Reznor ZQYRA-8 Parts List

IMPORTANT

1. Always include complete model and serial

number so that any specication change can

be considered for parts shipment. It can save

time and expense.

2. Specications are subject to change without

notice.

3. We reserve the right to substitute functional

replacements.

4. Order by Part No.; not Option Designation.

Form P-ZQYRA (6-16)

Obsoletes Form P-ZQYRA (5-17-16)

Applies to: Replacement Parts for

Z Series Model ZQYRA

Ventilation Unit

A

Accumulator 7

B

BacNet® Card 3

Belt 6

Wheel Belt 5

Blower Assembly 6

C

Cabinet Parts 8

Cable for Controller 3

Cable Splitter and Signal Booster 4

Charge Compensator 7

Check Valve 7

CO2 Sensor 4

Condenser Coil 7

Evaporator Coil 7

Compressor 7

Compressor Digital Controller 3

Connection Cable 4

Contactor 3

Digital Controller 3

Corner Post 8

Cover 8

Crankcase Heater 7

D

Damper 5

Discharge Air Temperature Sen-

sor 4

Disconnect Switch 5

Display 3

Remote Unit Display 4

Distribution Block 3

Door 8

Drain Cover 8

Duct Angle Support 8

E

Electric Heat 5

Electric Heating Element 3

Electric Module Support 5

Exhaust Fan 6

F

Fan Support 6

Fan Support Bracket 6

Filter Drier 7

Filters 8

Fuse 3

Fuse Clip 3

H

Heat Module 5

Exhaust Hood 8

Inlet Air Hood 8

I

Inlet Ring 6

L

Lifting Lug 8

LON® Communication Card 3

M

Damper Motor 5

Wheel Motor 5

Compressor Mounting Kit 7

O

Occupancy Switch 4

Overload Relay 3

P

Panel 8

Molded Plug 7

Dirty Filter Pressure Switch 3

High Pressure Switch 7

Low Pressure Switch 7

R

Rating Plate 2

Relay 3

Relay Module 3

Reversing Valve 7

Roof Curb 8

S

Humidity and Temperature Sensor 4

Indoor Air Quality (VOC and CO)

Sensor 4

Temperature Sensor 3

Serial No. 2

Shaft Extension 5

Sheave 6

Socket 3

Start/Stop Switch 4

Supply Fan 6

Air Proving Switch 3

T

Temperature Sensor 3

Terminal Block Kit for Controller 3

Terminal Bracket 3

Thermistor 7

Thermostatic Expansion Valve 7

Time Clock Wall Switch 4

Transformer 3

W

Enthalpy Wheel

Cassette 5

Wheel Segment 5

Wheel Supports 5

DANGER

This unit contains R-410A high pressure refrigerant. Hazards exist that could result

in personal injury or death. Installation, maintenance, and service should only be

performed by an HVAC technician qualied in R-410A refrigerant and using proper tools

and equipment. Due to much higher pressure of R-410A refrigerant, DO NOT USE service

equipment or tools designed for R22 refrigerant.

IMPORTANT: Do not release refrigerant to the atmosphere! If required service

procedures include the adding or removing of refrigerant, the service technician

must comply with all federal, state, and local laws. Service should only be performed

by a qualied HVAC technician.

Form P-ZQYRA (6-16), PN262961R10, Page 1

Rating Plate and Serial No.

Example of a Rating Plate

MERCER, PA. USA 16137

MADE IN MEXICO

FOR INDUSTRIAL/COMMERCIAL USE ONLY

SUITABLE FOR INDOOR OR OUTDOOR USE

MODEL [ A ] [ B ]

SERIAL NO. [ ]

[ C ] VOLTS [ C ] PH [ C ] HZ

MINIMUM CIRCUIT AMPACITY (MCA) [ V } AMPS

MAXIMUM FUSE SIZE/*CIRCUIT BREAKER (MOP) [ W } AMPS

MINIMUM CIRCUIT AMPACITY (MCA) [ D } AMPS

MAXIMUM FUSE SIZE/*CIRCUIT BREAKER (MOP) [ E } AMPS

SHORT-CIRCUIT CURRENT: 5,000 RMS SYMMETRICAL, [ C ] V MAXIMUM

QTY FLA WATTS

SUPPLY AIR BLOWER MOTOR 1 [ F ] [ G ]

