Rheem RLNL-G Installation Manual

INSTALLATION INSTRUCTIONS

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION!

!

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

WARNING

!

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT AND OPERATION OF THIS

UNIT. READ THESE INSTRUCTIONS THOROUGHLY BEFORE

ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN IMPROPER

INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE

POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

ISO 9001:2008

FOR PACKAGE AIR CONDITIONERS FEATURING NEW

INDUSTRY STANDARD R410A REFRIGERANT

WITH CLEAR CONTROL

RLNL-G SERIES 15, 20 & 25 TON [52.8, 70.3, 87.9 kW]

60 HZ MODELS (COMPLIES WITH ASHRAE 90.1-2007)

25 TON IS OUTSIDE THE SCOPE OF

ARI STANDARD 340/360

[ ] INDICATES METRIC CONVERSIONS

92-23577-126-00

I. TABLE OF CONTENTS

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Checking Product Received. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Equipment Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Major Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

R-410A Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

General Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-10

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pre-Installation Check Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Outside Slab Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Rooftop Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cover Panel Installation/Conversion Procedure . . . . . . . . . . . . . . . . . . . . . 16

Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Internal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Thermostat/Humidity Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Indoor Air Flow Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Crankcase Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Airflow Performance Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-21

Pre-Start Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cooling Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Heating Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

HumidiDry™ System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Humidity Sensory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Refrigerant Solenoid Valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Variable Frequency Drive (VFD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

VFD Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Outdoor Fan Motor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Auxiliary Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Heater Kit Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26-27

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29-30

Charge Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-33

2

!

▲WARNING

PROPOSITION 65: THIS APPLIANCE

CONTAINS FIBERGLASS INSULATION. RESPIRABLE PARTICLES OF

FIBERGLASS ARE KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE

CANCER.

II. INTRODUCTION

This booklet contains the installation and operating instructions for your air conditioner. There are a few precautions that should be taken to derive maximum satisfaction

from it. Improper installation can result in unsatisfactory operation or dangerous conditions.

Read this booklet and any instructions packaged with separate equipment required to

make up the system prior to installation. Give this booklet to the owner and explain its

provisions. The owner should retain this booklet for future reference.

!

▲WARNING

THE MANUFACTURER’S WARRANTY

DOES NOT COVER ANY DAMAGE OR

DEFECT TO THE AIR CONDITIONER

CAUSED BY THE ATTACHMENT OR

USE OF ANY COMPONENTS, ACCESSORIES OR DEVICES (OTHER THAN

THOSE AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION WITH THE AIR CONDITIONER. YOU SHOULD BE AWARE

THAT THE USE OF UNAUTHORIZED

COMPONENTS, ACCESSORIES OR

DEVICES MAY ADVERSELY AFFECT

THE OPERATION OF THE AIR CONDITIONER AND MAY ALSO ENDANGER

LIFE AND PROPERTY. THE MANUFACTURER DISCLAIMS ANY RESPONSIBILITY FOR SUCH LOSS OR INJURY

RESULTING FROM THE USE OF SUCH

UNAUTHORIZED COMPONENTS,

ACCESSORIES OR DEVICES.

!

▲WARNING

DISCONNECT ALL POWER TO THE

UNIT BEFORE STARTING MAINTENANCE. FAILURE TO DO SO CAN

RESULT IN SEVERE ELECTRICAL

SHOCK OR DEATH.

III. CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for any damage from shipment. Claims for damage,

either shipping or concealed, should be filed immediately with the shipping company.

Check the unit model number, heating size, electrical characteristics, and accessories

to determine if they are correct.

IV. EQUIPMENT PROTECTION FROM THE

ENVIRONMENT

The metal parts of this unit may be subject to rust or deterioration in adverse environmental conditions. This oxidation could shorten the equipment’s useful life. Salt spray,

fog or mist in seacoast areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such as paper mills and petroleum refineries are especially corrosive.

If the unit is to be installed in an area where contaminants are likely to be a problem, special attention should be given to the equipment location and exposure.

1. Avoid having lawn sprinkler heads spray direction on the unit cabinet.

2. In coastal areas, locate the unit on the side of the building away from the waterfront.

3. Shielding provided by a fence or shrubs may give some protection.

Regular maintenance will reduce the buildup of contaminants and help to protect the unit’s finish.

1. Frequent washing of the cabinet, fan blade and coil with fresh water will remove

most of the salt or other contaminants that build up on the unit.

2. Regular cleaning and waxing of the cabinet with a good automobile polish will provide some protection.

3. A good liquid cleaner may be used several times a year to remove matter that will

not wash off with water.

Several different types of protective coatings are offered in some areas. These coatings may provide some benefit, but the effectiveness of such coating materials cannot

be verified by the equipment manufacturer.

The best protection is frequent cleaning, maintenance and minimal exposure to

contaminants.

V. SPECIFICATIONS

A. GENERAL

The Packaged Air Conditioner is available without heat or with 20, 40, 60 or 75 kW

electric heat. Cooling capacities of 15, 20, and 25 nominal tons of cooling are available. Units are convertible from bottom supply and return to horizontal supply and

return by relocation of supply and return air access panels. See cover installation

detail.

The units are weatherized for mounting outside of the building.

The information on the rating plate is in compliance with the FTC and DOE rating for

single phase units. The following information is for three phase units which are not

covered under the DOE certification program.

1. The efficiency rating of this unit is a product thermal efficiency rating determined

under continuous operating conditions independent of any installed system.

3

B. MAJOR COMPONENTS

The unit includes a hermetically-sealed refrigerating system (consisting of compressors, condenser coil, evaporator coil with thermal expansion valves, micro-channel

reheat coil, solenoid valves), circulation air blower, condenser fans, variable frequency drive (VFD) outdoor fan motor controller (OFMC) and all necessary internal electrical wiring. The cooling system of these units is factory-evacuated, charged and

performance tested. Refrigerant amount and type are indicated on rating plate.

C. R-410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22

must accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than

R-22. Recovery and recycle equipment, pumps, hoses and the like need to have

design pressure ratings appropriate for R-410A. Manifold sets need to range up to 800

psig high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to

have a service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig

service pressure rating. DOT 4BA400 or DOT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safe-

ly with nitrogen or a mixture of R-410A and nitrogen.

