Page 1

GROUP 3

FACSIMILE

Page 2

CONTENTS

INTRODUCTION

SECTION 1. FAX MACHINE OVERVIEW

1-1. FACSIMILE PROCESS . . . . . . . . . . . . . . . . 1-1-1

1-1-1. What is a Fax Machine? . . . . . . . . . . . . . . . 1-1-1

1-1-2. Thermal Paper Fax Terminals . . . . . . . . . . . . . 1-1-2

1. Transmitting . . . . . . . . . . . . . . . . . . . . 1-1-2

2. Receiving . . . . . . . . . . . . . . . . . . . . . 1-1-3

1-1-3. Plain Paper Fax Terminals . . . . . . . . . . . . . . 1-1-4

1. Transmitting . . . . . . . . . . . . . . . . . . . . 1-1-4

2. Receiving . . . . . . . . . . . . . . . . . . . . . 1-1-4

1-2. OVERALL SYSTEM CONTROL . . . . . . . . . . . . . 1-2-1

1-2-1. Thermal Paper Fax Machines . . . . . . . . . . . . . 1-2-1

1-2-2. Plain Paper Fax Machines . . . . . . . . . . . . . . 1-2-5

1-2-3. Communication Between CPU’s . . . . . . . . . . . 1-2-7

1. Serial Interface . . . . . . . . . . . . . . . . . . . 1-2-7

2. Parallel Interface . . . . . . . . . . . . . . . . . . 1-2-7

1-3. VIDEO DATA PATH . . . . . . . . . . . . . . . . . . 1-3-1

1-3-1. Transmission . . . . . . . . . . . . . . . . . . . 1-3-1

1. Scanning . . . . . . . . . . . . . . . . . . . . . 1-3-1

2. Data Processing . . . . . . . . . . . . . . . . . . 1-3-2

1-3-2. Reception . . . . . . . . . . . . . . . . . . . . 1-3-5

1. Thermal Printers . . . . . . . . . . . . . . . . . . 1-3-5

2. Laser Printers . . . . . . . . . . . . . . . . . . . 1-3-7

1-3-3. Copying . . . . . . . . . . . . . . . . . . . . . 1-3-10

1. Thermal Printers . . . . . . . . . . . . . . . . . . 1-3-10

Single Copy . . . . . . . . . . . . . . . . . . . . 1-3-10

Multi-page Copying . . . . . . . . . . . . . . . . . 1-3-10

2. Laser Printers . . . . . . . . . . . . . . . . . . . 1-3-11

Single Copy . . . . . . . . . . . . . . . . . . . . 1-3-11

Multi-page Copying . . . . . . . . . . . . . . . . . 1-3-11

1-4. POWER DISTRIBUTION . . . . . . . . . . . . . . . . 1-4-1

1-4-1. Typical Power Distribution Circuits . . . . . . . . . . . 1-4-1

1. Thermal Printer Fax . . . . . . . . . . . . . . . . . 1-4-1

2. Laser Printer Fax . . . . . . . . . . . . . . . . . . 1-4-2

1-4-2. Power Supply Activation . . . . . . . . . . . . . . . 1-4-3

1-4-3. Memory Back-up . . . . . . . . . . . . . . . . . 1-4-4

1-4-4. Interlock Switch Safety Circuits in Laser Faxes . . . . . . 1-4-7

Page 3

SECTION 2. TRANSMISSION

2-1. DOCUMENT DETECTION . . . . . . . . . . . . . . . 2-1-1

2-1-1. Document Table Mechanism . . . . . . . . . . . . . 2-1-1

1. Sensors . . . . . . . . . . . . . . . . . . . . . 2-1-1

2. Document Guides . . . . . . . . . . . . . . . . . 2-1-3

3. Shutter . . . . . . . . . . . . . . . . . . . . . . 2-1-4

2-1-2. Scanner Lamp . . . . . . . . . . . . . . . . . . 2-1-5

2-2. DOCUMENT FEED AND SEPARATION . . . . . . . . . . 2-2-1

2-2-1. Pick-up and Feed . . . . . . . . . . . . . . . . . 2-2-1

1. Overview . . . . . . . . . . . . . . . . . . . . . 2-2-1

2. Electromagnetic Clutch Mechanism . . . . . . . . . . . 2-2-3

Prefeed . . . . . . . . . . . . . . . . . . . . . 2-2-4

Scanning . . . . . . . . . . . . . . . . . . . . . 2-2-5

Feed-out and Stamping . . . . . . . . . . . . . . . 2-2-6

3. Mechanical Clutch Mechanism . . . . . . . . . . . . . 2-2-8

3. Electrical Components . . . . . . . . . . . . . . . . 2-2-11

4. Resolution . . . . . . . . . . . . . . . . . . . . 2-2-12

5. Document Jam Conditions . . . . . . . . . . . . . . 2-2-13

2-2-2. Separation Mechanism . . . . . . . . . . . . . . . 2-2-13

2-2-3. Manual Feed . . . . . . . . . . . . . . . . . . . 2-2-15

2-3. VIDEO PROCESSING . . . . . . . . . . . . . . . . . 2-3-1

2-3-1. Outline . . . . . . . . . . . . . . . . . . . . . 2-3-1

1. Principle . . . . . . . . . . . . . . . . . . . . . 2-3-1

2. Optic Path . . . . . . . . . . . . . . . . . . . . . 2-3-2

3. Scan Line . . . . . . . . . . . . . . . . . . . . . 2-3-3

4. Scanning . . . . . . . . . . . . . . . . . . . . . 2-3-4

5. Signal Processing . . . . . . . . . . . . . . . . . . 2-3-6

2-3-2. CCD Drive . . . . . . . . . . . . . . . . . . . . 2-3-7

2-3-3. Data Correction . . . . . . . . . . . . . . . . . . 2-3-8

1. Overview . . . . . . . . . . . . . . . . . . . . . 2-3-8

2. DC Filtering and Amplification . . . . . . . . . . . . . 2-3-10

3. Auto Shading and A/D Conversion . . . . . . . . . . . 2-3-10

4. Peak Hold . . . . . . . . . . . . . . . . . . . . . 2-3-11

5. Correction for Scanner Irregularities . . . . . . . . . . . 2-3-11

2-3-4. Digital Data Processing Steps . . . . . . . . . . . . 2-3-12

1. Overview . . . . . . . . . . . . . . . . . . . . . 2-3-12

2. Gamma Correction . . . . . . . . . . . . . . . . . 2-3-14

3. MTF . . . . . . . . . . . . . . . . . . . . . . . 2-3-14

4. Thresholding . . . . . . . . . . . . . . . . . . . 2-3-15

5. Background Detection . . . . . . . . . . . . . . . . 2-3-15

6. OR Processing . . . . . . . . . . . . . . . . . . . 2-3-16

Page 4

7. Reduction . . . . . . . . . . . . . . . . . . . . . 2-3-17

Main Scan Reduction . . . . . . . . . . . . . . . . 2-3-17

Sub-Scan Reduction . . . . . . . . . . . . . . . . 2-3-18

8. Edge Detection . . . . . . . . . . . . . . . . . . . 2-3-19

9. Halftone . . . . . . . . . . . . . . . . . . . . . 2-3-19

Basic Halftone Process . . . . . . . . . . . . . . . 2-3-19

Error Diffusion Halftone Process . . . . . . . . . . . . 2-3-20

10. Image/Text Detection and Process Selection . . . . . . . 2-3-21

11. Storage in SAF Memory . . . . . . . . . . . . . . . 2-3-21

2-4. CALL COLLISION PREVENTION . . . . . . . . . . . . 2-4-1

2-4-1. Overview . . . . . . . . . . . . . . . . . . . . . 2-4-1

2-4-2. PSTN Circuit . . . . . . . . . . . . . . . . . . . 2-4-2

1. DC Loop - Overview . . . . . . . . . . . . . . . . . 2-4-2

2. DC Loop through Telephone . . . . . . . . . . . . . 2-4-3

3. DC Loop through Fax Machine with External Telephone . . . 2-4-4

2-4-3. Call Collision Prevention in Fax Machines . . . . . . . . 2-4-5

2-5. DC LOOP CLOSURE AND LINE MONITORING . . . . . . . 2-5-1

2-5-1. DC Loop Closure . . . . . . . . . . . . . . . . . 2-5-1

2-5-2. Line Monitoring . . . . . . . . . . . . . . . . . . 2-5-3

1. Line Current Monitoring . . . . . . . . . . . . . . . 2-5-3

2. Dial Tone Monitoring . . . . . . . . . . . . . . . . . 2-5-4

3. Switching Line Monitoring On/Off . . . . . . . . . . . . 2-5-5

2-6. DIALLING . . . . . . . . . . . . . . . . . . . . . . 2-6-1

2-6-1. Pulse Dialling . . . . . . . . . . . . . . . . . . . 2-6-1

2-6-2. Tone Dialling . . . . . . . . . . . . . . . . . . . 2-6-4

2-6-3. Pauses . . . . . . . . . . . . . . . . . . . . . 2-6-6

2-7. SIGNAL DETECTION . . . . . . . . . . . . . . . . . 2-7-1

2-7-1. Busy Tone Detection . . . . . . . . . . . . . . . . 2-7-2

2-7-2. Ringback Tone Detection . . . . . . . . . . . . . . 2-7-4

2-7-3. CED Detection . . . . . . . . . . . . . . . . . . 2-7-5

2-8. DATA TRANSMISSION . . . . . . . . . . . . . . . . 2-8-1

2-8-1. Processing in the CPU . . . . . . . . . . . . . . . 2-8-1

1. Compression . . . . . . . . . . . . . . . . . . . 2-8-2

2. Data Transfer to the Modem . . . . . . . . . . . . . . 2-8-3

Without ECM . . . . . . . . . . . . . . . . . . . 2-8-3

With ECM . . . . . . . . . . . . . . . . . . . . . 2-8-4

2-8-2. Modulation . . . . . . . . . . . . . . . . . . . . 2-8-4

2-8-3. Attenuation . . . . . . . . . . . . . . . . . . . . 2-8-5

2-8-4. Exit to the Network . . . . . . . . . . . . . . . . . 2-8-6

2-9. RETURN TO STANDBY . . . . . . . . . . . . . . . . 2-9-1

Page 5

2-10. OTHERS . . . . . . . . . . . . . . . . . . . . . . 2-10-1

2-10-1. Manual Dialling . . . . . . . . . . . . . . . . . . 2-10-1

2-10-2. Immediate Transmission . . . . . . . . . . . . . . 2-10-3

2-10-3. Redialling . . . . . . . . . . . . . . . . . . . . 2-10-3

2-10-4. International Dialling . . . . . . . . . . . . . . . . 2-10-4

2-11. AUTO DIALLING FROM BEHIND A PABX . . . . . . . . 2-11-1

2-11-1. Outline . . . . . . . . . . . . . . . . . . . . . 2-11-1

2-11-2. Line Monitoring . . . . . . . . . . . . . . . . . . 2-11-2

1. Line Current . . . . . . . . . . . . . . . . . . . . 2-11-2

2. Dial Tone . . . . . . . . . . . . . . . . . . . . . 2-11-2

3. Busy Tone Detection . . . . . . . . . . . . . . . . 2-11-2

4. Ringback Tone Detection . . . . . . . . . . . . . . . 2-11-2

2-11-3. Access to the PSTN . . . . . . . . . . . . . . . . 2-11-3

1. Loop Start . . . . . . . . . . . . . . . . . . . . 2-11-3

2. Ground Start . . . . . . . . . . . . . . . . . . . 2-11-4

3. Flash Start . . . . . . . . . . . . . . . . . . . . 2-11-4

4. Pauses . . . . . . . . . . . . . . . . . . . . . . 2-11-5

SECTION 3. RECEPTION - THERMAL PRINTER MODELS

3-1. RINGING SIGNAL DETECTION . . . . . . . . . . . . . 3-1-1

3-1-1. Monitoring the Line . . . . . . . . . . . . . . . . . 3-1-1

3-1-2. Signal Analysis . . . . . . . . . . . . . . . . . . 3-1-2

3-2. DC LOOP CLOSURE . . . . . . . . . . . . . . . . . 3-2-1

3-3. DATA RECEPTION . . . . . . . . . . . . . . . . . . 3-3-1

3-4. PAPER FEED . . . . . . . . . . . . . . . . . . . . 3-4-1

3-4-1. Mechanism . . . . . . . . . . . . . . . . . . . . 3-4-1

1. Overview . . . . . . . . . . . . . . . . . . . . . 3-4-1

2. Procedure . . . . . . . . . . . . . . . . . . . . 3-4-2

3. Resolution . . . . . . . . . . . . . . . . . . . . 3-4-3

3-4-2. Jam Detection . . . . . . . . . . . . . . . . . . 3-4-4

3-4-3. Paper Width Detection . . . . . . . . . . . . . . . 3-4-5

3-4-4. Paper Near-end Detection . . . . . . . . . . . . . . 3-4-6

3-4-5. Paper End Detection . . . . . . . . . . . . . . . . 3-4-6

3-4-6. Printer Cover Switch . . . . . . . . . . . . . . . . 3-4-6

Page 6

3-5. PRINTING . . . . . . . . . . . . . . . . . . . . . . 3-5-1

3-5-1. Data Processing . . . . . . . . . . . . . . . . . . 3-5-1

1. Reduction . . . . . . . . . . . . . . . . . . . . 3-5-1

2. Smoothing . . . . . . . . . . . . . . . . . . . . 3-5-2

3-5-2. Thermal Head . . . . . . . . . . . . . . . . . . . 3-5-3

3-5-3. Printing at the Different Resolutions . . . . . . . . . . 3-5-5

3-5-4. Overheat Protection . . . . . . . . . . . . . . . . 3-5-6

3-6. CUTTING . . . . . . . . . . . . . . . . . . . . . . 3-6-1

3-6-1. Cutter Mechanism . . . . . . . . . . . . . . . . . 3-6-1

3-6-2. Cutter Jam Detection . . . . . . . . . . . . . . . . 3-6-2

3-7. OTHERS . . . . . . . . . . . . . . . . . . . . . . 3-7-1

3-7-1. Voice Message . . . . . . . . . . . . . . . . . . 3-7-1

1. Storing the Voice Message . . . . . . . . . . . . . . 3-7-2

2. Playing Back the Voice Message . . . . . . . . . . . . 3-7-2

3. Voice Message Transmission . . . . . . . . . . . . . 3-7-2

3-7-2. Remote Control . . . . . . . . . . . . . . . . . . 3-7-3

SECTION 4. RECEPTION - LASER PRINTER MODELS

4-1. PRINTING - MASTER . . . . . . . . . . . . . . . . . 4-1-1

4-1-1. Overview . . . . . . . . . . . . . . . . . . . . . 4-1-1

4-1-2. Master Units . . . . . . . . . . . . . . . . . . . 4-1-2

1. Overview . . . . . . . . . . . . . . . . . . . . . 4-1-2

2. Master Belt . . . . . . . . . . . . . . . . . . . . 4-1-3

3. Master Unit Interlock Switch . . . . . . . . . . . . . . 4-1-3

4. Master Home Position Sensor . . . . . . . . . . . . . 4-1-4

5. Master Belt Drive . . . . . . . . . . . . . . . . . . 4-1-5

Master Belt Rotation Timing . . . . . . . . . . . . . . 4-1-7

- Masters with bond seams - . . . . . . . . . . . . 4-1-7

- Masters with no bond seam - . . . . . . . . . . . 4-1-7

4-2. PRINTING - CHARGE . . . . . . . . . . . . . . . . . 4-2-1

4-2-1. Outline . . . . . . . . . . . . . . . . . . . . . 4-2-1

4-2-2. Charge Corona Unit . . . . . . . . . . . . . . . . 4-2-1

4-2-3. Ozone Fans . . . . . . . . . . . . . . . . . . . 4-2-2

Page 7

4-3. PRINTING - EXPOSURE . . . . . . . . . . . . . . . . 4-3-1

4-3-1. Outline . . . . . . . . . . . . . . . . . . . . . 4-3-1

4-3-2. The Latent Image . . . . . . . . . . . . . . . . . 4-3-2

4-3-3. Optical Path . . . . . . . . . . . . . . . . . . . 4-3-3

1. Laser Diode Unit . . . . . . . . . . . . . . . . . . 4-3-4

2. Cylindrical Lens . . . . . . . . . . . . . . . . . . 4-3-4

3. Polygonal Mirror . . . . . . . . . . . . . . . . . . 4-3-5

4. Fθ Lenses . . . . . . . . . . . . . . . . . . . . . 4-3-7

5. Second Mirror . . . . . . . . . . . . . . . . . . . 4-3-8

6. Focusing Lens . . . . . . . . . . . . . . . . . . . 4-3-8

7. Main Scan Start Detector . . . . . . . . . . . . . . . 4-3-9

4-3-4. Electronic Control . . . . . . . . . . . . . . . . . 4-3-10

1. Polygonal Mirror Motor Drive . . . . . . . . . . . . . 4-3-10

2. Laser Diode Drive . . . . . . . . . . . . . . . . . . 4-3-11

3. Laser Diode Power Control . . . . . . . . . . . . . . 4-3-13

4. Laser Main Scan Synchronization . . . . . . . . . . . 4-3-15

4-3-5. Data Signal Generation . . . . . . . . . . . . . . . 4-3-17

1. Data Path . . . . . . . . . . . . . . . . . . . . . 4-3-17

2. Smoothing . . . . . . . . . . . . . . . . . . . . 4-3-19

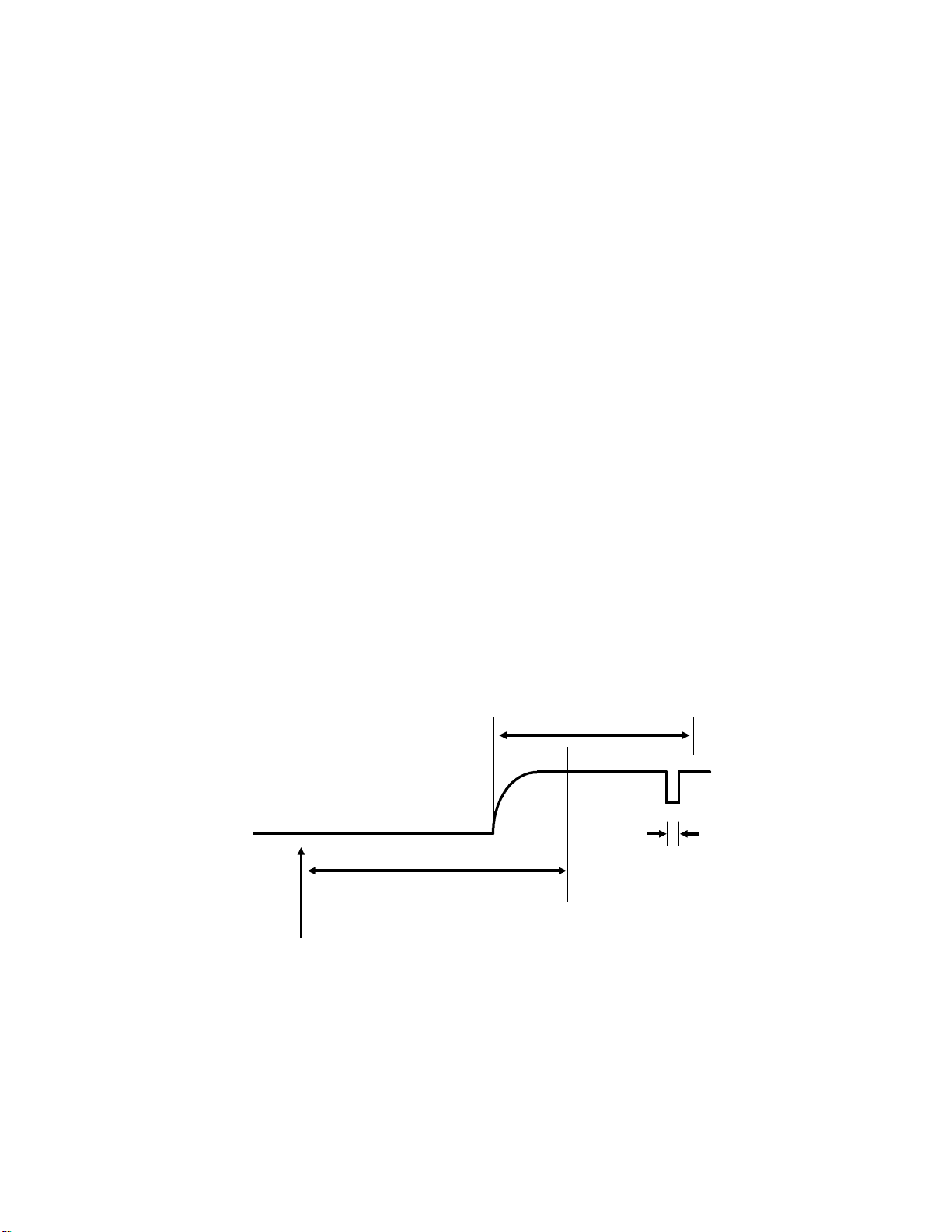

3. Laser Signal Profile . . . . . . . . . . . . . . . . . 4-3-20

4. Page Separation and Reduction of Received Data . . . . . 4-3-22

4-4. PRINTING - DEVELOPMENT . . . . . . . . . . . . . . 4-4-1

4-4-1. Outline . . . . . . . . . . . . . . . . . . . . . 4-4-1

4-4-2. Development Unit Components . . . . . . . . . . . . 4-4-3

- Development Roller - . . . . . . . . . . . . . . . . 4-4-3

- Toner Metering Blade - . . . . . . . . . . . . . . . 4-4-3

4-4-3. Development Bias . . . . . . . . . . . . . . . . . 4-4-4

4-4-5. Development Drive . . . . . . . . . . . . . . . . . 4-4-9

4-5. PRINTING - PAPER FEED . . . . . . . . . . . . . . . 4-5-1

4-5-1. Outline . . . . . . . . . . . . . . . . . . . . . 4-5-1

4-5-2. Paper Lift . . . . . . . . . . . . . . . . . . . . 4-5-2

4-5-3. Pick-up and Feed Mechanism . . . . . . . . . . . . 4-5-4

4-5-4. Separation Mechanism . . . . . . . . . . . . . . . 4-5-7

4-5-5. Registration . . . . . . . . . . . . . . . . . . . 4-5-10

4-5-6. Jam Detection . . . . . . . . . . . . . . . . . . 4-5-10

4-5-7. Paper Size Detection . . . . . . . . . . . . . . . . 4-5-11

4-5-8. Paper End and Near-end Detection . . . . . . . . . . 4-5-12

4-5-9. Paper Size Selection . . . . . . . . . . . . . . . . 4-5-13

4-6. PRINTING - TRANSFER AND SEPARATION . . . . . . . . 4-6-1

4-6-1. Overview . . . . . . . . . . . . . . . . . . . . . 4-6-1

4-6-2. Transfer Corona Unit . . . . . . . . . . . . . . . . 4-6-2

Page 8

4-7. PRINTING - FUSING . . . . . . . . . . . . . . . . . 4-7-1

4-7-1. Outline . . . . . . . . . . . . . . . . . . . . . 4-7-1

4-7-2. Fusing Unit Drive . . . . . . . . . . . . . . . . . 4-7-2

4-7-3. Pressure Roller . . . . . . . . . . . . . . . . . . 4-7-2

4-7-4. Fusing Lamp Control Circuit . . . . . . . . . . . . . 4-7-3

1. Standby Mode . . . . . . . . . . . . . . . . . . . 4-7-3

2. Printing . . . . . . . . . . . . . . . . . . . . . . 4-7-3

3. Control Circuit . . . . . . . . . . . . . . . . . . . 4-7-4

4-8. PRINTING - FEED-OUT . . . . . . . . . . . . . . . . 4-8-1

4-9. PRINTING - CLEANING . . . . . . . . . . . . . . . . 4-9-1

4-10. PRINTING - QUENCHING . . . . . . . . . . . . . . . 4-10-1

APPENDIX

A. FACSIMILE SPECIFICATIONS AND FEATURES

B. PROTOCOL

C. TROUBLESHOOTING TECHNIQUES

D. COMMONLY-USED COMPONENTS

E. COMPRESSION TECHNIQUES

F. MODULATION TECHNIQUES

G. TABLE OF MODEL NAMES

H. FACSIMILE HISTORY AND BACKGROUND

Page 9

INTRODUCTION

This is a reference book containing general descriptions of the mechanisms,

circuits, and data processing techniques that are common to most Group 3

facsimile machines.

