Page 1

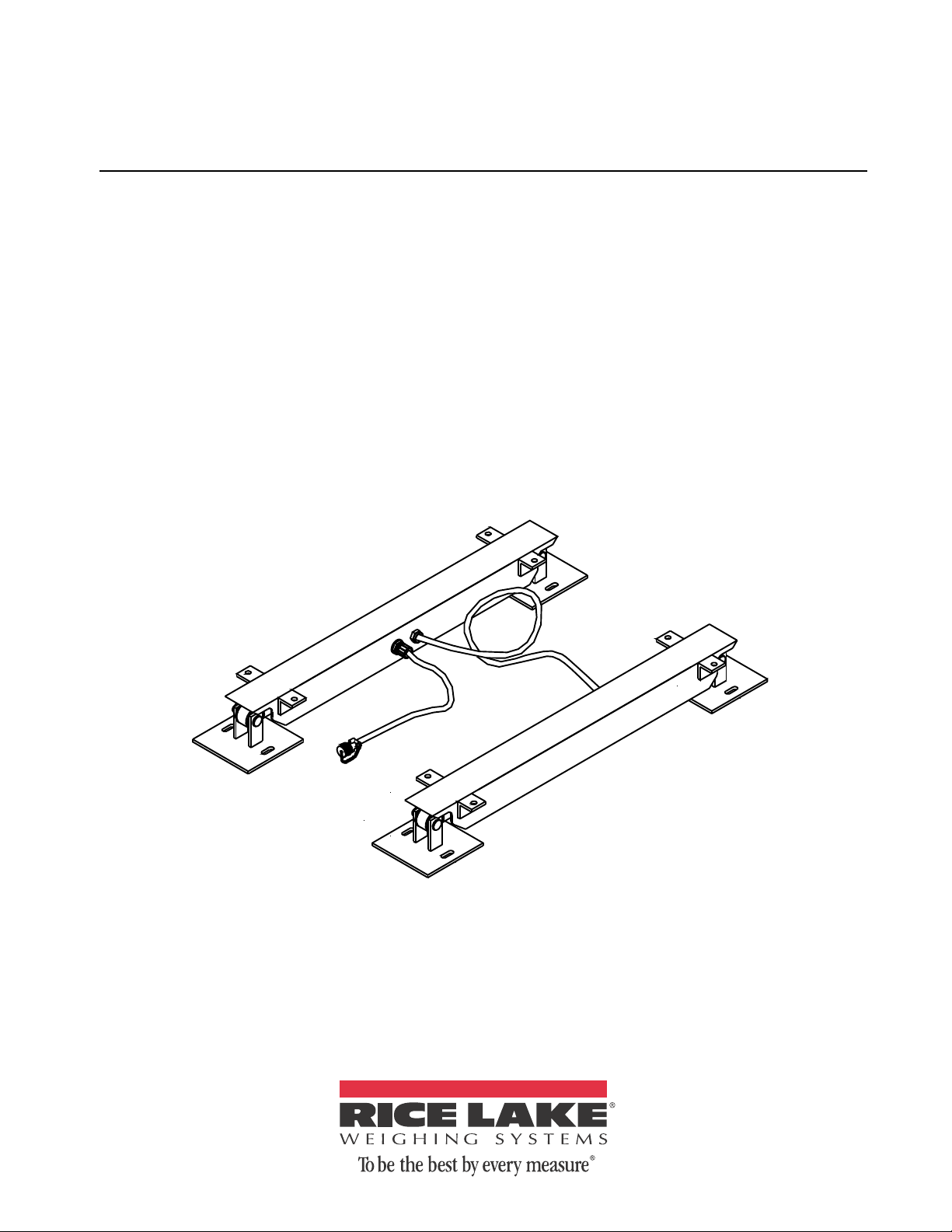

KLU Series

Universal Weighbars

Operator’s Manual

127469 Rev B

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction.................................................................................................................................. 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Technical Specifications............................................................................................................. 2

3.0 Installation ................................................................................................................................... 3

4.0 Parts List ...................................................................................................................................... 4

5.0 Maintenance ................................................................................................................................ 8

5.1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.0 Troubleshooting ......................................................................................................................... 10

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.2 Drifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3 Abnormally Large Reading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

KLU Series Limited Warranty................................................................................................................. 14

For More Information ............................................................................................................................. 15

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

August 27, 2013

Page 4

ii KLU Series Operator’s Manual

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

1.0 Introduction

Important

WARNING

WARNING

The electronic weighing equipment you have purchased has been manufactured using high quality components and

the latest production techniques to ensure reliable, trouble-free operation for years to come. To obtain the best

possible performance from your weighing equipment, please read this manual carefully.

