Page 1

Laser LT

RD-1550 - 1.5" Remote Display

Version 1.0

Installation & Operation Manual

114035 Rev B

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

About This Manual ................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Tokens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2.2 Remote Keypress Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 Installation and Setup.................................................................................................................. 5

2.1 Unpacking and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Wall Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.1 Cable Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3.2 AC Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.3 DC Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.4 Serial Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.5 Reset Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3.6 Commport Jumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.0 Configuration ............................................................................................................................ 12

3.1 Auto-Learn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Manual Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Testing the Remote Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.6 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7 Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.8 Demand Print Displaying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.9 Run Mode Serial Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.9.1 Laser LT Display Message Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.9.2 Laser LT Set Red/Green LED Command: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.9.3 Laser LT Get Digital Input Command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.9.4 Laser LT Query Display Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.10 Configuration with Revolutionâ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.10.2 Comm Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.10.3 Formatting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.0 EDP Commands.......................................................................................................................... 25

4.1 Annunciator and Weight Position EDP Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.1 Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.1.2 Annunciators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2 Parameter Setting Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3 Reporting Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.0 Options ....................................................................................................................................... 29

5.1 Visor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

February 13, 2014

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

Page 4

6.0 Appendix .................................................................................................................................... 30

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

6.1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.3 Updating the Laser LT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4 Front Panel Display Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.5.1 UL Approved Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.6 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.7 Parts Kit Contents (PN 115525) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.8 Laser LT Enclosure Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.9 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Laser LT Remote Display Limited Warranty........................................................................................... 38

Page 5

About This Manual

Hardware Features

• IP69K Stainless Steel enclosure

• Display/CPU boa rd with 4 comm ports and an

option board slot

• Power Supply

• Keypad/overlay

Standard Features

The Laser LT remote display has six, 1.5 inch digits.

The Laser LT uses an Auto-Learn function which

automatically determines the serial settings and data

format used by the attached indicator.

Additional standard features include:

• Hold displayed weight (demand input)

• Adjustable intensity

• Auto-sensing 115/230 VAC power supply or

9-36V DC power supply

• Annunciators for weighing mode, units and

status

• Daisy chaining

• Controllable red and green annunciators

• Key pad for configurable serial control of host

indicator functions

• Two digital inputs

• Addressable for displaying specific data

• Heavy-duty latch locking feature

Configurable Features

• Front panel configuration by navigation

through menus

• Revolution utility for uploading/downloading

configuration

• Auto Learn function for setting baud rate and

displaying weight data

• Port configuration for the host/keypress

commands/daisy chain functions

Optional Features

Optional features of the Laser LT remote display

include the following:

• Field-installable metal visor (PN 115138)

• Fiber optic board (PN 96736)

• RS-232/422 board (PN 108579)

• Ethernet TCP/IP board (PN 77142)

• Ethernet wireless board (PN 108671)

• USB board (PN 93245 requires USB cable PN

95357)

• UL approved unit

This manual is intended for use by service technicians responsible for installing and servicing the Laser LT

remote display.

Installation procedures are presented in the order likely to

configuration, and on-site installation.

This manual can be viewed and downloaded from the Rice Lake Weighing Systems web site at

www.ricelake.com. Rice Lake Weighing Systems is an ISO 9001 registered company.

be followed by the installer: pre-installation setup,

®

LED

1.0 Introduction

The Laser LT remote display features a bright LED display and non-glare filtered lens for use in a wide variety of

applications. The Laser LT is available with a six-digit display. The Laser LT remote display is designed to work

with most digital weight indicators, host computers, and peripherals using 20mA current loop or RS-232

communications.

This manual provides installation and configuration instructions for

The Laser LT comes in three types of models:

• AC powered, 90-260 VAC

• DC powered, 9-36 VDC

• Board Only, requires 7.5 VDC power

the display.

Introduction 1

Page 6

1. 1 S af et y

WARNING

Note

Important

WARNING

Important

CAUTION

WARNING

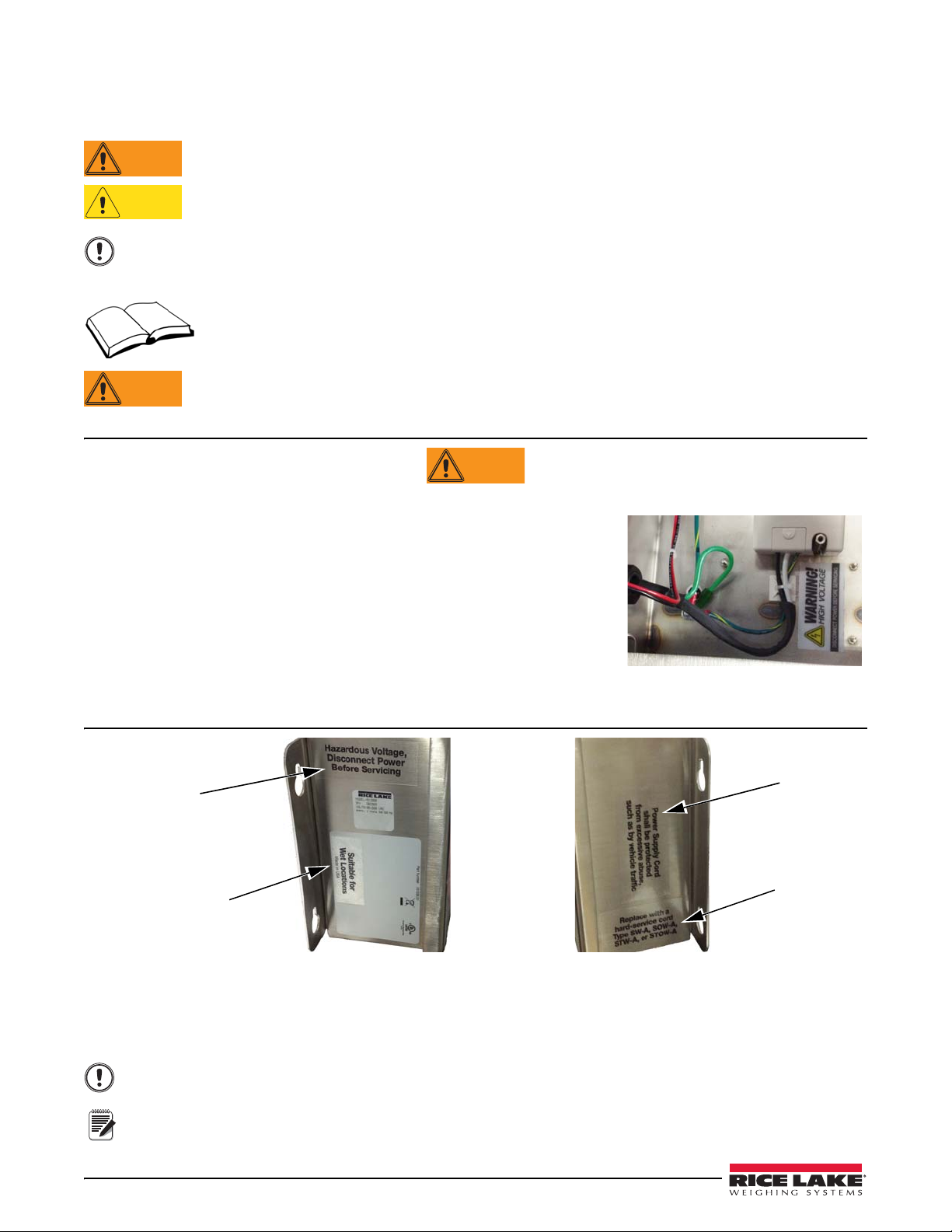

Figure 1-1. Safety Label PN 16861

All Models

PN 154025

PN 154027

PN 154026

PN 154028

Safety Symbol Definitions

Indicates a potentially hazardous situation that, if not avoided, could result in serious injury or death, and

includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided may result in minor or moderate injury.

Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption to and loss of data.

Safety Precautions

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this Manual. Failure to follow the instructions or heed the warnings could result in injury or

dea

th. Contact any Rice Lake Weighing Systems dealer for replacement manuals. Proper care is your

responsibility.

Some procedures described in this manual require work inside the indi

are to be performed by qualified service personnel only.

General Safety

Failure to heed may result in serious injury or death.

DO NOT allow minors (children) or inexper

DO NOT operate without all shields and guards in place.

DO NOT place fingers into slots or possible pinch points.

DO NOT use this product if any of the

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Before opening the unit, ensure the power cord

ienced persons to operate this unit.

components are cracked.

is disconnected from the outlet.

cator enclosure. These procedures

UL48 Approved Safety

UL48 Approval for:

Figure 1-2. Safety Labels – UL Approved Models

• wet location

• cord connected

• stationary sign

Test operation of ground fault circuit interrupt

All labels should be in legible condition, if not replace using the part numbers shown above.

er each time the sign is plugged in.

