 117 120~

Pressure Roller Temp. (°C)

198

190

185

180

110 115 120 125 130 135 140 145

Lower Limit

Mode 8

Operating Temperature

Lower Limit

B047D001.WMF

The relationship between the hot roller and pressure roller temperatures has been

changed due to the thin-shell, Teflon coated roller.

2-8

Page 26

11 May, 2001 ENERGY STAR COMPLIANT MACHINES (ALL THE DESTINATION)

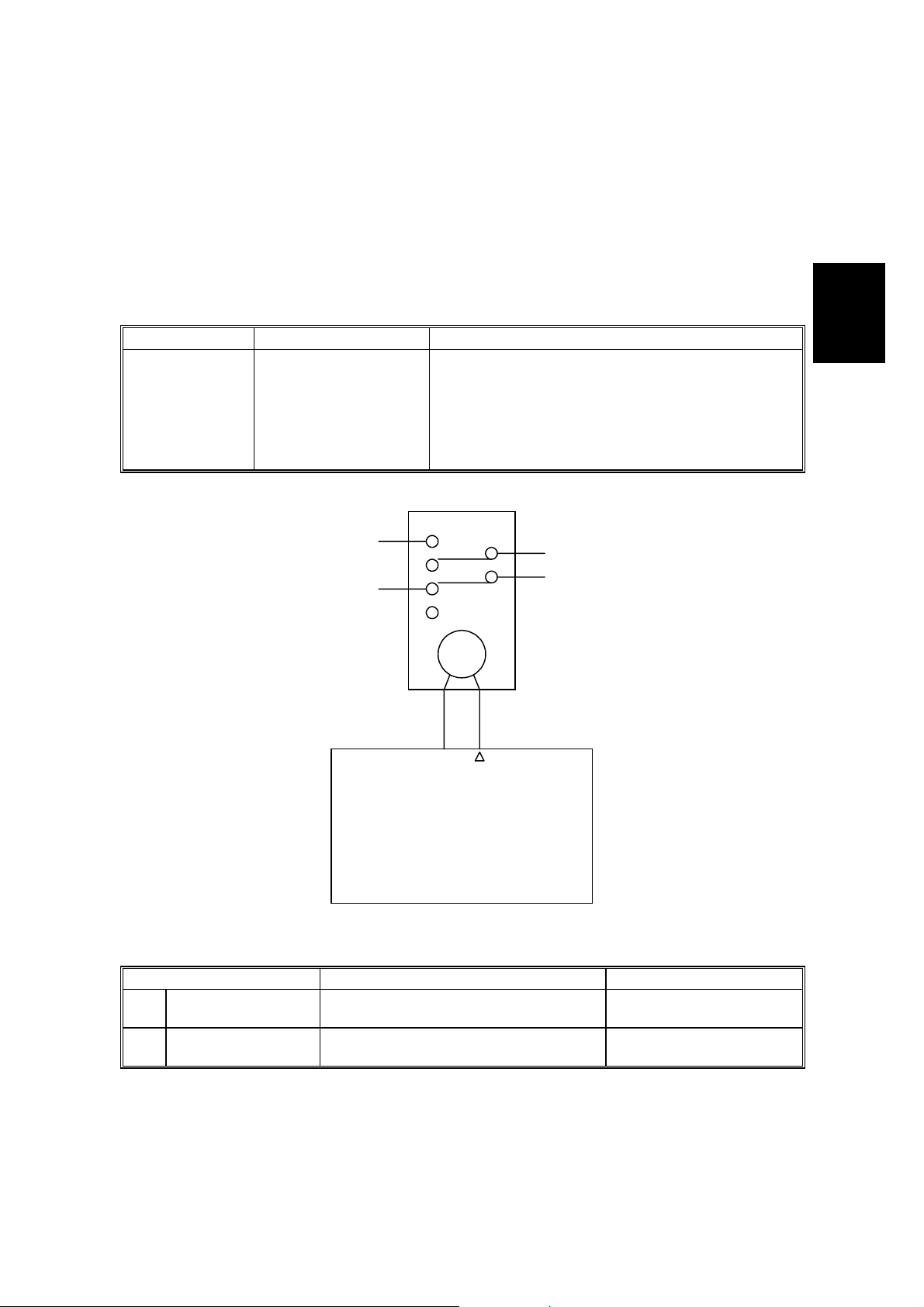

2.10 ENERGY STAR COMPLIANT MACHINES (ALL THE DESTINATION)

In conjunction with the modification for the Energy Star compliance, field

technicians need to understand the new operation modes, and must be able to

configure the machine for the customer’s specific environment/requirements. This

section lists all the differences between the Energy Star compliant machines and

the previous models.

Mode Non-Energy Star Energy Star

Starts timing once the last copy job is

complete. When the specified time has

Auto Off Mode Not available

passed, the copier turns off.

The time can be adjusted from 1 to 240

minutes.

Default: 30 minutes

RA

CN102

-A3

-B13

24]

[24]

!

AA

V

Detailed

Descriptions

Power Relay [

B047D002.WMF

Mode No. Function Data

Auto Shut-off Time

*15

Setting

AOF Auto off enable. 0: Disable

*33

Determines the auto shut-off time.

2-9

1 ← 30 → 240

1: Enable

Page 27

11 May, 2001 INSTALLATION REQUIREMENTS

3. INSTALLATION

3.1 INSTALLATION REQUIREMENTS

3.1.1 ENVIRONMENT

1. Temperature Range:

2. Humidity Range: 20% to 80% RH

3. Ambient Illumination: Less than 1,500 lux (do not expose to direct

4. Ventilation: Room air should turn over at least 3 times per hour.

5. Ambient Dust: Less than 0.10 mg/m3 (2.7 x 10-6 oz/yd3)

6. If the location is air-conditioned or heated, place the machine as follows:

a) Where it will not be subjected to sudden temperature changes from low to

high, or vice versa.

b) Where it will not be directly exposed to cool air from an air conditioner in

the summer.

c) Where it will not be directly expos ed to heat.

7. Avoid exposure to corrosive gases.

8. Avoid installing anywhere higher than 2,000 m (6,500 ft) above sea level.

9. Place the machine on a strong and level base.

10. Avoid any area where the machine may be subjected to frequent, strong

vibration.

