Page 1

G410/G411

IMAGE SCANNER

OPERATOR’S MANUAL

Page 2

Safety Information

When using your machine, the following safety precautions should be always be followed

Safety During Operation

In this manual, the following important symbols are used:

WARNING:

Ignoring this warning could cause serious injury or even

death.

CAUTION:

Ignoring this caution could cause injury or damage to proper ty.

Examples of Indications

Symbol R means a situation that requires you take care.

Do NOT carry out the operation represented by this symbol .

This example means “Do not take apart”.

Symbols ● mean you MUST perform this operation.

This example means “You must remove the wall plug”.

i

Page 3

Safety Information

W arnings

••

•

Only connect the machine to the power source described

••

on the inside front cover of this manual.

••

•

Avoid multi-wiring.

••

••

•

Do not damage, break or make any modifications to the

••

power cord. Do not place heavy objects on it, pull it hard

or bend it more than necessary. These actions could cause

an electric shock or fire.

••

•

Do not plug or unplug the power cord with your hands wet.

••

Otherwise, an electric shock might occur.

••

•

Make sure the wall outlet is near the machine and easily

••

accessible so that in event of an emergency it can be

unplugged easily.

••

•

Do not remove any covers or screws other than those

••

specified in this manual. Some parts of the machine are at

a high voltage and could give you an electric shock. When

the machine needs to be checked, adjusted, or repaired,

contact your service representatives.

••

•

Do not take apart or attempt any modifications to this

••

machine. There is a risk of fire, electric shock, explosion or

loss of sight.

••

•

If the machine looks damaged or breaks down, smoke is

••

coming out, there is a strange smell or anything looks

unusual, immediately turn off the power switch then

unplug the power cord from the wall. Do not continue

using the machine in this condition. Contact your service

representative.

••

•

If metal, liquid, or foreign matter falls into the machine,

••

turn off the power switch, and unplug the power cord.

Contact your service representative. Do not keep using the

machine with a fault or defect.

••

•

Do not put any metal objects or containers holding

••

water(e.g. vases, flowerpots, glasses) on the machine. If

the contents fall inside the machine, a fire or electric

ii

shock could occur.

Page 4

CA UTION

•

Keep the machine away from humidity and dust. A fire or an

electric shock might occur.

•

Do not place the machine on an unstable or tilted surface. If it

topples over, it could cause injury.

•

When you move the machine, unplug the power cord from the

wall outlet to avoid fire or electric shock.

•

When the machine will not be used for a long time, unplug the

power cord.

••

•

When you pull out the plug from the socket, grip the plug to

••

avoid damaging the cord and causing fire or electric shock.

•

This machine has been tested for safety using this supplier’s

parts and consumables. We recommend you only use these

specified supplies.

Safety Information

iii

Page 5

Important Information

Important Information

1. Read all of these instructions and keep them for later reference.

2. Follow all warnings and instructions marked on the machine.

3. Unplug this machine from the wall outlet before cleaning. Do not use liquid cleaners or

aerosol cleaners.

4. Do not use this machine near water.

5. Do not place this machine on an unstable cart, stand, or table. The machine could fall and

suffer serious damage.

6. Slots and openings in the cabinet and the back or bottom are provided for ventilation; to

ensure reliable operation of the machine and protect it from overheating, these openings must

not be blocked or covered. The openings should never be blocked by placing the machine on

a bed, sofa, rug, or other similar surface. This machine should never be placed near or over

a radiator or heat register . This machine should not be placed in a built-in installation unless

proper ventilation is provided.

7. This machine should be operated from the type of power source indicated on the marking

label. If you are not sure of type of power available, contact your dealer or local power

company.

8. This machine is equipped with a 3-wire grounding-type plug, a plug having a third (grouding)

pin. This plug will only fit into a grounding -type outlet. This is a safety feature. If you are

unable to insert the plug into the outlet, contact your electrician to replace your outlet. Do not

defeat the purpose of the grounding-type plug by removing its grounding pin. (This does not

apply in countries in which a 2-wire, nongrounded type of plug is used.)

9. Do not place this machine where the cord will be walked on.

10. If an extension cord is used with this machine, make sure that the total of the ampere ratings

on the devices plugged into the extension cord does not exceed the extension cord ampere

rating. Also make sure that the total of all machines plugged into the wall outlet does not

exceed 15 amperes.

11. Never push objects of any kind into this device through cabinet slots as they may touch

dangerous voltage points or short out parts that could result in a risk of fire or electric shock.

Never spill liquid of any kind on the machine.

12. Except as specifically explained in the operator’s manual, do not attempt to service this device

yourself. Opening or removing those covers that are marked “Do Not Remove” may expose

you to dangerous, voltage points or to other risks. Refer all servicing in those compartment

to service personel.

iv

Page 6

Important Information

13. Unplug this machine from the wall outlet and refer servicing to qualified service personal

under the following conditions;

A. When the power cord or plug is damaged or frayed.

B. If liquid has been spilled into the machine.

C. If the machine has been exposed to rain or water.

D. If the machine does not operate normally when the operating instructions are followed.

Adjust only those controls that are covered by the operating instructions since improper

adjustment of other controls may result in damage and will often required extensive

work by a qualified technician to restore the machine to normal operation.

E. If the machine has been dropped or the cabinet has been damaged.

F. If the machine exhibits a distinct change in performance, indicating a need for service.

14. Make sure that your wall outlet is close to the machine and is easily accessible.

When you plug the machine into the outlet, make sure the plug is inserted firmly .

15. The main plug on this machine must be used to disconnect main power .

T wo kinds of size notation are employed in this manual.

v

Page 7

How to Read This Manual

How to Read This Manual

In this manual, the following symbols are used:

Warning

This symbol indicates a potentially hazardous situation that might result in death or serious

injury when you misuse the machine without following the instructions under this symbol.

Be sure to read the instructions, all of which are described in the Safety Information section.

Caution

This symbol indicates a potentially hazardous situation that might result in minor or moderate

injury or property damage that does not involve personal injury when you misuse the machine

without following the instructions under this symbol. Be sure to read the instructions, all of

which are described in the Safety Information section.

* The statements above are notes for your safety .

Important

If this instruction is not followed, paper might be misfeed, originals might be damaged, or data might be lost. Be sure to read this.

Note

This symbol indicates precautions for operation, or actions to take after misoperation.

Limitation

This symbol indicates numerical limits, functions that cannot be used together, or

conditions in which a particular function cannot be used.

Reference

This symbol indicates a reference.

{}

Keys built into the machine’s operation panel.

vi

Page 8

Table of Contents

T ab le of Contents

Safety Information ---------------------------------------------------------------------- i

Safety During Operation ----------------------------------------------------------- i

Examples of Indications------------------------------------------------------------ i

Important Information ---------------------------------------------------------------- iv

How to Read This Manual -----------------------------------------------------------v i

1. Introduction

Features ----------------------------------------------------------------------------------- 1

Ultra-fast scanning ----------------------------------------------------------------1

Simultaneous scanning of both sides of a document ---------------------------

(Duplex Model only) ----------------------------------------------------------- 1

Direct operation using the buttons on the scanner -----------------------------(Manual Scanning function) ------------------------------------------------------ 1

Large 150-sheet paper capacity --------------------------------------------------1

Printing on scanned documents (optional) -------------------------------------- 1

Space-saving design --------------------------------------------------------------- 2

Supports both TWAIN and ISIS ------------------------------------------------ 2

Guide to the Scanner------------------------------------------------------------------ 3

Understanding the Indicators --------------------------------------------------- 5

2. Setting up the Scanner

Preparing for Installation ----------------------------------------------------------- 7

Checking the Scanner Location ------------------------------------------------- 7

Connecting to the Host Computer ---------------------------------------------- 10

What is SCSI? ---------------------------------------------------------------------- 1 0

SCSI Connection Requirements for the Scanner ------------------------- 10

Setting the SCSI ID --------------------------------------------------------------- 11

Connecting the SCSI Cable (No Connection to Other Port) -----------11

Connecting the SCSI Cable (Connection to Other Port) ---------------- 12

Connecting the Power Cable ----------------------------------------------------- 1 3

Turning On/Off the Scanner Power ---------------------------------------------15

Turning On the Scanner Power ------------------------------------------------15

Turning Off the Scanner Power ------------------------------------------------ 15

Initializing the Scanner -------------------------------------------------------------16

vii

Page 9

Table of Contents

3. Setting Originals

Originals----------------------------------------------------------------------------------17

Recommended Sizes and Weights of Originals --------------------------17

Difficult to Detect Sizes-----------------------------------------------------------18

Original Sizes and Scanning Area--------------------------------------------19

Setting Originals -----------------------------------------------------------------------20

Setting the Original on the Contact Glass-----------------------------------20

Setting the Original in the Auto Document Feeder (ADF) --------------21

4. Scanning Originals

General Scanning Method --------------------------------------------------------- 25

Manual Scanning ---------------------------------------------------------------------- 26

5. Troubleshooting

When Scanning Does Not Start---------------------------------------------------27

Error Indicators and Solutions ----------------------------------------------------28

Procedures to Correct Errors in the ADF -------------------------------------29

When an Original is Jammed in

the Auto Document Feeder (ADF) -----------------------------------------29

When an Original was Not Output Properly from

the Auto Document Feeder (ADF) -----------------------------------------29

When There is a Problem with the Operation of

the Document Table ------------------------------------------------------------29

When Characters Printed by the Endorser are Too Light or

the Original Gets Dirty -----------------------------------------------------------30

Replacing the Ink Ribbon -------------------------------------------------------- 30

Cleaning the Endorser ------------------------------------------------------------ 32

viii

Page 10

Table of Contents

6. Appendices

Maintenance ----------------------------------------------------------------------------33

Cleaning the Scanner ------------------------------------------------------------ 3 3

Cleaning the Contact Glass, Slit Glass, White Sheet, and Platen ---------- 34

Cleaning the Feed Roller and Drum ------------------------------------------- 34

Cleaning the White Roller (Duplex Model Only) ---------------------------- 36

Moving the Scanner -------------------------------------------------------------- 3 8

Carrying the Scanner a Short Distance ---------------------------------------- 39

Shipping the Scanner ------------------------------------------------------------ 39

Disposing of the Scanner -------------------------------------------------------39

Options -----------------------------------------------------------------------------------40

Image Processing Unit Type A -------------------------------------------------4 0

Red Lamp Unit Type A -----------------------------------------------------------40

Endorser Unit Type A(Printing Function) ------------------------------------ 4 1

Specifications --------------------------------------------------------------------------42

Scanner Electrical and Hardware Specifications ------------------------- 4 2

DIP Switches----------------------------------------------------------------------------43

Functions --------------------------------------------------------------------------------44

Preview-------------------------------------------------------------------------------44

Scan-----------------------------------------------------------------------------------45

Scanning Composition ----------------------------------------------------------- 4 5

Binary Scanning/Threshold ----------------------------------------------------- 4 6

Halftone Scanning ---------------------------------------------------------------- 47

Gray Scale Scanning -------------------------------------------------------------48

Area Extraction ---------------------------------------------------------------------49

Section Area (Multi-area Settings) --------------------------------------------50

Auto Photo/Letter ------------------------------------------------------------------51

Resolution ---------------------------------------------------------------------------52

Brightness ---------------------------------------------------------------------------53

Contrast ------------------------------------------------------------------------------53

Gamma Correction ---------------------------------------------------------------- 5 4

Binary Filters ------------------------------------------------------------------------55

Parameter Download ------------------------------------------------------------- 5 5

Document Size Detection ------------------------------------------------------- 5 6

Erase Background ---------------------------------------------------------------- 57

Index --------------------------------------------------------------------------------------- 5 8

ix

Page 11

x

Page 12

1. Introduction

Features

This section describes the features of this scanner.