2 Laser LT Installation and Operation Manual

Page 7

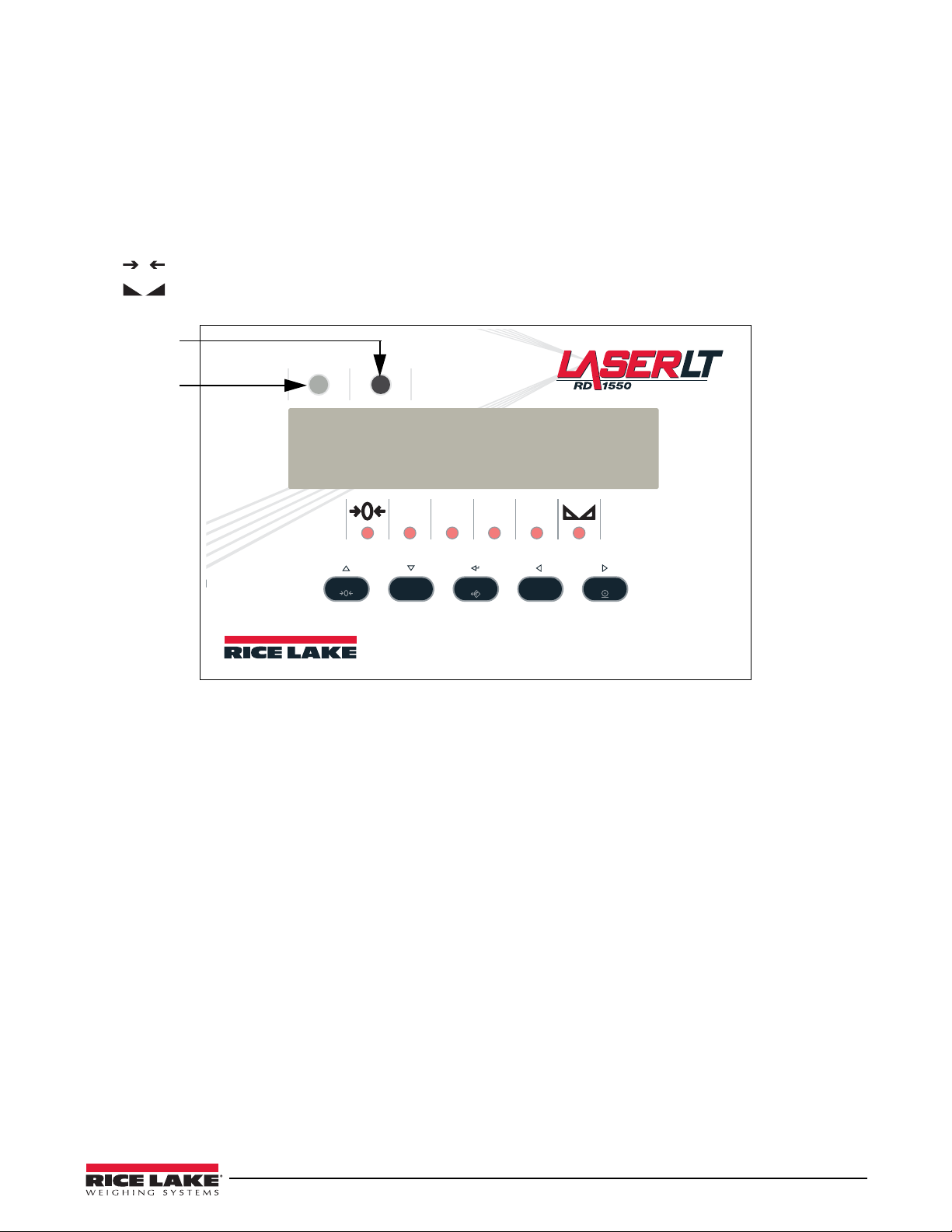

1.2 Annunciators

0

Red (stop)

annunciator

Green (go)

annunciator

The Laser LT remote display uses a set of six designated LED annunciators (shown in Figure 1-3) and a red and

green (stop/go feature lights). The annunicators are dependent on the status characte

with ASCII characters (tokens) and are shown in Table 4 -1 on page 25 and the default status characters are show n

in Table 3-2 on page 15.

GR and NT annunciators are lit to show whether the displayed weight is a gross or net weight.

•

•

lb, kg annunciators indicate the units associated with the displayed value and represent primary and secondary

units.

r. They can also be associated

•

•

indicates center of zero.

indicates a standstill condition.

GR NT lb kg

ZERO

G/N

B/N

TARE

UNITS

Figure 1-3. Front Panel Display

PRINTUNITS

Introduction 3

Page 8

1.2.1 Tokens

The Laser LT has tokens that can be used in the general formatting of a serial string. The Laser LT will light the

status annunicators (tokens) based on the ASCII characters sent in the serial string. Those tokens are:

• Gross Character

• Net Character

• P rimary Character

• Secondary Character

• Negative Character

• Overload Character

• Center of Zero Character

• M otion Character

These tokens and their function are explained i

1.2.2 Remote Keypress Functions

n further detail in Table 4-1 on page 25 and 25.

The keypresses can be programmed to send up to 32 character commands. The default commands are shown in

Table 1-1.

Command

KZERO

KGROSSNET

KTARE

KUNITS

KPRINT

Table 1-1. Remote Keypress Function

For more information on keypress functions, refer to Table 4-2 on page 27.

4 Laser LT Installation and Operation Manual

Page 9

2.0 Installation and Setup

WARNING

CAUTION

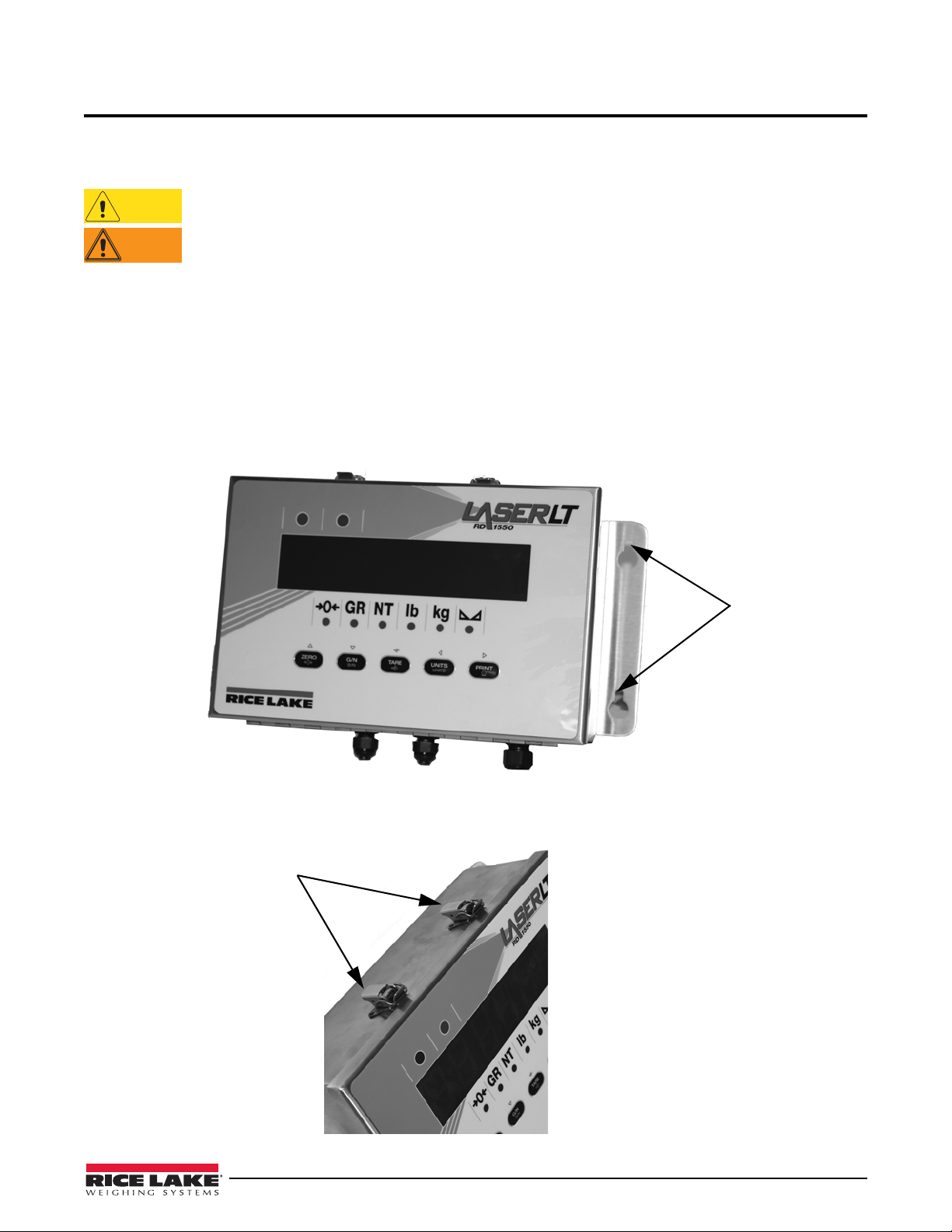

Four keyhole slots

(only two shown)

Two latches secure the lid of the

Laser LT

The Laser LT remote display can be easily set up and configured. This section describes basic installation, AC

wiring, RS-232 and 20mA current loop connections. Once installation setup is complete, go to Section 3.0 for

information on configuring the Laser LT.

Use a wrist strap to ground yourself and protect components from electrostatic discharge (ESD) when

working inside the enclosure.

The

Laser LT has no on/off switch. Before opening the unit, ensure the power cord is disconnected from

the power outlet.

2.1 Unpacking and Assembly

Immediately after unpacking, visually inspect the Laser LT remote display for damage. If any parts were damaged

in shipment, notify Rice Lake Weighing Systems and the shipper immediately. The shipping carton contains the

remote display, a parts kit, and this manual. Parts kits contents are listed in Table 6-5 on page 35.

2.2 Wall Mounting

The Laser LT remote display can be mounted to any vertical surface.

Select a site for installing the Laser

installation screws or wall anchors to secure the remote display to a wall.

LT. The unit has four keyhole slots on the outer flange of the unit and uses four

Once the enclosure is secured, the front cover can be unlatched to access inside of the enclosure.