Details such as the timing of various mechanical operations, error conditions,

and the types of adjustment available differ widely from model to model. Because of this, the descriptions in this book are general. For more specific details concerning a particular model, the reader must refer to the Service

Manual for that model.

However, in some cases, it is possible to be more comprehensive, and this

has been done wherever possible. For example, the operation of the relays

and the other components in the network interface hardware have to meet local governmental requirements. These requirements are different for each

country, but each model has to operate in the same way.

Future Service Manuals will not contain extensive descriptions of theory,

processes, or circuits. They will only contain machine-specific field service related information. There will be some short descriptions to outline important

points and to explain any variations in standard processes. In addition, as

scanner and printer mechanisms often vary widely from model to model,

Service Manuals will illustrate these. Important mechanisms and circuits,

such as those related to safety in laser printers, will be covered. Wherever

necessary, the Service Manuals will contain references to this book so that

the reader can pick up background information.

New models often employ new techniques, so updates and addenda to this

book will be issued to cover these in the future as they arise. New pages will

be issued in the form of a technical bulletin. Recipients of these pages will be

able to add them to the relevant sections of this manual.

This book consists of the following sections.

Section 1. Fax Machine Overview

This section outlines the processes used in thermal and laser faxes.

Section 2. Transmission

This section explains how a fax machine scans and transmits a fax message.

Section 3. Reception - Thermal Printers

This section explains how a thermal printer based fax machine receives and

prints a fax message.

Section 4. Reception - Laser Printers

This section explains how a laser printer based fax machine receives and

prints a fax message.

Page 10

Appendix A. Facsimile Specifications and Features

This section briefly explains each of the specifications and features that are

quoted at the front of each Service Manual.

Appendix B. Protocol

This section outlines the protocol signalling between two fax terminals. It explains how features such as Turnaround Polling and Transfer Request are

executed. ECM is also explained.

Appendix C. Troubleshooting Techniques

This section describes general troubleshooting techniques, including communication troubleshooting.

Appendix D. Commonly-used Components

This section gives a little theoretical background on components such as

CCDs, thermal heads, and motors.

Appendix E. Compression Techniques

This section explains the data compression techniques used by fax machines.

Appendix F. Modulation Techniques

This section explains modulation techniques used by fax modems.

Appendix G. Table of Model Names

This is a table of the model names used in various regions.

Appendix H. Facsimile History and Background

This section supplies some information concerning the history of the development of the facsimile machine.

Page 11

SECTION 1. FAX MACHINE OVERVIEW

This section outlines the facsimile processes used in thermal and laser faxes.

The following sections are included.

Section 1-1. Facsimile Process

This section explains what a fax machine is and briefly outlines the major mechanical processes involved in transmitting and receiving a fax message.

Section 1-2. Overall Machine Control

This section describes how a typical fax machine is controlled. The functions

of major electronic components and memory units are explained. The various methods of communication between cpu’s are also outlined.

Section 1-3. Video Data Path

This section shows the path of facsimile data through the machine. The

paths for transmission and reception are explained.

Section 1-4. Power Distribution

This section shows how power is distributed through a typical fax machine.

Memory back-up circuits and safety features are also described.

Page 12

1-1. FACSIMILE PROCESS

This section has two purposes.

• To briefly explain what a fax machine is.

• To broadly outline each phase of the transmission and reception proc-

esses (each step is explained in more detail in sections 2, 3, and 4). For

each machine, there will be slight differences but the basic steps are the

same. Examples are given for thermal and plain paper fax terminals.

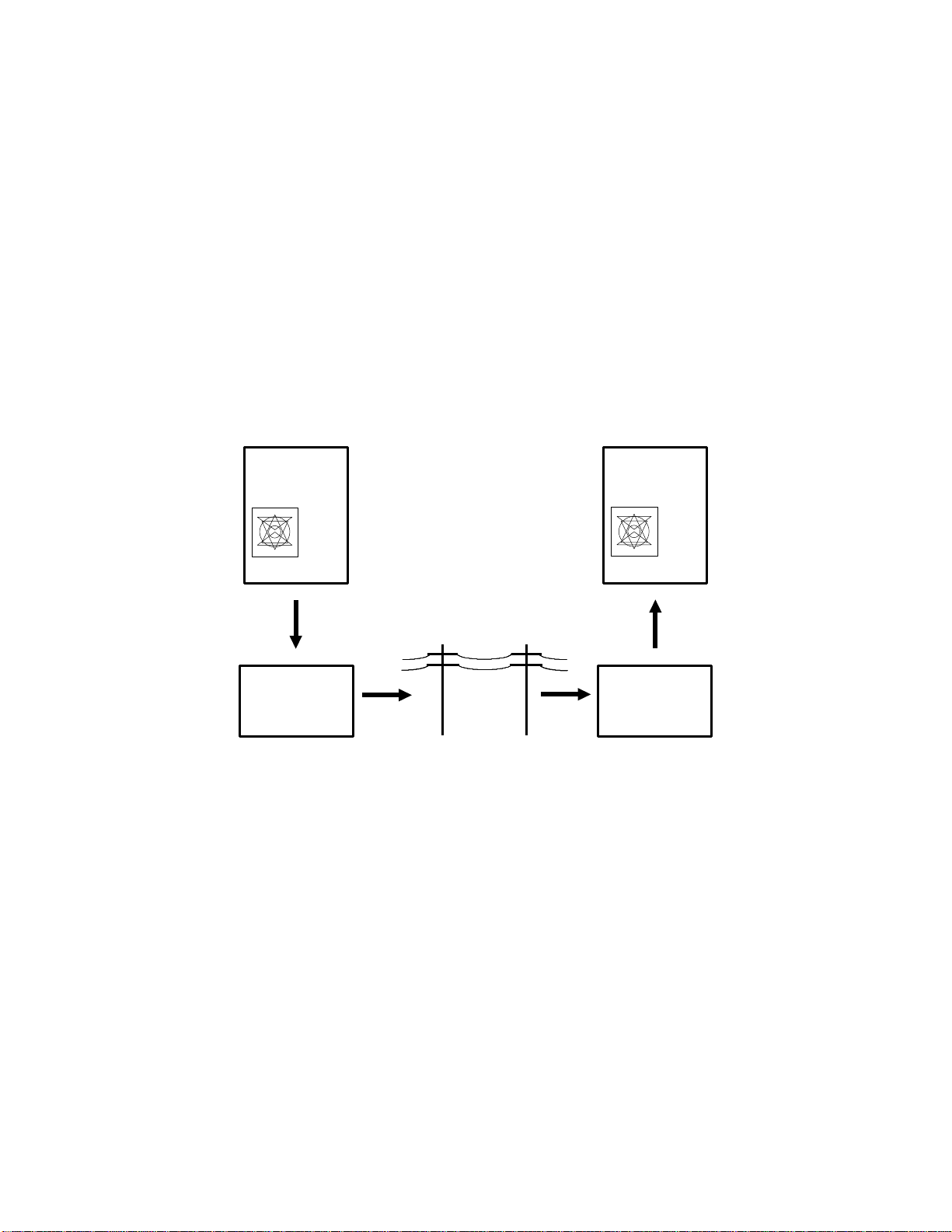

1-1-1. What is a Fax Machine?

Facsimile, commonly known as fax, is used for sending written, printed, or

graphic information from one location to another. The communication can be

across the room or across the world. A simple block diagram of fax operation

is shown below.

ORIGINAL

RECEIVED

FAX MESSAGE

--- ---- -- ---- -

------ --- ---- --

---- --- - - --- -

-- -- -

- -- --

-- -- -

- --- -

-- ---- -- --- --

SCANNING

CONVERSION

TRANSMITTING

FAX MACHINE

TELEPHONE LINE

--- ---- -- ---- -

------ --- ---- --

---- --- - - --- -

-- -- -

- -- --

-- -- -

- --- -

-- ---- -- --- --

PRINTING

CONVERSION

RECEIVING

FAX MACHINE

Facsimile machines combine scanner and printer technology with telephone

equipment to send copies to a remote location. There are three basic steps

in a facsimile transmission.

• A light source scans the writing and drawings on the original, and con-

verts the information into an electrical signal.

• This signal is sent over the telephone line to a receiving fax machine.

• The receiving machine converts the incoming signal into a copy of the

original.

Facsimile machines can transmit alphanumeric and graphic characters. Anything that can be put on paper, from handwritten notes to photographs, can

be sent by fax.

1-1-1

Page 13

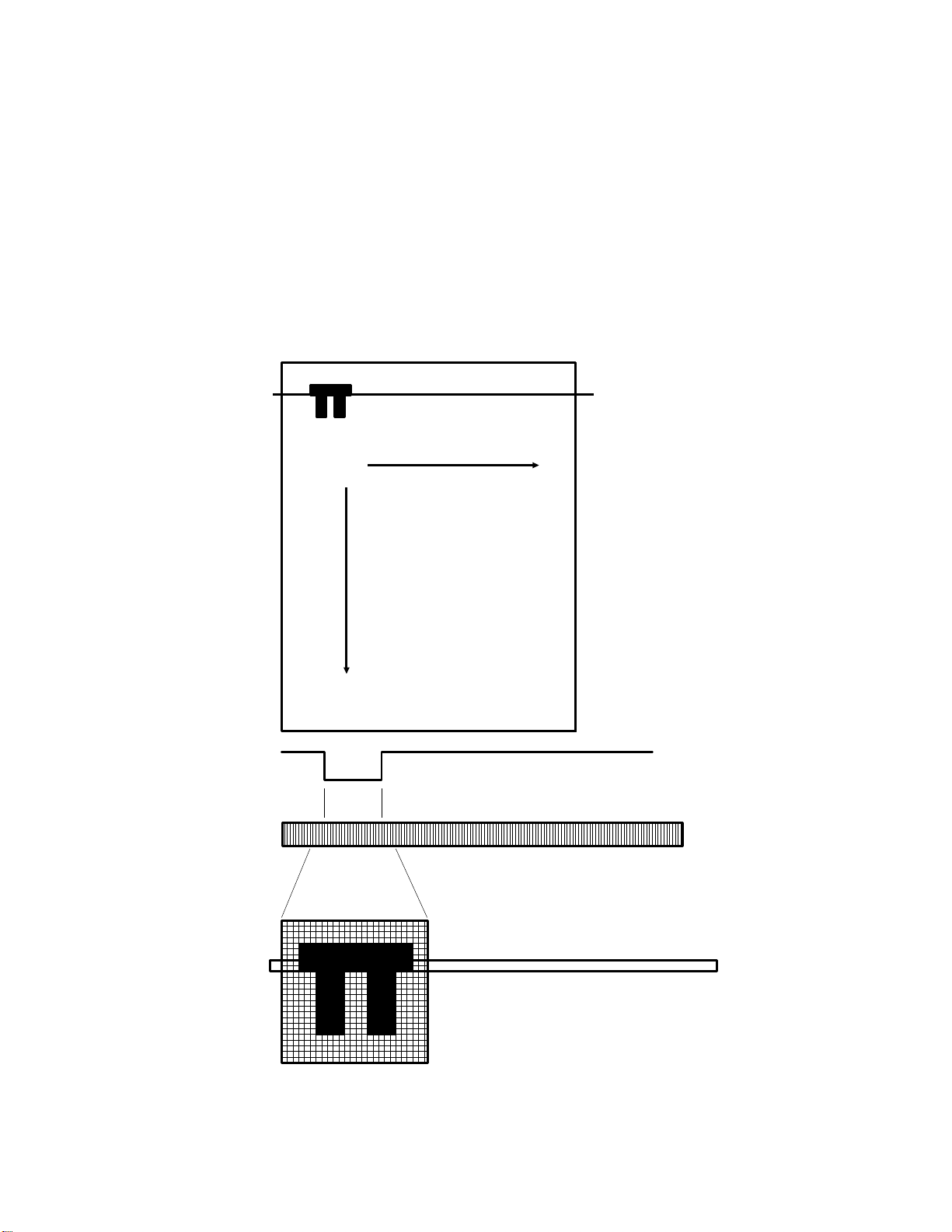

1-1-2. Thermal Paper Fax Terminals

These machines contain a thermal printer.

1. Transmitting

Exposure

[B]

Document Feed

[A]

[C]

1. Document Feed

The original (also known as the document) is fed into the scanner [A] one

page at a time.

2. Exposure

A fluorescent lamp or xenon lamp [B] illuminates the document as it passes

the exposure glass. Light reflected from the document passes to the CCD

(Charge Coupled Device). The CCD [C] converts the light reflected from the

document into an analog electrical signal.

3. Transmission

Other circuits inside the machine take the output from the CCD and convert it

into a data signal for transmission over the telephone network.

1-1-2

Page 14

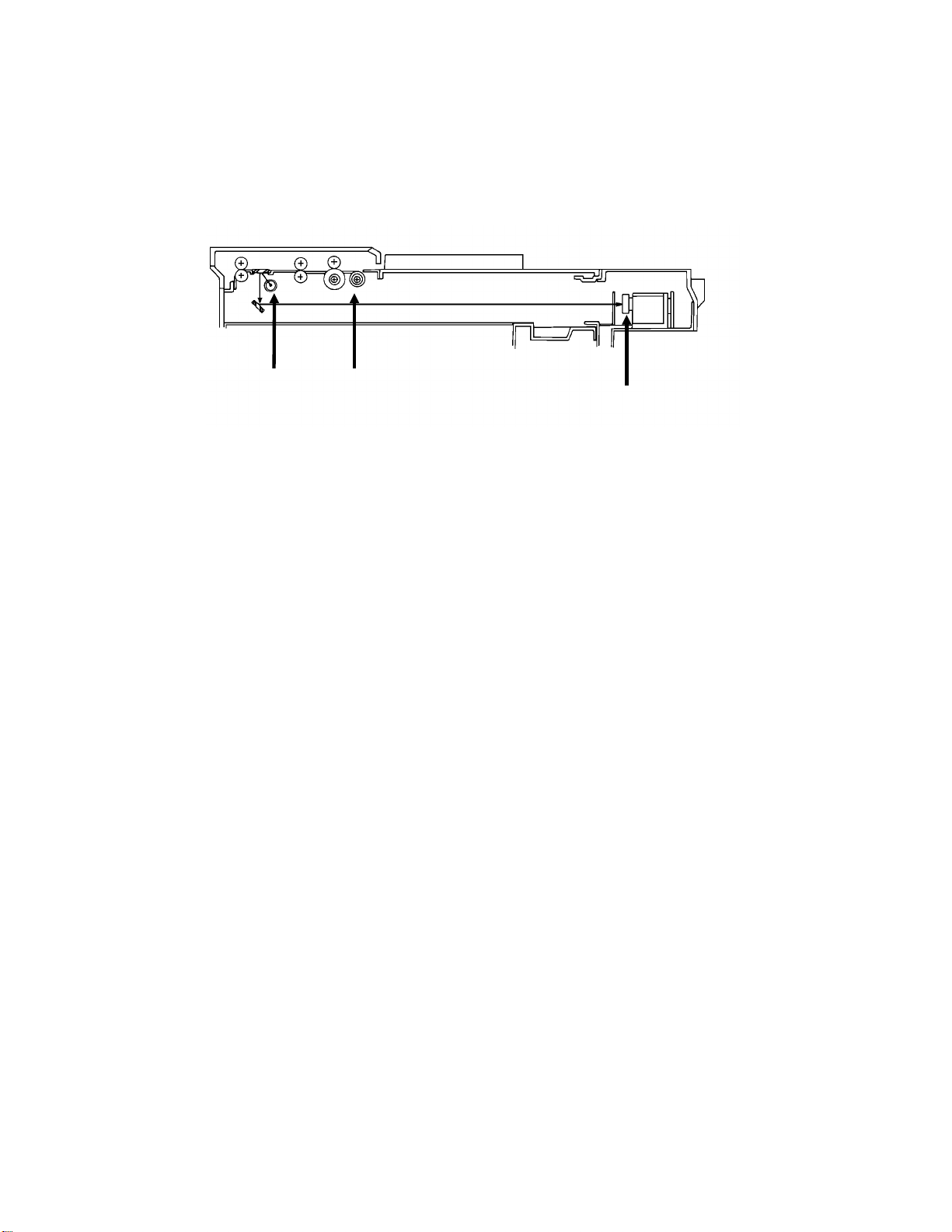

2. Receiving

[C]

Cutting

[D]

Printing

[A]

Paper Feed

[B]

1. Reception of Data

Circuits inside the machine take the signal from the telephone line and convert it into a series of black and white dots for printing.

2. Paper Feed

The rx motor drives the platen roller [A], which feeds the thermal paper [B]

past the thermal head [C].

3. Printing

To print the data, the machine uses a thermal head. The thermal head consists of a line of heating elements. The paper is specially treated to make it

turn dark when heated. The received data is reproduced one line at a time as

the paper is fed past the thermal head; a black dot on the line currently being

printed is reproduced by heating the element at the appropriate location on

the thermal head.

4. Cutting

After printing, the cutter [D] automatically cuts off the received page from the

paper roll. Some machines do not have a cutter.

