Page 1

920i Based Truck In/Out System

Software Application

Version 1.01

Operator’s Manual

78855 Rev A

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction and System Overview.............................................................................................. 1

2.0 Supervisor Mode.......................................................................................................................... 2

2.1 Customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Report Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.5.1 Print Sample. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.2 Set EOL Delay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.3 Report Printer Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.4 Printer Ticket Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.5 View Data Fields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.6 Format Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5.7 Clear Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Transactions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.9 Set Date Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.10 Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.0 Scale Select............................................................................................................................... 13

4.0 Weighing.................................................................................................................................... 14

4.1 Weigh In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1.1 Customer Selection - Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.2 Product Selection - Optional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1.3 Project Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1.4 Weigh In Canceled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Weigh Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.2.1 Truck Number or Transaction Lookup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Weigh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.3.1 Customer Selection - Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.2 Product Selection - Optional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3.3 Project Selection - Optional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.0 Appendix .................................................................................................................................... 21

5.1 Serial Port Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1.1 Required 920i Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Default Ticket Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EPD Software License Agreement......................................................................................................... 24

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

Version 1.01 May 2, 2014 3:00 pm

Contents i

Page 4

ii 920i Based Truck In/Out Weigh Program

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

1.0 Introduction and System Overview

Weigh

Weigh Out

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

Supervisor

Mode

Select

=>

Scale

#1

Truck

Ta re

Gross

Customer

Product

Project

Net

Weigh In

Scale

Select

This manual provides information on using a truck in/out weighing program (PN 77297) for manual truck

transactions using Rice Lake Weighing System’s 920i digital weight indicator. Stored IDs let you keep a database of

truck IDs, customer product and project information, and weigh-in weights in the indicator’s memory and are

accessed by simply scrolling through the

automatically store up to 100 truck ID’s and tare weig hts, 9 50 customers, 1000 products, an d 1000 projects.

While this manual gives basic information about this program, it only addresses those settings that are important to the

operation of the truck in/out program. For further information on the installation, configuration, and operation of the

920i, consult the 920i Installation Manual, PN 67887.

To install the truck in/out program onto your 920i programmable indicator, it must be in configuration mode before

.cod file can be sent. You can send the .cod file directly from iRev by using the Download Configuration... selection

the

Communications menu and specifying that you want to send the .cod file.

on the

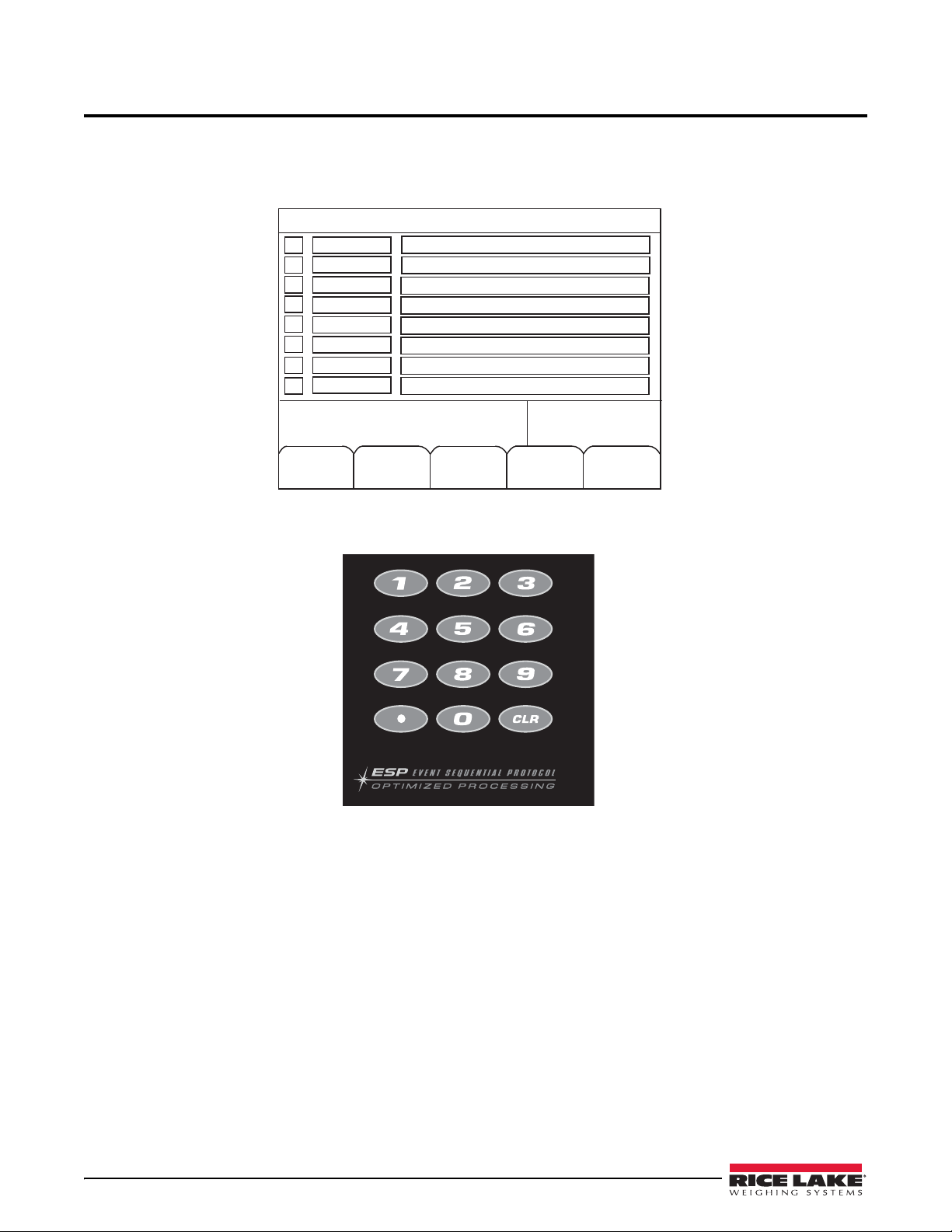

The following main menu screen is shown.

