Page 1

6 January 1990

1. SPECIFICATIONS

Roll Paper Size: Width: 210 mm (81/2 in.) to 1030 mm (36 in.)

Length: 150 meters

Cut Size: 100 mm (4 in.) to 3600 mm (141 in.)

----Change between millimeters and inches by

DIP switch

----1 mm or 0.1 in. per step

----Maximum length can be changed to 5,000

mm or 200 in. by SP mode.

Cutting Speed: 8.5 seconds (A1 size)

Paper Transport Velocity: 100 mm/s

Repeat Quantity: 1 to 99

Auto Reset: 2 minutes (Can be changed to 1 minute, 5

minutes, or no auto reset by SP mode.)

Control: Microprocessor

Total Counter: 6 digits (displayed by SP mode)

Power Source: 115 V, 60 Hz, 0.8 A

220 V, 50 Hz, 0.5 A

240 V, 50 Hz, 0.5 A

Power Consumption: Maximum = 150 W

Dimensions (W x D x H): 1,350 x 250 x 361 millimeters

53.15 x 9.84 x 14.21 inches

Weight: 34 kg, 75 lb

7-1

Page 2

6 January 1990

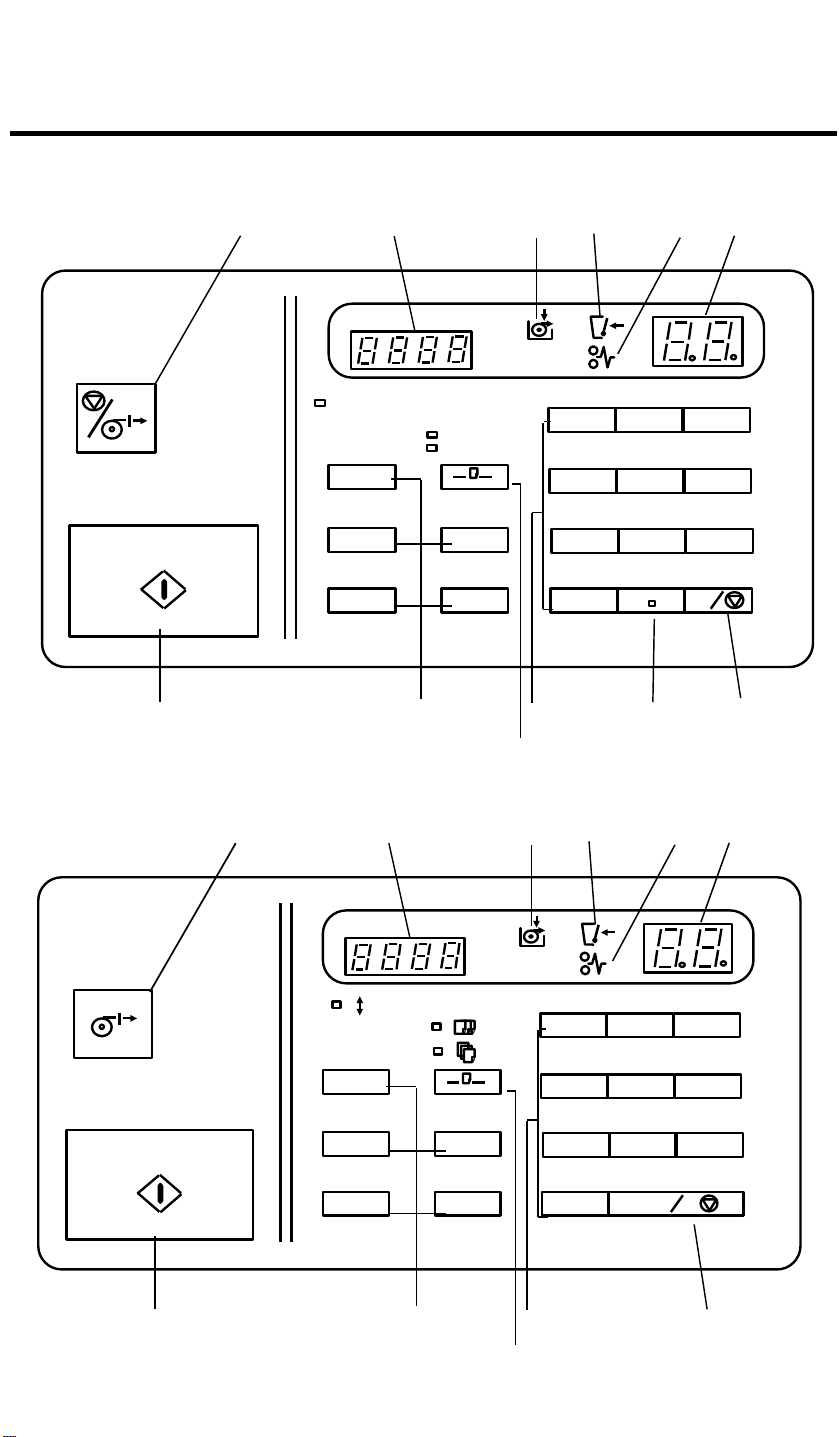

2. OPERATION PANEL

-- 115 V Version --

Stop/Cut

Start

7

1 2 3 4 65

inch

Range of input size

4" 141"

~

Input Size

Set Quantity

inch

1

4

7

2 3

5 6

8

0

8

10

9

11 12

9

Clear/Stop

C

-- 220/240 V Version --

7

1 2 3 4 65

100-3600mm

[ ]

m m

1

4

7

2 3

5 6

8

0 C

8

10

9

9

12

7-2

Page 3

1. Stop/Cut Key

Press to stop paper feeding and cut the paper.

2. Length Counter

Displays the cut length.

3. Load Roll Paper Indicator

Lights when it is time to install a new roll of paper.

4. Cover Open Indicator

Lights when one of the covers is open

5. Misfeed Indicator

Lights if paper misfeeds within the roll cutter.

6 January 1990

6. Cut Quantity Counter

Displays the number of sheets to be cut.

7. Start Key

Press to start machine operation.

8. Length Program Keys

Frequently used cut lengths can be stored and recalled using these keys.

9. Quantity/Size Select Key

Press to select "Input Size" or "Set Quantity".

10. Number Keys

Use to enter the desired length and cut quantity.

11. Decimal key

Press to enter a decimal point.

12. Clear/Stop Key

Press to cancel the length and cut quantity entered. While feeding, press to

stop the machine.

