Page 1

Programmable HMI Indicator/Controller

Version 3.05

Installation Manual

67887

Page 2

Page 3

Contents

About This Manual ................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

1.1 Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Indicator Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Softkey Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 System Configurations and Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5 Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.0 Installation ................................................................................................................................... 7

2.1 Unpacking and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Enclosure Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.1 Cable Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.2 Load Cells. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.3 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.4 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Installing Option Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.5 Expansion Board Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.6 Enclosure Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.7 CPU Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.8 Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.9 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.10 Parts Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.11 Replacement Parts and Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.0 Configuration ............................................................................................................................. 19

3.1 Configuration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.1 iRev Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.1.2 Serial Command Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.3 Front Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.4 Multi-Range and Multi-Interval Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.5 Total Scale Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Menu Structures and Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2.1 SCALES Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2.2 SERIAL Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.2.3 FEATURE Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.2.4 PFORMT Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.2.5 SETPTS Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3.2.6 DIG I/O Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.2.7 Analog Output Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.2.8 Version Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.0 Calibration ................................................................................................................................. 50

4.1 Gravity Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.2 Front Panel Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.3 Serial Command Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.4 iRev Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com or obtained

by calling 715-234-9171 and asking for the training department

© 2007 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Version 3.05, August 2007

Page 4

5.0 Using iRev .................................................................................................................................. 54

5.1 Installing and Starting the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.2 Hardware Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

5.3 Configuring Scales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3.1 Configuring Other Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.3.2 Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.4 Configuring the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

5.5 Connecting to the Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.5.1 Downloading to the Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.5.2 Uploading Configuration to iRev . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

5.6 Installing Software Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.0 Print Formatting ......................................................................................................................... 57

6.1 Print Formatting Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.2 Default Print Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.3 Customizing Print Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.3.1 Using iRev . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.3.2 Using the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.3.3 Using Serial Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7.0 Truck Modes .............................................................................................................................. 63

7.1 Using the Truck Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.2 Using the Truck Regs Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7.3 Weigh-In Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.4 Weigh-Out Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.5 Single-Transaction Tare Weights and IDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

8.0 Setpoints .................................................................................................................................... 65

8.1 Batch and Continuous Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.2 Setpoint Menu Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.3 Batch Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

8.4 Batching Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

9.0 Serial Commands ...................................................................................................................... 84

9.1 The Serial Command Set. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.1.1 Key Press Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

9.1.2 Reporting Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.1.3 Clear and Reset Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.1.4 Parameter Setting Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.1.5 Normal Mode Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

9.1.6 Batching Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.7 Database Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.2 Widget Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.2.1 Scale Widgets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.2.2 Bitmap Widgets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.2.3 Bargraph Widgets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.2.4 Label Widgets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.2.5 Numeric Widgets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.2.6 Symbol Widgets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

10.0 Appendix .................................................................................................................................. 101

10.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

10.1.1 Option Card Diagnostic Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.1.2 Using the HARDWARE Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.1.3 User Program Diagnostic Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

10.1.4 Using the XE Serial Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

10.2 Regulatory Mode Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10.3 PS/2 Keyboard Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

10.4 Serial Scale Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

10.5 Local/Remote Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

ii 920i Installation Manual

Page 5

10.6 Custom Stream Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10.7 Stream Formatting Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.7.1 Toledo 8142 Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

10.7.2 Cardinal 738 Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

10.7.3 Weightronix WI -120 Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.8 Data Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10.9 Digital Filtering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.10 Conversion Factors for Secondary Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

10.11 Audit Trail Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.11.1 Displaying Audit Trail Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.11.2 Printing Audit Trail Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10.12 Dimension Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

10.13 Printed Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10.14 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

920i Limited Warranty ......................................................................................................................... 123

iii

Page 6

iv 920i Installation Manual

Page 7

About This Manual

This manual is intended for use by service technicians

®

920i

responsible for installing and servicing

digital

weight indicators. This manual applies to Version

3.05 of the

920i indicator software.

Configuration and calibration of the indicator can be

™

iRev

accomplished using the

configuration utility,

serial commands, or the indicator front panel keys.

Section 3.1 on page 19 for information about

See

configuration methods.

1.0 Introduction

The 920i is a programmable, multi-channel digital

weight indicator/controller. The configuration can be

performed using the front panel, with an attached

1

®

PS/2

Custom event-driven programs can be written with the

iRite language up to 512K in program size. These

programs are compiled with an

which can only be downloaded into the indicator. The

RLWS Web Update utility can be used to download

920i firmware upgrades to a PC from the RLWS web

site;

software into the

Onboard Features

Features of the basic 920i include:

-type keyboard, or using the iRev utility.

iRite compiler utility,

iRev provides functions for installing the new

920i.

• Support for A/D scale or serial scale inputs.

The maximum number of scale inputs is 28;

these can be combined to represent up to 32

scale configurations.

• Four digital I/O channels on main board, each

configurable as either input or output.

• Four serial ports on main board (Ports 1–4)

support duplex RS-232 up to 115200 bps. Port

2 supports hardware handshaking and remote

keyboard input; Ports 3 and 4 support 20mA

output; Port 4 supports 2-wire RS-485

communications.

• External DB-9 and DIN-8 connectors for

serial connection to a PC and attachment of

PS/2-type remote keyboard.

• Available in 115 VAC and 230 VAC North

American and European versions.

1. PS/2® is a registered trademark of IBM Corporation.

Some procedures described in this manual

require work inside the indicator enclosure.

These procedures are to be performed by

qualified service personnel only.

Authorized distributors and their employees

can view or download this manual from the

Rice Lake Weighing Systems distributor

www.ricelake.com.

site at

The Operator Card included with this manual

provides basic operating instructions for users of the

920i. Please leave the Operator Card with the

indicator when installation and configuration are

complete.

Other features include:

• 62K of non-volatile RAM can be allocated to

databases using the

iRev database editor.

• Configurable print formats can be defined for

up to 1000 characters each. These formats are

used to print gross or net weights, truck in/out

weights, setpoint weights, accumulator

weights, alert messages, and header

information. Additional print formats can be

created with

iRite.

• Six truck modes to store and recall weights

for gross, tare, and net printing. The truck

register contains fields for ID number, weight,

and the transaction time and date. Weights can

be stored permanently or erased at the end of

the transaction.

• The setpoint engine supports 31 configurable

setpoint kinds. Setpoints can be arranged in a

sequential batch routine of up to 100 steps. If

setpoints are configured as free running

setpoints, they can be tied to program control.

This allows for simultaneous batching

operations to be written with the

iRite

language.

The 920i is NTEP-certified for Classes III and III L at

10,000 divisions. See

Section 10.14 on page 122 for

more information about additional certifications and

approvals.

Option Cards

The CPU board provides two slots for installing A/D

or other option cards. Additional option cards can be

added using either two-card or six-card expansion

boards connected to the CPU board via the expansion

bus. Available option cards include:

Introduction 1

Page 8

• Single- and dual-channel A/D cards to drive up to

sixteen 350Ω load cells per A/D card. A/D cards

support both 4- and 6-wire load cell connections.

A/D cards are matched to allow interchangeability

without having to recalibrate the scale. Calibration

includes support for latitude and elevation

compensation, millivolt calibration, and five-point

linearization.

• Analog output card for 0–10 VDC or 0–20 mA

tracking of gross or net weight values.

• Dual-channel serial expansion card provides one

additional RS-485 port or two ports for either

RS-232 or 20mA communications at up to

19200 bps.

• 24-channel digital I/O expansion card.

• 1MB memory expansion card for expanded

database capability.

• Pulse input card for use with pulse count and

pulse rate setpoints.

• Dual-channel analog input card supports 0–10

VDC, 0–20 mA, ambient temperature, and four

types of thermocouple.

• Bus interface cards for Ethernet,

EtherNet/IP

1

™

, DeviceNet

2

™

, Allen-Bradley

Remote I/O3, and Profibus® DP networks4.

See Section 2.5 on page 12 for detailed information

about expansion board configurations. Part numbers

of available option cards and expansion boards are

listed in

Front Panel

Section 1.4 on page 4.

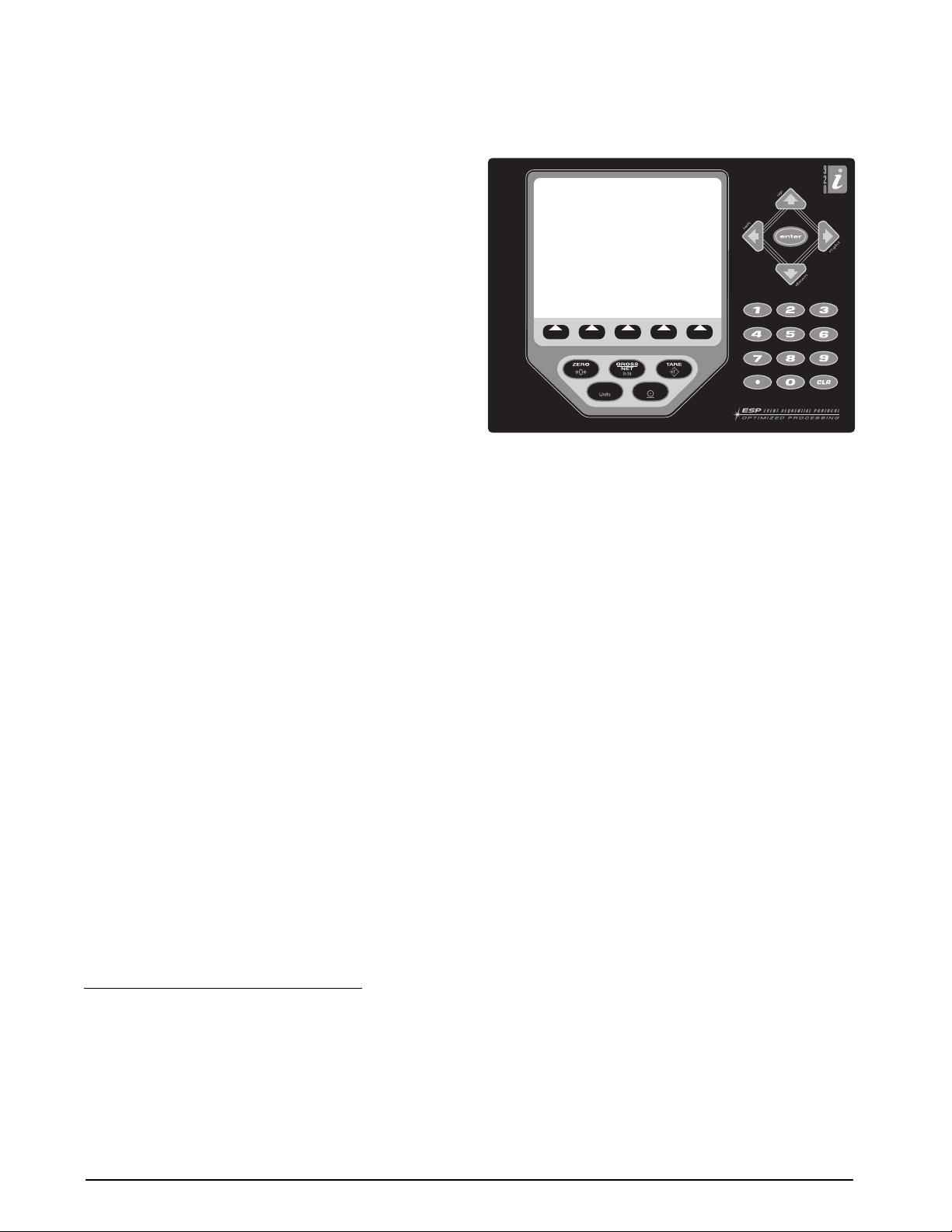

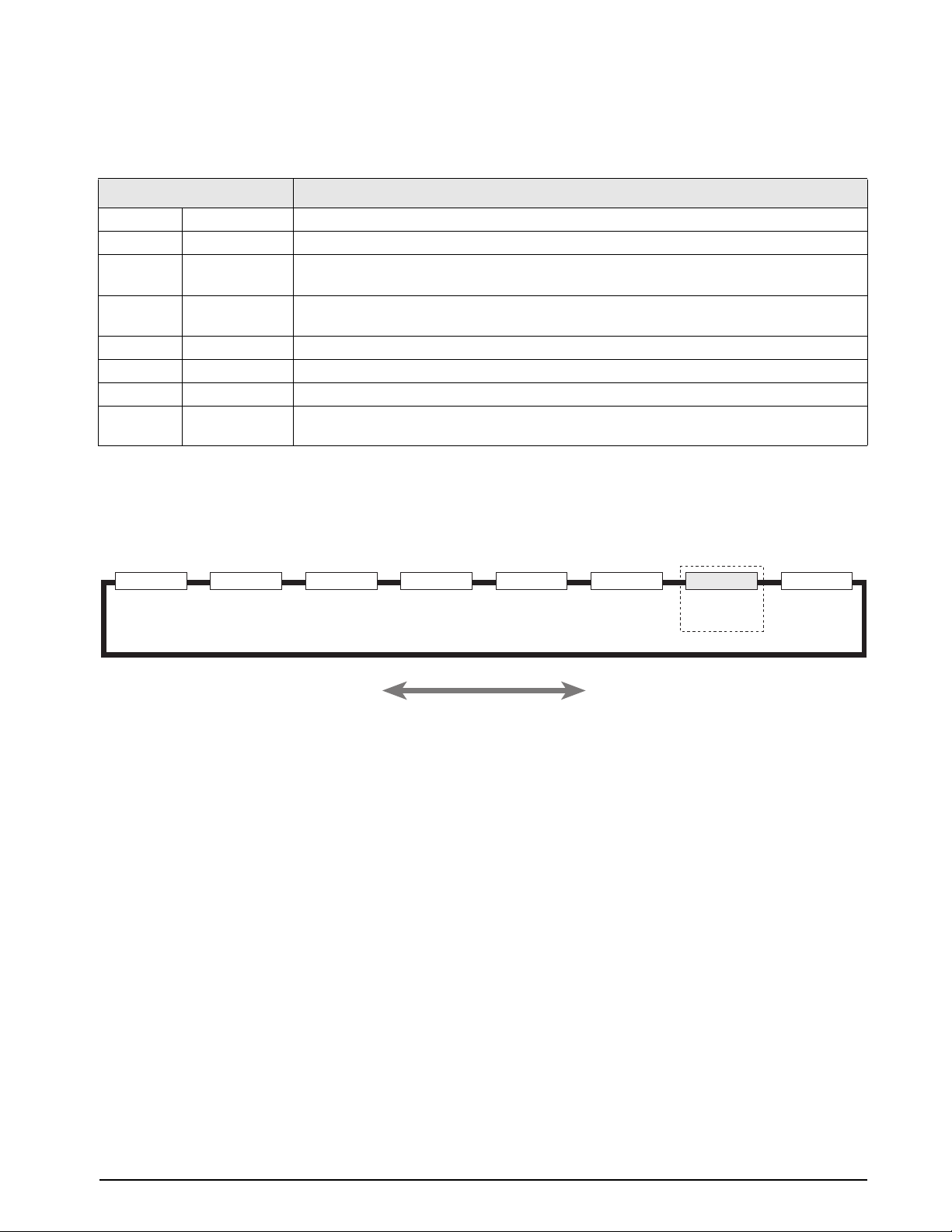

The 920i front panel, shown in Figure 1-1, consists of

a 27-button keypad with a large backlit LCD display.

The keys are grouped as five configurable softkeys,

five primary scale function keys, four navigation keys,

and numeric entry keys. The display can be

graphically configured using

iRev software.

Weight information is displayed with a graphical scale

in six font sizes up to 1.2 inches. Up to four scale

widgets can be displayed in legal-for-trade,

multiple-scale applications. Status areas on the display

are used for operator prompts and entering data. The

remainder of the display can be graphically

configured for representation of a specific application.

1. EtherNet/IP™ is a trademark of ControlNet

International, Ltd., under license by the Open

DeviceNet Vendor Association.

2. DeviceNet™ is a trademark of the Open DeviceNet

Vendor Association.

3. Allen-Bradley®, PLC®, and SLC™ are trademarks of

Allen-Bradley Company, Inc., a Rockwell International

company.

4. Profibus® is a registered trademark of Profibus

International.

Display contrast can be adjusted with the LCD

contrast potentiometer.