1-1-3

Page 15

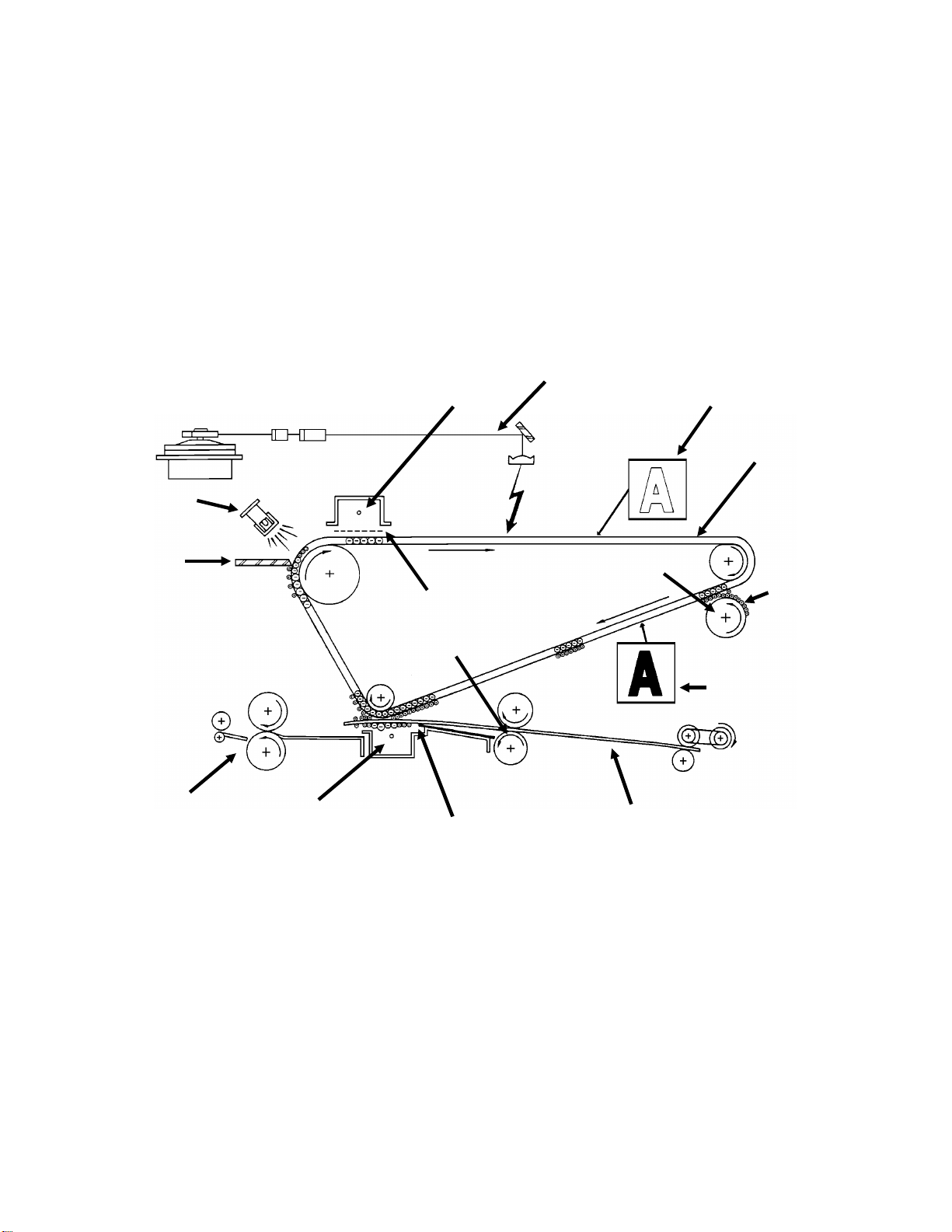

1-1-3. Plain Paper Fax Terminals

These machines contain a laser printer. Two types of printer mechanism are

commonly used; one uses positively-charged toner, and one uses negativelycharged toner. Note the differences in charge polarities in some of the printing processes. The master unit is the centre of the printer, as shown below.

1. Transmitting

This is exactly the same as for thermal paper fax terminals.

2. Receiving

[O]

Quenching

[N]

Cleaning

Fusing

[M]

[L]

Charge

Transfer

[A]

Exposure

[C]

[J]

Registration

[K]

[D]

[E]

[B]

[G]

[F]

Development

[H]

Paper Feed

[I]

1. Reception of Data

Circuits inside the machine take the signal from the telephone line and convert it into a series of black and white dots for printing.

2. Charge

In the dark, the charge corona wire [A] gives a negative charge to the master

[B]. The grid plate [C] under the charge corona wire ensures that the charge

is applied uniformly. The negative charge remains on the surface of the master because the master has a high electrical resistance in the dark.

1-1-4

Page 16

3. Exposure

The received data signal is converted into a series of black and white dots for

printing.

Write-to-white (positive toner): To print the data, a laser beam [D] scans

across the master, switching on to make a white dot on the copy, and switching off to make a black dot.

Write-to-black (negative toner): The laser beam switches on to make a

black dot on the copy, and switches off to make a white dot.

Both types: The charge on the master goes to ground in areas exposed to

the beam, thus producing an electrical latent image [E] on the master surface.

4. Development

Write-to-white (positive toner): A thin layer of positively charged toner [F]

on the development roller [G] comes into contact with the latent image on

the master surface. Toner particles are attracted to the negatively charged areas of the master belt surface [H].

Write-to-black (negative toner): A thin layer of negatively charged toner on

the development roller comes into contact with the latent image on the master surface. Toner particles are attracted to the least negatively charged areas

of the master belt surface.

5. Paper Feed

Paper [I] is fed from the cassette. The paper is plain paper, as used in a photocopier.

6. Registration

The registration roller [J] stops the paper momentarily to correct skew, and it

allows the paper into the image transfer area [K] at the correct time.

7. Image Transfer

Copy paper is fed to the master surface while the transfer corona wire [L] applies a strong charge to the back of the paper; the charge is of opposite sign

to that of the toner. This charge pulls the toner particles from the master surface onto the paper. The paper then separates from the master and passes

into the fusing unit.

8. Fusing

In the fusing unit [M], the image is fused to the copy paper by two rollers

which apply heat and pressure.

9. Cleaning

In preparation for the next copy, the cleaning blade [N] removes any remaining toner from the master surface.

10. Quenching

The light from the quenching lamp [O] electrically neutralizes the master surface.

1-1-5

Page 17

1-2. OVERALL SYSTEM CONTROL

This section shows how a fax machine is organized and controlled. The responsibilities of each cpu and major control component are described.

The internal organization of most fax machines is very similar. Typical examples are given below. Note that the diagrams show only how the machine is

controlled; the path of video data is not explained in this section.

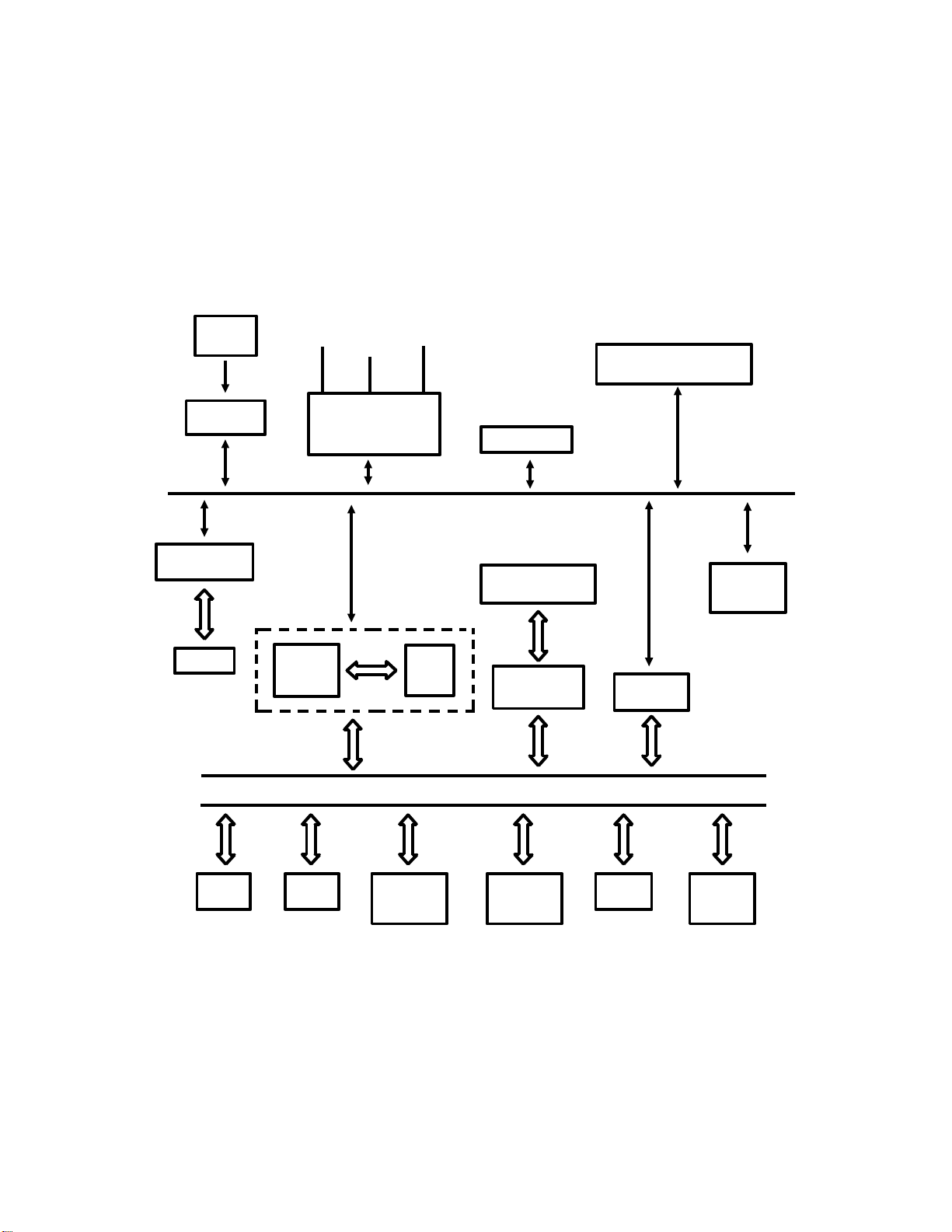

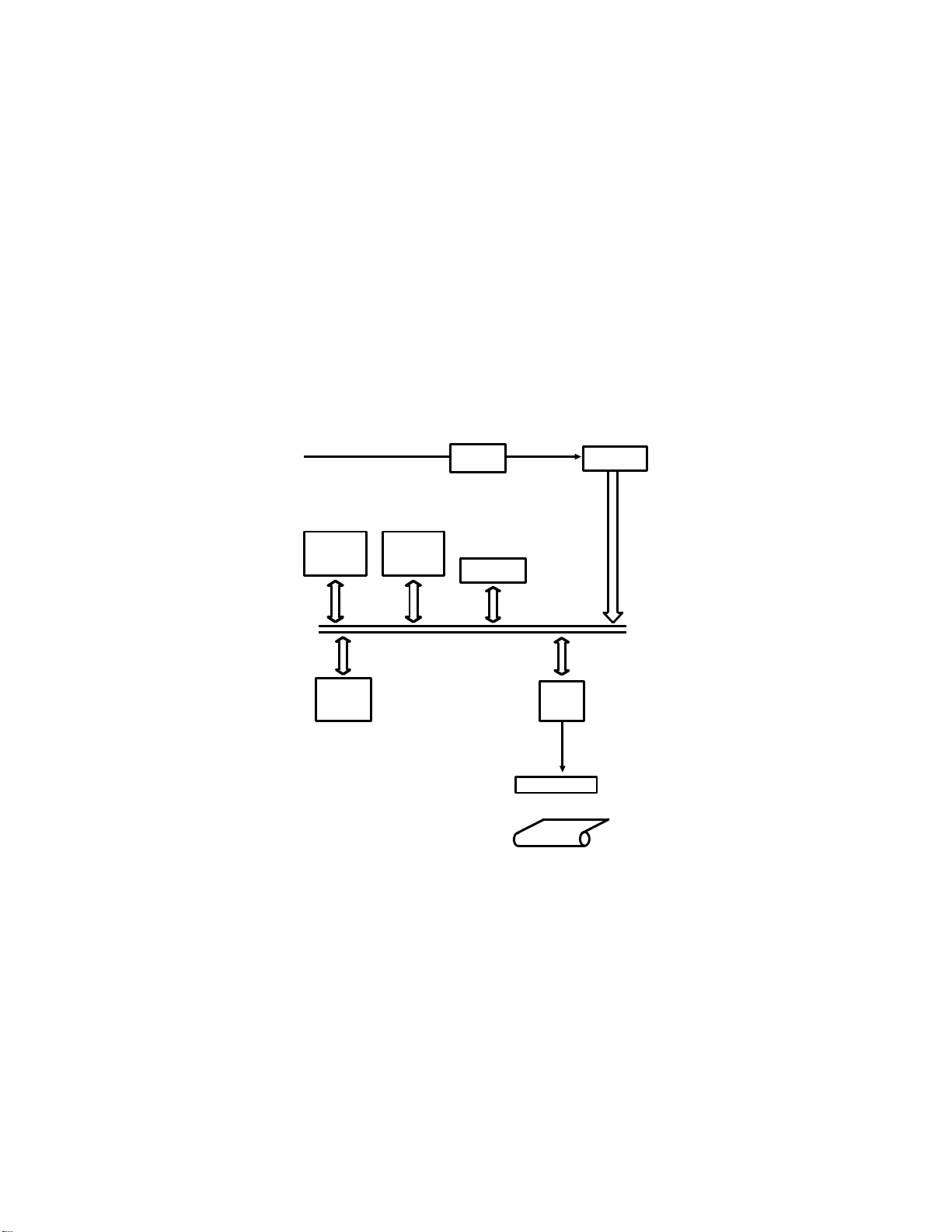

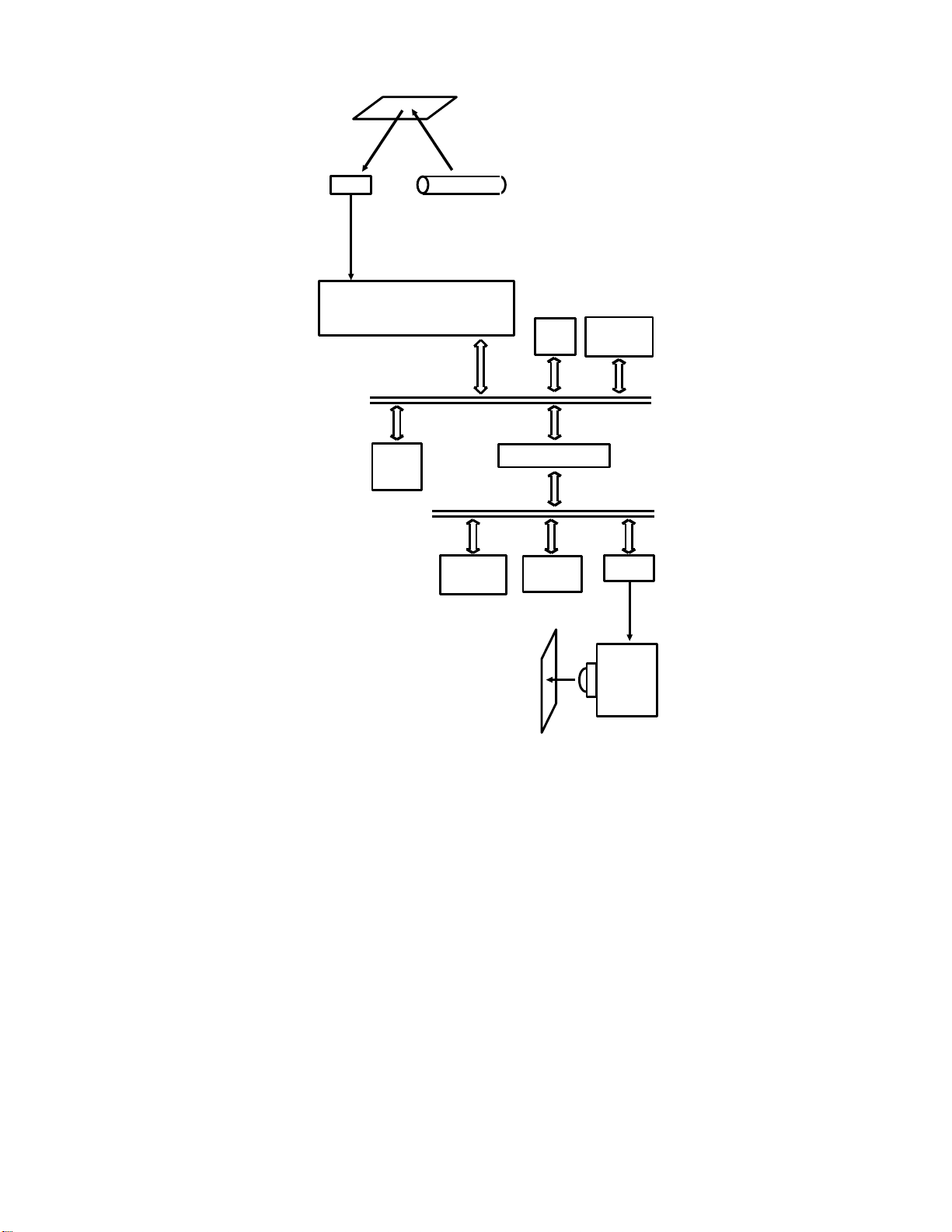

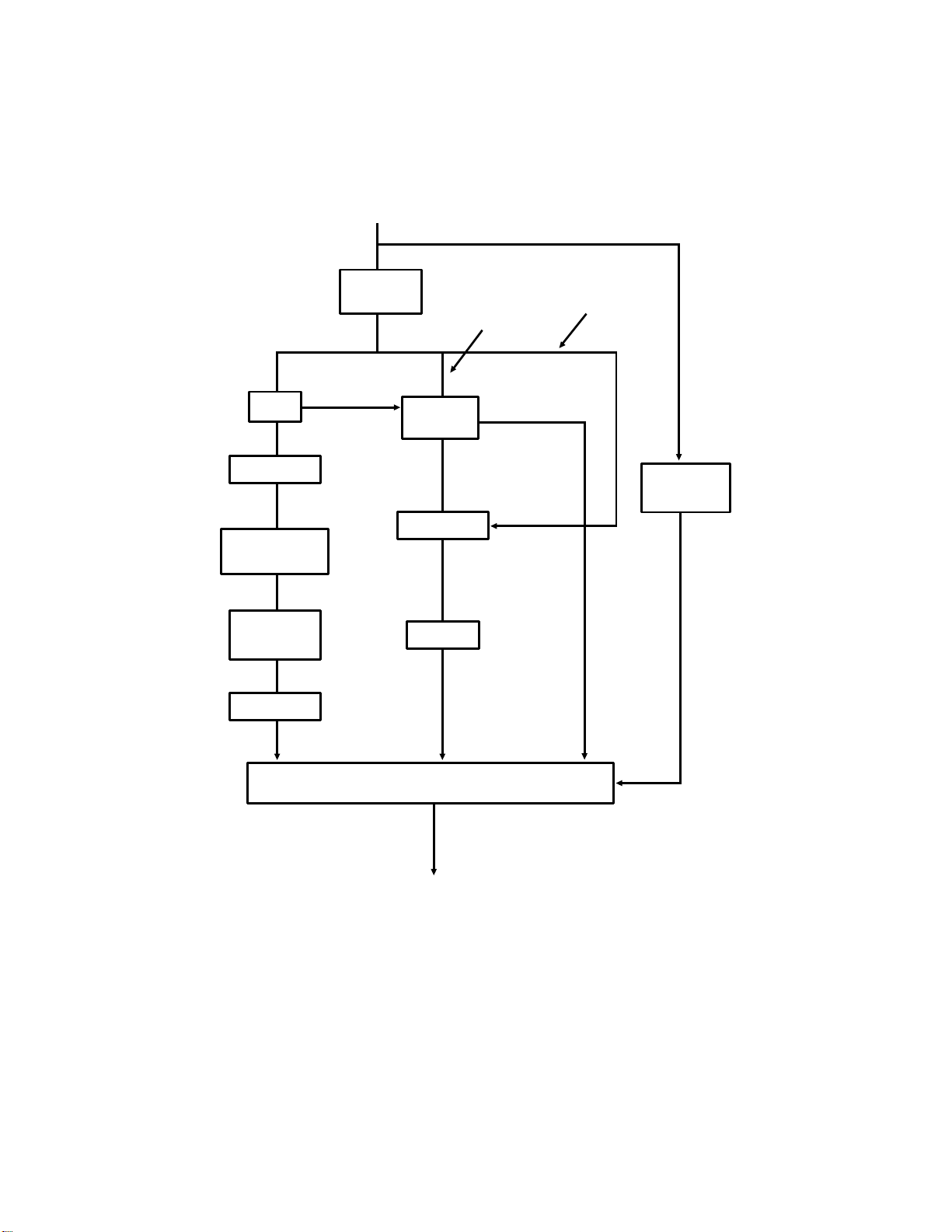

1-2-1. Thermal Paper Fax Machines

Scanner

Sensors

Operation

Panel CPU

Voice Message

Processor

Memory

External

Line Handset

Tel

Network

Interface

Circuits

CPU

CONTROL SIGNALS

I/O

Port

SBU (CCD)

Video Processing

Memory

Video

Processor

Scanner and Printer Drive

Components and Sensors

Thermal

Head

THERMAL

PRINTERS

ONLY

Modem

DATA AND ADDRESS BUS

RAMROM

SAF

Memory

ECM

Memory

FIFO

Line

Buffer

The centre of the machine is the cpu. This controls the machine. (In machines that have more than one major cpu, the controlling cpu is called the

Main CPU.) An LSI gate array called the I/O Port controls much of the machine in conjunction with the cpu. So, to simplify the diagram, the cpu and

the I/O Port are considered to be one unit.

1-2-1

Page 18

Data and address buses link the cpu to the major data processing and storage components of the machine. Control signals drive the mechanical and

electrical components of the scanner, network interface, and printer.

The components shown on the diagram on the previous page are explained

below.

ROM (Read Only Memory)

This contains the system software, which controls all aspects of the machine’s operation.

RAM (Random Access Memory)

This contains work areas for the cpu, and programmable system parameters

(such as bit switches). If the main power is switched off, the RAM is not

erased. This is because a battery supplies back-up power to the RAM if the

main power is off (see section 1-4-3 for more details on battery back-up).

