Ricoh FW830 Service Manual SF

SHEET FEEDER

(Machine Code A453)

31 December 1992 SPECIFICATIONS

1. SPECIFICATIONS

1. Copy Paper Size: Maximum: A1, D sideways

Minimum: A4, A (81/2 x 11 in) lengthwise

2. Tray Capacity: 100 sheets (Bond Paper)

50 sheets (Translucent Paper)

3. Power Source: +24 volts and +5 volts from the copie r

4. Dimensions

(H x W x D):

5. Weight: 26 kg, 57.3 lb

144 x 1,180 x 805 mm

5.7 x 46.5 x 31.7 in

1

SPECIFICATIONS 31 December 1992

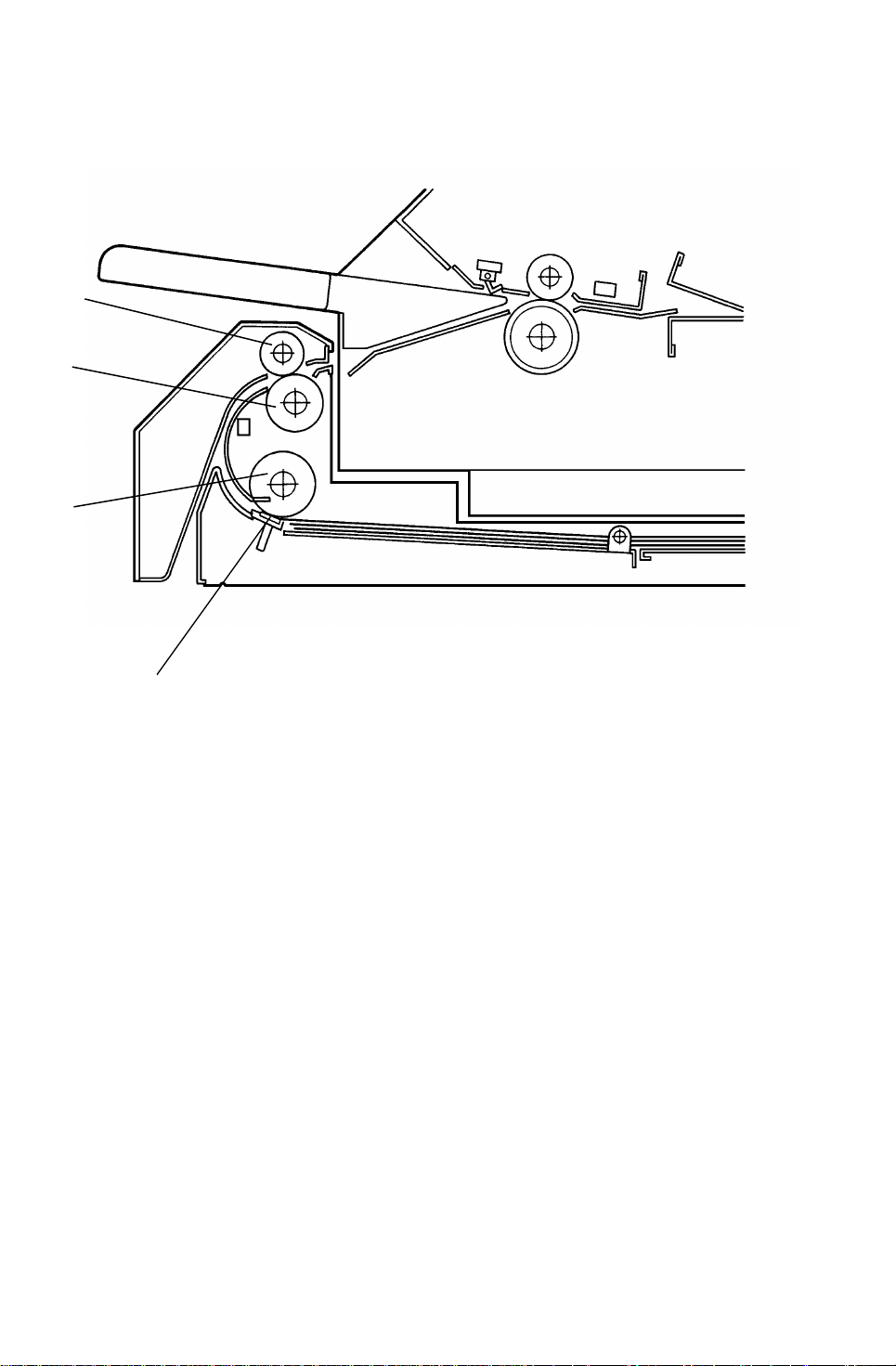

1.1 MECHANICAL COMPONE NT LAYO UT

1

2

3

4

1. Upper Relay Roller

2. Lower Relay Roller

3. Paper Feed Roller

4. Friction Pad

