Page 1

CS750 Crane Scale

Users Manual

Intercomp Co.

3839 County Road 116

Medina, MN 55340

(763)-476-2531

1-800-328-3336

Fax: 763-476-2613

www.intercompcompany.com

Manual#: 700002-R

Page 1 of 27

Page 2

Table of Contents

CS750, Users

Rev R, May 2009

INTRODUCTION ....................................................................................................................................................... 3

S

PECIFICATIONS

Controls................................................................................................................................................................3

Electrical.............................................................................................................................................................. 3

Performance.........................................................................................................................................................3

Environmental ...................................................................................................................................................... 3

Physical................................................................................................................................................................ 3

W

EIGHTS AND MEASURES

O

PTIONAL EQUIPMENT

OPERATIONS............................................................................................................................................................. 5

O

PERATING PRACTICES

D

ISPLAY

C

ONTROLS

ON........................................................................................................................................................................ 7

OFF...................................................................................................................................................................... 7

ZERO....................................................................................................................................................................7

BACK LIGHT....................................................................................................................................................... 7

Hidden key ........................................................................................................................................................... 7

R

EMOTE CONTROL

O

PERATION

Use .......................................................................................................................................................................9

Periodic Maintenance .......................................................................................................................................... 9

P

OWER/BATTERIES

Replacement .........................................................................................................................................................9

Rechargeable (Ni-cad) ......................................................................................................................................... 9

.........................................................................................................................................................3

......................................................................................................................................... 4

............................................................................................................................................... 4

.............................................................................................................................................. 5

.................................................................................................................................................................... 6

................................................................................................................................................................. 6

....................................................................................................................................................8

................................................................................................................................................................ 9

....................................................................................................................................................9

MAINTENANCE....................................................................................................................................................... 10

P

ERIODIC INSPECTION

Service Categories ............................................................................................................................................. 10

Inspection Requirements ....................................................................................................................................10

Removal from Service Criteria...........................................................................................................................11

C

ALIBRATION

How to test the calibration .................................................................................................................................12

Calibration switch..............................................................................................................................................13

Enabling the Calibration switch ........................................................................................................................13

How to calibrate the scale..................................................................................................................................13

Weight calibration.............................................................................................................................................. 18

L

EGAL-FOR-TRADE SEALING

TROUBLESHOOTING ............................................................................................................................................19

ERROR MESSAGES ................................................................................................................................................ 21

PARTS AND ACCESSORIES.................................................................................................................................. 22

P

ARTS LIST

SERIAL OUTPUT (OPTIONAL) ............................................................................................................................24

HOW TO REACH INTERCOMP SERVICE.........................................................................................................27

...........................................................................................................................................................12

.............................................................................................................................................................. 23

.............................................................................................................................................. 10

...................................................................................................................................18

Page 2 of 27

Page 3

CS750, Users

Rev R, May 2009

Introduction

This manual contains specifications, operation instructions, and calibration instructions

for Intercomp's model CS750 crane scale.

Specifications

Controls

General: Zero, On, Off, Backlight

Display: 5 digit LCD.

Indicators: lb, kg.

Electrical

Batteries: 6 X D-size disposable alkaline dry cells or rechargeable Nickel-

Cadmium cells.

Battery life: Up to 250 hours with alkaline batteries. Approximately 80 hours

on a set of fully charged Ni-Cad cells.

Resolution: 20 bit A/D delivers over 1,000,000 internal counts.

Filtering: 6 Pole, 10 Hertz low pass.

Auto off: Low battery, or after adjustable time without use or motion.

Sleep

mode:

Auto-Zero: Satisfies all HB-44 requirements; selectable 0.6, 1, or 3

Display sleep mode after adjustable time without use or motion.

graduations.

Performance

Accuracy: ±0.1% of applied load or ± display graduation, whichever is greater.

Environmental

Humidity: 10 to 95% Non-Condensing

Temperature: Storage: -40 C to +75 C. / -40 F to +170 F.

Operating -10 C to +50 C. / +14 F to +122 F.

Physical

Dimensions:

Control Box: 4.25" x 5" x 8.5". / 10.8 cm X

12.7 cm x 21.6 cm.

Lifting eye to hook (Standard): 12" / 30.5 cm.

Weight: 7.5 lb. / 3.4 kg.

Page 3 of 27

Page 4

CS750, Users

Rev R, May 2009

Weights and Measures

The CS750 meets or exceeds class III standards for 3000

division accuracy from 300 lb to 1000 lb. The certification was

completed by the National Type Evaluation Program (NTEP)s in

accordance with the National Institute of Standards and Technology

(NIST) Handbook 44. A NTEP Certificate of Conformance Number

96-135 was issued under the National Conference of Weights and

Measures.

Optional Equipment

RS232 Serial data output (100721)

This option adds an RS232 connection so the unit may transmit a continuous output to

communicate with a computer or remote display.

LED Display (100725)

Optional LED (light emitting diode) display instead of the standard LCD (liquid crystal

display) display. An LED is fully readable in pitch-dark lighting situations.

Battery pack and 120V external charger (100730)

Rechargeable Ni-Cad battery pack (6 D-cells) with 120V external charger. Standard

power uses 6 disposable alkaline dry cells.

Battery pack and 220V external charger (100731)

Rechargeable Ni-Cad battery pack (6 D-cells) with 220V external charger. Standard

power uses 6 disposable alkaline dry cells.

Direct Power on crane unit, 120V (100723)

This option allows the CS750 to use 120V power instead of batteries.

