Page 1

SERVICE MANUAL

FT5034C

Page 2

CONTENTS

1. INSTALLATION.................................................... 2

2. OVERVIEW........................................................... 7

3. COPY PROCESS ................................................. 11

4. SECTION DESCRIPTIONS .................................. 13

5. SP MODE/DIP SW TABLE................................... 92

6. CALL SERVICE CONDITIONS ............................ 98

7. PREVENTIVE MAINTENANCE............................105

8. TROUBLESHOOTING..........................................114

9. ELECTRICAL DATA

- 1 -

Page 3

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS....................3

1.2 INSTALLATION PROCEDURE..........................4

- 2 -

Page 4

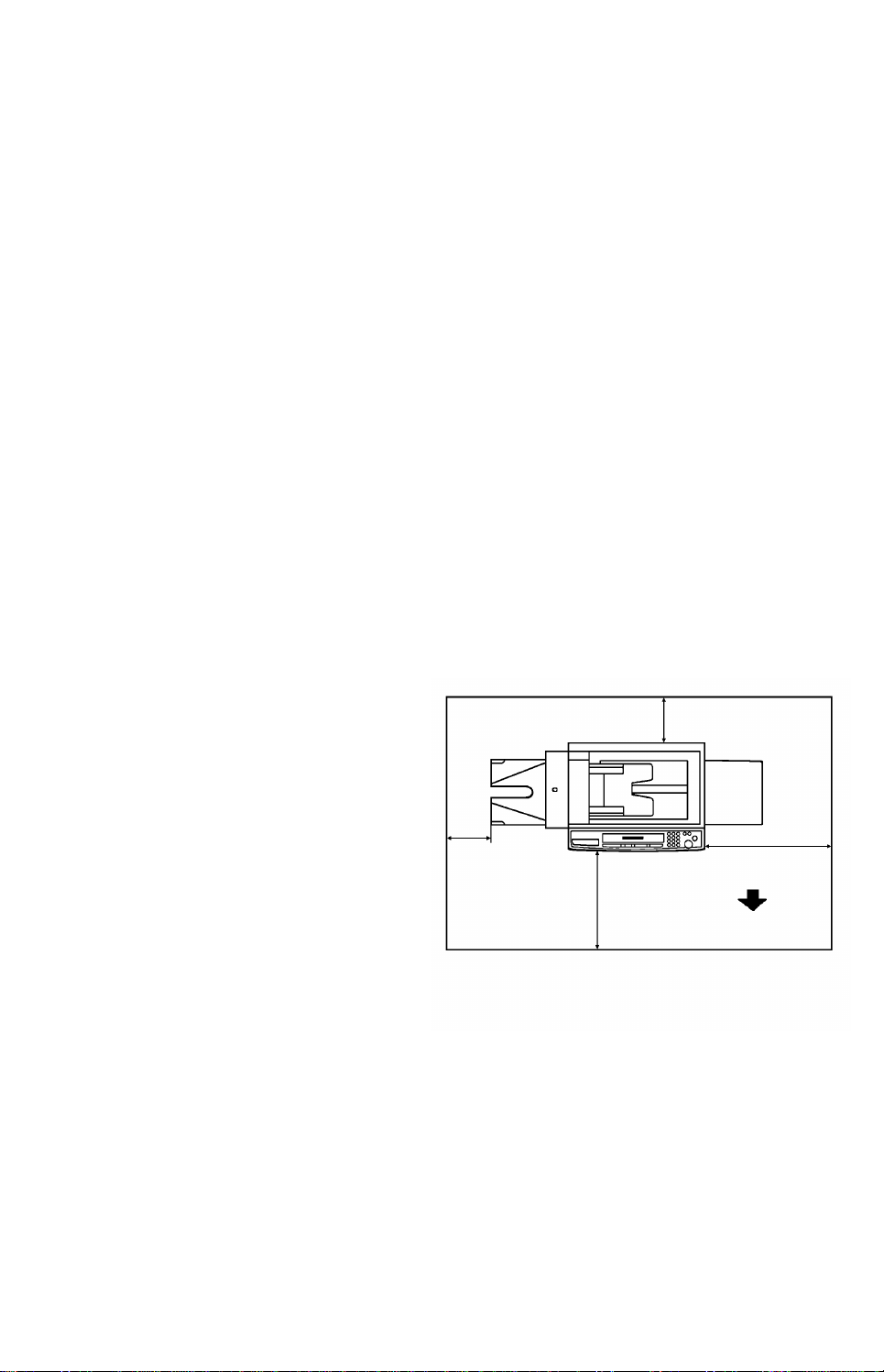

1.1 INSTALLATION REQUIRE MENTS

more than 10 cm

The installation loca tion should be carefully chose n be cau se en vironmental

conditions greatly aff ect the perf ormance of a copier.

1. Environments to Avoid

• Avoid any area exposed to direct sunlight or strong light (Illumination must be

less than 1500 Lux).

• Avoid any area expose d to extre mes of temperature and humidity (standard

condition: 10°C ~ 30°C, 15% ~ 90%).

• Avoid any area expose d to hea te d air fro m a hea te r.

• Avoid any area where tempe rature suddenly changes from low to high or vice

versa.

• Avoid placing the copier in an area filled with dust, and subjected to frequent

strong vibration.

• Avoid narrow space (10 m

2. Access to Copier

3

).

Place the copier near a power source, providing clearan ce as shown. The copier

must be level within 5 mm both front to rear a nd left to right.

3. Power Connection

• Input voltage level:

220 V/50 Hz, more than 10 A

• Avoid connecting the power cord

to a socket that already has

power cords attached

• Permissible voltage fluctuat ion:

220 V (±10%)

• Avoid using a power cord

more than

50 cm

more than

70 cm

more than 80 cm

Front

extension. If you must use one,

make sure that it can carry 250

V, 10 A and that it is less than 5

m long.

4. Earth Connection

• Be sure to ground the mach ine prop erly.

• Do not connect the grounding wire to a gas pipe.

- 3 -

Page 5

1.2 INSTALLATION PROCEDURE

NOTE: 1. When lifting and movin g th e

copier, grasp the black painted

stays on each side as shown.

2. When the optional sorter is

installed, the above mentioned

stays can not be held. Wear

gloves to protect hands from the

edges of the copier base plate.

3. When transporting the cop ier,

remove all the developer and

toner inside the machine. Also

make sure to lock the scanner

with the lock plate.

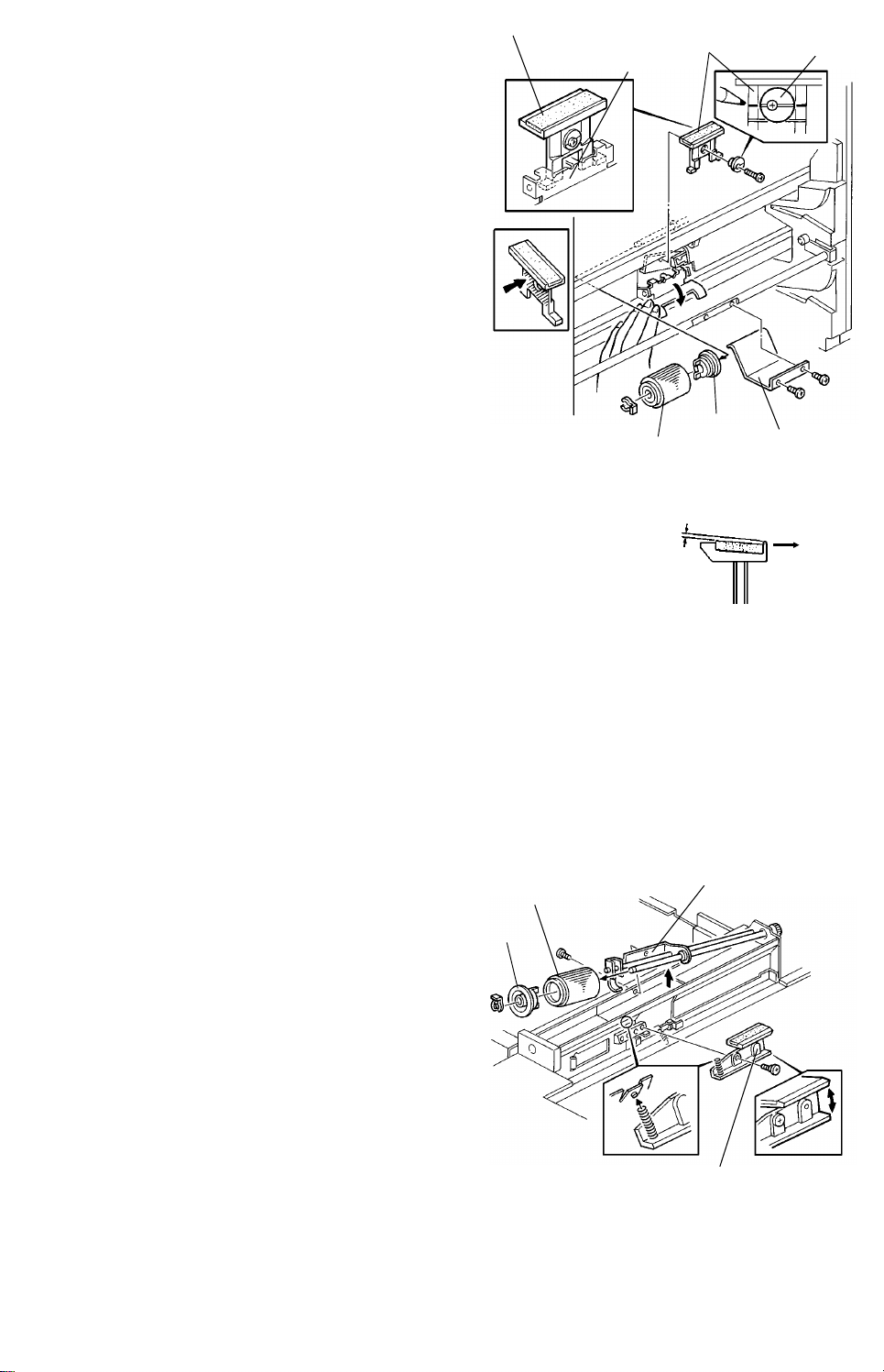

1. Unpacking and Clamps Removal

1. Remove the shipping tapes from the copier

as follows:

1) From platen cover to front cover

2) Manual table

3) Feed guide (cassette insert sectio n)

Scanner Lock

Plate Cover

4) Transport guide plate

5) T/S corona unit

6) Toner shield glass

7) Front loading cassett e leve r

8) Operation panel cover

9) PTL, QL filter

10) Relay lower guide plate

2. Remove the seal from the toner tank

entrance.

3. Remove the wedge (red) from between the

registration rollers.

4. Remove the scanner lock plate cover.

5. Remove the scanner lock plate (1 screw).

(Save the scanner lock plate for future use.)

6. Reinstall the scanner lo ck plate cover.

Scanner Lock

Plate

Development

Lock Leve r

7. Adjust the machine level by tu rning the

rubber foot on the base plate.

- 4 -

Page 6

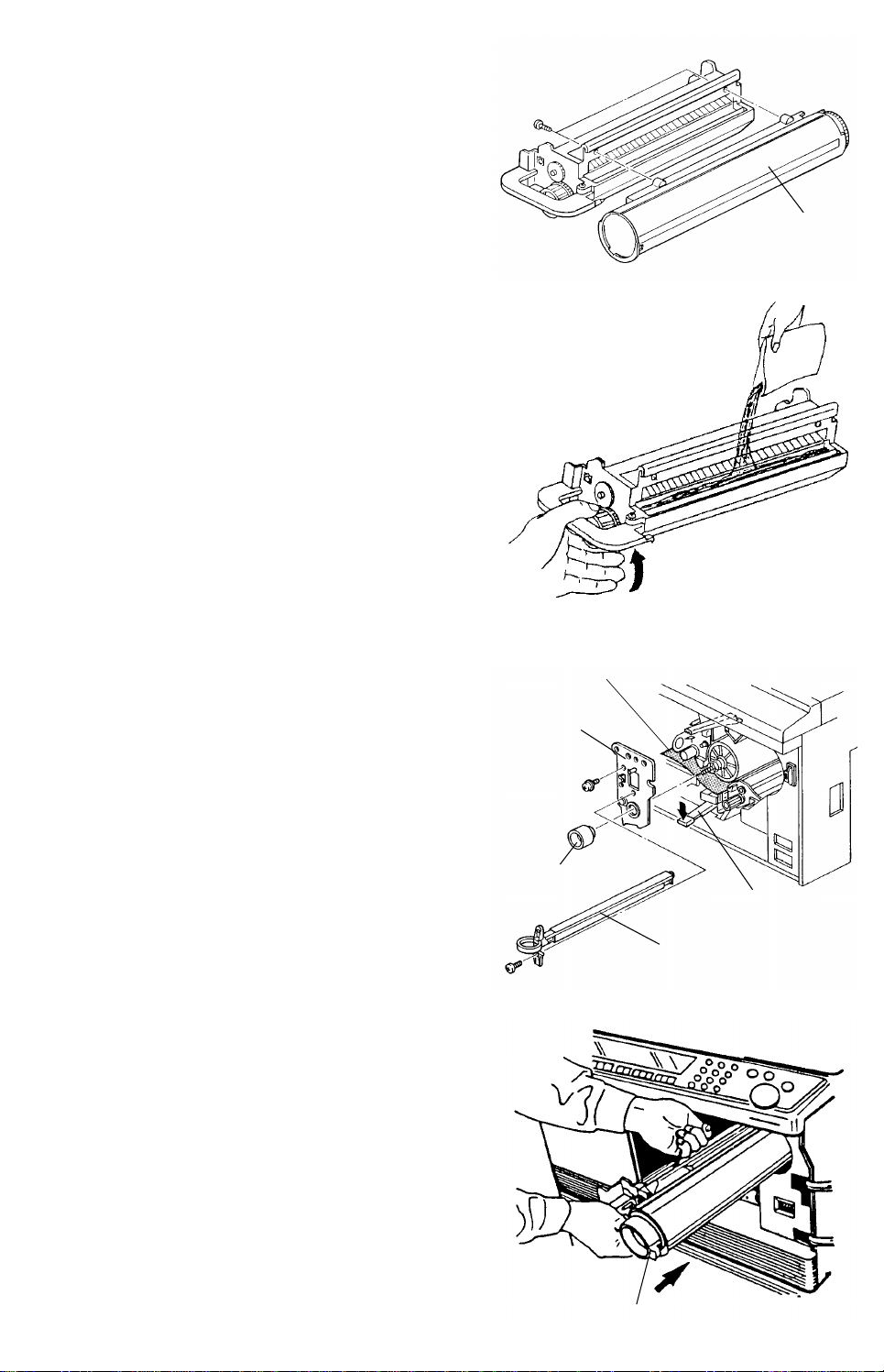

2. Developer Supply

Charge Corona Unit

Place a clean sheet of pape r on yo ur work

surface.

1. Raise the development lock le ver and pu ll

out the development unit. Place the unit on

a clean shee t of paper.

2. Separate the toner tank from the

development unit (2 screws).

3. Pour one bag of developer (1 kg) into the

development unit while turn ing the knob

counterclockwise to distribute the developer

evenly.

4. Remount the toner tank on the development

unit.

NOTE: Make sure that there is no gap

between the toner tank and the

development unit.

3. Drum Protective Sheet Removal

1. Lower the T/S corona unit lever.

Toner Tank

Drum Protective

Sheet

Drum Stay

2. Remove the charge corona unit together

with the wire cleaner (1 screw).

3. Remove the drum stay (1 knob and 1

screw). The drum knob is reverse threaded.

4. Pull out the drum prot ect ive sheet.

5. Reinstall the drum stay an d the charge

corona unit with the wire cleaner.

6. Raise the T/S corona unit lever.

4. Development Unit Installation

1. When installing the development unit, be

sure the development unit rail is pro perly

engaged with the unit guide rail on the

copier. (Make sure that the PTL and QL

filters are in their original position s.)

2. Shake the toner cartridge well and insert

the cartridge. (Refer to the ton er sup ply

guide decal on the front right cove r.)

Drum Knob

T/S Corona Unit

Lever

Toner Cartridge

- 5 -

Page 7

5. Perform the Drum Conditioning

(This operation must be performed after

developer and drum insta llation.)

1. Open the front right cover and move the

drum conditioning switch on the re verse

side of the operation pan el to the left. Close

the front right cover a nd switch the power

on. (The Start key changes from red to

green after 2 min.)

2. Lower the platen cover and enter "99"

using the number keys and press the Sta rt

key. (Drum conditioning takes about 5 min.)

3. After the drum conditioning is finished,

open the front right cover, move the drum

conditioning switch to the right an d close

the front right cover.

4. Place the paper size actuato r a nd size

decal on the cassette (A4 lengthwise or B5

lengthwise) and load paper into the

cassette.

Drum Conditioning

Switch

5. Check the machine operation and copy

quality.

