Page 1

COLOR CONTROLLER E-22C

SERVICE MANUAL

Page 2

It is the reader's responsibility when discussing the information contained within this document to

All product names, domain names or product illustrations, including desktop images, used in this

2013 RICOH Americas Corporation. All rights reserved.

maintain a level of confidentiality that is in the best interest of Ricoh Americas Corporation and its

member companies.

NO PART OF T HIS DOC UM EN T M AY BE REP RODUCED IN ANY

FASHION AND DIS TRIBUTED W ITHOUT THE PRIOR

PERMISSION OF RICOH AMERICAS CORPORATION.

document are trademarks, registered trade mar k s or t he pr oper t y of their respective companies.

They are used throughout this book in an informational or editorial fashion only and for the benefit

of such companies. No such use, or the use of any trade name, or web site is intended to convey

endorsement or other affiliation with Ricoh products.

Page 3

The Service Manual contains information

regarding service techniques, procedures,

Untrained and uncertified users utilizing

WARNING

processes and spare parts of office equipment

distributed by Ricoh Americas Corporation.

Users of this manual should be either service

trained or certified by successfully completing a

Ricoh Technical Training Program.

information contained in this service manual to

repair or modify Ricoh equipment risk personal

injury, damage to property or loss of warranty

protection.

Ricoh Americas Corporation

Page 4

REV. NO.

DATE

COMMENTS

*

LEGEND

PRODUCT

COMPANY

CODE

D730 Fiery E-22C Fiery E-22C Fiery E-22C

LANIER RICOH SAVIN

DOCUMENTATION HISTORY

10/2013 Original Printing

Page 5

COLOR CONTROLLER E-22C

TABLE OF CONTENTS

1. INSTALLATION .......................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS ............................................................ 1-1

1.1.1 ENVIRONMENT ............................................................................... 1-1

1.1.2 MACHINE LEVEL ............................................................................. 1-1

1.1.3 MINIMUM SP ACE REQUIREMENTS ............................................... 1-2

1.1.4 POWER REQUIREMENTS .............................................................. 1-2

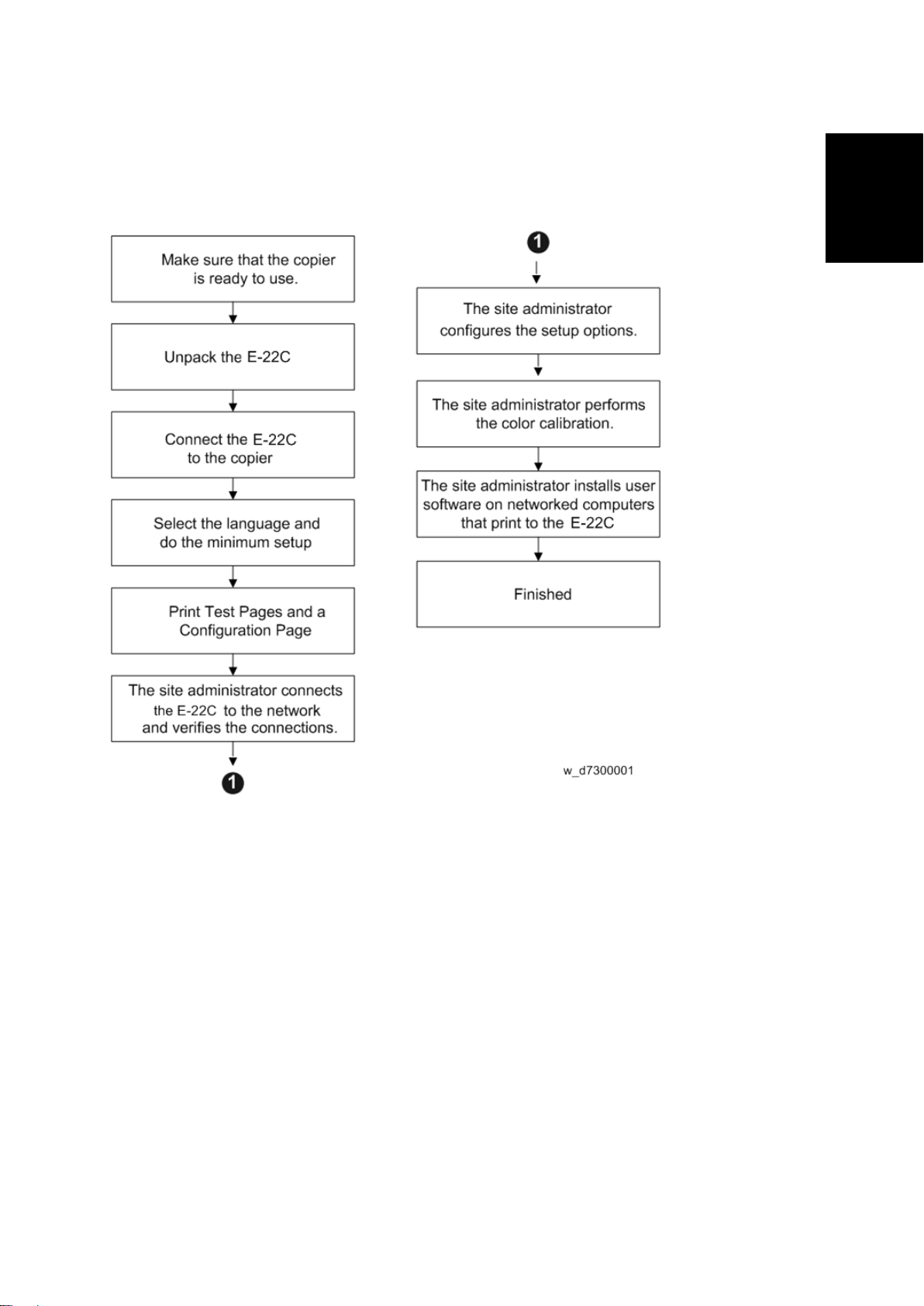

1.2 INSTALLATION FLOW CHART ................................................................. 1-3

1.3 MACHINE INSTALLATION ........................................................................ 1-4

1.3.1 SETTING CUSTOMER EXPECTATIONS ........................................ 1-4

1.3.2 UNPACKING THE E-22C ................................................................. 1-5

1.3.3 UNPACKING THE CONNECTION BOARD ...................................... 1-6

Color Controller Connection Board Type M3 (For D146 / D147) .......... 1-6

Color Controller Connection Board Type M4 (For D148 / D149 / D150)1-7

1.3.4 FRONT AND BACK PANELS ........................................................... 1-7

1.3.5 CONNECTING E-22C TO THE COPIER ........................................ 1-10

Preparation for Installing E-22C (For Machine Code: D146 / D147) .. 1-10

Preparation for Installing E-22C (For Machine Code: D148 / D149 / D150)

........................................................................................................... 1-12

1.3.6 STARTUP AND INITIAL SETUP .................................................... 1-15

1.3.7 DISABLING THE GW SCANNER (CUS TOMIZATION) .................. 1-17

1.3.8 VERI FYING THE CONNECTION (LOCAL TEST PRINT) .............. 1-18

1.3.9 VERI FYING CONNECTION TO THE NETWORK .......................... 1-20

1.4 INSTALLING OPTIONAL FEATURES ..................................................... 1-22

1.4.1 OPTIONAL FEATURES FOR E -22C .............................................. 1-22

1.4.2 INSTALLING SOFTWARE FOR EFI IMPOSE/COMPOSE ............ 1-22

1.4.3 AC TIVATE OPTIONAL FEATURES ............................................... 1-23

Optional Features Which Require Activation. ..................................... 1-23

Preparation: Requirements for Activation ........................................... 1-23

Important Notes for Ac ti v at ion ............................................................ 1-24

Automatic Activation and Manual Activation ....................................... 1-24

Confirming the Activated Options ....................................................... 1-25

Access to the Manage Options Window (Auto/Manual Activation) ..... 1-26

Activation Procedure .......................................................................... 1-29

SM i D730

Page 6

Deactivation of Client Options ............................................................ 1-40

View deactivation status and LAC ...................................................... 1-43

Reactivation of Client Options ............................................................ 1-43

Restoring Activated Client Options ..................................................... 1-44

Troubleshooting for Ac ti v at ion ............................................................ 1-45

2. GENERAL OPERATIONS FOR SERVICING .............................. 2-1

2.1 START-UP, SHUT-DOWN, AND REBOOT ............................................... 2-1

2.1.1 STARTING THE COPIER AND THE E-22C ..................................... 2-1

2.1.2 SHUTTING DOWN THE COPIER AND THE E-22C ......................... 2-1

2.1.3 SHUTTING DOWN THE E-22C ONLY ............................................. 2-2

2.1.4 RESTARTING THE E-22C ............................................................... 2-3

2.1.5 REBOOTING THE E-22C ................................................................. 2-4

2.2 CANCELLING THE CURRENT P RINT JOB .............................................. 2-5

2.3 PRINTING THE CONFIGURATION PAGE OR TEST SHEETS ................ 2-6

2.4 RUNNING THE E-22C SETUP .................................................................. 2-7

2.4.1 TO ACCESS THE SETUP MENU..................................................... 2-7

2.4.2 TO EXIT FROM THE SETUP MENU ................................................ 2-8

2.5 BA CKUP / RESTORE THE SYST EM SETTINGS ..................................... 2-9

2.5.1 TO ACCESS CONFIGURE WEBTOOLS USING A INTERNET WEB

BROWSER .............................................................................................. 2-10

2.5.2 TO BACK UP E-22C SETTINGS .................................................... 2-10

2.5.3 TO RESTORE THE E-22C S ETTINGS .......................................... 2-11

3. REPLACEMENT ......................................................................... 3-1

3.1 GENERAL CAUTION ................................................................................. 3-1

3.2 COVER REMOVAL .................................................................................... 3-2

3.2.1 SIDE COVER FOR THE E-22C ........................................................ 3-2

3.3 UNIT REMOVAL ........................................................................................ 3-3

3.3.1 VIDEO BOARD ................................................................................. 3-3

3.3.2 DIAGNOSTIC LED BOARD .............................................................. 3-4

3.3.3 HARD DIS K DRIVE (HDD) ............................................................... 3-5

3.3.4 POWER SUPPLY UNIT .................................................................... 3-6

3.3.5 FANS ................................................................................................ 3-7

3.3.6 MOTHERBOARD.............................................................................. 3-8

When installing the Keychip ............................................................... 3-12

3.3.7 MEMORY – 2GB DIMM .................................................................. 3-13

3.3.8 CPU AND CO OLING ASSEMBLY .................................................. 3-14

Overview ............................................................................................ 3-14

Cooling assembly removal procedure ................................................ 3-14

D730 ii SM

Page 7

CPU removal procedure ..................................................................... 3-14

3.3.9 LITHI UM BATTERY ........................................................................ 3-16

3.3.10 GIGABIT ETHERNET CONTROLLER ...................................... 3-17

For Machine Code: D146 / D147 ........................................................ 3-17

For Machine Code: D148 / D149 / D150 ............................................ 3-17

3.3.11 CABLES CONNECTED TO THE FRONT PANEL .................... 3-20

3.3.12 SOFT POWER PUSH BUTTON ............................................... 3-22

3.4 CLE ARING PROCEDURE FOR CMOS .................................................. 3-24

4. SOFTWARE MAINTENANCE ..................................................... 4-1

4.1 GENERAL NOTES AND CAUTIONS ........................................................ 4-1

4.2 CLEARING THE QUEUED PRINT JOBS IN THE E-22C .......................... 4-3

4.3 RESTORING THE E-22C TO FACTO RY DEF AULTS ............................... 4-5

4.4 S YSTEM SOFTWARE INSTALLATION PROCEDURE ............................. 4-7

4.4.1 OVERVIEW ...................................................................................... 4-7

4.4.2 INSTALLING SYSTEM SOFTWARE OVER THE NETWORK PORT4-8

4.4.3 INSTALLING SYSTEM SOFTWARE USING A USB DRIVE .......... 4-13

Preparation ......................................................................................... 4-13

Installation Procedure......................................................................... 4-13

4.5 PAT CH INSTALLATION PROCEDURE .................................................. 4-18

5. TROUBLESHOOTING ................................................................ 5-1

5.1 OVERVIEW ................................................................................................ 5-1

5.2 LE D DIAGNOSTIC CODES ....................................................................... 5-2

5.2.1 OVERVIEW ...................................................................................... 5-2

1: Rebooting the E-22C ........................................................................ 5-2

2: Checking the components ................................................................ 5-2

3: Turn on the E-22C Power ................................................................. 5-3

5.2.2 LED DI AGNOSTIC CODE TABLES .................................................. 5-4

5.3 ERRORS AND SUGGESTED ACTIONS ................................................... 5-6

5.3.1 START-UP PROBLEMS ................................................................... 5-6

5.3.2 SYSTEM PROBLEMS .................................................................... 5-10

5.3.3 SYSTEM SOFTWARE INSTALLATION ......................................... 5-12

Network Port Method.......................................................................... 5-13

USB Drive Method ............................................................................. 5-15

5.3.4 NETWORK PROBLEMS ................................................................. 5-17

5.3.5 PRINTING PROBLEMS .................................................................. 5-20

5.4 TEST THE VOLTAGE SUPPLIES ........................................................... 5-26

6. DETAILED SECTION DESCRIPTIONS ...................................... 6-1

SM iii D730

Page 8

6.1 BL OCK DIAGRAM AND FUNCTIONS ....................................................... 6-1

6.1.1 NETWORKING ................................................................................. 6-2

6.1.2 VIDEO BOARD ................................................................................. 6-2

6.1.3 HARD DIS K DRIVE .......................................................................... 6-2

6.1.4 NON-VOLATILE MEMORY .............................................................. 6-2

6.1.5 VOLATILE MEMORY ........................................................................ 6-2

6.2 PRINT DATA PROCESSING ..................................................................... 6-3

6.2.1 FLOW CHART .................................................................................. 6-3

7. SPECIFICATIONS ....................................................................... 7-1

7.1 GENERAL SPECIFICATIONS ................................................................... 7-1

D730 iv SM

Page 9

READ THIS FIRST

Safety Information

When using this machine, the following safety precautions should always be followed.

