Page 1

JB1010

Ten-Channel Junction Box

Insta l l ati on

Manual

To be the best by every measure

36329

Page 2

Page 3

Contents

1.0 Introduction ......................................................................................................................................1

2.0 Mounting the Enclosure ...................................................................................................................2

3.0 General Wiring Guide lines ...............................................................................................................2

4.0 Wiring for New Systems ..................................................................................................................3

5.0 Trimming Load Cell Output...............................................................................................................4

5.1 Trimming Individual Cells ......................................................................................................................... 4

5.2 Trimming Cells in Sections .......................................................................................................................4

5.3 Trimming Both Individual Cells and Sections (Full Feature) .................................................................... 5

6.0 Transient Protection System ............................................................................................................6

7.0 Switchbank SWA and SWB 1-8 Switch Functions ...........................................................................7

8.0 Using the JB1010 In an Existing System .........................................................................................8

9.0 Schematic Drawing of Connector Section (Two Load Cells) ..........................................................9

Authorized distributors and their em ploy ees can

view or download this manual from the Rice Lake

Weigh ing Systems distributor site at

com.

Copyright© 2010 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifi cation subject to change without notice.

December 2010

www.rlws.

Page 4

1.0 Introduction

SHD

–SIG

+SIG

–EXC

+EXC

+EXC

–EXC

+SIG

–SIG

SHD

CELL A CELL B

SHD

–SIG

+SIG

–EXC

+EXC

+EXC

–EXC

+SIG

-SIG

SHD

SHD

–SIG

