Reznor XE Installation Manual

NOTICE:

The information contained on the following page(s) was produced

prior to May 1, 2014. On that date Reznor became part of

Nortek, Inc.

References to any other company afliations are no longer valid.

©2014 Reznor, LLC. All Rights Reserved.

Trademark notice: Reznor is registered in at least the United States.

0514 PDF Form Cover1

®

Table of Contents Para. Page

Installation and Operation ......... 1-29 ... 1-30

Check Installation and Start-Up ... 30 . 30-31

Optional Accessories ................. 31-36 . 31-41

Service/Maintenance .................. 37-41 . 41-44

Index by Page Number

Adjusting Blower Speed ............................... 24

Optional Air Flow Proving Switch .............. 2 4

Opt High Ambient Limit Control .................. 2 5

AquaSaver Timer Adjustment ........................ 34

Belts ............................................................... 24

Blocked Vent Switch ...................................... 25

Blower Motors ............................................... 24

Blower Rotation ............................................. 24

Burner Air Adjustment .................................. 30

Burner Rack Removal ..................................... 42

Burners ........................................................... 29

Carryover System ........................................... 29

Check Installation and Start-Up ....................30

Chlorines .......................................................... 7

Cleaning Pilot and Main Burners .................. 42

Cleaning the Heat Exchanger ........................ 4 2

Clearances ........................................................ 7

Optional Cooling Coil Cabinet ..................... 38

Combustion Air Requirements ........................ 7

Condensate Drain .......................................... 13

Location of Controls ...................................... 17

Cooling Coil Cabinet .................................... 38

Optional Dampers and Controls ....................35

Dimensional Data ............................................ 3

Direct Digital Control System ....................... 29

Discharge Dampers ........................................ 39

Disconnect Switch ......................................... 17

Duct Connections .......................................... 13

Optional Ductstat .......................................... 26

Electrical Supply and Connections ...............16

Optional Electronic Modulation .................. 26

Opt Evaporative Cooling Module ................ 3 2

Optional Fan Control .................................... 25

Optional Dirty Filter Switch .........................38

Filter Arrangements ....................................... 38

Optional Filter Rack and Filters .................... 37

Gas Piping and Pressures .............................. 14

Gas V alve ........................................................41

General ............................................................. 1

Hazard Intensity Levels ................................... 2

Ignition Controller ......................................... 29

Installation Codes ............................................ 2

Limit Control .................................................24

Manifold Pressure Setting ............................. 15

Optional Mechanical Modulation ................. 26

Mounting Furnaces (Indoor) ........................... 8

Mounting Outdoor Models ............................. 8

Optional Equipment ...................................... 31

100% Outside Air Hood ................................31

Pilot and Ignition Systems ............................ 29

Reverse Flow, Limit Control ..........................25

Roof Curb Assembly and Installation .............. 9

30% Screened Air Hood Opening ................ 32

Optional 4-foot Stack Extension ................... 1 2

Start-Up .......................................................... 30

Suspending Furnaces ....................................... 8

Troubleshooting ............................................ 43

Optional Two-Stage Operation ..................... 25

Uncrating ......................................................... 2

V alve ...............................................................25

Variable Frequency Drive .............................. 24

Vent Cap Installation ..................................... 12

Optional Power Venting ................................ 12

Venting ........................................................... 11

Venting Requirements .................................... 11

Optional Vertical Flue Discharge .................. 1 3

Warranty ........................................................... 2

Wiring Diagrams ............................................ 18

Form I-XE/CRGB/RPB (V ersion C)

Obsoletes Form I-XE/RGB /RPB (V ersion B)

Installation / Operation / Maintenance

Applies to: Model Series

XE, CRGB, RPB Packaged

Duct Furnace Assemblies

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don't touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier .

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in

open containers in the vicinity of this appliance is hazardous.

WARNING: Improper installation, adjustment, alteration, service, or

maintenance can cause property damage, injury or death. Read the

installation, operation, and maintenance instructions thoroughly before

installing or servicing this equipment.

WARNING: Gas-fired appliances are not designed for use in hazardous

atmospheres containing flammable vapors or combustible dust, in

atmospheres containing chlorinated or halogenated hydrocarbons, or in

applications with airborne silicone substances. See Hazard Levels, Page 2.

GENERAL

Installation should be done by a qualified agency in accordance with the instructions in this

manual and in compliance with all codes and requirements of authorities having jurisdiction.

The instructions in this manual apply to the packaged systems listed below.

Model Series

Designation

Installation Vent CFM

XE Standard

Indoor

HXE High

CRGB Standard

HCRGB High

Outdoor

RPB Standard

HRPB High

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 1

Characteristics

Thermal

Efficiency

Gravity

80%

Power

1. Approval and Installation Codes

p

p

p

p

p

p

The models covered in this manual are design certified or approved duct

furnaces that are factory assembled with air handing components, creating a unified packaged furnace/blower system. The packaged system

models listed on page 1 are design-certified to ANSI and CSA Standards

by the Canadian Standards Association. All models are approved for

installation in the United States. All models except Model CRGB and

Model HCRGB are approved for installation in Canada. All furnaces are

approved for use with either natural gas or propane. The type of fuel for

which the furnace is equipped and the correct firing rate are shown on

the rating plate attached to the unit. Electrical characteristics are shown

on both the motor nameplate and the unit rating plate.