Ultra-fast scanning

When scanning A4K (8½” × 11”K), monochrome at 200dpi, this scanner can scan 55 (57)

pages/minute. When scanning A4K (8½” × 11”K), monochrome at 400dpi, this scanner can

scan 31 (32) pages/minute. During double-sided scanning, when scanning A4K (8½” × 11”K),

monochrome at 200dpi, this scanner can scan 81 (84) pages/minute.

* When using the Auto Document Feeder (ADF) in binary scanning, these speeds apply to

the second and subsequent sheets.

Simultaneous scanning of both sides of a document (Duplex Model only)

If a document consists of individual, separate sheets, both sides of each sheet can be scanned

simultaneously. This capability eliminates the bother of having to flip document sheets over.

Direct operation using the buttons on the scanner (Manual Scanning function)

If using a driver that supports the Manual Scanning function, scanning can be initiated by

pressing the {Start} button on the scanner . This function is useful when scanning a document

that needs to be set in place for each scan.

Large 150-sheet paper capacity

Up to 150 sheets* can be placed in the scanner’s Auto Document Feeder (ADF).

* A4 (64g/m2) or 8½” × 11” (20lb)

Printing on scanned documents (optional)

The Endorser Unit Type A is provided as an optional mechanism that prints a symbol or the

number of documents that have been scanned by the Auto Document Feeder (ADF). This

capability is useful for referencing scanned data or confirming that a document has been scanned.

1

Page 13

1. Introduction

Space-saving design

This scanner is designed in a “wingless” style, in which there are no protruding elements, such as

a document tray. This design allows the scanner to be set up next to a wall, and permits office

space to be used more effectively .

Supports both TWAIN and ISIS

The scanner supports both the standard TWAIN and the newer ISIS driver, allowing the scanner

to function with a wide range of software.

2

Page 14

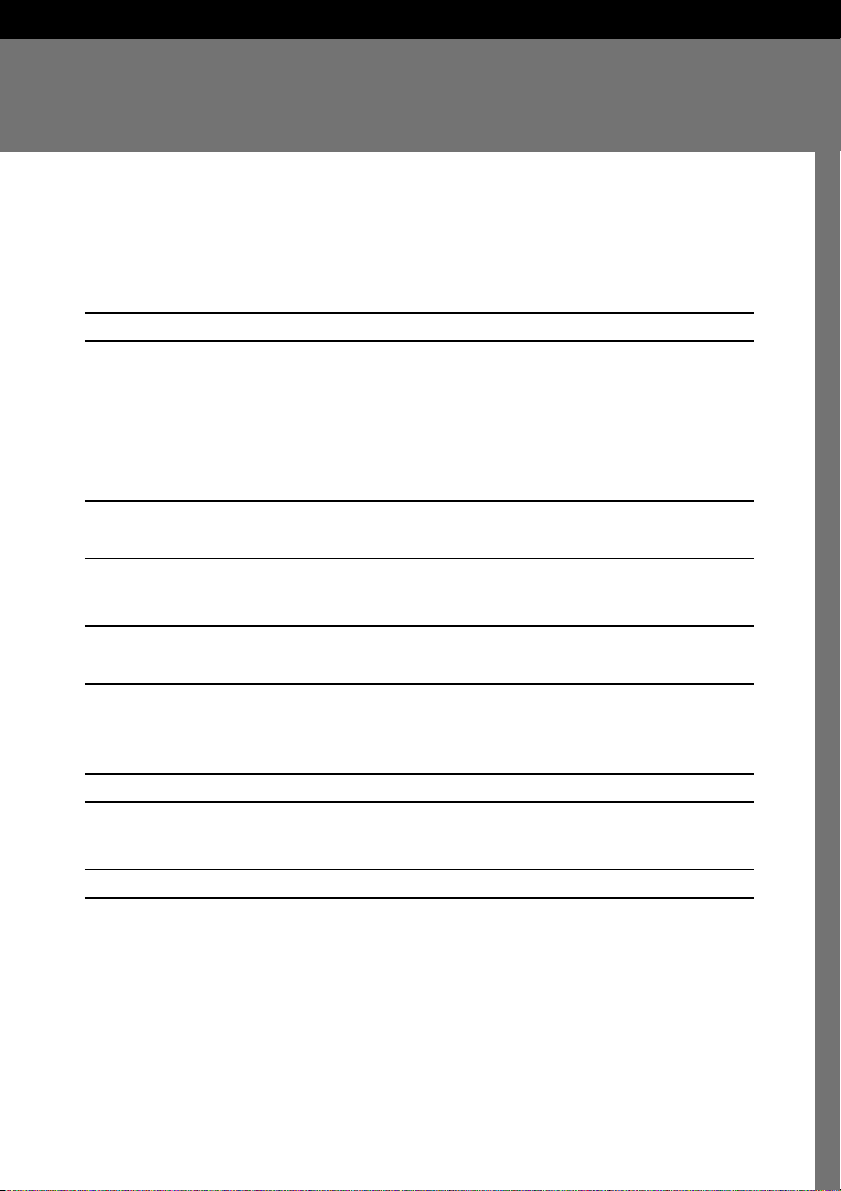

Guide to the Scanner

Guide to the Scanner

2

3

4

5

6

7

8

9

1. Auto Document Feeder (ADF)

This is used to automatically feed and scan

documents.

2. Document Table

Documents that are to be scanned by the

Auto Document Feeder (ADF) are placed

here.

3. Auxiliary Table

This table can be extended outwards when

placing large documents in the Auto Document Feeder (ADF).

4. Endorser Cover

Open this cover in order to clean the Endorser (printing function) or replace the

ink.

5. Output Table

After a document has been scanned by

the Auto Document Feeder (ADF), it is

output here.

10

TH2H010E

6. Stopper

This stops documents that have been

scanned and output by the Auto Document Feeder (ADF).

7. Power Switch

This switch is used to turn the scanner

power on and off.

{{

8.

{Clear Modes

{{

This button is used to stop manual scanning.

{{

9.

10. Scanner Indicators

}}

{Start

} Button

{{

}}

This button is used to start manual scanning.

These indicators can be used to check the

status of the scanner.

}}

} Button

}}

1

3

Page 15

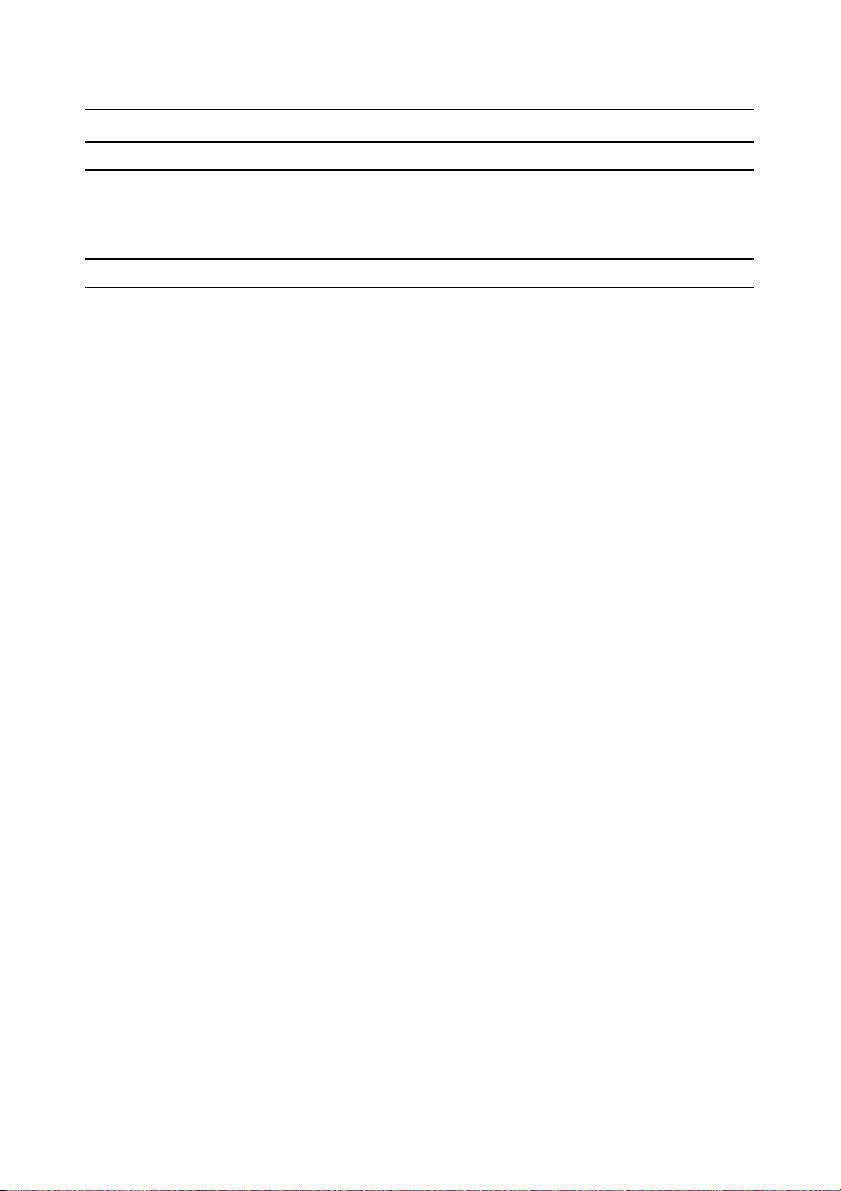

1. Introduction

TH2H020E

1

2

1. White Sheet

This presses the document down on the

contact glass.

