Page 1

CS5000

Users Manual

Intercomp Co.

3839 County Road 116

Medina MN 55340 U.S.A.

(763)-476-2531

1-800-328-3336

Fax: 763-476-2613

www.intercompcompany.com

Manual#: 700008-V

Page 1 of 31

Page 2

CS5000, Users

Rev V, January, 2008

Table of Contents

INTRODUCTION ............................................................................................................................................................ 3

S

PECIFICATIONS

Controls..................................................................................................................................................................... 3

Electrical................................................................................................................................................................... 3

Performance.............................................................................................................................................................. 3

Environmental ........................................................................................................................................................... 3

Physical..................................................................................................................................................................... 4

Radio ......................................................................................................................................................................... 5

P

ARTS AND OPTIONAL EQUIPMENT

OPERATIONS .................................................................................................................................................................. 7

D

ISPLAY (BASE

Indicators .................................................................................................................................................................. 7

C

ONTROLS - HEAD (SCALE

ON............................................................................................................................................................................. 7

C

ONTROLS - BASE (CONTROLLER

S

ETUP

........................................................................................................................................................................... 10

lb/kg Switching ........................................................................................................................................................ 10

Setting time and date............................................................................................................................................... 10

P

OWER/BATTERIES

CALIBRATION.............................................................................................................................................................. 12

.............................................................................................................................................................. 3

................................................................................................................................. 5

) ............................................................................................................................................................. 7

) ............................................................................................................................................ 7

) .................................................................................................................................. 8

....................................................................................................................................................... 11

H

OW TO TEST THE CALIBRATION

C

ALIBRATION SWITCH

H

OW TO CALIBRATE THE SCALE

L

EGAL-FOR-TRADE SEALING

ERROR MESSAGES ..................................................................................................................................................... 17

TROUBLESHOOTING ................................................................................................................................................. 18

PARTS AND ACCESSORIES....................................................................................................................................... 20

P

ARTS LIST:

P

ARTS LIST: 2K LB CAPACITY

P

ARTS LIST: 5K LB,

P

ARTS LIST:

SERIAL OUTPUT.......................................................................................................................................................... 28

E

XAMPLE CONNECTIONS

HOW TO REACH INTERCOMP SERVICE.............................................................................................................. 31

500

20K

.................................................................................................................................................. 12

LB CAPACITY

10K

LB,

30K

................................................................................................................................... 12

................................................................................................................................... 13

........................................................................................................................................ 16

..................................................................................................................................... 21

...................................................................................................................................... 23

LB CAPACITY

LB CAPACITY

.............................................................................................................................................. 29

......................................................................................................................... 25

....................................................................................................................... 27

"This document is the property of Intercomp Co. It contains material and

information that is confidential and protected under federal and/or state trade

secret, unfair competition, and copyright law. Any reproduction, use or

disclosure without written permission from Intercomp Co. is prohibited".

2

Page 3

CS5000, Users

Rev V, January, 2008

Introduction

This manual contains specifications, operation instructions, and calibration instructions for

Intercomp's model CS5000 crane scale.

Specifications

Controls

General: Head:

Base:

Display: Base: 5 ½ digit LED.

Indicators: Head:

Base:

On (Base remotely turns the scale head off).

On/Off ,Zero, Print, Total, Display Total, Clear Total, Tare

Set, Tare Display, Tare Clear.

power.

lb/kg, Tare, Net, Gross, On-screen Motion, Total.

Electrical

Batteries:

(Base and Head)

Battery life: Up to 50 hours with alkaline batteries. Approximately 20

Resolution: 20 bit A/D delivers over 1,000,000 internal counts.

Filtering: 6 Pole, 10 Hertz low pass.

Auto off: Low battery, or after adjustable time without use or motion.

Auto-Zero: Satisfies all HB-44 requirements; selectable 0.6, 1, or 3

8 X D-size disposable alkaline dry cells or rechargeable

Nickel-Cadmium cells.

hours on a set of fully charged Ni-Cad cells.

graduations.

Performance

Accuracy: ±0.1% of applied load or ± display graduation, whichever

is greater.

Speed 2 readings / sec.

Transmitting Range Up to 500 ft / 150 meters

Environmental

Humidity: 10 to 95% Non-Condensing

Temperature: Storage: -40 C to +75 C. / -40 F to +170 F.

Operating -10 C to +50 C. / +14 F to +122 F.

3

Page 4

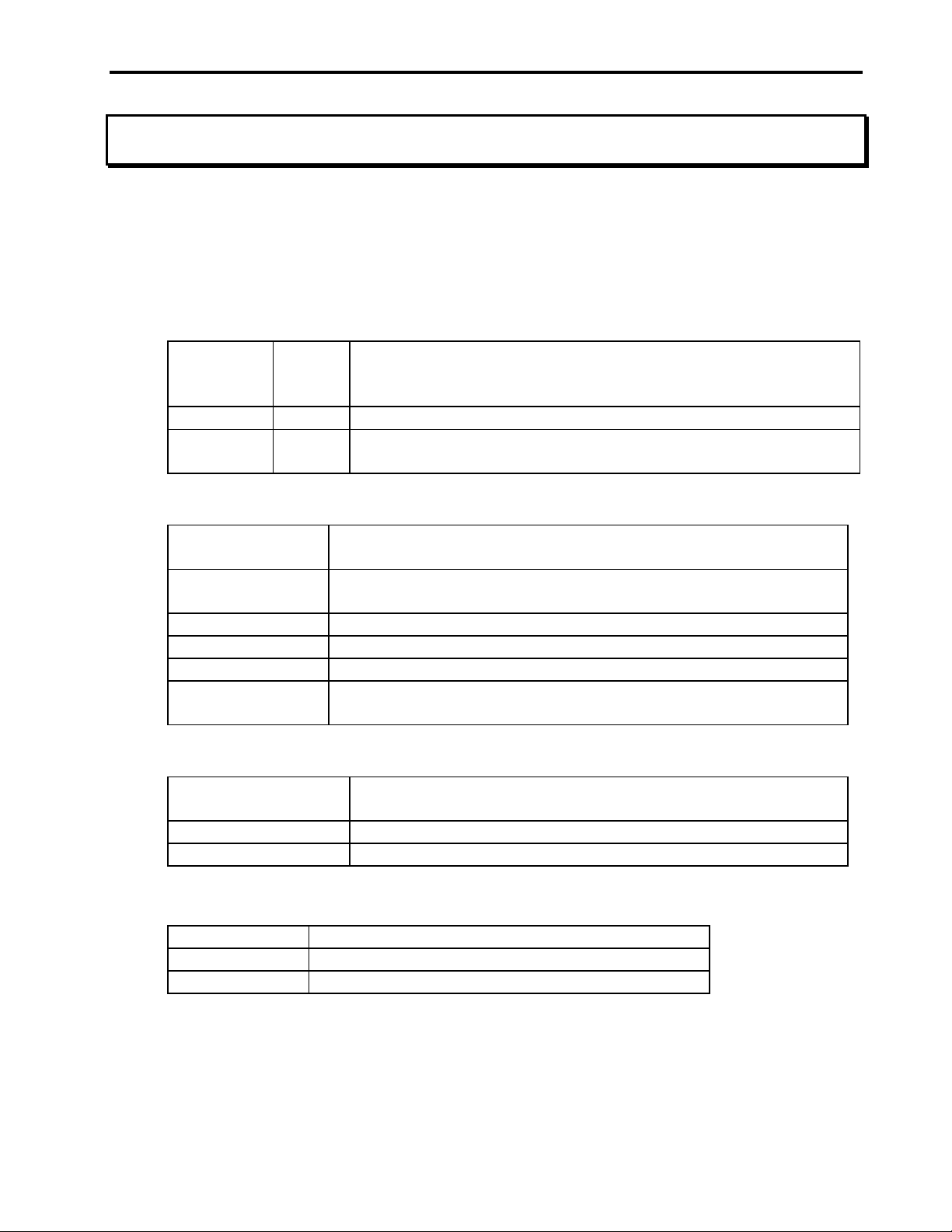

Physical

CS5000, Users

Rev V, January, 2008

Capacity Graduation

500 lb

250 kg

2,000 lb

1,000 kg

5,000 lb

2,500 kg

10,000 lb

5,000 kg

20,000 lb

10,000 kg

30,000 lb

15,000 kg

50,000 lb

*

25,000 kg

70,000 lb

*

35,000 kg

100,000 lb

50,00 kg

*

0.1 kg

0.5 kg

0.5 kg

0.2 lb

1 lb

1 lb

2 lb

1 kg

5 lb

2 kg

10 lb

5 kg

10 lb

5 kg

20 lb

10 kg

20 lb

10 kg

A

in:

mm:

in:

mm:

in:

mm:

in:

mm:

in:

mm:

in:

mm:

in:

mm:

in:

mm:

in:

mm:

19.3

490

19.3

490

22.0

558

22.0

558

37.15

944

39.15

994

43.5

1105

48.6

1234

56.0

1422

B C D Hook Eye nut

3.06

77.7

3.06

77.7

3.06

77.7

3.06

7.77

6.25

159

6.25

159

6.00

152

6.00

152

7.75

197

1.44

35.1

1.44

35.1

1.82

44.5

1.75

44.5

2.60

65.8

3.00

76.2

3.66

93.0

4.56

116

5.06

129

1.41

35.8

1.41

35.8

1.69

42.9

1.69

42.9

2.41

61.2

3.19

81.3

3.62

92.0

3.75

92.3

4.25

108

The

dimensions

below are

top to

bottom

shackle,

eye to eye

on 25-50

ton / 12.5 –

25 metric

ton models

17.0

432

17.0

432

18.0

457

C/L 3 ton

S1 swivel

C/L 3 ton

S1 swivel

C/L 5 ton

S1 swivel

C/L 5 ton

S1 swivel

C/L 10 ton

S1 swivel

C/L 15 ton

S1 swivel

C/L 25 ton

S1 swivel

C/L 35 ton

S1 swivel

C/L 45 ton

S1 swivel

or

shackle

C/L #7

eye nut

C/L #7

eye nut

C/L #7 eye

nut

C/L #7 eye

nut

C/L # 11

eye nut

C/L # 11

eye nut

C/L 40 ton

#2140

C/L 40 ton

#2140

C/L 50 ton

#2140

Approx

Weight

48 lb

22 kg

50 lb

23 kg

58 lb

26 kg

58 lb

26 kg

97 lb

44 kg

122 lb

55 kg

220 lb

100 kg

248 lb

113 kg

392 lb

178 kg

4

Page 5

CS5000, Users

!

Rev V, January, 2008

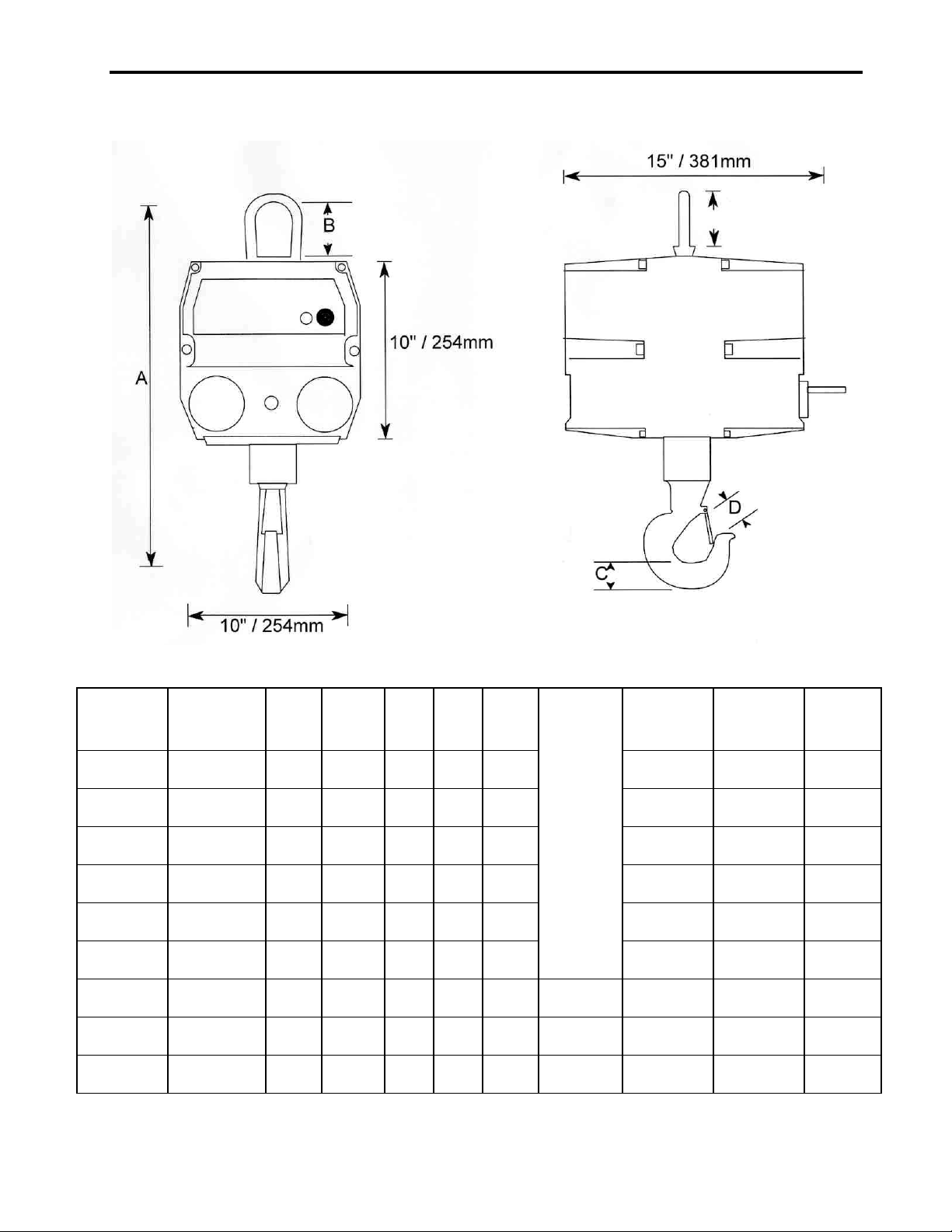

Radio

Radio frequency

(US/Canada)

License requirements None. Pre-approved US/FCC, CAN/IC, EUR/EN

Range 200’ / 60m indoor, 300’ / 90m line of sight

WARNING:

type transmitting devices, a separation distance of 20cm or more should

be maintained between the antenna of this device and persons during

operation, with the exception of hands, wrist, feet, and ankles. To ensure

2.4 GHz, FHSS, 50 mW output power

To satisfy FCC RF exposure requirements for mobile

Parts and Optional Equipment

Oversized top lifting eye (100744)

This part is applicable to 500 lb - 10,000 lb capacity models.

Oversized top shackle (100745)

This part is applicable to 20,000 lb and 30,000 lb capacity models.

Oversized top shackle (100746)

This part is applicable to 50,000 lb and 70,000 lb capacity models.

Oversized top shackle (100747)

This part is applicable to 100,000 lb capacity models.