15°C to 30°C (50°F to 86°F)

sunlight).

Installation

3-1

Page 28

INSTALLATION REQUIREMENTS 11 May, 2001

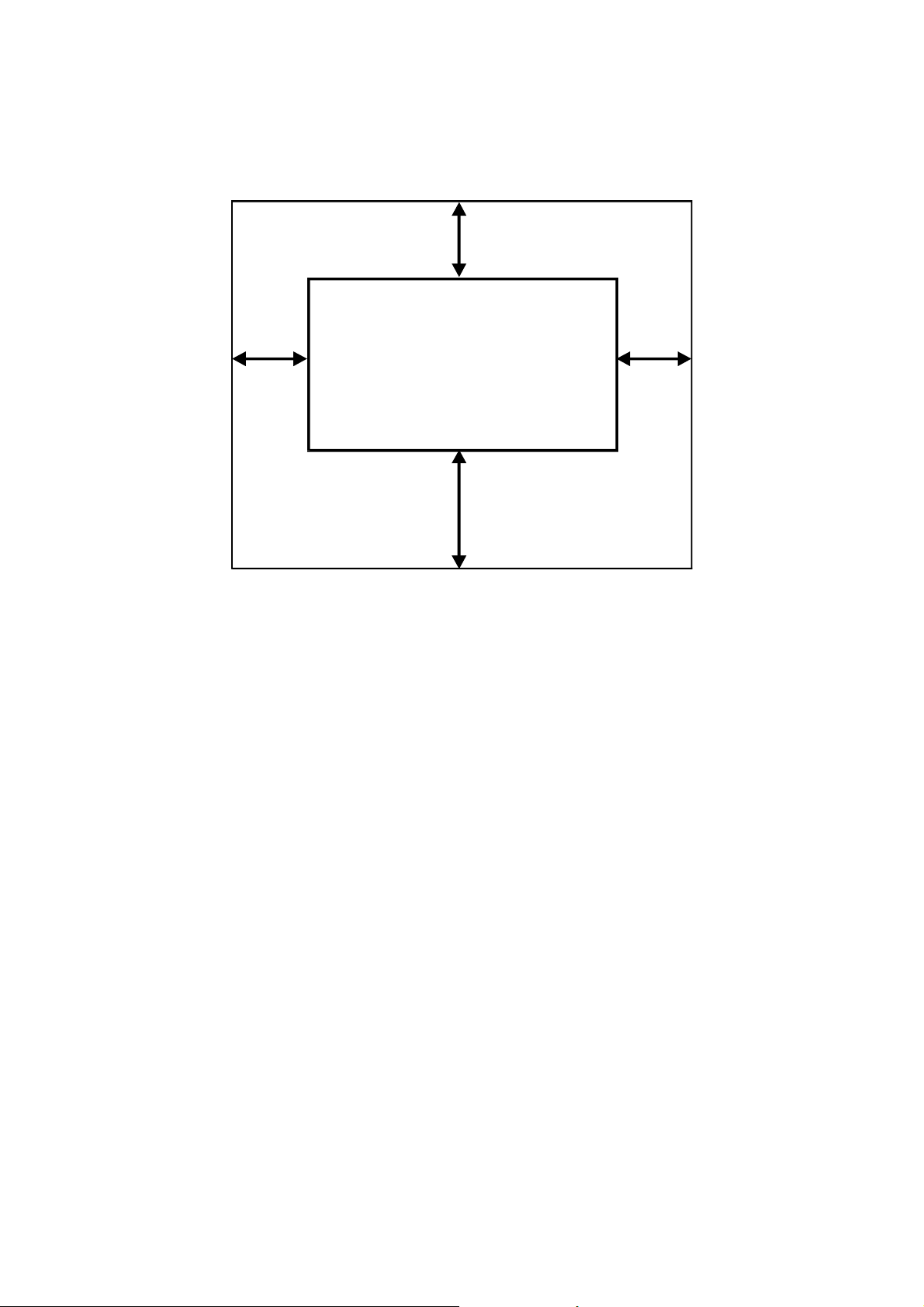

3.1.2 MINIMUM SPACE REQUIREMENTS

Back 600 mm

Left

600 mm

1. Front: 1,000 mm (39 in)

2. Back: 600 mm (24 in)

3. Right: 600 mm (24 in)

4. Left: 600 mm (24 in)

3.1.3 MACHINE LEVEL

Right

600 mm

Front 1,000 mm

B047I505.WMF

1. Front to back: Within 5 mm (0.2") of level

2. Right to left: Within 5 mm (0.2") of level

Make sure that the machine is level using a carpente r’s level.

3-2

Page 29

11 May, 2001 INSTALLATION REQUIREMENTS

3.1.4 POWER SOURCE

Important:

The machine must be installed in a building/facility equipped with a protective

device such as a circuit breaker, as the machine relies on such devices for

protection against over-current and short circuits.

1. Input Voltage Level: 120 V, 60 Hz

More than 12 A (for U.S.A. version)

220 ~ 240 V, 50/60 Hz

More than 7 A (f or European version)

2. Permissible Voltage

±10%

Fluctuation:

3. Do not set anything on the power cord.

NOTE: 1) Make sure the plug is firmly inserted in the outlet.

2) Avoid multi-wiring.

Installation

3-3

Page 30

INSTALLATION PROCEDURE 11 May, 2001

3.2 INSTALLATION PROCEDURE

3.2.1 COPIER

Accessory Check

Check the accessories and their quantities according to the following list:

- B048 copier -

Original Guides........................................................................ 6 pcs

Operating Instruction Holder.................................................... 1 pc

Operating Sheet ...................................................................... 1 pc

Caution Decal (-27 only).......................................................... 1 pc

Operating Instructions (-17 only).............................................. 1 pc

Original Guide Wire................................................................. 1 pc

- B047 copier -

Guide Wires............................................................................. 2 pcs

Copy Tray................................................................................ 1 pc

Copy Guide.............................................................................. 1 pc

Operating Instruction Holder.................................................... 1 pc

Operating Sheet ...................................................................... 1 pc

Caution Decal (-27 only).......................................................... 1 pc

Operating Instructions (-17 only).............................................. 1 pc

3-4

Page 31

11 May, 2001 INSTALLATION PROCEDURE

[D]

[A]

[B]

[C]

B047I024.WMF

Preparation for the B047 copier on the roll feeder.