Supervisor main menu using the down arrow on the 920i. The 920i can

The main screen consists of general information that will be added as information is accessed from the database.

Weigh Select this softkey to do a single weighment

Weigh In Allows truck ID entry; generates weigh-in ticket

Weigh Out Allows truck ID entry; generates weigh-out ticket

Scale Select For multi-scale applications, provides a prompt to enter the scale number to be displayed

Supervisor Mode Allows information to be added to the database

All of the softkeys access additional function parameters and are explained in further detail in the following sections.

Figure 1-1. Main Screen

Softkey Description

Table 1-1. Softkey Descriptions

Introduction and System Overview 1

Page 6

2.0 Supervisor Mode

Exit to

Weigh

Set Date/

Time

10/22/07

08:05AM

SCALE #1

Clear

1

2

3

4

Product

Customer

8

7

6

5

Edit

Edit

Edit

Edit

Go to

Edit

Change

Truck

Project

Report Name

Transactions

Password

System

Diagnostics

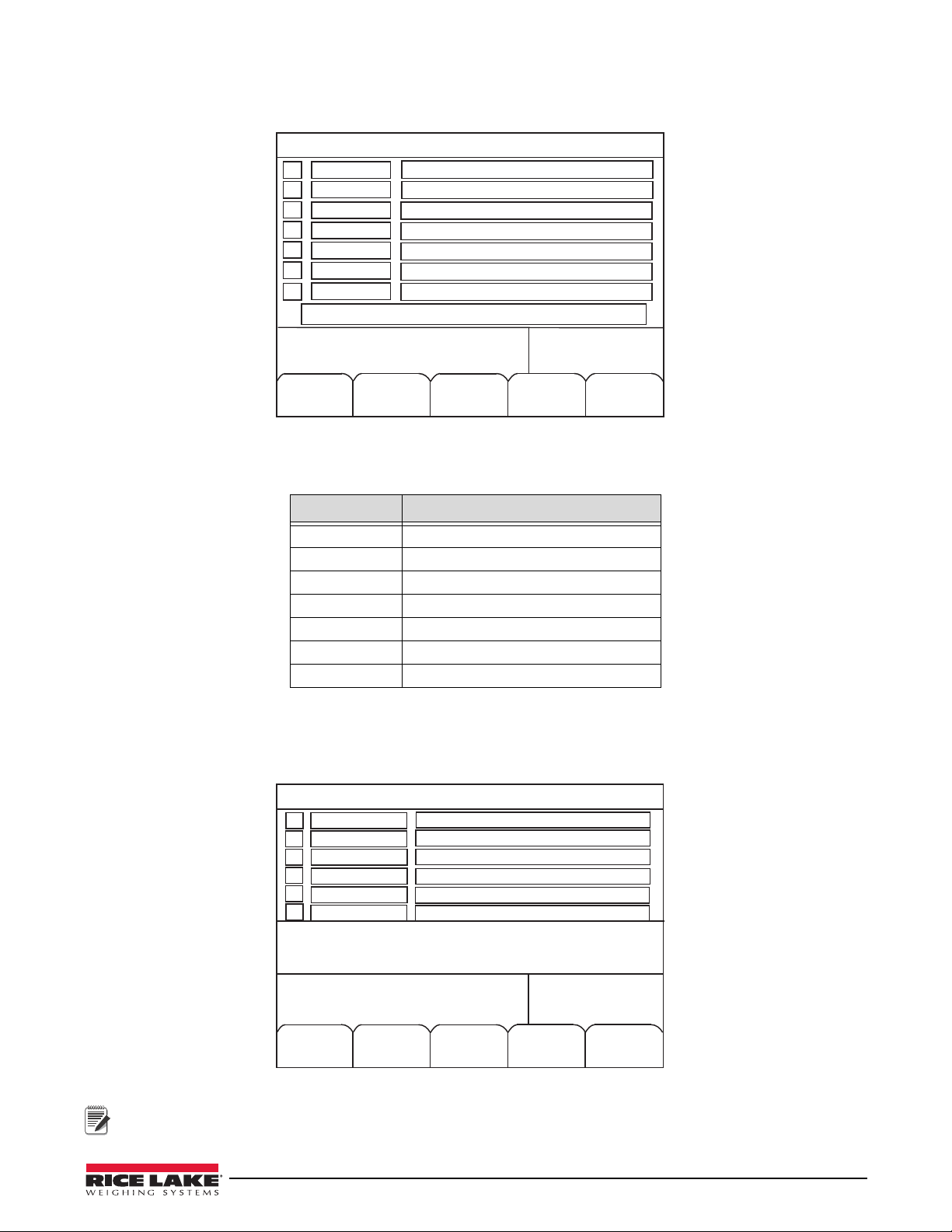

Within the supervisors screen you are able to enter/edit customers, products, trucks, projects, and access report

functions.