Figure 2-1. Keyhole Slots for Mounting

Figure 2-2. Enclosure Latches

Installation and Setup 5

Page 10

2.3 Wiring

WARNING

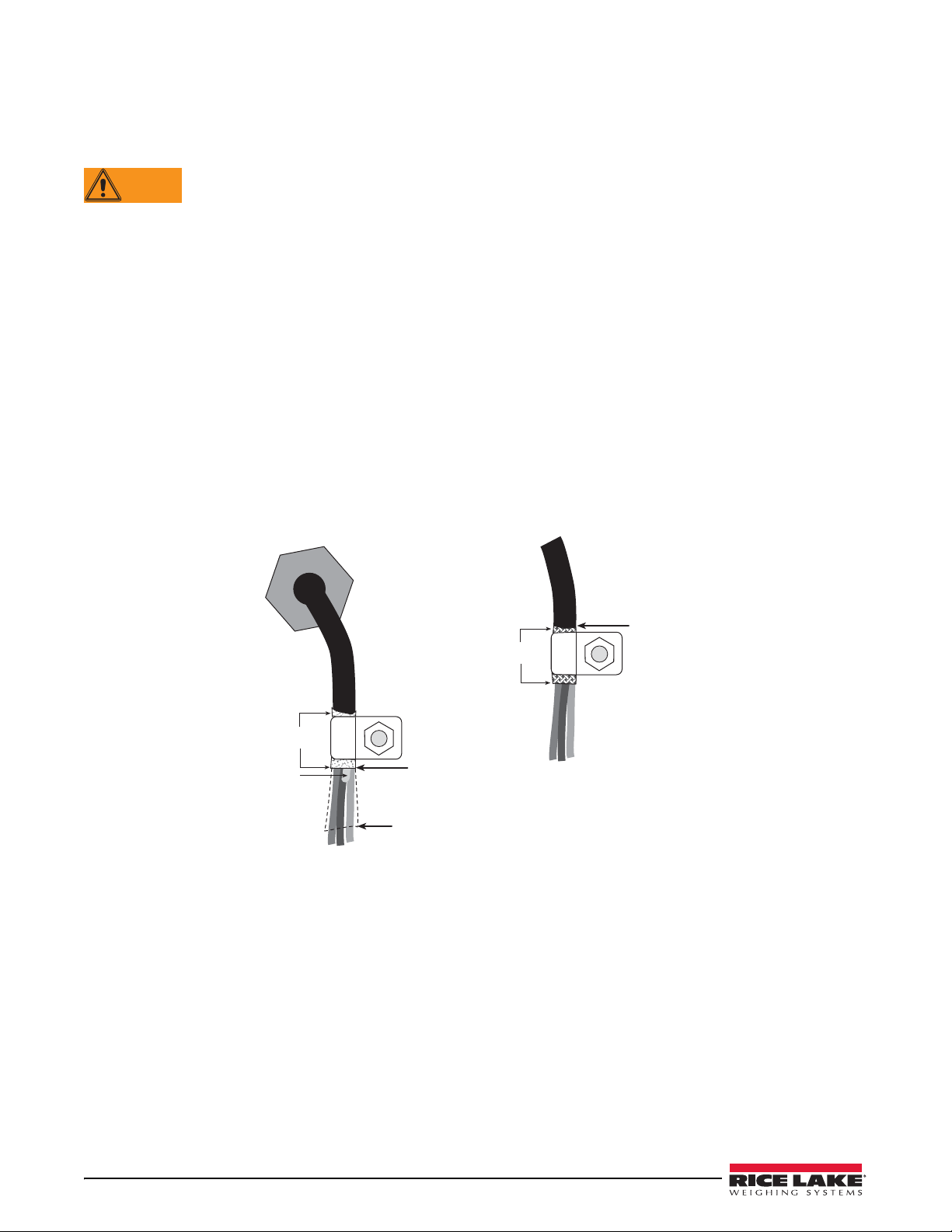

Cord grip

Insulated cable

Foil (silver side out)

Grounding clamp

Shield wire (cut)

Length of foil before folding

back on cable insulation

Cut insulation here

for foil-shielded cables

Braid

Cut insulation here

for braided cables

NOTE: Install lockwashers

first, against enclosure,

under grounding clamp

The Laser LT remote display provides two cord grips located on the underside of the enclosure for cabling; one for

inputs, and one for outputs. An AC power cord is supplied with the unit. Only the serial communications cable

must be connected. Use the following steps to wire the remote display.

The Laser LT remote display has no on/off switch. Before opening the unit, ensure the power cord is

disconnected from the power outlet.

Open the remote display by unlatching the lid (shown in Figure 2-2).

2.3.1 Cable Grounding

Except for the power cord, all cables routed through the cord grips shou ld be grounded against the Laser LT

enclosure. Do the following to ground shielded cables:

• Use the lockwashers, clamps, and kep nuts provided in the parts kit to install gro

enclosure studs adjacent to cord grips. Install grounding clamps only for cord grips that will be used; do

not tighten nuts.

• Route cables through cord grips and grounding clamps to determi

ne cable lengths required to reach cable

connectors. Mark cables to remove insulation and shield as described below:

• For cables with foil shielding, strip insulation and foil from the

grounding clamp (see Figure 2-3). Fold the foil shield back on the c

cable half an inch (15 mm) past the

able where the cable passes through the

clamp. Ensure silver (conductive) side of foil is turned outward for contact with the

• For cables with braided shielding, strip cable insulation and braided shield from a point just

grounding clamp. Strip another half inch (15 mm) of insulation only to expose the braid where the cable

passes through the clamp (see Figure 2-3).

unding clamps on the

grounding clamp.

past the

6 Laser LT Installation and Operation Manual

Figure 2-3. Grounding Clamp Attachment for Foil-Shielded and Braided Cabling

• Route stripped cables through cord grips and clamps. Ensure shields contact grounding clamps as shown in

Figure 2-3. Tighten grounding clamp nuts.

• Finish installation using cable ties to secure cables inside

of indicator enclosure.

Page 11

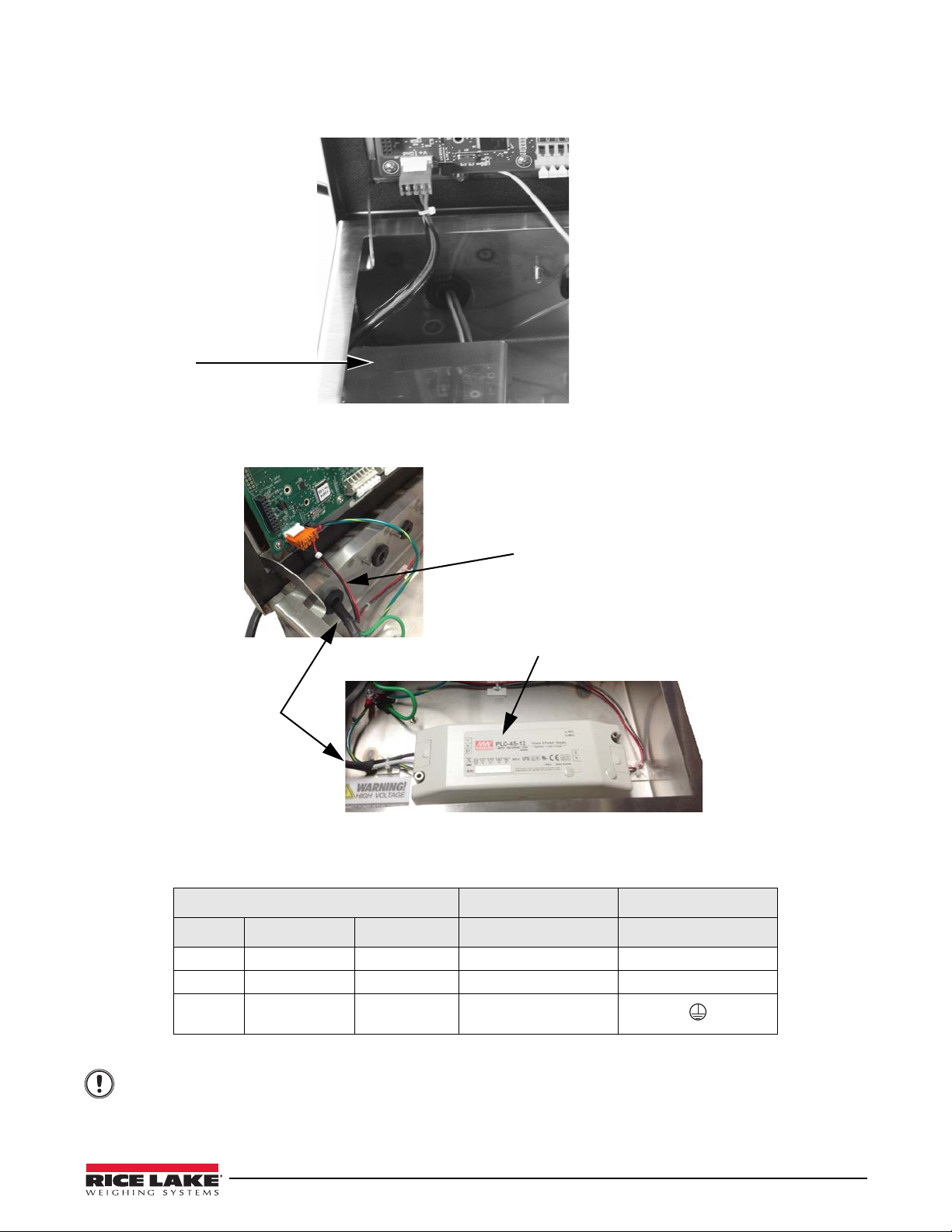

2.3.2 AC Wiring

Power Supply

UL Approved Power

Supply

Power Cord

Cable assembly, power

supply to CPU

Important

The Laser LT AC power cord comes in through a cord grip to the AC to DC power supply. The DC then goes to J5

on the main CPU board (see Table 2-3 on page 9).

Figure 2-4. AC Wiring

Refer to the following table for AC wiring connections.

Figure 2-5. UL Approved Unit Wiring

3-pin Terminal Block To Power Supply To P o w e r S up p l y

Pin Wire Color Pin UL Approved Unit

1 Neutral Blue or White 1 N

2 Hot Brown or Black 2 L

3 Ground Green or

Ensure that a ground wire is attached to the grounding stud located on the enclosure backplate.

Ground Tab

een/Yellow

Gr

Table 2-1. AC Wiring Connections

Installation and Setup 7

Page 12

2.3.3 DC Wiring

PIN 1

Alternatively a 9-36V DC power converter may be supplied. To connect DC power to the DC to DC converter,

wire the positive voltage to pin 1 (red wire - right hand side of connector), ground to pin 3 (black wire-left side) on

CN1 DC power supply .