Direct Power on crane unit, 220V (100727)

This option allows the CS750 to use 220V power instead of batteries.

Set Points, dual channel, (100792)

This option allows for 2 external set points. When the specified weight (set point) is

reached, a logic level high will be on the set point connection. Set points are used with

some other device (e.g. alarm, relay) in conjunction to the CS750.

Page 4 of 27

Page 5

CS750, Users

Rev R, May 2009

Operations

Operating Practices

Warning: The crane scale will be operated by qualified designated persons, trainees

under the direct supervision of designated persons, maintenance and test personnel

when in performance of their assigned duties, or lifting device inspectors.

Warning: Do not exceed the rated load limit of the crane scale.

Warning: The crane scale shall be applied to the load in accordance with the

instruction manual.

Warning: Prior to lifting the operator shall make sure that all ropes or chains are not

kinked and if multiple lines are used they are not twisted around each other.

Warning: Ensure that the load is correctly distributed for crane scale use.

Warning: Ensure the temperature of the load does not exceed the maximum

temperature limits of the crane scale.

Warning: Ensure that swinging of the crane scale is minimized when positioning it over

the load.

Warning: Avoid any sudden acceleration of deceleration when moving the load.

Warning: Do not allow the crane scale or the lifter to come into contact with any

obstruction when moving the load.

Warning: Do not operate the crane scale if it has damaged, malfunctioning or missing

parts.

Warning: Do not lift people with the crane scale.

Warning: Do not lift suspended loads over people.

Warning: Do not use the crane scale to pull side loads or to slide loads unless

specifically authorized by a qualified person.

Warning: Do not leave suspended loads unattended.

Warning: Do not remove or obscure warning labels.

Warning: Do not operate the crane scale without having read and understood the

operating manual.

Page 5 of 27

Page 6

CS750, Users

Rev R, May 2009

Warning: Stay clear of suspended loads.

Warning: Do not lift loads higher than necessary.

Warning: Do not make alterations or modifications to the crane scale.

Warning: Ensure all portions of the human body are kept clear of all device involved

with the rigging during the lift.

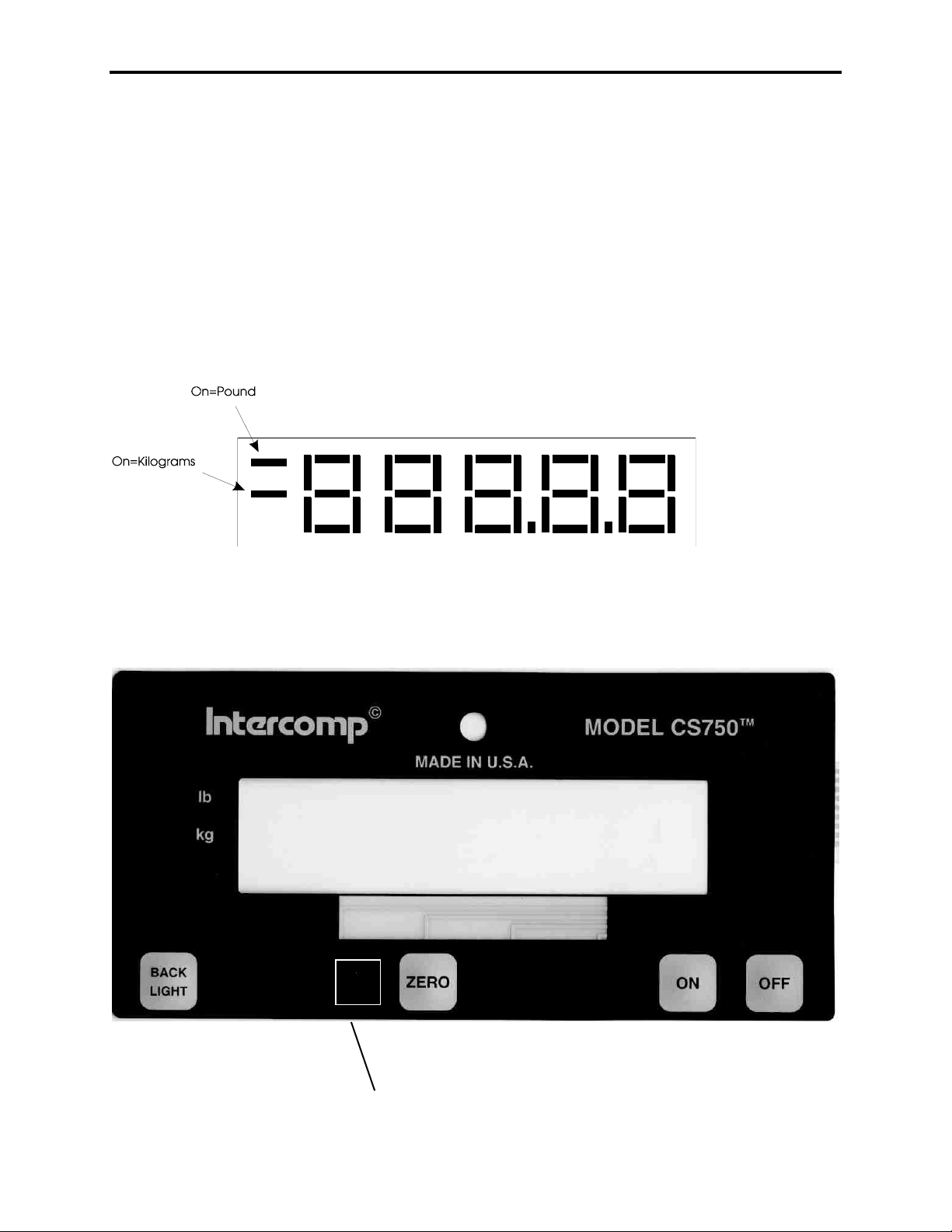

Display

Controls

Hidden key

Page 6 of 27

Page 7

CS750, Users

Rev R, May 2009

ON

Press this button to turn the scale on. The scale tests itself; when these tests

have completed successfully, the system begins weighing.