Safety During Operation

In this manual, the following important symbols are used:

Indicates a potentially hazardous situation which, if instructions are not followed, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if instructions are not followed, may result in

minor or moderate injury or damage to property.

Connect the power cord directly into a wall outlet and never use an extension cord.

Disconnect the power plug (by pulling the plug, not the cable) if the power cable or plug

becomes frayed or otherwise damaged.

To avoid hazardous electric shock, do not remove any covers or screws other than those

specified in this manual.

Turn off the power and disconnect the power plug (by pulling the plug, not the cable) if

any of the following occurs:

1) You spill something into the machine.

2) You suspect that your machine needs service or repair.

3) The external housing of your machine has been damaged.

Protect the machine from dampness or wet weather, such as rain and snow.

Unplug the power cord from the wall outlet before you move the machine. While moving

the machine, you should take care that the power cord will not be damaged under the

machine.

When you disconnect the plug from the wall outlet, always pull the plug (not the cable).

Risk of explosion if battery is replaced by an incorrect type.

Dispose of used batteries according to the instructions.

ACHTUNG (Deutch)

Die batterie darf nur durch eine des gleichen Typs ersetzt warden, da anderenfalls

Explosionsgefahr besteht.

Sie die debrauchten Batterien entsprechend den gegebenen Anweisungen.

Page 10

Power Cord Precautions

To reduce the risk of electric shock or damage to the equipment:

User the appropriate power cord which was set up by your manufacturer's authorized service

provider.

Do not place objects on AC power cords or cables. Arrange them so that no one may

accidentally step on or trip over them.

Do not pull on a cord or cable. When unplugging from the electrical outlet, grasp the cord by

the plug.

Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

Power Supply

The socket-outlet shall be installed near the product and shall be easily accessible.

Netzanschluss (Deutch)

Die Wandsteckdose sollte in der Nähe Geräts installiert und leicht zugänglich sein.

Use of controls, adjustment or performance of procedures other than those specified in

this manual may result in hazardous radiation exposure.

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1). Before disassembling or assembling parts of the controller, make sure that the

AC power cord is unplugged.

2). The wall outlet should be near the controller and easily accessible.

3). Note that some components of the controller are supplied with electrical voltage even

if the main power switch is turned off.

4). If any operation check has to be made with exterior covers off while the main switch is

turned on, keep hands away from electrified or mechanically driven components.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1). The controller must be installed and maintained by a customer service representative

who has completed the training course on the controller.

2). The danger of explosion exists if the battery on the motherboard is incorrectly

replaced. Replace the battery only with the equivalent type recommended by the

manufacturer. Discard the used motherboard battery in accordance with the

manufacturer’s instructions and local regulations.

Page 11

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1). Dispose of replaced parts in accordance with local regulations.

2). When keeping used lithium batteries in order to dispose of them later, do not put more

than 100 batteries per sealed box. Storing larger numbers or not sealing them apart may

lead to chemical reactions and heat build-up.

Symbols:

Symbol What it means

Refer to section number/document

Screw

Connector

Clamp

Trademarks:

Windows ® is a registered trademark of Microsoft Corporation in the United States and /or other

countries.

Fiery ® is a registered trademark of Electronics For Imaging, Incorporated.

PostScript ® is a registered trademark of Adobe Systems, Incorporated.

Ethernet ® is a registered trademark of Xerox Corporation.

Macintosh ® is a registered trademark of Apple Computer, Incorporated.

Pentium ® is a registered trademark of Intel Corporation.

Other product names used herein are for identification purposes only and may be trademarks of

their respective companies. We disclaim any and all rights involved with those marks.

Page 12

Page 13

INSTALLATION

Page 14

Page 15

Installation

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

1. Temperature Range:

5°C to 40°C (41°F to 104°F)

2. Humidity Range:

10% to 85% RH

3. Ambient Illumination:

Less than 1500 lux (do not expose to direct sunlight or strong light)

4. Ambient Dust:

3

Less than 0.10 mg/m

Installation Requirements

5. If the place of installation is air-conditioned or heated, do not place the machine where it will

be:

1) Subjected to sudden temperature changes

2) Directly exposed to cool air from an air-conditioner

3) Directly exposed to heat from a heater

6. Do not place the machine where it will be exposed to corrosive gases.

7. Do not install the machine at any location over 3,048 m (10,000 feet) above sea level.

8. Place the controller on a strong and level base.

9. Do not place the machine where it may be subjected to strong vibrations.

10. Do not connect the machine to a power source shared with another electrical appliance.

11. The machine can generate an electromagnetic field, which could interfere with radio or

television reception.

1.1.2 MACHINE LEVEL

1. Front to back: Within ±5° (0.2") away from level

2. Right to left: Within ±5° (0.2") away from

level

SM 1-1 D730

Page 16

Installation Requirements

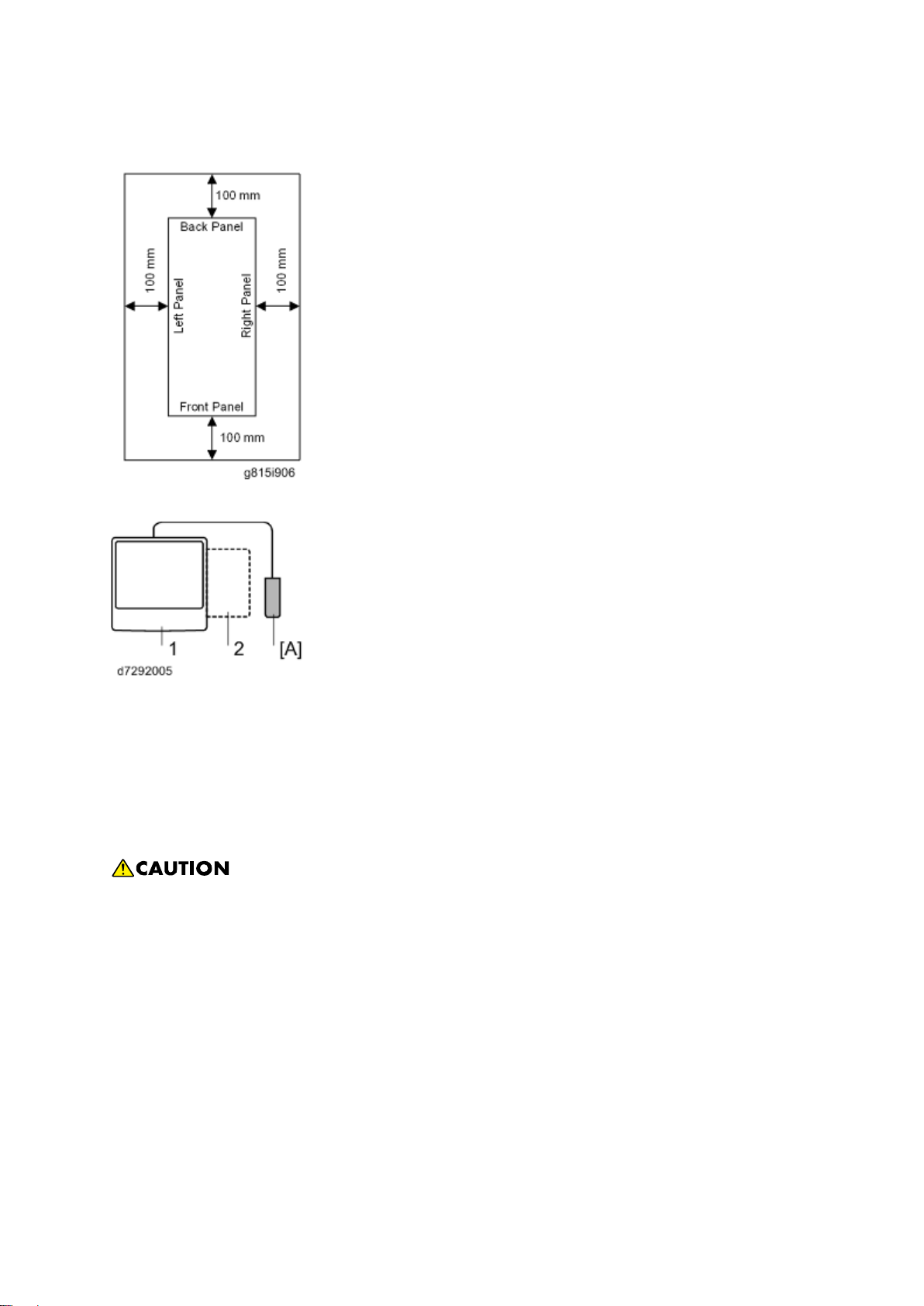

1.1.3 MINIMUM SPACE REQUIREMENTS

Place the machine near the power source, providing clearance as shown.

1. Copier

2. Large Capacity Tray

You may place the machine [A] on the right side of the large capacity tray or copier as shown (top

view) in the illustration.

1.1.4 POWER REQUIREMENTS

Insert firmly the plug in the outlet.

Avoid using an outlet extension plug or cord.

Ground the machine. Avoid using a 3-pronged adapter in a 2-hole ungrounded outlet.

Use the supplied AC power cord with this product.

1. Input voltage level: 100 - 240V, 50 - 60Hz; 3A

2. Do not put anything on the AC power cord.

D730 1-2 SM

Page 17

Installation

1.2 INSTALLATION FLOW CHART

Recommended installation steps are as follows:

Installation Flow Char t

SM 1-3 D730

Page 18

Machine Installatio n

1.3 MACHINE INSTALLATION

1.3.1 SETTING CUSTOMER EXPECTATIONS

Before installation, the customer should be informed of the following:

Some nodes on the network may be unavailable for up to one hour.

The copier may be unavailable for up to one hour

The site administrator should be available during the installation for assistance with network

connectivity issues.

Equipment downtime and impact on the network can be minimized if the site administrator

installs a network node for the E-22C and confirms network connection for the E-22C

installation.

The site administrator should have a networked computer available during the installation.

The appropriate software should already be installed. Documentation for the networked

computer and the network operating software should be available.

The site administrator should install the user software shipped with the E-22C (user

documentation is also included) onto the networked PCs and Mac OS computers that will

print to the E-22C.

This guide covers hardware installation and service. It provides general information on

connecting the E-22C to the customer's network. For network setup and configuration

information, refer the site administrator to the "Configuration and Setup" manual.

D730 1-4 SM

Page 19

Machine Installatio n

Installation

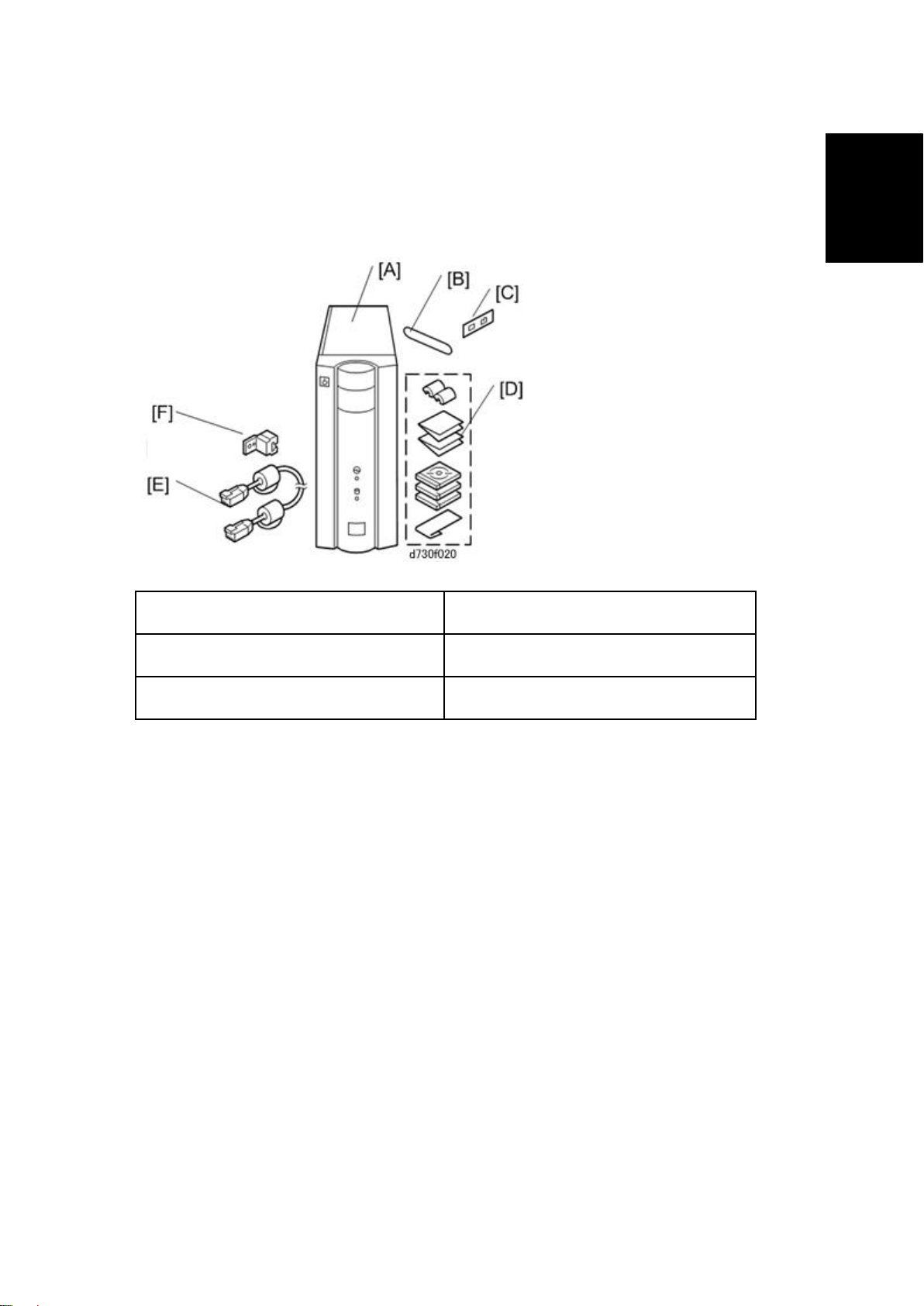

1.3.2 UNPACKING THE E-22C

1. Open the box and remove the packing material.

2. Remove the contents from the top container. Inspect the contents for visible damage.

The top container should include the following items:

[A]: E-22C [D]: Media Pack

[B]: Fiery Keytop Seal [E]: Interface Cable

[C]: Fierydriven Logo [F]: Protection Plate (For E-22C)

3. Give the Media Pack [D] to the site administrator.

4. Take the remaining components out of the top container.

5. Remove the top container and any packing materials.

6. Carefully lift the E-22C out of the box.

SM 1-5 D730

Page 20

Machine Installatio n

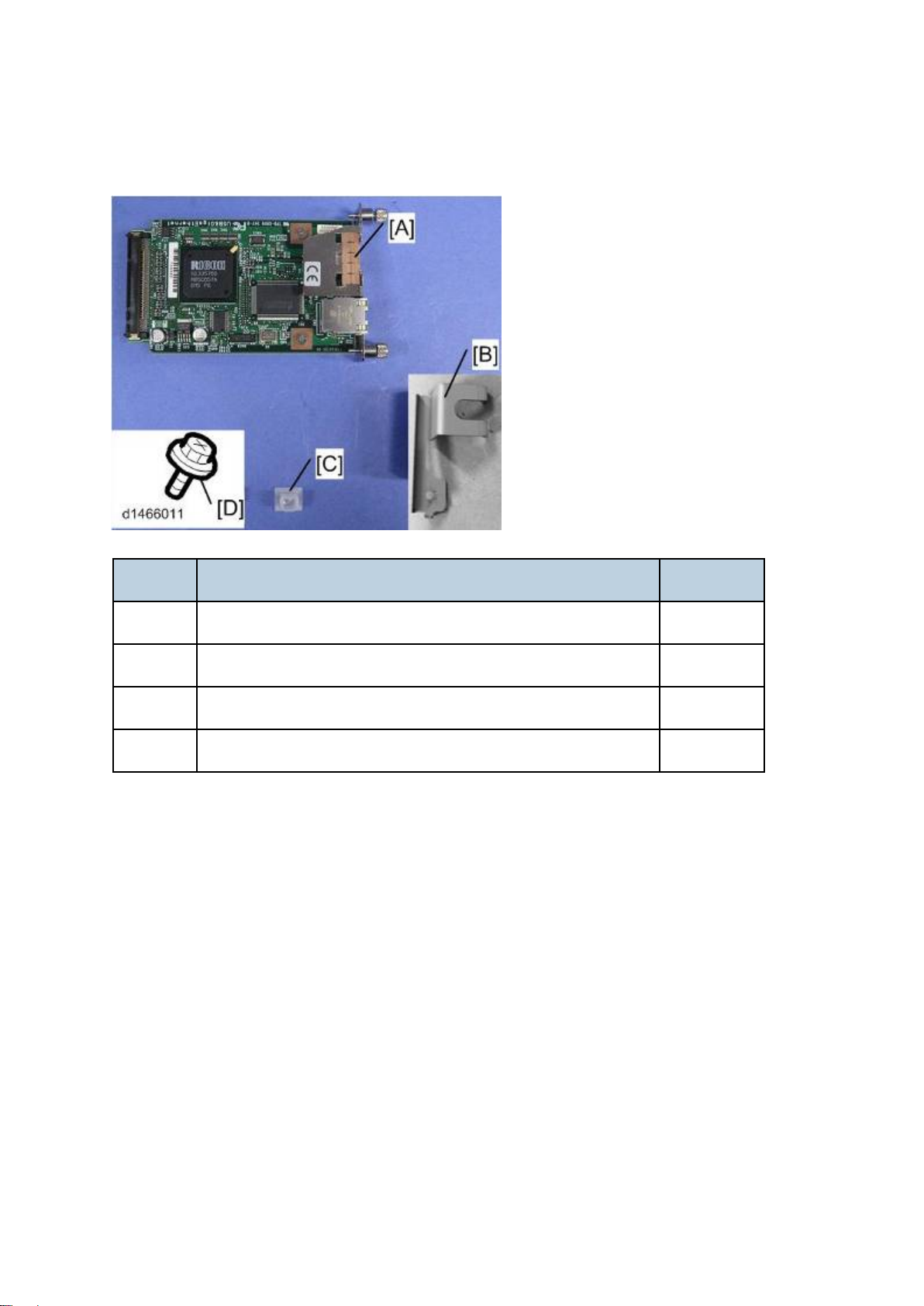

1.3.3 UNPACKING THE CONNECTION BOARD

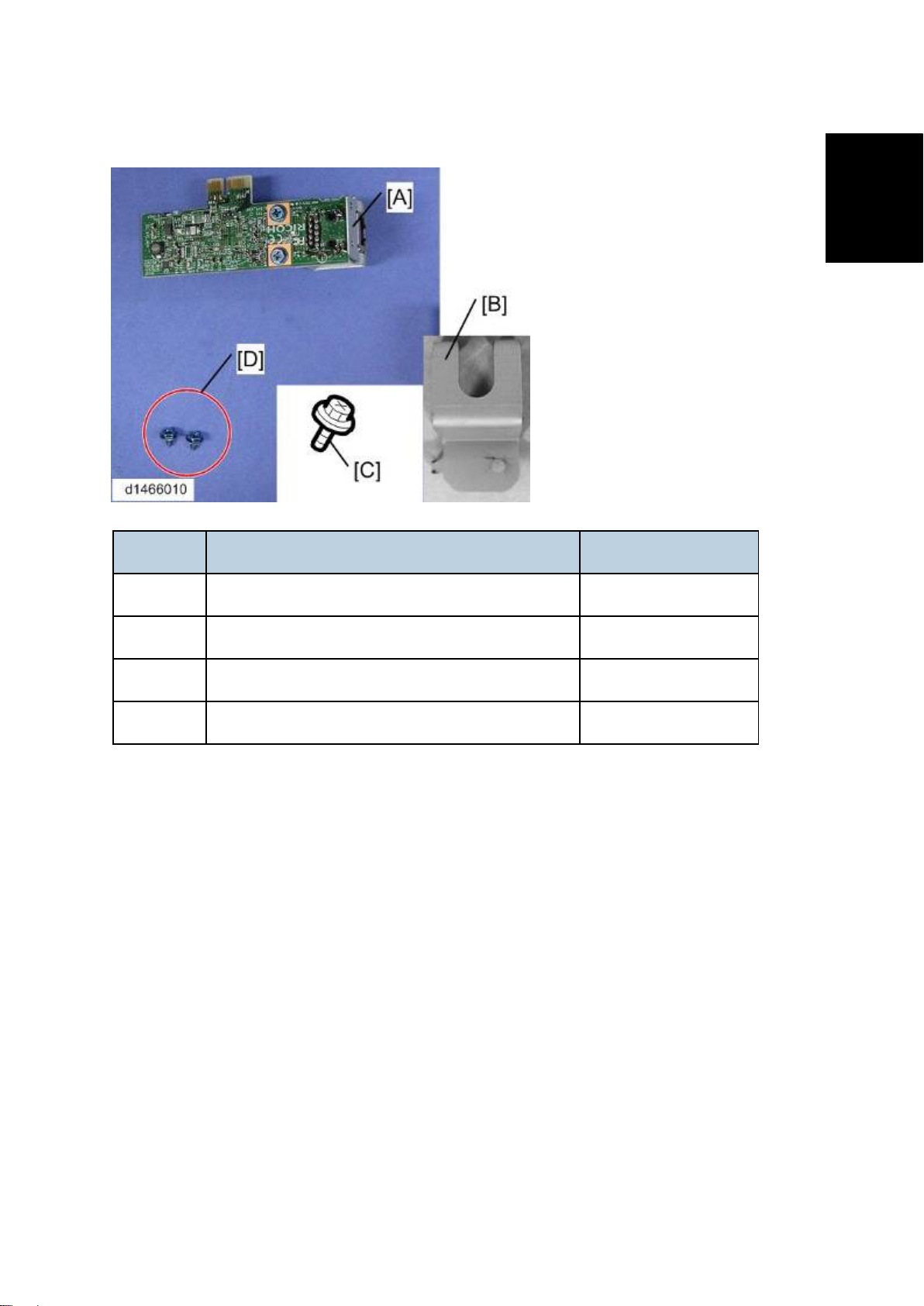

Color Controller Connection Board Type M3 (For D146 / D147)

Name Q’ty

A Gigabit Ethernet PCB 1

B Protection Plate 1

C Port Cap (for USB port) 1

D Screw (M3 x 8) 1

D730 1-6 SM

Page 21

Machine Installatio n

Installation

Color Controller Connection Board Type M4 (For D148 / D149 / D150)

Name Q’ty

A Gigabit Ethernet PCB 1

B Protection Plate 1

C Screw (M3 x 8) 1

D Screw (M3 x 6) 2

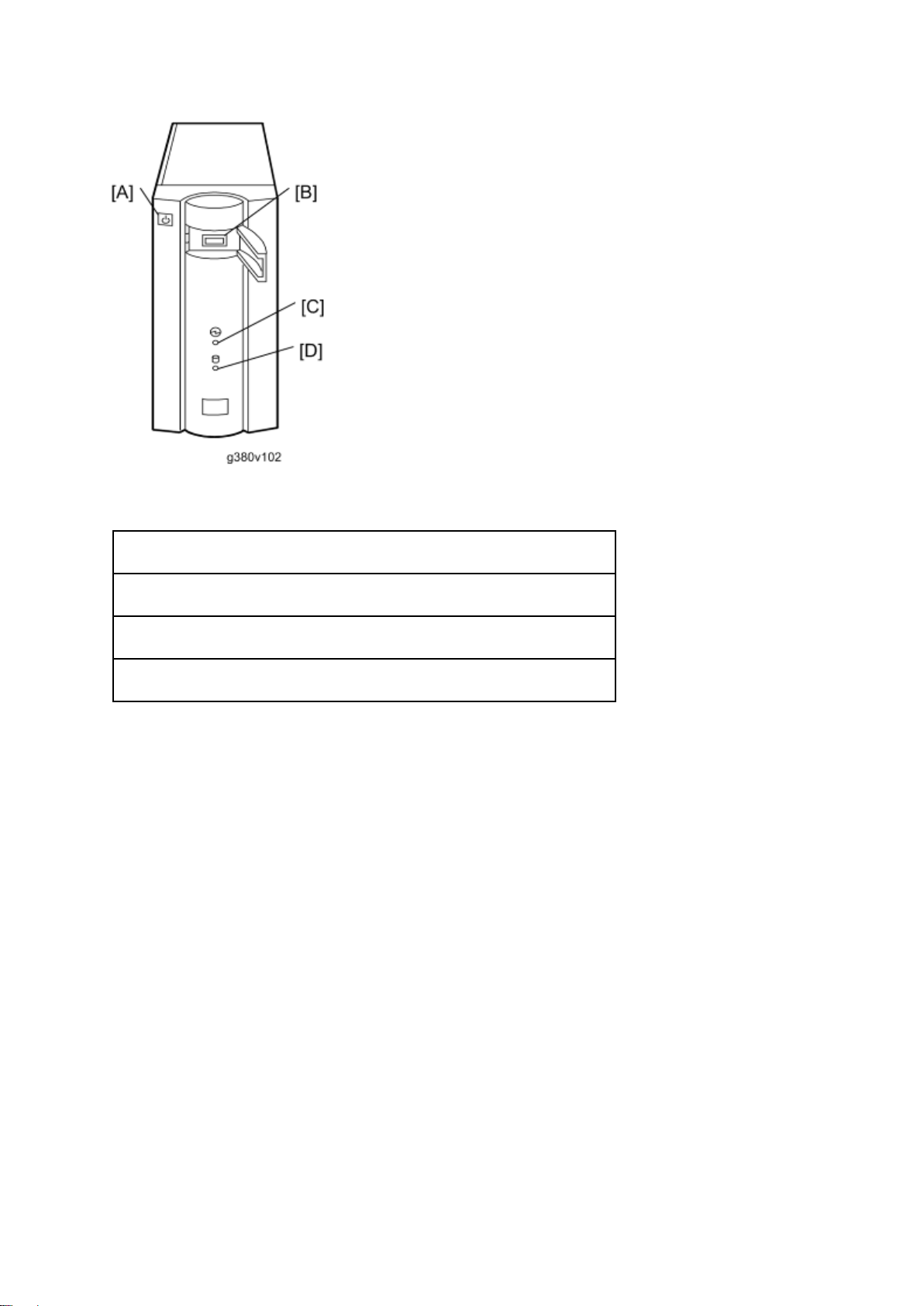

1.3.4 FRONT AND BACK PANELS

After unpacking the E-22C, familiarize yourself with the front and back panels before you connect

the E-22C to the Copier.

