Page 1

Intercomp

SW Scale System

Users Manual

Intercomp Co.

14465 23rd Ave. N.

Minneapolis, MN 55447

(763)-476-2531

1-800-328-3336

Fax 763-476-2613

www.intercomp-racing.com

Page 2

SW Users

Rev G, February, 2000

Table of Contents

INTRODUCTION................................................................................................................................................ 4

SPECIFICATIONS ................................................................................................................................................. 4

Controls........................................................................................................................................................ 4

Electrical...................................................................................................................................................... 4

Performance................................................................................................................................................. 4

Environmental.............................................................................................................................................. 4

Physical........................................................................................................................................................ 5

OPTIONAL EQUIPMENT ....................................................................................................................................... 5

SETUP..................................................................................................................................................................6

SYSTEM ............................................................................................................................................................. 6

QUICK START ..................................................................................................................................................... 7

OPTIONAL EXTERNAL PRINTER ........................................................................................................................... 7

OPERATIONS..................................................................................................................................................... 8

OVERVIEW......................................................................................................................................................... 8

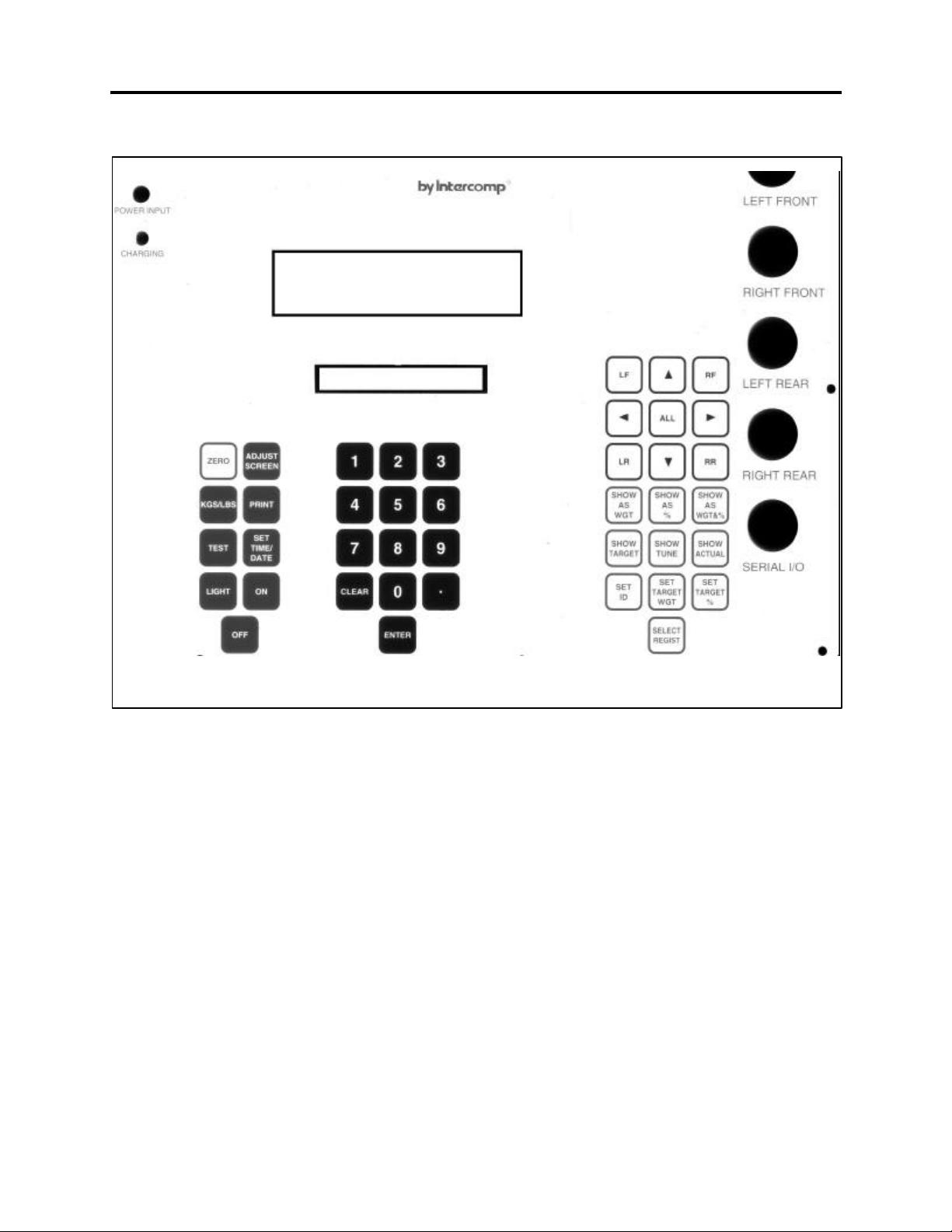

CONTROLS......................................................................................................................................................... 9

ZEROING PADS.................................................................................................................................................... 9

SELECTING PADS ...............................................................................................................................................10

DISPLAY FORMAT ..............................................................................................................................................10

Period..........................................................................................................................................................10

Show as WGT...............................................................................................................................................11

Show as %....................................................................................................................................................11

Show as WGT & %.......................................................................................................................................11

Show ACTUAL.............................................................................................................................................11

Show TARGET.............................................................................................................................................11

Show TUNE.................................................................................................................................................11

ENTERING A NUMBER.........................................................................................................................................11

TARGET WEIGHTS AND REGISTERS.....................................................................................................................12

Select Register.............................................................................................................................................12

Set ID..........................................................................................................................................................12

Set Target WGT...........................................................................................................................................12

Set Target %................................................................................................................................................13

FEATURES MENU...............................................................................................................................................13

CG (Center of Gravity)................................................................................................................................14

Vertical CG (Vertical Center of Gravity) .....................................................................................................15

Special Displays..........................................................................................................................................16

TIME AND DATE ................................................................................................................................................16

PERCENTAGES...................................................................................................................................................17

OTHER OPERATIONS..........................................................................................................................................18

KGS/LBS .....................................................................................................................................................18

TEST ...........................................................................................................................................................18

LIGHT.........................................................................................................................................................18

ADJUST SCREEN .......................................................................................................................................18

