Reznor YDHA060 Service Manual

Y

CQS

C

N

E

E

V

N

G

O

A

C

C

U

S

T

O

M

CQS

E

Q

R

U

A

P

L

I

R

T

Y

O

D

U

C

T

Form O-Y (4-16)

Obsoletes Form O-Y (11-15)

Operation / Maintenance / Service

Applies to: Models YDHA, YDMA, and YDSA

Packaged Rooftop Equipment

Model YDHA High Outside

Air (Conditioned

Ventilation)

P

R

O

C

E

S

R

G

S

E

N

T

P

U

-

T

R

A

T

S

M

Y

E

T

T

S

N

Y

S

A

R

R

A

W

Model YDMA -

Conditioned

Makeup Air

R-410A

Refrigerant

Model YDSA -

Space

Conditioning

DANGER

This unit contains R-410A high pressure refrigerant. Hazards exist that

could result in personal injury or death. Installation, maintenance, and

service should only be performed by an HVAC technician qualied in R-410A

refrigerant and using proper tools and equipment. Due to much higher

pressure of R-410A refrigerant, DO NOT USE service equipment or tools

designed for R22 refrigerant.

IMPORTANT: Do not release refrigerant to the atmosphere! If required

service procedures include the adding or removing of refrigerant, the service

technician must comply with all federal, state and local laws. The procedures

discussed in this manual should only be performed by a qualied HVAC

technician.

Form O-Y P/N 273647R5, Page 1

Table of Contents

1.0 General .......................................................2

2.0 Maintenance Requirements .....................2

2.1 Maintenance Schedule ...........................................3

2.2 Control Locations ....................................................4

2.3 Cabinet Size 1 or 2 by Model & Size Cross-Referenced

to Heat Section Size & Type ...........................5

3.0 Maintenance and Service Procedures -

Unit & Cooling Components ....................6

3.1 Filters ......................................................................6

3.2 Supply Fan and Variable Frequency Drive .............8

3.3 Optional Dampers and Damper Actuator ................9

3.4 Condenser Fans ...................................................10

3.5 Coils and Related Cooling Components ...............10

3.6 Check Refrigerant Pressure and Temperatures

(subcooling and superheat) ...........................17

3.7 Compressor Operation, Maint, and Replacement 19

3.8 Other Controls.......................................................27

4.0 Maintenance/Service Procedures - Power

Exhaust and Energy Recovery ..............27

4.1 Power Exhaust, Option PE ...................................27

4.2 Energy Recovery Wheel,

Option EW .....................................................28

5.0 Maintenance/Service Procedures - Gas

Heat Section ............................................32

5.1 Gas Heat Controls ................................................32

5.2 Combustion Air and Venting .................................37

5.3 Vent Maintenance and Operation .........................40

5.4 Burner and Heat Exchanger .................................41

6.0 Maintenance/Service Procedures - Electric

Heat Section ............................................42

7.0 Troubleshooting ......................................43

7.1 Troubleshooting - Refrigeration ............................43

7.2 Troubleshooting Compressor Digital Controller ...45

7.3 Troubleshooting the Heat Section ........................46

INDEX .............................................................48

1.0 General

Denitions of Hazard

Intensity Levels used

in this Manual

2.0 Maintenance

Requirements

Form O-Y, PN 273647R5, Page 2

This booklet includes operation, maintenance, and service information for Model

YDHA, Model YDMA, and Model YDSA. Before beginning any procedure, carefully

review the information, paying particular attention to the warnings. Handling of refrig-

erant should only be performed by a certied HVAC technician with knowledge of

the requirements of R-410A refrigerant and in compliance with all codes and requirements of authorities having jurisdiction.

There are warning labels on the unit and throughout this manual. For your safety,

comply with all warnings during installation, operation, and service of this system.

See denitions of Hazard Intensity Levels of warnings below.

HAZARD INTENSITY LEVELS

1. DANGER: Failure to comply will result in severe personal injury or death

and/or property damage.

2. WARNING: Failure to comply could result in severe personal injury or

death and/or property damage.

3. CAUTION: Failure to comply could result in minor personal injury and/or

property damage.

To ensure long life and satisfactory performance, a system that is operating under

normal conditions should be inspected according to the Maintenance Schedule in

Paragraph 2.1. If in an area where an unusual amount of dust or soot or other impurities are present in the air, more frequent inspection is recommended.

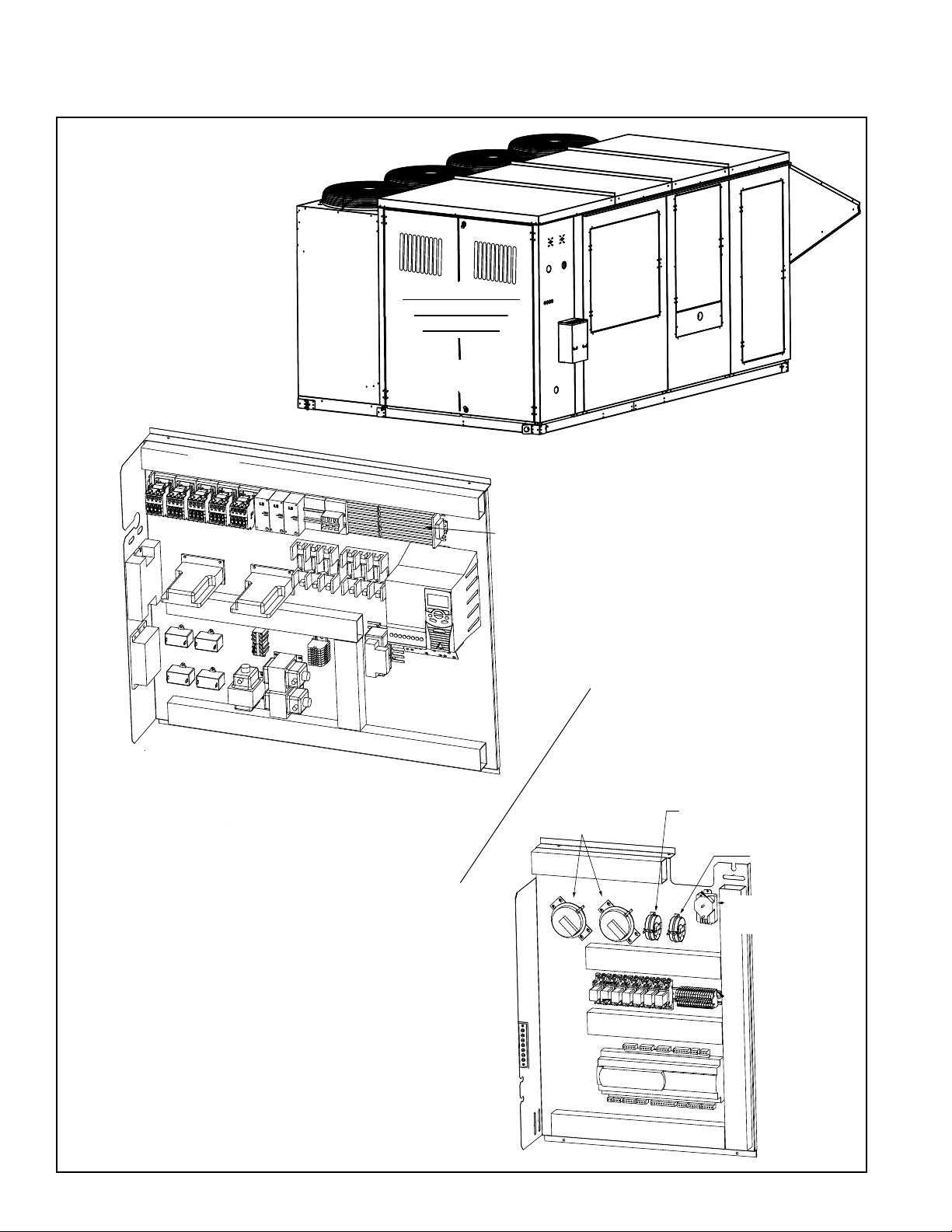

Refer to the illustration in FIGURE 1, shown on page 4 and follow the instructions in

the paragraphs referenced below to maintain this equipment. Maintenance requirements apply to all Models and Sizes unless noted.

IMPORTANT: Do not release refrigerant to the atmosphere! If

required service procedures include the adding or removing

of refrigerant, the service technician must comply with all

federal, state and local laws. The procedures discussed in

this manual should only be performed by a qualied HVAC

technician familiar with R-410A refrigerant.

WARNING

Lock power OFF before performing any maintenance

procedure (except where power is required such as

checking refrigerant pressure and temperature). Lock

disconnect switch in OFF position. If the system has a gas

heat section, when you turn off the power supply, turn off

the gas. See Hazard Levels on page 2.

If replacement parts are required, use only factory-authorized parts. For

information, contact your local distributor.

2.1 Maintenance

Schedule

Monthly

□ Inspect all lters; clean or replace as needed. See Paragraph 3.1, page 6.

□ Inspect the cooling coil condensate drain; clean as needed. For information, see

Paragraph 3.5, page 10.

Annually

All Models - Beginning of the cooling season or more frequently

in year-round cooling climate:

□ Inspect the wiring for any damaged wire. Replace damaged wiring.

□ Inspect the cooling coil condensate drain pan. Clean the coil cabinet, clean the

drain pan, and ll the trap.

□ Inspect/clean condenser fans. See Paragraph 3.4, page 10.

□ Inspect/clean all coils. See Paragraph 3.5, page 10.

□ Check refrigerant temperatures and pressures (superheat and subcooling).

These checks are done when the unit is operating. See Paragraph 3.6, page 17.

□ Check compressor operation. See Paragraph 3.7, page 19.

Systems with the Optional energy recovery wheel: See Paragraph 4.0, page 27.

□ Inspect the wheel and clean as needed.

□ Check wheel RPM and drive components.

□ Check wheel seals.

Systems with the Optional gas heat section (beginning of the heating

season) - See Paragraph 5.0, page 32:

□ Clean all dirt and grease from the combustion air openings and the venter

assembly.