SOFTKEY1 SOFTKEY2

Enclosures

SOFTKEY3

SOFTKEY4 SOFTKEY5

PRINT

UNITS

Figure 1-1. 920i Front Panel

The 920i is available in four enclosures: universal

(tilt-stand), deep enclosure, panel mount, and wall

mount. Stainless steel enclosures are rated for NEMA

4X/IP66. This manual provides assembly drawings

and replacement parts lists for the universal model;

supplemental documentation provides information

specific to the panel mount and wall mount models

Section 1.4 on page 4).

(

1.1 Operating Modes

The 920i has two modes of operation:

Normal mode

Normal mode is the weighing mode of the

indicator. The indicator displays gross, net, or tare

weights as required, using the secondary display

to indicate scale status and the type of weight

value displayed. Once configuration is complete

and a legal seal is affixed to the large fillister-head

screw on the indicator enclosure, this is the only

mode in which the

Setup mode

Most of the procedures described in this manual

require the indicator to be in setup mode,

including configuration and calibration.

To enter setup mode, remove the large fillister

head screw from the enclosure. Insert a

screwdriver or a similar tool into the access hole

and press the setup switch once. The indicator

display changes to show scale configuration

menus.

920i can operate.

2 920i Installation Manual

Page 9

1.2 Indicator Operations

Basic 920i operations are summarized below:

Toggle Gross/Net Mode

Press the GROSS/NET key to switch the display mode

from gross to net, or from net to gross. If a tare value

has been entered or acquired, the net value is the gross

weight minus the tare. If no tare has been entered or

acquired, the display remains in gross mode.

Gross mode is indicated by the word Gross (or Brutto in

OIML mode); net mode is indicated by the word

Toggle Units

Press the UNITS key to switch between primary,

secondary, and tertiary units.

Zero Scale

1. In gross mode, remove all weight from the scale

and wait for the standstill annunciator (

2. Press the ZERO key. The center of zero ( )

annunciator lights to indicate the scale is zeroed.

Acquire Tare

1. Place container on scale and wait for the

standstill annunciator (

).

2. Press the TARE key to acquire the tare weight of

the container.

3. Display shifts to net weight and shows the word

Net on the display.

Remove Stored Tare Value

1. Remove all weight from the scale and wait for

the standstill annunciator (

).

2. Press the TA RE key (or, in OIML mode, the

ZERO key). Display shifts to gross weight and

shows the word

Print Ticket

Gross.

1. Wait for the standstill annunciator ( ).

2. Press the PRINT key to send data to the serial

port. To print tickets using auxiliary formats,

press the number key for the format, then press

PRINT. For example, to print using AUXFMT2,

2, then PRINT.

press

Accumulator Functions

The accumulator must be enabled before use in either

normal mode or setpoint operations. Once enabled,

weight (net weight if a tare is in the system) is

accumulated whenever a print operation is performed

using the

PRINT key, digital input, or serial command.

The scale must return to zero (net zero if a tare is in

the system) before the next accumulation.

The Display Accum softkey can be configured to

display the current accumulator value. Printing while

the accumulator is displayed, or when the setpoint

PSHACCUM function is active, uses the ACCFMT

print format (see

Section 6.0 on page 57).

Press the CLEAR key twice to clear the accumulator.

Net.

).

1.3 Softkey Operations

Softkeys can be defined to provide additional operator

functions for specific applications. Softkey assignments

are listed on the tabs shown at the bottom of the LCD

display; softkey functions are activated by pressing the

arrow keys below the softkey tabs (

page 2).

The particular set of softkeys shown on the display is

determined by the indicator configuration and

program.

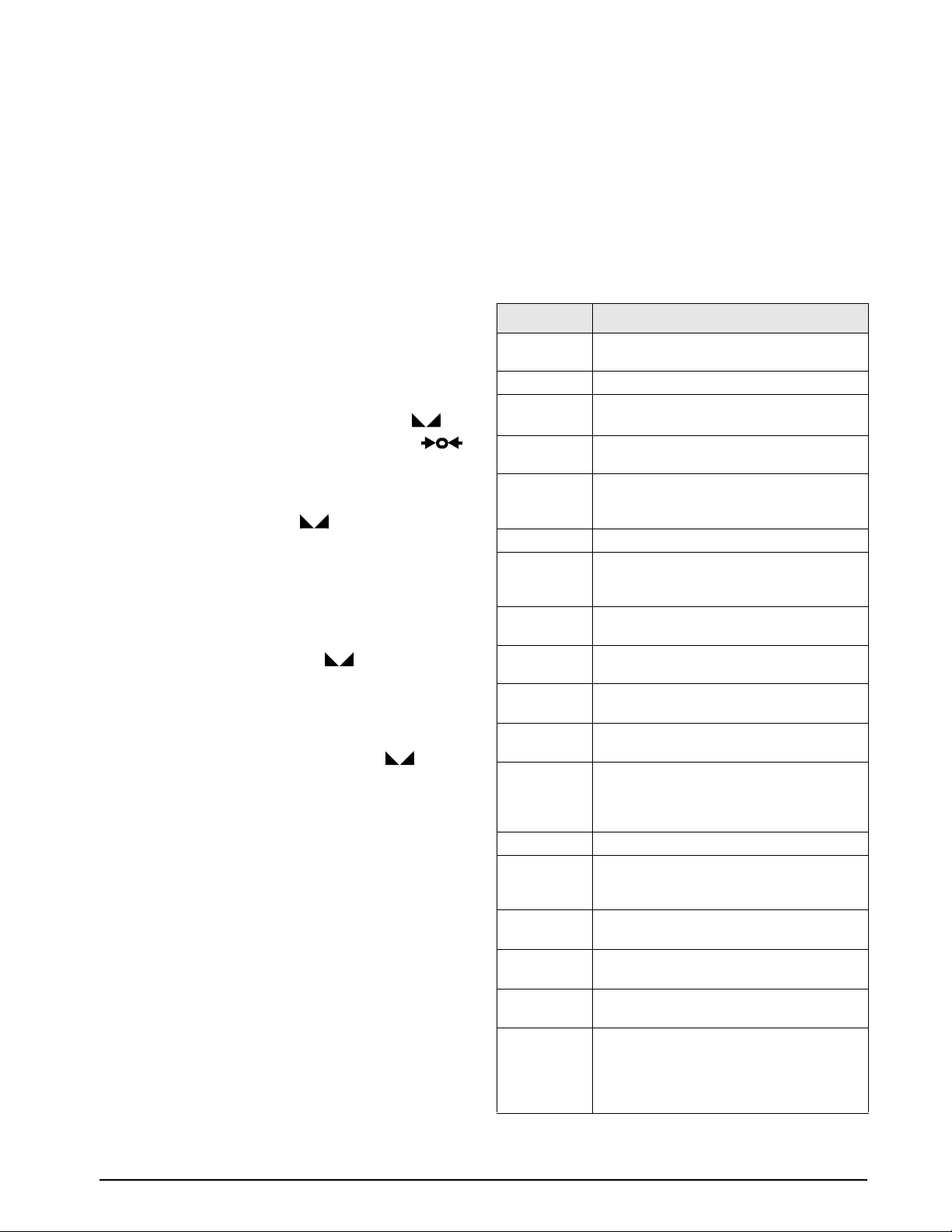

Softkey Description

Time/Date Displays current time and date; allows time

and date change.

Display Tare Displays tare value for the current scale

Display

Accum

Display ROC Displays rate-of-change value, if enabled,

Setpoint Displays a menu of configured setpoints;

Batch Start Starts a configured batch.

Batch Stop Stops a running batch and turns off all

Batch Pause Pauses a running batch. (Same as stop, but

Batch Reset Stops a batch and resets it to the first batch

Weigh In Allows truck ID entry; generates weigh-in

Weigh Out Allows truck ID entry; generates weigh-out

Truck R e g s Displays truck register; allows deletion of

Unit ID Allows display or change of Unit ID.

Select Scale For multi-scale applications, provides a

Diagnostics Provides access to diagnostic displays for

Alibi Allows previous print transactions to be

F1–F10 User-programmable keys; defined by

More… For applications with more than five defined

Displays accumulator value, if enabled, for

the current scale.

for the current scale.

allows display and change of some setpoint

parameters.

associated digital outputs. Requires a batch

start to resume processing.

digital outputs, if on, are not turned off.)

step.

ticket for truck weighing applications.

ticket for truck weighing applications.

individual or all entries. Truck register can be

printed by pressing the

truck register is displayed.

prompt to enter the scale number to be

displayed.

attached

recalled and reprinted.

application.

softkeys, the More… key is automatically

assigned to the fifth softkey position. Press

More… to toggle between groups of

softkeys.

Table 1-1. Configurable Softkeys

iQUBE junction boxes.

Figure 1-1 on

PRINT key while the

Introduction 3

Page 10

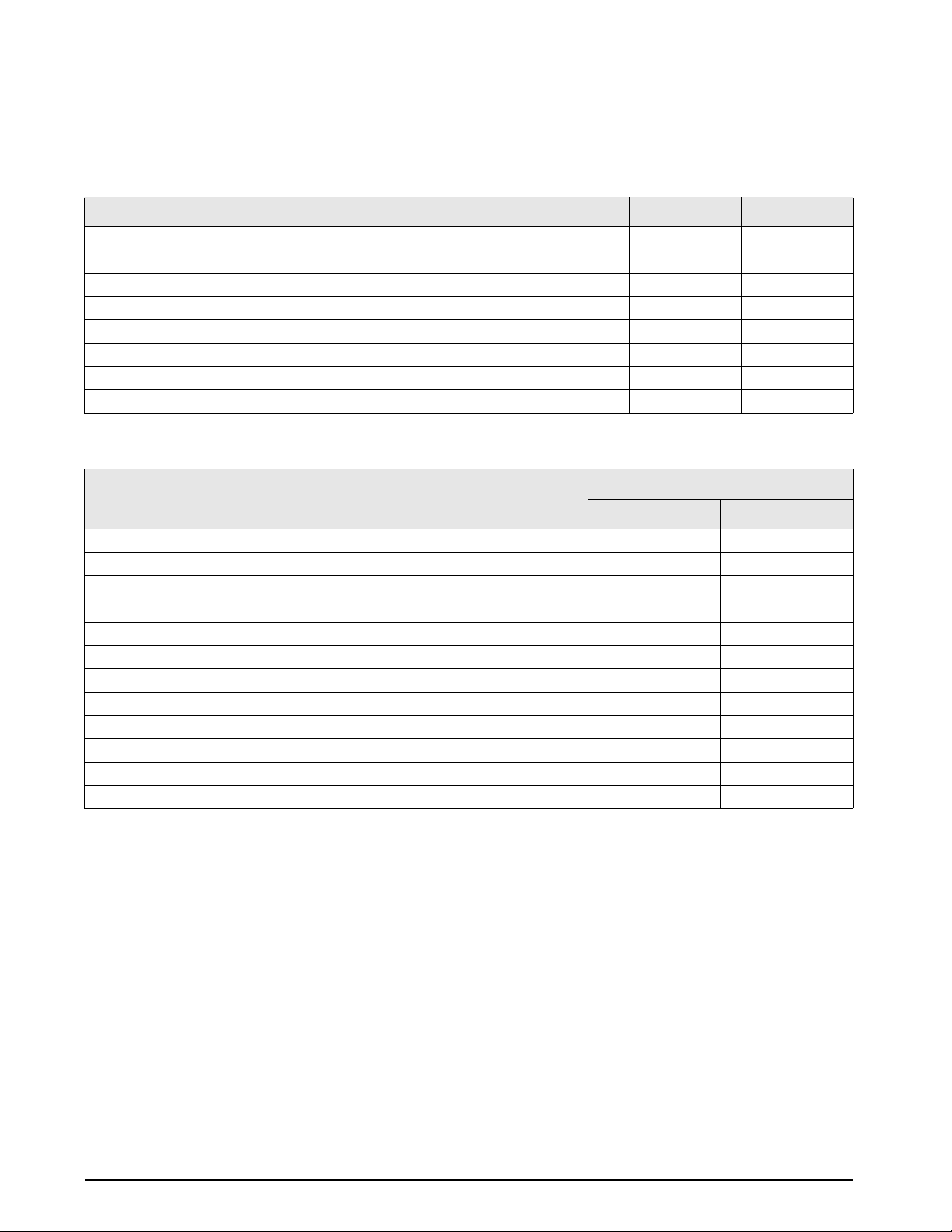

1.4 System Configurations and Options

Table 1-2 lists the 920i system models and part numbers. All models include CPU board with two option card

slots, PS/2 and DB-9 communications ports. Each model comes equipped with a single- or dual-channel A/D

card installed in Slot 1 (see

Feature Universal Deep Universal Panel Mount Wall Mount

CPU board with two option card slots X X X X

Single- or dual-channel A/D card in slot 1 X X X X

DIN-8 and DB-9 communications ports X X X X

25W internal power supply X

65W internal power supply X X X

Supports internal 2-card expansion board X X X

Supports internal 6-card expansion board X

Supports internal relay rack X

Tabl e 1-3).

Table 1-2. 920i Model Features

Model PNs

System Model

Universal (tilt stand) model, 115 VAC 67527 69767

Universal (tilt stand) model, 230 VAC, North American, NEMA 15-5 power cord 67615 69772

Universal (tilt stand) model, 230 VAC, European, CEE 7/7 power cord 69522 69774

Deep enclosure model, 115 VAC 82455 82456

Deep enclosure model, 230 VAC, North American, NEMA 15-5 power cord 82457 82458

Deep enclosure model, 230 VAC, European, CEE 7/7 power cord 82459 82460

Panel mount model, 115 VAC 69764 69771

Panel mount model, 230 VAC, North American, NEMA 15-5 power cord 69766 69777

Panel mount model, 230 VAC, European, CEE 7/7 power cord 72137 72138

Wall mount model, 115 VAC 69763 69770

Wall mount model, 230 VAC, North American, NEMA 15-5 power cord 69765 69776

Wall mount model, 230 VAC, European, CEE 7/7 power cord 72133 72134

Single-Channel A/D Dual-Channel A/D

Table 1-3. Part Numbers for 920i Models

4 920i Installation Manual

Page 11

Option Cards

Tabl e 1-4 lists the available 920i option cards. Any of

the listed option cards can be installed in Slot 2 of the

CPU board or in any available slot of an attached

expansion board.

Option Card PN

Single-channel A/D card 68532

Dual-channel A/D card 68533

Analog output card 67602

Dual serial port expansion card 67604

24-channel digital I/O expansion card 67601

1MB NV RAM memory expansion card 67600

Pulse input card 67603

Ethernet communications card 71986

EtherNet/IP communications card 87803

DeviceNet interface card 68541

Allen-Bradley Remote I/O interface card 68539

Profibus DP interface card 68540

Analog input card with thermocouple input 87697

Table 1-4. Part Numbers for 920i Option Cards

Expansion Boards

Table 1-5 lists the expansion boards available for the

panel mount and wall mount enclosures. The panel

mount enclosure can accommodate a single 2-card

expansion board; the wall mount enclosure supports

either a 2-card or a 6-card expansion board. Any of

the available option cards can be installed in any

available expansion board slot.

A second two- or six-card expansion board can also be

connected to the

slots. Consult factory for details. See

920i, providing up to 14 option card

Section 2.5 on

page 12 for detailed information about slot and serial

port assignments for expanded system configurations.

Expansion Board PN

Two-card expansion board for panel mount

enclosure, slots 3–4. Includes 2-inch, 34-pin

ribbon cable and power supply cable.

Two-card expansion board for wall mount

enclosure, slots 3–4. Includes 24-inch, 34-pin

ribbon cable and power supply cable.

Six-card expansion board for wall mount

enclosure, slots 3–8. Includes 16-inch, 34-pin

ribbon cable and power supply cable.

Table 1-5. Part Numbers for 920i Expansion Boards

71743

69782

69783

Relay Options

8-, 16-, and 24-channel relay racks are available for all

920i systems. Relays can be installed internally in the

wall mount enclosure; all other models require an

external enclosure for the relays. Consult factory for

details.

DC Power Supplies

Two DC power supplies are available for mobile 920i

applications:

PN 97474, 9–36 VDC supply

PN 99480, 10–60 VDC supply

Consult factory for more information.

Outdoor Display

An optional display, PN 100759, is available for

applications requiring use of the

920i in bright, sunlit

environments. Consult factory for details.

1.5 Summary of Changes

Principal changes for Version 3.05 for the 920i

indicator include the following:

• Support for local/remote indicator configurations

provides function equivalent to a legal-for-trade

remote display with keypad for truck scale and

similar applications. See

page 106 for more information.