Static RAM ( SRAM), Pseudo-static RAM (PSRAM), and Dynamic RAM ( DRAM)

SRAM can be connected to a battery, which provides back-up power if the main power

switch is turned off. (In some cases, a capacitor with a high charge capacity is used to

supply back-up power to the SRAM.) The power from the battery prevents the data from

being erased. SRAM is commonly used for storing vital system parameters, but may also

be used as SAF memory. However, the high cost of SRAM prevents its use as SAF

memory in low-cost fax machines.

Recently developed types of DRAM can also be backed up by a battery. However, unlike

SRAM, it needs a periodic refresh from a DRAM controller or the contents are erased. The

SAF memory in most fax machines is DRAM.

PSRAM, like SRAM, can be backed up by a battery and does not need periodic refresh.

However, PSRAM is more like DRAM in its internal structure.

SAF Memory (Store And Forward Memory)

When a user stores a fax message in the memory for sending later or broadcasting, the message goes into the SAF memory. Also, incoming confidential

messages and ’substitute’ receptions are held in this memory.

Not all fax machines have this memory. In some models with no or low SAF

memory capacity, the ECM memory may be used as a SAF memory. The exact method of use and the limitations on use differ from machine to machine.

However, generally, battery back-up is disabled while the memory is being

used for ECM.

SAF memory is usually DRAM, but the small SAF/ECM memory is usually

PSRAM.

1-2-2

Page 19

Line Buffer

This memory buffer ensures synchronization of video data transfer between

different components of the circuit (see section 1-3). If the line buffer is too

small, the scanner mechanism will have to keep stopping and starting, leading to excessive noise. A line buffer size of four or eight lines is typical.

ECM Memory (Error Correction Mode Memory)

ECM is an optional extension to Group 3 protocol that provides a more reliable way to send data over noisy lines. Using ECM, data is assembled into

protocol frames. ECM requires RAM for assembly into and extraction from

protocol frames. This memory is the ECM memory; it is normally PSRAM,

without battery back-up.

With ECM, image data is arranged in protocol frames (256 bytes in each

frame), and transmitted in blocks made up of 256 frames. Therefore, each

block is 64 kbytes. Normally, one page of compressed image data can be

sent in one block, but more than one may be needed if halftone mode was

used when scanning the original.

Single Buffer and Double Buffer ECM Memory

Single Buffer (64 kbytes): This memory is only large enough to hold one block. After

receiving a block of compressed facsimile data from the remote terminal into ECM

memory, the data is reconstructed and printed. The next block cannot be received until

printing has finished. The first block is deleted from memory after printing.

Double Buffer (128 kbytes): This memory can hold two blocks. While one block is being

printed, the next block can be received into the other half of the double buffer memory.

This ensures continuous operation, saving time and overall communication charges.

In some machines with a single buffer only, SAF memory or hard disk memory are used

to provide double buffer capability.

ECM is explained in more detail in Appendix B. For full details, see a recent

version of CCITT recommendation T.30.

FIFO Memory (First-In First-Out Memory)

The FIFO synchronizes the transfer of video data to the modem (transmission) or from the modem (reception). It also acts as a buffer, ensuring that

there is always some data for the modem to pick up, modulate, and send

out. The FIFO also has some unique functions, in addition to synchronizing

data transfer from the cpu to the modem, as explained in section 2-8.

The actual use of the FIFO and Line Buffer in each communication mode is

outlined in section 1-3.

CCD (Charge Coupled Device)

The CCD generates the video image signal. This is an analog signal.

1-2-3

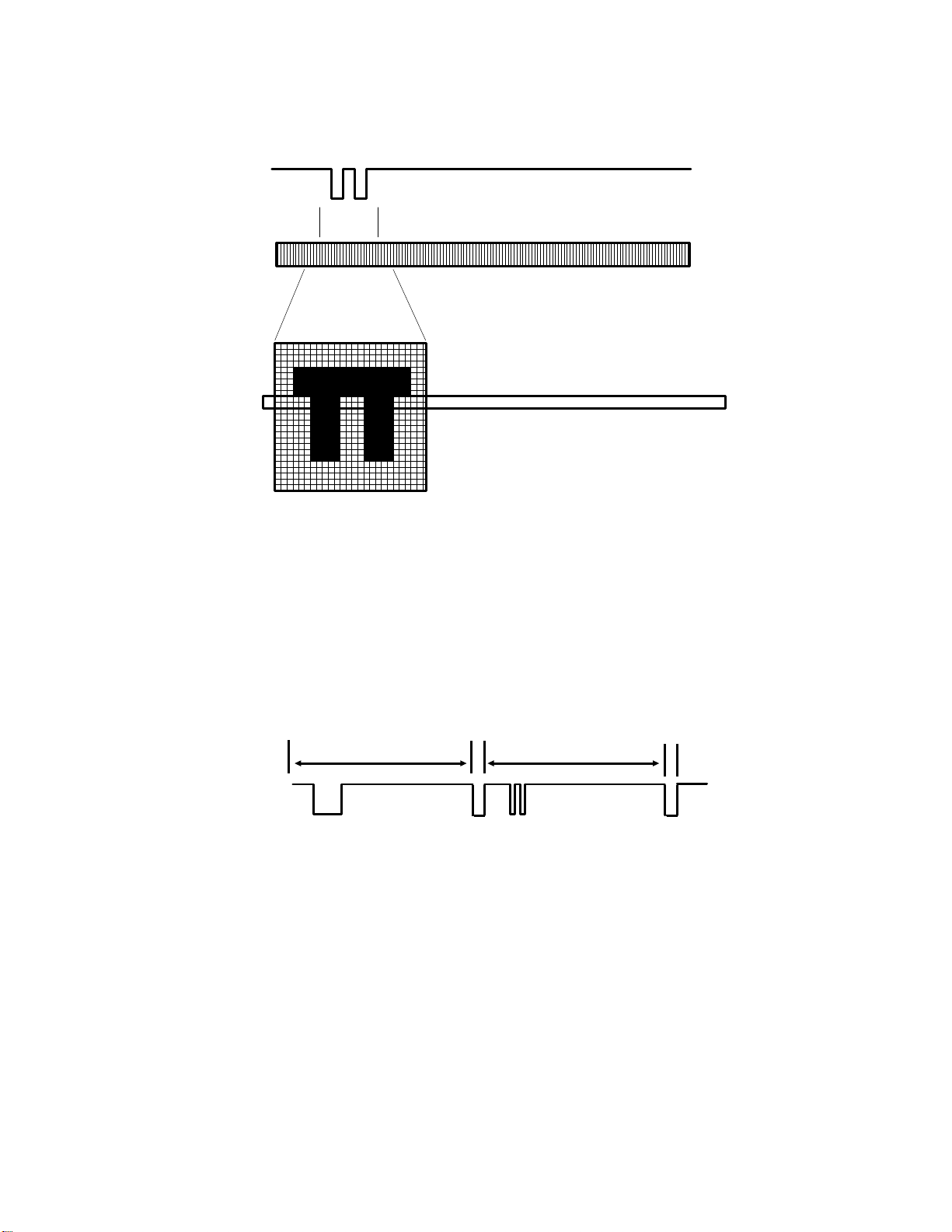

Page 20

Modem

During transmission, the modem converts the data into a form that can be

sent out on the telephone line in accordance with the appropriate CCITT V-series recommendations; this process is called Modulation. During reception,

the modem converts incoming data into a form that the machine can work

with; this process is called Demodulation. The term ’modem’ is derived from

these two processes; MOdulation/DEModulation. The different types of

modulation encountered in fax machines are described in appendix F (for full

details see the CCITT V-series recommendations).

Video Processor

This contains circuits that process the output of the CCD. Using digital techniques, the quality of the image can be improved before transmission.

Video Processing Memory

Some of the digital video processing techniques require a work area.

Scanner and Printer Drive Components and Sensors

Every machine has motors, lamps, solenoids, electromagnetic clutches, sensors, and switches.

Thermal Head

This prints received images on the thermal paper.

Network Interface Circuits

The filters, relays, attenuators and other components in these circuits interface the machine with the public telephone network. These circuits ensure

that the machine connects to the line and dials in the correct way. They also

ensure that the machine and the network equipment do not damage each

other.

Voice Message Processor

This converts voice messages from analog (audio) to digital for storage in the

memory. It also retrieves the message for memory when it is needed for sending out over the telephone line.

Operation Panel

This is the ’user-machine interface’. The operation panel may have one or

two cpu’s to control the LCD, and the keys and indicators. In many models,

the operation panel cpu’s monitor the sensors in the scanner mechanism.

The operation panel may contain a microphone for storing the voice message and for making telephone conversations as part of a speakerphone;

however, the handset is normally used for these purposes.

1-2-4

Page 21

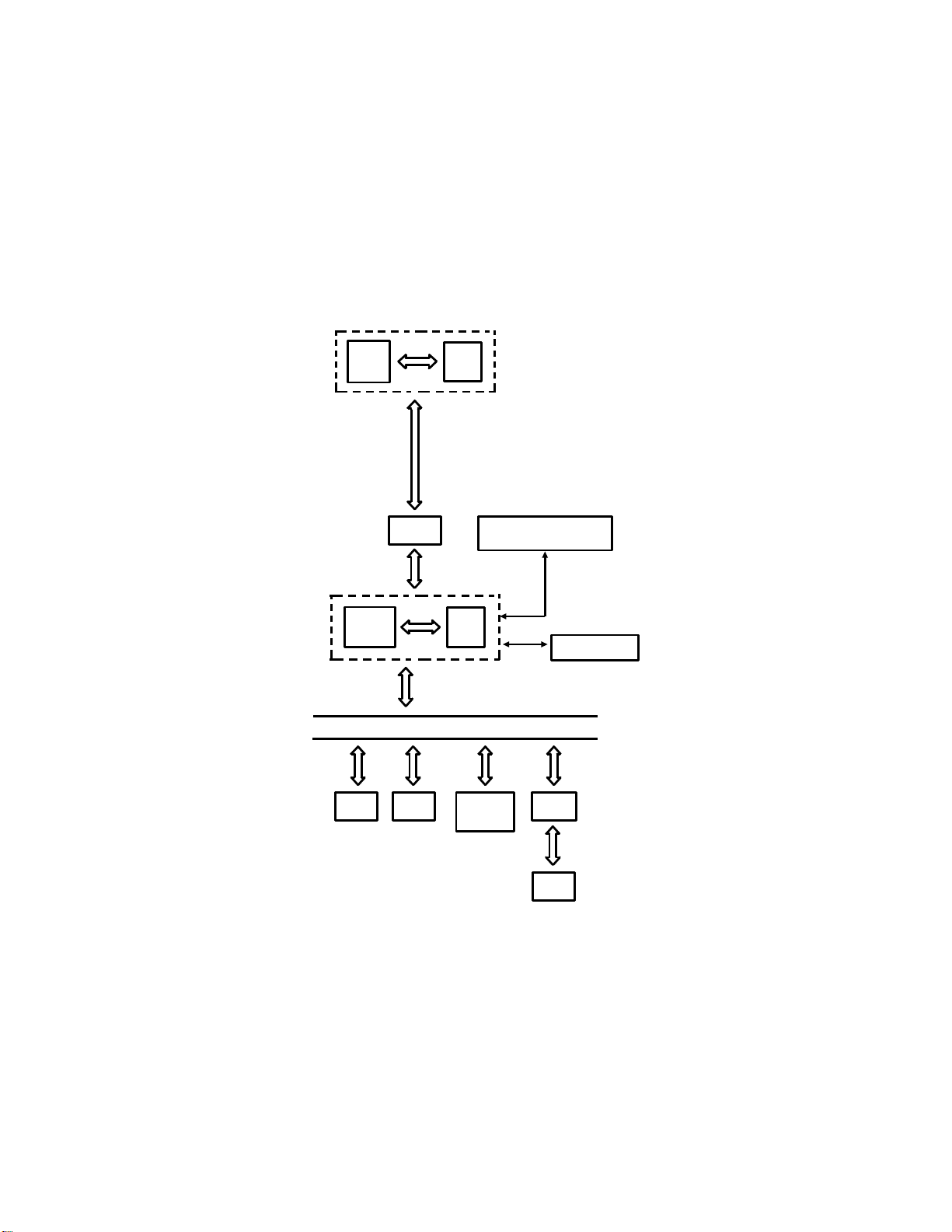

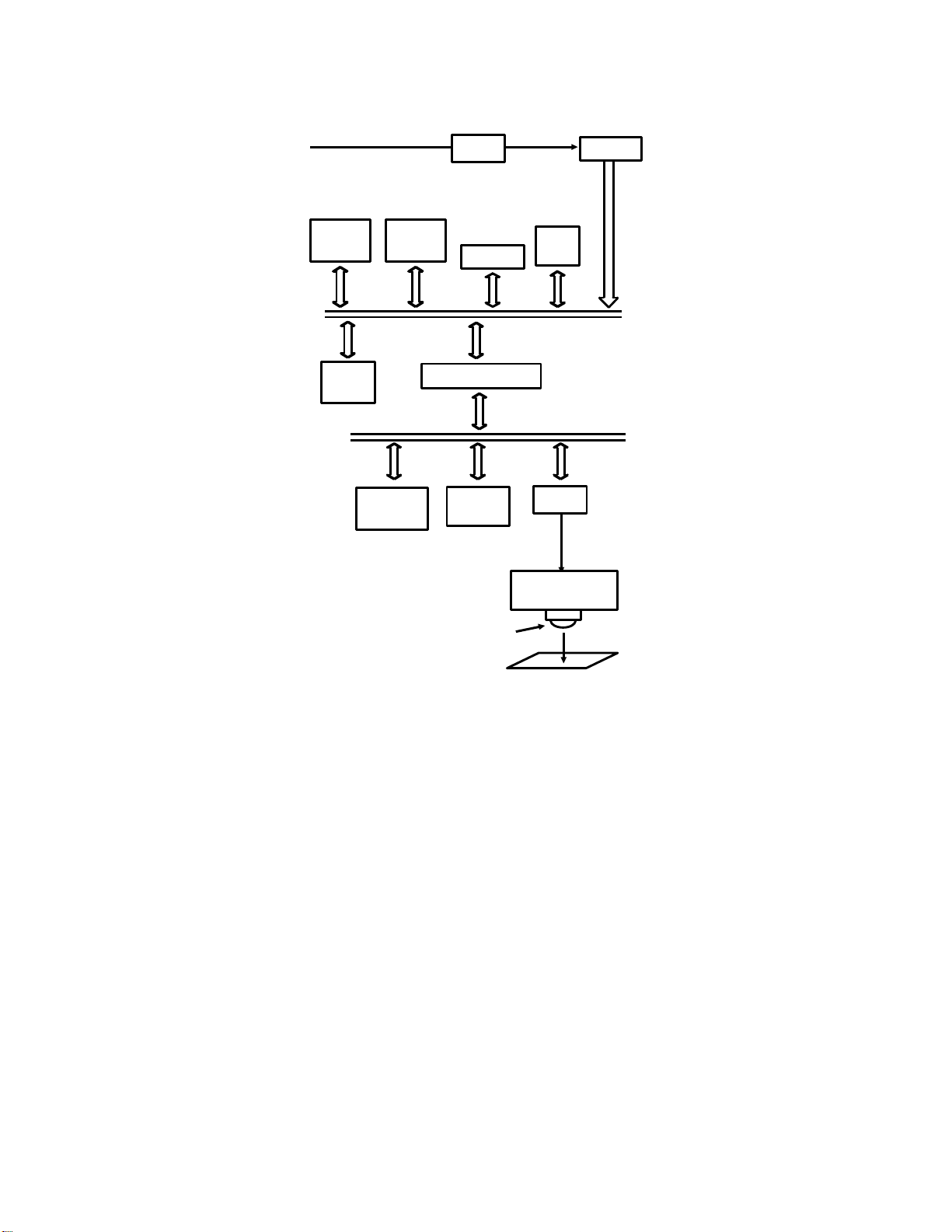

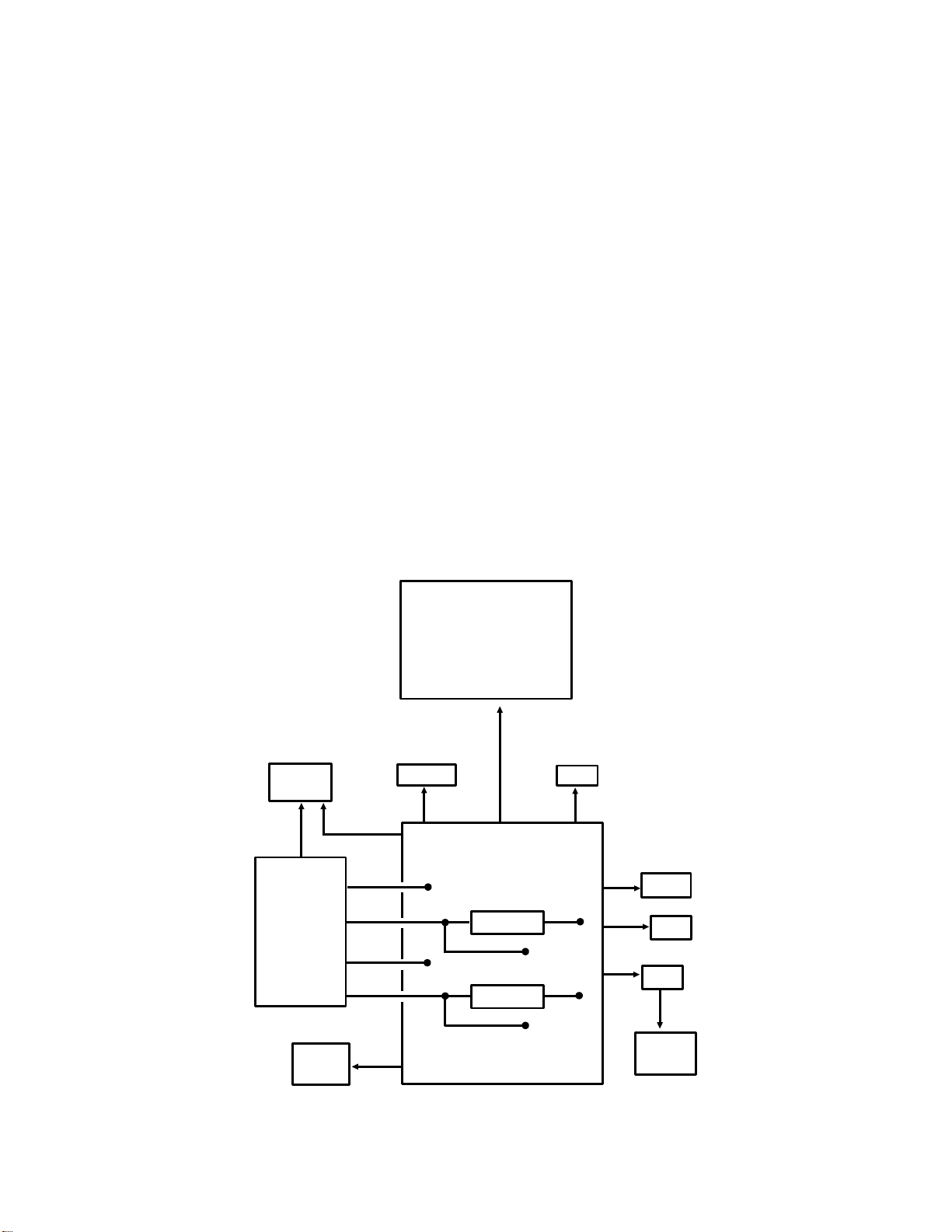

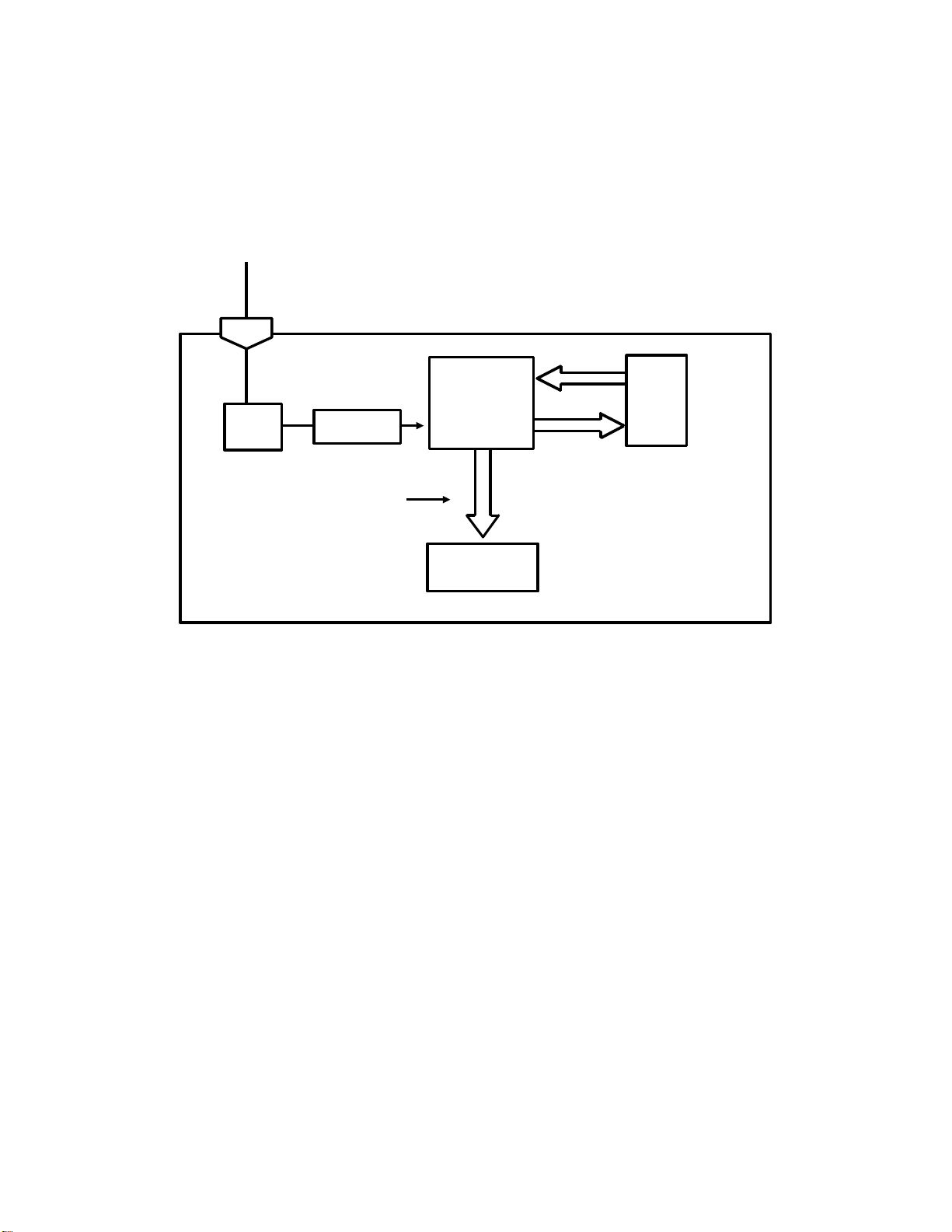

1-2-2. Plain Paper Fax Machines

Plain paper fax machines, having a laser printer engine, are more complex,

and often require more than one major cpu. The cpu that controls the machine overall is called the Main CPU (see section 1-2-1).

