SECTION 1

OVERALL MACHINE INFORMATION

6 January 1990

1. SPECIFICATIONS

Configuration: Table top

Copy Process: Electrostatic transfer system

Original Feed: Sheet feed

Original Size: Maximum: 914 x 3,600 mm

Minimum: 182 x 257 mm (B5 lengthwise)

Copy Size: Same as "Original Size"

Copying Speed: Manual feed: 5 cpm (A1/D sideways)

Tray feed: 6 cpm (A1/D sideways)

First Copy: 22 seconds (A1 sideways)

Warm-up Time: Within 7 minutes (Room temperature 20

Copy Counter: 1 to 9

o

C)

Automatic Reset: 2 minutes after copying is finished (can be set

to 1, 3, 4, or 5 minutes or to no auto reset)

Photoconductor: Organic photoconductor drum

Drum Charge: Single-wire with grid plate (Negative Charge)

Reproduction Ratio: 1 : 1 (

±0.5%)

Exposure System: Slit exposure via fiber optic array

Exposure Lamp: Fluorescent lamp (65 W)

Development: Dual-component dry toner system

Toner Replenishment: Cartridge system (750 g toner/cartridge)

Toner Consumption: 1,600 A1 or D copies per cartridge (7% original)

Development Bias: Negative

Toner Density Control: Pattern density detection by photosensor and

direct toner density detection by induction

sensor

Image Density Adjustment: Development bias control + exposure control +

grid voltage control

Auto Image Density

Development bias control and exposure control

Control:

1-1

6 January 1990

Image Transfer: Single wire dc corona (negative charge) with

pre-transfer lamp

Paper Separation: Dual wire ac corona and pick-off pawls

Cleaning: Cleaning blade

Quenching: Photo quenching by LEDs

Paper Feeding: Manual feed (auto sheet feeder optional)

Image Fusing: Heat and pressure type, teflon (upper) and

silicone rubber (lower) rollers

Fusing Lamp: Halogen lamp (115 V: 1,100 W, 220/240 V:

1,100 W)

Self-diagnostic Codes: 14 codes, displayed in copy counter

Power Source: 115 V/60 Hz....12 A

220 V/50 Hz....7 A

240 V/50 Hz....7 A

Power Consumption: Maximum: 1.4 kW

Warm-up: 1.2 kW

Ready: 0.1 to 1.2 kW

Copy cycle: 1.4 kW

Ozone Output: Less than 0.1 ppm (1000 ft

at least 3 times per hour)

Dimensions (W x D x H): 1,410 x 800 x 600 mm

55.51 x 31.50 x 23.62 in

Weight: 180 kg, 397 lb

Optional Equipment: ---- Automatic sheet feeder

---- Roll cutter

---- Paper spool

3

room, air turnover

1-2

2. OPERATOR CONTROLS

2.1 OPERATION PANEL

6 January 1990

9

8

7

6

5

4

10

11

12

13

14

15

16

3

17

2

18

1

19

26

25

24

1. Manual Image Density

Indicators

Show the image density level

selected by the Lighter and Darker

keys.

20

21

22

23

2. Lighter Copy Indicator

There are 14 manual ID levels but

only 7 manual ID LEDs. The Lighter

Copy indicator lights when manual

ID levels from 8 to 14 are selected.

1-3

6 January 1990

3. Wait Indicator

Indicates that the machine is not ready

to copy.

4. Select Paper Key

Press to select manual feed or the auto

sheet feeder.

5. Ready Indicator

Lights when the machine is ready to

make copies.

6. Auto Sheet Feed Indicator

Lights when the auto sheet feeder is

selected.

7. Manual Feed Indicator

Lights when the manual paper feed

mode is selected.

8. Add Paper Indicator

Lights when the auto sheet feeder runs

out of paper.

9. Add Toner Indicator

Lights when it is time to install a new

toner cartridge.

10. Original Misfeed Indicator

Lights if an original misfeeds within the

copier.

11. Misfeed Indicator

Lights if paper misfeeds within the

copier.

12. Close Unit Indicator

Indicates that one of the copier’s units

is open. The copier will not operate until

it is completely closed.

13. Toner Collection Bottle Indicator

Lights when it is time to empty the toner

collection bottle.

15. Copy Counter

Displays the number of copies entered,

the number of copies made, and

service codes.

16. Copy Exit Way Key

Selects either upper or lower copy exit.

17. Lead Edge Erase Indicators

Shows the width of the leading edge

erase margin.

18. Lead Edge Erase Key

Selects the amount of leading edge

erase.

19. Clear Modes Key

Press to clear the copier of previously

entered settings.

20. Clear/Stop Key

Press to cancel the copy number

entered. While copying, press to stop

copy operation.

21. Plus Key

Press to increase the number of copies

to be made. (The maximum repeat

copies is 9.)

22. Minus Key

Press to decrease the number of

copies to be made.

23. Auto Image Density Indicator

Lights when the copier is automatically

controlling the image density.

24. Auto Image Density Key

Press to enter and exit the auto image

density mode.

25. Darker Key

Press to make copies darker

14. Call Service Indicator

Indicates that there are functional

problems within the copier.

26. Lighter Key

Press to make copies lighter.

1-4

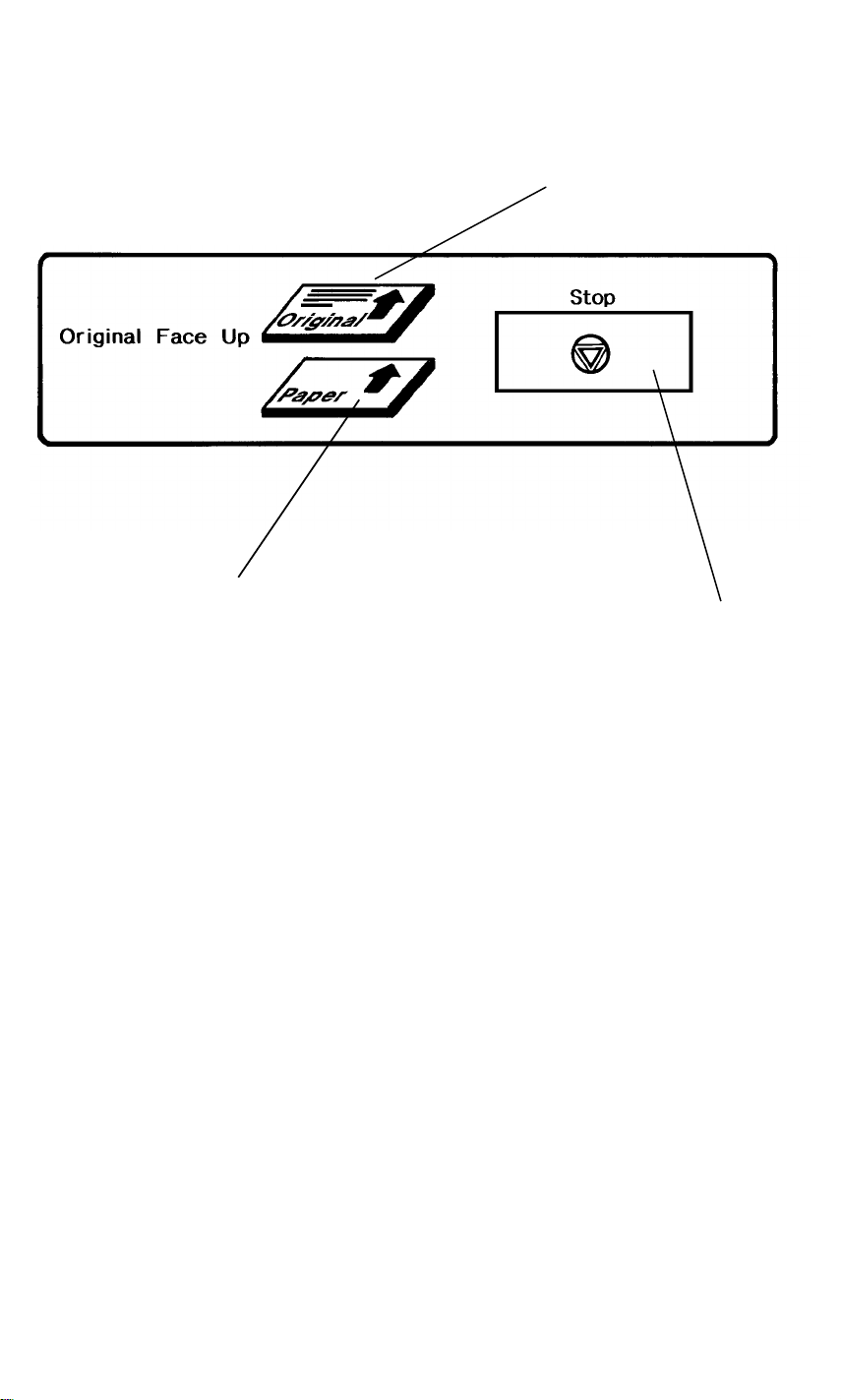

2.2 INDICATOR PANEL

6 January 1990

1

3

2

1. Insert Original Indicator

Lights when the machine is ready for an original to be inserted. Turns off

when an original is inserted.

2. Stop Key

Press to stop the copier during a copy cycle (emergency stop).

3. Insert Copy Paper Indicator

Lights when the machine is ready for a sheet of copy paper to be inserted.

Turns off when a sheet of copy paper is inserted.

1-5

6 January 1990

3. DRUM PROCESSES

12

8

3

7

4

5

6

1. Charge

In the dark the charge corona unit applies a negative charge to the drum.

The grid plate ensures the charge is applied uniformly. The charge remains

on the surface of the drum because the photoconductive drum has a high

electrical resistance in the dark.

2. Exposure

High intensity light from a fluorescent lamp is reflected from the moving

original through the fiber optic array. The charge on the drum surface is

dissipated in direct proportion to the intensity of the reflected light, thus

producing an electric latent image on the drum surface.

1-6

6 January 1990

3. Development

The magnetic developer brush on the development roller comes in contact

with the latent image on the drum surface. Toner particles are

electrostatically attracted to the negatively charged latent image areas.

4. Pre-Transfer Lamp

The pre-transfer lamp illuminates the drum prior to image transfer. This

reduces the attraction between the toner and the drum, thus making image

transfer easier.