SM 1-7 D730

Page 22

Machine Installatio n

Front Panel

[A]: Soft Power Push Button

[B]: Front Panel USB Port

[C]: Power Indicator

[D]: HDD Access Indicator

D730 1-8 SM

Page 23

Installation

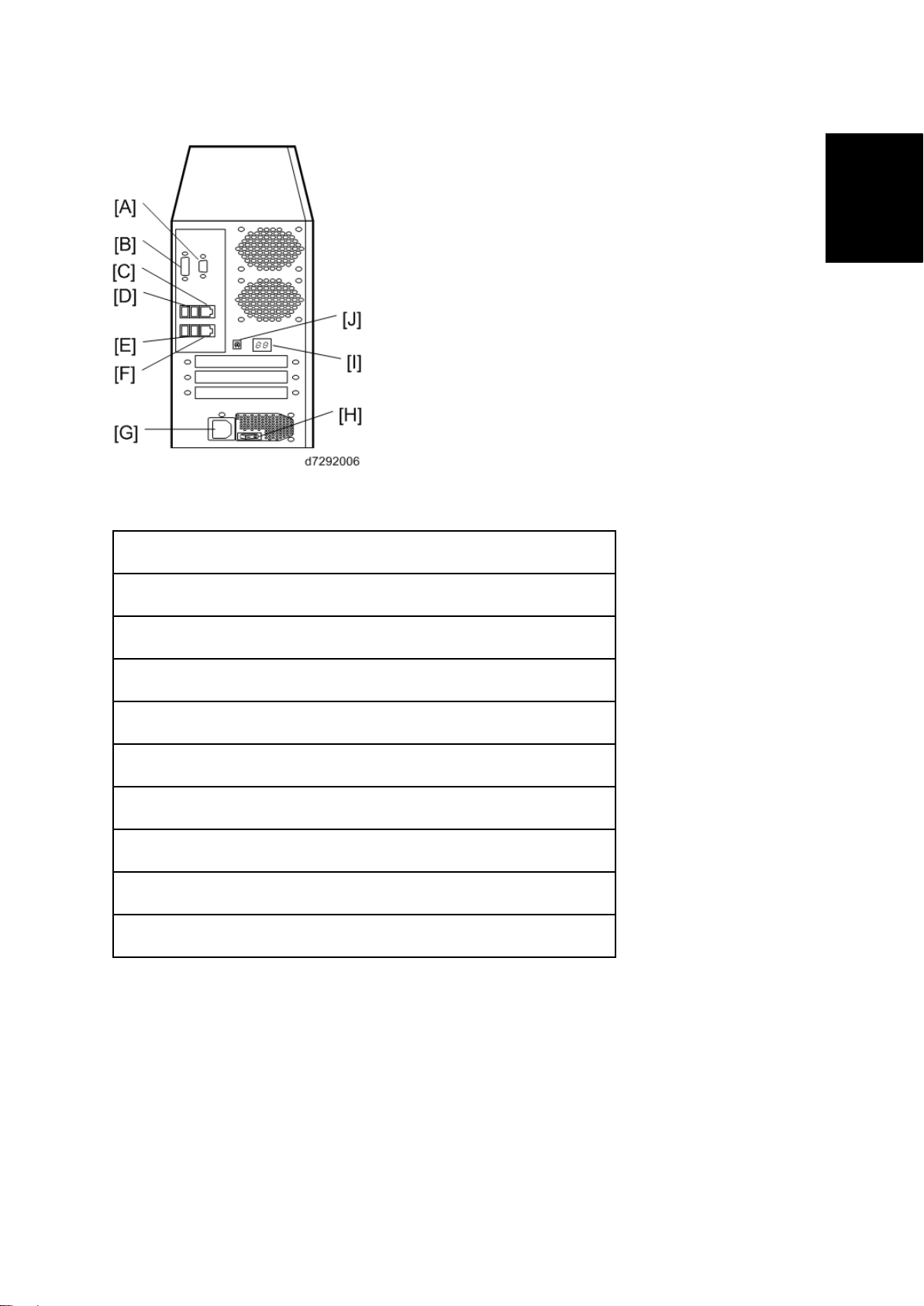

Back Panel

Machine Installatio n

[A]: Not used (monitor port)

[B]: Not used (monitor port)

[C]: LAN Connector (For customer use)

[D]: Back Panel USB Ports

[E]: Back Panel USB Ports

[F]: Gigabit Ethernet connector

[G]: Power Connector

[H]: Main Power Switch

[I]: Diagnostic LEDs (For service use only)

[J]: Service Switches (For service use only)

SM 1-9 D730

Page 24

Machine Installatio n

1.3.5 CONNECTING E-22C TO THE COPIER

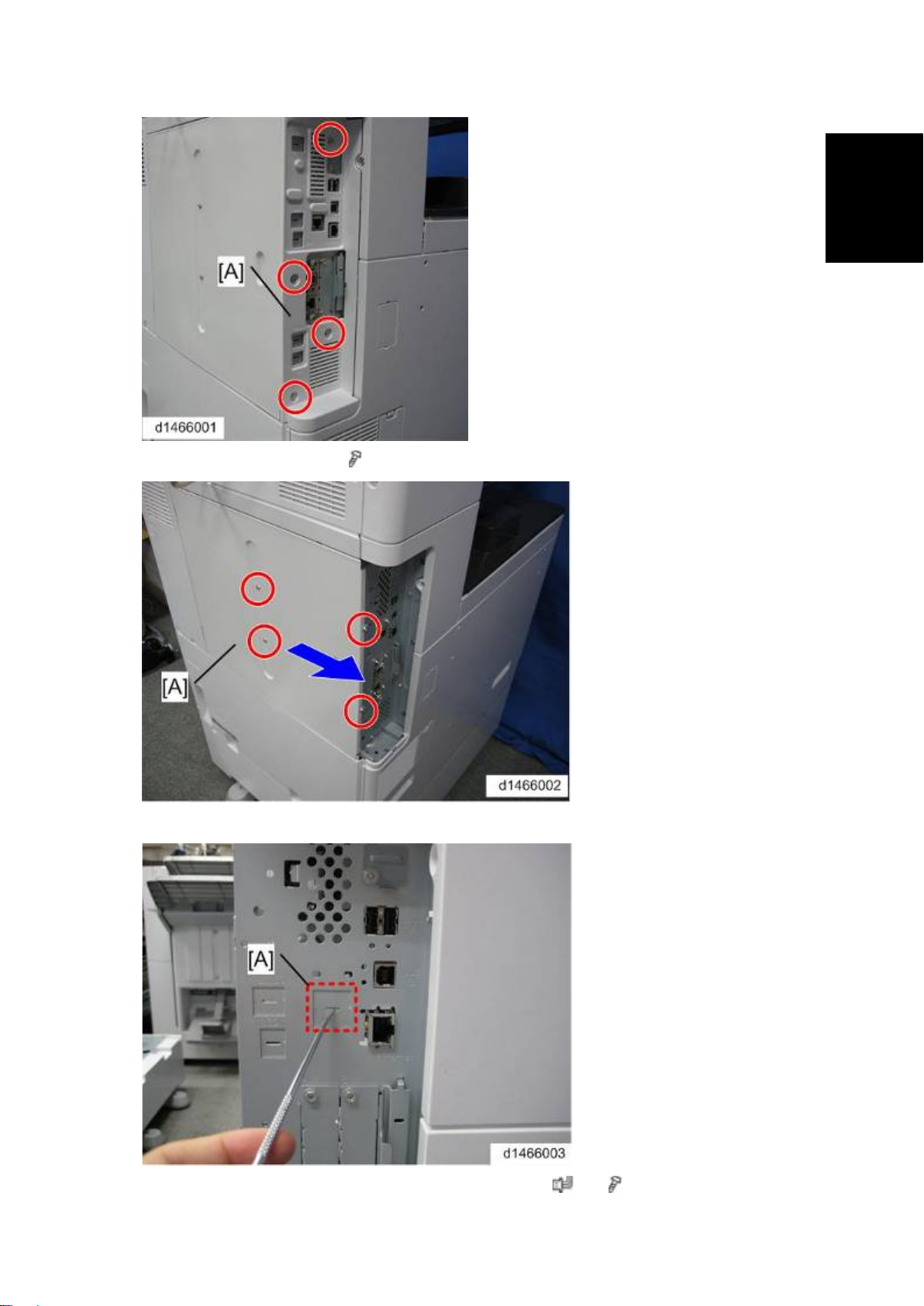

Preparation for Installing E-22C (For Machine Code: D146 / D147)

After you unpack the E-22C, connect the E-22C to the copier before you connect it to the network.

This is to confirm that there are no problems with the hardware and controller itself.

Turn the controller main power switch and copier main power switch to off and disconnect

the power cords before you do these procedures.

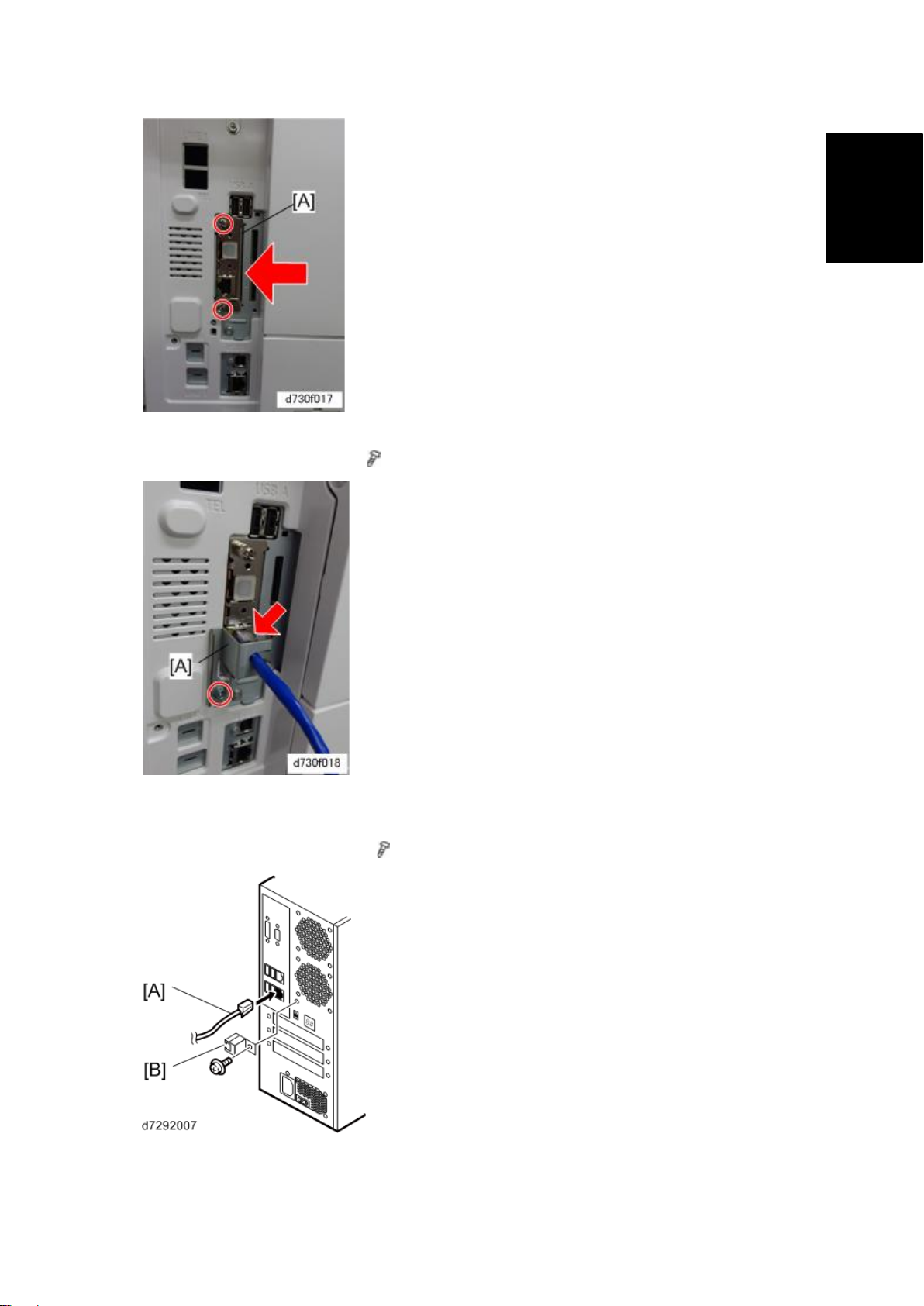

1. Attach the Port Cap[A] to the Gigabit Ethernet connector.

2. Controller I/F Cover [A] (

3. Insert the Gigabit Ethernet controller [A] and fasten it (knob-screw x 2).

x 2).