PRINTING (OPTIONAL).......................................................................................................................................18

Print Time/Date...........................................................................................................................................18

Print Screen.................................................................................................................................................18

Print Register ..............................................................................................................................................18

POWER / BATTERIES..........................................................................................................................................19

Replacement................................................................................................................................................19

2

Page 3

SW Users

Rev G, February, 2000

ERROR MESSAGES..........................................................................................................................................20

APPENDIX A: PRINTOUT EXAMPLES .........................................................................................................21

REGISTER TICKET..............................................................................................................................................21

BASIC SCREEN PRINTOUTS.................................................................................................................................22

SPECIAL SCREEN PRINTOUTS..............................................................................................................................24

APPENDIX B: DISPLAY SCREEN EXAMPLES............................................................................................25

BASIC DISPLAYS ................................................................................................................................................25

SPECIAL DISPLAYS.............................................................................................................................................26

APPENDIX C: C.G. / VERTICAL C.G. NOTES..............................................................................................27

CENTER OF GRAVITY.........................................................................................................................................27

VERTICAL CENTER OF GRAVITY.........................................................................................................................30

SERIAL OUTPUT (OPTIONAL)......................................................................................................................34

PRINTER ...........................................................................................................................................................34

EXAMPLE CONNECTIONS ...................................................................................................................................35

HOW TO REACH INTERCOMP SERVICE ...................................................................................................36

3

Page 4

SW Users

Rev G, February, 2000

Introduction

This manual contains specifications and operating instructions for Intercomp's SW

Scale System.

Specifications

Controls

General: Zero, Kg/Lb, Test, Light, Adjust Screen, Print, Set

Time/Date, On, Off

Numeric: 13-key standard layout

Channel selection: LF, RF, LR, RR, ALL

Weight and Percent 8-key Weight and Percent selection

Storage Registers 2-key register and I.D. selection

Display: 1” 2 x 16 character(0.35”) alphanumeric LCD

readout

Indicators: lb/kg, Lo Bat.

Electrical

Voltage: 12 VAC/VDC, 120/240 VAC

Batteries: 12 x AA-size disposable alkaline cells or rechargeable Nickel-

Cadmium cells

Filtering: Analog: Trans-besel filter

Digital: Average of several internal weights gives steady

readings for unstable loads

Auto-zero: Satisfies all HB-44 requirements

Input/Output: Input: 4 analog channels

Output: RS232 serial

Performance

Speed:

Accuracy:

Divisions: 6000 lb/ 2800 kg capacity: graduation = 1 lb/0.5 kg

≈1 sec to typical reading (static)

±0.1% of applied load or ± display graduation, whichever is

greater

8800 lb/ 4000 kg capacity: graduation = 1 lb/0.5 kg

Environmental

Humidity: 10 to 95% non-condensing

Temperature:

Storage: -40° C to +75° C. / -40° F to +170° F

Operating -10° C to +40° C. / +14° F to +104° F

4

Page 5

SW Users

Rev G, February, 2000

Physical

2.5” Weigh Pad Dimensions:

Weight:

Carrying Case /

Control Box

Dimensions: 17” x 11” x 7”

Weight: 10 lb/ 4.5 kg

Material: ABS structural foam

15” x 15” x 2.5” per pad

23 lb / 10.5 kg

Optional Equipment

15” x 15” Ramp, Snap In, cast aluminum (100330)

This option allows you to drive the car onto the pads in the case that you are not using

a setup rack or jacking the car up.

220 VAC/ 50 Hz Power Pack (100546)

220 VAC plug-in transformer provides direct power to the SW control box.

Tape Printer

An external tape printer can be connected and powered from the control box. Example

printouts are shown in Appendix A. Also see sections titled Optional External Printer

and Printing.

RS232 serial data output (100158)

If the tape printer is not used, this option provides a RS232 output so the system may

be connected to a computer or printer.

System Carrying Case (100056)