The areas directly controlled by the main cpu are the same those controlled

by the cpu in thermal faxes (this is the basic facsimile engine, minus thermal

head and printer components). The difference is that the printer components

are often controlled through another major cpu, known as the slave cpu, as

shown below.

Main

CPU

Slave

CPU

I/O

Port

Buffer

DATA AND ADDRESS BUS

RAMROM

Printer Drive Components

I/O

Port

Page

Memory

and Sensors

Laser Diode

LIF

RAM

The additional components are as follows.

Slave CPU

This cpu controls the laser printer engine, under the control of the main cpu.

It is assisted by an I/O Port, which is similar in function to that of the main

cpu. (In some laser faxes, some of the scanner components are also controlled by the slave cpu.)

1-2-5

Page 22

Buffer

This is an interface for commands, responses, and data passing between the

two cpu’s.

Page Memory

This memory holds one page of data for printing. Printing does not begin until the complete page has been assembled here. Data from the network

comes into the page memory through the modem (or from the SAF memory

in the case of substitute or confidential reception), under the control of the

main cpu.

LIF (Laser Interface)

When a complete page has been assembled in the page memory, it passes

to the LIF. The LIF controls transfer of data from the page memory to the laser diode. It also contains data processing circuits, including those for

smoothing the data to 16 x 15.4 dots/mm before printing.

RAM

The LIF uses this memory as a work area for data processing.

ROM

This contains printer control software.

Laser Diode

The machine writes the image on the master by switching a laser beam

on/off. A laser diode generates this laser beam.

Printer Drive Components and Sensors

A laser printer mechanism is more complex than a thermal printer. The components of a laser printer will be explained in section 4.

Hard Disk

Some machines have a hard disk instead of a RAM SAF memory. The hard disk may also

store system parameters, Quick Dial Codes and so on.

1-2-6

Page 23

1-2-3. Communication Between CPU’s

Most machines have more than one cpu, but most of these are of minor importance, controlling certain areas of the machine, such as the operation

panel. The major cpu’s control the machine, but delegate responsibilities to

the other cpu’s. In thermal fax machines, there is one major cpu (called the

cpu). Laser fax machines often have two major cpu’s; the overall controlling

cpu is called the main cpu, and the other is called the slave cpu.

The number of cpu’s and their areas of responsibility vary from model to

model, so descriptions of circuits in this manual will be very generalized.

Communication between cpu’s is normally done in one of two ways; a serial

interface or a parallel interface. These are outlined below.

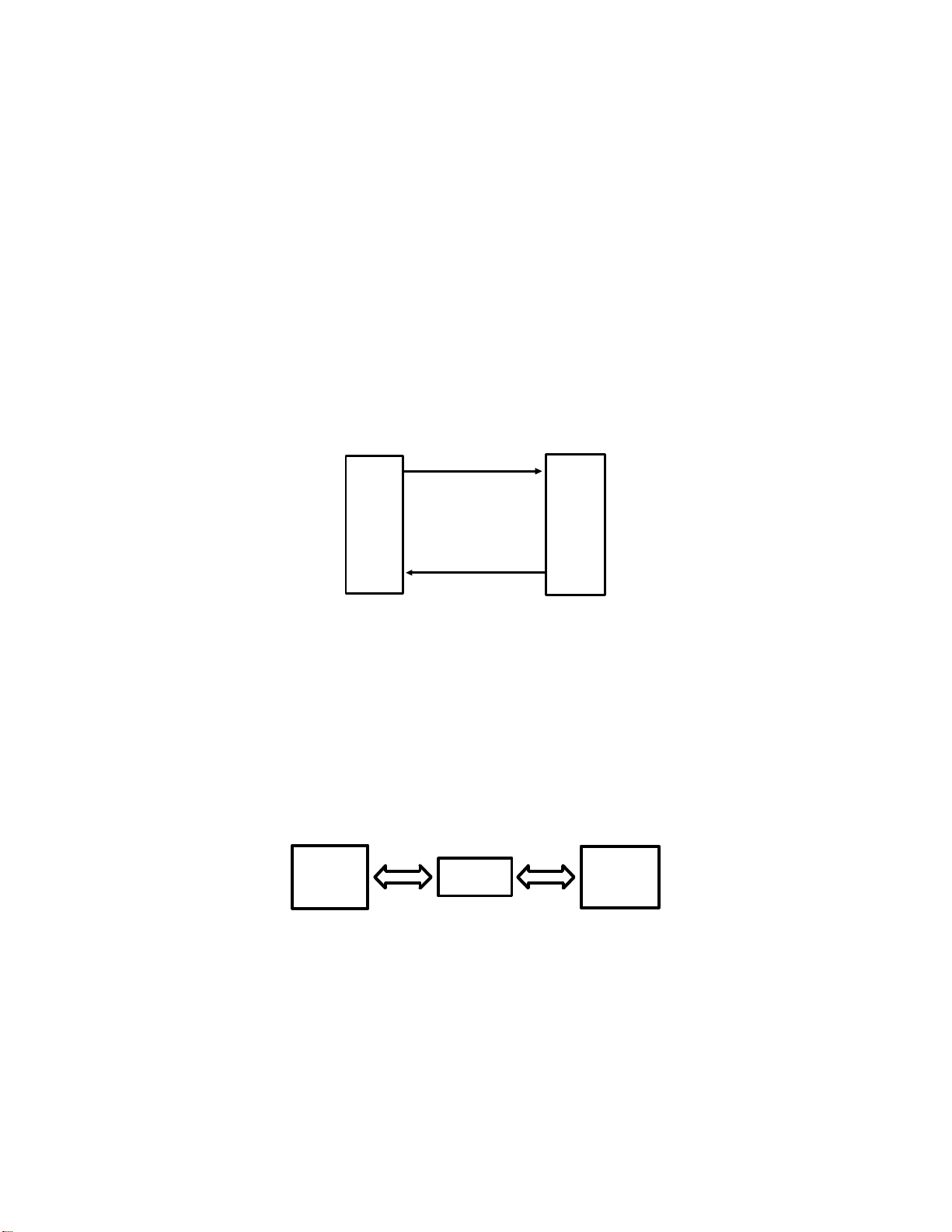

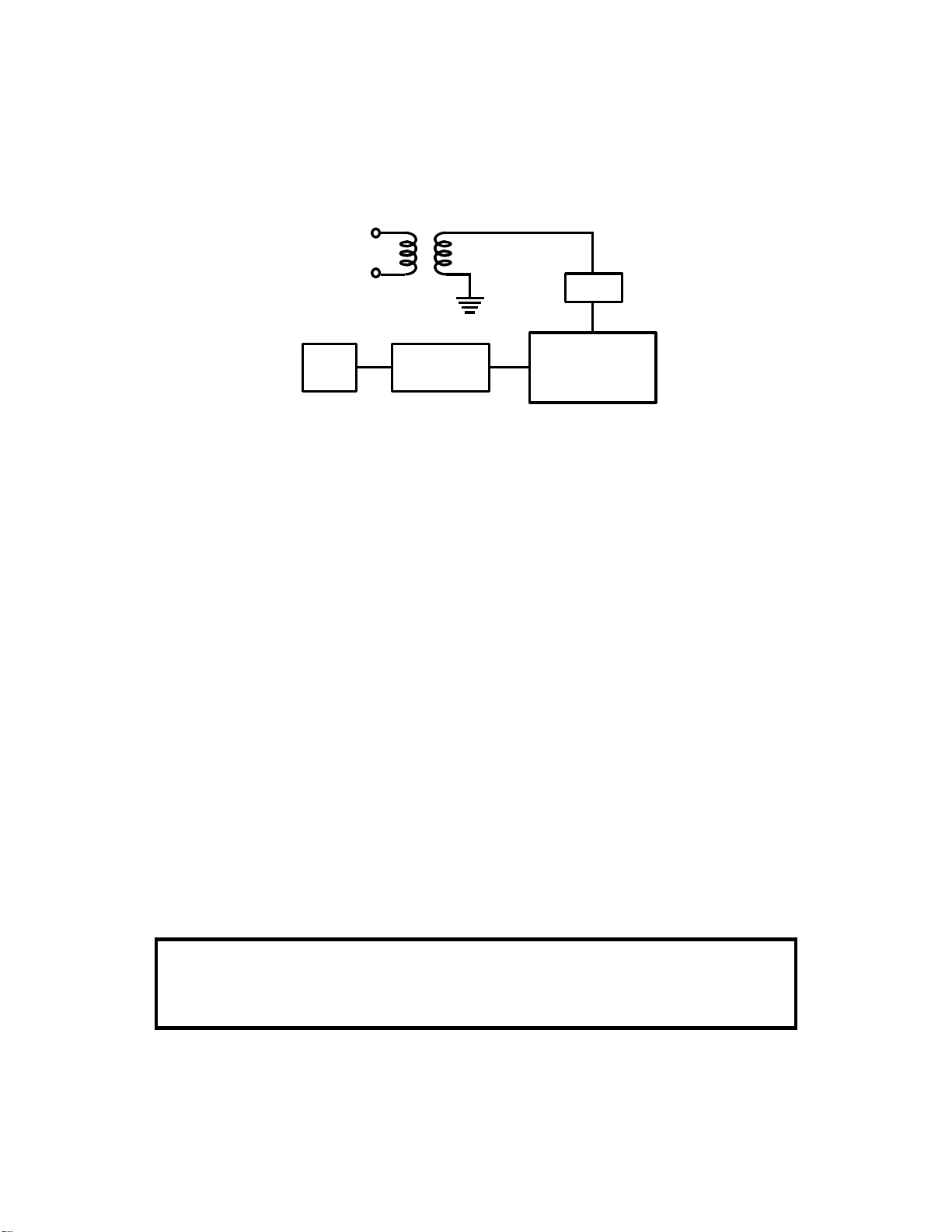

1. Serial Interface

COMMANDS

Main

CPU

RESPONSES

Slave

CPU

The serial interface most commonly used between two cpu’s consists of a

command line from the main cpu, and a response line from the slave cpu.

There may also be a clock signal to synchronize the interface, and a reset signal.

Serial interfaces are often used when the slave cpu shown in the diagram is a

minor cpu for monitoring sensors and controlling mechanical components.

2. Parallel Interface

Main

CPU

Buffer

Slave

CPU

A parallel interface typically has 8 or 16 wires for carrying data between the

two cpu’s. Data can pass in either direction on these wires. A buffer is normally included between the two cpu’s.

A parallel interface is normally used when the cpu is receiving and processing video data, as well as controlling mechanical components. A typical example would be between the main and slave cpu’s in a laser fax machine.

1-2-7

Page 24

1-3. VIDEO DATA PATH

This section outlines the path of video data through the machine in transmission, reception, and copying modes.

1-3-1. Transmission

This section explains the path of data through the machine during transmission. The main description is for memory transmission with ECM. Following

this main description are diagrams showing the differences between memory

transmission with ECM and the following:

• Memory transmission without ECM

• Immediate transmission with ECM

• Immediate transmission without ECM

1. Scanning

Scanner

Fluorescent Lamp

Shading Plate

Shading Plate

CCD

Lens Block

Profile

When the user presses the Start key on the operation panel, the original

(also known as the document) passes into the scanner, where it is illuminated

by the fluorescent lamp.

Light is reflected from the document through a shading plate, which allows

more light to pass through from the ends of the lamp than from the centre;

this compensates for the fact that the ends of the lamp are not so bright as

the centre.

Other types of lamp

Xenon lamp : If a xenon lamp is used, the difference in brightness is smaller than with a

conventional fluorescent lamp, and the xenon lamp is brighter, but this problem still exists.

LED array: This is a strip of photodiodes. As all the diodes are equally bright, a shading

plate is not needed.

After passing through the shading plate, the light is focused by the lens block

onto the CCD.

1-3-1

Page 25

2. Data Processing

Fluorescent

Lamp

Original

CCD

Analog Signal

ECM

Memory

SAF

Memory

Line

Buffer

To the

Network

Processor

FIFO

RAM

Variable Resistor

Video

CPU

8-bit

Attenuator

Modem

Gain Control

Circuit

CCD and Analog Video Processing

The CCD (Charge Coupled Device) is a row of photoelectric elements. It generates an analog video signal from the light reflected from the document. This

signal passes to the Video Processor, which corrects the data for scanner irregularities and converts it to digital (the signal from each element of the

CCD is typically represented by four bits).

For more about CCDs, see Appendix D.

Contact Image Sensor

In some cheaper models, a contact image sensor (CIS) is used instead of a CCD. The

image sensor is directly below the exposure glass; no mirrors, lenses, or shading plates

are used (the image sensor elements are self-focusing).

1-3-2

Page 26

Digital Video Processing

The Video Processor also does digital video data processing (e.g., halftone,

MTF), and converts the data to eight-bit parallel.

If the original is wider than the paper in the printer at the other end, data will

be deleted in the main scan and sub-scan directions to make the data fit on

the paper at the other end. This process is known as reduction.

After video processing, the signal from each CCD element is represented by

one bit (unless reduction was done).

See section 2-3 for full details on video data processing.

Storage to SAF Memory

After leaving the Video Processor, the data is compressed and then stored in

the SAF memory. The compression method used varies from model to

model. A simple compression technique such as MH gives fast data storage,

but the data takes up more room in the memory. More complex compression

techniques such as MR or MMR compress the data more effectively so that

less memory space is used, but they increase the scanning time.

Retrieval from SAF Memory

When it is time to send the data, the data comes out of the memory into the

cpu. The cpu reconstructs the raw data, and passes it to the line buffer.

(Lines of data that were stored as uncoded data go from the memory straight

to the line buffer.)

Compression

The cpu then compresses the data in accordance with the method agreed in

the set-up protocol that was exchanged between the two machines.

ECM Data Frame Assembly

Using the ECM memory, the cpu assembles the data into ECM data frames,

which are sent to the modem and the line.

Modulation

The modem converts the data to serial and modulates it.

Attenuation

The data then passes through an attenuator, which adjusts the tx level (this is

the output power of the data signal). It then passes through a variable resistor on the NCU, which can be used to adjust the tx level. The data then

passes to the network.

Flow charts for the different transmission modes are given on the next page.

1-3-3

Page 27

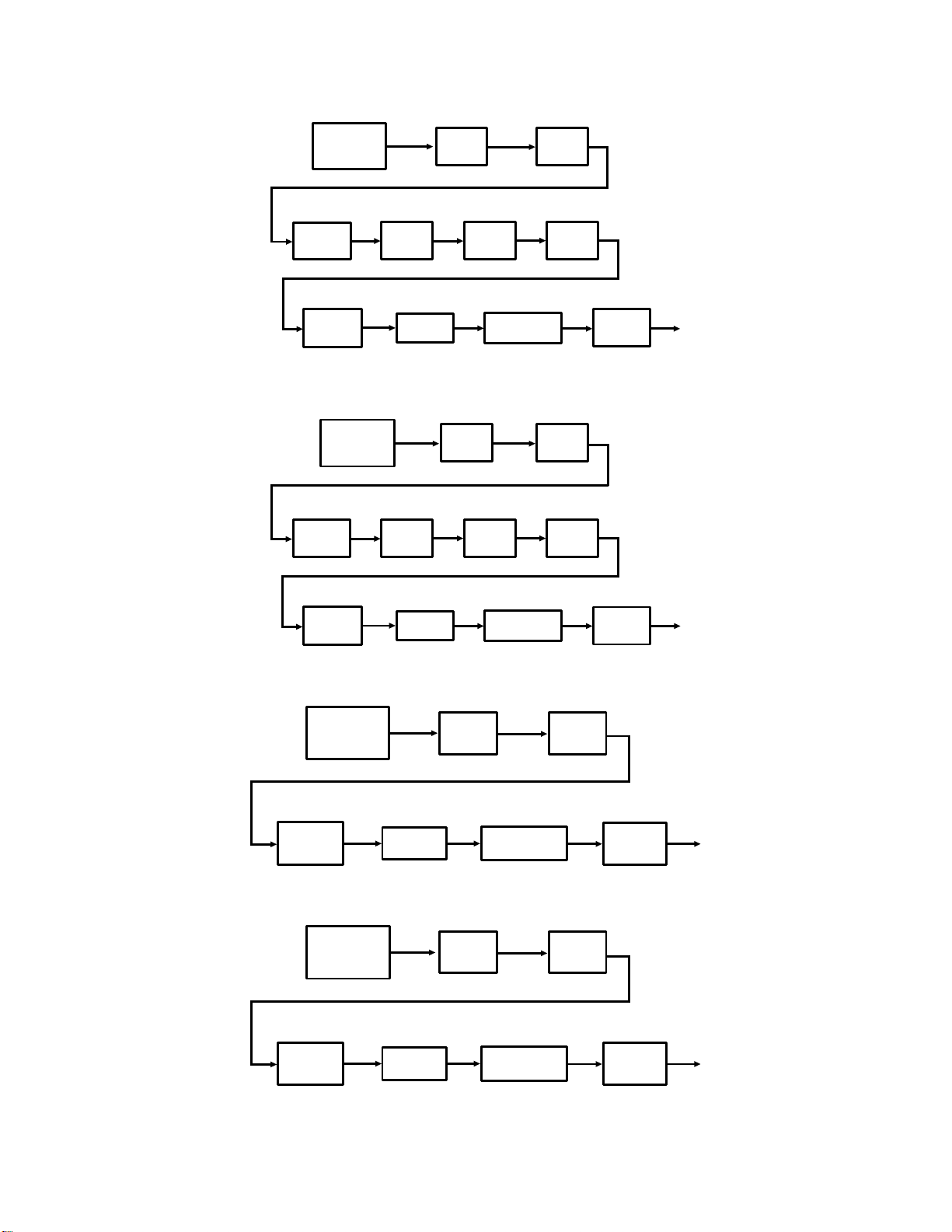

1. Memory Transmission, with ECM

Video

Processor

Reconstruction Compression

SAF

Memory

Line

Buffer

Line

Buffer

Compression

CPU

CPUCPU

ECM

Memory

Modem Attenuator

2. Memory Transmission, without ECM

Video

Processor

Reconstruction Compression

SAF

Memory

FIFO

Memory

CPU CPU

Modem Attenuator

3. Immediate Transmission, with ECM

Video

Processor

Line

Buffer

Buffer

Line

Buffer

Gain

Control

Compression

CPU

Line

Gain

Control

Compression

CPU

ECM

Memory

Modem Attenuator

4. Immediate Transmission, without ECM

Video

Processor

FIFO

Memory

Modem Attenuator

Line

Buffer

1-3-4

Gain

Control

Compression

CPU

Gain

Control

Page 28

1-3-2. Reception

This section explains the path of data through the machine during reception.

The data paths for thermal printers and laser printers are explained separately.

The main description is for basic reception without ECM. Following this main

description are diagrams showing the differences between basic reception

with ECM and the following:

• Basic reception without ECM

• Memory reception without ECM

• Memory reception with ECM

1. Thermal Printers

From the

Network

SAF

Memory

Line

Buffer

ECM

Memory

Filter

I/O Port

Thermal

Head

Modem

CPU

Thermal

Paper

Data from the line passes through a filter to remove unwanted frequencies.

Then it goes to the modem, which demodulates the data and converts it to

parallel.

1-3-5

Page 29

Reconstruction

The data coming from the modem is compressed data. This data passes

from the modem through the FIFO memory to the cpu where it is decoded,

using the line buffer.