QTY FLA [ U ]

EXHAUST AIR BLOWER MOTOR 1 [ H ] [ J ]

QTY FLA HP

ENTHALPY WHEEL MOTOR 1 [ K ] [ L ]

QTY RLA (EA) LRA (EA)

COMPRESSOR 1 [ M ] [ N ]

REFRIGERANT - R410A CHARGE - [ P ] LBS

TEST PRESSURES: HIGH 600 PSIG; LOW 45 PSIG

EQUIPPED FOR OPERATION AT SUPPLY AIR FLOW RANGE OF [ Q ] SCFM

AGAINST A STATIC PRESSURE RANGE OF [ R ] INCHES WATER COLUMN

WIRE DIAGRAM [ S ]

ELECTRIC HEAT [ T ] kW (if equipped)

*HACR TYPE REQUIRED PER NEC

Rating Plate Key

A = Model

B = Manufacture Date (month and year)

C = Volts/PH/HZ

D = Minimum Circuit Ampacity

E = Maximum Fuse Amps

F = Full Load Amps (supply air blower motor)

G = Watts (supply air blower motor)

H = Full Load Amps (exhaust air blower motor)

J = Watts or HP (exhaust air blower motor) - See U below.

K = Full Load Amps (enthalpy wheel motor)

L = HP (enthalpy wheel motor)

M = Rated Load Amps (compressor)

N = Locked Rotor Amps (compressor)

P = Refrigerant Charge (lbs of R410-A)

Q = Airow (SCFM)

R = Static Pressure (inches w.c.)

S = Wiring Diagram P/N

T = kW (electric heat)