- 6 -

Page 8

2. OVERVIEW

2.1 SPECIFICATIONS..............................................8

2.2 GUIDE TO COMPONENTS................................9

- 7 -

Page 9

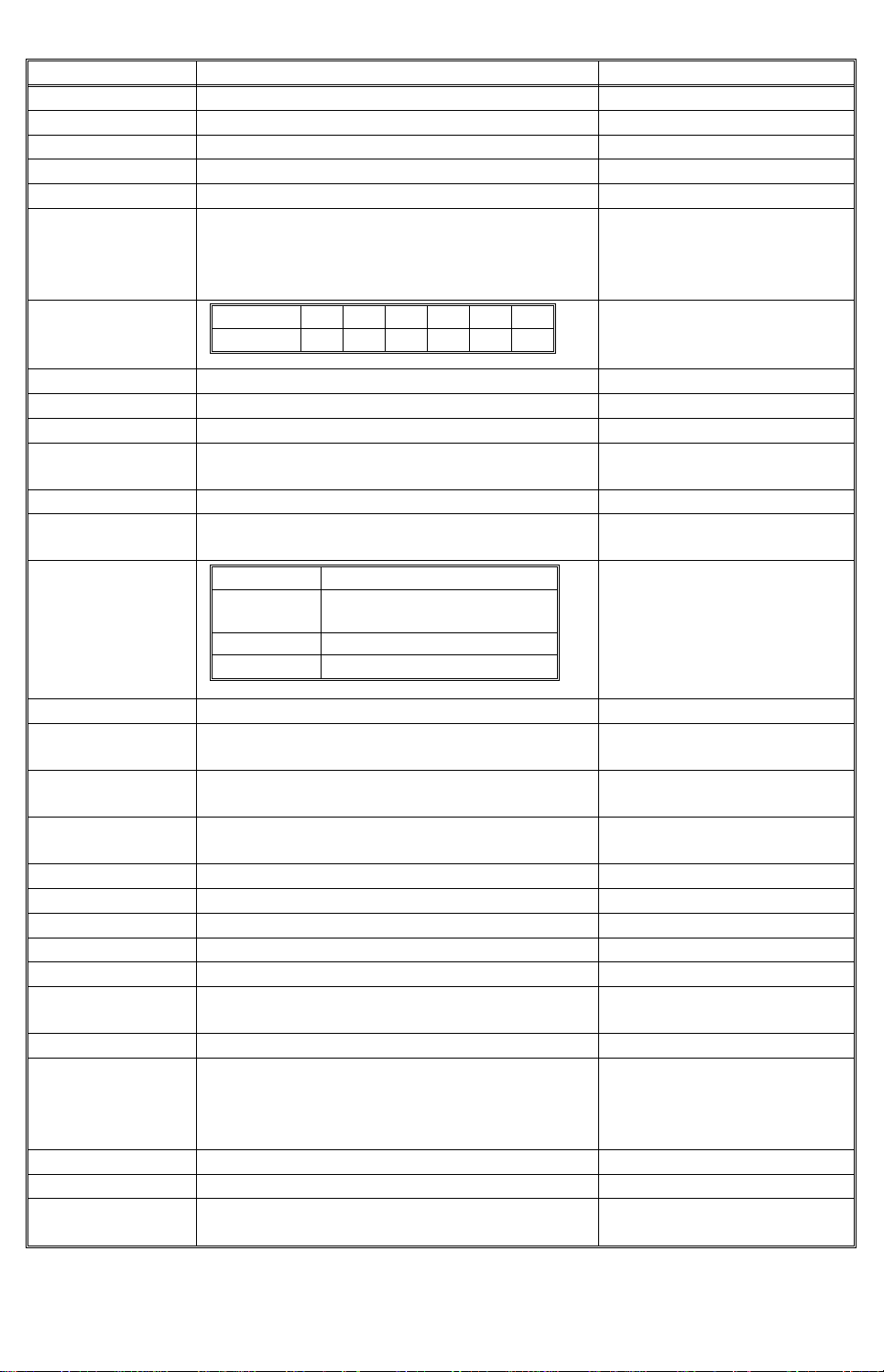

2.1 SPECIFICATIONS

Items Specifications Remarks

Configuration Desk top

Copy Process Dry electrostatic transfer system

Originals Sheet/book

Original Size Maximum A3

Copy Paper Size Maximum A3, Minimum A6 Lengthwise

Copy Paper Weight 52 g/m

Copy Speed

2

~ 157 g/m

Originals A3 B4 A4 B5 A4R B5R

Speed 20 23 34 37 26 30

Warm-up Time Less than 2 min.

First Copy Time 4.5 seconds/A4 sideways

Copy Number Input 1 to 99, Numeric key pad

Paper Feed Three Cassettes (including the front loading

cassette) + Bypass Feed Table

Charge System Dual wire corotron system

Exposure System Slit exposure

(exposure lamp: 180 V, 320 W)

Reproduction

Ratios

Full Size 1 : 1

Reduction 93%, 87%, 82%, 71%, 61%,

Enlargement 115%, 122%, 141%

Zoom 50%~200% in 1% steps

Photoconductor Selenium-drum (F type)

Development

Magnetic brush system

System

Image Density

Control

Toner

Development Bias system + Exposure Control

System

Cartridge exchange (300 g): oilless

Replenishment

Cleaning Type Cleaning blade and brush with PCC

Image Fusing Heat roll type (220 V, 800 W)

Image Transfer Corotron system

Paper Separation Dual wire ac corona and pick-off pawls

Quenching System Photo-quenching

Auto Clear All input modes are reset 60 seconds after the

copier is last used.

Power Source 220 V/50 Hz, 8 A

Power

Consumption

Maximum: Less than 1.5 kW

Average: Warm-up 0.8 kW

Weight 79 kg

Dimensions 765 (W) x 666 (D) x 426 (H) mm

Peripheral

Sorter and Auto Document Feeder

Equipment

2

50%

Stand by 0.18 kW

Copy cycle 1.0 kW

F/L cassette: 64 ~ 90 g/m

1st & 2nd cassette:

52 ~ 127 g/m

2

2

By-pass feed: 52 ~ 157 g/m

Cassette: 250 sheets x 3

Bypass Feed: 50 sheets

Reproduction Ratio Change:

Full size ↔ Reduction or

Enlargement:

Less than 3.5 seconds

Enlargement ↔ Reduction:

Less than 5.0 seconds

2

- 8 -

Page 10

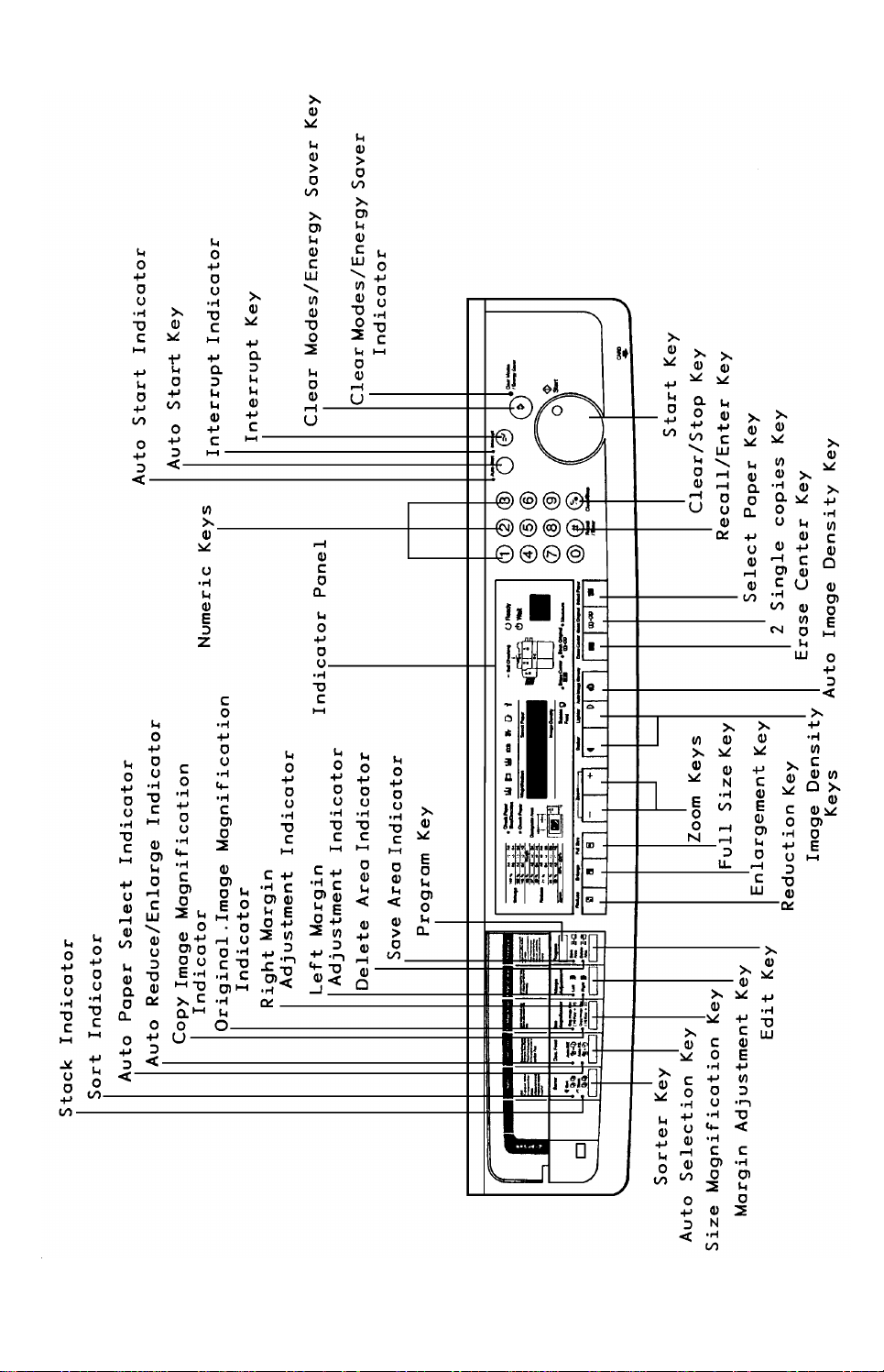

2.2 GUIDE TO COMPONENTS

1. Operation Panel

- 9 -

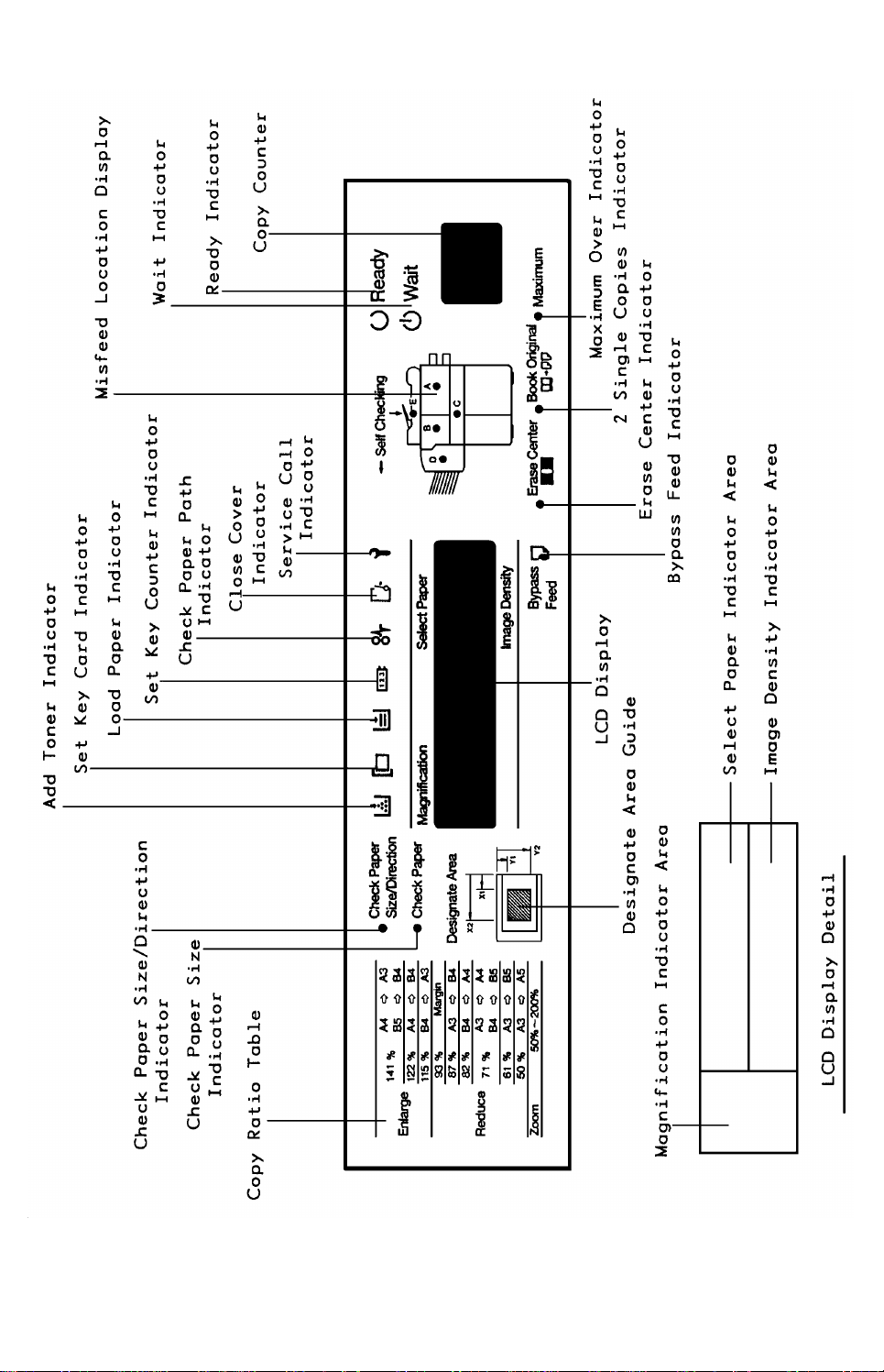

Page 11

2. Indicator Panel

- 10 -

Page 12

3. COPY PROCESS

3.1 COPY PROCESS DIAGRAM .............................12

- 11 -

Page 13

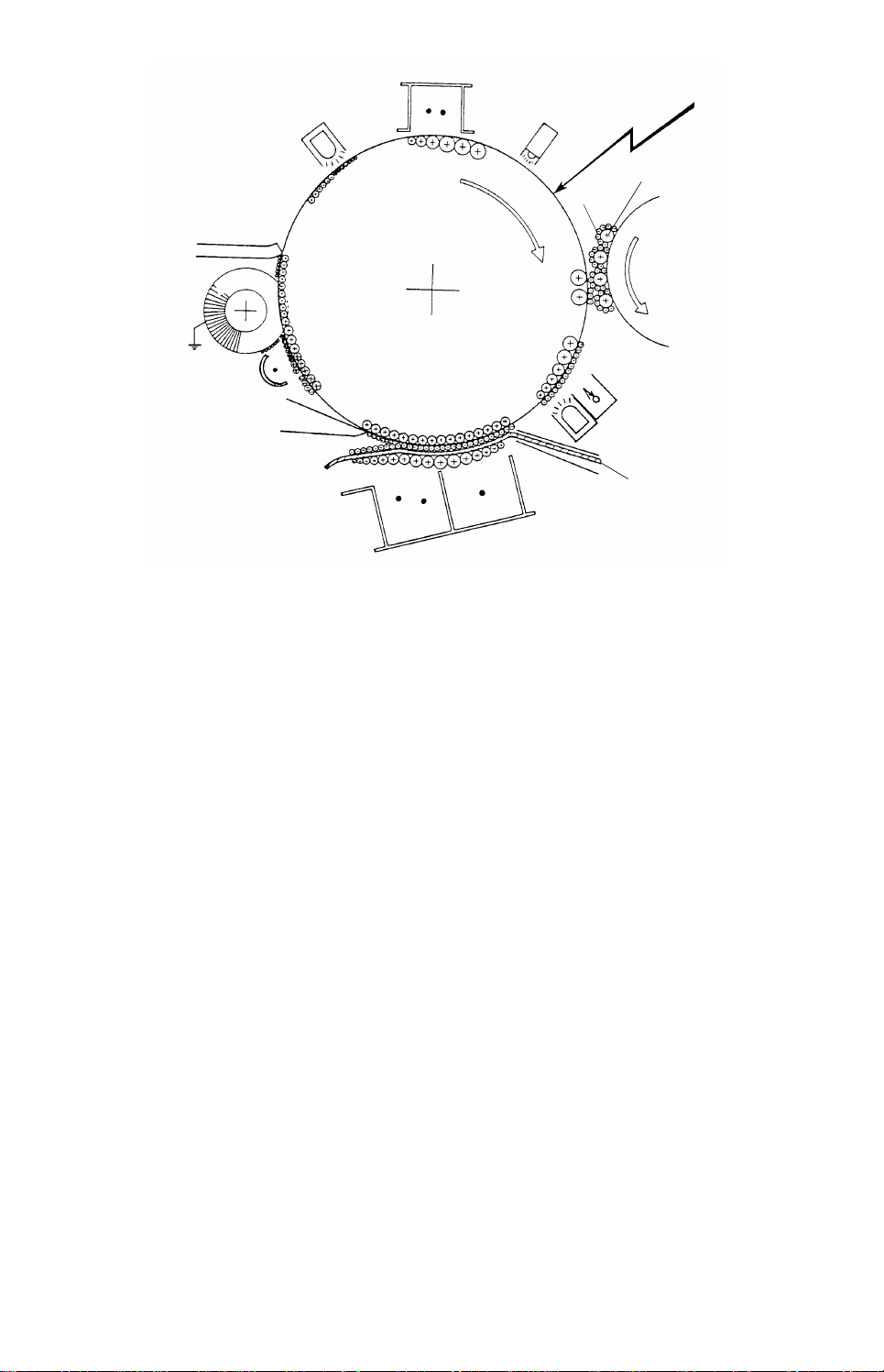

3.1 COPY PROCESS DIAGRAM

Toner

Quenching

Lamp

Charge Corona Unit

Erase Lamp

Exposure

Carrier

Cleaning Blade

Cleaning

Brush

Pre-Cleaning

Corona (PCC)

Pick-off Pawls

1. DRUM CHARGE

In the dark the charge corona unit gives a uniform

positive charge to the selenium drum. The charge

remains on the surface of the drum because th e

photoconductive selenium has high electrical resistance

in the dark.

2. ERASE

The erase lamp illumi na tes the areas of the ch arg ed

drum surface that wil l no t be use d fo r the cop y imag e.

The resistance of the drum in the illumi na ted areas

drops and the charge on those areas dissipates.

3. EXPOSURE

An image of the original is ref le ct ed ont o the selenium

drum surface via the optics assembly. The charge on

the drum surface is dissipated in direct proportion to the

intensity of the reflected light, thus producing an

electrica l la tent image on th e drum surface.

4. DEVELOPMENT

Negatively charged toner is attracted to the positively

charged areas of the drum, thus develop ing th e late nt

image. (The negativ e tri bo el ec tric charge is caused by

rubbing action between the carrier an d toner particles. )

5. ID SENSOR

The main CPU checks toner density by directly sensi ng

the image densit y at the beginning of the fi rst cop y cy cl e

after the main switch is turned on, and at every 10th

copy after that.

6. PRE-TRANSFER LAMP (PTL)

The PTL illuminates the dr um to remov e al l po si tive

charge from the exposed areas of the drum. This

prevents the toner particle s from being reatt rac ted to

the drum surface during paper separation and makes

paper separation easi er.

F TYPE

Photoconductor Drum

Separation

Corona Wire

Development

Roller

ID Sensor

Pre-Transfer Lamp

Paper

Transfer

Corona Wire

7. IMAGE TRANSFER

Paper is fed to the drum su rfa ce at th e proper time so

as to align the copy pap er an d the developed image on

the drum surface . Then, a strong positive charge is

applied to the reverse side of the copy paper, providing

the electrical force to pull the toner pa rti cl es from the

drum surface to the copy pap er. At the same ti me , th e

copy paper is electrically attracted to the drum surface.

8. PAPER SEPARATION

A strong ac corona discharge is applied to the reverse

side of the copy paper, gradually reducing the positive

charge on the copy paper and breaking the electrical

attraction between the paper and the drum. Then, the

stiffness of the copy paper causes it to separate from

the drum surface. The pick-off pawls help paper which

has low stiffness to separate from the drum.

