Page 1

NINE-TRAY MAILBOX

AND

BRIDGE UNIT

(Codes: G909 and G912)

Page 2

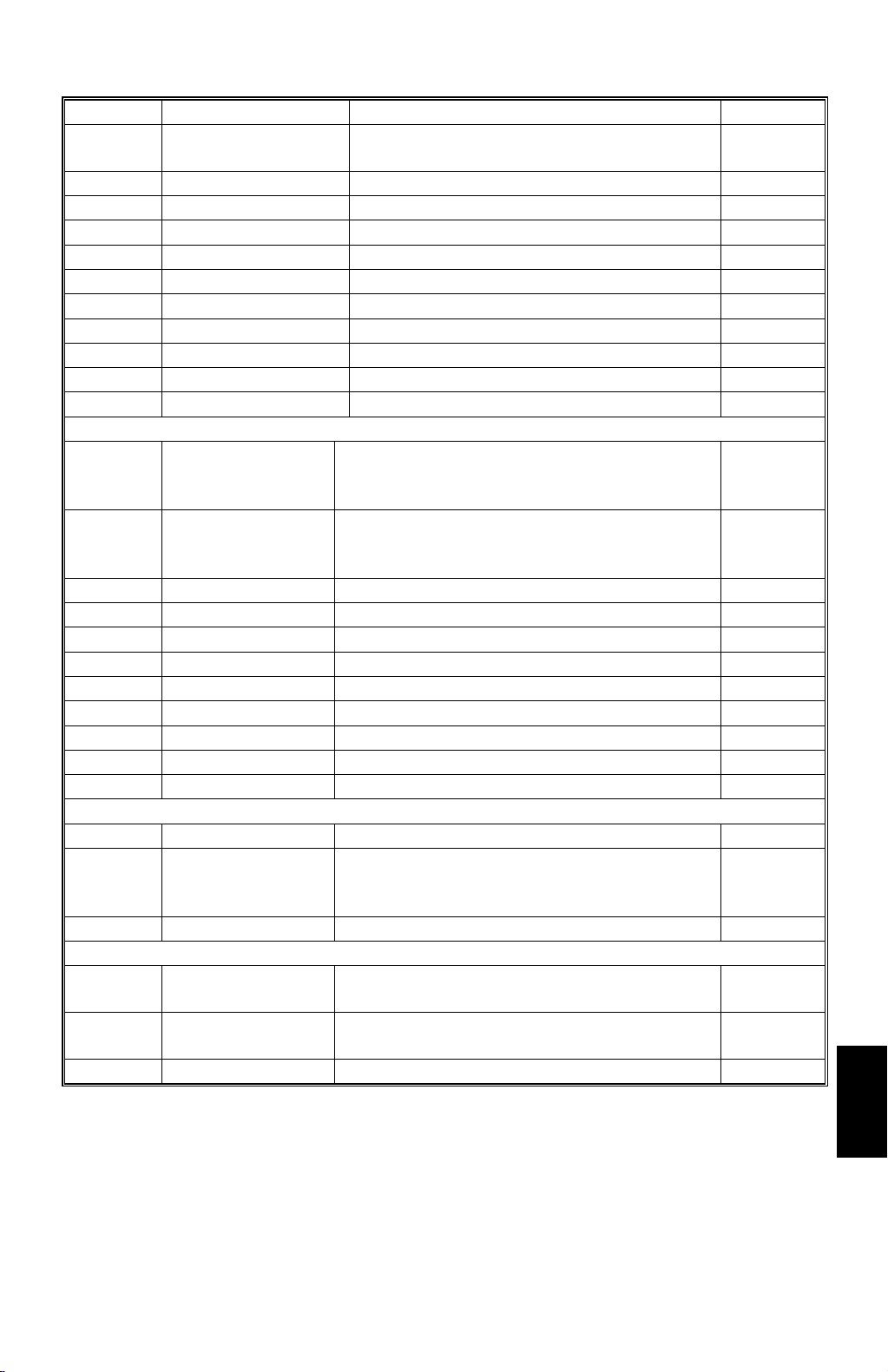

30 October 1998 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Number of Trays 9 trays + proof tray

Tray Capacity: Trays and proof tray: 100 sheets (80 g/m2, 20 lb)

Paper Size for Trays: Trays:

Maximum: A3 or 11” x 17”

Minimum: A5 (LEF) or 11” x 8

Proof tray:

Maximum: A3 or 11” x 17”

Minimum: A6 (LEF) or 11” x 8

Paper Weight: Trays: 60 ~ 90 g/m2, 16 ~ 24 lb

Proof tray: 52 ~ 157 g/m2, 14 ~ 42 lb

Power Consumption: 48 W or less (average)

Power Source: DC24 V, 5 V (from the printer)

1/2

1/2

”

”

Dimensions (W x D x H): 600 x 545 x 970 mm (23.6” x 21.5” x 38.2”)

Weight: 38 kg, 83.6 lb

• Specifications are subject to change without notice.