When B047 copier is placed on the roll feeder, first remo ve the lower front cover [A]

and the manual feed table [B] for installatio n.

1. Remove the lower front cover [A] (2 screws), reinforcement plate [C] (1 screw),

bracket [D] (4 screws) (which is hung by the harness), and the manual feed

table [B].

2. Put back the bracket and reinforcement plate.

Installation

3-5

Page 32

INSTALLATION PROCEDURE 11 May, 2001

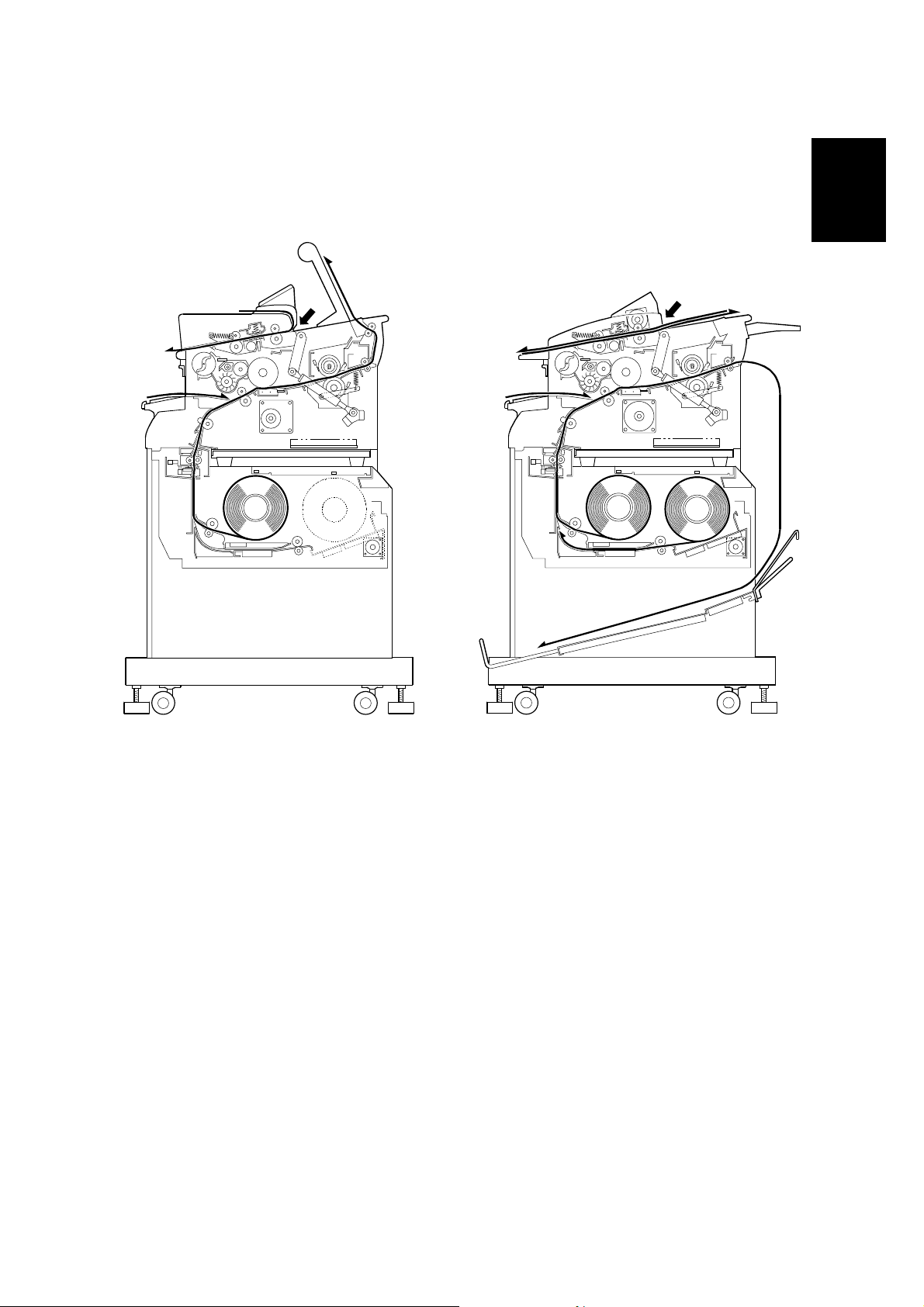

- B047 model -

[E]

[B]

- B048 model -

[F]

[F]

[C]

B047I500.WMF

[A]

[F]

[B]

[E]

[F]

[D]

[A]

B048I502.WMF

NOTE: The installation procedures are not shipped with the copier, always bring

this manual with you.

!

CAUTION

1. Unplug the power cord before performing the following procedures.

2. Before starting the installation, make sure the machine is level.

3. The copier is very heavy (85 kg, 187 lbs). To avoid serious injury, make

sure that you have a sufficient number of people to assist you. It takes

at least two people to lift the copier safely.

4. Please be careful not to get your hand caught under the copier as you

place the copier onto the table or roll feeder.

NOTE: Keep the shipping retainers after installing the machine. They will be

reused if the machine is moved to another location in the future.

1. For either the table or the roll feeder, lower the feet [A] (table: 2 feet, roll feeder:

4 feet) so that it does not move while the copier is being installed.

2. Place the copier [B] on the table [C] or roll feeder [D] (Place the copier feet [E]

into the table holes [F]).

!

WARNING

The copier is not attached to the table. Pushing the copier too hard may

cause it to fall. While moving the copier, always push the table.

3-6

Page 33

11 May, 2001 INSTALLATION PROCEDURE

B047I001.WMF

[A]

[J]

[C]

[D]

[A]

[B]

[L]

[K]

[J]

[F]

[I]

[D]

[E]

[L]

B047I103.WMF

Installation

[G]

B047I104.WMF

[H]

B047I105.WMF

3. Remove all the tape strips [A] as shown.

4. Open the original feed unit [B].

5. Remove the cushion [C] and close the original feed unit.

6. Release the lock levers [D] and open the paper path section [E].

7. Remove the right upper cover [F] (2 screws).

8. Remove the drum protection sheet [G] and remove the screw [H]. This applies

cleaning blade pressure to the drum.