2. Quick Reference Guide For R-410A

• R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than

R-22. Ensure that servicing equipment is designed to operate with R-410A.

• R-410A refrigerant cylinders are pink.

• R-410A, as with other HFC’s is only compatible with POE oils.

• Vacuum pumps will not remove moisture from POE oil.

• R-410A systems are to be charged with liquid refrigerants. Prior to March 1999, R410A refrigerant cylinders had a dip tube. These cylinders should be kept upright

for equipment charging. Post March 1999 cylinders do not have a dip tube and

should be inverted to ensure liquid charging of the equipment.

• Do not install a suction line filter drier in the liquid line.

• A liquid line filter drier is standard on every unit.

• Desiccant (drying agent) must be compatible for POE oils and R-410A.

; equipment designs

!

▲CAUTION

R-410A systems operate at higher pressures than R-22 systems. Do not use R22 service equipment or components on

R-410A equipment.

4

3. Evaporator Coil / TXV

The thermostatic expansion valve is specifically designed to operate with R-410A. DO

NOT use an R-22 TXV. The existing evaporator must be replaced with the factory

specified TXV evaporator specifically designed for R-410A.

4. Tools Required For Installing & Servicing R-410A Models

Manifold Sets:

-Up to 800 PSIG High side

-Up to 250 PSIG Low Side

-550 PSIG Low Side Retard

Manifold Hoses:

-Service Pressure Rating of 800 PSIG

Recovery Cylinders:

-400 PSIG Pressure Rating

-Dept. of Transportation 4BA400 or BW400

CONTROL

ACCESS

BLOWER

ACCESS

HEATER

ACCESS

RETURN

AIR

SUPPLY

AIR

CONDENSER COIL

(RIGHT SIDE)

ALTERNATE

ELECTRICAL ENTRY

(LOW VOLTAGE)

ELECTRICAL ENTRY

(POWER)