+SIG

–EXC

+EXC

+EXC

–EXC

+SIG

–SIG

SHD

CELL A

CELL B

SHD

–SIG

+SIG

–EXC

+EXC

+EXC

–EXC

+SIG

–SIG

SHD

CELL A

CELL B

SHD

-SIG

+SIG

–EXC

+EXC

+EXC

-EXC

+SIG

–SIG

SHD

CELL A

CELL B

+EX

+SE

–EX

–SE

+SI

–SI

SHD

CELL

1A

CELL

3A

CELL/SECT

4B

CELL

5A

CELL/SECT

6B

CELL

7A

CELL/SECT

8B

CELL

9A

CELL/SECT

10B

SECT5

+EXC

SECT5

–EXC

SECT4

+EXC

SECT4

–EXC

SECT3

+EXC

SECT3

–EXC

SECT2

+EXC

SECT2

–EXC

SECT1

+EXC

SECT1

–EXC

TO INDICATOR

SECTION 1 SECTION 2 SECTION 3 SECTION 4 SECTION 5

JB1010

CELL/SECT

2B

CELL A CELL B

100KΩ

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

TRANSIENT PROTECTION

SW1B

SW1A

SW2B

SW2A

SW3B

SW3A

SW4B

SW4A

SW5B

SW5A

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

100KΩ

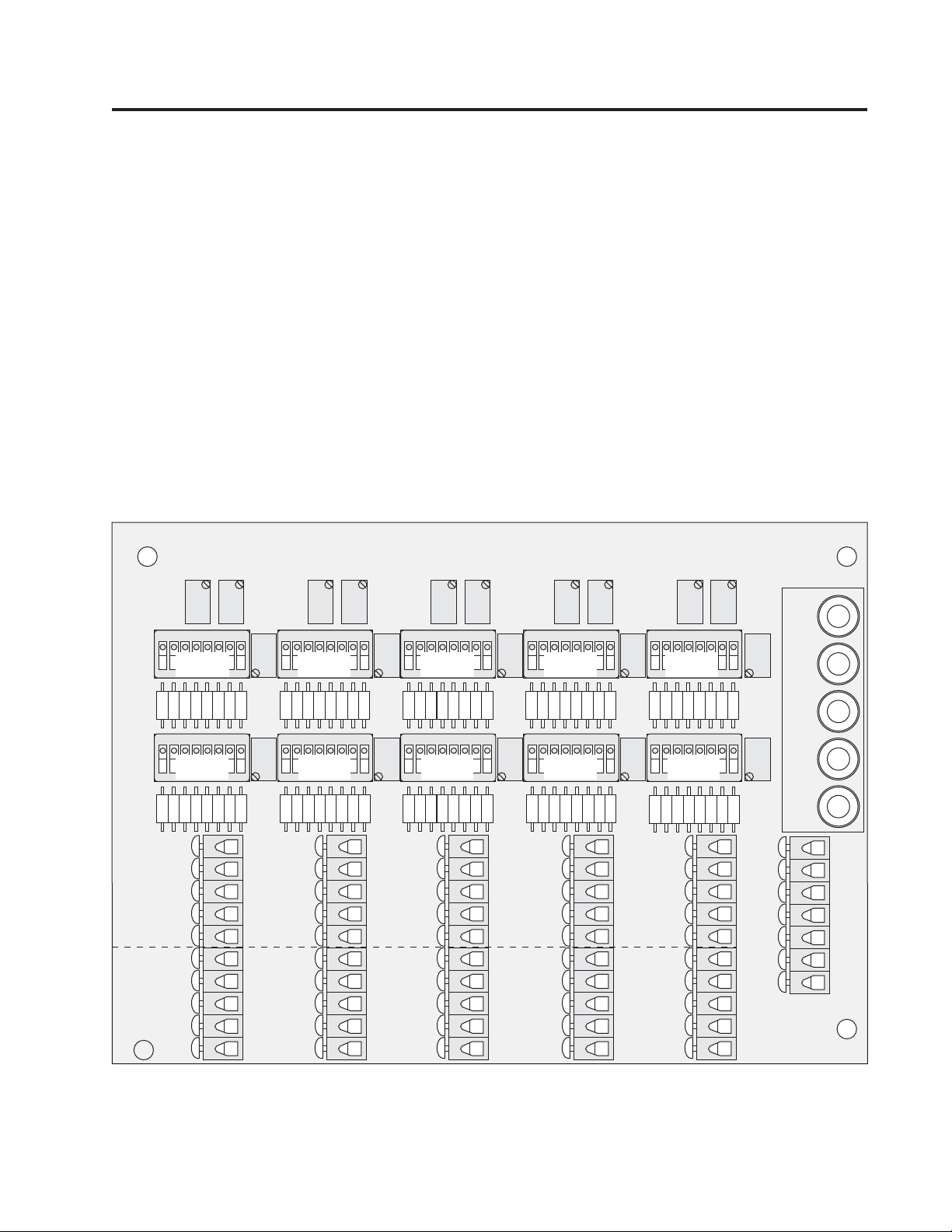

The JB1010 is a summing junction box and trimming device for up to ten strain gauge load cells. In new applications that use a single junction box, the JB1010 can be custom con fi g ured to fi t many unique ap pli ca tions.

It allows either signal or excitation trimming of three load cell arrangements: individual load cells, pairs of load

cells in sec tions, or a combination of individual/and paired load cells. It allows use of an odd number of load

cells without modifi cation.

As a re place ment board for existing applications in the fi eld—even as part of a multiple junction box trim ming

network—the JB1010 can re place many boards. It is ide al as a single replacement product for many sep a rate

boards for truck scales, tank scales, and track scales. This product can be used in multiple con fi g u ra tions. Most

of these confi gurations are used to match existing systems using multiple junc tion boxes.

When the JB1010 is used as a re place ment for existing junction boxes, the confi guration characteristics of the

other trim ming devices must be matched for proper operation. Help for de ter min ing the characteristics of exist-

ing devices will be found in Section 8.0, Using the JB1010 in an Existing System.

Standard JB1010 units have a local tran sient sup pres sion net work that provides zone pro tec tion against most

light ning induced tran sients, par tic u lar ly when used with cell wiring in metal conduit.