These units must be installed in accordance with local building codes. In

the absence of local codes, in the United States, the unit must be installed in accordance with the National Fuel Gas Code NFPA54/ANSI

Z223.1 (latest edition). A Canadian installation must be in accordance

with the CSA B149.1 Natural Gas and Propane Installation Code. These

codes are available from CSA Information Services, 1-800-463-6727.

Local authorities having jurisdiction should be consulted before installation is made to verify local codes and installation procedure requirements.

Special Installations (Aircraft Hangars/Garages)

Installations in aircraft hangars should be in accordance with NFP A No.

409 (latest edition), Standard for Aircraft Hangars; in public garages in

accordance with NFPA No. 88A (latest edition), Standard for Parking

Structures; and for repair garages in accordance with NFPA No. 88B

(latest edition), Standard for Repair Garages. In Canada, installations in

aircraft hangars should be in accordance with the requirements of the

enforcing authorities, and in public garages in accordance with CSA

B149.1 codes.

WARNING: To ensure safety, follow the lighting

instructions located on the outlet box cover plate

in the heater section of the packaged furnace

assembly .

HAZARD INTENSITY LEVELS

used for W arnings in this Manual

1. DANGER: Failure to comply will result in

severe personal injury or death and/or

property damage.

2. W ARNING: Failure to comply could result in

severe personal injury or death and/or

property damage.

3. CAUTION: Failure to comply could result in

minor personal injury and/or property damage.

3. Uncrating and Preparation

This furnace was test operated and inspected at the factory prior to

crating and was in operating condition. If the equipment has incurred

any damage in shipment, document the damage with the carrier and

contact your Reznor distributor.

Check the rating plate for the gas specifications and electrical characteristics of the furnace to be sure that they are compatible with the gas and

electric at the installation site. Read this booklet and become familiar

with the installation requirements of your particular model. If you do

not have knowledge of local requirements, check with the local gas

company or any other local agencies who might have requirements

concerning this installation. Before beginning, make preparations for

necessary supplies, tools, and manpower.

Check to see if there are any field-installed options that need to be

assembled to the furnace prior to installation.

Option Parts - Some gas control options will have parts either shipped

loose with the heater or shipped separately. If your unit is equipped

with any of the following gas control options, be sure these parts are

available at the job site.

2. Warranty

Refer to limited warranty information on the warranty card in the

"Owner's Envelope".

W ARRANTY : Warranty is void if......

a . Packaged furnaces are used in atmospheres containing

flammable vapors or atmospheres containing

chlorinated or halogenated hydrocarbons or any

contaminant (silicone, aluminium oxide, etc.) that

adheres to the spark ignition flame sensing probe.

b . Wiring is not in accordance with the diagram furnished

with the heater .

c. Unit is installed without proper clearances to

combustible materials or without proper ventilation and

air for combustion. (See Paragraphs 5 and 6.)

d . Furnace air throughput is not adjusted within the range

specified on the rating plate.

Heating -- Gas Option AG7

Thermostat, P/N 48033

Cont rol O

Makeu

Gas Control

tions Option AG9

O

(If an o

remote console O

is ordered, the

control switch

is mounted on

the console.) O

Other shipped-separate options could include a roof curb, a cooling coil

cabinet, a screened outside air hood, a gas shutoff valve, a condensate

drain fitting, a thermostat, a different control switch, a power venter, a

remote console, a manual fan switch, a vertical vent terminal, a gas

supply regulator, and/or a disconnect switch. Or, if equipped with an

optional evaporative cooling module, a water hammer arrestor or fill and

drain or freeze kit could be shipped separately.