□ Check the heat exchanger, burner, and venter for scale, dust, or lint

accumulation. Clean as needed.

□ Check the gas valves to ensure that gas ow is being shutoff completely.

Systems with the Optional electric heat section (beginning of the

heating season) - See Paragraph 6.0, page 42:

□ Check wiring connections.

□ Check the heat section and elements for dust or lint accumulation. Clean as

needed.

Form O-Y P/N 273647R5, Page 3

2.0 Maintenance Requirements (cont'd)

2.2 Control Locations

FIGURE 1 Access Doors

and High and

Low Voltage

Control

Locations

A

Comp

Cond

Condenser

Section

HIGH VOLTAGE CONTROL PANEL

Contactors

A

B

B

Cond

DH

Comp

Comp

Condenser Fans

Electrical / Control

Compartments

(See below.)

Optional Gas or

Electric Heat Section

Supply

Fan

Access

Inlet Air

Hood

Coil and

Filter Access

Damper Access

Optional Wheel Access

Compressor

Optional

Low

Ambient

Controller

- ECM

Condenser

Fan

Optional

Low

Ambient

Controller

- Std

Condenser

Fan

Controllers (by circuit)

A

1

2

Capacitors

3

4

Transformers 75 VA

Opt

DH

Fuse Blocks

Gas Heat Section Controls

Ignition controller and combustion air pressure

switch are located on the side wall next to the

gas manifold and burner. See FIGURE 23, page

32.

VFD

VFD Line

Reactor

High Voltage Bus Bar

- Compressor & Condenser

Contactors

- 3-Phase Supply Wire

Connections

- Optional Phase

Loss Monitor

- Optional Power

Exhaust Contactor

- Optional Energy

Wheel Contactor

- Optional Energy Wheel

Preheat Contactor

LOW VOLTAGE PANEL

* Optional Dirty Filter

Pressure Switch (1 or 2)

Relays

Optional Exhaust Airflow

Pressure Switch

High Side Tubing - Yellow

Low Side Tubing - Clear

Supply Air

Pressure Switch

High Side Tubing - Blue

Low Side Tubing - Clear

Optional Pressure

Sensor Transducer

(tubing is field supplied)

* Dirty Filter Switch for

System Filters (BE18)

High Side Tubing - Red

Low Side Tubing - Clear

Dirty Filter Switch for

Wheel Filters (BE28)

High Side Tubing - Green

Low Side Tubing - Clear

Form O-Y, PN 273647R5, Page 4

Thermostat Terminal Strip

Carel Controller

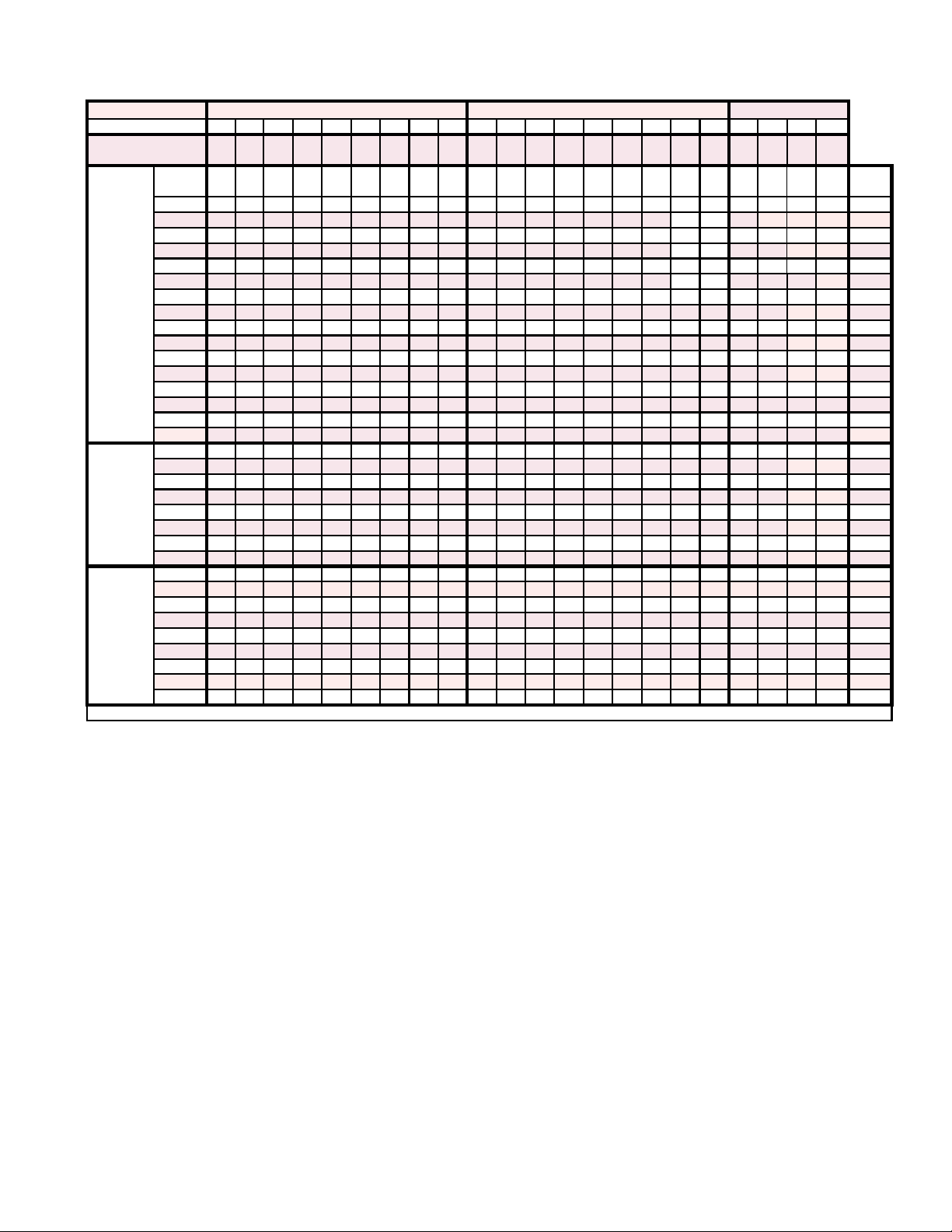

2.3 Cabinet Size 1 or 2 by Model & Size Cross-Referenced to Heat Section Size & Type

Model YDHA YDMA YDSA

Nominal Cooling

Capacity (Tons)

Standard

Efciency

Gas Heat

Section

High

Efciency

Gas Heat

Section

Electric

Heat

Section

* Gas heat sections with dual furnaces.

Size 60 90 120 150 180 210 240 300 360 60 90 120 150 180 210 240 300 360 120 150 180 210