• The description for setting rate of change (ROC)

parameters has been changed. See

page 27 for details.

• New values have been added to the STREAM

parameter on the SERIAL menu to allow

streaming of keypad events to another indicator

(4KEYS, KEYPAD) and, for the local/remote

function, to send the complete display image

(DISPLAY). See

Section 3.2.2 for more

information.

• Reprinting of any previous print transaction is

now supported by the alibi feature. The feature is

enabled using the ALIBI parameter on the

FEATURE menu; print transactions can be

recalled by assigning an

configured using the FEATURE menu (see

Section 3.2.3 on page 38).

• New IMAGE parameter on the FEATURE menu

allows inversion of the display image

(blue-on-white or white-on-blue) for support of

the outdoor display option. See

• Display and printing of audit trail information is

described in

Section 10.11 on page 116.

Section 10.5 on

Table 3-3 on

Alibi softkey, also

Section 3.2.3.

Introduction 5

Page 12

Version 3.0 changes for the 920i indicator include the

following:

• The desktop model of the 920i has been

discontinued. Drawings and parts lists for the

desktop model have been removed from this

manual.

• Added support for multi-range and

multi-interval scale configurations.

• Zero tracking, zero range, and motion band

parameters (SCALES menu) have been

changed to allow numeric values.

• Added peak hold function to SCALES menu.

• Added last zero and temporary zero functions

to calibration menus to allow recalibration

based on previous zero values.

• Enhanced print formatting with addition of

audit format and twenty auxiliary formats.

• The SERIAL menu has been restructured to

provide additional parameters for configuring

RS-485 communications. See

Figure 3-10 on

page 35.

• A new digital input count (DINCNT) setpoint,

used to count digital input pulses, has been

added to the supported setpoint kinds. See

Section 8.0 on page 65.

• A SENSE parameter has been added to

optionally invert the value of setpoint digital

outputs. See

Section 8.0 on page 65.

• TRIGGER (digital output trigger) has been

added as a selection under the DIG I/O menu

Section 3.2.6 on page 46) for custom

(see

applications.

• Support has been added for EtherNet/IP and

analog input/thermocouple option cards.

6 920i Installation Manual

Page 13

2.0 Installation

This section describes procedures for connecting load

cell, digital I/O, and serial communications cables to

920i indicator. Assembly drawings and

the

replacement parts lists for the universal model are

included for the service technician. See

Section 10.12

on page 117 for dimension drawings of the all models.

• Use a wrist strap to ground yourself and

protect components from electrostatic

discharge (ESD) when working inside the

indicator enclosure.

• This unit uses double pole/neutral fusing

which could create an electric shock hazard.

Procedures requiring work inside the

indicator must be performed by qualified

service personnel only.

• The supply cord serves as the power

disconnect for the

920i. The power outlet

supplying the indicator must be installed near

the unit and be easily accessible.

2.1 Unpacking and Assembly

Immediately after unpacking, visually inspect the 920i

to ensure all components are included and

undamaged. The shipping carton should contain the

indicator, this manual, and a parts kit. If any parts

were damaged in shipment, notify Rice Lake

Weighing Systems and the shipper immediately.

See Section 2.10 on page 14 for parts kit contents.

2.2 Enclosure Disassembly

The indicator enclosure must be opened to install

option cards and to connect cables for installed option

cards.

The 920i has no on/off switch. Before

opening the unit, ensure the power cord is

disconnected from the power outlet.

Ensure power to the indicator is disconnected, then

place the indicator face-down on an antistatic work

mat. Remove the screws that hold the backplate to the

enclosure body, then lift the backplate away from the

enclosure and set it aside.

2.3 Cable Connections

The universal model of the 920i provides six cord

grips for cabling into the indicator: one for the power

cord, five to accommodate cabling for option cards.

Install plugs in all unused cord grips to prevent

moisture from entering the enclosure.

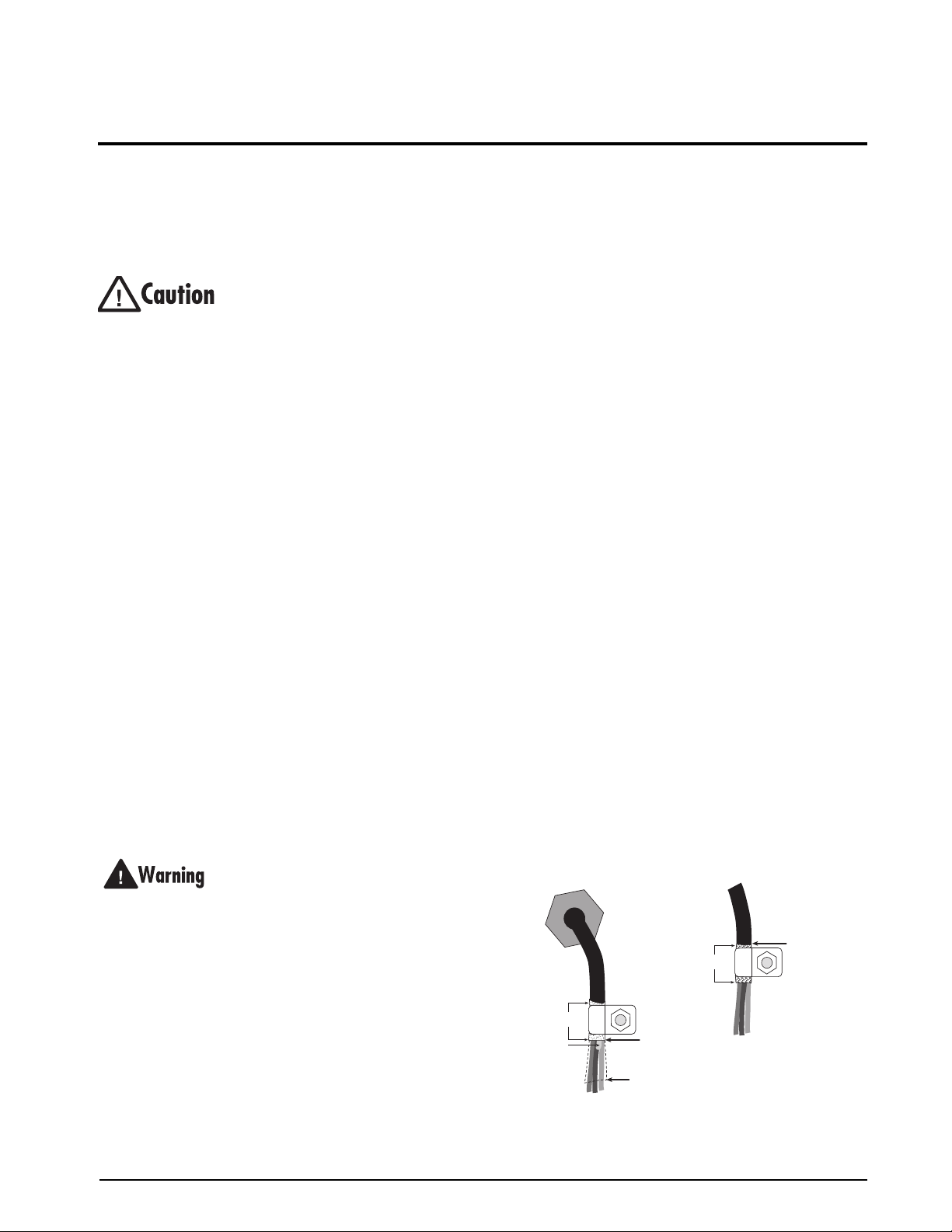

2.3.1 Cable Grounding

Except for the power cord, all cables routed through

the cord grips should be grounded against the

indicator enclosure. Do the following to ground

shielded cables:

• Use the lockwashers, clamps, and kep nuts

provided in the parts kit to install grounding

clamps on the enclosure studs adjacent to cord

grips. Install grounding clamps only for cord

grips that will be used; do not tighten nuts.

• Route cables through cord grips and

grounding clamps to determine cable lengths

required to reach cable connectors. Mark

cables to remove insulation and shield as

described below:

• For cables with foil shielding, strip insulation

and foil from the cable half an inch (15 mm)

past the grounding clamp (see

Fold the foil shield back on the cable where

the cable passes through the clamp. Ensure

silver (conductive) side of foil is turned

outward for contact with the grounding

clamp.

• For cables with braided shielding, strip cable

insulation and braided shield from a point just

past the grounding clamp. Strip another half

inch (15 mm) of insulation only to expose the

braid where the cable passes through the

clamp (see

Foil (silver side out)

Shield wire (cut)

Figure 2-1).

Cord grip

Insulated cable

Grounding clamp

Cut insulation here

for foil-shielded cables

Length of foil before folding

back on cable insulation

Braid

Figure 2-1).

NOTE: Install lockwashers

first, against enclosure,

under grounding clamp

Cut insulation here

for braided cables

Figure 2-1. Grounding Clamp Attachment for

Foil-Shielded and Braided Cabling

Installation 7

Page 14

• For load cell cables, cut the shield wire just

past the grounding clamp. Shield wire

function is provided by contact between the

cable shield and the grounding clamp.

• Route stripped cables through cord grips and

clamps. Ensure shields contact grounding

clamps as shown in

Figure 2-1. Tighten

grounding clamp nuts.

• Finish installation using cable ties to secure

cables inside of indicator enclosure.

2.3.2 Load Cells

To attach cable from a load cell or junction box to an

installed A/D card, route the cable through the cord

grip and ground the shield wire as described in

Section 2.3.1 on page 7.

Next, remove connector J1 from the A/D card. The

connector plugs into a header on the A/D card (see

Figure 2-2). Wire the load cell cable from the load cell

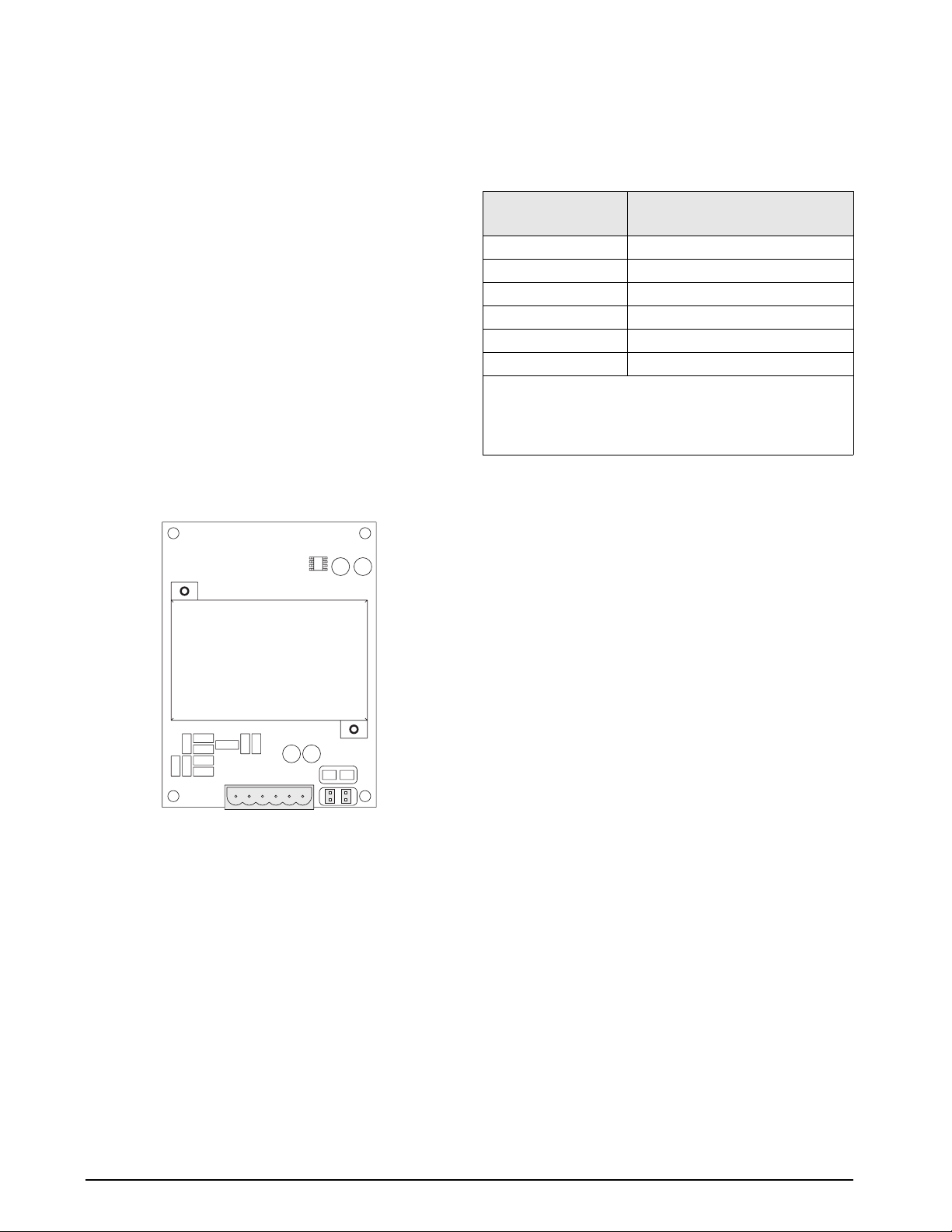

or junction box to connector J1 as shown in Tab le 2-1.

When connections are complete, reinstall load cell

connector on the A/D card and use two cable ties to

secure the load cell cable to the inside of the

enclosure.

A/D Card

Connector Pin Function

1 +SIG

2 –SIG

3 +SENSE

4 –SENSE

5 +EXC

6 –EXC

• For 6-wire load cell connections to connector J1, remove

jumpers JP1 and JP2.

• For 6-wire load cell connections to connector J2 (dual A/D

cards), remove jumpers JP3 and JP4.

Table 2-1. A/D Card Pin Assignments

J1

JP2JP1

SIG–

SIG+

Figure 2-2. Single-Channel A/D Card

If using 6-wire load cell cable (with sense wires),

remove jumpers JP1 and JP2 before reinstalling

connector J1. For 4-wire installation, leave jumpers

JP1 and JP2 on. For 6-wire load cell connections on

dual-channel A/D cards, remove jumpers JP3 and JP4

for connections to J2.

8 920i Installation Manual

SEN+

SEN–

EXC–

EXC+

Page 15

2.3.3 Serial Communications

The four communications ports on the 920i CPU

board support full duplex RS-232, 20 mA output, or

RS-485 communications at up to 115200 bps.

To attach serial communications cables, route the

cable through the cord grip and ground the shield wire

as described in

Section 2.3.1 on page 7. Remove the

serial connector from the CPU board and wire to the

connector. Once cables are attached, plug the

connector into the header on the board. Use cable ties

to secure serial cables to the inside of the enclosure.