tion

Air -- Option AG3, AG6, AG8 or AG13

Control Switch, P/N 29054

Remote Temperature Selector, P/N 48042

tional

Control Switch, P/N 29054

tion AG15

Remote Temperature Selector, P/N 115848

Stage Adder Module, P /N 115849

Control Switch, P/N 29054

tion AG16

Remote Temperature Selector, P/N 115848

Stage Adder Module, P /N 115849

Remote Display Module, P/N 115852

Control Switch, P/N 29054

Option AG39

Remote Temperature Selector, P/N 174849

Form I-XE/CRGB/RPB, Page 2

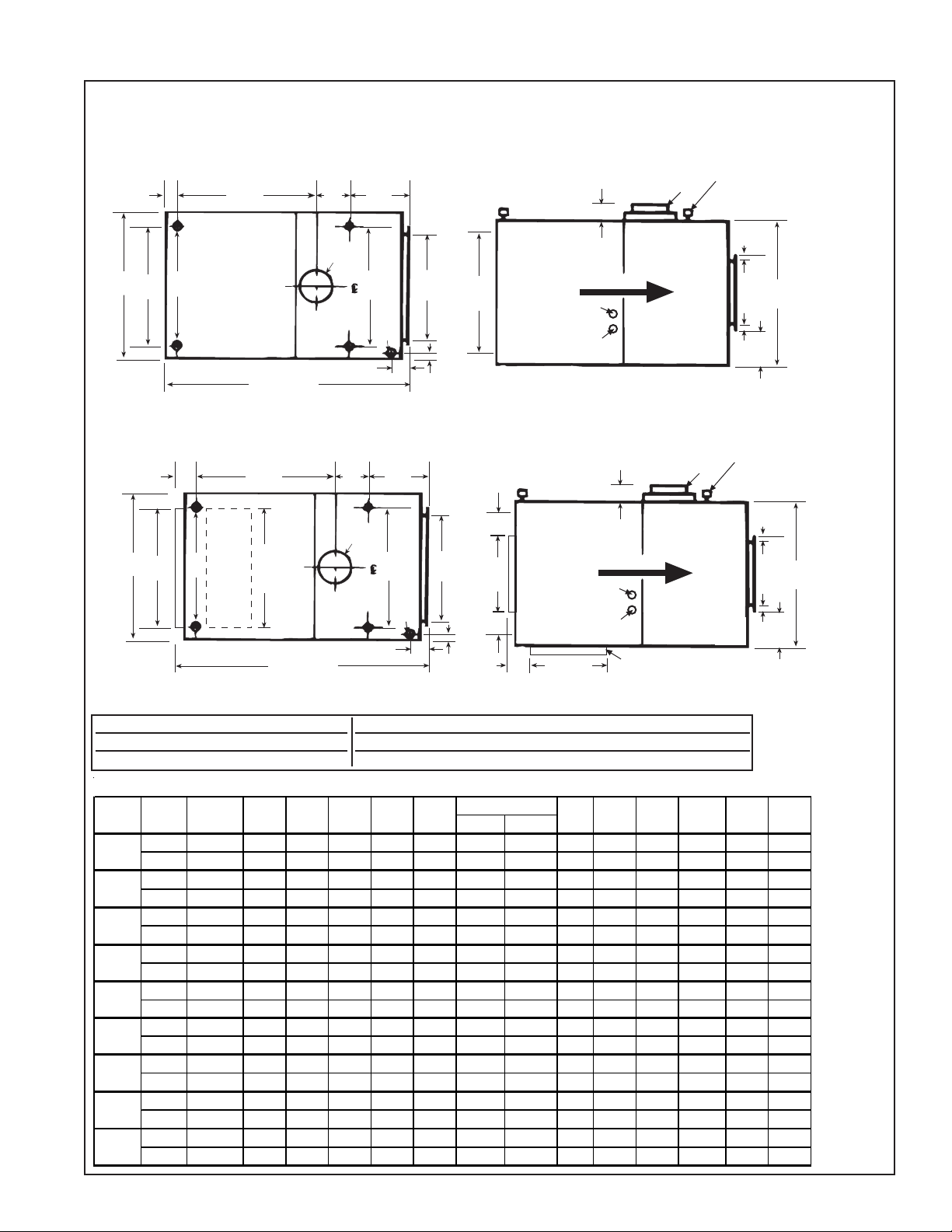

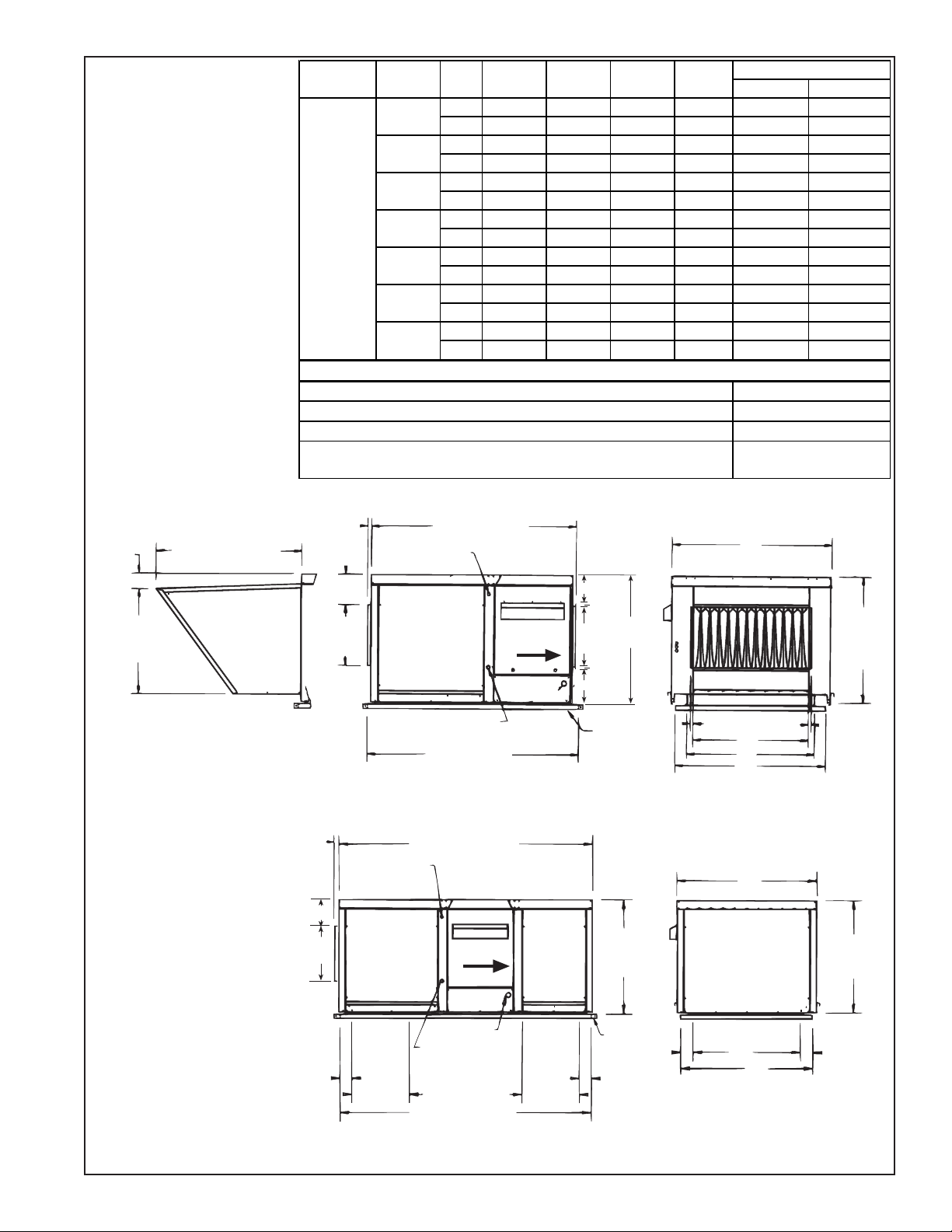

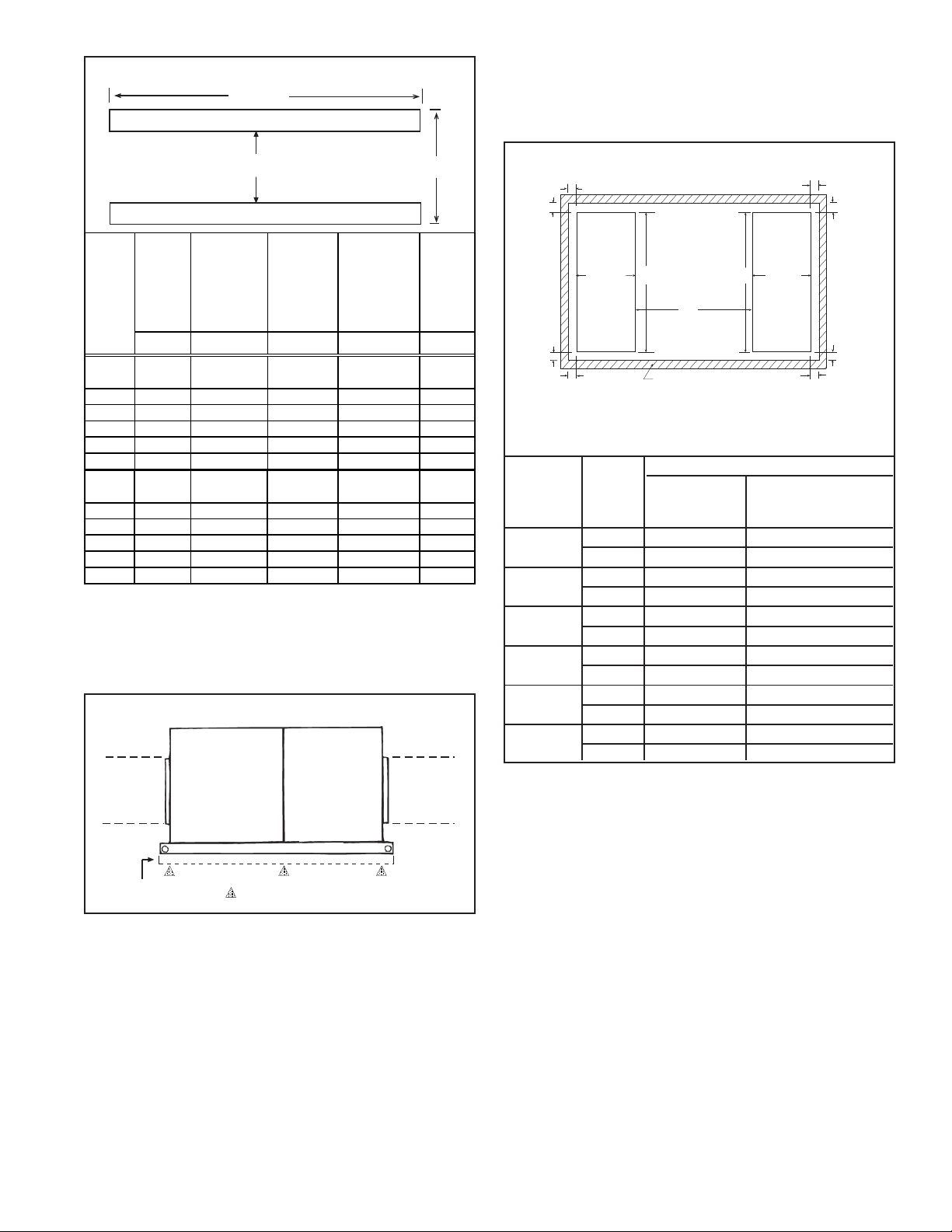

4. Dimensions

FIGURE 1A - Dimensions (inches and mm) of Indoor/Gravity V ented System

Dimensions of Model (H)XE with Standard Blower Cabinet (Standard blower cabinet has "full open" end and will not accommo-

date dampers. An optional cabinet is available with a smaller horizontal inlet that will accommodate dampers; see dimensional

drawing below . An optional bottom inlet will also accommodate dampers.)

3/4 (19)

Top View

J

G

F

Side View

3-5/8 (92)

(4)Mounting Sockets

K

1 IPS free turning

female pipe thread

3/4 (19)

18

(457)

3/4

(19)

8 (203)

H

W

K

X

C

B

A

E

Control Wiring

Blower Furnace

Gas

Supply Wiring

