Ricoh CS110 SPECIFICATIONS

SORTER

31 October 1995 SPECIFICATIONS

1. SPECIFICATIONS

Number of Bins: 10 bins

Paper Size for Bins: Maximum A3, 11" x 17"

Minimum A5, 51/2" x 81/2"

Paper Weight: 64 to 90 g/m2 (17 to 24 lb)

Bin Capacity: Sort/Stack 20 sheets / A4, 81/2" x11"

Mode 15 sheets / B4, 81/2" x 14"

10 sheets / A3, 11" x 17"

Top Bin Capacity:

(Non-Sort/Stack Mode)

Power Source: +5 volts and +24 volts from the copier

Power Consumption: 7.7 W

Dimensions:

(W x D x H)

Weight: 7.5 kg (16.5 lb)

100 sheets (all sizes)

402 mm x 443 mm x 217 mm

(15.8" x 17.4" x 8.5")

1

6

5

COMPONENT LAYOUT 31 October 1995

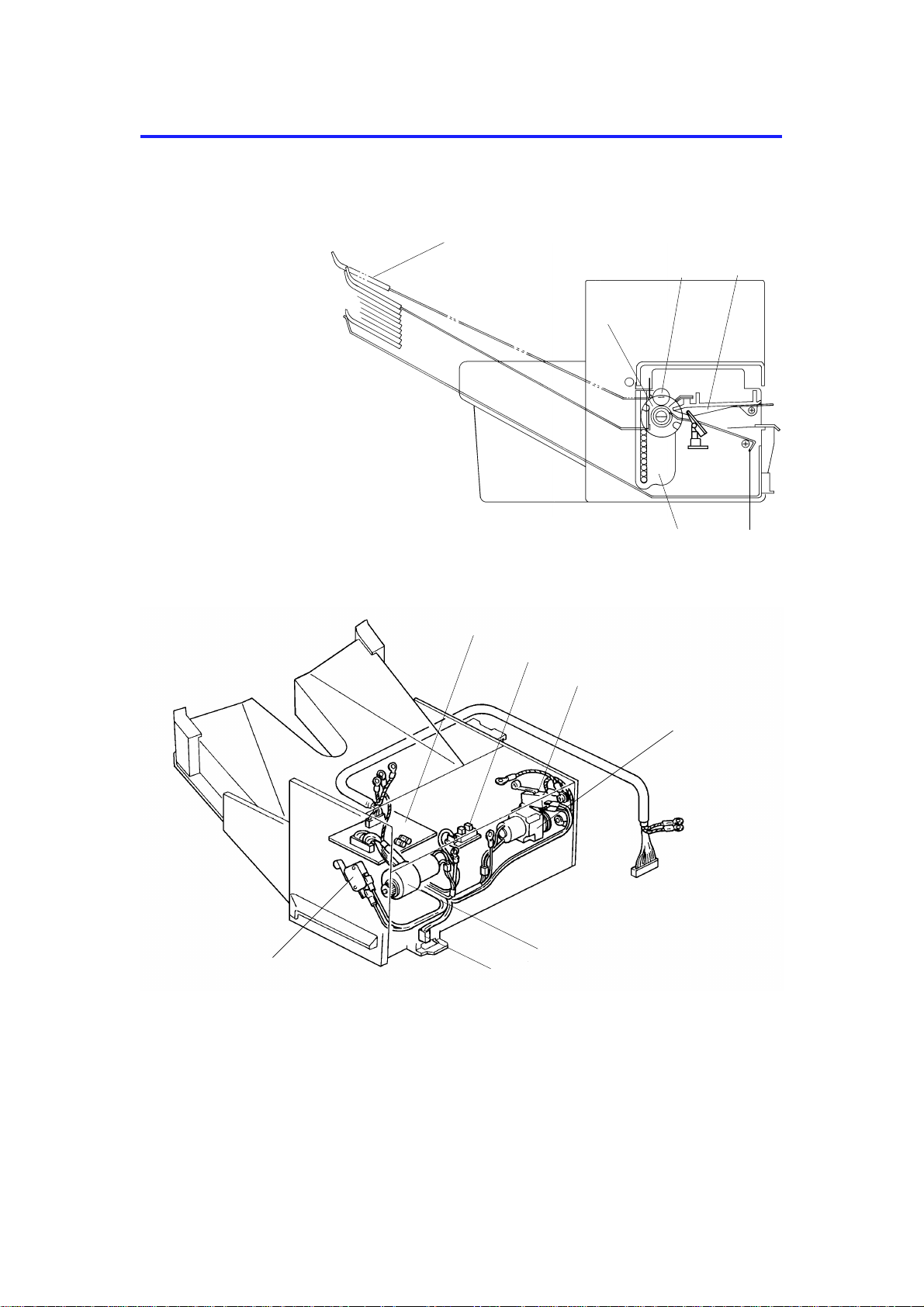