Note: If you used the remote control to turn off the scale (the last time), you must

first press the OFF key, then press the ON key.

OFF

Press this button to turn the scale off.

ZERO

Tells the scale to display a zero weight. This button is used any time the scale

shows a non-zero value with no weight on the hook. If you press ZERO with

weight on the hook, that weight becomes the zero condition for the scale. This

can be useful to cancel the weight of any weighing fixtures, such as containers,

chains or cables. When this weight is removed, a negative weight shows until

the system is zeroed again. NOTE: The “zero” command will be delayed any

time a change in weight is detected. If there is continuous motion for more than

20 or 30 seconds, the zero command will be rejected and the scale will return to

normal weighing.

NOTE: The scale contains a feature called Auto Zero Tracking (AZT), which

corrects for slight zero changes during normal operation. If small weights are

added slowly, the scale could zero them off.

BACK LIGHT

Turns the back light on or off for the LED display.

Hidden key

The switch referred to as the hidden key is unlabeled and located directly to the

left of the ZERO key. This switch has no function except during calibration.

Page 7 of 27

Page 8

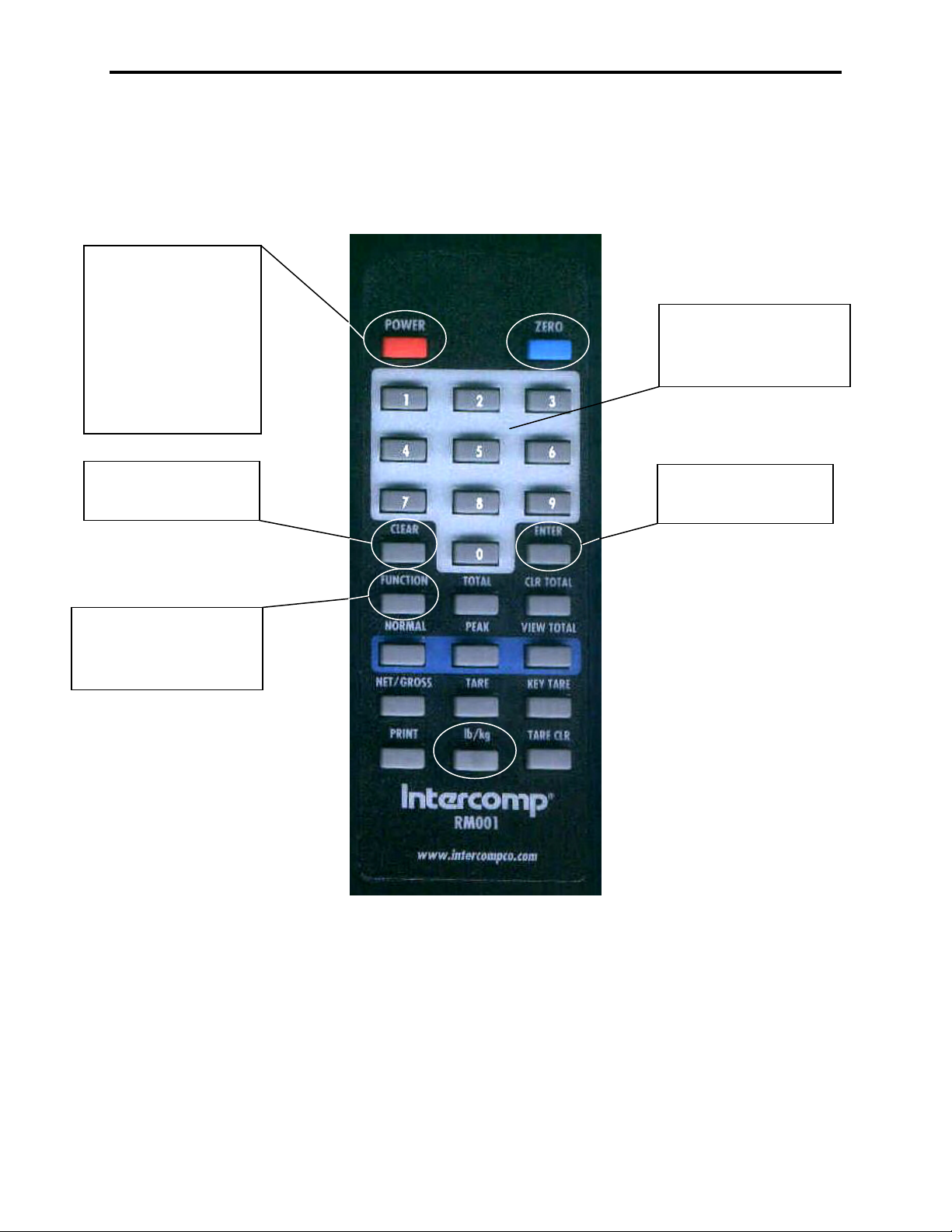

Remote Control

The circled keys on the diagram below are active for the CS750 crane scale.

Notes: Need to

press twice to turn

on.