C

O

N

D

E

N

S

E

R

C

O

I

L

SUPPLY AIR

RETURN

AIR

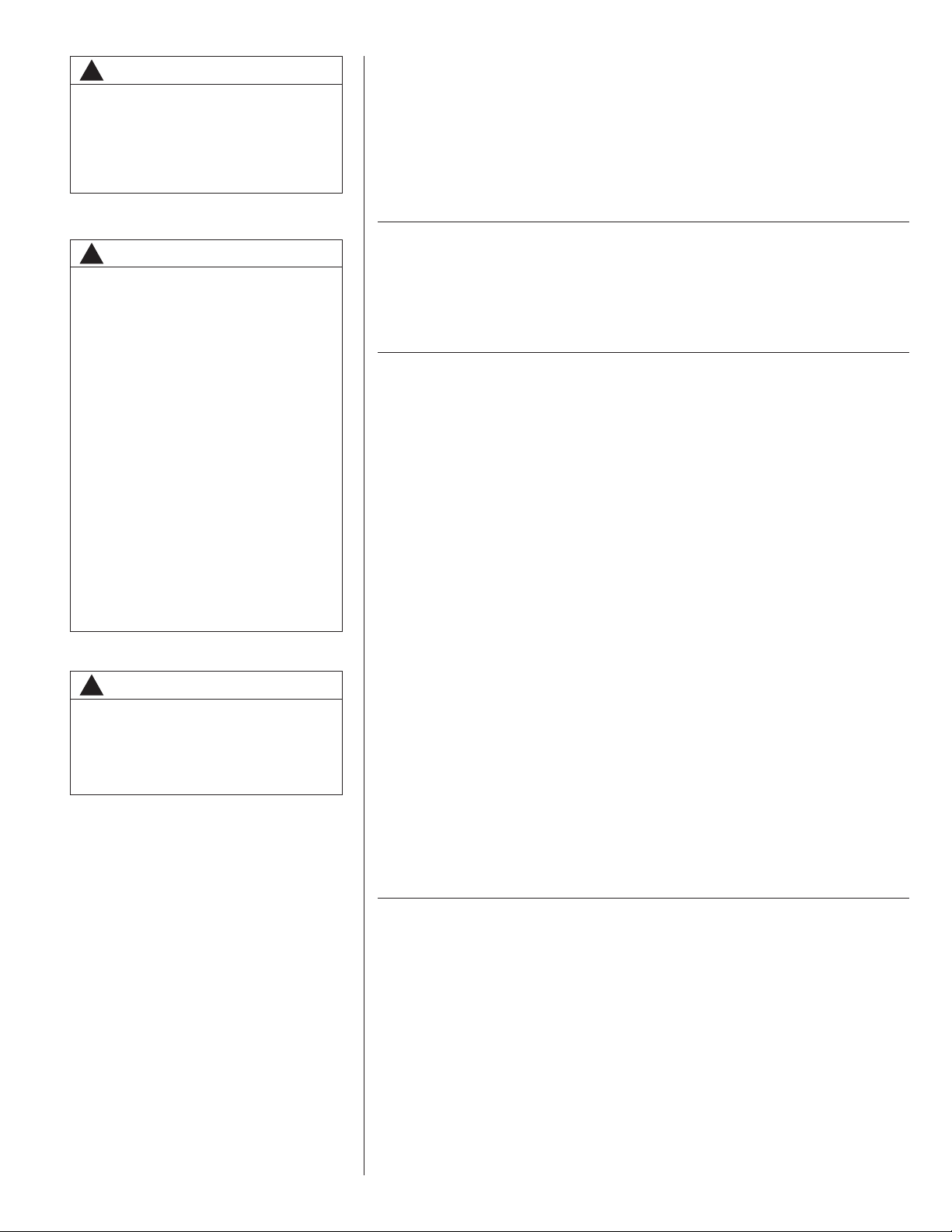

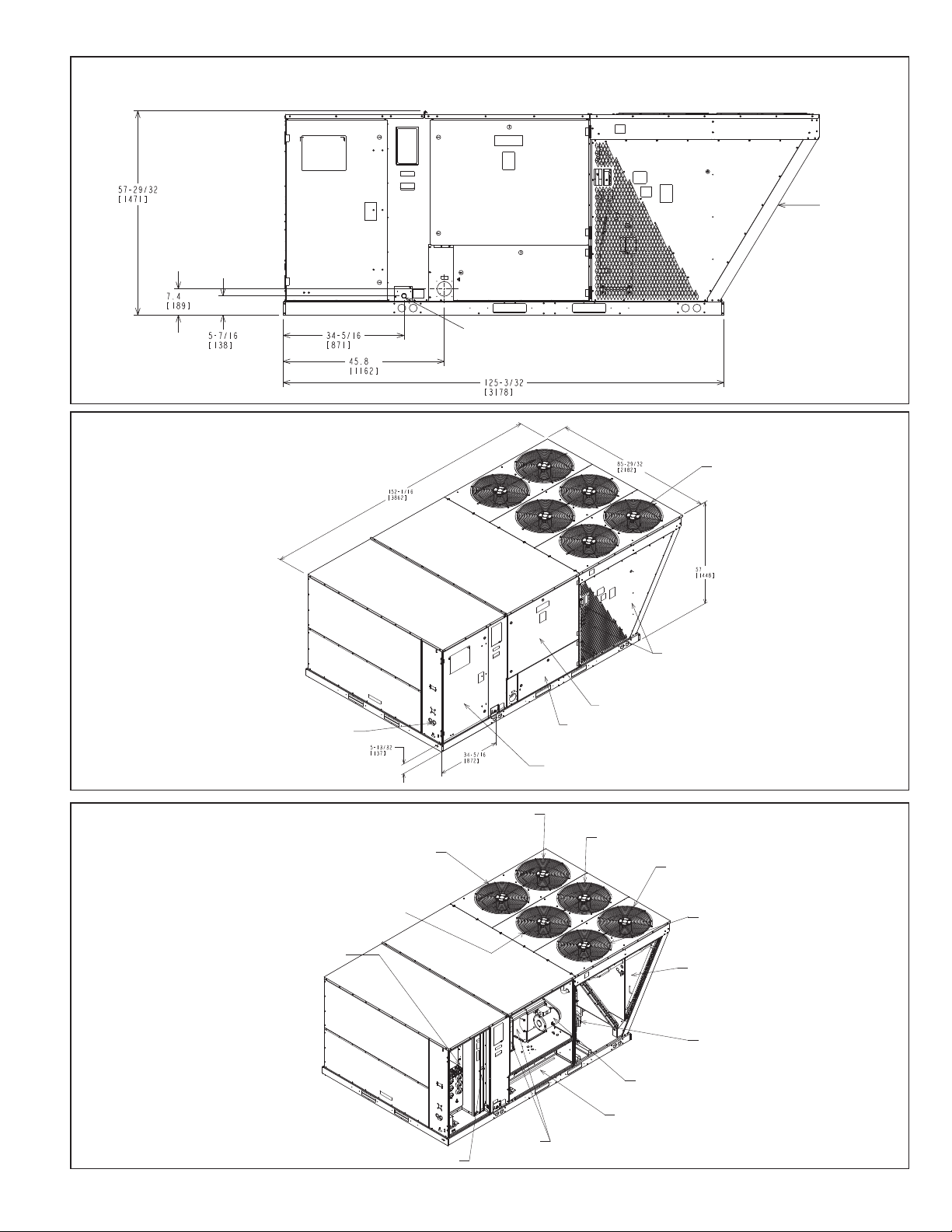

FIGURE 1

UNIT DIMENSIONS (BOTTOM VIEW)

FIGURE 2

UNIT DIMENSIONS (BOTTOM VIEW)

(FRONT SIDE)

Typical Dimensions Shown

in Inches (± .125)

ST-A1125-02B

(RIGHT

SIDE)

Typical Dimensions Shown

in Inches (± .125 tolerance)

ST-A1125-09B

5

SUPPLY COVER

REMOVE COVER PLATE WHEN

CONVERTING FROM DOWNFLOW

TO HORIZONTAL CONFIGURATION.