Figure 2-6. DC Power Supply

Connector Pin Function

CN1 1 V+

2 NC

3 V- (GND)

Table 2-2. CN1 DC Power Supply Connections

8 Laser LT Installation and Operation Manual

Page 13

2.3.4 Serial Wiring

Serial communications are connected to the CPU board using clamp spring connectors on J2, J3 and J4 (see

Table 2-3 for wiring positions ).

To connect the communications

1. If the enclosure is not open, make sure power is disconnecte

cable to the remote display, do the following:

d from the unit and open the latches on the

enclosure.

2. Loosen the serial cable cord grip an

d push enough communications cable into the enclosure to allow

attachment to the CPU board.

3. Strip 1/4" (.65 cm) of insulation from the serial cable ends.

4. Make cable connections for RS-232, or 20 mA current loop communications. Communications can be

ma

de to any port. Com options are set up on ports 3 and 4. See Configuration of ports (host, keypad, daisy

chain) in Table 3-3 on page 19.

5. Remove any excess cable from inside the enclosure. T

ighten the serial cable cord grip.

Use the following table for wiring positions.

Connector Pin Assignment Function Port Position

J1 1 I/O 2 Digital I/O

2 I/O 1

3 GND

4 +5

J2 1 RX+ (20mA) Port 1 (20 mA)

2 RX- (20mA)

3 TX+ (20mA)

4 TX- (20mA)

5 V+ (20mA)

6 GND (20mA)

J3 1 RTS Port 2 (RS-232)

2 DTR

3 RX

4 TX

5 GND

6 GND

J4 1 TX Port 3 RS-232 or

m Option Port

2 RX

3 GND

4 TX Port 4 RS-232 or

5 RX

6 GND

J5 1 +V Input Power Input

2 +V Input

3 - V Input (GND)

4 - V Input (GND)

J7 Header Com Port Option Slot Port 3 and 4

Co

m Option Port

Co

Table 2-3. Serial Communications Wiring

Installation and Setup 9

Page 14

Communications Cable Distance Limitations

20mA Serial Communication Active/Passive

Slide Switches

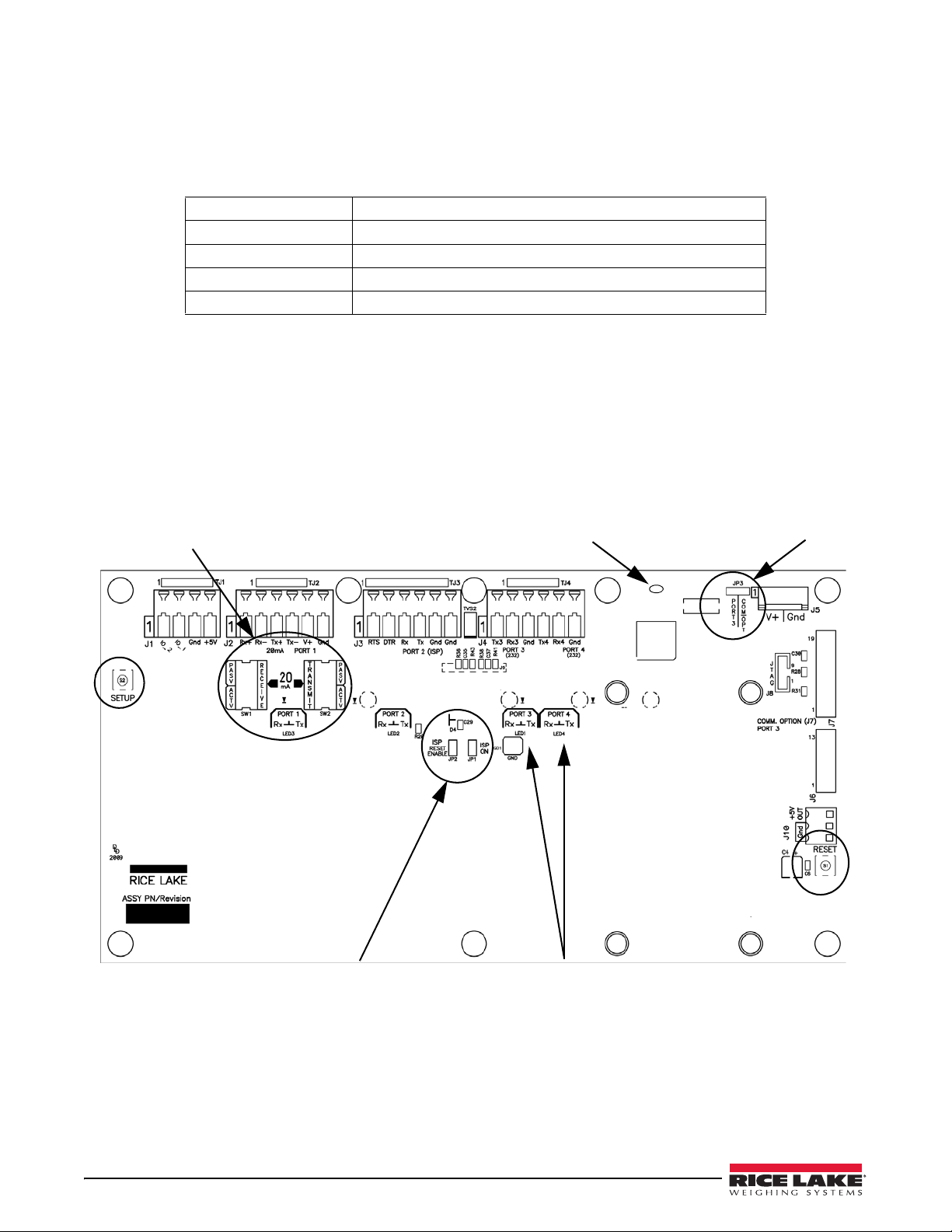

Commport Jumper for Comm 3

Remote display Heartbeat

(also shown in Fig. 2-7)

In system programming jumpers

(described in Section 6.0)

Port LEDs

The maximum cable lengths that can be used for various communications types depend on a number of factors.

These include: output impendance of the transmitter, electrical noise in the environment; cable capacitance, gauge,

termination, and shielding.

Given that these and other factors will af

fect the maximum usable cable length, the following distances can be used

as a general guide for the Laser LT communications cabling.

RS-232 50 ft (15 m) @ 19,200 baud rate

RS-422 1000 ft (300 m) Twisted pair cable

Fiber Optic 375 ft (114 m)

USB 16.5 ft (5 m)

802.11 330 ft (100 m)

Table 2-4. Communications Cable Distance Limitation Chart

20 mA Current Loop

The 20 mA current loop communication is provided on connector J2 (Port 1) of the CPU board (Figure 2-7,

Table 2-3). Select active or passive switch settings with

The 20 mA switches enable active or passive selection of

S1 (receive) and S2 (transmit).

the 20 mA current loop communication. Refer to

Figure 2-7 for the switch location on the CPU board.

RS-232

RS-232 connections are provided on connectors J3 and J4 of the CPU board (Figure 2-7).

2.3.5 Reset Switch

The reset switch enables a simulated power up reset. It then goes back to normal operation mode. The res et switch

eliminates having to unplug the unit to do a reset. Refer to Figure 2-7 for the reset switch location on the CPU

board.

10 Laser LT Installation and Operation Manual

Figure 2-7. Jumper Pin Locations

Page 15

2.3.6 Commport Jumper

Move jumper to

the right when

using an option

card.

Heartbeat

display

Option card seated

onto J7 of the CPU

board of Laser LT

The com port jumper (shown in Figure 2-7, upper right hand corner) is used when an option card is plugged into J7

on the CPU board (see Figure 2-9 for the J7 location). Availa

ble option boards include:

• F iber optic board - accessed Port 3

• RS-232/422 board - acces sed Port 3

• E thernet TCP/IP board - accessed Port 3

• USB board - acces sed Port 3

• E thernet wireless - accessed Port 4

If using one of the listed option boards, the commport

jumper setting must be moved to the right.