NOTE: Be sure to remove the protective sheet before removing the pressure

screw. Otherwise, the cleaning blade will clamp the sheet to the drum,

and the drum may be damaged.

9. Open the fusing exit section [I]. Remove the two strips of shipping tape [J] and

the protection sheet [K].

10. Remove two strips of shipping tape [L]. Close the paper path section and fusing

exit section.

3-7

Page 34

INSTALLATION PROCEDURE 11 May, 2001

[A]

[E]

[C]

[B]

B047I503.WMF

[D]

B047I504.WMF

11. Open the original feed unit [A], manual feed table [B], and toner supply cover

[C]. Remove the sheet [D] covering the developer entrance. Pour 1 kg of the

developer [E] into the development unit evenly across its width as shown.

NOTE: Close the paper path section before opening the toner supply cover. If

the paper path section is open, the toner supply cover could fall off.

12. Plug in the power supply cord and turn on the main switch.

3-8

Page 35

11 May, 2001 INSTALLATION PROCEDURE

[A]

[C]

Installation

[B][D]

[E]

B435I508.WMF

NOTE: If the fusing temperature is lower than 60°C when the main switch is turned

on, the main motor must rotate to generate a triboelectric charge on the

developer and toner. However, to prevent damage to the hot roller, the

main motor will wait until the hot roller’s temperature reaches 80°C before

rotating. This may take a few minutes.

In this case, it is not necessary to use the SP mode to load the developer.

Skip steps 13 to 16. After the developer is loaded from the development

entrance, turn off the main switch to stop the main motor. Pour in the

second 1 kg of developer.

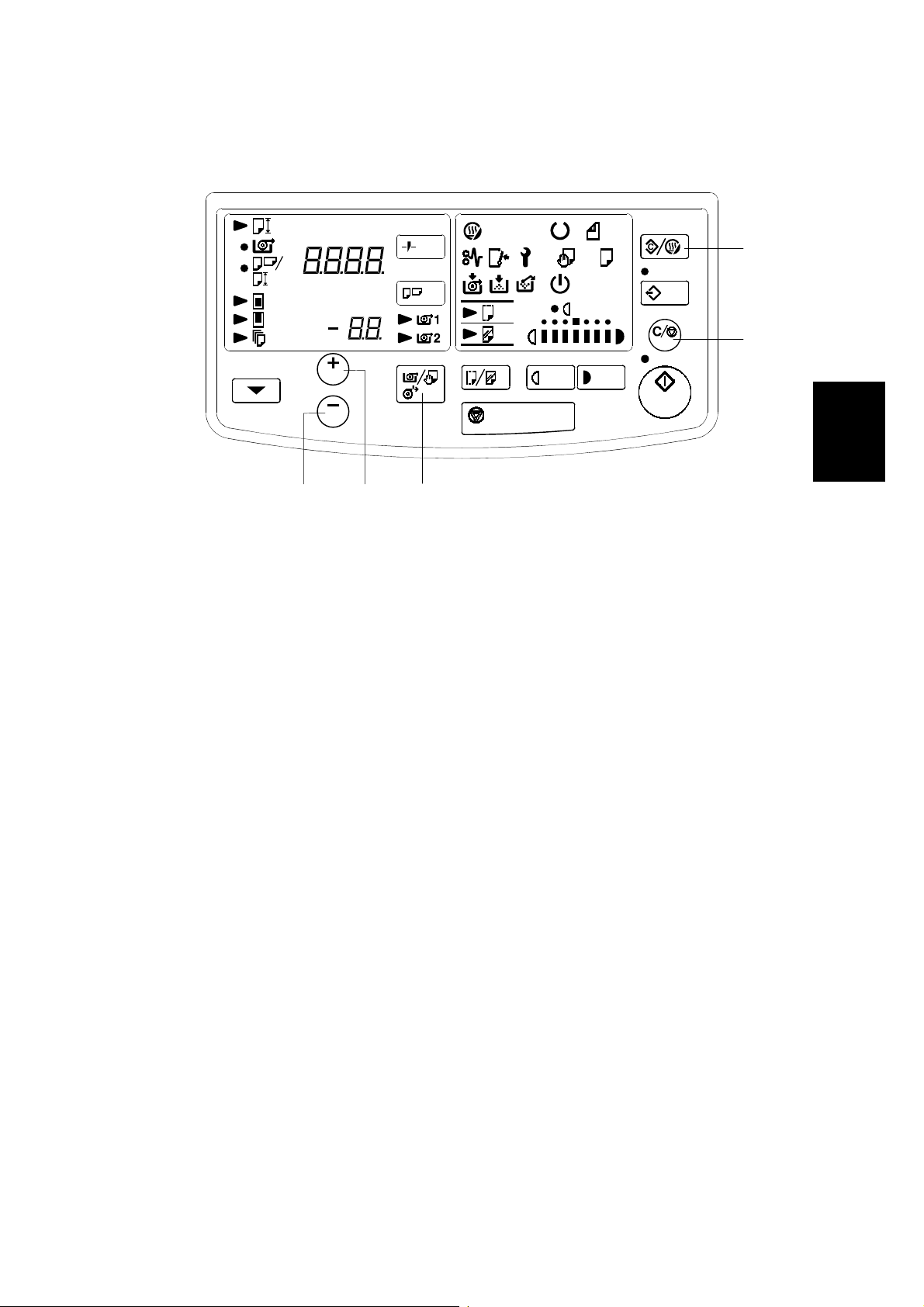

13. To begin main motor rotation, enter the SP INPUT/OUTPUT mode by pressing

the following keys on the operation panel:

Clear Mode key [A]

+ key [B]

+ key [B]

Clear/Stop key [C]

Clear/Stop key [C] again and hold for at least 3 seconds.

14. After 3 seconds, the wrench and toner end indicators will blink (SP

INPUT/OUTPUT mode).