Tabl e 2-2 shows the pin assignments for Ports 1, 3,

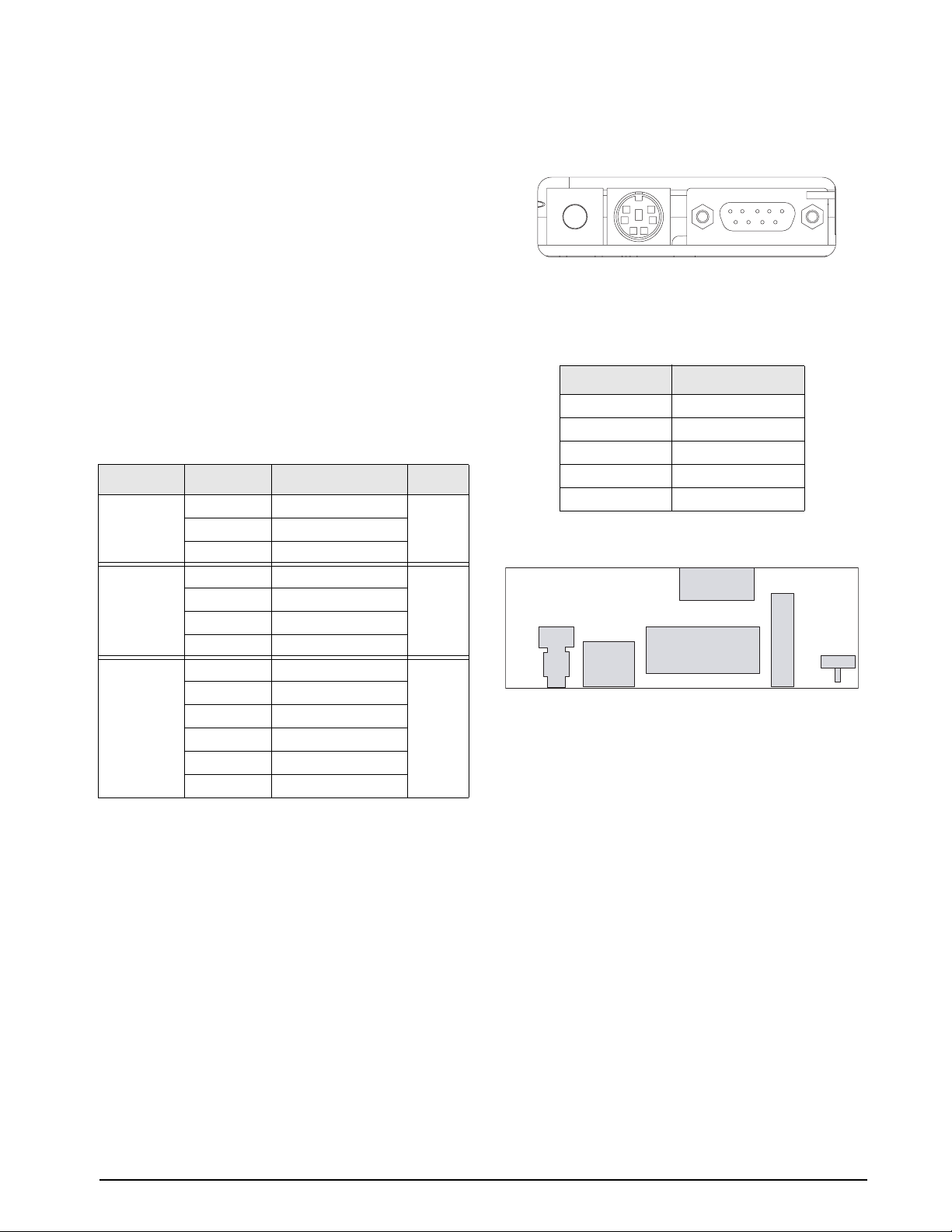

and 4. Port 2 provides DIN-8 and DB-9 connectors for

remote keyboard attachment of PS/2-type personal

computer keyboards (see

Figure 2-3). The DB-9

connector pin assignments for Port 2 are shown in

Tabl e 2-3; see Section 10.3 on page 105 for

information about the PS/2 keyboard interface.

Connector Pin Signal Port

J11

J9

J10

1 GND

2 RS-232 RxD

3 RS-232 TxD

1 GND / –20mA OUT

2 RS-232 RxD

3 RS-232 TxD

4 +20mA OUT

1 GND / –20mA OUT

2 RS-232 RxD

3 RS-232 TxD

4 +20mA OUT

5 RS-485 A

6 RS-485 B

1

3

4

DIN-8 Connector for

PS/2 Remote Keyboard

LCD Contrast

DB-9 Connector

for Port 2 / J8

Figure 2-3. Interface Board Connections

DB-9 Pin Signal

2 TxD

3 RxD

5 GND

7 CTS

8 RTS

Table 2-3. DB-9 Connector Pin Assignments

J4

Optional

Keyboard Connector

LCD

Contrast

VR1

J1

DIN-8

Connector

1

J2

DB-9 Connector

CLK

PWR

RET

DAT

Figure 2-4. Interface Board, Top View

1

J3

Setup

Switch

PB1

to CPU Board / J8

Ribbon Cable Connector

Table 2-2. Serial Port Pin Assignments

Serial ports are configured using the SERIAL menu.

Section 3.2.2 on page 33 for configuration

See

information.

An optional dual-channel serial communications

expansion card, PN 67604, is also available. Each

serial expansion card provides two additional serial

ports, including one port that supports RS-485

communications. Both ports on the expansion card

can support RS-232 or 20mA connections.

Installation 9

Page 16

J5

OPTION CARD

CONNECTOR

J6

OPTION CARD

CONNECTOR

POWER

SUPPLY

–6VDC

GND

GND

+6VDC

PIEZO

BUZZER

OPTION

INTERFACE

BOARD

CONNECTION

BATTERY

SW2

J13

J8

PORT 2

PORT 1

1

JP3

1

J9

SLOT 1

PORT 3

OPTION CARD LOCATIONS

REMOTE

SETUP

SWITCH

J15

J10

PORT 4

SW1

BOOT

MODE

1

SLOT 2

EXPANSION BUS

J2

J7

1

J1

DIGITAL I/O

J11

GND

RS-232 TxD

RS-232 RxD

RS-232 TxD

+20mA OUT

RS-232 RxD

GND / –20mA OUT

Figure 2-5. 920i CPU Board, Showing Option Card Locations

2.3.4 Digital I/O

Digital inputs can be set to provide many indicator

functions, including all keypad functions. Digital

inputs are active low (0 VDC), inactive high (5 VDC).

Digital outputs are typically used to control relays that

drive other equipment. Outputs are designed to sink,

rather than source, switching current. Each output is a

normally open collector circuit, capable of sinking 24

mA when active. Digital outputs are wired to switch

relays when the digital output is active (low, 0 VDC)

with reference to a 5 VDC supply.

GND

DIO1

DIO2

DIO3

DIO4

RS-232 TxD

+20mA OUT

RS-232 RxD

GND / –20mA OUT

RS-485 TxD −

RS-485 TxD +

+5VDC

Tabl e 2-4 shows the pin assignments for connector J2.

J2 Pin J2 Signal

1 +5 VDC

2 GND

3 DIO 1

4 DIO 2

5 DIO 3

6 DIO 4

Table 2-4. J2 Pin Assignments (Digital I/O)

10 920i Installation Manual

Page 17

Digital inputs and outputs are configured using the

DIG I/O menu. See

Section 3.2.6 on page 46 for

configuration information.

An optional 24-channel digital I/O expansion card,

PN 67601, is available for applications requiring more

digital I/O channels.

NOTE: Digital I/O points can be configured to count

active pulse inputs by setting them to PROGIN

(DIGIN menu) and using the

iRite DigInSsBbActivate

handler with a timer to turn the handler on and off.

However, the fastest pulse rate that can be counted

using a digital input is 10Hz (10 pulses per second).

More demanding applications can use the pulse input

option card (PN 67603) to count pulses in the

4–4000Hz range.

J5

J6

2.4 Installing Option Cards

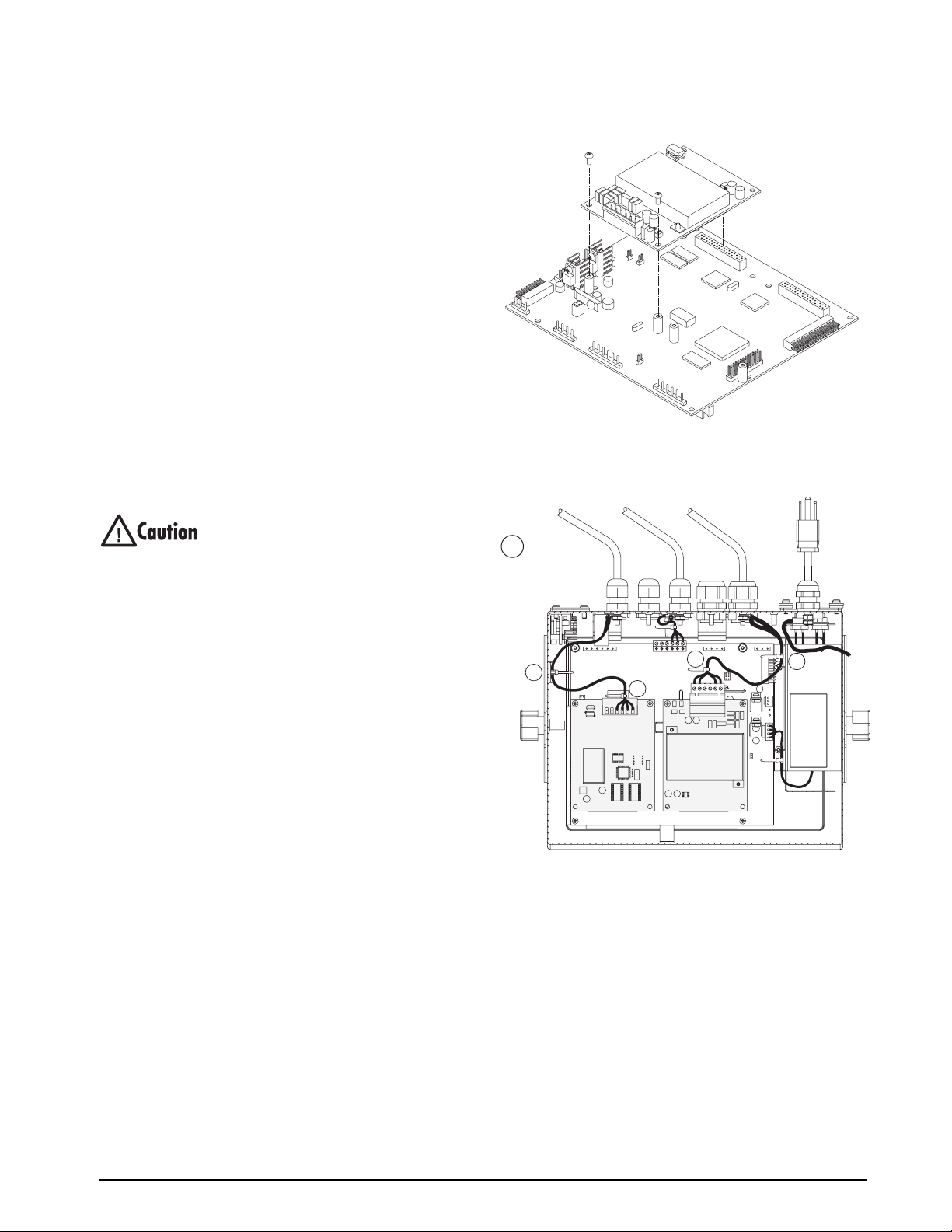

Each option card is shipped with installation

instructions specific to that card. The general

procedure for all option cards is as follows:

Option cards are not hot-pluggable.

Disconnect power to the 920i before

installing option cards.

1. Disconnect power to the indicator. Remove

backplate as described in Section 2.2 on page 7.

2. Carefully align the large option card connector

with connector J5 or J6 on the CPU board (see

Figure 2-6). Press down to seat the option card

in the CPU board connector.

3. Use the screws provided in the option kit to

secure the other end of the option card to the

threaded standoffs on the CPU board (see

Figure 2-6).

4. Make connections to the option card as required.

Use cable ties to secure loose cables inside the

enclosure as shown in

installation is complete, reassemble the

enclosure as described in

page 13.

Figure 2-7. When

Section 2.6 on

Figure 2-6. Installing Option Card Onto CPU Board

CT

INDICATES

OPTION CARD

CABLE TIES

CT

CT

PULSE INPUT

CARD

Figure 2-7. Installed Option Cards, Showing Secured

CT

DUAL A/D

CARD

Cables

CT

DISCONNECT POWER BEFORE SERVICING

WARNING!

HIGH VOLTAGE

The 920i automatically recognizes all installed option

cards when the unit is powered on. No

hardware-specific configuration is required to identify

the newly-installed card to the system.

Installation 11

Page 18

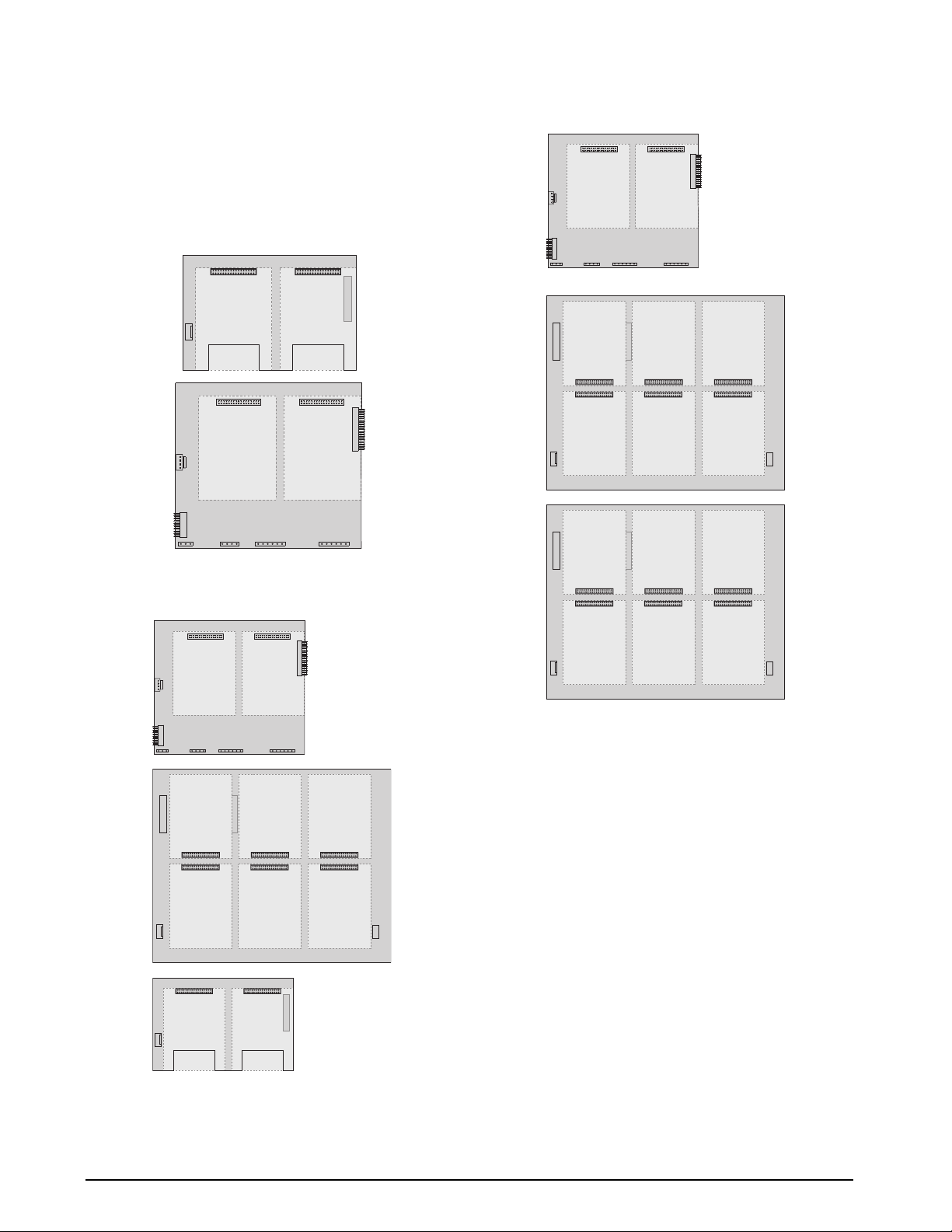

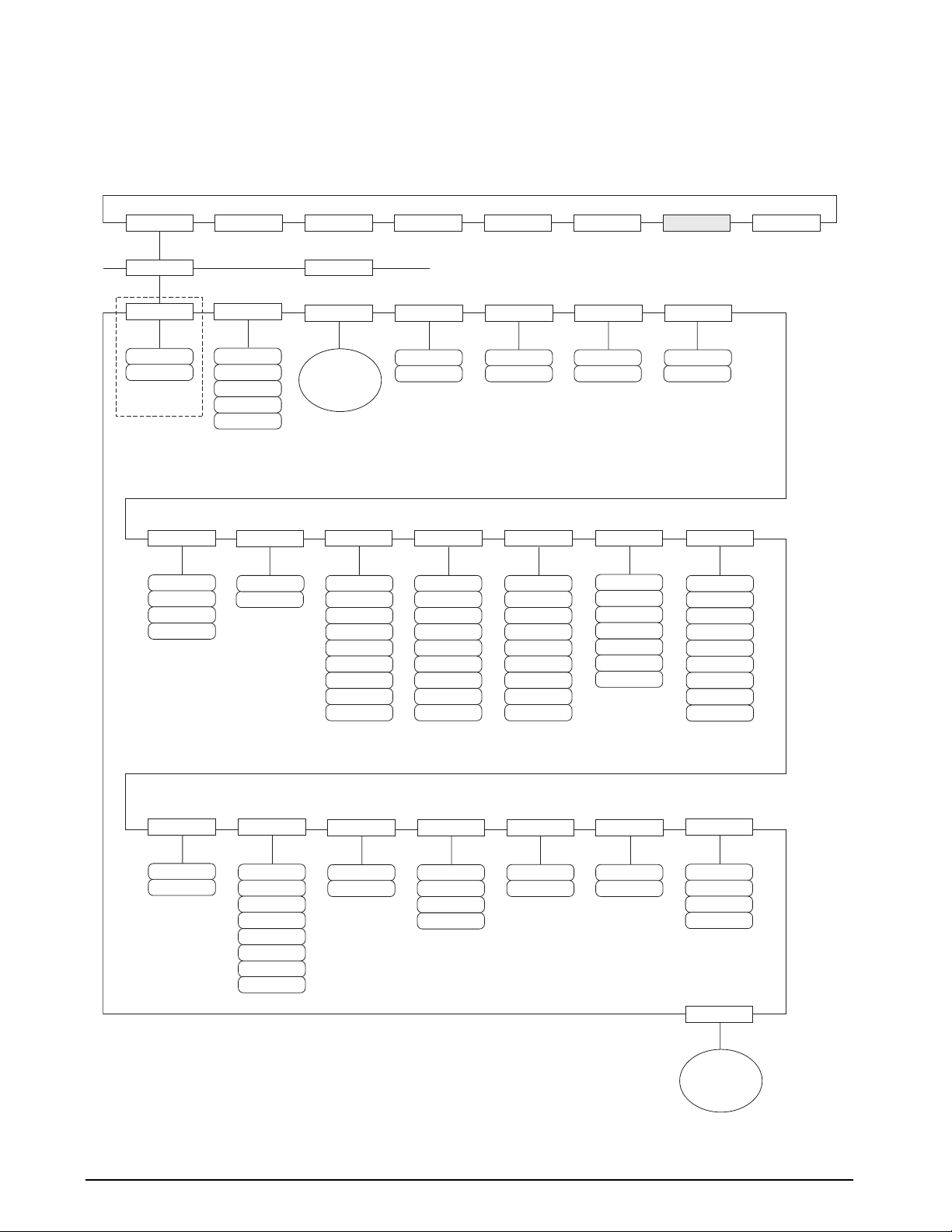

2.5 Expansion Board Configurations

Two- and six-card expansion boards allow up to

fourteen option cards to be attached to the

Figures

2-8 through 2-10 show the slot numbers

assigned for various combinations of two- and

six-card expansion boards. A single six-card

expansion board is assigned slots 3–8.