G909-1

Options

Page 3

COMPONENT LAYOUT 30 October 1998

1.2 COMPONENT LAYOUT

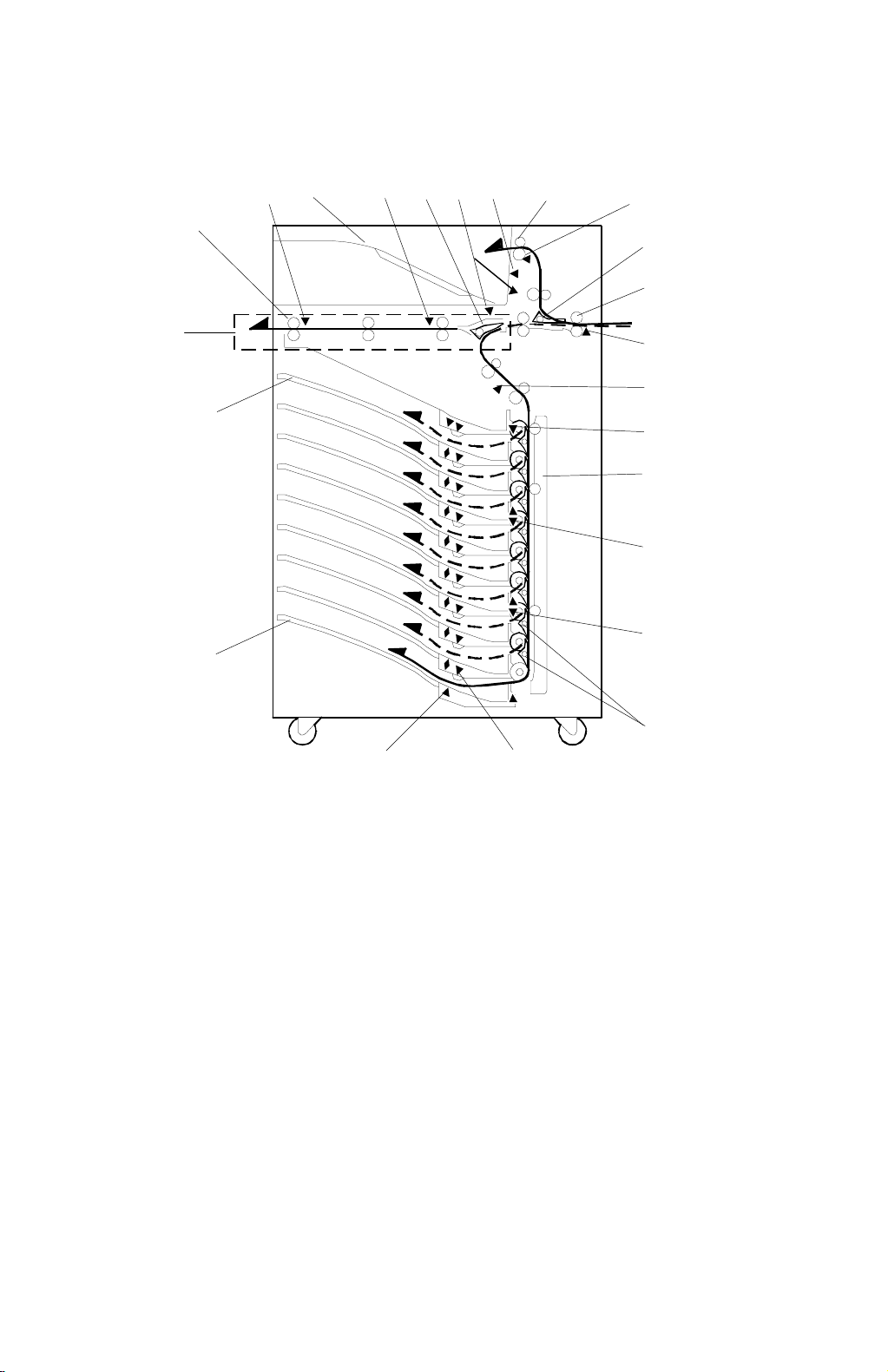

1.2.1 MECHANICAL COMPONENT LAYOUT

23

1

22

21

3

2

4

5

7

6

8

9

10

11

12

13

14

15

16

17

20

1. Bridge Exit Roller

2. Bridge Exit Sensor

3. Proof Tray

4. Bridge Relay Sensor

5. Relay Junction Gate

6. Proof Tray Paper Sensor

7. Proof Tray Paper Overflow Sensor

8. Proof Tray Exit Roller

9. Proof Tray Exit Sensor

10. Proof Tray Junction Gate

11. Entrance Roller

12. Entrance Sensor

18

19

G909V500.WMF

13. Relay Sensor

14. Tray Exit Sensor 1

15. Vertical Transp or t G uide

16. Tray Exit Sensor 2

17. Tray Exit Sensor 3

18. Tray Gates

19. Paper Overflow Sensor

20. Paper Sensor

21. 9th Tray

22. 1st Tray

23. Bridge Unit

G909-2

Page 4

30 October 1998 COMPONENT LAYOUT

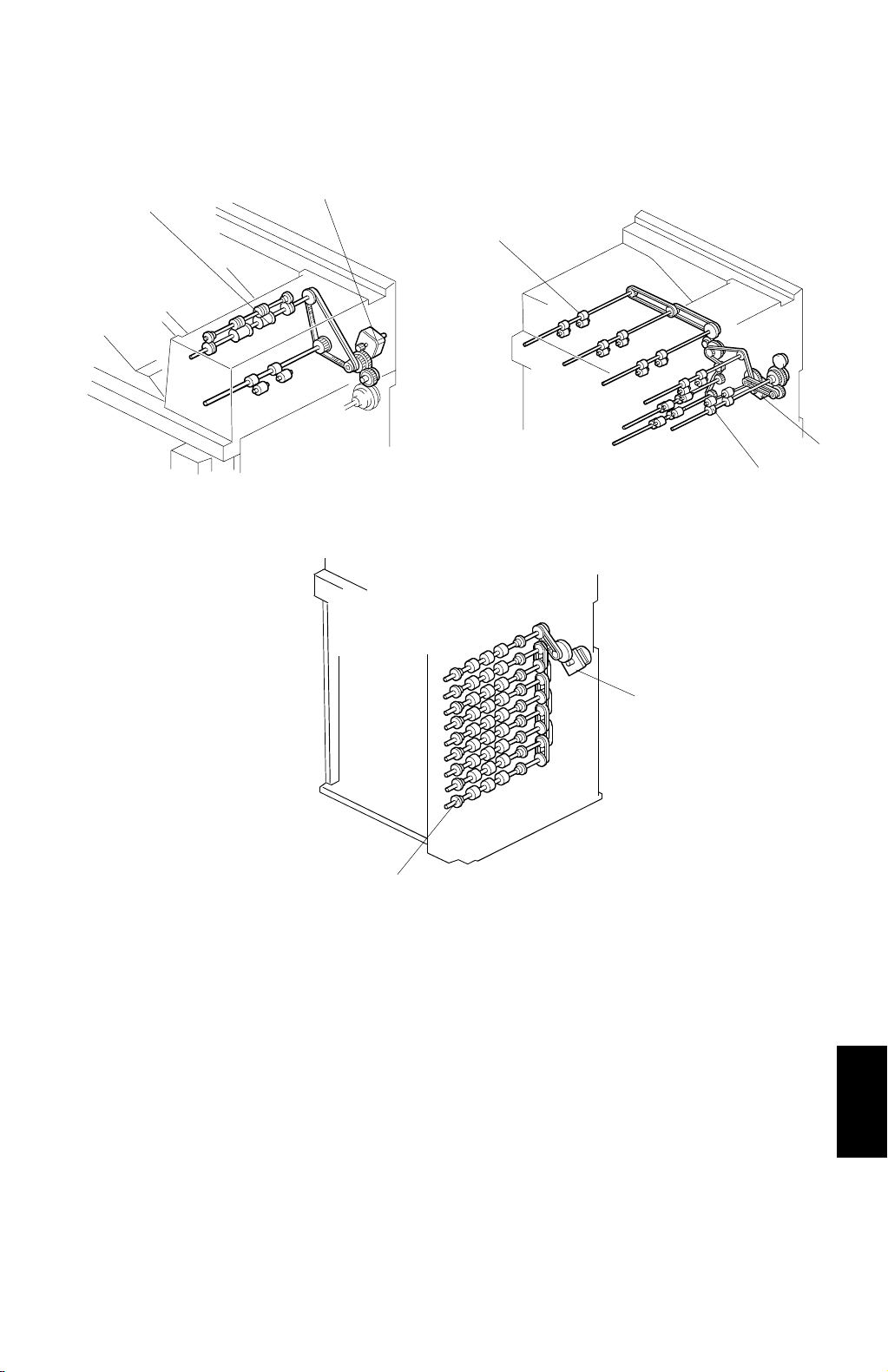

1.2.2 DRIVE LAYOUT

1

2

3

4

5

G909V501.WMF

G909V502.WMF

6

1. Proof Tray Exit Roller

2. Proof Tray Transport Motor

3. Bridge Exit Roller

4. Transport Motor

7

G909V503.WMF

5. Entrance Roller

6. Vertical Transport Motor

7. Tray Feed-out Roller

Options

G909-3

Page 5

ELECTRICAL COMPONENT DESCRIPTIONS 30 October 1998

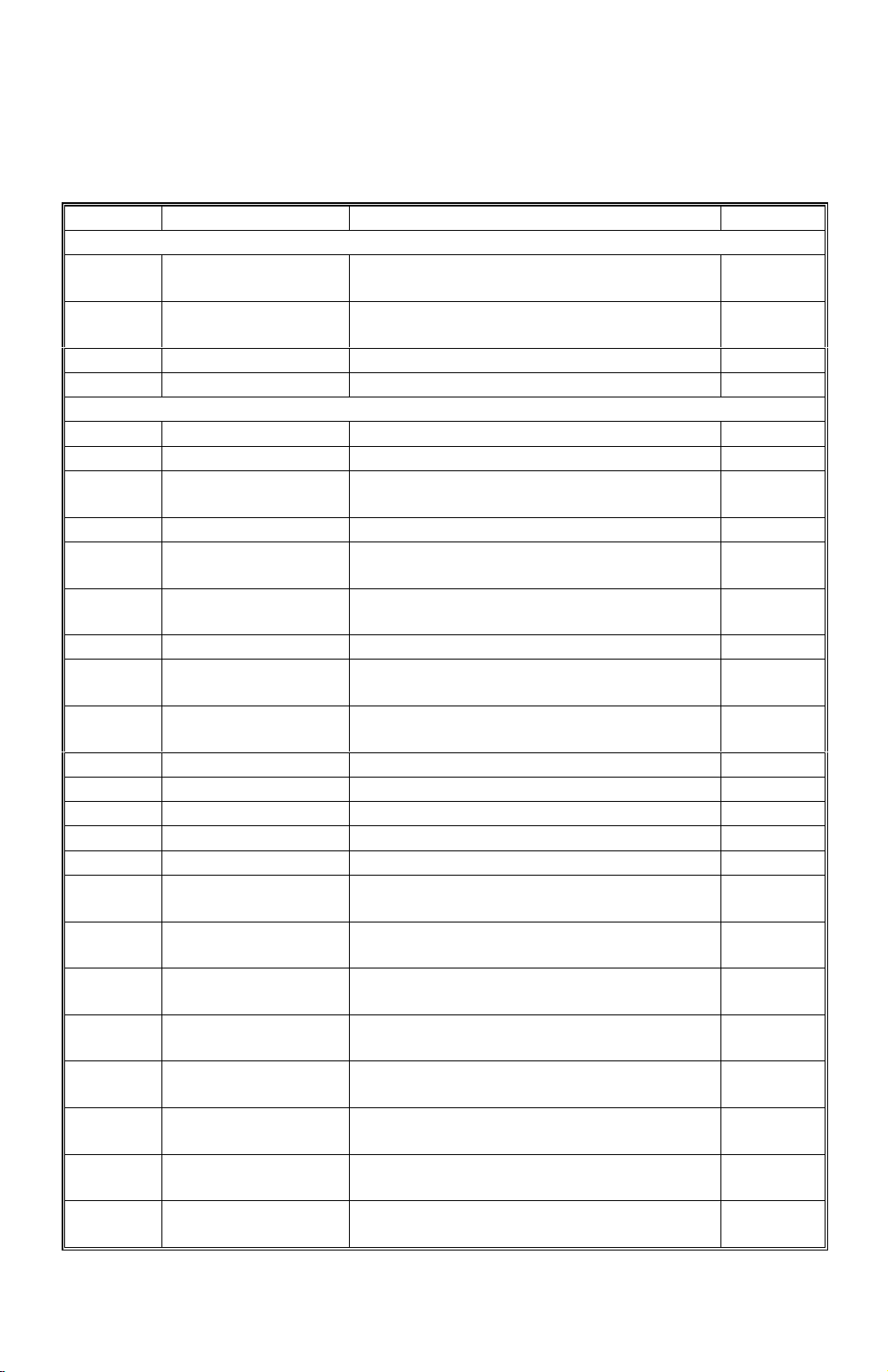

1.3 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout and the point-to-point diagram on the

waterproof paper in the pocket for symbols and index numbers.

Symbols Name Function Index No.