7-3

Page 4

6 January 1990

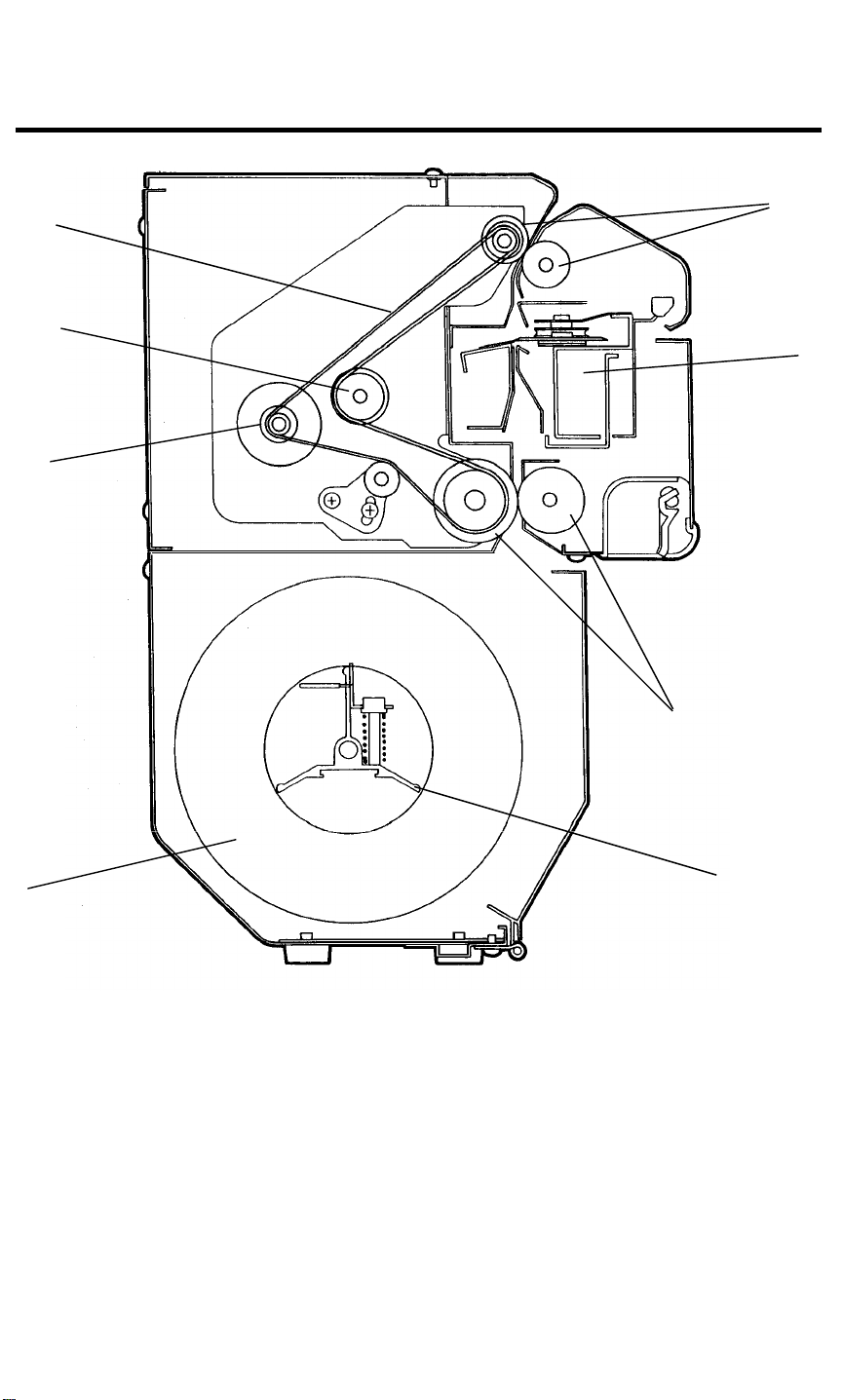

3. MECHANICAL COMPONENT LAYOUT

3

2

1

6

4

5

8

1. Main Motor Pulley----16Z

2. Idle Pulley

3. Timing Belt

4. Exit Rollers

7-4

5. Cutter Unit

6. Paper Feed Rollers

7. Paper Roll Spool

8. Paper Roll

7

Page 5

6 January 1990

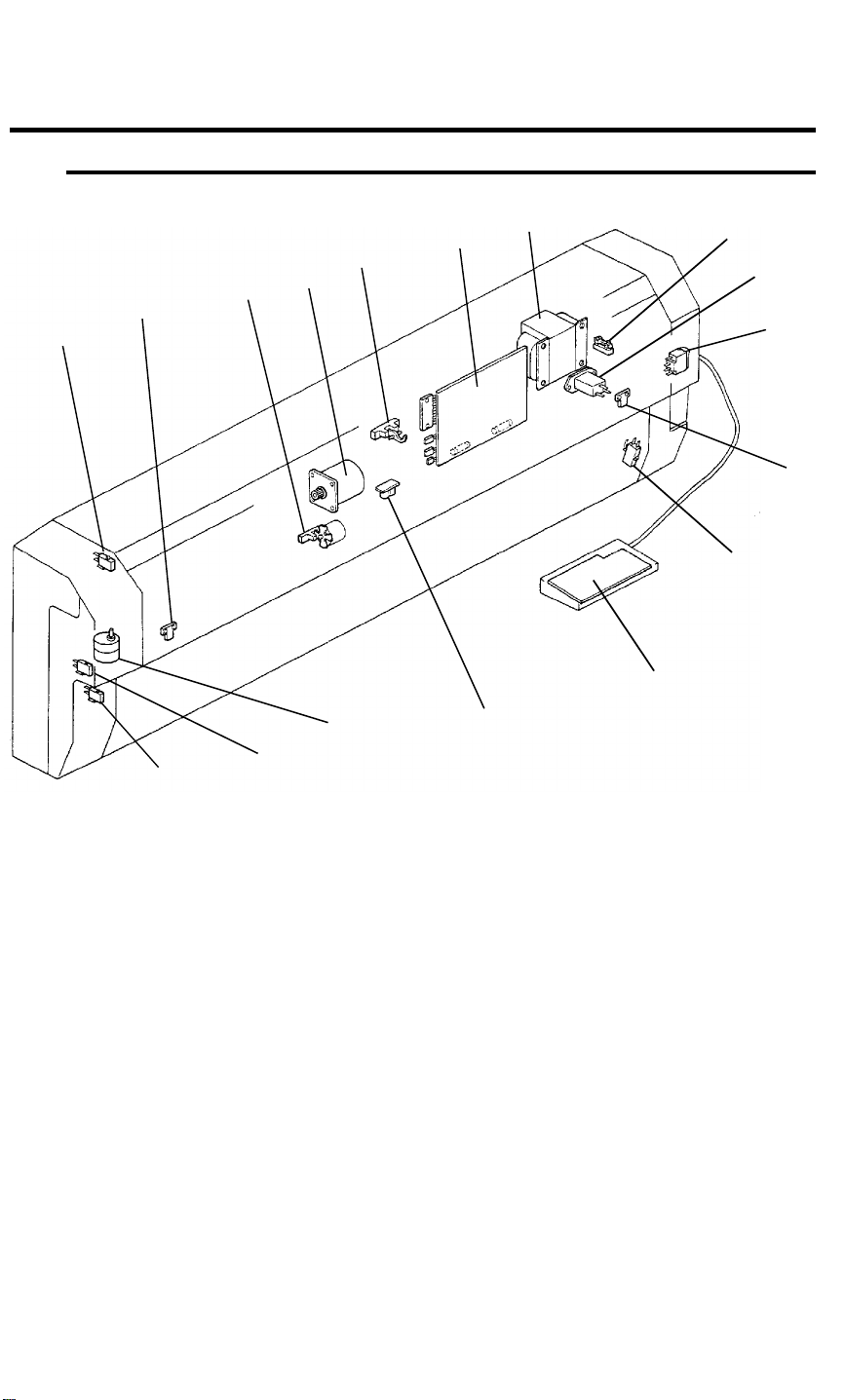

4. ELECTRICAL COMPONENT LAYOUT AND

DESCRIPTION

5

3

2

1

17

4

15

16

6

7

13

14

8

9

10

11

12

SYMBOL NAME FUNCTION LOCATION

Motors

M1 Main Motor Drives all mechanical components

4

except the cutter unit.

M2 Cutter Motor Drives the cutter. 15

Switches

SW1 Main Switch Supplies power to the unit. 10

SW2 Unit Safety

Switch

SW3 Upper Safety

Switch

Cuts power when the entire roll cutter

unit is lifted.

Cuts power when the upper cover is

opened.

7-5

12

1

Page 6

6 January 1990

SYMBOL NAME FUNCTION LOCATION

SW4 Middle Safety

Switch

SW5 Lower Safety

Switch

Cuts power when the middle cover is

opened.

Cuts power when the lower cover is

opened.

Sensors

S1 Paper End Sen-

Detects when the roll paper runs out. 14

sor

S2 Left Cutter Sen-

sor

S3 Right Cutter

Sensor

S4 Paper Exit Sen-

sor

Detects whether or not the cutter is at

the left home position.

Detects whether or not the cutter is at

the right home position.

Misfeed detector. Also detects the

leading edge of paper to start paper

length pulse count.

S5 Pulse Generator Supplies timing pulses to the main

board. (Photointerrupter)

16

17

2

11

5

3

Printed Circuit Boards

PCB1 Main Board Controls all cutter unit functions. 6

PCB2 Operation Panel Contains the operator controls and

indicators.

Others

TR Transformer Steps down the line voltage to 20 Vac

and 10 Vdc.

FU Fuse Protects the unit from excess voltage

input.

NF Noise Filter Filters out electrical noise on the ac

power input lines.

13

7

8

9

7-6

Page 7

6 January 1990

5. MECHANICAL OPERATION

5.1 BASIC OPERATION

The paper feed rollers, which are turned by the main motor, feed paper from

the paper roll through the cutter unit to the paper exit sensor. When the

paper exit sensor detects the leading edge of the paper, the roll cutter’s

microprocessor starts measuring the length of the paper. (The paper length

is measured by counting the number of steps as the main motor [stepper

motor] turns.) When the paper reaches the the proper length, paper feed

stops and the cutter unit cuts the paper. After that, the exit rollers hold the

paper until it is pulled out by the operator. When the paper is pulled out, the

machine returns to the stand-by condition.