Holds the 4 platform scales, indicator, cables, and manual

5

Page 6

Setup

System

SW Users

Rev G, February, 2000

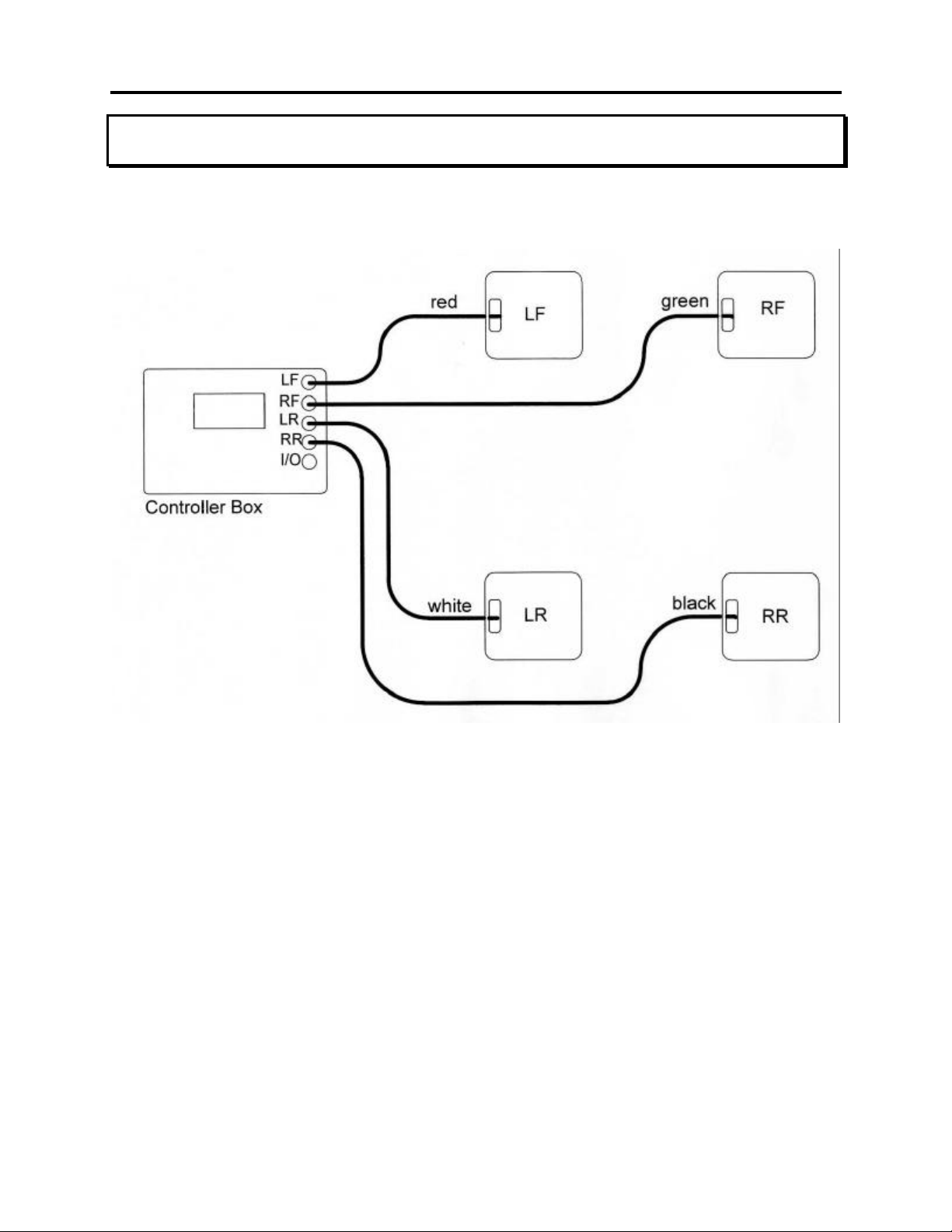

System setup configuration

1. Place the four pads near their appropriate car tire: LF by left front, RF by right front

and so on.

2. Connect one end of each cable to a pad: LF-Red cable, RF-Green cable, LR-White

cable, RR-Black cable.

3. Connect the free end of each cable to the control box: LF-Red cable, RF-Green

cable, LR-White cable, RR-Black cable.

4. Turn the control box on.

5. Jack the car onto each pad.

6

Page 7

SW Users

Rev G, February, 2000

Quick Start

Setup the scales as described in SETUP on previous page. Turn the scales 'on'; after

a copyright screen you will see a display screen with five weights and a percentage.

The four weights that are on the left are the individual wheel weights. The weight in the

upper right is the total selected weight. The percentage is the percentage of selected

weight to total weight. You can switch to display the percentage of each pad by

pressing SHOW AS % and go back to the weights by pressing SHOW AS WGT. The

weights and percentages are displayed in the same pattern as a car left front, right

front, left rear, right rear. You can select or deselect a pad by pressing the LF, RF, LR,

RR (left front, right front, left rear, right rear); each time you press the button a select

arrow will turn on and off to the right of that pads weight. The T (or total) display line

shows the total weight on all four pads, and the percentage shown is the percentage of

selected weight to the total weight.

Optional External Printer

Press the on/off rocker switch to the right to turn the printer 'on', and to the left to turn it

off.

If the on/off switch is held down to the right when the printer is turned on the printer will

do a self print test. After the printer is 'on' holding the switch to the right will feed the

paper through the printer.

To load paper in the printer, insert the paper into the metal slot at the back of the

printer as far as it will go, then hold the on/off switch to the right to feed the paper.

7

Page 8

SW Users

Rev G, February, 2000

Operations

Overview

The SW scale system is designed to independently measure the force applied by each

tire of a car. This is referred to as the ACTUAL weight applied by each tire. The user

can enter the weight they want applied by each tire, this is know as the TARGET

weight. The TUNE weight is the amount of weight that needs to be added to a tire to

reach the TARGET weight. If a TUNE weight is negative it implies that the tires weight

is greater than the TARGET weight.

The SW scale can also perform a number of calculations automatically. Rather than

displaying the wheel weights (Actual, Target, Tune) the user can select to display the

weights as a percentage of the total weight, or as a percentage and weight.

Additionally the user can select pads in groups (such as left front and left rear, or left

rear and right front) and the scale will calculate what percentage of the total weight that

group is.

The scale has five additional special display modes:

TGT, TUN: In this mode the target and tune weight of all four wheels

are displayed.

SIDES: The side totals are displayed.

BITE: The front and rear bites (LF-RF and LR-RR) are displayed.

CENTER OF GRAVITY: With entry of the cars axle width and wheel base the scale

will calculate the location of the center of gravity front to

back and side to side.

VERTICAL CENTER

OF GRAVITY:

With entry of the cars wheel base and by lifting the back of

the car, the scale will calculate the vertical center of

gravity.

8

Page 9

Controls

SW Users

Rev G, February, 2000

Zeroing pads

To set the current weight on a pad to zero press the ZERO button. The scale will then

ask you to press LF, RF, LR, RR, or ZERO. Pressing ZERO again will zero all of the

weigh pads; the other key presses will zero only that weigh pad (i.e. LF: left front pad

only, and so on).

When the scale is turned 'off' the current zero will be remembered. That means that if

a car is on the weigh pads and the unit is turned 'off'; when the scale is turned 'on' the

current weight will be displayed, not zero.

9

Page 10

SW Users

Rev G, February, 2000

Selecting pads

On various display screens a S, T, and % line are shown; they have the following

means:

S: Total selected weight (total of pads turned on).

T: Total weight (total of all four pads).

%: The percentage the total selected weight is to the total weight.

To change which pads are selected use the LF, RF, LR, RR, ALL, left arrow, right

arrow, up arrow, down arrow. The arrow to the right of each pads weight display is

turned on if the pad is selected and off if it is not.

LF: Toggles left front pad on and off.

RF: Toggles right front pad on and off.

LR: Toggles left rear pad on and off.

RR: Toggles right rear pad on and off.

ALL: Turns all four pads on.

Left arrow: Turns LF and LR on, RF and RR off; for left side.

Right arrow: Turns LF and LR off, RF and RR on; for right side.

Up arrow: Turns LF and RF on, LR and RR off; for front side.

Left arrow: Turns LF and RF off, LR and RR on; for rear side.

Display format

The SW Scale has nine basic display screens. The Actual (weight on pad), Target

(weight you want on the pad), and Tune (the difference); can be displayed as either

weight, percentage, or weight and percentage. This gives a total of nine screens (see

appendix B for display screen examples).