5 7.5 10 12.5 15 17.5 20 25 30 5 7.5 10 12.5 15 17.5 20 25 30 10 12.5 15 17.5

Opt

Code

H50 1 1 1 -- -- -- -- -- -- 1 -- -- -- -- -- -- -- -- -- -- -- -- H50

H75 1 1 1 1 2 -- -- -- -- 1 1 1 -- -- -- -- -- -- -- -- -- -- H75

H100 1 1 1 1 2 2 2 -- -- 1 1 1 1 -- -- -- -- -- 2 -- -- -- H100

H102* 1 1 1 1 2 2 2 -- -- 1 1 1 1 -- -- -- -- -- 2 -- -- -- H102*

H125* 1 1 1 1 2 2 2 -- -- 1 1 1 1 2 -- -- -- -- 2 2 -- -- H125*

H150* 1 1 1 1 2 2 2 -- -- 1 1 1 1 2 2 -- -- -- 2 2 3 -- H150*

H175* 1 1 1 1 2 2 2 -- -- 1 1 1 1 2 2 2 -- -- 2 2 3 3 H175*

H200 -- 1 1 1 2 2 2 3 3 1 1 1 1 2 2 2 3 3 2 2 3 3 H200

H202* -- 1 1 1 2 2 2 3 3 1 1 1 1 2 2 2 3 3 2 2 3 3 H202*

H300 -- 1 1 1 2 2 2 3 3 -- 1 1 1 2 2 2 3 3 2 2 3 3 H300

H400 -- -- 1 1 2 2 2 3 3 -- -- 1 1 2 2 2 3 3 2 2 3 3 H400

H402* -- -- 1 1 2 2 2 3 3 -- -- 1 1 2 2 2 3 3 2 2 3 3 H402*

H502* -- -- -- -- 2 2 2 3 3 -- -- -- -- 2 2 2 3 3 -- -- 3 3 H502*

H602* -- -- -- -- 2 2 2 3 3 -- -- -- -- 2 2 2 3 3 -- -- --- 3 H602*

H702* -- -- -- -H802* -- -- -- -- -- -- -- 3 3 -- -- -- -- -- -- -- 3 3 -- -- -- -- H802*

G150 1 1 1 1 2 2 2 -- -- 1 1 1 1 2 2 2 -- -- 2 2 3 3 G150

G225 1 1 1 1 2 2 2 3 3 1 1 1 1 2 2 2 3 3 2 2 3 3 G225

G300 -- 1 1 1 2 2 2 3 3 -- -- 1 1 2 2 2 3 3 2 2 3 3 G300

G302* -- 1 1 1 2 2 2 3 3 -- -- 1 1 2 2 2 3 3 2 2 3 3 G302*

G372* -- -- -- -- 2 2 2 3 3 -- -- -- -- 2 2 2 3 3 -- 2 3 3 G372*

G452* -- -- -- -- 2 2 2 3 3 -- -- -- -- 2 2 2 3 3 -- -- 3 3 G452*

G525* -- -- -- -- -- -- -- 3 3 -- -- -- -- -- -- -- 3 3 -- -- -- -- G525*

G602* -- -- -- -- -- -- -- 3 3 -- -- -- -- -- -- -- 3 3 -- -- -- -- G602*

E20 1 1 1 1 2 2 2 -- -- 1 1 1 1 2 2 2 -- -- 2 2 3 3 E20

E30 1 1 1 1 2 2 2 3 3 1 1 1 1 2 2 2 3 3 2 2 3 3 E30

E40 -- 1 1 1 2 2 2 3 3 -- 1 1 1 2 2 2 3 3 2 2 3 3 E40

E50 -- 1 1 1 2 2 2 3 3 -- 1 1 1 2 2 2 3 3 2 2 3 3 E50

E60 -- 1 1 1 2 2 2 3 3 -- 1 1 1 2 2 2 3 3 2 2 3 3 E60

E70 -- -- 1 1 2 2 2 3 3 -- -- 1 1 2 2 2 3 3 2 2 3 3 E70

E80 -- -- 1 1 2 2 2 3 3 -- -E90 -- -- 1 1 2 2 2 3 3 -- -- 1 1 2 2 2 3 3 2 2 3 3 E90

E120 -- -- -- -- 2 2 2 3 3 -- -- -- -- 2 2 2 3 3 -- -- 3 3 E120

-- -- -- 3 3 -- -- -- -- -- -- -- 3 3 -- -- -- -- H702*

1 1 2 2 2 3 3 2 2 3 3 E80

Opt

Code

Form O-Y P/N 273647R5, Page 5

3.0 Maintenance

Filter Clip

P/N 284026

and Service

Procedures Unit & Cooling

Components

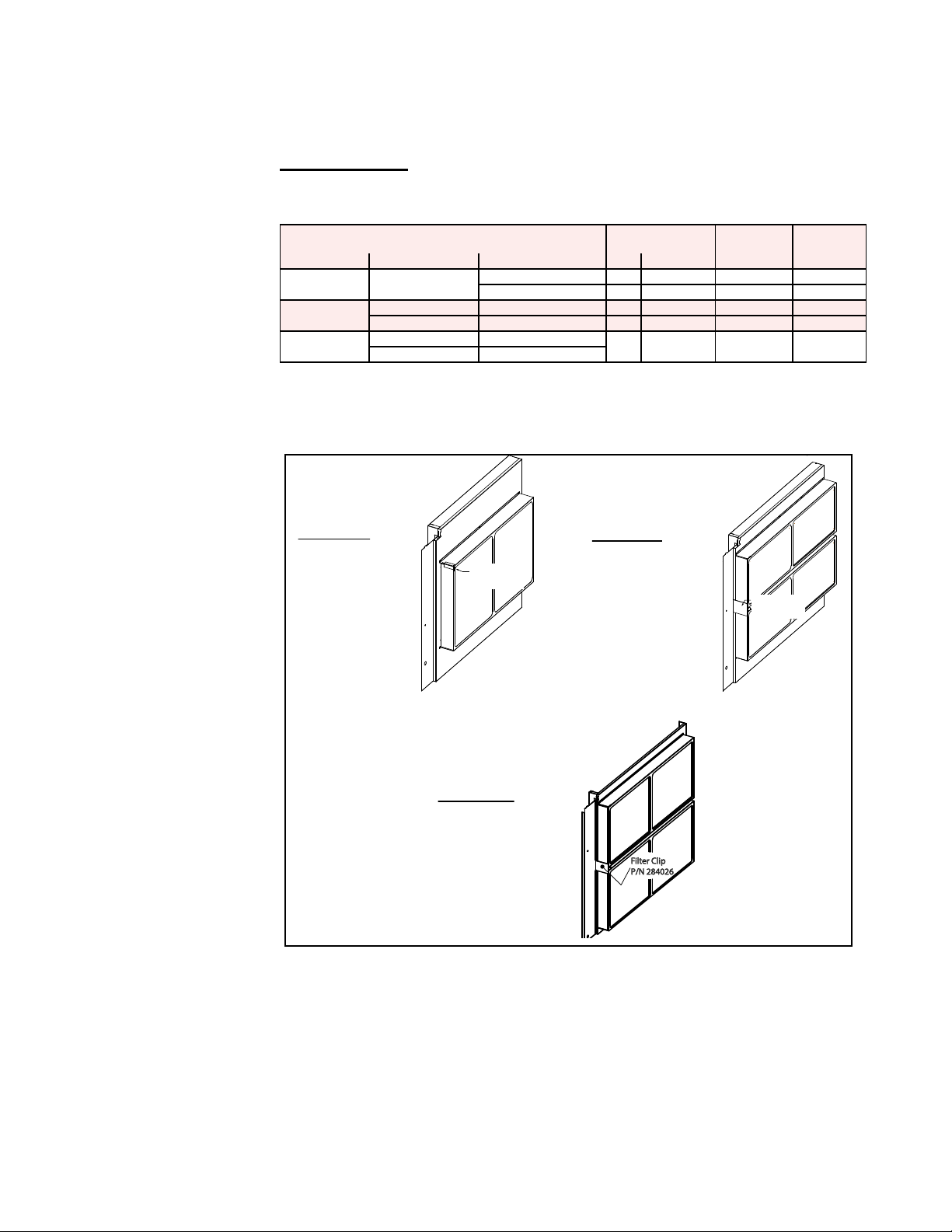

3.1 Filters

Systems with disposable lters require more frequent lter inspection. Exposure to

humid makeup air can accelerate lter degradation. Replace lters when needed

using the same type of lters as the original.

Supply Air Filters - The supply air lters are 4-inch pleated disposable lters.

Replacement lters are listed in the table below. Do not use any other type of lters.

FIGURE 2 - Installing

Replacement Supply

Air Filters

Replacement Filters by Model Size and Cabinet Size

Cabinet Size Model(s) Model Sizes Qty Size P/N P/N

1

2

3

YDHA & YDMA

YDHA & YDMA 180, 210, 240 4 16 x 25 211128 256666

YDSA 120, 150 4 16 x 25 211128 256666

YDHA & YDMA 300 & 360

YDSA 180 & 210

060 1 16 x 25 211128 256666

090, 120, 150 2 20 x 24 222480 260828

4" Disposable

Pleated

4 25 x 29 235757 235758

MERV 8 MERV 13

To access supply air lters, open the cooling coil / lter door. Follow the instructions

that apply.

Cabinet Size 0

(see table above)

Instructions:

1) Slide filter clip

left and remove.

2) Slide filters out.

3) Install new filters.

4) Replace filter clip.

Filter Clip,

P/N 272222

Filter

Filter

Cabinet Size 2

(see table above)

Instructions:

1) Slide filter clip tab

from the slot in

the filter support.

Rotate clip slightly

and remove filter

clip.

2) Slide filters out.

3) Install new filters.

4) Replace filter clip.

Filter

Filter Clip,

P/N 272707

Filter

Filter

Filter

Form O-Y, PN 273647R5, Page 6

Cabinet Size 3

(see table above)

Instructions:

1) Slide filter clip tab

from the slot in the

filter support.

Rotate the clip slightly

and remove filter clip.

2) Slide filters out.

3) Install new filters.

4) Replace filter clip.

Filter

Filter

Filter

Filter

3.1 Filters (cont'd)

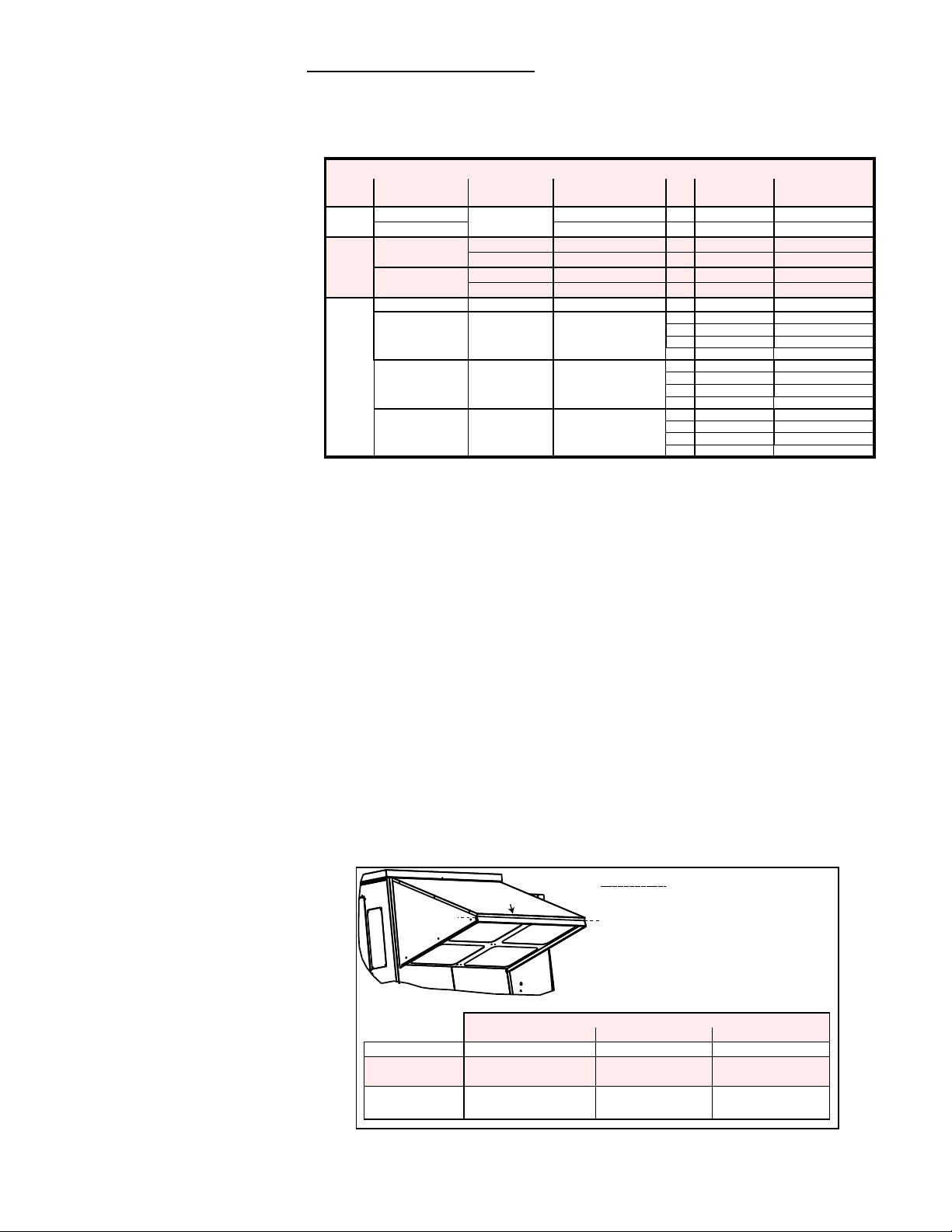

Energy Recovery Wheel Filters - The energy recovery wheel has two 1-inch lters

in both the supply and exhaust airstreams. Replacements are listed below. Size of lter is determined by CFM. Permanent lters may be washed and dried and re-used.