1. Press the

shown in Figure 2-1.

2. Using the numeric keypad on the 920i or the front panel keypad, select the desired field.

Supervisor Mode softkey from the main menu screen to access the supervisor menu main screen,

Figure 2-1. Supervisor Menu Main Screen

Figure 2-2. 920i Numeric Keypad

2 920i Based Truck In/Out Weigh Program

Page 7

2.1 Customer

Exit to

Weigh

06/08/13

08:05AM

SCALE #1

Phone

1

2

3

4

7

6

5

ID

Name

Address 1

Address 2

Address 3

Accum

Enter Selection Number

Menu/

Cancel

Customer

Home

Cancel

10/22/13

08:05AM

SCALE #1

End

Customer

Enter ID

A B C D E F G H I J K L M N O P Q R S T U V W X Y Z

a b c d e f g h i j k l m n o p q r s t u v w x y z

! # $ & ? ( ) < > + * % = / \ “ . , : ; ‘ | ~[ ] { }

1

4

3

2

5

6

ID

Name

Address 1

Address 2

Address 3

Phone

Note

1. Select 1 - Customer, to access the customer entry screen, shown in Figure 2-3.

Figure 2-3. Customer Entry Screen

2. Enter the field number to be edited using the numeric keypad. The following table lists the amount of

characters allowed for each field.

Field Characters Allowed

ID 16 character alphanumeric

Name 20 character alphanumeric

Address 1 20 character alphanumeric

Address 2 20 character alphanumeric

Address 3 20 character alphanumeric

Phone 20 character alphanumeric

Accum Can’t edit, view only

Table 2-1. Customer Entry Character Parameters

3. Enter customer information using the

menu.

4. Move the cursor back down to the

When entering the customer ID, if it is not currently found in the program, the on-screen prompt tells you that it’s

not found, but adding that entered customer ID number. Press the Save softkey to save the new customer ID.

up/down, right/left navigation keys, to scroll through the alpha-numeric

Enter line and press enter to save.

Figure 2-4. Customer Entry ID Screen

Supervisor Mode 3

Page 8

You can use the up/down arrows on the navigation pad on the 920i to scroll through and view customer

Note

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

ID

Name

Rate

Accum

Total

Enter Selection Number

Menu/

Cancel

Products

information already entered into the database.

5. Enter other customer parameters, using the same steps.

6. When complete, press the

Exit to Weigh softkey to access the weigh screen or the Menu/Cancel softkey to go to

the Supervisor main menu.

2.2 Product

1. Select 2 - Product, from the Supervisor’s main menu to access the product parameter screens.

Figure 2-5. Product Entry Screen

2. Enter the field number to be edited on the numeric keypad. The following table lists the amount of characters

allowed for each field.

Field Characters Allowed

ID 16 character alphanumeric

Name 20 character alphanumeric

Rate Numeric

Accum Can’t edit/view only

Total Can’t edit/view only

Table 2-2. Product Entry Character Parameters

3. Use the

up/down navigation keys, to scroll through the alpha-numeric menu to edit or enter the product

information.

4. Press

enter to save the values. Additional entries can be made by using the navigation keys to add additional

products.

5. When complete, use the

Menu/Cancel softkey to go to the Supervisor Main Menu screen.

4 920i Based Truck In/Out Weigh Program

Page 9

2.3 Truck

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

ID

Ta re

Descrip

Accum

Enter Selection Number

Menu/

Cancel

Trucks

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

ID

Name

Descrip 1

Descrip 2

Enter Selection Number

Menu/

Cancel

Projects

Accum

1. Select 3 - Truck , from the Supervisor’s main menu to access the truck parameter screen.

Figure 2-6. Truck Entry Screen

2. Enter the field number to be edited on the numeric keypad. The following table lists the amount of characters

allowed for each field.

Field Characters Allowed

ID 16 character alphanumeric

Tare Numeric (keyed or from scale)

Descrip 20 character alphanumeric

Accum Can’t edit/view only

Table 2-3. Truck Entry Character Parameters

3. Using the

4. Press

up/down navigation keys, to scroll through the alpha-numeric to edit or enter the truck information.

Save softkey to save the values. Additional entries can be made by using the navigation keys to add

additional truck numbers.

5. To store a tare value taken from the scale, press the

2 key after selecting an ID and press enter with nothing

entered. This stores the the current weight on the scale as the tare.

6. When complete, use the

Menu/Cancel softkey to go to the Supervisor Main Menu screen.

2.4 Project

1. Select 4 - Project from the Supervisor’s main menu to access the project parameters screen.

Figure 2-7. Project Entry Screen

Supervisor Mode 5

Page 10

2. Enter the field number to be edited on the numeric keypad. The following table lists the amount of characters

Clear

Format

Format

Ticket

10/22/07

08:05AM

SCALE #1

Edit Header 2

1

2

3

4

Product Report

Customer Repor t

8

7

6

5

Print

Print

Print

Print

Edit Header 1

Print

Edit Header 3

Transaction Report

Truck Repor t

Project Report

Reports

View Data

Fields

More=>

Menu

Set EOL Report

Delay

Printer Port Tckt Format

10/22/07

08:05AM

SCALE #1

Edit Header 2

1

2

3

4

Product Report

Customer Report

8

7

6

5

Print

Print

Print

Print

Edit Header 1

Print

Edit Header 3

Transaction Report

Truck Report

Pr

oject Repor

t

Reports

Print

Sample

<=More

Print

allowed for each field.