5. Image Transfer

Copy paper is fed to the drum surface at the proper time to align the copy

paper and the developed image on the drum surface. Then a strong negative

charge is applied to the back side of the paper. The negative charge pulls

the toner particles from the drum surface onto the paper.

6. Paper Separation

A strong ac corona discharge is applied to the back side of the copy paper,

reducing the charge on the paper and breaking the electrostatic attraction

between the paper and the drum. Then, the stiffness of the copy paper

causes it to separate from the drum. The pick-off pawls help to separate

paper which has low stiffness.

7. Cleaning

The cleaning blade removes any toner remaining on the drum surface.

8. Quenching

The light from the quenching lamp electrically neutralizes the surface of the

drum.

1-7

6 January 1990

4. MECHANICAL COMPONENT LAYOUT

8

6

7

5

10

12

9

11

14

13

15

16

17

18

19

4

20

3

21

22

2

1

23

24

25

26

27

28

3940

1. 1st Feed Detector

2. 2nd Feed Detector

3. Toner Cartridge

4. 5th Press Roller

5. Original Recycle Gate

6. Original Set Detector

7. Front Original Feed Roller

8. 1st Press Rollers

9. Original Exit Detector

10. 1st Original Transport

Detector

11. Exposure Lamp

12. Platen Roller

13. Fiber Optic Array

14. Charge Corona Unit

38

36

34

37

15. 2nd Original Transport

Detector

16. Original Registration

Rollers

17. 4th Press Rollers

18. 2nd Press Rollers

19. Rear Original Feed Roller

20. 3rd Press Rollers

21. Quenching Lamp

22. Upper Exit Rollers

23. Upper Exit Sensor

24. Exit Rollers

25. Exit Gate

26. Exit Detector

27. Lower Exit Sensor

35

32

33

31

30

28. Hot Roller

29. Pressure Roller

30. Transport Belt

31. Transport Sensor

32. Cleaning Unit

33. Pick-off Pawls

34. OPC Drum

35. T/S Corona Unit

36. Paper Registration Rollers

37. Pre-Transfer Lamp

38. Registration Sensor

39. Development Unit

40. Manual Feed Rollers

29

1-8

5. DRIVE LAYOUT

6 January 1990

28

27

26

25

24

23

29

2

3

4

5

6

7

8

10

9

1

11

12

13

14

22

1. Original Drive Belt 2

2. Rear Original Feed Rollers

3. Original Drive Clutch

4. Main Drive Motor

5. Original Registration Rollers

6. Original Drive Belt 3

7. Platen Roller

8. Front Original Feed Rollers

9. Development Roller Gear

10. Auger Gear

21

19

11. Toner Supply Clutch

12. Development Motor

13. Paper Feed Clutch

14. Paper Feed Drive Chain

15. Development Drive Belt

16. Paddle Roller Gear

17. Registration Roller Clutch

18. Drum Drive Gear

19. Toner Collection Coil Gear

20. Feed/Fusing Drive Belt 2

1820

17

16

21. Fusing Drive Chain

22. Drum Drive Belt

23. Feed/Fusing Drive Belt 1

24. Transport Roller Sprocket

25. Hot Roller Sprocket

26. Lower Exit Roller Sprocket

27. Exit Roller Drive Chain

28. Upper Exit Roller Sprocket

29. Original Drive Belt 1

15

1-9

6 January 1990

6. ELECTRICAL COMPONENT LAYOUT

6.1 MIDDLE AND UPPER SECTIONS

1

43

7

5

3

4

2

6

8

10

9

11

12

14

13

16

15

17

18

19

20

42

40

39

41

37

38

36

35

34

33

32

31

1-10

30

29

28

27

26

25

21

22

23

24

6.2 LOWER AND FUSING SECTIONS

6 January 1990

44

65

45

46

47

48

49

50

51

52

53

54

55

56

57

64

63

62

1-11

61

60

59

58

6 January 1990

1. Development Motor

2. Development Motor

Capacitor

3. Charge/Bias PP

4. Lamp Regulator

5. Main Motor Capacitor

6. Light Sensor

7. Cooling Fan

8. Original Feed Clutch

9. Main Motor

10. Indicator Panel

11. 1st Original Transport

Detector

12. Original Registration

Sensor

13. 2nd Original

Transport Detector

14. Auto Density Sensor

15. Upper Exit Sensor

16. Exit Sensor

17. Lower Exit Sensor

18. Pattern Shutter SOL

19. Upper Safety Switch

20. Rear Safety Switch

21. Exit Gate SOL

22. Pulse Generator

23. Exhaust Fan

24. Toner Overflow

Sensor

25. Recycle Gate SOL

26. Main Board

27. Exposure Lamp

28. Recycle Gate

Detector

29. Operation Panel

30. Pre-Transfer Lamp

31. ID Sensor

32. Pick-off Pawl SOL

33. Registration Sensor

34. 2nd Feed Detector

35. 1st Feed Detector

36. Toner Density Sensor

37. Paper Stopper SOL

38. Original Exit Detector

39. Original Set Detector

40. Original Stopper SOL

41. Quenching Lamp

42. Toner Cover SW

43. Toner Supply SOL

44. Manual Feed SOL

45. Registration SOL

46. Fusing Lamp

47. Transfer/Separation

PP

48. DC Power Supply

49. Hot Roller Thermistor

50. AC Controller 2

51. AC Controller 1

52. Fusing Thermofuse

(x2)

53. Pressure Roller

Thermistor

54. Triac

55. Vacuum Fan

56. Circuit Breaker

57. Noise Filter

58. AC Terminal Block

59. Auto Feeder Safety

Switch

60. Main Switch

61. Total Counter

62. Lower Safety Switch

63. Vacuum Fan Motor

Capacitor

64. Transport Sensor

65. Anticondensation

Heater

1-12

6 January 1990

7. ELECTRICAL COMPONENT DESCRIPTIONS

SYMBOL NAME FUNCTION LOCATION

Motors

M1 Main Motor Drives all mechanical components

except the development unit and the

fans. (100 Vac)

M2 Development

Motor

M3 Exhaust Fan

Motor

M4 Cooling Fan Mo-

tor

M5 Vacuum Fan Provides suction so that paper is held

Magnetic Clutches

MC1 Original Feed

Clutch

MC2 Registration

Clutch

Solenoids

Drives the development unit. (100 Vac) 1

Removes heat from around the fusing

unit. (100 Vac)

Provides air flow to the optics cavity.

(100 Vac)

firmly on the transport belts and

rollers. (100 Vac)

Drives the original feed mechanism. 8

Drives the registration rollers. 45

9

23

7

55

SOL1 Toner Supply

Solenoid

SOL2 Pattern Shutter

Solenoid

SOL3 Exit Gate Sole-

noid

SOL4 Pick-off Pawl

Solenoid

SOL6 Paper Stopper

Solenoid

SOL7 Manual Feed

Solenoid

SOL8 Recycle Gate

Solenoid

Turns on to supply toner to the

development unit.

On ID check cycles, this solenoid

turns on to move the pattern plate into

the light path.

Controls the position of the exit gate.

(When ON, the paper exits downward;

when OFF, the paper exits upward.)

Moves the pick-off pawls against the

drum.

Moves the paper stopper down to

prevent paper from being inserted.

Turns ON to engage the manual feed

clutch.

Controls the position of the recycle

gate. (ON = recycle gate in down

position,

OFF = recycle gate in up position.)

1-13

43

18

21

32

37

44

19

6 January 1990

SYMBOL NAME FUNCTION LOCATION

SOL9 Original Stopper

Solenoid

SOL10 Auto Feeder So-

lenoid 1

SOL11 Auto Feeder So-

lenoid 2

Moves the original stopper down to

prevent an original from being inserted.

Turns the paper feed roller of the auto

sheet feeder.

turns the relay rollers of the auto sheet

feeder.

40

----

----

Switches

SW1 Main Switch Supplies power to the copier. 60

SW2 Upper Safety

Switch

SW3 Lower Safety

Switch

SW4 Rear Safety

Switch

SW5 Toner Cover

Switch

Cuts ac 100 volt power when the

upper unit is opened.

Cuts ac 100 volt power when the

middle unit is opened.

Cuts ac 100 volt power when the

paper exit unit is opened.

Cuts power to the toner supply

solenoid and the main motor when the

25

62

20

42

toner cartridge cover is opened.

SW6 Auto Feeder

Safety Switch

Prevents main motor operation when

the auto feeder is not set.

59

Sensors and Detectors

S1 Image Density

Sensor

S2 Toner Density

Sensor

S3 Toner Overflow

Sensor

S4 Pulse Generator Supplies timing pulses to the main

Detects the image density of the test

pattern on the drum.

Detects the density of toner in the

developer.

Detects when the used toner tank is

full.

31

36

24

22

board (photointerrupter).

S5 Original Set De-

Detects when an original is inserted. 39

tector

S6 1st Original

Monitors movement of the original. 11

Transport

Detector

S7 2nd Original

Monitors movement of the original. 13

Transport

Detector

S8 Original Regis-

tration Sensor

SYMBOL NAME FUNCTION LOCATION

Detects when the original lead edge

passes the original registration rollers.

12

S9

1-14

6 January 1990

Original Exit De-

Monitors movement of the original. 38

tector

S10 Recycle Gate

Detector

S11 1st Feed

Detects whether the recycle gate is in

the up or down position.

Detects when copy paper is inserted. 35

Detector

S12 2nd Feed

Detector

Monitors copy paper movement

between the manual feed rollers and

the registration rollers.

S13 Registration

Sensor

S14 Transport

Sensor

Detects when copy paper arrives at

the registration rollers.

Monitors paper movement between

the transfer/separation section and the

fusing unit.

S15 Exit Detector Monitors copy paper movement

through the exit unit.

S16 Upper Exit

Sensor

S17 Lower Exit

Sensor

S18 Auto Sheet

Feeder Sensor

Monitors copy paper movement

through the upper exit guides.

Monitors copy paper movement

through the lower exit guides.

Detects misfeeds in the auto sheet

feeder.

28

34

33

64

16

15

17

----

S19 Paper End De-

tector

Detects when the auto sheet feeder

runs out of paper.

Printed Circuit Boards

PCB1 Main Board Controls all copier functions both

directly and through other PCBs.

PCB2 DC Power

Supply

Provides dc power for all components

of the machine.