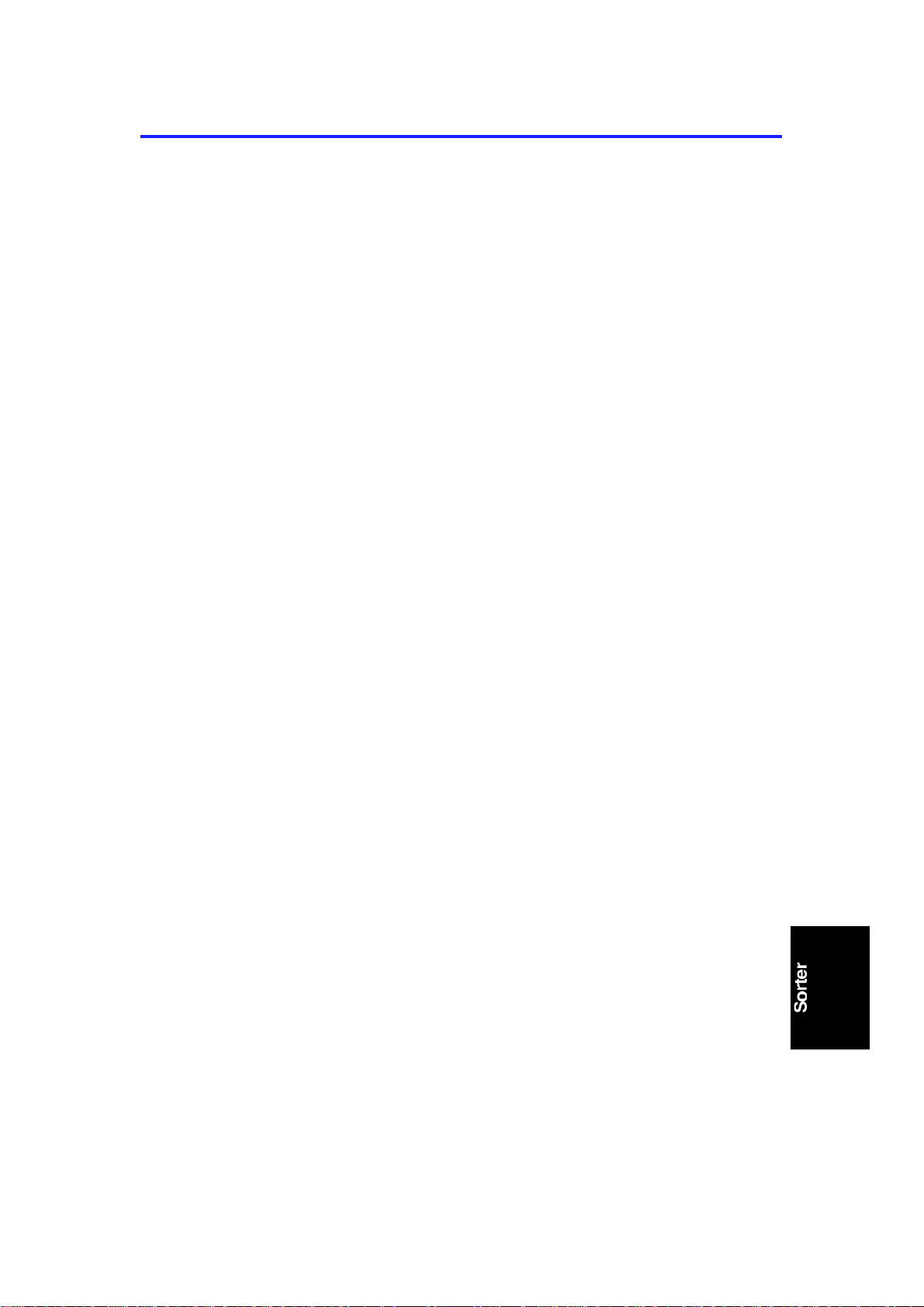

2. COMPONENT LAYOUT

– Mechanical Components –

1

3

2

1. Bin

2. Transfer Wheel

3. Exit Roller

4. Upper Paper Guide

5. Lower Paper Guide

6. Bin Guide

6

4

5

– Electrical Components –

7

1. Sorter Main Board 5. Sorter Switch

2. Paper Sensor 6. Bin Drive Mot or

3. Wheel Switch 7. Home Position Switch

4. Roller Drive Motor

A490V500.img

1

2

3

4

A490V501.img

2

31 October 1995 ELECTRICAL COMPONENT DESCRIPTIONS

3. ELECTRICAL COMPONENT DESCRIPTIONS

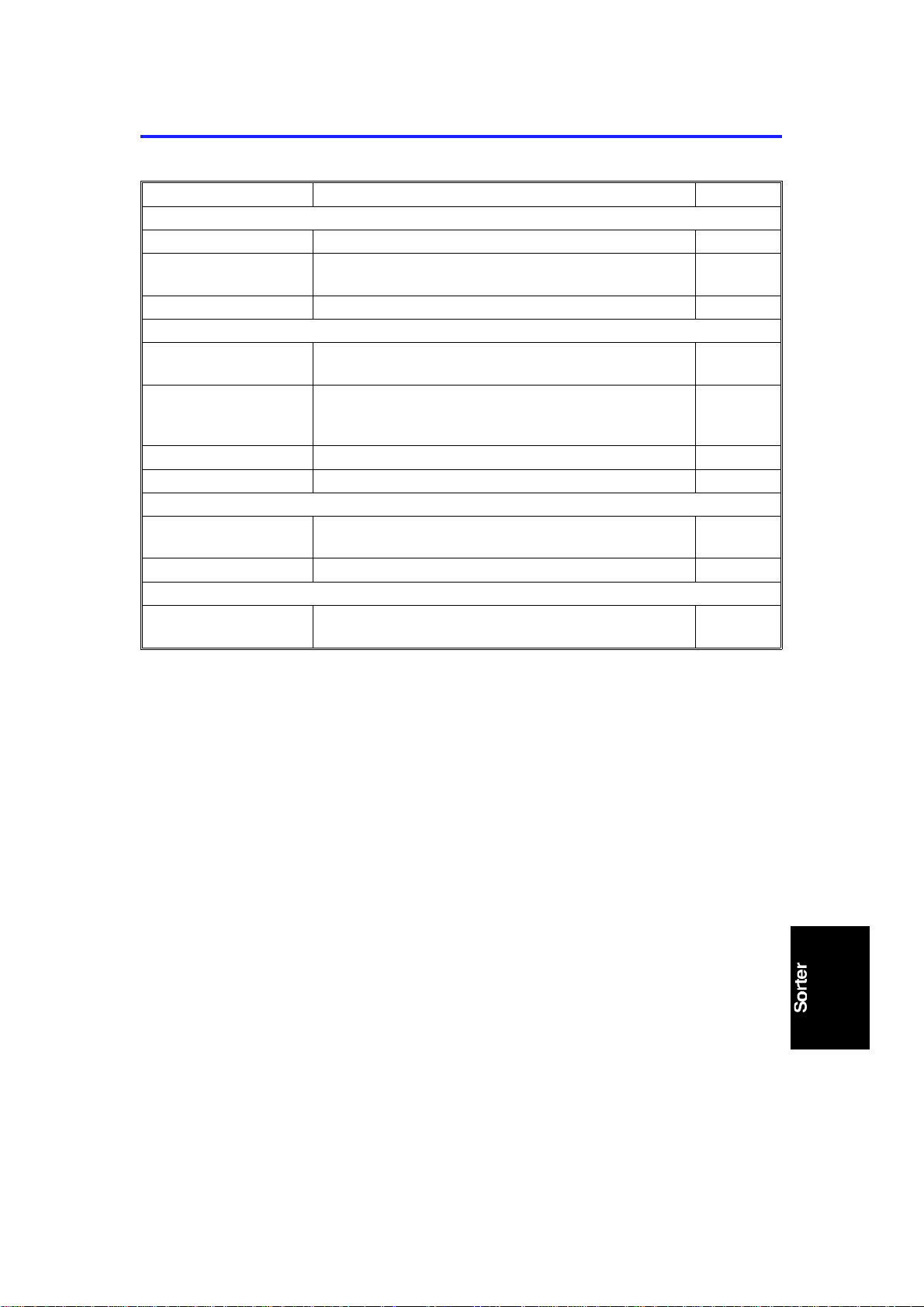

Name Function Index No.

Motors

Roller Drive Motor A DC motor that drives the lower exit rollers. 4

Bin Drive Motor A reversible DC motor that to moves the bins up or

down.

Switches

Wheel Switch Detects the rotation of the transfer wheel and stops it

in the correct position.

Sorter Switch Reed switch that becomes activated when the sorter

is in the proper position (aligned next to the copier).

Also works as a jam reset switch for the sorter.

Home Position Switch Informs the CPU that all the bins are lowered. 7

Sensor

Paper Sensor Serves as the misfeed sensor for the sorter and also

sets exit roller and bin drive timing.

6

3

5

2

Printed Circuit Board

Sorter Main Board Serves as the communication board between the

copier main board and the sorter.

