Page 1

Trimming Procedure

TRIMMING

Whenever a substantial

amount of trim is necessary

to equalize output (more

than 5% of normal output),

check for other possible

problems. The best trim is

always the least amount of

trim.

TEST WEIGHTS

CAUTION: When loading

the corners, do not exceed

the concentrated load

capacity (CLC) specified by

the scale manufacturer.

POST SCREW

PLUGS

CAUTION: To prevent water

and other contaminants

from entering the J-Box, fill

any unused cable grips with

post screw plugs, part

number 19538.

Trimming is a process of equalizing the output from multiple individual

load cells, or from pairs of cells if using the section trim format. When

all errors except cell mismatch and cable extensions or reductions have

been corrected, continue with the trimming procedure below.

1. Set all potentiometers fully counter-clockwise to give maximum

signal output from each cell.

2. Make sure isolation resistors corresponding to any unused terminals have been cut to disable use of these channels.

3. Zero the indicator and place calibrated test weights over each load

cell in turn (or over each section) without allowing the weights to

overhang the sides. The amount of test weights used depends on

the scale configuration; for specific recommendations, refer to

Handbook 44 Field Manual, published by the Institute for Weights

and Measures. For a four-cell platform, we recommend using

25% of scale capacity.

4. Record the value each time weight is placed on the scale and allow

the scale to return to zero to check for friction or other mechanical

problems. Select the load cell or section which has the lowest

value as your reference point—this cell or section will not be

trimmed.

5. Now replace the same test load over each cell or section and trim

each with its potentiometer down to the reference level cell or

section. As corner corrections are somewhat interactive, check all

cells or sections again for repeatability.

6. Tighten all wiring connections. Pull excess cable out of the

enclosure and tighten the cord grip assemblies with a wrench. To

be watertight, each cord grip must be tightened so the rubber

sleeve begins to protrude from the hub.

7. Unused hubs must be plugged to prevent moisture entry. See the

Electronic Replacement Parts and Components catalog to order

extra hole plugs.

8. Insert a commercial desiccant containing antioxidant properties

into the junction box before closing. If the enclosure is in a damp

or wet area, change the desiccant every four to six months.

9. Replace the cover and tighten the cover screws in an alternating

pattern to be certain the gasket is compressed equally in all

locations.

JB1010ST

Ten-Channel Signal Trim Junction Box

Installation

Manual

CABLE DRIP LOOPS

If cables will be exposed to

water or other liquids, bend

a short downward loop in all

cables near the cord grips

so any fluids draining down

the cables will drip off

before reaching the junction

box.

Authorized distributors and their employees

can view or download this manual from the

Rice Lake Weighing Systems distributor site

at www.rlws.com.

3

68812

Page 2

Introduction

Wiring

The JB1010ST Junction Box can accommodate two, four, six, eight, or

ten load cells with transient protection components. This board cannot

be used with an odd number of cells. Any unused channels require

modification. Load cell output can be trimmed with potentiometers

either individually or in pairs.

When correctly installed, the NEMA 4X stainless steel enclosure will

withstand 40 psi water pressure. It is not, however, designed for highpressure washdown applications, exposure to steam, or exposure to

high-temperature liquids.

Mounting the Junction Box Enclosure

Mount the enclosure in a location convenient for servicing and away

from standing water. Try to mount the enclosure in a location that will

not require extending the load cell cables. Depending on the mounting

surface, the enclosure is attached using the four suitable fasteners.

Figure 1 below shows dimensions for mounting the enclosure.

9.19"

(233.4mm)

8.58"

(217.9mm)

8.06"

(204.7mm)

0.44"

(11.1mm)

5.19"

(131.8mm)

5.94"

(150.8mm)

