Rheem RPWL-120 Installation Manual

INSTALLATION INSTRUCTIONS

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION!

!

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT AND OPERATION OF THIS UNIT.

READ THESE INSTRUCTIONS THOROUGHLY BEFORE

ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN IMPROPER

INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE

POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

ea r t h f r i e n d l y r e f r i g e r a n t

earth

r

y r

dly

fr

FOR HIGH EFFICIENCY REMOTE HEAT PUMPS

FEATURING INDUSTRY STANDARD R-410A

RPWL-090 AND -120 UNITS

7.5 & 10 NOMINAL TONS [26 & 35 kW]

[ ] INDICATES METRIC CONVERSIONS

SUPERSEDES 92-103191-01-02

92-103191-01-03

TABLE OF CONTENTS

Standard Unit Features.................................................2 - 5

Unit Dimensions............................................................6 - 7

Performance Data Table....................................................8

Electrical & Physical Data Table........................................8

Installation........................................................................10

Piping...............................................................................11

Wiring...............................................................................13

Leak Testing ....................................................................14

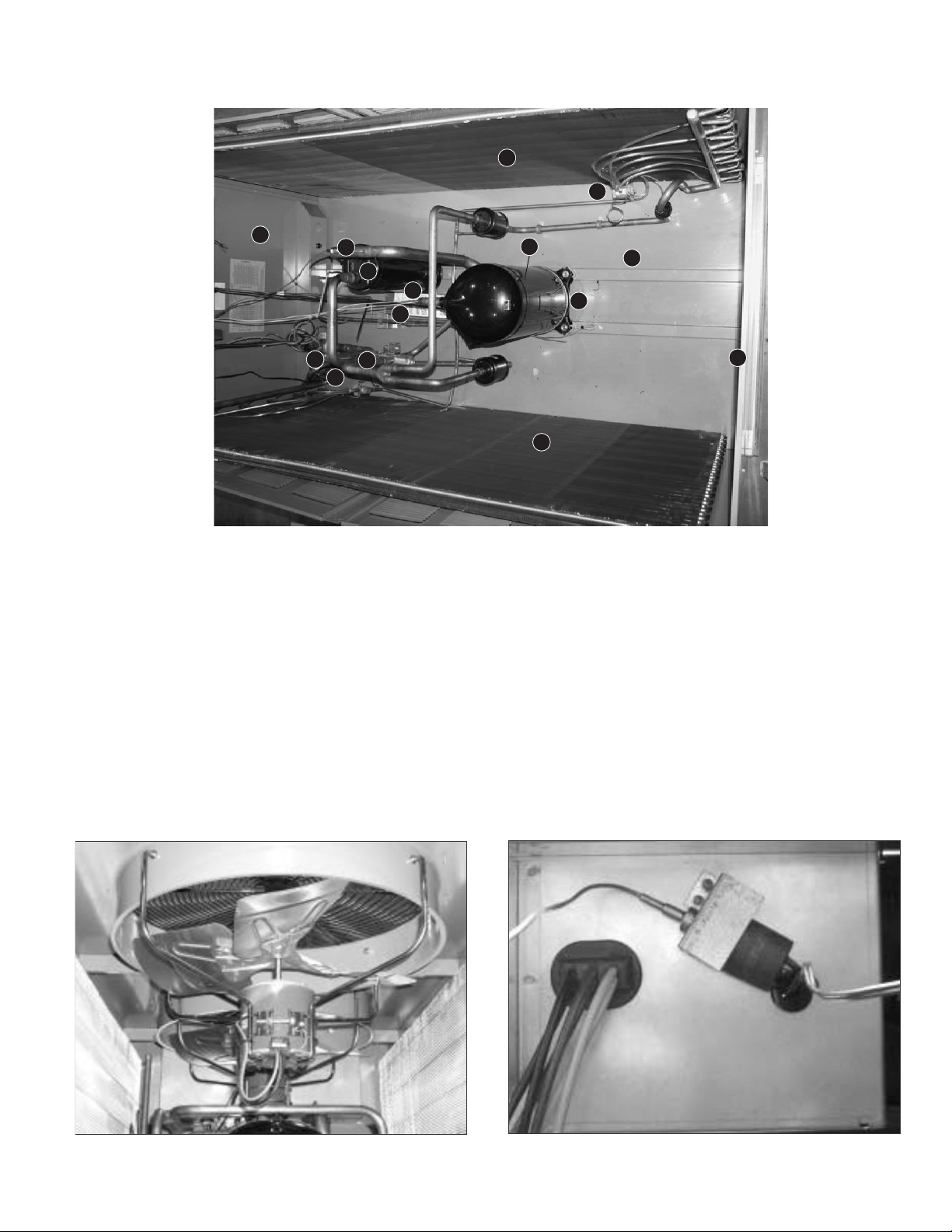

STANDARD UNIT FEATURES

➊

Evacuation & Charging ....................................................14

Final Leak Testing............................................................14

Maintenance & Operation ................................................17

Pre-Start Check ...............................................................17

Sequence of Operation....................................................17

Accessories......................................................................18

Trouble Shooting Flow Charts ..................................19 - 21

Wiring Diagrams .......................................................22 - 23

7.5 TON FEATURES & BENEFITS

1. CABINET—Galvanized steel with powder coat paint

finish. The powder coat paint finish is high gloss, durable

and capable of withstanding a 1000-hour salt spray test

per ASTM B 117. All access panels can be opened or

removed without affecting the structural strength of the

unit. Stamped louvered panels offer 100% protection for

the condenser coil.