The ON key on

the scale must be

pressed to initially

turn on the

CS750.

Numeric keypad:

Used when entering

a number

CS750, Users

Rev R, May 2009

Used when

entering a number

Calibrate: Press to

advance through

calibration menu

Used when

entering a number

Remote Control Keypad Layout

Page 8 of 27

Page 9

Operation

Use

Periodic Maintenance

CS750, Users

Rev R, May 2009

Power/Batteries

Replacement

On the right side panel, remove the two screws that hold the back plate secure.

Slide this plate out to access the batteries inside. Change the cells, being

careful to note battery orientation.

You may use 6 rechargeable Nickel-Cadmium “D” cells or 6 standard “D” cells in

the CS750.

Warning: Do not plug the charger in while there are standard “D”

cells inside. This could result in damage to the batteries and your

scale.

Rechargeable (Ni-cad)

The typical recharge time for Ni-Cad cells is 16 hours. The rechargeable

batteries have a life span up to 1000 cycles.

Page 9 of 27

Page 10

CS750, Users

Rev R, May 2009

Maintenance

Periodic Inspection

The crane scale and all associated adaptive devices require periodic inspection and

maintenance. The frequency and recording of the inspection requirements are found in

service categories below and are dependant on the type of service that the equipment

is used in as described below.

Service Categories

Normal Service – Crane scale is operated at less than 85% of it’s capacity except for

isolated instances. Complete the frequent service inspection monthly and record the

periodic service inspection annually.

Heavy Service – Crane scale is operated at 85% - 100% of it’s capacity as part of

normal usage. Complete the frequent service inspection weekly to monthly and record

the periodic service inspection semi-annually.

Severe Service – Crane scale is operated at 85% - 100% of it’s capacity and used in

environmental conditions that are unfavorable, harmful or detrimental to the use of the

crane scale. Complete the frequent service inspection daily to weekly and record the

periodic service inspection quarterly.

Inspection Requirements

Frequent Service Inspection (records not required)

A frequent visual inspection is completed at intervals indicated by the service category

above by the operator or designated person of the following.

1. Inspect for structural deformation, cracks or excessive wear of any part of the

crane scale or associated adaptive devices.

2. Inspect for loose or missing guards, fasteners, covers, stops, or nameplates.

3. Inspect all functional operating mechanisms and automatic hold and release

mechanisms for improper adjustments interfering with operation of the crane

scale or associated adaptive devices.

4. Inspect for distortion such as bending, twisting, or increased throat opening (if

applicable)

Periodic Service Inspection (records required)

A periodic visual inspection is completed at intervals indicated by the service category

above by the operator or designated person and documented to provide the basis for

continuing evaluation. The periodic inspection will cover areas in the frequent service

inspection above and the following.

1. Inspect for loose bolts or fasteners.

2. Inspect for cracked or worn gears, pulleys, sheaves, sprockets, bearings, chains,

and belts.

Page 10 of 27

Page 11

CS750, Users

Rev R, May 2009

3. Inspect for excessive wear of linkages and other mechanical parts.

4. Inspect for excessive wear at hoist hooking points and load support clevices or

pins.

5. Inspect for any visible bends or twists of all used rigging devices.

6. Inspect all latches and locks for proper operation (if applicable)

Removal from Service Criteria

Note: Replacement parts of any device or parts of any device used in any aspect of

rigging to lift a load shall be at least equal to the original manufacture’s specifications

Hooks

Hooks shall be removed from service if damage such as the following is found and shall

only be returned to service if a qualified person approves their continued use and

initiates corrective action.

1. Hooks show cracks, nicks, or gouges.

2. Hook has wear exceeding 10% of the original sectional dimension.

3. Hook has any visible bend or twist from the plane of the unbent hook.

4. Hook has an increase in throat opening of 5% not to exceed ¼ of an inch.

5. If self-locking hooks have the inability to lock.

6. A hook latch that is inoperable (if applicable)

Shackles

Shackles shall be removed from service if damage such as the following is visible and

shall only be returned to service when approved by a qualified person.

1. If the manufacturers name or trademark and / or the rated load identification is

missing or illegible.

2. The device shows signs of heat damage including weld spatter or arc strikes.

3. The device shows excessive pitting or corrosion.

4. The device is bent, twisted, distorted, stretched, elongated, cracked, or has

broken load-bearing components.

5. The device has excessive nicks or gouges.

6. The device has a 10% reduction of the original or catalog dimension at any point

around the body or pin.

7. The device has incomplete pin engagement.

8. The device has excessive thread damage.

9. The device shows evidence of unauthorized welding.

10. Any other condition including visible damage that causes doubt to the continued

use of the shackle.

Page 11 of 27

Page 12

CS750, Users

Rev R, May 2009

Calibration

How to test the calibration

This calibration procedure should be performed annually for normal operating

conditions. If the scale is dropped or damaged, or service has been performed on the

scale, use this calibration check. Recommend calibration points at 10% intervals from

10% through 100% of the scales capacity.

1. Press the ON switch. The display does a lamp test; during this time the scale does

a quick check of itself. Then the weighing system starts weigh mode.

2. Intercomp recommends that you allow the electronics to operate for three minutes

after first turning power on. This allows the electronics to become stable for

maximum accuracy before you check the calibrations.

3. Make sure no weight is on the hook. Press the ZERO switch. The weight shown is

zero.

4. Apply weights throughout the weighing range, and verify the correct weight is

displayed at each step. (+/- 0.1% of applied load or ±1 display graduation, whichever

is greater)

5. If possible apply a weight of 105% of capacity, and verify the scale shows “OE

the display.

