Page 1

2

Note

Note

Note

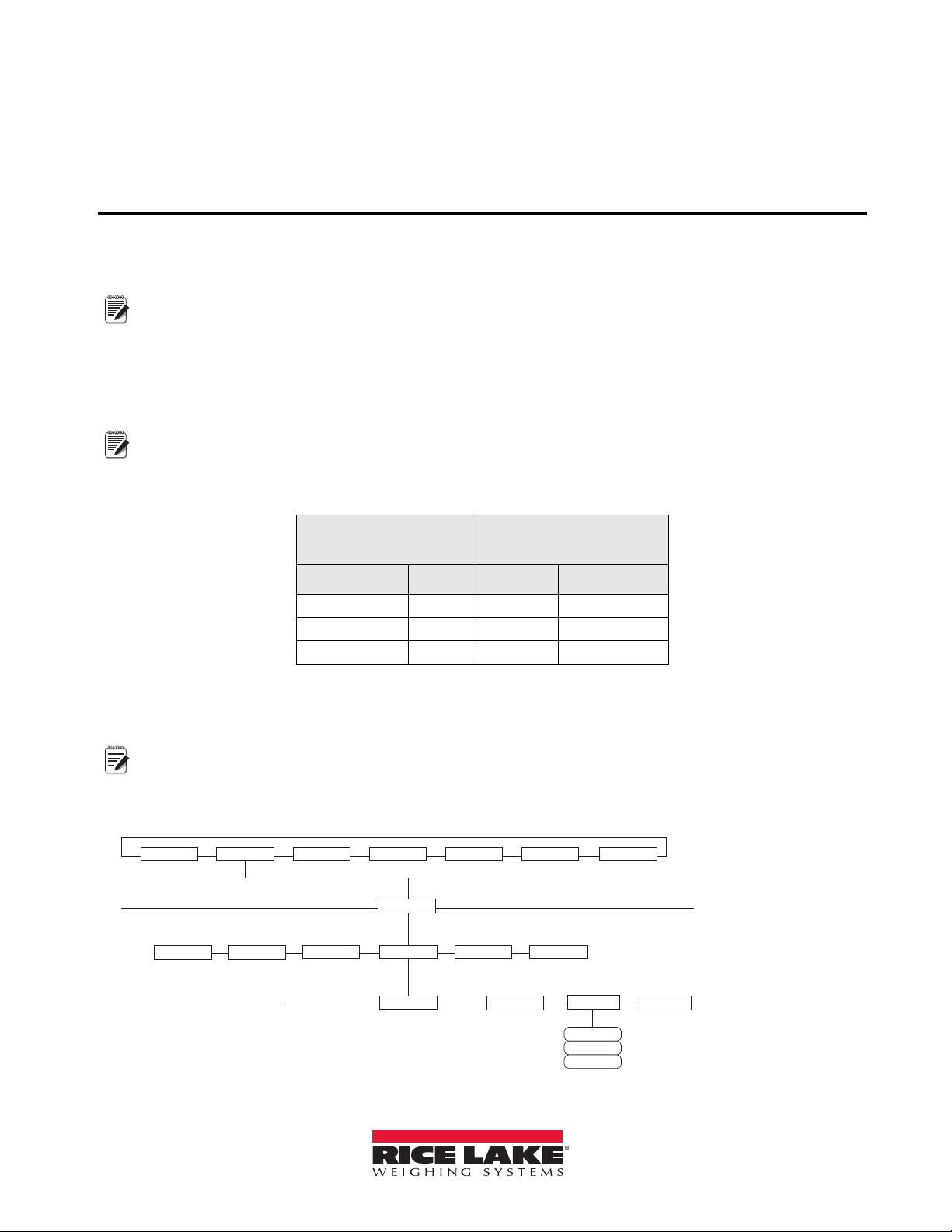

SCALES SERIAL FEATURE PFORMT SETPTS DIG I/O VERS

PORT 4

CONFIG

PROGIN CMD

…

SCALE

IQUBE2IND SC

DISPLAY

COMM SEL

PORTTYPE

UPDATE

232

422

485

iQUBE

®

Junction Box

Quick-Start Guide

This document will guide you though a typical iQUBE2® installation with RLWS recommended settings. It

assumes an 8-cell truck scale is being used with two

wiring information.