The SHOW AS (WGT, %, or WGT & %) keys pick how the information will be

displayed. The SHOW (TARGET, TUNE, or ACTUAL) keys pick what information will

be displayed.

Period

Pressing the period (.) key will display information about the current display,

press period to return to the normal screen. The information displayed is: what

is currently being viewed, the current unit of measure, and the current register

number; see Appendix B.

10

Page 11

SW Users

Rev G, February, 2000

Show as WGT

Pressing this key will switch the display to show the weight assigned to each

pad. The weight displayed will be Actual, Target, or Tune.

Show as %

Pressing this key will switch the display to show the percentage on each pad.

The percentage displayed will be of the Actual, Target, or Tune.

Show as WGT & %

Pressing this key will switch the display to show the weight and percentage

assigned to each pad. The weight and percentage displayed will be Actual,

Target, or Tune.

Show ACTUAL

Pressing this key will switch the display to show the actual weight applied to

each pad. The weight displayed will be as a weight, percentage, or weight and

percentage.

Show TARGET

Pressing this key will switch the display to show the target weight of each pad.

The weight displayed will be as a weight, percentage, or weight and percentage.

Show TUNE

Pressing this key will switch the display to show the tune weight of each pad.

The weight displayed will be as a weight, percentage, or weight and percentage.

Entering a number

At times it will be necessary for you to enter a number. The screen will display four

zeros '0000'. Use the numeric key pad to enter the number, when complete press the

enter key.

To clear all four digits to zero press the CLEAR key.

11

Page 12

SW Users

Rev G, February, 2000

Target Weights and Registers

The target weights represent the four weights that you want the actual wheel weights to

be at. The SW Scale is capable of storing 127 sets of target weights with an additional

10 character label ID. These stored target weights are retained even when the units is

turned off.

Select Register

Each register has the following information:

Ten character label ID.

LF target weight

RF target weight

LR target weight

RR target weight

When the scale is turned on it defaults to register 1. To select a different

register press SELECT REGIST, then enter the new register's number. When a

register is used for the first time or the data in it has be corrupted, the message

"Register Empty" will momentarily flash on the screen and the register will be

reset. The valid register numbers are 1 to 127.

Set ID

To set the 10 character label ID for a register you must first select that register

than press SET ID. The current ID will appear on the screen with the left most

character flashing. Use the arrow keys to change the ID and when finished

press ENTER.

Left arrow: Move the cursor one place to the left.

Right arrow: Move the cursor one place to the right.

Up arrow: Increase the flashing character (i.e. an A to a B).

Down arrow: Decrease the flashing character (i.e. a B to an A).

Set Target WGT

There are three methods under SET TARGET WGT for setting the target

weights:

1: Current actual

2: Wedge

3: Key in

From the SET TARGET WGT menu press 1 through 3 given your choice.

12

Page 13

SW Users

Rev G, February, 2000

Current Actual

This method takes the current weight on the pads and saves them as the

targets.

Wedge

The wedge method requires you to enter the desired total weight, the left

side percentage, the rear side percentage, and the wedge (LR+RF)

percentage. From this information the scale calculates what the four

wheel target weights must be.

Keying

This method simply allows you to enter the four target weights.

Set Target %

SET TARGET % allows you to specify the total weight of the car, than enter what

percentage of that total you want each wheels target to be set to.

Features Menu

You enter the features menu by pressing the ENTER key. This menu gives you access

to the special display modes that are available. Press the number of your choice.

1: CG (Center of Gravity) Also see Appendix C

2: Vertical CG (Vertical Center of Gravity) Also see Appendix C

3: Special Displays

4: Normal Weighing

Normal weighing (choice 4) returns you to displaying the actual weight as a weight.

This is the equivalent to pressing SHOW AS WGT and than SHOW ACTUAL.

See Appendix B for display screen examples.

13

Page 14

SW Users

Rev G, February, 2000

CG (Center of Gravity)

Center of Gravity Examples

The center of gravity of an object, such as a car, is the point at which the object

balance if placed on a pivot point. In the diagram above the weights would

represent the weight applied by two tires of a car. If the two tires were the same

weight the center of gravity would be exactly in the middle. If one tire were

heavier the center of gravity would move toward the heavy tire.

There are three axis on a car: front to back, left to right, and up to down. The

center of gravity on the first two can be determined directly from the weight of

each wheel, the up to down, or vertical, requires that one end of the car be lifted;

it is addressed in the next section.

Center of Gravity

The CG calculation requires that you enter the axle width and the wheel base.

Make sure that the front tires are aligned straight forward before you measure

them. The axle width is from the outside of a left tire to the outside of a right tire.

The wheel base is from the middle of a front tire to the middle of a rear tire. If

the measurements are made according the above diagram the results are from

the marked reference point.

14

Page 15

SW Users

Rev G, February, 2000

After the axle width and wheel base are entered the scale will display the

location of the center of gravity from the left front to right front tire, and from the

left front to left rear tire (see center of gravity diagram on previous page).

Additionally the percentage of the wheel base (left front to left rear), and the

percentage of the axle width (left front to right front) is shown. The screen

information will be updated if the wheel weights are shifted.

Vertical CG (Vertical Center of Gravity)

CG movement has been exaggerated to illustrate point

There is a point referred to as the vertical center of gravity that the car would

balance on if it were turned on it's side. As you can see from the drawing above

if the back of the car is lifted the front to back center of gravity will move forward,

the amount of movement is related to how high up the center of gravity is in the

car. The SW Scale will calculate the vertical center of gravity.

See instructions on next page

15

Page 16

SW Users

Rev G, February, 2000

1. Press ENTER to enter the features menu.

2. Select #2 to start Vertical CG.

3. Have the car level with the ground.

4. Enter the wheel base (refer to the center of gravity section above).

5. The scale will display the current CG.

6. The scale will ask you to raise the rear wheels.

7. Raise the back of the car and weigh pads. A good 'rule of thumb' is raise the

back one inch for each foot of wheel base.

8. Press Enter.

9. Enter the amount the back wheels were raised in tenths (which unit you use

inches, centimeters, etc.; doesn't matter the result will be in the same units).