5.2 OPENING AND

CLOSING MECHANISM

To load a roll of paper the roll

cutter must be opened as shown in

the illustration. Gas springs on

either end of the machine aid in

opening the unit, and lock pins

hold the unit in place when it is in

either the fully opened position or

when it is closed.

5.3 DRIVE MECHANISM

All rollers are driven by the main

motor (stepper motor) through a

timing belt [A]. A pulse generator

[B] makes timing pulses as the

main motor turns. These pulses

are used to control all machine

operations.

A

B

7-7

Page 8

6 January 1990

5.4 CUTTER OPERATION

The cutter unit uses a sliding rotary cutting blade which is pulled past a fixed

blade by a drive wire. The rotary cutting blade allows the cutter unit to cut

paper in both directions. There are home position sensors at both ends of

the cutter unit. The cutter motor turns off, stopping the cutting action, when

the rotary cutting blade turns on one of these sensors.

5.5 SERVICE CALL CONDITIONS

Code E1 (Abnormal Drive Motor)

Code E1 lights if the CPU does not receive the input signal from the pulse

generator for one second after the drive motor turns on.

Code E2 (Abnormal Cutter Motor)

Code E2 lights if both left and right cutter sensors turn on at the same time or

the left or right sensor does not turn on/off 2 seconds after the cutter motor

turns on. To reset E1 and/or E2, turn the main switch off and on.

7-8

Page 9

6 January 1990

6. SERVICE TABLES

6.1 SERVICE PROGRAM MODE

-- SP Mode Operation --

1. While simultaniously pressing the "0" and "Clear/Stop" keys, turn on the

Main switch.

2. Enter the proper numbers in the Length Counter and Cut Quantity

Counter as shown in the following table.

3. Press the Quantity/Size Select key. (This step is not necessarty for input

mode.)

Type

Set

Mode

Input

Mode

Length

Counter

1

2

Function

Auto Reset

(minutes)

Maximum Cut

Length (mm)

3600 5000 ---- ----

Cut Quantity Counter

0 1 2 3

2 1 5 None

3 Key Tone ON OFF ---- ---4

61

62

63

64

65

Count

Up/Down

Roll End

Sensor

Paper Exit

Sensor

Left Cutter

Sensor

Right Cutter

Sensor

Cover

Switches (x4)

Up Down ---- ----

No paper

No paper

Paper

present

Paper

present

---- ----

---- ----

OFF ON ---- ----

OFF ON ---- ----

ON OFF ---- ----

Out-

put

Mode

66

Pulse

Generator

Photointer-

rupter open

Photointer-

rupter blocked

---- ----

70 Free Run OFF ON ---- ---71 Main Motor OFF ON ---- ---72 Cutter Motor OFF ON ---- ----

73

Total Counter

(operate)

OFF ON ---- ----

7-9

Page 10

6 January 1990

Type

Other

Length

Counter

81

91

Function

Total Counter

(check)

Cut Length

Adjustment

---- ---- ---- ----

---- ---- ---- ----

Cut Quantity Counter

0 1 2 3

6.2 TEST POINTS AND DIP SWITCHES

6.2.1 Test Points

Function TP No.

GND TP-1

VA (24 V) TP-2

Paper End Sensor TP-3

VC (5 V) TP-4

6.2.2 DIP Switch

The DIP switch is used to set the machine for either millimeters or inches

SW No. OFF ON Note

1 Millimeters Inches Length counter

2 ---- ---- Not used

7-10

Page 11

6.3 SIGNAL LEVELS

Signal Name I/O CN No. Signal Level

6 January 1990

Safety Switch I 102--2

Paper Exit Sensor I 102--3

Pulse Generator I 102--4

Left Cutter Sensor I 102--5

Right Cutter Sensor I 102--7

102--8

Cutter Motor O

and

102-9

Paper End Sensor I 101-2

5 V

Door Open

5 V

ON

5 V

5 V

ON

24 V

ON

Roll End

7-11

Page 12

6 January 1990

7. REPLACEMENT AND ADJUSTMENT

7.1 CUTTER UNIT REMOVAL

[A]

[B]

[D]

[E]

[C]

[H]

[G]

[F]

1. Remove the left covers [A,B], the release knob [C], and the right covers

[D,E].