Field Characters Allowed

ID 20 character alphanumeric

Name 20 character alphanumeric

Descrip 1 20 character alphanumeric

Descrip 2 20 character alphanumeric

Accum Can’t edit/view only

Table 2-4. Project Entry Character Parameters

3. Use the Up/down navigation keys to scroll through the alphanumeric keys to edit or enter the project

information.

4. Press

5. When complete, use the

Save softkey to save.

Menu/Cancel softkey to go to the Supervisor Main Menu screen.

2.5 Report Menu

1. Select 5 - Report Menu from the Supervisor’s main menu to access the reporting parameter screens.

Figure 2-8. Report Entry Screen

Figure 2-9. Report Entry Screen (more)

2. There are several types of reports that can be generated through this screen which include customer reports,

product reports, transaction reports, truck reports, and project reports. To access a particular report, select the

number using the numeric keypad on the 920i. The report will be printed on the attached printer.

6 920i Based Truck In/Out Weigh Program

Page 11

2.5.1 Print Sample

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

Print

Print

Print

Enter Selection Number

Menu/

Cancel

Weigh Sample

Weigh In Sample

Weigh Out Sample

Item Data Field

1Truck ID

2Product ID

3Customer ID

4 Time and Date

5Gross

6Tare

7Net

8Value

9 Transaction #

10 Truck Description

11 Product Name

12 Customer Name

13 Header 1

14 Header 2

15 Header 3

16 Customer Address 1

17 Customer Address 2

18 Customer Address 3

19 Customer Phone

20 Customer Accum

21 Product Rate

22 Product Accum

Item Data Field

23 Product Total

24 Truck Accum

25 Net in Tons

26 Project ID

27 Project Name

28 Project Description 1

29 Project Description 2

30 Project Accum

/Transmit Text

C Transmit Character -

decimal value

Item Data Field

1. Select the Print Sample softkey to access the print selections.

Figure 2-10. Print Sample Selections Screen

2.5.2 Set EOL Delay

Enter the delay between printed lines if the printer buffer is getting overloaded.

The default setting is 2 and time is entered in milliseconds.

2.5.3 Report Printer Port

Enter the port that the reports (including customer, product, project, truck, transaction, and ticket format reports) will

print.

The default setting is port 3, although ports 1-4 can be used.

2.5.4 Printer Ticket Formats

This prints the contents of the weigh ticket, weigh in ticket, and the weigh out ticket for ticket formatting to see what

has been currently entered and it will be printed on the report printer.

2.5.5 View Data Fields

Select the View Data Fields softkey to view a list of available ticket fields. Table 2-5 lists the available ticket fields.

Table 2-5. Available Ticket Fields

Supervisor Mode 7

Page 12

2.5.6 Format Ticket

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

Format

Format

Format

Enter Selection Number

Menu/

Cancel

Weigh Ticket

Weigh In Ticket

Weigh Out Ticket

Choose Type to Format

Home

Cancel

10/22/07

08:05AM

SCALE #1

End

Weigh Ticket Format

Enter Row

Press Cancel to End

Note

1. Format a ticket by selecting the Format Ticket softkey screen as shown in Figure 2-8 and select the print

format to be edited. The following screen is displayed.

Figure 2-11. Format Ticket Select

2. Choose the type of ticket format type by using the numeric keypad to select 1, 2, or 3. Figure 2-12 illustrates an

example of the weigh ticket format screen.

3. Enter information and press enter to save your entry.

This can also be done through the Database Editor. To view the database rows/columns for the sample ticket

shown below, see Appendix 7.2.

8 920i Based Truck In/Out Weigh Program

Figure 2-12. Format Ticket Screen

Table 1-1. Data Fields Parameters

Page 13

Figure 2-13. Weigh Ticket Example

10/22/07

08:05AM

SCALE #1

Clear Transactions

No

Are You Sure?

Yes

2.5.7 Clear Format

1. Select the Clear Format (Figure 2-8) softkey to clear the ticket format.

2.6 Transactions

1. Select 6 - Tr an sa ct io ns from the Supervisor’s main menu to delete all stored transactions. The following

screen is displayed.

Figure 2-14. Transaction Menu Screen.

2. If you wish to clear all transactions from the database, press the Yes softkey. After pressing Yes or No to clear

the transaction database, it will prompt asking if the user wants to clear all of the accumulated totals.

Supervisor Mode 9

Page 14

Figure 2-15. Clear Accumulated Totals Screen

10/22/07

08:05AM

SCALE #1

Clear All Accum Totals?

No

Are You Sure?

Yes

Exit to

Weigh

10/22/07

08:05AM

SCALE #1

1

2

3

4

7

6

5

Store Tr

ansaction Recor

ds

Allow Transient Customers

Print on Weigh In

Transaction Number

Menu

Use Stored Tar e

Weigh Out By

Yes

Yes

0

Yes

Yes

Truck ID

Yes

0

9

8

Tare Key Enabled to Modify Truck Tares

Yes

Yes

Project Auto Prompt in Weighs

Yes

Customer Auto Prompt in Weighs

Product Auto Prompt in Weighs

Edit

Labels

3. Press Yes to clear all of the customer, truck, product, and project accu mulations.

2.7 Password

1. Select 7 - Password from the Supervisor’s main menu to access the password parameter screen.

2. Follow the on-screen prompt to either keep the password or change the password.

3. Press

enter to save the entry .