The load bar consists of a steel tube containing load cell mounts,

two factory calibrated load cells. The load bars are of solid construction and, therefore, do not require any

horizontal checking (check rods). Load bars are designed to withstand horizontal loads in the same range as their

capacity without any damage. Care should be taken to remove the possibility of horizontal impacts with the scale

platform. Impacts or collisions tend to create very high forces.

The versatility of the load bars allows any platform or container

beneath them. Various indicator combinations can be matched to the load bars to meet specialized applications.

1. 1 S af et y

Safety Symbol Definitions:

Indicates a potentially hazardous situation that, if not avoided could result in serious injury or death, and

includes hazards that are exposed when guards are removed.

load cells, and mounting pads. Each bar contains

to become a weigh scale by placing a set of bars

Indicates information about procedures that, if not obs

corruption to and loss of data.

General Safety

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions or heed the warnings could result in injury or

death. Contact any Rice Lake Weighing Systems dealer for replacement manuals. Proper care is your

responsibility.

Failure to heed may result in serious injury of death.

DO NOT allow minors (children) or inexper

DO NOT operate without all shields and guards in place.

DO NOT jump on the scale.

DO NOT use for purposes other than weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load bearing component that is

DO NOT use this product if any of the

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

ienced persons to operate this unit.

worn beyond 5% of the original dimension.

components are cracked.