Motors

M1

M2 Transport

M3 Vertical Transport Drives all tray feed-out rollers. 19

Sensors

S1 Bridge Exit Detects misfeeds. 1

S2 Bridge Relay Detect s misfeeds. 2

S3

S4 Proof Exit Detects misfeeds. 4

S5 Proof Cover

S6 Entrance

S7 Relay Detects misfeeds. 10

S8

S9

S10 Tray Exit 1 Detect s misfeeds. 21

S11 Tray Exit 2 Detect s misfeeds. 25

S12 Tray Exit 3 Detect s misfeeds. 29

S13 Tray Exit 4 Detect s misfeeds. 32

S14 Paper 0 Contains an LED for paper sensor 1. 47

S15 Paper 1

S16 Paper 2

S17 Paper 3

S18 Paper 4

S19 Paper 5

S20 Paper 6

S21 Paper 7

S22 Paper 8

Proof Tray

Transport

Proof Tray Paper

Overflow

Proof Tray Paper 1

(LED)

Proof Tray Paper 2

(Photo Transistor)

Drives all the proof tray rollers.

Drives all rollers in the entrance area and

all rollers in the bridge unit.

Detects paper overflow in the proof tray.

Detects whether the proof cover is open

or closed.

Detects copy paper entering the mail box

and detects misfeeds.

Informs the CPU when there is paper on

the proof tray.

Informs the CPU when there is paper on

the proof tray.

Informs the CPU when there is paper on

the 1st tray.

Informs the CPU when there is paper on

the 2nd tray.

Informs the CPU when there is paper on

the 3rd tray.

Informs the CPU when there is paper on

the 4th tray.

Informs the CPU when there is paper on

the 5th tray.

Informs the CPU when there is paper on

the 6th tray.

Informs the CPU when there is paper on

the 7th tray.

Informs the CPU when there is paper on

the 8th tray.

7

8

3

6

9

14

13

15

43

41

39

37

36

35

34

G909-4

Page 6

30 October 1998 ELECTRICAL COMPONENT DESCRIPTIONS

Symbols Name Function Index No.

S23 Paper 9

Informs the CPU when there is paper on

the 9th tray.

33

S24 Paper Overflow 1 Detects paper overflow in the 1st tray. 49

S25 Paper Overflow 2 Detects paper overflow in the 2nd tray. 46

S26 Paper Overflow 3 Detects paper overflow in the 3rd tray. 44

S27 Paper Overflow 4 Detects paper overflow in the 4th tray. 42

S28 Paper Overflow 5 Detects paper overflow in the 5th tray. 40

S29 Paper Overflow 6 Detects paper overflow in the 6th tray. 38

S30 Paper Overflow 7 Detects paper overflow in the 7th tray. 28

S31 Paper Overflow 8 Detects paper overflow in the 8th tray. 30

S32 Paper Overflow 9 Detects paper overflow in the 9th tray. 31

Solenoids

Opens and closes the proof junction gate

to direct paper either into the proof tray or

to the trays.

Opens and closes the relay junction gate to

direct paper either to the bridge unit or to

the trays.

17

15

SOL1

SOL2

Proof Tray

Junction Gate

Relay Junction

Gate

SOL3 1st Tray Opens and closes the 1st tray gate. 16

SOL4 2nd Tray Opens and closes the 2nd tray gate. 18

SOL5 3rd Tray Opens and closes the 3rd tray gate. 20

SOL6 4th Tray Opens and closes the 4th tray gate. 22

SOL7 5th Tray Opens and closes the 5th tray gate. 23

SOL8 6th Tray Opens and closes the 6th tray gate. 24

SOL9 7th Tray Opens and closes the 7th tray gate. 26

SOL10 8th Tray Opens and closes the 8th tray gate. 27

PCBs

PCB1 Main Control Controls all sorter functions 48

Drives the motors in the proof unit and

PCB2 Proof Control

informs the sensor status to the main

control board.

Switches

SW1 Bridge Co ver

SW2 Front Cover

Cuts the +24 V power line and detects

when the bridge cover is opened.

Cuts the +24 V power line and detects

when the front cover is opened.

G909-5

5

12

11

Options

Page 7

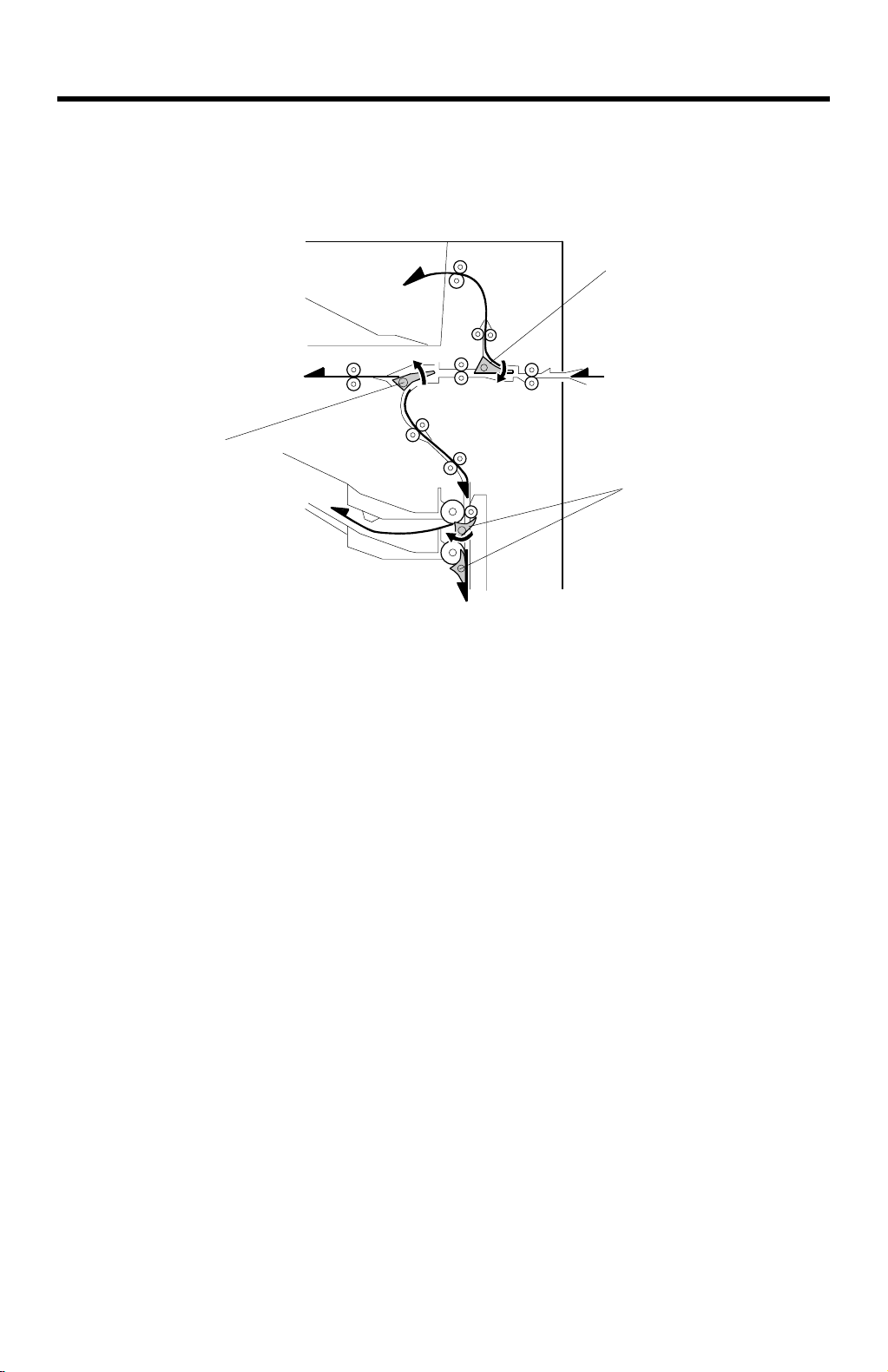

BASIC OPERATION 30 October 1998

2. DETAILED DESCRIPTIONS

2.1 BASIC OPERATION

[A]

[B]

[C]

G909D505.WMF

Proof Tray

When the proof tray is selected as the output tray and the exit sensor of the main

machine is actuated by the leading edge of the paper, the transport motor and

proof tray transport motor turn on, turning the transport rollers.

Soon after the motors start, the proof tray junction gate solenoid energizes and the

proof tray junction gate [A] is lowered so that the paper goes to the proof tray.

When the last page passes the proof tray exit sensor and feeds out, the proof tray

junction gate solenoid and the proof tray transport motor turn off.

Bridge Unit

The relay junction gate [B] in the bridge unit delivers the paper either to the finisher

or down to the trays. When the finisher is selected as the output tray, the relay

junction gate stays closed, and the paper goes to the bridge unit. When a tray is

selected as the output tray, the relay junction gate solenoid energizes and the relay

junction gate is open so that the paper goes downwards to the tray area.

Trays

When the proof tray is selected as the outp ut tray, the transport motor a nd the

vertical transport motor turn on. Each tray gate [C] is individually controlled by a

solenoid. When a solenoid is energized, the tray gate opens and the paper goes

into the tray.