2.8 System

1. Select 8 - System from the Supervisor’s main menu to access the system parameters. The following screen is

displayed.

2. Select the parameter to access using the numeric keypad. The following describes the system parameters.

10 920i Based Truck In/Out Weigh Program

Store Transaction Records

Yes – transaction database is updated after every transaction.

No – nothing is updated.

Allow Transient Customers

Yes – updates the database when a new customer is added on the fly.

No – does not save this data and the only way to add to the database is through the Supervisor softkey.

Figure 2-16. System Parameters

Page 15

Print on Weigh In

Selects whether or not a ticket will be printed after a truck is weighed in.

Transaction Number

Displays the current transaction number and also allows the number to be reset. The next transaction number

will be 1 higher than the value shown.

Use Stored Tare

Yes – uses the stored tare in the vehicle database.

Weigh Out By

When you press the Weigh Out button, the Weigh Out By prompt looks up the first weight reading that was

taken depending on if it was set up for a truck ID or a tran ID. This parameter toggles between Truck ID and

Tran ID, the default is T ruck ID.

Tare Key Enabled

Yes – allows the tare key to be pressed in between transactions and will prompt for a truck ID, either new or

currently stored. After entering an ID, the 920i will take the weight on the scale and store it as the tare for that

truck ID, as a quick way to edit tares.

No – function is disabled.

Customer Auto Prompt on Weighs

Yes – at weigh or weigh in after prompting for a truck ID the system will prompt for a Customer ID, Product

ID, and Project ID.

No – system will prompt for Truck ID only and o ther ID can be selected separately.

Product Auto Prompt on Weighs

Yes – at weigh or weigh in after prompting for a truck ID, the system will prompt for a product ID.

No – system will prompt for Truck ID only and y ou can select other IDs separately.

Project Auto Prompt on Weighs

Yes – at weigh or weigh in after prompting for a truck ID, the system will prompt for a project ID.

No – system will prompt for Truck ID only and y ou can select other IDs separately.

Edit Labels Softkey

Press this key and follow the prompts to change the labels for the actual words, Customer, Project, Product,

Truck in the screens and displayed messages throughout the s yst em.

and

The defaults are Customer, Project, Product, and T ruck.

3. When complete, use the

Menu softkey to exit out of the system menu screen.

2.9 Set Date Time

1. Press the Set Date Time softkey to access the time and date.

2. Use the on-screen prompts to enter the month, day, year, and time.

Supervisor Mode 11

Page 16

2.10 Diagnostics

Note

10/22/07

08:05AM

SCALE #1

Diagnostics

NAME

DEADLOAD

0.1871

1.1509

0.7567

0.3791

0.0931

0.7079

CURRENT

0.2159

0.0547

0.7301

0.3583

0.1565

0.6655

A2-Load Cell 2

A3-Load Cell 3

A4-Load Cell 4

A5-Load Cell 5

A6-Load Cell 6

A7-Load Cell 7

System 1

44 weighments over 1000 grads

17.24608

Cell OK

Previous Done

Cell

Emulation

Next

Figure 2-17 shows an example of a 920i display of iQube diagnostic information. Information shown includes the

following:

• Cell name

• Cell deadload value (mV )

• Current individual cell and total values (mV)

• Number of weighments

• Cell status for highlighted cell. Use the indicator navigation keys to select cells.

Displayed deadload and current values are raw millivolt values. All diagnostic measurements use corrected mV

values:

corrected_value = current_value – deadload_value

Figure 2-17. 920i Diagnostic Display

The 920i diagnostic display can be shown by pressing the Diagnostic softkey (if configured).

In setup mode, diagnostic information can be shown by going to the VERS menu, pressing the

then the

Access through the VERS menu also displays softkeys for

Emulation

Next softkey.

Clear Diagnostics and, if cell emulation is enabled, Cell

. If cell emulation is set to AUTO2 or MANUAL2, a Snapshot softkey is also shown.

Contact softkey,

12 920i Based Truck In/Out Weigh Program

Page 17

3.0 Scale Select

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale Select

Scale Number

Scale

#1

Truck

Customer

Product

If more than one scale is connected to the 920i, the Scale Select softkey allows the user to select which scale to use.

Figure 3-1. Scale Selection Screen

1. Use the numeric keypad to select the scale number.

2. Press the

3. To end out of the scale selection screen, press the

enter key to save the scale number .

Cancel softkey .

Scale Select 13

Page 18

4.0 Weighing

Home

Product

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Customer

Project

Project

Select

Enter Truck ID

Note

Note

Cancel

Customer

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

Complete

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Product

Project

4.1 Weigh In

The general weigh-in procedure is as follows:

1. The truck moves onto the scale for weigh-in.

2. Press the

Weigh In softkey. The following screen is displayed.

Figure 4-1. Weigh In Screen

3. Enter the truck ID by using the numeric keys on the 920i. Press enter to save the ID number .

4. Enter the Customer ID, Product ID, and Project ID as the series of prompts come up.

5. After valid truck IDs are entered the following screen is displayed.

If the truck ID has already been entered and a weigh in has already been complete, the following error message

appears on the user screen:

“Error, Truck is Weighed In.”