erved, could result in damage to equipment or

Introduction 1

Page 6

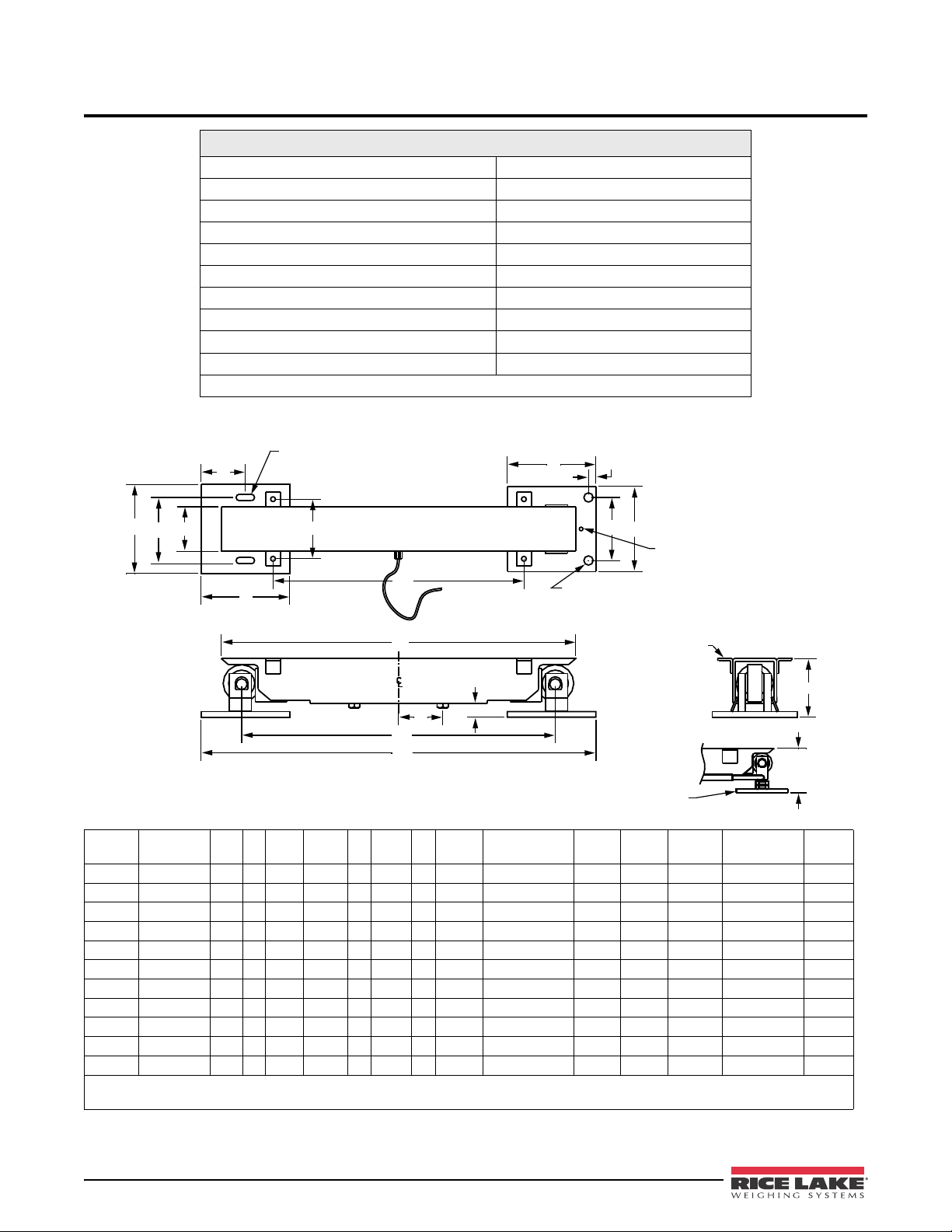

2.0 Technical Specifications

SLOTTED HOLE 7/16" x 1 1/4"

MODELS 1-5 KLU

1 KLU

2 KLU

4 KLU

F

W

C

G

B

A

E

E

C

G

F

L

D

N

P

K

H

H(a)

LOAD CELL CABLE

(20' LONG)

HOLE FOR LEVELING SCREWS

(1/2" N.C.) 8,16,30,45,60 KLU

1" Ø MOUNTING HOLES (8 & 16 KLU)

1.25" Ø MOUNTING HOLES (30,45,60 KLU)

2" x 2" x 1/4" ANGLE

2" WIDE - 2 KLU

1.5" x 1.5" x 1/8" ANGLE

1.5" WIDE - .1-1 KLU

5" Ø PAD - .1-5,1,2,4 KLU

7" Ø PAD - 8,16 KLU

For all KLU Series Load Bars

Nominal Output 2.5 mV/V *

Max. Excitation Voltage +15V D.C.

Thermal Shift 0.0012% FS/°F

Thermal Sensitivity Shift 0.0008% of Reading/°F

Hysterisis 0.02% FS

Non Linearity 0.02% FS

Operating Temp. range -40 to 105°F (-40 to 40°C)

Overload Capacity 150% of Rated Capacity

Side Discrimination 1000:1

Bridge Resistance 350 Ohms

* Output is standardized for e

ach load bar. Contact factory for details.

Table 2-1. Specifications

KLU

Model

*.1,.2,.3 100 to 300 15 5 4 1/4 L-2 1/4 6 6 3 3 7/8 4 1/4 - 4 3/4 7/8 22 L+3 3/4 --- 3

*0.5,1 500 to 1000 15 5 4 1/4 L-1 3/4 6 6 3 3 7/8 4 1/4 - 4 3/4 7/8 22 L+4 1/4 --- 3

60KLUR 60000 10 8 8 1/2 L-5 1/2 12 11 1/2 1 7 7/8 --- 1 7/8 44-120 L+6 1/2 (L/2)-20 1/4 6

60KLUP 60000 10 8 --- L-5 1/2 6 8 -- --- 7 7/8 1 7/8 44-120 L+3/4 (L/2)-20 1/4 6

*These Load Bars available in only 22” lengths.

All measurement are in inches.