15. Use the + and – keys [D] to select 23, then press the RF Select key [E]. The

main motor will begin rotating.

16. Press the RF Select key to stop the main motor once the developer is loaded

from the development entrance. Pour in the second 1 kg of developer into the

development unit evenly across its width (Total: 2 kg). Press the Clear

Modes/Stand by key 3 times to leave the SP mode.

3-9

Page 36

INSTALLATION PROCEDURE 11 May, 2001

[A]

[D]

[B][C][E]

[F]

B435I508.WMF

17. To enter the SP mode, press the following keys on the operation panel:

Clear key [A]

+ key [B]

– key [C]

Clear/Stop key [D]

Clear/Stop key [D] again and hold for at least 3 seconds.

18. After 3 seconds. The roll paper end and call se rvice in dicators will blink (SP

mode).

19. Using the + and – keys, select 36. Enter “1” by pressing the following keys.

Function Select key [E]

+ key

RF Select key [F]

This begins the developer initialization. Initialization takes about five minutes,

after which the copier will automatically retu rn to the normal operation mode.

3-10

Page 37

11 May, 2001 INSTALLATION PROCEDURE

[A]

[B]

[C]

B047I507.WMF

20. Install the toner cartridge [A] as shown.

1) Shake the cartridge 5 to 10 times and insert it into the toner hopper.

2) Peel off the green tape [B] from right to left to expose the clear tape and

toner supply holes.

3) Rotate the knob [C] of the cartridge clockwise until it stops.

Installation

3-11

Page 38

INSTALLATION PROCEDURE 11 May, 2001

[B]

[A]

B047I506.WMF

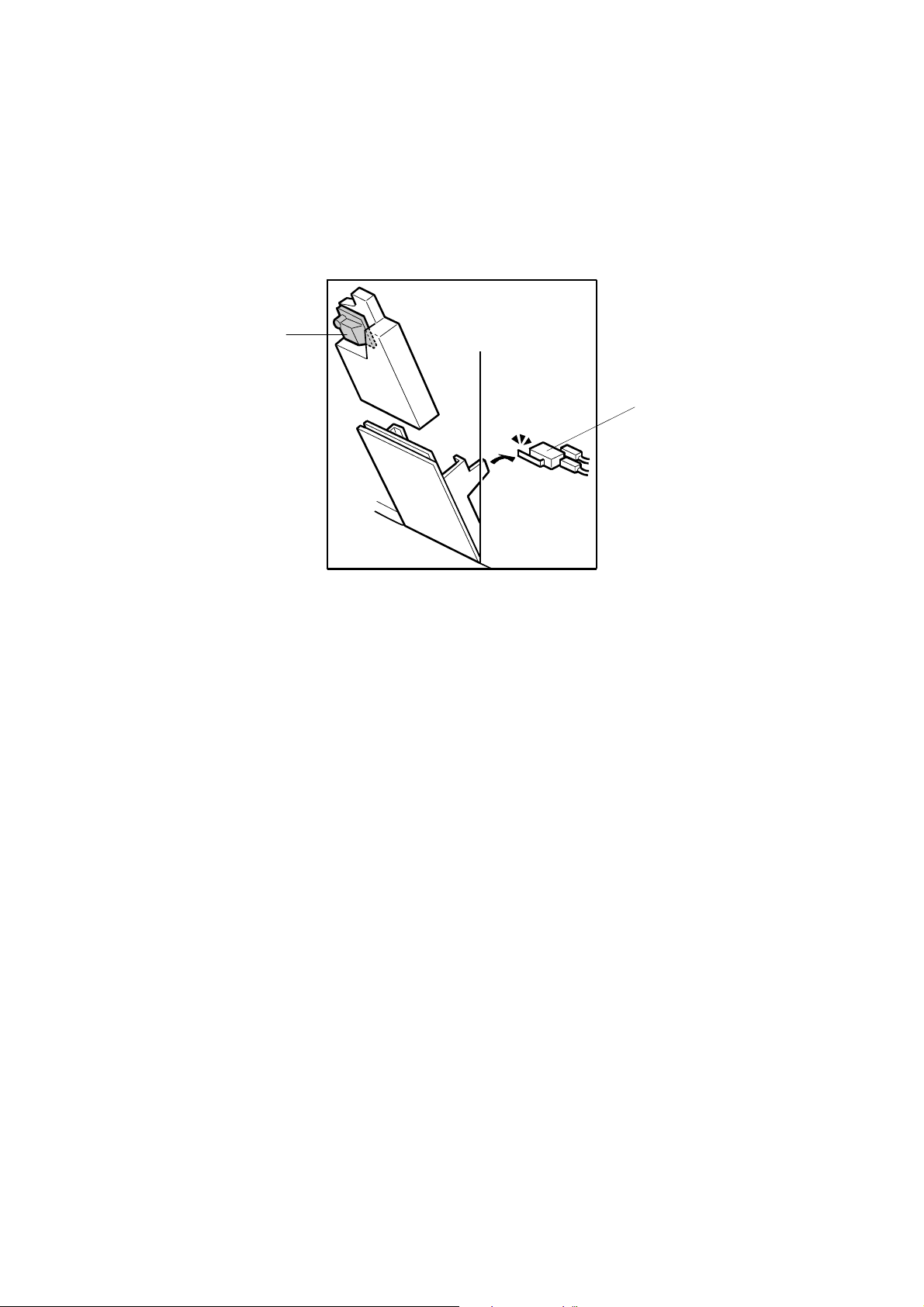

B048 copier only (step 21)

[C]

[E]

[D]

B047I509.WMF

21. Install the original guides [A] and original guide wire [B].

B047 copier only (step 22 and 23)

22. Attach the guide wires [C] to the copy tray [D].

23. Install the copy tray [D] and copy guide [E].

Both copiers (step 24 and 25)

24. Reinstall all the covers.

25. Check the copy quality and copier operation.

26. Install the optional roll feeder. (Refer to the Roll Feeder 1 and 2 Installation

procedures)

NOTE: While the roll feeder is optional for the B047, it is required for the B048.

You must install a roll feeder for the B048 to function properly.