6. Remove weights and verify the display returns to zero.

7. If there is a failure to meet any of the conditions above, please refer to the

Calibration Procedure.

8. When all the conditions above are correct, the scale is operational.

How to enter a number

During this routine you will be asked to enter numbers at many points. The scale will

show a number (originally all zeros) with a blinking digit. Press the ZERO key to

increase the blinking digit. Press the hidden key to move to other digits. When you are

finished entering the number press the ZERO and hidden keys together.

Three point span

The scale has a three point calibration feature which reduces the effects on nonlinearity in the load cells. This requires that you place three weights on the cell during

calibration. The first weight must be greater than zero, the second greater than the

first, and the final weight somewhere between the second and the capacity.

OE” on

OEOE

Page 12 of 27

Page 13

CS750, Users

Rev R, May 2009

Calibration switch

The calibration of the scale is protected from accidental change by a switch just inside

the right side panel.

Enabling the Calibration switch

Using a screwdriver, remove the right side plate and move the switch to “CAL”.

When you are done calibrating, return the switch to “RUN” to protect against

change.

How to calibrate the scale

The following details the calibration procedure for the crane scale. There are eight

parameters that can be set without moving the calibration blocking switch, followed by

five more parameters and calibration that require the calibration blocking switch be in

the enabled position.

Display Parameter Note Default

ee-ee

ee-ee

ee-eeee-ee

EE-00

EE-00

EE-00EE-00

EE-01

EE-01

EE-01EE-01

EE-02

EE-02

EE-02EE-02

EE-03

EE-03

EE-03EE-03

EE-04

EE-04

EE-04EE-04

EE-05

EE-05

EE-05EE-05

EE-06

EE-06

EE-06EE-06

EE-07

EE-07

EE-07EE-07

ee-08

ee-08

ee-08ee-08

ee-09

ee-09

ee-09ee-09

EE-10

EE-10

EE-10EE-10

EE-11

EE-11

EE-11EE-11

EE-12

EE-12

EE-12EE-12

EE-13

EE-13

EE-13EE-13

EE-14

EE-14

EE-14EE-14

LL-00

LL-00

LL-00LL-00

LL-01

LL-01

LL-01LL-01

LL-02

LL-02

LL-02LL-02

LL-03

LL-03

LL-03LL-03

Information saved

Skip

Sample Rate 1 to 64 4

Update Rate 1 to 32 4

Demand Output 1=Continuous off

Baud Rate 0 to 9 0

Auto-off Time 0 to 255; 0=off 20

Power up in KG 1=kg, 0=lb 0

Not Used Not Used 0

Sleep Mode Time 0 to 255; 0=off 5

Set Point 1 1 to 99999 99999

Set Point 2 1 to 99999 99999

Information saved

Check for calibration

blocking switch

AZT 0=off,1=0.6,2=1,3=3 2

Zero Range 0=off,1=on 0

Canadian Specifications 0=off, 1=on 0

Initial Zero Range 0=off, 1=on 0

Graduation 0 to 11 6

Information saved

Zero read Enter capacity

First weight Enter first weight

Second weight Enter second weight

Third weight Enter third weight

0=no skip, 1=”EE-10

0=Continuous on

EE-10”, 2=”LL-00

EE-10EE-10

LL-00”

LL-00LL-00

0

0

Page 13 of 27

Page 14

Start up

1. Move the calibration blocking switch to the “CAL” position if you intend to

calibrate.

2. Turn scale power ON and wait for scale to warm up (3 minutes from power

on).

3. Press ZERO and hidden keys together and release to enter the calibration

mode.

First ten parameters

4. The scale shows “EE-EE

To skip to “LL-00

5. The scale shows “EE-00

64). The sample rate is the number of past readings that are averaged

together to make a reading.

6. The scale shows “EE-01

32). The update rate is the speed at which the displayed weight is updated.

The smaller the number the faster the display will be updated.

7. The scale shows “EE-02

continuous on the optional serial output. For this product, you should always

set this to "Continuous" (0).

8. The scale shows “EE-03

serial output (0 to 7).

LL-00” enter “2222”. No skips will occur with an entry of “0000”.

LL-00LL-00

CS750, Users

Rev R, May 2009

EE-EE”. Press the zero key. To skip to “EE-10

EE-EEEE-EE

EE-00”. Press the zero key. Enter the sample rate (1 to

EE-00EE-00

EE-01”. Press the zero key. Enter the update rate (1 to

EE-01EE-01

EE-02”. Press the zero key. Enter demand versus

EE-02EE-02

Setting

0 Continuous on

1 Continuous off

EE-03”. Press the zero key. Enter the baud rate of the

EE-03EE-03

Setting Baud Rate

0 9600

1 4800

2 2400

3 1200

4 600

5 300

6 150

7 75

8 19.2K

9 38.4K

Type

EE-10” enter a “1111”.

EE-10EE-10

Page 14 of 27

Page 15

CS750, Users

Rev R, May 2009

9. The scale shows “EE-04

minutes (0 to 255). The auto off time is how long the scale will remain ON

without any activity (a key being pressed or a change in weight). An entry of

0 turns the auto off feature OFF.

10. The scale shows “EE-05

the scale should turn ON in; pounds or kilograms (0 to 1).

11. The scale shows”EE-06

CS750.

12. The scale shows “EE-07

minutes (0 to 255). The sleep mode time is how long the scale's display will

remain ON without any activity (a key being pressed or a change in weight).