2. EQUIPMENT GROUND—Lug for field connection of

ground wire.

3. CONTACTOR—The contactor is an electrical switch

which operates the compressor and outdoor fans. Its

24 volt coil is activated on a call for cooling or heating.

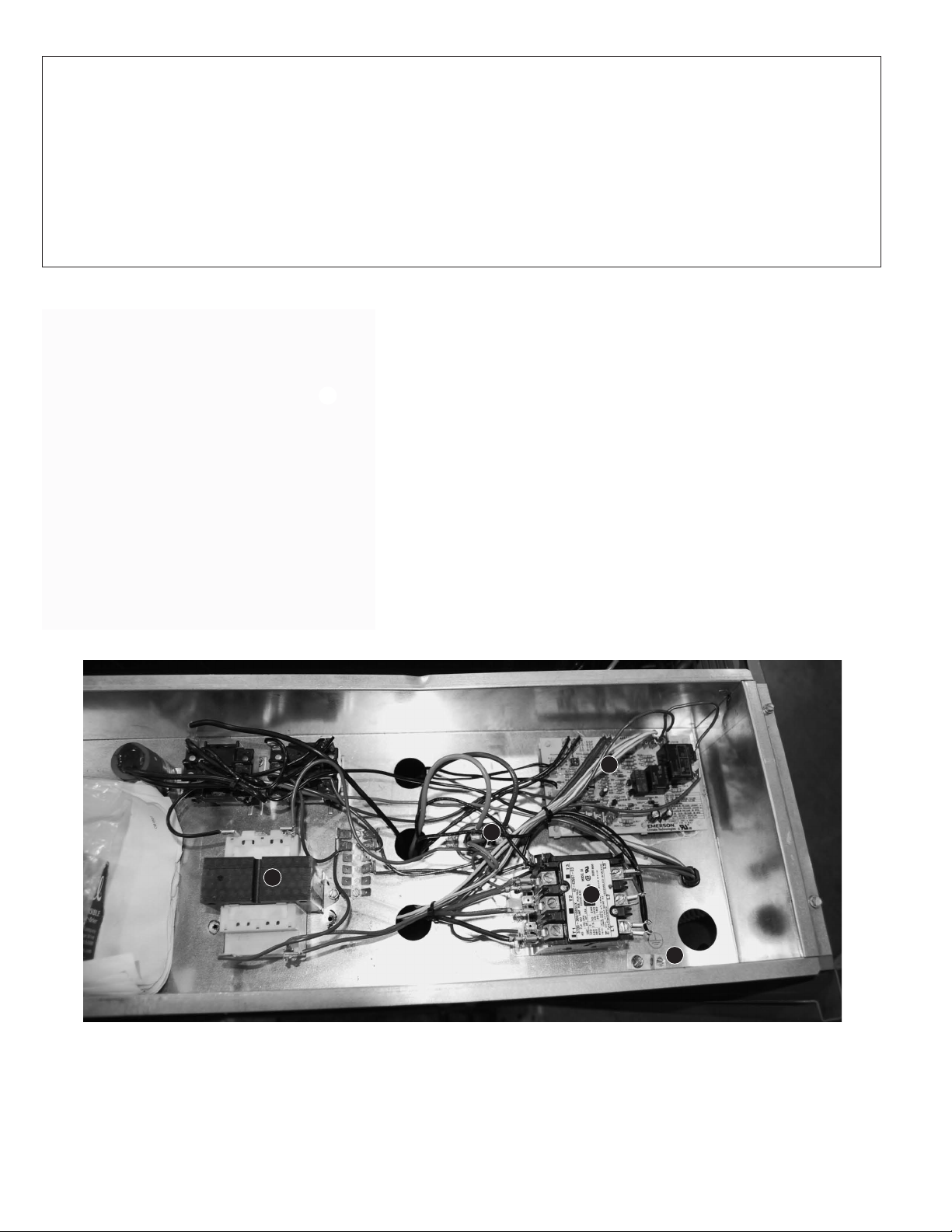

CONTROL BOX

4

4. TRANSFORMER—75 VA step-down type, from Line to 24 volts

with resetable circuit breaker.

5. CAPACITOR—Help provide starting torque necessary to boost

the condenser fan motor to operating speed by directing their

stored energy to the starter winding in step with the running

winding.

6. DEMAND DEFROST CONTROL—Used when unit is in heating

mode to defrost outdoor coil.