10. The results will be displayed

Special Displays

Item #3 in the features menu is special displays, this choice allows you to

activate three alternate weight displays (see Appendix B for display screen

examples).

1. ACT, TGT, TUN

2. Sides

3. Bite

Act, Tgt, Tun

In this display mode the screen shows:

1. All four pads’ actual weights.

2. All four pads’ target weights.

3. All four pads’ tune weights.

Wheels and Sides

In this display mode the screen shows:

1. The actual weight of all four pads.

2. The wedge (LR+RF) as a percentage of the total weight.

3. The four sides as percentages of the total weight: Left, Right, Front,

Rear.

4. The total weight.

Sides and Bite

In this display mode the screen shows:

1. The wedge weight (LR+RF).

2. The four side weights: Left, Right, Front, Rear.

3. The front bite (LF-RF).

4. The rear bite (LR-RR).

5. The total weight.

Time and Date

When the SET TIME/DATE key is pressed the current time and date will be displayed.

16

Page 17

SW Users

Rev G, February, 2000

Press a key to return to normal weighing or press SET TIME/DATE again to set the

time and date.

Number Min Max

Month 1 12

Day 1 31

Year 0 99

Hours 1 12

Minutes 0 59

Seconds 0 59

am=0, pm=1 0 1

The clock starts running when the am/pm number is entered. If the year is from 93 to

99 it is 1993 through 1999, 0 to 92 is 2000 through 2092.

Percentages

Technical Note:

The percentages for each pad are rounded off to the nearest 0.1 %, as an

example, 24.95 to 25.049 would round to 25.0. The selected percentage is a

total of the selected pads individual percentages. The percentage will be

calculated only if all the numbers involved are greater than zero.

17

Page 18

Other Operations

KGS/LBS

Pressing the KGS/LBS key toggles the scale from pounds to kilograms, or from

kilograms to pounds. When switching from pounds to kilograms the target

weights will be converted to kilograms and rounded to the nearest 0.5 kg.

TEST

Pressing the test key will restart the SW control box. This is the equivalent to

turning the box off than back on. This key will also cancel a printout that is in

progress.

LIGHT

The backlight is not available on the SW Scale model.

ADJUST SCREEN

The adjust screen key is used to change the contrast level on the display

screen. Adjusting the contrast can improve the readability of the display when

viewed from different angles.

SW Users

Rev G, February, 2000

To adjust the contrast press Adjust Screen, then use the up and down arrow

keys to increase and decrease the contrast.

Printing (Optional)

Pressing the PRINT button will bring up the print command menu.

1: PRINT SCREEN

2: PRINT REGISTER

Print Time/Date

When in the print command menu, pressing the SET TIME/DATE will print the

time and date.

Print Screen

If print screen is selected a ticket will print that contains the information on the

current display screen (i.e. actual as wgt, actual as percentage, and so on).

See Appendix A for the example printouts.

Print Register

If print register is selected a ticket will print that contains all the current weight

information. See Appendix A for an example.

18

Page 19

SW Users

Rev G, February, 2000

Power / Batteries

You may use rechargeable Nickel-Cadmium ‘D’-cells or standard alkaline ‘D’ cells in

the SW system.

WARNING: Do not plug the charger in while there are standard ‘D’ cells

inside. This could result in damage to the batteries and your scale.

Your scale will operate indefinitely off of the charger while the batteries charge. The

scale can be left on or off while the charger is plugged in.

With fully charged batteries the scale will operate from six to eight hours off of battery

power. This specified time could be reduced if the printer is left on or a lot of printing is

done.

Replacement

Remove the screws on the control box panel. Remove the 2 screws on the

battery holder plate. Change cells, being careful to insert with correct polarity.

Fasten the battery holder plate.