An entry of 0 turns the sleep mode feature OFF. The sleep mode is designed

to conserve battery life on scales with a LED display.

EE-04”. Press the zero key. Enter the auto off time in

EE-04EE-04

EE-05”. Press the zero key. Enter what unit of measure

EE-05EE-05

Setting Units to turn ON in

0 pounds (lb)

1 kilograms (kg)

EE-06”. Press the zero key. This function not used by

EE-06EE-06

EE-07”. Press the zero key. Enter the sleep mode time in

EE-07EE-07

13. The scale shows “EE-08

SET POINT 1

This is an optional feature that allows for an external set point. When the

specified weight (set point) is reached, a logic level high will be on the set

point connection. Set points are used with some other device (e.g. alarm,

relay) in conjunction to the CS750.

To activate a set point press the Set Point 1 (or Set Point 2) key. Enter

the weight you want the set point to activate.

Note: If the scale is over capacity (“OE

will always become active.

SET POINT 2

Operates the same as Set Point 1.

14. The scale shows “EE-09

EE-08”. Press the zero key. Enter set point 1.

EE-08EE-08

OE” will be displayed) the set points

OEOE

EE-09”. Press the zero key. Enter set point 2.

EE-09EE-09

Check for calibration blocking switch

•At this point the scale saves any changes that have been made.

•A check is than made to see whether or not the calibration blocking switch is

enabled. If enabled, (CAL), the calibration procedure will continue. If disabled,

(RUN), the scale returns to normal weighing.

Page 15 of 27

Page 16

Last five parameters.

15. The scale shows “EE-10

The AZT size is the number of graduations the auto zero tracking can

remove.

16. The scale shows “EE-11

is on or off (0 to 1). If the zero range is ON the push-button zero and AZSM

can only operate within +/- 5% of the original zero obtained at calibration.

17. The scale shows “EE-12

Canadian specification selection. Use the following table to select the

Canadian specifications setting. When Canadian specifications are set (1):

“EE-10

EE-10”, “EE-11

EE-10EE-10

A “0” setting implies normal operation:

A “1” setting implies Canadian specifications are used.

EE-11”, and “EE-13

EE-11EE-11

1: AZT size is determined by the setting of “EE-10

2: Zero operates over full range allowed by “EE-11

3: The over-capacity point is determined by the setting of “EE-13

1: The AZT size fixed at 0.6d regardless of “EE-10

2: The IZSM (initial zero setting mechanism on power up) must be

within +/- 10% of the zero obtained at calibration.

3: The push-button zero and AZSM can only operate within +/-

2% of the IZSM.

4: The over-capacity point is 103% of capacity above the IZSM.

CS750, Users

Rev R, May 2009

EE-10”. Press the zero key. Enter the AZT size (0 to 3).

EE-10EE-10

Setting AZT size

0 Off

1 0.6

2 1.0

3 3.0

EE-11”. Press the zero key. Enter whether the zero range

EE-11EE-11

Setting Zero range

0 Off

1 On

EE-12”. Press the zero key. The scale shows the current

EE-12EE-12

EE-13” have no meaning.

EE-13EE-13

Setting Canadian

Specification

0 Off

1 On

EE-10”.

EE-10EE-10

EE-11”.

EE-11EE-11

EE-13”.

EE-13EE-13

EE-10” setting.

EE-10EE-10

Page 16 of 27

Page 17

CS750, Users

Rev R, May 2009

18. The scale shows “EE-13

EE-13”. Press the zero key. The scale shows the current

EE-13EE-13

initial zero range setting. Use the following table to select the “initial zero

range” setting:

Setting Initial zero range

0 Off

1 On

A “0” setting implies: The initial zero setting mechanism (IZSM) will work

over the entire range of the scale capacity and the over-capacity point is 103%

above the zero obtained at calibration.

A “1” setting implies: The IZSM must be within +/- 10% of the zero

obtained at calibration and the over-capacity point is 103% above the IZSM.

19. The scale shows “EE-14

EE-14”. Press the zero key. The scale shows the current

EE-14EE-14

graduation selection. Use the following table to select a graduation value.

Settings Count by in lb Count by in kg

0 100 50

1 50 20

2 20 10

3 10 5

4 5 2

5 2 1

6 1 0.5

7 0.5 0.2

8 0.2 0.1

9 0.1 0.05

10 0.05 0.02

11 0.02 0.01

12 0.01 0.01

NOTE: The stated accuracy specifications are based on the graduation setting in

the table below. If the graduation setting is set other than the value in the table

below the accuracy specification remains with the graduation size listed below.

If your capacity is: Set your graduation to:

25 lb / 12.5 kg .01 lb / .01 kg (12)

50 lb / 25 kg .02 lb / .01 kg (11)

100 lb / 50 kg .05 lb / .02 kg (10)

250 lb / 125 kg .1 lb / 0.05 kg (9)

300 lb / 150 kg .1 lb / 0.05 kg (9)

500 lb / 250 kg 0.2 lb / 0.1 kg (8)

1000 lb / 500 kg 0.5 lb / 0.2 kg (7)

Page 17 of 27

Page 18

CS750, Users

Rev R, May 2009

Save

•At this point the scale saves any changes that have been made. This allows

changes to be made to “EE-10

calibration. The scale can be turned off and any changes so far will be saved.

EE-10” through “EE-14

EE-10EE-10

EE-14” without having to do a complete

EE-14EE-14

Weight calibration

20. The scale shows “LL-00

reads the pad zero. On the next screen, enter the scale's capacity.