6

5

3

2

7. AUTO-RESET HIGH PRESSURE CONTROL, AND AUTO-

RESET LOW PRESSURE CONTROL—To provide compressor

protection under abnormally high head pressure conditions

(outdoor fan failure, restriction, dirty coil, etc.) or abnormally low

suction pressure conditions (restrictions, TEV failure, loss of

charge, indoor blower failure, etc.) while eliminating nuisance

tripping sometimes experienced with conventional control

systems.

2

7.5 TON

FEATURES & BENEFITS

8

7

10

13

11

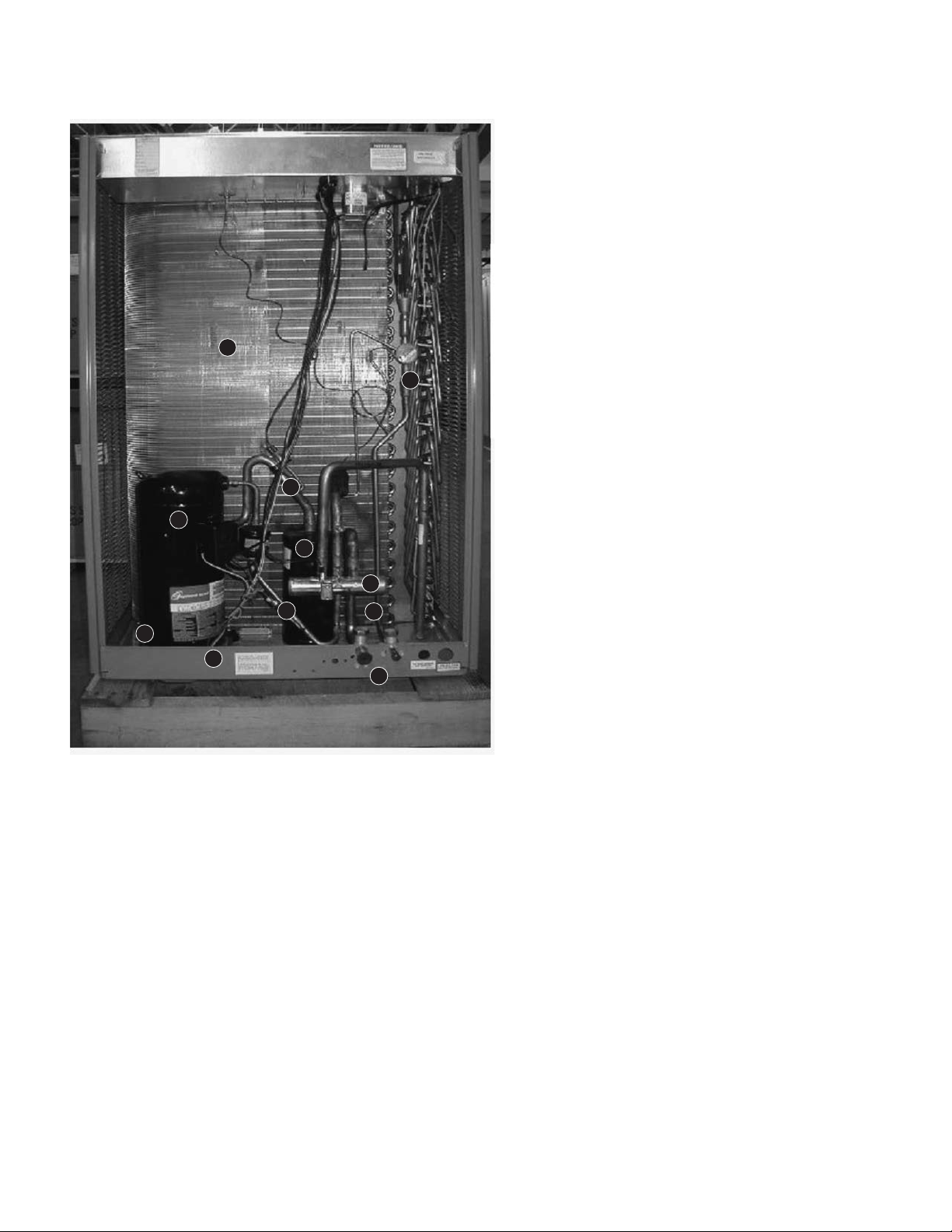

8. COIL—Constructed with copper tubes and aluminum fins mechan -

ically bonded to tubes for maximum heat transfer capabilities. All coil

assemblies are leak tested up to 550 PSIG (3792 kPa) internal

pressure.

SERVICE ACCESS—Control box with separate line and control

voltages, as well as compressor and other refrigerant controls are

accessible through access panels. An electrical access cover may

be opened or removed without affecting normal operation of the unit.

Condenser fan motors are equipped with molded plugs for easy

removal. Louver panels and end access panel can be removed for

coil cleaning.

9. BASE PAN—Galvanized steel with powder coat paint finish.

10. COMPRESSOR—The Scroll Compressor is hermetically sealed with

internal high temperature protection, and durable insulation on motor

windings. The entire compressor is mounted on rubber grommets

top reduce vibration and noise.

11. TX VALVE—Used when unit is in heating mode and outdoor coil

functions as evaporator.