1

SLOT 3SLOT 4

SLOT 1 SLOT 2

CPU BOARD

SLOT 0

920i.

SLOT 1 SLOT 2

CPU BOARD

SLOT 0

SLOT 3SLOT 4 SLOT 5

SLOT 6 SLOT 7 SLOT 8

Figure 2-8. CPU Board with Two-Card Expansion Board

SLOT 1 SLOT 2

CPU BOARD

SLOT 0

SLOT 3SLOT 4 SLOT 5

SLOT 6 SLOT 7 SLOT 8

1

SLOT 9 SLOT 10

SLOT 9 SLOT 10 SLOT 11

SLOT 12 SLOT 13SLOT 14

Figure 2-10. CPU Board with Two Six-Card Expansion

Boards

NOTES:

• The maximum number of option board slots is

fourteen: two onboard slots, plus two six-card

expansion boards.

• The two-card expansion board is always

placed at the end of the expansion bus. No

more than one two-card expansion board can

be used in any system configuration.

• The panel mount enclosure can accommodate

a single two-card expansion board.

• The wall mount enclosure can accommodate a

two-card or a six-card expansion board.

• Systems using two six-card expansion boards

are housed in a custom enclosure.

Figure 2-9. CPU Board with Two- and Six-Card Expansion

Boards

12 920i Installation Manual

Page 19

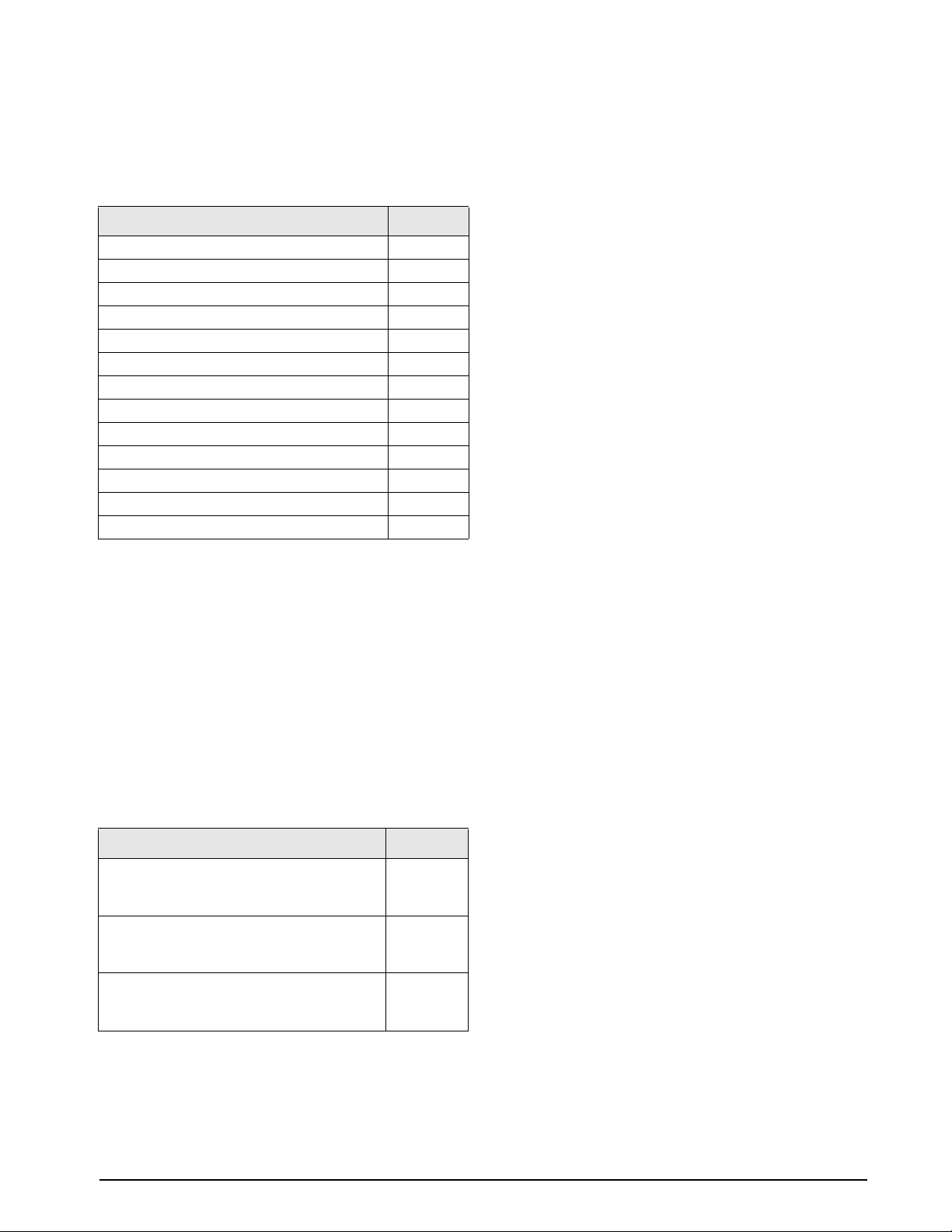

Expansion Board Serial Port Assignments

Serial port numbers are reserved for each option card

slot, regardless of the type of cards actually installed.

Two port numbers are reserved for each slot that could

contain a dual-channel serial expansion card.

Table 2-5 shows the port numbers assigned to each

slot.

Slot Number Serial Port Assignments

CPU board 1–4

1 5–6

2 7–8

3 9–10

4 11–12

5 13–14

6 15–16

7 17–18

8 19–20

9 21–22

10 23–24

11 25–26

12 27–28

13 29–30

14 31–32

Table 2-5. Expansion Board Serial Port Assignments

For example, in a system with a two-card expansion

board, port assignments are reserved as shown in

Figure 2-11. If the only serial card installed in this

system is in SLOT 4 of the expansion board, the

system consists of serial ports 1–4 (on the CPU board)

and ports 11–12.

PORTS

9–10

1

SLOT 3SLOT 4

PORTS

5–6

PORTS

11–12

PORTS

7–8

SLOT 1 SLOT 2

PORT

2

PORT

1

CPU BOARD

PORT3PORT

4

SLOT 0

2.6 Enclosure Reassembly

Once cabling is complete, position the backplate over

the enclosure and reinstall the backplate screws. Use

the torque pattern shown in

Figure 2-12 to prevent

distorting the backplate gasket. Torque screws to 15

in-lb (1.7 N-m).

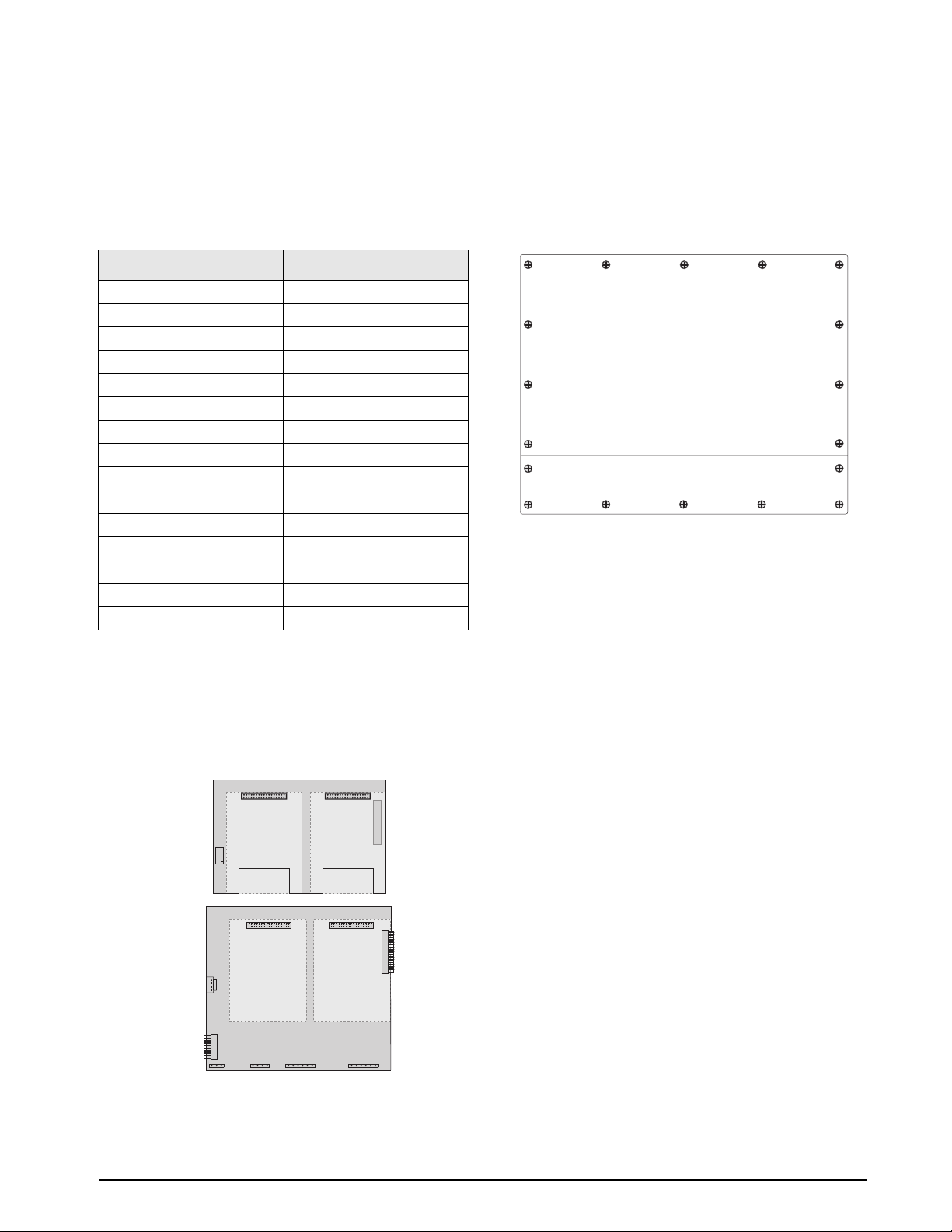

16 12

14

5

3

1

17

Figure 2-12. 920i Enclosure Backplate

Torque backplate s crews

to 15 in-lb (1.7 N-m)

9

8

7

10

11

18

13

6

2

4

15

2.7 CPU Board Removal

If you must remove the 920i CPU board, use the

following procedure:

1. Disconnect power to the indicator. Remove

backplate as described in Section 2.2 on

page 7.

2. Unplug connectors J9, J10, and J11 (serial

communications), J2 (digital I/O), P1 (power

supply), and connectors to any installed

option cards.

3. Remove any installed option cards.

4. Remove the five phillips head screws and two

kep nuts from the CPU board.

5. Gently lift up the CPU board, then disconnect

connectors J12 (power to display), J4 (ribbon

cable, J3 (keypad connector), then the cable

J8 (Port 2 serial port).

6. Remove CPU board from the enclosure. If

necessary, cut cable ties to shift cables out of

the way.

To replace the CPU board, reverse the above

procedure. Be sure to reinstall cable ties to secure all

cables inside the indicator enclosure.

Figure 2-11. Serial Port Assignments, Two-Card

Expansion Board

Installation 13

Page 20

2.8 Fuse Replacement

Fuses for the universal and deep enclosure models of

920i are located under a cover plate on the outside

the

of the enclosure. Remove the cover plate, replace the

fuses, and reinstall the cover plate (see

To protect against the risk of fire, replace

fuses only with same type and rating fuse.

Figure 2-13).

See Section 10.14 on page 122 for

complete fuse specifications.

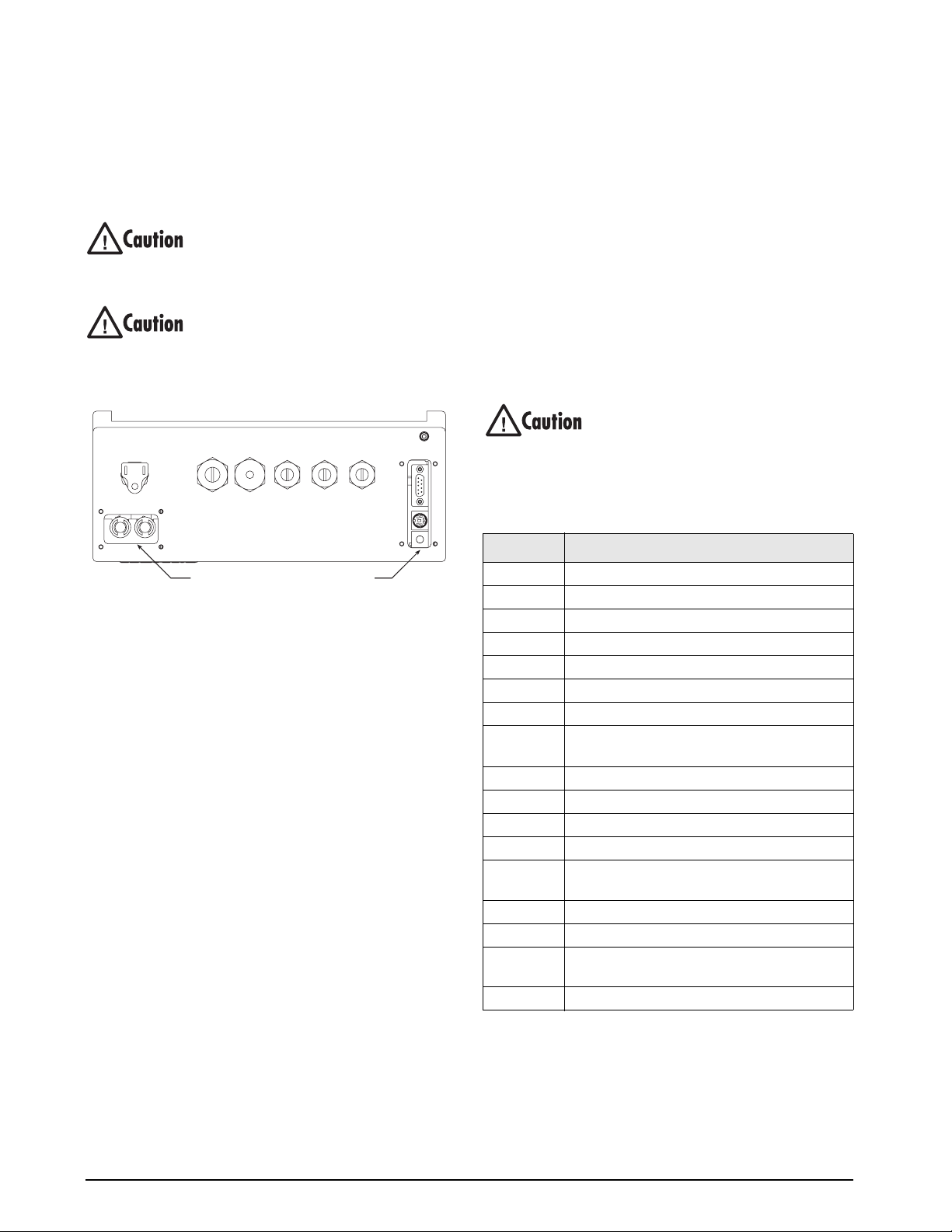

Interface board and fuse access cover

plates must be in place for use in NEMA

4X/IP66 applications.

l

Torque fuse and interface board access covers to

Figure 2-13. Interface Board and Fuse Locations,

8 in-lb (0.90 N-m)

Fuses

F1 & F2

Universal Model

Interface Board

2.9 Battery Replacement

The lithium battery on the CPU board maintains the

real-time clock and protects data stored in the system

RAM when the indicator is not connected to AC

power.