Figure 2-8. Commport Jumper Location

Figure 2-9. Option Board Location on the CPU Board

Installation and Setup 11

Page 16

3.0 Configuration

PRI CHR

L=76

PRI LOC

000000

SEC CHR

K - 75

SEC LOC

000000

GRS CHR

G - 71

GRS LOC

000000

NET CHR

N - 78

NET LOC

000000

MOT LOC

000000

LW POS

000000

NET LOC

000000

MOT CHR

M - 77

O - 79

OVR CHR

000000

OVR LOC

COZ LOC

000000

COZ CHR

Z - 90

SP IND

DWM4 1

Toledo

None

LB-OZ

F2500

FRAME

BAUD

1200

9600

2400

4800

19200

38400

57600

1115200

BITS

8 NONE

7 ODD

7 EVEN

000000

NEG LOC

[-] 45

NEG CHR

E CHAR

LF

CR

FF

ETX

STX

SOH

CR

LF

FF

ETX

SCHAR

SBITS

2

1

On

Off

LEARN

SERIAL TEST KEYPAD DIGIO VERS

CONFIG

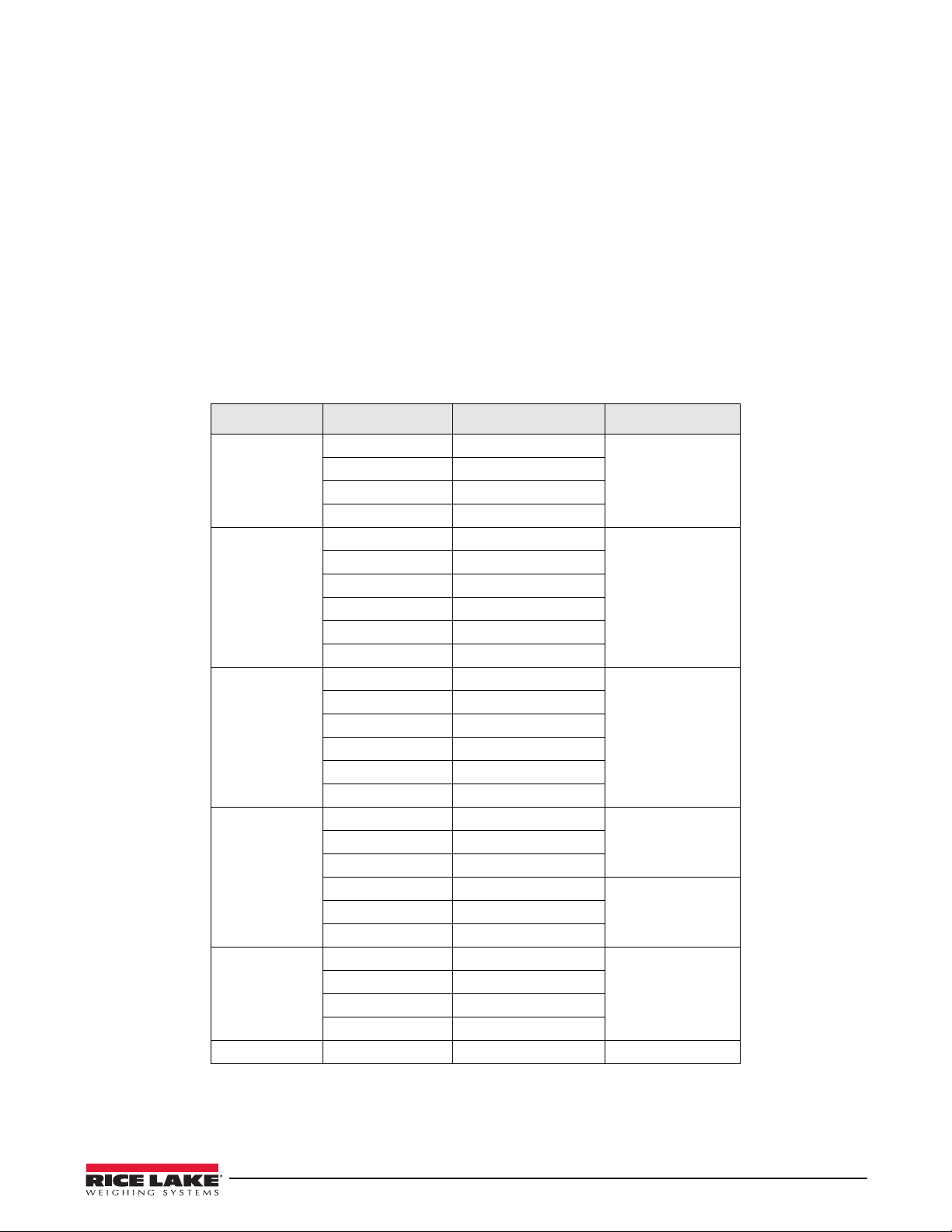

Once the Laser LT remote display is installed, it may need to be configured. This can be done manually through the

front panel and is explained in Sections 3.2 through 3.6.

Using Auto-Learn (Section 3.1) simplifies installation by automatically detecting the

data rate used by the indicator and may eliminate the need for

Use the Revolution Utility to help configure the Lase

r LT using your PC. Revolution can be used to program and

configuration.

configure the Laser LT and is further explained in See Section 3.10 on page 24 of this manual.

3.1 Auto-Learn

The Laser LT remote display incorporates a software feature called Auto-Learn. Auto-Learn examines the serial

data stream sent from the attached indicator and attempts to determine the data settings and format used by the

indicator.

communications format and

Figure 3-1. AutoLearn Menu Parameters

12 Laser LT Installation and Operation Manual

Page 17

Use the following quick steps for Auto-Learn.

LOCK

On

Off

LW POS

000000

NODATA

No Com

Blank

STDSTL

On

Off

On

Off

SCHAR

STX

SOH

CR

LF

SERIAL TEST KEYPAD DIGIO VERS

CONFIG

E CHAR

LF

CR

FF

ETX

HOLD WT SUPP 0

Off

On

Note

Setup

Button

1. Ensure that Lock in Configuration mode is set to the Off position.

Figure 3-2. Lock Parameter Location

2. Set up the Host Port.

3. Enter the Auto-Learn feature from Run Mode by pressing an d h old ing th e

4. If this does not work, and Learn fails, use Revolution

• It is recommended to set the parameter lock to the On position (see Table 3-4), to eliminate any un-intentional

changes from occurring.

• If the displayed weight is not correctly positioned, press and ho

seconds then release, to shift the displayed data string. The data will move one position. Repeat this as many

times as necessary to move the data over another position.

Utility software (Section 3.10 on page 24).

ld the right (unit) and left (print) buttons for three

Gross/Net key for three seconds.

3.2 Manual Configuration

To begin configuration, open the enclosure to access the CPU board (Figure 3-3).

Figure 3-3. Laser LT CPU Board

The setup button is located on the CPU board (Figure 3-3).This allows access into Configuration Mode.

Press the

SETUP button to access main menu configuration parameters.

Configuration 13

Page 18

The Laser LT remote display can be configured using a series of menus accessed from the front panel of the unit as

G/N

B/N

ZERO

PRINTUNITS

UNITS

TARE

TESTSERIALCONFIG VERSKEYPAD DIGIO

shown in

Figure 3-4.

Figure 3-4. Configuration Setup Buttons

Use the UP/DOWN, LEFT/RIGHT buttons to navigate through menu items and the ENTER button for setting a

selection.

Table 3-1 summarizes the functions of

Menu Menu Function Table/Section Number

CONFIG Configuration. Displays brightness and other parameters associat

the remote display

SERIAL Serial. Configures serial ports Table 3-3 and 3-4

TEST Test. System hardware tests Tab l e 3 - 5

KEYPAD Keypad. Configures keypad operation and

press to be modified to comply with other manufacterers

DIGIO Digitial I/O. Assigns digital input functions Section 3.6

VERS Version. Displays installed software version number Section 3.7

each of the main menus and Figure 3-5 illustrates the main menu selections.

ed with configuring

allows the strings sent with each keypad

Tab l e 3 - 2

Section 3.5

Table 3-1. Laser LT Remote Display Menu Summary

Figure 3-5. Laser LT Main Menu Flow

14 Laser LT Installation and Operation Manual

Page 19

Figure 3-6 shows the Configuration menu.

PRI CHR

L=76

PRI LOC

000000

SEC CHR

K - 75

SEC LOC

000000

GRS CHR

G - 71

GRS LOC

000000

LOCK

On

Off

LW POS

000000

NODATA

No Com

Blank

STDSTL

On

Off

SP INDCOZ LOC

000000

COZ CHR

Z - 90

On

Off

DWM4 1

Toledo

None

LB-OZ

F2500

SCHAR

STX

SOH

CR

LF

FF

ETX

SERIAL TEST KEYPAD DIGIO VERS

CONFIG

E CHAR

LF

CR

FF

ETX

HOLD WT SUPP 0

Off

On

NET LOC

000000

MOT LOC

000000

NEG LOC

000000

OVR CHR

O - 79

NET LOC

000000

MOT CHR

M - 77

OVR LOC

000000

NEG CHR

[-] 45N - 78

NET CHR

CONFIG Menu

Parameter Choices Description

Level 2 Submenus

HOLD WT Off

STDSTL Off

NO DATA No Com

LOCK Off

S CHAR STX

On

On

Blank

On

Figure 3-6. Configuration Main Menu Choices

Select On to enable this feature to keep

communication is lost or when using demand updated weight to prevent the

remote display from going into a NO DATA error condition.

Select On to blank the display when the

Selects what to display when the

“NO COM” or blank screen.

Select On to make sure the current settings don’t get changed and to disable

Auto-Le

The

arn. When off, the system enables Auto-Learn.

Laser LT scans for this character to determine the start of a packet.

the last weight displayed if

scale is in motion.

Laser LT is not receiving recognizable data -

CR

SOH

LF

FF

ETX

Table 3-2. Configuration Menu Summary - Level 2

Configuration 15

Page 20

CONFIG Menu

E CHAR CR

LF

FF

ETX

LW POS 000000 Defines the position of the last character in a weight. Range 0-63 with 0 as the

SUPP O On

Off

PRI CHR L = 76 Allows the user the select the primary unit character

PRI LOC 000000 This is the character location in the string format. A 0 (zero) indicates that the

The Laser LT scans for this character to determine the end of a packet.

default.

• With a 0 setting, the Laser LT will search from the end of the data stream

for the first group of digits.

• With a non-zero setting, the Las er LT will begin searching for digits at the

specified location.

• If LWPOS is past the weight in the data stream, it will work its way back to

the first group of digits it finds.

• A custom setting of this parameter is how a particular value is displayed

from a multi-weight data stream.

Enable (on) or disable (off) leading zero suppression.

Laser LT will look for the character anywhere in the incoming data. The range is

0-63

SEC CHR K - 75 Allows the user to select the secondary unit character

SEC LOC 000000 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The range is

0-63

GRS CHR G - 71 Allows the user to select the gross character

GRS LOC 000000 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The range is

0-63

NET CHR N - 78 Allows the user to select the net character

NET LOC 000000 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The range is

0-63

MOT CHR M - 77 Allows the user to select the motion status character

MOT LOC 000000 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The range is

0-63

NEG CHR [-] 45 Allows the user to select the negative polarity status character.

NEG LOC 000000 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The range is

0-63

OVR CHR O - 79 Allows the user to select the overload status character.

OVR LOC 000000 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The range is

0-63

COZ CHR Z - 90 Allows the user to select the center of zero status character

COZ LOC 000000 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The range is

0-63

Table 3-2. Configuration Menu Summary - Level 2

16 Laser LT Installation and Operation Manual

Page 21

CONFIG Menu

SP IND

None

To le do

DWM4 1

LB-OZ

F2500 Fairbanks

Table 3-2. Configuration Menu Summary - Level 2

Select, decode status, and settings for special indicator types.