9. PRE-CLEANING CORONA (PCC)

The PCC applies a positive charge to any toner

remaining on the drum after image transfer. This

causes repulsion between the toner particles and the

drum and thereby makes cleaning more effective.

10. CLEANING

The cleaning brus h removes part of the tone r o n th e

drum and loosens the remainder. The cleaning bl ad e

then scrape s of f the loosened t on er.

11. QUENCHING

The light fro m th e quenching la mp, which is a cold

cathode tube, electrically neutralizes the surface of the

selenium drum.

- 12 -

Page 14

4. SECTION DESCRIPTIONS

4.1 MECHANICAL COMPONENT LAYOUT............14

4.2 DRIVE LAYOUT

(INCLUDING PERIPHERALS) ...........................15

4.3 ELECTRICAL COMPONENT LAYOUT .............16

4.4 PAPER FEED AND REGISTRATION ................18

4.5 OPTICS...............................................................28

4.6 AROUND THE DRUM ........................................44

4.7 DEVELOPMENT AND TONER SUPPLY...........50

4.8 ID SENSOR AND PTL........................................62

4.9 IMAGE TRANSFER, PAPER SEPARATION

AND PAPER TRANSPORT................................71

4.10 CLEANING .......................................................75

4.11 FUSING.............................................................83

4.12 MISFEED CHECK ............................................89

4.13 PULSE GENERATOR ......................................90

4.14 OTHERS...........................................................91

- 13 -

Page 15

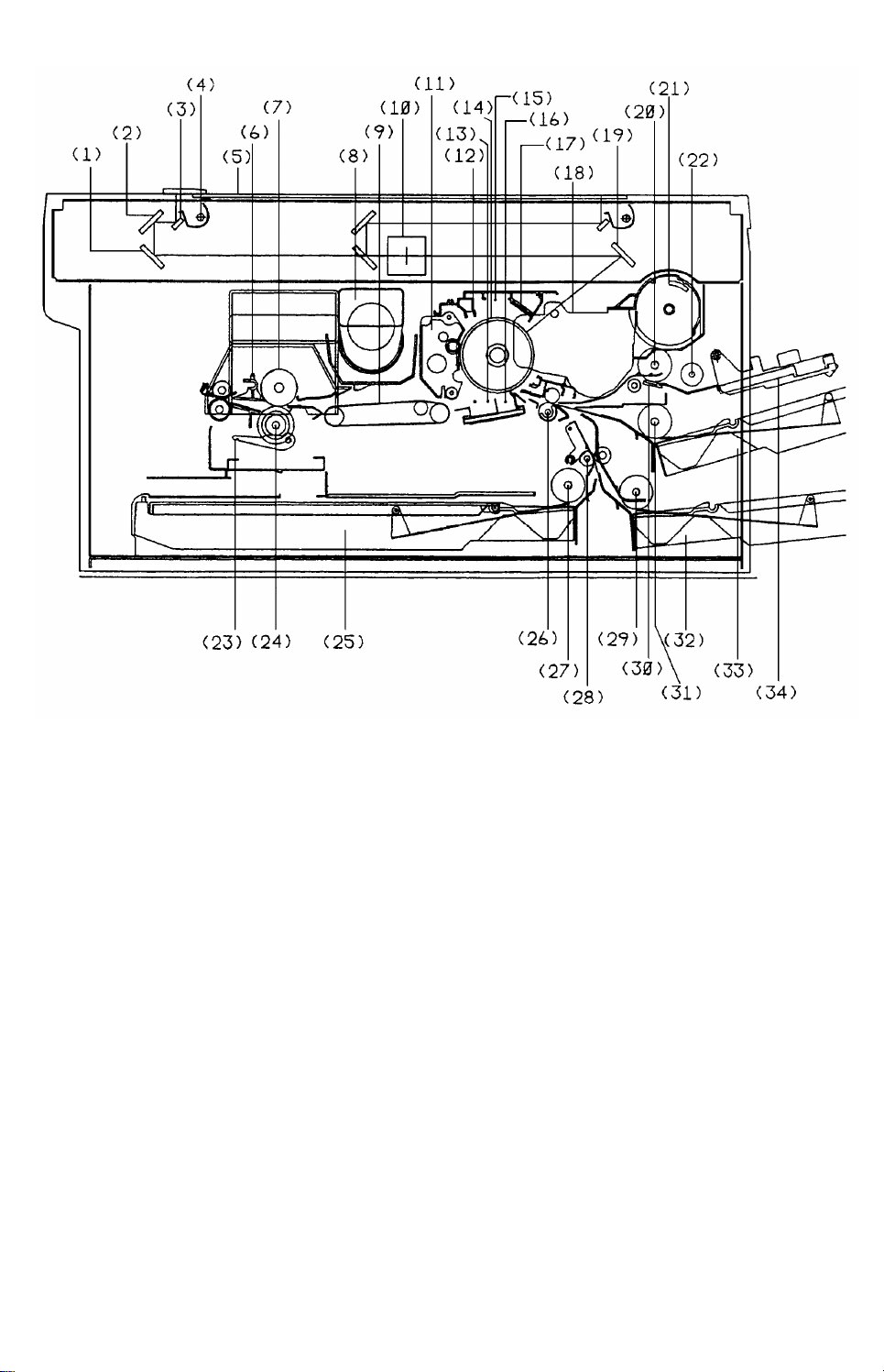

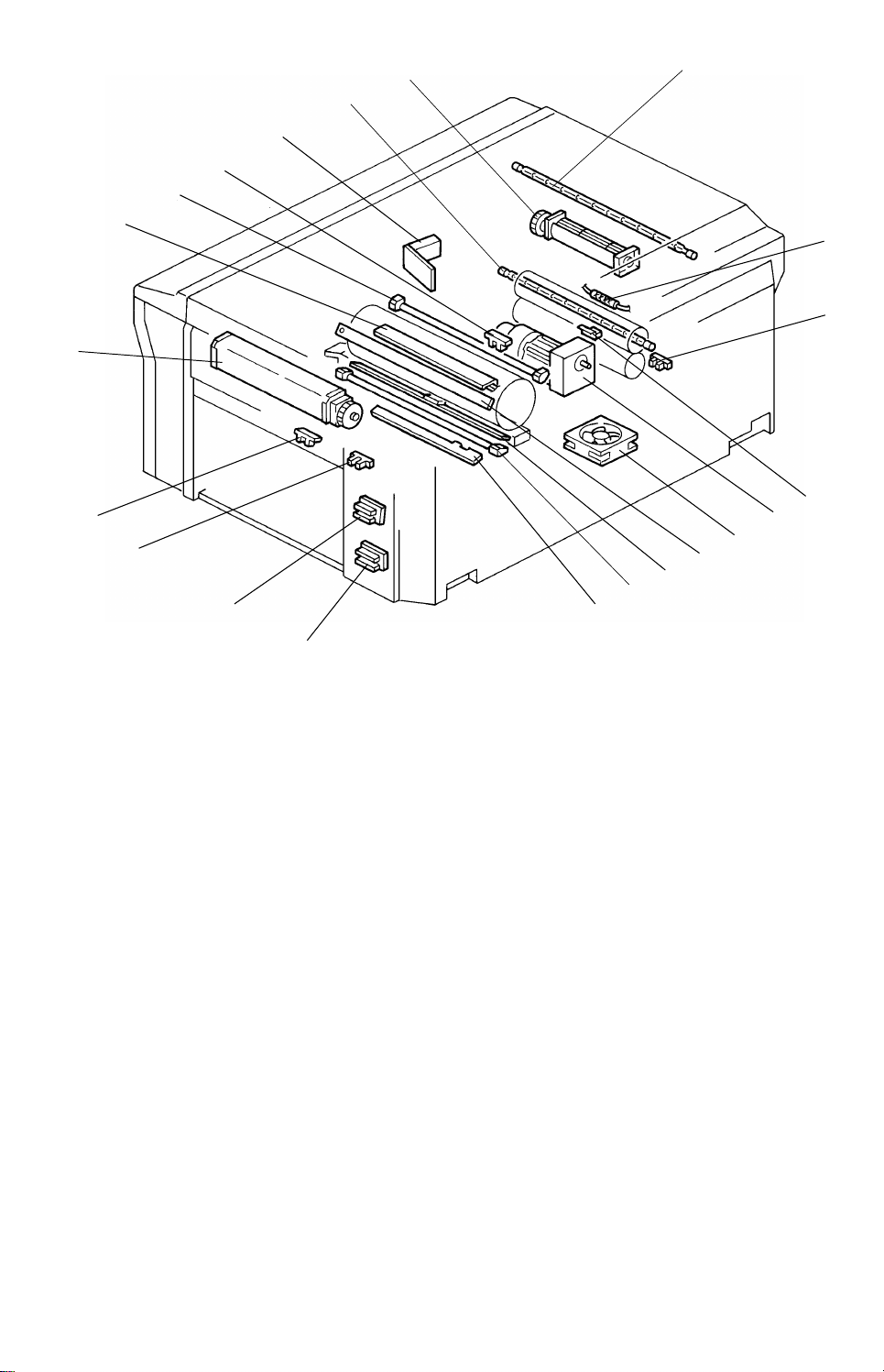

4.1 MECHANICAL COMPONENT LAYOUT

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Exposure Glass

6. Hot Roller Stripper

7. Hot Roller

8. Main Motor

9. Transport Belt

10. Lens

11. Cleaning Unit

12. Quenching Lamp

13. Separation Corona Wire

14. Drum

15. Charge Corona Wire

16. Transfer Corona Wire

17. Erase Lamp

18. Development Unit

19. 4th Mirror

20. Feed Roller (By-pass Feed)

21. Toner Tank

22. Pick-up Roller

23. Pressure Lever

24. Pressure Roller

25. Front Loading Ass’y

26. Registration Roller

27. Feed Roller (F/L)

28. Relay Roller

29. Feed Roller (2nd)

30. Friction Pad

31. Feed Roller (1st)

32. 2nd Casse tte

33. 1st Cassette

34. By-pass Feed Table

- 14 -

Page 16

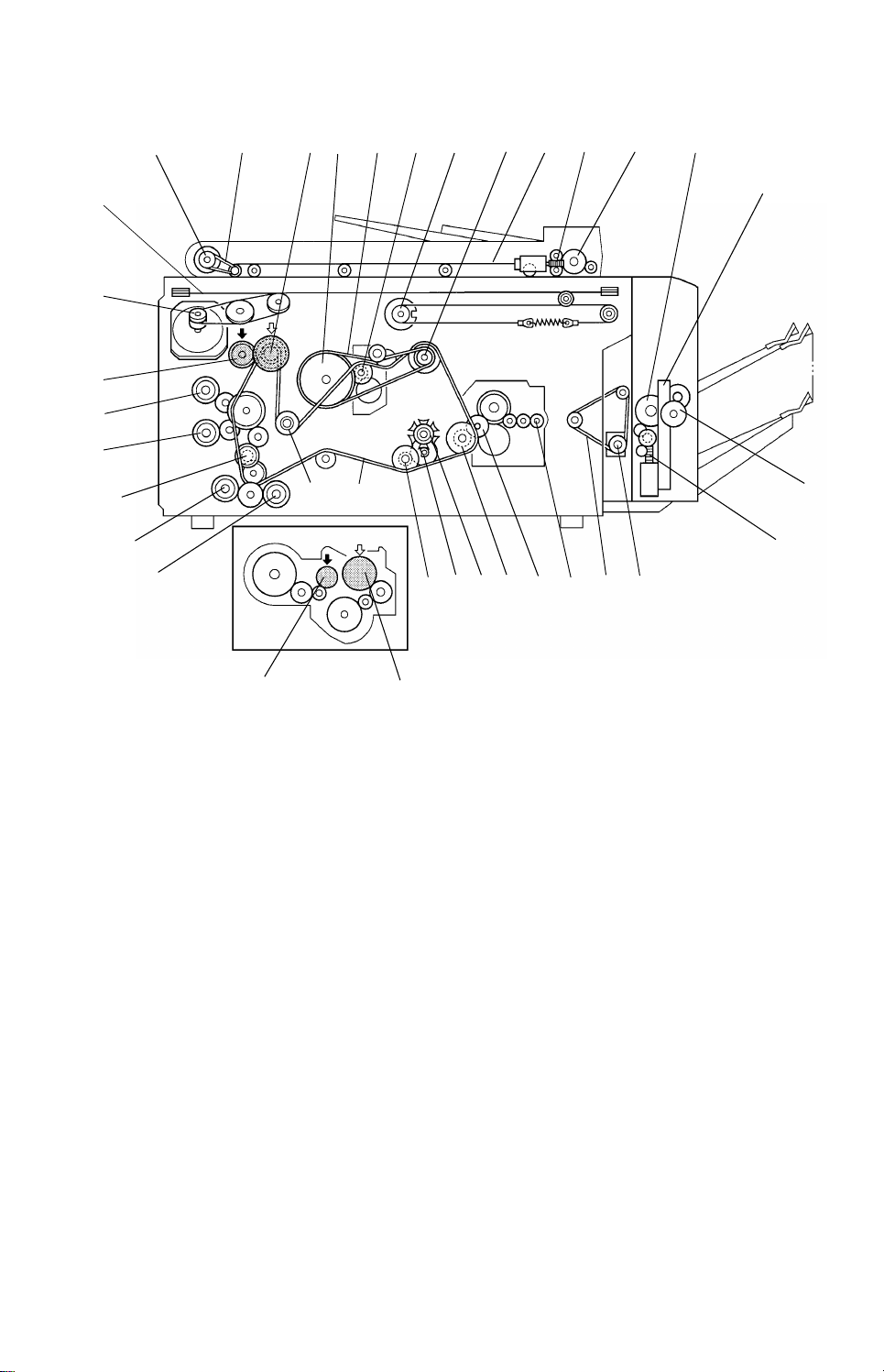

4.2 DRIVE LAYOUT (INCLUDING PERIPHERALS)

33

32

31

30

29

28

1234567

2425

27

26

2223

89

21

20

19

10 11

17

18

12

13

14

15

16

35

1. DF Feed-out Roller

2. Feed-out Roller Drive Belt

3. Pulse Generator Sprocket/Toner

Supply Drive Gear

→ 34. Development Drive Gear

4. Drum Drive Pulley

5. Drum Drive Belt

6. Cleaning Drive Sprocket

7. 2nd Scanner Drive Pulley

8. Main Motor Sprocket

9. DF Transport Belt

10. DF Belt Drive Motor Gear

11. DF Feed Roller

12. Bin Transfer Wheel

13. Bin Support Rack

14. Bin Support Pinion Gear

15. Bin Drive Motor Gear

16. (Sorter Adapter) Feed Motor Pulley

34

17. Sorter Adapter Drive Belt

18. Fusing Exit Roller Gear

19. Fusing Drive Release Gear

20. Transport/Fusing Drive Sprocket

21. Cam Wheel

22. Cam Drive Gear

23. Cam Drive Sprocket

24. Main Drive Chain

25. Registration Clutch

26. F/L Feed Clutch

27. 2nd Cassette Feed Clutch

28. Relay Clutch

29. 1st Cassette Feed Clut ch

30. By-pass Feed Clutch

31. Toner Supply Clutch

→ 35. Toner Supply Drive Gear

32. Scanner Motor Pulley

33. Scanner Drive Wire

- 15 -

Page 17

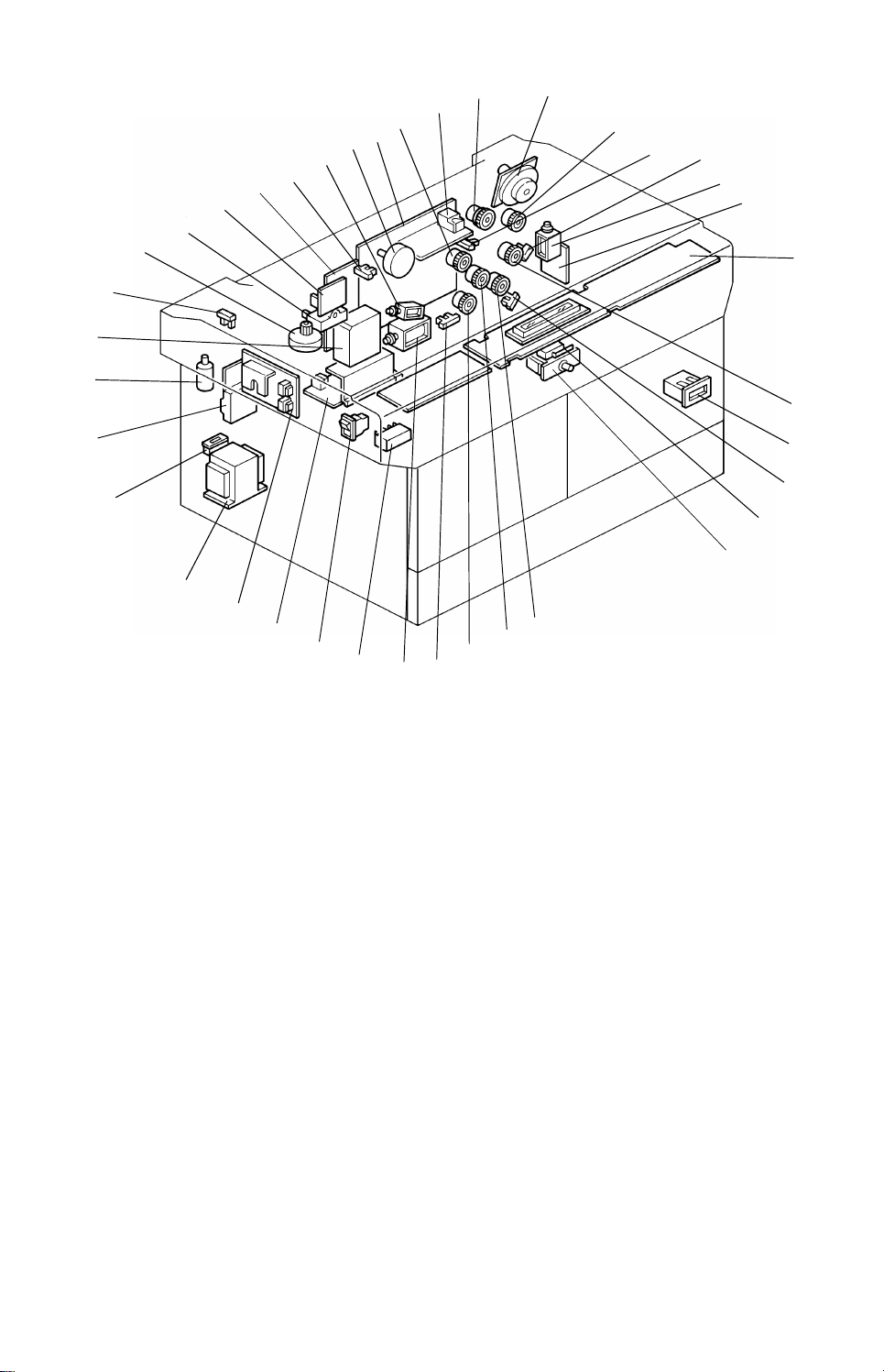

4.3 ELECTRICAL COMPONENT LAYOUT

1

13

24

36

35

34

33

32

31

30

29

28

27

26

25

23

22

21

20

19

18

17

37

16

15

38

14

2

3

4

5

6

7

8

9

10

11

12

1. Scanner Motor

2. By-pass Feed Clutch

3. Pulse Generator Sensor

4. 1st Cassette Paper End Sen sor

5. By-pass Pick-up Solenoid

6. Feed Control Board

7. Operation Panel Board

8. 1st Feed Clutch

9. Total Counter

10. 2nd Cassette Pap er End Sensor

11. Door Switch

12. Door Switch

13. 2nd Feed C lutch

14. Relay Roller Clutch

15. F/L (Front Loading) Feed Clutch

16. F/L Tray Paper End Sensor

17. Cleaning Solenoid

18. Main Power Relay

19. Main Switch

20. Power Supply Board

21. Lamp Regulator Board

22. Power Transformer

23. Main Fuse

24. Fusing Control Board

25. Noise Filter

26. Power Pack - T/S/PCC

27. Scanner Home Position Sensor

28. Lens Motor

29. Main Motor Capacitor

30. Lamp Stabilizer

31. ADF Control Board