AIRFLOW

Entrance

Entrance

FurnaceBlower

4 (102)

59 (1499)

2-1/8

(54)

Dimensions of Model (H)XE with Optional Blower Cabinet (Optional blower cabinet has a horizontal inlet that will accommodate

dampers. The cabinet also has a bottom inlet that is shipped with a cap; the bottom inlet will accommodate dampers.)

Top View

J

C

W

1-3/4 (44)

X

C

Blower

60 (1524)

Dimension Key:

A x 18" (457mm) = Discharge Opening

B = Hanger Centerline - Furnace Section

G

F

3-1/4 (83)

K

B

A

19-1/2

(495)

Control Wiring

Furnace

Gas

D

Supply Wiring

4 (102)

2-1/8

(54)

3-1/4 (83)

C x E = Return Air Opening with Standard Cabinet

C x 19-1/2" (495mm) = Return Air Openings with Optional Cabinet

X = Hanger Centerline - Standard and Optional Blower Cabinet

Entrance

Entrance

19-1/2

(495)

Side View

3-5/8 (92)

AIRFLOW

Vertical return air

opening is capped

at the factory.

(4)Mounting Sockets

K

1 IPS free turning

female pipe thread

FurnaceBlower

3/4 (19)

18

H

(457)

3/4

(19)

8 (203)

Dimensions (inches and mm ) - Gravity-Vented/I ndoor Mo dels XE/H XE

Gas Connection

Natural Propa ne

75

100

125

150,

175

200,

225

250

300

350

400

inche s

mm

inche s

mm

inche s

mm

inche s

mm

inche s

mm