G909-6

Page 8

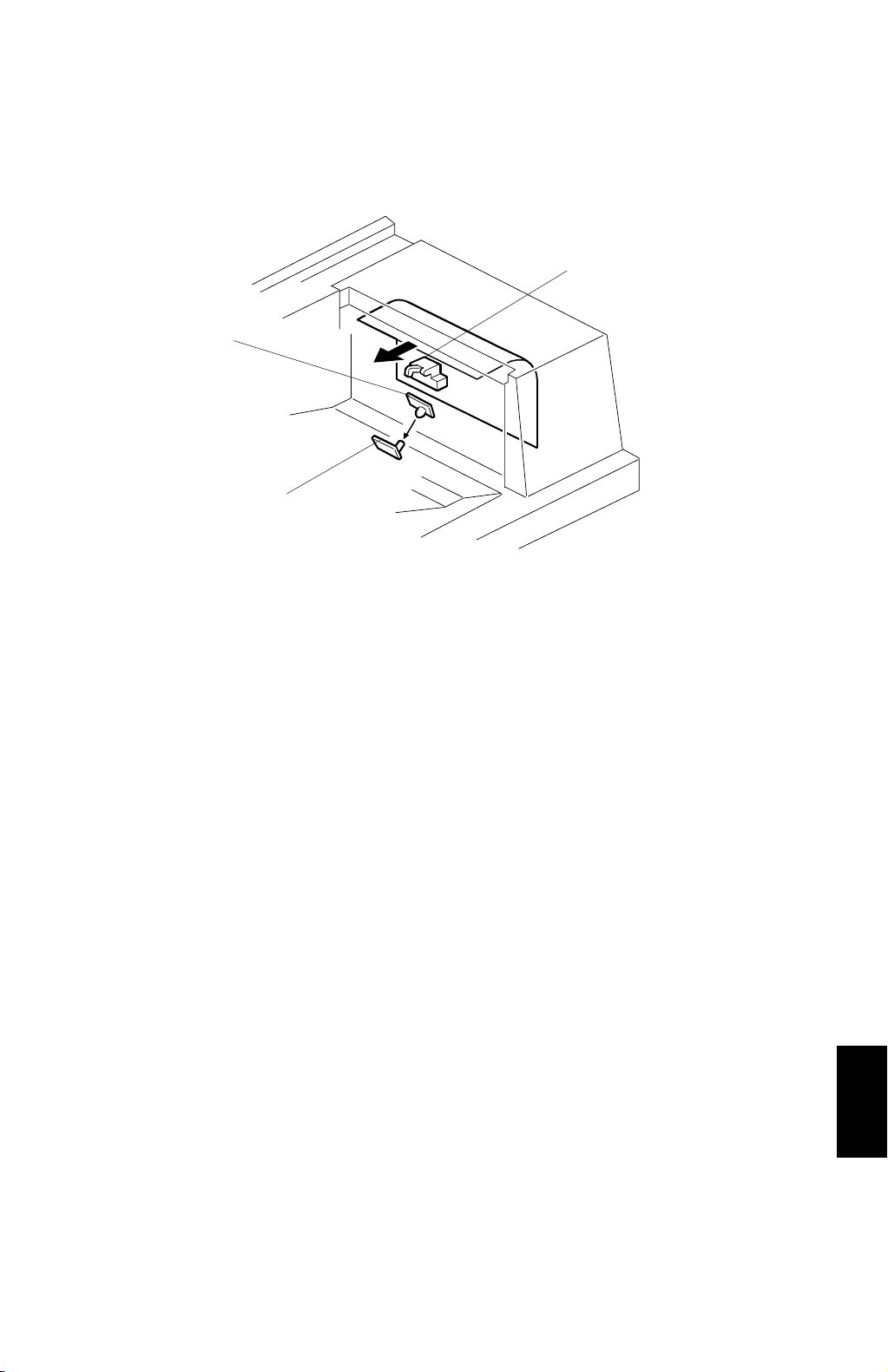

30 October 1998 PROOF TRAY SENSORS

2.2 PROOF TRAY SENSORS

[C]

[A]

[B]

G909D504.WMF

2.2.1 PAPER SENSOR

The paper sensor in the proof tray consists of two sensor boards; one is an LED

board [A] and the other is a phototransistor board [B]. The sensor detects

whether or not there is paper on the proof tray. When there is paper on the

proof tray, the paper interrupts the light from the LED.

2.2.2 PAPER OVERFLOW SENSOR

Also, there is a paper overflow sensor [C] in the proof tray. The machine detects

paper overflow when the top sheet of the paper stack pushes up the sensor

feeler. When this occurs, a message will be d isplayed on the operation panel

and the machine stops printing until the paper stack on the proof tray is

removed.

G909-7

Options

Page 9

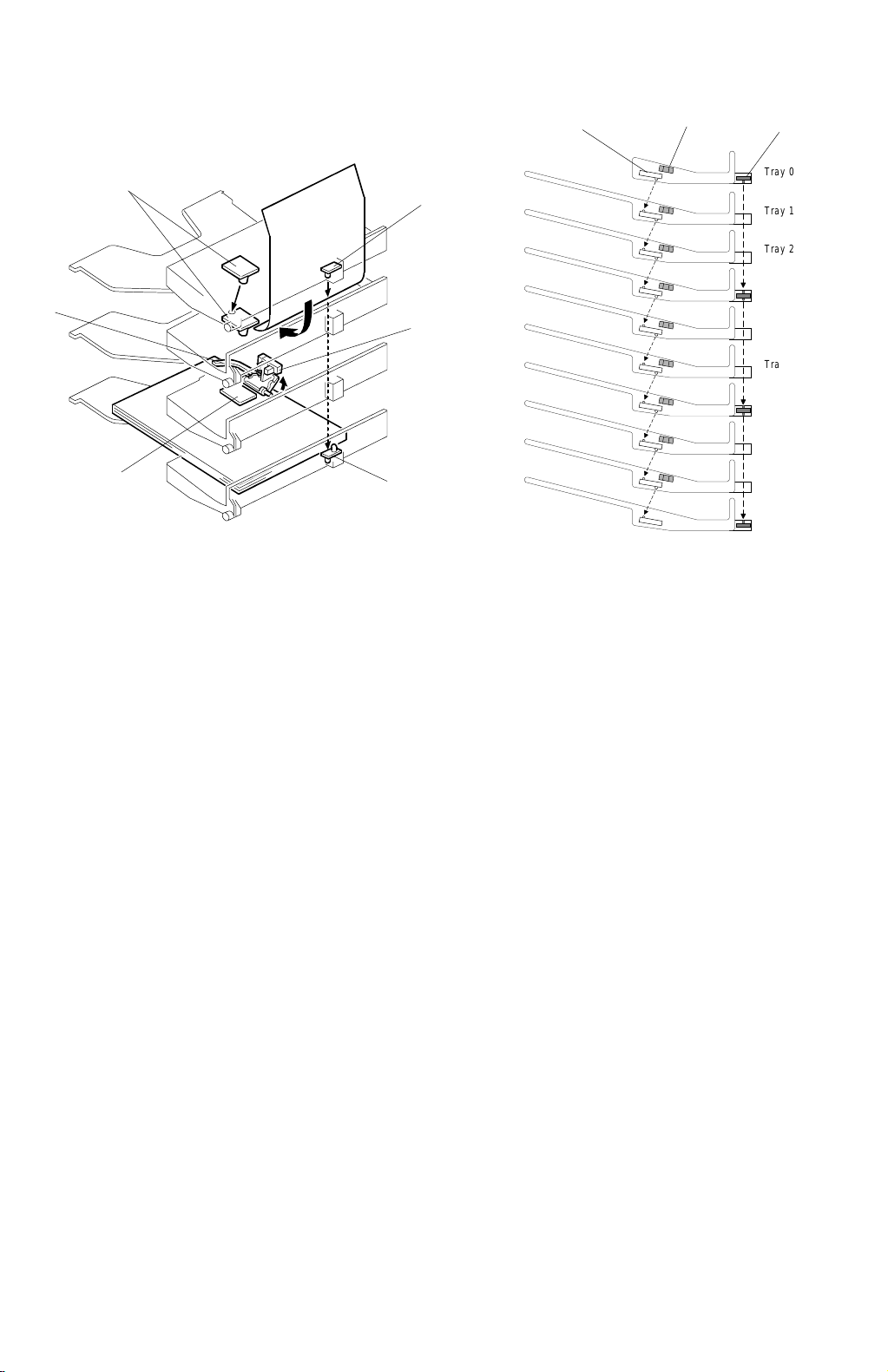

TRAY SENSORS 30 October 1998

2.3 TRAY SENSORS

[A]

[C]

[A]

2.3.1 PAPER SENSOR

G909D506.WMF

[D]

[D]

[B]

[A]

[B]

Tray 0

Tray 1

Tray 2

Tray 3

Tray 4

Tray 5

Tray 6

Tray 7

Tray 8

Tray 9

G909D507.WMF

[D]

There is a paper sensor [A] for each tray (total 10 pcs). The paper sensors in

the tray 1 to tray 8 contain an LED and a phototransistor. The paper sensor in

the tray 0 contains only an LED. The paper sensor in the tray 9 contains only a

phototransistor. Th e paper det ecti on mecha ni s m an d thei r func ti on ar e the

same as for the proof tray.