2. Contact Glass

This is where the document is placed.

3. ADF Cover

Open this cover to clear paper jams, etc.

4. Power Connector

Connect the power cable here.

5. Rotar y Switch

This switch is used to set the SCSI ID.

6. SCSI Connector

Connect the SCSI interface cable here.

4

3

456789

7. Interface for Reverse Side Scanning

This is an extension interface for reverse

side scanning. (Duplex Model only)

8. DIP Switches

These switches are used to set the operating mode.

9. Reset Switch

This switch resets the scanner as if the

power had been turned off and then back

on again. This switch is used to make

new DIP switch and rotary switch settings valid.

Page 16

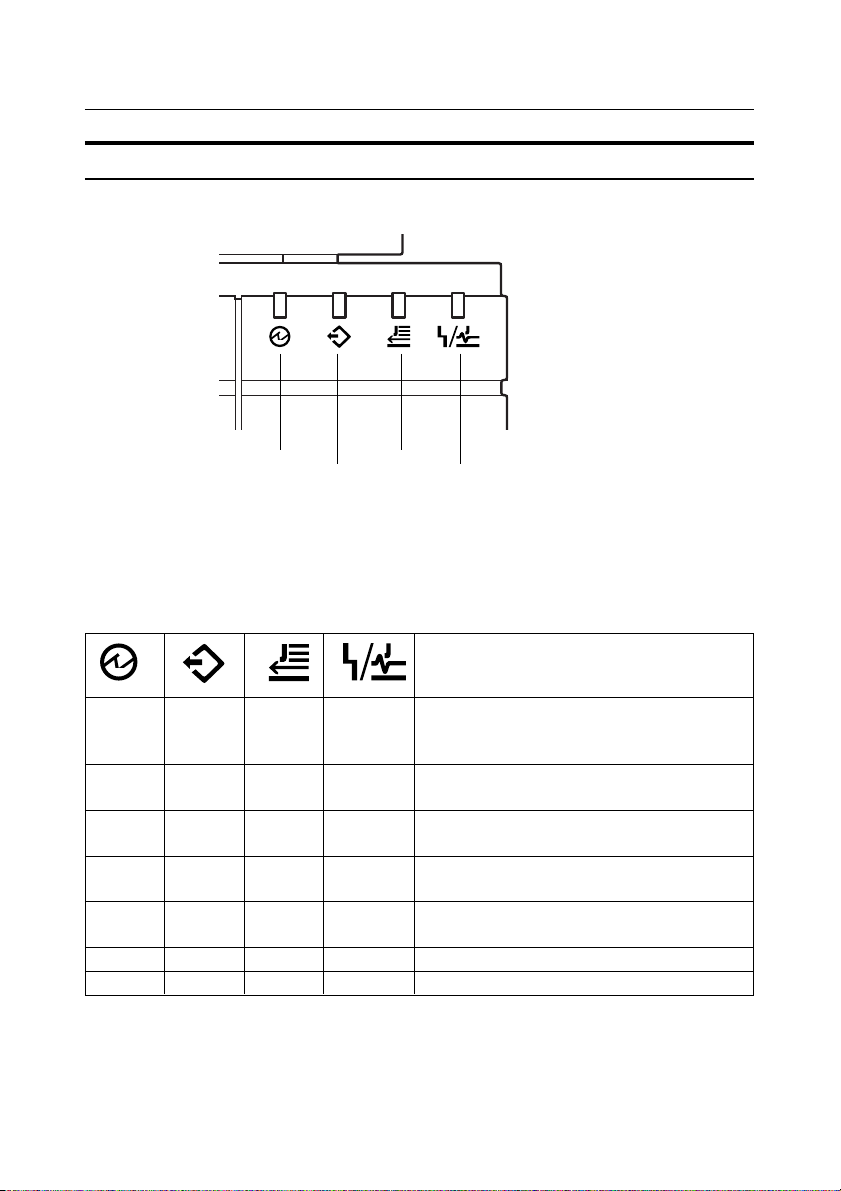

Understanding the Indicators

The scanner has the following indicators:

Guide to the Scanner

TH2H030E

1: Power On

2: Machine Busy

3: Document in Place

4: Error

When the scanner is in a normal operating state, the indicators will light in one of the combinations shown below . If the indicators light in any other pattern, an error has occurred. Refer to p.

28, “Error Indicators and Solutions.”

❍❍❍❍When the power has just been turned on, or the

❍●●●When there is no document in the Auto Docu-

❍●❍●When there is a document in the Auto Document

❍❍●●When scanned data is being transferred (and there

❍❍❍●When scanned data is being transferred (and there

❍●✕●When the scanner is ready for manual scanning

✕●●●When the scanner is ready by Low Power Mode

❍ :On

✕ : Flashing

● : Off

1

2

3

4

Description

Reset switch has been pressed (This combination

is displayed only for a few seconds.)

ment Feeder, and no document is being scanned

Feeder, but the document is not being scanned

is no document in the ADF)

is a document in the ADF)

5

Page 17

1. Introduction

6

Page 18

2. Setting up the Scanner

This chapter explains the preparations that are necessary in order to use the scanner.

Preparing for Installation

Checking the Scanner Location

Set up the scanner in a location that satisfies the following conditions:

❖❖

❖ Setup location

❖❖

Warning:

••

•

Make sure the wall outlet is near the machine and easily

••

accessible so that in event of an emergency it can be

unplugged easily.

Caution

•

Keep the machine away from humidity and dust. A fire or an

electric shock might occur.

•

Do not place the machine on an unstable or tilted surface. If it

topples over, it could cause injury.

Set up the scanner on a flat, stable surface.

• The surface must be level to within 5mm ( 0.2”) on all sides.

7

Page 19

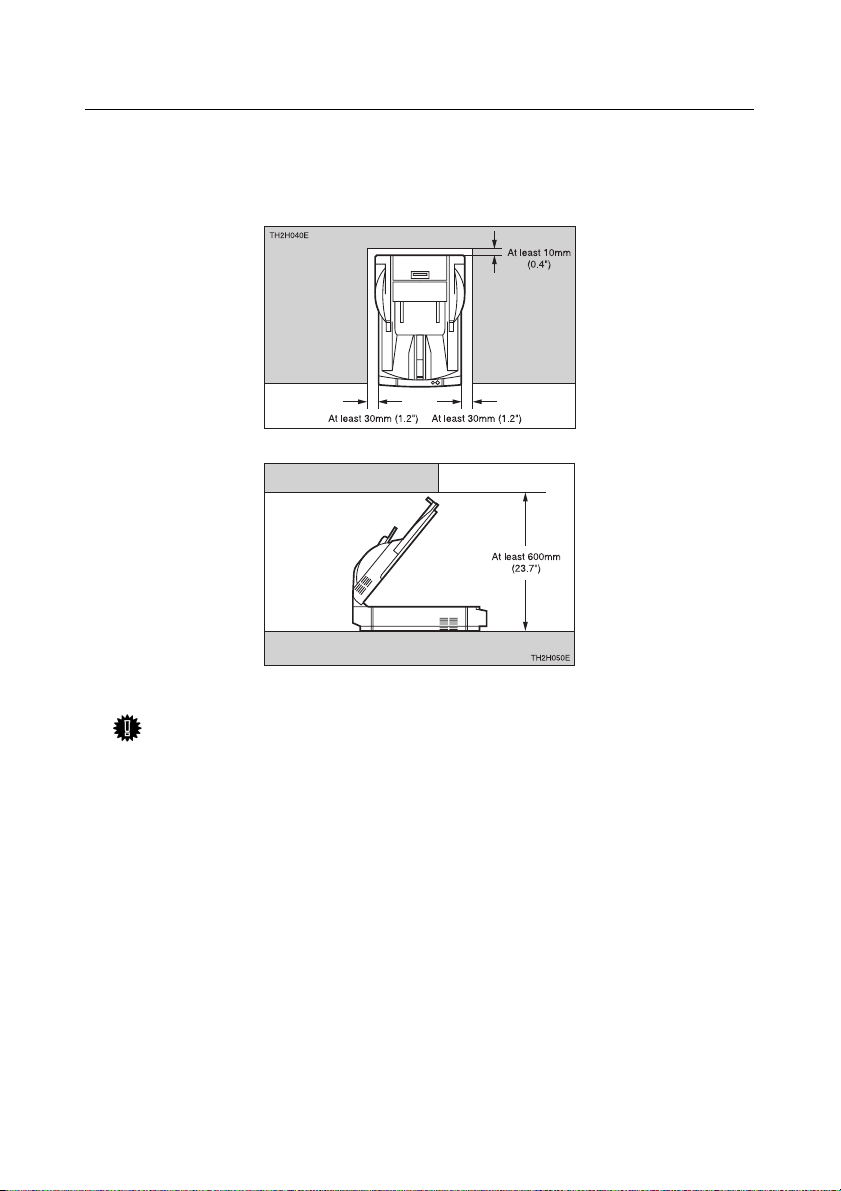

2. Setting up the Scanner

❖❖

❖ Installation space

❖❖

Set up the scanner in a location where there is enough space to provide the clearance shown

in the figure below .

❖❖

❖ Installation environment

❖❖

Important

❒ Do not set up the scanner in any of the types of locations listed below. Doing so

could cause the scanner to malfunction.

• In a location exposed to direct sunlight

• In a location where the scanner will be subjected to blowing air or radiant heat,

such as near an air conditioner or heater

• In a location near other electronic devices, such as a radio or television set

• In a location subject to extreme temperatures or humidity

• Near a humidifier

8

Page 20

Preparing for Installation

Set up the scanner in a location where the temperature and humidity will fall within the ranges

shown below.