PCB3 AC Controller 1 Provides ac power to the fusing lamp

and triac.

PCB4 Lamp Regulator Provides power to the exposure lamp. 4

PCB5 AC Controller 2 Provides ac power to the main motor

and development motor.

PCB6 Indicator Panel Contains the paper and original

insertion indicators and the original

feed stop key.

PCB7 Operation Panel Contains the operator controls and

indicators.

----

26

48

51

50

10

29

1-15

6 January 1990

SYMBOL NAME FUNCTION LOCATION

Lamps

L1 Exposure Lamp Provides light to reflect the original’s

27

image onto the drum.

L2 Quenching

Lamp

Neutralizes any charge remaining on

the drum surface after cleaning.

41

L3 Fusing Lamp Provides heat to the fusing unit. 46

L4 Pre-Transfer

Lamp (PTL)

Reduces the charge on the drum

surface prior to image transfer.

30

Power Packs

P1 Charge/Bias

Power Pack

Provides high voltage power for the

charge corona, charge grid, and

3

development bias.

P2 Transfer/Sepa-

ration Power

Pack

Provides high voltage power for the

transfer corona and separation

coronas.

47

Thermistors

TH1 Hot Roller

Thermistor

TH2 Pressure Roller

Thermistor

Monitors the hot roller’s surface

temperature.

Monitors the pressure roller’s surface

temperature.

49

53

TH3 Exposure Lamp

Thermistor

Monitors the fluorescent lamp’s

temperature.

----

Thermofuses

TF1 Fusing

Thermofuse

TF2 Exposure Lamp

Thermofuse

Protects against fusing overheat. (Two

thermofuses in parallel.)

Protects against exposure lamp

overheat.

52

27

Heaters

H1 Lamp Heater Warms the scanning lamp. ---H2 Anticondensa-

tion Heater

Keeps moisture from forming inside

the copier.

65

1-16

6 January 1990

SYMBOL NAME FUNCTION LOCATION

Others

CO1 Total Counter Keeps track of the total length of

61

copies made.

NF Noise Filter Filters electrical noise on the ac power

57

input lines.

TR Transformer Steps down the line voltage to 100

----

Vac.

TR Triac Provides ac power to the fusing lamp. 54

1-17

6 January 1990

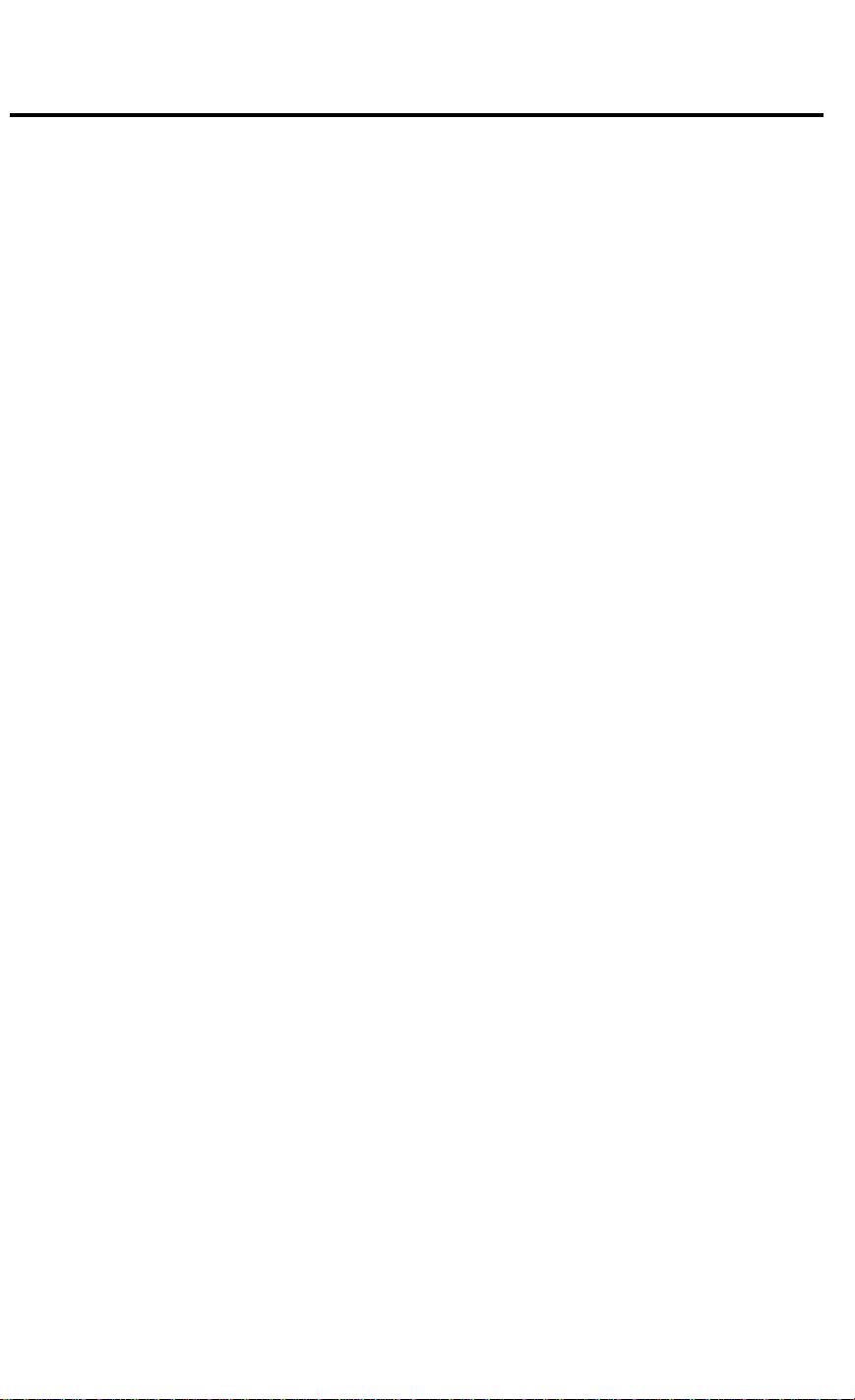

8. AC POWER DISTRIBUTION

Interlock Switches

SW3 SW4 SW2

Hot

C.B

Main Switch

(SW1)

Neutral

T304

N. F

T306

T307

T305

AC

Controller 1

(PCB3)

Thermofuse(x2)

T309 T1

T310 G

T308

Fusing Lamp(L3)

T2

CN3

-4

-5

Triac

Lamp

Regulator

(PCB4)

Exposure Lamp(L1)

Trans-

fomer

Anticondensation Heater

Exhaust

Fan

M3

Cooling

Fan

CN1

-1

M4

-2

CN3

-1

-2

Vacuum

Fan

Main

Motor

Develop-

ment

Motor

M1

M2

CN402

-1

-2

CN404

-1

-2

AC Controller 2(PCB5)

1-18

M5

CN401-1

CN401-2

6 January 1990

The preceding schematic shows how ac power is distributed in this machine.

The ac power from the wall outlet passes through the noise filter, circuit

breaker, and three interlock switches to the transformer and to ac controller

1.

AC controller 1 powers the fusing lamp with direct wall outlet ac power.

The main board controls the fusing lamp through the triac.

The transformer steps the ac power down to 100 volts and then provides it to

the main switch. If the main switch is off, power is applied only to the

anticondensation heater. If it is on, at 100 volts goes to the fan motors, ac

controller 2, and the lamp regulator.

AC controller 2 provides ac 100 volts power to the main motor and

development motor. RA401/402 turn the motors on and off.

1-19

6 January 1990

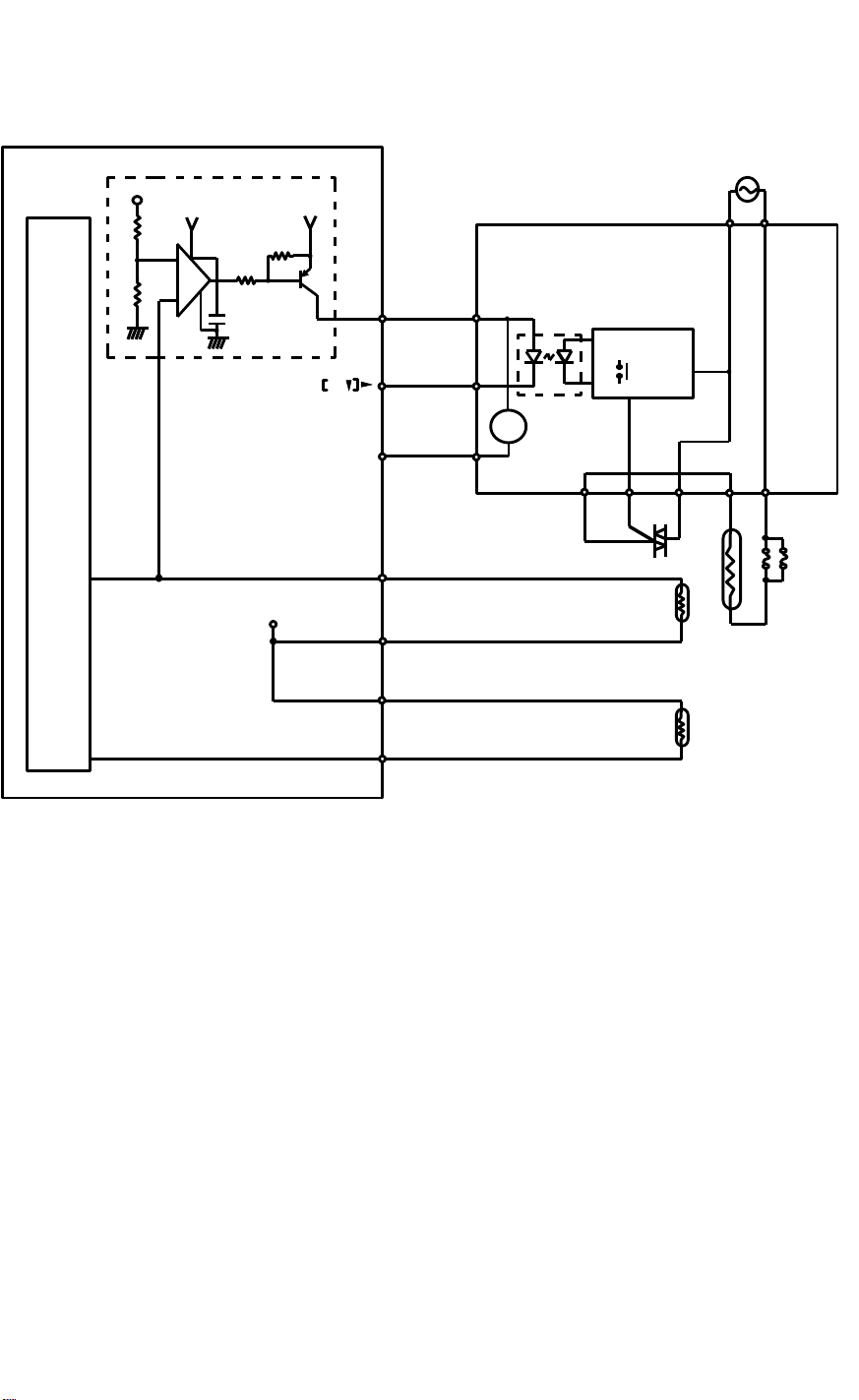

9. DC POWER SUPPLY

FU1

CN1-1

AC LINE

5A

ZNR

CN2-1

S

W

I

C

H

I

N

G

Vcc

C. GND

CN2-2

DC5V

C

O

N

T

CN1-3

AC NEUTRAL

R

O

L

FG

Vaa

FU2

8A

Above is a simplified schematic of the dc power supply.