Data protected by the CPU board battery includes

time and date, truck and tare memory, onboard

database information, and setpoint configuration.

Use iRev to store a copy of the indicator configuration

on a PC before attempting battery replacement. If any

data is lost, the indicator configuration can be restored

from the PC.

NOTE: Memory option card data is also protected by a

lithium battery. All database information stored on a memory

card is lost if the memory card battery fails.

Watch for the low battery warning on the LCD display

and periodically check the battery voltage on both the

CPU board and on any installed memory option cards.

Batteries should be replaced when the indicator low

battery warning comes on, or when battery voltage

falls to 2.2 VDC. Life expectancy of the battery is ten

years.

Replacement Procedure

For best results, replace the battery while in weigh

mode and with AC power applied. Use care not to

bend the battery retaining spring.

If the battery must be replaced with power removed,

do the following immediately after restoring power:

1. Place indicator in setup mode.

2. Go to the Version Menu and press the Reset

Config

softkey. If connected using iRev,

configuration can be reset by using monitor

mode to enter the RESETCONFIGURATION

command followed by the RS command.

See Figure 2-5 on page 10 for CPU board battery

location and orientation (positive side up).

Risk of explosion if battery is replaced

with incorrect type. Dispose of batteries

per manufacturer instruction.

2.10 Parts Kit Contents

Tabl e 2-6 lists the parts kit contents for the universal

model of the 920i.

PN Description

14626 Kep nuts, 8-32NC (4)

14862 Machine screws, 8-32NC x 3/8 (12)

75068 Sealing washers (14)

15133 Lock washers, No. 8, Type A (4)

30623 Machine screws, 8-32NC x 7/16 (2)

15631 Cable ties (4–single A/D, 6–dual A/D)

15665 Reducing glands for 1/2 NPT cord grips (2)

15887 6-position screw terminal for load cell

connection (1–single A/D, 2–dual A/D)

19538 Cord grip plugs (4–single A/D, 3–dual A/D)

42350 Capacity label (1–single A/D, 2–dual A/D)

53075 Cable shield ground clamps (4)

70599 6-position screw terminals for J2 and J10 (2)

71126 4-position screw terminal for J9 and optional

keyboard connection (2)

71125 3-position screw terminal for J11 (1)

42149 Rubber feet for tilt stand (4)

15144 Nylon washers for tilt stand, 1/4 x 1 x 1/16 (2,

universal model only)

68403 Wing knobs for tilt stand (2)

Table 2-6. Parts Kit Contents

14 920i Installation Manual

Page 21

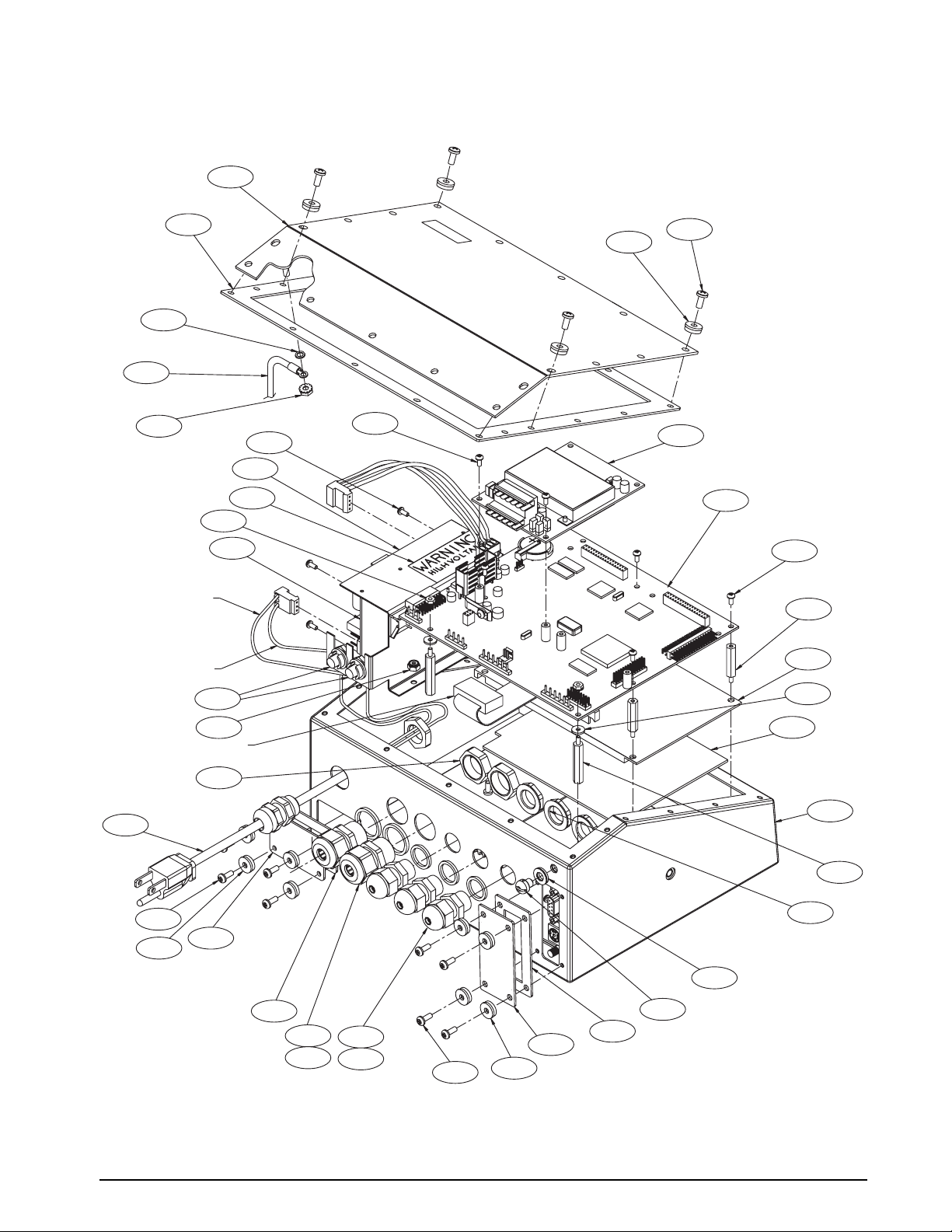

2.11 Replacement Parts and Assembly Drawings

Tabl e 2-7 lists replacement parts for the 920i universal enclosure model, including all parts referenced in Figures

2-14 through 2-16. For assembly drawings and replacement parts information for other enclosures, see the 920i

Panel Mount Installation Instructions, PN 69989 and the 920i Wall Mount Installation Instructions, PN 69988.

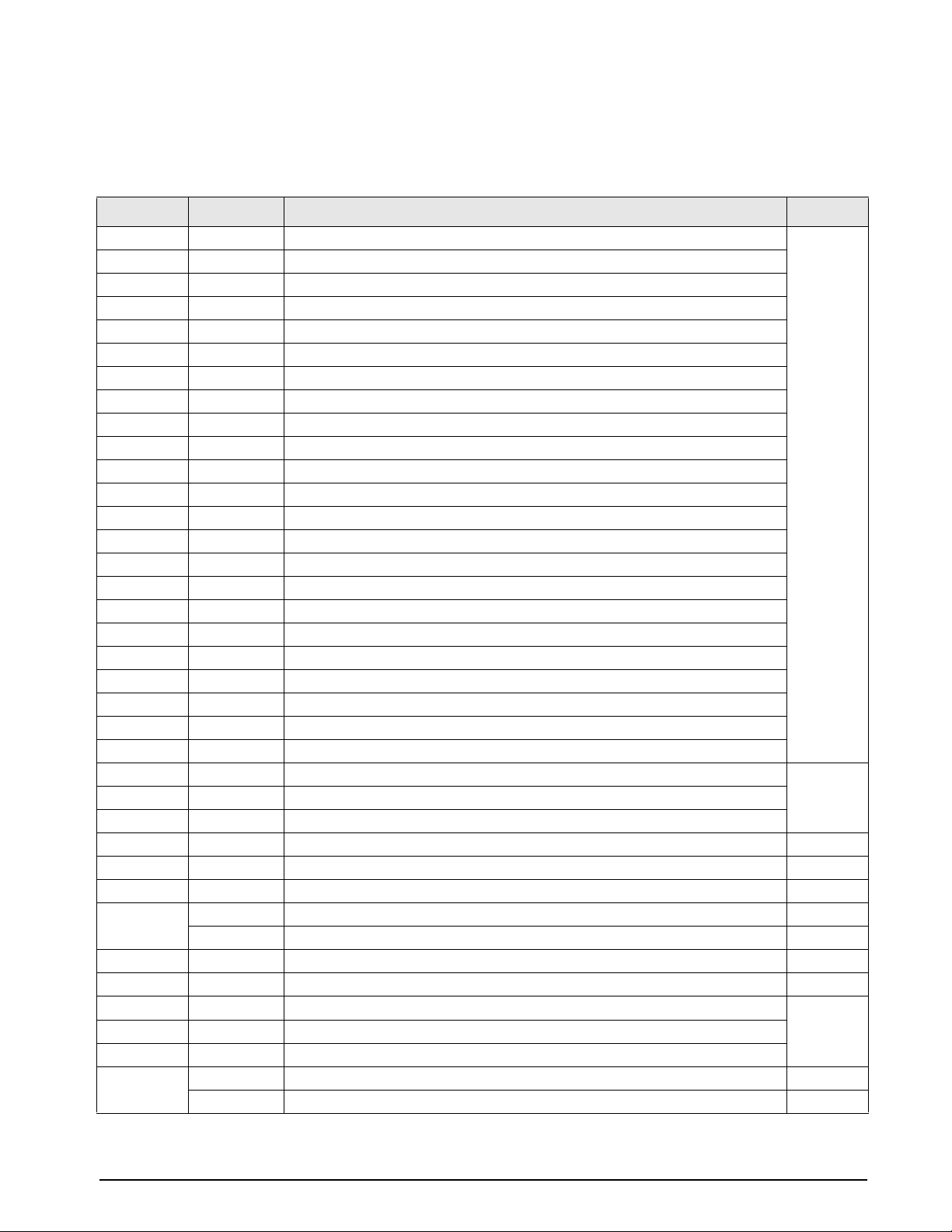

Ref Number PN Description (Quantity) See Figure

1 67529 Enclosure, universal (1) 2-14

2 68598 Protective lens (1)

3 67614 LCD display (1)

4 68425 Fuse access coverplate (1)

5 68621 Fuse access coverplate gasket (1)

6 67886 Standoffs, short (4)

7 68661 Standoffs, long (2)

8 70912 CPU board (1)

9 14618 Kep nuts, 4-40NC (2)

10 67613 Power supply, ±6VDC, 25W (1)

11 67536 Power supply bracket (1)

12 16861 High voltage warning label (1)

13 14624 Lock nuts, 6-32NC, nylon (2)

14 14822 Machine screws, 4-40NC x 1/4 (11)

15 67530 Interface board connector plate (1)

16 67535 Interface board gasket (1)

17 14862 Machine screws, 8-32NC x 3/8 (4)*

18 75068 Sealing washers (12)*

19 32365 Setup switch access screw, 1/4 x 20NC x 1/4 (1)

20 44676 Sealing washer for setup switch access screw (1)

21 15626 Cord grips, PG9 (3)

22 15627 Lock nuts, PCN9 (3)

23 30375 Nylon seal rings for PG9 cord grips (3)

25 15134 Lock washers, No. 8, Type A (3) 2-15

26 14626 Kep nuts, 8-32NC (3)*

27 45043 Ground wire, 4 in w/ No. 8 eye connector (1)

28 68424 Enclosure backplate, universal (1) 2-14

29 67532 Backplate gasket, universal (1) 2-14

30 15631 Cable tie, 3-in nylon (1)* 2-16

31 67795 Power cord assembly, 115 VAC and 230 VAC North American units (1) 2-14

69998 Power cord assembly, 230 VAC European units (1) —

32 67796 Power supply cable assembly, to CPU board (1) 2-15

33 68662 Ribbon cable to interface board, universal (1) 2-15

34 16892 Ground/Earth label (1) 2-15

35 15650 Cable tie mounts, 3/4 in. (4)

40 53308 Model/serial number label (1)

41 68532 Single-channel A/D card (1, can be single- or dual-channel A/D) —

68533 Dual-channel A/D card (1, can be single- or dual-channel A/D) 2-15

Table 2-7. Replacement Parts

Installation 15

Page 22

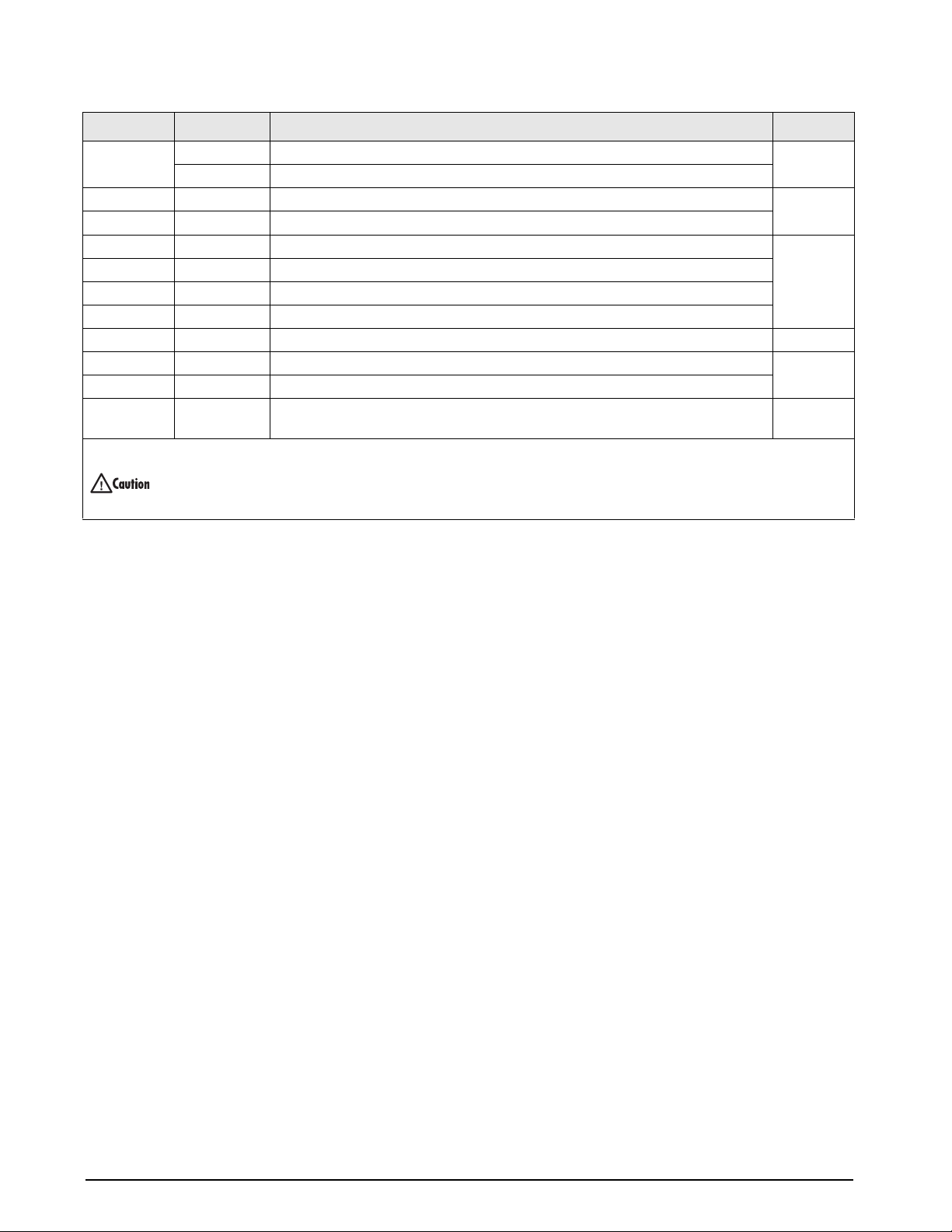

Ref Number PN Description (Quantity) See Figure

43 71027 Fuses (115 VAC models), 2 A Time-Lag TR5 (2) 2-14

71026 Fuses (230 VAC models), 2 A Time-Lag TR5 (2)

45 67869 Interface board (1) 2-15

46 14832 Machine screws, 4-40NC x 3/8 (2)

47 22086 Machine screws, 6-32NC x 1/4 (8) 2-14

50 15628 Cord grips, 1/2 NPT (2)

52 30376 Nylon seal rings for 1/2 NPT cord grips (2)

53 15630 Lock nuts for 1/2 NPT cord grips (2)

54 70069 3V Lithium coin battery 2-16

55 69898 Nylon spacers (4) 2-14

— 66502 Switch panel membrane (1)

— 97257 16M SDRAM replacement SIMM (1) Older CPU boards with 4M SDRAM SIMMs

must be upgraded to the 16M SDRAM to run Version 3 software.

