Page 1

AUTOMATIC DOCUMENT FEEDER

(ADF)

– DF42 –

Page 2

CONTENTS

1. ADF EXTERIOR ................................................... 2

2. INSTALLATION PROCEDURE............................ 3

3. SPECIFICATIONS................................................ 6

4. MECHANICAL COMPONENT LAYOUT.............. 7

5. ELECTRICAL COMPONENT LAYOUT ............... 8

6. FUNCTIONAL OPERATION ................................ 9

7. REPLACEMENT...................................................13

- 1 -

Page 3

1. ADF EXTERIOR

1

2

3

45

1. Original Table

Place the originals to be fe d int o the ADF here.

2. Original Guides

Adjust these guides to cent er th e orig ina ls so tha t they are correctly fed onto the

exposure glass.

3. Original Stacker

Originals are stacked here af te r t hey exit from the ADF.

4. Insert Original Indicator

The green light is on while it is possible to place origin als in the ADF. After an

original is set, the light goes out.

5. Original Jam Indicato r

This indicator lights when an original jam occurs.

- 2 -

Page 4

2. INSTALLATION PROCEDURE

2.1 ACCESSORY CHECK

1. ADF Control Board.................................................................1 piece

2. Philips Screw with Flat Washer - M4 x 12......................... .. .. .2 pieces

3. Electric Screw - M4 x 8...........................................................1 piece

4. Plastic Cap..............................................................................1 piece

5. Stud Screw for Magnet Catch.............. .. .................................2 pieces

6. Philips Pan Head Screw - M4 x 8 (round head).....................2 pieces

7. Hinge Stud Screw...................................................................2 pieces

- 3 -

Page 5

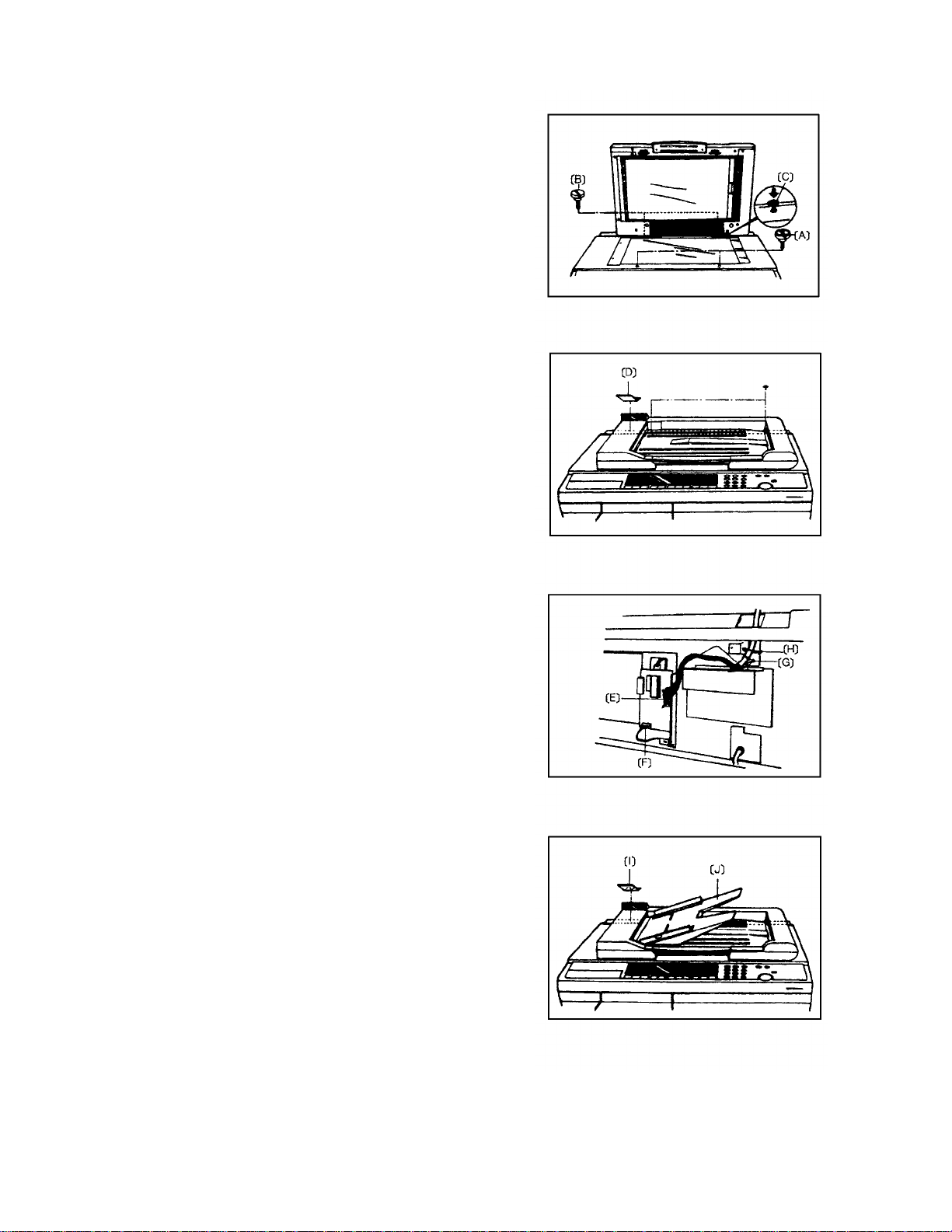

2.2 INSTALLATION PROCEDURE

• Make sure that main switch is turned off.

1. Remove the platen cover, 2 stud screws for

the platen cover, and 2 screws fixing the top

cover at the rear side.