Anti heat shield (100720)

Bottom plate with standard hook rated for 0° - 1000°.

Medium anti heat shield (100670)

1000° - 1500° protection. Includes oversized hook and custom swivel.

Extreme anti heat shield (100671)

1500° - 2500° protection. Includes oversized hook and custom swivel.

Remote load cell input and summing (100724)

Load cell input with electronic summing board. An external load cell can be connected to

the CS5000. The scale averages the signals from the 2 load cell outputs.

RS232 Serial data output (100721)

The CS5000 has an RS232 connection so the unit may communicate with a printer or

computer.

LED Display on crane unit (100725)

Optional LED (light emitting diode) display on the head. An LED display is fully readable

in pitch-dark lighting situations.

5

Page 6

CS5000, Users

Rev V, January, 2008

LCD Display on crane unit (100726)

Optional LCD (liquid crystal display) display on the head.

Anti-magnetic shielding (100722)

Provides protection from high magnetic fields.

Battery pack and 120V external charger (100730)

Rechargeable Ni-Cad battery pack (8 D-cells) with 120V external charger. Standard

power uses 8 disposable alkaline dry cells.

Battery pack and 220V external charger (100731)

Rechargeable Ni-Cad battery pack (8 D-cells) with 220V external charger. Standard

power uses 8 disposable alkaline dry cells.

Battery pack, Ni-Cad (100733)

D size rechargeable battery pack (qty: 8).

Direct Power on crane unit, 120V (100723)

This option allows the CS5000 to use 120V power instead of batteries.

Direct Power on crane unit, 220V (100727)

This option allows the CS5000 to use 220V power instead of batteries.

6

Page 7

Operations

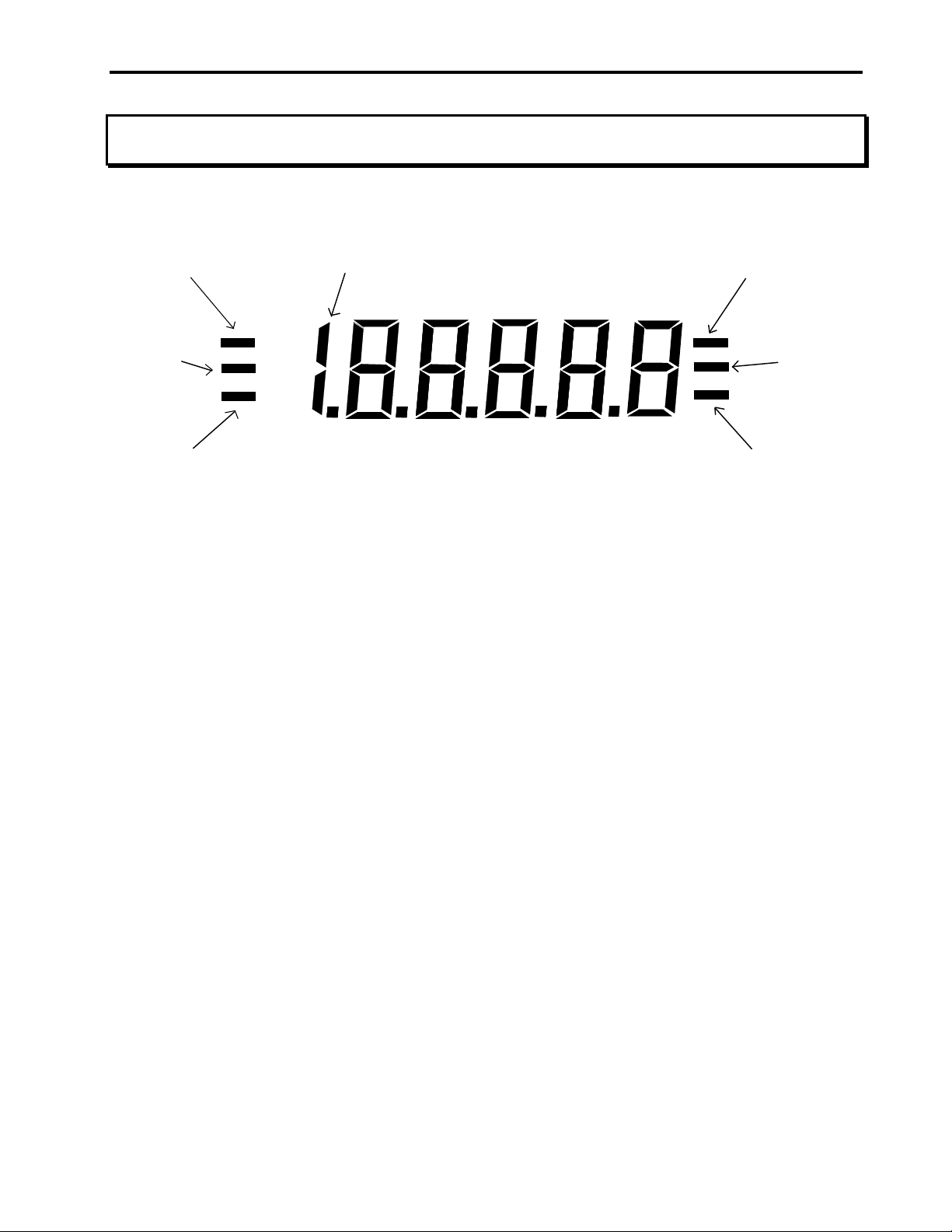

Display (Base)

Total

kg Optional: displays ‘1’ or blank Gross

lb Tare

CS5000, Users

Rev V, January, 2008

Net

Indicators

kg: Indicates the scale is weighing in kilograms. When lit, the scale is in kg mode.

Press TOTAL DISPLAY and TARE DISPLAY together to toggle units.

Total: Indicates that the current number displayed is the total. The net indicator

will also be lit to represent that the total totalizes the net weights.

lb: Indicates the scale is weighing in pounds. When lit, the scale is in lb mode.

Press TOTAL DISPLAY and TARE DISPLAY together to toggle units.

Gross: This indicator is lit when the display represents that the gross weight is

being displayed.

Net: This indicator is lit when a tare value is set and the weight shown is the

calculated net weight.

Tare: This indicator is lit while the tare weight is being displayed.

Controls - Head (scale)

ON

Press this button to turn the scale on.

7

Page 8

Controls - Base (controller)

ON/OFF

Press this button to turn the base unit on. The scale tests itself, then displays

“-----

-----“ or “HO-00

----------

displayed. Press this button again to turn the scale off. The head will turn off

automatically.

PRINT

Pressing this key will output an RS-232 signal containing the Gross, Net, Tare, total

weight, and the time and date. Note: The print key will only function when there is

no motion. Also see the ‘Serial Output' section in this manual.

ZERO

Tells the scale to display a zero weight. This button is used any time the scale

shows a non-zero value with no weight on the hook. If you press ZERO with

weight on the hook, that weight becomes the zero condition for the scale. This can

be useful to cancel the weight of any weighing fixtures, such as containers, chains

or cables. When this weight is removed, a negative weight shows until the system

is zeroed again.

NOTES: When ZERO is pressed, the CS5000 will display "-----

reading is taken. If there is continuous motion for more than 20 or 30 seconds, the

zero command will be rejected and the scale will return to normal weighing.

The scale contains a feature called Auto Zero Tracking (AZT), which corrects for

slight zero changes during normal operation. If small weights are added slowly, the

scale could zero them off.