Load cells or simulators must be connected before following the instructions listed in this document. RS-422 and

RS-485 are used interchangeably. TEDS is not supported.

iQUBE

2

CPU boards. Refer to Page 4 for iQUBE2 CPU board

Configuration using 920i

Establish a Connection

1. Connect the iQUBE2® and the 920i® using an RS-422 connection.

RS-422 is recommended over RS-232 due to the 115,200 baud rate of the iQUBE2. RS-232 has a maximum

distance of 10 feet and RS-422 has a maximum dist

2. The below table shows connections needed for RS-422 communications between a host 920i and the

iQUBE

2

. Two-wire half duplex is available on Port 4 of the 920i.

920i Board

J10 Connector (Port 4)

RS-422 Signal Pin Pin RS-422 Signal

GND 1 1 GND1

RS-422 A 5 4 RS-485 A

RS-422 B 6 5 RS-485 B

Table 1. 2-wire RS-422 connections for 920i host

ance of 1000 feet at this high baud rate.

iQUBE

J7 Connector

2

3. Ensure S2 dip switches on the iQUBE2 CPU board are set to 485 (1,2 both set to OFF). See the iQUBE

CPU Board illustration in Figure 12 on page 4 for S2 dip switch location.

If a change is made to switch position, cycle power on the iQUBE2 while in Setup mode, as switch position is read

on power-up. Once power has been re-applied,

place SW1 in the OFF position.

4. On the 920i, enter Configuration mode and navigate to the SERIAL menu.

5. Change the PORTTYPE parameter to

422 (see Figure 2).

