Page 1

86547

IGB/IGX Series

(Overseas Specifications)

Service Manual

The First Edition

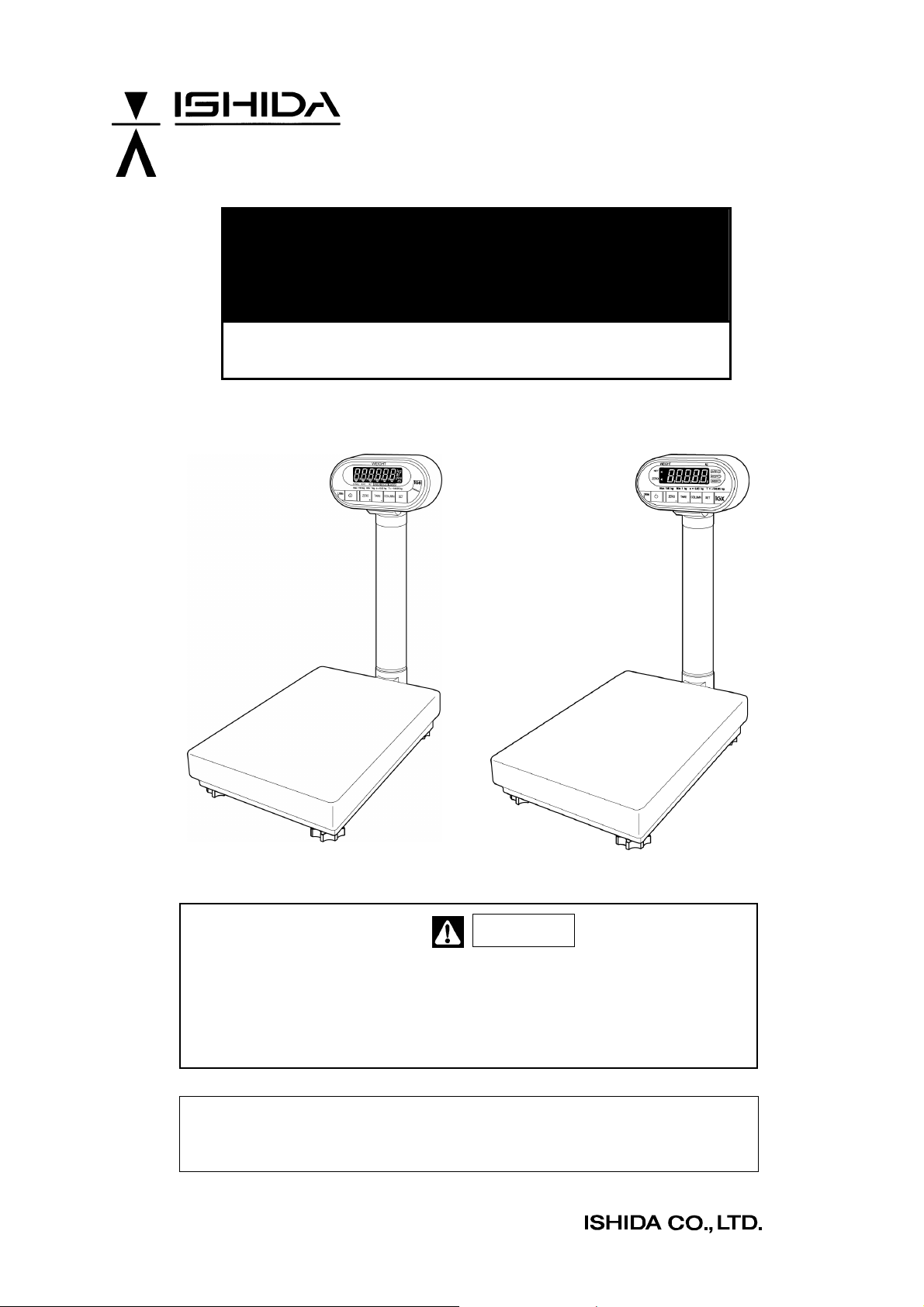

IGB Series IGX Series

Read this manual thoroughly and do not perform installation, operation,

maintenance, or inspection unless you fully understand all of the contents.

Keep this manual in a safe place where you can refer to it easily while

installing, operating, and carrying out maintenance or inspections.

This manual is for use by service personnel of our company or qualified to

perform maintenance services for this machine. Use by anyone except the

above personnel is not permitted.

Manual No. 085-3435-07

Warning

Page 2

CONTENTS

CHAPTER 1. PRODUCT OVERVIEW ..................................................................................................3

1.1 Machine Outline.............................................................................................................................3

1.2 Standard Specifications .................................................................................................................3

1.3 Appearance ...................................................................................................................................5

1.4 Display Unit ...................................................................................................................................6

1.5 Outer Dimensions..........................................................................................................................7

CHAPTER 2 TEST MODE.....................................................................................................................9

2.1 Operation.......................................................................................................................................9

2.1.1 Starting Each Mode ................................................................................................................9

2.1.2 Ending Test Mode...................................................................................................................9

2.1.3 Test Mode Flow ....................................................................................................................10

2.1.4 Key Functions.......................................................................................................................10

2.1.5 Mode List..............................................................................................................................11

2.2 C1 Mode (Country No., Scale No., Zero point, Span adjustment)................................................12

2.2.1 Country No. Table.................................................................................................................12

2.2.2 Scale No. Table ....................................................................................................................13

2.2.3 Operation Procedure ............................................................................................................14

2.3 C2 Mode: Key Check...................................................................................................................18

2.4 C3 Mode: Display Check 1 (Simplified Check) ............................................................................18

2.5 C4 Mode: Display Check 2 (Detailed Check)...............................................................................19

2.6 C5 Mode: Program No Display ....................................................................................................19

2.7 C6 Mode: RAM Clear and E2ROM Clear ....................................................................................20

2.8 C7 Mode: Weighing Condition Setting.........................................................................................21

2.9 C8 Mode: E2ROM Data Reading.................................................................................................24

2.10 C9 Mode: Board Inspection (A/D Check, I/F Check)....................................................................26

CHAPTER 3 HARDWARE CONFIGURATION ...................................................................................27

3.1 Mechanical Parts .........................................................................................................................27

3.1.1 Load Cell ..............................................................................................................................30

3.2 Electric Parts (IGB Series)...........................................................................................................31

3.2.1 IGB Block Diagram ...............................................................................................................31

3.2.2 Main Board (PS-018)............................................................................................................32

3.2.3 Power Board (PS-019) .........................................................................................................33

3.3 Electric Parts (IGX Series)...........................................................................................................34

3.3.1 IGX Block Diagram ...............................................................................................................34

3.3.2 Main Board (PS-016)............................................................................................................35

CHAPTER 4 MAINTENANCE .............................................................................................................37

4.1 Disassembly Procedure for Display Unit......................................................................................37

4.2 Replacement of Main Board ........................................................................................................38

4.2.1 IGB Series ............................................................................................................................38

4.2.2 IGX Series ............................................................................................................................39

4.3 Replacing and Adjusting Load Cell ..............................................................................................41

4.3.1 Checking and Adjusting Gap of Four-corner Limit ................................................................42

4.3.2 Performing Zero Point and Span Adjustments......................................................................43

4.4 Troubleshooting ...........................................................................................................................44

Manual No. 085-3435-07 1/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 3

OUTLINE

• Purpose of this manual

• This manual is to be used as a reference for the maintenance servicing of IGB or IGX series.

• Related manual

• For placing the product, mounting the display pole, setup mode and setup values, refer to the

operation manual.

• Symbols in the description

1. Warning symbols

Symbol Meaning

Danger

Warning

Caution

Indicates information that, if not heeded, is likely to result in loss of life or serious

injury.

Indicates information that, if not heeded, may result in loss of life or serious

injury.

Indicates information that, if not heeded, could result in relatively serious injury,

damage to the machine or faulty operation.

2. Explanatory symbols

Symbol Meaning

Note

Indicates additional information of particular importance.

Reference

Information

Reference

Information

Indicates a page to refer to.

Indicates information to help you understand the related text.

• Readers of this manual

This manual is designated for use by servicing personnel. Use by other personnel is not permitted.

• This manual may be revised in accordance with modifications to the machine.

• All rights are reserved. Copying any part of this manual is prohibited without the permission of Ishida.

Manual No. 085-3435-07 2/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 4

Chapter 1. Product Overview

1.1 Machine Outline

• The base of software used is the same as that of the IGB and IGX Series. Therefore, the Setup and

Test mode items are same as those of the IGB and IGX Series. The machine functions are available

within these standard specifications.

• A check function of the upper and lower weight limits are standardly provided with the IGB and IGX

Series.

• The main board is different from that of the IGB and IGX Series. However, basic operations are same

for these models.

• For the IGB Series, an LCD is adopted, and either two dry batteries or an AC adapter can be used as a

power source.

• For the IGX Series, a VFD is adopted, and a wide selection of power sources ranging from 100 VAC to

240 VAC is available.

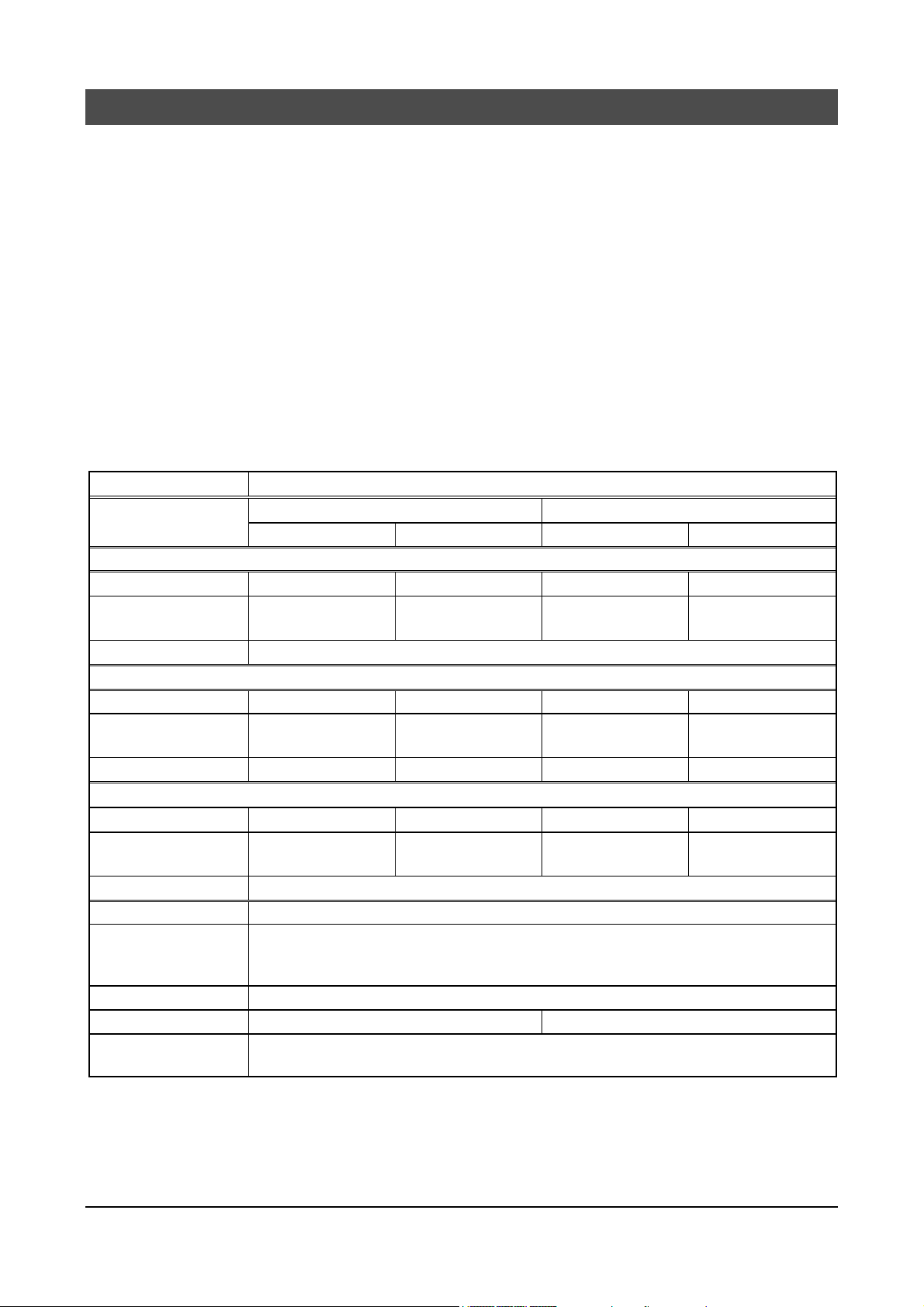

1.2 Standard Specifications

Item Contents

Model Name

OIML R76 Class III

Weighing Capacity 60kg 150kg 60kg 150kg

Graduation 0.02kg 0.05kg 0.02kg 0.05kg

Accuracy 1/3000

Non-OIML (ASIA)