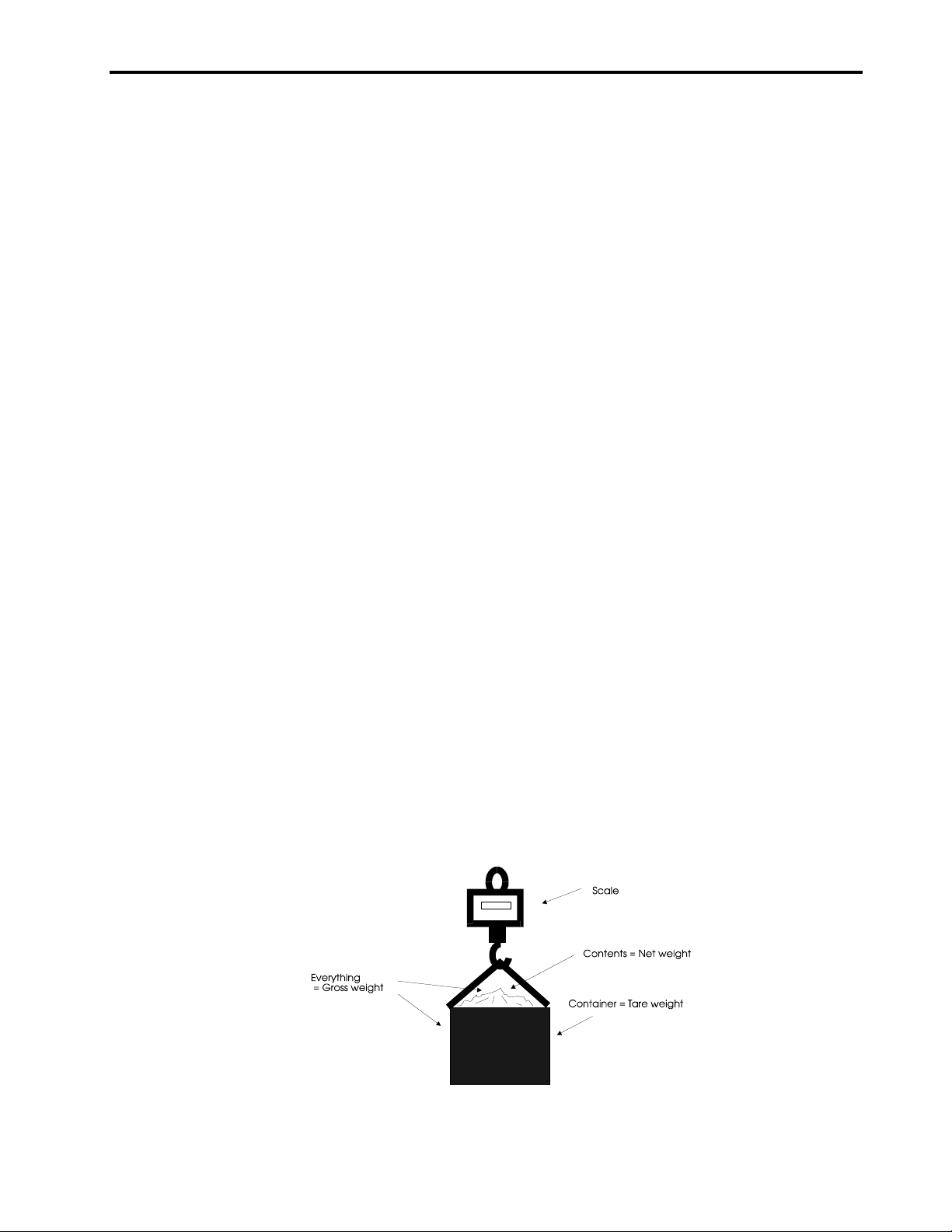

TARE

Use this button to read a tare weight into memory. This tare weight will be

subtracted from a gross weight, giving you the net weight. This is useful for

canceling the weight of a container used in weighing. A segment on the right side

of the display shows that the net weight is being calculated.

NOTE: When TARE is pressed, the CS5000 will display "

reading is taken. If there is continuous motion for more than 20 or 30 seconds, the

tare command will be rejected and the scale will return to normal weighing.

HO-00”. When a weight is received from the scale head it will be

HO-00HO-00

8

CS5000, Users

Rev V, January, 2008

-----" until a stable

----------

-----

-----

----------

" until a stable

Page 9

CS5000, Users

Rev V, January, 2008

TARE DISPLAY

You may press the TARE DISPLAY button to display the tare weight. Pressing the

TARE DISPLAY button a second time will return to the gross or net display.

TARE CLEAR

This button is used to clear a stored tare weight to zero.

TOTAL

By pressing this button, the current net weight is added to the total. Note: If the tare

weight is zero, the net weight is equal to the gross weight.

TOTAL DISPLAY

Pressing the TOTAL DISPLAY screen will switch the display to show the current

total weight. Pressing the key a second time will return to normal weighing.

TOTAL CLEAR

Clears the total to zero.

9

Page 10

CS5000, Users

Rev V, January, 2008

Setup

Use the following procedure to setup and weigh:

1: Hook CS5000 scale head onto hoist.

2: Turn on CS5000 scale head.

3: Turn on CS5000 base.

4: Hook any weighing fixtures onto CS5000 hook (chains, etc.)

5: Hook any weighing bin or platform onto CS5000 hook or fixtures.

6: Hoist into air so that it is free swinging.

7: Press ZERO on base. The CS5000 will wait for a stable zero reading.

8: Proceed with weighing.

lb/kg Switching

Press the TOTAL DISPLAY and TARE DISPLAY keys together to switch lb/kg. This

toggles the weighing system between pound (English) and kilogram (SI metric) units of

measure. The current unit of measure is shown by the left indicators of the CS5000 base

(as shown in the section Display (Base) ).