32. 2nd Scanner Home Position Sensor

33. Pick-off Solenoid

34. 2nd Scanner Motor

35. Main Board

36. Registration Clutch

37. Power Pack - C/B

38. Toner Supply Clutch

- 16 -

Page 18

3939

545352

454647

59

58

57

56

55

40

41

42

43

51

44

50

49

39. Exposure Lamp

40. Thermofuse

41. Fusing Exit Sensor

42. Fusing Thermistor

43. Main Motor

44. Vacuum Fan

45. Erase Lamp

46. ID Sensor Board

47. PTL (Pre-Transfer Lamp)

48. Registration Sensor Boa rd

49. 2nd Cassette Paper S ize Se nso r

48

50. 1st Cassette Paper Size Sensor

51. By-pass Table Sensor

52. By-pass Paper End Sensor

53. Optics Cooling Fan

54. Drum Heater

55. QL (Quenching Lamp)

56. Lens Home Position Sensor

57. ADS Sensor

58. Fusing Heater

59. Exhaust Blower

- 17 -

Page 19

4.4 PAPER FEED AND REGISTRATION

Friction Pad

4.4.1 Mechanical Parts

1. Overview

In total this machine has fo ur feed stations. They are th ree cassette feed stations

and a by-pass feed station.

The 1st and 2nd feed statio ns ea ch use a size adjustable cassette , bu t the 3rd feed

station located inside the copier uses only an A3 cassette.

The capacity of each cassette is 250 sheets. The maximum pap er cap acity of the

by-pass feed station is 50 she ets.

All four feed stations use the feed rolle r and frictio n pa d syste m . On ly the by-pa ss

feed station uses a pick-up roller.

2. Feed System

1) Feed Roller

The CPU starts paper feed by energizing

the appropriate paper feed clutch (the

paper feed clutches are all magnetic

clutches).

The CPU turns on the paper feed clutch for

the required station, at a programmed time

after the Start key is pressed.

Upon receiving the sign al fro m t he

registration sensor, th e CPU tu rns of f the

paper feed clutch.

Feed Roller

1st Feed Clutch

2nd Feed

Clutch

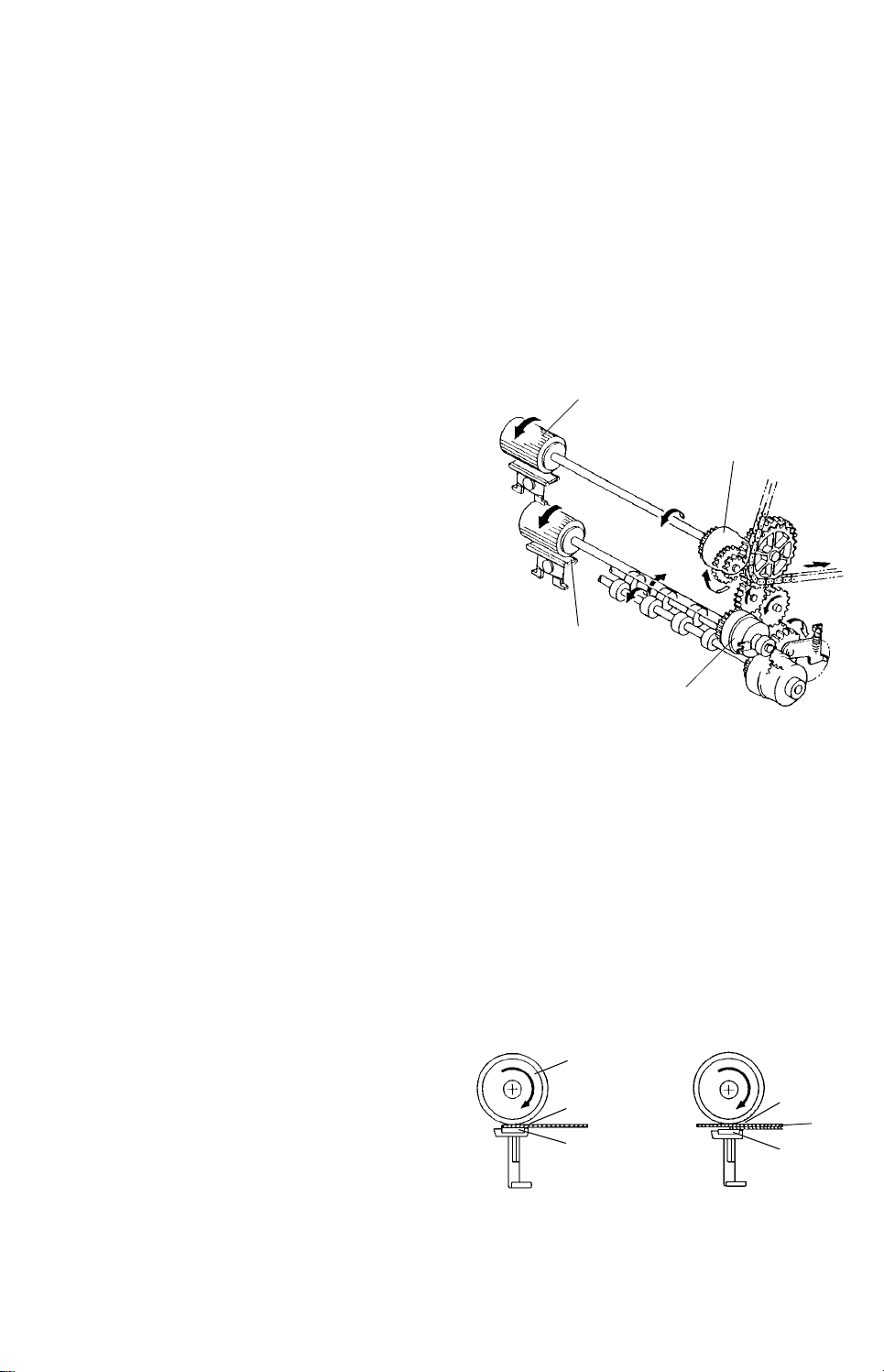

2) Friction Pad Feed System

When a cassette is inserte d int o th e copier, the friction pad contacts the feed

roller (in the by-pass feed stat ion, it always contacts the feed roller). The friction

pad holder is mounted on one end of the swivel plate with a swivel screw, so it

automatically applies even pressure against the fee d roller and the copy paper.

The coefficients of frictio n are µ 1 > µ 2 > µ3.

<Single sheet

feeding>

Feed Roller

µ1

µ2

<Multiple sheet

feeding>

The coefficient of friction between

the friction pad and paper.

µ1

µ3

µ2

- 18 -

Page 20

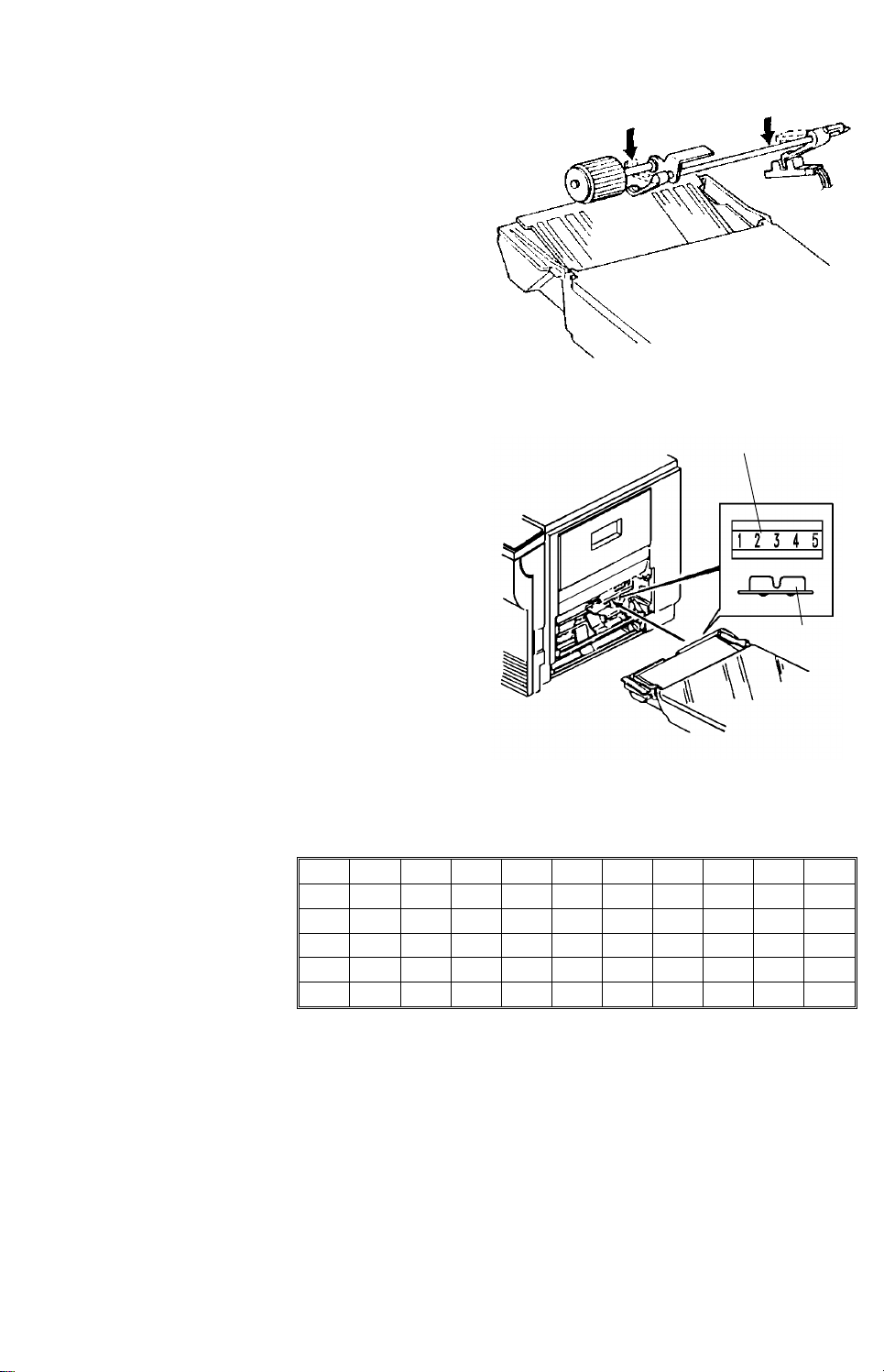

3. Paper End Detection and Paper Size Detection

1) Paper End Detection

This machine uses a photointerrupter

sensor for paper end detection. The paper

end actuator, which is on th e same shaft as

the paper end feeler, pivots into the sensor.

2) Paper Size Detection

Paper size is detected by an array of five

photointerrupt ers in the cassette entrance.

The paper size sensors are actuate d by a

plate on the front of the cassette. Each

paper size has its own unique combina tio n

of notches in the act uator plate.

(For the front loading feed station , if paper

is detected, the copier aut oma tically

detects A3 size. The A3 casset te has a

paper size actuator in case it is used in the

1st or 2nd feeding stat ion for some reason.)

Size Detection Code

A3 B4 A4 A4R B5 B5R A5 A5R B6 B6R

1 ●●❍●❍●❍●❍●

2❍●❍❍●●❍❍●●

3❍❍●●●●❍❍❍❍

4❍❍❍❍❍❍●●●●

5❍❍❍❍❍❍❍❍❍❍

Paper Size Sensor

Actuator Plate

Detected: ❍

Not detected: ●

Other sizes are indicated as ❋ on the

operation panel.

- 19 -

Page 21

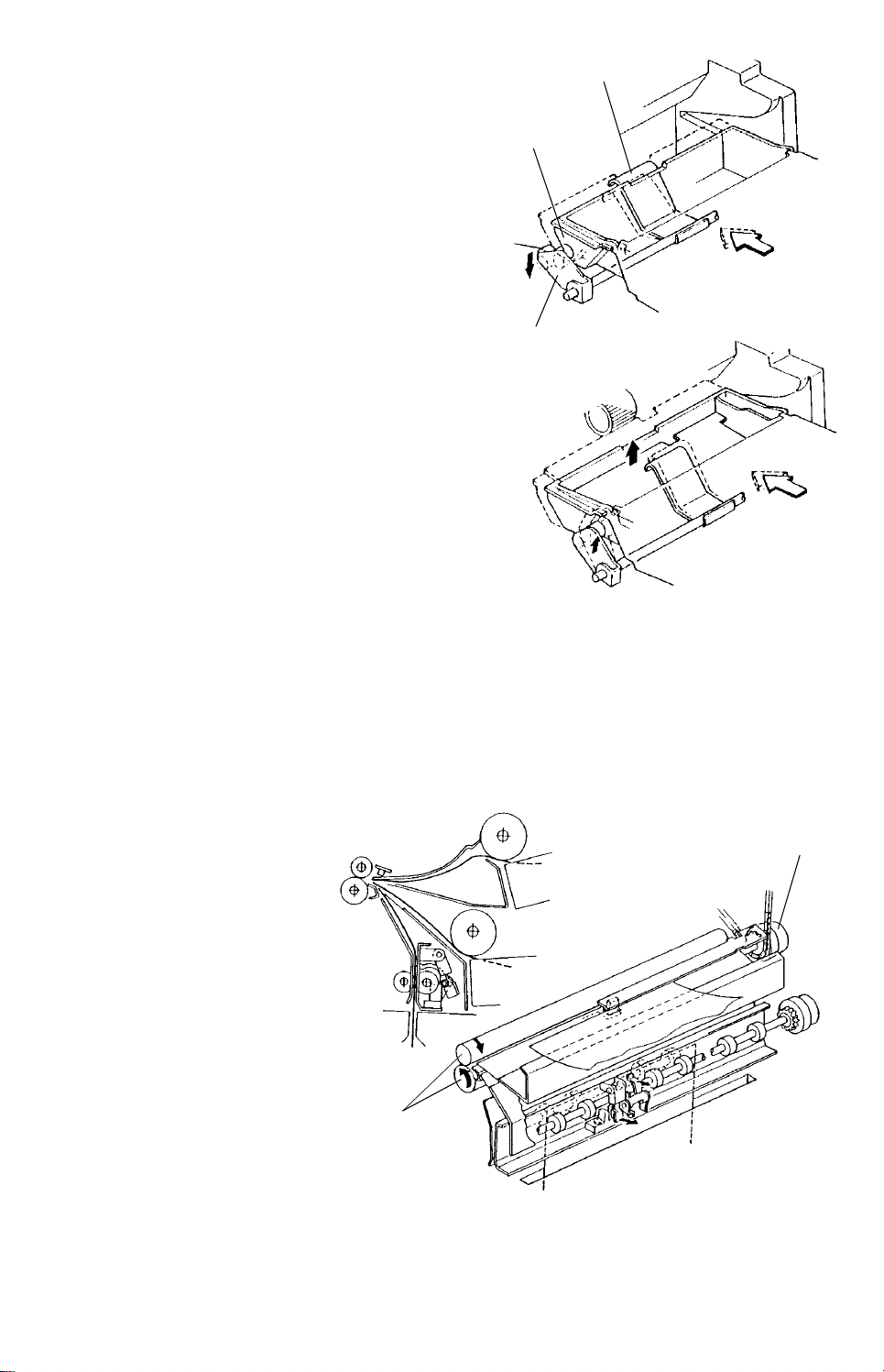

4. Paper Lift Mechanism

Cassette Arm

When a cassette is inserte d int o the copier, the

curved release guide s on th e sides of the

cassette press against the rollers on the

release levers and force the release levers

down. The release leve rs rotate the cassette

arm shaft, moving the cassette arm down and

out of the way.

When the cassette is fully se at ed , the release

guides allow the release leve rs to move back

up. The cassette arm then presses up the

cassette bottom plate until the paper contact s

the paper feed roller.

Release Guide

Release Lever

5. Registration

The registration rollers have two fu nct ions. One is to adjust the image leading edge

on the drum. Anothe r is to preve nt paper skew.

The registration roller is driven by the registra tio n clut ch and the switch -on timing of

the clutch can be adjuste d with DGS103 on the main board in 1 mm step s.