3-12

Page 39

11 May, 2001 INSTALLATION PROCEDURE

3.2.2 TABLE (B439)

Accessory Check

Check the accessories and their quantities according to the following list:

Top Plate ................................................................................ 1

Left Side Plate ........................................................................ 1

Right Side Plate ...................................................................... 1

Middle Plate ............................................................................ 1

Rear Cover ............................................................................. 1

Screws with Spring Washers – M4x8 .....................................14

Installation

3-13

Page 40

INSTALLATION PROCEDURE 11 May, 2001

[C]

[B]

[F]

[A]

B439I500.WMF

[A]

[E]

[B]

[D]

B439I551.WMF

1. Loosely install the top plate [A], left [B], and right side plate [C] (6 screws).

2. Turn the table up-side down. Be sure to ro tate it as shown in the illustration.

[C]

3. Install the middle plate [D] and rear cover [E] (4 screws each).

4. Tighten all the screws until the spring washers [F] are completely flat.

5. Turn the table right-side up.

3-14

Page 41

11 May, 2001 INSTALLATION PROCEDURE

3.2.3 COPY TRAY (B440)

Accessory Check

Check the accessories and their quantities against the following list:

Copy Tray Stay........................................................................ 1

Copy Tray Support................................................................... 1

Copy Tray Guides.................................................................... 2

Copy Tray Sheets (with rubber pads)...................................... 3

Rear Copy Trays...................................................................... 3

Copy Tray Stoppers................................................................. 2

Stepped Screws – M4.............................................................. 2

Screws with Flat Washers – M4x6........................................... 6

Tray Sheet Guides................................................................... 3

Rear Copy Tray Sheets (no rubber pads)................................ 3

NOTE: The copy tray is an option for the B048 copier. When the copy tray is

installed on the copier, the roll feeder (B435/B436) is required.

Installation

3-15

Page 42

INSTALLATION PROCEDURE 11 May, 2001

[C]

[D]

[A]

B440I117.WMF

[E]

[F]

[G]

B440I121.WMF

[A]

1. Place the copy tray stay [A] under the copy tray as shown.

[B]

B440I118.WMF

[H]

B440I119.WMF

2. Adhere the copy tray sheets (the Mylar strips with rubber pads) [B] to the

table’s middle plate [C]. Make sure the center copy tray sheets is positioned

between the screw holes [D] on the copy tray as shown. The left and right copy

tray sheets should be positioned over the screw holes.

3. Lift the copy tray stay and install the two stepped screws [E] to the left and right

side plates [F, G]. After the screws are in place, hook the copy tray stay [A] on

the screws. Then secure it to the left and right side plates (2 screws for each:

M4x6 with flat washers).

NOTE: Be careful when installing the copy tray stay. Do not scratch the

surface of the table.

4. Install the copy tray support [H] (2 screws: M4x6 with flat washers).

3-16

Page 43

11 May, 2001 INSTALLATION PROCEDURE

[B]

[A]

B440I113.WMF

B440I115.WMF

0±2mm

0±2mm

[C]

10±5mm

0±5mm

[C]

B440I114.WMF

B440I116.WMF

10±5mm

Installation

5. Remove the rear cover [A] (2 screws).

6. Attach the rear copy tray sheets [B] and the tray sheet guides [C] to the rear

cover as shown.

7. Install the rear cover (2 screws).

3-17

Page 44

INSTALLATION PROCEDURE 11 May, 2001

[A]

[B]

B440I120.WMF

[C]

60±10mm

[D]

60±10mm

80±10mm

B440I123.WMF

8. Hook the rear copy trays [A] onto the copy tray stay [B].

9. Attach the copy tray stoppers [C] onto the bottom of the middle plate [D].

3-18

Page 45

11 May, 2001 INSTALLATION PROCEDURE

3.2.4 ROLL FEEDER1 AND 2 (B435/B436)

Accessory Check

Check the accessories and their quantities according to the following list:

Harness Covers....................................................................... 2 pcs

Ground Plates.......................................................................... 2 pcs

Roll Feeder Drive Board.......................................................... 1 pc

Left Joint Bracket..................................................................... 1 pc

Right Joint Bracket................................................................... 1 pc

Screws – M4x8 (Blue).............................................................. 4 pcs

Screws – M4x8 (Silver)............................................................10 pcs

Screws with Flat Washers – M4x10......................................... 2 pcs

Screw with a Spring Washer – M4x8....................................... 1 pc

Screws with Flat Washers – M3x6........................................... 2 pcs

Installation

Left Joint Cover........................................................................ 1 pc

Right Joint Cover..................................................................... 1 pc

Harness Clamp........................................................................ 2 pcs

Paper Holder

1 Roll................................................................................... 2 pcs

2 Roll................................................................................... 4 pcs

Guide Plate.............................................................................. 1 pc

Front Joint Cover..................................................................... 1 pc

Cutter Blade Caution Decal (-27 only)..................................... 1 pc

Joint Harness........................................................................... 1 pc

3-19

Page 46

INSTALLATION PROCEDURE 11 May, 2001

[D]

[A]

[B]

[C]

B047I024.WMF

Preparation for the B047 copier on the roll feeder.

When B047 copier is placed on the roll feeder, first remo ve the lower front cover [A]

and the manual feed table [B] for installatio n.

1. Remove the lower front cover [A] (2 screws), reinforcement plate [C] (1 screw),

bracket [D] (4 screws) (which is hung by the harness), and the manual feed

table [B].

2. Put back the bracket and reinforcement plate.

3-20

Page 47

11 May, 2001 INSTALLATION PROCEDURE

[C]

[E]

[D]

[E]

[B]

Installation

[A]

!

CAUTION

1. Unplug the main machine’s power cord before starting the following

procedure.

2. Before starting the installation, make sure the machine is level.

3. The copier is very heavy (85 kg, 187 lbs). To avoid serious injury, make

sure that you have a sufficient number of people to assist you. It takes

at least two people to lift the copier safely.

4. Please be careful not to get your hand caught under the copier as you

place the copier onto the roll feeder.

1. Lower the feet [A] (4 feet) so that the roll feeder [B] does not move while the

copier [C] is being installed.

!

CAUTION

Do not open the paper tray until the copier is placed on top of the roll

feeder. The paper tray drawer is very heavy. Without the copier weight to

hold it down, the roll feeder will fall over. The tray is shipped with a safety

latch holding the drawer shut.