The dc power supply provides +5 volts (Vc) and +24 volts (Va) from CN2-2

and CN2-7 respectively to the main board. Also +24 volts (Va) is provided to

the charge/bias power pack from CN2-6 and to the transfer/separation power

pack from CN2-8.

CN2-3,4,5

A. GND

CN2-6,7,8

DC24V

1-20

SECTION 2

DETAILED SECTION DESCRIPTIONS

6 January 1990

1. DRUM

1.1 DRUM CHARACTERISTICS

The organic photoconductor (OPC) drum has the following characteristics:

• It is able to accept a high negative electrical charge in the dark. (The elec-

trical resistance of the OPC drum is high in the absence of light.)

• The electric charge on the drum surface dissipates when the drum is ex-

posed to light. (The conductivity of the OPC drum is greatly enhanced by

exposure to light.)

• Dissipating an amount of charge in direct proportion to the intensity of the

light. That is, where stronger light is directed to the photoconductor surface, a smaller voltage remains on the selenium.

The OPC drum used in this model has high sensitivity, good color

reproduction, and good reproduction of low contrast originals (pencil originals,

etc.)

1.2 HANDLING THE DRUM

The organic photoconductor drum is very sensitive to light, temperature, and

corrosive gases. Please observe the following cautions when handling the

OPC drum.

1. Never expose the drum to sunlight.

2. Never expose the drum to light of more than 1000 Lux for more than a

minute.

3. Never touch the drum surface with bare hands. When the drum surface is

touched with bare hands or becomes dirty, wipe with a dry cloth or clean

with wet cotton. Wipe with a dry cloth after cleaning with wet cotton.

4. Never use alcohol when cleaning the drum. (Alcohol tends to dissolve the

OPC layer.)

5. Store the drum in a cool, dry place away from heat.

6. Take care not to scratch the drum as the OPC layer is thin and easily

damaged.

7. Never expose the drum to corrosive gases such as ammonia gas.

2-1

6 January 1990

1.3 DRUM DRIVE

[F]

[B]

[E]

[D]

[C]

[G]

[J]

[H]

[I]

[A]

The OPC drum [A] is 80 millimeters in diameter and 970 millimeters long. It

turns constantly when the main motor [B] is on.

When the main motor turns on, drive is transmitted to the drum as follows:

main motor drive gear [C] ⇒ idle gear [D] ⇒ main drive pulley gear [E] ⇒ drum

drive belt [F] ⇒ drum drive gear [G] ⇒ drum flange [H] ⇒ drum

When the drum knob [I] is tightened, the right flange [J] presses firmly against

the drum so that the drum is held tightly between the flanges. The drum and

flanges turn together when the main motor is on.

2-2

2. CHARGE

2.1 OVERVIEW

6 January 1990

P1

[A]

[B]

Charge

P1

Grid

This model uses a single wire corona unit [A] to charge the OPC (organic

photoconductor) drum [B]. The corona wire generates a corona of negative

ions when a high negative voltage is applied to it by the charge/grid power

pack [P1].

To make the negative corona uniform, a grid consisting of 8 wires is installed

on the charge corona unit between the corona wire and the drum. This grid

drains off any charge in excess of --940 volts, thus preventing fluctuation of

the charge potential.

2-3

6 January 1990

2.2 CHARGE CORONA CIRCUIT

Charge / Bias PP

DC/DC

Converter

DC/DC

Converter

CN1-1

CN1-2

CN1-3

CN1-6

CN1-10

CN2

-6

CN107

-B14

CN110

-1

-8

DC Power

24V Va

GND

Main Board

24

Charge

Grid Drive

0/5

Grid monitor

0

2.5

The main power supply board supplies +24 volts (Va) to the charge/bias

power pack as the power supply source. About 8 seconds after the Start key

is pressed, the CPU drops CN107-B14 from +24 volts to 0 volt. This actuates

the dc/dc converter within the power pack which applies a high negative

voltage of approximately --5.3 kV to the charge corona wire. The corona wire

then generates a negative corona charge.

The grid limits the maximum corona charge to --940 volts. This ensures that

the charge does not fluctuate and an even charge is applied to the drum

surface. When developing the test pattern for the image density sensor, the

grid charge is --460 volts.

The copy grid voltage, and ID sensor grid voltage amounts can be adjusted

using service program modes #23 and #22, respectively.

The grid drive signal applied to CN1-6 is a pulse width modulated signal. As

the width of the pulses applied increases, the strength of the grid charge also

increases. The main board monitors the grid charge at CN110-8 and controls

the width of the drive pulses based on this feedback.

2-4

3. EXPOSURE

3.1 OVERVIEW

[A]

6 January 1990

[D]

[F]

[E]

[B]

Light from the exposure lamp [A] reflects off the original and through the fiber

optics [B] to the OPC drum [C]. During exposure, the original moves across

the exposure glass at the same speed as the drum’s peripheral velocity.

The platen roller [D] presses the original [E] flat against the exposure glass [F]

just above the fiber optic array. This ensures that the image is properly

focused. (The original must be within 0.2 mm of the exposure glass surface.)

The exposure lamp is a 100 V, 65 W fluorescent lamp. This lamp has a heater

which prevents a reduction in light output due to low temperatures. The heater

maintains the lamp’s temperature at 40oC

[C]

2-5

6 January 1990

3.2 ORIGINAL FEED

3.2.1 Basic Operation

[G]

[F]

[I]

[B]

[A]

[C]

[H]

[L]

[J]

[K]

[E]

When the original is inserted on the original table [A], it activates the original

set detector [B]. The main motor then turns on. Two seconds later the original

feed clutch turns on to start turning the front original feed rollers [C], rear

original feed rollers [D], and original registration rollers [E]. The two second

delay allows time for the operator to align the lead edge of the original against

the first set of rollers to prevent skew.

[D]

The original is fed past the 1st and 2nd original transport detectors [F,G] and

around the rear original feed rollers to the original registration rollers. The

original feed clutch turns off 0.2 second after the original’s leading edge

activates the original registration sensor [H]. The original remains at this

position until a sheet of copy paper is fed.

Just before the copy paper reaches the registration sensor, the original feed

clutch turns on again and original feed resumes. The original passes between

the platen roller [I] and the exposure glass [J] and from there to the front

original feed rollers. The original’s image density is measured by the ADS at

this time. The original’s image is reflected through the fiber optic array to the

drum as it passes between the platen roller and the exposure glass.

If making a single copy, the original then exits the machine. However, if

making repeat copies, the recycle gate [L] directs the original around the front

original rollers to the upper part of the original transport mechanism. The

original transport cycle then repeats.

The maximum original length for repeat copying is 610 millimeters. If the

operator attempts repeat copying with an original longer than 610 millimeters,

it will automatically feed out after making a single copy.