%RH

%RH

10°C 80%

80

60

40

20

80

60

40

20

15°C

70%

15°C

30%

10°C 15%

10

50°F 80%

59°F

70%

59°F

30%

50°F 15%

50 80 90

20

60 70

27°C 80%

25°C

70%

25°C

30%

32°C 15%

30

Recommended rangeUsable range

80.6°F 80%

77°F

70%

77°F

30%

89.6°F 15%

Recommended rangeUsable range

32°C

54%

°C

TH2H061E

89.6°F

54%

°F

TH2H070E

Important

❒ Save the box and cushioning material in which the scanner was packed so that they

can be used if it is necessary to transport the scanner in the future.

9

Page 21

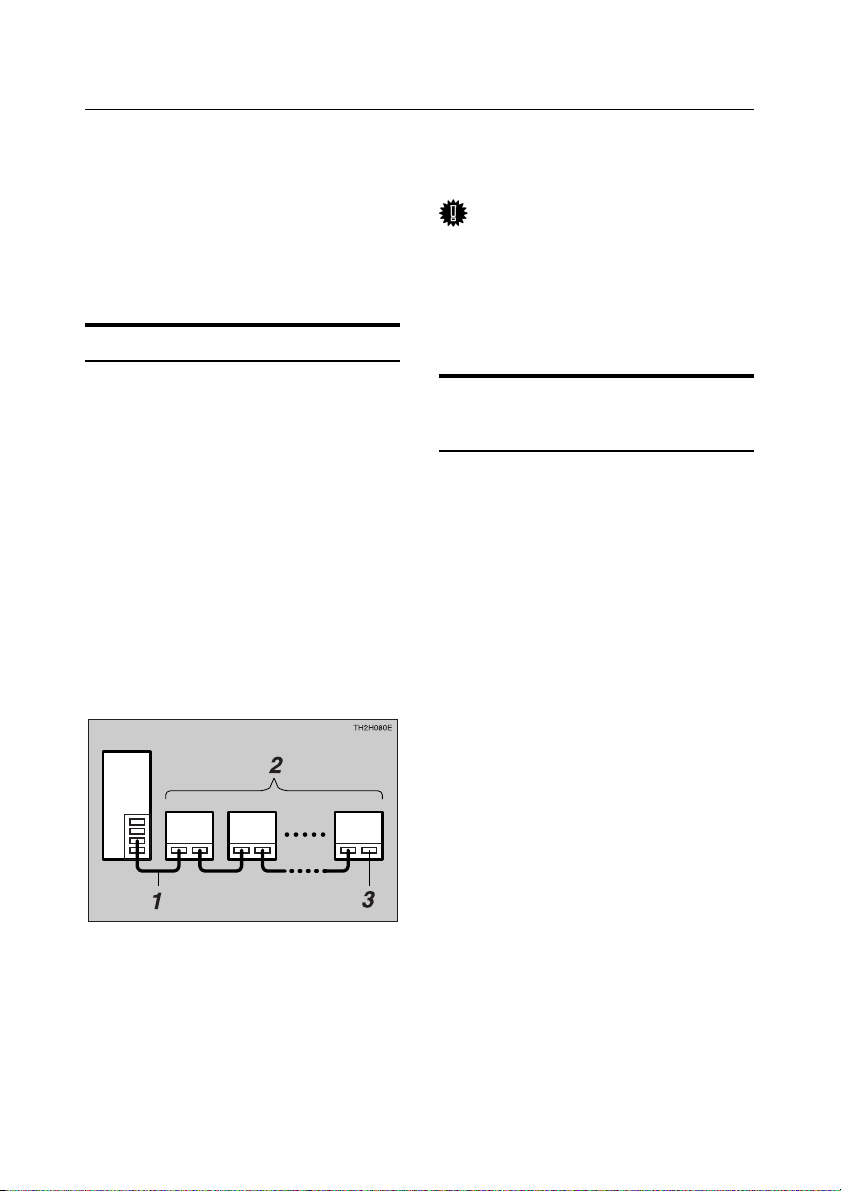

2. Setting up the Scanner

Connecting to the Host Computer

This scanner connects to a host personal

computer through a SCSI interface. This

section provides an overview of SCSI, and

explains how to connect the scanner to a host

computer.

What is SCSI?

“SCSI” (Small Computer System Interface)

is an interface standard that is used for highspeed data transfer between a peripheral device

and a host computer.

• In a SCSI connection, ANSI-compliant

SCSI cables are used to connect one or

more peripheral devices in daisy chain

fashion to the host computer.

• Each device is assigned a unique SCSI

ID (0 to 7), which must be set for the

device before turning on the power and

before turning on the computer.

• The last device in the daisy chain requires

a terminator.

1: SCSI cables

2: Up to 7 devices

3: Terminator

Important

❒ If two or more devices in a daisy chain

share the same SCSI ID, misoperation

and data loss may result. Set a unique

SCSI ID for this scanner that does not

duplicate the SCSI ID of any other device.

SCSI Connection Requirements for the Scanner

• This scanner complies with the SCSI-2

standard. SCSI-1-compliant peripheral

devices can also be connected and used

with this scanner. T he SCSI interface on

the scanner has a 50-pin half-pitch (pin

type) connector. Connect an ANSIcompliant shielded SCSI-2 cable to the

scanner. Note that some combinations of

cables and SCSI boards will not work

together properly, so check this carefully .

• If you are using a SCSI board and driver

software that supports SCAM, the SCSI

ID of this scanner will be set automatically, so there is no need to set the ID. If

you are using a driver that does not have

a SCAM function, it will be necessary to

set the SCSI ID for the scanner if the

SCSI ID is identical to that of another

device that is connected.

• The scanner’s terminator can be enabled

or disabled by turning a DIP switch on or

off.

10

Page 22

Connecting to the Host Computer

Important

❒ The total length of the SCSI cables, in-

cluding the length of the cable inside

the personal computer, should be no

more than 3m (9.8 ft.) when using synchronous transfer, and no more than 6m

(19.7 ft.) when using asynchronous

transfer.

❒ Some combinations of SCSI boards and

peripheral devices that are connected

simultaneously may not work together

properly.

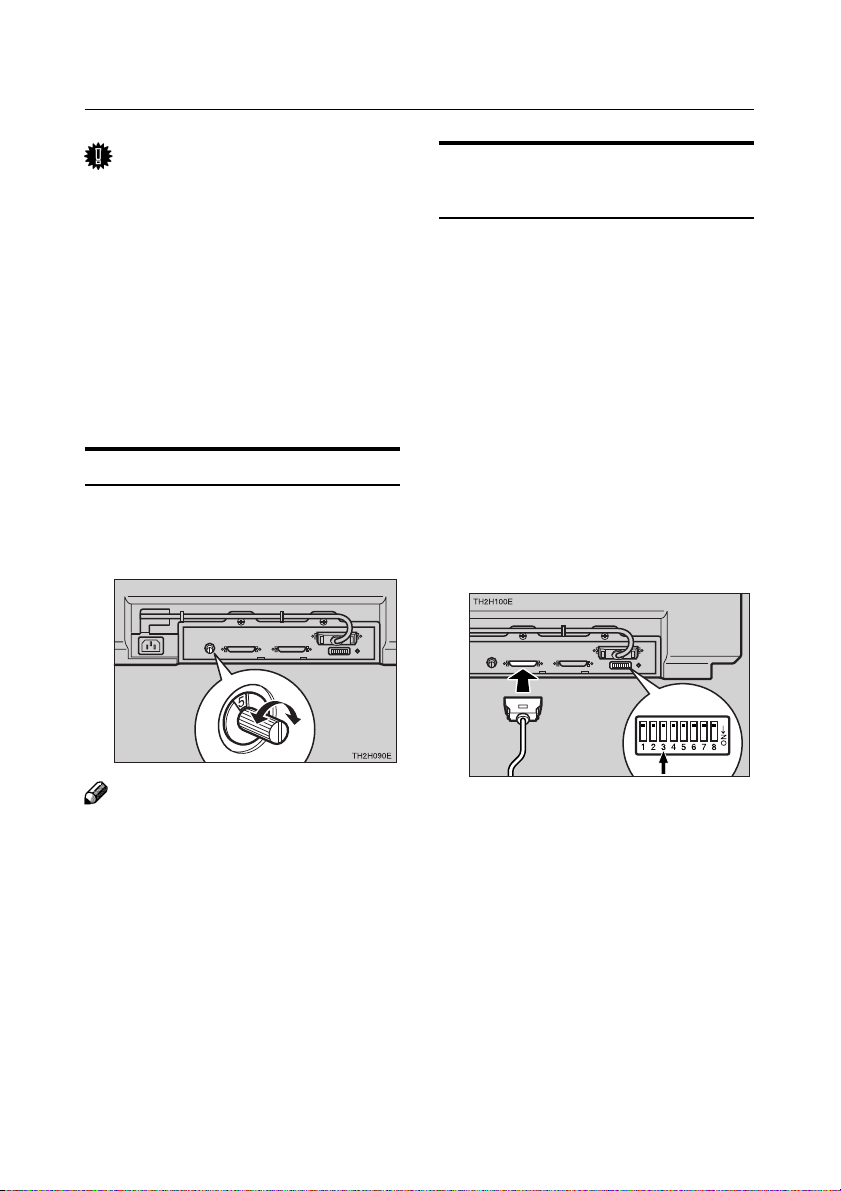

Setting the SCSI ID

T urn the r otary switch to set the SCSI

A

ID number.

Connecting the SCSI Cable (No Connection to Other Port)

Turn off the host computer and all

A

peripheral devices that will be connected through the SCSI interface.

Use SCSI cables to connect the per-

BB

B

BB

sonal computer and the peripheral devices in daisy chain fashion, with this

scanner at the end of the daisy chain.

(Use either of the two SCSI connectors on the scanner.)

Set DIP switch 3 to off.

CC

C

CC

This enables the scanner’s internal terminator. F or details on the functions of the

DIP switches, refer to P.43, “DIP

Switches.”

Note

❒ If you change the setting while the

power is on, it is necessary to initialize

the scanner. Refer to P.16, “Initializing the Scanner.”

11

Page 23

2. Setting up the Scanner

Connecting the SCSI Cable (Connection to Other Port)

T urn off the host computer and all pe-

AA

A

AA

ripheral devices that will be connected

through the SCSI interface.