B436I102.WMF

2. Place the copier on the roll feeder. Fit the copier feet [D] into the roll feeder

holes [E].

!

WARNING

The copier is not attached to the roll feeder. Pushing the copier too hard

may cause it to fall. While moving the copier, always push the roll feeder.

3-21

Page 48

INSTALLATION PROCEDURE 11 May, 2001

[B]

[A]

[C]

B435I507.WMF

[B]

[F]

[A]

[D]

B435I506.WMF

3. Release the lock lever [A] and open the copier paper path section [B].

[E]

4. Remove the copier’s left lower cover [C] (2 screws), lower right front cover [D]

(2 screws), lower right middle cover [E], and toner collection bottle [F] (1

connector).

3-22

Page 49

11 May, 2001 INSTALLATION PROCEDURE

[A]

[E]

[B]

B435I105.WMF

B435I101.WMF

Installation

[C]

B435I104.WMF

[D]

B435I127.WMF

5. Pull out the paper tray [A] and install the left [B] and right [C] joint brackets (2

screws each: blue).

6. Remove the paper tray stopper [D] (1 screw).

NOTE: After the copier has been placed on the roll feeder, the paper tray can

be pulled out and the paper tray stopper can be removed.

7. If necessary, adhere the appropriate language cutter blade caution decal [E]

over the English decal on the paper tray as shown (-27 only).

3-23

Page 50

INSTALLATION PROCEDURE 11 May, 2001

B435I106.WMF

[A]

[G]

[B]

[F]

[B]

[C]

B435I122.WMF

[D]

B435I124.WMF

[E]

[I]

B435I110.WMF

B435I108.WMF

[D]

8. Remove the roll feeder’s rear cover [A] (6 screws).

9. Remove the copier’s rear cover [B] (2 screws).

10. Remove the small caps [C] from the copier’s rear cover using cutting pliers.

11. Install the roll feeder drive board [D].

12. Connect the following harness connectors as shown.

DC harness [E] — Roll Feeder Drive board

Joint harness [F] — Roll Feeder Drive board

Joint harness [G] — Copier Main Control board (3 clamps)

AC harness [H] — AC Drive board [I]

[H]

3-24

Page 51

11 May, 2001 INSTALLATION PROCEDURE

[B]

[A]

[C]

[A]

B435I107.WMF

[C]

Installation

B435I109.WMF

B435I125.WMF

13. Install the grounding plates [A] (1 screw for each: M4x8).

14. Secure the grounding wire [B] (1 screw: M4x8 with a spring washer) to the

copier.

NOTE: To ensure proper grounding, tighten the ground wire’s screws until the

spring washer is completely flat.

15. Install the harness covers [C] (1 screw for each: M4x10 with flat washers).

NOTE: Fold the harness covers around the harness, then attach with a single

screw.

16. Reinstall the rear cover of the roll feeder (6 screws).

17. Clamp the power cord to the rear cover of the roll feeder (2 screws: M4x8).

18. Put back the copier’s rear cover.

3-25

Page 52

INSTALLATION PROCEDURE 11 May, 2001

[A]

B436I103.WMF

[B]

B435I111.WMF

[C, D]

B435I112.WMF

19. Hook the guide plate [A] on the copier and then secure it (2screws: M4x8).

20. Install the front joint cover [B] (2 screws: M3x6 with flat washers).

21. Reassemble the copier.

22. Install the left and right joint covers [C, D] (2 screws for each: M4x8 each).

3-26

Page 53

11 May, 2001 INSTALLATION PROCEDURE

[A]

[G]

[D]

[B][C][E]

Length

Temperature

NORMAL XX 42 XX 45

[F]

300

PRG.

NO.

1100

B435I508.WMF

PRG.

NO.

23. Plug in the power supply cord and turn on the main switch.

24. To enter the SP mode, press the following keys on the operation panel:

Clear Modes key [A]

+ key [B]

– key [C]

Clear/Stop key [D]

Clear/Stop key [D] again and hold it for at least 3 seconds.

25. After 3 seconds, the roll paper end and ca ll service indicators will blink (SP

mode).

26. Select 40 using the + and - keys. Enter “1” (B435: 1 roll) or “2” (B436: 2 rolls)

by pressing the following keys.

Function Select key [E]

+ key

RF Select key [F].

Installation

27. To set the paper cut length adjustments, input values into SP modes 42 and 45

as listed on the decal attached to the right side plate.

NOTE: 1) When the values for SP modes 42 and 45 are set, the paper cut

length adjustment values for vellum and film are automatically

entered (SP modes 43, 44, 46 and 47).

2) In the case of the 2 roll feeder, you must enter values for both the

1st and 2nd roll. The value for the 1st roll can only be entered when

the corresponding indicator [G] is blinking (same for 2nd roll). Use

the Function Select Key to switch between the two rolls.

28. Press the Clear Modes key 3 times to leave the SP mode.

29. Check the roll feeder operation.

3-27

Page 54

INSTALLATION PROCEDURE 11 May, 2001

3.2.5 ROLL CUTTING RAIL (B437)

The installation is identical to that of the A163 copier’s roll cutting rail (A570).

Please refer to the A163 service manual for details. The roll cutting rail and the roll

feeder cannot both be installed on the same machine at the same time.

3-28

Page 55

11 May, 2001 SERVICE TOOLS

4. SERVICE TABLES

4.3 SERVICE TOOLS

4.3.1 SERVICE PROGRAM MODE

Service Program Mode Table

1. A “*” before the mode number means that the mode can be accessed by

customers or sales representative.

2. In the data column, the default value is printed in bold letters.

The default settings for se veral items depend on the machine destination (ref er

to page 4-28.).