Weighing Capacity 60kg 150kg 60kg 150kg

Graduation 0.01kg 0.02kg 0.01kg 0.02kg

Accuracy 1/6000 1/7500 1/6000 1/7500

lb/kg Switching Specification (USA)

Weighing Capacity 150lb/60kg 300lb/150kg 150lb/60kg 300lb/150kg

Graduation 0.05lb/0.02kg 0.1lb/0.05kg 0.05lb/0.02kg 0.1lb/0.05kg

Accuracy 1/3000

Weighing Platter 550mm (L) x 400mm (W)

Exterior Material

Display Angle Adjust Angle adjustable from the horizon (0°) to the front, Knob locking method

Weight 16.0kg (excluding batteries) 16.8kg

Environmental

Condition

IGB-60 IGB-150 IGX-60 IGX-150

Display: ABS resins

Display pole: Aluminum die-cast

Weighing platter: Stainless (SUS304)

Temperature from -5°C to +40°C, Relative humidity 80%RH (max.) without condensation

IGB Series IGX Series

Manual No. 085-3435-07 3/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 5

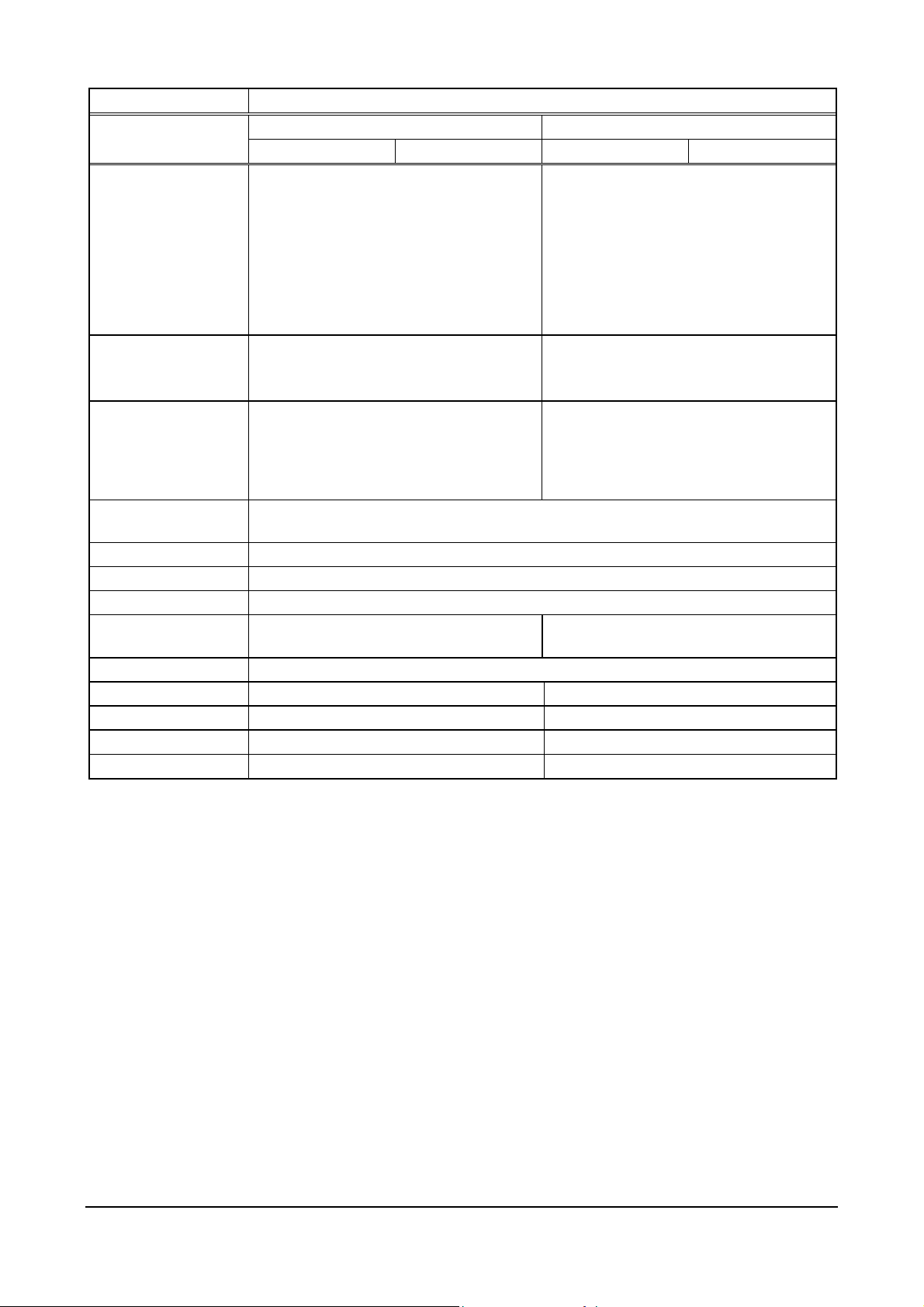

Item Contents

Model Name

Power Source

Power Consumption 25mA

Display LCD

Tare Subtraction Key-in tare

Preset Function [Program Mode] 10 PLUs from PLU 1 to PLU 10 (Tare weight, Upper limit, Lower limit)

Upper Limit Range More than the lower limit, within 5 digits (99999)

Lower Limit Range Less than the upper limit, (5 digits in case of the upper limit = 0)

Auto Power Off [Setup Mode] None/10min./ 20min./ 30min./

Auto Preset Call-up [Setup Mode] Function “Yes”/”No” selection (PLU 1 is called up when the power is ON.)

Battery Check Mode Yes No

Buzzer No [Setup Mode]

ON/OFF Switch No [Setup Mode]

Option AC adapter (Dealer option)

IGB-60 IGB-150 IGX-60 IGX-150

Two dry batteries (not included with the

machine), or optional AC adapter

[Battery Life]

Conditions: No option, Temperature 20°C,

Relative humidity 60%RH

Two “D” size alkaline batteries (Approx. 500H

continuous use)

Numerics: 6 digits, Height 25mm

Mark: Battery. Zero point, Now subtracting

tare, Stable, Weight unit (kg・lb), Over,

Under, Accept

Preset tare

40min./ 50min./ 60min.

IGB Series IGX Series

The required transformer is provided for

each 100VAC, 120VAC, 220VAC, or

240VAC.

100VAC: 57mA

120VAC: 46mA

220VAC: 28mA

240VAC: 23mA

VFD

Numerics: 5 + 1/2 digits, Height 29mm

Mark: Zero point, Now subtracting tare

LED

Over, Under, Accept

No

Manual No. 085-3435-07 4/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 6

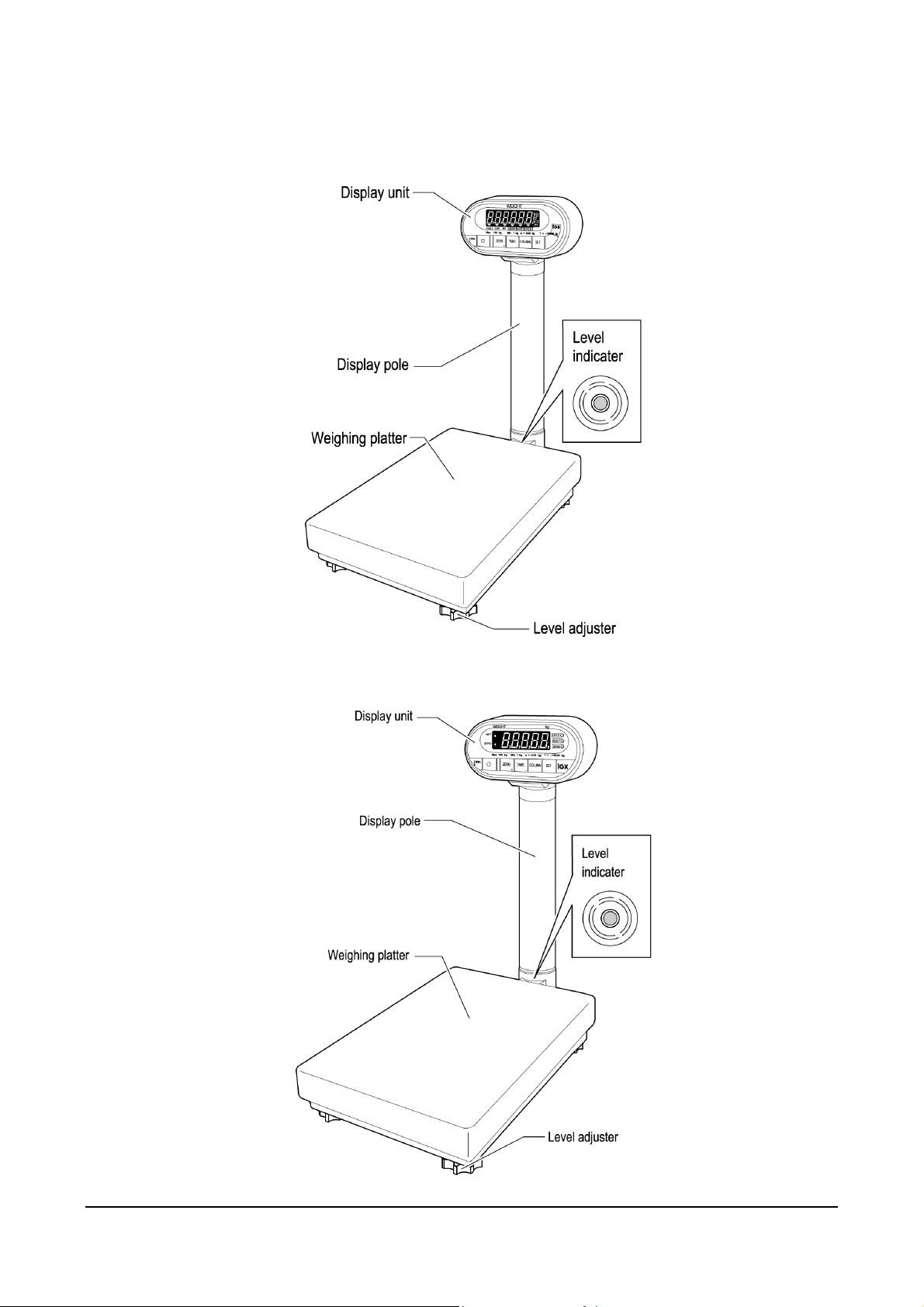

1.3 Appearance

IGB Series (Asia/Oceania Specification)