1

3

OVERALL MACHINE CONTROL 31 October 1995

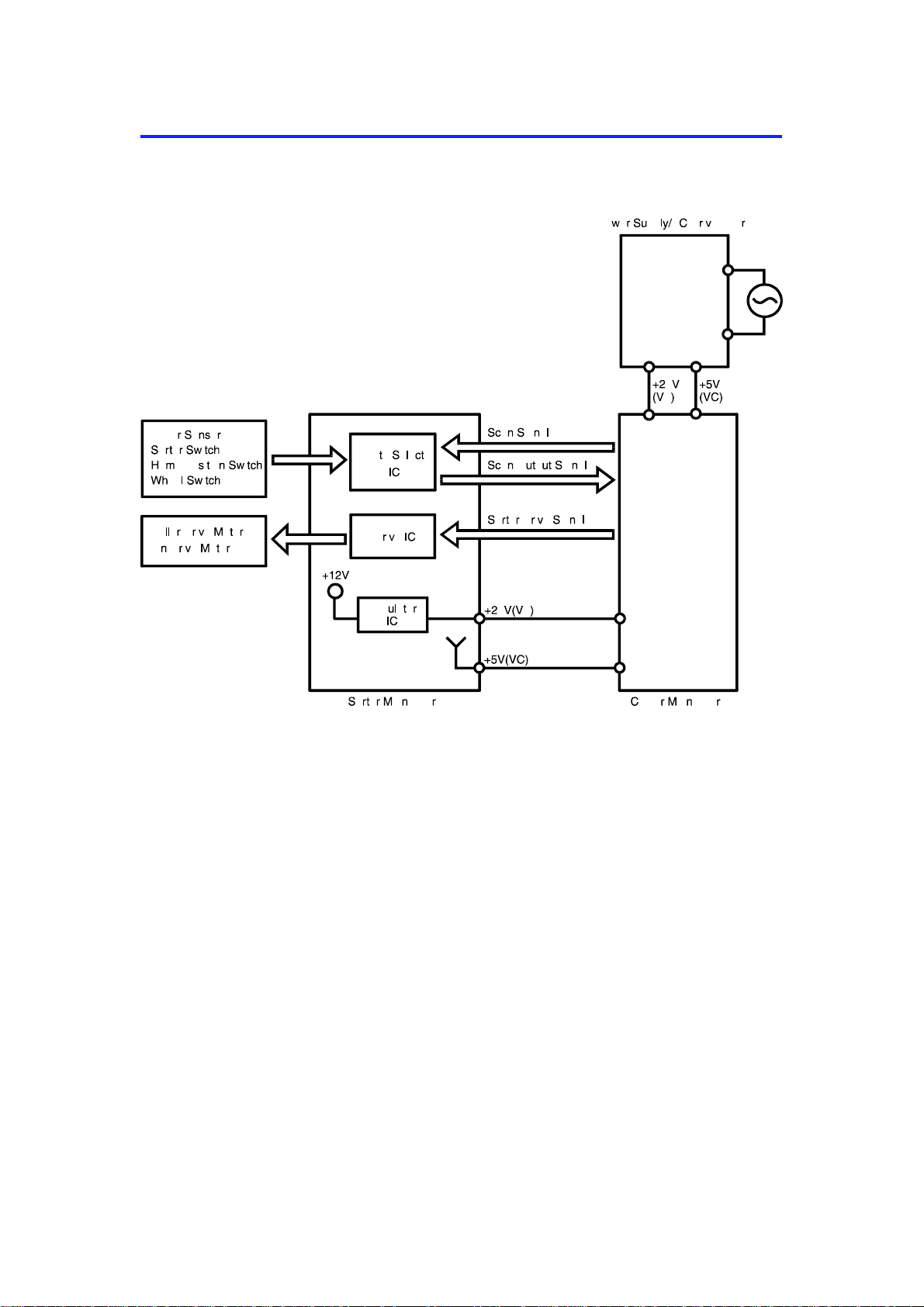

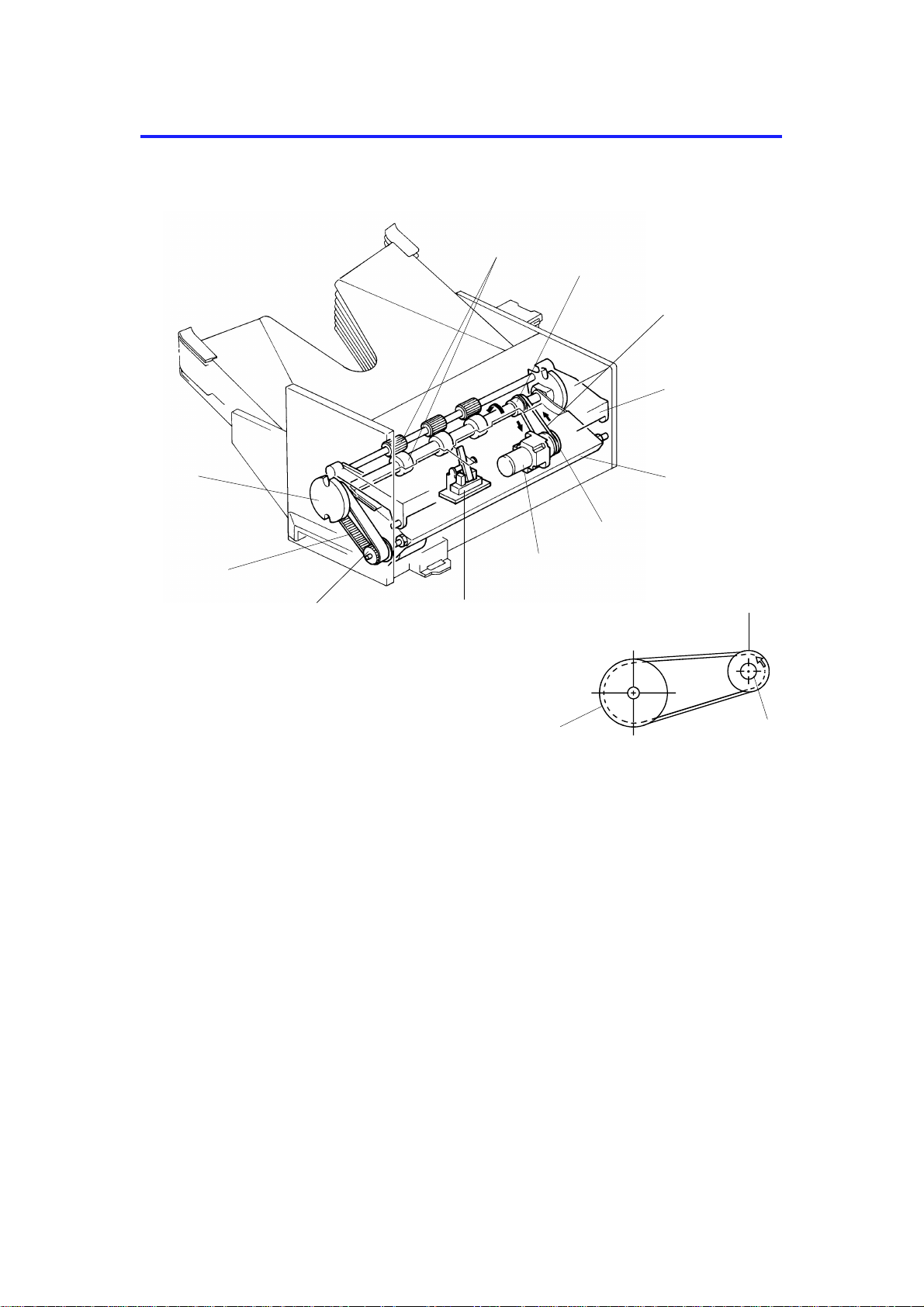

4. OVERALL MACHINE CONTROL

A490D500.wmf

The copier main board provide s +24 volt s (VA) and +5 volts (VC) to th e sort er

main board. +24 volts powers the roller drive motor, and +5 volts po wers all

sensors and switches. Also, the regulator IC changes +2 4 volt s to +12 volts,

which powers the bin drive motor.

The copier main board controls t he sorter drive and checks the status of the

sorter via the sorter main board. The copier main board sends the scan

signals to the data select IC on th e sort er main board. After receiving the

scan signals, the data sele ct IC ou tp uts the status of the senso r a nd switches

as the scan output signal.

The copier main board also sends the sorte r drive signal to the drive IC on

the sorter main board. Af te r receiving the drive signal, the drive IC turn s on

the appropriate motors.

4

31 October 1995 BASIC OPERATION

5. BASIC OPERATION

– Clear Mode –

When the main switch of the copier is turned on, the sorter automatically

assumes the clear mode. In this mo de, all copies are stacked in the first bin.

The sorter also assumes the clear mod e whe n eit he r the inte rrupt mode or

the manual feed mode is selected.

Sorter operation be gin s wh en a copy act ua te s t he copie r e xit sen sor. At this

time, the roller drive motor energizes. Whe n the paper exits onto the sorte r

bin, the paper sensor is de-activated and the roller drive motor is then

de-energized. The copier main board monitors the paper sensor through the

sorter main board to check for pape r misfee ds.

– Sort Mode –

Pressing the Sorter ke y once shifts the copier to the sort mo de. In this mode,

all copies of the first original are delivered to separa te bins sta rtin g from the

top. The copies of the second original are delivered to th e same bins, but

starting from the bottom. The cop ies of the third origin al sta rt from the top and

so on. The bin drive motor turns on to advance th e bin one step , 25 0

milliseconds after the copy has gone th rou gh the pape r sen sor. If th e Cop y

Quantity, Clear/Stop , Bo ok Cop y, or Sorter key is pressed when sort mode

has been selected, all bins shift to the home po sitio n.

– Stack Mode –

Pressing the Sorter ke y twice shif ts the copier to the stack mode. In this

mode, all copies of the first origina l are de livere d to the first bin , all copies of

the second original are delivere d to the secon d bin , an d so on. The bin drive

motor turns on to advance the bin one ste p, 250 milliseconds after the last

copy of the original has gone through the pap er sen sor. If th e Sorter key is

pressed when stack mode has been selected, all bins shift to home position.