U = Watts or HP Spec of J for Exhaust Blower Motor

(by option code) = A23 - HP; A24 - Watts

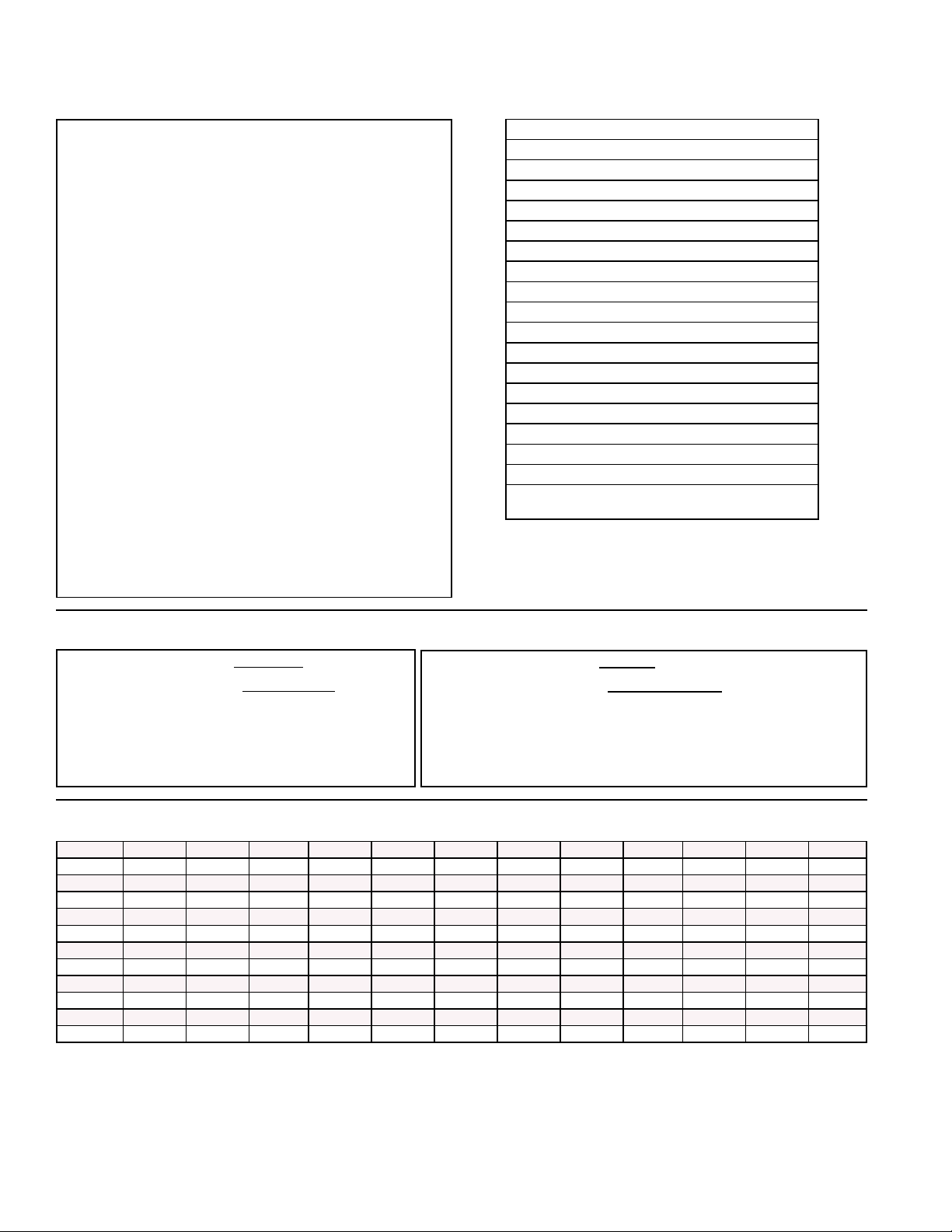

Decoding a Serial No.

Serial No. - ALL Models BEFORE June, 2015

Sample: BLL 00000 X

Elements: 1 | 2 | 3

Key:

1 = Date of Manufacture (See table below)

2 = Consecutive number

3 = Plant of Manufacture (X = Monterrey)

Serial No. - ALL Models AFTER June, 2015

Sample: BOF 3060 000000

Elements: 1 | 2 | 3

Key:

1 = Date of Manufacture (See table below)

2 = Plant of Manufacture (3060 = Mercer; 3062 = Monterrey)

3 = Consecutive number

Date of Manufacture Code in the Serial No.