2. Remove the cutter front cover [F] and the knob plate [G].

3. Disconnect the cutter connector [H].

4. Remove the 4 screws (2 at each end) that secure the cutter unit and slide

out the unit in the arrow direction.

7-12

Page 13

6 January 1990

7.2 REPLACEMENT OF THE PAPER EXIT SENSOR AND PULSE GENERATOR

[B]

1. Remove the rear cover [A].

2. Disconnect the connectors

of the paper exit sensor and

the pulse generator.

3. Remove the main motor unit

[B]

4. Remove the paper exit sensor

[C] from the main motor unit.

[A]

[C]

5. Remove the pulse generator

disc [D] and the pulse

generator photointerruptor [E].

[E]

[D]

7-13

Page 14

6 January 1990

7.3 CUT LENGTH ADJUSTMENT

1. Cut 100 mm and 500 mm sheets with the roll cutter and then measure

their length.

2. Select SP mode 91. (Cut length adjustment)

3. Enter the actual length of the "100 mm" sheet. (Enter up to one digit past

the decimal point.)

4. Press the Quantity/Size Select key.

5. Enter the actual length of the "500 mm" sheet. (Enter up to one digit past

the decimal point.)

6. Turn off the main switch. (The new data will be saved in RAM.)

7. Again cut "100 mm" and "500 mm" sheets and check their length.

8. If the length of each of these sheets is not correct, repeat steps 2 through

7.

7-14

Page 15

6 January 1990

8. INSTALLATION PROCEDURE

8.1 ACCESSORY CHECK

Check the accessories and their quantities according to the following list:

1. Paper Size Labels .................................................................1 set

2. Paper Spool ..........................................................................1 pc

3. Power Supply Cord...............................................................1 pc

4. Pan Head Screw....................................................................8 pcs

5. Mounting Plate ......................................................................1 pc

6. Decal.....................................................................................1 pc

7. Nylon Clip..............................................................................2 pcs

CAUTION: The A023 copier must be placed on the table before the roll

paper cutter is installed. Otherwise, the table may become

unbalanced during installation.

8.2 INSTALLATION PROCEDURE

1. Remove all strips of

shipping tape from

the unit.

2. Remove the left and

right cover plates

from the table.

7-15

Page 16

6 January 1990

3. Remove the left covers [A,B], the release knob [C],

and the right covers [D,E].

4. Hook the right

mounting arm [F]

in the right mounting slot [G].

[A]

[D]

[B]

[E]

[C]

[G]

NOTE: The right mount-

ing arm must

be set first for

proper alignment.

5. Hook the left mounting arm [H] in the

left mounting slot

[I].

[I]

[F]

[H]

7-16

Page 17

6. Push the roll cutter

in at position (1) until the left mounting

arm is set securely.

Then, push in at position (2) until the

right mounting arm

is set securely.

7. Secure the roll paper cutter to the table with 8 screws.

6 January 1990

8. Remove 4 spacers

from the right and

left sides (2 spacers each) of the

unit.

7-17

Page 18

6 January 1990

9. Secure the 2 spacers to the left and

right side brackets

[A] respectively.

(For future use if

the machine is

moved.)

10. Install the left and

right covers and

the release knob.

[A]

7-18

Page 19

11. Install the power

cord using the two

nylon clamps as

shown.

12. Peel the paper from

the back of the

mounting plate

which is packed as

an accessory, and

stick it in the depression in the paper feed table.

6 January 1990

13. Place the operation

panel unit on the

mounting plate.

14. Register the desired

standard paper

lengths and stick

the labels on the

operation panel.

7-19

Page 20

6 January 1990

15. Adhere the decal to

the main copier

16. Remove all shipping

retainers from the

roll cutter.

17. Mount a roll of paper on the paper

spool and place it

in the cutter unit.

18. Plug in the power

cord and turn on

the main switch of

the roll cutter unit.

7-20

Loading...

Loading...