21. The scale shows “LL-01

on the hook, press the zero key. Then enter the value of the applied weight.

22. The scale shows “LL-02

stable on the hook, press the zero key. Then enter the value of the applied

weight.

23. The scale shows “LL-03

on the hook, press the zero key. Then enter the value of the applied weight.

LL-00”. With no weight on hook press the zero key. This

LL-00LL-00

LL-01”. Apply the first weight. With the first weight stable

LL-01LL-01

LL-02”. Apply the second weight. With the second weight

LL-02LL-02

LL-03”. Apply the third weight. With the third weight stable

LL-03LL-03

Finish

•The new calibration information is saved.

24. Return the calibration blocking switch to it's original position (RUN). This

prevents accidental entry into the calibration mode.

25. Verify the calibration.

26. Calibration complete.

Legal-for-Trade Sealing

1. On the left side of the CS750, replace the 2 front screws with the drilled screws

provided.

2. Thread a lead & wire seal through the 2 screws on the left side.

3. Crimp the lead seal tightly.

4. On the right side of the CS750, replace the 2 front screws with the drilled screws

provided.

5. Thread a lead & wire seal through the 2 screws on the right side.

6. Crimp the lead seal tightly.

Page 18 of 27

Page 19

CS750, Users

Rev R, May 2009

Troubleshooting

WARNING

change in calibration while others may or may not change the calibration,

depending on the nature of the problem.

The reference designators for the IC chips are on the “A/D 20-BIT” board unless

indicated otherwise.

Problem: no power, nothing on display

Fix:

If nothing can be seen on the display, there is probably no power reaching the

scale circuitry. Possible causes: bad or shorted battery pack, bad switch circuit,

bad voltage regulator, or bad keypad. Power might be reaching the unit, but the

power supply might be shorted by a component or PCB trace in the power

supply circuitry.

Problem: random display (display usually reads “8.8. 8.”)

Fix:

Check crystal (Y1). If the micro-controller is not receiving the correct or any

oscillation, the microprocessor is not able to function properly. Other possibilities

could be bad microprocessor (U1) or display driver (U1 & U2 on “GPI DISPLAY”

board) circuitry not functioning.

Problem: low battery indicator won’t turn off (display blinks “LB

Fix:

The display will be blinking “LB

Look at the cells and charger circuit for these problems. If that is not the cause,

the display driver (U1 & U2 on the GPI display board) or low voltage circuitry

could be bad.

: Changing some parts on the circuit board may cause a large

LB”)

LBLB

LB”. Check to make sure battery power is too low.

LBLB

Page 19 of 27

Page 20

Problem: rechargeable battery life has decreased

Fix:

The rechargeable batteries provided by Intercomp are high quality, high capacity

Ni-Cad. However, all Ni-Cad batteries can exhibit some “memory” effects if they

are repeatedly discharged to a certain point before recharging. If your observed

battery life has decreased significantly from its initial performance, you may want

to try this battery-conditioning sequence: Fully discharge the batteries by

running the CS750 until the display blinks “LB

LB” (low battery) and keep the unit

LBLB

powered until the batteries are fully discharged. Following this, recharge the

battery completely (typical charge time is 16 hours). This discharge/recharge

cycle may need to be repeated. If this does not help, you may need to replace

the Ni-Cad batteries.

Problem: scale shuts off by itself

Fix:

Check the battery holder terminals. They may be bent and not making solid

contact. If the scale turns off immediately after you take your finger off the

button, there may be defective power circuitry or a bad keypad.

Problem: scale “locks up”

Fix:

The microprocessor (U1) may need to be replaced. The microprocessor support

circuitry could also be bad.

Problem: weights jump or drift

Fix:

Try increasing the sample rate as described in the calibration section (pg 13). If

this does not help, the problem could be a bad load cell, defective amplifier (U5),

bad A/D chip (U6), or contamination on the circuit board.

CS750, Users

Rev R, May 2009

Page 20 of 27

Page 21

CS750, Users

Rev R, May 2009

Error Messages

[Minus signs cycle across the display]: The CS750 has entered sleep mode.

Press any key or change the weight to return to normal weighing.

NOTE: a pressed key here will perform its designated function as well as exit the scale

from sleep mode.

[Minus signs fill the display]: The CS750 is waiting for a stable reading to continue.

LB

LB

LBLB

OE

OE

OE OE

DISE

DISE

DISE DISE

EEPE

EEPE

EEPEEEPE

OL

OL

OLOL

E-0

E-0

E-0E-0

Low batteries. This message blinks, and if ignored too long the unit will

shut itself off.

The scale is over capacity or outside the A/D converter range. Reduce the

load to the scale.

Display error, the scale is unable to display the number completely. Press

zero to return the weight reading to zero.

EEPROM error, the scale has had it's calibration corrupted or destroyed;

the scale will require calibration.

Zero overload; the CS750 has attempted to zero a reading outside of its

zero-range limit. This message can occur only when the “Zero range” or

“Canadian specifications” is turned on. See “EE-11

“calibration” section.

This message occurs if the scale is turned on with a load applied which is

greater than +/- 10% of capacity. Return the scale's load to zero. This only

occurs when “Canadian specifications” or “Initial zero range” is turned on.

See “EE-12

EE-12” and “EE-13

EE-12EE-12

EE-13” in the “calibration” section.