Registration

Clutch

Registr ation

Rollers

- 20 -

Page 22

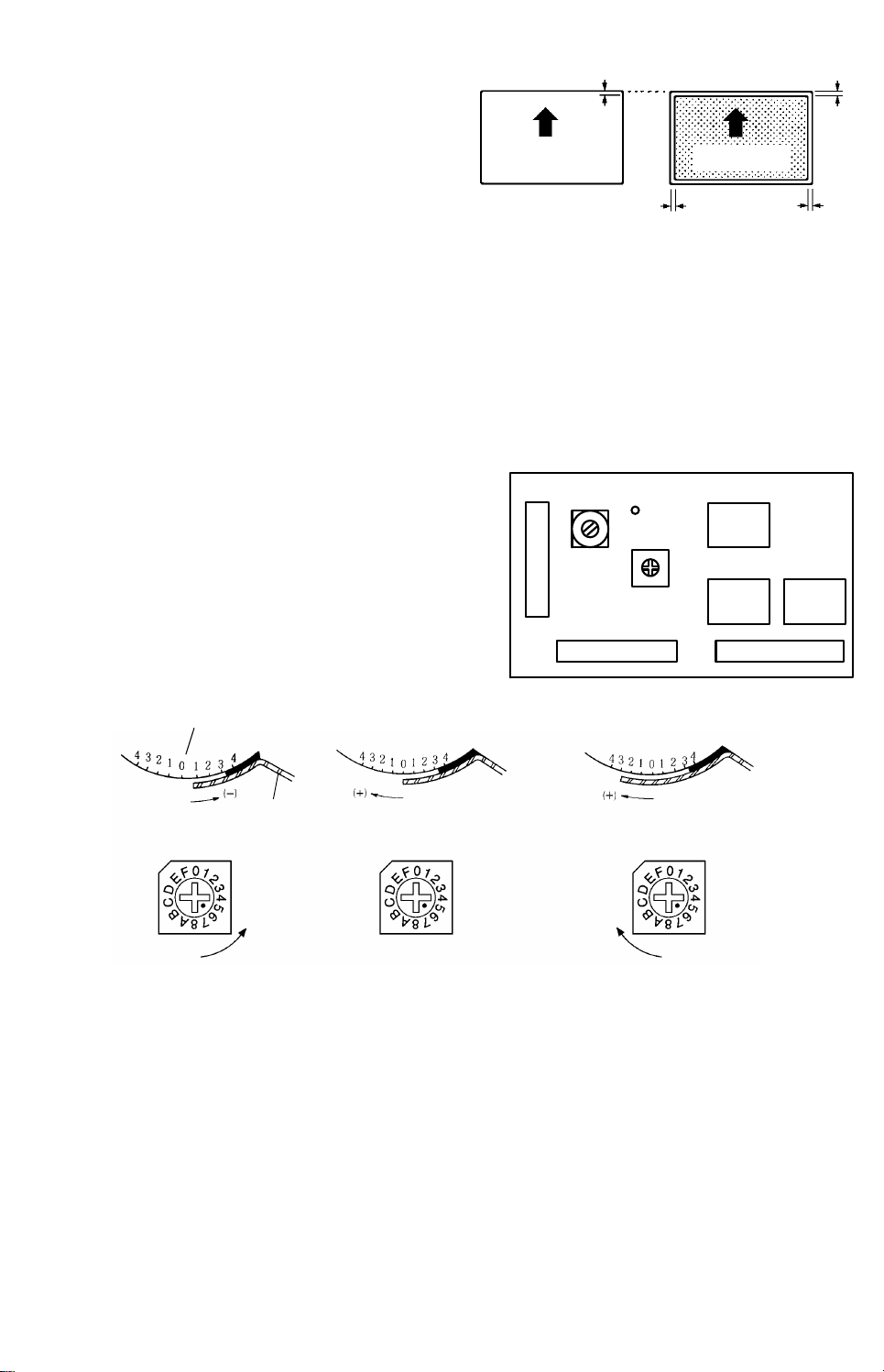

1) Registration Standard

Copy (A4)

(Main Board)

Drum

The registration standard is 0 ± 2mm. If it

is 0 mm, the paper lead edge and

original lead edge is the same . Bu t du e

to lead edge erase, the copy image has

a blank margin (3.5 ± 2.5 mm).

Original (A4)

a

bc

2) Registration Adjustment

Registration can be adju ste d by DGS103 on

the main board.

Origina l le ad

edge posi tion

de

a: lead edge erase (3.5 ± 0.5 mm)

b: registration (0 ± 2 mm)

c: lead edge blank margin

(a + b =3.5 ± 2.5 mm)

d, e: side margin (2 ± 2 mm at each side,

for full size copies. The total of both

side margins is less than 4 mm)

TP103

(PSEN)

DGS103

VR101

CN102 CN101

IC107

IC120 IC115

Paper

6. By-pass Feed Station

The by-pass feed table do es no t use the same feed mechanism as the other f ee din g

stations. It uses a pick-up rolle r in additio n to the feed roller and friction pad system.

To use a larger size than B4 at the by-pa ss fee d ta ble, the large cassette must be

installed in order to support the tra iling part of the paper.

When the by-pass feed table is opened, the pick-up soleno id tu rns on and off once ,

The by-pass feed table, add pap er, and inte rrupt indicators turn on, and the Start key

turns red.

- 21 -

Page 23

When paper is loaded onto th e by-p ass feed table, the paper end sen sor is

Feed Roller (2nd)

de-actuated and Sta rt key tu rns green.

When the Start key is pressed, the pick-up roller is lo were d by th e by-pass pick-up

solenoid to conta ct th e pa pe r stack. When the paper reaches the fee d rolle r, th e

pick-up roller moves up away from the pape r stack.

The size of copy paper is measured at the by-pa ss fee d sta tio n from the first copy as

follows. While the copy paper passe s under the registration sensor, the sensor

output changes from low to hig h. The CPU cou nt s the perio d of the high signa l and

calculates the paper len gth. The scanner return po sitio n corre sponds to this

calculated paper leng th.

When the by-pass feed table is opened, the by-pass table se nso r (a photo interrupter)

is activated and the copier enters by-p ass feed mode.

The by-pass feed mode is the same as interrupt mode. When the by-pa ss f ee d ta ble

is opened, the copier stores th e pre vious job settings in memory.

When the by-pass table is opened, the operator can use the 1st and 2nd cassette

stations before load ing pap er on to the by-pass feed table. Howe ver, whenever paper

is loaded onto the by-pass f ee d ta ble , other feeding statio ns can no t be select ed .

7. Front Loading Feed

The front loading fee d sta tion is located at the bottom of the copier. This is only an

A3 paper feeding station. The F/L tray pape r end senso r (a pho tointerrupter) on the

rear side plate detects bo th paper end and whether or not th e front loading station is

in position.

The direction of the pap er pa th is:

Feed Roller → Relay Roller → Registration Roller → T/S Corona Unit

Registration Roller

Feed Roller

Front Loading Cassette

Relay Rol ler

- 22 -

Page 24

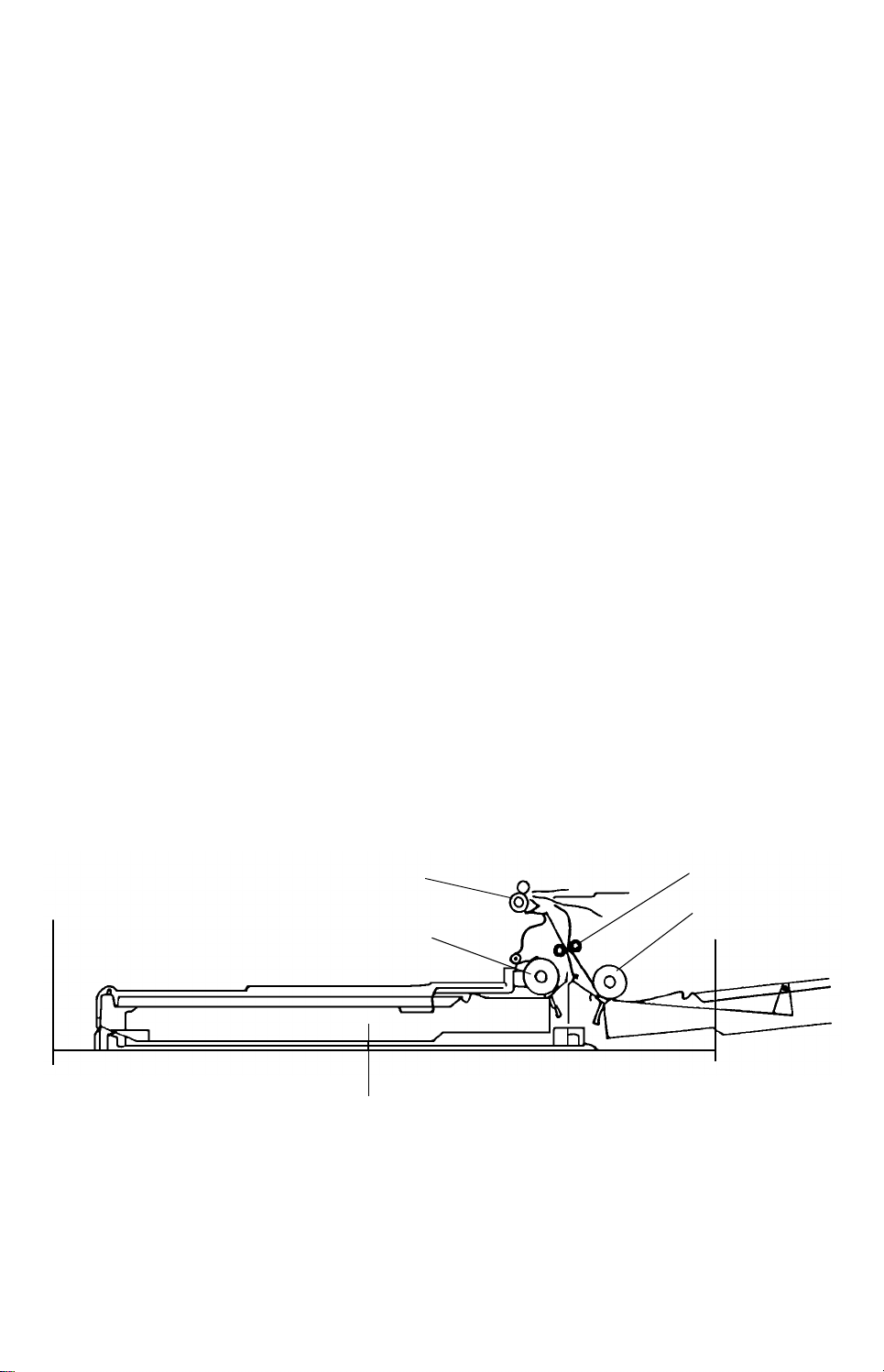

8. Electrical Control

ON

Signal I/O

Main Control Board

CN NO. Signal Level

Size 1 I 102–24B Detection: 5 V

Size 2 I 102–22A

Size 3 I 102–24A

No detection: 0 V

Size 4 I 102–22B

Size 5 I 102–25A

Paper End 1 I 102–23B Paper end:

Paper End 2

I 102–25B

detection

1st Feed MC O 101–5A

2nd Feed MC O 101–3A

By-pass Feed MC O 101–10A

24 V

F/L Feed MC O 101–2A

Relay Roller MC O 101–15A

Registration MC O 101–14B

By-pass Feed

Table Sensor

Registration Sensor

I 101–15A

closed

5 V

no paper

I 101–4A

open

paper

Scan Signal

T0 → 1st feed station

size detection

→ 1st feed station

paper end

detection

→ By-pass feed

paper end

detection

T1 → 2nd feed station

size detection

→ 2nd feed station

paper end

detection

→ By-pass feed

station table

open detection

4.4.2 Replacement and Adjustment

1. Paper Size Sensor Replacement (1st

and 2nd feed stations)

1. Remove the paper size sensor from the

sensor bracket (1 screw).

2. Remove the connector an d rep lace the

sensor.

Paper Size Sensor

- 23 -

Page 25

2. By-pass Feed Table Replacement

Upper By-pass Feed

Guide Plate

1. Open the by-pass fe ed tab le an d remove

the by-pass feed table hinges from the

positioning pins by pressing them inward .

2. Remove the by-pass feed table.

3. Feed Rollers and Friction Pads Replacement

NOTE: Replace the feed roller and th e

friction pad as a set to maintain a

good paper feed and separation

ability.

Snap Ring

1. By-pass Feed Station

1) Remove the by-pass feed tab le.

By-pass Feed

Table

Friction Pad

MT78

2) Remove the upper by-pass fee d gu ide

plate (2 screws).

3) Remove the pick-up roller, feed roller,

and gear (2 snap rings).

NOTE: When reinstalling the feed

roller, make sure that the hub is

positioned toward the rear on

Hub

Pick-up

Roller

Feed Roller

Friction Pad Holder

the shaft.

4) Remove the friction pad hold er by pressing the lower hooks using long no se

pliers.

5) Peel off the friction pad and stick a new

pad on the friction pad holder.

NOTE: Check that the friction pad is

A = 0.05 ~ 0.35 mm

(Front)

0.05 to 0.35 mm below the

surface of the front lip .

6) Grease both sides of the friction pad hold er with Mobil Temp 78.

7) Reinstall the friction pad holde r and the by-pa ss fee d ta ble .

NOTE: 1) Do not touch the surface of the new friction pad with oily fingers.

2) Be careful not to damage the pressu re sprin gs.

3) The lip side should be positio ned towards the outside of the

machine.

- 24 -

Page 26

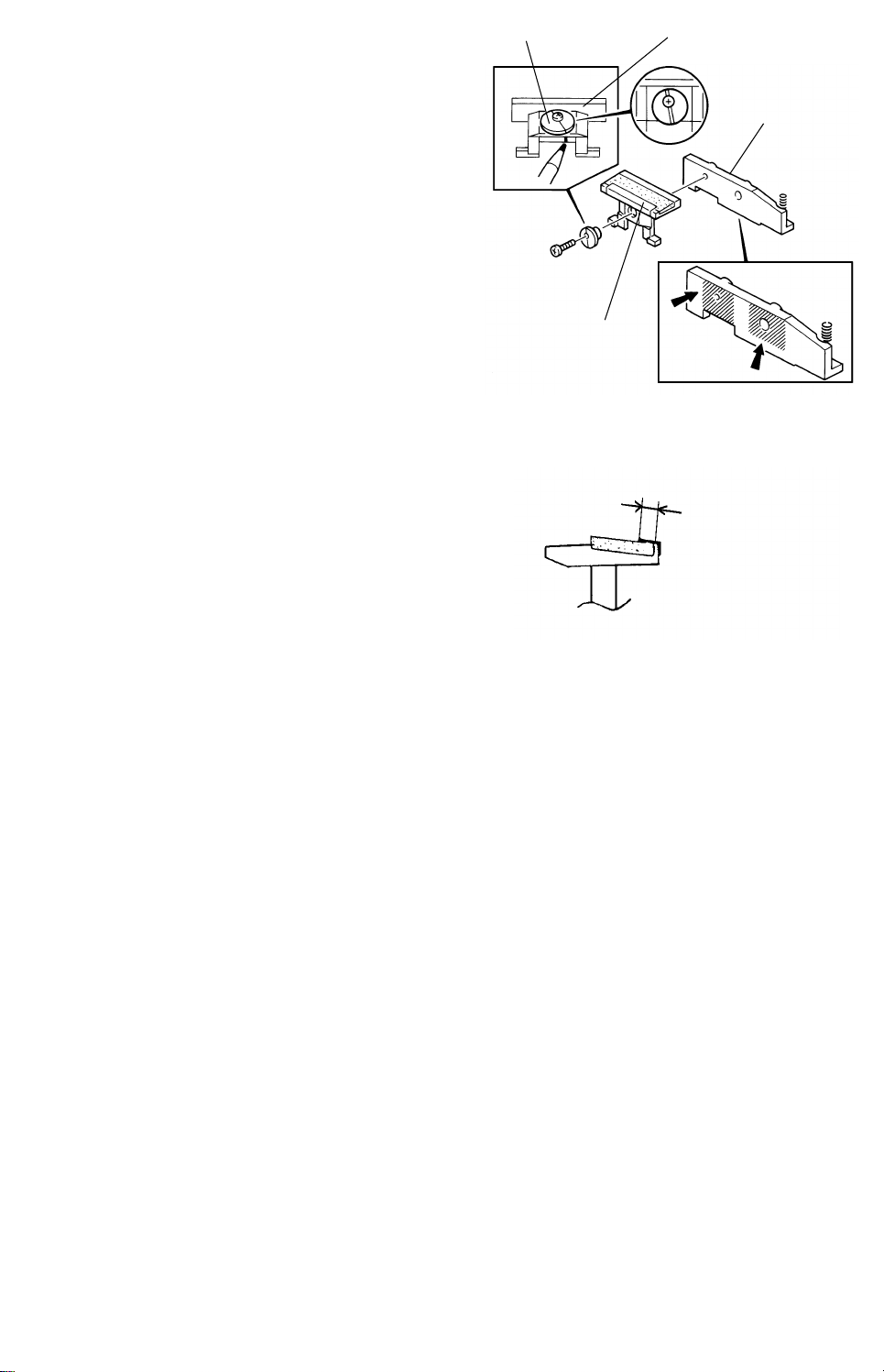

2. 1st and 2nd Feed Stations

Pad Positioning

Mechanis m

Friction

Pad Holder

Hub

1) Remove the feed roller and hub (1

snap ring).

NOTE: When reinstalling the feed

roller, make sure that the hub

is positioned toward th e rea r

on the shaft.

2) Remove the cassette arm (2 screws).

3) Mark the position of the eccentric cam

groove on the friction pad holder.

Friction Pad

Eccentric

Cam

4) Remove the friction pad holder (1

screw and 1 eccentric cam).

5) Peel off the friction pad and stick a new

pad on the friction pad holder.

NOTE: Check that the friction pad is 0.05

to 0.35 mm below the surface of

the front lip.

6) Clean and grease the swivel surface of

the friction pad holder with Mobil Temp 78.

7) Reinstall the friction pad holder.

NOTE: Be sure the legs of the friction pad holder are positioned und er th e

spring loaded pad positio nin g mechanism.

The eccentric cam should be secured in the origin al po sitio n

referring to the mark made in step 3).