Capacity

(lb) A B C D E F G H

2 2000 L-12 5 4 1/8 L-2 1/4 6 6 3 4 4 1/2 - 5 1 27-48 L+3 3/4 (L/2)-12 1/2 3

4 4000 L-12 5 4 1/4 L-2 1/2 6 6 3 4 4 1/2 - 5 1 28-72 L+3 1/2 (L/2)-12 1/2 3

8 8000 L-12 6 4 1/2 L-3 1/4 8 6 1 5 1/4 6 - 6 1/2 1 1/4 30-96 L+4 3/4 (L/2)-13 3/8 4

16 16000 L-12 6 4 1/2 L-2 3/4 8 6 1 5 1/4 6 - 6 1/2 1 1/4 30-96 L+5 1/4 (L/2)-13 3/8 4

30 30000 L-12 7 8 L-4 1/2 8 10 1 6 15/16 --- 1 15/16 34-120 L+5 1/2 (L/2)-15 1/4 5

45 45000 L-12 7 8

60 60000 L-12 8 8 1/2 L-5 1/2 12 11 1/2 1 7 7/8 --- 1 7/8 44-120 L+5 1/2 (L/2)-20 1/4 6

L-4 1/2 8 10 1 6 15/16 --- 1 15/16 34-120 L+5 1/2 (L/2)-15 1/4 5

Table 2-2. Dimensions

H(a)

Portable Bar K L N P W

2 KLU Series Universal Weighbars Operator’s Manual

Page 7

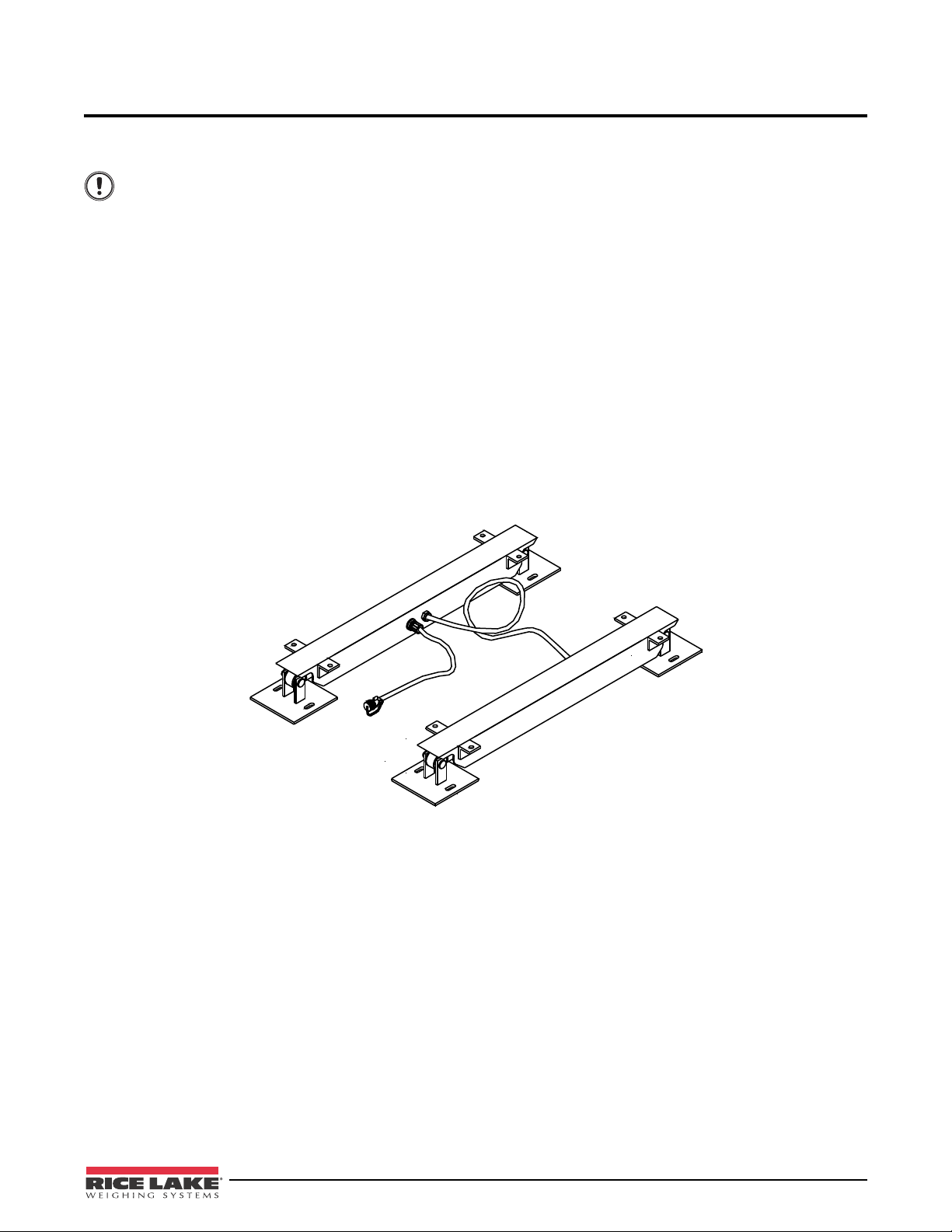

3.0 Installation

Important

The following points are to help ensure proper installation of the load bars. If any further assistance is required,

please contact your nearest factory or dealer.