19

Page 20

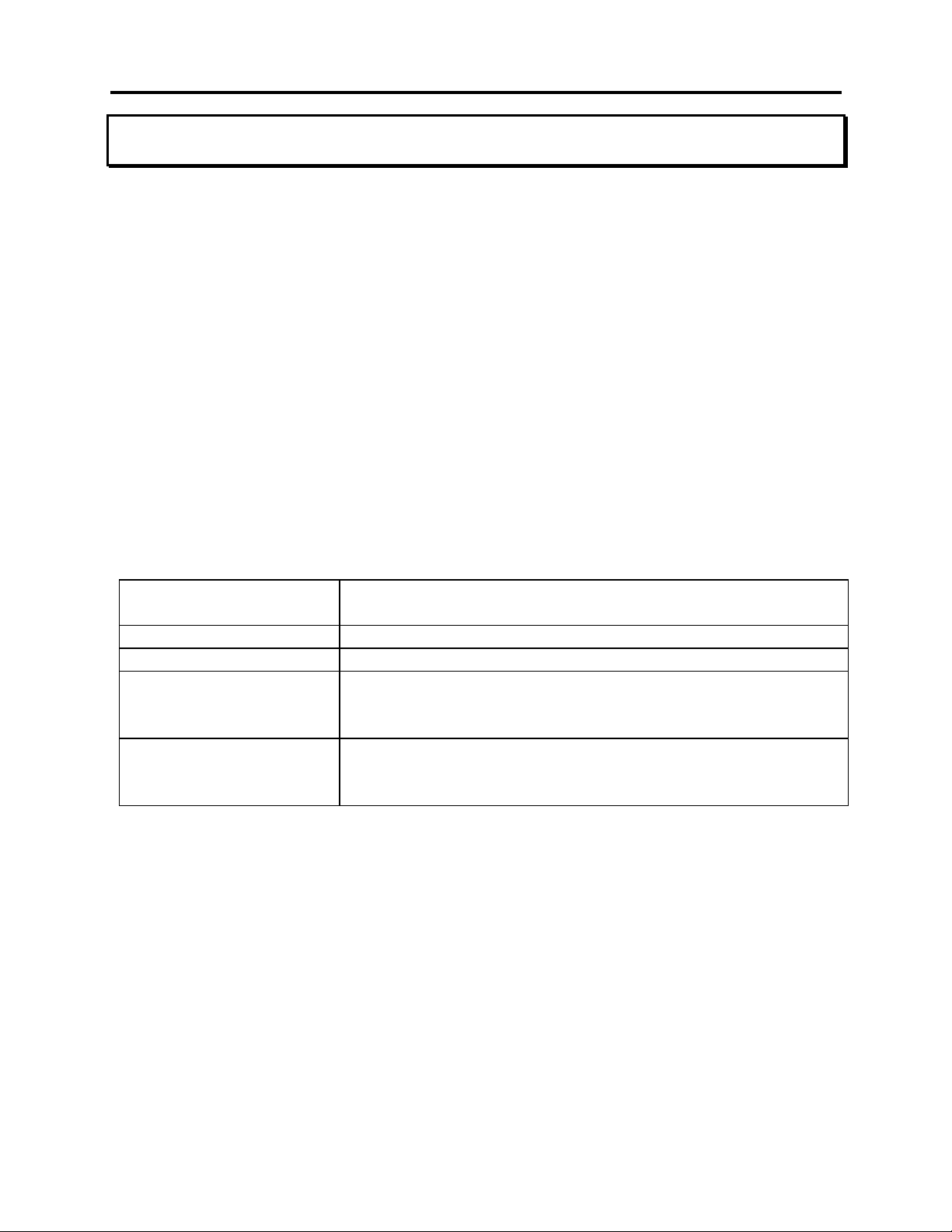

Error messages

SW Users

Rev G, February, 2000

PRESS TEST

OFF

REGISTER EMPTY

LOW BATTERY

As the message implies, press the TEST key to restart the SW

control box. If this message repeatedly returns and won't allow

you into the normal weighing mode, call Intercomp for service.

The weight present on the pad exceeds the pads capacity, or

the pad is not plugged in, or the pad may have failed. The

weight of an 'off' pad is set to zero so the scale can be

operated without a pad plugged in.

The register that was chosen has never been used or the data

in it was corrupted.

Battery power is low. Scale will shut off after displaying “Low

Battery”. If Ni-Cad cells are being used, recharge the batteries.

If you are using alkaline cells, replace the batteries.

20

Page 21

Rev G, February, 2000

Appendix A: Printout Examples

This section contains examples of the possible printouts for the SW. See the

Operations/Printing section.

Register Ticket

SW SCALES

BY INTERCOMP

MAR 1,1994

01:10:00pm

REG: 1

TRACK #1

TARGET LB

LF 1500_ RF 1500_

LR 1500 RR 1500

SW Users

SELECTED 3000 50.0%

TOTAL 6000

TUNE LB

LF 500_ RF 500_

LR 500 RR 500

SELECTED 1000 50.0%

TOTAL 2000

ACTUAL LB

LF 1000_ RF 1000_

LR 1000 RR 1000

SELECTED 2000 50.0%

TOTAL 4000

FRONT 2000 50.0%

RIGHT 2000 50.0%

LEFT 2000 50.0%

REAR 2000 50.0%

WEDGE 2000 50.0%

FBITE 0

RBITE 0

21

Page 22

Basic Screen Printouts

SW Users

Rev G, February, 2000

Actual as weight:

Mar 1, 1994

01:10:00pm

ACTUAL LB

LF 1000_ RF 1000_

LR 1000 RR 1000

SELECTED 2000 50.0%

TOTAL 4000

Target as weight:

Mar 1, 1994

01:10:00pm

TARGET LB

LF 1500_ RF 1500_

LR 1500 LR 1500

SELECTED 3000 50.0%

TOTAL 6000

Actual as percentage:

Mar 1, 1994

01:10:00pm

ACTUAL %

LF 25.0_ RF 25.0_

LR 25.0 RR 25.0

SELECTED 2000 50.0%

TOTAL 4000

Target as percentage:

Mar 1, 1994

01:10:00pm

TARGET %

LF 25.0_ RF 25.0_

LR 25.0 RR 25.0

SELECTED 3000 50.0%

TOTAL 2000

Tune as weight:

Mar 1, 1994

01:10:00pm

TUNE LB

LF 500_ RF 500_

LR 500 RR 500

SELECTED 1000 50.0%

TOTAL 2000

Tune as percentage:

Mar 1, 1994

01:10:00pm

TUNE %

LF 25.0_ RF 25.0_

LR 25.0 RR 25.0

SELECTED 1000 50.0%

TOTAL 2000

22

Page 23

Actual as weight and percentage:

Mar 1, 1994

01:10:00pm

ACTUAL LB

LF 1000_ RF 1000_

LR 1000 RR 1000

ACTUAL %

LF 25.0_ RF 25.0_

LR 25.0 RR 25.0

SELECTED 2000 50.0%

TOTAL 4000

Target as weight and percentage:

Mar 1, 1994

01:10:00pm

TARGET LB

LF 1500_ RF 1500_

LR 1500 RR 1500

SW Users

Rev G, February, 2000

TARGET %

LF 25.0_ RF 25.0_

LR 25.0 RR 25.0

SELECTED 3000 50.0%

TOTAL 6000

Tune as weight and percentage

Mar 1, 1994

01:10:00pm

TUNE LB

LF 500_ RF 500_

LR 500 RR 500

TUNE %

LF 25.0_ RF 25.0_

LR 25.0 RR 25.0

SELECTED 1000 50.0%

TOTAL 2000

23

Page 24

Special Screen Printouts

SW Users

Rev G, February, 2000

Actual, Target and Tune:

Mar 1, 1994

01:10:00pm

LF RF LR RR

ACT 1000 1000 1000 1000

TGT 1500 1500 1500 1500

TUN 500 500 500 500

Wheels and Sides:

Mar 1, 1994

01:10:00pm

ACTUAL LB

LF 1000_ RF 1000_

LR 1000 RR 1000

SELECTED 2000 50.0%

TOTAL 4000

FRONT 2000 50.0%

RIGHT 2000 50.0%

LEFT 2000 50.0%

REAR 2000 50.0%

WEDGE 2000 50.0%

Center of Gravity:

Mar 1, 1994

01:10:00pm

CENTER OF GRAVITY

FROM LF TO RF 50.0

50.0% OF 100.0

FROM LF TO LR50.0

50.0% OF 200.0

Vertical Center of Gravity:

Mar 1, 1994

01:10:00pm

VERTICAL CG

VERTICAL CG 0.0

ORIGINAL CG 100.0

CURRENT CG 100.0

WHEEL BASE 200.0

HEIGHT 10.0

Sides and Bites:

Mar 1, 1994

01:10:00pm

ACTUAL LB

LF 1000_ RF 1000_

LR 1000 RR 1000

SELECTED 2000 50.0%

TOTAL 4000

FRONT 2000 50.0%

RIGHT 2000 50.0%

LEFT 2000 50.0%

REAR 2000 50.0%

WEDGE 2000 50.0%

FBITE 0

RBITE 0

24

Page 25

SW Users

LF

RF

LR

RR

LR

RR

Rev G, February, 2000

Appendix B: Display Screen Examples

Basic displays

Show Actual, Target, or Tune as

Period (.) key pressed:

What is being

shown

ACTUAL AS WGT

(LB) REG: 1

(LB or KG)

Register #: (1-127)

What is being shown:

ACTUAL AS WGT

ACTUAL AS %

ACTUAL AS WT%

TARGET AS WGT

TARGET AS %

TARGET AS WT%

TUNE AS WGT

TUNE AS %

TUNE AS WT%

TGT/TUN

SIDES

BITE

CG

VCG

percentage:

Selected

1500← 1500← 3000

1500← 1500← 50.0

Total

Percentage

Show Actual, Target, or Tune as weight:

Selected

Left Front

1500← 1500 3000

1500← 1500 50.0

Left Rear

Right Front

Total Selected

Weight

Selected

Percentage

Right Rear

Show Actual, Target, or Tune as weight

and percentage:

LF

Weight

RF

1500 1500 25.0 25.0

1500 1500 25.0 25.0

LR

RR

LF

Percentage

RF

25

Page 26

Special displays

Target

Tune

LF

LF

Front

Rear

Rear Bite

SW Users

Rev G, February, 2000

Target, and Tune:

500 500 500 500

200 200 200 200

Sides:

Left Side

LS 1000 RS 2000

F 500 R 2500

LR

LR

Right Side

RF RR

RF RR

Center of Gravity:

Center of Gravity

LF TO RF 50.0

LR TO LR 100.0

Center of Gravity

Vertical Center of Gravity:

Vertical

Center of Gravity

VCG = 0.0

Left to Right

Front to Back

Bite:

Front Bite

RB 22

FB 20

26

Page 27

SW Users

REV G, February, 2000

Appendix C: C.G. / Vertical C.G. notes

Center of Gravity

This appendix deals with the use of scales to determine static tire loading and center of

balance. For detailed instructions on using this weight and balance information for

performance tuning of a racing chassis, please refer to a book like "Chassis

Engineering" by Herb Adams. This note is intended for use by racers, chassis setup

personnel, and any other interested persons.

Q: What is the "Center of Gravity?"

A: CENTER OF GRAVITY (CG) - That point about which the car would balance if

suspended. This point has a longitudinal (front to back) part , a lateral (side to side)

and vertical (up and down) part.

Q: Why do I care about the C.G.?

A: The C.G. has many impacts on how a car handles. The better a car handles, the

faster you can go!

With certain qualifications:

a) The higher the center of gravity the more the body will roll in a turn, accelerating

or braking.

b) The closer the C.G. is to the front or rear end the more weight that end will carry.

c) Moving components can change the C.G., as can adding or subtracting weight.

A good rule of thumb is the lower and more centrally located the C.G. under the most

demanding traction conditions, the better. For circle track racers this is in a turn, for

dragsters this is in a straight line.

Q: How do I find the longitudinal and lateral C.G. points?

A (part 1): Using an Intercomp SW scale you can find the horizontal C.G. this way:

Measure the wheel base and track. Center of gravity will be measured from the

center of the tire contact patch; use the center of the tire for the track, and the center

of the hub for the wheel base. The scale will use the left front pad as the reference

point for all calculations. Use inches to the nearest tenth of an inch.

Scale the car normally. When you have all four wheel weights on the display press

the ENTER key. This pulls up the features menu. Press 1 for C.G. calculation.

Enter the track width measurement taken above and press enter. Next enter the

wheel base measured above.

The display shows you side to side and front to back C.G. The first and third lines

display the C.G. in inches from the left front tire. The second and fourth line show

this value as percentage of wheel base and track, starting from the left front wheel.

A (part 2): If you are using other scales, this involves a little work with a calculator.

27

Page 28

SW Users

REV G, February, 2000

1) The first requirement is to measure the wheel base and track. Center of gravity

will be measured from the center of the tire contact patch; use the center of the

tire for the track, and the center of the hub for the wheel base. For our

calculations we must select a point as the starting point of our measurements;

this can be any point. We will select the center of the left front hub as our home

point. Picking this point will simplify some calculations. Use inches to the

nearest tenth of an inch. Each one of these measurements is called a moment

arm.

2) Weigh the car. Add all the weight together. This sum is called the total weight.

3) Take each wheel weight and multiply the weight by the distance measurement.

This is done on each axis. This product is called the moment. Please see the

worked example below.

4) Add up the moments for each axis; this total is called the total moment.

5) Divide the total moment for each axis by the total weight. This gives the

center of gravity.

See Figure 1 on next page

28

Page 29

Figure 1: C.G. calculations

SW Users

REV G, February, 2000

LF=684lb RF=570lb

Track=60”

WheelBase=105”

LR=912lb RR=674lb

Manual C.G. calculation

side to side:

Find total weight:

Total weight 2850lb

Find moments

LF 684x0” = 0 in-lb

RF 570x60” = 34200 in=lb

LR 912x0” = 0 in-lb

RR 684x60” = 41040 in-lb

Total moment 75240 in-lb

Find C.G.

Total moment: 75240 in-lb

Total weight: 2850 lb

LF 684lb

RF 570lb

LR 912lb

RR 684lb

=26.4”

26.4”

58.8”

C.G. location

Repeat for front to back

Total weight from above

Find moments

LF 684x0” =0” in-lb

RF 570x0” =0” inlb

LR 912x105” =95760 in-lb

RR 684x105” =71820 in-lb

Total moment 167580 in-lb

Find C.G.