2

31 December 1992 SPECIFICATIONS

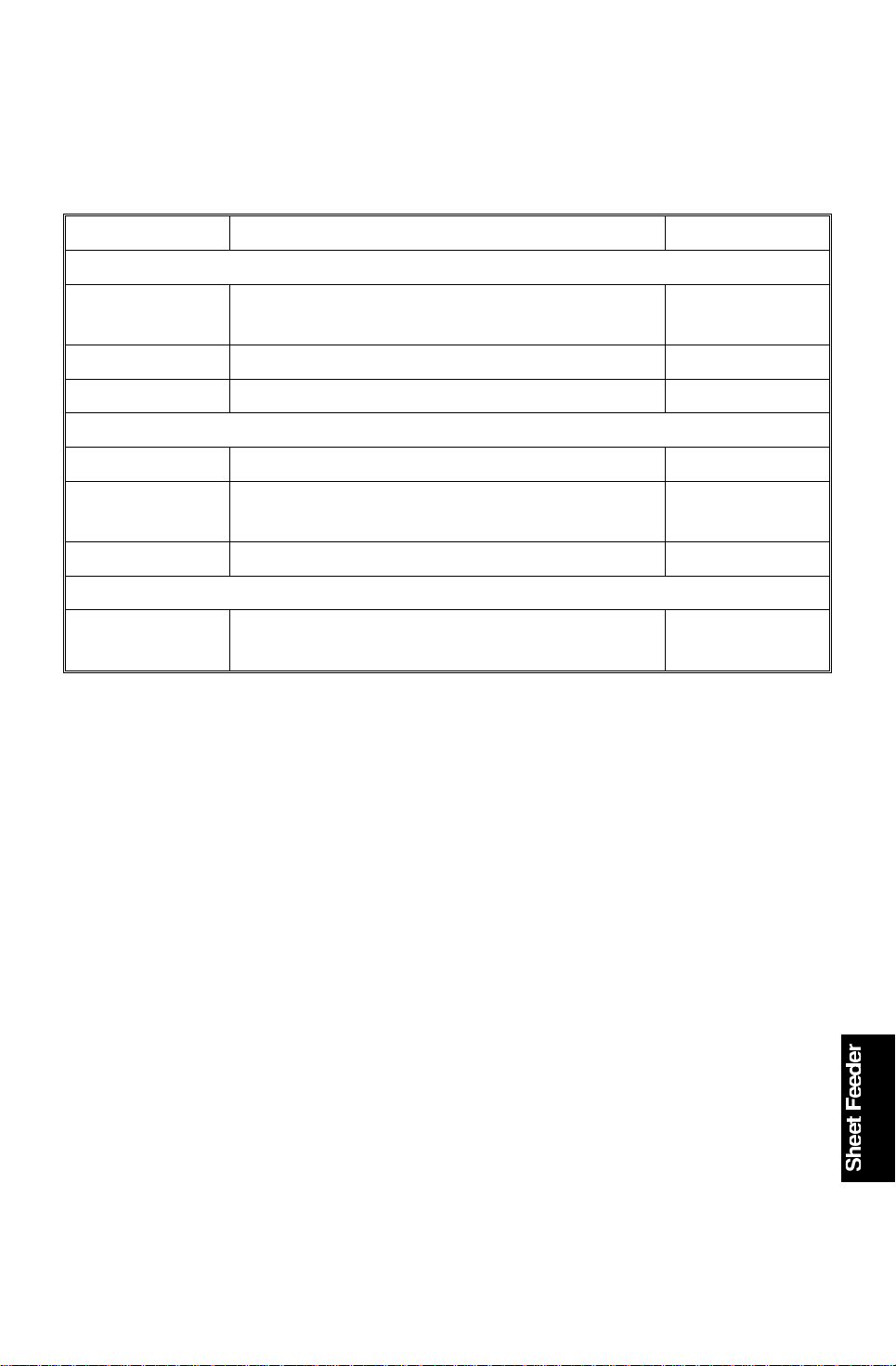

1.2 ELECTRICAL COMPO NENT DE SCRI P TI ONS

Refer to the electrical compone nt layou t on the reverse side of the Poin t to

Point (Water proof paper) ind ex nu mbe rs.

NAME FUNCTION Index No.

Solenoids

Sheet Feeder 1 Turns the paper feed roller of the sheet

feeder.

Sheet Feeder 2 Turns the relay rollers of the sheet feeder. 73

Sensors

Paper Entrance Dete cts misfeeds in the sheet feeder. 74

Paper End Detects when the she et fee de r ru ns ou t of

paper.

Switch

Feed Pressure Detects if the position of the feed pressure

lever is 3 or not.