When planning an outdoor location for the load bars, choose a site which will allow for adequate

drainage away from the scale. Immersing the load cells in

warranty.

• Try to install the load bars on a firm, level surface. The load bars do not have to be installed perfectly

level, but a substantial slope will decrease accuracy. All weight transfer must take place through the

pads at the end of each load bar. Make sure there is no contact between the ground and the center of the

load bar.

• Install the load bars in the upright position. This will allow for accurate weighing and will help keep

foreign material out of the load bar.

any

• Do not drill into or weld onto the load bars as this may

Secure the load bars to the weighing platform using the mounting lugs supplied.

• Install the cable so that it is not stepped on or run ov

covered under warranty.

• When constructing the weighing platform, ensure exce

inaccuracies in weighing and could damage the cable.

water can damage the load cells and void the

cause internal structural or electrical damage.

er. Cable failure due to physical damage is not

ssive sagging does not occur. This may cause

Figure 3-1. KLU Series Universal Weighbars

Installation 3

Page 8

4.0 Parts List

100107

Portable

Pad Upright

Jam Nut

Portable Pad

Bearing Collar

Bearing

Snap Ring

Spacer

Foam Seal

100963

for .X 4KLU

Washer

100609

for 8, 16KLU

Pad

8, 16 KLU Pads Only

Load Cell

.1 1 KLU

54243

Set Screws

Load Pin

Items may not be exactly

as shown

Load Bar

Tube

100547

Bolt for

Load Cell

Load Cell

2 16 KLU

Figure 4-1. For 0.1 - 16 KLU Load Bar Parts

4 KLU Series Universal Weighbars Operator’s Manual

Page 9

0.x KLU 1 KLU 2 KLU 4 KLU 8 KLU 16 KLU

Description

Bearing 101211 1012114 101212 101212 101216 101216

Bearing Collar 54203 54203 55203 56203 63203 63203

*Bearing Collar Assembly 54202 54202 55202 56202 63202 63202

Cotter Pin (5/32” x 1”) 100963 100963 100963 100963 100963 100963

Foam Seal 101232 101232 101232 101233 101234 101234

Hex Mounting Bolt 100735 100735 100735 100735 100718 100718

**Load Bar Tube 59206 59206 61206 62206 63206 64206

Load Cell 60201.X 60201 61201 62201 63201 64201

Load Cell Assm. (Incl. 202) 60200.X 60200 61200 62200 63200 64200

Load Pin 54209 54209 54209 54209 63209 63209

Load Pin Lock Bolt ----- ----- ----- ----- 100609 100609

Load Pin Spacer 54210 54210 54210 56210 63210 63210

Pad 54207 54207 54207 54207 63207 63207

Pad Base Plate 54207P-2 54207P-2 54207P-2 54207P-2 63207P-2 63207P-2

***Pad Portable Upright 54207PX 54207PX 54207PX 54207PX 63207PX 63207PX

Rodent Guard 54243 54243 ----- ----- ----- -----

Set Screw 100802 100802 100802 100802 100806 100806

Snap Button Cover 101008 101008 ----- ----- ----- -----

Snap Ring 101226 101226 101226 101227 101231 101231

Stop Tube 100107 100107 100107 100107 100107 100107

Washer 100931 100931 100931 100931 100938 100938

Operators Manual 127469 127469 127469 127469 127469 127469

*Assembly includes: collar, bearing, snap r

**0.1 -> 1 KLU load bars available only in 22" lengths, specify length for others

***Portable Pad 54207PA(clockwise), 54207PB(counter clockwise) direction is determined by look down from top of load bar

and determining direction the stop rod is pointing.