2.3.2 PAPER OVERFLOW SENSOR

There is a paper overflow sensor [B] above each tray. The machine detects

paper overflow in a tray when the top of the paper stack pushes up the sensor

feeler [C]. At this condition occurs, the printing job is stopped until the paper

stack will be removed.

2.3.3 TRAY EXIT SENSOR

There is a tray exit sensor board [D] above the 1st tray (the mounting above

tray 1 is called ‘tray 0’) and on trays 3, 6, and 9. The tray exit sensor board on

trays 3 and 6 contains an LED and a phototransistor.

The tray exit sensor board above the 1st tray contains only an LED. The tray

sensor board on the 9th tray contains only a phototransistor.

The machine detects paper leaving trays 1 to 3 using the sensor above tray 1

and the one on tray 3. When paper passes between those sensors, the light

from the LED above tray 1 is interrupted.

G909-8

Page 10

30 October 1998 TIMING CHART AND MISFEED DETECTION

2.4 TIMING CHART AND MISFEED DETECTION

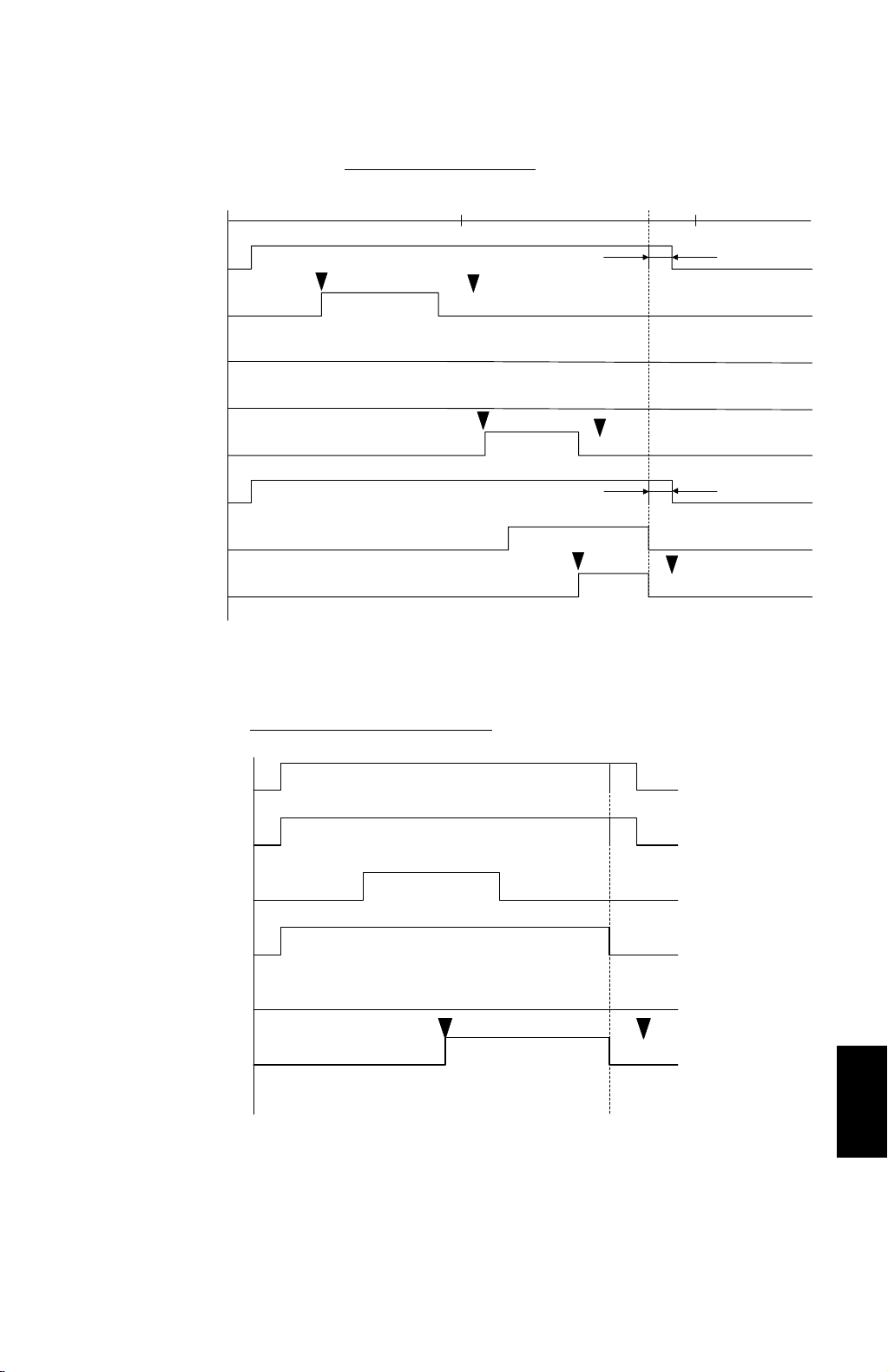

A4 Sideways (to 1st Tray)

1 s 2 s

Transport Motor

Entrance Sensor

Proof Junction Gate Sol.

Relay Junction Gate Sol.

Relay Sensor

Vertical Transport Motor

1st Tray Sol.

Tray Exit Sensor

J1

J6

J2

A4 Sideways (to Proof Tray)

J5

100 pulses

J6

100 pulses

J6

G909D502.WMF

Transport Motor

Proof Transport Motor

Entrance Sensor

Proof Junction Gate Sol.

Relay Junction Gate Sol.

Proof Exit Sensor

J3 J6

G909D500.WMF

Options

G909-9

Page 11

TIMING CHART AND MISFEED DETECTION 30 October 1998

A4 Sideways (to Bridge Unit)

Transport Motor

Entrance Sensor

Proof Junction

Gate Sol.

Relay Junction

Gate Sol.

Bridge Relay

J4

Sensor

J6

Bridge Exit Sensor

G909D501.WMF

J6

1. On check

J1: The entrance sensor does not turn on within 2460 pulses after the exit sensor

of the main machine has been turned on.

J2: The relay sensor does not turn on within 1965 pulses after the entrance sensor

has been turned on.

J3:

The proof tray exit sensor does not turn on within 1665 pulses after the

entrance sensor has been turned on.

J4:

The bridge relay sensor does not turn on within 1954 pulses after the entrance

sensor has been turned on.

J5: The appropriate tray exit sensor does not turn on within the appropriate number

of pulses (see below) after the relay sensor has been turned on.

J5 jam timing

Tray

Exit

Sensor

Tray No.123456789

Pulses 72 139 176 206 242 273 304 343 375

Sensor 1 Sensor 2 Sensor 3

2. Off check

J6: A sensor does not turn off the specified number of pulses after that sensor has

been turned on.

Number of pulses = Paper length (in the paper feed direction) x 1.5

1 pulse = 0.1707 mm

G909-10

Page 12

30 October 1998 MAILBOX (G909)

3. INSTALLATION PROCEDURE

3.1 MAILBOX (G909)

3.1.1 ACCESSORY CHECK

Check the accessories in the box against the following list.

No. Description Q’ty Note

1 Front Joint Bracket 1

2 Rear Joint Bracket 1

3 Exit Guide Mylar 1 For A229

4 Proof Tray Attachment 1 For A230, A231, and A232

5 Upper Grounding Plate 1 For A230, A231, and A232

Lower Grounding Plate

6

7 Cushion 1

8 Tapping Screw - M4 x 14 4

9 Tray Decals 1

10 Installation Procedure 1

One for A230,A231, and A232

2

Two for A229

7

3

4

2

1

6

8

9

G909I501.WMF

5

3.1.2 REQUIREMENT OPTIONS FOR MAIN MACHINE

When the mailbox is going to be installed to A 230, A231, and A232 machines, the

following options for main machine must be required.

1. Bridge Unit Type 450 (A688)

Options

2. Paper Tray Unit – PS360 (A682)

G909-11

Page 13

MAILBOX (G909) 30 October 1998

3.1.3 INSTALLATION PROCEDURE

[C]

G909I500.WMF

[B]

[A]

[D]

G909I509.WMF

- A230, A231, and A232 machines -

CAUTION

ø

Unplug the main machine power cord before starting the following

procedure.

NOTE:

1) When the finisher (A697) will be inst alled on the machine, th e bridge

unit for the mailbox (G912) must be installed.

2) The bridge unit for the mailbox must be installed before installing this

unit on the main machine.

1. Unpack the finisher and remove the tapes.

- A230, A231, and A232 machines -

2. Attach the front joint bracket [A] and rear joint bracket [B] to the main machine

(2 screws each).

3. Attach the upper grounding plate [C] (1 screw).

4. Peel off the backing of the double sided tape that is attached to the lower

grounding plate [D].

5. Attach one lower grounding plate to the center of the bottom edge of the paper

tray unit as shown.

Go to step 7.

G909-12

Page 14

30 October 1998 MAILBOX (G909)

[D]

[C]

[B]

[A]

[I]

[E]

G909I506.WMF

- A229 machine -

G909I510.WMF

[J]

[K]

- A229 machines -

2. Remove the four plastic caps [A] from the copier’s left cover.

3. Remove the connector cover [B].

4. Attach the front joint bracket [C] and rear joint bracket [D] to the main machine

(2 screws each).