12. CRANKCASE HEATER—Minimizes refrigerant migration to com pres sor cump.

13. SUCTION LINE ACCUMULATOR—To prevent liquid slugginig of

compressor.

14. REFRIGERANT CONNECTIONS—All field sweat joints are made

external of the unit and are located close to the ground for a neat

looking installation.

15. SERVICE VALVES—Standard on liquid line and vapor line.

16. REVERSING VALVE—Sized for maximum capacity and efficiency,

24V coil, energized in heating.

12

16

7

15

9

14

3

STANDARD UNIT FEATURES

2

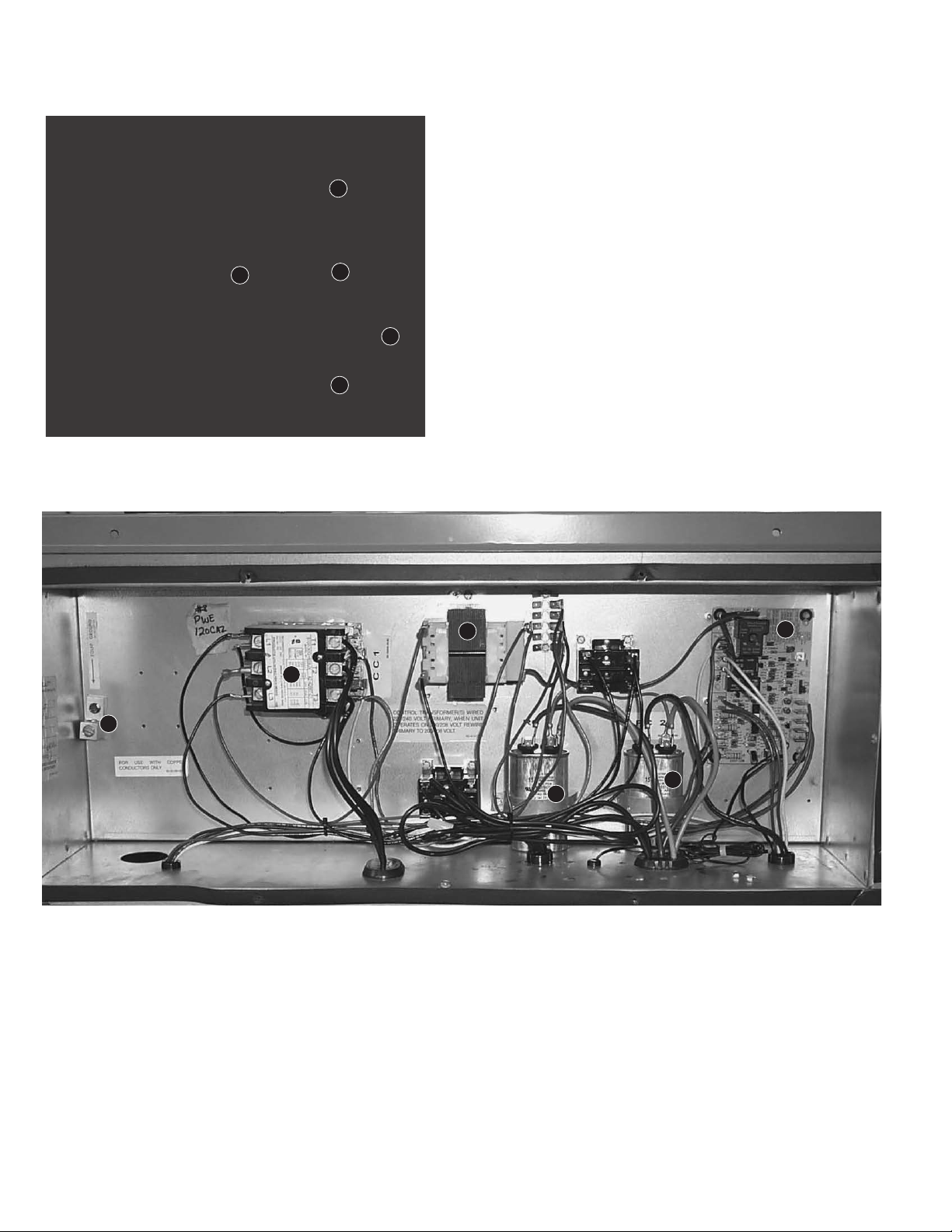

CONTROL BOX

10 TON FEATURES & BENEFITS

1. BASE RAILS—Commercial grade base rails for handling

9

9

8

1

any rigging.

2. CABINET—Galvanized steel with powder coat paint

finish. The powder coat paint finish is high gloss, durable

and capable of withstanding a 1000-hour salt spray test

per ASTM B 117. All access panels can be opened or

removed without affecting the structural strength of the

unit. Stamped louvered panels offer 100% protection for

the condenser coil.

4

3

3. EQUIPMENT GROUND—Lug for field connection of ground wire.

4. CONTACTOR—The contactor is an electrical switch which oper-

ates the compressor and outdoor fans. Its 24 volt coil is activated

on a call for cooling or heating.