Specify load bar length in inches

Part # Part # Part # Part # Part # Part #

ing, seals, set screws

Table 4-1. 0.1 - 16 KLU Load Bar Parts

Parts List 5

Page 10

67207R-2

Upper Pad

Removable

60 KLU Only

67207R-3

Lower Pad

Removable

60 KLU Only

Portable Pad

Bearing Collar

Bearing

Snap Ring

Spacer

Foam Seal

67214

100593

Pad Permanent

Set Screws

Load Pin

Load Cell

Bolt for

Load Cell

Load Bar

Tube

100547

Figure 4-2. For 30, 45, 60 KLU Load Bars

6 KLU Series Universal Weighbars Operator’s Manual

Page 11

30 KLU 45 KLU 60 KLU

Description

Bearing 101214 128760 101214 128760 101217 127241

Bearing Collar 65203 66203 127834 67203 127837

*Bearing Collar Assembly1 65202 66202 127833 67202

Foam Bearing Seal 101235 126824 101235 126824 101236 126825

Hex Mounting Bolt (Gr. 8) 100700 126999 100700 126999 100700 126999

Liquid-Tite Connector (3/8) 100547 127146 100547 127146 100547 127146

Load Bar Tube (Specify Length) 65206 66206 67206

Load Cell 65201 66201 67201

Load Cell Assembly (Incl. 202) 65200 127824 66200 127831 67200 127836

Load Pin 65209 127829 65209 127829 67209 127848

Load Pin (Removable Pad) ----- ----- 67209R 127849

Load Pin Lock Bolt 100593 127010 100593 127010 100593 127010

Load Pin Spacer 65210 127830 65210 127830 67210 127850

Load Pin Spacer (Removable Pad) ----- ----- 67210R 127851

Load Pin Stop 67214 127852 67214 127852 67214 127852

Pad – Permanent 65207 127826 65207 127826 65207 127826

Pad – Portable ----- 65207P 127828 67207P 127845

Pad – Removable ----- ----- 67207R 127846

Setscrew 100807 126985 100807 126985 100814 126986

Snap Ring 101229 126808 101229 126808 101230 126809

Operators Manual 127469 127469 127469

*Assembly includes: collar, bearing, snap r

Part # Part # Part #

ing, seals and set screws.

Table 4-2. For 30, 45, 60 KLU Load Bars

Parts List 7

Page 12

5.0 Maintenance

XXXXXXXXXXXXXX

WZERO

*CAL*

Display and edit

zero calibration

A/D count value

Display and edit

test weight value

WVAL

*CAL*

Display and edit

span calibration

A/D count value

WSPAN

VERSPROGRM PFORMTSERIALCALIBRCONFIG FORMAT

Press Enter to

remove offset from

zero and span

calibrations

REZERO

*CAL*

The most common type of problem that can occur is the load is not supported completely by the load bar pads. On

a regular basis check around and under the weigh apparatus to see if any debris has collected near the scale. Any

ice, dirt, mud or manure that builds up around the weigh apparatus can cause inaccurate readings. The scale should

be kept clean to ensure proper operation.

It should also be noted that an excess of debris on top o

type of scale you have, there may be a limited range of weight you can “zero” off the scale. Always keep the buildup of material on top of the scale to a minimum.

Lubrication of the bearings in your scale is also important. The bearings

in the parts list diagrams in Figure 4-1 and Figure 4-2. Inject grease into the bearings using a syringe at least once

every two years. Use good high-pressure grease to lubricate the bearings completely. Do not use an excess of

grease – it should lubricate the bearing without bleeding around the foam seal.

5.1 Calibration

All Load cells are calibrated at the factory to reduce installation errors. Over the course of time, however, the load

cells may drift out of calibration slightly. Normally when a scale's load cells go out of calibration, the digital

indicator is adjusted to compensate for this.

The KLU Series Loa

configuration utility. Each method consists of the following steps:

• Zero calibration

• Entering the test weight value

• Span calibration

• Optional rezero calibration for test weights using hooks or chains.

The following sections describe the

dbars can be calibrated using the front panel, EDP commands, or the Revolution

calibration procedure for each of the calibration methods.

f the scale could also cause problems. Depending on the

are located in the bearing collar, as shown

®

Front Panel Calibration

To calibrate the indicator using the front panel, do the following:

8 KLU Series Universal Weighbars Operator’s Manual

Figure 5-1. Calibration (CALIBR) Menu

1. Place the indicator in setup mode (display reads

CONFIG) and remove all weight from the scale platform.

If your test weights require hooks or chains, place the hooks or chains on the scale for zero calibration.