D730 1-10 SM

Page 25

Machine Installatio n

Installation

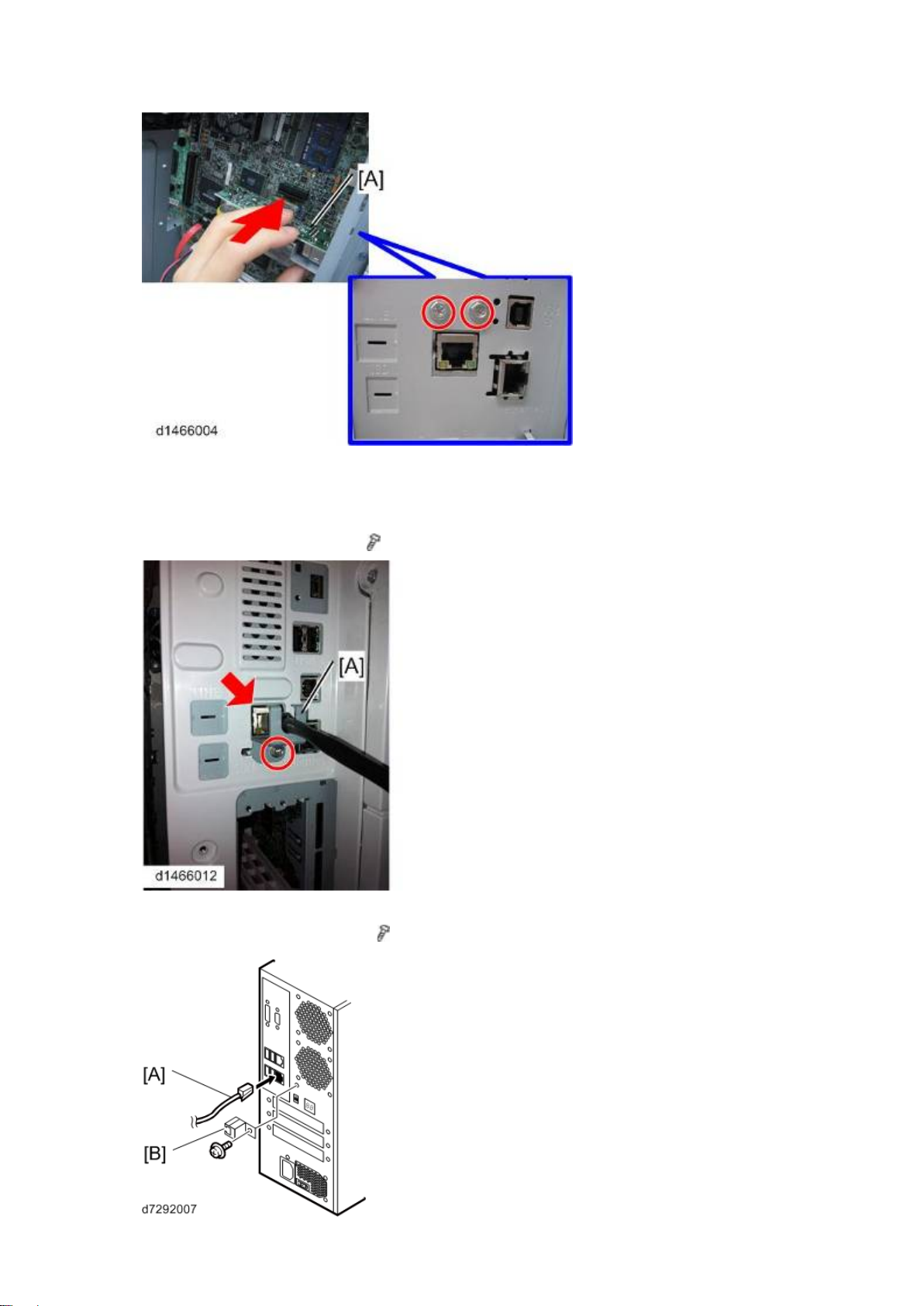

4. Connect the interface cable to the copier Gigabit Ethernet connector and then fix it

with the protection plate [A] (

x 1).

5. Connect the power cord of the copier to a power outlet.

6. Connect the interface cable [A] to the E-22C.

7. Attach the protector plate [B] (

x1).

8. Connect the appropriate AC power cord to the power connector at the back of the

E-22C.

SM 1-11 D730

Page 26

Machine Installation

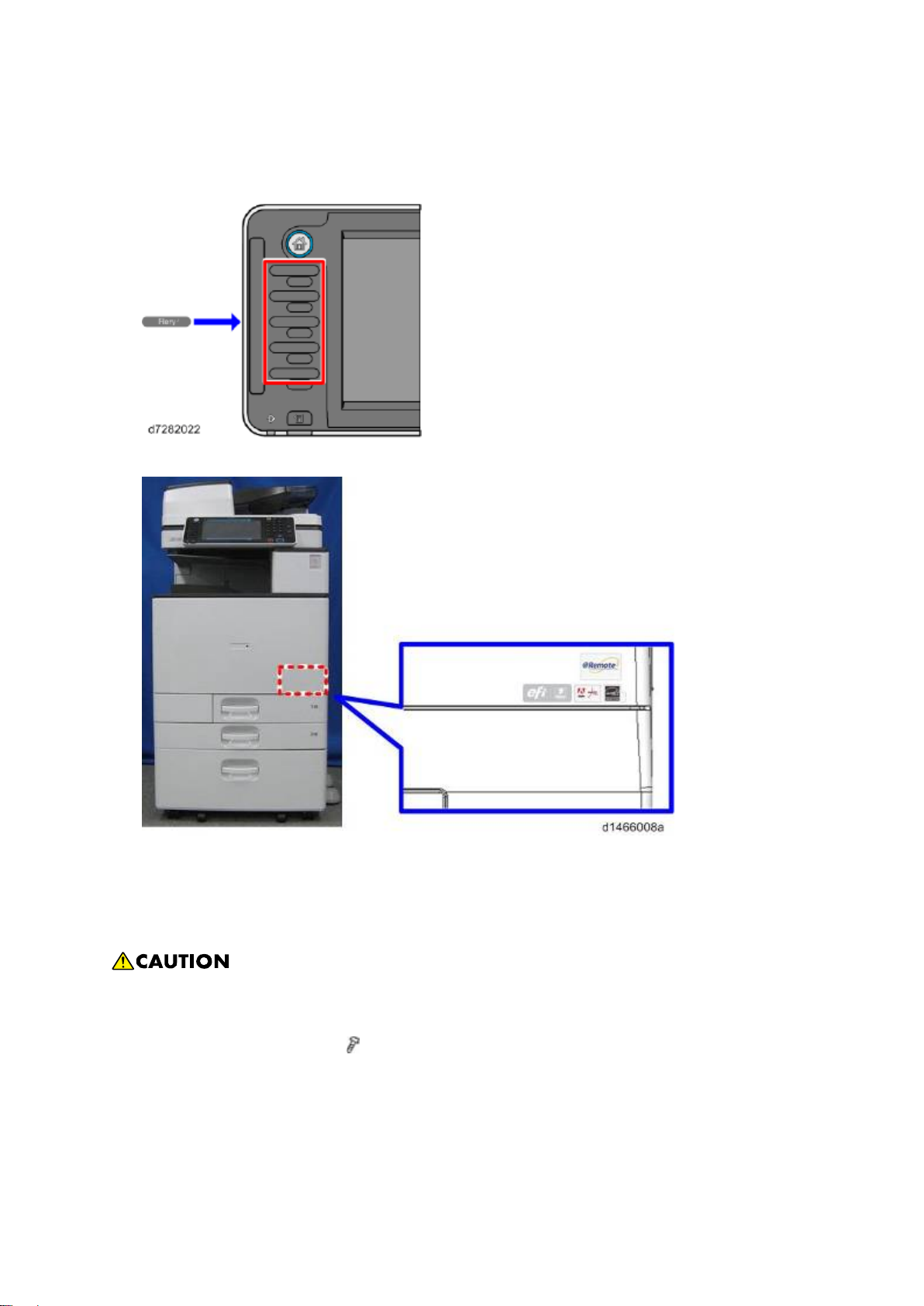

9. Attach the Fiery key top seal to the area above the function key to which the Fiery

function is assigned.

For information on function key configuration, see the Operating Instructions.

10. Attach the Fiery Decal to the copier front cover.

Preparation for Installing E-22C (For Machine Code: D148 / D149 / D150)

After you unpack the E-22C, connect the E-22C to the copier before you connect it to the network.

This is to confirm that there are no problems with the hardware and controller itself.

Turn the controller main power switch and copier main power switch to off and disconnect

the power cords before you do these procedures.

1. Controller Side Cover [A] (

D730 1-12 SM

x 4).

Page 27

Installation

2. Rear Controller Cover [A] (

Machine Installatio n

x 4).

3. Remove the slot cover [A] with a screwdriver.

4. Attach the Gigabit Ethernet controller [A] as shown. ( x 1, x 2).

SM 1-13 D730

Page 28

Machine Installatio n

5. Reassemble the controller cover and the controller side cover.

6. Connect the power cord of the copier to a power outlet.

7. Connect the interface cable to the copier Gigabit Ethernet connector and then fix it

with the protection plate [A] (

x 1).

8. Connect the interface cable [A] to the E-22C.

9. Attach the protector plate [B] (

x1).

D730 1-14 SM

Page 29

Machine Installatio n

Installation

10. Connect the appropriate AC power cord to the power connector at the back of the

E-22C.

11. Attach the Fiery key top seal to the area above the function key to which the Fiery

function is assigned.

For information on function key configuration, see the Operating Instructions.

12. Attach the Fiery Decal to the copier front cover.

1.3.6 STARTUP AND INITIAL SETUP

1. Make sure that the power cord of the copier is connected to a power outlet and switch

on the copier main power.

2. Enter SP mode.

3. Change the setting of SP5193-001 from "0" to "1".

4. Change the setting of SP5895-001 from "0" to "1".

5. Change the setting of SP4201-003 from “11” to “15”.

6. Change the setting of SP4201-004 from “11” to “15”.

7. Turn the copier main power switch off and wait until the main power indicator is off.

8. Turn the copier main power switch on.

The copier must be turned on before you turn the E-22C on.

Make sure that all firmware modules for the copier are updated to the newest

versions. If they are not, update them before you turn on the E-22C. (

Service Manual)

Copier

9. Turn the main power switch on the E-22C back panel to ON.

10. Press and release the soft power push button on the front panel of the E-22C.

11. Allow startup to proceed without interruption, while you watch the diagnostic LEDs on

the back panel of the E-22C.

SM 1-15 D730

Page 30

Machine Installatio n

12. When the diagnostic LEDs remain at '00', go to the copier operation panel and press

the Home button on the operation panel of the copier and wait for a few minutes until

the Fiery icon appears on the Home screen.

13. Touch the Fiery icon. "Please Wait!" will be shown on the copier operation panel for a

while.

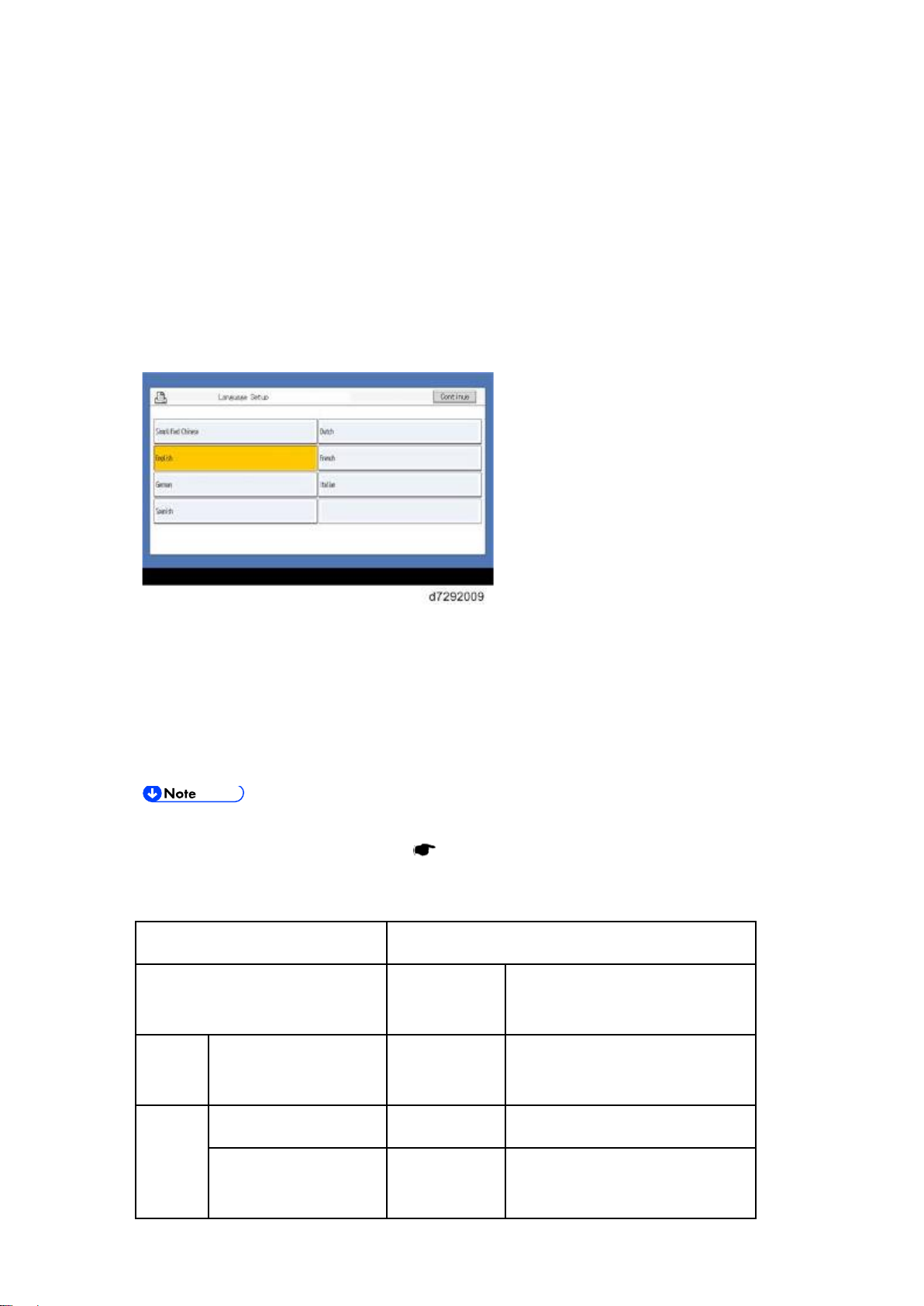

14. Within about three minutes, the language selection screen is shown. (If this screen is

not shown, then press the Home button on the operation panel of the copier and then

touch the Fiery icon again.)