5. TRANSFORMER—75 VA step-down type, from Line to 24 volts

with resetable circuit breaker.

6. CAPACITORS—Help provide starting torque necessary to boost

the condenser fan motors to operating speed by directing their

stored energy to the starter winding in step with the running

winding.

5

7

6

6

7. DEMAND DEFROST CONTROL—Used when unit is in heating

mode to defrost outdoor coil.

8. COILS—Constructed with copper tubes and aluminum fins

mechanically bonded to tubes for maximum heat transfer capabilities.

All coil assemblies are leak tested up to 550 PSIG [3792 kPa] internal

pressure.

4

LOW AMBIENT CONTROL—A pressure sensitive fan cycling control

allows cooling operation of unit down to 0°F [-18°C].

STANDARD UNIT FEATURES (cont.) – 10 TON FEATURES & BENEFITS

UNIT INTERIOR-TOP VIEW

9

9. SERVICE ACCESS—Control box with separate line and control

voltages, as well as compressor and other refrigerant controls are

accessible through access panels. An electrical access cover may

be opened or removed without affecting normal operation of the

unit. Condenser fan motors are equipped with molded plugs for

easy removal. Louver panels and end access panel can be

removed for coil cleaning.

10. BASE PAN—Galvanized steel with powder coat paint finish.

11. COMPRESSOR—The Scroll Compressor is hermetically sealed

with internal high temperature protection, and durable insulation on

motor windings. The entire compressor is mounted on rubber

grommets to reduce vibration and noise.

12. TX VALVE—Used when unit is in heating mode and outdoor coil

functions as evaporator.

13. FILTER DRIER—Field installed in liquid line.

14. CRANKCASE HEATER—Minimizes refrigerant migration to com-

pressor sump.

15. REVERSING VALVE—Sized for maximum capacity and efficiency,

24V coil, energized in heating.

19

16

17

15

12

13

16

8

12

11

10

14

9

8

16. AUTO-RESET HIGH PRESSURE CONTROL, AND AUTO-RESET

LOW PRESSURE CONTROL—To provide compressor protection

under abnormally high head pressure conditions (outdoor fan failure,

restriction, dirty coil, etc.) or abnormally low suction pressure cond i tions (restrictions, TEV failure, loss of charge, indoor blower failure,

etc.) while eliminating nuisance tripping sometimes experienced with

conventional control systems.

17. SUCTION LINE ACCUMULATOR—To prevent liquid slugging of

compressor.

18. REFRIGERANT CONNECTIONS—All field sweat joints are made

external of the unit and are located close to the ground for a neat

looking installation.