2. Press

3. With

progress. When complete, the A/D count for the zero calibration is displayed. Press

until the display reads CALIBR (see Figure 5-1). Press to go to zero calibration (WZERO).

WZERO displayed, press to calibrate zero. The indicator displays *CAL* while calibration is in

again to save the

zero calibration value and go to the next prompt (WVAL).

4. With

WVAL displayed, place test weights on the scale and press to show the test weight value. Use the

numeric keypad to enter the actual test weight, then press to save the value and go to span calibration

(WSPAN).

5. With

6. The rezero function is used to remove a

WSPAN displayed, press to calibrate span. The indicator displays *CAL* while calibration is in

progress. When complete, the A/D count for the span calibration

span calibration value and go to

the next prompt (REZERO).

is displayed. Press again to save the

calibration offset when hooks or chains are used to hang the test

weights.

• If no other apparatus was used to hang the test weights during calibration, remove the test weights and

to return to the CALIBR menu.

ss

pre

Page 13

• If hooks or chains were used during calibration, remove these and the test weights from the scale. With

Note

all weight removed, press

values. The indicator displays

complete, the adjusted A/D count for the zero calibration is displayed. Press

press

7. Press

to return to the CALIBR menu.

until the display reads CONFIG, then press to exit setup mode.

To perform the calibration using EDP commands or Revolution®, consult the indicator operator's manual.

to rezero the scale. This function adjusts the zero and span calibration

*CAL* while the zero and span calibrations are adjusted. When

to enter the value, then

Maintenance 9

Page 14

6.0 Troubleshooting

Note

6.1 General

If you are having trouble with your load bars, a few simple procedures should help you determine where the

problem lies. First, inspect the scale for any physical damage. Take special note of the cable and connectors.

Wiggle the cables and connectors while watching the indicator display. If the readout jumps while moving a cable

or connector, there is likely a short or loose connection. Repair or replace the cable or connector as appropriate.

6.2 Drifting

If the scale readout is drifting, moisture may be present somewhere in the scale's electrical circuit. Check for

moisture in any of the connectors, junction boxes, or load bars. Dry any location where you suspect moisture is

present. If you find a location where moisture is collecting on a regular basis, seal the location with a waterproof

sealant.

6.3 Abnormally Large Reading

If the indicator shows a very large number and the readout cannot be changed using the indicators zero adjustment,

there may be a problem in the circuit. To locate this type of problem, a series of electrical resistance measurements

must be made. To perform these checks, you will need an accurate ohmmeter and a soldering iron.

To locate a faulty component with the ohmmeter, start by taking readings in th

indicator cable (this is the cable the runs into your scale). The connector has four pins labelled A, B, C and D, the

following chart lists the appropriate resistance readings. Remember, when making this type of measurement the

power must be OFF. Further, be careful that your fingers are not making contact with the probes on the ohmmeter

– if they are, the reading you take may be incorrect.

e connector that plugs into the

2-Load Bar

*Wire Color Connector Pin

White – Red D – C 145Ω 290Ω 395Ω

White-Green D – B 175Ω 350Ω 350Ω

White-Black D – A 145Ω 290Ω 395Ω

Black-Green A – B 145Ω 290Ω 45Ω

Black-Red A – C 197.5Ω 395Ω 790Ω

Green-Red B – C 145Ω 290Ω 745Ω

White-Brown

Brown-Red

Black-GND

GND-Frame

*See Figure 6-1

**Valid only if Loadbar is disconnected from rest of circuit.

***Valid only if Load Cell is disconnected from rest of circuit.

This chart is only valid at a temperature of 22°C. Resistance will vary slightly with temperature.

Table 6-1. Ohmmeter Readings

System

>10MΩ >10MΩ >10MΩ

0 0 0

**One Load Bar

***Single Load

Cell

350

Ω

45

Ω

The readings in Table 6-1 should be within 5 ohms of the value shown. The readings are slightly temperature

dependent and as a result will not match Table 6-1 exactly. However, all the readings you take

the table by the same percentage. For example, if

the resistance across pins D & C reads 142Ω ±1Ω, resistance

should differ from

across pins D & A should also read 142Ω ±1Ω. In other words the values equal in Tabl e 6-1 should also be equal

when you take your measurements. If the readings correspond to the values in the table an electrical problem in the

scale is not likely. If any readings across pins of the connector differ from the chart, each load cell must be checked

individually.