[H]

[G]

[F]

5. Peel off the backing of the double-sided tape that is attached to the lower

grounding plate [E].

6. Attach two lower grounding plates to the bottom edge of the paper tray unit as

shown.

- All machines -

7. The position of the cushion [F] depends on which main machine the mailbox is

installed. Attach the cushion to the plate as follows:

• Position [G] for A230, A231, and A232 machines.

• Position [H] for A229 machines.

NOTE:

When attaching the cushion to position [H], cut about 40 mm (1.6

inches) off one edge of the cushion.

8. Open the front cover [I] of the mailbox, and remove the screw [J] that secures

the locking lever [K]. Then pull the locking lever.

G909-13

Options

Page 15

MAILBOX (G909) 30 October 1998

[B]

G909I503.WMF

[D]

[A]

[C]

G909I502.WMF

9. Align the mailbox on the joint brackets, and lock it in place by pushing the

locking lever [A].

10. Secure the locking lever (1 screw) and close the front door.

11. Connect the mailbox cable [B] to the main machine.

A230/A231/A232 machines only:

12.

Peel off t he backing of the double sided

tape that is attached to the proof tray attachment [C].

13. Install the proof tray attachment on the proof tray.

A229 machines only:

14.

Install the exit guide mylar [D] on the upper cover just

above the anti-static brush.

15. Turn on the main switch and check the mailbox operation.

G909-14

Page 16

30 October 1998 BRIDGE UNIT FOR MAILBOX (G912)

3.2 BRIDGE UNIT FOR MAILBOX (G912)

3.2.1 ACCESSORY CHECK

Check the accessories in the box against the following list.

No. Description Q’ty

1. Guide Plate Bracket 1

2 Cable 1

3 Cover Switch 1

4 Grounding Bracket 1

5 Finisher Shielding Plat e 1

6Screw - M4 x 8 9

7Screw - M4 x 4 4

8Screw - M3 x 6 2

1

5

2

4

6

7

3

8

G912I500.WMF

Options

G909-15

Page 17

BRIDGE UNIT FOR MAILBOX (G912) 30 October 1998

3.2.2 INSTALLATION PROCEDURE

[A]

[D]

[E]

G912I506.WMF

[B]

G909I508.WMF

CAUTION

ø

[A]

Unplug the main machine power cord before starting the following

procedure.

NOTE:

1) This bridge unit for the mailbox must be installed when the 3000 sheet

finisher (A697) will be installed.

2) The 3000 sheet finisher (A697) can be installed only for A232 and A229

machines.

[C]

1. Unpack the bridge unit and remove the shipping retainers [A].

NOTE:

Do not remove the protective sheet [B] at this time.

2. Remove the mailbox if it has been installed.

3. Remove the rear cover [C] of the mailbox (8 screws).

4. Remove the proof tray unit [D] (6 screws, 1 connector).

5. Remove the cover [E].

G909-16

Page 18

30 October 1998 BRIDGE UNIT FOR MAILBOX (G912)

[B]

[C]

[A]

G912I503.WMF

[F]

[D]

G912I504.WMF

[E]

G912I505.WMF

[D]

6. Open the left front cover [A] of the mailbox, and remove the inner plate [B] (3

screws).

7. Install the guide plate bracket [C] (4 screws - M4 x 4).

8. Route the cable [D] and clamp it as shown.

9. Connect the cover switch [E] to the cable then install the cover switch (2 screws

– M4 x 8).

10. Remove the paper guide plate [F] (2 screws).

G909-17

Options

Page 19

BRIDGE UNIT FOR MAILBOX (G912) 30 October 1998

[B]

[A]

G912I501.WMF

[C]

[F]

[D]

[E]

G912I507.WMF

[H]

[G]

G912I508.WMF

[H]

11. Pull up the tab [A] of the protective sheet.

NOTE:

1) Do not remove the protective sheet at this time.

2) Make sure that all mylars are held between the two folded halves of

the protective sheet.

12. Turn over the bridge unit [B] and insert the protective sheet [C] into the gap [D]

between the paper guides, then put the bridge unit on the mailbox [E].

NOTE:

When holding the bridge unit, do not touch the timing belt. Otherwise

the timing belt may come off the gear.

13. Remove the tape [F] of the protective sheet.

14. Open the upper paper guide [G] then pull out the protective sheet [H].

NOTE:

Check that all mylars are set into the gap between the paper guides.

G909-18

Page 20

30 October 1998 BRIDGE UNIT FOR MAILBOX (G912)

[C]

[C]

[B]

[B]

[D]

[A]

[C]

[B]

G912I509.WMF

G912I513.WMF

[F]

G912I510.WMF

[E]

15. Secure the bridge unit [A] (4 screws – M4 x 8).

16. Route the cables [B] through the openings [C].

17. Route the solenoid harness [D] through the opening [C].

18. Connect the cables to the solenoid and sensors and clamp the cable as shown.

19. Reinstall the rear cover and proof tray unit.

20. Install the mailbox on the main machine (refer to the Mailbox Installation

procedure for more detail).

When the 3000 sheet finisher (A697) is going to be installed, do steps 21 to

25.

Options

21. Install the front joint bracket [E] and rear joint bracket [F] which are contained in

the finisher’s accessory box.

G909-19

Page 21

BRIDGE UNIT FOR MAILBOX (G912) 30 October 1998

[A]

G912I502.WMF

[B]

G912I512.WMF

22. Remove the seal [A].

23. Attach the grounding bracket [B] (3 screws - M4 x 8).

24. Attach the shielding plate [C] to the finisher (2 screws – M3 x 8).

25. Attach the finisher to the mailbox (refer to the finisher installation procedure).

26. Turn on the main switch of the main machine and check the bridge unit

operation. (Select a copy mode that uses the finisher .)

G909-20

Page 22

30 October 1998 PROOF TRAY UNIT

4. REPLACEMENT AND ADJUSTMENT

4.1 PROOF TRAY UNIT

4.1.1 PROOF TRAY SENSOR AND PAPER OVERFLOW SENSORS

[B]

[G]

[E]

[D]

[A]

G909R501.WMF

[C]

G909R500.WMF

1. Remove the rear cover [A] (8 screws).

2. Remove the proof tray unit [B] (6 screws).

3. Remove two screws [C], then turn over the proof tray unit.

4. Remove the sensor bracket [D] (2 screws, 1 clamp).

5. Remove the proof tray paper sensor [E] (1 screw each).

[E]

[F]

G909R502.WMF

6. Remove the proof tray paper overflow sensor [F].

4.1.2 PROOF TRANSPORT UNIT

1. Remove the proof tray unit [B] and remove two screws [C].

2. Turn over the proof tray unit and remove the proof transport unit [G] (2 screws).

G909-21

Options

Page 23

TRAY UNIT 30 October 1998

4.2 TRAY UNIT

4.2.1 TRAYS

[E]

[A]

[C]

[B]

G909R503.WMF

[G]

G909R504.WMF

1. Remove the rear cover (8 screws).

2. Disconnect the cable [A] of the tray which will be removed.

[D]

G909R505.WMF

[F]

3. Remove the grounding wire [B] (1 screw, 1 washer) and remove the tray

stopper [C].

NOTE:

When reinstalling the tray stopper, push the stopper to the left agains t

the tray.

4. Open the front cover [D] and remove the cover bracket [E] (1 screw), then

remove the front cover.

5. Remove the two screws [F] which secure the tray.

6. Remove the tray [G]. (First move the tray to the left and gently bend it, then

remove the tray.)

G909-22

Page 24

30 October 1998 TRAY UNIT

4.2.2 PAPER SENSOR, PAPER OVERFLOW SENSOR, AND TRAY

EXIT SENSOR

[A]

[E]

NOTE:

When removing the paper sensor or paper overflow sensor for the 1st tray,

or the tray exit sensor above the 1st tray, first remove the 1st tray and

remove the sensor cover, then remove these sensors.

1. Remove the tray (see Trays).

2. Remove the sensor cover [A] (3 screws).

[B]

[C]

[D]

[F]

G909R506.WMF

Paper Overflow Sensor

3. Remove the grounding wire [B] (1 screw) and paper overflow sensor bracket

[C] (1 screw).

4. Remove the paper overflow sensor [D] (1 connector).

Paper Sensor

5. Remove the paper sensor [E] (1 screw, 1 connector).

Tray Exit Sensor (above the 1st tray, and in the 3rd, 6th, and 9th trays)

6. Remove the tray exit sensor [F] (1 screw, 1 connector).

7. After replacing the tray exit sensor, perform the tray exit sensor adjustment

(see Tray Exit Sensor Adjustment).

NOTE:

After replacing the tray exit sensor, do not put the rear cover back on

the mailbox, because the tray exit sensor adjustment must be done

first.

Options

G909-23

Page 25

TRAY UNIT 30 October 1998

4.2.3 MAIN CONTROL BOARD

[A]

G909R508.WMF

[B]

G909R509.WMF

1. Remove the rear cover [A] (8 screws).

2. Remove the main control board [B] (all connectors).

3. After replacing the main control board, perform the tray exit sensor adjustment

(see Tray Exit Sensor Adjustment).