MT78

Feed Roller

A = 0.05 ~ 0.35 mm

Cassette Arm

(Front)

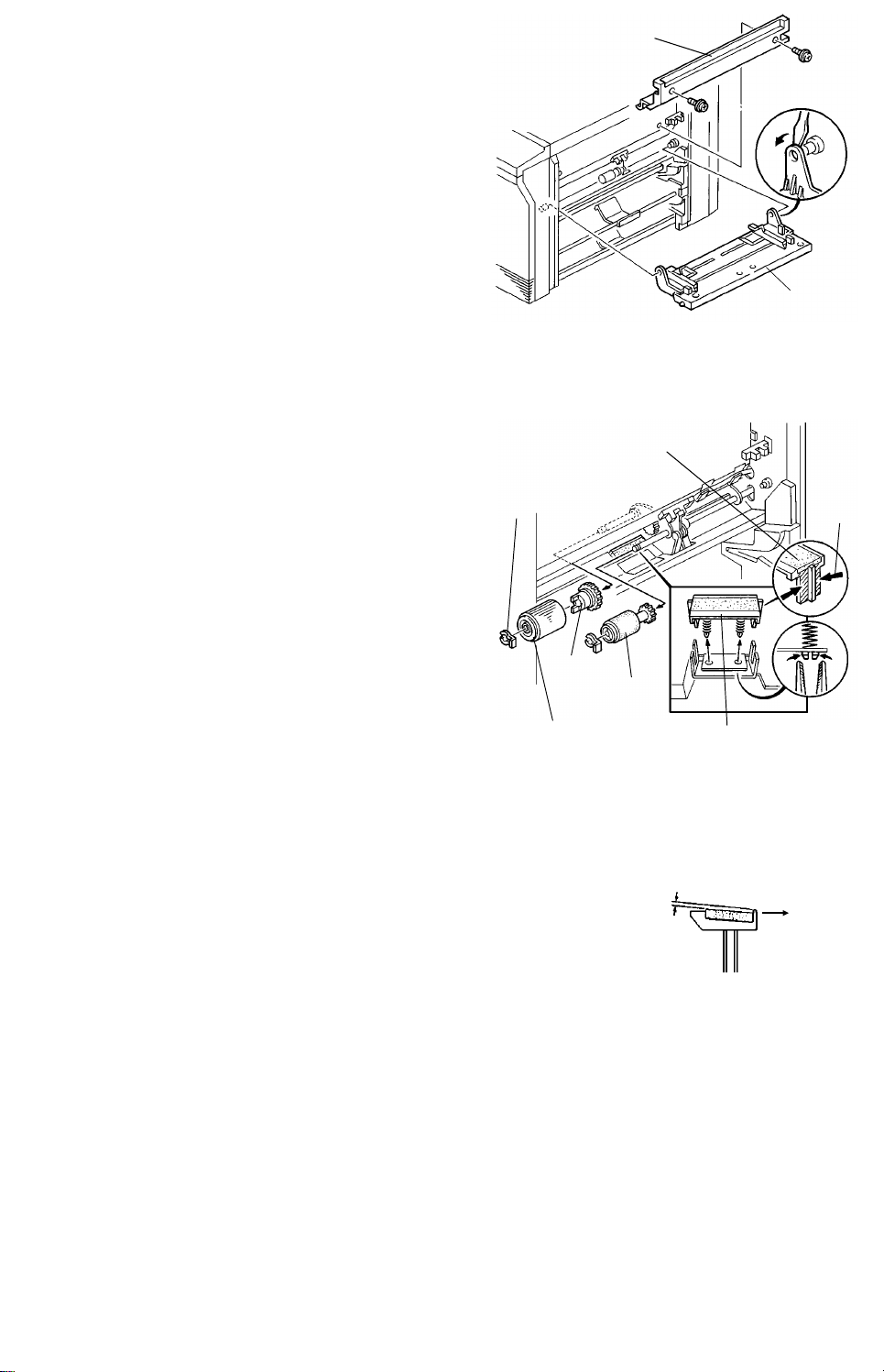

4. F/L Feed Station

1. Pull out the F/L tray and remo ve th e A3

cassette.

2. Remove the screw securing the feed roller

bracket.

3. Remove the F/L feed roller (1 snap ring).

NOTE: When reinstalling the feed roller,

make sure that the hub is

positioned towa rd th e front on the

shaft.

4. Remove the friction pad assembly (1

stepped screw).

- 25 -

Feed Roller

Hub

Feed Roller

Bracket

Friction Pad

Assembly

Page 27

5. Mark the position of the eccentric cam

MT78

P

groove on the friction pad holder.

Eccentric Cam

Friction Pad Holder

6. Remove the friction pad holder f rom th e

holder bracket (1 screw and 1 eccentric

cam).

7. Peel off the entrance mylar and the friction

pad and stick new ones on the friction pad

holder.

NOTE: Check that the friction pad is 0.05

to 0.35 mm below the surface of

the front lip.

Make sure that the overlapping

length of the entrance mylar on the

friction pad (P) is 2.5 to 3 mm.

Holder Bracket

Entrance Mylar

2.5 ~ 3.0 mm

8. Clean and grease the swivel surface of the friction pad holder with Mobil Temp

78.

9. Reinstall the friction pad hold er on the hold er bra cket .

NOTE: The eccentric cam should be secure d in the original position refe rring to

the mark made in step 5).

10. Clean and grease the swivel surface of the holde r b racke t with Mo bil Temp 78.

11. Reattach the friction pad assemb ly to the F/L fee din g sta tio n.

NOTE: Be sure the legs of the friction pa d ho lde r are po sitio ne d unde r the

spring loaded pad positioning mechanism. Make sure that the pressure

spring is properly positioned and the frictio n pa d asse mbly swivels

smoothly.

- 26 -

Page 28

5. Friction Pad Pressure Adjustment

(fig. 2)

NOTE: This adjustment is require d when multifeeds or misfeeds occur with th e

customer’s brand of paper.

If replacement of the fee d rolle r and the frictio n pa d does no t solve the

problem, do the following adjustment.

1. Remove the cassette.

2. Turn the eccentric cam [A] to adjust the

friction pad pressure as shown in figu res 1

and 2.

NOTE: If the eccentric ca m groove is

aligned vertically, the gap between

the feed roller and the friction pad

will become narrower or wider as

shown in figure 3.

• When multifeed occurs, make

the gap narrower.

• When misfeed occurs, make the

gap wider.

[A]

(fig. 1)

Narrow Normal Wide

(fig. 3)

- 27 -

Page 29

4.5 OPTICS

2nd Mirror

Scanner Motor

4.5.1 Mechanical Parts

1. Overview

Exposure La mp

3rd Mirror

Reflector

1st Mirror

Lens

4th Mirror

Toner Shield

Glass

During the copy cycle, an image of the original is reflecte d onto the drum surface via

the optics assembly as follows.

Light path:

Exposure Lamp → Original → First Mirror → Second Mirror → Third Mirror → Lens

→ Fourth Mirror → Ton er Sh ield Glass → Drum

(When the exposure lamp is positioned close to the far left, it is at the home position.)

This model has ten standard repro du ctio n ratios: six reductions, three enla rge ments,

and full size. In addition, it has a zoom fu nct ion.

The user can change th e rep roduction ratio in one perce nt st eps f rom 50 % to 200 %.

This machine has an automatic ima ge control system in which the copier comput es

the correct image density and adjusts the deve lop ment bias as a result of measuring

the original background densit y using the ADS sen sor.

2. Scanner Drive

1st Scanner

2nd Scanner

Scanner Drive

Wire

Damper wheel

Scanner Home

Position Sensor

- 28 -

Page 30

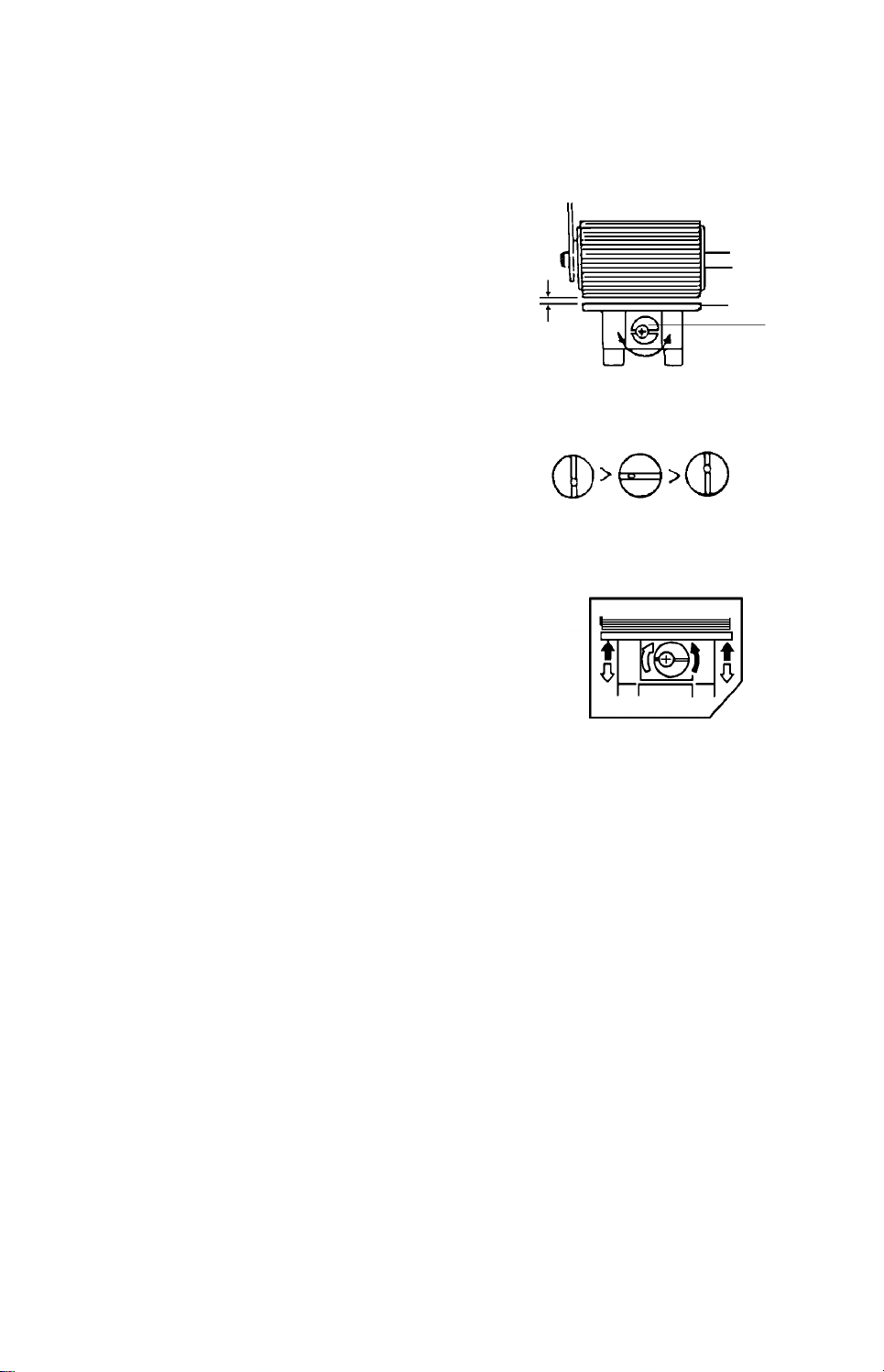

This model uses a dc servomotor to drive th e scanners.

Lens Drive Wire

Full Size

(Reduction)

The scanner motor chan ge s the scann er spe ed dep en din g on the reproduction ratio.

3. Lens/Mirror Positioning

The lens motor (a stepping motor) changes the

lens and 2nd scanner posit ion in accord an ce

with the selected rep roduction ratio to provide

Lens Drive

Pulley

Lens Home

Position Sensor

the proper optical dista nce between the lens

and the drum surface.

1. Lens Positioning

The output gea r o f th e lens motor engages

the gear of the lens drive pulley directly.

Lens Drive Bracket

The lens drive wire is wrapped around the

lens drive pulley and is connected to the

Lens Motor

lens drive bracket. As the lens mot or is a

stepper motor, the rotation of the lens drive

pulley moves the lens back and forth in

discrete steps.

The lens home position sensor informs the

optics CPU (IC403) when the lens is at the

Lens Movement

Lens H.P.

Sensor

(Enlargement)

full size position (home position). The

optics CPU determines the lens stop

position in reduction and enlargement

modes by counting the number of steps the

motor makes.

When the reproduction rat io is chan ged,

the lens moves directly to th e sele cted lens

position.

When the lens moves from one

enlargement ratio to another or from one

reduction ratio to ano th er, it does not

moves to the home position.

- 29 -

Page 31

2. Light Shading Mechanism

Shading

Cam Plate

The machine is designed so tha t the

intensity of the light across the drum is

uniform at 100% reproduct ion . However,

the intensity of the light striking the drum

tends to increase toward the edges when

the reproduction rat io is d ecre ased, as a

result of the change in position of the le ns.

For this reason, a light shading mechanism

has been installed to pre ven t un even

illumination when making reduced copies.

When the lens moves in the reduction

direction, the groove cams move th e

shading plates closer together.

The plates block part of the lig ht passing

through the lens to keep the intensi ty of the

light on the drum even.

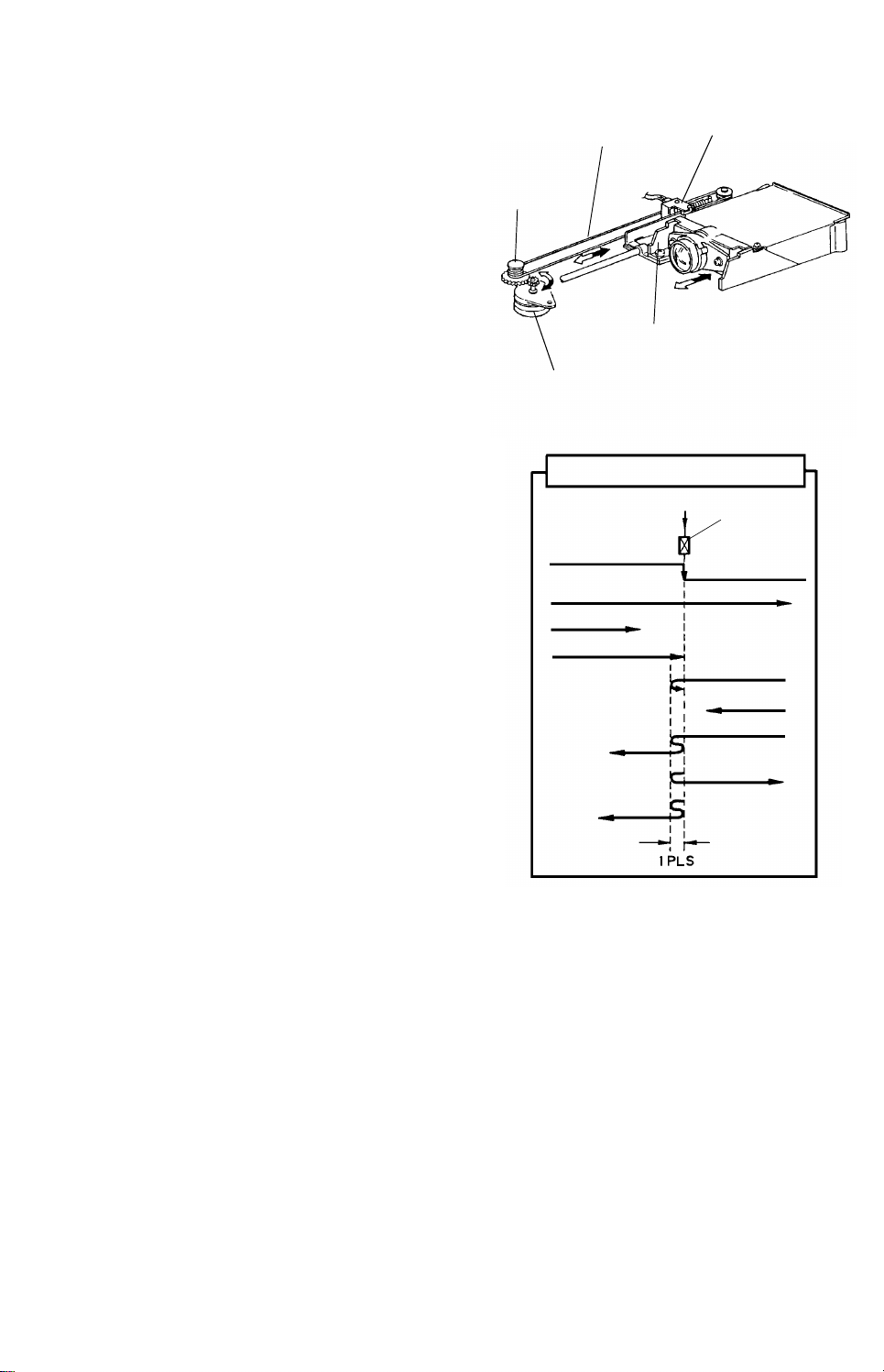

3. 2nd Scanner Drive

In order to provide the proper optical

distance between th e original and the lens,

this model uses a stepper moto r to move

the second scanner.

A separate motor is used because the

second scanner must tra vel a lon g distance

in order to accommodat e a wide ra ng e of

reproduction ratios.

When the second scanner moto r drives the

second scanner drive pulley, the wire

pulleys rotate as shown by the black

arrows (➡).

So, the second scanne r moves in the

direction of the white arrow (ð).

Shading Plate

2nd Scanner

Drive Pulley

Groove Cam

2nd Scanner

2nd Scanner

Pulley

- 30 -

Page 32

When the second scanner moves fro m enlargement to reduction or fro m re duction to

enlargement, it does not move to the home position.

NOTE

1) When the zoom key is pressed, the buzzer rings at reproduction ratios between

50 ~ 155% but does not ring at 15 6 ~ 2 00 % an d the speed of the reprod uction

ratio indicator is higher.

2) The effective original area is restricte d at repro du ctio n rat ios of 156 ~ 200% . This

causes partial enlargeme nt beca use the lens rest ricts exposure lamp movement.

ex): Effective origina l area at 200% enlargement.

Copying can be in the range as sho wn.

With 200% enlargement, an A5 original

can be copied onto A3 paper but the

trailing 84 mm does not appear on the

copy image. So, the trailing 42 mm of the

A5 original is not copied.

Formula of the effective vertical

enlargement are a:

180

– 180 M + 438

M

Where M: reproduction ratio

(200% is 2)

180: focus distance

438: maximum amount of

movement

- 31 -

Page 33

4. Automatic Image Density Sensing (ADS)

Manual image

density mode

This copier has an ADS system for good quality copy images. Light from the

exposure lamp is reflected from the original and travels to the ADS sen sor on the

lens base via the mirror.

Sampling starts 3 millimeters from the leadin g edge of the orig ina l in full size

mode.

The length and width differ for each reproduct ion ratio.

The photosensor circuit converts the light intensity to a voltage.

The detected voltage is amplified and sent to th e main board.

It then computes the background density of the original from the maximum

sample voltage and changes the development bias accordingly.

The exposure lamp volta ge is constant (equal to the volta ge at the manual

density level 4) regardless of the image density of the original.

Original scale

1) Comparison of the manual image

density key and the auto ima ge

density key.

When the manual image density

mode is selected, the exposure lamp

voltage and the development bias

for each level are as shown to the

right.

Only the exposure lamp volta ge

varies according to the in pu t.

This is based on preventio n of ID

level decrease at high manual image

density levels.