15. Select the desired language button, and touch "Continue".

English

Dutch

French

German

Italian

Spanish

After you have selected a language, you cannot change the language unless you

perform "Factory Defaults" (

page 4-5) or re-install the system software.

The default settings for the E-22C depend on the language selection as follows:

Selected Language & Measurement Unit

English - Metric / Dutch / Spanish

English - US

/ Italian / German/ French

PS

Default Paper Sizes US Metric

Setting

Paper Size Letter A4

PCL

Setting

Paper Size System

US Metric

Pages

D730 1-16 SM

Page 31

Machine Installatio n

Installation

If you selected "English" at the language selection screen, you are prompted to select the

Measurement Units. Select either "US" or "Metric", and then touch "Continue".

16. The System will reboot. Press the Home button on the copier operation panel and wait

for a few minutes until the Fiery icon appears on the Home screen.

17. Touch the Fiery icon and wait about a few minutes until the Fiery menu screen

appears.

18. To confirm that the reboot was successful, press the Fiery tab.

19. Now the E-22C can be used with the default settings (minimum setup).

The E-22C setup options should be configured later by the site administrator.

1.3.7 DISABLING THE GW SCANNER (CUSTOMIZATION)

The GW Scanner feature can still be used when a Fiery controller is installed.

However, if the customer wants to disable the GW Scanner feature (customization request), it can

be disabled by the following procedure.

1. Change the setting of SP5895-002 from "0" to "1".

2. Press the [User Tools/Counter] key.

3. Press [Edit Home].

4. Press [Delete icon].

5. Select the Scanner icon.

6. Press [OK].

7. Press the [User Tools/Counter] key.

SM 1-17 D730

Page 32

Machine Installatio n

1.3.8 VERIFYING THE CONNECTION (LOCAL TEST PRINT)

After you connect the E-22C to the copier, print the Test Page and the Configuration Page to verify

that the connection between the E-22C and the copier is good.

1. Make sure that the copier is not in use.

2. Check the settings in the following table, and make sure that Letter or A4 paper is

loaded in at least one of the paper trays of the copier.

PS Setting Default

Paper Size

Setup Option "US" "Metric" "US" "Metric"

Configuration Page requires… Letter A4 - -

PS Test Page requires… Letter A4 - -

PCL Test Page requires… - - Letter A4

3. Press the Home button on the operation panel of the copier and wait for a few minutes

until the Fiery icon appears on the Home screen.

4. Touch the Fiery icon to access to the Fiery menu screen.

5. Move to the "Fiery" tab.

PCL Setting Paper Size

for System Setting

6. Touch "Printable Info".

D730 1-18 SM

Page 33

Installation

7. Print the following pages:

Configuration Page

PS Test Page

PCL Test Page

8. Examine the quality of the test pages.

Machine Installatio n

All patches should be visible, but it is acceptable if they are very faint in the 5% and 2%

ranges.

Each patch set should show uniform gradation from patch to patch as the shade lightens

from 100% to 0%.

Poor image quality may indicate that the copier needs service. For more information, see

the documentation provided with the copier.

SM 1-19 D730

Page 34

Machine Installatio n

1.3.9 VERIFYING CONNECTION TO THE NETWORK

The E-22C provides twisted pair connectivity to an Ethernet network.

Cable requirements:

10BaseT (Ethernet): Unshielded Twisted Pair (UTP), Category 3 or higher

100BaseTX (Fast Ethernet): UTP, Category 5 or higher (4-pair/8-wire, short length)

1000BaseT (Gigabit Ethernet): UTP, Category 5e or higher (4-pair/8-wire, short-length)

If the print engine is 230V, use a shielded network cable.

1. Turn off the E-22C power before connecting the E-22C to any network device.

2. Connect the network cable to the LAN connector on the E-22C.

3. Make sure that the copier power is switched on.

4. Turn the power switch on the E-22C back panel to ON.

5. Press and release the soft power push button on the front panel of the E-22C.

6. Allow startup to proceed without interruption, while you watch the diagnostic LED on

the back panel of the E-22C. When the diagnostic LEDs show '00', go to the copier

operation panel.

7. Press the Home button on the operation panel of the copier and wait for a few minutes

until the Fiery icon appears on the Home screen.

8. Touch the Fiery icon and wait about a few minutes until the Fiery menu screen

appears.

9. Move to the Fiery tab.

10. Touch "Setup".

11. You are asked to enter an administrator password. (The default is "Fiery .1")

12. Ask the site administrator to configure the Setup options.

It is the site administrator's responsibility to configure the correct setup options for

the network and user environment. The default settings in the setup may be

adequate, but they may not be optimal for the user's environment. Refer the site

administrator to the "Configuration and Setup" manual for setup information.

D730 1-20 SM

Page 35

Machine Installatio n

Installation

If more than one E-22C unit should be installed at the customer site with almost the

same system settings, tell the site administrator that the "Backup and Restore"

feature will be useful. (

This feature is explained in the "Configuration and Setup"

manual.)

If initial setup (with the exclusion of changing the IP Address/DNS/WINS) is not yet

done, Fiery Setup Wizard menu is selectable from WebTools and

CommandWorkStation. For details of Fiery Setup Wizard, refer to the Configuration

and Setup Guide.

13. After configuring the Setup options, verify the network connection.

14. Ask the site administrator to install the printer driver on a client PC, and to make a test

print from that PC.

SM 1-21 D730

Page 36

Installing Optiona l Fe atures

1.4 INSTALLING OPTIONAL FEATURES

1.4.1 OPTIONAL FEATURES FOR E-22C

The following options can be purchased and installed to E-22C:

Fiery Graphic Arts Basic Plus Package (B)

Productivity Package (B)

Spot-On (B)

Auto Trapping (B)

Hot Folders & Virtual Printers (B)

Fiery Impose (A+B)

Fiery Compose (A+B)

Fiery Impose-Compose (A+B)

(This is a package set of Fiery Impose and Compose.)

EFI Color Profiler Suite (with ES-2000) (C)

EFI Color Profiler Suite (Software only) (C)

EFI Spectrometer ES-2000

Required Action:

A: Needs additional software installation.

page 1-22

B: Needs activation with a license code.

page 1-23

C: Needs software installation and activation in a unique way.

Please refer to the manual included in the software package

1.4.2 INSTALLING SOFTWARE FOR EFI IMPOSE/COMPOSE

To use the features of EFI Impose/Compose, install and activate the software in the following

order.

1. Install Command WorkStation (from the User Software DVD of E-22C).

manual

Utility

2. Activate Impose/Compose.

3. Install Adobe Acrobat and Enfocus PitStop (from the CD included in the option

package).

D730 1-22 SM

Utility manual

page 1-23

Page 37

Installing Optiona l Fe atures

Installation

1.4.3 ACTIVATE OPTIONAL FEATURES

Some of the options need to be activated (make ready for use through licensing), with an LAC

(License Activation Code) which is provided with the optional feature box or envelope.

Optional Features Which Require Activation.

Server Options:

The license file is stored in the key chip on the motherboard of E-22.

Fiery Graphic Arts Basic Plus Package

Productivity Package

Spot-On

Auto Trapping

Hot Folders & Virtual Printers

Client Options:

The license file is stored in the HDD of the Client PC.

Fiery Impose

Fiery Compose

Preparation: Requirements for Activation

LAC (License Activation Code)

A unique code of 25 digits that is printed on a sheet when open the optional feature

box/envelope.

An installed E-22C.

A PC with a web browser installed.

Command WorkStation (Must be installed for Client Options)

Internet Access Environment

If the customer has already a USB dongle for a Client Option (purchased for previous

models, etc.), it can be used with E-22C

SM 1-23 D730

Page 38

Installing Optiona l Fe atures

Important Notes for Activation

1. If you have multiple Fiery options to activate, you must activate them one at a time. It is not

possible to activate several options at once.

2. If the keychip (Server Options) or PC (Client Options) becomes defective, the following's are

needed as evidence in order to get recovered.

Defective key chip

LAC

Option Name

Serial Number of E-22C

OS on the client PC where the software was installed.

The configuration page that shows that the defective key chip had the optional feature

license installed.

Therefore, please be sure that you always print a configuration page and note the above

information and keep them together when you activate a new optional feature on the E-22C.

Automatic Activation and Manual Activation

There are two ways to activate the optional features: "Automatic" and "Manual".

Required Environment for Automatic Activation:

<Server Options>

1. The E-22C must be connected to the Internet.

If the E-22C is not connected to the Internet directly, you can configure a proxy

server for the connection.

2. At the same time, a PC that can access to E-22C with the web browser is needed.

You can also start the activation procedure with the Command WorkStation, but

later web browser access is required.

<Client Options>

1. The PC where the optional feature will be installed and used must be connected to the

Internet.

2. At the same time, the same PC needs to access to E-22C with Command WorkStation

and web browser.

D730 1-24 SM

Page 39

Installing Optiona l Fe atures

Installation

Required Environment for Manual Activation:

<Server Options>

If the E-22C is not connected to the Internet, manual steps are required to transfer data

between the E-22C and the EFI licensing website using another PC that is connected to the

Internet.

1. The PC where the optional feature will be installed, must be connected to the Internet

with web browser.

2. There is also another PC that can access to the E-22C with web browser is needed.

The above two PCs can be as same single PC (by switching the roles by changing

the location/connection).

<Client Options>

If the PC where the optional feature will be installed, your PC is not connected to the Internet,

manual steps are required to transfer data between the PC and the EFI licensing website

using another PC that is connected to the Internet.

1. A PC where the optional feature will be installed, must be connected to E-22C with the

Command WorkStation.

2. Another PC that can access to the Internet is needed.

The above two PCs can be the same single PC (by switching the roles by changing

the location/connection).

Confirming the Activated Options

There are three ways to confirm the activated options for a particular unit of E-22C.

1. Print the configuration sheet.

page 2-6

2. Confirm from WebTools.

Launch the web browser and enter the IP address of E-22C in the URL column to execute the

Web Tools.

Click the Home tab and confirm the installed options.

SM 1-25 D730

Page 40

Installing Optiona l Fe atures

3. Confirm from Command WorkStation.

Launch Command WorkStation and move to Device Center > General > General Info >

Option/Package to confirm.

Access to the Manage Options Window (Auto/Manual Activation)

Activation will be done from the Manage Fiery Options window.

The names of options shown on the following screen samples may differ from the names

of options for E-22C.

<Manage Options window for Server Options>

D730 1-26 SM

Page 41

Installing Optiona l Fe atures

Installation

<Manage Options window for Client Options>

The procedure to access to the Manage Fiery Options window differs between Server Options

and Client Options.

Server Options' procedure

There are two ways to access to the Manage Server Options window.

1. Access from the WebTools.

Launch the web browser and enter the IP address of E-22C in the URL column to

execute the Web Tools.

Click the Home tab and then click Manage.

2. Access from the Command WorkStation.

Launch Command WorkStation and move to Device Center > General > General Info >

Option/Package and click Manage.

SM 1-27 D730

Page 42

Installing Optiona l Fe atures

Client Options' procedure

There are two ways to access to the Manage Client Options window.

1. Access from Command WorkStation.

Launch Command WorkStation, right-click a job and select Preview, and then select Help

> Manage License.

2. Access from Command WorkStation's Help.

Launch Command WorkStation, right-click a job and select Impose or Compose. If you

are prompted to activate or not, click Yes.

D730 1-28 SM

Page 43

Installation

Activation Procedure

<Automatic Activation Procedure>

1. In the Manage Options window, click Activate.

<Manage Options window for Server Options>

Installing Optiona l Fe atures

<Manage Options window for Client Options>

2. To agree to the terms and conditions of the license agreement, click Continue.

3. For License Activation Code, type the LAC and....

SM 1-29 D730

Page 44

Installing Optiona l Fe atures

Server Options: click Activate.

Client Options: click Continue.

If the E-22C needs a proxy server to connect to Internet, the following screen may

appear. In such case, click the link of "use a proxy server" and fill in the necessary

information for proxy server, then click Apply. Then click Continue.

4. If the Fiery option name is correct, click Activate.

5. The Fiery option is activated.

D730 1-30 SM

Page 45

Installation

<Server Option>

<Client Option>

Installing Optiona l Fe atures

6. If the activation requires a restart of the Fiery print controller, click Restart to restart

now, or click Finish to activate more options before restarting.

If the activation does not require a restart of the Fiery print controller, just click Finish.