To access lters, open the wheel door. Slide the lters out of the lter racks.

Do not operate the system without lters in place.

Filter Application by Cabinet & ER Wheel Sizes

Cabinet

Size

1

2

3

ER Wheel Size Model Model Size Qty Filter Size

30" dia

36" dia

36" dia

46" dia

36" dia

46" dia

52"dia

58"dia

YDHA & YDMA 060, 090, 120, 150

090, 120, 150

YDHA & YDMA 180, 210, 240 4 20 x 25 101610

YDSA 120, 150 4 20 x 25 101610

YDHA & YDMA 180, 210, 240 4 25 x25 119779

YDSA 120, 150 4 25 x 25 119779

YDSA 180, 210

YDSA 180, 210 4 16 x 20 101607

YDHA 300, 360 4 16 x 20 101607

YDHA & YDMA 300, 360 4 16 x 20 101607

4 16 x 16 104102

4 20 x 20 101608

4 20 X 25 101610

4 20 x 20 101608

2 16 x 25 101609

2 20 x 25 101610

4 20 x 20 101608

2 16 x 25 101609

2 20 x 25 101610

4 20 x 20 101608

2 16 x 25 101609

2 20 x 25 101610

1" Permanent

P/N

Dirty Filter Switch (Options BE18 or BE28)

Systems may be equipped with a dirty lter pressure switch (Option BE18) that will

trigger an alarm when the resistance through the inlet air lters indicates that lter

replacement is required. Systems with an energy recovery wheel may be equipped

with two dirty lter pressure switches (Option BE28), one for the inlet air lters and

one for the energy recovery wheel supply lters.

When performing maintenance, check the condition of the sensing tubes to be sure

that they are not blocked. Check the wiring connections. To set a new dirty lter

switch, see Installation Form I-Y, Paragraph 8.3. Replacement switch is P/N 105507.

FIGURE 3 - Removing

and Installing Filters

in the Outside Air

Hood

Permanent Filters in the Outside Air Hood (Option AS16)

If equipped with an outside air hood, there are 1" permanent, aluminum lters at the

entrance of the hood. The lters act as a moisture eliminator and bird screen. See

FIGURE 3, shown below. When inspecting the inlet air lters, inspect the outside air

hood lters. If cleaning is needed, remove the lters, clean, rinse, dry and re-install.

NOTE: If it is more convenient to keep an extra clean set of lters, lter sizes and part

numbers are listed below.

Instructions:

Front Cover

Filter

Filter

YSDA Models -- 120, 150 180, 210

YDHA, YDMA

Models

Filter No / Size /

(Qty)

060, 090, 120, 150 180, 210, 240 300, 360

Filter

Filter

1 2 3

101607

16x20x1 - (4)

1) Remove two screws,

one on each end of

the front cover.

Remove the cover.

2) Slide filters out.

3) Clean and dry filters.

4) Return filters to hood

and replace cover.

Cabinet Size

101610

20x25x1 - (4)

101609

16x25x1 - (8)

Form O-Y P/N 273647R5, Page 7

3.0 Maintenance and Service Procedures - Unit & Cooling Components (cont'd)

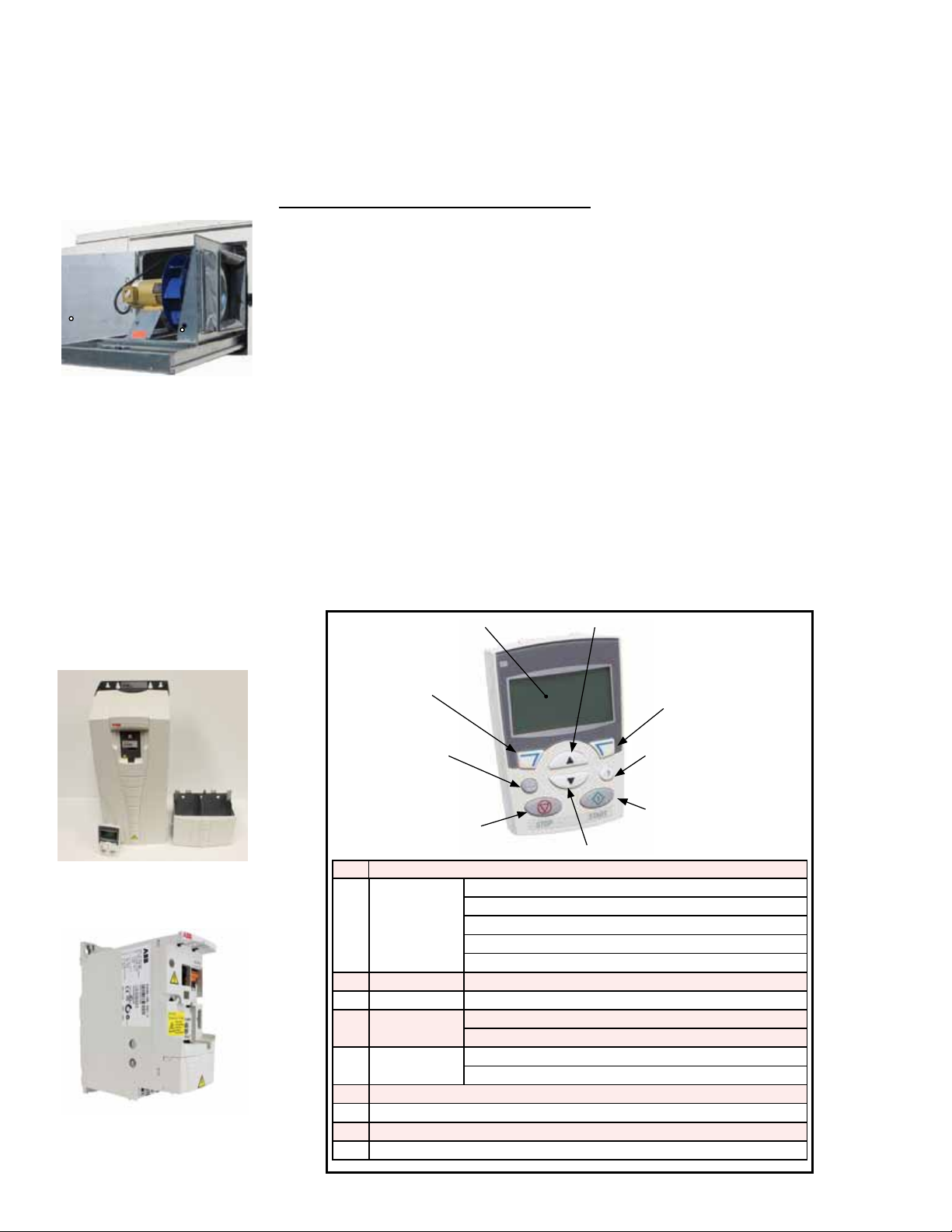

3.2 Supply Fan

and Variable

Frequency Drive

Supply fan in "slide

out" position

Approx fan sled

screw locations

Variable Frequency

Drive

FIGURE 4 - VFD

Display

Fan motors are permanently lubricated; lubrication is not required, During

maintenance, remove any accumulation of dirt and grease. The fan CFM was

checked and balanced at startup. To recheck, follow the instructions in the installation

manual, Form I-Y, Paragraph 10.3.

If service is required, the supply fan is mounted on a sled that will slide out of the

cabinet.

Instructions for sliding out the supply fan:

1. Turn off the power and lock the disconnect switch.

2. Open the supply fan door and the cooling cabinet door.

3. The exible duct joining the supply fan to the cooling compartment is visible.

Locate the metal ange holding the duct to the cabinet. Remove the two screws

from fan sled (locations shown in picture on the left) and the ange to free the duct

so that it can be slid out with the fan.

4. Open the electrical box on the fan. Mark and disconnect the wires.

5. Carefully slide the complete fan sled out of the cabinet.

6. When service is complete, slide the sled into the cabinet. Re-connect the wires

and re-attach the ange to hold the exible duct in place. If the pressure tube was

removed during service, be sure to re-attach it securely. Reinstall two screws into

the fan sled.

Function: When the main controller calls for supply fan operation, a variable fre-

quency drive (VFD) responds to operate the motor.

The VFD is located on the high voltage electrical panel (See FIGURE 1, page 4).

Control of the variable frequency drive module is dictated by the main controller, and

depending on what was ordered, can function in response to temperature, CO

, or

2

pressure controls. !

Service: Remove any dirt or dust. Check the wire connections. If a VFD needs

to be replaced, use a factory-authorized replacement designed for the application.

1) LCD Display

4) UP

Variable Frequency

Drive Model ACS550

Variable Frequency

Drive Model ACS355

2) RESET / EXIT

6) LOC / REM

8) STOP

5) DOWN

Code Control Panel Display

1 LCD display -

Divided into 5

areas

2 RESET / EXIT Resets faults and exits to higher menus

3 MENU / ENTER Menu selection and saves value

4 UP Scrolls up through menu / list

5 DOWN Scrolls down through menu / list

6 LOC / REM - VFD controlled by main controller

7 DIR - Changes the direction of the motor

8 STOP - Stops the drive

9 START - Starts the drive

Upper left - Control location

Upper right - unit of the displayed value

Center - Parameters and signal values, menus and alarm codes

Lower left and center - Operation state

Lower right - Motor rotation

Increases value of parameters or reference values

Decreases value of parameters or reference values

3) MENU / ENTER

7) DIR

9) START

Form O-Y, PN 273647R5, Page 8

3.0 Maintenance and Service Procedures - Unit & Cooling (cont'd)

3.2 Supply Fan and Variable Frequency Drive (cont'd)

Air Proving Switch

P/N 234712

Set Point 0.10 I.W.C.