5

[J]

EXIT ROLLER DRIVE 31 October 1995

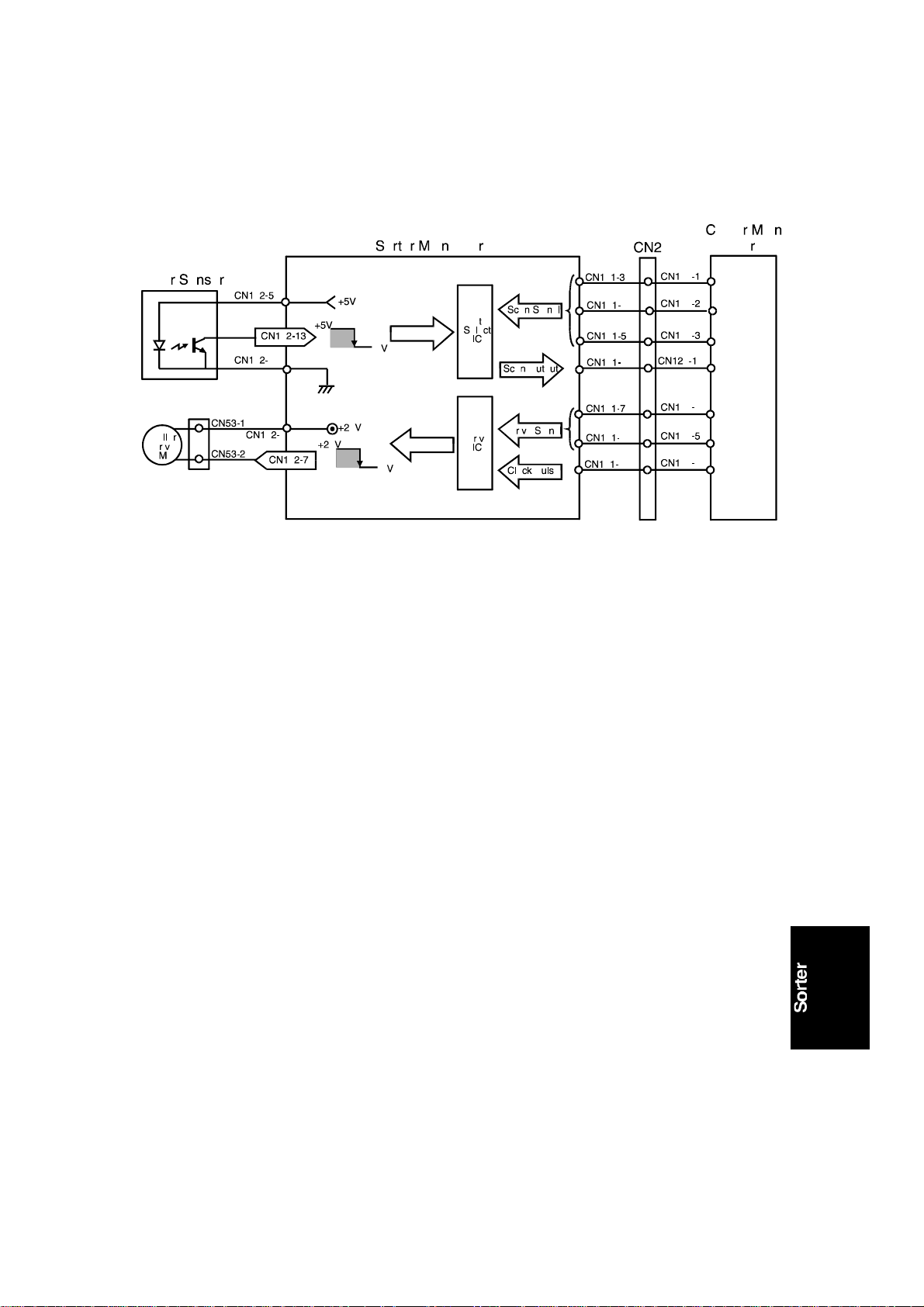

6. EXIT ROLLER DRIVE

6.1 ROLLER DRIVE MECHANISM

[A]

[I]

[D]

[F]

[K]

[L]

[G]

[C]

[H]

[H]

[B]

A490D501.img

[L]

F: Transfer Wheel

A490D502.wmf

G: Bin Drive Belt

H: Bin Drive Pulley

I: Exit Roller Pulley

J: Upper Paper Guid e

K: Lower Paper Guide

L: Roller Drive Motor Pulley

The exit rollers [A] take over pape r tra nsp ort from the copier. When the copy

paper actuates the copier exit sensor, the exit rollers start rotatin g. The exit

rollers continue to rotate for 2 50 millise con ds af te r the copy pape r has go ne

through th e pa per sensor [B].

The roller drive motor [C] rotates the lower exit roller via the rolle r drive belt

[D]. The shaft of the lower exit roller is a cylindrical cavity type which rotates

around the transfer whee l shaf t [E]. The paper sensor is positioned just in

front of the exit rollers. The paper sensor detects misfeeds in the sorter.

[E]

6

31 October 1995 EXIT ROLLER DRIVE

6.2 ROLLER DRIVE CIRCUI T

A490D503.wmf

To turn on the roller drive motor, the copier main board sends a drive signal

to the drive IC on the sorter main board. Aft er receiving the drive signal, the

drive IC drops CN102-7 from +24 to 0 volt to turn on the roller drive moto r.