In addition to the NEMA 4 FRP junction box, the JB1010 is also available as a board-only product.

Figure 1-1. JB1010 Board

1

Page 5

2.0 Mounting the Enclosure

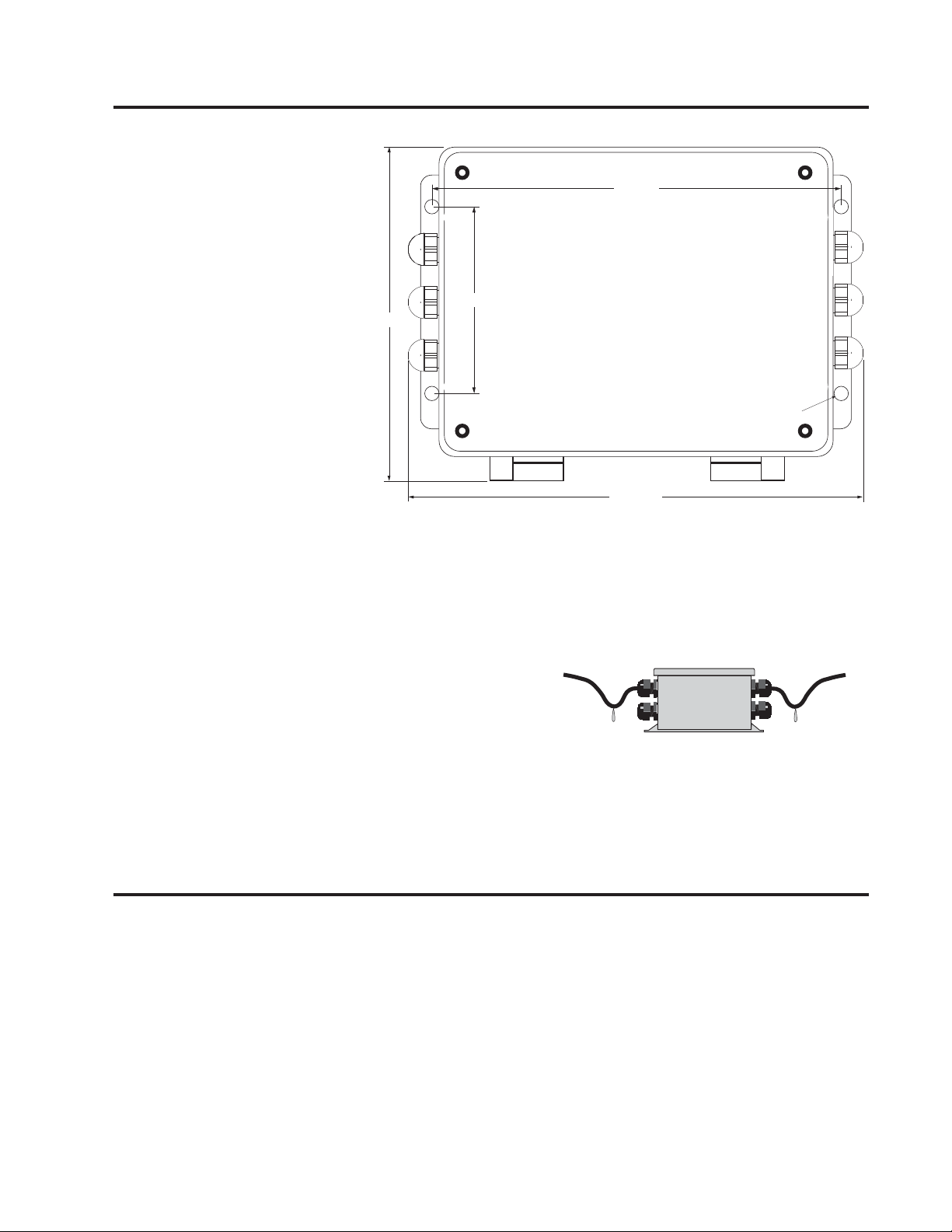

The JB1010 has 4.0" x 8.75" mount ing centers for #10 or 1/4" screws.