None

Toledo or Fairbanks format

SPECIAL NOTES:

• If using a Metler Toledo indicator named something other than a numeric

model, you may need to set to None

• If using a Metler Toledo numbered model indicator, set to Toledo

Flexweigh DWM4 1 mode 1 format

Condec pound ounce format

Fairbanks 2500 and 9401 compatible format

Configuration 17

Page 22

3.3 Serial Communications

PORT 1 PORT

2

CONFIG

SERIAL

TEST

PORT 3

KEYPAD

DIGIO

VERS

PORT 4

BAUD BITS

7 ODD

8 NONE

SBITS

2

1

ECHO

ON

OFF

19200

38400

57600

1115200

1200

2400

4800

HOST

KEYDST

DAISY

PORT 1

PORT 1

PORT 1

PORT 2

PORT 2

PORT 2

PORT 3

PORT 3

PORT 3

PORT 4

PORT 4

PORT 4

OFF

OFF

7 EVEN

ADDRES

0-31

9600

The Laser LT remote display has four serial ports available:

• Port 1, 2, 3, and 4 - Provides communication with the indica

There are four sub-parameters associated with Ports 1, 2,

independently configured for baud rate, 7 or 8 bits, 1 or

3 and 4 which are shown in Figure 3-7. Each port can be

2 stop bits and whether an EDP command will echo to the

host (see Table 3-4).

The role of the port is also assigned which is host, key destination, or a daisy chain.

tor and other remote or serial devices.

18 Laser LT Installation and Operation Manual

Figure 3-7. Serial Menu

Page 23

Serial Menu

Parameter Choices Description

Level 2 Submenus

Port 1, 2, 3, and 4 BAUD

DATA BITS

STOP BITS

ECHO

Configure Ports 1, 2, 3, and 4. See Level 3 submenu parameter descriptions.

HOST PORT 2

PORT 1

PORT 3

PORT 4

KEYDST PORT 2

OFF

PORT 1

PORT 3

PORT 4

DAISY OFF

PORT 1

PORT 2

PORT 3

PORT 4

ADDRES 0 t

hrough 31 Assign a command address by selecting a number between 0-31. See

Allows the user to select which port is conn

host device.

Allows the user to select which port the k

This allows the user to select which port will echo data received from the host

device.

Section 3.9.1 for Run Mode Commands

ey press data will be sent to.

Table 3-3. Serial Communication Menu Summary

Serial Menu

Port 1, 2, 3, and 4 Parameter Choices Description

Level 3 Submenus

Parameters

BAUD 9600

1200

2400

4800

19200

38400

57600

19200

57600

115200

BITS 8 NONE

7 ODD

7 EVEN

SBITS 1

2

ECHO On

Off

Baud rate. Selects the transmission speeds for Po

and 4

Selects the bits of data of Ports 1, 2, 3, and 4

Selects the number of stop bits of Ports 1, 2, 3, and 4

This enables or disables echoing of r

characters.

ected to the weight indicator or

rts 1, 2, 3,

eceived EDP command

Table 3-4. Port 1, 2, 3 and 4 Serial Menu

Configuration 19

Page 24

3.4 Testing the Remote Display

CONFIG

SERIAL

TEST

VERS

DISPLA

INTENS

DIGIO

KEYPAD

1-7

STRTUP

On

O

RESET

EDIT

Display first 6

characters of format

ENABLE

Display and edit

active character and

ASCII value

Delete active

character

Scroll right in format stringScroll left in format string

Increment ASCII value of active characterDecrement ASCII value of active character

Press to insert a space

before the active character

Off

On

CONFIG

SERIAL

TEST

KEYPAD

DIGIO VERS

The Laser LT remote display provides a test menu to check the hardware of the remote display. These tests can be

accessed through the main menu (Figure 3-8).

TEST Menu

Parameter Choices Description

Figure 3-8. Test Menu Choices

DISPLA When this feature is enabled, all LEDs remain lit until

a key is pressed with the exception of

the ENTER or DOWN key.

INTENS 7

This allows the user to select the degree of br

1

the dimmest and 7 being the brightest.

ightness between the values of 1-7 with 1 being

2

3

4

5

6

STRTUP On

Off

RESET

When this feature is enabled, a display check is performed and the software version number

is shown at powerup.

The reset parameter resets the

Laser LT remote display to default parameters

Table 3-5. Test Menu Descriptions

3.5 Keypad

By using the keypad parameter, the user is able to configure keypad operation and allows strings to be sent with

each keypad press which can be modified to comply with other manufacturers.

Figure 3-9. Keypad Menu

See Section 6.4 for how characters are displayed.

20 Laser LT Installation and Operation Manual

Page 25

Label Default Description

CONFIG

SERIAL

TEST

VERS

DIO1

DIO2

DIGIO

KEYPAD

OFF

ZERO

REDLED

GRNLED

REDLED

GRNLED

ZERO

OFF

GRSNET

TARE

UNITS

PRINT

GRSNET

TARE

UNITS

PRINT

CONFIG

SERIAL

TEST

KEYPAD

VERSION

DIGIO VERS

KEYPAD 1

KEYPAD 2

KEYPAD 3

KEYPAD 4

Zero

G/N

Tare

Units

ENABLE = ON

STRING = KZERO<13>

ENABLE = ON

STRING = KGROSSNET<13>

ENABLE = ON

STRING = KTARE<13>

ENABLE = ON

Keypad strings are captured using the

following format for all 5 keys:

KEYPAD1.STRING = <KZERO<13>

KZERO is a string which can be up to 32

haracters

c

<13> is the ASCII for carriage return.

STRING = KUNITS<13>

KEYPAD 5

Print

ENABLE = ON

STRING = KPRINT<13>

Table 3-6. Keypress Parameter Settings

3.6 Digital I/O

When enabled, the digital inputs control the Red/Green light status LEDs or the front panel keypress as shown in

Figure 3-10. See J1 in Table 2-1 for wiring.

Figure 3-10. Digital I/O Menu

Digital I/O Logic Status

DIO1 0 - GND Active

1 (+ 5V) Inactive

DIO2 0 - GND Active

1 (+5V) Inactive

Table 3-7. Digital I/O Descriptions

3.7 Version

When Version is selected from the main menu choices (Figure 3-11), the current software version is shown on the

remote display.

Figure 3-11. Version Menu

Configuration 21

Page 26

3.8 Demand Print Displaying

Note

The indicator and the Laser LT remote display can be set up to do a demand print display for such applications as

cattle weighing. This is useful if you want to show and keep the last weight of an animal.

Using Auto-Learn, ensure

HOLD WT is on and continuously push the print button on the indicator to learn a demand

print display .

3.9 Run Mode Serial Commands

The Laser LT remote display has the ability to receive commands that display messages, or read a digital I/O

(2 inputs). If the Laser L

program can be written to allow the user to send messages utilizing softkeys or events. When sending messages

from a user program, the user can send one message to temporarily override the streamed weight display or send

multiple messages to be displayed one at a time for several seconds each, replacing the weight display all together

if desired.

The following commands are valid only while in run mode and on the host port.

3.9.1Laser LT Display Message Command

The display message command will place an alpha-numeric message on the display. The weigh annunicators

(gross, net, etc) will be cleared but the Red and Green LEDs will retain their current state.

|<AA>DM<timeout>|<message>!

or

|<AA><DM><message>!

Response: None

Where:

| = Pipe character (0x 7C)

AA = Two byte address, ASCII digits (00-31)

DM = Literal DM

Timeout = The number of milliseconds to hold

the message will remain on the display until replaced with another message or a weight string.

message = The message to be displayed

! = Exclamation point character (0 x21)

T remote display is interfaced with a programmable smart indicator like the 920i, a user

the message on the display. If a timeout value is not included then

3.9.2 Laser LT Set Red/Green LED Command:

This command will set the state of the red and green LEDs at the upper left of the Laser LT.

The red and green LEDs can also be configured to operate via

the digital inputs. An LED controlled from a digital

input will ignore serial commands.

|<AA>SL<data>!

Response: None

Where:

| = Pipe character (0x7C)

AA = Two byte address, ASCII digits (00-31)

SL = Literal SL

Data = The LED state data

0 = both red and green off

1 = red on

2 = red off

3 = green on

4 = green off

5 = both red and green on

! = Exclamation point character (0 x21)

3.9.3 Laser LT Get Digital Input Command

The Get Digital Input command will return the state of the requested digital input.

22 Laser LT Installation and Operation Manual

Page 27

|<AA>GR<data>!

Response: <State><CR>

Where:

| = Pipe character (0x7C)

AA = Two byte address, ASCII digits (00-31)

GR = Literal GR

Data = 1 or 2

CR = Carriage return, (0x 0D)

State = The state of the requested relay, possible responses:

1 = On

1 = Off

2 = On

2 = Off

! = Exclamation point character (0 x21)

3.9.4 Laser LT Query Display Command

The query display command will return what is currently being displayed and is mainly intended for testing.

An example of a possible operation would be to transmit a weight string or a display message command to the

Laser LT, let it set the display, transmit the query display command and capture the response. The response could

then be compared against what was expected.

|<AA>QD!

Response: <displayed>,<annunicator state><CR>

Where:

| = Pipe character (0x7C)

AA = Two byte address, ASCII digits (00-31)

QD = Literal QD

displayed = 6 characters minimum, up to 12 with decimal points.

A space (hex 20) represents a blank.

<CR> = Carriage return, (0x 0D)

<annuciator state> = The sum of the lit annunicators. For example: a value of 17 indicates that the lb and gross

annunicators are lit.

lb = 1

kg = 2

red = 4

green = 8

gross = 16

net = 32

center zero = 64

standstill = 128

! = Exclamation point character (0 x21)

Configuration 23

Page 28

3.10 Configuration with Revolution

Revolution is a user-friendly tool for configuring the Laser LT using your PC. Revolution can be used to program

and configure the Laser LT.