G909-24

Page 26

30 October 1998 TRAY UNIT

4.2.4 TRAY EXIT SENSOR ADJ USTM ENT

This sensor adjustment must be performed after replacing the tray exit sensor or

main control board, using the special paper that comes with the spare part for the

tray exit sensor.

The tray exit sensor board has two devices: LED and phototransistor. So, when

replacing the tray exit sensor on the 3rd tray, the sensor adjustment must be done

between trays 1 and 3 and between trays 4 and 6. When replacing the main control

board, this sensor adjustment must be done for all sensors. The sensor adjustment

procedure is as follows.

[E]

[A]

[D]

[B]

G909R507.WMF

[C]

Example: Sensor adjustment between trays 1 and 3

1. Insert the special paper (which comes with the tray exit sensor) into the

entrance guide of the mailbox.

2. Turn the transport motor gear [A] counterclockwise to transport the paper to the

tray unit.

3. When the leading edge of the paper reaches the tray feed-out roller, turn the

vertical transport motor [B] clockwise to transport the paper to the appropriate

tray.

4. Open the tray gate by pushing the plunger of the tray solenoid [C], and

transport the paper until half of it has fed out to the tray.

5. Change switches 1 and 2 of the DIP switch on the main control board to ON.

Options

6. Make sure that the interface cable is connected to the main machine and turn

the main switch on.

G909-25

Page 27

TRAY UNIT 30 October 1998

7. Fully turn the appropriate variable resistor (VR) [D] clockwise, then check that

the appropriate LED [E] has turned off (the relationship between tray, VR, and

LED are shown in the table below).

8. Turn back the VR slowly until the LED just turns on.

9. Measure the voltage between TP3 on the main control board and the frame of

the mailbox and confirm the voltage is greater than 3.5 V. If it is not, adjust the

voltage using the VR (the relationship between tray, TP, and VR are shown in

the table below).

10. Remove the special paper from the tray, then measure the voltage on the main

control board in the same way as step 9. The voltage should be smaller than

1.2 V.

11. After adjusting, change the DIP switch setting to the default (all switches off)

and reassemble the machine.

Adjusted Sensor VR No. LED No. TP No.

Trays 1 to 3 VR1 LED 2 TP3

Trays 4 to 6 VR2 LED 3 TP4

Trays 7 to 9 VR3 LED 4 TP13

NOTE:

The DIP switches to change are the same regardless of the adjusted

sensor.

G909-26

Page 28

30 October 1998 DIP SWITCHES/VRIABLE RESISTORS/LEDS

5. SERVICE TABLES

5.1 DIP SWITCHES/VRIABLE RESISTORS/LEDS

5.1.1 DIP SWITCHES

0 = OFF 1 = ON

Item

Default 0000

Motor Test 1000

Solenoid Test 0100

Tray Exit Sensor Check 1100

Paper Sensor Check

(1st to 3rd trays)

Paper Sensor Check

(4th to 6th trays)

Paper Sensor Check

(7th to 9th trays)

Proof Tray Sensors Check1110

Paper Overflow Sensor

Check (1st to 3rd trays)

Paper Overflow Sensor

Check (4th to 6th trays)

Switch No.

1234

When detecting paper between the

1st and 3rd trays, LED2 will light.

When detecting paper between the

4th and 6th trays, LED3 will light.

When detecting paper between the

7th and 9th trays, LED4 will light.

0010When the 1st tray paper sensor is

activated, LED2 will light.

When the 2nd tray paper sensor is

activated, LED3 will light.

When the 3rd tray paper sensor is

activated, LED4 will light.

1010When the 4th tray paper sensor is

activated, LED2 will light.

When the 5th tray paper sensor is

activated, LED3 will light.

When the 6th tray paper sensor is

activated, LED4 will light.

0110

0001When the 1st paper overflow

1001When the 4th paper overflow

When the 7th tray paper sensor is

activated, LED2 will light.

When the 8th tray paper sensor is

activated, LED3 will light.

When the 9th tray paper sensor is

activated, LED4 will light.

When the proof paper overflow

sensor is activated, LED2 will light.

When the proof paper sensor is

activated, LED3 will light.

sensor is activated, LED2 will light.

When the 2nd paper overflow

sensor is activated, LED3 will light.

When the 3rd paper overflow

sensor is activated, LED4 will light.

sensor is activated, LED2 will light.

Function

Options

G909-27

Page 29

DIP SWITCHES/VRIABLE RESISTORS/ LEDS 30 October 1998

Item

Paper Overflow Sensor

Check (4th to 6th trays)

Paper Overflow Sensor

Check (7th to 9th trays)

Entrance, Bridge Relay,

and Bridge Exit Sensor

Check

Proof Exit and Relay

Sensor Check

Free Run 1111

Switch No.

1234

1001

0101When the 7th paper overflow

1101When the entrance sensor is

0011When the proof exit sensor is

Function

When the 5th paper overflow

sensor is activated, LED3 will light.

When the 6th paper overflow

sensor is activated, LED4 will light.

sensor is activated, LED2 will light.

When the 8th paper overflow

sensor is activated, LED3 will light.

When the 9th paper overflow

sensor is activated, LED4 will light.

activated, LED4 will light.

When th e bridge relay s ensor is

activated, LED3 will light.

When the bridge exit sensor is

activated, LED2 will light.

activated, LED4 will light.

When the relay sensor is activated,

LED3 will light.

5.1.2 VARIABLE RESISTORS

Number Function

VR1 Adjusts the tray exit sensor sensitivity between trays 1 and 3

VR2 Adjusts the tray exit sensor sensitivity between trays 4 and 6

VR3 Adjusts the tray exit sensor sensitivity between trays 7 and 9

5.1.3 LEDS

Number Monitored Signal

LED1 Monitors the software operation.

Blinking: Normal operation

Others: Abnormal operation

LED2

LED3

LED4

The LED lights when the appropriate sensor is activated. (Refer to the

DIP switch table for more details.)

G909-28

Page 30

12

3

4

5

678 910

11 12

A

B

C

D

Proof Tray

Transport

Proof Tray

E

Junction Gate

Proof Tray

Cover

Proof Tray

F

Exit

Proof Tray

Paper Oerflow

Proof Tray

Paper 1

G

Proof Tray

Paper 2

POINT TO POINT DIAGRAM (Mail Box/Bridge Unit: G909/G912)

CN4-1

CN4-2

CN4-3

CN4-4

CN4-5

CN4-6

CN4-7

CN4-8

CN4-9

CN4-10

CN2-1

CN2-2

CN2-3

CN2-4

CN2-5

CN2-6

CN2-7

CN2-8

CN30-1

CN30-2

CN30-3

CN30-4

CN30-5

CN30-6

CN30-7

CN31-1

CN31-2

CN31-3

CN31-4

CN31-5

CN31-6

CN31-7

CN32-1

CN32-2

CN32-3

CN32-4

CN32-5

CN32-6

CN32-7

CN33-1

CN33-2

CN33-3

CN33-4

CN33-5

CN33-6

CN33-7

5

5

GND

GND

TXD

GND

RXD

GND

24

24

24

GND

GND

GND

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

Paper 0

(S14)

Paper 1

(S15)

Paper 2

(S16)

Paper 3

(S17)

FINISHER

CN302-1

CN302-2

CN302-3

CN301-1

CN301-2

CN301-3

CN302-1

CN302-2

CN302-3

CN302-1

CN302-2

CN302-3

CN302-1

CN302-2

CN302-3

CN301-1

CN301-2

CN301-3

S24

S10

S25

S26

S27

S11

Paper

Overflow 1

Tray Exit 1

Paper

Overflow 2

Paper

Overflow 3

Paper

Overflow 4

Tray Exit 2

(S8)

(S9)

M1

SOL 1

S5

S4

S3

CN56-1

CN56-2

CN56-3

CN56-4

CN51-1

CN51-2

CN52-1

CN52-2

CN52-3

CN53-1

CN53-2

CN53-3

CN54-1

CN54-2

CN54-3

CN55-3

CN55-4

CN55-2

CN55-1

[ 24] A

st

[ 24]/A

st

[ 24] B

st

[ 24]/B

st

[24]

[ 24] Junction Gate Sol.t

[5]

GND

[ 5] Tray Cover Sn.t

[5]

GND

[ 5] Tray Exit Sn.t

[5]

GND

[ 5] Paper Overflow Sn.t

GND

[5]

[ 5] Paper Sn.s

[5]

COPIER

PROOF

TRAY

CONTROL

(PCB 2)

Bridge Unit

CN50-15

CN50-14

CN50-13

CN50-12

CN50-11

CN50-10

CN50-9

CN50-8

CN50-7

CN50-6

CN50-5

CN50-4

CN50-3

CN50-2

CN50-1

24

24

24

GND

GND

GND

5

5

GND

GND

TXD

GND

RXD

GND

CN1-1

CN1-2

CN1-3

CN1-4

CN1-5

CN1-6

CN1-7

CN1-8

CN1-9

CN3-9

CN3-8

CN3-7

CN3-6

CN3-5

CN3-4

CN3-3

CN3-2

CN3-1

CN5-1

CN5-2

CN5-3

CN5-4

CN5-5

CN5-6

CN5-7

CN5-8

CN5-9

CN5-10

CN5-11

CN5-12

CN5-13

CN5-14

CN5-15

MAIN CONTROL

(PCB 1)

[24]

[24]

GND

GND

[5]

GND

[5]

[ 5] Proof Tray Cover Sn.

t

[ 5] Joint

t

[ 24] Junction Gate Sol.

t

[ 5] Proof Tray Exit Sn.

s

[ 5] Paper Overflow Sn.

t

[ 5] Paper Sn.

s

[ 5] Motor Enable

t

[ 5] Motor Clock

t

GND

[ 5] Paper Overflow 1 Sn.

t

GND

s

[ 5] Paper 1 Sn.

t

[ 5] Paper Overflow 2 Sn.