Mount the en clo sure for proper

ser vice access. Avoid mounting on

weighbridges where vi bra tion and

shock loads may loosen con nec tions

and locations prone to fl ood ing.

8.750"

Mounting

The standard JB1010 has wa ter proof nylon cord grips to seal the

7.875"

4.000" Mounting

ca bles and pro vide strain relief.

Ca ble diameters from 0.157" to

0.314" can be used with these grips.

When in stall ing the cables into the

enclosure, leave the strain re lief

Ø.313"

loose until the con nec tions have

been rout ed with the en clo sure ful ly

open. When com plet ed, tight en the

grips with a wrench to pre vent wa ter

10.750"

from wicking into the box. To prevent water and other contaminants

from entering the junction box, fi ll

any unused cable grips with post screw plugs; P/N 19538.

If cables will be exposed to fl uids, bend a short down ward loop in all cables near the cord grips so any fl uids

draining down the cables will drip off before reaching the junction box (see Figure 2-2).

Use a quality desiccant in the enclosure and replace it at least

every six months. Replace it more often if the en vi ron ment is

very damp or is regularly wetted down.

If using the transient protection grounding feature, install the

fi ttings with a wrench and use an electrical grade lubricant such

®

as WD-40

on threads and fi ttings. Connect the ground lug to a

single system ground rod (if locally connected) or to the grounding lug on the AC tran sient protector for the indicator or load cell power supply.

3.0 General Wiring Guide lines

The JB1010 is a universal trimming board, designed to trim almost any set of new or existing load cells in nearly

any confi guration. To properly wire the JB1010, fi rst determine what kind of application you have.

If the JB1010 is the only trimming junction box in a new system, continue on to the next page.

If the JB1010 replaces one or more boards in an existing system, skip to Section 8.0.

2

Page 6

Wire Preparation

The JB1010 uses spring-loaded, quick-connect wire terminals. These con nec tors are very re li able if used properly.

To prepare the wires, strip 3/8" of in su la tion from the in di vid u al wires. If the con duc tors are

stranded wires, tin the ends of the wires using wire solder with a non-cor ro sive solder fl ux.

Inserting the Wires into the Terminals

Push down on the plastic lever with a pen or small screw driv er to compress the spring. See Figure

3-1. Install the wire into the com pres sion clamps. Push the wire into the con nec tor until the wire

is fully seated. Make sure the clamp is resting on the stripped portion of the wire and not on the

insulation. Release the lever and pull on the wire to make sure it is secure.

4.0 Wiring for New Systems

Use the following procedure to set up a new system.

1. Connect all cells with trimming disabled as shown in Figure 4-1.

2. Connect the cells to the junction box using the connectors marked Sections

1 to 5, Cell A and B. If pairs of load cells are to be trimmed in sec tions (as

with truck or track scales), wire both cells to the same ten-position con nec tor. If using less than ten cells, leave unused connectors empty.

3. If you have an odd number of load cells, connect the odd cell to a Cell A

input unused cell connector. Confi gure that con nec tor as shown in Figure

4-2. You must disable the trim ming to any unused cell connectors, shown

in Figure 4-1.

4. Connect the indicator cable to the terminal strip marked

TO IN DI CA TOR.

Use six wire shielded cable and activate the remote sensing of the in di ca tor.

Remote sensing will compensate for resistance changes due to en vi ron men tal

changes.

TO DISABLE ANY CHANNEL

NO TRIMMING

1 2 3 4 5 6 7 8

O

F

F

ROCKER

DOWN

O

1 2 3 4 5 6 7 8

F

F

Figure 3-1.

Wire Terminals

CELL/SECT

CELL

"B"

"A"

Figure 4-1.