72

75

76

3

BASIC OPERATION 31 December 1992

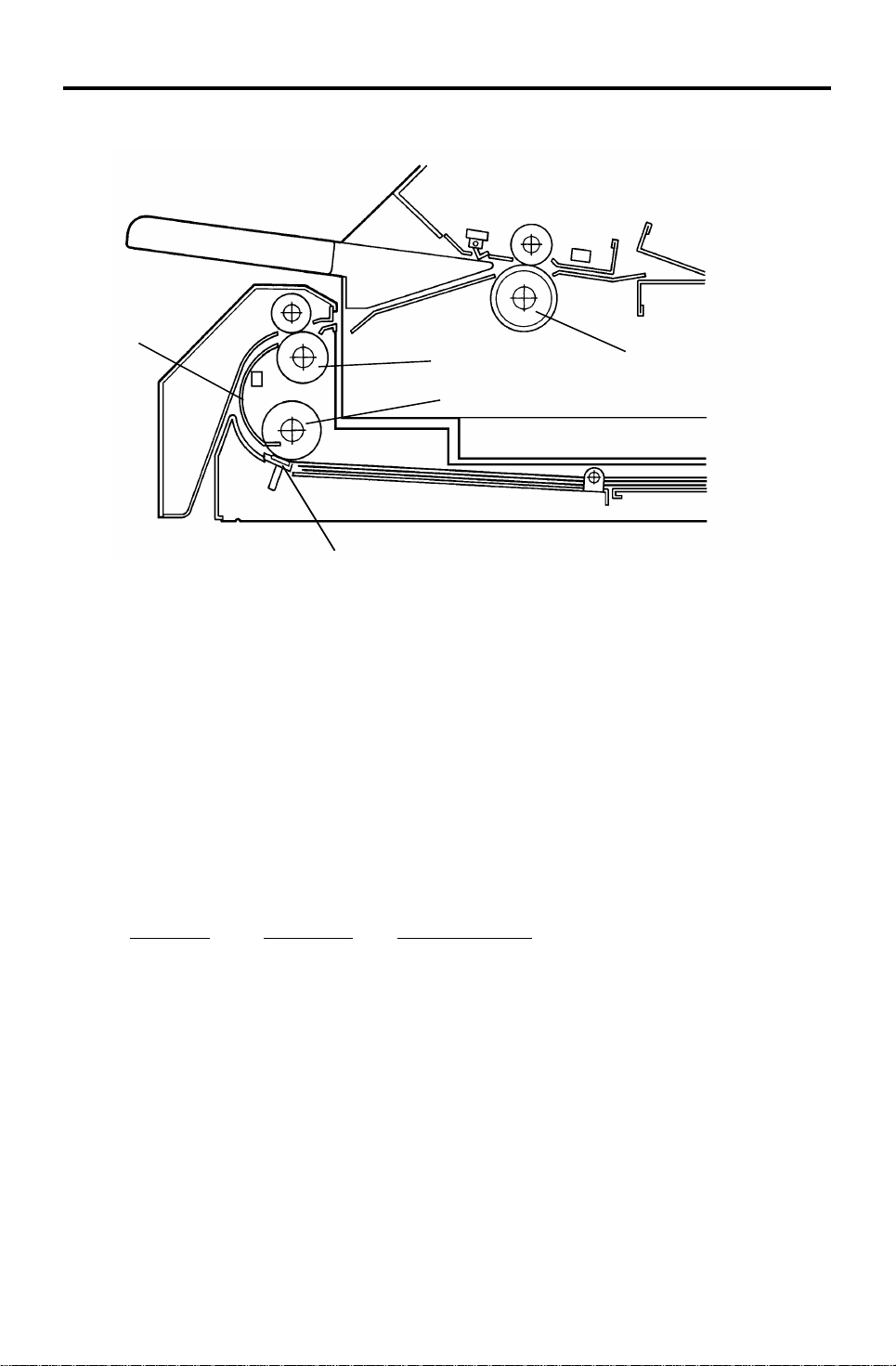

2. BASIC OPERATION

[D]

[B]

[A]

[C]

Sheet Feeder operation be gin s when an orig ina l is inserted into the original

entrance. At the appropriate timing , th e paper fee d roller [A] and the relay

rollers [B] start turning. The pape r fee d roller f eeds th e to p she et of pape r

past the friction pad [C] to the turn guides [D]. The relay rollers th en feed the

paper to the manual feed rollers [E]. From that point onwards the paper feed

continues in the same way as manu al fe ed .

This model uses the friction pad method for paper feeding. The pressure of

the friction pad must be greater for translucent paper than for bond paper.

The friction lever can be used to change the pressu re of the frictio n pad.

There are three settings.

[E]

Position Pressure Kind of Paper

1 standard Bond Paper

2 stronger Translucent Paper (A3, A4)

3 strongest Translucent Paper (A1, A2)

NOTE: When position 3 is selected, the copy paper feeding spe ed

becomes slower and paper/orig ina l re gist ration will not function

properly. To correct this, the CPU delays original feed and the

copying speed becomes ha lf (1/2) of the standard speed.