Use SCSI cables to connect the per-

BB

B

BB

sonal computer and the peripheral devices in daisy chain fashion, with this

scanner in the middle of the daisy

chain.

Set DIP switch 3 to on.

CC

C

CC

This disables the scanner’s internal terminator. F or details on the functions of the

DIP switches, refer to P.43, “DIP

Switches.”

12

Page 24

Connecting the Power Cable

Connecting the Power Cable

This section explains how to connect the power ca ble to the scanner .

Warning

••

•

Only connect the machine to the power source described

••

on the inside front cover of this manual.

••

•

Avoid multi-wiring.

••

••

•

Do not damage, break or make any modifications to the

••

power cord. Do not place heavy objects on it, pull it hard

or bend it more than necessary. These actions could cause

an electric shock or fire.

••

•

Do not plug or unplug the power cord with your hands wet.

••

Otherwise, an electric shock might occur.

Warning

••

•

Be sure to ground the scanner. Failure to ground the

••

scanner could result in fire or electric shock. If there is no

ground connection available, consult your dealer.

Caution

•

When you pull out the plug from the socket, grip the plug to

avoid damaging the cord and causing fire or electric shock.

Confirm that the power switch is off.

AA

A

AA

13

Page 25

2. Setting up the Scanner

Push the power cable plug all of the way into the power connector on the scanner.

BB

B

BB

Note

❒ Use the power cable that was provided with this scanner.

Plug the other end of the power cable into the power outlet.

CC

C

CC

14

Page 26

Turning On/Off the Scanner Power

Turning On/Off the Scanner Power

Turning On the Scanner Power

When turning on the power, turn on each device in the daisy chain one by one, starting from the

device that is at the opposite end of the daisy chain away from the host computer and working

towards the host computer. T urn on the host computer last.

Press the power switch so that it is in the “Power On” position as shown below.

AA

A

AA

Turning Off the Scanner Power

Press the power switch so that it is in the “Power Off” position as above.

AA

A

AA

15

Page 27

2. Setting up the Scanner

Initializing the Scanner

If the SCSI ID rotary switch or DIP switch settings have been changed while the power is on, it

is necessary to initialize the scanner in order to put the new settings into effect. To initialize the

scanner, either turn the power off and then back on again, or else perform the procedure described

below:

Using an object with a thin tip, such as a ballpoint pen, press the reset switch located

AA

A

AA

on the back of the scanner.

Doing so puts the scanner into the same state as if the power had been turned off and then

back on again.

16

Page 28

3. Setting Originals

This section explains how to set originals that are to be scanned in the scanner .

Originals can be set either on the contact glass or in the Auto Document Feeder (ADF). The Auto

Document Feeder (ADF) is useful when you want to scan multiple originals consecutively .

Originals

Recommended Sizes and Weights of Originals

Where original is set Original size

Contact glass Up to A3

Up to 11" x 17"

Auto Document Feeder (ADF) Maximum:A3K

Minimum:69 x 120mm

Maximum:11” x 17”K

Minimum:2.75” x 4.75”

❖❖

❖ Originals that cannot be set in the Auto Document Feeder (ADF)

❖❖

Setting an original that falls in one of the following categories in the Auto Document Feeder

(ADF) could result in a paper jam or in damage to the original. Such originals should be

placed on the contact glass.

• An original that does not fall within the “Recommended Sizes and Weights of

Originals”

• An original that includes staples, paper clips, glue, or other adhesives

• An original that has holes or is torn

• An original that is warped, creased, or wrinkled

• An original that is pasted together

• An original that has some sort of surface treatment, including thermal paper, art

board, silver paper, carbon paper, or conductive paper.

• An original that has index tabs, stick-on notes, or other protrusions

• An original on paper that does not slide easily, such as tracing paper

• An original on thin, fragile paper

• An original that is not of a suitable thickness, such as a postcard

⇒ “Recommended Sizes and Weights of Originals”

• An original that is bound, such as a book

Original weight

---

41 ~ 128g/m

11 ~ 34lb

2

17

Page 29

3. Setting Originals

• An original that is highly transparent, such as transparencies or tracing paper

• An original that has markedly curled edges, such as shown below

5mm(0.2") or more

10mm(0.4") or more

Difficult to Detect Sizes

When the optional Image Processing Unit T ype A is installed, the scanner can automatically detect

the size of an original. However, the sizes of the following types of originals are difficult to detect

properly, even if using a scanner driver that supports automatic detection of the size of the

original:

• An original that has index tabs, stick-on notes, or other protrusions

• An original that is highly transparent, such as transparencies or tracing paper

• Documents on a dark background

• Documents with text, illustrations, or filled in portions on the leading edge

• An original that is not A3K, B4K, A4K, B5K, A5K, B6K, A6K, DLTK, LTK, or

HLTK (when set on the contact glass)

18

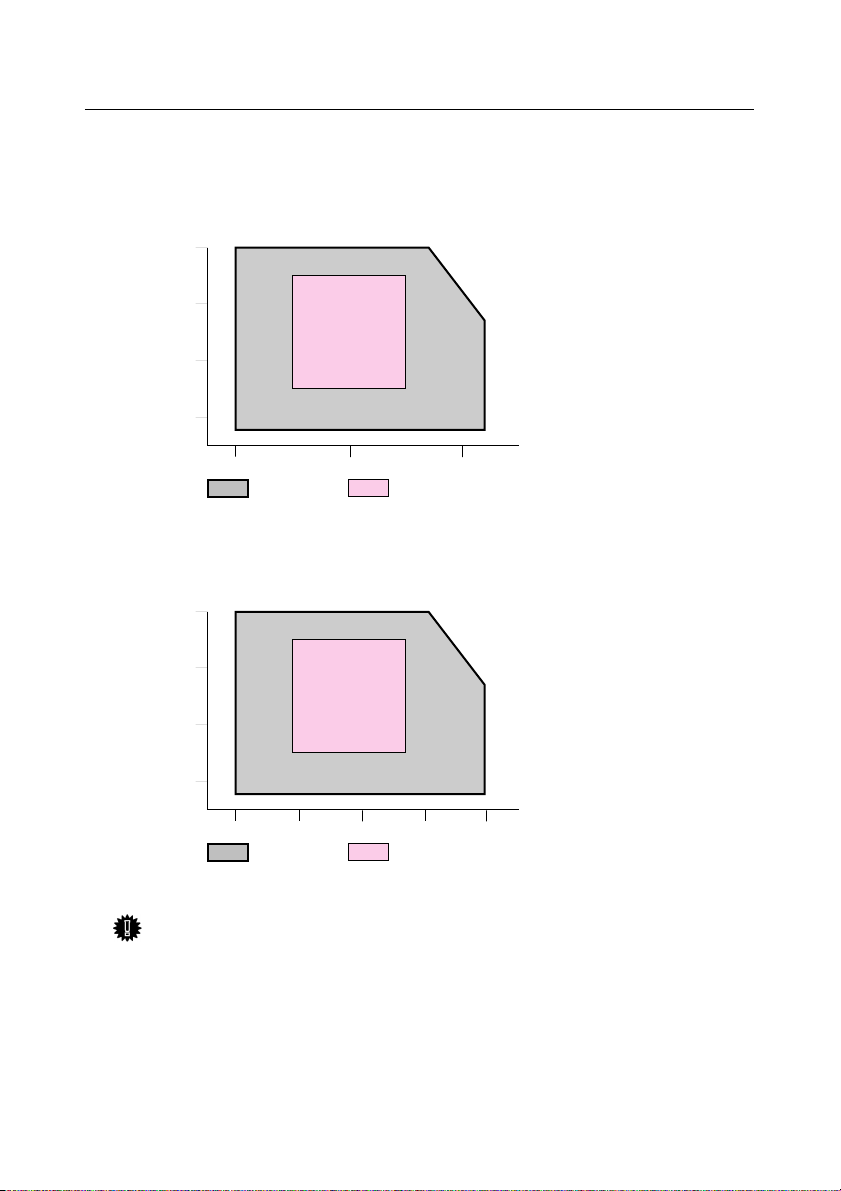

Page 30

Original sizes that can be detected automatically

Original size Paper sizes used in Japan Paper sizes used overseas Irregular sizes

Where original KKKLKLKLKLK (DTL)K (LG) K (LT) K (LT) L (HLT) K (HLT) K

is placed

Contact glass ✔✔✔ ✔ ✔ ✔ ✔ ✔ ✔ ✔

Auto Document

Feeder (ADF)

A3 B 4 A4 A4 B 5 B 5 A5 A 5 B6 B 6 A6 11”x17” 8½”x14” 8½”x11” 8½”x5½” 8½”x5½” 8½”x5½”

✔✔✔✔✔✔✔✔✔✔✔ ✔ ✔✔✔✔✔ ✔

Original Sizes and Scanning Area

❖❖

❖ Contact glass

❖❖

❖❖

❖ Auto Document Feeder (ADF)

❖❖

Originals

19

Page 31

3. Setting Originals

Setting Originals

Setting the Original on the Contact Glass

Caution

••

•

Be careful not to pinch your fingers when closing the Auto

••

Document Feeder (ADF).

Open the Auto Document Feeder (ADF).

AA

A

AA

With the side to be scanned facing down, place the original on the contact glass, and

BB

B

BB

align it with the home position and scale.

1: Home position

2: Scale

Important

❒ Do not press down on the contact glass. Strong localized pressure on the contact glass

could cause it to break.

Gently close the Auto Document Feeder (ADF).

CC

C

CC

20

Page 32

Setting Originals

Setting the Original in the Auto Document Feeder (ADF)

Note

❒ Do not set originals in the Auto Document Feeder (ADF) in excess of the upper limit

mark. (Stacked height: Not more than 15mm (0.6"))

❒ The number of sheets that can be set in the Auto Document Feeder (ADF) at one time

depends on the size and weight (thickness) of the originals. Use the following table as

a guide:

thgiehdekcatSthgieWeziS

2

m/g501

mm51

)"6.0(

)bl42(

2

m/g46

)bl02(

,5A,4A

)TLH,TL(

3A

)TLD(

3A,5A,4A

)TLD,TLH,TL(

forebmuN

nactahtsteehs

teseb

011

08

051

Limitation

❒ When the original has a dark background, the scanner may not be able to recognize

that a document has been placed in the ADF. If this happens, place the document on the

contact glass instead.

Align the originals on the ADF.

AA

A

AA

• When scanning large originals, pull out the auxiliary table.