Revolution can be downloaded from the Rice Lake Weighing Systems web site at:www.ricelake.com/support/

ware/firmware/Revolution Scale Software.

soft

Use the following steps to configure

1. Select Revolution from the start up menu. The

following start up scre

the Laser LT using Revolution.

en appears.

Figure 3-12. Start up Screen

2. To begin using Revolution, click New in the

File menu (see Figure 3-11 arrow). A select

indicator screen appears. Select the Laser LT to

access and press

OK.

Figure 3-14. New File Screen

There are three categories which can be

configured. They are:

• General Configuration

•Comm Ports

• Formatting

3.10.1 General

General Configuration can be set up through this tab

such as selecting the Digital I/O, locking the Learn

Mode and so on.

Figure 3-13. Select Indicator

3. The chosen screen will appear as shown in

Figure 3-14.

24 Laser LT Installation and Operation Manual

Figure 3-15. General Tab

Parameter settings are further explained in the

following flow charts:

Page 29

Configuration menu found in Figure 3-15

Note

Keypad menu found in Figure 3-16

Digital I/O menu found in Figure 3-15

Figure 3-16. Keypad Setup

3.10.2 Comm Ports

Select the Comm Ports icon to access and set up Ports 1

through 4 information such as baud rate, data bits,

stopbits and echoing.

3.10.3 Formatting

Information must be uploaded prior to using

the Formatting screen in Revolution.

With Revolution running and the new file screen

shown (from Figure 3-14), select

the upper toolbar. Select

Communications from

Connect and then select

upload configuration.

Select the Formatting icon to access

the general

formatting screen shown in Figure 3-18. This would

generally be used when the Laser

LT Auto Learn failed

to display weight or annunicators. By viewing

information on the screen, you are able to see what

information the Laser LT has captured. Changes can be

made and downloaded to the Laser LT to customize the

display weight and annunicators.

Figure 3-17. Comm Port Screen

See Figure 3-6 for more information on setting these

parameters.

Figure 3-18. Formatting Screen

From this screen you can set up annuciator and weight

parsing.

The first text box on the screen shows the last received

data that the LaserL

T sends when data is uploaded.

This is a "snapshot" of 50 characters that the LaserLT

received from the host. It will display the ASCII value

of each character in the frame. Use the start character

and end character's ASCII values to determine the

frame. Characters between the start and end characters

make up the frame. You should only refer to the first

full frame. There may be half of a frame at the

beginning due to the timing of when the LaserLT sent

the "last received" data.

Look at each location to see what it is and what token

eeds to be updated.

n

Configuration 25

Page 30

If the cursor is placed before the first character after the

start character, it will be LOC1. Each character after

that is LOC2 through the end of the frame. If the

character is L for the primary and it is at LOC10, then

you need to put the cursor before the L and click

SELECT for the primary token. Revolution will plug in

the character and location.

Continue with all known characters and download this

new data and the LaserLT should now display a proper

weight with the available tokens.

The below is a sample of Section Print. The parameters

tell the LaserLT how to decode the stream.

• Center of Zero Character: 90

• Center of Zero Location: 0

• Overload Character: 79

• Overload Location: 0

• Gross Character: 71

• Gross Location: 11

• Net Character: 78

• Net Location: 0

• M otion Character: 77

• M otion Location: 0

• Primary Character: 76

• Primary Location: 10

• Secondary Location: 10

• Negative Character: 45

• Negative Location: 0

• Last Weight Position: 0

• E nd Character: CR

• Start Character: STX

• Special Indicator: None

26 Laser LT Installation and Operation Manual

Page 31

4.0 EDP Commands

Note

<STX> <POL> <wwwwwww> <UNIT> <G/N> <S> <TERM>

ASCII 02

decimal

Polarity:

<space> = Positive

<–> = Negative

Weight: 7 digits, right-justified, dummy

zeroes, decimal point with no leading

zeroes except for leading zero immediately

preceding the decimal point. Leading

zeroes transmitted as spaces.

L = pounds

K = kilograms

T = tons

G = grains

<space> = grams

O = ounces

G = Gross

N = Net

Status:

<space> = valid

I = Invalid

M = Motion

O = Over/under range

Z = Center of zero

<CR> <LF>

or <CR>

The Laser LT remote display can be controlled by a personal computer or a remote keyboard connected to the

remote display . Control is provided by a set of EDP (Electronic Data Processing) commands that can simulate front

panel key press functions, display and change setup parameters and perform reporting functions.

EDP commands are able to view or change the parameters either in Run or Co

mode, the user must send the command

Any port that is selected for the host port will not accept EDP commands. A host device cannot change any

parameters using the port the data is being sent out on.

SAVE.CFG when finished.

4.1 Annunciator and Weight Position EDP Commands

The Laser LT uses an Auto-Learn function which automatically determines the serial settings and data format used

by the attached indicator. EDP commands are used for manually configuring the weight stream parsing.

4.1.1 Data Formats

Continuous Output Serial Data Format

If continuous transmission is configured for a serial port in the Host (STREAM parameter set to LFT or INDUST

on the SERIAL menu), the Laser LT receives data using the Consolidated Controls serial data format shown in

Figure 4-1:

nfiguration mode. If used in the Run

Figure 4-1. Continuous Output Serial Data Format

4.1.2 Annunciators

The following table lists the EDP commands for configuring the annunciators.

Command Default Value Description

COZ.CHAR 90 (Z) Allows the user to select the center of zer

COZ.LOC 0 This is the character location in the string format. A 0 (zer

Laser LT will look for the character anywhere in the incoming data. The

range is 0-63

GROSS.CHAR 71 (G) Allows the user to select the gross character

GROSS.LOC 0 This is the character location in the string format. A 0 (zer

Laser LT will look for the character anywhere in the incoming data. The

range is 0-63

NEG.CHAR 45 (-) Allows the user to select

NEG.LOC 0 This is the character location in the string format. A 0 (zer

Laser LT will look for the character anywhere in the incoming data. The

range is 0-63

NET.CHAR 78 (N) Allows the user to select the net character

Table 4-1. Annunciator and Weight Position EDP Commands

o status character

o) indicates that the

o) indicates that the

the negative character

o) indicates that the

EDP Commands 25

Page 32

Command Default Value Description

NET.LOC 0 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The

range is 0-63

PRI.CHAR 76 (L) Allows the user the select primary unit character

PRI.LOC 0 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The

range is 0-63

SEC.CHAR 75 (K) Allows the user to select the secondary unit character

SEC.LOC 0 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The

range is 0-63

MOTION.CHAR 77 (M) Allows the user to select the motion status character. When a motion

character is received, the standstill annunciator is turned off. When no

motion character is being received, the standstill annunciator is turned on.

MOTION.LOC 0 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The

range is 0-63

OVR.CHAR 79 (O) Allows the user to select the overload status character

OVR.LOC 0 This is the character location in the string format. A 0 (zero) indicates that the

Laser LT will look for the character anywhere in the incoming data. The

range is 0-63

LWPOS 0 Defines the position of the last charactor in a weight. Range 0-63 with 0 as

the default.

• With a 0 setting, the LaserLT will search from the end of the data stream

for the first group of digits.

• With a non-zero setting, the LaserLT will begin searching for digits at the

specified location.

• If LWPOS is past the weight in the data stream, it will work its way back

to the first group of digits it finds.

• A custom setting of this parameter is how a particular value is displayed

from a multi-weight data stream.

ENDCHAR CR Choices:

CR

LF

FF

ETX

The terminating character of the received weight stream

SPECIALINDICATOR NONE

TOLEDO

DWM4 1 (Flexweigh)

LB - OZ

F2500 (Fairbanks)

STARTCHAR STX

CR

SOH

LF

FF

ETX

This configures the Laser LT to use a serial stream that requires special

handling.

Defines which character indicates the start of a weight stream.

Table 4-1. Annunciator and Weight Position EDP Commands

26 Laser LT Installation and Operation Manual

Page 33

4.2 Parameter Setting Commands

The following table describes EDP parameter setting commands with descriptions and ranges.

Command Choices Description

DAISY OFF

PORT 1

PORT 2

PORT 3

PORT 4

DIO1 OFF

REDLED

GRNLED

ZERO

TAR E

UNITS

PRINT

GRSNET

DIO2 OFF

REDLED

GRNLED

ZERO

TAR E

UNITS

PRINT

GRSNET

HOLDWEIGHT OFF

ON

HOST PORT 2

PORT 1

PORT 3

PORT 4

INTENSITY 7

1

2

3

4

5

6

KEYDST PORT 2

OFF

PORT 1

PORT 3

PORT 4

LOCK OFF

ON

NODATA NO COM

BLANK

STANDSTILL OFF

ON

STARTUP ON

OFF

SUPPRESSZERO ON

OFF

This is the port that will echo the weight data to another remote display

Select which LED or front panel key function is controlled by this digital I/O

point. Note: DIO1 and DIO2 could both be set to the same front panel key

function.

Select which LED or front panel key function is controlled by this digital I/O

point. Note: DIO1 and DIO2 could both be set to the same front panel key

function.

Holds the last received weight on the display instead of showing an error if

communications are lost or the host is sending demand data.

The port to receive weight data from the indicator on.

The intensity of the LED elements with 1 = dimmest and 7 = brightest

This is the port that will transmit keypress commands.

Locks (on) or unlocks (off) access to the Learn Mode.

This parameter allows the display to either display NO COM or go blank

when data transmission is lost, unless over-ridden by the hold weight

parameter.

Select On to blank the display when the scale is in motion.

This defines whether or not to do a display check and version display on

power up.

On = this performs the test and shows the version

Off = this goes straight into the operation

Enable (on) or disable (off) leading zero suppression.