RETURN COVER

COMPRESSOR ACCESS

RETURN

AIR

SUPPLY AIR

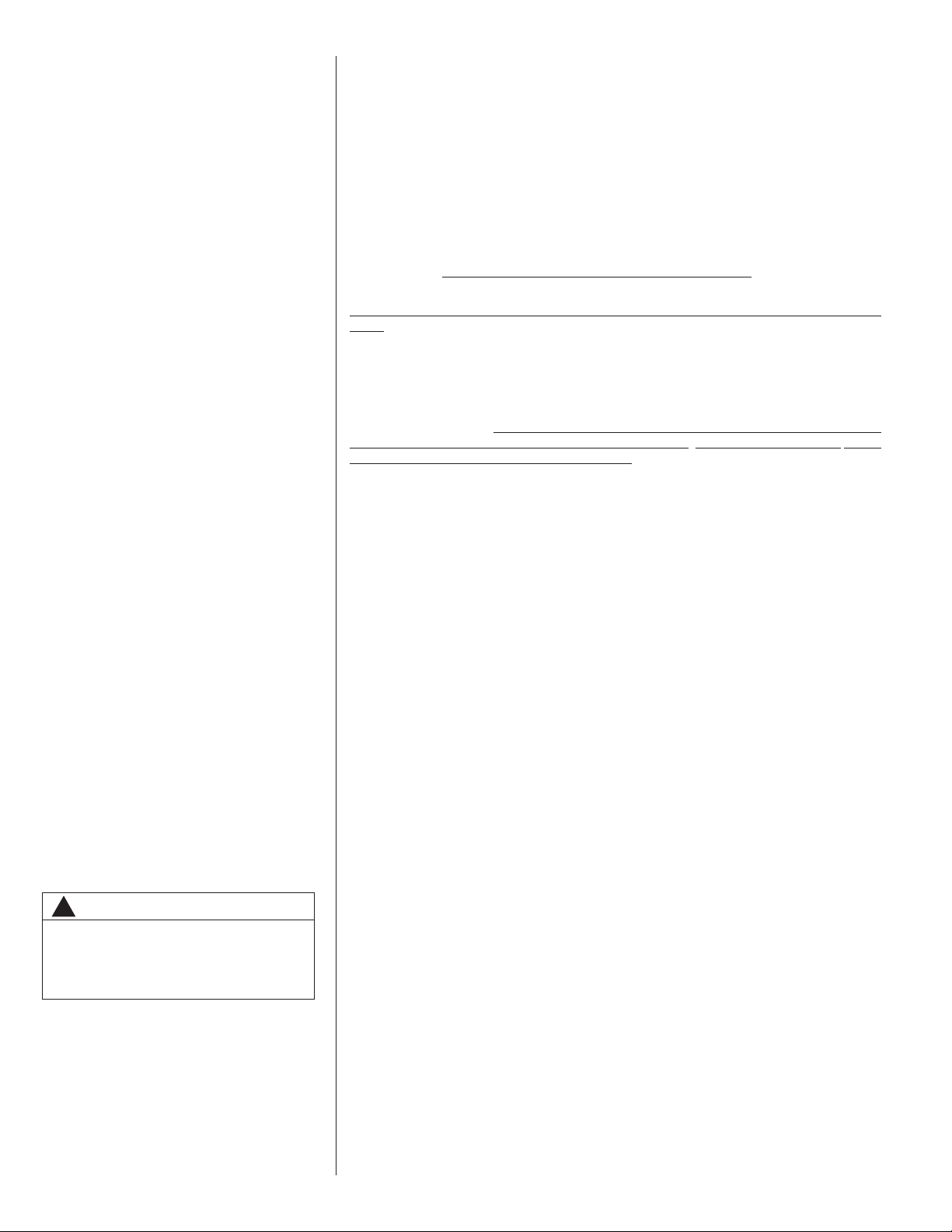

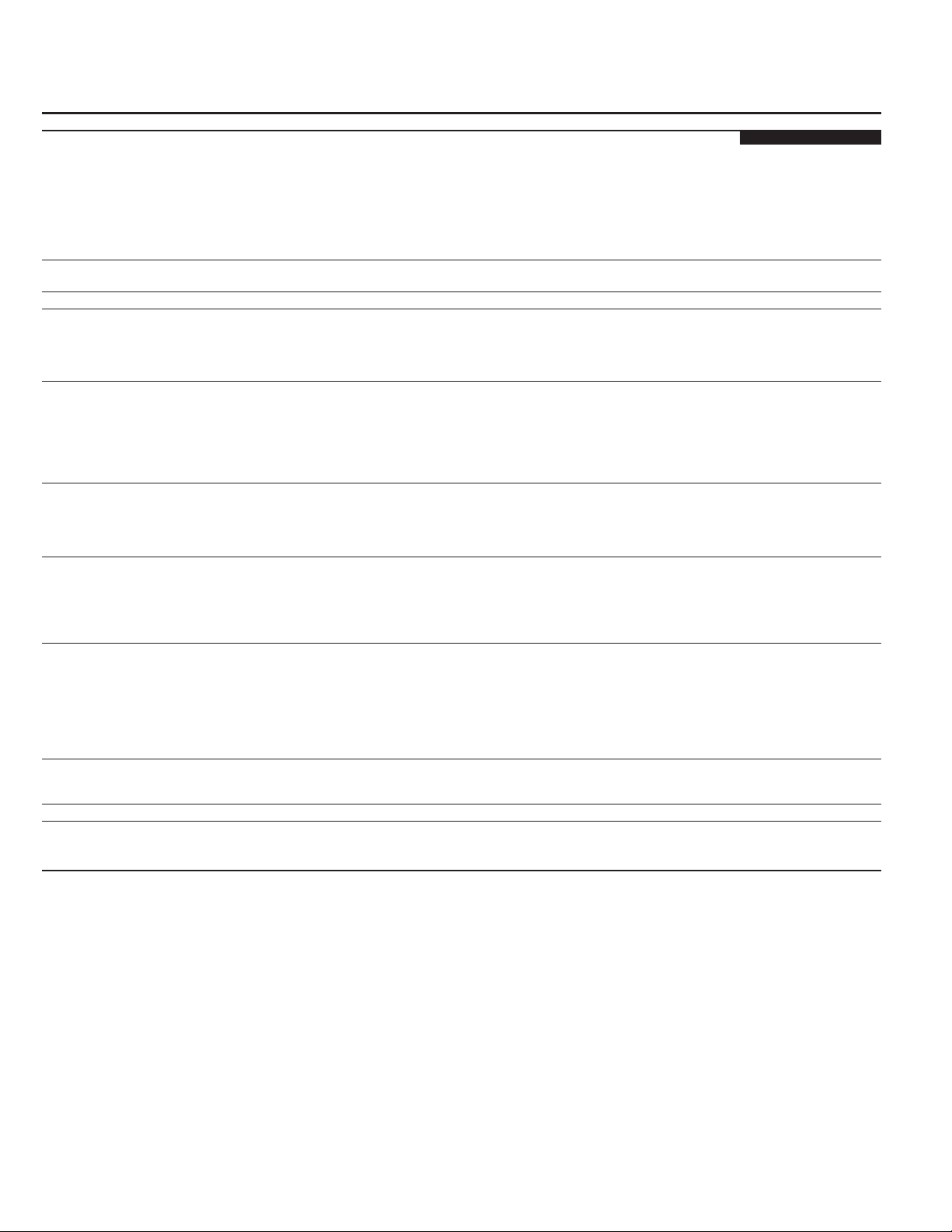

FIGURE 3

OUTDOOR FAN #2

2

OUTDOOR FAN #1

1

3

OUTDOOR FAN #3

6

5

4

OUTDOOR FAN #5

OUTDOOR FAN #4

OUTDOOR FAN #6

OUTDOOR COIL

SUPPLY AIR

FILTER RACK

RETURN COMPARTMENT

COMPRESSOR #2

UNIT DIMENSIONS

FIGURE 4

UNIT DIMENSIONS

REAR VIEW

ST-A1125-03

FIGURE 5

COMPONENT LOCATION

CONDENSER COIL

(RIGHT SIDE)