Note: In machines with SAF memory, the data is also stored in the memory

in case the printer jams or runs out of paper; after the user corrects

the fault, the message will be printed out from the memory and no

data will be lost. However, in some models, if the paper ends but the

paper end sensor did not detect a black stripe at the end of the roll,

the page being printed will be lost.

Smoothing

The cpu then smooths the data, to remove jagged edges from the data. The

resolution of the received data is upgraded into the highest that the printer

can print; this is typically 8 x 7.7 dots per mm.

Printing

The cpu converts the data to serial, and passes it to the thermal head

through the line buffer.

1-3-6

Page 30

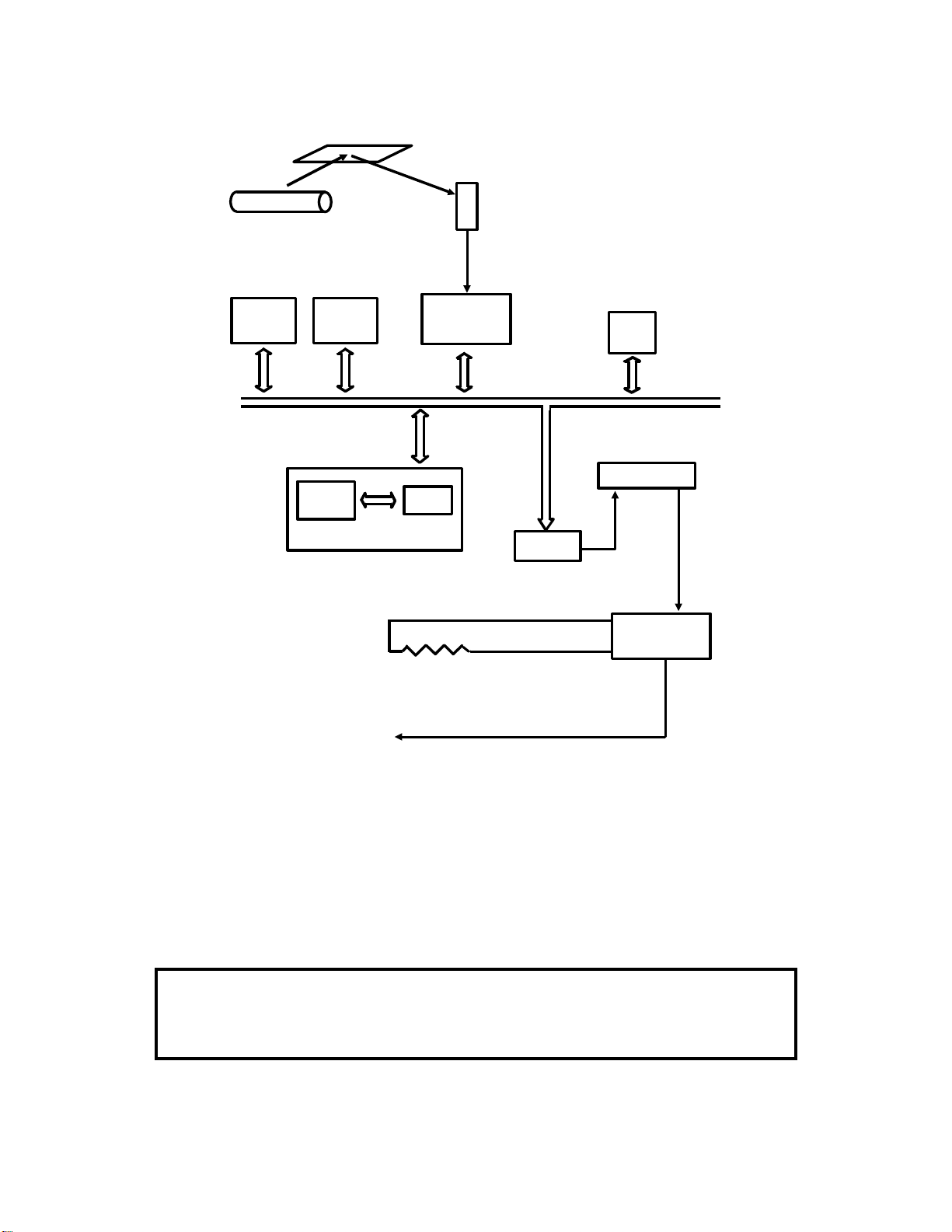

2. Laser Printers

From the

Network

SAF

Memory

Line

Buffer

ECM

Memory

Page

Memory

Filter

I/O Port

Buffer

Slave

CPU

Modem

Main

CPU

LIF

Laser Diode

Driver

Laser Diode

Copy Paper

Data from the line passes through a filter to remove unwanted frequencies.

Then it goes to the modem, which demodulates the data and converts it to

parallel.

Reconstruction

From the modem, the data goes to the SAF memory, where it is held in case

the printer jams or runs out of paper or toner; after the user corrects the fault,

the message will be printed out from the memory and no data will be lost.

The data coming from the modem is compressed data. From the SAF memory, the data passes to the cpu where it is decoded using the line buffer.

1-3-7

Page 31

Page Assembly

The data then goes through the slave cpu to the page memory. When a full

page of data has been assembled in the page memory, the data goes to the

LIF (Laser Interface). If the page is too long for the paper in the cassette, the

data is split into two pages and/or reduced in the page memory.

Smoothing

The LIF smooths the data. Smoothing removes jagged edges, converting the

resolution of the received image into the highest resolution that the printer

can accept. This is typically 8 x 15.4 dots per mm or 16 x 15.4 dots per mm

for a laser printer.

The LIF converts the data to serial before passing it to the laser diode.

Printing

The laser beam switches on/off in accordance with the data signal, and forms

a latent image on the master surface. This latent image is developed with

toner, the toner is transferred to copy paper, and finally the toner is fused to

the copy paper.

Flow charts for the different reception modes are on the next page.

1-3-8

Page 32

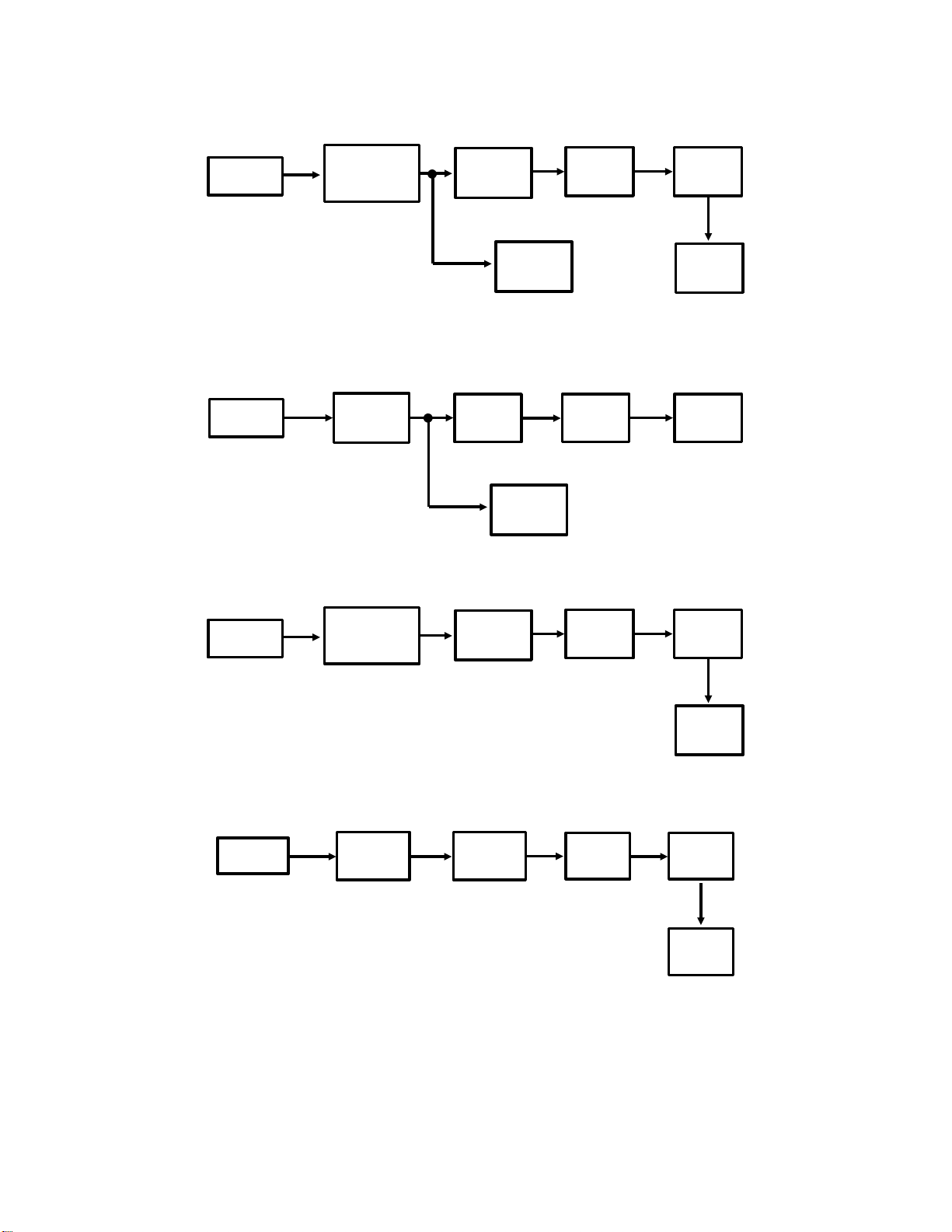

1. Basic Reception with ECM

Reconstruction

Modem

ECM Data

Extraction

2. Basic Reception without ECM

Modem

FIFO

Memory

3. Memory Reception with ECM

ECM

Memory

SAF

Memory

Reconstruction

Main

CPU

SAF

Memory

Main

CPU

Line

Buffer

Reconstruction

Line

Buffer

Printer

Engine

Printer

Engine

Modem

ECM Data

Extraction

4. Memory Reception without ECM

Modem

FIFO

Memory

SAF

Memory

SAF

Memory

Main

CPU

Reconstruction

Main

CPU

Line

Buffer

Printer

Engine

Line

Buffer

Printer

Engine

1-3-9

Page 33

1-3-3. Copying

Basically, the data path for copying is a hybrid of the scanner and printer circuits. The data paths for thermal printers and laser printers are shown below.

1. Thermal Printers

Original

CCD

Fluorescent

Lamp

Video

Processor

SAF

Memory

Line

Buffer

Thermal

Head

CPU

Thermal

Paper

Single Copy

The data from the Video Processor passes to the cpu. The cpu converts the

data to serial and passes it to the thermal head.

Multi-page Copying

This can only be done in machines with SAF memory (it may be disabled in

the factory, because this function can cause stress to the thermal head).

Data from the Video Processor passes to the cpu where it is compressed

and stored in the SAF memory. To print the page, the data comes out of the

SAF into the cpu, which decodes the data and sends it to the thermal head.

1-3-10

Page 34

2. Laser Printers

CCD

Fluorescent

Video

Processor

Lamp

Original

Main

CPU

SAF

Memory

Line

Buffer

Page

Memory

Copy Paper

Buffer

Slave

CPU

LIF

Laser

Diode

Driver

Single Copy

The data from the Video Processor passes to the cpu. The cpu converts the

data to serial and passes it to the page memory and the laser printer.

Multi-page Copying

Data from the Video Processor passes to the cpu where it is compressed

and stored in the SAF memory. To print the page, the data comes out of the

SAF into the cpu, which decodes the data and sends it to the page memory

and the laser printer circuit.

1-3-11

Page 35

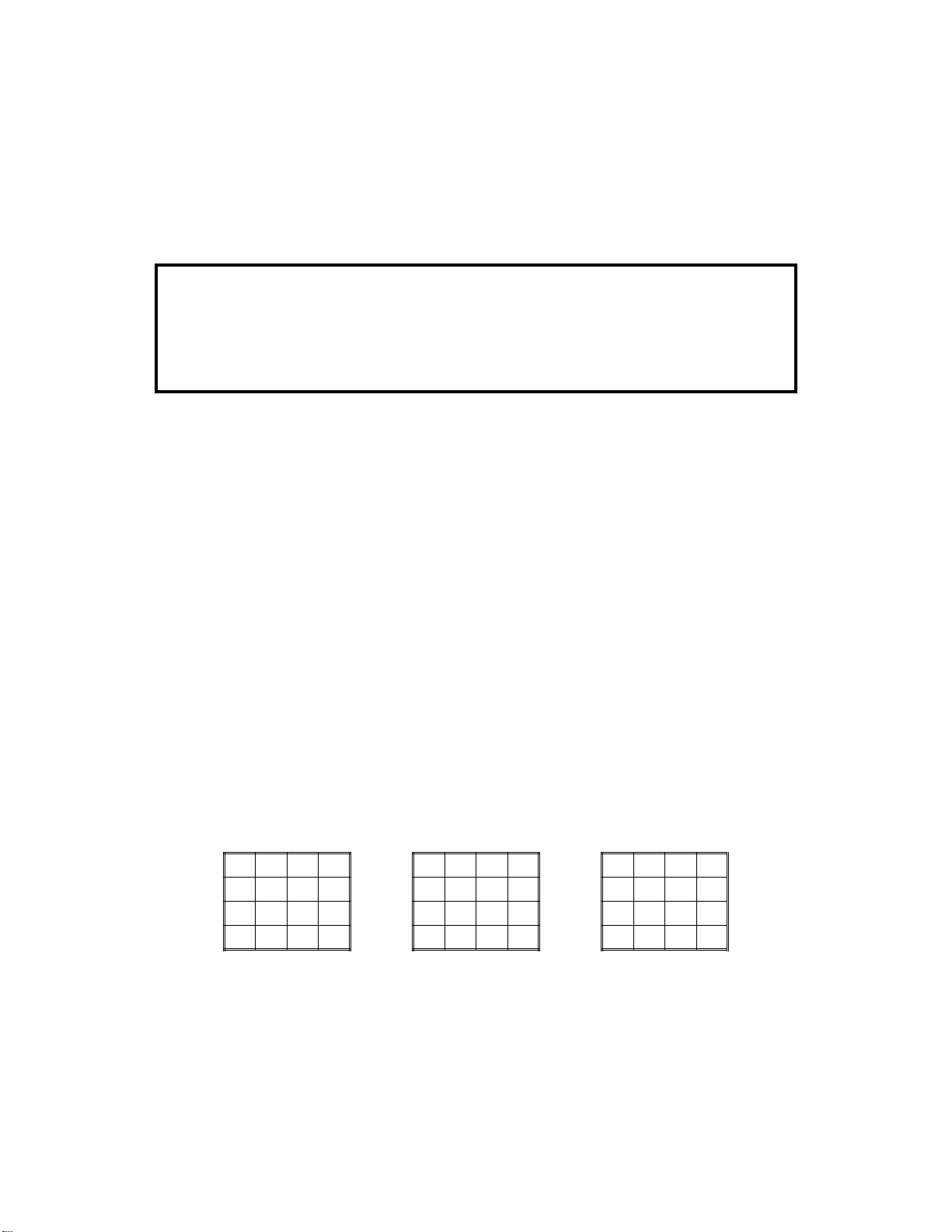

1-4. POWER DISTRIBUTION

This section explains power distribution in a typical fax machine. It also explains features such as battery back-up, power supply activation in standby

mode, and safety measures such as interlock switches.

1-4-1. Typical Power Distribution Circuits

Fax machines require a main power supply of 230 ±10V, 50 Hz.

The Power Supply Unit (PSU) generates the voltages needed by the machine

from the ac main power supply and passes them to the main PCB, which is

commonly called the FCU. There may be some regulators on the FCU to generate additional power supplies, as shown in the following example. The FCU

distributes the voltages to the components of the machine. However, the supplies to the thermal head (thermal printers) and the fusing unit and PSU fan

(laser printers) normally come straight from the PSU.

The following diagrams show some typical circuits. The components used differ from model to model.

1. Thermal Printer Fax

Thermal

Head

+24VD

PSU

+5V

Printer

Sensors

+5V

+24VS

+24VD

-12V

+5V

Tx Motor

Rx Motor

ADF Clutch

Document Feed-out Clutch

Stamp Solenoid

Fluorescent Lamp Driver

Cutter Motor

+24VD

Modem

+5V

- 12V

+12V

+5V

Regulator

+24VD

Regulator

+24VS

FCU

+24VS

- 12V

NCU

+12V

- 5V

- 5V+5V

+5V

MBU

+5V

- 5V

SBU

OPU

+5V

Scanner

Sensors

+12V

+5V

1-4-1

Page 36

2. Laser Printer Fax

Tx Motor

Master Belt Drive Motor

ADF Clutch

Document Feed-out Clutch

Stamp Solenoid

Quenching Lamp

Fluorescent Lamp

Pentagonal Mirror Motor

PSU Fan

+24VS

AC Main

Power

Fusing

Lamp

Thermistor

+5V

+24VD

PSU

Master Unit

Interlock Switch

+24VD

+5V

+24VS

+24VD

-12V

+24V

+5VS

+5V

Modem

- 12V

+5V

+12V

+5V

+24VD

Laser Diode

S5V

+24VD

+5V

Regulator

Regulator

LDDR

S5V

-12V

UIB

+24VS

FCU

+24VS

- 12V

LSD

NCU

+12V

- 5V

+5V

-12V

- 5V+5V

Sensors:

Document

Document Width

+5V

Scan Line

Scanner Cover Switch

Toner Overflow Sensor

+5V

MBU

+5V

- 5V

SBU

OPU

Power Pack

+12V

+5V

+24VD

Upper Unit

Interlock Switch

Right Cover

Interlock Switch

+5VS

+24VD

Registration Sensor Board

+24VD

Charge and Transfer Corona Fans

Registration Clutch

Upper Paper Feed Solenoid

Upper Paper Lift Solenoid

+5V

+24VD

1-4-2

+24VD

Main Motor

+5V

Fusing Unit Fan

Sensors:

Copy Feed-out

Right Cover Switch

Paper End

Paper Near-end

Paper Height

Toner End

Paper Size

Page 37

1-4-2. Power Supply Activation

In most models, the motors, solenoids, and electromagnetic clutches need a

+24V supply. When the machine is on standby, this power supply is not

needed. However, +24V is needed during standby mode, (see section 2-10-

1). So, in most fax machines (but not all), the +24V supply is divided into two

channels. The +24VS channel supplies the power needed during standby

mode, and the +24VD supply powers the motors and so on.

Note

In some models, the +24VD supply is kept on permanently, and there is no +24VS power

supply.

PSU

+24V

+24VD

A

+24VD

CPU

B

During standby, +24VD is switched off. When the cpu detects an incoming

call, or a document being placed in the feeder, the cpu turns on +24VD. It

does this by sending the +24VD activation signal [A] high.

The cpu switches off +24VD when the machine returns to standby. In some

models, the cpu will also switch +24VD off when it detects that certain covers

are open; this avoids exposing a user or technician to hazardous voltages.

In some laser printers, the machine also switches on +24VD when the fusing

lamp temperature falls below a certain level (e.g., 65 °C) in standby mode;

the fusing lamp is kept at a fairly high temperature during standby so that the

warm-up time is kept to a minimum. The +24VD supply drives the ac switching circuit that transfers power to the fusing lamp; see section 4-7 for details.

1-4-3

Page 38

1-4-3. Memory Back-up

Circuit Type 1: SRAM SAF and Parameter Memory

+5V

Switching

Voltage

Detector

+5V

Circuit

Real Time Clock,

RAM,

Voice Message

Memory, and

DRAM Controller

Battery

Switch

Battery

1

+24V

Battery

Switch

Switching

Circuit

Regulator

Voltage

Detector

Battery

2

[A]

Memory

Monitor

SAF

Memory

[B]

To avoid loss of data when the power is switched off, there are back up circuits for the SAF memory, the voice message memory, the system parameter

RAM, DRAM controller, and the real time clock in the cpu. Battery 1 backs up

the system parameter RAM and voice message memory, and keeps the real

time clock going. Battery 2, which is rechargeable, backs up the SAF memory.

The DRAM controller periodically refreshes the contents of the DRAM, even

while the main power is off, so that data is not lost.

1-4-4

Page 39

When the main power is on, +5V powers the memories, the DRAM controller,

and the real time clock. The +24V supply keeps Battery 2 fully charged. The

cpu keeps the SAF memory back-up circuit off while there is no data in the

SAF memory. The cpu controls the SAF back-up circuit through a memory

monitor device, which also operates when the main power has been

switched off.

When the main power is switched off, the function of the back-up circuit depends on whether there is any data in the SAF memory.

If there is no data in the SAF, the memory monitor disables SAF memory

back-up [A]. However, battery 1 backs up the parameter RAM, clock, and

voice message memory.

If there is data in the SAF, the memory monitor enables SAF memory back-up

[A] and Battery 2 backs up the SAF memory. Battery 2 also backs up the

RAM, clock, DRAM controller, and voice message memory; this increases the

lifetime of battery 1, which is not rechargeable. If the back-up voltage at the

SAF falls below 4.5 Volts, signal [B] to the memory monitor changes state.

The memory monitor then disables SAF memory backup (signal [A] in the

diagram on the previous page), and battery 1 will start to back up the RAM,

clock, DRAM controller, and voice message memory. The battery cannot reliably back up the SAF memory if the voltage falls below 4.5 V.