Year Jan Feb Mar Apr May June July Aug Sept Oct Nov Dec

2010 BJA BJB BJC BJD BJE BJF BJG BJH BJI BJJ BJK BJL

2011 BKA BKB BKC BKD BKE BKF BKG BKH BKI BKJ BKK BKL

2012 BLA BLB BLC BLD BLE BLF BLG BLH BLI BLJ BLK BLL

2013 BMA BMB BMC BMD BME BMF BMG BMH BMI BMJ BMK BML

2014 BNA BNB BNC BND BNE BNF BNG BNH BNI BNJ BNK BNL

2015 BOA BOB BOC BOD BOE BOF BOG BOH BOI BOJ BOK BOL

2016 B PA BPB BPC BPD BPE BPF BPG BPH BPI BPJ BPK BPL

2017 BQA BQB BQC BQD BQE BQF BQG BQH BQI BQJ BQK BQL

2018 BRA BRB BRC BRD BRE BRF BRG BRH BRI BRJ BRK BRL

2019 BSA BSB BSC BSD BSE BSF BSG BSH BSI BSJ BSK BSL

2020 B TA BTB BTC BTD BTE BTF BTG BTH BTI BTJ BTK BTL

Form P-ZQYRA (616), PN262961R10, Page 2

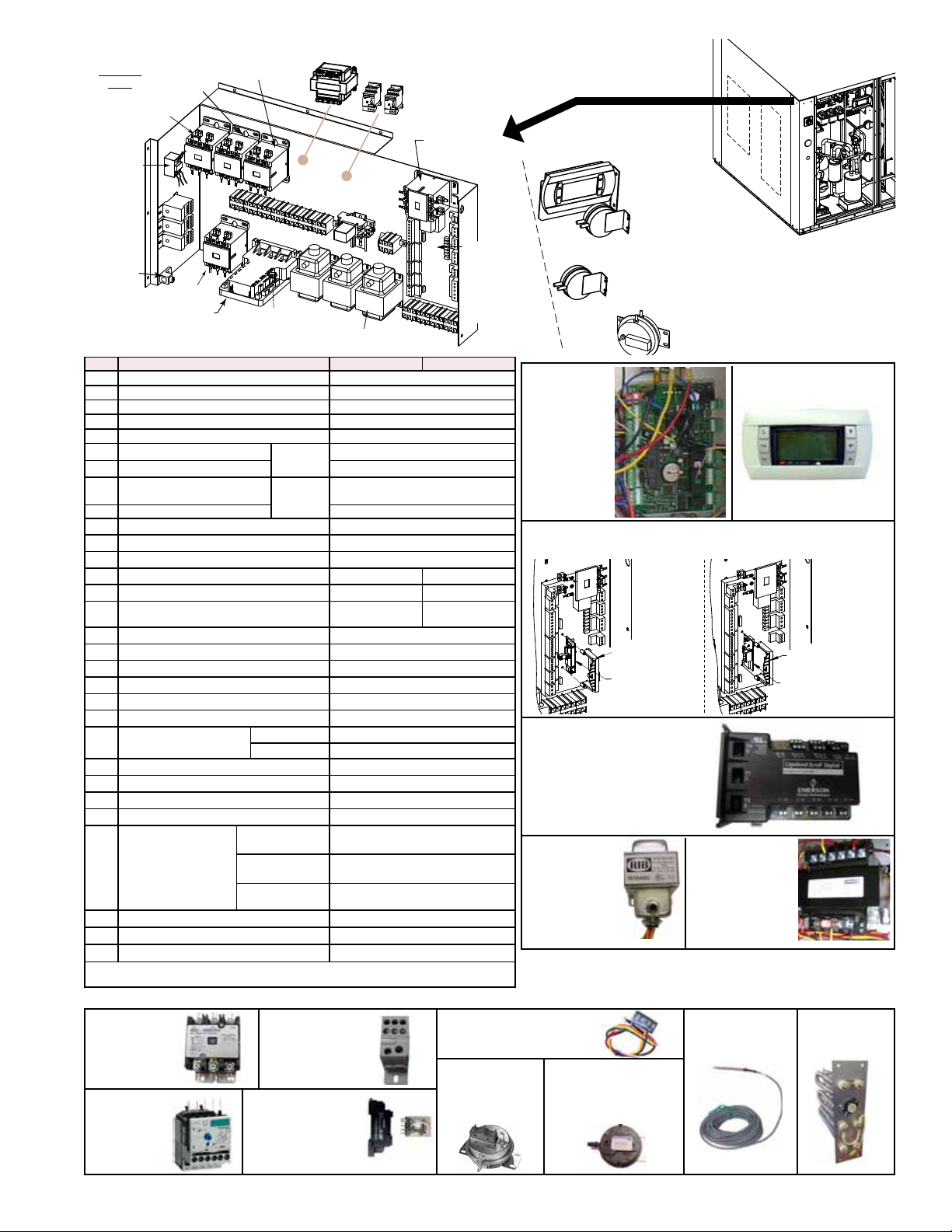

21 - Option

BE18

Dirty Filter

Switch

22 - Air Proving

Switch (exhaust),

P/N 197031 set

at 0.35” w.c.

22 - Air Proving Switch (supply),

P/N 197031 set at 0.35” w.c.

14 - Contactor (electric

preheat option)

14 - Contactor

(wheel)

15 - Contactor

(fans)

20 - Multi

Voltage

Relay Module

(time

schedule

clock,

Opt CN7A)

16 -

Distribution

Blocks -

A, B, and C

14 - Contactor

(heat pump)

Grounding

Lug

10 - Digital Controller

(Compressor)

Control Transformer

(optional damper motor)

Control

Transformers

1 - Unit Controller

(NOTE: If unit has

Opt BHB8 BACnet®

card (6 & 7) or Opt

BHB7 LONworks®

card (8 & 9), it is

located on the

controller.)