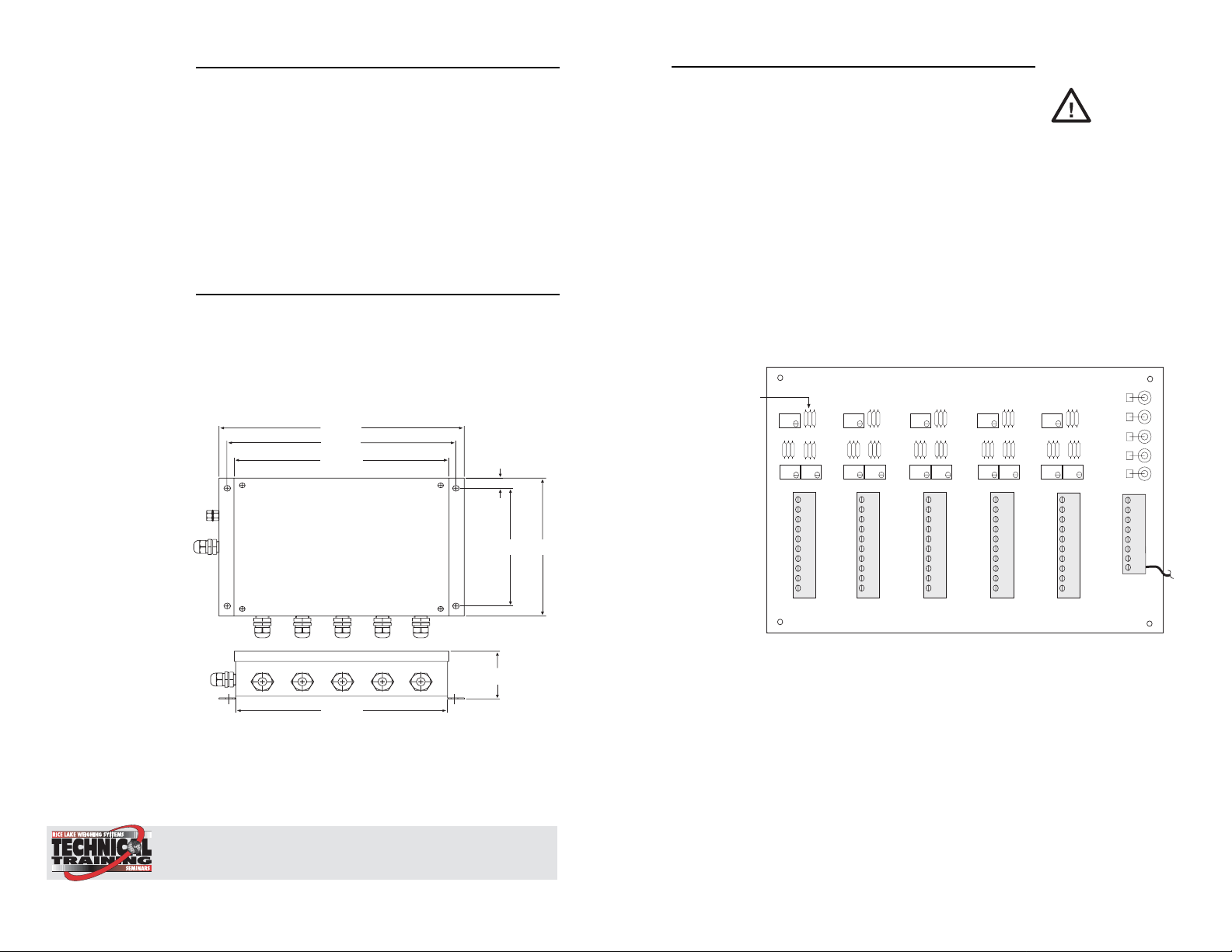

The terminal strips are labeled “Cell 1” through “Cell 10” and are used

to connect the individual load cells. Determine the number of load cells

to be connected to the junction box. The JB1010ST has been designed

to connect and trim two, four, six, eight, or ten load cells only. Load cell

output can be trimmed with potentiometers individually, or paired

channels may be trimmed as a section. If using the paired-channel

section trim, there must be two load cells attached to each section.

After determining the wiring pattern, route the load cell cables through

the nylon cord grip assemblies and leave the grips loose until final

closure. Before connecting load cell cables to the terminals, check that

all wire ends have been properly stripped and tinned.

Determine the color coding of the load cells used and connect each load

cell cable to its terminal according to the labels by the terminals. For

each cable, twist the woven shield into a single “wire” and attach it to

the shield pin on its terminal strip. Disable any unused channels by cutting

the isolation resistors corresponding to those channels.

REMOVE ISOLATION

RESISTORS TO

DISABLE UNUSED

CHANNELS

SECTION 1 TRIM SECTION 2 TRIM SECTION 3 TRIM SECTION 4 TRIM SECTION 5 TRIM

CELL #1 CELL #2 CELL #3 CELL #4 CELL #5 CELL #6 CELL #7 CELL #8 CELL #9 CELL #10

SHIELD

-SIG

+SIG

-EX

CELL #2

+EX

+EX

-EX

+SIG

CELL #1

-SIG

SHIELD

SECTION 1

MULTIPLE LOAD CELL TRIMMING BOARD - MODEL UJB-10LCT - REV. B

Turn pot’s CW for maximum output

SHIELD

1

-SIG

2

3

+SIG

4

-EX

5

+EX

1

+EX

2

-EX

3

+SIG

CELL #3 CELL #4

4

-SIG

5

SHIELD

SECTION 2 SECTION 3 SECTION 4 SECTION 5

SHIELD

1

-SIG

2

3

+SIG

4

-EX

5

+EX

1

+EX

2

-EX

3

+SIG

CELL #5 CELL #6

4

-SIG

5

SHIELD

SHIELD

CELL #7 CELL #8

SHIELD

-SIG

+SIG

+SIG

-SIG

1

2

3

4

-EX

5

+EX

1

+EX

2

-EX

3

4

5

1

2

3

4

5

1

2

3

4

5

DO NOT USE WITH AN ODD NUMBER OF LOAD CELLS

FIGURE 2: MAIN BOARD

LOAD CELL

CAUTION: Do not attempt

to use an odd number of

load cells with the

JB1010ST. You must use

both channels for each

section.

WIRING PATTERN

See back cover of Rice

Lake Weighing Systems

Load Cell Guide

color codes.

SHIELD

1

-SIG

2

3

+SIG

4

-EX

5

+EX

1

+EX

2

-EX

3

+SIG

CELL #9 CELL #10

4

-SIG

5

SHIELD

+SEN

-SEN

+SIG

-SIG

SHIELD

EARTH

for wiring

GT5

GT4

GT3

GT2

GT1

+EX

-EX

INDICATOR

1

2

3

4

5

6

7

8

7.94"

(201.6mm)

FIGURE 1. ENCLOSURE DIMENSIONS

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.rlws.com or obtained by calling

© 2003 Rice Lake Weighing Systems, Inc., Rice Lake, WI USA. All Rights Reserved

Rice Lake Weighing Systems, Inc. 230 West Coleman Street, Rice Lake, WI 54868

715-234-9171 and asking for the training department.

2.06"

(52.3mm)

January 2003

The INDICATOR terminal strip is for connecting the main cable to the

indicator. Determine the indicator’s load cell input connections from

the operating manual. Run a cable from your indicator terminal into the

junction box through the larger cord grip and make the connections on

the INDICATOR terminal.

2

SENSE LEADS

Use sense leads to

compensate for temperature

changes, especially if the

indicator is located far from

the junction box.

Loading...

Loading...