4

31 December 1992 BASIC OPERATION

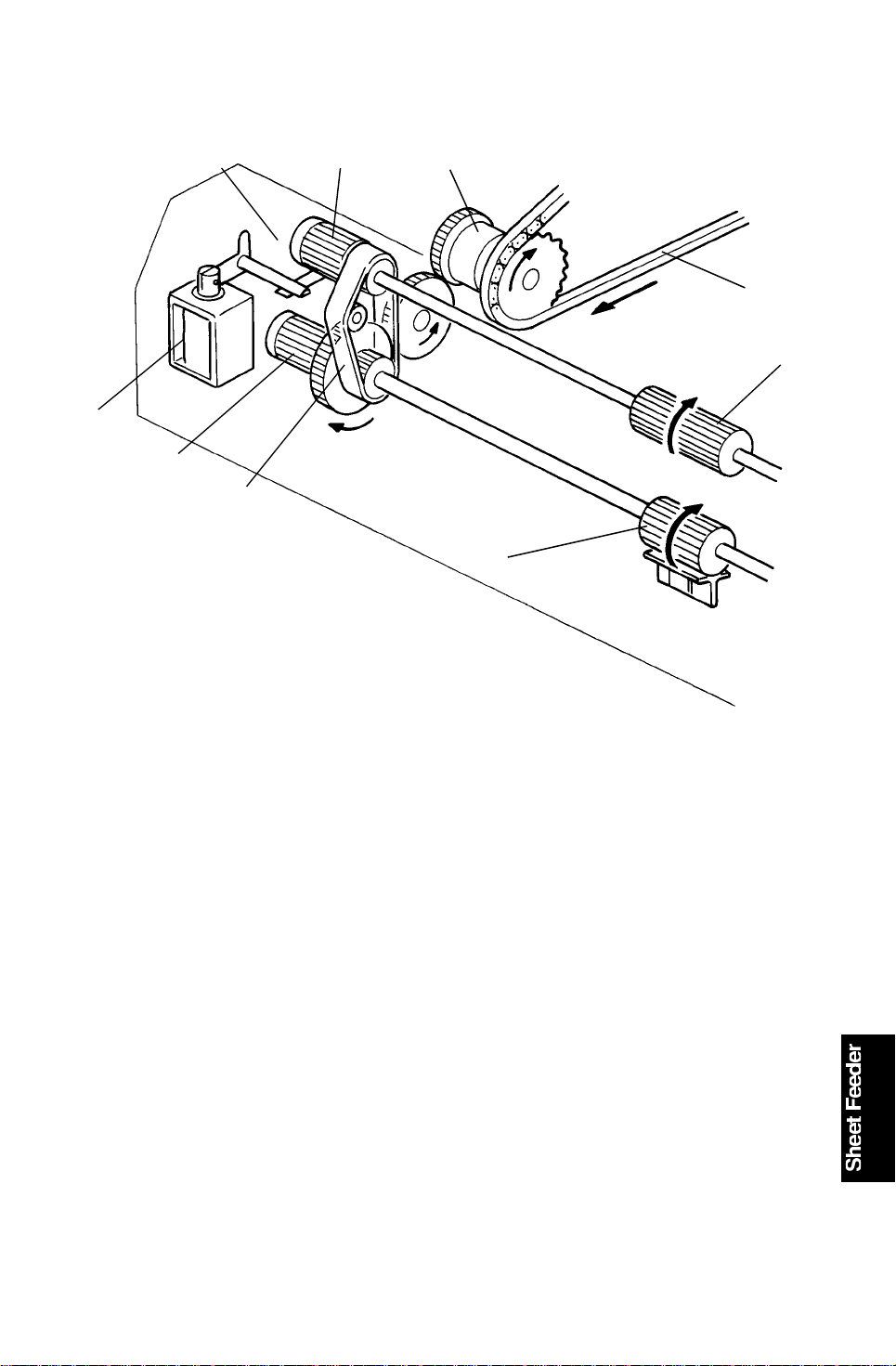

2.1 DRIVE MECHANISM

[G]

[E]

[D]

[C]

[H]

[B]

[A]

[F]

[I]

Constant drive is provided fro m the main mot or via the paper feed drive chain

[A], to the drive sprocket [B] , an d through gears to the feed drive belt [C].

Engaging and disengaging the sheet feeder solenoid 1 [D] allows the spring

clutch [E] to turn, thus driving the relay roller [F]. Engaging and disengaging

the sheet feeder sole noid 2 [G] allows the spring clutch [H] to turn , thus

driving the paper feed roller [I].