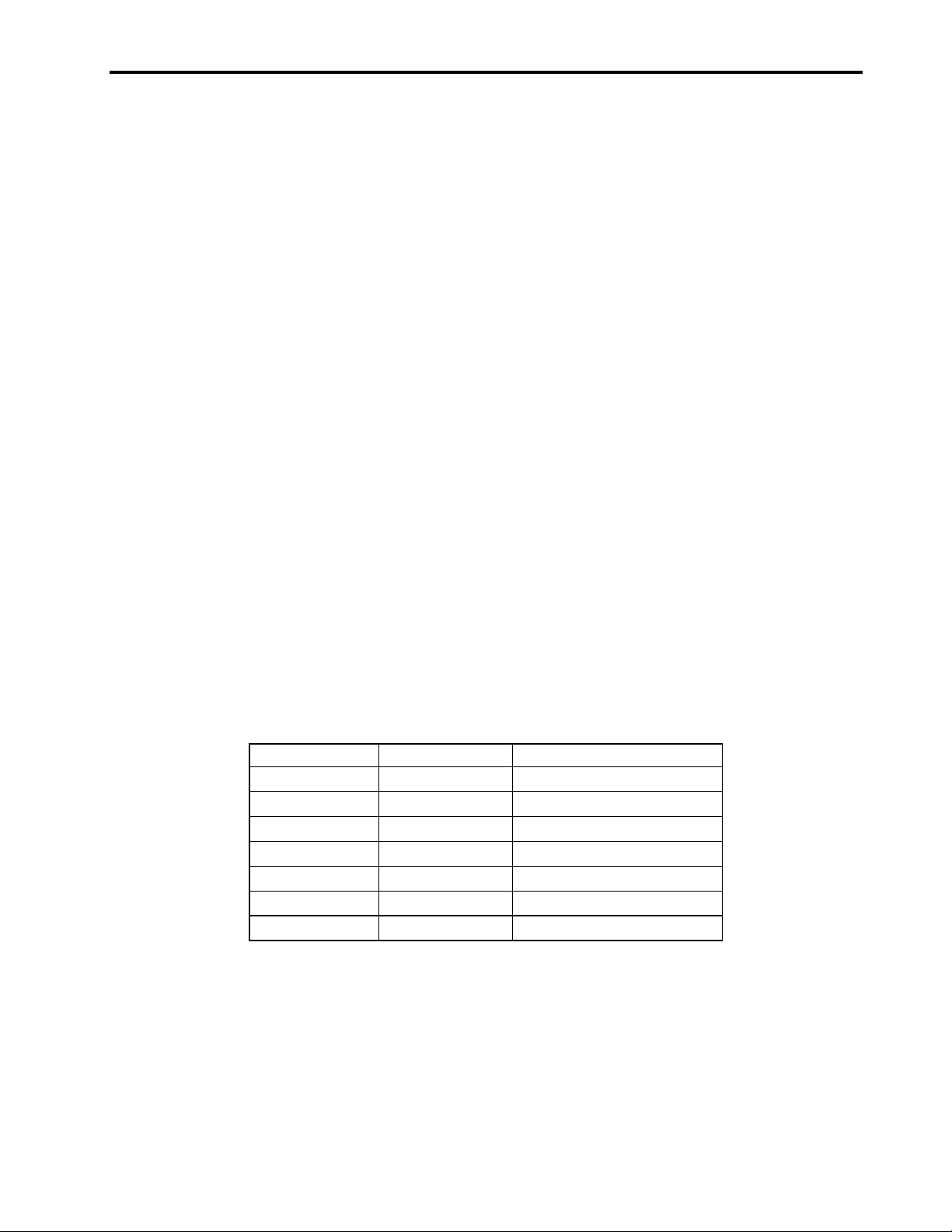

Setting time and date

To set the time and date press the three keys labeled TARE, TARE DISPLAY, and TARE

CLEAR together and release. The scale will then ask you to enter seven numbers

representing the month, day, year, hour, minute, second, and am/pm. You increase the

number by pressing the TARE DISPLAY button. When the number is set, pressing the

TARE button moves on to the next number. When you have completed entry of all seven

numbers press the TARE CLEAR button to exit and start the clock running. The numbers

are displayed in the following format Hx-yy, were x is the number being set and yy is the

value. The following chart shows the seven values and their ranges.

Display Meaning Range

H1-yy

H1-yy

H1-yyH1-yy

H2-yy

H2-yy

H2-yyH2-yy

H3-yy

H3-yy

H3-yyH3-yy

H4-yy

H4-yy

H4-yyH4-yy

H5-yy

H5-yy

H5-yyH5-yy

H6-yy

H6-yy

H6-yyH6-yy

H7-yy

H7-yy

H7-yyH7-yy

If the year is set prior to '91 it will be displayed as 20xx.

Month 1-12

Day 1-31

Year 0-99

Hour 1-12

Minutes 0-59

Seconds 0-59

am/pm 0-1 (0 = am, 1 = pm)

10

Page 11

CS5000, Users

Rev V, January, 2008

Power/Batteries

Head:

Remove the two caps in the back of the CS5000 head. Tip the old cells out.

Change the 8 ‘D’ cells, being careful to put the positive end in first (The end with

the bump). Replace the battery caps.

Base:

Loosen the 2 screws that latch the lid tight so the lid can be opened. Replace the 8

‘D’ cells, being careful to note the polarity indicated on the battery holders. Close

lid and retighten the screws for the latches.

You may use rechargeable 8 Nickel-Cadmium 'D' cells or 8 standard alkaline 'D'

cells in the CS3000.

Warning: If you have the optional charger, do not plug the charger in

while there are standard ‘D’ cells inside. This could result in damage

to the batteries and your scale.

The typical recharge time for Ni-cad cells is 16 hours. The rechargeable batteries

have a life span up to 1000 cycles.

11

Page 12

CS5000, Users

Rev V, January, 2008

Calibration

How to test the calibration

This calibration procedure should be performed annually for normal operating conditions.

If the scale is dropped or damaged, or service has been performed on the scale, use this

calibration check.

1. Turn on the head and the base. The display does a lamp test; during this time the

scale does a quick check of itself. Then the weighing system starts weigh mode.

2. Intercomp recommends that you allow the electronics to operate for three minutes

after first turning power on. This allows the electronics to become stable for maximum

accuracy before you check the calibrations.

3. Make sure no weight is on the hook. Press the ZERO button. Press the TARE

CLEAR button to clear the tare. The weight shown is zero.

4. Apply weights throughout the weighing range, and verify the correct weight (+/- 0.1%)

is displayed at each step.

5. If possible apply a weight of 105% of capacity, and verify the scale shows OE on the

display.

6. Remove weights and verify the display returns to zero.

7. If there is a failure to meet any of the conditions above, please refer to the Calibration

Procedure.

8. When all the conditions above are correct, the scale is operational.

Calibration Switch

The calibration of the scale is protected from accidental change by a switch protected by

an access plug. The access plug is located on the front of the scale head above the “ON”

switch, and is covered by a calibration sticker (seal). The switch is set in the “calibration

blocked” mode at the factory.

Enabling the Calibration switch

First, remove the calibration sticker which covers the access plug. Using a ¼” Allen

wrench, remove the access plug. Insert the Allen wrench in to the hole and press

the switch once. The scale is now set to allow calibration.

How to enter a number

During this routine you will be asked to enter numbers at many points. You must use the

ZERO and PRINT switches to enter these numbers. The scale will show 5 digits but there

are actually 6 digits because the leftmost digit is initially invisible. The active digit will be

blinking. Press the ZERO key to increase the value of the blinking digit. Press the PRINT

key to move the blinking digit one place to the left. When you advance to the leftmost

digit, the display will initially be blank (value of 0). This display segment can be toggled

between 0 and 1. When you are finished entering the number press both the ZERO and

PRINT switches simultaneously to go on.

12

Page 13

CS5000, Users

Rev V, January, 2008

Three point span

The scale has a three point calibration feature which reduces the effects on non-linearity

in the load cells. This requires that you place three weights on the cell during calibration.

The first weight must be greater than zero, the second greater than the first, and the final

weight somewhere between the second and the capacity.

How to Calibrate the Scale

There are three parameters that can be set without moving the calibration switch, followed

by three more parameters and the actual calibration which require the calibration switch to

be in the enabled position.

Default

Display Parameter Note

EE-00

EE-00

EE-00EE-00

EE-01

EE-01

EE-01EE-01

EE-02

EE-02

EE-02EE-02

EE-03

EE-03

EE-03EE-03

EE-04

EE-04

EE-04EE-04

EE-05

EE-05

EE-05EE-05

LL-00

LL-00

LL-00LL-00

LL-01

LL-01

LL-01LL-01

LL-02

LL-02

LL-02LL-02

LL-03

LL-03

LL-03LL-03

1. Access the calibration switch and press once if you intend to calibrate. See

2. Turn both the base and head on. Wait for scale to warm up (2-3 minutes).

3. Press ZERO and PRINT together and release to enter the calibration mode.

4. The scale displays “EE-00

Sample Rate 1 to 64 4

Update Rate 1 to 32 4

Power up in kg 1=kg, 0=lb 0

Information saved

Check for calibration blocking switch

AZT 0=off,1=0.6,2=1,3=3 2

Canadian Specifications 0=off, 1=on 0

Graduation 0 to 11 6

Information saved

Zero read Enter capacity

First weight Enter first weight

Second weight Enter second weight

Third weight Enter third weight

Information saved

Calibration Switch.

EE-00”. Press the ZERO and PRINT keys simultaneously.