IGX Series (Asia/Oceania Specification)

Manual No. 085-3435-07 5/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 7

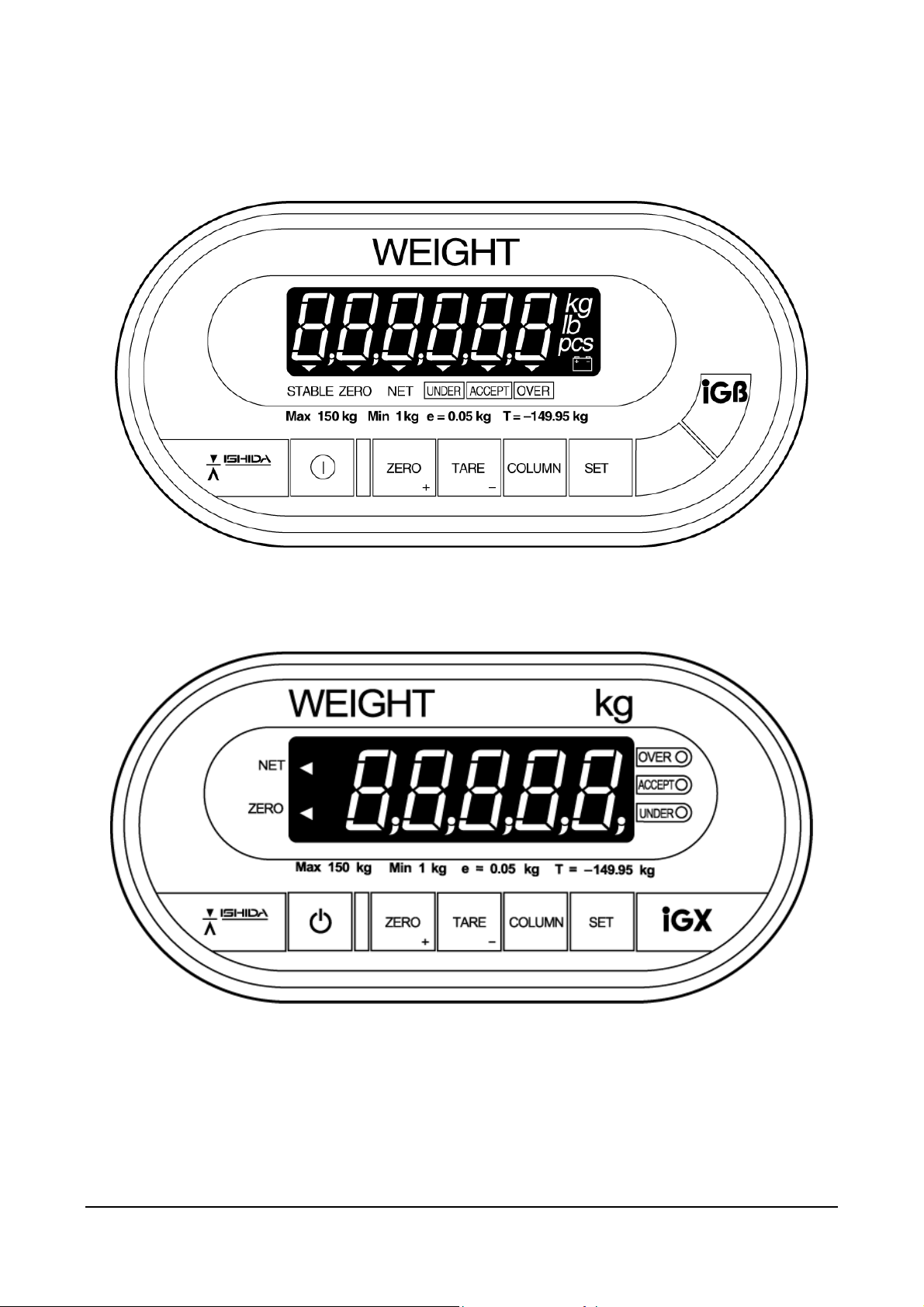

1.4 Display Unit

IGB Series (Asia/Oceania Specification)

IGX Series (Asia/Oceania Specification)

Manual No. 085-3435-07 6/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 8

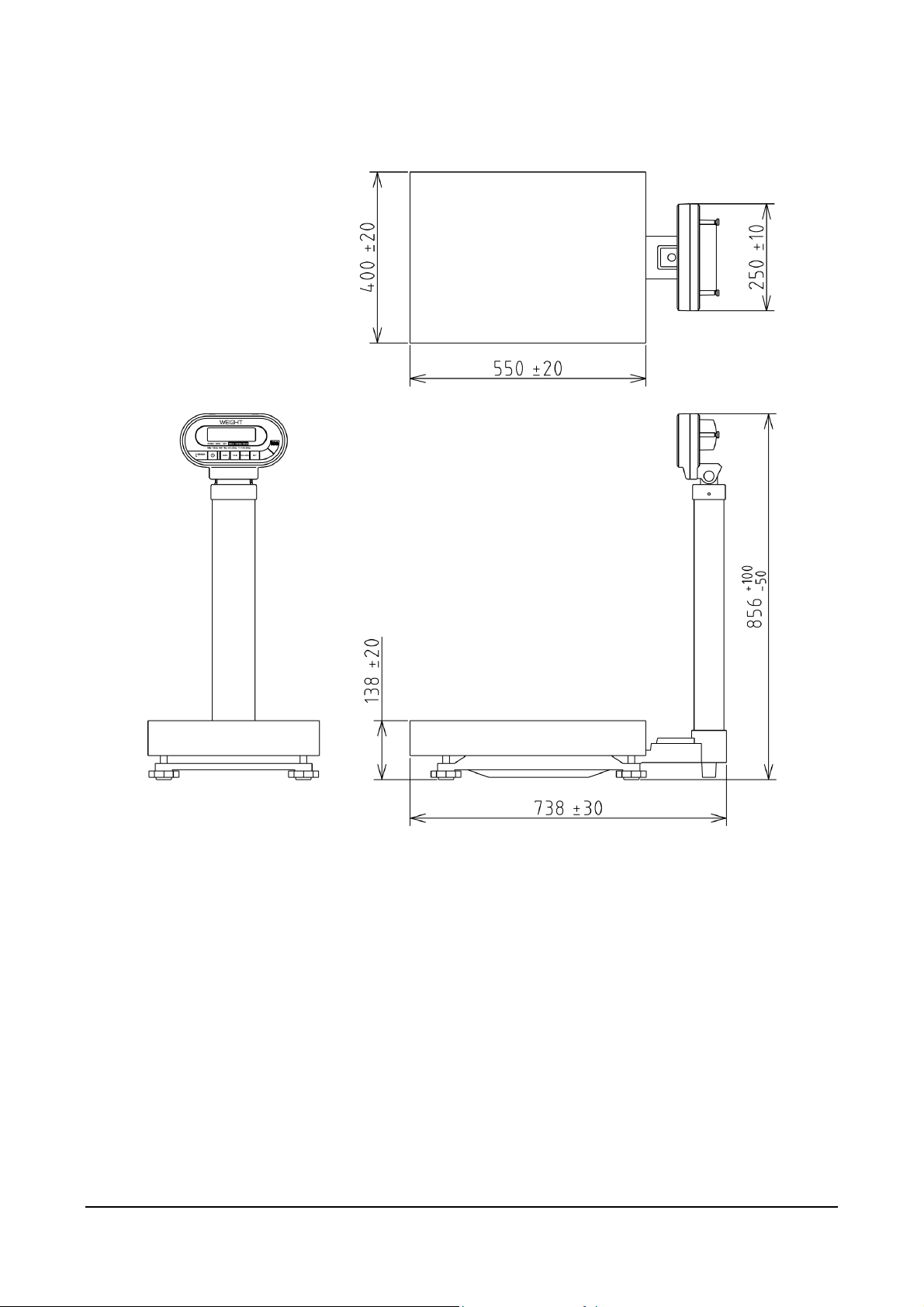

1.5 Outer Dimensions

(Unit: mm)

Manual No. 085-3435-07 7/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 9

memo

Manual No. 085-3435-07 8/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 10

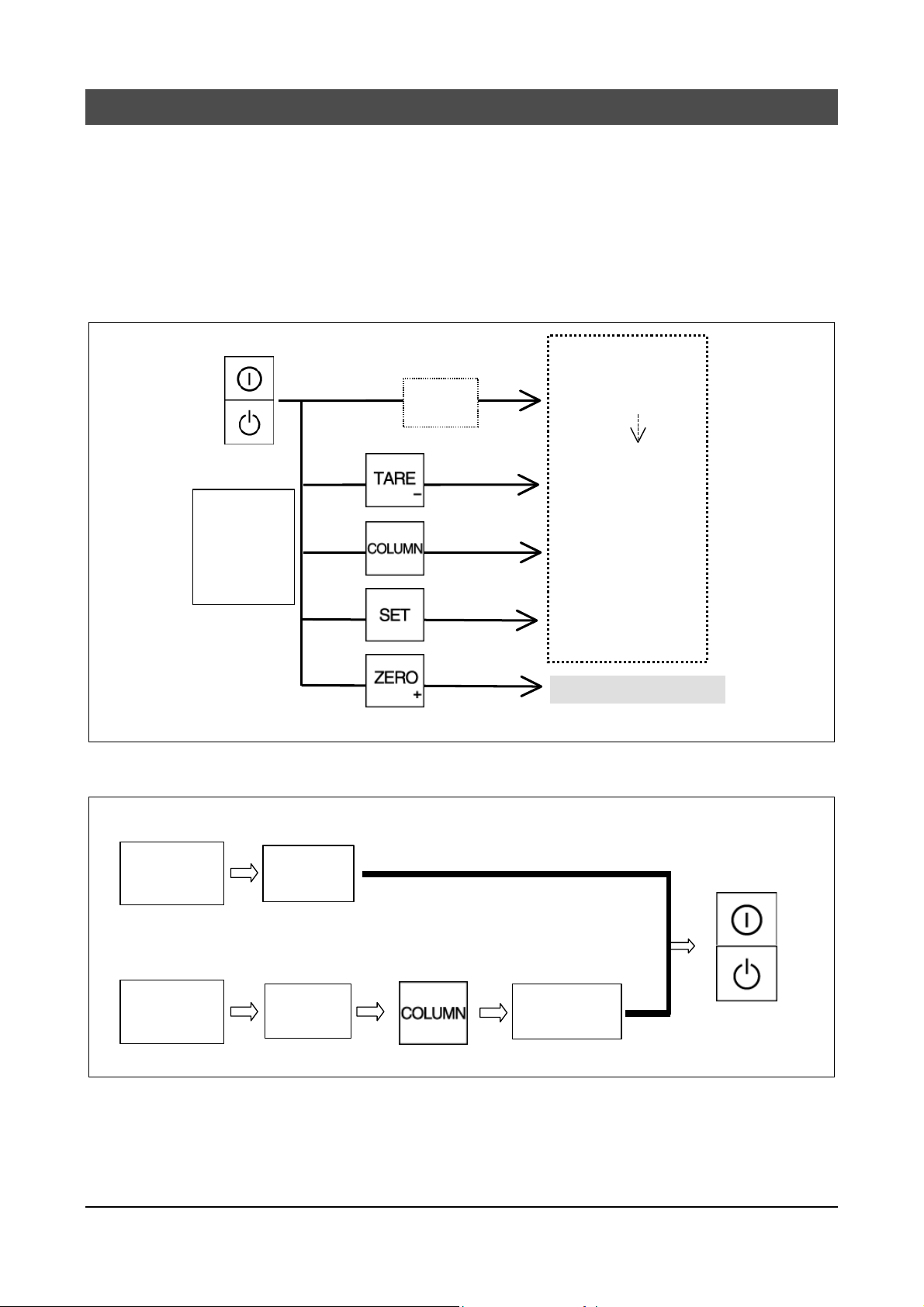

Chapter 2 Test Mode

The Test Mode is used to check the machine when maintenance is performed or to perform settings.