When the paper sensor is actu at ed , CN102-13 drops to LOW. The cop ier

main board outputs th ree scan signals to the data select IC. Th e sta tus of the

sensor changes the resulting scan output signal. Using the scan output

signal, the copier main board dete rmine s the stat us of the senso r. The CPU

limits the operation time of the ro ller drive motor to 5 seconds.

7

[C]

[D’]

[H]

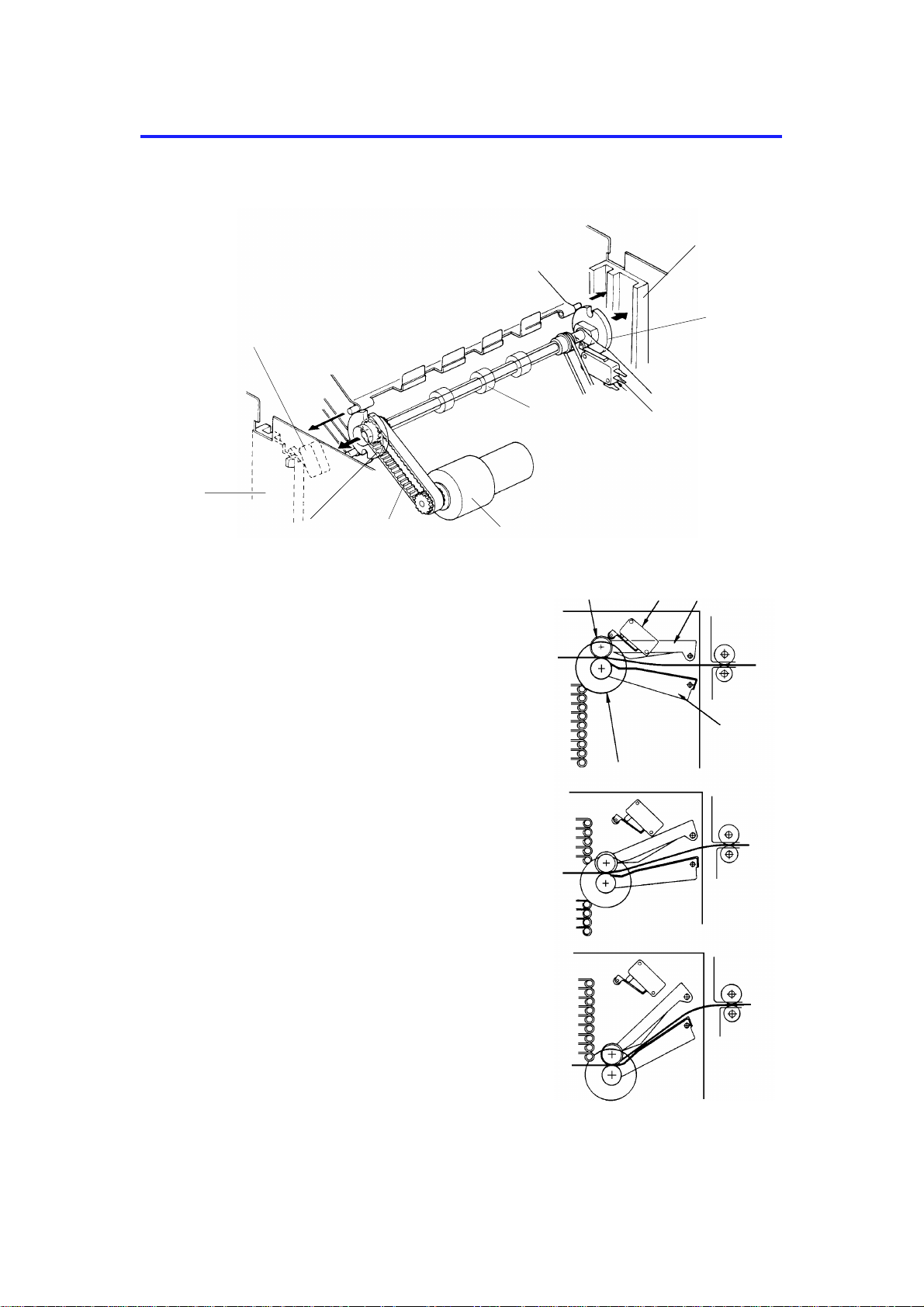

BIN DRIVE 31 October 1995

7. BIN DRIVE

7.1 BIN DRIVE MECHANISM

[B’]

[E]

[G]

[D]

[B]

[F]