EE-00EE-00

Enter the sample rate (1 to 64), ('4' is suggested, although if your readout is too

jumpy, you can increase this value). The sample rate is the number of past

readings that are averages together to make a reading. (Press ZERO and PRINT

keys to enter this number.)

13

Page 14

CS5000, Users

Rev V, January, 2008

5. The scale displays “EE-01

EE-01”. Press the ZERO and PRINT keys. Enter the display

EE-01EE-01

update rate (1 to 32), ('4' is suggested). The display update rate is the speed at

which the display is updated, with 1 being the fastest. (Press the ZERO and PRINT

keys to enter this number.

6. The scale displays “EE-02

EE-02”. Press the ZERO and PRINT keys. Enter what unit of

EE-02EE-02

measure the scale should operate in; pounds or kilograms (0 to 1). (Press the

ZERO and PRINT keys to enter this number.)

Setting Units to operate in

0 pounds (lb)

1 kilograms (kg)

Note: At this point the changes you entered will be saved and the scale could be turned

off if you don't wish to change the calibration.

7. The scale shows “EE-03

EE-03”. Press the ZERO and PRINT keys. Enter the desired

EE-03EE-03

AZT size. The AZT size is the number of graduations the auto zero tracking can

remove. Note: At this point if the calibration blocking switch is not in the enabled

position, the scale will not save the new AZT value. It will instead display the “E1

E1”

E1E1

error message and return to normal weighing. See “Calibration switch” to

change this.

Setting AZT size

0 Off

1 0.6

2 1

3 3

8. The scale shows “EE-04

EE-04”. Press the ZERO and PRINT keys. The scale shows the

EE-04EE-04

current Canadian specification selection. Use the following table to select the

Canadian specifications setting.

Setting Canadian

Specification

0 Off

1 On

A '0' setting implies normal operation:

1: AZT size is determined by setting of EE-03

EE-03.

EE-03EE-03

2: Zero operates over full range of capacity.

3: Over capacity is 103% from the zero obtained at calibration.

A '1' setting implies Canadian specifications are used:

1: The AZT size fixed at 0.6d regardless of EE-03

EE-03 setting.

EE-03EE-03

14

Page 15

CS5000, Users

Count by

Count by

Rev V, January, 2008

2: The IZSM (initial zero setting mechanism on power up) must be within +/- 10% of the

zero obtained at calibration.

3: The push-button zero and AZSM can only operate within +/- 2% of the IZSM.

4: The overcapacity point is 103% of capacity above the IZSM.

9. The scale shows “EE-05

EE-05”. Press the ZERO and PRINT keys. Enter the desired

EE-05EE-05

graduation. Use the following table to select a graduation value. (Press the ZERO

and PRINT keys to enter this value.)

Setting

in lb

in kg

0 100 50

1 50 20

2 20 10

3 10 5

4 5 2

5 2 1

6 1 0.5

7 0.5 0.2

8 0.2 0.1

9 0.1 0.05

10 0.05 0.02

11 0.02 0.01

NOTE: To meet stated accuracy statements, it is suggested that you choose your

graduation setting from the table below:

If your capacity is: Set your graduation to:

500 lb / 250 kg 0.2 lb / 0.1 kg (8)

1000 lb / 250 kg 0.5 lb / 0.2 kg (7)

2,000 lb / 1,000 kg 1 lb / 0.5 kg (6)

5,000 lb / 2,500 kg 1 lb / 0.5 kg (6)

10,000 lb / 5,000 kg 2 lb / 1 kg (5)

20,000 lb / 10,000 kg 5 lb / 2 kg (4)

30,000 lb / 15,000 kg 10 lb / 5 kg (3)

50,000 lb / 25,000 kg 10 lb / 5 kg (3)

70,000 lb / 35,000 kg 20 lb / 10 kg (2)

100,000 lb / 50,000 kg 20 lb / 10 kg (2)

Note: The changes will again be saved here and the scale could be turned off if you

don't wish to change the calibration.

15

Page 16

CS5000, Users

Rev V, January, 2008

10. The scale displays “LL-00

enter the capacity, in the units (lb or kg) that you are calibrating in. With no weight

on the hook, press the ZERO and PRINT keys to enter in this capacity. Max

capacity is 99999 lbs. Special versions allow a max capacity of 199999 lbs.

11. The scale shows “LL-01

keys. On the next screen enter the weight being applied. With the weight on the

hook and its exact value shown on the CS5000 screen, press the ZERO and

PRINT keys to enter in the weight.

12. The scale shows “LL-02

PRINT keys. On the next screen enter the weight being applied. With the weight

on the hook and its exact value shown on the CS5000 screen, press the ZERO and

PRINT keys to enter in the weight.

13. The scale shows “LL-03

keys. On the next screen enter the weight being applied. With the weight on the

hook and its exact value shown on the CS5000 screen, press the ZERO and

PRINT keys to enter in the weight.

LL-00”. Press the ZERO and PRINT keys. On the next screen

LL-00LL-00

LL-01”. Apply the first weight and press the ZERO and PRINT

LL-01LL-01

LL-02”. Apply the second weight and press the ZERO and

LL-02LL-02

LL-03”. Apply the final weight and press the ZERO and PRINT

LL-03LL-03

Finish

The new calibration information is saved.

14. Press the calibration switch ONCE to disable calibration. This will prevent

accidental entry into the calibration mode. If you are unsure of whether the switch is

enabled or disabled, start going thorough the calibration menu again. After the

“AZT” menu item, the scale should return to normal weighing instead of saving the

AZT value and proceeding to EE-04

15. Replace the access plug which will cover the calibration switch.

16. Cover this plug with a new calibration seal (e.g. foil calibration sticker).

17. Verify the calibration.

18. Calibration complete.

EE-04. See the “calibration switch” section.

EE-04EE-04

Legal-for-Trade Sealing

For qualified calibration facilities:

1. After calibration push the calibration switch. The calibration switch is located on the

upper right hand corner on the backside (side with battery caps) of the scale.

2. Verify that the scale returns to normal weighing when trying to access the weight

calibration.

3. Replace the set screw that covers the cal switch.

4. Apply the protection sticker (sticker must adhere to Intercomp’s specifications).

16

Page 17

Rev V, January, 2008

Error Messages

[display reads “-----

also occurs when the unit is first turned on, or after ZERO or TARE is pressed.

EE-00

EE-00

EE-00EE-00

OL-00

OL-00

OL-00OL-00

OE-00

OE-00

OE-00 OE-00

OS

OS

OSOS

HO-00

HO-00

HO-00HO-00

LB-00

LB-00

LB-00LB-00

BLB

BLB

BLBBLB

EO:

EO:

EO:EO:

E1

E1

E1E1

-----“]: The CS5000 is waiting for a stable reading to continue. This

----------

EEPROM error, the scale has had it's calibration corrupted or destroyed;

the scale will require recalibration.

Zero overload, the zero has moved outside it's limit. Return the scale's load

to the initial zero-set and press ZERO, or turn the unit off and then back on.

See 'Canadian specifications' (EE-04

The scale is over capacity. Reduce the load applied to the scale.

Display error, the scale is unable to display the number completely.

Head off, the scale head is turned off or the communication link between

the scale head and base has otherwise failed. If both base and head are on

and you get this message, try rotating or moving the base slightly. This can

sometimes have a substantial effect on the signal received.

The scale head is low in batteries. Turn the scale base off first, then replace

the 8 'D' cell batteries in the head.

The batteries in the base controller require recharging or replacement

This message occurs if the scale is turned on with a load applied which is

greater than ±10% capacity. Return the scale’s load to zero. This only

occurs when Canadian specifications are turned on. See EE-04

‘Calibration section’.