SECT

+EXC

SWB

SECT

-EXC

SWA

5. Turn on the indicator. If the indicator reading appears stable, consider

doing a tem po rary cal i bra tion. Set a known weight on the scale deck and

perform a cal i bra tion se quence to set the sen si tiv i ty of the meter to about

the fi nal cal i bra tion required.

If the sys tem fails to repeat to zero or ex hib its in sta bil i ty, you must fi x

the problem before continuing. You cannot trim a system that will not

re peat.

If all you want to do is connect the cells in parallel, you are fi nished. Do

a fi nal calibration of the system using the zero and span ad just ments on

the weight indicator.

6. If you want to trim the system for matched load cell output, go to Step 1

on the following page.

3

ODD NUMBER OF CELLS

INDIVIDUAL (A) ONLY

1K ISOLATION RESISTORS

O

1 2 3 4 5 6 7 8

F

F

ROCKER

DOWN

O

1 2 3 4 5 6 7 8

F

F

A IS ODD NUMBERED CELL

B IS UNUSED

Figure 4-2.

SIGNAL TRIM

CELL

CELL/SECT

"A"

"B"

SECT

+EXC

SWB

SECT

-EXC

SWA

Page 7

5.0 Trimming Load Cell Output

1 2 3 4 5 6 7

1 2 3 4 5 6 7 8

CELL

"A"

CELL/SECT

"B"

SECT

+EXC

SECT

-EXC

SWB

SWA

SIGNAL TRIM

INDIVIDUAL CELLS

1K ISOLATION RESISTORS

O

F

F

O

F

F

ROCKER

DOWN

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

SECT

+EXC

SECT

-EXC

SWB

SWA

SIGNAL TRIM

SECTIONS ONLY

1K ISOLATION RESISTORS

CELL

"A"

CELL/SECT

"B"

O

F

F

O

F

F

ROCKER

DOWN

5.1 Trimming Individual Cells

1. Determine what and how you want to trim. If the cells will be trimmed

individually, we recommend a sig nal trim mode. While you can select either

2.5KΩ or 1KΩ iso la tion re sis tors, we recommend the 1KΩ resistors.

Engage trim ming for only those ter mi nals which have load cells con nect ed.

If using signal trim for individual cells with 1KΩ iso la tion re sis tors, con fi g ure the switch es as shown in Figure 5-1.

If using a different trimming combination (2.5KΩ resisitors, section trim,

or excitation trim), see Section 7.0 Complete Switch Settings Chart.

2. Turn all potentiometers fully clockwise. This produces the max i mum voltage (minimum trim) on all cells. Always begin with minimum trim; never

“center the pots.”

3. Place a test weight on the scale di rect ly over each load cell in turn to de ter mine which cell has the low est out put. This can be determined by watching

the display on the indicator. This cell will be used as the system ref er ence

and will not be trimmed.

4. Trim individual load cells by placing the test weight over each individual cell in turn. Turn the po ten ti om e ter for that cell counterclockwise until the reading produced by the cell match es that of the ref er ence

cell.

Trim odd-numbered cells using the po ten ti om e ters marked

Cell A; trim even-numbered cells with the

po ten ti om e ter marked Cell/Sect B. It doesn’t matter what the absolute cell outputs are, as long as they

are the same.

5. Readings are somewhat interactive, and you may have to repeat the trimming procedure to get extremely

close matching of outputs.

6. Once the cell outputs are the same, do a fi nal calibration of the system using the zero and span ad just-

ments on the weight indicator.

5.2 Trimming Cells in Sections

Trimming in sections assumes there are an even number of load cells to be trimmed

in pairs. We recommend using the 1KΩ signal trim section mode shown in Fig ure

5-2 if possible.

In this and other confi guration modes using both section and signal trim, the

Sect B potentiometer trims both the A and B load cells. Turn ing the Cell/Sect B

po ten ti om e ter counterclockwise decreases output and trims the section com prised

of the two load cells wired to the con nec tor below the SWA switchbank.