• Adjust the stopper on the output table according to the size of the originals.

1: Auxiliary table

2: Stopper

21

Page 33

3. Setting Originals

Note

❒ When scanning an original that is A5K(HLTK) size or smaller, pull the stopper out of the

output table, turn it around, slide it back into the table, and adjust the position. (Refer to the

diagram below .)

Important

❒ When the stopper is extended, do not grasp the stopper when opening or closing the

Auto Document Feeder (ADF).

Put the originals in order. If they are to be scanned in page sequence, put them in

BB

B

BB

order as illustrated below .

Simplex scanning

22

Duplex scanning

Page 34

Setting Originals

Fan the sheets, and then line up their edges.

CC

C

CC

With the first page facing up on top, place the originals in the A uto Document F eeder

DD

D

DD

(ADF), and adjust the positions of the guides so that they touch the edges of the

original.

1: Guides

23

Page 35

3. Setting Originals

24

Page 36

4. Scanning Originals

General Scanning Method

Scanning of an original is initiated by software that is TWAIN or ISIS compatible. The method

of operation depends on the software. For details, refer to the manual that was supplied with your

software.

Limitation

❒ When using double-sided scanning, if the leading edge of the reverse side of the document is

dark, the scanned image may appear whitish.

25

Page 37

4. Scanning Originals

Manual Scanning

By setting up a scanner driver that supports the manual scanning function, scanning can be

initiated by pressing the {Start} button.

If the manual scanning function is used, then communications between the scanner and the

personal computer are no longer needed in cases where it is necessary to set the original in the

scanner one sheet at a time, for example.

Set the manual scanning function through the scanner driver.

AA

A

AA

Set the original in the scanner.

BB

B

BB

{{

Press the

CC

C

CC

1: {Clear Modes} Button

2: {Start} Button

}}

{Start

} button. To end manual scanning, press the

{{

}}

TH2H220E

{{

{Clear Modes

{{

}}

} button.

}}

26

Page 38

5. T roubleshooting

When Scanning Does not Start

If scanning does not start, check the following:

Item to check Action

Is the power on? Turn on the power .

Is the SCSI ID set properly? If there are any other SCSI devices

connected, the host computer may not be

able to recognize the scanner if it has the

same SCSI ID as another device. Refer to

P.11, “Setting the SCSI ID,” and set a

unique SCSI ID for the scanner.

Are the DIP switches set properly? The correct DIP switch settings depend on

whether this scanner is the last device in the

SCSI daisy chain. Refer to P.11,

“Connecting the SCSI Cable,” and set the

DIP switches properly.

Are the SCSI cables connected securey? If any cables are disconnected, connect

them.

Are the indicators on or flashing? The nature of an error can be determined

according to the pattern in which the four

indicators are on or flashing. Refer to P.28,

“Error Indicators and Solutions. ”

Is the scanner driver selected properly? For details on scanner driver setup, refer to

the manual or help information for your

scanner driver .

Are the software settings correct? For details on software settings, refer to the

manual or help information for your

software.

27

Page 39

5. Troubleshooting

Error Indicators and Solutions

When the indicators are on or flashing in any of the following combinations, an error has

occurred. After conf irming the nature of the error, tak e the appropriate action.

Description of error

❍●● ❍The Auto Document Feeder

(ADF) or the ADF cover is

not closed properly .

❍●✕ ❍An original is jammed in

the Auto Document Feeder

(ADF).

❍●❍ ❍An original was not output

properly from the Auto

Document Feeder (ADF).

❍●✕ ✕There is a problem with the

operation of the document

table.

✕✕❍ ●The Endorser (printing

function) may have

malfunctioned.

✕✕✕ ✕System error

❍ :On

✕ : Flashing

● : Off

Action

Close the Auto Document

Feeder (ADF) or the ADF

cover.

Refer to P.29, “Procedures

to Correct Errors in the

ADF ,” and remove the

jammed paper.

Refer to P.29, “Procedures

to Correct Errors in the

ADF ,” and remove the paper

that was not output.

Refer to P.29, “Procedures

to Correct Errors in the

ADF” and open and close

the ADF cover.

Try opening and closing the

Auto Document Feeder

(ADF) several times. If the

same error occurs, contact a

service center.

Contact a service center.

28

Page 40

Procedures to Correct Errors in the ADF

Procedures to Correct Errors in the ADF

When an Original is Jammed in the Auto Document Feeder (ADF)

Open the ADF cover.

AA

A

AA

Turn the drum knob in the direction

BB

B

BB

indicated by the arrow.

1: Knob

2: Feed roller

Remove the original from the output

CC

C

CC

table.

When an Original was Not Output Properly from the Auto Document Feeder (ADF)

Open the ADF cover.

AA

A

AA

Pull out the original.

BB

B

BB

When There is a Problem with

the Operation of the Document Table

Remove the original from the Auto

AA

A

AA

Document Feeder (ADF).

Open the ADF cover.

BB

B

BB

Note

❒ If the leading edge of a original is

jammed in the feed rollers, grasp the

leading edge of the original and gently

pull it out in the direction of the ADF

cover.

Close the ADF cover.

CC

C

CC

29

Page 41

5. Troubleshooting

When Characters Printed by the Endorser are Too Light or the Original Gets Dirt y

Replacing the Ink Ribbon

Caution

•

When you pull out the plug from the socket, grip the plug to

avoid damaging the cord and causing fire or electric shock.

Replace the ink ribbon if the Endorser’s printing becomes too light.

Turn off scanner power, and unplug the power cable from the power outlet.

AA

A

AA

Flip open the Endorser cover (located towards the rear of the output table), and pull

BB

B

BB

the cover out.

30

Grasp the green portion of the Endorser, and turn it in the direction indicated by the

CC

C

CC

arrow until it clicks.

Page 42

When Characters Printed by the Endorser are Too Light

or the Original Gets Dirty

Raise the rear portion of the Endorser ,

DD

D

DD

and then pull the Endorser out.

Important

❒ Do not pull on the Endorser’s cord.

Place the Endorser down with the

EE

E

EE

printing section facing up.

Important

❒ Do not touch the printing section of the

Endorser. Doing so may get your fingers dirty , and could damage the printing

section.

Gently press the old ink ribbon car-

FF

F

FF

tridge down

Push a new ink ribbon cartridge into

GG

G

GG

the Endorser.

Align the endorser with the hooks on

HH

H

HH

the scanner as shown in the diagram.

, and then pull it out

➀➀

➀

➀➀

.

➁➁

➁

➁➁

31

Page 43

5. Troubleshooting

Push the Endorser in until it clicks,

II

I

II

and tuck the Endorser’s power cord

into the appropriate hook.

Slide the protrusion on the bottom of

JJ

J

JJ

the cover into the output table, and

then push the cover closed.

Cleaning the Endorser

If paper scraps and dust accumulate in the

vicinity of the printing section of the Endorser, printing quality will be adversely

affected. If the printing section becomes dirty ,

gently wipe the portion shown in white in

the illustration below with a dry, soft cloth.

Important

❒ Do not wipe any portion other than that

which is shown in white above. In addition, do not touch the printing section.

Doing so may get your fingers dirty , and

could damage the printing section.

32

Page 44

Maintenance

Cleaning the Scanner

Warning

••

•

Do not remove any covers or screws other than those

••

specified in this manual. Some parts of the machine are at a

high voltage and could give you an electric shock. When the

machine needs to be checked, adjusted, or repaired,

contact your service representatives.

••

•

Do not take apart or attempt any modifications to this

••

machine. There is a risk of fire, electric shock, explosion or

loss of sight.

Caution

•

When you pull out the plug from the socket, grip the plug to

avoid damaging the cord and causing fire or electric shock.

6. Appendices

Periodic cleaning is required in order to maintain this scanner in good condition.

First, wipe away any dirt with a dry, soft cloth. If the dirt cannot be removed with a dry cloth,

moisten a soft cloth with water, wring it out thoroughly , and then wipe away the dirt. If water is

not sufficient to remove the dirt, wipe off the dirt with a mild detergent solution, then wipe the

detergent away with water, and then wipe the area with a dry cloth until all moisture has been

removed.

Important

❒ Do not use volatile chemicals such as benzene or paint thinner to clean the scanner, and do

not spray insect sprays, etc., on the scanner. Such chemicals could deform, discolor, or

crack scanner components.

❒ If there is any dust or dirt inside the scanner, wipe it away with a dry , clean cloth.

33

Page 45

6. Appendices

Cleaning the Contact Glass, Slit Glass, White Sheet, and Platen

Caution

••

•

Be careful not to pinch your fingers when closing the Auto

••

Document Feeder (ADF).

Turn off scanner power, and unplug the power cable from the power outlet.

AA

A

AA

Wipe these components with a soft, dry cloth.

BB

B

BB

1: White Sheet

2: Platen

3: Slit Glass

4: Contact Glass

Cleaning the Feed Roller and Drum

34

Turn off scanner power, and unplug the power cable from the power outlet.

AA

A

AA

Open the ADF cover, and then while turning the feed roller and drum by hand, wipe

BB

B

BB

them with a damp cloth that has been thoroughly wrung out.

To turn the drum, turn the blue knob.

1: Feed Roller

2: Drum

3: Knob

Page 46

Maintenance

Note

❒ Always clean the feed roller after scanning an original that was written in pencil or with

some other material that is not solidly fixed on the paper .

If you do not clean the feed roller, it may dirty the next original that is scanned.

35

Page 47

6. Appendices

Cleaning the White Roller (Duplex Model Only)

If white stripes (in the normal paper direction) appear in the image from the reverse side of the

original when a double-sided document is scanned, clean the white roller according to the procedure

described below .

Turn off scanner power, and unplug the power cable from the power outlet.

AA

A

AA

Open the A uto Document F eeder (ADF), and pull off the white sheet (which is held in

BB

B

BB

place by cellophane tape).

While turning the blue knob on the drum in the direction indicated by the arrow , wipe

CC

C

CC

the white roller with a damp cloth that has been thoroughly wrung out.

36

1: White roller

2: Drum

Place the white sheet on the contact glass with the reverse side facing up.

DD

D

DD

Page 48

Maintenance

Align the arrow on the reverse side of the white sheet with the document home

EE

E

EE

position.

Note

❒ Make sure that the white sheet does not lie on the scales.