ST-A1125-08B

6

ST-A1125-05

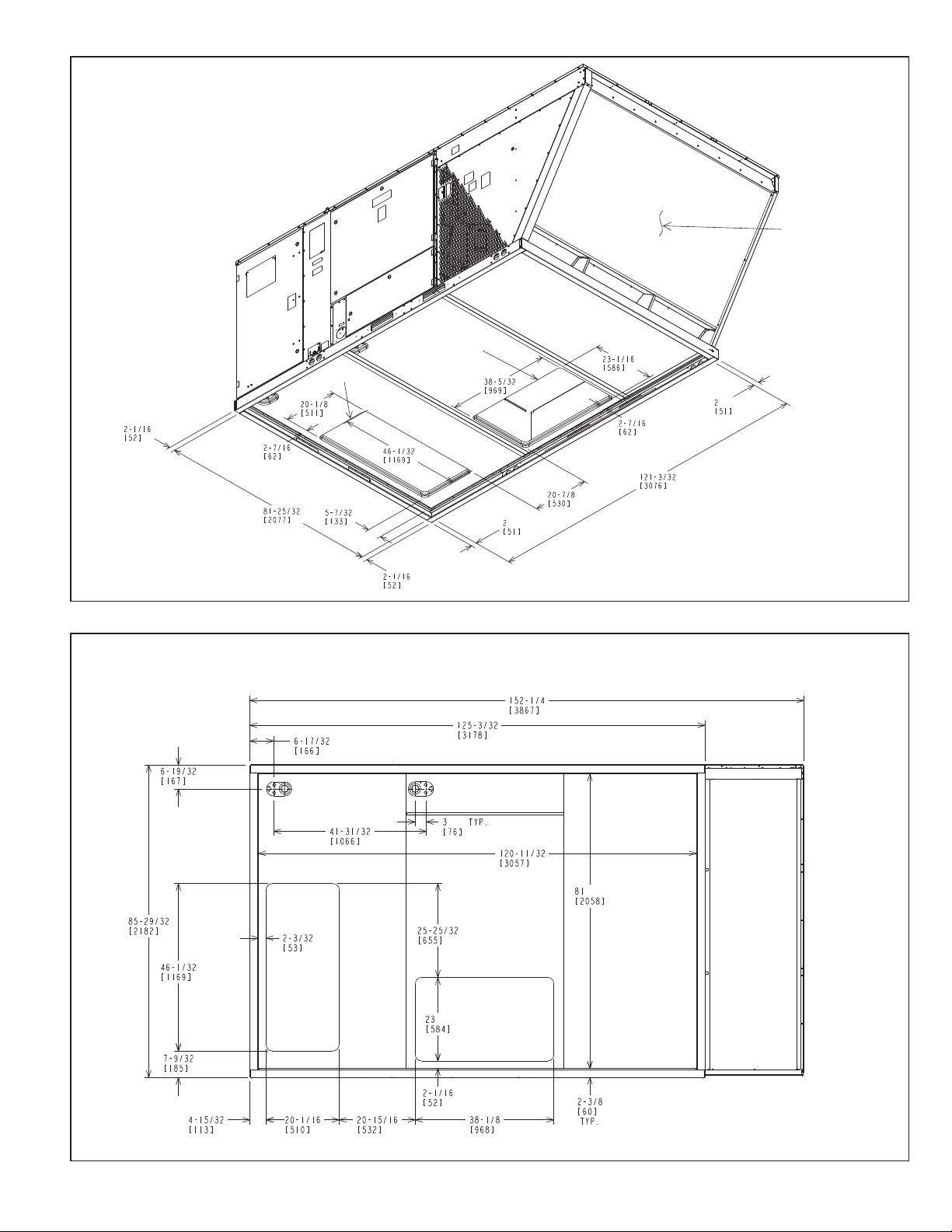

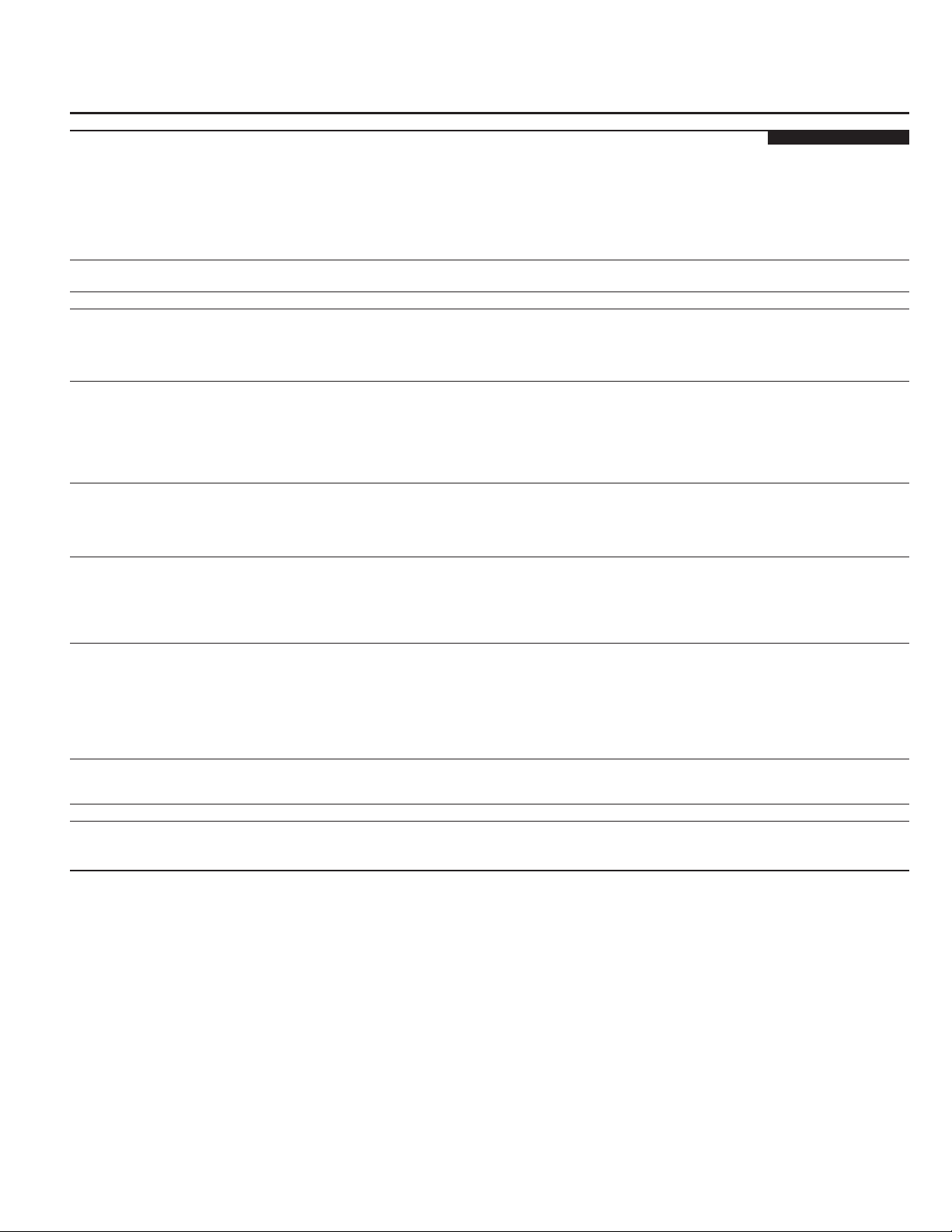

Control Box

&

Filter Access

Blower Access

Electric Heat Access

Compressor Access

(Both Sides)

Condenser

Coil

(Right Side)

Condensate Drain 1” FNPT

FIGURE 6

CONTROL/FILTER

ACCESS

CONTROL POWER ENTRY

ELECTRIC HEAT ACCESS

BLOWER ACCESS

COMPRESSOR ACCESS

OUTDOOR

FANS

1

2

3

4

5

6

OUTDOOR FAN #4

OUTDOOR FAN #1

OUTDOOR FAN #5

OUTDOOR FAN #6

OUTDOOR FAN #3

OUTDOOR FAN #2

CONTROL COMPARTMENT

FILTER OPENING

BLOWERS

ELECTRIC HEAT COMPARTMENT

CONDENSER COIL

ASSEMBLY

INDOOR MOTOR

COMPRESSOR #1

UNIT DIMENSIONS & COMPONENT ACCESS

FIGURE 7

UNIT DIMENSIONS & COMPONENT ACCESS

(FRONT SIDE)

Condenser Fan

Discharge Air

ST-A1125-06B

FIGURE 8

INTERNAL COMPONENT LOCATIONS

ST-A1125-01B

ST-A1125-04B

7

GENERAL DATA - RLNL

Model RLNL- Series G180CR G180CS G180DR G180DS

Cooling Performance

Gross Cooling Capacity Btu [kW] 188,000 [55.08] 188,000 [55.08] 188,000 [55.08] 188,000 [55.08]

EER, SEER

1

2

11.1/NA 11.1/NA 11.1/NA 11.1/NA

Continued ->

Nominal CFM/AHRI Rated CFM [L/s] 6000/5900 [2831/2784] 6000/5900 [2831/2784] 6000/5900 [2831/2784] 6000/5900 [2831/2784]

AHRI Net Cooling Capacity Btu [kW] 182,000 [53.33] 182,000 [53.33] 182,000 [53.33] 182,000 [53.33]

Net Sensible Capacity Btu [kW] 135,700 [39.76] 135,700 [39.76] 135,700 [39.76] 135,700 [39.76]

Net Latent Capacity Btu [kW] 46,300 [13.57] 46,300 [13.57] 46,300 [13.57] 46,300 [13.57]

3

(Standard / VFD) 14.6 14.6 14.6 14.6

IEER

Net System Power kW 16.35 16.35 16.35 16.35

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 53.3 [4.95] 53.3 [4.95] 53.3 [4.95] 53.3 [4.95]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 26.67 [2.48] 26.67 [2.48] 26.67 [2.48] 26.67 [2.48]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Re-Heat Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type MicroChannel MicroChannel MicroChannel MicroChannel