Remember to disable any unused channels as shown in Figure 4-1.

4

Cell/

Figure 5-2.

Page 8

5.3 Trimming Both Individual Cells and Sections (Full Feature)

The following is the trimming procedure for a new installation with 1K double

isolation full loadcell signal and section execitation trim. All other types of calibration should be similar with only dipswitch changes for the required confi guration.

1. Connect all loadcells to the J-Box.

• Set dip switches SWB position 1, 3, 4, 5, 6, 7 ON, and 2 and 8 OFF.

• Set dip switches SWA all in the ON position.

2. Perform a reference point calibration. The scale should be stable and

return to zero after calibration. If it does not do this, correct the problem

in the scale before attempting to do any trimming of the scale.

3. Enable the signal trim for all loadcells.

• Set dip switches SWB all in the ON position.

• Set dip switches SWA position 1, 3, 5, 7 ON, and 2, 4, 6, 8 OFF.

4. Using Pot A and Pot B for their respective cells, trim each loadcell by

placing a test weight on the loadcell that is being trimmed in each section

and trim it's respective pot so that it matches other weight reading of the

other loadcell in that section pair. Do this to each section. The section weights do not have to match the

actual test weight, just the other loadcell in that pair.

ROCKER

FULL FEATURE

INDIVIDUAL TRIM: SIGNAL

SECTION TRIM: EXCITATION

1K ISOLATION RESISTORS

CELL

O

1 2 3 4 5 6 7

F

F

DOWN

O

1 2 3 4 5 6 7

F

F

"A"

CELL/SECT

"B"

SECT

+EXC

8

SWB

SECT

-EXC

8

SWA

5. Enable execitation trim for all loadcells

• Set dip switches SWB position 1 and 7 OFF.

6. Using the pot for sect +exe and sect -exe, trim each section with a test weight so that it matches the

other sections by using a test weight. The value on your indicator may not match your test weight actual

weight.

7. Perform a fi nal calibration. The scale should return back to zero and repeat. Make any small adjustments

as required.

Notes:

Loadcell A pot is a signal trim pot that can be set up as follows:

• with A2 and A4 OFF, do just the odd loadcell signal trim

• with A2, A4, A6, A8, and B2 ON, the pot will do section signal trim.

Loadcell B pot is a signal trim pot that can be set up as follows:

• with A6 and A8 OFF, do just the even loadcell signal trim.

• with A2, A4, A6, A8, and B8 ON, the pot will do section signal trim.

Section +exe pot adjust:

• with B7 OFF, pot will do section +exe trim

Section -exe pot adjust:

• with B1 OFF, pot will do section -exe trim

5

Page 9

6.0 Transient Protection System

The tran sient pro tec tion net work uses gas tubes selected for low leak age to ground in a network that has been

prov en ef fec tive with load cells. Con nect the ground stud on the junction-box enclosure to a suitable low im ped ance ground. If a local ground is used, make sure that it is a single ground rod and not a “net work”. The

best place to ground is to the ground lug on the side of the tran sient suppressor which protects the source of the

ex ci ta tion voltage. This keeps the system on a single point ground.

If the gas tubes are hit by lightning or transients related to lightning, they may begin to leak to ground. This

problem usually shows up as in sta bil i ty, drift, or an overload or underload con di tion on the in di ca tor. If this

occurs, remove the ground wire and see if the problem persists. If it goes away, then the board may be bad or

load cells may be damaged. Use a quality volt me ter with a nano-sieman conductivity range to fi nd the leakage

to ground and cor rect it. Gas tubes that fail while pro tect ing against transients are intentionally sacrifi cial and

not a war ran ty item. They are simply performing their function in the system.

If you think the board may be damaged, record the current DIP switch settings, then reset the DIP switches to

disable all trim ming as shown in Figure 4-1. Disconnect the ground wire from the JB1010. This ef fec tive ly

hooks all cells in parallel, dis ables all trim and isolation, and removes any leakage source to ground. If the

sys tem problems still persist, check the load cell cable and load cells for dam age.