1: Home position

2: Scales

Gently close the Auto Document Feeder (ADF), and press it down on it firmly.

FF

F

FF

Open the Auto Document Feeder (ADF) again, and rub a cloth against the entire

GG

G

GG

surface of the white sheet.

37

Page 49

6. Appendices

Moving the Scanner

Caution

••

•

The scanner weighs a maximum 29kg. When moving the

••

scanner, always hold it with the Auto Document Feeder

(ADF) against yourself, and lift it up slowly so as not to

strain yourself. Trying to lift the scanner even though it is

too heavy for you, or handling the scanner carelessly and

dropping it can result in injury.

••

•

When it is necessary to move the scanner a long distance,

••

contact a service center.

Caution

•

When you move the machine, unplug the power cord from the

wall outlet to avoid fire or electric shock.

•

When the machine will not be used for a long time, unplug the

power cord.

Caution

•

When you pull out the plug from the socket, grip the plug to

avoid damaging the cord and causing fire or electric shock.

• The minimum time for which will be kept inventories of replacement parts needed for

maintenance services is seven years from the date that a model goes out of production.

Accordingly, after this period has elapsed, it may not be possible to accept a unit for repairs.

• If you contact a service center, they will prepare the scanner for safe shipment for you.

However , you will be responsible for the actual packing and shipping of the scanner .

38

Page 50

Maintenance

Carrying the Scanner a Short Distance

Turn off scanner power, and unplug the power cable from the power outlet.

AA

A

AA

Disconnect the SCSI cables.

BB

B

BB

Grasping the scanner on the sides, above the bottom, and with the Auto Document

CC

C

CC

Feeder (ADF) closest to yourself, carry the scanner to its new location.

Important

❒ When carr ying the scanner, try to keep it as level as possible.

Shipping the Scanner

When shipping the scanner, pack it in its original shipping carton.

Important

❒ Disconnect all cables.

❒ Because the scanner is a precision instrument, pack it carefully so that it will not be

damaged while in transit.

Disposing of the Scanner

When you wish to dispose of your scanner, contact your dealer or a service center .

39

Page 51

6. Appendices

Options

This section describes options that are sold separately .

Image Processing Unit T ype A

Note

❒ The Image Processing Unit Type A is an option.

If this option is used, the following image processing features become possible:

Dynamic Threshold

This function automatically determines a suitable threshold value on the basis of the brightness

of the original, and converts the scanned image to binary data.

Limitation

❒ During double-sided scanning, this function is valid only for the front side of the original.

Auto Photo/Letter

This function automatically identifies the text portions of an original and the photographic

portions, and scans each in a suitable scan mode.

Limitation

❒ During double-sided scanning, this function is valid only for the front side of the original.

Document Size Detection

This function automatically detects the width of an original, and sends the information to the

host computer.

Section Area

This function selects an area within an original and sets scanning conditions for that area.

Limitation

❒ During double-sided scanning, this function is valid only for the front side of the original.

For details on installing the Image Processing Unit T ype A, refer to the supplement, “Setting up

the Image Processing Unit T ype A. ”

Red Lamp Unit T ype A

Note

❒ The Red Lamp Unit Type A is an option. The Red Lamp Unit Type A can be used to

eliminate red elements, such as marker or red pen. T o install or replace the Red Lamp Unit

T ype A, contact your dealer or a service center .

40

Page 52

Options

Endorser Unit T ype A (Printing Function)

Note

❒ The Endorser Unit Type A (Printing Function) is an option for some models, and is

standard equipment on other models.

The Endorser Unit T ype A (printing function) can print a symbol or number on originals that ha ve

been scanned by the Auto Document Feeder (ADF). The Endorser Unit Type A (printing

function) settings are made through the scanner driver . F or details on ho w to set the Endorser

Unit T ype A, refer to the manual and help provided for the scanner driv er that you will be using.

41

Page 53

6. Appendices

Specifications

Scanner Electrical and Hardware Specifications

T yp e Desktop flatbed scanner

Scanning methods Fixed original scanning and moving original scanning

Scanning area Main-direction: 298mm (11.7”) max.

Sub-direction: 432mm (17”) max.

Resolution Main-scanning: 400dpi

Sub-scanning: 400dpi

Gray scale 8 bits/pixel

Scanning time 0.65 seconds (A4K/200dpi/binary)

0.62 seconds (L TK/200dpi/binary)

Scanning speed Simplex Model: 55ppm (A4K/200dpi/binary)

57ppm (L TK/200dpi/binary)

Duplex Model: 81ppm (A4K/200dpi/binary)

84ppm (L TK/200dpi/binary)

*ppm: pages per minute

W arm-up time Max. 15 seconds

Interface SCSI-2 50-pin half-pitch (pin type) x 2

Power consumption Simplex Model:

50W maximum when in standby (options installed)

90W maximum when operating (options installed)

Duplex Model:

80W maximum when in standby (options installed)

120W maximum when operating (options installed)

Size 470mm (W) x 677mm (D) x 278mm (H)

18.5” (W) x 26.7” (D) x 10.9” (H)

W eight Simplex Model: Approximately 25kg (55.1lb)

Duplex Model: Approximately 29kg (63.9lb)

(Add 2kg (4.4lb) when the Endorser Unit T ype A is installed.)

42

Page 54

DIP Switches

DIP Switches

Only the settings of DIP switches 1 through 3 can be changed. Do not change the settings of the

other switches.

Leave these set to “OFF;” do not

change.

OFF: Internal SCSI terminator on

ON: Internal SCSI terminator off

OFF: SCSI synchronous transfer

enabled

ON: SCSI synchronous transfer

disabled

OFF: SCAM function enabled

ON: SCAM function disabled

Important

❒ If multiple devices that support the SCAM function are connected on the same daisy

chain, the host will not be able to recognize the IDs. In this case, set DIP switch 1 to

“ON” (SCAM function disabled), and set the SCSI ID with the rotary switch.

❒ If the daisy chain is too long, or if a nonstandard SCSI cable is used, misoperation may

occur during synchronous transfer. In this case, set DIP switch 2 to “ON” (SCSI

synchronous transfer disabled).

❒ If this scanner is connected in the middle of a daisy chain, set DIP switch 3 to “ON”

(internal SCSI terminator off).

43

Page 55

6. Appendices

Functions

The scanner driver can be used to perform the following image processing functions:

Preview (P .44)

Scan (P.45)

Scanning Composition (P.45)

Binary Scanning/Threshold (P.46)

Halftone Scanning (P .47)

Gray Scale Scanning (P .48)

Area Extraction (P .49)

Section Area (Multi-area Settings) (P .50)

Auto Photo/Letter (P.51)

Resolution (P .52)

Brightness (P.53)

Contrast (P.53)

Gamma Correction (P .54)

Binary Filters (P .55)

Parameter Download (P .55)

Document Size Detection (P .56)

Erase Background (P .57)

Note

❒ The scanner operates according to the scanner driver settings, but some scanner driv-

ers do not support all of the scanner functions. In such a case, the unsupported functions are not available for use.

In addition, the names used in this manual for certain functions may differ from the

names used by the scanner driver. For details, refer to the scanner driver manual.

Preview

This function scans the entire scanning area at low resolution (100dpi*). The preview image can

then be viewed while setting the scanning area for the final scan. The preview function can also

be used to get a quick view of the scannable area.

* “dpi” is an abbreviation for “dots per inch,” and indicates resolution. A larger v alue indicates

greater detail.

44

Page 56

Functions

Scan

This function scans an original once the scanning area, scanning composition, resolution, and

other values have been set.

When setting these values, consideration should be given to the original that is to be scanned and

to the output device (display , printer, etc.). F or example, it is meaningless to scan an original at

high resolution if the resolution of the output device is lower than the scanning resolution,

especially because high-resolution scanning uses a great deal of memory and requires more

processing time.

Scanning Composition

There are three scanning composition modes: binary scanning, halftone scanning, and multivalue scanning.

❖❖

❖ Binary scanning

❖❖

This mode scans the original in black and white. This mode is used to scan originals that

consist only of text, line drawings, and other elements that lack intermediate colors.

❖❖

❖ Halftone scanning

❖❖

This mode scans the original in pseudo-halftones created by dots. This mode is used to

output an original that contains intermediate colors, such as a photo, on an output device that

can only express binary per pixel, such as a laser printer .

❖❖

❖ Gray Scale scanning

❖❖

This mode scans the original with 16 or 256 gradations. This mode is used to output an

original that contains intermediate colors on an output device that can express different

gradations for a single pixel, such as a Dye Sublimation printer or a display.

Original Binary

Halftone Gray Scale

45

Page 57

6. Appendices

Binary Scanning/Threshold

The binary scanning function converts the original into black and white image data. If the original

contains any intermediate colors, they are compared with the threshold value and determined to be

either black or white accordingly. The thr eshold value can be set to an y of 255 gradations; any

intermediate colors that are brighter than the threshold value are scanned as “white,” and those that

are darker than the threshold value are scanned as “black.” This mode should be used to scan

originals that have no intermediate colors and consist of only two colors, such as text or line

drawings.

The threshold value should be set according to the intensity of the original. For example, setting

a high threshold value when scanning faint text will produce text that is much clearer . Conv ersely,

setting a low threshold value when scanning an original that is on a colored background (such as

text on colored paper) will eliminate the background color from the scan.

There are two modes for the threshold value setting:

❖❖

❖ Standard mode

❖❖

Any one of 255 values can be set.

❖❖

❖ Dynamic threshold mode

❖❖

This function is valid only when the optional Image Processing Unit Type A is installed.

With this mode, the optimal threshold value (given the brightness of the original) is set

automatically.

Original Low threshold value

High threshold value Dynamic threshold mode

46

Page 58

Functions

Halftone Scanning

Halftone scanning converts the original into an image consisting of pseudo-halftones produced

by dot shading (in which shading is achieved through combinations of black and white dots, as

in newspaper photographs). This function is used to output an original that has intermediate

tones, such as a photo, on an output device that can only produce monochrome output, such as a

laser printer.

Because halftone scanning expresses pseudo-halftones, it does not require as much memory,

making it effective for filing a large volume of images. There are eleven types of halftones (ten

dot shading patterns and one error diffusion pattern) for selection. It is also possible to scan and

download your own dot shading patterns.

The names in parentheses indicate the names under the ISIS driver .