MicroChannel Depth in. [mm] 0.709 [18] 0.709 [18] 0.709 [18] 0.709 [18]

Face Area sq. ft. [sq. m] 19.9 [1.85] 19.9 [1.85] 19.9 [1.85] 19.9 [1.85]

Rows / FPI [FPcm] 1 / 23 [9] 1 / 23 [9] 1 / 23 [9] 1 / 23 [9]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457x229] 2/18x9 [457x229] 2/18x9 [457x229] 2/18x9 [457x229]

Drive Type Belt (Adjustable) Belt (Adjustable) Belt (Adjustable) Belt (Adjustable)

No. Speeds (Standard / VFD) Multiple Multiple Multiple Multiple

No. Motors 1111

Motor HP 3535

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 184 56 184

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 299/211 [8477/5982] 299/211 [8477/5982] 299/211 [8477/5982] 299/211 [8477/5982]

Weights

Net Weight lbs. [kg] 1906 [865] 1935 [878] 1906 [865] 1935 [878]

Ship Weight lbs. [kg] 2032 [922] 2061 [935] 2032 [922] 2061 [935]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. AHRI capacity is net and includes

the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment certification program, which is

based on AHRI Standard 210/240 or 360.

2. EER and/or SEER are rated at AHRI conditions and in accordance with DOE test procedures.

3. Integrated Energy Efficiency Ratio (IEER) is rated in accordance with AHRI Standard 210/240 or 340/360.

4. Not applicable to these units.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270. 25 Ton Model is outside the scope of AHRI Standard 340/360.

8

GENERAL DATA - RLNL

Model RLNL- Series G240CR G240CS G240DR G240DS

Cooling Performance

Gross Cooling Capacity Btu [kW] 244,000 [71.49] 244,000 [71.49] 244,000 [71.49] 244,000 [71.49]

EER, SEER

1

2

11.1/NA 11.1/NA 11.1/NA 11.1/NA

Continued ->

Nominal CFM/AHRI Rated CFM [L/s] 8000/7725 [3775/3645] 8000/7725 [3775/3645] 8000/7725 [3775/3645] 8000/7725 [3775/3645]

AHRI Net Cooling Capacity Btu [kW] 234,000 [68.56] 234,000 [68.56]] 234,000 [68.56]] 234,000 [68.56]

Net Sensible Capacity Btu [kW] 171,600 [50.28] 171,600 [50.28] 171,600 [50.28] 171,600 [50.28]