Press enter without keying in an ID for any of the above as it is not necessary to enter those. If Auto-prompt is

set to No in the Supervisor System menu this will not prompt through all IDs and the user will have to press

individual softkeys to select customer, project, product IDs separately.

Figure 4-2. Truck ID Data

14 920i Based Truck In/Out Weigh Program

Page 19

4.1.1 Customer Selection - Optional

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Customer

Enter Customer

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Product

Enter Prod ID

1. Enter the customer selection by using the up/down, right/left navigation keys, to scroll through the numeric

menu.

2. Press

enter to save the customer selection or press enter without typing anything into the Enter Customer field.

Figure 4-3. Customer Selection Screen

4.1.2 Product Selection - Optional

1. Enter the product selection by using the up/down, right/left navigation keys, to scroll through the

alpha-numeric menu.

2. Press

enter to save the product selection or press enter without typing anything into the Enter Prod ID field.

Figure 4-4. Product Selection Screen

Weighing 15

Page 20

4.1.3 Project Selection

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Product

Enter Prod ID

Weigh

Weigh Out

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

Supervisor

Mode

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Weigh In

Scale

Select

Complete

Project

1. Enter the project selection by using the up/down, right/left navigation keys, to scroll through the

alpha-numeric menu.

2. Press

3. Once the customer and product and project are entered and saved, press the Complete softkey to complete the

enter to save the project selection or press enter without typing anything into the Enter Project field.

Figure 4-5. Project Selection Screen

weigh in. The following screen is shown and the indicator generates a weigh-in ticket.

4.1.4 Weigh In Canceled

If you want to quit the weigh in, use the Cancel softkey (shown in Figure 4-5) to cancel the weigh in process.

16 920i Based Truck In/Out Weigh Program

Figure 4-6. Weigh In Complete Screen

Page 21

4.2 Weigh Out

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Truck Lookup

Enter Number

Project

Cancel

Customer

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

Complete

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Product

Project

The general weigh-out procedure is as follows:

4.2.1 Truck Number or Transaction Lookup

1. Enter the truck number or the transaction lookup number (depending on what you have set up in the

Supervisor menu system parameter) by using the up/down, right/left navigation keys, to scroll through the

alpha-numeric menu.

Figure 4-7. Weigh Out Truck Number

2. Press enter to save the truck number.

3. Once the customer and product are entered and saved, press the Complete softkey to complete the weigh in.

The truck ID (temporarily stored), is then deleted from the truck database.

Figure 4-8. Truck Info Screen

Weighing 17

Page 22

4.3 Weigh

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Select

Enter Truck ID

Scale

#1

Truck

Customer

Product

Project

Gross Tare

Net

Note

Cancel

Customer

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

Complete

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Product

Project

1. To perform a single weighment, select the Weigh softkey. The truck ID entry screen is displayed.

Figure 4-9. Truck ID Entry Screen

2. Use the up/down, right/left navigation keys, to scroll through the alpha-numeric menu to enter the truck ID

(shown in Figure 4-9).

3. Move the cursor back down to the Truck ID entry and press

entered, it will prompt for a tare (Figure 6-7).

4. Enter the Customer ID, Product ID, and Project ID as the series of prompts come up.

Press enter without keying in an ID for any of the above as it is not necessary to enter those. If Auto-prompt is

set to No in the Supervisor System menu this will not prompt through all IDs and the user will have to press

individual softkeys to select customer, project, product IDs separately.

5. The following screen is now displayed.You can select customer or product from the menu softkeys if they have

not been entered.

enter to save the truck ID. If no tare has been

18 920i Based Truck In/Out Weigh Program

Figure 4-10. Customer Selection

Page 23

4.3.1 Customer Selection - Optional

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Customer

Enter Customer

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Product

Enter Prod ID

1. Enter the customer selection by using the up/down right/left navigation keys to scroll through the numeric

menu.

2. Press

enter to save the customer selection.

Figure 4-11. Customer Selection Screen

4.3.2 Product Selection - Optional

1. Enter the product selection by using the up/down, right/left navigation keys, to scroll through the

alpha-numeric menu.

2. Press

enter to save the product selection.

Figure 4-12. Product Selection Screen

Weighing 19

Page 24

4.3.3 Project Selection - Optional

Home

Cancel

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

End

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Project

Project

Enter Project

Weigh

Weigh Out

10/22/07

08:05AM

SCALE #1

-888.8888

Mode

Units

Supervisor

Mode

Scale

#1

Truck

Ta re

Gross

Customer

Product

Net

Weigh In

Scale

Select

Complete

Project

1. Enter the product selection by using the up/down, right/left navigation keys, to scroll through the

alpha-numeric menu.

2. Press the

3. Once the truck is weighed the following screen is displayed. Now the truck can exit the scale.

Complete softkey, to finish the weighment.