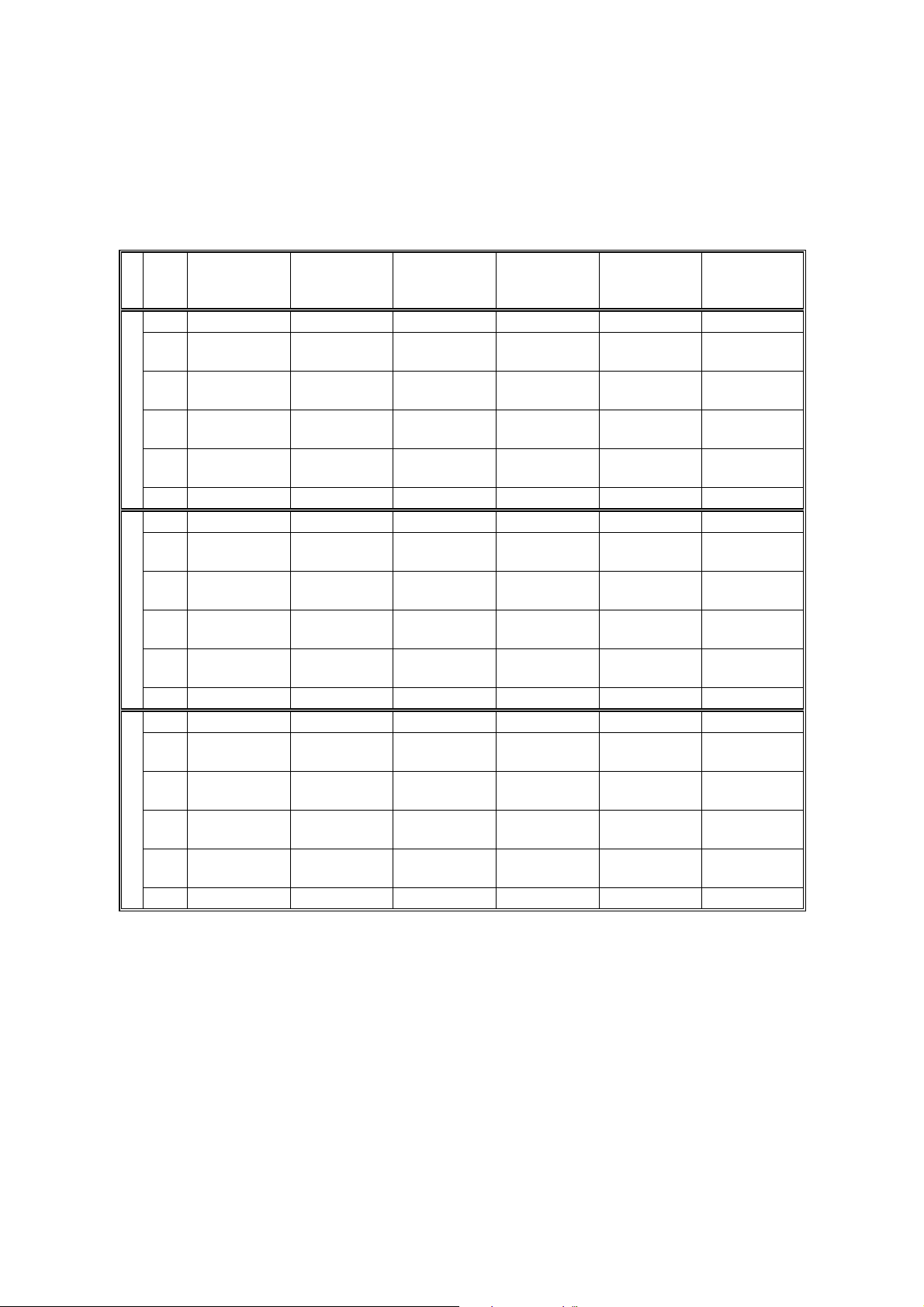

Mode No. Function Data

Fusing

Temperature 1

(Normal)

*1

Fusing

Temperature 2

*2

(High)

Fusing

Temperature 3

*3

(Low)

Copy Count

*4

Up/Down

Beeper On/Off Turns the beeper on and off. 0: On

*5

Paper Feed Out

Waiting Time

Setting

*6

Manual Feed Start

Time Setting

*7

Selects the fusing temperature for

plain paper.

Selects the fusing temperature for

translucent paper.

Selects the fusing temperature for

translucent film.

Select weather the user displa y panel

counts up or down.

Sets the copy time-out. Begins timing

when a sheet of copy paper has been

manually fed, or if the Roll Feed Select

key is pressed. If a copy is not made

within the specified time limit, the copy

paper is ejected.

Sets the manual feed delay. The timer

begins when the entrance sensor

detects the paper’s leading edge.

Once the specified time has passed,

the registration rollers start rotating.

0: Mode 1

1: Mode 2

2: Mode 3

3: Mode 4

4: Mode 5

5: Mode 6

6: Mode 7

0: Mode 5

1: Mode 6

2: Mode 7

3: Mode 8

0: Mode 2

1: Mode 3

2: Mode 4

3: Mode 5

0: Up

1: Down

1: Off

2: Turn the beeper off

when holding the button

down to rapidly change

the edge margin or

paper length.

0: 2 minutes

1: 1 minute

2: 3 minutes

3: 4 minutes

4: 5 minutes

0: 2 seconds

1: 0.7 second

2: 1 second

3: 3 seconds

4: 4 seconds

5: 5 seconds

Tables

Service

4-1

Page 56

SERVICE TOOLS 11 May, 2001

Mode No. Function Data

Leading Edge

Increase/Decrease

Speed Setting

*8

Auto Reset Time

Setting

*9

Auto Energy Saver

Mode

*10

Screen Message

Setting

*11

Leading Edge

Increase/Decrease

Adjustment

Preliminary Interval

*12

This sets the speed at which the

leading edge setting increases or

decreases.

When the customer holds down the +

or – key, there is a brief pause. After a

selected number of 0.25 second

intervals (See SP 12), the values begin

to change at the selected speed.

Sets the delay for the auto reset. After

finishing a copy job, the machine will

wait the specified amount of time. If no

other jobs are begun, it will then

automatically reset the copy settings to

its default values.

Enables and disables the auto energy

saver mode. If enabled, the machine

will automatically go into energy saver

mode after it auto resets.

Selects one of the options indicated on

the display in the energy saver mode.

When the user hold downs the + or –

key to change the leading edge

margin, print number or paper length,

there is a pause before the values

begin to change rapidly.

This paused is measured in 0.25