Net Latent Capacity Btu [kW] 62,400 [18.28] 62,400 [18.28] 62,400 [18.28] 62,400 [18.28]

3

(Standard / VFD) 14.8 14.8 14.8 14.8

IEER

Net System Power kW 21.04 21.04 21.04 21.04

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 53.3 [4.95] 53.3 [4.95] 53.3 [4.95] 53.3 [4.95]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 26.67 [2.48] 26.67 [2.48] 26.67 [2.48] 26.67 [2.48]

Rows / FPI [FPcm] 3 / 13 [7] 3 / 13 [7] 3 / 13 [7] 3 / 13 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Re-Heat Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type MicroChannel MicroChannel MicroChannel MicroChannel

MicroChannel Depth in. [mm] 0.709 [18] 0.709 [18] 0.709 [18] 0.709 [18]

Face Area sq. ft. [sq. m] 19.9 [1.85] 19.9 [1.85] 19.9 [1.85] 19.9 [1.85]

Rows / FPI [FPcm] 1 / 23 [9] 1 / 23 [9] 1 / 23 [9] 1 / 23 [9]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 6/24 [609.6] 6/24 [609.6] 6/24 [609.6] 6/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 19800 [9344] 19800 [9344] 19800 [9344] 19800 [9344]

No. Motors/HP 6 at 1/3 HP 6 at 1/3 HP 6 at 1/3 HP 6 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457x229] 2/18x9 [457x229] 2/18x9 [457x229] 2/18x9 [457x229]

Drive Type Belt (Adjustable) Belt (Adjustable) Belt (Adjustable) Belt (Adjustable)

No. Speeds (Standard / VFD) Multiple Multiple Multiple Multiple

No. Motors 1111

Motor HP 5 7 1/2 5 7 1/2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 184 213 184 184

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 430/331 [1219/9384] 430/331 [1219/9384] 430/331 [1219/9384] 430/331 [1219/9384]

Weights

Net Weight lbs. [kg] 2231 [1012] 2269 [1029] 2231 [1012] 2269 [1029]

Ship Weight lbs. [kg] 2357 [1069] 2395 [1086] 2357 [1069] 2395 [1086]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. AHRI capacity is net and includes

the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment certification program, which is

based on AHRI Standard 210/240 or 360.

2. EER and/or SEER are rated at AHRI conditions and in accordance with DOE test procedures.

3. Integrated Energy Efficiency Ratio (IEER) is rated in accordance with AHRI Standard 210/240 or 340/360.

4. Not applicable to these units.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270. 25 Ton Model is outside the scope of AHRI Standard 340/360.

9

GENERAL DATA - RLNL

Model RLNL- Series G300CR G300CS G300DR G300DS

Cooling Performance

Gross Cooling Capacity Btu [kW] 304,000 [89.07] 304,000 [89.07] 304,000 [89.07] 304,000 [89.07]

EER, SEER

1

2

10/NA 10/NA 10/NA 10/NA

Nominal CFM/AHRI Rated CFM [L/s] 10000/9575 [4719/4518] 10000/9575 [4719/4518] 10000/9575 [4719/4518] 10000/9575 [4719/4518]

AHRI Net Cooling Capacity Btu [kW] 288,000 [84.38] 288,000 [84.38] 288,000 [84.38] 288,000 [84.38]

Net Sensible Capacity Btu [kW] 210,000 [61.53] 210,000 [61.53] 210,000 [61.53] 210,000 [61.53]

Net Latent Capacity Btu [kW] 78,000 [22.85] 78,000 [22.85] 78,000 [22.85] 78,000 [22.85]

3

(Standard / VFD) 14.1 14.1 14.1 14.1

IEER

Net System Power kW 26.87 26.87 26.87 26.87

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 53.3 [4.95] 53.3 [4.95] 53.3 [4.95] 53.3 [4.95]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 26.67 [2.48] 26.67 [2.48] 26.67 [2.48] 26.67 [2.48]

Rows / FPI [FPcm] 4 / 15 [6] 4 / 15 [6] 4 / 15 [6] 4 / 15 [6]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Re-Heat Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type MicroChannel MicroChannel MicroChannel MicroChannel

MicroChannel Depth in. [mm] 0.709 [18] 0.709 [18] 0.709 [18] 0.709 [18]

Face Area sq. ft. [sq. m] 19.9 [1.85] 19.9 [1.85] 19.9 [1.85] 19.9 [1.85]

Rows / FPI [FPcm] 1 / 23 [9] 1 / 23 [9] 1 / 23 [9] 1 / 23 [9]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 6/24 [609.6] 6/24 [609.6] 6/24 [609.6] 6/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 19800 [9344] 19800 [9344] 19800 [9344] 19800 [9344]

No. Motors/HP 6 at 1/3 HP 6 at 1/3 HP 6 at 1/3 HP 6 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457x229] 2/18x9 [457x229] 2/18x9 [457x229] 2/18x9 [457x229]

Drive Type Belt (Adjustable) Belt (Adjustable) Belt (Adjustable) Belt (Adjustable)

No. Speeds (Standard / VFD) Multiple Multiple Multiple Multiple

No. Motors 1111

Motor HP 7 1/2 10 7 1/2 10

Motor RPM 1725 1725 1725 1725

Motor Frame Size 213 215 213 215

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508] (8)2x25x20 [51x635x508]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 464/357 [13154/10121] 464/357 [13154/10121] 464/357 [13154/10121] 464/357 [13154/10121]

Weights

Net Weight lbs. [kg] 2330 [1057] 2341 [1062] 2330 [1057] 2341 [1062]

Ship Weight lbs. [kg] 2456 [1114] 2467 [1119] 2456 [1114] 2467 [1119]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. AHRI capacity is net and includes

the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner Equipment certification program, which is

based on AHRI Standard 210/240 or 360.

2. EER and/or SEER are rated at AHRI conditions and in accordance with DOE test procedures.

3. Integrated Energy Efficiency Ratio (IEER) is rated in accordance with AHRI Standard 210/240 or 340/360.

4. Not applicable to these units.

5. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270. 25 Ton Model is outside the scope of AHRI Standard 340/360.