19. SERVICE VALVE—Standard on liquid line, and vapor line.

5

5

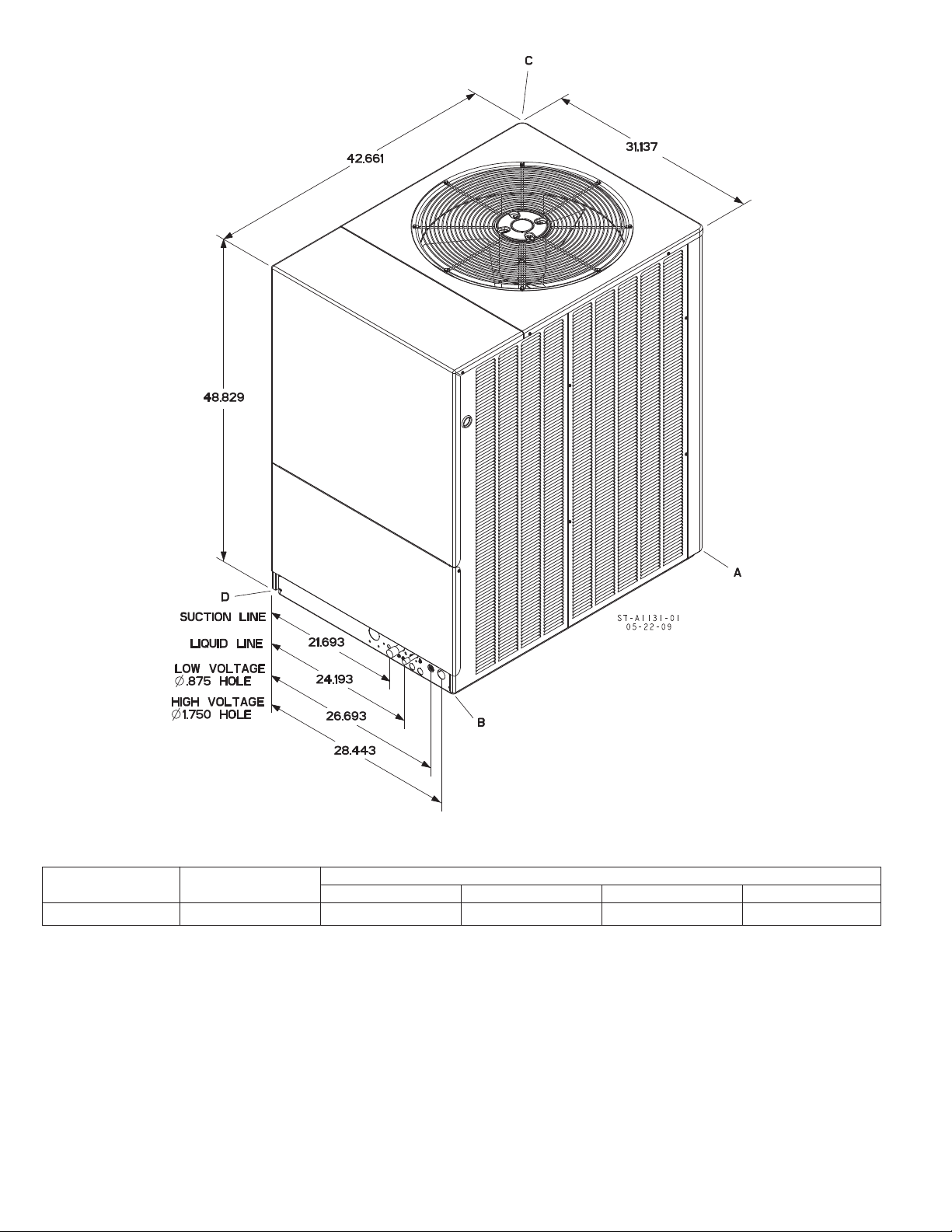

UNIT DIMENSIONS & WEIGHTS

7.5 TON

7.5 TON [26.38 kW]

CORNER WEIGHTS (LBS.) [kg]

MODEL

RPWL-090 398 [180.5] 67 [30.4] 102 [46.3] 92 [41.7] 137 [62.1]

6

TOTAL WEIGHT

LBS. [KG]

ABCD

Corner Weights, Lbs. [kg]

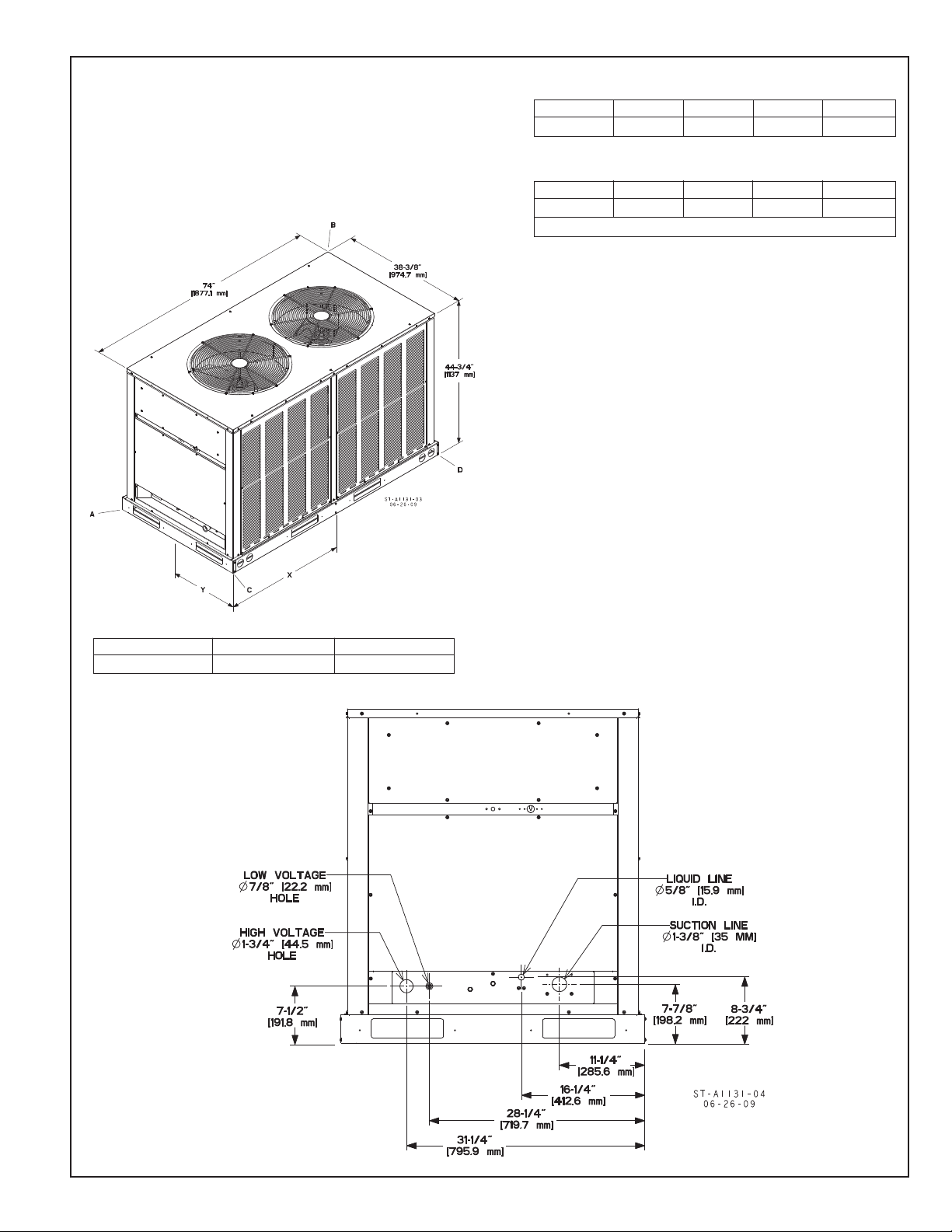

UNIT DIMENSIONS & WEIGHTS

10 TON

FIGURE 2

UNIT DIMENSIONS

CORNER WEIGHTS (PERCENTAGE)