Output voltage + Development Bias Control

➀ ➁ ➂ ➃ ➄ ➅ ➆

V0-4

0

V

V0+6

V

0+11

V

0+16

0+23

V

V

0+23

(V0 is the voltage of the lamp at the

manual image density level 2. )

- 32 -

Page 34

Manual image

16 Pitch

R: 1 mm Pitch

0 7 F

density mode

level

1 320 V

2 290 V

3 260 V0+6

4 260 V

5 260 V

6 260 V

7 320 V

B VVDE VB V

V

0–4

0

0+11

0+16

0+23

0+23

~ 1.65 440 V0+11

1.65~2.16 380 V

2.16~2.65 320 V

ADS mode

2.65 ~ 260 V

0+11

0+11

0+11

Drum temperature: 30°C

VB: Development bias voltage

V: Lamp voltage

VDE: ADS input voltage

(V0 is the voltage of the lamp at

the manual image density level 2. )

2) Function of DPS102 on th e Main Boa rd

• DPS102

No.12345678

ON

OFF

Nor-

mal

large

á

ON

OFF

â

small

ON ON

ON OFF ON OFF

OFF ON OFF ON

OFF OFF OFF OFF

OFF OFF

OFF ON OFF ON

ON OFF ON OFF

ON ON ON ON

TB: 0.2%

Pitch

large

á

ON

OFF

â

small

ON ON

OFF OFF

E: 0.8 mm

Pitch

Nor-

mal

(OFF)

TB: Vertical magnification

E: Lead edge erase

R: Lead edge registration

DGS103

(Scanner speed)

- 33 -

Page 35

4.5.2 Replacement and Adjustment

Left Scale

1. Exposure Glass Removal

1. Take off the left scale (2 short screws).

2. Grasp the left edge of the exposure glass

and lift it up slightly. Slide the other edge

out from under the right glass holder.

Remove the exposure glass.

NOTE: Be sure that the two screws a re

M4 x 6 but others are M4 x 8.

2. Exposure Lamp Replacement

CAUTION: Be sure that the main switch is

turned off before replacement.

1. Remove the exposure glass.

2. Move the first scanner to the position

where the rear frame is cut out.

Exposure Glass

Reflector Cover

Release Lever

3. Remove the reflector cover (2 screws).

4. Wrap a strip of paper around the expo sure

lamp as shown.

5. Press the release lever on the front lamp

terminal as shown and take out the lamp .

(Do not touch the reflect or or the new

exposure lamp with your bare hand s; use a

strip of paper as shown.)

NOTE: The blister on the lamp must poin t

toward the mouth of the reflector

as shown.

Blister

Exposure La mp

Reflector Cover

Reflector

- 34 -

Page 36

3. Exposure Lamp Positioning

Filament

CAUTION: Be sure that the main switch is

turned off before adjustment.

1. Remove the exposure glass.

2. To correct the position of the filamen t in

parallel with the sight hole, tu rn the

adjusting screw.

NOTE: 1. Do not adjust vertically using

the adjusting knob.

2. If the adjustment is incorrect ,

uneven image density or dirty

background will appear on the

copy image.

4. 2nd and 3rd Mirror Replacement

Reflector Cover

Adjusting Screw

Exposure

Lamp

2nd Mirror

Front Spring

Plate

1. Remove the front spring plate.

2. Carefully pull the mirror towards the front.

NOTE: Be careful not to dro p rear spring plate.

Rear Spring Plate

2nd Mirror

- 35 -

Page 37

3. Take off the protective sheet only a t both ends of th e mirror.

Sub Reflector

Upper

Seal

4. Check that the rear sprin g pla te is set properly.

5. Insert the mirror into the front side plate cut ou t and set it on the rear spring plat e

properly.

6. Locate the bottom of the front spring plate and rotate the to p of the spring into

position.

NOTE:

1. Install the mirrors with the

reflecting surface facing

2. Attach the spring pla te to

the lens as shown.

Spring plate

Reflecting

surface

Spring plate

7. Check whether the mirrors vibra te as sh own .

If so, reinstall the sprin g pla tes after bending them.

NOTE: To prevent vibration, replace the

spring plates whenever the mirrors

are replaced.

8. Remove the rest of the protective sheet.

5. 1st Mirror Replacement

the nonreflecting surface.

Check vibration

1. Remove the top cover (12 screws).

2. Remove the sub reflector (2 screws).

3. Remove the upper seal at th e front side.

4. Free the lamp harness fro m t he bracke t (1

screw).

5. Lift the 1st scanne r through the positio n

where the front frame is cut out.

6. Remove the front spring plate.

7. Pull the mirror towards the front of the

machine while holding the rear sprin g plate

with your fingers.

8. Remove the rear spring plate.

9. Take off the protective sheet only at both

ends of the mirror.

- 36 -

Rear Spring Plate

Front Spring Plat e

Lamp Harness

Page 38

10. Position the rear spring pla te and hold it with you r f ing er while in sert ing the mirror

Spring plate

into the rear spring plate through the ho le in the front of the scanne r.

NOTE: 1. Install the mirror with the reflecting surfa ce up permost .

2. Install the mirror with th e cutout part facing down.

3. Attach the sprin g plate to the non reflect ing surface.

Reflecting surface

Cutout part

11. Position the front spring plate.

12. Make sure that the mirror do es not vibrate.

13. Remove the rest of the protective sheet.

14. Reinstall the othe r co mpo ne nt s.

- 37 -

Page 39

6. Scanner Drive Wire Replacement

Wire Clamp

Damper Wheel

Scanner Drive Wire

Tension Spring

1. Turn off the main switch.

2. Remove the platen cover, the mounting studs, and the top cover.

3. Remove the left scale (2 sho rt screws) an d th e exposure glass.

4. Remove the rear cover (3 screws) and lower th e PCB plate (2 screws).

5. Remove the damper wheel.

6. Loosen the wire clamp screw.

7. Remove the lamp stabilizer bracke t (1 screw).

8. Move the 2nd scanne r to the return position.

9. Unhook the tension spring and remove the spring. Take ou t th e old wire.

10. Remove the home position sensor bracket (1 screw).

- 38 -

Page 40

WP2

(2nd Scanner Pulle y)

Scanner Drive Pulley

7)

Damper Wheel

WP3

5)

6)

WP4

11)

3)

WP5

WP6

10)

9)

Wire Clamp

4)

8)

Bead

2) Long End

WP1

1) Short End

11. Run the scanner drive wire over t he pulle ys in the follo wing order.

1) Attach the tensio n spring to the short end eyele t an d ho ok the other end of

spring to the cut out in the optics frame temporarily.

2) Set the bead of the scanne r drive wire in the holes in the 2nd scanner drive

pulley with the short end located at the lower side (WP1).

3) Two and half turns (WP1)

4) Outer track (WP2)

5) Lower side (Wire Clamp)

6) Lower track (WP3)

7) Inner track (WP4)

8) Three and half turns from lower to upper (Scanner Drive Pulley)

9) Outer track (WP4)

10) Lower track (WP5)

11) Inner track (WP2)

12) Outer track (WP6)

12. Set the long end eyele t in th e ho ok of the ten sion spring.

13. Reset the damper wheel.

14. Rotate the scanner drive pulle y and ma ke sure that the scanner drive wire moves

smoothly and that the r e is no ove rlapping on the scanner drive pulle y.

- 39 -

Page 41

7. Wire Clamp Positioning

When the second scanner is 52 mm from the left opt ics frame , secure the first

scanner wire clamp so that its end is positioned about 1 mm inside the home position

sensor.

When the copy image is enlarged, move th e wire clamp to the lef t, and when the

copy image is reduced, move the wire clamp to the right.

Standard

Scanner H.P.

Sensor

Horizontal magnification : ±0.5%

Vertical magnification: ±1%

Vertical magnification can be

adjusted by DPS102 on the

optics control board.

Wire Clamp

Scanner H.P.

Sensor

Left Optics

Frame

8. Scanner Motor Replacement

1. Turn off the main switch.

2. Remove the platen cover, the mounting studs, and the top cover (8 screws).

3. Remove the left scale (2 sho rt screws) an d th e exposure glass.

4. Remove the rear cover (3 screws) and lower th e main board bracket (2 screws).

5. Tape the scanner drive pulley and the wire pulle ys A .

6. Loosen the scanner drive pulley (2 Allen screws).

7. Remove the scanner drive pulley from th e motor shaft.

8. Remove the nylon wire clamp on the left side of the toner supply clutch bracket.

9. Remove the scanner motor (4 screws and 2 con nectors).

Scanner Motor

Wire Clamp

Scanner Drive

Pulley

- 40 -

Page 42

9. Lens Motor Replacement

Wire Saddle

Left Fork

1. Remove the fusing unit an d th e left inner

cover (2 screws).

2. Remove the rear cover (3 screws) and

lower the main board bracket (2 screws).

3. Disconnect the lens motor connector

(yellow) and free the harness from the wire

saddle.

4. Remove the left cover (4 screws) and the

exit guide plate (2 screws).

5. Remove the lamp regulator (2 screws and

2 connectors).

Lens Motor

Harness

Exit Guide

Plate

Lamp Regulator

6. Remove the left scale (2 short screws) and

the exposure glass.

7. Remove the lens housing cover (3 screws)

and remove the lens drive wire from the

pulleys by removing the te nsion spring.

NOTE: When reinstalling the lens drive

wire, do the following steps

referring to the illustration:

1) Set the bead of the lens drive

wire in the left fork and wrap the

wire around the lens drive

pulley for three and half turns.

2) Run the wire on the tension

pulley and set the wire bead in

the right fork.

3) Set the tension spring.

8. Move the scanners to the return position

and take out the lens drive pulley from the

motor shaft (1 E-ring).

Lens Drive

Pulley

Lens Housing Cover

Fusing Upper

Guide Plate

Tension Spring

Right Fork

Lens Drive

Wire

Tension

Pulley

9. Remove the screws from the front and rear

side plates (2 for the front and 1 for the

rear) which secure the fusing upper guide

plate.

10. Remove 3 screws that secure the lens

motor assembly to the optics base plate.

11. Take out the lens motor assembly f rom th e

left side while lowering the fusing upper

guide plate.

- 41 -

Lens Motor

Lens Drive

Pulley

Motor

Bracket

Lens Drive

Pulley

Page 43

12. Remove the lens motor cover from the motor assembly (1 screw).

13. Remove the lens motor from t he bracke t (2 screws).

14. Install the new motor on the motor bracket and reassemble the copier.

10. Light Intensity Adjustment

(Exposure Lamp Voltage Adjustment)

NOTE: a. This adjustment should be

done when the rest time

compensation of the bias

voltage is 0V. If the main power

switch has just been turned on,

make ten copies before

proceeding to check the light

intensity. The test copy should

be made 10 seconds after the

tenth copy was made.

VR1

b. ADS voltage adjustme nt must

be done after light intensity

adjustment.

Lamp Regulator

Board

ADJUSTMENT STANDARD:

Level 2 of the gray scale on the OS-A3 chart sho uld be faintly visible on the copy

when the 4th level of the density control is selected.

1. Clean the optics (mirrors, lens, reflect ors, expo sure glass, toner shield glass).

2. Turn on the main switch and allow it to warm up.

3. Set the image density level at the No. 4 position and make 11 test copies of the

OS-A3 test chart.

4. Confirm that the second level of the gray scale is faintly visible on the 11th copy.

If the light intensity is not correct , pro cee d to step s 5 and 6.

5. Remove the left cover (4 screws). (If a sort er is installed, the sorter and the sort er

adapter should be remo ved .)

6. Adjust VR1 on the lamp regulat or bo ard to ach ieve prop erly illumin ated copies.

NOTE:

• If the test copies were made within 3 minutes after making the

previous copies, check the ligh t intensity on the 4th copy.

• If it is over 3 minutes, check the light intensity on the 6th cop y.

- 42 -

Page 44

11. ADS Voltage Adjustment

NOTE: 1. ADS voltage adju stme nt is required in the following cases.

1) Exposure lamp voltage adjustment.

2) Exposure lamp replacement.

3) When using ADS mode, abnormal co py imag e ap pears.

4) Main board replacement.

1. Place more then 5 sheets of A3 pape r o n th e exp osure glass.

2. Turn on DIP SW101-1 on the main board (free run mode).

3. Set SP mode (88) to "11". (Ref er to the SP mode access procedure. )

4. Leave SP mode.

5. Access ADS input mode as shown.

Interrupt key → "4" key → Interrupt key

6. Press the Start key.

7. Adjust the ADS voltage to 3.0 ± 0.06 V as displayed in the ma gnification indicator

of the operation pa ne l by using VR102 on the main board.

NOTE: 1. Remove the 1st cassette from the copier to make full scans so that

the adjustment will be easy.

2. Adjusting VR10 2 sho uld be done based on the dat a af ter 3 scans.

3. The ADS data is based on the da ta when the exposure lamp moves

from the home position to the center of exposure glass.

4. After the adjustment, be sure that the SP mod e an d DIP SW a re

reset. (Set SP mode (88) to "10".)

5. When adjusting ADS volt ag e, set the image density mode to

"automatic image density mode".

- 43 -

Page 45

4.6 AROUND THE DRUM

4.6.1 Mechanical Parts

1. Overview

The drum drive belt turns the drum pulley when the main mot or is on. The rear drum

flange is secured by a screw on th e dru m sh af t an d the drum spring presses the

drum onto the rear drum flange.

Drum

Drum Spring

Drum Shaft

Rear Drum Flange

Drum Drive Belt

Drum Drive Pulley

So, the rotation is transmitted from the drum drive pu lley to the drum sha ft and then

through the rear drum flange to the drum.

2. Drum Charge

Power Pack C/B

In the dark the corona wires ge ne rat e a coro na

of positive ions when the C/B power pack

applies a high positive voltage (+5.0 kV ~ 7.5

kV).

Charge

Corona Unit

The selenium coating receives a uniform

positive charge (700 ± 50 V) as it rot ates past

the corona unit.

The main motor fan provid es a smoo th flow of

air to the interior of th e cha rge corona unit to

prevent uneven build-up of positive ions.

The diameter of the charg e coro na wire is 0.08

mm and the wire surface is coated with carbon.

The wire cleaner cleans off any particle s on th e

wires when someone pulls out the coro na unit

and pushes it back.

- 44 -

Main Motor Fan

Wire Cleaner

Page 46

3. Erase Lamp

The erase lamp illuminates the area of the cha rge d dru m surface that will not be

used for the copy image.

The erase lamp reduces to ne r consu mption and the drum cleaning loa d.

Erase Unit

Charged Area

Charge

Corona Unit

Original Lead Edge

Front Endbloc k

Cover

[Density Detection Cycle]

Left Scale

Sensor Pattern

Original Lead

Edge

Sensor

Pattern

Origina l Le ad

Edge

Exposure Glass

Toner Image

Original

Paper

Sensor Pattern

Charged Area

A: Lead Edge Erase Margin --- 3.5 ± 0.5 mm

B: Side Margins --- 2 ± 2 mm each

(For full size copies the total of both side

margins is less than 4 mm.)

LO: Original Image width

LC: Charged width on the Drum

EL: Lead Edge Erase

ES: Side Erase

R: Lead Edge Registration --- 0 ± 2 mm

A+R:Lead Edge Blank Margin --- 3.5 ± 2.5 mm

The erase lamp consists of a line of 64 LEDs ext en din g across the full width of the

drum.

The erase lamp performs lea d ed ge erase and sid e era se.

The erase lamp unit also has two thermistors: TH-1 and TH-2.

Both of these thermistors detect th e temperature around the drum.

TH-1 determines the proper rest time compe nsa tio n, and TH-2 controls th e

development bias voltage.

- 45 -

Page 47

1. Lead Edge Erase

The entire line of LEDs turns on when the main mot or tu rns on . The y stay on unti l

the erase margin slight ly overlaps the lead edge of the orig ina l ima ge area on th e

drum (Lead Edge Erase Margin).

This prevents the toner densit y sensor pattern from being develo ped on every

copy cycle and prevents the edge of the orig ina l from ap pearing on the copy

image. The width of the lead edge blank margin can be adju sted with DIP

SW102-5, 6 and -7 on the ma in board.

During image density detection cycles (once eve ry ten cycles), th e cen ter block

of erase lamps turns off long enoug h fo r t he senso r p at te rn to be developed.

2. Side Erase

Based on the paper size and on the reproduction ratio, the LEDs turn on in pairs

(one on each side) to discharg e th e drum potential on both sides. For A3

copying, the drum pote ntial is not erased by the erase lamp but by the charg e

corona end blocks.

3. Erase Lamp

32 LEDs

Erase lamp segments are turned on and off based on the cassette data and

reproduction ratio da ta as shown on the next page.

For full size and enlargement copyin g, on/ of f switch ing is based only on cassette

data. For reduction cop ying, it is based on an OR circuit between casse tte data

and reproduction rat io da ta .

- 46 -

Page 48

4. Erase Data

• Cassette Data (0: off, 1: on)

Cassette Size 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

A3 00000000000000000

B4 11110000000000000

A4 00000000000000000

A4 Lengthwise 1 1 1 1 1 1 1 1 1 1 0 0 00000

B5 11110000000000000

B5 Lengthwise 1 1 1 1 1 1 1 1 1 1 1 1 10000

A5 11111111110000000

A5 Lengthwise 1 1 1 1 1 1 1 1 1 1 1 1 11110

B6 11111111111110000

B6 Lengthwise 1 1 1 1 1 1 1 1 1 1 1 1 11110

00000000000000000

Reproduction Ratio Data (0: off, 1: on)

•

Ratio (%) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17

50 ~ 53 11111111111111110

54 ~ 57 11111111111111100

58 ~ 60 11111111111111000

61 ~ 63 11111111111110000

64 ~ 67 11111111111100000

68 ~ 70 11111111111000000

71 ~ 72 11111111110000000

73 ~ 75 11111111100000000

76 ~ 78 11111111000000000

79 ~ 81 11111110000000000

82 ~ 84 11111100000000000

85 ~ 87 11111000000000000

88 ~ 91 11110000000000000

92 ~ 94 11100000000000000

95 ~ 97 11000000000000000

98 ~ 99 10000000000000000

100 00000000000000000

- 47 -

Page 49

4. QL and PTL

Lamp Stabilizer

Pre-Transfer Lamp

In preparation for the next copy cycle, light

Quenching Lamp

from the quenching lamp neutralizes any latent

image charge remaining on the drum.

The cold cathode lamp used for qu en chin g is

similar to the PTL; however, th e ligh t intensity

of the QL is slightly less than tha t of the PTL.

This is because of the darkness of the filte r

colors. The cold cathod e lamp has th e

characteristics of low power consumption and

low heat output combined with strong, even

light outp ut.

5. Drum Heater

The drum heater (8 W) is located above the drum to warm the drum when the main

switch is off.

- 48 -

Page 50

6. Drum Section Timing (For the 1st feed station, A4)

Main Switch

Start Key

Blade Solenoid

Erase Lamp

QL/PTL

Bias

T/S

• PCC

1st Feed MC

Charge Corona

Scanner

ID Sensor LED

Pick-off Pawl Solenoid

Toner Supply Clutch

Fusing Exit Sensor

T1: When the Start key turns on, the QL, PTL, and Erase lamp ligh t.