Outside Air Humidity

and Temperature

Sensor

Function: The airow proving switch is a pressure switch that veries to the main

controller that the supply fan is operating. If equipped with power exhaust or an

energy recovery wheel, there is a second air proving switch that veries the exhaust

fan is operating. See location in FIGURE 1, page 4.

Service: If a switch needs to be replaced, use a factory-authorized replacement

designed for the application.

Function: All systems have an outside air humidity and temperature sensor in the

outside air inlet. The sensor is wired to the system controller in the electrical compartment.

Service: Check the wiring. If the sensor needs replaced, use a factory-authorized

replacement designed for the application.

FIGURE 5 - Outdoor

Air Sensor, P/N

222754, is mounted

in the outside air

inlet (behind the

hood)

3.3 Optional

Dampers

and Damper

Actuator

Inlet Air Dampers

Location: Dampers and damper motors are located in the inlet air opening.

Function: Dampers operate in response to a variety of controls (GF Options).

Service: Clean dampers and controls of dust and dirt.

2-Position Damper Actuator (Options AR7, AR8, AR2D, AR2L, AR2Y)

Function: The 2-position damper motor opens and closes the dampers in response

to unit operation or a eld-supplied time clock. The motor closes the dampers on

heater shutdown.

Modulating Damper Actuator (Options AR25, AR2G, AR2H, AR2M)

Function: The modulating damper motor actuates the dampers in response to the

selected control with actuation from input switch settings.

The motor closes the inlet dampers on heater shutdown.

Service: Other than external cleaning, there is no service required on the dampers or

the damper motor. If the damper, control, or motor need to be replaced, replace with

a factory-authorized replacement.

For additional information on damper controls (Options GF 1-9), see the system

installation manual Form I-Y.

FIGURE 6 - Damper

Actuator is mounted

on the damper frame

and is accessible

through the Damper

Access Door (See

FIGURE 1, page 4).

Form O-Y P/N 273647R5, Page 9

3.0 Maintenance and Service Procedures - Unit & Cooling (cont'd)

3.4 Condenser Fans

3.5 Coils and

Related Cooling

Components

Condenser Coil

Cleaning Instructions

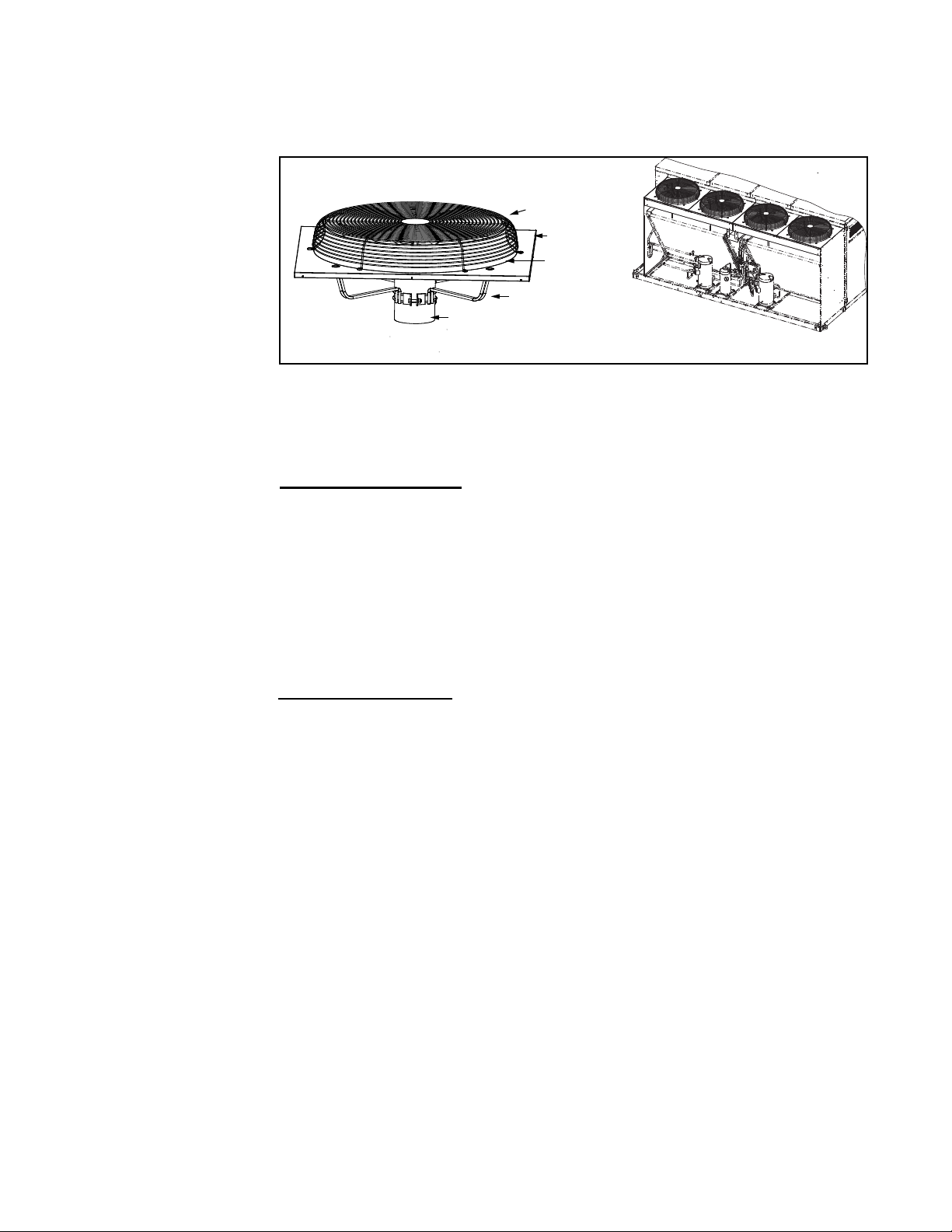

Depending on the model size, there are two or four condenser fans. Fan motors may

be either standard efciency or ECM speed control. If parts need to be replaced, use

only factory authorized replacement parts.

FIGURE 7 - Condenser Fans

Guard

Housing

Propeller Fan

Fan Support

Motor

Condenser Fan Section Assembly

The DX cooling system is equipped with copper nned coils. Inspect all cooling

system coils at the beginning of the cooling season or more often if needed. Follow

the cleaning instructions below. If additional cleaning is required or if a coil must be

removed for any reason, consult the factory. Be prepared to provide rating plate and

specic installation information.

Condensing Coil Access - The condensing coils are visible on the side of the unit

(below the condenser fans).

1. Verify that the electrical power has been turned off and the disconnect switch

locked.

2. Use a soft brush to remove any dirt and debris from the coils.

3. Spray with cold or warm (not hot) water and a cleaning solution (non-acid based

coil cleaner is recommended). Due to possible damage to the coil, DO NOT use

high pressure spray.

4. When clean, rinse with cool, clean water.

Evaporator

Coil Cleaning

Instructions:

Evaporator Coil Access - The evaporative coils can be accessed by opening the coil

cabinet door.

Inspect coils for debris, dirt, grease, lint, pollen, mold, or any element which would

obstruct heat transfer or airow. Inspect coils and tubing for physical damage. Inspect

feeders, piping connections, coil headers, and return bends for signs of fatigue, rubbing, and physical damage.

Clean the coils annually, or more often if needed. Use the proper tools and follow the

instructions carefully to avoid damaging the coil. Use of a non-acid based coil cleaner

is recommended. Due to possible damage to the coil, DO NOT use high pressure

spray.

1. Verify that the electrical power has been turned off and the disconnect switch

locked.

2. Open the cooling coil door.

3. Use a soft brush to remove any dirt and debris from both sides of the coil.

4. Spray with cold or warm (not hot) water and a cleaning solution (non-acid based

coil cleaner is recommended). Due to possible damage to the coil, DO NOT use

high pressure spray. First spray the leaving airow side, then the inlet airow side.

As much as possible, spray the solution perpendicular to the face of the coil.

Follow the instructions on the cleaning solution. When cleaning process is

complete, rinse both sides with cool, clean water.