2-6

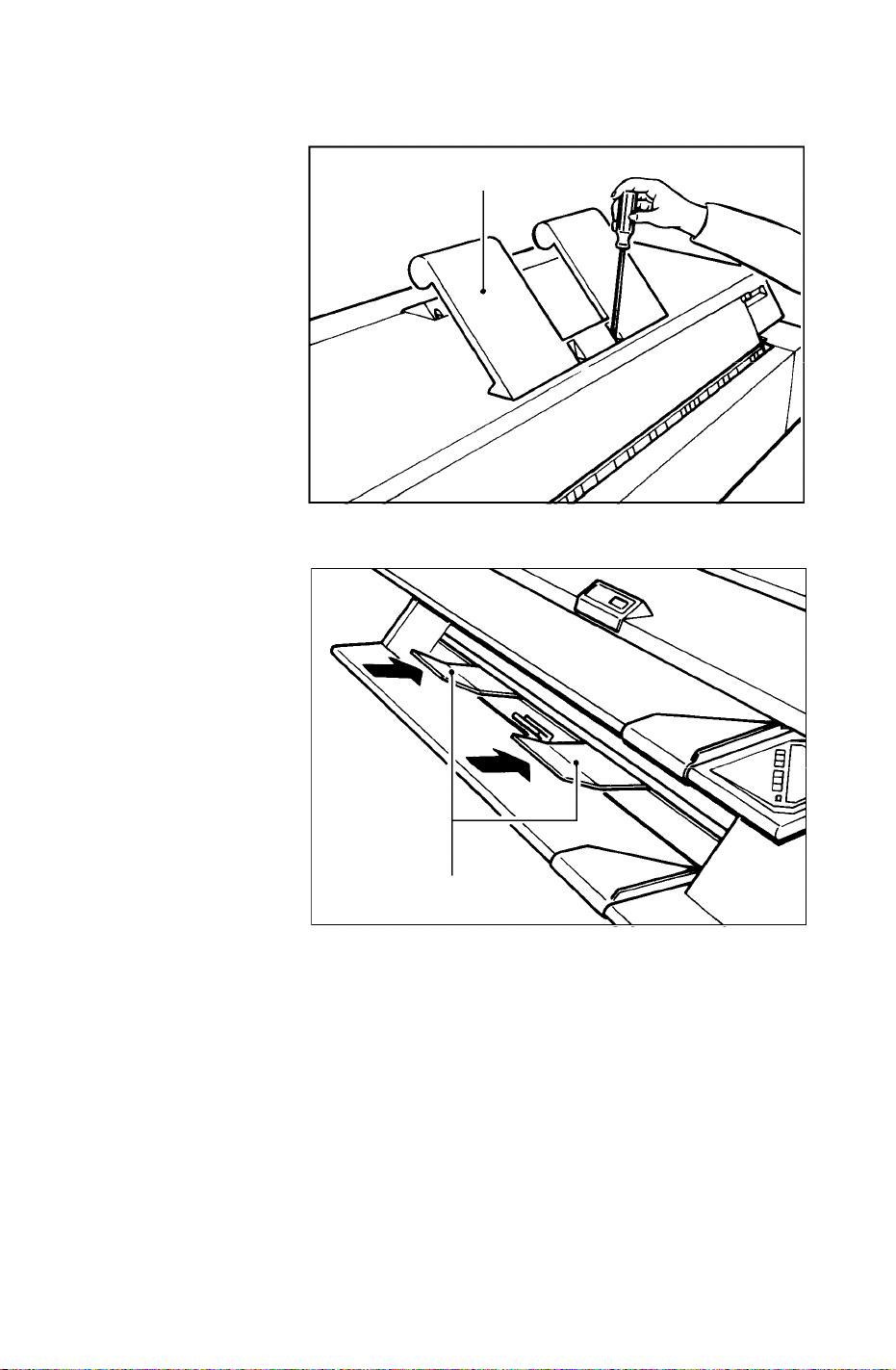

3.2.2 Drive Mechanism

[A]

6 January 1990

[B]

[C]

Drive power from the main motor is provided to the original transport

mechanism from the original drive pulley through original drive belt 2 [A].

When the original drive clutch [B] is energized, original drive belt 3 [C] starts

turning the front original feed rollers and the original registration rollers. The

rear original feed rollers are driven directly by the original drive clutch.

2-7

6 January 1990

3.3 ORIGINAL STOPPER MECHANISM

[A]

[B]

Originals should not be inserted during a copy cycle. To prevent originals from

being inserted, the machine locks the feeler of the original set detector in the

down position while copying. This is accomplished by the original stopper

solenoid [A].

When the original stopper solenoid turns on, the stopper arm [B] rotates

against the feeler of the original set sensor. This locks the feeler in the down

position so that originals can only be inserted as far as the original set sensor.

2-8

3.4 EXPOSURE LAMP CONTROL

[PCB4]

6 January 1990

+5V

PWM

CN1-1

CN1-2

CN2-1

CN2-2

CN2-2

LAMP

REGULATOR

T

CN3-1

CN3-2

CN3-4

CN3-5

Lamp OFF (+5V)

Lamp ON (GND)

T = 1.0 ms

Duty = 15% to 100%

[L1]

Exp. Lamp

The lamp regulator receives 100 volts ac at CN1-1 and CN1-2. It also

receives +5 volts, which is used in the lamp regulator’s control circuit, from the

main board at CN2-1. The control signal, which is a pulse width modulated

(PWM) signal, is received at CN2-2. The PWM signal has a period (T) of 1

millisecond and a duty of 15% to 100%.

The basic light intensity level is determined either by the image density

selected from the operation panel (manual ID control) or by the original’s

background level as sensed by the ADS. The CPU uses the light sensor to

monitor the actual light intensity. The light sensor directly senses the lamp’s

light output and feeds a light intensity signal back to the main board. This

feedback allows the CPU to compensate for variations in light intensity due to

the lamp’s age or temperature.

2-9

6 January 1990

3.5 MANUAL ID CONTROL VS ADS

1.4

Light

Sensor

Output

(Volts)

1.2

1.0

0.8

0.6

1 2

3 4

6

5

7

9 10 11

8

12

13

14

Manual ID Level

Darker Lighter

3.5.1 Manual ID Control

When in manual image density mode, the user can select one of 14 manual

ID levels. For each level, the intensity of the light output by the exposure lamp

(as measured by the light sensor) is fixed. This is shown in the above graph.

For manual ID levels 2 through 7, the development roller bias also varies.

(See the section on development bias.)

2-10

Vod/Vsd VS [V]

0 ∼ 0.18 0.86

0.19 ∼ 0.46 1.74

0.47 ∼ 0.49 1.64

0.50 ∼ 0.53 1.54

0.54 ∼ 0.57 1.45

0.58 ∼ 0.61 1.37

0.62 ∼ 0.65 1.29

0.66 ∼ 0.69 1.21

0.70 ∼ 0.73 1.15

0.74 ∼ 0.77 1.05

0.78 ∼ 0.85 0.94

6 January 1990

0.86 ∼ 0.86

VS: Light Sensor Voltage

VOD: Original Density Detecting Voltage

VSD: Standard Pattern (White Plate) Density Detecting Voltage

3.5.2 ADS Control

When automatic image density sensing (ADS) is used, the exposure light

intensity varies depending on the background image density of the original.

The preceding table shows how the exposure light intensity changes

depending on the VOD/VSD ratio.

Use service program mode #10 to select the default ID setting. It can be set to

ADS or Manual ID level 4. The factory setting is ADS.

NOTE: If the exposure lamp cannot output sufficient light, service call

condition "E1" exists. However, copying is still possible. Refer to the

"SERVICE CALL CONDITIONS" table.

2-11

6 January 1990

3.6 AUTO DENSITY SENSOR (ADS)

[A]

Center Line

10mm

Sampled Area

33.5 mm

18 mm

The ADS [A] measures the reflectivity of the original’s background. Based on

the originals background image density, the CPU automatically adjusts the

development bias and exposure light intensity to achieve a good copy image.

The ADS is located at the original registration rollers. It reads the white plate

(standard white), which is located above the ADS, prior to the arrival of the

original. This standard white level (VSD) is used for comparison with the

background level of the original (VOD).

The ADS samples a 43.5 mm by 10 mm area near the leading edge of the

original. As shown in the above illustration, sampling starts 15 mm from the

leading edge.

The highest voltage detected by the ADS is held (peak hold) and used for the

exposure voltage adjustment.

2-12

3.6.1 ADS Circuit

6 January 1990

R404

PD-

401

6

5

LAMP401

IC401

D401

7

C404

C403

2

3

R403

R401

IC401

CN401-1

8

1

4

C401

R402

C402

CN401-3

CN401-5

CN401-2

CN401-4

CN401-6

CN401-7

Vcc(+5V)

ADS:OUT

ADS ADJUST

C-GND

ADS RESET

Vcc(+5V)

SENSOR LAMP

The ADS circuit is powered by +5 volts, which is provided at CN401-1 for the

detection circuit and CN401-6 for the lamp. The CPU resets the ADS by

dropping CN401-4 to 0 volt; this discharges C403 to reset the peak hold

function. The resistance of PD401 varies with the strength of the light striking

it. The two op-amps amplify the effect of the change in PD401 and output the

ADS signal at CN401-3.

2-13

6 January 1990

3.7 LAMP HEATER

[A]

[B]

This copier uses a fluorescent lamp [A] as the exposure light source. The

output of the exposure lamp varies depending on the temperature; low

temperatures especially degrade the light output. To prevent fluctuations in

temperature from affecting the copy image, the lamp heater [B] keeps the

lamp’s temperature at 40°C.

2-14

3.8 LAMP HEATER CONTROL CIRCUIT

6 January 1990

AC 100 V

PCB1

L. Heater ON

TH3

Short

TH3

Input

TH3

Open

Va2424

00/5

GND

00/5

00/5

PCB5

CN107

-A2

-B2

-A1

5Vc

-B3

-A3

-B1

-B4

CN407

-2

-1

CN408

-3

-2

-1

-5

-4

+

SSR

401

Comparator

Circuit

CN401

-2

~

~

-1

CN406-1

H1

CN406-2

CN407-4

TH3

CN407-3

The lamp thermistor, which is mounted together with the lamp heater,

monitors the lamp temperature. Based on the input from this thermistor at

CN107-B1, the CPU on the main board determines whether or not to turn on

the lamp heater. To turn on the lamp heater, the main board drops CN107-B2

to 0 volts. This turns on SSR401 on ac controller 2, which provides ac power

to the heater.

If the exposure lamp thermistor short circuits, the comparator circuit drops

CN107-B3 to LOW. The copier then stops operation, the Call Service

Indicator (wrench mark) lights, and "E" and "8" are alternately displayed in the

Copy Counter.

If there exposure lamp thermistor circuit becomes open, the comparator circuit

changes CN107-B4 from LOW to a 5 volt pulses. The copier then stops

operation, the Call Service Indicator (wrench mark) lights, and "E" and "7" are

alternately displayed in the Copy Counter.

2-15

6 January 1990

4. DEVELOPMENT

4.1 OVERVIEW

[C]

[A]

When the main motor turns on, the paddle roller [A] and development roller

[B] start turning. The paddle roller picks up developer in its paddles and

transports it to the development roller. Internal permanent magnets in the

development roller attract the developer to the development roller sleeve.

The turning sleeve of the development roller then carries the developer past

the doctor blade [C]. The doctor blade trims the developer to the desired

thickness and creates backspill to the cross-mixing mechanism.

[B]

The development roller continues to turn, carrying the developer to the

selenium drum. When the developer brush contacts the drum surface, the

negatively charged areas of the drum surface attracts and holds the positively

charged toner. In this way, the latent image is developed.

Negative bias is applied to the development roller to prevent toner from being

attracted to non-image areas on the drum that may have residual positive

charge. The bias also controls image density.

After turning about 100 degrees more, the development roller releases the

developer into the developer tank. The developer is agitated by the paddle

roller and the cross-mixing mechanism.

Also, in this machine, rotation of the paddle roller and development roller tend

to cause air pressure inside the unit to become higher than the air pressure

around the development unit. Therefore, a hole fitted with a filter, has been

added to the top of the unit to relieve air pressure and to minimize toner

scattering.