Return the switches to their previous positions you have marked down once the problem has been re paired. If

new cells have been added, they must be trimmed as part of re-calibration.

6

Page 10

7.0 Switchbank SWA and SWB 1-8 Switch Functions

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7

8

SECT

+EXC

SECT

-EXC

SWB

SWA

A IS ODD NUMBERED CELL

B IS EVEN NUMBERED CELL

CELL

"A"

CELL/SECT

"B"

ROCKER

DOWN

O

F

F

O

F

F

A IS ODD NUMBERED CELL

NOTE: A is odd numbered cell, B is even numbered cell, unless otherwise noted.

AWS

1A

noitalosISMHOK1nO

tceleSrotsiseRnoitalosIgiS-llecdaoLddO

noitalosISMHOK5.2ffO

ssapyBrotsiseRnoitalosIgiS-llecdaoLddO

2A

)noitalosISMHOK0(dessapyBrotsiseRnoitalosIgiS-nO

hctiwS1AybdetceleSrotsiseRnoitalosIffO

tceleSrotsiseRnoitalosIgiS+llecdaoLddO

3A

noitalosIrotsiseRSMHOK1nO

noitalosIrotsiseRSMHOK5.2ffO

ssapyBrotsiseRnoitalosIgiS+llecdaoLddO

4A

)noitalosISMHOK0(dessapyBrotsiseRnoitalosIgiS+nO

hctiwS3AybdetceleSrotsiseRnoitalosIffO

tceleSrotsiseRnoitalosIgiS-llecdaoLnevE

5A

noitalosISMHOK1nO

noitalosISMHOK5.2ffO

ssapyBrotsiseRnoitalosIgiS-llecdaoLnevE

6A

)noitalosISMHOK0(dessapyBrotsiseRnotalosIgiS-nO

hctiwS5AybdetceleSrotsiseRnoitalosIffO

tceleSrotsiseRnoitalosIgiS+llecdaoLnevE

7A

noitalosIrotsiseRSMHOK1nO

noitalosIrotsiseRSMHOK5.2ffO

ssapyBrotsiseRnoitalosIgiS+llecdaoLnevE

8A

)noitalosISMHOK0(dessapyBrotsiseRnoitalosIgiS+nO

hctiwS7AybdetceleSrotsiseRnoitalosIffO

BWS

mirTexE-noitceSelbasiD

1B

ffOmirTexE-noitceSnO

nOmirTexE-noitceSffO

elbanEmirTlangiSllecdaoLddO

2B

delbanEmirTllecdaoLddOnO

delbasiDmirTlangiSllecdaoLddOffO

tceleSrotsiseRnoitalosIgiS-llecdaoLnoitceS

3B

4B

5B

noitalosInoitceSrotsiseRSMHOK1nO

noitalosInoitceSrotsiseRSMHOK.2ffO

ssapyBrotsiseRnoitalosIgiS-llecdaoLnoitceS

)noitalosISMHOK0(dessapyBrotsiseRnoitalosIgiS-nO

hctiwS3BybdetceleSrotsiseRnoitalosIffO

tceleSrotsiseRnoitalosIgiS+llecdaoLnoitceS

noitalosInoitceSrotsiseRSMHOK1nO

B IS EVEN NUMBERED CELL

CELL

CELL/SECT

"A"

"B"