G : Exit Roller

H : Upper Paper Guide

I: Lower Paper Guide

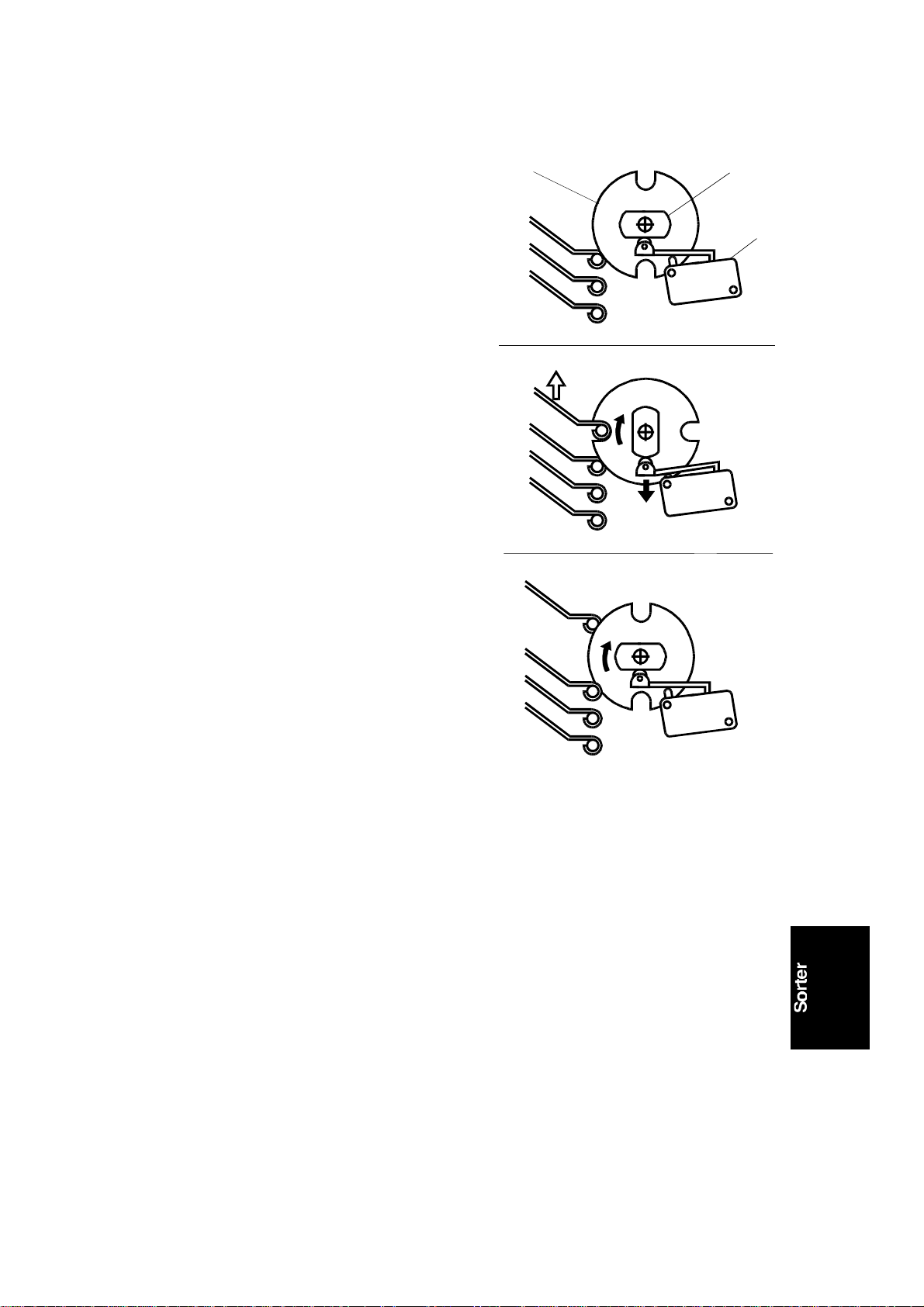

The bin drive mechanism moves

the bins up and down to receive

copies under the dire ctio n of the

copier CPU. The main

components in this mechanism

are the bin drive motor [A], two

transfer wheels [B, B ’] , the wheel

switch [C], and the bins

themselves.

Pins on either side of each bin are

inserted into slots called bin

guides [D,D’]. The bins slide up

and down in the bin guides. The

bins sit on each other with the

lower bin resting on the

permanently-mounted 10th bin.

The upper and lower paper guides

pivot up and down depending on

the height of the bin to be picked

up or released.

[A]

[G]

A490D504.img

[E]

[I]

[B]

A490D505.img

8

OFF

OFF

31 October 1995 BIN DRIVE

The home position switch [E]

informs the CPU when all the bins

are lowered.

To move the bins up, the bin drive

motor turns clockwise (as viewed

from the front). A timing belt [F]

turns the transfer wheels.

The transfer wheels have two

slots in them 180 degrees ap art .

As the transfer wheels turn, these

slots engage the bins and lift them

up. Each time the transfer wheels

turn 180 degrees, they raise one

bin.

To move the bins down, the CPU

reverses the bin drive motor and

the above process reverses.

The CPU monitors the position of

the bins through pulses generated

by the wheel switch and the

actuator cam [J]. The actu at or

cam has two flat sides that are

180 degrees apart and is mounted

behind the rear transfer wheel. A

pulse is generated each time one

of the lobes of the actu ator cam

passes the wheel switch.

[B]

[J]

[C]

ON

A490D506.wmf

9

Loading...

Loading...