MODEL ABCD

RPWL-120 26% 24% 26% 24%

CORNER WEIGHTS (LBS.) [kg]

MODEL ABCD

RPWL-120 167 [75.7] 160 [72.6] 160 [72.6] 167 [75.7]

TOTAL WEIGHT, 120 = 654 LBS. [296.6 kg]

MODEL X” Y”

RPWL-120 31.2 18.9

7

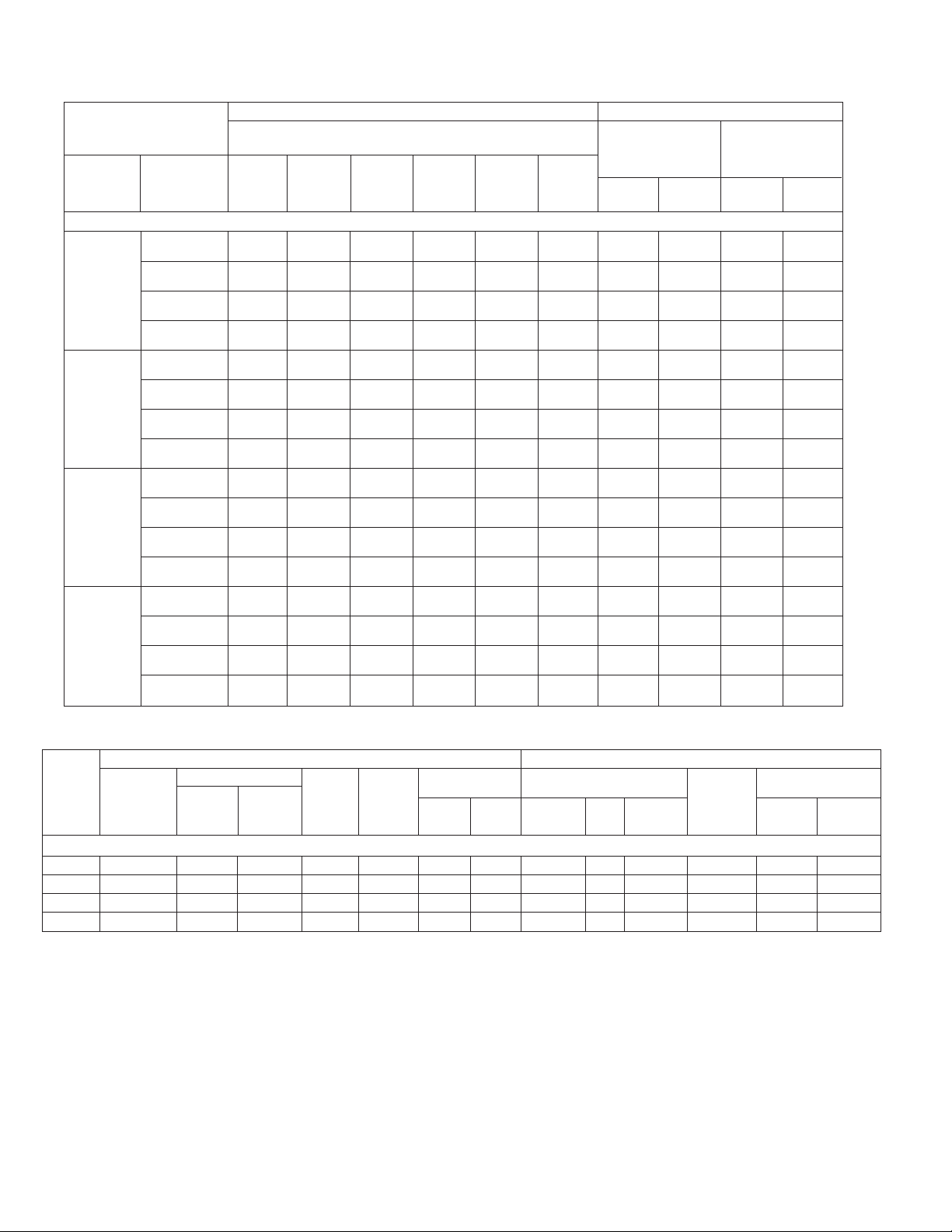

Performance Data @ ARI Standard Conditions

Note: Only these combinations of indoor/outdoor units are approved and any other combination should not be used.