Error during calibration. It is caused by either the calibration strap being

disabled, or a failure in the communication link. The scale will then exit

calibration mode and return to normal weighing after a few seconds. See

“Calibration switch” section.

EE-04 in the 'calibration' section).

EE-04EE-04

EE-04 in the

EE-04EE-04

CS5000, Users

17

Page 18

CS5000, Users

Rev V, January, 2008

Troubleshooting

Caution: Changing some parts on the circuit board may cause a large

change in calibration while others may or may not change the calibration,

depending on the nature of the problem.

The base unit contains the “MPC board” and the “GPI Display board” The head contains

the “A/D board”.

Problem: base only displays “HO-00

Problem: no power, nothing on display

Fix (applies to the base and the head):

Problem: random display (display usually reads “8888.8888.8888.”)

Fix:

Problem: low battery indication won’t turn off

Fix:

HO-00“, no communication

HO-00HO-00

Fix:

Check the power on the head (LED labeled POWER). If the head does have

sufficient power, this is probably a communication problem. Open the base unit

and locate the transceiver. If the LED lights labeled RXD Data and TXD Data are

not blinking, the transceivers are not communicating. Check to make sure the

base and head unit have power. Also make sure they are within range and rotate

units to try to get communication.

If nothing can be seen on the display, there is probably no power reaching the base

circuitry. Possible causes at: bad or shorted battery pack, bad switch circuit, bad

voltage regulator. Power might be reaching the unit, but the power supply might be

shorted by a component or PCB trace in the power supply circuitry.

On MPC board: check crystal (Y2). If the micro-controller is not receiving the

correct or any oscillation, the microprocessor is not able to function properly. Other

possibilities could be bad microprocessor (U1) on MPC board or display driver (U1

& U2 on “GPI DISPLAY” board) circuitry not functioning.

The display will show a low battery condition (“LB-00

base controller). Check if battery power is too low. Look at the cells and charger

circuit for these problems. If that is not the cause, the display driver( U1 & U2 on

the “GPI DISPLAY” board) or low voltage circuitry could be bad.

LB-00” for the head, or “BLB

LB-00LB-00

BLB” for the

BLBBLB

18

Page 19

Problem: rechargeable battery life has decreased

Fix:

The rechargeable batteries provided by Intercomp are high quality, high capacity

Ni-Cad. However, all Ni-Cad batteries can exhibit some “memory” effects if they

are repeatedly discharged to a certain point before recharging. If your observed

battery life has decreased significantly from its initial performance, you may want to

try this battery-conditioning sequence: Fully discharge the batteries by running the

CS5000 until the display blinks “LB

LB” (low battery) and keep the unit powered until

LBLB

the batteries are fully discharged. Following this, recharge the battery completely

(typical charge time is 16 hours). This discharge/recharge cycle may need to be

repeated. If this does not help, you may need to replace the Ni-Cad batteries.

Problem: scale shuts off by itself

Fix:

Check the battery holder terminals. They may be bent and not making solid

contact. If the scale turns off immediately after you take your finger off the button,

there may be defective power circuitry or a bad keypad.

Problem: scale “locks up”

Fix:

The microprocessor (U1) on the MPC board may need to be replaced. The

microprocessor support circuitry could also be bad.

Problem: weights jump or drift

Fix:

Try increasing the sample rate as described in the calibration section (pg. 13).

Pertains to A/D board: If this does not help, the problem could be a bad load cell,

defective amplifier (U5), bad A/D chip (U6), or contamination on the A/D circuit

board.

CS5000, Users

Rev V, January, 2008

19

Page 20

Parts and Accessories

Diagram: 500 lb capacity models

CS5000, Users

Rev V, January, 2008

See following page for parts list

20

Page 21

Parts List: 500 lb capacity

Item # QTY Part # Description

1 1 00072 control harness

2 6 250058 button cover

3 12 600058 .375-16 screw

4 1 250089 keypad overlay

5 1 250090 logo overlay

6 1 500804 CS5000 display end

7 1 250095 window overlay

8 1 220063 4-pin MTA

9 1 603057 loadcell

10 1 insert

11 1 500817 display window

12 1 600064 .50-20unf screw

13 1 500838 loadcell threaded adapter

14 1 500739 loadcell retainer

15 1 500736 lower loadcell adapter

16 1 500824 loadcell housing

17 1 500710 retaining ring gasket

18 1 500709 top retaining ring

19 1 500713 retaining ring spacer

20 2 600020 .25-20 screw

21 4 600023 .25-20 set screw

22 2 600019 .25-20 screw

23 1 601039 eye nut

24 2 500805 housing gasket

25 1 500823 eye nut

26 2 500707 battery tube

27 20 600008 6-32 screw

28 4 330042 battery spring

29 2 500706 battery plate

30 2 500705 battery cap

31 2 600014 8-32 screw

32 2 500708 battery tube end

33 2 601047 wing nut

34 1 000075 battery harness assembly

35 1 603035 assembly screw

36 1 603035 swivel hook assembly

37 1 603035 assembly nut

38 16 601014 .031 nylon washer

39 4 601032 6-32 m/f standoff

40 4 601002 6-32 nut

41 1 500808 right board mount

42 4 601028 vibration mount

43 1 000095 display board

44 4 601015 .062 nylon washer

45 4 600035 8-32 screw

46 4 601018 6-32 standoff

47 1 000094 A/D board

48 1 500807 left board mount

49 4 600015 8-32 unc screw

50 1 500803 lower retaining ring

51 2 500818 bellows

52 1 820027 hose clamp

CS5000, Users

Rev V, January, 2008

21

Page 22

CS5000, Users

Rev V, January, 2008

Diagram: 2K lb capacity models

Please see following page for parts table

22

Page 23

Parts List: 2K lb capacity

Item # QTY Part # Description

1 1 00072 control harness

2 6 250058 button cover

3 12 600058 .375-16 screw

4 1 250089 keypad overlay

5 1 250090 logo overlay

6 1 500804 CS5000 display end

7 1 250095 window overlay

8 1 220063 4-pin MTA

9 4 600023 .25-20 set screw

10 1 000062 loadcell (2K capacity CS5000)

11 1 insert

12 1 500817 display window

13 1 500838 loadcell threaded adapter

14 1 500739 loadcell retainer

15 1 500824 loadcell housing

16 1 500710 retaining ring gasket

17 1 500709 top retaining ring

18 1 500713 retaining ring spacer

19 2 600020 .25-20 screw

20 2 600019 .25-20 screw

21 1 601039 eye nut

22 2 500805 housing gasket

23 1 500823 eye nut

24 2 500707 battery tube

25 20 600008 6-32 screw

26 4 330042 battery spring

27 2 500706 battery plate

28 2 500705 battery cap

29 2 600014 8-32 screw

30 2 500708 battery tube end

31 2 601047 wing nut

32 1 000075 battery harness assembly

33 1 603035 assembly screw

34 1 603035 swivel hook assembly

35 1 603035 assembly nut

36 16 601014 .031 nylon washer

37 4 601032 6-32 m/f standoff

38 4 601002 6-32 nut

39 1 500808 right board mount

40 4 601028 vibration mount

41 1 000095 display board

42 4 601015 .062 nylon washer

43 4 600035 8-32 screw

44 4 601018 6-32 standoff

45 1 000094 A/D board

46 1 500807 left board mount

47 4 600015 8-32 unc screw

48 1 500803 lower retaining ring

49 2 500818 bellows

50 1 820027 hose clamp

CS5000, Users

Rev V, January, 2008

23

Page 24

Diagram: 5K lb, 10K lb capacities

CS5000, Users

Rev V, January, 2008

See the following page for parts list

24

Page 25

Parts List: 5K lb, 10K lb capacity

Item # QTY Part # Description

1 1 00072 control harness

2 6 250058 button cover

3 12 600058 .375-16 screw

4 1 250089 keypad overlay

5 1 250090 logo overlay

6 1 500804 CS5000 display end

7 1 250095 window overlay

8 1 220063 4-pin MTA

9 4 600023 .25-20 set screw

10 1 000073 loadcell (5K and 10K capacity CS5000)