Battery Switches

During operation, the battery switches must always be on. If the switches are not kept on,

the contents of the memory will be lost if the main power is turned off. When the PCB

with the battery is removed, the battery switch can be turned off.

In some models, there is only a small SAF memory (normally a PSRAM),

which also acts as an ECM memory. If ECM data enters the SAF memory,

the cpu will instruct the memory monitor to disable SAF memory back-up (signal [A] in the diagram on the previous page).

1-4-5

Page 40

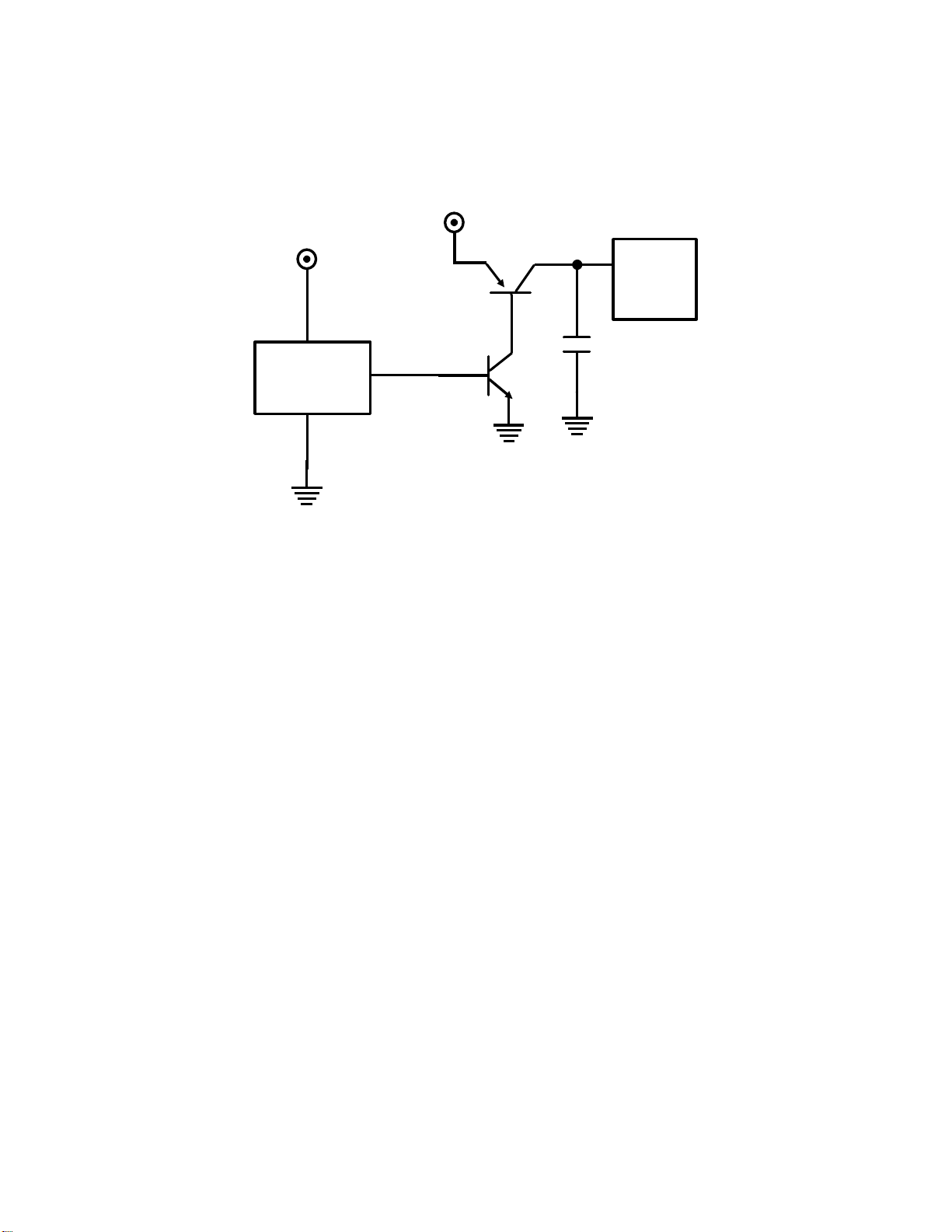

Circuit Type 2: Capacitor Back-up for Small SAF Memories

Some models that only have a small SAF memory. This memory also func-

tions as the ECM memory. In many cases, this small SAF memory is backedup by a charged capacitor instead of a battery.

+5V

+5V

Small

SAF

Q2

+

Memory

Voltage

Detector

A

Q1

When the main power is on, signal A from the voltage detector is high. Q1

and Q2 turn on, and the +5V supply powers the small SAF memory. At the

same time, the +5V supply charges the capacitor. The power must be on for

a certain time (typically about 10 minutes) before the capacitor is fully

charged.

If the main power goes off, the charge in the capacitor can back up the small

SAF memory for about 5 minutes.

As explained for Circuit Type 1, back-up is disabled when the small SAF memory is being used for ECM.

1-4-6

Page 41

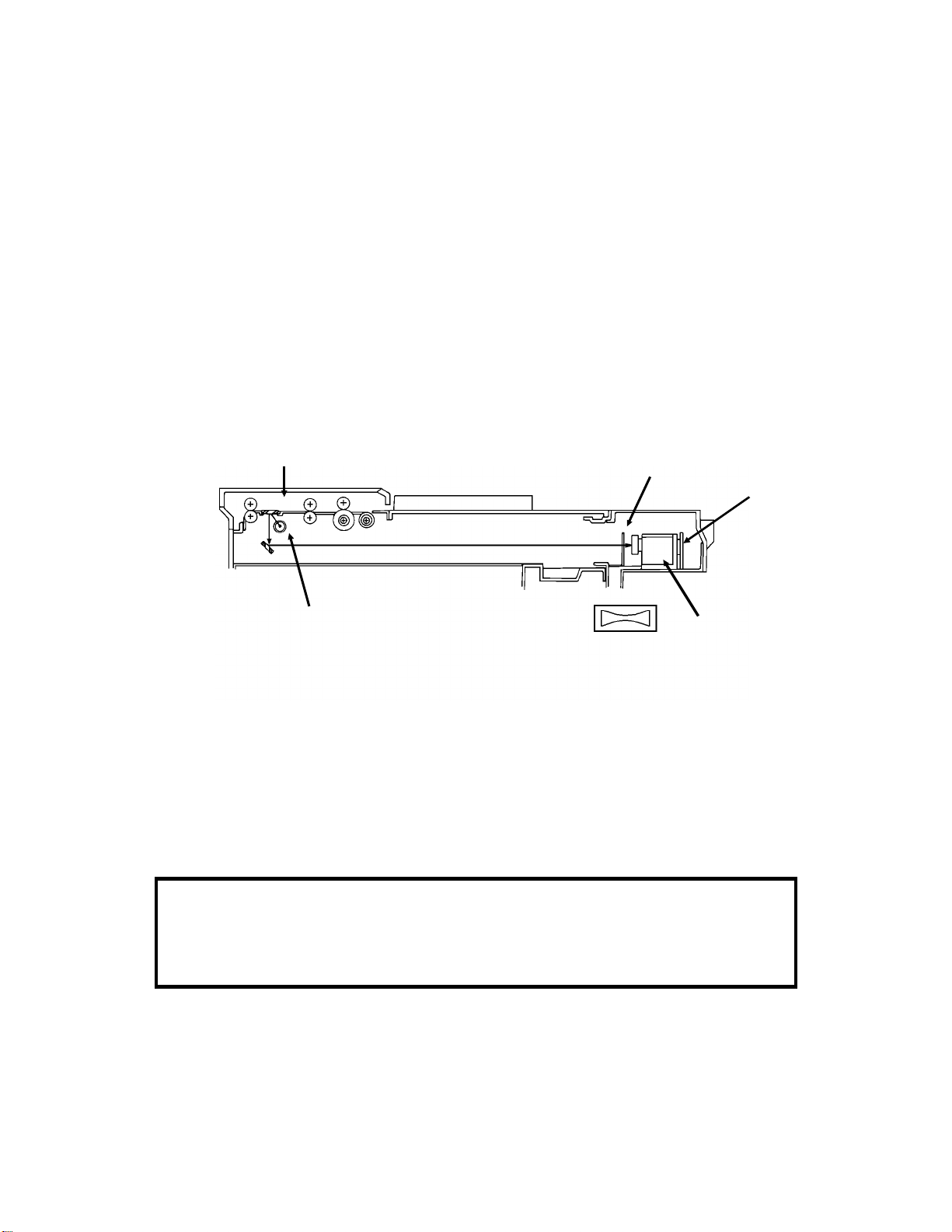

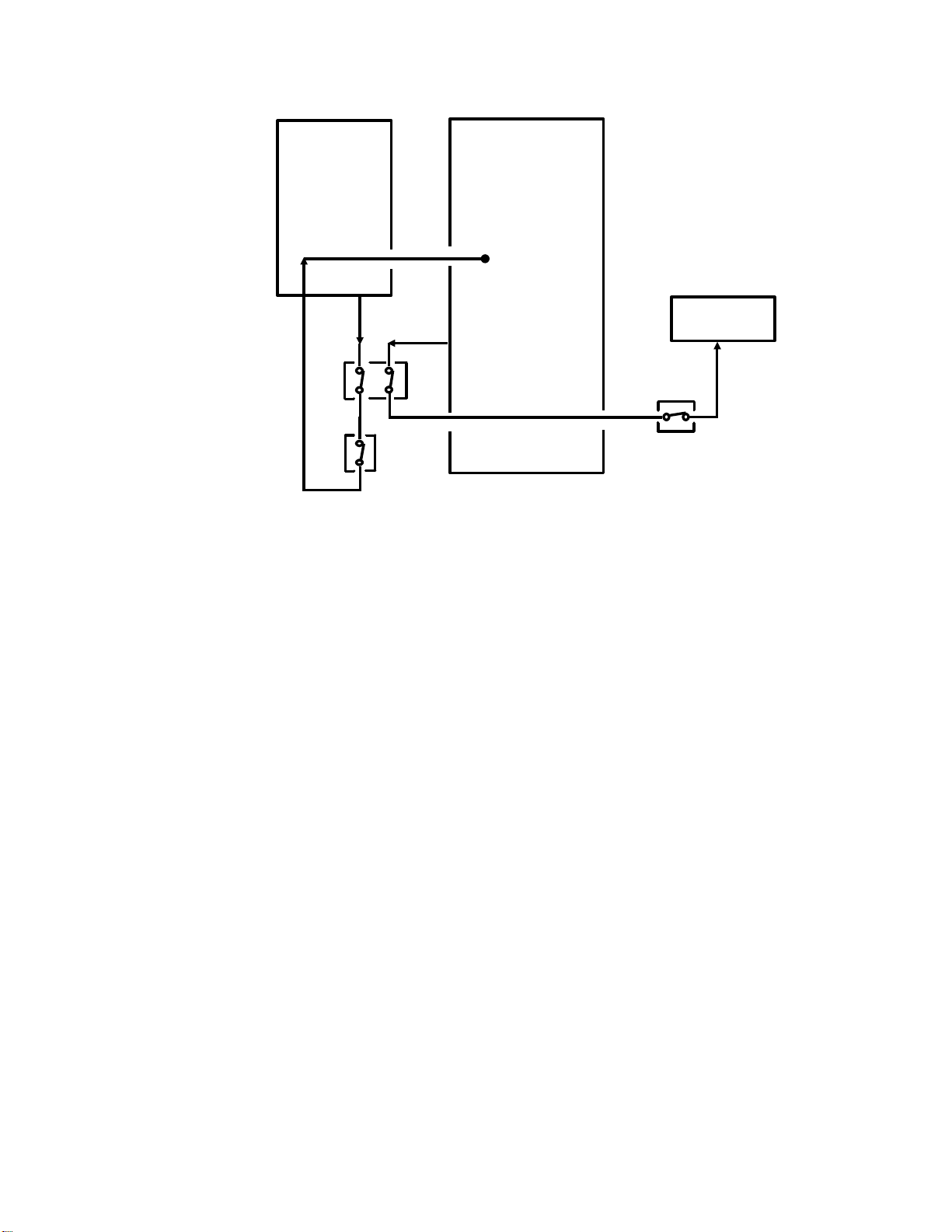

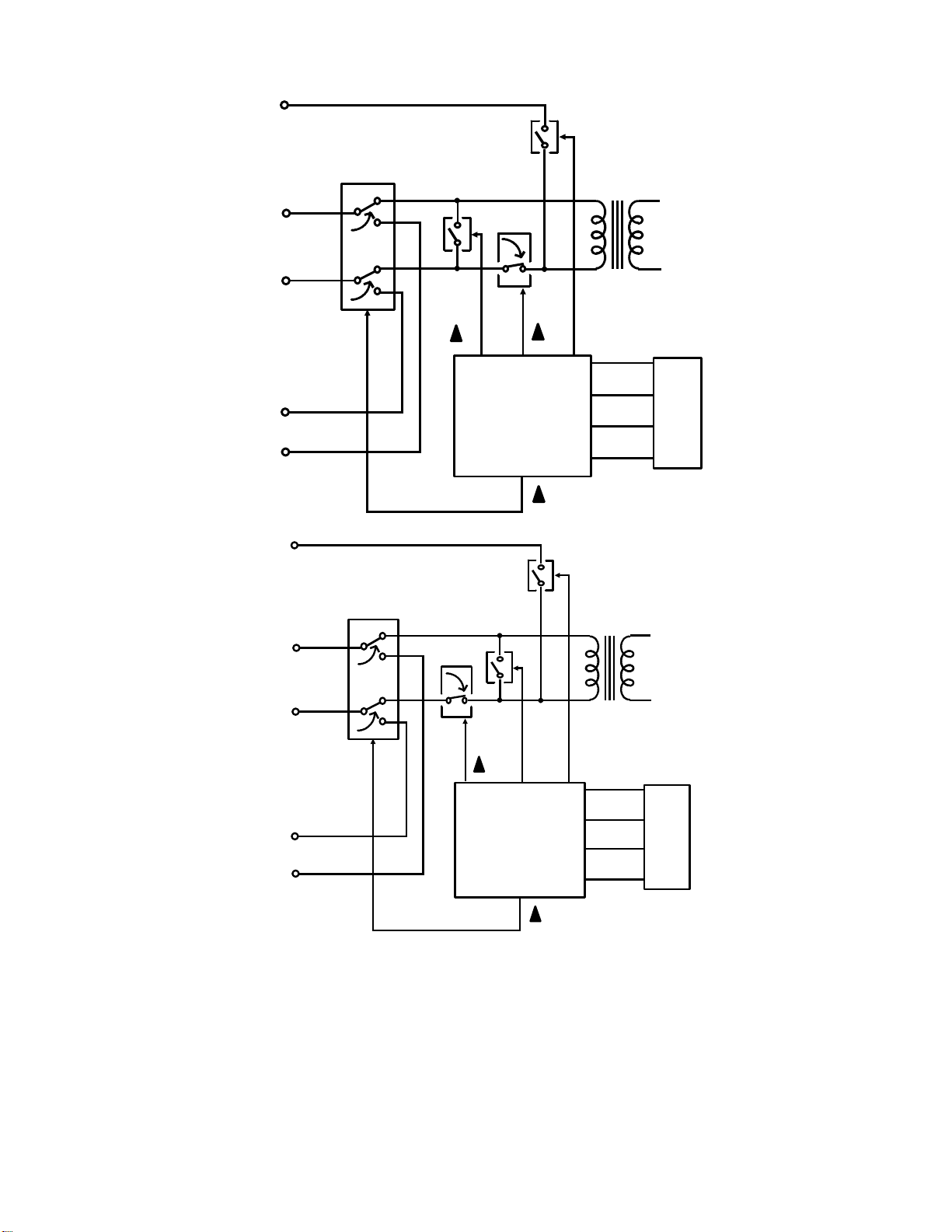

1-4-4. Interlock Switch Safety Circuits in Laser Faxes

FCU

Laser Diode

Driver

+5VLD

+5VS

Master Unit

Interlock Switch

+24VD

Upper Unit

Interlock Switch

Right Cover

Interlock Switch

PSU

+24VD

+24V

+5V

In laser fax machines, the +24VD supply powers the high voltage components of the machine. Because of this, interlock switches or microswitches

are installed to break the +24VD supply if any of the covers are opened. This

prevents the user from becoming exposed to high voltages at the charge and

transfer coronas and the development unit if the covers are opened.

The interlock switches are safety features, cutting off +24VD (for the power

pack and other components) and +5VLD (for the laser diode). In the example shown above, the switches operate as follows; some models are simpler.

• Upper unit interlock switch: Open when either the upper unit or the

copy exit cover are open; breaks the +24VD and +5VS supplies.

• Right cover interlock switch: Open when the right cover (by the develop-

ment unit) is open; breaks the +24VD supply.

• Master unit interlock switch: Open when the upper unit is open or when

there is no master unit; breaks the +5VLD supply.

Note that power to the laser diode driver is cut if the user opens the upper

unit or removes the master; these actions open the master unit interlock

switch, and cut the power to the laser diode driver.

If the scanner cover is opened, the +24VD supply is cut by the cpu in some

models; the +24VD supply does not usually pass through the scanner cover

switch. If the machine has a lower cassette installed, the cover switches in

the lower cassette do not usually affect the +24VD supply.

1-4-7

Page 42

SECTION 2. TRANSMISSION

This section explains how the machine sends a fax message. It covers document feed and scanning, video data processing, and the communication control circuits for transmission.

When they leave the factory, most machines that have memory are set up for

automatic dialling and transmission from memory. Sections 2-1 to 2-9 are

based on the steps taken by this type of machine. Other modes, such as

transmission without memory, send later, automatic dialling from behind a

PABX, and manual dialling will be explained separately in sections 2-10 and 2-

11.

Below, there follows a brief outline of the individual steps for memory trans-

mission with automatic dialling. These steps are basically the same for most

machines.

Document Detection (Section 2-1) - The user places the document in the

feeder, and the cpu turns on the fluorescent lamp when it detects the document.

Document Feed (Section 2-2) - The machine feeds the document through

the scanner.

Video Processing (Section 2-3) - The machine scans the document, converts the scanned data to digital, and passes it through the video processing

circuits.

Call Collision Prevention (Section 2-4) - After the document has been

scanned, the machine checks whether a fax message is coming in. (The machine cannot dial while a message is coming in.)

DC Loop Closure and Line Monitoring (Section 2-5) - If there is no incoming call, the machine closes the circuit between itself and the telephone exchange. The machine will monitor the line for dial tone and/or line current if

required by local conditions (this is required in some European countries).

Dialling (Section 2-6) - The machine dials the other party.

Signal Detection (Section 2-7) - The machine then waits for a signal from

the other party before going into tx mode, if required by local conditions (this

is required in some European countries).

Data Transmission (Section 2-8) - The data passes from the memory out to

the line through the modem and network interface circuits.

Return to Standby (Section 2-9) - The machine returns to standby mode.

Page 43

2-1. DOCUMENT DETECTION

2-1-1. Document Table Mechanism

1. Sensors

The first step in sending a fax message is to place the document in the document feeder. This section explains how the machine detects when the user

has placed a document in the feeder.

The following diagram shows a typical document table mechanism.

[B]

[C]

[A]

The document feeder entrance has sensors to detect the document.

Machines that only accept A4-width [8.3"] paper only have one sensor. This

is the document sensor [A].

Machines that accept B4-width [10.1"] paper also have a B4-width document

sensor [B]. Machines that accept A3-width [11.7"] paper have a B4 document sensor and an A3-width document sensor [C].

2-1-1

Page 44

[B]

[A]

[C]

The document sensor is usually a photointerrupter. When a document is

placed in the feeder, the document pushes the document sensor actuator [A].

The B4-width document sensor and the A3-width document sensor are also

usually photointerrupters. Documents B4 width or wider push the B4-width

document sensor actuator [B] and documents A3 width or wider push the B4width and A3-width [C] document sensor actuators.

Why is document width detection necessary?

Document width detection is necessary in machines with document feeders that can

accept wide originals. This is because some machines cannot print received documents

that are wider than A4-width [8.3"]. If such a machine receives a page wider than this,

only the central A4-width would be printed. Clearly, this is not acceptable, so the

message width must be reduced to fit on the paper in the printer.

The cpu in the sending machine determines the type of reduction that is needed by

comparing the outputs of the document width sensors with the width of copy paper in the

remote terminal (this is informed in the protocol exchanged between the two terminals at

the start of communication). The sending machine normally does the reduction.

For more on reduction, see section 2-3-7.

2-1-2

Page 45

2. Document Guides

[A]

The document guides [A] are connected to each other by a rack and pinion

system. If one is moved, the other moves. The document guides ensure that

the pages are fed in without skewing.

2-1-3

Page 46

3. Shutter

[A]

[C]

[D]

[B]

Some machines, especially those with a high-capacity document feeder,

have a shutter mechanism. This mechanism prevents the user from forcing a

document too far into the feeder, which could lead to double feeding. When

the machine is in standby mode, the shutter [A] is down, preventing the user

from pushing paper into the scanner past the pick-up roller [B]. When the

pick-up roller lifts up, the shutter lifts to allow paper past the pick-up roller.

In this typical example, a tab [C] on the document feed roller shaft [D]

pushes up the shutter as the pick-up roller lifts up. When the pick-up roller

drops, the shutter blocks the document feed path again. See section 2-2 for

details about the document feed mechanism and the pick-up roller.