SWB

O

1 2 3 4 5 6 7 8

F

F

SECT

+EXC

noitalosInoitceSrotsiseRSMHOK.2ffO

ssapyBrotsiseRnoitalosIgiS+llecdaoLnoitceS

6B

)noitalosISMHOK0(dessapyBrotsiseRnoitalosIgiS+nO

hctiwS5BybdetceleSrotsiseRnoitalosIffO

mirTexE+noitceSelbasiD

7B

ffOmirTexE+noitceSnO

nOmirTexE+noitceSffO

ROCKER

DOWN

O

1 2 3 4 5 6 7

F

F

SWA

8

SECT

-EXC

elbanEmirTlangiSllecdaoLnevE

8B

delbanEmirTllecdaoLnevEnO

delbasiDmirTlangiSllecdaoLnevEffO

7

Page 11

8.0 Using the JB1010 In an Existing System

Large vehicle scales often have two, three, or four junction boxes connected into a network. When servicing

these scales, you don’t have a choice of what’s going to fail. When one of the junction boxes fails, it shuts the

whole scale down. The service technician rarely has the right board with him to replace a third party junction

board. As a universal board, the JB1010 can usually serve as a replacement.

The JB1010 can be adapted to match almost any common (and some uncommon) summing boards. To do this,

you can study the old board, look for isolation resistors, and see how the trimming works. Sometimes, however,

you have to make an intelligent guess.

Most large trimming boards use signal trim. If you see a large number of resistors on the circuit board, it is a good

bet that the board is a signal trim board. Most signal trim boards either have 2.5KΩ or 1KΩ isolation resistors.

If the board has both individual cell and section trimming, then there are often two sets of isolation resistors.

Use the following strategy to identify and match existing trim boards:

1. Are there many resistors on the existing board? If so, what is the value of the ones most prevalent on

the board. These are almost always the isolation resistors. If you can’t read the value, guess 2.5KΩ.

2. Are there any adjustment potentiometers for individual cells? Are there any adjustment po ten ti om e ters

for sections? Are there both? If there is only a single set of potentiometers, then use the value of the

isolation resistors. Guess 2.5KΩ if you aren’t sure. If there are both individual and section trimpots,

then choose the double isolation examples shown Section 7.0.

3. If you can’t fi nd any isolation resistors, set up the board to disable trimming. Read on to tell if the trim

you have selected is correct. Disable any unused channels.

4. If the junction box you are replacing has an expansion port, use any unused cell (disable trim on it fi rst)

as the expansion output.

In any case, power up the system and see if the indicator appears to work. If you get stable numbers, you are

on the right track.

If you are using signal trimming, you can tell if the isolation resistors match by the output of the cells. Put a

weight on cells connected to the existing box and record the value. Put the same weight on a cell connected

to the JB1010. If the reading is nearly the same, then the isolation resistor setting is probably correct. If the

weight from the JB1010 is much too high, then the isolation resistors you have chosen are too low for the rest

of the system or the system may have two layers of isolation resistors. If the weight from the JB1010 is much

too low, then the isolation resistors you have chosen are too high for the rest of the system. You must match

the isolation resistors as closely as possible so that the cell outputs are nearly the same. Once this matching is

done, then trim the total system like any other scale.

8

Page 12

9.0 Schematic Drawing of Connector Section (Two Load Cells)

–SIGNAL BUSS +SIGNAL BUSS

A2

BYPASS

ISOLATION

B4

BYPASS

ISOLATION

A1

1K/2.5K SELECT

2.49K 1.66K

A4

B2

100KΩ

CELL A

TRIM ENABLE

+E

–S +S

REF ONLY

1K/2.5K SELECT

2.49K 1.66K

2.49K 1.66K

BYPASS

ISOLATION

4.99K

B3

1K/2.5K SELECT

B6

A3

BYPASS

ISOLATION

2.49K 1.66K

A6

BYPASS

ISOLATION

B5

1K/2.5K SELECT

A5

1K/2.5K SELECT

2.49K 1.66K

100KΩ - CELL B

–S

A8

B8

TRIM ENABLE

+E

REF ONLY

BYPASS

ISOLATION

4.99K

+S

A7

1K/2.5K SELECT

2.49K 1.66K

–E

B1 B7

10Ω

100Ω

–EXC BUSS

9

–E

10Ω

+EXC BUSS

100Ω

Page 13

Page 14

PN 36329 11/2011

Loading...

Loading...