Figure 4-13. Project Selection Screen

20 920i Based Truck In/Out Weigh Program

Figure 4-14. Weigh Selection Complete

Page 25

5.0 Appendix

Control ASCII Dec. Hex ASCII Dec. Hex ASCII Dec. Hex ASCII Dec Hex

Ctrl-@ NUL 00 00 space 32 20 @ 64 40 ` 96 60

Ctrl-A SOH 01 01 ! 33 21 A 65 41 a 97 61

Ctrl-B STX 02 02 “ 34 22 B 66 42 b 98 62

Ctrl-C ETX 03 03 # 35 23 C 67 43 c 99 63

Ctrl-D EOT 04 04 $ 36 24 D 68 44 d 100 64

Ctrl-E ENQ 05 05 % 37 25 E 69 45 e 101 65

Ctrl-F ACK 06 06 & 38 26 F 70 46 f 102 66

Ctrl-G BEL 07 07 ’ 39 27 G 71 47 g 103 67

Ctrl-H BS 08 08 ( 40 28 H 72 48 h 104 68

Ctrl-I HT 09 09 ) 41 29 I 73 49 i 105 69

Ctrl-J LF 10 0A * 42 2A J 74 4A j 106 6A

Ctrl-K VT 11 0B + 43 2B K 75 4B k 107 6B

Ctrl-L FF 12 0C , 44 2C L 76 4C l 108 6C

Ctrl-M CR 13 0D - 45 2D M 77 4D m 109 6D

Ctrl-N SO 14 0E . 46 2E N 78 4E n 110 6E

Ctrl-O SI 15 0F / 47 2F O 79 4F o 111 6F

Ctrl-P DLE 16 10 0 48 30 P 80 50 p 112 70

Ctrl-Q DC1 17 11 1 49 31 Q 81 51 q 113 71

Ctrl-R DC2 18 12 2 50 32 R 82 52 r 114 72

Ctrl-S DC3 19 13 3 51 33 S 83 53 s 115 73

Ctrl-T DC4 20 14 4 52 34 T 84 54 t 116 74

Ctrl-U NAK 21 15 5 53 35 U 85 55 u 117 75

Ctrl-V SYN 22 16 6 54 36 V 86 56 v 118 76

Ctrl-W ETB 23 17 7 55 37 W 87 57 w 119 77

Ctrl-X CAN 24 18 8 56 38 X 88 58 x 120 78

Ctrl-Y EM 25 19 9 57 39 Y 89 59 y 121 79

Ctrl-Z SUB 26 1A : 58 3A Z 90 5A z 122 7A

Ctrl-[ ESC 27 1B ; 59 3B [ 91 5B { 123 7B

Ctrl-\ FS 28 1C < 60 3C \ 92 5C | 124 7C

Ctrl-] GS 29 1D = 61 3D ] 93 5D } 125 7D

Ctrl-^ RS 30 1E > 62 3E ^ 94 5E ~ 126 7E

Ctrl-_ US 31 1F ? 63 3F _ 95 5F DEL 127 7F

Figure 5-1. ASCII Character Chart (Part 1)

Appendix 21

Page 26

ASCII Dec Hex ASCII Dec Hex ASCII Dec Hex ASCII Dec Hex

Ç 128 80 á 160 A0 192 C0 a 224 E0

ü 129 81 í 161 A1 193 C1 b 225 E1

é 130 82 ó 162 A2 194 C2 G 226 E2

â 131 83 ú 163 A3 195 C3 p 227 E3

ä 132 84 ñ 164 A4 196 C4 S 228 E4

à 133 85 Ñ 165 A5 197 C5 s 229 E5

å 134 86 ª 166 A6 198 C6 m 230 E6

ç 135 87 º 167 A7 199 C7 t 231 E7

ê 136 88 ¿ 168 A8 200 C8 F 232 E8

ë 137 89 169 A9 201 C9 Q 233 E9

è 138 8A ¬ 170 AA 202 CA W 234 EA

ï 139 8B 1/2 171 AB 203 CB d 235 EB

î 140 8C 1/4 172 AC 204 CC • 236 EC

ì 141 8D ¡ 173 AD 205 CD f 237 ED

Ä 142 8E « 174 AE 206 CE Œ 238 EE

Å 143 8F » 175 AF 207 CF « 239 EF

É 144 90 176 B0 208 D0 ½ 240 F0

æ 145 91 177 B1 209 D1 ± 241 F1

Æ 146 92 178 B2 210 D2 Š 242 F2

ô 147 93 179 B3 211 D3 £ 243 F3

ö 148 94 180 B4 212 D4 Û 244 F4

ò 149 95 181 B5 213 D5 € 245 F5

û 150 96 182 B6 214 D6 ³ 246 F6

ù 151 97 183 B7 215 D7 ª 247 F7

ÿ 152 98 184 B8 216 D8 × 248 F8

Ö 153 99 185 B9 217 D9 ² 249 F9

Ü 154 9A 186 BA 218 DA 250 FA

¢ 155 9B 187 BB 219 DB 251 FB

£ 156 9C 188 BC 220 DC 252 FC

¥ 157 9D 189 BD 221 DD

Pts 158 9E 190 BE 222 DE 254 FE

ƒ 159 9F 191 BF 223 DF 255 FF

2

253 FD

Figure 5-2. ASCII Character Chart (Part 2)

5.1 Serial Port Usage

The following table lists the serial ports for the 920i and their uses with the truck in/out program.

920i Serial Port Description

1 Unused by program

2 Unused by program

3Printer output

4 Unused by program

Table 5-1. Serial Port Descriptions

22 920i Based Truck In/Out Weigh Program

Page 27

5.1.1 Required 920i Hardware

Slot # Description

Slot 1 Single channel A/D card

Slot 2 1 MB memory card

Table 5-2. Required Hardware

5.2 Default Ticket Format

An example of the default ticket format shown on page 10 is shown below using the formatted database

rows/columns.