2.1 Operation

The keys used in the following diagram are for Asia/Oceania specifications. For specifications for other

countries, use the corresponding keys.

2.1.1 Starting Each Mode

Scale ON

Release

ON/OFF key,

Then press one

of these keys

while all

segments are

illuminated

Start

Check

Operation Manual

Normal Mode

Voltage Check

(IGB only)

Setup Mode

Program Mode

Test Mode

2.1.2 Ending Test Mode

C1 Mode

C2 Mode

C3 to C9

Mode

In Mode

In Mode

Press for 2 seconds or more

You cannot return to Cx mode.

C3 to C9

Mode

Scale OFF

Manual No. 085-3435-07 9/45 IGB/IGX Series (Overseas Specifications) Service Manual

Page 11

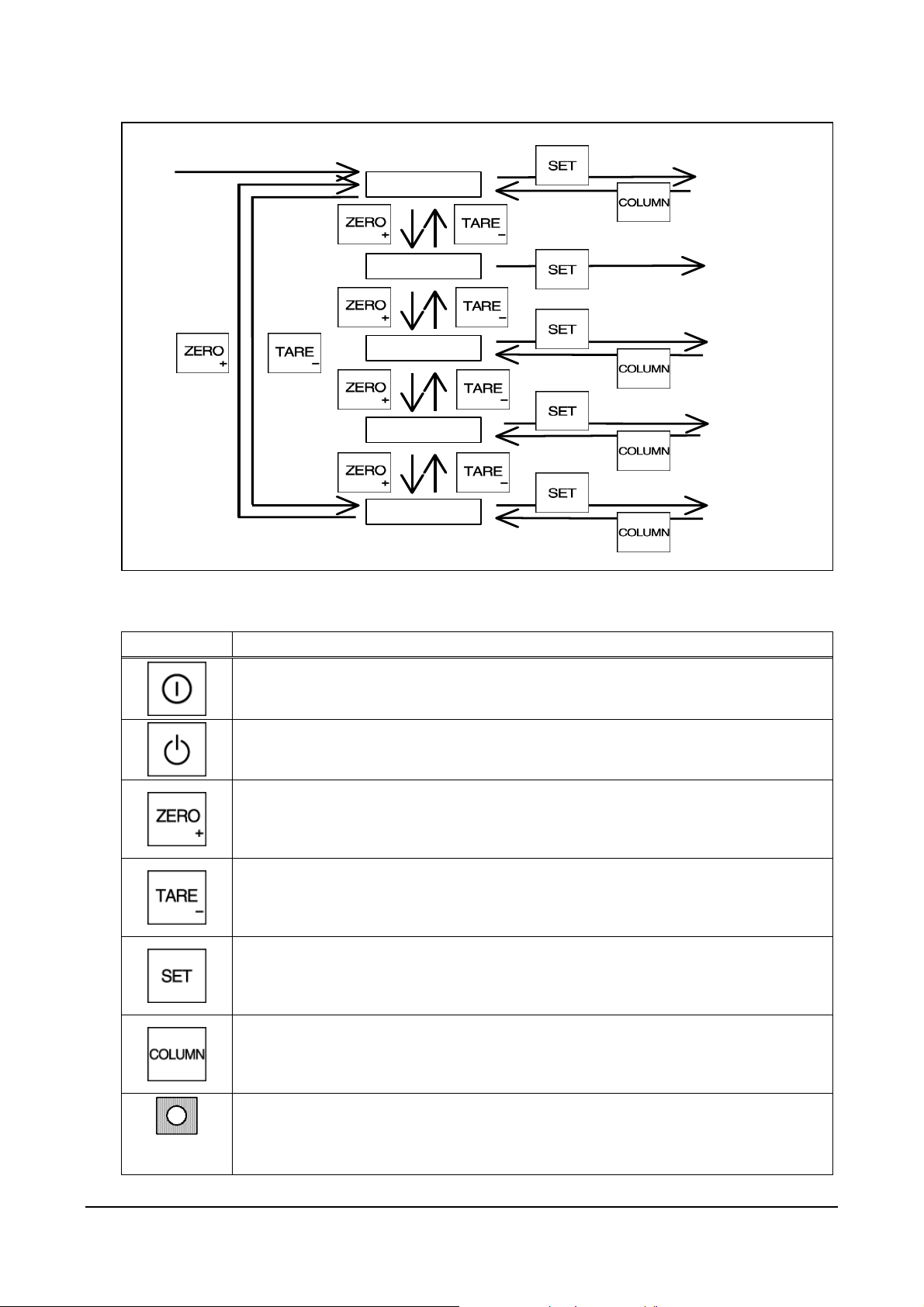

2.1.3 Test Mode Flow

2.1.4 Key Functions

C1

C2

C3 to C6

C8, C9

C7

To each C1

mode setup

Key check

mode

Each mode

operation

Scale function

Setup mode

Each mode

operation

Key Function

Turns the power ON or OFF for the IGB Series.

Turns the power ON or OFF for the IGX Series.

+5V is always supplied to the circuit voltage.

Increases the numeric value (when the numeric value is set).

Advances the mode (when conditions are set).

Adjusts the zero point.

Decreases the numeric value (when the numeric value is set).

Reverses the mode (when conditions are set).

Adjusts the span point.

Determines the data in the Details Mode.

Changes between “+ Adjust” (ZERO ³ key [u display]) and “- Adjust” (TARE key

[d display]) when the span is adjusted.

Returns to each mode.

(Tact switch on the main board)

Saves the E2ROM data of each item setting of C1 mode.

Memory

switch

Manual No. 085-3435-07 10/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 12

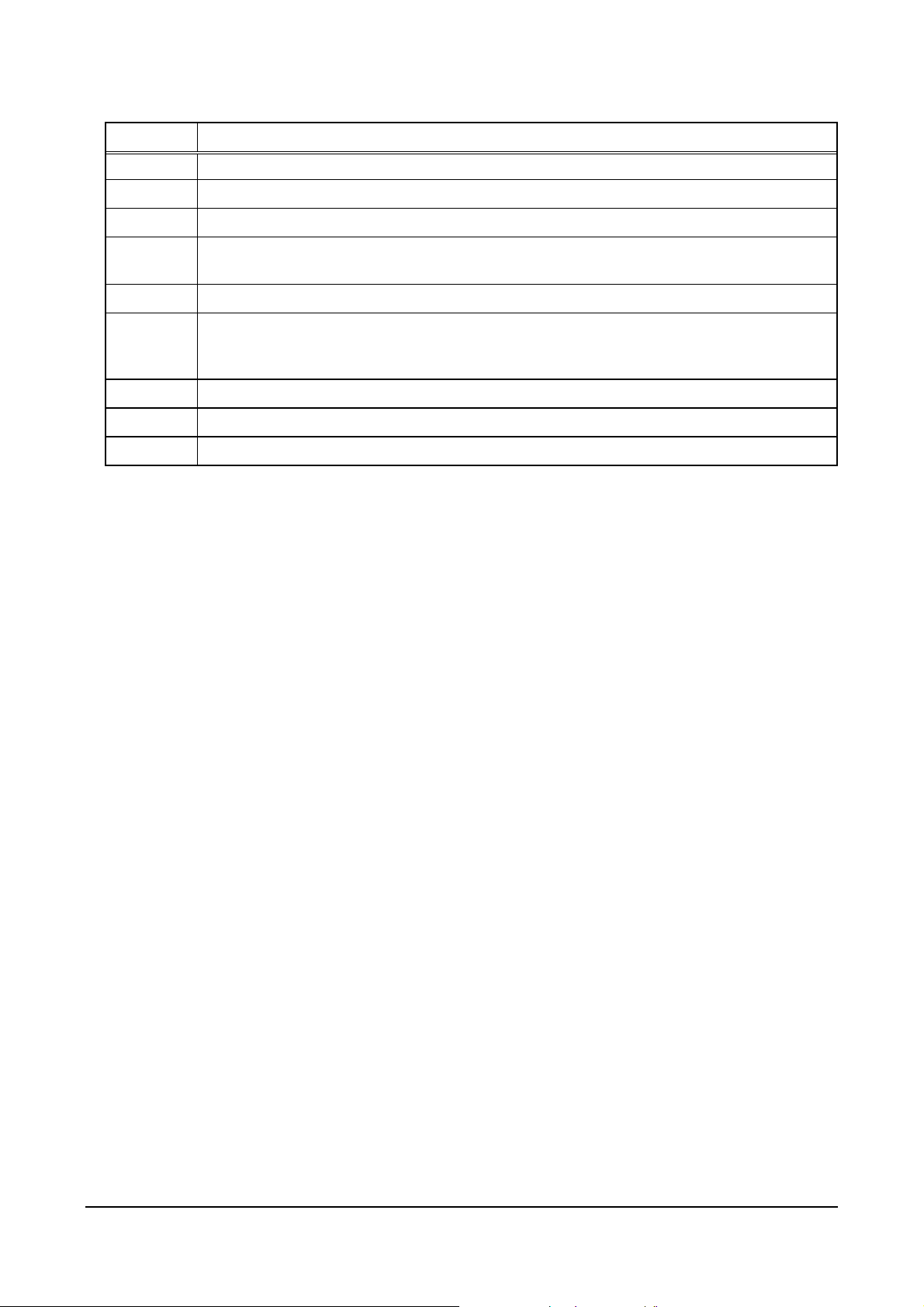

2.1.5 Mode List

Mode Contents

*C1 Country No., Scale No., Zero point, Span adjustment

C2 Key check

C3 Display check 1 (simplified check), All LEDs light up

C4

C5 Program No. display

*C6

*C7 Settings for weighing conditions

C8 Reading E2ROM data

C9 Board check (A/D check, Interface check) for factory inspection

Display check 2 (detailed check), Each segment lights in sequence for each display

digit.