inche s

mm

inche s

mm

inche s

mm

inche s

mm

ABSize

12-1/2 13-1/2 17-3/8 9-1/2 27-3/4 18 1/2 1/2 3-3/4 32-1/4 36-1/2 5 Rd 22 16-1/4

318 343 441 241 705 457 13 13 95 819 927 127 Rd 559 413

12-1/2 13-1/2 17-3/8 9-1/2 27-3/4 18 1/2 1/2 3-3/4 32-1/4 36-1/2 6 Rd 22 16-1/4

318 343 441 241 705 457 13 13 95 819 927 152 Rd 559 413

15-1/4 16-1/4 17-3/8 9-1/2 27-3/4 18 1/2 1/2 3-3/4 32-1/4 36-1/2 7 Ov 22 16-1/4

387 413 441 241 705 457 13 13 95 819 927 178 Ov 559 413

20-3/4 21-3/4 23 9-1/2 27-3/4 19-3/8 1/2 1/2 2-3/8 32-1/4 36-1/2 8 Ov 27-1/2 21-3/4

527 552 584 241 705 492 13 13 60 819 927 203 Ov 699 552

26-1/4 27-1/4 28-3/8 12-1/2 30-3/4 18 1/2 1/2 2-1/4 35-1/4 38 8 Rd 33 27-1/4

667 692 721 318 781 457 13 13 57 895 965 203 Rd 838 692

34-1/2 35-1/2 36-5/8 12-1/2 30-3/4 18 1/2 1/2 2-1/4 35-1/4 38 10 Ov 41-1/4 35-1/2

876 902 930 318 781 457 13 13 57 895 965 254 Ov 1048 902

34-1/2 35-1/2 36-5/8 12-1/2 30-3/4 18 3/4 1/2 2-1/4 35-1/4 38 10 Ov 41-1/4 35-1/2

876 902 930 318 781 457 19 13 57 895 965 254 Ov 1048 902

40 41 42-1/8 12-1/2 30-3/4 19-3/8 3/4 1/2 7/8 35-1/4 38 12 Ov 46-3/4 41

1016 1041 1070 318 781 492 19 13 22 895 965 305 Ov 1187 1041

45-1/2 46-1/2 47-5/8 12-1/2 30-3/4 18 3/4 1/2 2-1/4 35-1/4 38 12 Ov 52-1/4 46-1/2