2-1-4

Page 47

2-1-2. Scanner Lamp

Fluorescent Lamp Driver

A B

+24VD

CPU

FCU

When the cpu detects a document at the document sensor, it turns on the

+24VD supply as explained in section 1-4.

At about the same time, it turns on the lamp, which illuminates the document

(the scanner reads the document by converting the light reflected from the

document into a video signal).

When a fluorescent lamp is used, the cpu drops pin A to low to preheat the

fluorescent lamp. After 2 s, the cpu drops pin B to low to light the lamp.

Instead of a fluorescent lamp, a xenon lamp or LED array may be used. Xenon lamps and LED arrays do not need preheating. Document feed usually

begins shortly after the lamp is switched on.

The different types of lamp used in fax machine scanners are briefly discussed in Appendix D.

Cross-references

Photointerrupters: Appendix D

LED arrays, Xenon lamps, Fluorescent lamps: Appendix D

+24VD power supply: section 1-4-2 Document feed mechanism: section 2-2

Reduction: section 2-3-7. Protocol: Appendix B

2-1-5

Page 48

October 15th, 1991

2-2. DOCUMENT FEED AND SEPARATION

Memory transmission: After the user presses Start, the document is fed in.

It stops at the auto shading position, and is then scanned and stored into

memory.

Immediate transmission: After dialling and handshaking with the other terminal, the machine starts to feed the document into the scanner. The document

is scanned and transmitted. Immediate transmission is outlined in section 210-2.

Memory transmission is the default mode of most machines, and this will be

described below in detail.

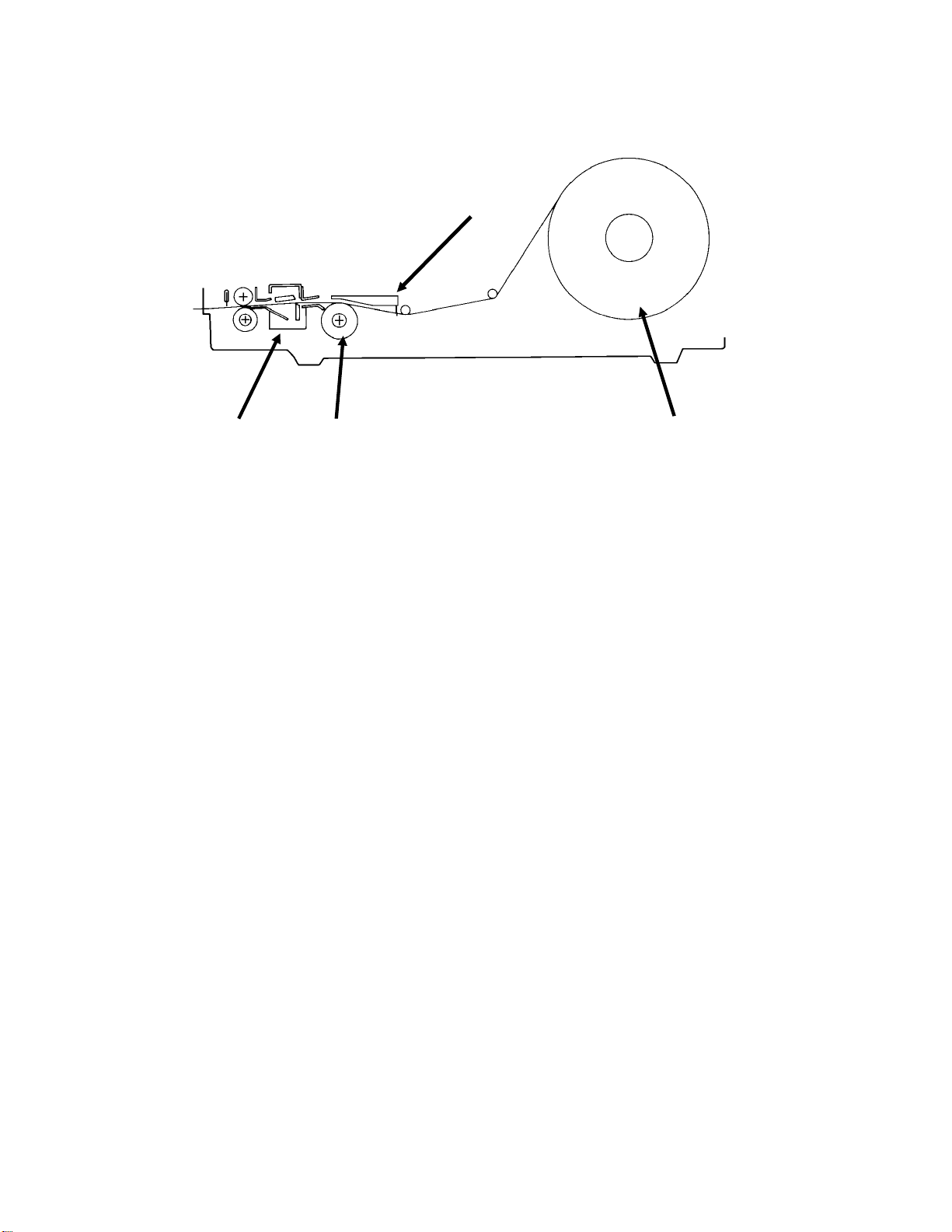

2-2-1. Pick-up and Feed

1. Overview

After the user has pressed the Start key, the machine starts to feed the document into the scanner. The pick-up and feed mechanism must feed the document into the scanner one page at a time. The mechanism must also

minimize the gap between pages during scanning, to reduce the user’s communication costs (immediate transmission) or the time needed for scanning

(memory transmission).

Document feed mechanisms have at least the following components.

• Tx motor - This stepper motor drives the scanner.

• Scan line sensor - This detects when the leading edge of the docu-

ment is approaching the auto shading position.

• Document pick-up roller - This picks up the first page of the document

and passes it to the document feed roller.

• Document feed roller - This feeds the page into the scanner.

• Document separation roller - This makes sure that only one page at a

time goes into the scanner.

• Marker (Stamp) - This makes a mark on the reverse side of the docu-

ment to inform the user of successful scanning or storing of the page.

Not all models have this component.

Some mechanisms are more complex, and have more components, as will

be seen in the following pages.

The surfaces of the document feed path are treated with antistatic material to

prevent dust from accumulating, which would lead to errors such as nonfeed.

2-2-1

Page 49

October 15th, 1991

There are some other terms to understand.

• Auto shading position - When the leading edge of the document

reaches this location (a short distance before the scan line), the scanner stops and the machine scans a white strip which is directly above

the scan line. The white level scan line taken here is used to correct the

scanned image data for scanner irregularities (see section 2-3-3).

• Scan line - This is directly above the CCD. The image data is read here.

Pick-up Rollers

Rubber pick-up rollers harden when they feed documents that have traces of silicone oil

on them (some photocopiers use silicone oil in their fusing units). Because of this, some

models are supplied with two pick-up rollers; the rubber roller, and a metallic roller with a

rough surface.

The metallic roller is not affected by silicone oil. However, it may lead to document

damage if the user pulls documents out of the feeder without opening the cover. Also, in

some models, the metallic pick-up roller leads to a drop in the number of sheets that can

be placed in the feeder.

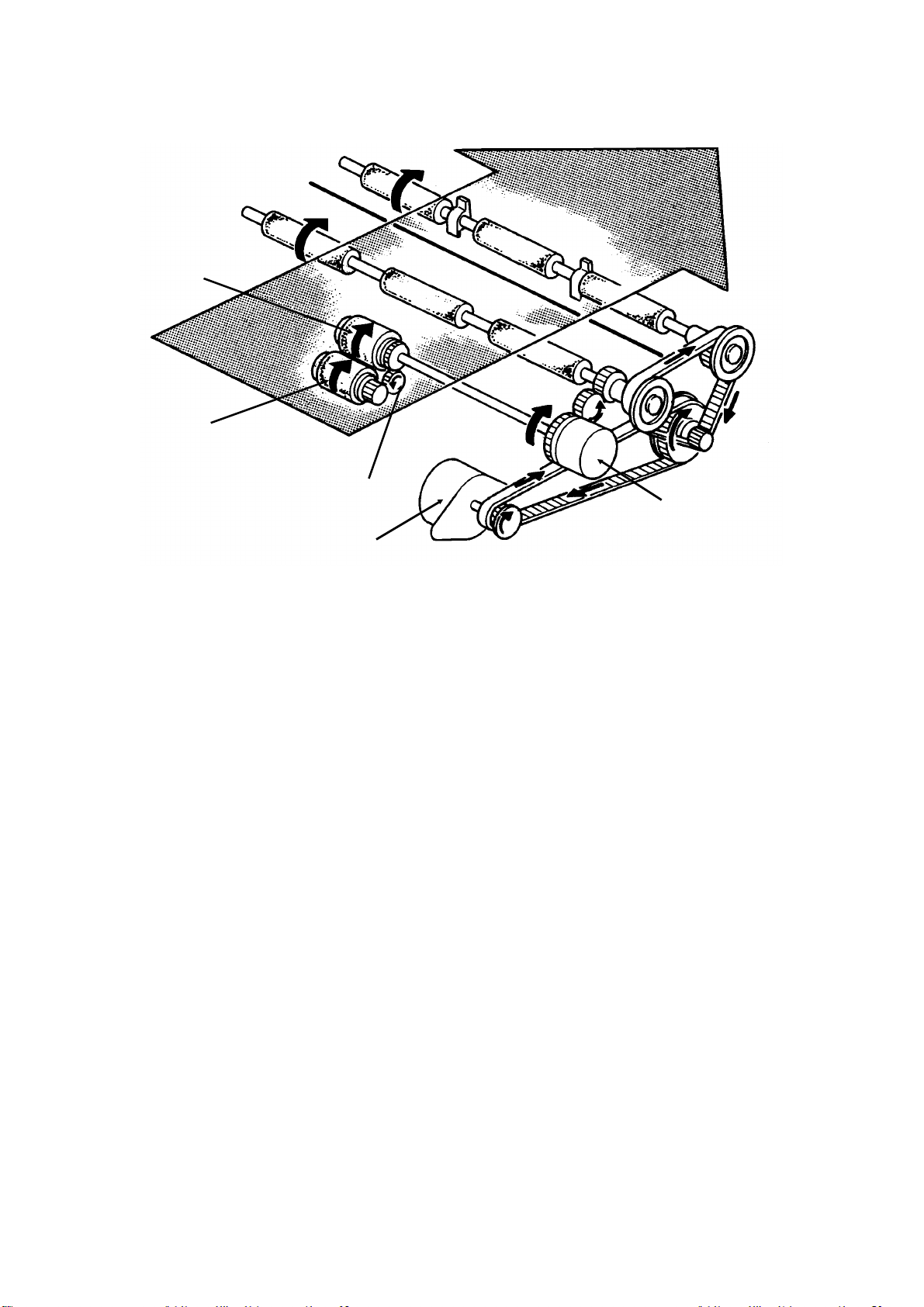

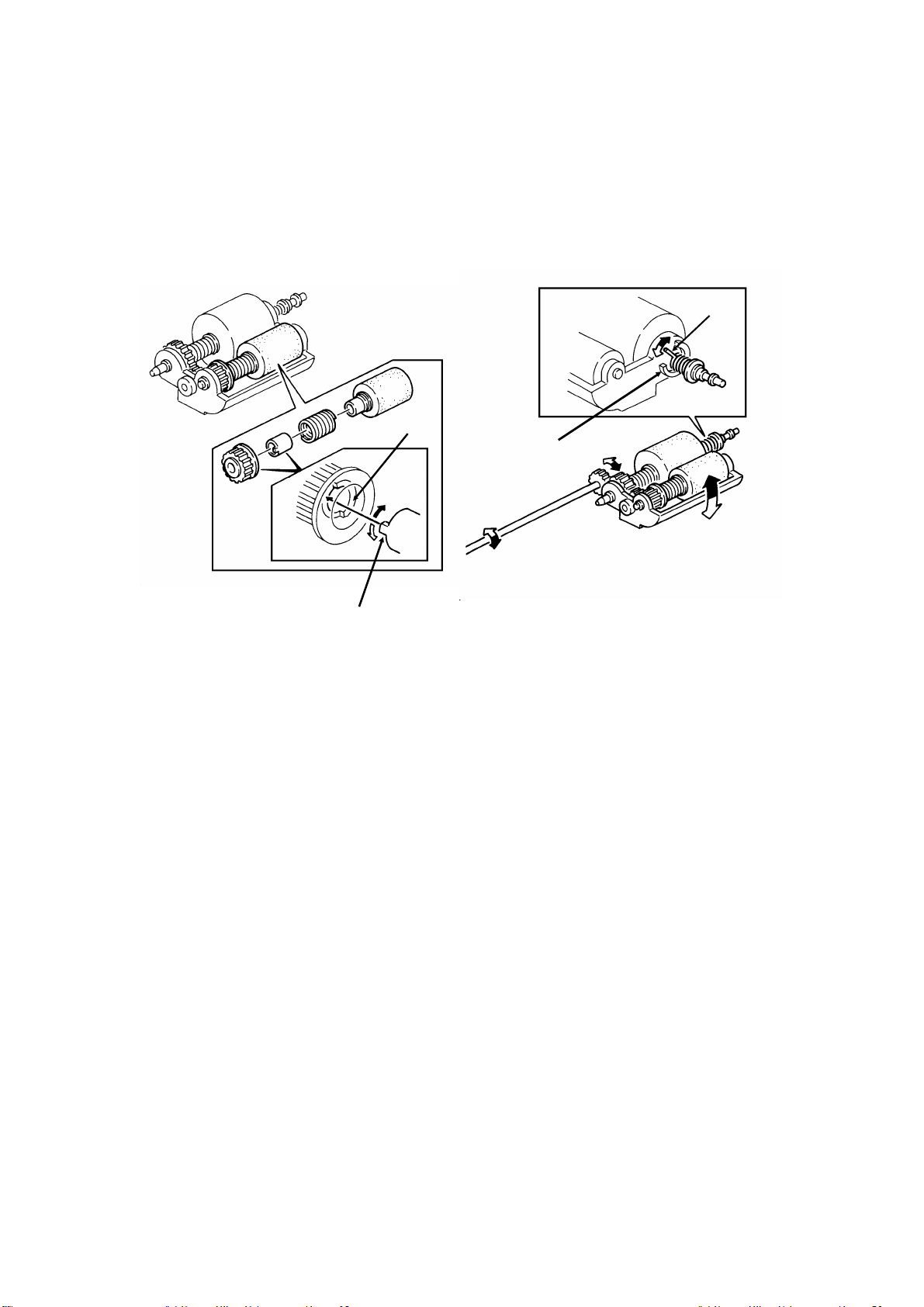

There are two basic types of document feed mechanism.

• Mechanical clutch mechanism

• Electromagnetic clutch mechanism

2-2-2

Page 50

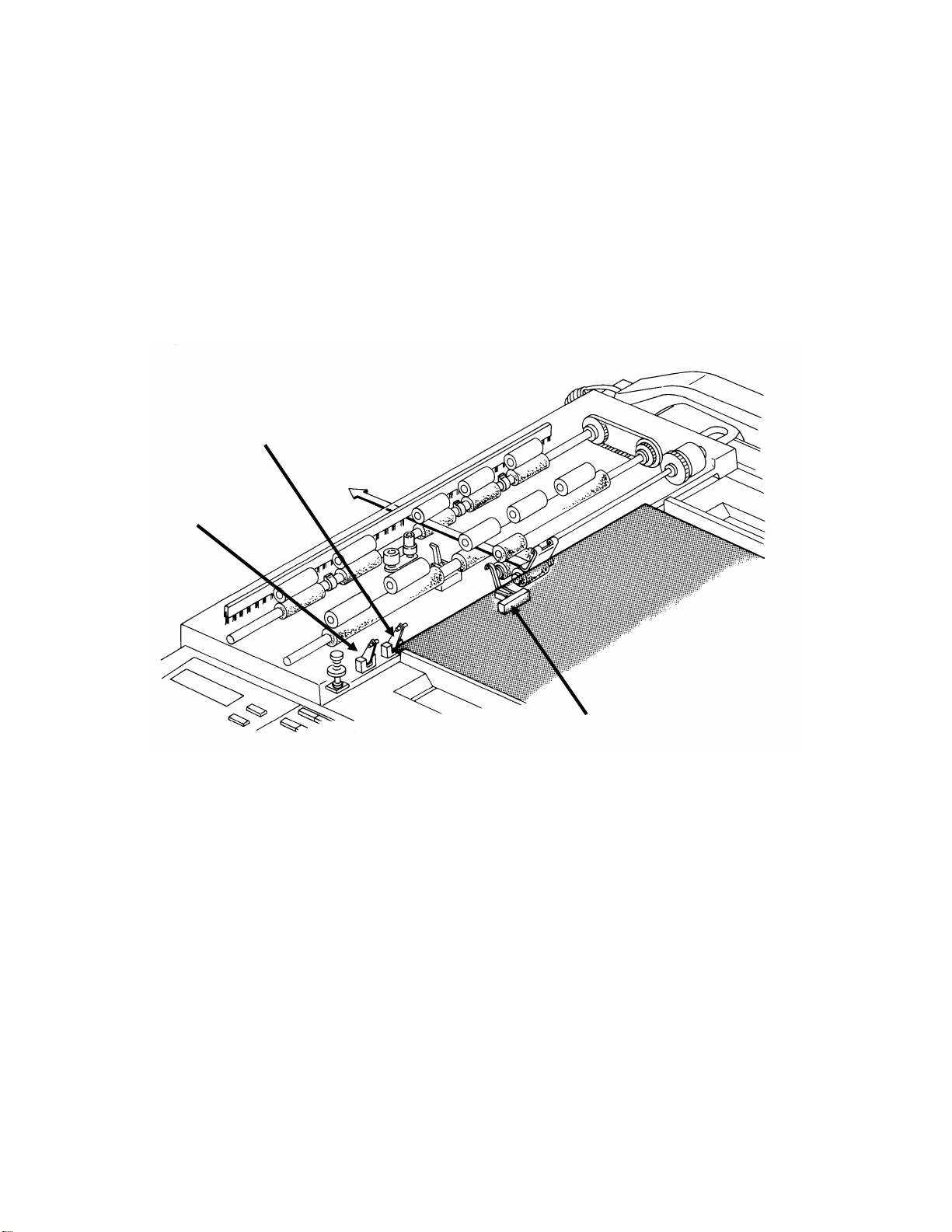

2. Electromagnetic Clutch Mechanism

Separation

Roller

Pick-up

Roller

Feed Roller

October 15th, 1991

ADF Clutch

Tx Motor

A typical electromagnetic clutch mechanism is shown above. In addition to

the major components listed on page 2-2-1, a mechanism of this type will

contain an ADF clutch and possibly one of the other two components in the

following list. The sensors are not shown in this diagram.

• ADF clutch - This electromagnetic clutch transfers tx motor drive to the

document feed and pick-up rollers. The clutch is turned on to drive the

document pick-up roller when a new page is required.

• Trailing edge sensor - This informs the cpu that it is time to start feed-

ing the next page. Not all models have this sensor.

• Document feed-out clutch - This holds the page at the stamping posi-

tion while the document feed roller is feeding the next page into the

scanner. Not all models have this component.

Either the trailing edge sensor or the document feed-out clutch will be used

to minimize the time between pages, as will be seen in the following pages.

2-2-3

Page 51

October 15th, 1991

The details of the document feed process differ from model to model (there is

a timing chart in the Service Manual for each model which illustrates the procedure). However, it is possible to provide a brief overview.

Prefeed

After the Start key is pressed, the document is fed to the auto shading position (this is known as prefeed).

1. The tx motor starts and the ADF clutch turns on. The ADF clutch transfers

tx motor drive to the feed roller and lifts the pick-up roller until it touches

the bottom page of the document.

2. The pick-up roller feeds the page to the feed and separation rollers. The

separation pressure plate above the separation roller spreads out the

edges of the pages of the document. The separation roller only allows

one page into the scanner. The one-way clutch on the feed roller shaft

prevents backward rotation of the separation roller from driving the feed

roller backwards.

3. When the leading edge of the document reaches the auto shading position (below the white strip on the upper scanner guide plate, just before

the scanning position), the tx motor and ADF clutch stop and auto shading is done.

Note: The auto shading position is at or slightly after the scan line sen-

sor. Depending on the model, auto shading is done either:

• When the document’s leading edge activates the scan line sen-

sor

• A short while after the scan line sensor is activated

In some models, the scanner continues to feed the paper during auto

shading (auto shading only takes about 20 ms, and the document is still

a short distance away from the scan line). However, for immediate transmission, the tx motor has to stop at about this time so that protocol can

be exchanged between the two terminals. The motor starts up again only

when connection with the other end and protocol compatibility have been

assured.

4. The machine then scans the white pressure plate for auto shading (see

section 2-3-3 for details on auto shading).

2-2-4

Page 52

October 15th, 1991

Scanning

1. When auto shading has finished, the tx motor feeds the page into the

scanner.

Note: The R1 and R2 rollers, driven by the tx motor, feed the page

through the scanner. The ADF clutch is switched off when these

rollers can feed the page without help from the feed roller. In

some machines, the ADF clutch does not turn back on at all after

auto shading, as the R1 rollers already have the leading edge of

the document. However, if there is a document feed-out clutch,