If activation requires a restart:

SM 1-31 D730

Page 46

Installing Optiona l Fe atures

<Server Option>

If activation does not require a restart:

<Server Option>

D730 1-32 SM

Page 47

Installing Optiona l Fe atures

Installation

<Client Option>

7. For Server Option only: Print the configuration sheet and keep it (for the case that the

key chip becomes defective).

page 2-6

<Manual Activation Procedure>

1. In the Manage Options window, click Activate.

<Manage Options window for Server Options>

<Manage Options window for Client Options>

2. To agree to the terms and conditions of the license agreement, click Continue.

SM 1-33 D730

Page 48

Installing Optiona l Features

3. For License Activation Code, type the LAC and....

Server Options: click Activate.

Client Options: click Continue.

4. Click Continue to proceed with the manual process.

5. Click Create Request File and save the file.

D730 1-34 SM

Page 49

Installing Optiona l Fe atures

Installation

6. Copy the request file to a PC that is connected to the Internet.

It is also possible that you use the same PC by changing the location/connection.

7. On the PC that is connected to the Internet, open a browser and go to

licensing.efi.com.

8. Click Browse, select the request file, and then click Upload.

9. If the Fiery option name is correct, click Continue.

SM 1-35 D730

Page 50

Installing Optiona l Fe atures

A license file is generated.

10. Click Download License File and save the file.

11. Copy the license file to the PC where you first entered the License Activation Code.

12. Return to the Generate License window and click Yes.

If you had closed that window, restart from step 1 (open the Manage Options window) and

click Activate, to reach to the following window.

13. Click Browse, select and open the license file, and then click Activate.

D730 1-36 SM

Page 51

Installation

14. The Fiery option is activated.

<Server Option>

Installing Optiona l Fe atures

SM 1-37 D730

Page 52

Installing Optiona l Fe atures

<Client Option>

15. If the activation requires a restart of the Fiery print controller, click Restart to restart

now, or click Finish to activate more options before restarting.

If the activation does not require a restart of the Fiery print controller, just click Finish.

If activation requires a restart:

<Server Option>

If activation does not require a restart:

D730 1-38 SM

Page 53

Installation

<Server Option>

<Client Option>

Installing Optiona l Fe atures

16. For Server Option only: Print the configuration sheet and keep it (for the case that the

key chip becomes defective).

SM 1-39 D730

page 2-6

Page 54

Installing Optiona l Fe atures

Deactivation of Client Options

If you want to transfer the license for a Client Option from one PC to another, you must first

deactivate the option.

Deactivation makes the License Activation Code (LAC) for the option available again. You can

activate the license on another PC using the LAC.

The deactivation process depends on whether your PC is connected to the Internet:

If your PC is connected to the Internet: Use Automatic deactivation.

If your PC is not connected to the Internet: Use Manual deactivation.

After deactivation is complete, you can View deactivation status and LAC of an option in the

deactivation history.

<Automatic Deactivation Procedure>

1. In the Manage Client Options window, under Activated Options, click Deactivate next

to the option that you want to deactivate.

If there is no Deactivate button next to the option, the option is activated by a dongle.

2. Click Deactivate to confirm the deactivation.

D730 1-40 SM

Page 55

Installation

The Client Option is deactivated, and the LAC is displayed.

Installing Optional Features

The LAC is available for reuse.

<Manual Deactivation Procedure>

1. In the Manage Client Options window, under Activated Options, click Deactivate next

to the option that you want to deactivate.

If there is no Deactivate button next to the option, the option is activated by a dongle.

2. Click Deactivate to confirm the deactivation.

SM 1-41 D730

Page 56

Installing Optiona l Fe atures

3. Click Continue to proceed with the manual process.

4. Click Create Request File and save the file. The Client Option is deactivated, and the

LAC is displayed.

5. Click Finish.

6. Copy the request file to a PC that is connected to the Internet.

7. On the PC that is connected to the Internet, open a browser and go to

licensing.efi.com.

8. Click Browse, select the request file, and then click Upload.

The LAC is available for reuse.

D730 1-42 SM

Page 57

Installing Optiona l Fe atures

Installation

View deactivation status and LAC

1. In the Manage Client Options window, click the deactivation history icon.

Deactivated options and their corresponding LACs are listed. If an option is selectable, the

deactivation may be incomplete.

To complete a deactivation, select the option, click Deactivate, and continue with manual

deactivation.

See Manual deactivation for more information.

Reactivation of Client Options

If the license for a Client Option is corrupted, the option does not function even though it appears

to be activated. When your PC starts, it attempts to reactivate a corrupted license by contacting

the licensing server. If reactivation fails (because of a network interruption, for example) you can

try to reactivate the option in the Manage Client Options window. You do not need to enter the

LAC.

The reactivation process depends on whether your PC is connected to the Internet:

If your PC is connected to the Internet: Use Automatic reactivation.

If your PC is not connected to the Internet: Use Manual reactivation.

<Automatic Reactivation Procedure>

1. In the Manage Client Options window, under Activated Options, click Reactivate next

to the option that you want to reactivate.

The Client Option is activated.

2. Click Finish.

<Manual Reactivation Procedure>

1. In the Manage Client Options window, under Activated Options, click Reactivate next

to the

2. Click Continue to proceed with the manual process.

3. Click Create Request File and save the file.

4. Copy the file to a PC that is connected to the Internet. (It is also possible to use the

option that you want to reactivate.

same PC by changing the location/connection.)

5. On the PC that is connected to the Internet, open a browser and go to

licensing.efi.com.

6. Click Browse, select the request file, and then click Upload.

License file is generated.

7. Click Download License File and save the file.

8. Copy the license file to the PC where you are reactivating the license.

9. Return to the Generate License window and click Yes.

SM 1-43 D730

Page 58

Installing Optiona l Fe atures

10. Click Browse, select and open the license file, and then click Activate.

11. The Client Option is reactivated.

12. Click Finish.

Restoring Activated Client Options

If the licensing record for Client Options is not available (because you reinstalled the system

software on your PC, for example) previously activated options do not appear to be activated.

When your PC starts, it attempts to restore the licensing record by contacting the licensing server.

If the restore fails (because of a network interruption, for example) you can try to restore the

options in the Manage Client Options window.

The restore process depends on whether your PC is connected to the Internet:

If your PC is connected to the Internet: Use Automatic restore

If your computer is not connected to the Internet: Use Manual restore

<Automatic Restore Procedure>

1. In the Manage Client Options window, click the link in the message about restoring

licenses.

The Client Options are restored.

2. If you have no additional options to activate, click OK. Otherwise, to activate additional

options, click Continue.

<Manual Restore Procedure>

1. In the Manage Client Options window, click the link in the message

licenses.

2. Click Continue to proceed with the manual process.

3. Click Create Request File and save the file.

4. Copy the file to a computer that is connected to the Internet. (It is also possible to use

the same PC by changing the location/connection.)

5. On the PC that is connected to the Internet, open a browser and go to

licensing.efi.com.

6. Click Browse, select the request file, and then click Upload.

A license file is generated.

7. Click Download License File and save the file.

about restoring

8. Copy the license file to the PC where you are restoring options.

9. Return to the Generate License window and click Yes.

10. Click Browse, select and open the license file, and then click Restore.

The Client Options are restored.

D730 1-44 SM

Page 59

Installing Optiona l Fe atures

Installation

Troubleshooting for Activation

If any error message or error code is shown during the activation procedure, take action as below

table.

If the problem persists, prepare the following information for report your problem to your support

XXXXX.

1. Serial Number of the controller.

2. Name of optional feature

3. LAC (License Activation Code)

4. OS of the PC

Error messages and recommended actions: From the license activation software:

Error message Action

The code you enter is invalid, please

correct it and try again.

The file you selected is invalid, please

select a different one and try again.

Error <number>

System error. Please contact Fiery dealer

or EFI technical support.

The LAC is not in the correct format. Try

entering the LAC again. Refer to the LAC

card if you have one.

During manual activation, you obtained a

license file from the EFI licensing website.

Check that you selected the correct license

file to upload.

If the error still occurs, for Client options,

you can restore Client options and try to

activate again.

There is a problem with the license file. Try

repeating the activation process from the

beginning. If the error occurs again, for

Client options, restore the options and try to

activate again. If the error still occurs,

contact technical support and provide the

error code shown in the message.

Error <number>

Proxy configuration is incorrect or proxy

server is down.

SM 1-45 D730

There is no Internet connection. Check that

the proxy settings are correct and try again.

If the problem persists, contact your

network administrator.

Page 60

Installing Optiona l Fe atures

Error message Action

Proxy setting incorrect.

Connection could not be established.

Error <number>

Session expired. Please start again from

Command WorkStation.

There is no Internet connection. Check that

the proxy settings are correct and try again.

If the problem persists, contact your

network administrator.

The license activation software was used in

a different browser window more recently

than this one. To continue, close this

window and open a new one:

If you are activating a license for an

option installed on the E-22C, click the

Manage button in Configure (in

Command WorkStation or in

WebTools).

If you are activating a license for a

Fiery JobMaster-Impose-Compose in

Command WorkStation, right-click a

Error <number>

Please reinstall Fiery Software and try

again.

Error <number>

Please reinstall Command WorkStation and

try again.

job and select Preview. In Preview,

select Help > Manage License.

The license activation software module is

corrupted and Fiery system software must

be reinstalled. Please contact technical

support and provide the error code shown

in the message.

The license activation software module is

corrupted. Reinstall Command WorkStation

and try again.

On Windows, go to Control Panel >

Add or Remove Programs and start

Fiery User Software in maintenance

mode. Select the Repair option and

then select Command WorkStation.

On Mac OS, use Fiery Software

Uninstaller to uninstall Command

WorkStation, and then reinstall

Command WorkStation.

D730 1-46 SM

Page 61

Installing Optiona l Fe atures

Installation

Error messages and recommended actions: From the EFI licensing service

Message ID Error message Action

XX0004 License Activation Code is

invalid.

XX0007 This option is already

activated.

XX0016 License Access Code has

already been used and is no

longer valid.

The LAC is not recognized. Check that

you entered the correct LAC. Refer to

the LAC card if you have one.

Check that the LAC is correct for the

option that you want to activate.

The license has already been activated

for another computer.

For Fiery

JobMaster-Impose-Compose, you

can deactivate the license on the

other computer and then activate it

on this one.

For E-22C options, these options

are not transferable. You must

obtain a new LAC.

XX0017 You must first choose the

Request File to upload.

XX0018 Call to the web service failed.

Please make sure that the

input file is correct.

XX0025 Unable to activate: Error

Code <number>

You should have generated a request

file on the E-22C or the computer where

the license will be activated. The EFI

licensing website needs this request file

to generate your license file.

You submitted the wrong request file or

the request file is corrupted. Try

submitting a different request file. If the

error occurs again, try regenerating the

request file.

An error occurred on the EFI licensing

service.

Contact technical support and provide

the error code shown in the message,

the LAC, and the serial number of your

E-22C.

SM 1-47 D730

Page 62

Installing Optiona l Fe atures

Message ID Error message Action

XX0002 Server failure. The EFI licensing website is unavailable.

Try again later.

XX0009 Unable to determine option

information.

XX0006 This option contains

unsupported features and

cannot be activated.

XX0011 Your system does not

support some of the features

included in this option. Do

you want to continue?

The EFI licensing website is unavailable.

Try again later.

Check that the feature(s) activated by

the LAC are correct for your E-22C

model.

Also check that you are not trying to use

an LAC for a E-22C option to activate a

license for Fiery

JobMaster-Impose-Compose, or vice

versa.

The LAC activates multiple features and

one or more features is not supported,

as shown in the list. Obtain a new LAC

that has only features that are

supported.

If you continue, you will not be able to

use any unsupported features and you

cannot use the LAC again.

XX0008 Some features of this option

are already activated. Do you

want to continue?

The LAC activates multiple features and

one or more features is already

activated, as shown in the list. Obtain a

new LAC that has only features that are

not already activated.

If you continue, you will be paying twice

for the same feature.

Error messages and recommended actions: From the EFI licensing service (Client Options

only)

D730 1-48 SM

Page 63

Installation

Message ID Error message Action

Installing Optiona l Fe atures

XX0026 Unable to deactivate: Error

Code <number>

Try to restore Client options and

deactivate again. If the error still occurs,

contact technical support and provide

the error code shown in the message.

XX0024 Unable to reactivate: Error

Code <number>

Try to restore Client options and

reactivate again. If the error still occurs,

contact technical support and provide

the error code shown in the message.

XX0027 No ID found. No licenses have been previously

activated on this computer, so you

cannot restore any licenses.

SM 1-49 D730

Page 64

Page 65

Installing Optiona l Fe atures

Installation

GENERAL OPERATIONS FOR

SERVICING

SM 1-1 D730

Page 66

Page 67

Start-Up, Shut-Down, and Reboot

General

2. GENERAL OPERATIONS FOR SERVICING

2.1 START-UP, SHUT-DOWN, AND REBOOT

The copier and the E-22C have separate main power switches. During normal operation, you can

leave the E-22C main power switch in the ON (I) position.

2.1.1 STARTING THE COPIER AND THE E-22C

1. Turn on the main power switch of the copier.

2. If the main power switch of the E-22C is OFF (O), turn on the main power switch of the

E-22C.

3. Press and release the soft power push button on the front of the E-22C. The controller

enters into the boot-up sequence.

4. After the E-22C and the copier become idle, press the Home button on the operation

panel of the copier and then touch the Fiery icon. The Fiery menu screen will appear on

the copier operation panel.

2.1.2 SHUTTING DOWN THE COPIER AND THE E-22C

Servicing

Operations For

1. Press the Home button on the operation panel of the copier and then touch the Fiery

icon. The fiery menu screen appears.