1156 1181 1210 318 781 457 19 13 57 895 965 305 Ov 1327 1181

CDEF WXGH J K

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 3

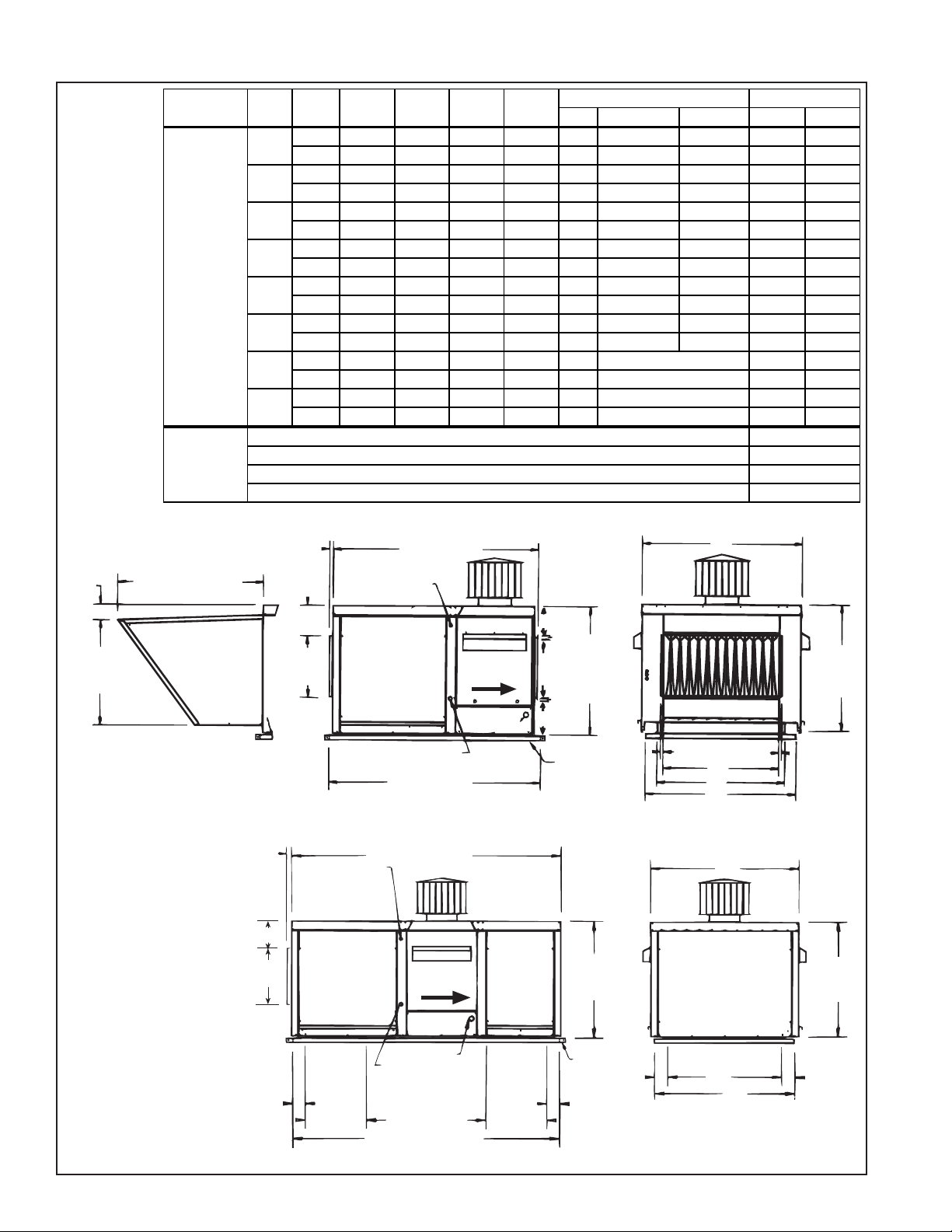

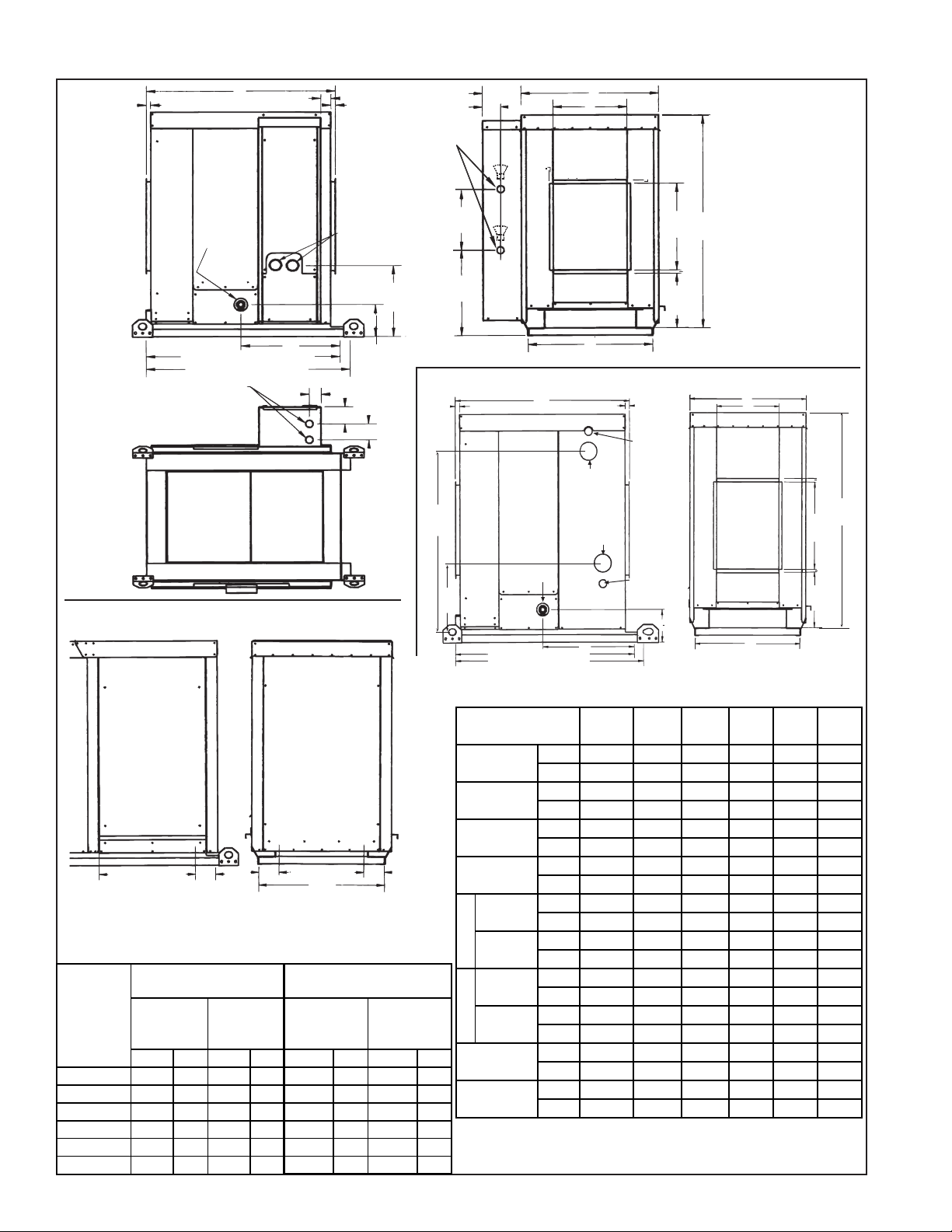

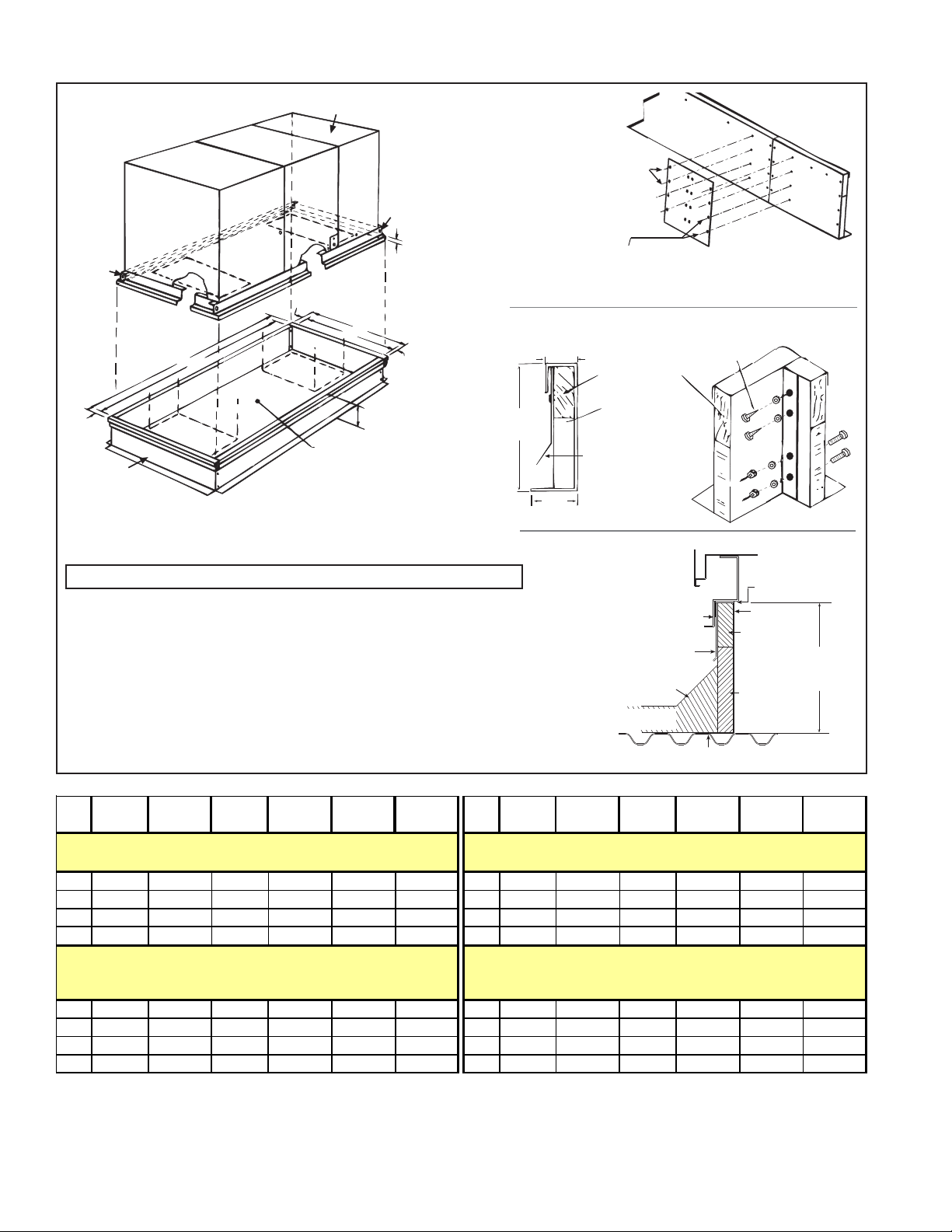

4. Dimensions (cont'd)

*

g

p

FIGURE 1B Dimensions,

Outdoor/

GravityV ented Model

Series CRGB

4-5/8

(117)

31-11/32

(796)

Model

Series

CRGB,

HCRGB

Size

75,

100

125

175

225

250

300

350

400

ABC

inches

inches

inches

inches

inches

inches

inches

inches

28-5/8 17-3/8 25-7/8 12-1/2 6 9 None 1/2 1/2

mm

727 441 657 318 152 229 None 13 13

28-5/8 17-3/8 25-7/8 15-1/4 8 11-1/2 None 1/2 1/2

mm

727 441 657 387 203 292 None 13 13

34-1/8 22-7/8 31-3/8 20-3/4 8 11-1/2 None 1/2 1/2

mm

867 581 797 527 203 292 None 13 13

39-5/8 28-3/8 36-7/8 26-1/4 10 15 None 1/2 1/2

mm

1006 721 937 667 254 381 None 13 13

47-7/8 36-5/8 45-1/8 34-1/2 10 15 None 1/2 1/2