Form O-Y, PN 273647R5, Page 10

3.5 Coils and Related Components (cont'd)

Condensate Drain

Use and Maintenance

Thermostatic

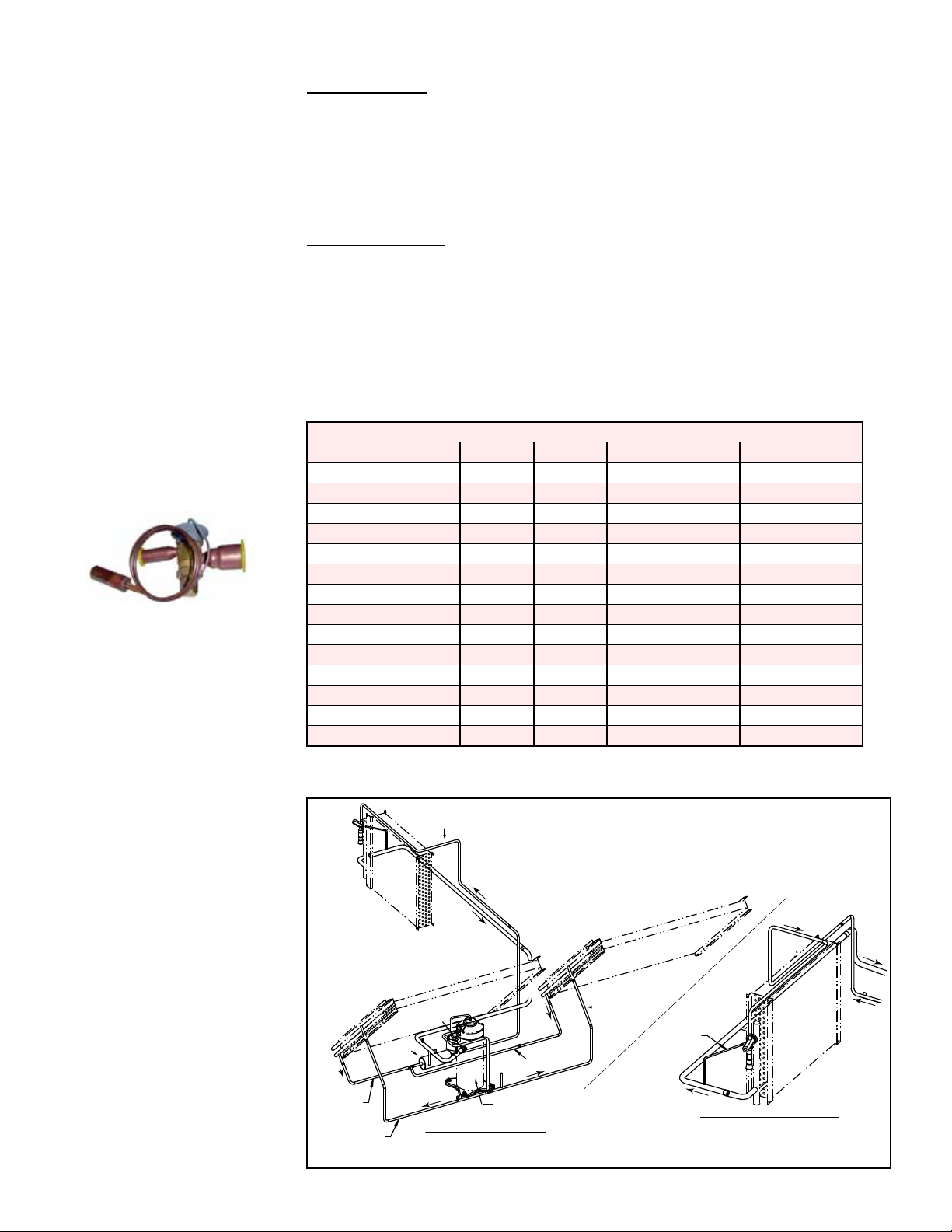

Expansion Valves

Thermostatic

Expansion Valve

Seasonal Usage - At the beginning of the cooling season, inspect and clean the

entire cooling coil cabinet including the condensate drain pan. Thoroughly clean dirt,

algae, grease, and other contaminants. Inspect condensate drain pan, trap, and pip-

ing; ll trap with water to ensure proper operation. During a wintertime shutdown of

the cooling system, it may be desirable to disconnect and remove all water from the

trap and drain to prevent freeze damage. If local building codes permit, trap may be

lled with an antifreeze solution. Or, piping may be designed with freeze plugs or

other freeze protection methods (such as a heat tape).

Year Round Usage - Climates or applications with cooling requirements year round

require more frequent inspections of the cooling coil cabinet and condensate drains.

Depending on climate, freeze protection of the trap may be required during noncooling days.

All refrigeration circuits have a thermostatic expansion valve. Thermostatic expansion

valves do not have replaceable parts. If a replacement valve is required, it must be for

R-410A refrigerant and must be sized correctly for the application. All refrigerant ser-

vice should be performed by a service technician qualied in R-410A refrigerant.

Replacement valve P/N's by Model, size, and circuit are listed in the table. Locations

are shown in FIGURES 8 through 14, shown on pages 11 through 14.

Thermostat Expansion (TXV) Valves by Circuit and P/N

Model / Size A B DH - Low Enthalpy DH - High Enthalpy

YDHA & YDMA 060 234987 -- 207303 --

YDHA 090 220556 -- -- 207303

YDMA 090 220556 -- 207303 --

YDHA & YDMA 120 234987 234987 -- 207303

YDSA 120 234960 234960 -- --

YDHA & YDMA 150 220555 220555 -- 207303

YDSA 150 220555 220555 -- --

YDHA & YDMA 180 220555 220555 207303 234960

YDSA 180 220555 220555 -- --

YDSA 210 220556 220555 -- --

YDHA & YDMA 210 220556 220556 207303 234960

YDHA & YDMA 240 220556 220556 207303 234960

YDHA & YDMA 300 261175 221175 234960 235729

YDHA & YDMA 360 220558 220558 234960 235729

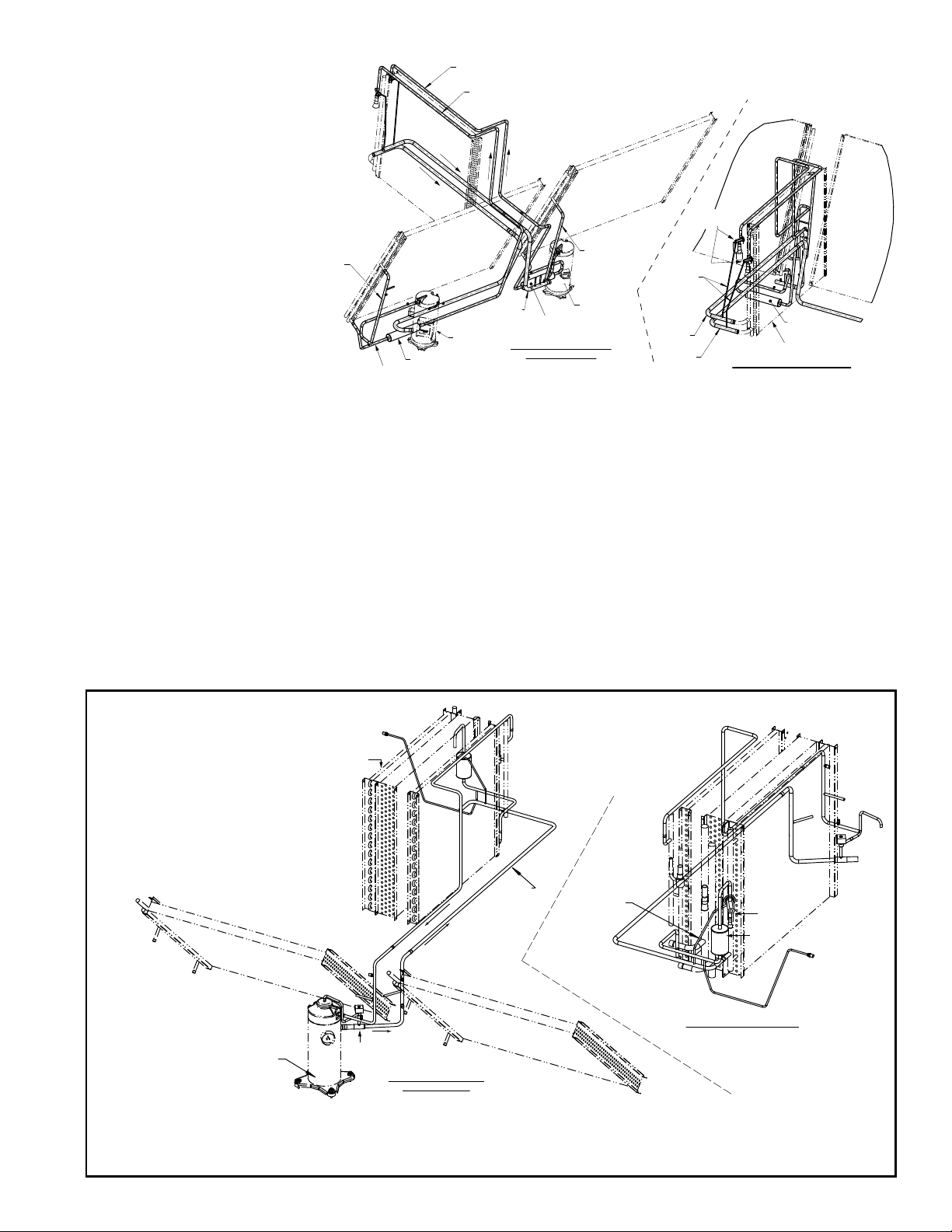

Refrigerant Circuits - Standard Cooling without Optional Bypass Valve or Reheat

FIGURE 8 - Cooling

Circuit - Models

YDHA and YDMA

Circuit A-1&2

Model JDHA 062 and 092 (Cabinet 0)

Sizes 060 and 090

Evaporator

Circuit A-1

Circuit A-1

Coil with

Single Circuit

Filter

Drier

Condenser Coil

Circuit A-1

Solenoid

Valve

Modulating

View from Compressor and

Condenser Section Side

Compressor

Circuit A-2

Condenser Coil

Circuit A-2

Circuit A-2

Equalizer

Evaporator

Tube

TXV

Valve

View from Cooling Cabinet Door

(Evaporator Coil Side)