* Additional parts included in parts kit.

To protect against the risk of fire, replace fuses only with same type and rating fuse.

See Section 10.14 on page 122 for complete fuse specifications.

—

Table 2-7. Replacement Parts (Continued)

16 920i Installation Manual

Page 23

28

29

C

F

G

BLUE WIRE

BROWN WIRE

9/2X

43/2X

10

11

12

18/12X/E

14/11X/A

A

17/4X/B

41

8

A

6/4X

3

55/4X/L

13/2X

FROM DISPLAY BOARD TO

BOTTOM OF CPU BOARD (J4)

53/2X

31

K

E

4

2

1

7/2X

22/3X

20

5

50/2X

52/2X

21/3X

23/3X

47/8X/K

15

E

16

19

Figure 2-14. 920i Universal Model Assembly

Installation 17

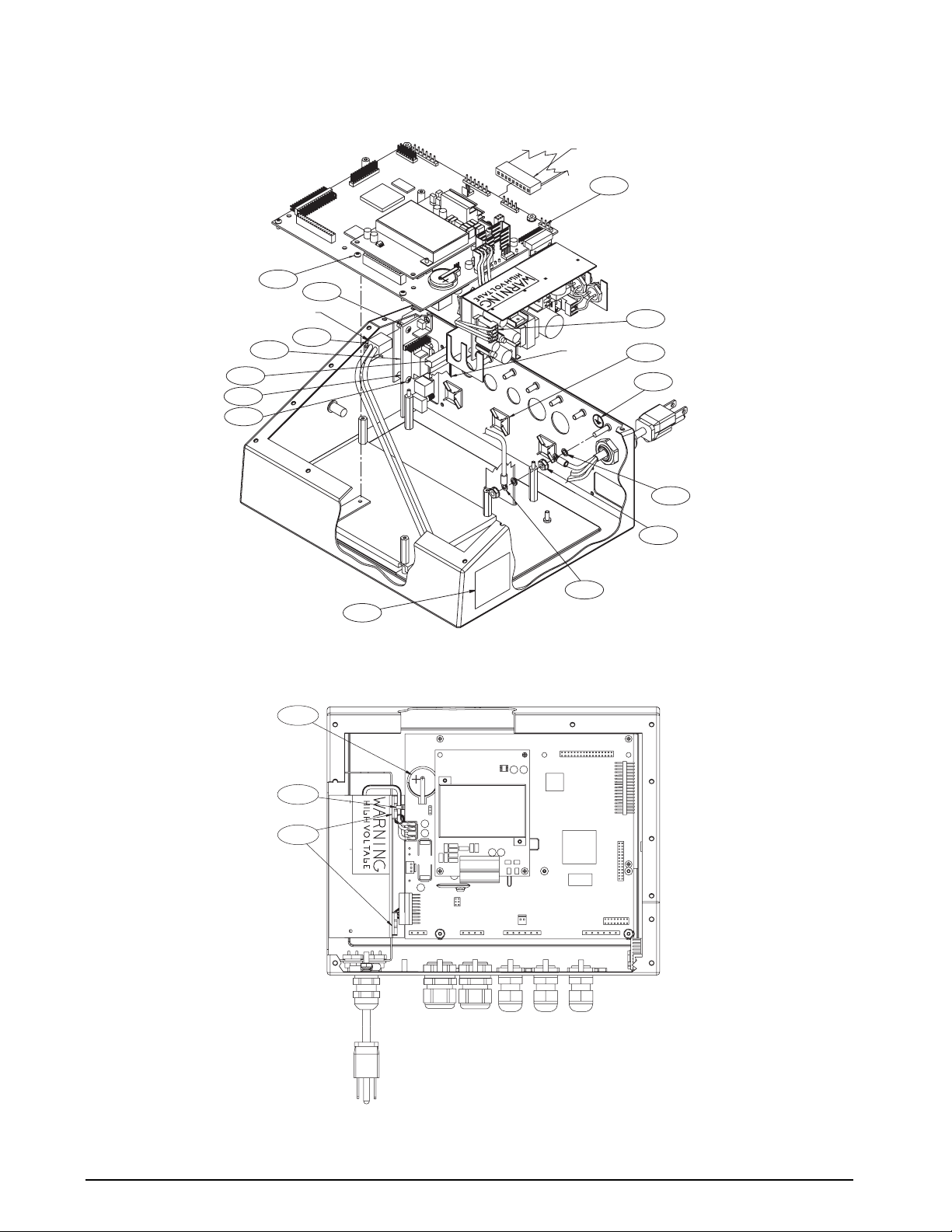

Page 24

A

FROM LCD DISPLAY

TO CPU BOARD (J12)

D

45

H

L

46/2X

FROM SWITCH MEMBRANE

TO BOTTOM OF CPU BOARD (J3)

33/H

L

32

RED STRIPE

WIRE

35/4X/D

34

25/3X/C

26/3X/G

TOP

27/F

40

Figure 2-15. 920i Universal Model CPU Board and Power Supply Components

54

30

D

Figure 2-16. 920i Universal Model, Back View with Backplate Removed

18 920i Installation Manual

Page 25

3.0 Configuration

To configure the 920i indicator, the indicator must be

placed in setup mode. The setup switch is accessed by

removing the large fillister head screw on the

backplate of the universal and deep enclosures.

Switch position is changed by inserting a screwdriver

into the access hole and pressing the switch.

When the indicator is placed in setup mode, a series of

menus is shown across the top of the display, along

with the words

Scale Configuration. The SCALES menu

is highlighted as the first used to configure the

indicator. Detailed descriptions of these menus are

provided in

Section 3.2.

3.1 Configuration Methods

The 920i indicator can be configured by using the

front panel keys to navigate through a series of

configuration menus or by sending commands or

configuration data to an indicator serial port.

Configuration using the menus is described in

Section 3.1.3.

Configuration using the serial port can be

accomplished using either the serial command set

described in

utility.

NOTE: Some configuration parameters, such as those

used to configure the

be accessed through the configuration menus.

provides the most complete and efficient

configuration interface for the

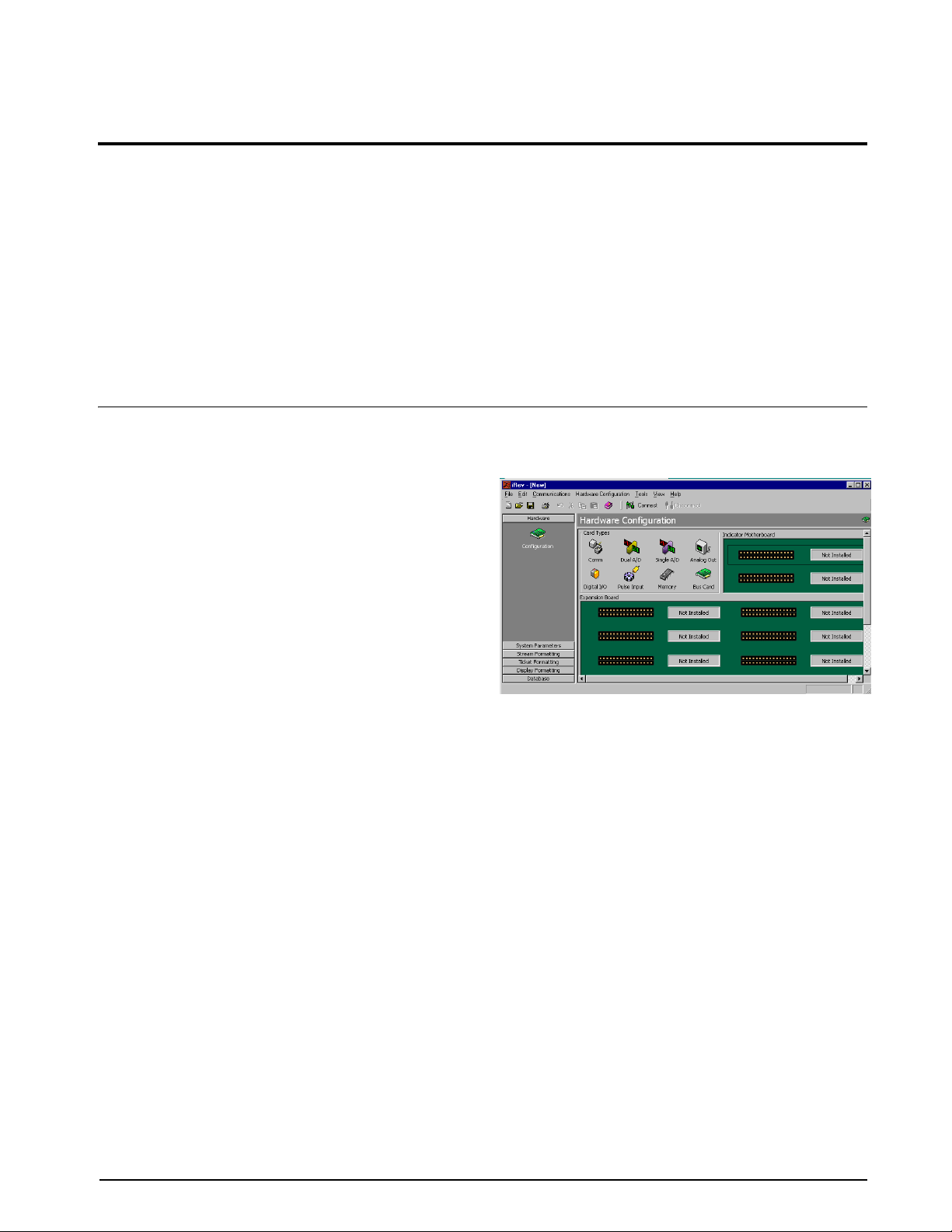

3.1.1 iRev Configuration

The iRev configuration utility provides the preferred

method for configuring the

on a personal computer to set configuration

parameters for the indicator. When

is complete, configuration data is downloaded to the

indicator.

iRev supports both uploading and downloading of

indicator configuration data. This capability allows

configuration data to be retrieved from one indicator,

edited, then downloaded to another indicator with an

identical hardware configuration.

Section 9.0 or the iRev configuration

920i display and widgets, cannot

iRev

920i.

920i indicator. iRev runs

iRev configuration

When configuration is complete, press the Exit or Save

and Exit

softkey to exit setup mode, then replace the

setup switch access screw.

•The Exit softkey exits setup mode without saving

parameter changes to NV RAM. Changes made

to the configuration remain in the system until

indicator power is cycled.

• Save and Exit writes all parameter changes to NV

RAM before returning to normal mode.

Figure 3-1. iRev Hardware Configuration Display

To use iRev, do the following:

1. Install iRev on an IBM-compatible personal

computer. See

Section 5.0 on page 54 for

detailed hardware and software requirements.

2. With both indicator and PC powered off,

connect the PC serial port to the RS-232 pins

on the indicator serial port.

3. Power up the PC and the indicator. Use the

setup switch to place the indicator in setup

mode.

4. Start the iRev program.

iRev provides online help for each of its configuration

displays. Parameter descriptions provided in this

manual for front panel configuration can also be used

when configuring the indicator using

iRev: The

interface is different, but the parameters set are the

same.

See Section 5.0 on page 54 for more information about

using iRev to configure the 920i.

Configuration 19

Page 26

3.1.2 Serial Command Configuration

The serial command set can be used to configure the

920i indicator using either a personal computer,

terminal, or remote keyboard. Like

iRev, serial

command configuration sends commands to the

indicator serial port; unlike

iRev, serial commands can

be sent using any external device capable of sending

ASCII characters over a serial connection.

Serial commands duplicate the functions available

using the indicator front panel and provide some

functions not otherwise available. Serial commands

can be used to simulate pressing front panel keys, to

configure the indicator, or to dump lists of parameter

settings. See

Section 9.0 on page 84 for more

information about using the serial command set.

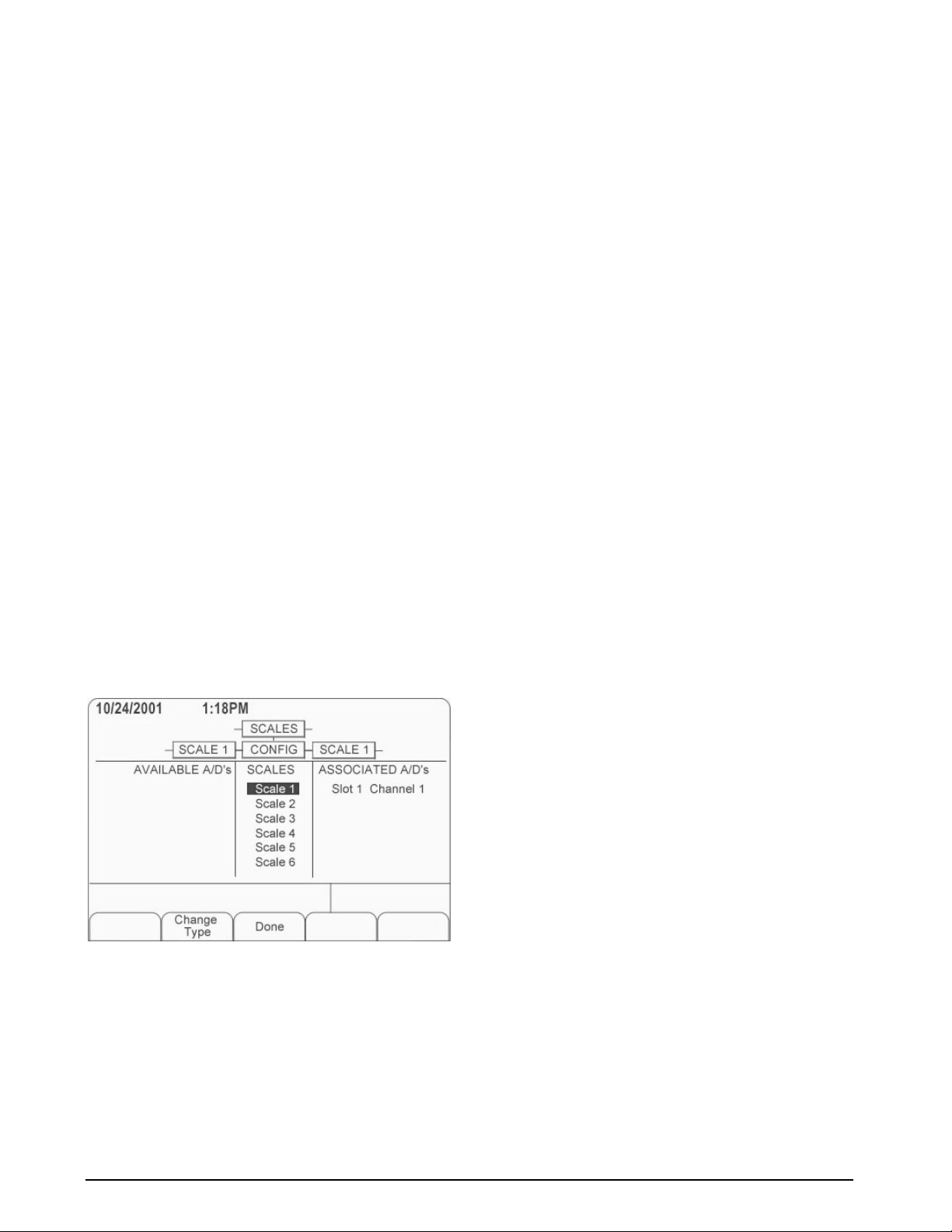

3.1.3 Front Panel Configuration

Use the CONFIG submenu under the SCALES menu

to configure A/D scales. For example, in an indicator

with a single-channel A/D card installed in Slot 1, the

Scale Configuration display will show the A/D listed

Slot 1 Channel 1) under the AVAILABLE A/D’s column.