10 KLU Series Universal Weighbars Operator’s Manual

Page 15

To check a load bar separately, it must be completely disconnected from the scale's electrical circuit. This is

Wire from

Load Bar 1

Black (-EX)

Green (+SIG)

Red (+EX)

White (-SIG)

Shield

Black (-EX)

Green (+SIG)

Red (+EX)

White (-SIG)

Shield

Wire from

Load Bar 2

Black (-EX)

Green (+SIG)

Red (+EX)

White (-SIG)

Shield

Wire to Instrument

accomplished by disconnecting the load bar at the scale's junction box,

contains a Weights & Measures seal, consult your scale dealer be

fore proceeding. To disconnect a load bar, loosen

Figure 6-1. However if the junction box

the screws on the circuit board for the load bar in question, and remove the wires. Resistance measurements can

now be taken as shown in Table 6-1, and should correspond with the values in the "One Load Bar" column in the

same way as described above. If not, consult your scale deale

r. The dealer may ask you to check the individual load

cells.

Figure 6-1. Junction Box Wire

When checking an individual load cell, it must be completely disconnected from the scale's electrical circuit. To

accomplish this, the wires will need to be taken apart at the load bar cable splice. See Figure 6-2 for the wiring of a

load bar system. The circuit diagram for the Load Cells of a single load bar is shown in Figure 6-4. Remember that

each load cell contains five wires, but each load bar has only

four wires running to the junction box. All five wires

must be disconnected to separate that load cell from the circuit.

Troubleshooting 11

Page 16

Top View

Load Bar 1

BR

BR

G

G

BK

R

W

BK

W

R

W

(-SIG)

BK

(-EX)

G (+SIG)

R (+EX)

Sealed Splice

(Solder, MCOAT-A, Silicone, Heat Shrink)

To Junction Box

Junction Box

to Junction Box

To Instrument

W

(-SIG)

BK

(-EX)

G (+SIG)

R (+EX)

BK

W

R

G

WH

Black

BR

BR

G

R

Sealed Splice

(Solder, MCOAT-A, Silicone, Heat Shrink)

Top View

Load Bar 2

Color Key

Color

Code

Black

Brown

Green

Red

White

BK

BR

G

R

W

DA

BC

Indicator

AD

CB

KLU Bar

A -EXC Black

B +SIG Green

C +EXC Red

D -SIG White

Connector

12 KLU Series Universal Weighbars Operator’s Manual

Figure 6-2. Load Bar System Wiring Diagram

Figure 6-3. Load Bar System Connection

Page 17

T = Tension

C = Compression

White

Tc

T

C

Tc

Red

Red Black

Brown Green

RedBlack

BrownGreen

Tc

T

C

Tc

Black

Load Cell

Load Cell

Loadbar

White Green

Figure 6-4. Load Bar Schematic

Troubleshooting 13

Page 18

KLU Series Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by the

Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in materials

and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent

electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a publication,

Protecting Your Components From Static Damage in Shipment, available from RLWS Equipment Return

Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was not

caused by accident, misuse, neglect, alteration, improper installation, improper repair or improper testing;

RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly

authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for

shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’ SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR

OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER

CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

© 2011 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

14 KLU Series Universal Weighbars Operator’s Manual

Page 19

For More Information

Web Site

• http://www.ricelake.com/products/livestock-solutions

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m. Monday through Friday and 8

a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Immediate/Emergency Service

For immediate assistance call toll-free 1-800-472-6703

Canadian and Mexican customers please call 1-800-321-6703

If you are calling after standard business hours and have an urgent scale outage or emergency, press 1 to reach

on-call personnel.

Fax

Fax Number 715-234-6967

Email

U.S. sales and product information at

• prodinfo@ricelake.com

International (non-U.S.) sales and product information at

• intlsales@ricelake.com

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

Troubleshooting 15

Page 20

16 KLU Series Universal Weighbars Operator’s Manual

Page 21

Page 22

230 W. Coleman St. Rice Lake, WI 54868 USA

U.S. 800-472-6703 Canada/Mexico 800-321-6703 International 715-234-9171 Europe +31 (0) 88 2349171

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 127469 Rev B 08/2013

Loading...

Loading...