2-16

4.2 DRIVE MECHANISM

6 January 1990

[D]

[C]

[F]

[G]

[H]

[B]

[I]

[E]

[A]

To reduce load on the main motor, the development unit uses a separate

drive motor [A]. The development drive pulley turns the development drive

belt [B] which turns the development drive gear [C]. The development drive

gear turns the development roller gear [D] and the paddle roller gear [E]. The

auger gear [F] is engaged with the paddle roller gear. Thus, the development

roller, paddle roller, and auger all turn when the development drive motor is

on.

The toner agitator gear [H] is also turned by an idle gear [G], which is

engaged with the auger gear. However the toner agitator does not turn unless

the toner supply clutch [I] is engaged. It engages when the toner supply

solenoid turns on.

2-17

6 January 1990

4.3 CROSS MIXING

[C]

[B]

[E]

[F]

[A]

[D]

"Crossmixing" keeps the toner and carrier evenly mixed in the developer and

evenly distributes the developer within the development unit. Crossmixing

also agitates the developer to generate the necessary triboelectric charge on

the toner and carrier particles.

The arrows in the above illustration show the developer movement directions

within the machine. The developer that is attracted to the development roller

[A] is split into two parts by the doctor blade [B]. One part (the magnetic

brush) goes on to develop the latent image on the drum. However, the other

part is trimmed off by the doctor blade and directed to the backspill plate [C].

As the developer slides down the backspill plate to the screw roller [D], part of

the developer falls into the auger inlets [E] and is transported to the left side of

the unit by the mixing auger [F], where it drops onto the paddle roller. As the

paddle roller rotates, its blades move the developer to the right. The amount

of developer moved to the right by the paddle roller is equal to the amount

moved to the left by the mixing auger.

2-18

4.4 TONER DENSITY CONTROL

ID Sensor

Check

Toner Sensor

Check

6 January 1990

ID sensor

normal?

No

Toner

sensor

normal?

No

Service Call

indicator ON

Yes

Yes

Toner

density

low?

Yes

Toner supply

solenoid ON

Original

longer than

1200 mm?

Yes

Toner

density

low?

Yes

Toner supply

solenoid ON

No

No

No

The flow chart above illustrates how the copier determines whether or not to

add toner.

This copier uses a dual sensor system to control toner density. The primary

sensor is the ID sensor (image density sensor). This sensor is a photosensor

and directly measures the density of the image on the drum using a test

pattern. This is done just before making the copy. If the test pattern image

density is too low, toner is added.

The secondary sensor is the toner sensor. It measures the ratio of toner to

carrier in the developer. This sensor is used only if the output of the ID sensor

is abnormal or the original is longer than 1200 millimeters. (For very long

originals, it is possible for the toner density to change while the copy is being

made.)

2-19

6 January 1990

4.4.1 Image Density Sensor

5.0

4.0

3.0

Voltage

(V)

2.0

1.0

0.5

LED Light Intensity

Weak Strong

+

_

4.0 0.2V

Standard Intensity

V

Threshold

Level

SG

Toner is

V

SP

0

supplied

No toner

is supplied.

Toner density is detected by developing the sensor pattern and by checking its reflectivity with the image

density sensor (photosensor). Light

from the sensor’s LED reflects from

the drum and activates the phototransistor. The output of the phototransistor goes to CN102-15 of the main

board.

An average reference voltage (Vsg) is

calculated from eight samples of bare

drum reflectivity. After that, an average voltage is calculated from eight

samples of sensor pattern reflectivity.

These two values are then compared

to determine whether toner should be

added or not as follows.

No toner supply condition: Vsp/Vsg < 0.125

Toner supply condition: Vsp/Vsg > 0.125

ID Sensor [S2]

2

1

3

CN102

-14

-15

-12

Main PCB [PCB1]

+5V

CPU

5

CN104

-B10

+24 V

SOL 1

If Vsp/Vsg becomes greater than 0.225, the toner near end condition exists.

The Add Toner indicator then starts flashing. When in the toner near end con-

2-20

6 January 1990

dition, 5.49 meters (=610 mm x 9) can be copied. After that, the toner end

condition is reached. The Add Toner indicator will light and the machine will

not operate.

The ID sensor checks toner density every 1220 mm. If Vsp/Vsg becomes

greater than 0.125 (1/8), then it starts checking toner density every 610 mm.

(If service program mode #21 is set to "1", the toner density will be checked

every 610 mm regardless of Vsp/Vsg.)

The toner supply amount (%) can be adjusted using service program mode

#17.

Using service program #34, Vsp, Vsg, and Vsp/Vsg can be displayed in the

copy counter.

2-21

6 January 1990

4.4.2 Toner Density Sensor

Toner Density Sensor (S2) Main Board (PCB1)

Control

Circuit

1

2

3

4

Coils

CN101-1

[24V] Va

-2

-3

-4

Analog Input

[7.0V] (Control)

GND

The toner density sensor works in conjunction with the ID sensor to control

the amount of toner in the developer mixture. It has three basic functions.

First, it controls the upper and lower limits of toner density. For example, if the

amount of toner in the developer is greater than the upper limit (analog input =

1.9 V), toner supply is prohibited no matter what the ID sensor input is.

(Analog input of 3.5 V is the lower limit.) Second, it checks toner density if an

original larger than 1220 mm is copied. Third, it takes over toner density

control completely if the ID sensor becomes abnormal (=Vsp > 2.5 V or Vsg <

2.5 V).

The toner density sensor is powered by 24 volts from CN101-1 of the main

board. The sensor’s sensitivity is set by the control signal applied from

CN101-1. The input signal from the sensor is applied to CN101-2. This is an

analog signal. When the toner density is at the standard level, the analog

signal is approximately 2.1 volts.

The active sensing element is a very small transformer with three coils. When

iron ferrite (carrier) is near the sensing element, the inductance of the coils

changes, causing the current through the transformer to change. As the

amount of toner in the developer increases, the effect of the carrier particles

decreases and the voltage applied to CN101-2 decreases. Conversely, when

the toner concentration drops due to use, the effect of the carrier on the

sensor coils increases and the voltage at CN101-2 also increases.

Service call "Ed" lights if the toner sensor output becomes less than 1.6 V or

more than 4.7 V

2-22

6 January 1990

4.5 DEVELOPMENT BIAS

4.5.1 Basic Concept

When the drum is exposed, most of the negative charge is eliminated from the

areas where light strikes the drum. This leaves a negative charge pattern

corresponding to the dark areas of the original. After exposure however, a

small residual charge of about --100 volts (for white paper) remains in the

exposed areas. This residual charge could attract positively charged toner

from the development roller and result in dirty background on the copy.

The development bias prevents such dirty background. A negative bias a little

larger than the residual charge is applied to the development roller. This

prevents the positively charged toner from being attracted to the background

areas of the latent image.

Manual ID Bias

Bias

(Volts)

-280

-240

-200

-180

-160

-120

1 2 3 4 5 6 7-14

Manual ID Setting

4.5.2 Manual Image Density Bias

When in manual image density mode, the development bias is applied as

shown by the above chart.

In addition to the development bias, the image density is also controlled by

varying the exposure light intensity. (See the exposure section.)

2-23

6 January 1990

Lighter

ADS

-300

-260

-220

-200

Normal

ADS

-280

-240

-200

-180

0.18 0.85

0.77

0.73

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Darker

ADS

-260

-220

-180

-160

ADS Vod/Vsd

Vod: Original Density Detecting Voltage (ADS out put voltage)

Vsd: Standard Pattern (White Plate) Density Detecting Voltage

4.5.3 Auto Image Density Bias

The above chart shows the development bias when in ADS mode. The ADS

can be switched to the "Darker" setting with service program mode #20.

In addition to the development bias, the image density is also controlled by

varying the exposure light intensity. (See the exposure section.)

4.5.4 Bias Adjustment

Bias

Adjustment

(Volts)

-40

-20

0

+20

+40

1 2 3 40

Program Mode #19

Using service program mode #19, the bias level can be increased or

decreased as shown in the above chart.

2-24

6 January 1990

4.6 IMAGE DENSITY SENSOR BIAS

The ID sensor bias is similar to the development bias; however, it is applied

only when developing the ID sensor pattern.

Basically, the ID sensor bias is fixed. The normal ID bias level is --240 volts,

but it can be changed using service program #18. The following table shows

the possible settings. You should clearly understand the effect of changing

the ID sensor bias. If the ID sensor bias is increased the sensor pattern will

become lighter. This will cause more toner to be added to the developer and

thus copy images will become darker and toner consumption will increase. If

the ID sensor bias is decreased, lighter images and less toner consumption

will result.

Service Program #18

Setting 0 1 2 3

ID Bias --240 --200 --280 --320

Factory Setting

A developer counter correction is applied to the ID sensor bias to compensate

for changes in the triboelectric properties of the developer as a new developer

mixture is broken in. The following table shows this correction. Notice that the

correction depends on the average Vsp/Vsg ratio as measured during initial

conditioning as well as on the developer counter. By factoring in the initial

conditioning Vsp/Vsg ratio, this correction compensates for slight variations

between different lots of developer as well as for changes in the developer

during the break-in period. After the initial conditioning, the copy counter will

display the density level (dL).

Developer Counter Correction

Initial Conditioning

dL

Vsp/Vsg

0--499 Copies 500--999 Copies More than 1000

Developer Counter

1 0--10 --40 V --20 V 0 V

2 10--15 --20 V 0 V 0 V

0 15--20 0 V 0 V 0 V

3 20--25 +20 V +20 V +20 V

4 >25 +40 V +40 V +40 V

NOTE: Perform the initial conditioning by SP#5 whenever the developer

mixture is replaced. Do not perform SP#5 when the drum is replaced.

There is a possibility of dLE being displayed. This means that there

was on ID sensor (Photo sensor) error during the initial conditioning.

2-25

6 January 1990

4.7 TONER SUPPLY

[C]

[B]

[A]

[B]

To allow a compact design, the toner supply mechanism is built into the toner

cartridge. An agitator [A] in the toner cartridge turns when the toner supply

solenoid is on (toner supply spring clutch engaged). As the agitator rotates,

mylar strips [B] on the ends of the agitator force toner through small holes (0.5

mm) in a plastic strip [C] along one side of the toner cartridge. The toner

particles thus ejected from the cartridge fall into the development unit and are

mixed into the developer. The toner agitator turns at 120 rpm and the toner

supply rate is approximately 36 grams per minute.

When supplying toner, the CPU turns on the toner supply solenoid the length

of time required to supply the amount of toner specified by service program

#17.