(

Use the

press the center softkey,

left navigation key to select the A/D, then

Add. The A/D is then moved

to the Associated A/D’s column. If no other A/D’s are

listed in the

softkey changes to

AVAILABLE A/D’s column, the center

Done, as shown in Figure 3-2.

Press Done to exit the Scale Configuration display.

See Section 10.4 on page 106 for information about

configuring serial scales.

3.1.4 Multi-Range and Multi-Interval Scales

The 920i supports multi-range and multi-interval

scales of either two or three ranges or intervals.

Multi-range scales provide two or three ranges, each

extending from zero to the maximum capacity

specified for the range, that can specify different scale

intervals (graduations). The scale interval changes as

the applied weight increases but does not reset to

lower range intervals until the scale returns to zero.

Multi-interval scales divide the scale into two or three

partial weighing ranges, each with different scale

intervals. The scale interval changes with both

increasing and decreasing loads applied.

To configure a multi-range or multi-interval scale, use

the SPLIT parameter to select 2RNG or 3RNG (for

multi-range scales), or 2INTVL or 3INTVL (for

multi-interval scales). Selecting a SPLIT value other

than OFF allows specification of decimal point,

display divisions, and maximum capacity for each

range or interval.

3.1.5 Total Scale Configuration

The output of two or more A/D scales or iQUBE

systems can be configured to function as a total scale.

Once configured and calibrated, the total scale can be

used as a source for other system functions, including

streaming, setpoints, print formatting, and analog

output.

To set up a total scale from the indicator front panel,

use the scale configuration display (see

Figure 3-2) to

select the A/D scales or iQUBE systems to configure

as a total scale. (Use the

available A/D scales or

Change Type softkey to show

iQUBE systems; use the right

navigation key to select the total scale sources.) In

iRev, assign the total scale to an unused position then

select source scales from the existing A/D scales or

iQUBE systems.

Figure 3-2. Scale Configuration Display

20 920i Installation Manual

The FORMAT configuration of the total scale (see

Figure 3-5 on page 26) should match that of the

source scales. However, the value specified for the

total scale GRADS parameter should be specified as

the sum of the GRADS values for the source scales.

For example: if SCALE 1 is set to GRADS=10000,

SCALE 2 to GRADS=5000, SCALE 3 (the total

scale) should be set to 15000 grads.

The total scale will show an overrange indication if

the maximum capacity of any source scale is

exceeded, and show dashes if any source scale reads a

negative value. Source scales will respond to Tare and

Zero operations performed on the total scale.

Page 27

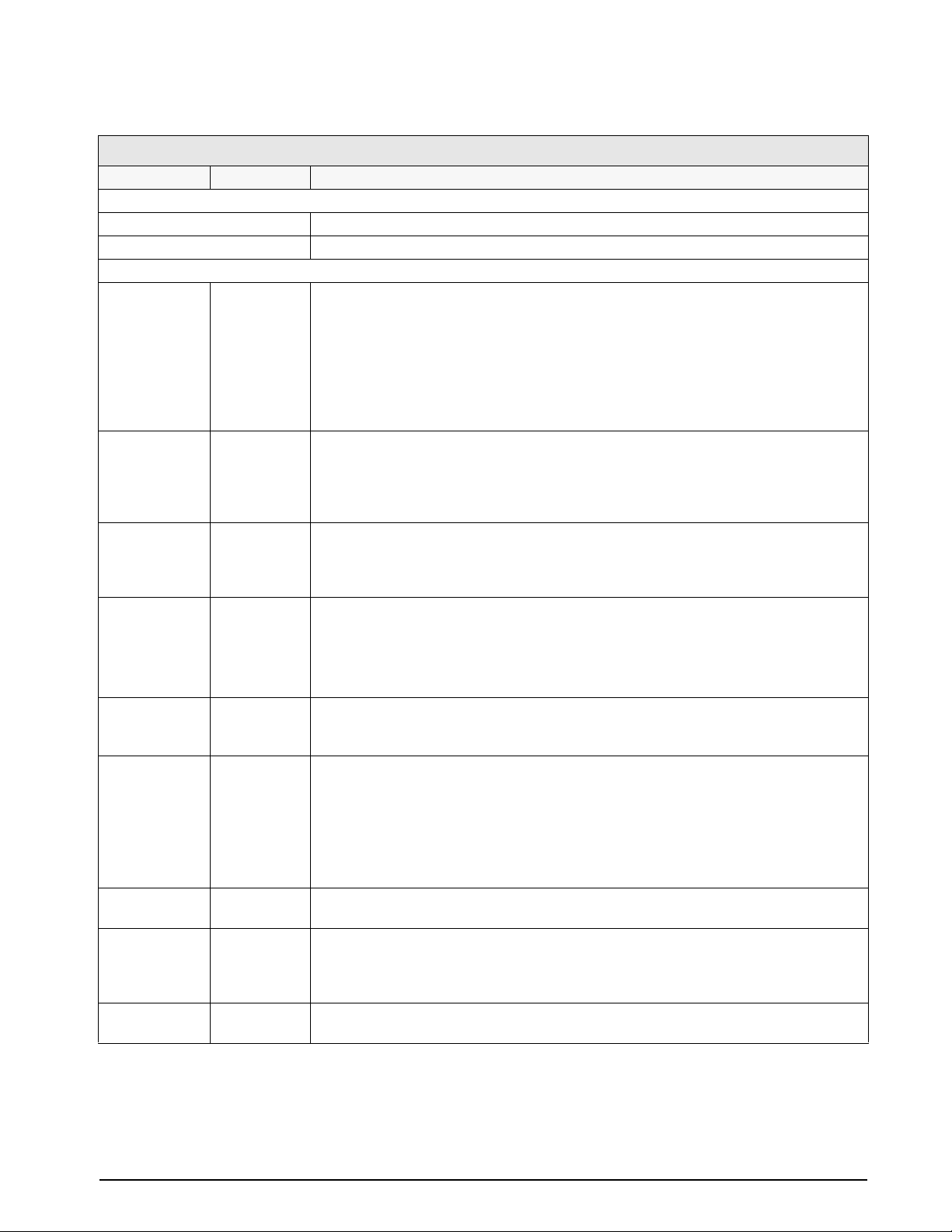

3.2 Menu Structures and Parameter Descriptions

The 920i indicator can be configured using a series of menus accessed through the indicator front panel when the

indicator is in setup mode.

Menu Menu Function

SCALES Configuration Configure and calibrate scales.

SERIAL Serial Configure communications ports.

FEATURE Feature Set date and time formats, truck mode, passwords, keyboard locks, regulatory mode, and

PFORMT Print Format Set print format used for header, gross, net, truck in/out, setpoint, and auxiliary ticket formats.

SETPTS Setpoints Configure setpoints and batching mode.

DIG I/O Digital I/O Assign digital input/output functions.

ALGOUT Analog Output Configure analog output module. Used only if analog output option is installed.

VERSION Version Display installed software version number. The Reset Config softkey on the Version menu can

The following sections provide graphic representations of the 920i menu structures and tables describing the

menu parameters. Default values are shown in bold type; numeric ranges and string values are shown in italic

type. Parameters shown surrounded by a dotted-line box only appear under the special circumstances explained

under each box.

Figure 3-1 summarizes the functions of each of the main menus.

initial consecutive number value, define softkeys and setpoint prompts.

Section 6.0 on page 57 for more information.

See

be used to restore all configuration parameters to their default values.

Table 3-1. 920i Menu Summary

SCALESSERIAL FEATURE PFORMT SETPTS DIG I/O ALGOUT VERS

Shown only if

Analog Output

card is installed

Figure 3-3. Configuration Menu Flow

Configuration 21

Page 28

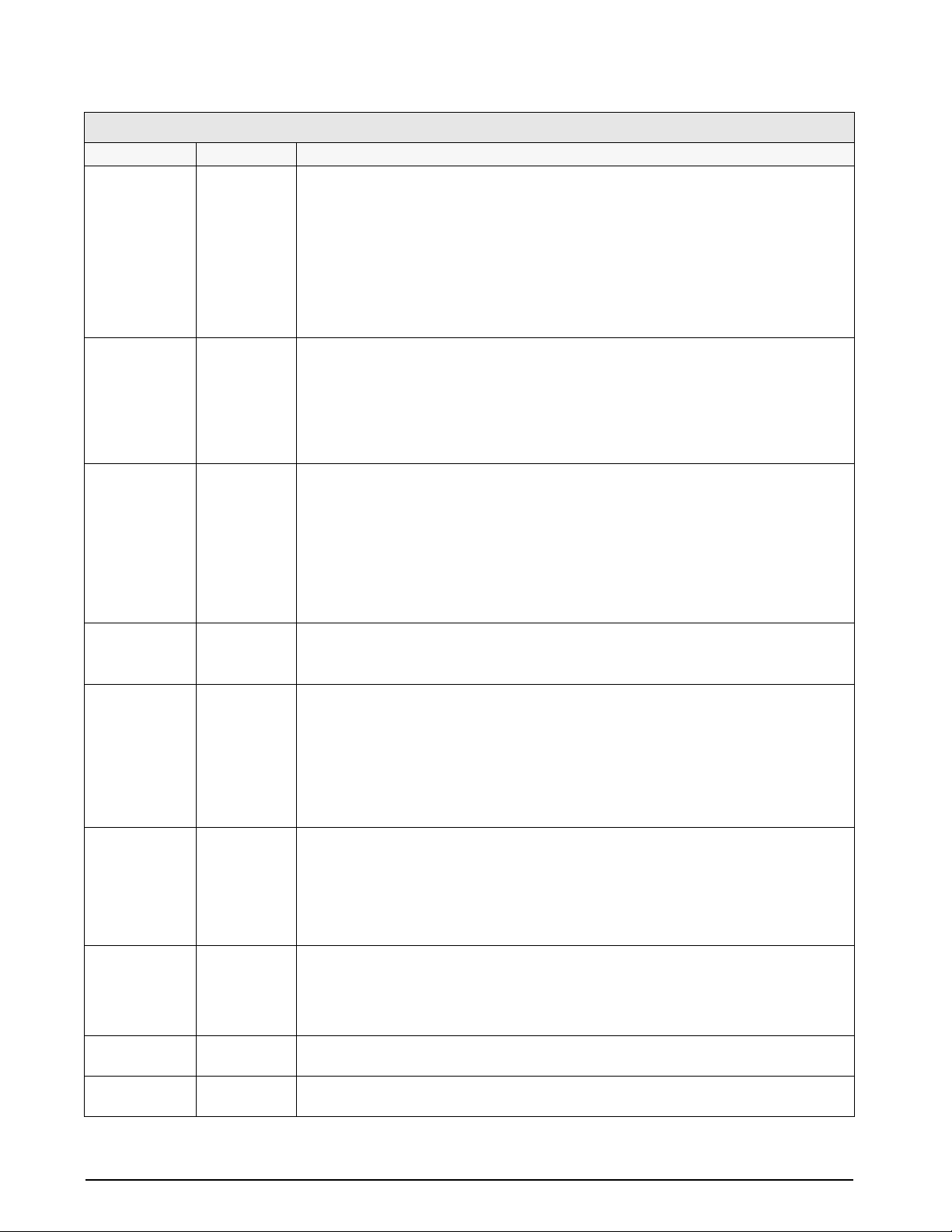

3.2.1 SCALES Menu

The SCALES menu is shown in Figure 3-4. The FORMAT submenu is shown in Figure 3-5 on page 26; the

CALIBR submenu is shown in Figure 3-7 on page 32. Parameters shown in each diagram are described in the

table following that diagram.

SCALESSERIAL FEATURE PFORMT SETPTS DIG I/O ALGOUT VERS

SCALE x

GRADS

10000

number

Specify for

SPLIT = OFF

OVRLOAD

FS+2%

FS+1D

FS+9D

CONFIG

SPLIT

OFF

2RNG

3RNG

2INTVL

3INTVL

WMTTHRH

1000

number

FS

FORMAT

See

FORMAT

Submenu

DIGFLT1 DIGFLT2

4

8

16

32

64

128

256

1

2

ZTRKBND

0

number

16

32

64

128

256

ZRANGE MOTBAND

1.900000

number

DIGFLT3

4

8

1

2

4

8

16

32

64

128

256

1

2

1

number

DFSENS

2OUT

4OUT

8OUT

16OUT

32OUT

64OUT

128OUT

SSTIME

10

number

DFTHRH

NONE

2D

5D

10D

20D

50D

100D

200D

250D

RATTRAP

OFF

ON

SMPRAT

120HZ

240HZ

480HZ

960HZ

7.5HZ

15HZ

30HZ

60HZ

22 920i Installation Manual

PWRUPMD TAREFN

GO

DELAY

BOTH

NOTARE

PBTARE

KEYED

Figure 3-4. SCALES Menu

ACCUM

OFF

ON

VISIBLE

ON

OFF

PEAK HOLD

OFF

NORMAL

BI-DIR

AUTO

CALIBR

See

CALIBR

Submenu

Page 29

SCALES Menu

Parameter Choices Description

Level 2 submenus

SCALEx Allows configuration and calibration of each scale

CONFIG Lists available and associated A/Ds

Level 3 submenus

GRADS 10000

1–9999999

SPLIT OFF

2RNG

3RNG

2INTVL

3INTVL

FORMAT PRIMAR

SECNDR

TERTIA

ROC

ZTRKBND 0

number

Specifies the number of full scale graduations if SPLIT=OFF. (For multi-range and

multi-interval scales (SPLIT

display divisions specified for the range or interval.)

The value entered must be in the range 1–9999999 and should be consistent with legal

requirements and environmental limits on system resolution.

To calculate GRADS, use the formula: GRADS = Capacity / Display Divisions.

Display divisions are specified under the FORMAT submenu.

Specifies whether the scale is full-range (OFF), multi-range (2RNG, 3RNG), or multi-interval

(2INTVL, 3INTVL). For multi-range and multi-interval scales, see the submenu shown in

Figure 3-6 on page 30 and parameter descriptions in Ta bl e 3-4 on page 31.

For standard scales (SPLIT=OFF), see Level 4 submenu descriptions in Table 3-3 on

page 27.

For multi-range and multi-interval scales, see Table 3-4 on page 31.

Automatically zeroes the scale when within the range specified, as long as the input is

within the ZRANGE and scale is at standstill. Specify the zero tracking band in ± display

divisions. Maximum legal value varies depending on local regulations.

≠ OFF), the GRADS value is derived from the capacity and

ZRANGE 1.900000

number

MOTBAND 1

number

SSTIME 10

number

OVRLOAD FS+2%

FS+1D

FS+9D

FS

WMTTHRH 1000

number

NOTE: For scales using linear calibration, do not set the zero tracking band to a value

greater than that specified for the first linearization point.

Selects the range within which the scale can be zeroed. The 1.900000 default value is ±

1.9% around the calibrated zero point, for a total range of 3.8%. Indicator must be at

standstill to zero the scale. Use the default value for legal-for-trade applications.

Sets the level, in display divisions, at which scale motion is detected. If motion is not