EE-13EE-13

EE-11” and “EE-12

EE-11EE-11

EE-12” in the

EE-12EE-12

Page 21 of 27

Page 22

Parts and Accessories

CS750, Users

Rev R, May 2009

Please see following page for parts table

Page 22 of 27

Page 23

Parts List

Item # QTY Part # Description

1 8 600016 8-32 screw

2 1 220135 charging jack nut

3 2 601013 4 pin MTA

4 1 500610 charging end plate

5 1 220135 charging jack

6 1 500619 battery mounting plate

7 1 000095 display board

8 1 000094 A/D board

9 1 500612 left side board mount

10 1 500615 right side board mount

11 4 601002 6-32 nut

12 4 601032 6-32 standoff

13 16 601014 .031 nylon washer

14 20 600008 6-32 screw

15 4 601015 .062 nylon washer

16 4 601018 6-32 standoff

17 1 000066 cal. switch assembly

18 2 600038 .25-20 screw

19 1 500613

500614

20 1 500606 housing machine

21 2 501201 endplate

22 1 250087 switch

23 1 label

24 1 250003 CS750 overlay

25 2 330029 o-ring

26 1 601016 grommet

27 1 500608 swivel

28 1 601055 .250 clevis pin

29 1 602009 .25-28 shoulder bolt

30 1 500607 hook

31 1 603000 safety latch

32 1 601056 cotter pin

33 1 500603

500604

34 2 601006

601008

35 1 603056

603031

603030

603055

603057

603058

36 1 220063 4-pin MTA

37 2 330027 battery holder

38 1 220061 2-pin MTA

top lifting eye assembly (25 lb - 100 lb capacity)

top lifting eye assembly (250 lb - 1K lb capacity)

loadcell retainer (25 lb - 750 lb capacity CS750)

loadcell retainer (1K lb capacity CS750)

.250-28 jam nut (25 lb - 100 lb capacity CS750)

.500-20 jam nut (250 lb - 1K lb capacity CS750)

loadcell (25 lb capacity CS750)

loadcell (50 lb capacity CS750)

loadcell (100 lb capacity CS750)

loadcell (250 lb capacity CS750)

loadcell (500 lb capacity CS 750)

loadcell (1K lb capacity CS750)

CS750, Users

Rev R, May, 2009

23

Page 24

CS750, Users

Rev R, May, 2009

Serial Output (Optional)

The CS750 can be connected to output to a scoreboard (continuous).

The signal comes out of the Serial I/O connector located on the side of the unit. The

connector has the following pinout:

Signal Pin

TXD 2

GND 7

The transmitted signal has the following characteristics:

Fixed 8 Data bits, no parity, 1 stop bit.

Baud rate is configurable under EE-03, see calibration section.

The output swings from -9 VDC to 9 VDC.

The scoreboard output is an externally available signal designed to drive a numeric

overhead display board or a computer's RS-232 input.

Transmitted data: #xxxxxxx>0@ cr lf

This data is repeatedly sent out about once a second, except that the transmission is

delayed whenever there is motion.

The xxxxxxx field will vary in length depending on the length of the number and could

contain a decimal point and/or a minus sign.

Item Meaning ASCII Hex ASCII Decimal

# start character 23 35

xxxxxxx data

> separator 3E 62

0 data identifier 30 48

@ end character 40 64

<cr> carriage return 0D 13

<lf> linefeed 0A 10

x

24

Page 25

CS750, Users

Rev R, May, 2009

The scoreboard is designed to work with Intercomp's S400 (4 inch) and SA2000 (2

inches) scoreboards. The following describes how to configure the S400 or SA2000 to

work with the scoreboard output.

The above diagram is the S400 switch pack layout, The SA2000 has pack C below B.

The switch is to the right for on and to the left for off.

Switch # Pack A Pack B Pack C

1 OFF OFF See next page

2 ON ON "

3 ON OFF "

4 ON OFF "

5 ON ON ON

6 OFF ON ON

7 OFF ON OFF

8 ON ON OFF

The above switches should be set on switch packs A, B, and C.

25

Page 26

CS750, Users

Rev R, May, 2009

Pack C, SW 1 to 4:

Baud Rate

C-1 C-2 C-3 C-4

9600 ON ON ON OFF

4800 OFF ON ON OFF

2400 ON ON OFF OFF

1200 OFF OFF ON OFF

600 ON OFF OFF ON

300 OFF ON OFF OFF

150 ON OFF OFF OFF

75 OFF OFF ON ON

The connection to an Intercomp S400 display is:

CS750 S400

2 (TXD) 2 (RXD)

7 (GND) 7 (GND)

The connection to an Intercomp SA2000 display is:

CS750 SA2000

2 3

7 7

The connection to a 9-pin PC communication port is:

CS750 PC 9-pin

2 2

7 5

Note: For some setups it may be necessary to jump pins [6, 1, and 4] together, and pins

[7 and 8] together on the PC port connector.

The connection to a 25-pin PC communication port is:

CS750 PC 25-pin

2 3

7 7

Note: For some setups it may be necessary to jump pins [6, 8, and 20] together, and

pins [4 and 5] together on the PC port connector.

26

Page 27

How to reach Intercomp Service

Things to know:

1. The service is for a CS750 crane scale.

2. When did you purchase your scale?

3. What is your serial number?

4. Whom did you purchase the scale through?

For Intercomp Service call or fax:

FAX # (763)-476-2613

(763)-476-2531

1-800-328-3336

or fill out Service Support Form:

www.intercompcompany.com

Copyright Intercomp Company 2009

All rights reserved

CS750, Users

Rev R, May, 2009

27

Loading...

Loading...