2. Remove 2 front screws fixing th e top cover

and secure 2 stud screws for the magnet

catch [A]. (Fig. 1)

3. Secure 2 hinge stud screws [ B] half way a nd

mount the ADF so that the holes in the ADF

hinge bracket are aligne d with the studs, then

slide the ADF to the right. (Fig. 1)

4. Secure the ADF hinge bracket to the copier

optics frame with 2 screws (M4 x 12) [C].

(Fig. 1)

5. Lower the ADF and tighten the hinge stud

screws [B].

Fig. 1

6. Remove the copier rear cover and the plastic

cap with no hole [D] (left rear side ). (Fig. 2)

7. Install the ADF contro l boa rd on the main

board as shown. (Fig. 3)

8. Run the ADF harness [E] thro ug h the rear left

hole in the top cover and con nect it to CN2

on the ADF control board.

9. Connect the power supply connector (4P

white) [F] to CN3 on the ADF con trol board.

10. Secure earth wire [G] with a electric screw

(M4 x 8). (Fig. 3)

11. Install the twist band [H] and place the

interface harness on it, the n twist it tigh tly.

(Fig. 3)

12. After attaching the plastic cap with a hole [I ],

attach the copier rear cove r. (Fig. 4)

Fig. 2

Fig. 3

- 4 -

Fig. 4

Page 6

2.3 OPERATION CHECK

1. Turn on the main switch and confirm that th e insert original indicator ( ) lights.

2. Wait for the ready condition.

NOTE: It takes about 2 minute s.

3. Square a stack of originals and inse rt th e orig inals until the insert original

indicator goes out.

4. Press the Start key, th en the ADF shou ld sta rt op erating.

5. Check if the original jam indica tor lights when a paper jam is incurred by grabbing

the original which is supposed to be fed in .

6. After removing the jammed paper fro m t he ADF, the original jam indicator should

go off when the ADF returns to its original position.

7. Square the stack of originals, and reset the originals.

2.4 NON-RECOMMENDED TYPES OF ORIGINAL

CAUTION: The following types of originals are not recommended for use

with the ADF. Please place them directly on the exposure gla ss of

the copier.