5

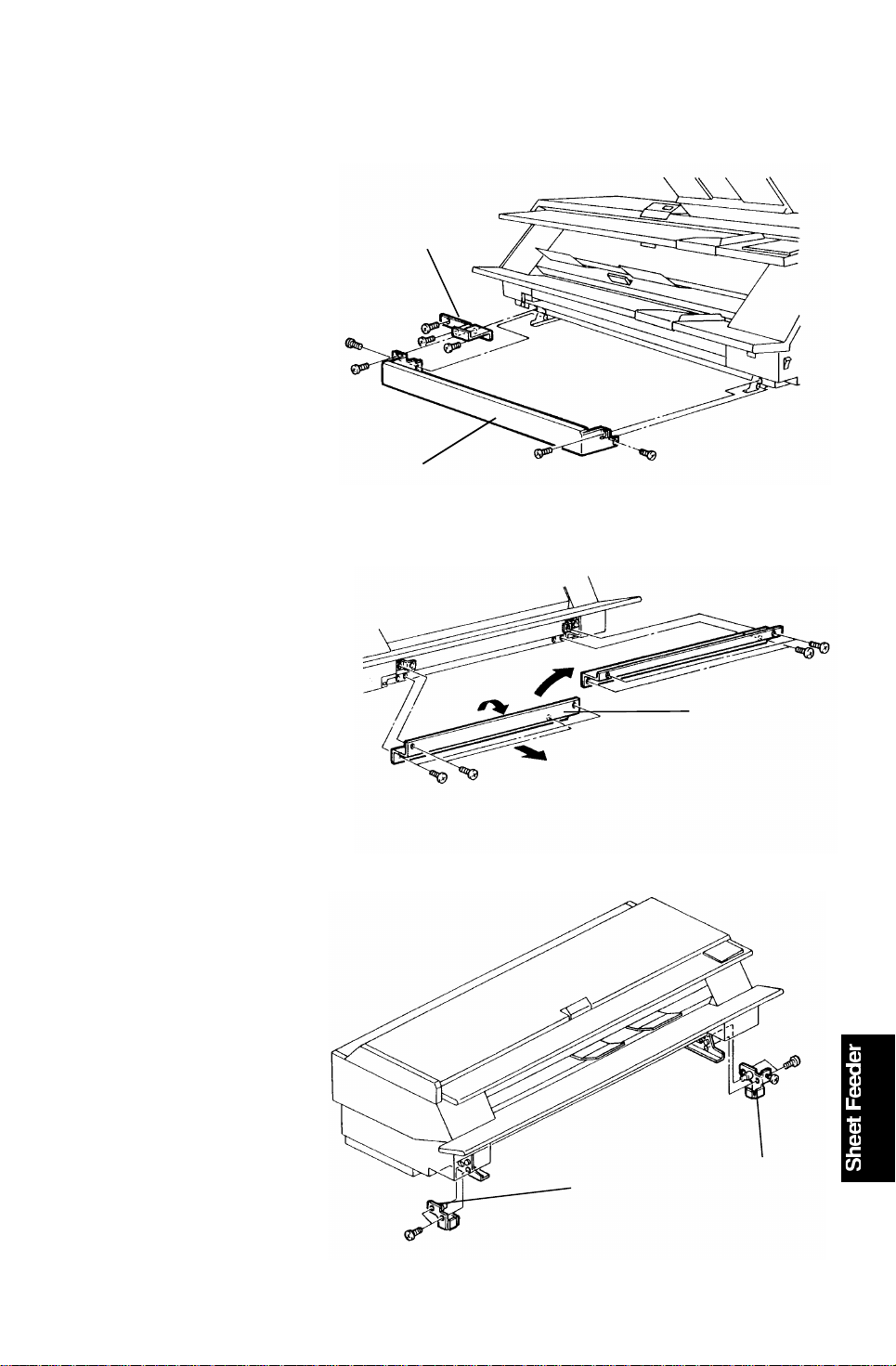

INSTALLATION PROCEDURE 31 December 1992

3. INSTALLATION PROCEDURE

3.1 ACCESSORY CHECK

Check the accessories and their q uant itie s according to the following list:

1. Right Feeder Stopper ............................................................. 1 pc

2. Left Feeder Stopper................................................................ 1 pc

3. Ground Wire............................................................................ 1 pc

4. Ground Wire Cover................................................................. 2 pcs

5. Right Rear Feeder Cover........................................................ 1 pc

6. Left Rear Feeder Cover........................ .. .. .. .. .. .. ................ .. .. .. 1 pc

7. Right Feeder Lock Bracket..................................................... 1 pc

8. Left Feeder Lock Bracket.... ............ ............ ............ ............ .... 1 pc

9. Safety Switch with Bracket ..................................................... 1 pc

10. Connector Socket wit h Bra cket... .. .. ................ .. .. .. .. .. .. ............ 1 pc

11. Shoulder Screw....................................................................... 1 pc

12. Pan Head Screw.....................................................................15 pcs

13. Harness Holder Bracket.......................................................... 2 pcs

14. Toothed Washer ..................................................................... 2 pcs

15. Cautio n Decal .. ....................................................................... 1 pc

CAUTION: Unplug the copier power cord before star ting the

following procedure.

6

[C]

31 December 1992 INSTALLATION PROCEDURE

3.2 INSTALLATION PROCE DURE

1. Remove the lower

front cover [A] (4

screws) and the

gear cover [B] (3

screws) from the

copier.

NOTE:

If the roll feeder has

been installed, then

these parts have

already been

removed.

2. Remove the front

lower plate [C] on

the copier (4

screws). Revolve

the plate 180

degrees and then

reinstall it in the

same position again.

[B]

[A]

3. Install the left and

right feeder lock

brackets [D, E] on

the front rail of the

copier. (2 screws

each)

[D]

7

[E]

Loading...

Loading...