Original

8 x 4 45° 6 x 6 90° 8 x 8 90° 16 x 8 45°

Error diffuson8 x 8 Bayer4 x 4 Spiral16 x 16 90°

47

Page 59

6. Appendices

180 LPI70 LPI 95 LPI

Gray Scale Scanning

Glay Scale scanning converts an original into image data consisting of 4-bit or 8-bit gradations.

Four bits can express 16 gradations, and eight bits can express 256 gradations. This function is

used to output an original that contains intermediate tones on an output device that can express

intermediate tones for a single pixel, such as a display or a Dye Sublimation printer.

Although a higher number of bits produces higher image quality, it is impor tant to remember that

the processing time will be longer. For e xample, when an area is scanned using the 8-bit multiscan mode, it requires eight times as much memory as when scanning the same area through

binary scanning or halftone scanning.

Original

4-bit image 8-bit image

48

Page 60

Functions

Area Extraction

This function extracts and scans a specified rectangular area within a scanning area.

For example, to scan just the photograph portion of the original shown below, specify the area

where the photograph is located. The rectangular area is specified by specifying the coordinates

of the upper left corner of the rectangle, and the vertical and horizontal lengths.

Specified area

Original

Scanned image

k

Scanned result

49

Page 61

6. Appendices

Section Area (Multi-area Settings)

This function permits the specification of up to four rectangular areas of any size within the

scanning area, each of which can be set as the scanning area. When overlapping areas are set, the

area that was set last takes priority .

For example, when a single original contains both text and photos, specify rectangular areas for

each, and then set binary scanning mode for the text areas and halftone scanning mode for the

photographs. This function allows each area to be scanned in its respective scanning mode in one

scan.

Limitation

❒ During double-sided scanning, this function is valid only for the front side of the original.

Note

❒ Note that scanning might not be performed in the specified manner if any of the four

rectangular areas overlap. In this case, either decrease the number of rectangles, or

else reduce them in size.

❒ This function is valid only when the optional Image Processing Unit T ype A is installed.

1. Binary scanning is set for the whole page

2. Halftone scanning is set for this area

3. Halftone scanning is set for this area

4. Halftone scanning is set for this area

Original

Result of settings

described above

50

k

When this function is not used

When entire original

was scanned through

binary scanning

When entire original was

scanned through halftone

scanning

Page 62

Functions

Auto Photo/Letter

This function automatically determines whether the image being scanned is text (binary image) or

photo (intermediate tone image), and scans the text areas in binary scanning mode and the photos

in halftone scanning mode. This function is used in order to automatically scan text in binary

scanning mode and photos in halftone scanning mode. This function allows you to scan an

original that contains both text and photos just once while automatically scanning each type of

area in the appropriate scanning mode without having to make special settings for each.

Note

❒ This function is valid only when the optional Image Processing Unit Type A is installed.

Original

Scanned in binary

scanning mode

Scanned in halftone

scanning mode

51

Page 63

6. Appendices

Resolution

This function permits setting separate resolutions for the main-scanning and the sub-scanning,

over a range of 100dpi to 800dpi (in 1dpi increments) for each. A high resolution setting requires

more free space in memory and requires more processing time.

Basically, when outputting a scanned image that is the same size as the original image, set the

same resolution as that of the output device. Image quality will suffer if the resolution is less than

that of the output device, and it is meaningless to set a resolution that is higher than the resolution

that the output device is capable of. However, if the output image is to be enlarged or reduced

compared to the original, change the resolution by the same ratio.

Limitation

❒ When this function is used during duplex scanning, the maximum image data size for the

reverse side is 360 million bytes.

Note

❒ When using this function, the image on the reverse side might be scanned through the

document, depending on the condition of the original.

Original

52

Low resolution High resolution

Page 64

Functions

Brightness

The brightness can be adjusted to 255 levels. If a high value is set for the brightness, the image

will become brighter overall. If a low value is set, the image will become darker overall.

When scanning a dark original, set a high value for the brightness; when scanning a bright

original, set a low value for the brightness. For example, if a dark original is scanned normally ,

any gradations in the darker portions will be lost and will appear to be solid black in the scanned

image. By increasing the brightness value in this case, the gradations in the darker portion will

also appear in the scanned image. Conversely, if the bright portions of an original become solid

white in the scanned image, lowering the brightness value will bring out the gradations in the

bright portion in the scanned image.

Low brightness High brightness

Contrast

The contrast can be adjusted to 255 levels. If a high contrast value is set, the resulting image will

have high contrast and will be sharply defined. If a low contrast value is set, the resulting lowcontrast image will have a softer feel.

To produce a sharp image, increase the contrast value, to produce a soft image, decrease the

contrast value. For example, when scanning a photo of metal, glass, etc., set a high contrast value

in order to achieve a sharp feel.

Low contrast High contrast

53

Page 65

6. Appendices

Gamma Correction

The following types of gamma correction are possible. However, different models of output

devices have different characteristics. Select a suitable gamma curve for the original that is to be

scanned and the output device.

❖❖

❖ Normal

❖❖

Emphasizes the contrast slightly, resulting in a some what sharp scanned image.

❖❖

❖ Sharp

❖❖

Emphasizes the contrast, resulting in a sharp scanned image.

❖❖

❖ Soft

❖❖

Decreases the contrast, resulting in a soft scanned image.

❖❖

❖ Linear

❖❖

Outputs the image as scanned.

❖❖

❖ User-defined

❖❖

Downloads a user-defined gamma curve for gamma correction.

Normal Sharp

Soft Linear

54

Page 66

Functions

Binary Filters

The following two filters can be used for binary scanning.

❖❖

❖ Noise removal

❖❖

This filter used to eliminate the unnecessary small dots that appear when scanning an original

that is the result of several generations of photocopying.

When filter is not used

❖❖

❖ Smoothing

❖❖

This filter is used to smooth out small bumps within an image.

When filter is not used

Note

❒ This function is valid only when the optional Image Processing Unit Type A is installed.

When filter is used

When filter is used

Parameter Download

This function allows a user to download user-created gamma curves and halftone patterns to the

scanner.

The details of how to download the data depends on the software being used.

55

Page 67

6. Appendices

Document Size Detection

This function automatically detects the width of the original, and sends the information to the

personal computer.

Document Size Detection on the Contact Glass

5mm (0.2")

Document Size Detection in the Auto Document Feeder (ADF)

5mm (0.2")

Note

❒ If there is any coloring on the leading edge (5mm, 0.2”) of the original, the size of the

original might not be detected properly.

❒ If the sheets of the original are not set in position properly, the size of the original

might not be detected properly. Line up the edges of the sheets of the original, and

position the guides on both sides so that they are touching the edges of the original and

will ensure that the original feeds straight into the ADF.

❒ This function is valid only when the optional Image Processing Unit T ype A is installed.

56

Page 68

Functions

Erase Background

This function permits selection of the white side dynamic range for scanning.

When Erase Background is disabled

The dynamic range is set so that a white original (D value: 0.07) reaches maximum output.

When Erase Background is enabled

During scanning, the portion of the original that is closest to white is deemed to be white, and

the dynamic range is set so that the portion in question reaches maximum output.

57

Page 69

6. Appendices

Index

A

ADF Cover ----------------------- 4, 29, 34

Area Extraction --------------------------- 49

Auto Document Feeder (ADF) --- 1, 3, 5,

17, 19, 21, 22, 23, 28, 29, 36, 37, 39

Auto Photo/Letter ------------------ 4 0, 51

Auxiliary Table ----------------------- 3, 21

B

Binary Filters ------------------------------ 5 5

Binary Scanning ---------------------- 45, 46

Brightness ---------------------------------- 53

C

{Clear Modes} Button ---------------- 3, 26

Contact Glass ------------ 4, 17, 19, 20, 34

Contrast ------------------------------------- 53

D

Daisy Chain --------------------------- 1 0, 4 3

DIP Switch --------------------- 4, 10, 27, 43

Document in Place -------------------------- 5

Document Size Detection ----------- 40, 56

Document Table ----------------------- 3, 29

Drum ---------------------------------------- 34

Duplex Model -------------------------- 1, 42

Dynamic Threshold------------------------ 40

E

F

Feed roller ----------------------------- 29, 35

G

Gamma Correction ------------------------ 5 4

Gray Scale Scanning ---------------- 45, 48

H

Halftone Scanning ------------------- 45, 47

Home Position ------------------------ 20, 37

I

Image Processing ------------------------- 40

Indicators --------------------------- 5, 27, 28

Initializing the Scanner ------------------ 16

ink ribbon ----------------------------------- 30

Interface for Reverse Side Scanning-------4

ISIS-------------------------------------- 2, 25

K

Knob ------------------------------ 29, 34, 36

M

Machine Busy ------------------------------- 5

Manual Scanning ------------------- 1, 5, 26

O

Output T able ------------------------ 3, 29, 30

Endorser ------- 1, 28, 30, 31, 32, 41, 42

Endorser Cover ------------------------- 3, 30

Erase Background ------------------------- 57

Error ------------------------------------------- 5

58

Page 70

Index

P

Parameter Download --------------------- 55

Platen --------------------------------------- 3 4

Power Cable -------------------------------- 13

Power Connector ----------------------- 4, 14

Power On -------------------------------------5

Power Switch ---------------------- 3, 13, 15

Preview ------------------------------------- 44

R

Red Lamp Unit ---------------------------- 4 0

Reset Switch ---------------------------- 4, 16

Resolution ---------------------------------- 5 2

Rotary Switch --------------------------- 4, 11

S

Scale ----------------------------------------- 20

SCAM --------------------------------- 10, 43

Scanner Indicators ---------------------------3

Scanning Composition -------------------- 45

SCSI----------------------------------------- 10

SCSI Board--------------------------------- 10

SCSI Cables ---------------- 10, 11, 27, 39

SCSI Connector------------------------------4

SCSI ID---------------------------10, 11, 27

Section Area (Multi-area Settings) ------- 50

Simplex Model ----------------------------- 42

Slit Glass------------------------------------ 34

{Start} Button --------------------------- 3, 26

Stopper ------------------------------ 3, 21, 22

T

Ter minator ------------------------ 10, 11, 43

Threshold ----------------------------------- 46

TWAIN --------------------------------- 2, 25

W

White Roller ------------------------------- 36

White Sheet ------------------------ 4, 34, 36

59

Page 71

6. Appendices

60

Loading...

Loading...