GND

[ 5] Paper 2 Sn.

s

[ 5] Paper Overflow 3 Sn.

t

GND

s

[ 5] Paper 3 Sn.

t

[ 5] Paper Overflow 4 Sn.

s

[ 5] Tray Exit 2 Sn.

[5]

[5]

[5]

NC

NC

[5]

NC

[5]

NC

[5]

NC

[5]

NC

[5]

[5]

[5]

A

B

C

D

E

F

G

H

J

K

L

M

CN6-1

Relay Junction

Gate

Bridge Cover

I

Bridge Relay

Bridge Exit

SOL 2

SW1

S2

S1

SW2

Front Cover

Relay

Entrance

Vertical Transport

S7

S6

M3

[24]

CN6-2

[ 24] Relay Junction Gate Sol.

t

CN6-3

[ 5] Unit

t

CN6-4

GND

CN6-5

[ 5] Bridge Cover Sw.

t

CN6-6

GND

CN6-7

[5]

CN6-8

[ 5] Bridge Relay Sn.

s

CN6-9

GND

CN6-10

[5]

CN6-11

GND

CN6-12

t

[ 5] Bridge Exit Sn.

CN9-1

[24]

CN9-2

[ 24] Front Cover Sw.t

CN10-1

[5]

CN10-2

GND

CN10-3

[ 5] Relay Sn.s

CN11-4

[5]

CN11-5

GND

CN11-6

[ 5] Entrance Sn.s

CN11-1

CN11-2

CN11-3

CN7-1

[5]

CN7-2

GND

CN7-3

FG

CN7-4

Hc (–)

CN7-5

Hc (+)

CN7-6

Hb (–)

CN7-7

Hb (+)

CN7-8

Ha (–)

CN7-9

Ha (+)

CN7-10

La

CN7-11

Lb

CN7-12

Lc

s

[ 5] Paper 4 Sn.

t

[ 5] Paper Overflow 5 Sn.

[ 5] Paper 5 Sn.

s

[ 5] Paper Overflow 6 Sn.

t

[ 5] Paper 6 Sn.

s

[ 5] Paper Overflow 7 Sn.

t

[ 5] Tray Exit 3 Sn.

s

s

[ 5] Paper 7 Sn.

t

[ 5] Paper Overflow 8 Sn.

s

[ 5] Paper 8 Sn.

t

[ 5] Paper Overflow 9 Sn.

GND

GND

GND

GND

GND

CN34-1

[5]

CN34-2

NC

CN34-3

[5]

CN34-4

CN34-5

CN34-6

CN34-7

NC

CN35-1

[5]

CN35-2

NC

CN35-3

[5]

CN35-4

CN35-5

CN35-6

CN35-7

NC

CN36-1

[5]

CN36-2

[5]

CN36-3

[5]

CN36-4

CN36-5

CN36-6

CN36-7

CN37-1

[5]

CN37-2

NC

CN37-3

[5]

CN37-4

CN37-5

CN37-6

CN37-7

NC

CN38-1

[5]

CN38-2

NC

CN38-3

[5]

CN38-4

CN38-5

CN38-6

CN38-7

NC

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

Paper 4

(S18)

Paper 5

(S19)

Paper 6

(S20)

Paper 7

(S21)

Paper 8

(S22)

CN302-1

CN302-2

CN302-3

CN302-1

CN302-2

CN302-3

CN302-1

CN302-2

CN302-3

CN301-1

CN301-2

CN301-3

CN302-1

CN302-2

CN302-3

CN302-1

CN302-2

CN302-3

S28

S29

S30

S12

S31

S32

Paper

Overflow 5

Paper

Overflow 6

Paper

Overflow 7

Tray Exit 3

Paper

Overflow 8

Paper

Overflow 9

I

J

K

L

M

H

N

O

P

Q

12

CN100-1

CN100-2

CN100-3

3

for

Checker

CN100-4

CN100-5

CN100-6

[24]

[ 24] 1st Tray Sol.t

CN21-1

CN21-2

SOL3

1st Tray

CN101-1

CN101-2

CN101-3

for

Checker

CN101-4

CN101-5

CN101-6

[24]

[ 24] 2nd Tray Sol.t

CN22-1

CN22-2

SOL4

2nd Tray

4

CN101-7

CN102-1

CN102-2

CN102-3

CN23-1

for

CN102-4

CN102-5

[24]

[ 24] 3rd Tray Sol.t

CN23-2

SOL5

3rd Tray

Checker

CN102-6

CN102-7

CN102-8

CN102-9

CN102-10

[24]

CN24-1

5

[ 24] 4th Tray Sol.t

CN24-2

SOL6

4th Tray

CN103-1

CN103-2

CN103-3

CN103-4

CN103-5

[24]

CN25-1

for

Checker

CN103-6

CN103-7

CN103-8

[ 24] 5th Tray Sol.t

CN25-2

SOL7

5th Tray

CN103-9

CN103-10

[24]

[ 24] 6th Tray Sol.t

CN26-1

CN26-2

SOL8

6th Tray

[24]

[ 24] 7th Tray Sol.t

CN27-1

CN27-2

SOL9

7th Tray

[ 5] Paper 9 Sn.

s

[ 5] Tray Exit 4 Sn.

s

st

[ 24] A

st

[ 24]/A

st

[ 24] B

st

[ 24]/B

[24]

[ 24] 8th Tray Sol.t

CN28-1

CN28-2

10

SOL

8th Tray

CN39-1

[5]

CN39-2

NC

CN39-3

NC

CN39-4

NC

CN39-5

CN39-6

NC

CN39-7

CN8-1

CN8-2

CN8-3

CN8-4

CN300-7

CN300-6

CN300-5

CN300-4

CN300-3

CN300-2

CN300-1

Paper 9

(S23)

M2

678 910

CN301-1

CN301-2

CN301-3

Transport

<>

Tray Exit 4

AC Line

DC Line

Pulse Signal

Signal Direction

Active High

Active Low

Voltage

Analog Signal

s

t

[]

[A]

S13

Signal Table

11 12

N

O

P

Q

Page 31

ELECTRICAL COMPONENT LAYOUT (G909/G912)

3

2

1

4

5

6

7

47

46

48

15

16

49

17

18

19

14

13

12

11

G909S500.WMF

8

9

10

45

44

43

42

41

40

39

38

37

36

35

20

21

22

23

24

25

26

27

28

29

30

31

32

34

33

G909S501.WMF

Symbols Name Index No. P to P.

Motors

M1 Proof Tray Transport 7 E2

M2 Transport 8 O10

M3 Vertical Transport 19 L4

Sensors

S1 Bridge Exit 1 I4

S2 Bridge Relay 2 I4

S3 Proof Tray Paper Overflow 3 S3

S4 Proof Exit 4 S4

S5 Proof Cover 6 S4

S6 Entrance 9 K4

S7 Relay 10 K4

S8 Proof Tray Paper 1 (LED) 14 G2

S9

S10 Tray Exit 1 21 E11

S11 Tray Exit 2 25 H11

S12 Tray Exit 3 29 K11

S13 Tray Exit 4 32 N11

S14 Paper 0 47 D10

S15 Paper 1 15 E10

S16 Paper 2 43 F10

S17 Paper 3 41 G10

S18 Paper 4 39 H10

S19 Paper 5 37 I10

S20 Paper 6 36 J10

S21 Paper 7 35 K10

S22 Paper 8 34 M10

S23 Paper 9 33 N10

S24 Paper Overflow 1 49 D11

S25 Paper Overflow 2 46 E11

S26 Paper Overflow 3 44 F11

S27 Paper Overflow 4 42 G11

S28 Paper Overflow 5 40 H11

S29 Paper Overflow 6 38 I11

S30 Paper Overflow 7 28 J11

S31 Paper Overflow 8 30 K11

S32 Paper Overflow 9 31 L11

Proof Tray Paper 2

(Photo Transistor)

13 G2

Symbols Name Index No. P to P.

Solenoids

SOL1 Proof Tray Junction Gate 17 E2

SOL2 Relay Junction Gate 15 H4

SOL3 1st Tray 16 Q3

SOL4 2nd Tray 18 Q4

SOL5 3rd Tray 20 Q5

SOL6 4th Tray 22 Q5

SOL7 5th Tray 23 Q6

SOL8 6th Tray 24 Q6

SOL9 7th Tray 26 Q7

SOL10 8th Tray 27 Q8

PCBs

PCB1 Main Control 48 B7

PCB2 Proof Control 5 F4

Switches

SW1 Bridge Co ver 12 I4

SW2 Front Cover 11 J4

Loading...

Loading...