1. Originals thicker than 105 g/m2 or thinner than 52 g/m2.

2. Paper with any kind of coatin g (such as carbon) on the back, or originals th at are

taped together.

3. Folded, curled, creased or damaged originals.

4. Bound, stapled, or clipped orig ina ls.

5. Mailing labels, perforated originals, or pasted originals,

6. OHP transparencies.

7. Thermal fax paper.

- 5 -

Page 7

3. SPECIFICATIONS

Original Size and Weight: B5 ~ A3 (weight: 52 ~ 105 g/m2)

Original Table Capacity: 30 sheets/A4, 15 sheets/A3 (70 g/ m2)

Copy Speed (1 to 1): 17 copies/minute for A4

Original Set: Face up, first sheet on top.

Original Separation: Separation Roller and Separat ion Belt

Original Set Position: Center Basis

Original Transportation: One Flat Belt

Original Detection: Photointerrupter

Power Source: DC 24 V, DC 5V (either 50 Hz or 60 Hz can be used)

from the copier

Dimensions: 626 (W) x 430 (D) x 56 (H) mm (without the Original Table)

Weight: 5 kg

- 6 -

Page 8

4. MECHANICAL COMPONENT LAYOUT

1

11

10

1312

14

89

7

6

5

2

3

4

1. Original Table

2. Feed-out Roller

3. (Feed-out Sensor)

4. Exit Transport Roller

5. Transport Belt

6. Belt Support Roller

7. (Pick-up Roller Position Sensor)

8. Transport Belt Drive Roller

9. Feed Roller

10. Registration Roller

11. (Registration Sensor )

12. Separation Belt

13. (Original Set Sensor)

14. Pick-up Roller

- 7 -

Page 9

5. ELECTRICAL COMPONENT LAYOUT

3

1

9

8

2

7

6

5

4

1. Indicator Panel 6. Pick-up Roller Position Sensor

2. ADF Motor 7. Original Set Sensor

3. ADF Position Sensor 8. Registration Sensor

4. Feed-out Sensor 9. Pulse Generator Sensor

5. Feed-in Clutch

- 8 -

Page 10

6. FUNCTIONAL OPERATION

Spring Plate

Pick-up Roller Position

Sensor

Transport Belt

6.1 SUMMARY

When an original is inserted face-u p into the ADF, the insert original ind icat or go es

off.

When the Start key is pressed, the pick-up roller starts turning and advances the

bottom original of the stack.

The feed roller and the friction belt are use d to feed-in and separate the originals.

Only the bottom original is fed because the friction belt preve nts any other originals

from feeding.

Registration rollers feed the original to the tran spo rt be lt until sligh tly af te r the origin al

trailing edge passes the regist rat ion sensor. Then the motor pauses and reverse s f or

a few pulses. This forces the original against the left scale and thus aligns the edge

of the original with th e scale .

When the scanner reaches the retu rn po sitio n at the end of scann ing the origin al,

the original is fed out from the ADF.

6.2 ORIGINAL PICK-UP • SEPARATION • FEED-IN MECHANISM

6.2.1 Original Pick -up

When an original is inserted, the insert origin al ind icator goes off. When the Start key

is pressed, the ADF motor and the feed-in clutch are energize d. Then the feed roller

starts turning.

The feed roller and the pick-up roller (a D-shaped roller) are linked by a timing belt .

Therefore the pick-up roller starts turning and advances the botto m original while the

clutch is on.

A spring plate is installed above th e pick-u p roller. This plate pushes down the

original stack against the pick-up roller to help the roller feed the bottom original.

Original Set Sensor

Friction Belt

Registration

Sensor

Friction Pad

Registration

Roller

Feed Roller

Left Scale

- 9 -

Pick-up Roller

Page 11

6.2.2 Original Separ ation

Friction Pad

Spring Plate

Pick-up Roller Position

Sensor

Transport Belt

The feed roller and the friction belt sepa rat er th e orig ina ls. The friction pad prevents

the uppermost original from be ing fed in .