RAM clear (Program mode data)

E2ROM clear (Program mode data and Test mode C1 data)

(Span adjustment is required)

Manual No. 085-3435-07 11/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 13

2.2 C1 Mode (Country No., Scale No., Zero point, Span adjustment)

e

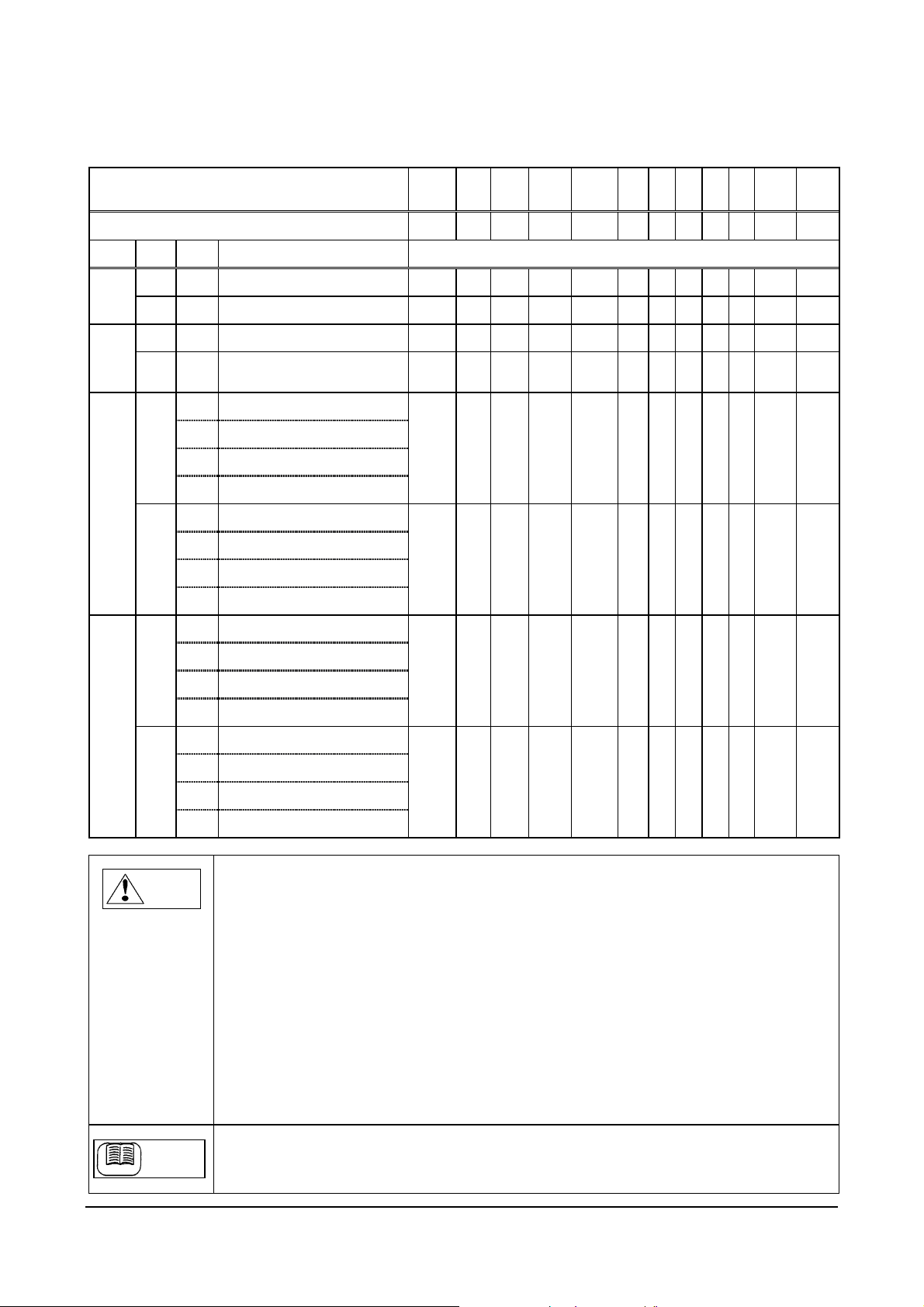

2.2.1 Country No. Table

Country Name USA 1 EU AUS ASIA USA 2 JPN

Country Code 0 1 2 3 4 5 6 7 8 9 10 99

ADRS POS WGT Function Default Data (Change not allowed)

112 A H Start width 2 2 2 2 2 2 2 2 2 2 4 -

B H Stable/Re-stable count 3 3 3 3 3 3 3 3 3 3 3 -

113 A H Stable/Re-stable width 4 4 4 4 4 4 4 4 4 4 4 -

B H

114 A 1 Zero point mark

2 Over-scale display

4 Display less than true zero

8 Decimal point display

B 1 Over-scale range

2 Tare subtraction

4 Tare clear with ZERO key

8 Zero suppress

115 A 1 Key-in tare subtraction

Re-stable operation start width

4 4 4 4 4 4 4 4 4 4 4 -

2 8 0 8 2 8 0 8 4 0 5 -

0 6 6 0 0 6 6 0 0 6 0 -

IDV

SET

2 Zero tracking

4 Micro weight follow-up

8 Unstable width

B 1 PLU display (IGB only)

2 Stable display (IWB only)

4 Reserved

8 Reserved

1. By setting the country code, weighing conditions will function based on the default data from

Note

address 112 to 115.

2. The data is set to meet certified conditions for each country, so there is no need to change the

data.

3. Position “A” indicates the upper position of one-byte data, and “B” indicates the lower position.

4. As for Weight, a function is selected with “1”, “2”, “4”, and “8” in bit unit, and “H” indicates

Hexadecimal data.

5. Individual setting value “99” cannot be entered. (Displayed only when settings are changed in C7

mode)

6. “USA 2” code is settings to allow changing between “lb” and “kg” at anytime even in cases other

than a stable condition at zero point. (“USA 1” can change between “lb” and “kg” only when the

condition is stabilized at zero point)

When using this function, a maximum of 0.2e error may occur in weighing immediately after the

change. This error is calibrated by zero point adjustment (or zero tracking), and an accurate

weighing is guaranteed.

When selecting the weighing capacity exclusively for either “lb” or “kg”, use “USA 1”.

0 0 0 0 0 0 0 0 0 0 4

0 6 6 6 4 6 6 6 5 5 5

-

-

Refer to “Weighing Condition Data Table” for detailed function selection.

Refe re nc

Reference

Manual No. 085-3435-07 12/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 14

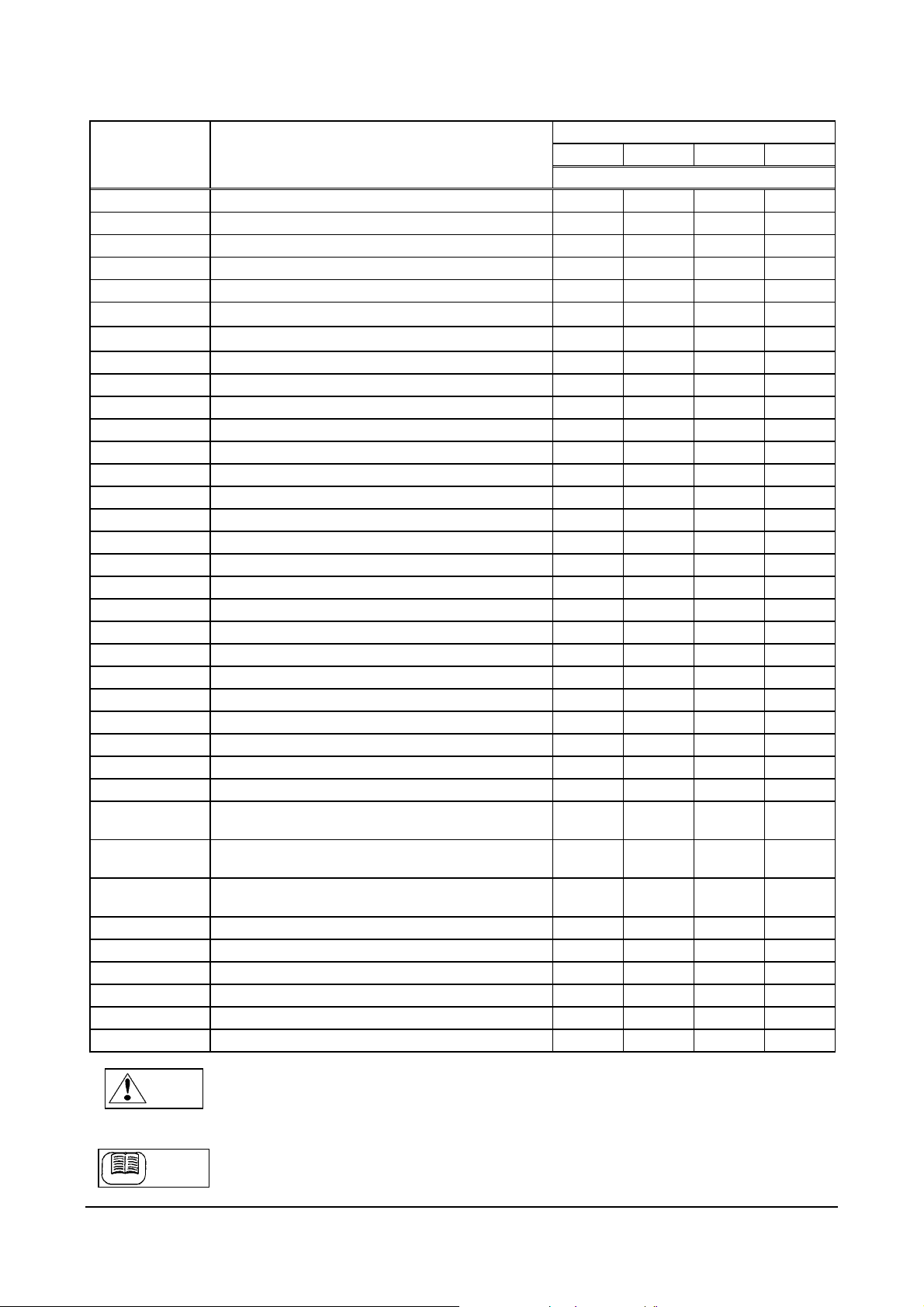

2.2.2 Scale No. Table

e

Scale No. Specifications

0 150kg (0.05kg/0.02kg) Multi Interval 6 C 3 8

1 60kg (0.02kg/0. 01kg) Multi Interval 2 B 3 8

2 30kg (0.01kg/0.005kg) Multi Interval B B 3 8

3 15kg (0.005kg/0.002kg) Multi Interval 7 C 3 8

4 6kg (0.002kg/0.001kg) Multi Interval 3 B 3 8

5 6000g (2g/1g) Multi Interval 0 B

6 3000g (1g/0.5g ) Multi Interval 9 B

7 120kg (0.02kg) 1/6000 Single Range 6 B 2 8

8 60kg (0.01kg) 1/6000 Single Range 2 B 2 8

9 30kg (0.005k g) 1/6000 Single Range B B 2 8

10 15kg (0.002kg) 1/7500 Single Range 7 B 2 8

11 6kg (0.001kg) 1/6000 Single Range 3 B 2 8

12 300kg (0.1kg) 1/3000 Single Range 1 B 2 8

13 150kg (0.05kg) 1/3000 Single Range A 8 2 8

14 60kg (0.02kg) 1/3000 Single Range 6 8 2 8

15 30kg (0.01kg) 1/3000 Single Range 2 8 2 8

16 15kg (0.005kg) 1/3000 Single Range B 8 2 8

17 6kg (0.002kg) 1/3000 Single Range 7 8 2 8

18 6000g (2g) 1/3000 Single Range 4 8 A 8

19 3000g (1g) 1/3000 Single Range 0 8 A 8

20 150kg/60kg (0.05kg/0.02kg) Dual Range 6 C 5 8

21 60kg/30kg (0.02kg/0.01kg) Dual Range 2 B 5 8

22 30kg/15kg (0.01kg/0.005kg) Dual R ange B B 5 8

23 15kg/6kg (0.005kg/0.002kg) Dual Range 7 C 5 8

24 6kg/3kg (0.002kg/0.001kg) Dual Range 3 B 5 8

25 6000g/3000 (2g/1g) Dual Range 0 B D 8

26 3000g/1500 (1g/0.5g) Dual Range 9 B D 8

27 150kg/150k (0.1kg/0.05k g Dual Range

Fishery specification

28 150kg (0.05kg) 1/3000 Single Range

Body weight specification

29 30kg (0.01kg) 1/3000 Single Range

Baby scale specification

30 300lb/150kg (1/3000) Multi Interval 6 C 7 8

31 150lb/60kg (1/ 3000) Multi Interval 2 B 7 8

32 60lb/30kg (1/3000) Multi Interval B B 7 8

33 30lb/15kg (1/3000) Multi Interval 7 C 7 8

34 15lb/6kg (1/3000) Multi Interval 3 B 7 8

99 Individual scale settings - - - -

1. By setting the Scale No., the scale will function acc ording to default data of addresses 110 and

111.