ARI Cooling Performance ARI Heating Performance (70°F [21°C] Indoor)

Model Numbers

Outdoor

Unit

RPWL-

Revised 6/3/2009

090CAZ RHGM-090Z# 86000 67400 18600 11 82 3000 90000 3.3 55000 2.2

090DAZ RHGM-090Z # 86000 67400 18600 11 82 3000 90000 3.3 55000 2.2

120CAZ RHGM-120Z # 116000 87100 28900 11 88 3750 120000 3.3 68000 2.2

120DAZ RHGM-120Z # 116000 87100 28900 11 88 3750 120000 3.3 68000 2.2

Indoor

Coil and/or

Air Handler

RHGM-090ZK 86000 67400 18600 11 82 3000 90000 3.3 55000 2.2

RHGM-090ZL 86000 67400 18600 11 82 3000 90000 3.3 55000 2.2

RHGM-090ZM 86000 67400 18600 11 82 3000 90000 3.3 55000 2.2

RHGM-090ZK 86000 67400 18600 11 82 3000 90000 3.3 55000 2.2

RHGM-090ZL 86000 67400 18600 11 82 3000 90000 3.3 55000 2.2

RHGM-090ZM 86000 67400 18600 11 82 3000 90000 3.3 55000 2.2

RHGM-120ZK 116000 87100 28900 11 88 3750 120000 3.3 68000 2.2

RHGM-120ZL 116000 87100 28900 11 88 3750 120000 3.3 68000 2.2

RHGM-120ZM 116000 87100 28900 11 88 3750 120000 3.3 68000 2.2

RHGM-120ZK 116000 87100 28900 11 88 3750 120000 3.3 68000 2.2

RHGM-120ZL 116000 87100 28900 11 88 3750 120000 3.3 68000 2.2

RHGM-120ZM 116000 87100 28900 11 88 3750 120000 3.3 68000 2.2

Total

Capacity

BTU/H

[kW]

[25.2] [19.7] [5.4] [1416] [26.4] [16.1]

[25.2] [19.7] [5.4] [1416] [26.4] [16.1]

[25.2] [19.7] [5.4] [1416] [26.4] [16.1]

[25.2] [19.7] [5.4] [1416] [26.4] [16.1]

[25.2] [19.7] [5.4] [1416] [26.4] [16.1]

[25.2] [19.7] [5.4] [1416] [26.4] [16.1]

[25.2] [19.7] [5.4] [1416] [26.4] [16.1]

[25.2] [19.7] [5.4] [1416] [26.4] [16.1]

[34.0] [25.5] [8.5] [1770] [35.2] [19.9]

[34.0] [25.5] [8.5] [1770] [35.2] [19.9]

[34.0] [25.5] [8.5] [1770] [35.2] [19.9]

[34.0] [25.5] [8.5] [1770] [35.2] [19.9]

[34.0] [25.5] [8.5] [1770] [35.2] [19.9]

[34.0] [25.5] [8.5] [1770] [35.2] [19.9]

[34.0] [25.5] [8.5] [1770] [35.2] [19.9]

[34.0] [25.5] [8.5] [1770] [35.2] [19.9]

80°F [26.5°C] DB / 67°F [19.5°C] WB Indoor Air

Sensible

95°F [35°C] DB Outdoor Air

Net

BTU/H

[kW]

Net

Latent

BTU/H

[kW]

EER

Sound

Rating

dB

Indoor

CFM

[L/s]

Outdoor Air

47°F [8.5°C] DB

43°F [6°C] WB

DOE High Temp.

BTU/H

[kW]

COP

Outdoor Air

17°F [8-.5°C] DB

15°F [-9.5°C] WB

DOE Low Temp.

BTU/H

[kW]

COP

Electrical and Physical Data

Electrical

Model

Number

RPWL-

Rev. 6/3/2009

090CAZ 3-60-208/230 25/25 190 4.2 36/36 45/45 60/60 34.5 [3.21] 2 5000 [2360] 372 [10546] 398 [180.5] 448 [203.2]

090DAZ 3-60-460 12.8 100 2.3 19 25 30 34.5 [3.21] 2 5000 [2360] 372 [10546] 398 [180.5] 448 [203.2]

120CAZ 3-60-208/230 30.1/30.1 225 4.8 43/43 50/50 70/70 32.88 [3.05] 2 7400 [3492] 436 [12361] 646 [293] 686 [311.2]

120DAZ 3-60-460 16.7 114 2.2 24 30 35 32.88 [3.05] 2 7400 [3492] 436 [12361] 646 [293] 686 [311.2]

Phase

Frequency

(Hz)

Voltage

(Volts)

Compressor

Rated Load

Amperes

(RLA)

Locked Rotor

Amperes

(LRA)

Fan Motor

Full Load

Amperes

(FLA)

Minimum

Circuit

Ampacity

Amperes

Fuse or HACR

Circuit Breaker

Minimum

Amperes

Maximum

Amperes

Face Area

Sq. Ft. [m

Outdoor Coil Weight

No.

2

]

Rows

CFM

[L/s]

Physical

Refrig.

Circuit

Oz. [g]

Per

Net

Lbs. [kg]

Shipping

Lbs. [kg]

8

Loading...

Loading...