Figure 2. PORTTYPE parameter

2

February 2011 119611

Page 2

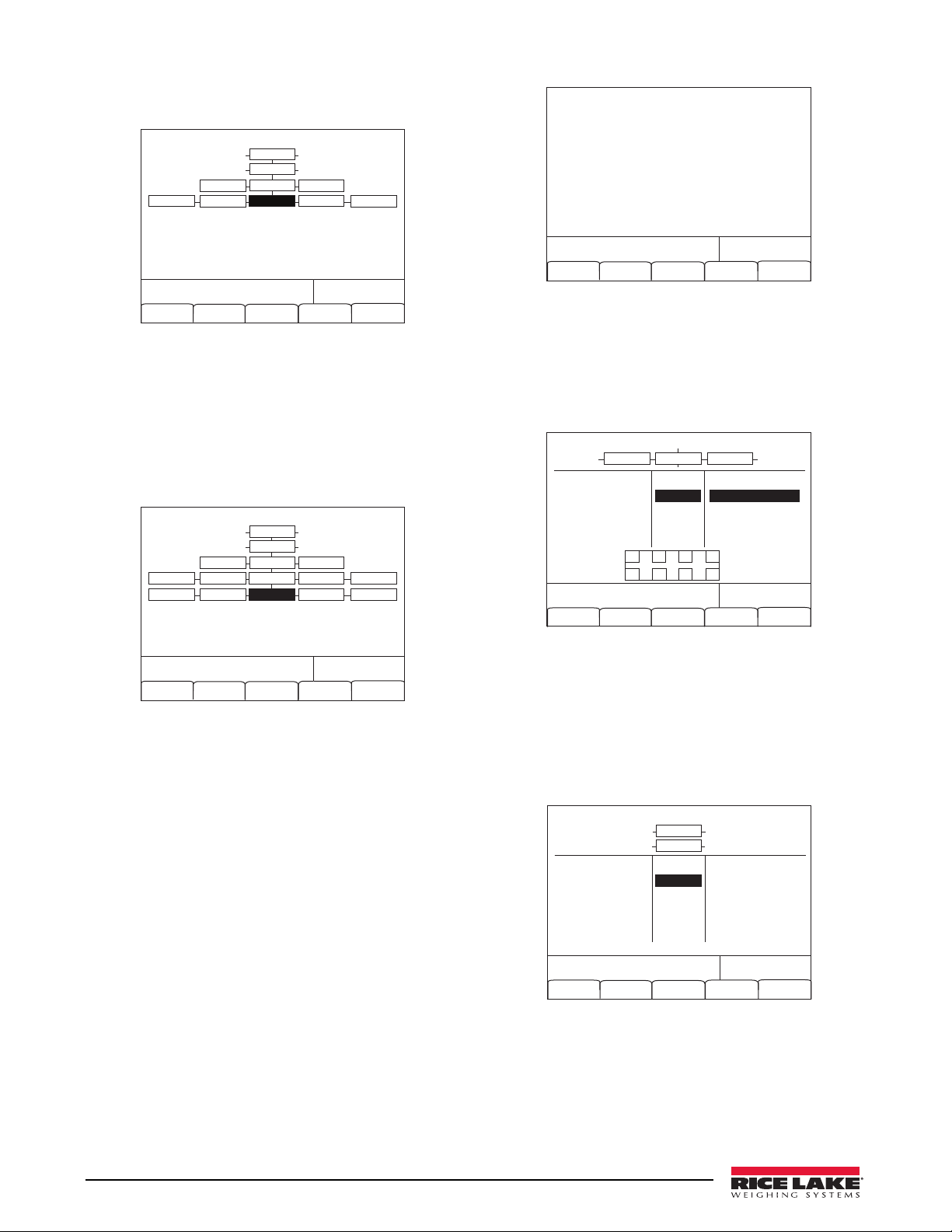

6. Navigate to the CONFIG menu and press the

12/20/2010

01:57PM

Connect

CONFIG COMM SEL

UPDATE

iQube2 Configuration

Default

Save

and Exit

Upload Download

IQUBE2

PORT4

SERIAL

PROGIN

DISPLAY

PORTTYPE

PORTTYPE

12/20/2010

01:57PM

CONFIG COMM SEL

UPDATE

iQube Boards

Number of iQube2 boards on port

Save

and Exit

Auto Assign

Manual

Assign

IQUBE2

PORT4

SERIAL

PROGIN

DISPLAY

PORTTYPE

PORTTYPE

BOARDS CELLS

COMM SCALES

DIGIO

12/20/2010

01:57PM

Auto Assign Edit

Primary

0 123XX456

Secondary

1) 65 456XX789

2) __ _________

3) __ _________

Done

12/20/2010

01:57PM

Remove

SCALES

AVAILABLE Cells ASSOCIATED CellsSCALES

CELL#1

CELL#2

CELL#3

CELL#4

CELL#5

CELL#6

Scale 1

Scale 2

Scale 3

Scale 4

Scale 5

CELLS

SMPRAT

A1 A3 B1 B3

A2 A4 B2 B4

12/20/2010

01:57PM

Connect

Default

Save

and Exit

Upload Download

CONFIG

SCALES

AVAILABLE IQUBES ASSOCIATED IQUBESSCALES

Port 4 - Scale 1

Scale 1

Scale 2

Scale 3

Scale 4

Scale 5

Connect softkey (see Figure 3).

Figure 5. Primary and Secondary Boards screen

Figure 3. CONFIG menu

7. The serial number will show (i.e., 123XX456

*NONE* *NONE* NONE*)

If the serial number does not show, check

wiring and dip switches.

Add a Secondary Board to the System

1. Under CONFIG, navigate to the BOARDS

parameter and select the Auto Assign softkey.

Figure 4. BOARDS parameter

2. Green lights on the iQUBE2 CPU boards will

start blinking on all cells.

3. Press and release the SETUP button (S1) on

sec

ondary board #1.

This makes cells 5-8 available to the system

and registers its s

erial number with the primary

board. The lights on the board will stop

blinking.

4. Once the secondary unit has

press the SETUP button (S1) on the primary

board.

5. You will see a screen showing the primary

oard serial number and any assigned

b

secondary board serial numbers.

2 iQUBE2 Quick-Start Guide

been assigned,

6. Press the Done softkey.

Configure and Add Load Cells

1. Under CELLS, set the capacity and m/v.

2. Add cells 5-8 to Scale 1 under the SCALES »

SERIAL menu.