2. Move to the Fiery tab.

3. Touch “Restart Fiery”.

4. Touch “Shut Down”, then touch “OK”.

The E-22C enters into the shut down sequence.

The diagnostic LEDs on the back panel of the E-22C will turn off.

SM 2-1 D730

Page 68

Start-Up, Shut-Down, and Reboot

5. Turn the copier main power switch off.

6. If the E-22C is being taken out of service, turn off the E-22C using its main power

switch. (For example, if someone needs to move the E-22C, disconnect cables, or open

the chassis.)

2.1.3 SHUTTING DOWN THE E-22C ONLY

1. Press the Home button on the operation panel of the copier and then touch the Fiery

icon. The Fiery menu screen appears.

2. Move to the Fiery tab.

3. Touch “Restart Fiery”.

4. Touch “Shut Down”, then touch “OK”.

The E-22C enters into the shut down sequence.

The diagnostic LEDs on the back panel of the E-22C will turn off.

5. If the E-22C is being taken out of service, turn off the E-22C using its main power

switch. (For example, if someone needs to move the E-22C, disconnect cables, or open

the chassis.)

D730 2-2 SM

Page 69

Start-Up, Shut-Down, and Reboot

General

2.1.4 RESTARTING THE E-22C

When restarting the E-22C to recover from a problem, try this procedure first. However, this

procedure will only restart the E-22C application software that is now running on the system OS.

To reboot the system OS (for example, after downloading a patch), see the next section

“Rebooting the E-22C (

1. Make sure that the E-22C is not in use.

2. Press the Home button on the operation panel of the copier and then touch the Fiery

icon. The Fiery menu screen appears.

3. Move to the Fiery tab.

4. Touch “Restart Fiery”.

page 2-4)”.

Servicing

Operations For

5. Touch “Restart Fiery Service”

6. Wait until the E-22C becomes idle.

SM 2-3 D730

Page 70

Start-Up, Shut-Down, and Reboot

2.1.5 REBOOTING THE E-22C

Use this procedure to reboot the system OS (for example, after downloading a patch).

1. Make sure that the E-22C is not in use.

2. Press the Home button on the operation panel of the copier and then touch the Fiery

icon. The Fiery menu screen appears.

3. Move to the Fiery tab.

4. Touch “Restart Fiery”.

5. Touch “Restart System”

6. Wait until the E-22C becomes idle.

D730 2-4 SM

Page 71

Cancelling the Current Print Job

General

2.2 CANCELLING THE CURRENT PRINT JOB

When you want to cancel the current print job, do the following:

1. Press the Home button on the operation panel of the copier and then touch the Fiery

icon to access the Fiery menu screen.

2. Move to the Job list tab.

Servicing

Operations For

3. From the Job List, touch the job that you want to cancel.

4. Touch “Cancel”.

SM 2-5 D730

Page 72

Printing the Configuration Page or Test Sheets

2.3 PRINTING THE CONFIGURATION PAGE OR TEST

SHEETS

1. Make sure that the E-22C is not in use.

2. Press the Home button on the operation panel of the copier and then touch the Fiery

icon to access the Fiery menu screen.

3. Move to the Fiery tab.

4. Touch “Printable Info”, then touch the desired key.

Configuration Page

PS Test Page

PCL Test Page

D730 2-6 SM

Page 73

Running the E-22C Setup

General

2.4 RUNNING THE E-22C SETUP

The following procedures show how to access the Setup menu from the Fiery menu screen.

When the network settings (protocol, IP Address, etc.) are already configured and the

“Enable Web Service” option is set to ON, you can also configure the E-22C setup from

“Configure Webtools”. To do this, use a web browser on a personal computer which is

connected to the network. For more detailed instructions, please refer to the

“Configuration and Setup” manual.

When you try to get access to the Setup menu, you are always asked to input an

administrator password. (The default password is “Fiery.1”) Ask the site administrator

to input the administrator password when you must get access to the Setup menu.

2.4.1 TO ACCESS THE SETUP MENU

Servicing

Operations For

1. Make sure that the E-22C is not in use.

2. Press the Home button on the operation panel of the copier and then touch the Fiery

icon to access the Fiery menu screen.

3. Move to the Fiery tab.

4. Touch “Setup”.

5. You may be asked to enter an administrator password. (Ask the site administrator to

enter the password. The default password is “Fiery.1”)

6. The main setup screen appears. For the details of each setup option value, refer to the

“Configuration and Setup” manual.

SM 2-7 D730

Page 74

Running the E-22C Setup

2.4.2 TO EXIT FROM THE SETUP MENU

1. At the main setup screen, touch ”Exit Setup”. The Fiery menu screen will disappear.

2. When you are prompted “System Requires to Reboot for Changes to Apply”, touch

“Reboot now”.

D730 2-8 SM

Page 75

Backup / Restore the System Set t in gs

General

2.5 BACKUP / RESTORE THE SYSTEM SETTINGS

The administrator at the customer site can back up the current E-22C configuration and restore it

later.

This feature is also useful when…

1. The customer purchases more than one unit of E-22C and wants to configure all of them with

almost the same system configuration.

2. The E-22C needs to be re-configured after system software installation.

The following items can be backed up to a configuration settings file:

Fiery System Settings (with the exclusion of Date/Time)

Color Settings

Scan Settings

FreeForm/VDP Resources

Server Presets

Servicing

Operations For

Fonts

Job Log

The configuration settings file is saved on the computer from which you access Configure

Webtools. Make sure that you do not save the configuration settings file to the E-22C

itself. Otherwise, when you reinstall system software, the configuration settings file

residing on the E-22C is deleted.

SM 2-9 D730

Page 76

Backup / Restore the System Set t in gs

2.5.1 TO ACCESS CONFIGURE WEBTOOLS USING A INTERNET

WEB BROWSER

The network settings (protocol, IP Address, etc) should be already configured and the

“Enable Web Service” option should be set to ON (default), in order to access the

Configure Webtools.

1. Start your internet web browser and type the IP address of the E-22C.

2. Click the Configure tab on the E-22C home page.

3. Click “Launch Configure”.

4. Log on as an Administrator with the appropriate password.

(The default password is “Fiery.1”.)

The same menu can also be accessed from inside the Command WorkStation

(Server > Backup & Restore).

2.5.2 TO BACK UP E-22C SETTINGS

1. Choose Configure > Server > Backup / Restore.

2. Click Backup.

3. Select the items to backup and click Next.

4. Specify the destination (drive/folder), filename and option ("Add date to the name")

and click Next.

5. The result of backup will be indicated as "Backup Summary". After you have checked

the result, click Finish.

The saved configuration settings file can only be restored to the same model

(E-22C).

D730 2-10 SM

Page 77

Backup / Restore the System Set t ings

General

2.5.3 TO RESTORE THE E-22C SETTINGS

1. Choose Configure > Server > Backup / Restore.

2. Click Restore.

3. Specify the file to restore.

Click the “Browse..." button and select the backed-up file.

4. Click Open.

The server name and static IP address are restored therefore if the restore operation

is used on more than one E-22C you must reconfigure them to be unique.

Servicing

Operations For

SM 2-11 D730

Page 78

Page 79

Backup / Restore the System Set t in gs

General

REPLACEMENT

Servicing

Operations For

SM 2-1 D730

Page 80

Page 81

General Caution

Replacement

3. REPLACEMENT

3.1 GENERAL CAUTION

Turn off the power and unplug the E-22C before attempting any of the procedures in this

section.

Before accessing internal components, position the E-22C so that it is resting on its right-hand

side on a flat, anti-static surface.

SM 3-1 D730

Page 82

Cover Removal

3.2 COVER REMOVAL

3.2.1 SIDE COVER FOR THE E-22C

1. Side cover [A] ( x 6)

D730 3-2 SM

Page 83

Replacement

3.3 UNIT REMOVAL

3.3.1 VIDEO BOARD

1. Remove the Video board with bracket [A]( x 2)

2. Pull the Video board [B].

Unit Removal

3. Bracket [A] (

x 2)

SM 3-3 D730

Page 84

Unit Removal

3.3.2 DIAGNOSTIC LED BOARD

1. Diagnostic LED board [A] ( x 2, x 1)

D730 3-4 SM

Page 85

Replacement

3.3.3 HARD DISK DRIVE (HDD)

1. HDD with bracket [A] ( x 4, x 2)

2. HDD [A] (

x 4)

Unit Removal

System software is not included on replacement HDDs. After installing a new HDD, be

sure to install system software (

If you notice that the E-22C takes longer than usual to start up after installing a new HDD

and system software, clear the CMOS. For details, see "Clearing Procedure for CMOS"

shown below (

page 3-24).

page 4-7).

SM 3-5 D730

Page 86

Unit Removal

3.3.4 POWER SUPPLY UNIT

1. Power supply unit [A] ( x 5, x 3).

D730 3-6 SM

Page 87

Replacement

3.3.5 FANS

1. Video board ( page 3-3)

Unit Removal

2. Fans [A] (

x 8, x 2)

SM 3-7 D730

Page 88

Unit Removal

3.3.6 MOTHERBOARD

1. Video board ( page 3-3)

2. Cables (

24-pin power connector from ATX24P_1 [A].

4-pin power connector from ATX POWER [B].

DIAG cable from PORT80 HDR [C].

Front panel cable from J20 [D].

PIN1 & 3 HDD LED

PIN2 & 4 Power LED

PIN6 & 8 Soft Switch

SATA data cable from SATA 6G0 [E].

USB cable from USB A1 [F].

3. Remove the Motherboard (

x 8):

x 5)

4. Remove the Memory (

5. Remove the CPU Cooling Assembly (

6. Remove the CPU (

When you replace the motherboard, remove the CPU and memory and attach them

to the new motherboard (

7. Keychip [A].

D730 3-8 SM

page 3-13)

page 3-14)

page 3-14)

page 3-14).

Page 89

Unit Removal

Replacement

8. CPU holder bracket (on the back side of the motherboard) [A]

The CPU holder bracket is attached to the motherboard with two strips of double-sided tape.

In order to prevent the motherboard from being damaged, put a small screwdriver between

the bracket and the motherboard as shown below and twist the screwdriver to detach the

CPU holder bracket.

When you replace the motherboard, move the CPU, CPU cooling assembly, video board,

Keychip, and the CPU holder bracket from the old board to the new board. The Keychip

contains option upgrade information and licensing information for the E-22C.

A new motherboard comes with a protective cover [A] on the CPU slot. Remove it before

using the motherboard.

SM 3-9 D730

Page 90

Unit Removal

For reassembling:

Make sure of where to connect the connectors for each cable.

Make sure that all connectors are inserted firmly in the sockets. Also, do not put the

connectors in the sockets the wrong way around.

D730 3-10 SM

Page 91

Unit Removal

Replacement

Connector Location

[A] DIAG cable PORT80 HDR

[B] 4-pin power ATX POWER

[C] CPU fan CPU_FAN

[D] Top chassis fan SYS_FAN

[E] Memory DIMM A1

[F] 24-pin power ATX24P_1

[G] Soft power button cable and activity LED J20 1 For HDD LED

SM 3-11 D730

Page 92

Unit Removal

cables 2 For Power LED

3 For Soft Switch

[H] Keychip J12

[I] SATA data cable SATA 6G0

[J] Front panel USB port USB A1

[K] Bottom chassis fan Rear Fan

[L] Video interface board PCIE_x16

When installing the Keychip

Make sure you install the Keychip in the correct direction. Installing it in the wrong direction may

damage the pins. The cutout [A] must be facing toward the center of the motherboard.

D730 3-12 SM

Page 93

Replacement

3.3.7 MEMORY – 2GB DIMM

1. Push outward on the levers [A] on each side of the DIMM.

2. Slide the DIMM [B] straight out of the socket.

Unit Removal

Always attach the DIMM [B] to the DIMM A1 socket.

Gently slide the DIMM straight down into the socket and press so that the levers lock the

DIMM into place. Make sure that the levers close securely around the ends of the DIMM.

DIMMs fit in the socket only one way.

SM 3-13 D730

Page 94

Unit Removal

3.3.8 CPU AND COOLING ASSEMBLY

Overview

You can replace the following parts.

Cooling Assembly only

CPU and Cooling Assembly (as a set). If you replace the CPU, you must replace the cooling

assembly also, as a set.

The cooling assembly consists of a fan with heat sink and a clip assembly.

Be careful not to damage the motherboard, the CPU, or the CPU socket when you

replace the cooling assembly. Remove the memory before you remove the cooling

assembly.

When you want to replace the CPU, replace the CPU and the cooling assembly as a set.

This is very important, because the thermal pad that is attached to a new heat sink will

make a good contact between the CPU and the heat sink when heated. If you attach a

used cooling assembly to a new CPU by mistake, the heat sink will not contact the CPU

properly, and this will cause the CPU to overheat.

When replacing the CPU holder bracket on the back side of the motherboard, remove the

release paper from the double-sided tape on the new CPU holder bracket first. Then,

attach the CPU holder bracket to the motherboard using the double-sided tape.

Cooling assembly removal procedure

1. Cooling assembly [A] ( x 4, x 1).

CPU removal procedure

1. Push the lever [A] to release the loadplate [B].

D730 3-14 SM

Page 95

Replacement

2. Grasp the CPU [A] by its edges and gently lift it from the socket.

Unit Removal

For Re-attaching:

Check the location of the arrow [A] on the CPU [C] and align it with the arrow on the

motherboard [B] when you insert the CPU into the socket [D]. (See the illustration below.)

Be careful not to bend the pins when you insert the CPU into the socket.

Set the CPU in the socket completely and without forcing it.

SM 3-15 D730