Form O-Y P/N 273647R5, Page 11

Coil

3.0 Maintenance and Service Procedures - Unit & Cooling (cont'd)

3.5 Coils and Related Components (cont'd)

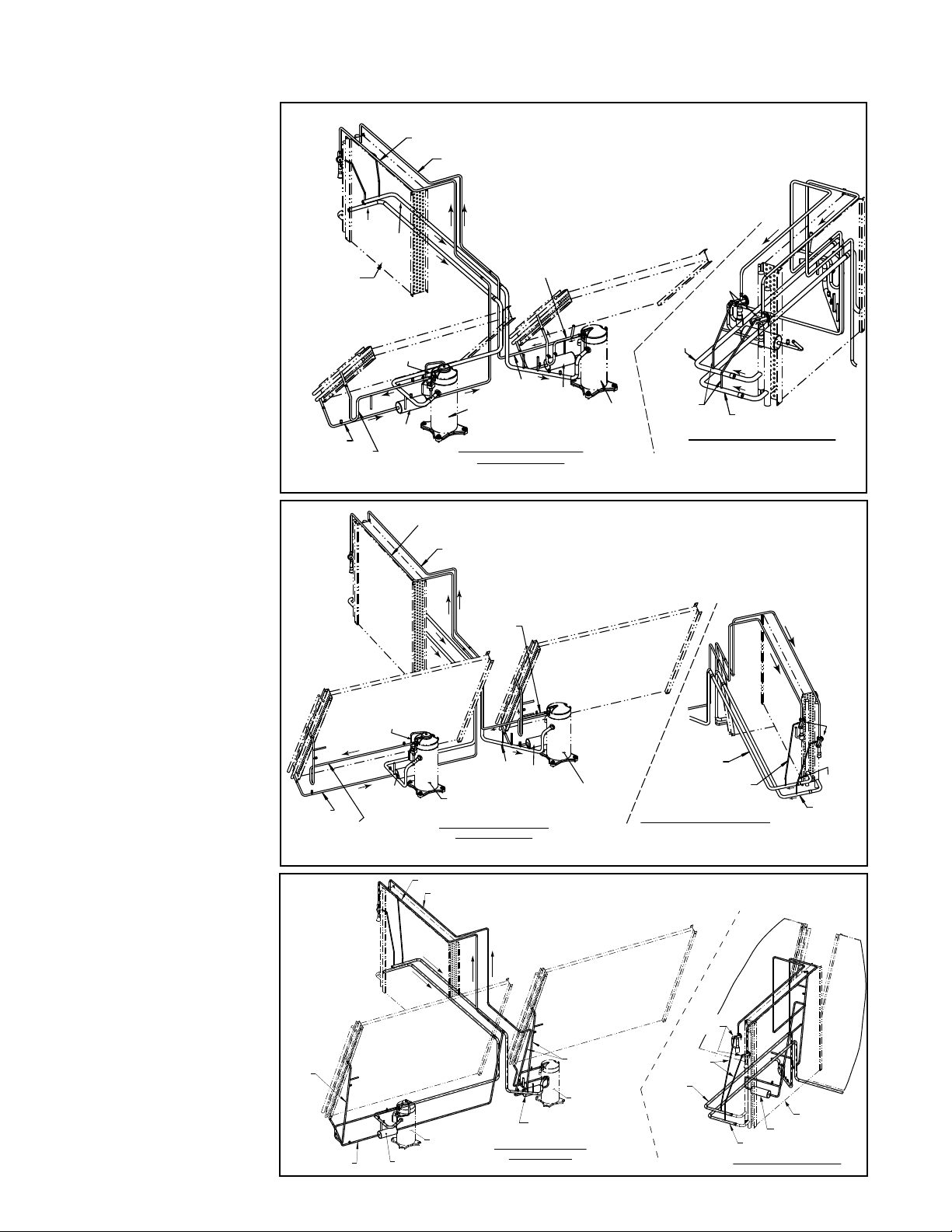

FIGURE 9 - Cooling

Circuits - Models

YDHA and YDMA

Sizes 120 and 150

Evaporator Coil

with intertwined

Circuits A & B

Circuit A

Circuit B

Circuit A

Condenser Coil

Circuit A

Solenoid Valve

Circuit B

Model JDHA 120 and 150 (Cabinet 1)

Condenser Coil

Circuit B

Circuit B

Valves

Circuit B

TXV

FIGURE 10 - Cooling

Circuits - Model YDSA

Sizes 120 and 150;

Models YDHA and

YDMA Sizes 180, 210,

and 240

Circuit A

Circuit A

Evaporator

Coil with

intertwined

Circuits A & B

Circuit A

Circuit A

Filter

Drier

Circuit A

Condenser Coil

Circuit A

Solenoid Valve

Filter

Drier

Circuit B

Modulating

Compressor

(Circuit A)

View from Compressor and

Condenser Section

Circuit B

Modulating

Compressor

(Circuit A)

View from Compressor and

Condenser Section

Model JDHA 180, 210, and 240 (Cabinet 2)

Circuit B

Circuit B

Filter

Drier

Filter

Drier

Compressor

(Circuit B)

Compressor

(Circuit B)

Condenser Coil

Circuit B

Equalizer

Tubes

View from Cooling Cabinet Door

Circuit B

View from Cooling Cabinet Door

(Evaporator Coil Side)

Circuit A

(Evaporator Coil Side)

Equalizer

Tube

Evaporator

Coil

Evaporator

Coil

TXV

Valves

Equalizer

Tube

Circuit A

FIGURE 11 - Cooling

Circuits - Model YDSA

Sizes 180 and 210

Form O-Y, PN 273647R5, Page 12

Circuit A

Evaporator Coil

with Intertwined

Circuits A & B

Circuit A

Circuit A

Condenser Coil

Circuit A

Filter Drier

Circuit B

Compressor

(Circuit A)

Model YDSA 180 and 210 (Cabinet 3)

Condenser Coil

Circuit B

Circuit B

Compressor

(Circuit B)

Filter Drier

View from Compressor and

Condenser Section

Equilizer Tube

Circuit B

TXV

Valves

Circuit A

View from Cooling Cabinet Door

(Evaporator Coil Side)

Evaporator Coil

Filter Drier

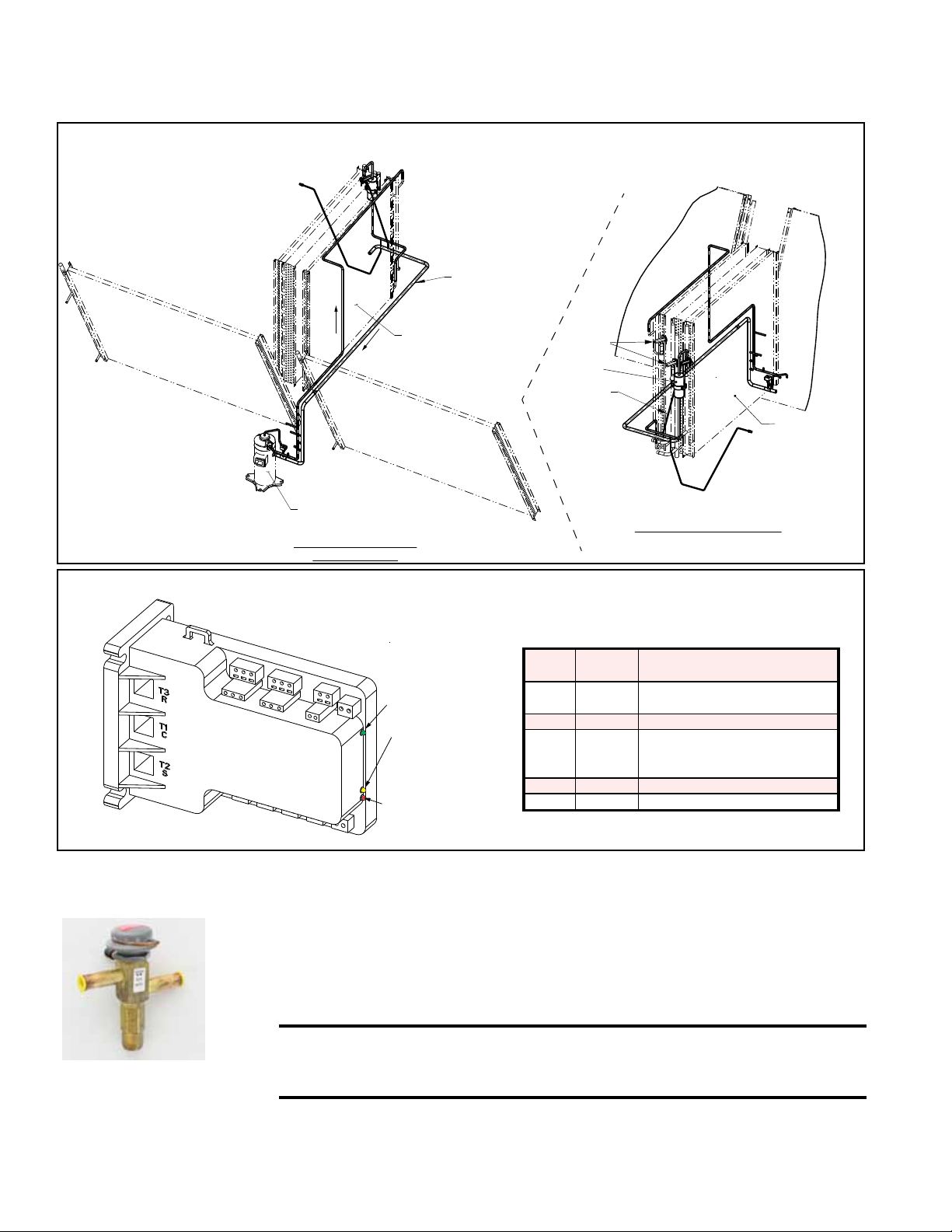

FIGURE 12 - Cooling

Circuits - Models

YDHA and YDMA

Sizes 300 and 360

Circuit B

Circuit A

Model JDHA 300 and 360 (Cabinet 3)

Condenser Coil

Circuit B

TXV

Valves

Optional Modulating

Reheat (High

Enthalpy Option

RPLE or Low

Enthalpy Option

RPHE)

Circuit A

Circuit A

Condenser Coil

Circuit A

Filter Drier

Compressor

(Circuit A)

Circuit B

Filter Drier

View from Compressor and

Condenser Section

Circuit B

Compressor

(Circuit B)

Equilizer Tube

Circuit B

Circuit A

Filter Drier

Evaporator Coil

View from Cooling Cabinet Door

(Evaporator Coil Side)

Function: Units equipped with optional reheat have a dedicated refrigerant system

(DH circuit) that precools the incoming air then directly uses the condenser waste

heat to reheat the air after it passes through the DX cooling coil. The reheat system

precooling evaporator coil is upstream of the main evaporator coil and the reheat

condenser coil is downstream. The upstream "precool" coil tempers outside air and

lowers the wet bulb depression of the air entering the main evaporator coil. The heat

removed at the precool coil is rejected to the downstream "reheat" coil.