Table 4-2. Laser LT Parameter Setting Descriptions

EDP Commands 27

Page 34

Note

Command Choices Description

PORTS 1 THRU 4 BAUD = 9600

BITS = 8 NONE

ECHO = ON

SBITS = 1 STOP BIT

KEYPAD 1 ENABLE = ON

STRING = KZERO<13>

KEYPAD 2 ENABLE = ON

STRING =

KGROSSN

KEYPAD 3 ENABLE = ON

STRING = KTARE<13>

KEYPAD 4 ENABLE = ON

STRING = KUNITS<13>

KEYPAD 5 ENABLE = ON

STRING = KPRINT<13>

ET<13>

Keypad strings are captured using the

KEYPAD1.STRING = <KZERO<13>

KZERO is a string which can be up to 32 characters

<13> is the ASCII for carriage return.

Table 4-2. Laser LT Parameter Setting Descriptions

4.3 Reporting Commands

Reporting commands send specific information to the serial port.

All Reporting commands are read only and will not function for baud rates lower than 4800.

following format for all 5 keys:

Parameter Function

DUMPALL Lists all configuration parameters.

DUMP.KEYPAD Lists only the 10 keypad parameters.

DUMP.PORT Lists only the 4 ports with 4 paramet

DUMP.SY List the parameters not dumped with the other commands.

BUILD Lists the date and time that this softwar

SYSMODE Returns the current mode in R

VERSION Returns the softwar

WHOAMI Returns the version of the Laser LT and the port that

COMMOPTS 7 = Empty

1 = RS-232/422

2 = USB/Serial

3 = Reserved

4 = Ethernet WiFi/Serial

5 = Ethernet

6 = Fiber Optic

Read only. Returns a numeric identifier for an installed option card

e version.

ers per port.

e version was compiled.

un or Setup.

you are connected to and its parameters.

Table 4-3. Laser LT Reporting Commands

28 Laser LT Installation and Operation Manual

Page 35

5.0 Options

5.1 Visor Installation

An optional visor can be installed on the Laser LT display. Figure 5-1 shows the remote display with the optional

visor installed.

Figure 5-1. Laser LT Remote Display w/ Optional Visor Installed

Mount the visor (PN 115138) on top of the remote display by opening the front cover, sliding the visor over the

latch assembly and reclose the latches on the enclosure.

Options 29

Page 36

6.0 Appendix

Note

6.1 Error Messages

The Laser LT remote display provides error messages. When an error occurs, the message is shown on the display.

Message Cause/Remedy

NO COM

ABORT

6.2 Troubleshooting

Prior to troubleshooting, it is important to default the Laser LT to the default settings. See Section 2.3.5 on page 10

for instructions on defaulting the unit.

Set the host port to match wiring.

Table 6-2 lists general troubleshooting tips for various error conditions.

Symptom Cause/Remedy

Power No Display on

Po

Communications No Communication Check for port LED blinking. Red is

Daisy Chain No Echoing Check parameters - verify that parameter Daisy is set to th

No communication with the ports and the device that it’s communicating with

The Laser LT failed to Auto Learn. See Troubleshooting Section 6.2.

Table 6-1. Error Messages

wer up

Not plugged in - Ensure that power is getting to the

should show a display check or weight data.

Blown fuse - Check fuse on power supply board and replace if necessary.

No power to CPU board - Using

Figure 10). Power output should b

No heartbeat - Verify that the heartbeat LED is blinking. See Figure 2-8 11 for heartbeat

location.

• Blinking annunciator - normal

• Solid light on annunciator - hardware error

• No light on annunciator - check power source

Check that the NO DATA parameter is set to NO COM (see Ta bl e 3-2) for default settings

as no communication can ca

Verify wiring - see Section 2.3.4 on page 9 for wiring information

Verify ports - Verify t hat the p ort is se t for the Host a

communicating with and is connected to the Host port.

Verify streaming - the indicator or other host device should be set to on or off.

on page 18)

Verify wirin g - Section 2.3.4 on page 9.

a voltmeter, check power on J5 of the CPU board (see

e approximately +7.5V

use a blank display

receive, and Green is transmit.

Laser LT. On power up, the display

nd the device that it is

e correct port (see Section 3.3

Table 6-2. Basic Troubleshooting

30 Laser LT Installation and Operation Manual

Page 37

6.3 Updating the Laser LT

If software needs to be updated for the Laser LT, the updater utility is available through Revolution.

A flash update cable (PN 115968) must be used to

Plug the flash update cable connector into the header TJ3 on the Laser LT CPU board and the other end into the

.

PC

Figure 6-1. Flash Update Cable Plugin Location on Laser LT

Follow on screen instructions to update the Laser LT.

To access the updater, select the Update icon from the main Revolution menu an

connect the CPU board of the Laser LT to a port on your PC.

d follow screen prompts.

Figure 6-2. Updater Screen for the Laser LT

Appendix 31

Page 38

6.4 Front Panel Display Characters

!

"

#

$

%

&

'

(

)

*

+

,

-

.

/

0

1

2

3

4

5

6

7

8

9

:

;

<

=

Figure 6-3 shows the 7-segment LED character set used to display alphanumeric characters on the Laser LT front

panel.

32 Laser LT Installation and Operation Manual

Figure 6-3. Laser LT Display Characters

Page 39

6.5 Replacement Parts

7

22

23

6.5.1 UL Approved Replacement Parts

Figure 6-4. UL Approved Power Supply Parts Illustration

Item No. Part No. Description

7 153811 Cable Assembly Power Supply to CPU

22 153600 Power Supply 12V 45Watt PLC-45-12

23 153808 AC Input Power Cord Assembly, GFCI

Table 6-3. UL Approved Power Supply Parts List

Appendix 33

Page 40

21

13

25

24

16

12

20

19

9

4

14

22

15

23

10

1

5

6

2

8

3

11

17

11

9

9

See Ground Detail

Ground Detail

7

18

34 Laser LT Installation and Operation Manual

Page 41

6.6 Replacement Parts

Table

6-1 lists selected replacement parts for the Laser LT remote display.

Item No. Part No. Description Qty

1 110384 Board Assembly, LED remote CPU 1

2 111848 Overlay, Laser LT 1

3 113535 Enclosure, Laser LT RD1550 1

4 113542 Power Suppy Cover, Laser LT 1550 1

5 113769 Lens 1

6 114019 Enclosure Gasket 1

7 114433 Cable Assembly 1

153811 UL Approved Item, see Figure 6-4 1

8 114549 Standoff 4-40NC x 9/16L x 3/16 Hex 11

9 14626 Kep Nut #8 4

10 14825 Machine Screw, 4-40NC x 1/4 pan head phillips 11

11 15134 Lock Washer, #8 internal tooth 3

12 15626 Gable Grip 1

13 15627 Locknut, PG9 1

14 16861 Label, Warning High Voltage 1

15 16892 Label, Earth Ground 1

16 30375 Nylon Sealing Ring 1

17 40672 Wire Assembly, Ground 9” w/ Eye Connector 1

18 53308 Label 1

19 68599 Sealing Ring 1

20 68600 Cord Grip 1

21 68601 Locknut 1

22 76556 AC Power Supply, 25 watt 1

97475 DC Power Supply, 25 watt 1

153600 UL Approved Item, see Figure 6-4 1

23 85202 Power Cord Assembly 1

153808 UL Approved Item, see Figure 6-4 1

24 88733 Breather Vent 1

25 88734 Breather Vent Nut 1

85791 Fuse, 2.5 amp, 5x20 mm, 250V 1

115968 Flash update cable, 1

0 position DB9 1

Table 6-4. Selected Replacement Parts

6.7 Parts Kit Contents (PN 115525)

Table 6-5 lists the parts kit contents for the Laser LT remote display.

Part No. Description

14626 Kep nuts, 3-32NC (3)

15133 Lock washers, No. 8, Type A (3)

15631 Cable ties, 3 inch nylon (2)

19538 Post only, slotted black 1/4 x 1 (1)

53075 Clamp, ground cable shield (3)

Table 6-5. Parts Kit Contents

Appendix 35

Page 42

6.8 Laser LT Enclosure Dimensions

36 Laser LT Installation and Operation Manual

Page 43

6.9 Specifications

U

L

C

US

LISTED

®

Display

Six digit LED, 7-segment character, 1.5 in height

Six annunicators for GR, NT, LB, KG, Motion and COZ

One Red, one Green light (serial or I/O controlled)

Overlay with contrast filtered lens

Optional visor for direct sunlight

Input Interface

Port 1 20mA bidirectional

Port 2 RS-232 bidirectional

Port 3 RS-232 or pluggable option for fiber optic, USB, Ethernet TCP/IP, RS-422

Port 4 RS-232 or pluggable option for wireless LAN

Output Interface

Echo Daisy chain output mode - port selectable

Keypad output mode Configurable str

Input Data Format

Learn mode or software selectable for data types

Baud Rate: 1200, 2400, 4800, 9600, 19,200

Characters: 7 Even, 7 Odd, 8 None

Stop bits: 1 or 2 selectable

Digital I/O

Two inputs for control of Red and Green annunicators and front panel keys

ings and port selectable

, 38,400, 57,600, 115,200

Power Supply

AC Power: Line voltages 115 or 230 VAC

Frequency 50 or 60 Hz

Power Consumption 1.5A @ 115 VAC (8W)

0.75A @ 230 VAC (8W)

Fusing 2.5A 5x20mm fuse

DC Power: Line voltages 9-36 VDC DC Input

Power Consumption 1.5A max

Fusing internal short cir

cuit protection

Rating/Material

NEMA 4X, IP69K, 304 Stainless Steel

Weight

10 lbs

Operating Temperature Range

-20F to 120F (-30C to 50C)

Warranty

Two-year limited warranty

UL Approval for UL Models Only

File Number: E355385

Appendix 37

Page 44

Laser LT Remote Display Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by the

Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in materials

and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements a re listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or improper

testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RL WS o r its duly

authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR

OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER

CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

38 Laser LT Installation and Operation Manual

Page 45

Page 46

230 W. Coleman St. t Rice Lake, WI 54868 t USA

U.S. 800-472-6703 t Canada/Mexico 800-321-6703 t International 715-234-9171 t Europe +31 (0) 88 2349171

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 02/2014

PN 114035 Rev B

Loading...

Loading...