2 The above data determines each specificati on, so changing the data is prohibited.

3 Data A indicates the upper position of the on e-byte data, and B indicates the lower position.

Refer to “Weighing Condition Data Table” for data details.

Referenc

Note

Reference

Address

110A 110B 111A 111B

Default Data

B

B

8

8

A 8 5 8

A 8 4 2

2 8 4 2

Manual No. 085-3435-07 13/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 15

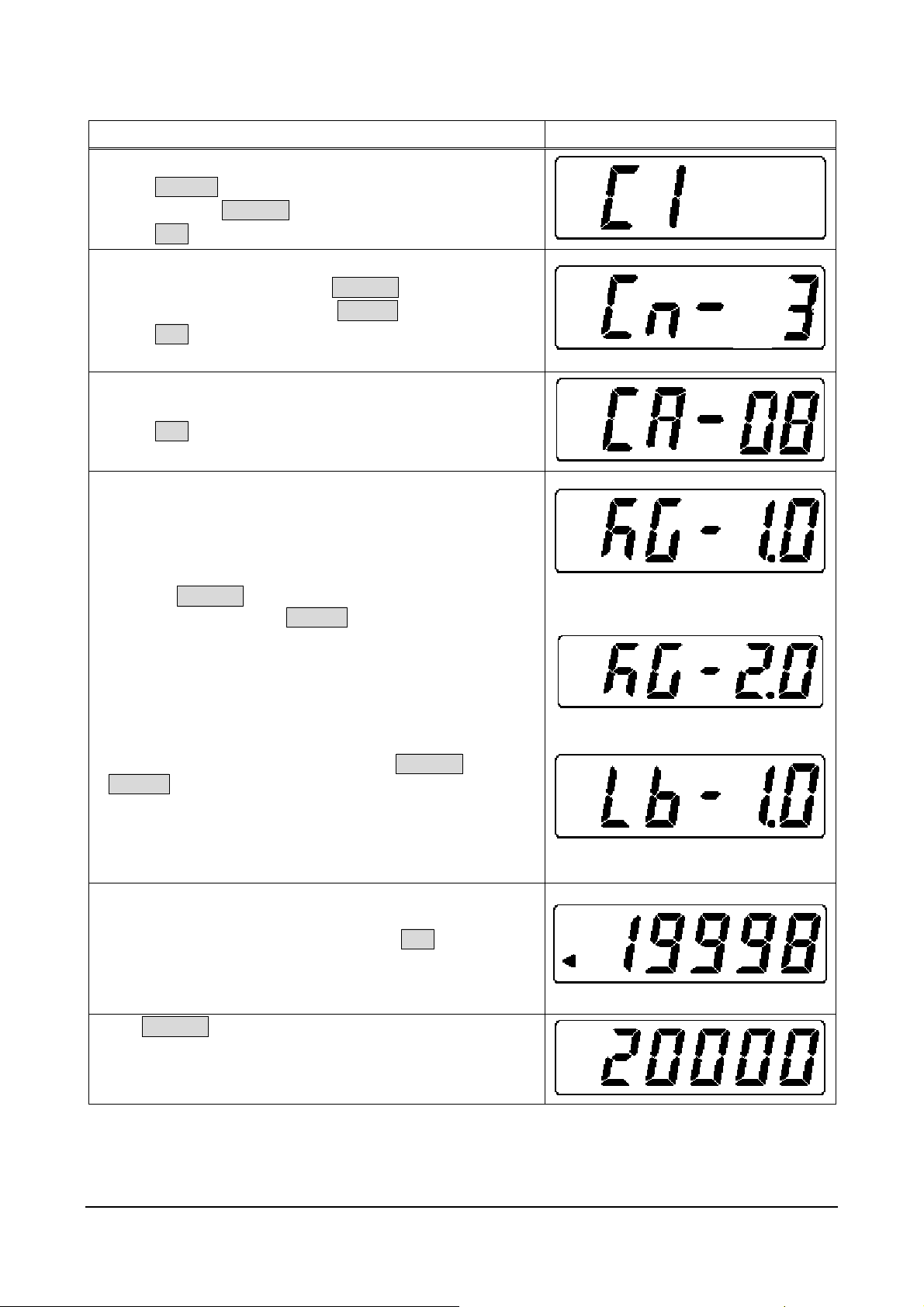

2.2.3 Operation Procedure

Operation Display

1. Starting Test Mode (C1)

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

Press SET.

2. Setting Country Number

To increase the number, press ZERO(+).

To decrease the number, press TARE(-).

Press SET.

[Example] Asia = 3

3. Setting Scale Number

When setting “60kg”, select “08”.

Press SET.

4. Selecting Weight at Span Adjustment

The following weight can be selected:

kg: 1/1.0→1/2.0→1/2.5→1/5.0 of weighing capacity

lb: 1/1.0→1/2.0→1/2.5→1/5.0 of weighing capacity

・ Pressing ZERO(+) selects the next item in the above

sequence, and pressing TARE(-) selects the previous item.

kg unit: Same weight is used as weighing

capacity.

[Example] Selecting “kg” unit and “1/2.0” for weighing

capacity “150kg” will require the total 75kg

weight.

To change between “lb” and “kg”, press ZERO(+) and

TARE(-) at the same time.

5. Zero Point Adjustment

After selecting the weight amount, ensure that nothing is

placed on the weighing platter, then press SET.

The previously set zero point A/D data will be displayed.

Zero point indicator W will light up.

Press ZERO(+) to set “20000” counts forcibly.

Zero point indicator W will go off.

kg unit: Half weight is used of weighing

capacity.

lb unit: Same weight is used as weighing

capacity.

Manual No. 085-3435-07 14/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 16

Operation Display

6. Span Adjustment

Place the selected weight on the weighing platter, then press

TARE(-).

[Example] 60kg Scale: Weight selection: “kg” unit and “1/1”

Place a 60kg weight, 30000 + Zero point 20000 =

50000 counts

In case of “kg” unit “1/2” for a weight selection, place

a 30kg weight, then 15000 + Zero point 20000 =

35000 counts

・ One graduation equals 5 counts.

Processing is automatically executed in the following order:

[Calib] (Calibration) Computing process executing

[C- OK] (Calibration OK) Computing result succeeded

[No. of adjusted counts] Computing result

[C-Err] will be displayed, indicating a computing result error

when span adjustment is performed without placing a weight.

Place a weight and press TARE(-).

7. Saving Data

To save Country No., Scale No., Zero point, and Span data in

E2ROM.

・ Remove the weight from the weighing platter.

・ Remove the seal covering the opening on the rear case of

display unit.

・ Insert a thin rod such as the inner shaft of a ball-point pen

into the hole, and push the Memory Switch located on the

main board.

When writing has finished normally, [S-OK] will be

displayed.

・ To release the above status, press COLUMN.

Then, the display will return to A/D data.

¾

¾

(Calibration error)

8. Finishing Procedure

OFF status

・ Press ON/OFF to finish this procedure.

Manual No. 085-3435-07 15/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 17

When Performing Fine Span Adjustment

1. Trimming

After span adjustment, press COLUMN while the A/D data

is displayed.

[Tri-] (Trimming) display will appear.

(This is possible even with the weight placed)

2. Trimming Up

Press ZERO(+), then [Tri -U] will be displayed.

Press ZERO(+) for the desired number of times to increase

the span.

3. Trimming Down

Press TARE(-), then [Tri-d] will be displayed.

Press TARE(-) for the desired number of times to decrease

the span.

Note

The change amount for one time may differ

depending on each machine; however,

approximately one count for one time is average.

4. Repeating Steps

Press COLUMN, then A/D data will be displayed.

Place a weight on the weighing platter, and perform

adjustment by repeating steps 1, 2, and 3 above.

5. Saving Data

After completing the adjustment, press COLUMN to save

the data.

Manual No. 085-3435-07 16/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 18

Memory Switch

The memory switch is located on the main board.

IGB Series

Memory switch

Memory switch

IGX Series

Pushing memory switch

Manual No. 085-3435-07 17/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 19

2.3 C2 Mode: Key Check

Operation Display

1. Starting Test Mode (C1)

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

2. Entering C2 Mode

Press ZERO(+).

3. Checking Keys

Press SET.

[KEY-0] indicates that there is no key entry.

4. Checking Keys

ZERO(+) p 1 TARE(-)p 2 ∗ p 3

SET p 4 EXT. INPUTp 5 MEMORY SW p 6

5. Finishing Procedure

Press ON/OFF to finish this procedure.

2.4 C3 Mode: Display Check 1 (Simplified Check)

Operation Display

1. Starting Test Mode (C1)

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

2. Entering C3 Mode

Press ZERO(+) twice.

3. Checking Displays

Press SET.

The display shows self-diagnostic check.

OFF status

¼

¼

4. Returning to Test Mode

Press COLUMN to return to Test Mode.

Manual No. 085-3435-07 18/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 20

2.5 C4 Mode: Display Check 2 (Detailed Check)

Operation Display

1. Starting Test Mode (C1)

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

2. Entering C4 Mode

Press ZERO(+) three times.

3. Checking Displays

Press SET.

The display shows self-diagnostic check.

4. Returning to Test Mode

Press COLUMN to return to Test Mode.

¼

2.6 C5 Mode: Program No Display

Operation Display

1. Starting Test Mode

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

2. Entering C5 Mode

Press ZERO(+) four times.

3. Displaying Program Number

Press SET.

The installed program number (D005) will be displayed.

4. Returning to Test Mode

Press COLUMN to return to Test Mode.

Manual No. 085-3435-07 19/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 21

2.7 C6 Mode: RAM Clear and E2ROM Clear

Operation Display

1. Starting Test Mode

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

2. Entering C6 Mode

Press ZERO(+) five times.

3. Press SET.

4. RAM Clear

(Preset data of Program Mode is cleared)

Press ZERO(+).

Press ZERO(+).

5. Press COLUMN to return to Test Mode.

E2ROM Clear (Initializing E2ROM data)

6. Press SET.

7. Push the Memory Switch (SW1) located on the main

board.

(This does not work when there has been no data

change)

C1 data and setting data (F01toF17) have been

Note

8. Press ON/OFF.

After initialization, nothing except “C1” will be displayed.

C1 data settings (Country No., Scale No., Zero point,

Span adjustment) are required.

initialized.

Settings are required.

Manual No. 085-3435-07 20/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 22

2.8 C7 Mode: Weighing Condition Setting

e

Setting Country No. and Scale No. determine the weighing conditions for securing certified

Note

1. Starting Test Mode

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

2. Entering C7 Mode

Press ZERO(+) six times.

Or, press TARE(-) three times.

3. Press SET.

To change data:

Select the desired data by pressing ZERO(+) to increase,

or TARE(-) to decrease the address.

To fix the data or advance the address:

Press SET.

specifications of the country.