2-26

5. IMAGE TRANSFER AND PAPER SEPARATION

[A]

6 January 1990

[E]

[B]

[C]

[D]

5.1 PRE-TRANSFER LAMP (PTL)

After the latent image is developed but before the image is transferred to the

copy paper, the drum surface is illuminated by the pre-transfer lamp [A]. This

illumination reduces the negative potential on the drum surface. This prevents

the toner particles from being re-attracted to the positively charged drum

during the paper separation process. It also makes image transfer and paper

separation easier.

5.2 IMAGE TRANSFER

The registration rollers [B] feed the copy paper through the transfer entrance

guides to the transfer section. A high negative voltage (about --5.0 kV) is

applied to the transfer corona wire [C], and the corona wire generates

negative ions. These negative ions are applied to the copy paper, and the

negative charge attracts the positive charged toner away from the drum and

onto the paper. In addition, the paper is held against the drum by the positive

counter charge on the drum.

5.3 PAPER SEPARATION

After image transfer, the copy must be separated from the drum. To break the

attraction between the paper and the drum, the separation corona wires [D]

apply an ac corona (4.0 kV) to the reverse side of the paper. The stiffness and

weight of the paper causes it to separate from the drum.

The separation corona has a negative component of approximately --200

volts. This negative component holds the toner on the paper to prevent it from

being reattracted to the drum during paper separation. The two pick-off pawls

[E] ensure that thin paper, paper with low stiffness, or upward curled paper

separates completely from the drum.

2-27

6 January 1990

5.4 PICK-OFF MECHANISM

[E]

[B]

[A]

[C]

[D]

The pick-off pawl solenoid [A] is energized 12 pulses after the registration

solenoid turns on to feed the copy paper to the drum. The pick-off lever [B]

then rotates clockwise and pushes up the pawl holder [C]. This releases the

two pick-off pawls [D], allowing them to rotate against the drum.

Just after the leading edge of the copy paper passes the transport sensor, the

pick-off solenoid turns off again. The pick-off spring [E] then pushes down the

pawl holder, which moves the pick-off pawls away from the drum.

2-28

5.5 T/S CORONA CIRCUIT

6 January 1990

+24 (Va)

T

-5.0 kV

S

AC 4.0 kV

DC -200 V

[P2]

DC/DC

Converter

DC/DC

Converter

DC/AC

Inverter

CN1-2

A. GND

CN1-1

[PCB1]

CN107CN1

-3

-B12

24

-4

-A13

24

-5

-B13

24

-6

-B11

Not Used

The T/S power pack is powered by +24 volts (Va) from the dc power supply.

The dc/dc converters and dc/ac inverter change the +24 volts to the high

voltages used by the transfer and separation coronas.

T. Trig

T. Sel

S. Trig

The main board (PCB1) turns on the transfer corona by dropping CN107-B12

(T.Trig) from 24 volts to 0 volt. This turns on the dc/dc converter, which

applies a high voltage of approximately --5.0 kV to the transfer corona wire.

The main board turns on the separation corona by dropping CN107-B13

(S.Trig) to 0 volt. The dc/dc converter and dc/ac inverter circuits then apply

approximately ac 4.0 kV and --200 V to the separation corona wires.

Normally, T.Sel is not used. However, if the user presses the Auto Image

Density key for longer than 3 seconds, the CPU uses both T.Trig and T.Sel to

turn on the transfer corona. This increases the transfer corona current from

150 µA (the normal value) to 250 µA. The higher transfer current may be

useful under high humidity conditions (When the higher transfer corona

current is selected, the manual ID display function inverts.)

2-29

6 January 1990

6. CLEANING

6.1 OVERVIEW

[A]

[B]

The cleaning blade [A] removes any toner remaining on the drum after the

image is transferred to the copy paper. The toner that is wiped off by the

cleaning blade drops onto the toner collection coil [B], which then moves it to

the used toner tank.

The cleaning blade pressure spring applies pressure to the exact center of the

cleaning blade so that pressure is evenly applied across the entire length of

the cleaning blade. Blade pressure is applied constantly; however, the blade

pressure can be relieved manually for drum removal.

2-30

6.2 COLLECTION OF USED TONER

[A]

[C]

[E]

6 January 1990

[B]

[D]

The toner collection coil moves used toner from the cleaning unit through the

used toner pipe [A] to the used toner tank [B]. The used toner tank can hold

about 800 grams of toner. On average, about 10,000 A2 sized copies can be

made before the used toner tank needs to be emptied. (This assumes 7%

originals and 80% transfer efficiency.) The toner overflow sensor [C] detects

when the used toner tank is full.

The toner collection bottle is vibrated to prevent used toner from building up in

one place and activating the toner overflow sensor too early. The shaft of the

first set of transport rollers has a cam [D] on the end. This cam is in contact

with a projection [E] of the used toner bottle. It turns when the main motor is

on and moves the used toner tank up and down as shown above right.

2-31

6 January 1990

6.3 TONER OVERFLOW SENSOR

+5 (Vc)

3

Toner Overflow Sensor 3]

[A]

[B]

Main Board

[PCB1]

CN107

-B22

2

1

0/5

0

OSC

Freq.

Detec-

tion

Tr.

Rectifier

The toner overflow sensor [A] signals the CPU when the toner collection bottle

is full.

A small tuning fork [B] is used as the sensing element of the toner overflow

sensor. This tuning fork is a damping element in a multivibrator circuit. As long

as there is nothing in contact with the tuning fork, the vibrating frequency of

the circuit stays low and the transistor stays off.

When toner presses against the tuning fork, the resistance of the piezoelectric

elements that are in contact with the tuning fork changes and the vibrating

frequency increases. The frequency detection circuit passes the higher

frequency signal to the rectifier which activates the switching transistor. The

transistor sends a LOW signal to CN107-B22.

When the CPU detects this LOW signal, it stops the copier and lights the

Toner Collection Bottle indicator.

2-32

7. QUENCHING

[A]

6 January 1990

[B]

+24 V

Quenching Lamp [2]

Main Board

[PCB1]

CN104

-B8

(-B9)

24

After the drum is cleaned, light from the quenching lamp neutralizes any

charge remaining on the drum. The quenching lamp turns on and off at the

same time as the main motor.

The quenching lamp consists of two PCBs containing 49 LEDs (light emitting

diodes) each. The LEDs output light in the 660 nm to 700 nm (red) range. The

main board turns on the quenching lamp LEDs by dropping CN104-B8 and

CN104-B9 to 0 volts. The two PCBs have identical circuits (shown above).

2-33

6 January 1990

8. PAPER FEED AND REGISTRATION

8.1 OVERVIEW

[B]

[A]

[D]

[C]

In this copier, paper is fed either manually or by the auto sheet feeder

(option).

For manual feed, the copy paper is inserted until it contacts the manual feed

rollers [A]. At that time the paper turns on the 1st feed detector [B], which

causes the main motor to turn on. Two seconds after the main motor turns on,

the manual feed solenoid turns on and the manual feed rollers start turning to

feed the paper to the registration rollers [C]. If using the auto sheet feeder,

copy paper feeds through the manual feed rollers automatically after the

original is inserted.

Just before the paper reaches the registration rollers it activates the

registration sensor [D]. The manual feed solenoid turns off 0.4 second after

that. The 0.4 second delay allows the leading edge of the paper to align

against the registration rollers (which are not turning at this time) to eliminate

skew.

The registration clutch turns on to feed the paper to the drum. It is energized

at the proper time to align the leading edge of the paper with the leading edge

of the developed image on the drum.

Fine and coarse registration adjustments can be made using service program

modes #26 and #27 respectively.

2-34

8.2 DRIVE MECHANISM

[A]

[B]

[F]

6 January 1990

[C]

[E]

[D]

Drive power from the main motor is provided to the paper feed and

registration drive mechanism from feed/fusing drive belt 2 [A] through the

manual feed/registration sprocket [B].

When the manual feed solenoid [C] is energized, the paper feed drive chain

[D] drives the manual feed roller [E]. Once the paper reaches the registration

sensor, the registration clutch [F] turns on, thus the registration roller [G] starts

turning.

[H]

[G]

The manual feed/registration sprocket is in contact with the transport/fusing

sprocket [H] which drives the transport and fusing units.

2-35

6 January 1990

9. PAPER TRANSPORT

[A]

[C]

[B]

[C]

[A]

[B]

After separation from the drum, the copy paper rides on the transport belts [A]

and transport rollers [B] to the fusing unit.

Airflow directly from the vacuum fan [C] holds the paper firmly against the

belts so that there is enough friction between the paper and the belts for

smooth transportation of the paper. The transport belts and transport rollers

are directly driven by the fusing drive chain (no clutch or solenoid); so, they

turn constantly when the main motor is on.

2-36

10. FUSING AND PAPER EXIT

10.1 OVERVIEW

6 January 1990

[A]

[C]

[L]

[F]

[D]

[I]

[G]

[H]

[B]

[E]

Two rollers fuse the image to the copy paper by applying heat and pressure.

The hot roller [A] is made of carbon-teflon and the pressure roller [B] is made

of silicone rubber. Pressure is constantly applied by the pressure levers at the

ends of the fusing unit.

The fusing lamp [C], which is located at the hot roller axis, is turned on and off

to maintain the operating temperature. The temperature control circuit (on the

main board) monitors the surface temperature of the hot roller and the

pressure roller through thermistors [D and E respectively].

2-37

[J][K]

6 January 1990

The hot roller strippers [F] separate the copy from the hot roller and direct it to

the fusing exit rollers [G]. After the fusing exit rollers, the exit gate [H] directs

the copy to either the upper or lower exit rollers [I and J].

When the exit gate solenoid is on, the exit gate directs the copy paper down

through the lower copy exit path. If the exit gate solenoid is off, the paper

goes through the upper copy exit path. The exit direction is selected using the

Copy Exit Way key.

A steel cleaning roller [K] removes toner from the pressure roller. This

effectively cleans toner from both the hot roller and pressure roller because

toner on the teflon surface of the hot roller sticks preferentially to the rubber of

the pressure roller. Then, toner on the pressure roller sticks preferentially to

the steel cleaning roller.

Two thermofuses (wired parallel) [L] provide backup overheat protection. (See

the section on fusing temperature control.)