Total moment 167580 in-lb

Total weight 2850 in-lb

29

= 58.8”

Page 30

SW Users

REV G, February, 2000

Vertical Center of Gravity

Q: How do I find the vertical C.G. point?

A (part 1): Using an Intercomp SW scale you can find the vertical C.G. this way:

Measure the wheel base and track. Longitudinal and lateral centers of gravity will be

measured from the center of the tire contact patch; use the center of the tire for the

track, and the center of the hub for the wheel base. The scale will use the left front pad

as the reference point for these calculations. Vertical C.G. will be measured from the

center of the wheel hub. Use inches to the nearest tenth of an inch.

Scale the car normally. When you have all four wheel weights on the display press the

“ENTER” key. This pulls up the features menu. Press 2 for the vertical C.G. point.

Type in the wheel base and press “ENTER”. The longitudinal C.G. in inches will be

shown.

Raise the rear tires. You want to raise the rear end about 1 inch per 10 to 12 inches of

wheel base.

An example: A 105 inch wheel base is a little less than nine feet, raise the rear end

nine inches. Do this by raising the mounting surface of the scale. This could be a

large block or some sort of support rack. When the car is on the scales and rocked in

to settle the bushings press enter. Type in the distance you have raised the surface of

the scale and press enter.

Done!

The first line shows the height of the vertical C.G. above the front wheel hubs. Line 1

shows the longitudinal C.G. when the car is flat. Line three shows longitudinal C.G. with

the car on an angle. It is this change along with the slope angle and the total weight

that is used to calculate the vertical C.G. location.

The last line is just the values you entered for wheel base and the amount you raised

the rear axle.

Add you hub height to get vertical C.G. above ground.

A (part 2): This will require a little work with a calculator.

First some explanation is in order. If you could just lay the car on its side you could just

measure the vertical C.G. directly. This presents some practical difficulties. You must

use a more indirect method.

Cont’d on next page

30

Page 31

Please examine this picture:

Small change for low C.G.

Flat position

Wheel base X Change in C.G.

High C.G.

SW Users

REV G, February, 2000

Low C.G.

Large change for high C.G.

Raised position

Flat position

As you can see, the higher the C.G. is, the more the C.G. will move forward when you

raise the rear wheels. With this change and a little geometry we can find out the actual

C.G. height. Please examine the picture below.

Unknown side

Raised position

Same angle

Known lift

As the car is lifted/rotated a triangle is formed by the front hub, wheel base, and known

lift. A second triangle is formed by vertical C.G. location, distance from the wheel base

line, and change in longitudinal C.G. location. These two triangles share the same

angles so they can be considered similar triangles and compared directly.

Change in C.G.

Vertical C.G. =

Known wheel base

Lift

31

Page 32

SW Users

REV G, February, 2000

1) The first requirement is to measure the wheel base. Center of gravity will be

measured from the center of the hub for the vertical C.G. For our calculations we

must select the center of the front hub for the math to work out correctly. Use inches

to the nearest tenth of an inch.

2) Weigh the car. Form total weights for the rear axle and total weight.

3) Multiply the rear axle weight by the wheel base measurement giving rear moment.

4) Find the longitudinal C.G. by dividing the rear moment by the total weight. Call this

the flat C.G.

5) Lift the rear end.

6) Weigh the car. Form total weights for the rear axles and total weight.

7) Multiply the rear axle weight by the wheel base measurement.

8) Find the longitudinal C.G. by dividing the rear moment by the total weight. Call this

the lifted C.G.

9) Solve this equation: Vertical C.G. = (wheel base X (flat C.G. - Lifted C.G.)) / lift

10) Add the hub height to get vertical C.G. above ground.

See Figure 2 for a summary

32

Page 33

Figure 2: Manual Vertical C.G.

Find longitudinal C.G.:

Rear wgt X Wheel base

Total Wgt

1577 lb x 105"

2850 lb

= 58.1"

Raise rear end and

find C.G. again:

1596 lb x 105"

2850 lb

= 58.5"

Solve for vertical C.G.:

V C.G. =

Wheel base X (F C.G - L C.G)

Lift

105" x (58.5" - 58.1")

9"

= 4.7"

Add in height of wheel hub:

Vertical C.G. = 13" + 4.7" = 17.7"

Wheel base = 105"

LF + RF = 1254 lb

F LR + RR

Lift = 9"

F C.G.

L C.G.

= 1596 lb

L LR + RR = 1577 lb

13"

V C.G = 4.7" from hub

V C.G. = 17.7" from ground

SW Users

REV G, February, 2000

33

Page 34

SW Users

REV G, February, 2000

Serial Output (Optional)

The serial output for the SW can output to a 1200-baud printer . The signal comes out

of the Serial I/O connector located in the lower right corner of the keypad. The

connector has the following pinout:

Signal Pin

9V Printer Power A

GND B

NC C

CTS D

TXD E

GND F

Printer

The printer output is designed to connect with a 1200-baud printer. The transmitted

signal has the following characteristics:

Fixed 1200 baud, 8 Data bits, no parity, 1 stop bit.

See the “Printing (optional)” and “Appendix A” sections for more information on printing.

34

Page 35

Example Connections

The connection to a 9-pin PC communication port is:

SWX (serial I/O) PC 9-pin

E 2

F 5

D 7

The connection to a 25-pin PC communication port is:

SWX (serial I/O) PC 25-pin

E 3

F 7

D 4

The connection to an Intercomp PDP printer is:

SWX (serial I/O) PDP 25-pin

D (CTS) 5 (RTS)

E (TXD) 2 (RXD)

F (GND) 7 (GND)

SW Users

REV G, February, 2000

If multiple displays are to be hooked up to a single SW Scale a RS-232 repeater might

be needed.

35

Page 36

How to reach Intercomp Service

Things to know:

Inform the Service Dept. that the product is a SW scale system.

When was the scale system purchased?

Where was the scale system purchased?

For Intercomp Service call or fax:

FAX # (763)-476-2613

(763)-476-2531

1-800-328-3336

or fill out Service Support Form at :

http://www.intercompco.com/

SW, Users

Rev G, February, 2000

Copyright Intercomp Company 1994, 95, 96, 97, 98, 99, 2000

ALL RIGHTS RESERVED

36

Loading...

Loading...