11 1 insert

12 1 500817 display window

13 1 500838 loadcell threaded adapter

14 1 500824 loadcell housing

15 1 500710 retaining ring gasket

16 1 500709 top retaining ring

17 2 600020 .25-20 screw

18 2 600019 .25-20 screw

19 1 601039 eye nut

20 2 500805 housing gasket

21 1 500823 eye nut

22 2 500707 battery tube

23 20 600008 6-32 screw

24 4 330042 battery spring

25 2 500706 battery plate

26 2 500705 battery cap

27 2 600014 8-32 screw

28 2 500708 battery tube end

29 2 601047 wing nut

30 1 000075 battery harness assembly

31 1 603035 assembly screw

32 1 603035 swivel hook assembly

33 1 603035 assembly nut

34 16 601014 .031 nylon washer

35 4 601032 6-32 m/f standoff

36 4 601002 6-32 nut

37 1 500808 right board mount

38 4 601028 vibration mount

39 1 000095 display board

40 4 601015 .062 nylon washer

41 4 600035 8-32 screw

42 4 601018 6-32 standoff

43 1 000094 A/D board

44 1 500807 left board mount

45 4 600015 8-32 unc screw

46 1 500803 lower retaining ring

47 2 500818 bellows

48 1 820027 hose clamp

CS5000, Users

Rev V, January, 2008

25

Page 26

Diagram: 20K lb, 30K lb, capacities

CS5000, Users

Rev V, January, 2008

Please see following page for parts list

26

Page 27

Parts List: 20K lb, 30K lb capacity

Item # QTY Part # Description

1 1 00072 control harness

2 6 250058 button cover

3 12 600058 .375-16 screw

4 1 250089 keypad overlay

5 1 250090 logo overlay

6 1 500804 CS5000 display end

7 1 250095 window overlay

8 1 220063 4-pin MTA

9 4 600023 .25-20 set screw

10 1 000073

000063

11 1 insert

12 1 500817 display window

13 1 601051 1-8 locking nut

14 1 500813 top loadcell adapter

15 2 602008 1-8 bolt

16 1 500824 loadcell housing

17 1 500710 retaining ring gasket

18 1 500709 top retaining ring

19 1 601039 eye nut

20 2 600019 .25-20 screw

21 2 600020 .25-20 screw

22 2 500805 housing gasket

23 1 500823 end plate

24 1 500946 lower loadcell adapter

25 2 500707 battery tube

26 20 600008 6-32 screw

27 4 330042 battery spring

28 2 500706 battery plate

29 2 500705 battery cap

30 2 600014 8-32 screw

31 2 500708 battery tube end

32 2 601047 wing nut

33 1 000075 battery harness assembly

34 1 603063 assembly screw

35 1 603063 swivel hook assembly

36 1 603063 assembly nut

37 16 601014 .031 nylon washer

38 4 601032 6-32 m/f standoff

39 4 601002 6-32 nut

40 1 500808 right board mount

41 4 601028 vibration mount

42 1 000095 display board

43 4 601015 .062 nylon washer

44 4 600035 8-32 screw

45 4 601018 6-32 standoff

46 1 000094 A/D board

47 1 500807 left board mount

48 4 600015 8-32 unc screw

49 1 500803 lower retaining ring

50 2 500818 bellows

51 1 820027 hose clamp

loadcell (20K capacity CS5000)

loadcell (30K capacity CS5000)

CS5000, Users

Rev V, January, 2008

27

Page 28

CS5000, Users

Rev V, January, 2008

Serial Output

The CS5000 base has available two communications channels, the standard interface for

both is RS-232. One is equipped with a CTS (clear to send) line and designed primarily for

hookup to a printer. The second channel consists of signal wires only and is designed

primarily for hookup to a score board or computer.

Channel 1 outputs a ticket:

cr/lf

-XXXXXX.X lb G cr/lf

-XXXXXX.X lb N cr/lf

-XXXXXX.X lb T cr/lf

-XXXXXX.X lb TOTAL cr/lf

lf

lf

JAN DD, 19YY HH:MM:SSam cr/lf (the 19 could be 20, and the a could be p)

lf

lf

Channel 2 outputs the net weight:

-XXXXXX.X lb cr/lf

There is a five switch dip pak located on the main circuit board inside the base unit, it's

switches have the following meanings:

Switch # On Off Function

1

2 1200

3 on

4

5

The Items in bold indicate the suggested defaults.

NOTE: The RS-232 communication parameters: Fixed 8 data bits, no parity, 1 stop bit.

Each channel will print under two conditions:

1: If the print key is pressed.

2: If the continuous print is turned on.

1200

on

on

9600 Channel 1 baud rate

9600

off

off Channel 2 continuous print

off RF interface (must be turned on, on CS5000)

Channel 2 baud rate

Channel 1 continuous print

28

Page 29

CS5000, Users

Rev V, January, 2008

The signals for the two channels exist the box through the six pin connector on the bottom

of the box. The wiring is listed on the following chart:

Pin# Connection

A CH1 TXD

B CH1 CTS

C CH1 GND

D CH2 TXD

E CH2 GND

F NC

Example Connections

The connection of CH1 to a 9-pin PC communications port is:

CS5000 9-pin PC

A (TXD) 2 (RXD)

B (CTS) 7 (RTS)

C (GND) 5 (GND)

NOTE: For some setups it may be necessary to jump pins [6, 1, and 4] together on

the PC port connector.

The connection of CH1 to a 25-pin PC communications port is:

CS5000 25-pin PC

A (TXD) 3 (RXD)

B (CTS) 4 (RTS)

C (GND) 7 (GND)

NOTE: For some setups it may be necessary to jump pins [6, 8, and 20] together

on the PC port connector.

The connection of CH2 to an Intercomp S400 display is:

CS5000 S400

D (TXD) 2 (RXD)

E (GND) 7 (GND)

The connection of CH2 to an Intercomp SA2000 display is:

CS5000 SA2000

D (TXD) 3 (RXD)

E (GND) 7 (GND)

cont’d on next page

29

Page 30

CS5000, Users

Rev V, January, 2008

The connection of CH2 to a 9-pin PC communication port is:

CS5000 PC 9-pin

D (TXD) 2 (RXD)

E (GND) 5 (GND)

Note: For some setups it may be necessary to jump pins [6, 1, and 4] together, and

pins [7 and 8] together on the PC port connector.

The connection of CH2 to a 25-pin PC communication port is:

CS5000 PC 25-pin

D (TXD) 3 (RXD)

E (GND) 7 (GND)

Note: For some setups it may be necessary to jump pins [6, 8, and 20] together,

and pins [4 and 5] together on the PC port connector.

30

Page 31

How to reach Intercomp Service

Things to know:

1. The service is for a CS5000 crane scale.

2. When did you purchase your scale?

3. What is your serial number?

4. Whom did you purchase the scale through?

For Intercomp Service call or fax:

FAX # (763)-476-2613

(763)-476-2531

1-800-328-3336

or fill out Service Support Form at:

www.intercompcompany.com

Copyright Intercomp Company 2008

All rights reserved

CS5000, Users

Rev V, January, 2008

31

Loading...

Loading...