Individual contents can be changed in this mode.

Specifications must be selected when used overseas.

Operation Display

3-digit address + A (Upper data) - Data

4. After changing data

Push the Memory Switch (SW1) located on the main

board.

(This does not work when there was no data change)

5. Press COLUMN twice to return to Test Mode.

Addresses for weighing condition settings are from 110 to 115.

Refer to the next page.

Refe re nc

Reference

3-digit address + B (Lower data) - Data

Manual No. 085-3435-07 21/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 23

Weighing Condition Setting Table

Address Weight Item Data

110A 1 Decimal point position 0: 0 1: 0.0

2 2: 0.00 3: 0.000

4 Minimum graduation 0: 1 (1-2 change in Dual range/ Multi Interval)

4: 2 (2-5-10 change in Dual range/ Multi Interval)

8 8: 5 (5-10-20 change in Dual range/ Multi Interval)

C: Invalid

110B - Accuracy (Resolution) 0: 1/500 1: 1/600 2: 1/750 3: 1/1000

4: 1/1200 5: 1/1500 6: 1/2000 7: 1/2500

8: 1/3000 9: 1/4000 A: 1/5000 B: 1/6000

C: 1/7500 D: 1/10000 E: 1/12000 F: 1/15000

111A

111B

1

Changing method 0: Single range LED stable display only (IGX)

1: 1/3000 Multi interval Stabe/Upper/Lower display (IGB)

2: Single range Upper/Lower display (IGX)

2

4

Weight unit

8

(Valid only for

communications)

1

2

Filter setting

Do not change the data.

4

8

3: 1/3000 Multi interval Stabe/Upper/Lower display (IGB)

4: Single range (Body weight specification)

5: 1/3000 Dual range (A/B range change)

6: Single range (lb/kg change)

7: 1/3000 Multi interval (lb/kg change)

<111A> <111B>

0 + 0: kg (kg - lb)

8 + 0: g

0 + 1: lb

8 + 1: oz

(Cut off) (Notch) (Output rate)

0: 0.66Hz 2.50Hz 400ms

2: 0.84Hz 3.20Hz 312ms

4: 1.05Hz 4.00Hz 250ms

6: 1.31Hz 5.00Hz 200ms

8: 1.68Hz 6.40Hz 156ms

A: 2.10Hz 8.00Hz 125ms

C: 2.62Hz 10.00Hz 100ms

E: 3.35Hz 12.80Hz 78ms

Manual No. 085-3435-07 22/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 24

Address Weight Item Data

112A - Start width 0: ±1/50 (±2%) of weighing capacity

1: ±1/25 (±4%) of weighing capacity

2: ±1/10 (±10%) of weighing capacity

3: ±1/7.5 (±13.3%) of weighing capacity

4: ±1/6 (±16.6%) of weighing capacity

5: ±1/5 (±20%) of weighing capacity

6: ±1/4 (±25%) of weighing capacity

7: ±1/3 (±33.3%) of weighing capacity

8: ±1/2 (±50%) of weighing capacity

9 and more: Invalid

112B - Stable/Re-stable count 0 through 15 times

113A - Stable/Re-stable width n=0 through 15 (±n/10 e)

113B - Re-stable operation start

width

114A

114B

115A

1 Zero point mark 0: Light at true zero 1: Light at dummy zero

2 Over-scale display 0: Blank 1:”OL”

4 Display below true zero 0: “-----------“ 1: Minus numeric value

8 Decimal point form 0: ”.” 1: ”,”

1 Over-scale range 0: Display upto +9e 1: Display upto +3e

2 Tare subtraction 0: Yes 1: No

4 Tare clear with ZERO key 0: No 1: Yes

8 Zero supress display

(Multi Interval

specification only)

1 Key-in preset tare

subtraction and preset

single weight function

Preset unit weight

function

2 Zero tracking 0: Yes 1: No

n=0 through 15 (±n/10 e)

0: Yes 1: No

0: Yes 1: No

4 Micro weight follow-up 0: Yes 1: No

8 Unstable width 0: ±0.5e 1: ±20e

115B

1 No. of PLUs and PLU

display (IGB only)

2 Stable display

(IGB only)

4 Weight unit cursor display 0: Always light 1: Light only when “No change”is set

8 Reserved

0: 10 PLUs 1: 5 PLUs

Display No display

0: “∗” display 1: “▼” cursor display

Manual No. 085-3435-07 23/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 25

2.9 C8 Mode: E2ROM Data Reading

e

Data from address 000 to address 127 can be read.

Operation Display

1. Starting Test Mode

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

2. Entering C8 Mode

Press ZERO(+) seven times.

Or, press TARE(-) twice.

3. Press SET.

To change an address

Press ZERO(+) to increase an address.

Press TARE(-) to decrease an address.

Address 000

TARE k ey

Address 110

Address 127

C8 Starting address

ZERO key

4. Press COLUMN to return to Test Mode.

Address 3 digits −Data 1 byte

E2ROM Data

Address Item Data Range Remarks

0 to 99

Preset data (10 PLUs)

Upper limit 17bit

Lower limit 17bit

0 to 60000

Data set in Program

Mode of Operation

Manual.

10 byte × 10 data

Tare amount (A range) 18bit

Tare amount (B range)/Single weight 20bit

Check sum 8bit

Refe re nc

Reference

Refer to IGB/IGX

Operation Manual.

100A Scale mode data Capacity (bit1)

0 to F

lb mode (bit2)

Counting (bit3)

100B Reserved -

Manual No. 085-3435-07 24/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 26

Address Item Data Range Remarks

e

101 100A and 100B check data

-

(Writing twice)

102A Selection of ON/OFF key function (bit 0)

Selection of Preset auto call-up function (bit 1)

Selection of 16/24 digit printer (bit 2)

Selection of Date print function (bit 3)

0 to 1 (F1)

0 to 1 (F2)

0 to 1 (F3)

0 to 1 (F4)

102B Selection of Preset No. print function (bit4)

Selection of single/consecutive chit print (bit5)

Selection of Tare amount print function (bit6)

Selection of Upper/Lower limits print function (bit7)

0 to 1 (F5)

0 to 1 (F6)

0 to 1 (F7)

0 to 1 (F8)

103A Baud rate setting (bit 0 to 3) 0 to F (F9)

103B Output message specification (bit 4 to 7) 0 to F (F10)

104A Data output method (bit 0 to 3) 0 to F (F11)

104B Data output condition (bit 4 to 7) 0 to F (F12)

105A Contact output signal setting (bit 0 to 3) 0 to F (F13)

105B Contact input signal setting (bit 4 to 7) 0 to F (F14)

Data set in Setup

Mode of Operation

Manual.

Reference

Refe re nc

Refer to IGB/IGX

Operation Manual.

106A High-level buzzer output setting (bit 0 to 3) 0 to F (F15)

106B Built-in buzzer selection function (bit 4 to 7) 0 to F (F16)

107A Automatic power off setting (bit 0 to 3) 0 to 6 (F17)

107B Reserved

108 to 109 Check sum from 102 to 107 -

110 to 115 Weighing condition setting data Refer to Weighing

condition setting table.

116A Country code (Refer to Country code table) 0 to F (Default 10: Japan)

116B Reserved 0

117A Reserved 0

117B Reserved 0

118 to 120 A/D zero point data (adref) 24 bit

121 to 123 A/D calibration data (adwidth) 24 bit

124

Weighing capacity setting (Refer to Capacity setting

table)

00 to 99 (Default 1: 60kg)

125A JAPAN only 0 to F

125B Span adjusted flag 5H or others

5H=OK

Others=Error

126, 127 Check sum from 100 to 113. -

Manual No. 085-3435-07 25/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 27

2.10 C9 Mode: Board Inspection (A/D Check, I/F Check)

This mode is for factory inspection, and shall not be used for maintenance.

Operation Display

1. Starting Test Mode

Press ON/OFF.

Press and hold ZERO(+) while all segments are lit.

2. Entering C9 Mode

Press ZERO(+) eight times.

Or, press TAR E(-) .

3. Press SET.

Span adjusted A/D data is displayed.

4. Press SET.

A/D converter output value is displayed.

However, the lower 3 bits of 24-bit output change rapidly and

are outside of visual inspection range, so they are excluded.

5. Press ZERO(+).

Used for A/D board drift inspection.

The inspection result is displayed: OK or Err

6. Press TARE(-).

Connect the inspection jig and all I/O ports are checked.

The inspection result is displayed: OK or Err

7. Press COLUMN to return to Key Test Mode.

Manual No. 085-3435-07 26/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 28

Chapter 3 Hardware Configuration

3.1 Mechanical Parts

Manual No. 085-3435-07 27/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 29

IGB Series Service Parts List

No. Part Name Remark Part No. Q'ty

1 CASE FRONT 900-0756-05 1

2 CASE REAR ’BATTERY’ 900-0753-04 1

3 COVER ’BATTERY’ 900-0754-08 1

6 BRACKET 900-0725-00 1

7 BRACKET ’DISPLAY’ 900-0726-03 1

10 WASHER ’RUBBER’ 900-0748-05 2

11 FILTER ’DISPLAY’ 900-0755-01 1

12 SHEET ’DISPLAY’ 60kg Varied per country 1

12 SHEET ’DISPLAY’ 150kg Varied per country 1

14 SHEET ’COVER’ 900-0793-03 1

15 SPRING 1 900-1013-05 1

16 SPRING 2 900-1014-18 1

17 CUSHION BATTERY 900-0319-01 4

18 NAME PLATE ’SPEC.’ 60kg Varied per country 1

18 NAME PLATE ’SPEC.’ 150kg Varied per country 1

19 PWB PS-018 900-0677-04 1

20 PWB PS-019 900-0767-06 1

22 CABLE LOCKING (PG-11) 900-0758-02 1

23 HARNESS 'S2' GND 900-0772-05 1

25 SCREW M 4×45 900-0842-02 2

26 SHEET 900-1064-05 2

31 SIDE COVER 900-0037-11 1

32 POLE STAND 900-0032-49 1

33 RUBBER RING 900-0207-07 1

34 PLATTER 072-8847-05 1

35 SHEET ’PLATTER ’ 900-0100-02 1

36 PLATE SUPPORT 900-0021-11 1

37 BASE 900-0020-35 1

38 FOOT ’LEVEL’ 900-0022-05 4

39 PLATE A ’LEVEL’ 900-0222-03 1

40 LEVEL UNIT ASS. 900-0315-15 1

41 BRACKET ’LEVEL’ 900-0010-01 1

42 LOAD CELL (LOC-ISS10-100kg) 60kg 900-0815-01 1

42 LOAD CELL (LOC-ISS10-300kg) 150kg 900-0816-05 1

Note: Part numbers may change without notice due to product improvements.