10

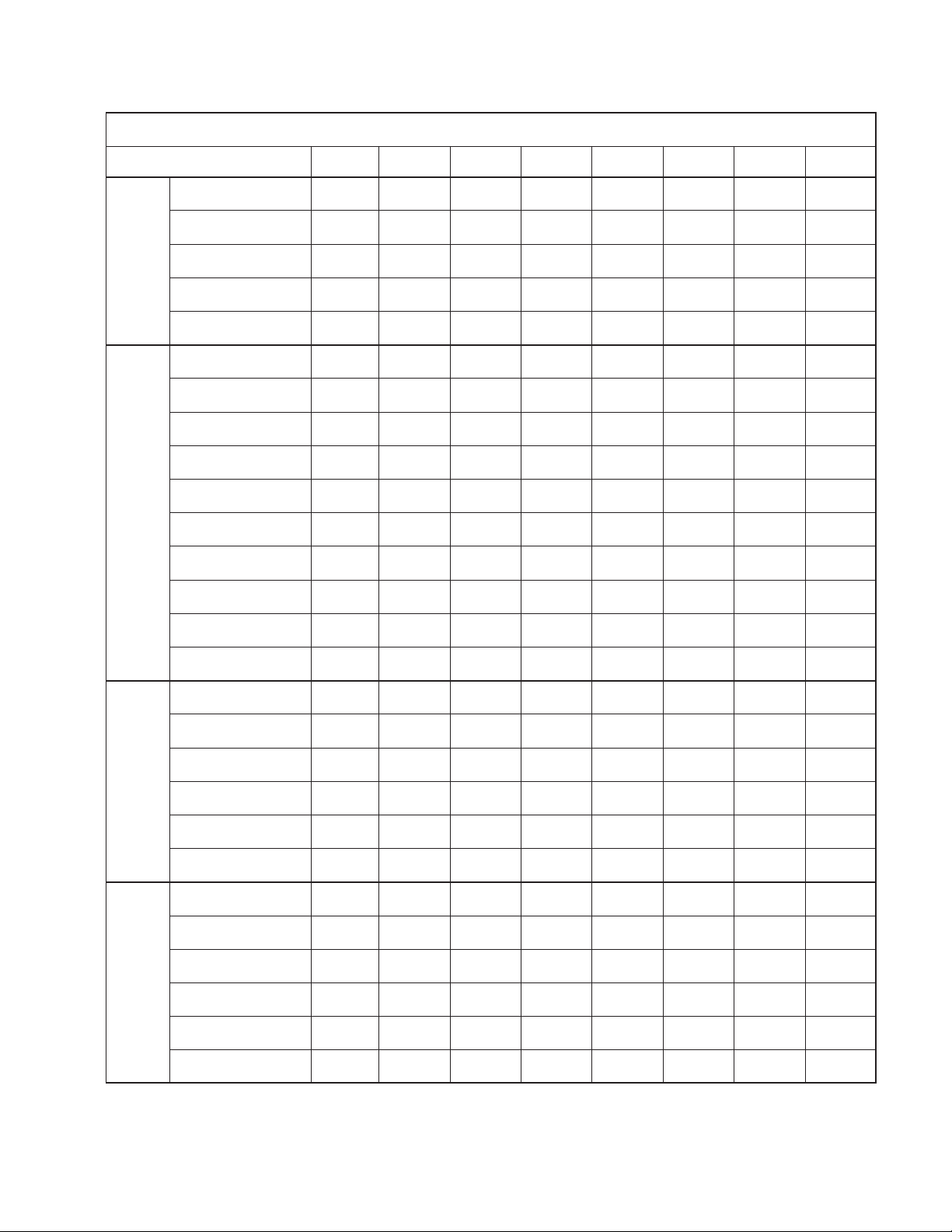

ELECTRICAL DATA - RLNL

G180CR G180CS G180DR G180DS G240CR G240CS G240DR G240DS

Unit Operating Voltage

Range

187-253 187-253 414-506 414-506 187-253 187-253 414-506 414-506

ELECTRICAL DATA - RLNL SERIES

Minimum Circuit

Ampacity

Minimum Overcurrent

Protection Device Size

Unit Information

Maximum Overcurrent

Protection Device Size

HP, Compressor 1

Amps (RLA), Comp. 1

Compressor Motor

Amps (LRA), Comp. 1

HP, Compressor 2

Amps (RLA), Comp. 2

Amps (LRA), Comp. 2

Volts

No.

Volts

Phase

RPM

208/230 208/230 460 460 208/230 208/230 460 460

78/78 81/81 38 40 101/101 109/109 52 56

90/90 90/90 45 45 110/110 125/125 60 60

100/100 100/100 45 50 125/125 125/125 60 70

22 2 2 2 2 22

200/230 200/230 460 460 200/230 200/230 460 460

33 3 3 3 3 33

3450 3450 3450 3450 3450 3450 3450 3450

77 7 710 10 10 10

25/25 25/25 12.2 12.2 33.3/33.3 33.3/33.3 17.9 17.9

164/164 164/164 100 100 239/239 239/239 125 125

77 7 77 1/2 7 1/2 7 1/2 7 1/2

25/25 25/25 12.2 12.2 29.5/29.5 29.5/29.5 14.7 14.7

164/164 164/164 100 100 195/195 195/195 95 95

Condenser Motor

Evaporator Fan

No.

Volts

Phase

HP

Amps (FLA, each)

Amps (LRA, each)

No.

Volts

Phase

HP

Amps (FLA, each)

Amps (LRA, each)

44 4 4 6 6 66

208/230 208/230 460 460 208/230 208/230 460 460

11 1 1 1 1 11

1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3

2.4/2.4 2.4/2.4 1.4 1.4 2.4/2.4 2.4/2.4 1.4 1.4

4.7/4.7 4.7./4.7 2.4 2.4 4.7/4.7 4.7/4.7 2.4 2.4

11 1 1 1 1 11

208/230 208/230 460 460 208/230 208/230 460 460

33 3 3 3 3 33

35 3 5 57 1/2 5 7 1/2

11.5/11.5 14.9/14.9 4.6 6.6 14.7/14.7 23.1/23.1 6.6 9.6

74.5/74.5 82.6/82.6 38.1 46.3 82.6/82.6 136/136 46.3 67

11

Loading...

Loading...