Friction Belt

Registration

Sensor

Registration

Roller

Feed Roller

Original Set Sensor

Left Scale

Pick-up Roller

µ1: Friction coefficient betwe en feed rolle r and origin al

µ2: Friction coefficient between friction belt and original

µ3: Friction coefficient be twe en origin al she et s.

µ1 > µ2 > µ3

6.2.3 Original Feed-in Mechanism

The bottom original separated by the frictio n belt is fed to the reg istra tio n rolle rs. The

registration rollers fe ed the origin al to the tran spo rt be lt, the n th e orig ina l p asse s the

registration sensor.

The ADF determines original size throu gh the use of the registration sensor.

The original’s length is calculated by countin g the numbe r of pulses while the

registration sensor is on.

Original size detection is necessary for the ADF’s feed-in/feed-out timing.

- 10 -

Page 12

6.3 ORIGINAL TRANSPORTATION MECHANISM

The transport belt is directly driven by the mot or’s worm-g ear.

The registration rollers feed the origina l to the tra nsp ort belt until slight ly aft er th e

original trailing edge passes the registration sensor. Then the motor pauses and

reverses for a few pulses. This forces the original against the left sca le an d th us

aligns the edge of the original with the scale to prevent original skew.

6.4 ORIGINAL FEED-OUT MECHANISM

The feed-out roller is connecte d to the tran spo rt be lt by th e feed -ou t rolle r d rive belt

(an O-ring belt). At the end of scanning, the ADF motor starts tu rnin g again after a

feed-out signal from the copier. Then the feed-o ut roller fe eds out the original from

the ADF.

6.5 NEXT ORIGINAL FEED

When the trailing edge of th e original passes the feed-out sensor, the feed-in clut ch

turns on to feed the next original. The feed-in clutch on timing depends on the

original size.

6.6 COMPLETION OF ORIGINAL FEED

There is a disk with a notch on the pick-up roller shaft . The flat surface of the pick-up

roller is positioned upward whe n the pick-u p rolle r positioning sensor detects the

notch.

When the feed-in clutch turns on, the pick-up roller rotates together with the feed

roller. During a copy job for a set of originals, the copier disregards the output of the

pick-up roller positioning sen sor. However, when the last original is fed out from th e

ADF, the ADF motor keeps turning and the feed-in clutch tu rns on until t he pick-up

roller positioning sensor dete cts th e notch in the pick-up roller sha ft. This is to

position the flat surface of the pick-up roller up ward for easy in sert ing of th e next set

of originals.

- 11 -

Page 13

6.7 ADF CONTROL BOARD

1. LED

LED1 - When the ADF is lifted, LED1 lights.

LED2 - When the registration sensor is

activated, LED2 lights.

CN1

CPU

DPS2

LED3 - When the feed-out sensor is activated,

LED3 lights.

LED3

LED2

LED1

2. DPS1

12

CN3

FUSE(125V,1.25A)

ON Motor Test ADF free run

OFF Normal Normal

• No 1 ON: Use to test the ADF drive without an original.

• No 2 ON: ADF free run while detecting originals.

* Start key is SW1.

NOTE: The DIP switch settings must be cha nged when the ma in switch is off.

SW1

DPS1

CN2

3. DPS2

Adjust it when the ADF misde te cts the original length.

• If the detected length is less than the actual original length, turn DPS2 clockwise.

• If the detected length is large r tha n the act ua l origin al length, turn

counterclockwise.

Ref.) The relation of each paper length is as follows:

A3 > B4 > A4 lengthwise > B5 lengthwise > A4 side ways > B5 side ways

NOTE: Turn the main switch off and on after the adjustment.