Manual No. 085-3435-07 28/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 30

IGX Series Service Parts List

No. Part Name Remark Part No. Q'ty

1 CASE FRONT 900-0756-05 1

2 CASE REAR ’TRANSFORMER’ 900-0757-09 1

3 COVER ’BATTERY’ 900-0754-08 1

6 BRACKET 900-0725-00 1

7 BRACKET ’DISPLAY’ 900-0726-03 1

8 PLATE EARTH 900-0727-07 1

9 BRACKET 'CASE' 900-0829-03 1

10 WASHER ’RUBBER ’ 900-0748-05 2

11 FILTER ’DISPLAY’ 900-0755-01 1

12 SHEET ’DISPLAY’ 60kg Varied per country 1

12 SHEET ’DISPLAY’ 150kg Varied per country 1

13 SHEET ’AC ADAPTER’ 900-0770-08 1

18 NAME PLATE ’SPEC ’ 60kg Varied per country 1

18

19 PWB PS-016 900-0676-01 1

21 TRANSFORMER ASSY 900-1697-02 1

22 CABLE LOCKING (PG-11) 900-0758-02 2

23 HARNESS 'S2' GND 900-0772-05 1

24 HARNESS 'C3' POWER CORD Varied per country 1

26 SHEET 900-1064-05 2

31 SIDE COVER 900-0037-11 1

32 POLE STAND 900-0032-49 1

33 RUBBER RING 900-0207-07 1

34 PLATTER 072-8847-05 1

35 SHEET ’PLATTER ’ 900-0100-02 1

36 PLATE SUPPORT 900-0021-11 1

37 BASE 900-0020-35 1

38 FOOT ’LEVEL ’ 900-0022-05 4

39 PLATE A ’LEVEL ’ 900-0222-03 1

NAME PLATE ’SPEC.’

150kg Varied per country 1

40 LEVEL UNIT ASS. 900-0315-15 1

41 BRACKET ’LEVEL ’ 900-0010-01 1

42 LOAD CELL (LOC-ISS10-100kg) 60kg 900-0815-01 1

42 LOAD CELL (LOC-ISS10-300kg) 150kg 900-0816-05 1

Note: Part numbers may change without notice due to product improvements.

Manual No. 085-3435-07 29/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 31

3.1.1 Load Cell

Load cell

Top of base

Bottom of base

Manual No. 085-3435-07 30/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 32

3.2 Electric Parts (IGB Series)

3.2.1 IGB Block Diagram

Display Unit

Main Board (PS-018)

XH 2p

Ferrite Core

Front Case

Rear Case

Power Board

(PS-019)

AC Adaptor

JACK

AC Adaptor

Scale Unit

XH 2p

MK 2p

Battery

Battery

Load Cell

Manual No. 085-3435-07 31/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 33

3.2.2 Main Board (PS-018)

Parts Surface of Main Board (The LCD and tact keys are installed on the soldering surface)

(1) SW1: Memory Switch

Used to write the data when performing initialization in Test Mode.

Used to save (write) the data in E2ROM after changing Country No. and Scale No., and performing

Span Adjustment.

(2) Connector XJ1

This connector is not used.

Pin No. Signal Name Pin No. Signal Name

1 IN1 6 NC

2 OUT4 7 RESET

3 OUT3 8 VPP

4 OUT2 9 GND

5 OUT1 10 VCC

(3) Connector XJ2

This connector is used for DC input.

Pin No. Signal Name

1 +DC

2 -DC

Manual No. 085-3435-07 32/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 34

(4) Connector XJ3

This connector is not used.

Pin No. Signal Name

1 Buzzer

2 DTR

3 RxD

4 TxD

5 GND

6 FG

(5) Program Memory Media

Mask ROM 256KB (Writing or replacement is not possible)

There is no compatibility between the IGB Series main board (PS-018) and the IGX Series

main board (PS-016); However, basic operations are same for these models.

3.2.3 Power Board (PS-019)

+

−

Batteries

Jack center +

Jack center −

CN2

2

1

GND

PS-019

CN3

1

To main board

2

When the DC plug of the AC adapter is inserted into the DC jack, the battery GND will be interrupted.

Manual No. 085-3435-07 33/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 35

3.3 Electric Parts (IGX Series)

3.3.1 IGX Block Diagram

Display Unit

Main Board (PS-016)

XH 7p

Front Case

Rear Case

Earth Board

(steel)

Fuse

holder

Transformer

EL-R 2P

EL-P 2P

AC Input

Scale Unit

Load Cell

Manual No. 085-3435-07 34/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 36

3.3.2 Main Board (PS-016)

Parts Surface of Main Board (The LCD and tact keys are installed on the soldering surface).

(1) SW1: Memory Switch

Used to write the data when performing initialization in Test Mode.

Used to save (write) the data in E2ROM after changing Country No. and Scale No., and performing

Span Adjustment.

(2) Connector XJ1

This connector is not used.

Pin No. Signal Name Pin No. Signal Name

1 IN1 6 NC

2 OUT4 7 RESET

3 OUT3 8 VPP

4 OUT2 9 GND

5 OUT1 10 VCC

(NC: Non connection)

(3) Connector XJ2

Power Input

Pin No. Signal Name

1 12VAC

2 0V

3 29VAC

4 0V

5 AC2

6 0V

7 AC1

Manual No. 085-3435-07 35/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 37

(4) Connector XJ3

This connector is not used.

Pin No. Signal Name

1 FG

2 GND

3 TxD

4 RxD

5 DTR

6 Buzzer

(5) Program Memory Media

Mask ROM 256KB (Writing or replacement is not possible)

There is no compatibility between the IGB Series main board (PS-018) and the IGX Series main

board (PS-016). However, basic operations are same for these models.

Manual No. 085-3435-07 36/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 38

Chapter 4 Maintenance

4.1 Disassembly Procedure for Display Unit

Disassembly procedure

If batteries are being used, make sure to remove them, or when using an AC adapter,

1

extract the cable from the power outlet. (IGB Series only) When using AC power, make

sure to extract the cable from the power outlet. (IGX Series only)

Remove the two angle-adjusting knobs.

2

Remove the Void Seal covering the sealing screw hole.

3

Remove the 8 screws (including the sealing screw mentioned above) that hold the front and

4

rear cases together.

Manual No. 085-3435-07 37/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 39

Open the front and rear cases.

5

IGB Series

Note: Reverse the procedure to re-assemble the display unit, then affix a new Void Seal

(Part No.: 040-9585-01 Size:

φ

21)

IGX Series

4.2 Replacement of Main Board

4.2.1 IGB Series

(1) The procedure for opening the Front and Rear Cases is described in the previous section.

(2) Main Board (PS-018)

Extract the cable from the XJ2

connector.

Desolder the four lead wires of the

Load Cell cable.

Manual No. 085-3435-07 38/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 40

Remove the four screws holding the main

board.

Reverse this procedure to install a new main board.

Note

After installing a new main board, carry out RAM Clear in C3 mode, adjust the scale

and set the user operation setup and program modes.

4.2.2 IGX Series

(1) The procedure for opening the Front and Rear Cases is described in the previous section.

(2) Main Board (PS-016)

Extract the cable from the XJ2 connector

Desolder the four lead wires of the Load Cell

cable

Manual No. 085-3435-07 39/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 41

Remove the screw holding the grounding

cable to the rear case

Remove the four screws holding the main

board

Reverse this procedure to install a new main board.

Note

After installing a new main board, carry out RAM Clear in C3 mode, adjust the scale

and set the user operation setup and program modes.

Manual No. 085-3435-07 40/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 42

4.3 Replacing and Adjusting Load Cell

Load Cell Specifications

Model Type

IGB/X -60 LOC-ISS10-100kg 100kg 2.0mV/V±5% 1500Ω±10Ω 1000Ω±3Ω

IGB/X -150 LOC-ISS10-300kg 300kg 2.0mV/V±5% 1500Ω±10Ω 1000Ω±3Ω

Using an allen wrench, remove the four hexagon-headed bolts and spacers fixing the load

1

cell unit from the top of the base.

Remove the four hexagon-headed bolts and spacers from the bottom of the base.

2

Rated

Capacity

Rated

Output

Resistance

Input

Output

Resistance

insulation

Resistance

5GΩ

5GΩ

Manual No. 085-3435-07 41/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 43

Remove the load cell unit. Then, install a new load cell unit and reverse the above

3

procedure.

4.3.1 Checking and Adjusting Gap of Four-corner Limit

In the two spots of the four-corner limit front and of the four-corner limit rear (display pole side), adjust

the gaps to the following values.

Manual No. 085-3435-07 42/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 44

4.3.2 Performing Zero Point and Span Adjustments

e

Refe re nc

Reference

Refer to 2.2 “C1 Mode” of Chapter 2 “Test Mode”.

Manual No. 085-3435-07 43/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 45

4.4 Troubleshooting

Symptoms Causes Remedies

The display does not appear when

ON/OFF is pressed.

Each ON/OFF key is shown below

for the IGB or IGX Series.

or

“Err” is displayed when the

ON/OFF key is pressed.

1. AC power is not supplied.

(IGX Series only)

2. Battery voltage is low.

(IGB Series only)

3. The ON/OFF key is

defective.

4. The main board is

defective.

1. E2ROM data is garbled.

• Check the voltage of the main

power outlet.

• Check the power cable, and replace

if necessary.

• Check the FUSE (1A 250V)

• Check the TRANS ASSY

• Check the main board PS-016

connector XJ2.

• Check batteries, and replace if

necessary.

• When using the AC adapter, confirm

that the adapter voltage is within the

range of 3.2 to 6VDC.

• Using the tester, check that the key

is conducting, and replace if

necessary.

• Replace the main board PS-016

(IGX) or PS-018 (IGB) with a normal

one, then check.

• Initialize E2ROM (all) in Test Mode

C6.

• (Span adjustment is required after

initialization)

• If recovery is not possible, the main

board may be defective. Replace if

necessary.

Test mode “C1” is displayed when

the ON/OFF key is pressed.

“-----“ is displayed after the

ON/OFF key is pressed and the

display is checked.

Scale data is in initialized

state.

1. A/D value at Zero point is

outside of start range, or

unstable.

Out of AD initial value

Load cell is defective.

2. Main board is defective.

• Perform span adjustment.

• Remove items from the weighing

platter.

• Check A/D value and adjust.

Perform Test Mode C1, and if the

value is unstable, first replace the

main board, then replace the load

cell.

If outside of the start range, perform

Zero and Span adjustments.

When performing Zero and Span

adjustments, if the weight that is

less than the weighing capacity

reaches the lower limit, replace the

load cell.

• Replace the main board PS-016

(IGX) or PS-018 (IGB) with a

normal one, then check.

Manual No. 085-3435-07 44/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 46

Symptoms Causes Remedies

Zero point or weight is unstable.

No response or input difficulty in

key operation.

1. Vibration due to wind or

conditions at place of

installation.

2. Interference to Weighing

platter, Platter support, or

Load cell.

3. Main board or Load cell is

defective.

4. Extraordinary

electromagnetic wave

1. Defective key

2. Bad clearance between

Keysheet and Keys (Main

board)

• If Weighing platter is subject to

wind, move the scale to the place

where there is no wind, or provide

something to block the wind.

If there is any vibration at the place

of installation, move the scale to the

place where there is no vibration.

Perform visual inspection to check

whether something is touching the

Weighing platter, Platter support, or

Load cell, and remove if any.

• Perform Test mode C1 and check

A/D value, and replace A/D board

and Load cell in this order, if

necessary.

• Determine the source and remove

it, or move the scale to a place

where the scale will not be subject

to the electromagnetic waves.

• Replace the tact key soldered to the

Main board.

• Install Main board along Keysheet

face.

Non-displaying part, double

display digit, or double segment.

3. Defective Main board

1. Defective Main board

• Replace Main board.

• Replace Main board.

Manual No. 085-3435-07 45/45 IGB/IGX Series (Overseas Specifications) Service Man ual

Page 47

ISHIDA CO.,LTD

44 SANNO-CHO,SHOGOIN,SAKYO-KU

KYOTO,606-8392 JAPAN

PHONE:81-75-771-4141

FACSIMILE:81-75-751-1634

ULR:http://www.ishida.co.jp

Design and specifications are subject change without notice.

Loading...

Loading...