Figure 6. Cells 5-8 added to Scale 1

3. Download to the iQUBE

2

.

Add iQUBE2 to the 920i

1. From the SCALES menu, drop down to

CONFIG.

2. Press the

Change Type softkey until Available

iQubes is displayed.

Figure 7. Scale Association screen

3. Select Port 4 - Scale 1 and press the ADD

softkey to add it to Associated iQUBES.

4. Press the

Save and Exit softkey.

5. Continue with calibration using Section 4.0 of

the i

nstallation manual.

Page 3

Configuration using iRev

1. If you have not already done so, complete

Steps 1 - 4 on page 1.

2. From the

Configure Communications

iRev4 File menu, select New.

1. From the System Parameters section, click the

Communications button.

the serial number found on the secondary

board (see Figure 12 on page 4). In the Addr

ess

text box, enter a number higher than one.

tarting secondary board address numbering at

S

65 is recommended (see Figure 10).

Figure 10. Secondary Board Communications

4. Click Configure Load Cell Assignments and

move desired cells to the right.

Figure 8. System Parameters section

2. Click on Port 4.

3. In the Ge

neral tab, set the Input Type to iQube2

and the Port Type to RS-485.

Configure and Add Load Cells and Secondary Board

1. Select the iQube2 tab.

Figure 9. Serial port iQUBE2 settings

2. Click Load Cell Configuration and update as

needed.

3. Click Secondary Board Communications.

In the Se

condary Board One ID text box, enter

Figure 11. Load cell assignments

5. Click Scale Property Configuration and update

as needed.

Configure Scale #1

1. From the System Parameters section, click the

Scales button (see Figure 8).

2. Double-click

3. Under So

Scale #1.

urce Types, select iQube2 Systems and

associate Port 4.

Save and Download Configuration to iQUBE

2

1. From the File menu, select Save As and save the

file with an appropriate name.

2. From the Communications me

Connect.

nu, select

3. Download all configuration steps. Also mark

the Download to

4. On the

920i, press the Save and Exit softkey.

A weight should now display on the

iQube2 checkbox.

920i.

5. Continue with calibration using Section 4.0 of

the i

nstallation manual.

iQUBE

2

Quick-Start Guide 3

Page 4

J6

POWER SUPPLY

CONNECTOR

+SIG

–SIG

+EXC

–EXC

+TD

–TD

J1

+SIG

–SIG

+EXC

–EXC

+TD

–TD

J2

J3

J4

–TD

+TD

–EXC

+EXC

–SIG

+SIG

–TD

+TD

–EXC

+EXC

–SIG

+SIG

S1

SW1

CONFIG SWITCH

S2

6 5 4 3 2 1

J7

SERIAL PORT 1

IO4

IO3

IO2

IO1

GND

+5V

J5

DIGITAL I/O

J12

M/S PORT

1

1

1

COMMUNICATIONS

PORT 2

J9

J10

J14

J8

TMS

TDI

TDO

TCK

GND

+3.3

CHANNEL 2 CHANNEL 1

CHANNEL 4 CHANNEL 3

485 232

HDPLX FDPLX

1 2

GND +V GND +V

1

RTS

DTR

RxD

TxD

GND1

GND

CFG OFF

HB1

########

J7 Pin RS-232 Signal

Figure 12. iQUBE2 CPU Board

1 GND1 GND1 GND1

2 RxD — Rx+

3 — — Rx–

4 — A / + Tx+

5 TxD B / – Tx–

6 — — —

Table 13. J7 (Port 1) pin assignments

RS-485 2-Wire

Signal

RS-485 4-Wire

Signal

J12 Pin Primary iQUBE2 Secondary iQUBE2

1 iQA iQA

2 iQB iQB

3 GND2 GND2

4 GND2 GND2

Table 14. J12 (M/S Port) pin assignments

OFF ON

1 RS-485 RS-232

2* 2-WIRE 4-WIRE

Table 15. S2 Switch settings

4 iQUBE2 Quick-Start Guide

Loading...

Loading...