2-38

10.2 DRIVE MECHANISM

10.2.1 Fusing Drive

[A]

[C]

[D]

6 January 1990

[B]

[G]

[F]

[E]

The hot roller is turned by the fusing drive chain as shown. The pressure roller

is friction driven by the hot roller. The fusing rollers turn constantly when the

main motor [A] is on, driven via the gears [B], through feed/fusing drive belts 1

[C] and 2 [D], the sprockets [E] and the fusing drive chain [F], to the hot roller

sprocket [G].

2-39

6 January 1990

10.2.2 Exit Roller Drive

[C]

[E]

[A]

[B]

[D]

The upper [A] and lower [B] exit rollers are driven by the main motor [C] via a

set of gears [D]. Finally, the exit roller drive chain [E] drives the exit rollers

through a sprocket as shown above.

The exit rollers turn constantly when the main motor is on.

2-40

10.3 FUSING TEMPERATURE CONTROL

6 January 1990

Overheat Protection

+5

+24

1K

IC107

6

_

1.3K

7

5

+

C

Q101

+24

24

A.GND

CN301

CN107-A25

CN107-A15

CN107-B25

AC Controller 1 [PCB3]

-5

-6

-3

RA

301

PC301

Drive Circuit

RA301

AC115,220,240

T304 T306

P

U

CN110-12

+5

CN110-11

CN110-9

T309 T310 T308 T307 T305

G

TR

L3

TH1

TH2

TF1

CN110-10

10.3.1 Fusing Circuit Operation

The fusing lamp is powered by AC controller 1 and controlled by the main

board.

AC controller 1 receives direct wall voltage ac power (not stepped down) at

T304 and T306. It also receives +24 volts at CN301-5. The ac power is

applied to the drive circuit, the fusing lamp (L3), and the triac (TR). The dc

power drives PC301 and RA301.

To turn on the fusing lamp, the main board drops CN107-A15 to LOW. This

activates the photocoupler (PC301) which in turn energizes the drive circuit.

The drive circuit turns on the triac to complete the lamp circuit, thus turning on

the lamp.

RA301 guards against a failure of the +24 volt power supply. When +24 volts

is applied at CN301-5, RA301 is energized and its ac contacts stay open. If

the +24 volts power stops, the ac contacts of RA301 close, stopping the drive

circuit and turning off the fusing lamp.

2-41

6 January 1990

10.3.2 Overheat Protection

The overheat protection circuit on the main board turns off the fusing lamp if

the temperature goes too high.

The input from TH1 goes to pin 5 of IC107 as well as to the CPU. As the

temperature of TH1 increases, its resistance decreases and therefore the

voltage at pin 5 of IC107 increases. If this voltage becomes greater than the

voltage at pin 6, the output at pin 7 becomes HIGH. Q101 then turns off and

cuts the +24 volt supply to ac controller 2. The fusing lamp then turns off. The

overheat protection circuit becomes effective at about 220 degrees.

TF1 (2 thermofuses in parallel) provides overheat protection in case a short

bypasses the control and drive circuits. These two fuses will open if they

reach approximately 192 degrees.

2-42

10.4 TEMPERATURE CONTROL

Hot

Roller

Temp.

195

o

10

190

SP #28

185

6 January 1990

180

175

170

165

160

75 80 85 90 95 100 105 110 115

o

8

Pressure Roller Temp.

o

8

SP #29

10

o

120

The main board monitors the temperature of the hot roller through TH1 and

the temperature of the pressure roller through TH2. The CPU determines

whether or not to turn on the fusing lamp based on the combination of the

input from these two thermistors. If the pressure roller is cool, the CPU keeps

the hot roller temperature high. However, if the pressure roller is hot, the CPU

decreases the operating temperature of the hot roller. The above graph

shows the relationship between the temperatures of the hot and pressure

rollers.

The operating temperature of the hot roller and pressure roller can be

adjusted using service programs #28 and #29. These programs are used to

compensate for variations in the response of different thermistors. Service

program #28 adjusts the hot roller temperature and service program #29

adjusts the pressure roller temperature. Both of these service programs shift

the temperature in 2 degree increments. The maximum change is 10 degrees

or --8 degrees. The fusing temperature can be monitored using service

program #32.

Also. the setting for fusing warm-up cycle (after main switch on) can be

adjusted using service program mode #14 to off or from one to three minutes,

in one minute increments.

2-43

6 January 1990

11. OTHERS

11.1 PULSE GENERATOR

[S4]

CN112-1

Main Board [PCB1]

+5V

CPU

CN112-3

CN112-2

The CPU controls the timing of all machine operations based on the number

of pulses it receives from the pulse generator. Pulses are generated by

rotating a disk with slots in it within a photointerruptor. As the disk rotates,

light from the LED activates the phototransistor each time a notch comes

between them. The pulse interval is 3.125 milliseconds.

If no pulses are received for one second during the copy cycle, the machine

will stop and display "Eb" in the copy counter.

2-44

11.2 OPERATION PANEL

6 January 1990

MAIN BOARD (PCB1)

CN106

Scan1

Scan2

Scan3

Scan4

Scan5

Key 1

Key 2

Key 3

Seg a

Seg b

Seg c

Seg d

Seg e

Seg f

Seg g

Seg h

-A11

-A13

-B11

-B13

-A12

CN106

-B15

-B16

-A16

-B7

-B6

-B5

-B4

-B3

-B2

-B1

-A1

CN201

-1

-2

-3

-4

-5

OPERATION PANEL (PCB7)

Key

Matrix

CN202

-1

-3

-2

LED Matrix

-4

-5 -6 -7-9-8 -10 -11

The above illustration shows the copier’s operation panel circuit in block form.

The operation panel circuit is driven by five scan pulse lines. The copier uses

LEDs for displays elements. To light any particular LED, the CPU drops the

appropriate segment line to 0 volt at the same time that the scan line

connected to the LED is being energized.

The CPU monitors the KEY lines (KEY1 to KEY3) to determine if a key has

been pressed. Each KEY line is used to monitor up to four keys on the

operation panel. A specific scan pulse appears at the appropriate KEY line

when a key on the operation panel is pressed.

2-45

6 January 1990

11.3 SOLENOIDS

Main Board [PCB1]

CN-1

[ +24]

SOL

CN-2

[+24] Va

To energize a solenoid, the main board drops CN-1 from +24 volts to 0 volt.

The following table gives the main board connector numbers for the solenoids used in this machine.

Name Symbol CN-1 CN-2

Toner Supply SOL1 CN104-B10 CN104-A10

Pattern Shutter SOL2 CN104-B13 CN104-A13

Exit Gate SOL3 CN109-10 CN109-11

Pick-off SOL4 CN104-B11 CN104-A11

Paper Stopper SOL6 CN104-B12 CN104-A12

Manual Feed SOL7 CN107-B6 CN107-A6

Recycle Gate SOL8 CN106-B10 CN106-A10

Original Stopper SOL9 CN105-B7 CN105-A

2-46

11.4 PHOTOINTERRUPTORS

6 January 1990

Photointerrupter

Photo TR ON

Output LOW

CN-1

CN-3

CN-2

Actuator Plate

Main Board (PCB1)

[+5V]

+5V

0V

0V

GND

Photo TR OFF

Output OPEN

Photointerruptors consist of a plastic encapsulated LED and a phototransistor

separated by an open slot. When the slot is empty, light from the LED

activates the phototransistor, and the sensor outputs a low (0 volt) signal.

When an actuator plate enters the slot, light from the LED is blocked and the

output becomes open. In this machine a +5 volt pulse is present at CN-2

when the output is open.

This machine uses three different types of photointerruptor as shown above

right. However, they all function in the same way.

The following table lists the photointerruptors used in this copier.

2-47

6 January 1990

Name Symbol CN-1 CN-3 CN-2

Pulse Generator S4 CN112-1 CN112-3 CN112-2

Original Set Detector S5 CN105-B4 CN105-A5 CN105-B5

1st Original

S6 CN105-B2 CN105-A3 CN105-B3

Transport Detector

2nd Original

S7 CN105-A1 CN105-B1 CN105-A2

Transport Detector

Original Exit

S9 CN106-A17 CN106-B17 CN106-B18

Detector

Recycle Gate

S10 CN106-A17 CN106-B14 CN106-B18

Detector

1st Feed Detector S11 CN104-B5 CN104-A6 CN104-B6

2nd Feed Detector S12 CN104-A4 CN104-B4 CN104-A5

Exit Detector S15 CN109-7 CN109-8 CN109-9

2-48

6 January 1990

12. SERVICE CALL CONDITIONS

When functional problems occur within the copier, the Call Service indicator

( ) lights. At the same time, "E" and a code number blink alternatively in the

copy counter display.

CODE E1 (Abnormal Exposure Lamp)

Code E1 blinks if the output voltage of the light sensor drops below 0.45 volts

and this condition continues for 20 seconds or more after the exposure lamp

on signal is output.

CODE E2 (Fusing Thermofuse Open)

Code E2 blinks if the fusing temperature does not reach 100oC within 4

minutes after the main switch is turned on.

CODE E3 (Hot Roller Thermistor Open)

Code E3 blinks if the resistance of the thermistor (TH1) is 126.5 kΩ or more, 2

minutes after the fusing lamp turns on.

CODE E4 (Hot Roller Thermistor Short)

Code E4 blinks if the resistance of the thermistor (TH1) is 0.1 kΩ or less, 2

minutes after the fusing lamp turns on.

CODE E5 (Pressure Roller Thermistor Open)

Code E5 blinks if the resistance of the thermistor (TH2) is 1 mΩ or more, 2

minutes after the fusing lamp turns on.

CODE E6 (Pressure Roller Thermistor Short)

Code E6 blinks if the resistance of the thermistor (TH2) is 0.5 kΩ or less, 2

minutes after the fusing lamp turns on.

CODE E7 (Exposure Lamp Thermistor Open)

Code E7 blinks if the resistance of the thermistor becomes 248 Ω or more,

and if this condition continues for 20 seconds.

CODE E8 (Exposure Lamp Thermistor Short)

Code E8 blinks if the resistance of the thermistor becomes 2.4 Ω or less, and

if this condition continues for 20 seconds.

CODE E9 (Fusing Overheat)

Code E9 blinks if the hot roller temperature reaches 200oC.

2-49

6 January 1990

CODE EA (Ready Failure)

Code EA blinks if the machine does not reach the ready condition (Ready