Operation of the DH circuit is controlled by the digital controller in the electrical

compartment. See FIGURE 1(shown on page 4) and Figures 13 and 14 (shown on

pages 13 & 14). The digital controller interfaces with the system controller and provides protection and diagnostics for compressor operation.

Service: See Troubleshooting Chart in Paragraph 7.2 on page 45 for identication of

alarm codes. Use only factory-authorized replacement parts.

FIGURE 13 - Optional

DH Circuit (Option

RPLE Low Enthalpy

Reheat Pump or

Option RPHE Low

Enthalpy Reheat Pump

Condenser Coil

Circuit A

Modulating

Compressor

(Optinal DH Circuit)

DH

Coil

Solenoid

Valve

View from Compressor and

DH

Coil

Condenser Section

Circuit DH

Condenser Coil

Circuit B

Model JDHA 060, 090, 120, and 150 (Cabinet 1)

Model JDHA 180, 210, and 240 (Cabinet 2)

Equalizer

Tube

View from Cooling Cabinet Door

(Evaporator Coil Side)

TXV Valve

Filter

Drier

Form O-Y P/N 273647R5, Page 13

3.0 Maintenance and Service Procedures - Unit & Cooling (cont'd)

3.5 Coils and Related Components (cont'd)

Optional Modulating Reheat (cont'd)

FIGURE 14 - Optional

DH Circuit (Option

RPLE High Enthalpy

Reheat Pump or

Option RPHE Low

Enthalpy Reheat Pump

Model JDHA 300 & 360 (Cabinet 3)

Circuit A & B

Condenser Coil

Circuit A

Modulating

Compressor

View from Compressor and

Condenser Section

Evaporator Coil

with Intertwined

Circuits A & B

Condenser Coil

Circuit B

TXV Valves

Filter Drier

Equilizer Tube

View from Cooling Cabinet Door

FIGURE 15 - Digital Controller for DH Circuit Compressor, P/N 266067

Compressor Digital

Modulating Operation

Optional Hot Gas

Bypass Valve

(Option AUC8)

T6

T4

T2

T5

T3

P6

T1

P5

Controller for

A1

A2

L1

LED

Color

Power Light

24

COM

Alarm Light

(Red LED) - See

Paragraph 7.2

shown on page 45.

(Green LED)

Compressor

Modulating

Solenoid Valve

Energized Light

(Yellow LED)

P4

P2

P3

P1

L2

M1

24

VAC

C4

C2

C3

C1

M2

U1

U2

V1

V2

Green Solid

Green Flashing Anti-short cycle timer is active

Yellow Solid

Red Not lit No abnormal operation alerts

Red Flashing See Paragraph 7.2 (page 45).

Function: The hot gas bypass valve allows some of the refrigerant gas from the suction line to be re-routed directly to the evaporator coil providing for expanded compressor modulation at low outside air temperatures. Hot gas bypass is only on the

non-modulating compressor circuit (Circuit B). See FIGURE 16 on page 15.

Service: To check the hot gas bypass valve setting, connect a pressure gauge to the

suction line and block the entering air to the evaporator coil. Suction pressure will

drop, and the hot gas bypass valve should begin to open at a approximately 115 psi

and will be fully open at 95 psi. When the valve begins to open it will be hot to the

touch (see caution below).

LED

State

Power (24VAC present at

power terminals)

Unloader (Solenoid valve

is energized; compressor

capacity is 0.)

Evaporator Coil

(Evaporator Coil Side)

Indicates

Hot Gas Bypass

Valve

Form O-Y, PN 273647R5, Page 14

CAUTION: Touching the operating hot gas bypass valve can cause

a burn. Use caution when checking and adjusting the valve. See

Hazard Levels, page 2.

If a hot gas bypass valve needs to be replaced, use only a factory-authorized

replacement for R-410A refrigerant. All refrigerant service should be done by a

qualied R-410A service technician.

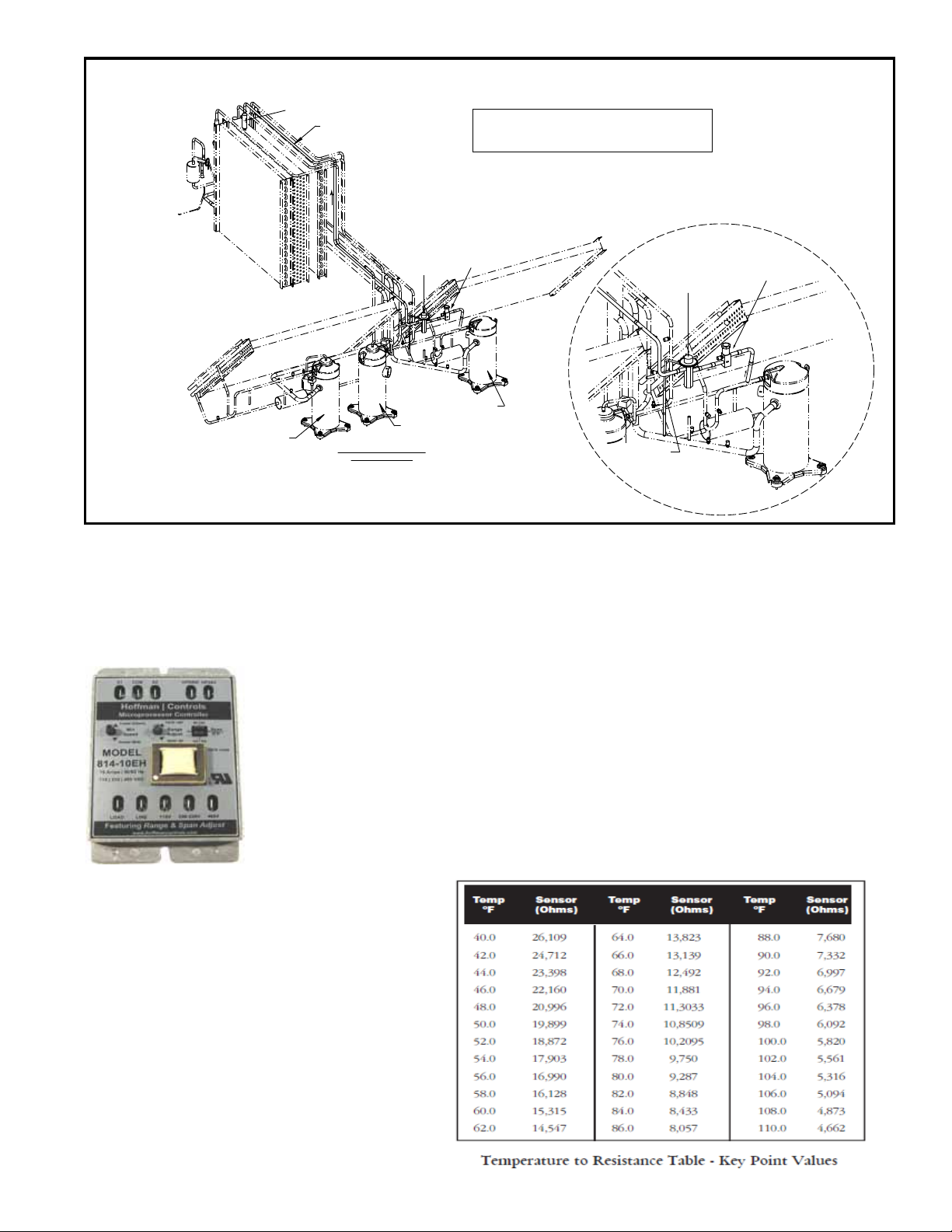

FIGURE 16 - Cooling Circuit B with Optional Bypass Valve (Option AUC8)

Hot Gas Bypass Check Valve at the Evaporator Coil

Circuit B with Optional Hot Gas Bypass

Model JDHA 120 and 150 (Cabinet 1) with Option AUC8

Model JDHA 180, 210, and 240 (Cabinet 2) with Option AUC8

Model JDHA 300 and 360 (Cabinet 3) with Option AUC8

Modulating

Compressor

(Circuit A)

Low Ambient Control,

Option BE8

Option BE Pressure

Controller with Fan

Option CUF3,

P/N 261041

Shutoff

Valve

Compressor

(Circuit B)

Condenser Coil

Circuit B

Equalizer

Tube

Hot Gas

Bypass Valve

Shutoff

Valve

Condenser

Coil - Circuit B

Condenser Coil

Circuit A

Hot Gas

Bypass Valve

Compressor

(Optional Circuit DH)

View from Compressor and

Condenser Section

If equipped with low ambient control, cooling is allowed to operate with an outside air tempera-

ture as low as 35°F (1.7°C).

Low Ambient Control for standard condenser fans (Option BE8

with Fan Option CUF3)

The electronic head pressure control modulates condenser fan motor speed in

low temperatures, varying the air volume through the condenser to regulate head

pressure. This model’s dual sensor input allows for the control of one or two

independent refrigerant circuits sharing the same fan motor(s). Only open, drip

proof, PSC or Shaded Pole motors are applicable for motor speed regulation. The

Controller monitors the liquid line temperature(degrees of excessive sub-cooling)

which is directly proportional to the head pressure. Speed modulation begins at 80°F

liquid line and proportionally reduces the fan to minimum speed once the liquid line

temperature reaches 50°F. Motor is turned off at liquid temperatures below or equal to

50°F. At 53°F the fan restarts at full speed; then modulates to minimum speed. When

the liquid temperature is 50°F and below the condenser fan motor will cycle between

minimum RPM and off to maintain proper condenser temperature (head pressure).

The above describes a 30ºF span (80ºF to 50ºF) function; a 25ºF span is also

available. The 25ºF span is recommended for High Efciency systems; 30ºF span for

typical systems. Variable condenser airow is modulated from full to minimum speed

over the selected span.

Temperature to

Resistance Table

Use Temperature

to Resistance table

shown on right to

verify proper sensor

operation.

Form O-Y P/N 273647R5, Page 15

Loading...

Loading...