Field Connection

Terminal Blocks

4 - Display

Module

5 - Bracket

Terminal Blocks

14 - Contactor

(supplemental

heating element)

19 - Relay

(damper motor)

Controls on either the side or

back wall of the Control

Compartment

11 - Resistor

12

12

12

Electrical

Panel

13 - Transformer (Size 8, 460V)

(13A - Fuse Clip & 13B Time Delay Fuse - Not Shown)

17 & 18 - Supply & Exhaust

Fan Overload Relays

(18A - Terminal Bracket - Not Shown)

Electrical Controls

Electrical Compartment

Controls on Top

with Compressor Below

Supply

Horizontal

Air Opening

Air Opening

Horizontal Return

Model ZQYRA

Code Description ZQYRA Size 8 Size 12

1 Digital Controller, Carel (programmed) 263663 (1010784 After 4, 2016)

2 Connection Cable for Controller 260175

3 Terminal Block Kit for Controller 260176 (260177 After 4, 2016)

4 Unit Display 267178

5 Display Bracket 269895

6 BacNet

7 Bracket for BacNet

8

9 Bracket for LON

®

Card (programmed)

®

Communication

LON

Card (programmed)

®

Card 262743

®

Card 262745

Option

BHB8

Option

262964

262963

BHB7

10 Compressor Digital Controller 266067

11 Digital Control Resistor, 560K ohms 268534

12 Transformer, 75 VA, 120/208-240/480 to 24 208989

13 Transformer, 200VA, 460/3/60 210862 --

13A Fuse Clip for 200VA transformer 257033 --

Time Delay Fuse for 200VA

13B

Transformer, 1/10-30a

259433 --

14 Contactor, 25 Amp, 24 vac coil (2) 216386

15 Contactor, 40 Amp, 24 vac Coil 216387

16 Distribution Block, 115 Amp 207641

17 Overload Relay, 4 amp 260181

18 Overload Relay, 12 amp 260182

18A Terminal Bracket (4) 260183

Relay (plug-in), 24vac,

19

DPDT and Socket

Relay P/N 211411

Socket P/N 211415

20 Multi-voltage Relay Module 260189

21 Dirty Filter Pressure Switch (Option BE18) 105507

22 Air Proving Switch, 0.35” w.c.(purple label) (2) 197031

23 Temp Sensor (on condenser coil header) * 269894

Electric Heating

24

Element

(in supply airstream) *

AK5

10kW@208V

AK6

10kW@230V

AK7

10kW@460V

272504

221687

221688

25 Bracket * for Element in Code 24 269982

26 Scr Power Control, Viconics #R820-443 220688 - (AK7)

27 Scr Power Control, Viconics #R820-343 234057 - (AK5 & AK6)

* On units manufactured beginning 12/12. If these parts are determined to be needed for defrost mode on

previously manufactured units, contact your distributor or Factory Service Depart. about a retrot procedure.

CODES

14 & 15-

Contactors

CODES

17 & 18 Overload

Relays

CODE 16 Distribution

Block

P/N 207641

CODE 19 Plugin Relay

& Socket

Relay P/N 211411

Socket P/N 211415

CODE 1 -

Digital

Controller

with software,

P/N 263663

(1010784

after 4, 2016)

CODES 6, 7, 8, & 9 - Optional Communication

Cards with Brackets on the Digital Controller

CODE 10 - Digital

Compressor

Controller, P/N 266067

CODE 11 - Resistor for

Digital Compressor

Controller, P/N 268534

CODE 12 -

75VA

Transformer,

P/N 208989

CODE 20 - MultiVoltage Relay

(used in Option CN7A)

CODE 21 -

Pressure

Switch

P/N 105507

CODE 22 Air Proving

Pressure Switch,

P/N 197031

CODE 4 - Display,

P/N 260178

CODE 5 - Bracket,

P/N 269895

Code 7 - Bracket

for BacNet® Card

Code 6 - BacNet®

Card, Option BHB8

Code 9 - Bracket

for LON® Card

Code 8 - LON®

Card, Option BHB7

CODE 13 -

200VA

Transformer,

P/N 210862

Fuse, P/N 259433

Clip, P/N 257033

CODE 23 Temp Sensor,

P/N 269894

Form P-ZQYRA (6-16), PN262961R10, Page 3

CODE 24 -

Heating

Element

Loading...

Loading...