- 12 -

Page 14

7. REPLACEMENT

Separation Bel t

Assembly

7.1 SEPARATION BELT REPLACEMENT

Tension Springs

Tension Bar

Belt Guide

Separation Belt

1. Remove the feed-in cover (3 screws).

2. Remove the separation belt assembly (2 screws).

3. Remove the 2 tension springs and the tension bar.

4. Remove the separation belt from the belt guide.

- 13 -

Page 15

7.2 TRANSPORT BELT REPLACEMENT

Belt Support Roller

Plastic Bushing

Original Table

Feed-out Cover

Transport Belt

Drive Roller

Feed-in Cover

Handle Cover

Bearing

Transport Belt

Front Transport Bracket

Holder Hook

Bearing

Transport Gear

1. Remove the original table from th e ADF by slidin g it to the right.

2. Turn off the main switch and remove the ADF fro m the copie r.

3. Place the ADF on a table wit h th e transport belt side up.

4. Remove the feed-in cover (3 screws), the handle cover (4 screws), and the

feed-out cover (2 screws).

5. Remove the transpo rt ge ar an d th e be arin g from the front side (1 E-ring).

6. Slide the other bearing on the transport belt drive roller shaft to the rear (1 E-ring ).

7. Free the transport belt drive roller from the ADF frame.

8. Remove the front transp ort bracke t from the ADF main cover (2 screws).

9. For all the belt support rollers, press down the belt support roller shaft to slide out

10. Take out the transport belt from the rollers.

11. Install a new transport be lt and reassemble the ADF.

the front end from the holder hook.

NOTE: Make sure that all the plastic bushin gs for the belt support roller shaft

are properly positioned in the hold er hooks (8 bu shin gs for the front and

rear).

- 14 -

Page 16

7.3 FEED ROLLER REPLACEMENT

Bearing

Bushing

Registration Idl e Roller

Bearing

Transport

Gear

Tie-wrap

Bushing

Feed-in Clutch

Transport Belt

Drive Roller

ADF Main Cover

Front Side Plate

1. Remove the original table from th e ADF by slidin g it to the right.

2. Turn off the main switch and remove the ADF fro m the copie r.

3. Place the ADF on a table wit h th e transport belt side up.

Feed Roller

Registration

Idle Roller

4. Remove the feed-in cover (3 screws) and th e hand le cove r (4 screws).

5. Remove the transpo rt ge ar an d th e be arin g from the front side (1 E-ring).

6. Slide the other bearing on the transport belt drive roller shaft to the rear (1 E-ring ).

7. Free the transport belt drive roller from the ADF frame.

8. Remove 2 screws securing the front side plate to the ADF main cover.

9. Remove the tie-wrap from the feed-in clutch.

10. Remove the feed-in clutch and the bushing from the feed roller shaft (1 E-ring).

11. Remove the bushing from the rear end of the feed roller sha ft (1 E-ring).

12. Slide the registration idle roller (2nd from the rear) to the rear of the shaft as

shown.

13. Free the rear end of the feed roller shaft free from the rear side pla te by shift ing it

to the front.

14. Remove the 3 registration idle rollers (at the rear side) from the feed rolle r sh af t.

15. Remove the feed roller from the shaft (1 E-ring).

16. Install a new feed roller on the sha ft and reassemble the ADF.

NOTE: • Make sure that the feed roller rotates counterclockwise (as seen fro m

the front) free ly o n th e shaft.

• When installing the feed-in clutch, make sure that the fork of the clutch

is properly engaged with the stopper.

- 15 -

Page 17

7.4 PICK-UP ROLLER REPLACEMENT

Plastic

Bushing

Pick-up

Roller

Pick-up Roller Assembly

ADF Main Cover

1. Perform steps 1 to 7 of the feed roller replacement.

2. Remove the pick-up roller assembly from the ADF main cove r (2 scre ws).

3. Remove the plastic bushing from th e pick-up roller shaft (1 E-ring).

4. Slide out the pick-up roller.

5. Install a new pick-up roller and reassemble the ADF.

NOTE: Be careful not to damage th e screw holes for the pick-up roller assembly

as they do not have metal inserts on the main cove r.

- 16 -

Loading...

Loading...