Row Column Te xt

1113

2114

3115

5 1 /Transaction Number

5209

614

71/Truck

7101

71210

81/Customer

8103

81212

91/Product

9102

91211

10 1 /Product Rate: $

10 18 21

11 18 /Gross:

11 24 5

12 18 /Tare:

12 24 6

13 18 /Net:

13 24 7

14 18 /Price: $

14 24 8

Table 5-3. Default Ticket Format

To put an ASCII character into the Ticket Format you would put the decimal value of the character preceded by the

letter C. So to put 3 line feeds and 1 carriage return character at the end of this ticket, you would add the row in the

database below. You could sepeate this out into four different database rows or put it all together like the example

shown below .

Row Column Te xt

15 1 C10C10C10C13

Appendix 23

Page 28

EPD Software License Agreement

Please Read Carefully. This is a legal Agreement between you (either an individual or an entity) and Rice Lake Weighing

Systems. If you do not agree to the terms of this Agreement, promptly return the disks and the accompanying items (including

written materials and binders or other containers) to the place you obtained them for a full refund. “Software” refers to any

programs or program components, disk, or EPROM based.

Rice Lake Weighing Systems SOFTWARE LICENSE

1. GRANT OF LICENSE. Rice Lake Weighing Systems grants to you the right to use one copy of the Ri ce

Lake Weighing systems software program identified above in the following manner. You may use one copy

of the SOFTWARE on any single computer connected to a single terminal (i.e. single CPU).

2. COPYRIGHT. The SOFTWARE is owned by Rice Lake We ighing Systems or its su ppliers and is protected by

United States copyright laws and international treaty provisions. Therefore, you must treat the SOFTWARE

like any other copyrighted material (e.g. a book or musical recording) except that you may either (a) make one

copy of the SOFTWARE solely for backup or archival purposes, or (b) transfer the SOFTWARE to a single

hard disk provided you keep the original solely for backup or archival purposes.

3. OTHER RESTRICTIONS. You may not rent or lease the SOFTWARE, but you may transfer the SOFTW ARE

and accompanying written materials on a permanent basis provided you retain no copies and the recipient

agrees to the terms of this Agreement. You may not reverse engineer, decompile, or disassemble the

SOFTWARE. Software and hardware systems may be transferred with written permission to RLWS. The

warranty becomes void. If the SOFTWARE is an update or has been updated, any transfer must include the

most recent update and all prior versions. The source code of the SOFTWARE is confidential information

owned by Rice Lake Weighing Systems. You may not disclose it to any third party, make derivative works

based upon it, or use it for any purpose except the specific uses expressly permitted in the user documentation

which accompanies the SOFTWARE.

LIMITED WARRANTY

Rice Lake Weighing Systems warrants that (a) the SOFTWARE will perform substantially in accordance with the accompanying

written materials for a period of ninety (90) days from the date of receipt; and (b) any hardware accompanying the SOFTWARE

will be free from defects in materials and workmanship under normal use and service for a period of one (1) year from the date of

receipt. Any implied warranties on the SOFTWARE and hardware are limited to ninety (90) days and one (1) year, respectively.

Some states/countries do not allow limitations on d uration o f im plied warrant y, so the above limitation may not apply to you.

CUSTOMER REMEDIES. Rice Lake Weighing Systems and its suppliers entire liability and your exclusive remedy shall be, at

Rice Lake Weighing Systems option, either (a) return of the price paid or (b) repair or replacement of the SOFTWARE or

hardware that does not meet Rice Lake Weighing Systems Limited Warranty and which is returned to Rice Lake Weighing

Systems with a copy of your receipt. This Limited Warranty is void if failure of the SOFTWARE or hardware ha s resulted from

accident, abuse, or misapplication. Any replacement SOFTWARE will be warranted for the remainder of the original warranty

period or thirty (30) days, whichever is longer.

NO OTHER W ARRANTIES. Rice Lake Weighing Systems and its suppliers disclaim all other warranties, either expr ess or

implied, including, but not limited to implied warranties of merchantability and fitness for a particular purpose, with

regard to the SOFTWARE, the accompanying written materials, and any accompanying hardware. This limited warranty

gives you specific legal rights. You may have others which vary from state/country to state/country.

NO LIABILITY FOR CONSEQUENTIAL DAMAG ES. In no event shall Rice Lake Weighing Systems or its suppliers be

liable for any damages whatsoever (including without limitation, damages for loss of business profits, business

interruption, loss of business information, or any other pecuniary loss) arising out of the use of or inability to use this Rice

Lake Weighing Systems product, even if Rice Lake Weighing Systems has been advised of the possibility of such damages.

Because some states/countries do not allow the exclusion or limitation of liability for consequential or incidental damages,

the above limitation may not apply to you.

© Rice Lake Weighing Systems, Inc., Rice Lake, WI USA. All Rights Reserved.

Rice Lake Weighing Systems • 230 West Coleman S treet • Rice Lake, Wisconsin 54868

24 920i Based Truck In/Out Weigh Program

Page 29

Page 30

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0) 88 2349171

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 05/2014 PN 78855 Rev A

Loading...

Loading...