T2: The charge corona turn s on 0. 68 second after the Start key is presse d.

T3: In the ID pattern mode, when the Start key is pressed, A5 widt h erase begins at

0.98 second. Afte r 0.1 8 seco nd the copy image will be erased (lead edge erase).

T4: 1.23 seconds af te r t he Sta r t key is pressed, mode erase begins.

T5: If full erase begins a ft er 2.49 seconds of erase, the charge turns off.

T6: The T/S charge, PCC, QL, PTL, and erase lamp turn off within 0.12 second after

the fusing exit sensor d et ect s t he trailing edge of the copy paper.

- 49 -

Page 51

4.7 DEVELOPMENT AND TONER SUPPLY SECTION

Paddle Rolle r

4.7.1 Overview

Negatively charged toner is attracted to the positive ly charg ed area s of the dru m,

developing the latent image.

The negative triboelectric cha rge on tone r particles is generated by friction betwee n

the carrier and toner particles.

Doctor Blade

Permanent Magnet

Development

Roller Sleeve

4.7.2 Mechanical Parts

1. Overview

The paddle roller picks up developer in it s paddles and transports it to the

development roller. In ternal permanent magnets in the development roller attract the

developer to the developmen t roller sleeve.

The turning sleeve of the deve lopment roller then carries the deve loper past the

doctor blade. The doctor blade trims the developer to the desired thickness and

creates back spill to the cross mixing mechanism.

The main CPU checks toner density usin g th e image density sensor.

When toner density is low, the toner sup ply clut ch turns on.

- 50 -

Page 52

2. Cross Mixing

Doctor Blade

This copier uses a standard cross mixin g

mechanism to keep the ton er an d de velo pe r

evenly mixed. It also help s agit ate the

developer to prevent clumping and helps

create the triboelectric charge.

The developer on the tu rning development

roller is split into two parts by the doctor blade.

The part that stays on the deve lopment roller

forms the magnetic brush an d de velo ps the

latent image on the drum. The part that is

trimmed off by the doctor blade goes to the

backspill plate.

As the developer slides down the backspill

plate to the paddle roller, it is moved slightly

toward the rear of the unit by the mixing vane s.

Part of the develope r falls into the auger inlet

and is transported to the front of the unit by the

mixing auger.

Development

Roller

Mixing Vanes

Auger

Backspill Plate

Paddle Rolle r

3. Drive Mechanism

The main motor turns the gears of the

development unit in the followin g ord er.

Development drive: A → B → C → D

Toner supply drive: E → F → G → H

The paddle roller knob has a one way clutch

inside. The one way clutch prevents the

development roller from turnin g in the opposite

direction, which would cause the deve lop er

brush to damage the uppe r b rush seal.

H

E

G

F

D

A

A: Development Drive Gear

B: Development Roller Gear

C: Idle Gear

D: Paddle Roller Gear

Auger Gear

Spring Plate

B

C

Paddle Rolle r

Knob

- 51 -

Page 53

4. Bias

Bias Terminal

Manual ID Level

ADS Data

The charge on the drum surface is dissipated

in direct proportion to the int ensity of the

reflected light from the origin al.

As the light intensity corresponding to the dark

areas of the image is weak, the drum potential

remains.

On the other hand, the majority of the drum

potential corresponding to the original

background disappe ars. However, the potential

does not disappear completely.

Therefore, a positive development bias is

applied to the development roller to prevent the

drum areas corresponding to the backgro un d

from being developed (this pre vents dirty

background).

The development bias voltag e is supp lied from

the power pack C/B to the bia s t ermin al via the

bias terminal plate.

From

power pack

- C/B

Development

Roller

Bias Terminal Plate

1. Bias Control Methods

a. Manual Image Density Control

When image density is set manually,

the developmen t bia s is cha nged as

shown.

The voltage applied to the expo sure

lamp also changes.

b. Automatic Image Density Selection

When automatic image density mode is

selected, the CPU measures the

background density of the original

through the ADS sensor and changes

the development bia s.

(at 30°C)

Bias

Voltage

(at 30°C)

Bias

Voltage

- 52 -

Page 54

c. Drum Temperature Compensation (TH2 )

The CPU changes the bias voltage to

compensate for varia tions in drum

sensitivity that are induced by

temperature chang es in the drum

cavity.

The compensation is ef fe ctive from 5

degrees to 50 degrees (Celsius).

5°C ~ 15°C: 14 V/1°C

15°C ~ 50°C: 6 V/1°C

d. Rest Time Compensation

The drum sensitivity often drops slightly ove r the first few cycles of a cop y

run. This is because the light from the exposure lamp fatigue s the drum

slightly, and it takes a few co pie s f or th e selenium to restabilize. The amo un t

that the sensitivity drops depen ds on the drum’s temperatur and the rest time

between copy runs – the longer the rest time , th e gre at er th e cha nge.

The copier increases the bias at the beg inin g of each copy run to prevent

variations in the image density of the first few copies produced. The amount

of bias increase is shown in the two ta ble s belo w. If the drum temperature is

less than 10 degrees Celsius, no rest time comp ensation is applied.

When the main switch is turned on, the CPU will automatically select the

greater than two hours rest time compe nsation level.

Bias

voltage

Base Level

Drum

TD: 10°C–20°C TD: 20°C–45°C

Copy#

Rest Time

0–10s One step down from previous

10s–3min. 10s–3min

3min–50min 30 30 0 0 0 3min–50min 60 60 30 30 0

50min–2hr 30 30 30 0 0 50min–2hr 90 60 60 30 30

2hr– 60 30 30 30 0 2hr– 120 90 90 60 30

If the drum temperature is less than 10 degrees Celsius, no rest time

•

1 2 3 4–5 6–10

states

Copy#

Rest Time

0–10s One step down from previous states

TD: Drum Temperature

1 2 3 4–5 6–10

30 30 30 0 0

compensation is applied.

- 53 -

Page 55

CAUTION: When performing a demonstration or during PM, make sur e that

Black Lead

the main switch is not turned on and off repeatedly.

2. Bias Measurement

The bias voltage can be measured by direct ly measuring the development roller

shaft using a digita l mu ltime ter, and checking the monitor using the input check

mode.

➀ Using a digital multimeter

a. Turn on the main switch.

b. Open the front cover an d force the door

switch to turn on.

More than 10 kΩ

c. Hook up the multimeter leads as shown

on the right. The red wire is hooked up

to the developme nt shaft and the black

wire is hooked up to the copier body.

d. At the manual ID le vel 4, set the copy

counter to "11" or more. After turning

the ready indicator on, press the Start

key and measure the bias voltage.

NOTE: Read the bias after the 11th copy

in order to get the value without

Red Lead

any rest time compensation.

➁ Using the input check mod e

a. Set SP mode (88) to "11".

b. Set the mode to the bias vo lta ge check mode as follows.

Interrupt key → Nume ric key "1" → Interrupt key

(After doing this, Vsp is disp laye d in the magnification ratio

indicator area.)

c. Set the copy counter t o "11" or mo re at the manu al ID level 4.

d. Press the Start key hold ing the nume ric ke y "0" and check the bias voltage in

the magnification ratio ind icat or.

NOTE: Read the bias afte r the 11t h cop y in orde r to ge t th e value without any

rest time compensation.

e. After measuring the bias voltage, set SP mode (88 ) to "1 0" .

- 54 -

Page 56

(Example)

for image

Bias

image area

Drum Temp = 30°C

Rest Time = Over 2 hours

Manual ID Level

5. Toner Supply Mechanism

If the toner density is detected too low thro ug h

the ID sensor, the toner supply clutch is turned

on and starts turning the toner supply drive

gear.

Then it turns the toner supply roller gear.

Toner catches in the grooves on the toner

supply roller. Then, as the groove s turn past

the opening, the toner drops into the

development unit.

The toner agitat or which is con ta ined in the

toner cartridge transports toner to the toner

supply section in the to ne r tan k.

non image area

Toner Supply

Drive Gear

Toner Supply

Roller Gear

Toner Supply

Clutch

for ID Sensor Pattern

Copy Cycle

Toner Agitato r

Toner Supply

Roller

6. Toner Supply Mode

This copier has two ways of con tro lling the amount of toner supp lied and can be

changed by using SP mode "30 ".

1. Detect Supply Mode (P-mode)

The main CPU checks toner density by directly detectin g the image densit y. If

toner density is too low, the toner supply clutch is turned on and toner is supplie d.

The check is performed at the beginnin g of the first cop y cycle after th e main

switch is turned on, and at every 10th cop y aft er th at .

2. Fixed Supply Mode (C-mode)

When the fixed supply mode is selecte d, a fixed amou nt of to ne r is added eve ry

copy cycle as determined by DIP SW101-3 and -4 .

- 55 -

Page 57

DPS 101

NO 1 2 MODE 3 4

3.5% OFF OFF

ON FREE RUN SP MODE C MODE

OFF NORMAL NORMAL P MODE

7% ON OFF

10.5% OFF ON

14% ON ON

15% OFF OFF

30% ON OFF

45% OFF ON

60% ON ON

TONER

DENSITY

NORMAL OF F OFF

LOW ON OFF

HIGH OFF ON

HIGHER ON ON

56

7. Toner End Detection

The CPU uses the image density sensor to det ect a toner en d con dit ion . The toner

end condition is reset by ope nin g the front cover for more than five seconds. If Vsp

becomes greater than 0.8 volt twice , th e CPU starts blinking the Add Toner indicato r.

After the indicat or sta rts blinking, the operator ca n make up to 50 cop ies, the n

copying is disabled.

CAUTION: This copier detects the toner end condi tion not by a mechani ca l

system but by a software system. If the main switc h is turne d off

or the front cover is opened for more 5 seconds without

replenishing toner, it will requi re another 61 copies for another

toner end condition to stop the machine.

If a customer continues in this wa y, the drum and other parts will

be damaged.

- 56 -

Page 58

8. Timing

Main Switch

Start Key

Blade Solenoid

Erase Lamp

QL/PTL

Bias

T/S

• PCC

1st Feed MC

Charge Corona

Scanner

ID Sensor LED

Pick-off Pawl Solenoid

Toner Supply Clutch

Fusing Exit Sensor

T1: When the Start key is pressed, the bias turns on after 0.13 second.

The bias voltage is constant (a t the no n-ima ge area level) reg ard less of ma nual

ID level.

Then the sensor patte rn bias is applied. 1.21 seconds aft er th e de velopment bias

starts its output, the bias fo r the copy imag e is app lied .

T2: If the toner densit y is too low, the toner supply clutch turns on 0.5 5 seco nd aft e r

the scanner motor reverses. The time is 0.98 second at the 30% supp ly ra te .

This operation continu es until th e next to ne r den sity che ck.

- 57 -

Page 59

9. Bias Voltage

1. Bias Control Signals and Output Volt ag e (withou t Temp erature Compensation)

NO

CN101-B18

Bias 4

CN101-B19

Bias 3

CN101-A18

Bias 2

CN101-A19

Bias 1

Output

(V)

Notch ADS

10001200

20010230

300112603 ~ 62.6 ~

401002902

5 0 1 0 1 320 1,7 2.16 ~ 2.6

60110350

7 0 1 1 1 380 1.65 ~ 2.16

81000410

9 1 0 0 1 440 ~ 1.65

10 1 0 1 0 500

11 1 0 1 1 500

12 1 1 0 0 530

13 1 1 0 1 560

14 1 1 1 0 590

15 1 1 1 1 620

1600000

2. Bias for Sensor Pattern

When the sensor pattern is deve lop ed , th e ID sensor bias is applied at +470 volts

and stays constant at +260 volt s in non image timing .

ID Sensor Bias

470 V

260 V

non image

image

ID Sensor Pattern

- 58 -

Page 60

DPS101

Development Unit

No 5 No 6 Toner Density Bias Voltage

OFF OFF Normal 470 V

ON OFF Low 440 V

OFF ON High 500 V

ON ON Higher 530 V

The ID sensor bias can be change d using DIP SW101-5 and -6 to adjust the overa ll

image density.

• By SP mode (34), the bias voltage can be increased by +90 volt s.

4.7.3 Replacement and Adjustment

NOTE: When removing or reinsta lling the deve lop ment unit, apply force towards

the right side to avoid scratching the drum.

1. Developer Replacement

1. Open the front cover, raise the

development unit rele ase lever, and pull

out the development unit. Place the unit on

a clean shee t of paper.

2. Separate the toner tank from the

development unit (2 screws).

Development Unit

Release Lever

Toner Tank

- 59 -

Page 61

3. Remove the development brush cover (2

Developer

Knob

screws).

4. Set the development unit on a large sheet

of paper with the unit’s inlet fa cing

downward.

5. Turn the paddle roller knob

counterclockwise. The developer will f all

out onto the paper.

6. Hold the unit at an angle and dump out the

developer that has collected at the ends of

the development un it.

7. Repeat the above steps until you have

removed all of the developer.

NOTE: If developer remains in the

development unit, the rotating part

might break because of

development roller overlo ad .

Development

Brush Cover

8. Pour one bag of developer into the

development unit while turn ing the knob

counterclockwise to distribute the

developer evenly.

- 60 -

Page 62

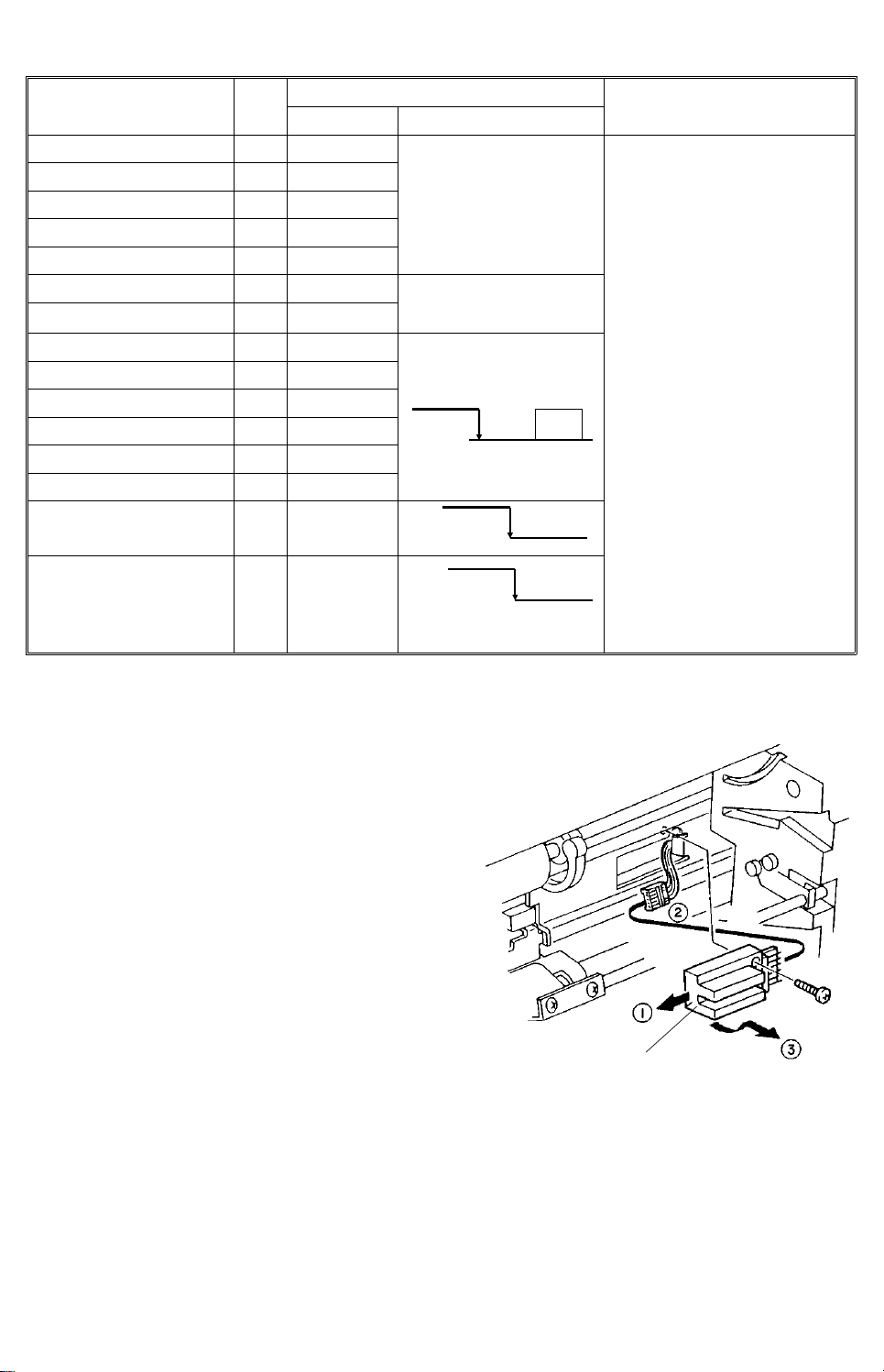

2. Toner Supply Clutch Replacement

1. Remove the rear cover (3 screws).

2. Lower the main board bracket (2 screws).

3. Remove the pulse generator assembly (1 screw).

4. Remove the toner supply clutch sto pp er (3 screws), the regist ration clutch

stopper (1 screw), and the develo pme nt drive sup po rt bra cket (3 screws, 1

E-ring, and 1 nylon clamp).

5. Remove the pulse generator disk.

6. Remove the toner supply clutch fro m t he drive sha ft.

7. Install a new toner supply clut ch.

8. Reassemble the copier.

NOTE: When reinstalling th e clut ch stoppers, make sure that the clutch forks

are properly engaged with the stoppers.

Development Drive

Support Bracket

Toner Supply

Clutch

Toner Supply

Clutch Stopper

Registration

Clutch Stopper

Pulse Generator

Disk

Pulse Generator

Ass’y

- 61 -

Page 63

4.8 ID SENSOR AND PTL

Drum

Pre-Transfer Lamp

ID Sensor

LED

4.8.1 Mec hanical Parts

1. Overview

ID Sensor

PTL

ID Sensor

This machine checks toner densit y using an ID

sensor. After the sensor pattern is developed,

its reflectivity is checked by the image density

sensor.

The sensor pattern image is made eve ry 10t h

copy. In the check cycle, th e sensor pattern is

exposed prior to exposure of the original. So,

this sensor pattern image doe s not app ear on

the paper. Normally this sensor pattern is

erased by an erase lamp.

After the latent imag e is d eve loped but before

the image is transferred to the copy pa per, the

drum surface is illuminated by the pre-transfe r

lamp. This illumination reduces the positive

potential on the drum surface. This is to

prevent the toner particles once attracted to