mm

1216 930 1146 876 254 381 None 13 13

47-7/8 36-5/8 45-1/8 34-1/2 10 15 None 3/4 1/2

mm

1216 930 1146 876 254 381 None 19 13

53-3/8 42-1/8 50-5/8 40 12 14-1/8 plus 12 3/4 1/2

mm

1362 1070 1286 1016 305 359 plus 305 19 13

58-7/8 47-5/8 56-1/8 45-1/2 12 14-1/8 plus 12 3/4 1/2

mm 1470 1210 1426 1156 305 359 plus 305 19 13

Standard Horizontal Air Inlet 19-1/2 (495) x B

ening

Air O

Dimensi ons

Optional Return Air Op ening (bottom) 19-1/2 (495) x B

Standard Horizontal Discharge Air Opening 18 (457) x D

Optional Vertical Discharge Air Opening (Op tion AQ5 or AQ8 Do wnturn Plenum****) 19-1/2 (495) x B

**** for downturn plenum with cooling coil cabinet, see page 6.

61-3/8 (1559)

Entrance

Blower

Cabinet

43-17/32 (1106)

Screened

Outside

Air Hood -

Option AS2

1-1/32 (26)

Control Wiring

5 (127)

19-1/2

(495)

Furnace

Airflow

Gas

D

I.D. Heig ht Extension Natural Propane

8-1/2(215)

3/4(19)

39-3/16*

18

(457)

3/4(19)

11-1/4(286)

Vent Cap Gas Connection

A

(995)

38-1/8**

(968)

NOTES:

*Height from top of

cabinet to top of curb

cap.

**Height from top of

cabinet to bottom of

cabinet side.

*** If system has a cooling

coil cabinet, add length

dimension on page 6 for full

system length.

**** The two-position

discharge dampers in

Option AQ8 fit in the

discharge air opening. The

damper motor fits inside the

downturn plenum cabinet.

For dimensions with

downturn plenum cabinet

with a cooling coil cabinet,

see page 6.

Form I-XE/CRGB/RPB, Page 4

1-1/32

(26)

5 (127)

19-1/2

(495)

4-3/32

(104)

Field Wiring

(line voltage)

61-7/8 (1572)

Left Side View with Horizontal Discharge

Field Control

86-11/16 (2202)

Wiring

Entrance

Blower

Cabinet

Optional

Return

Air Inlet

19-1/2

(495)

Furnace

Airflow

Gas

Field Wiring

(line voltage)

38-5/8 (981)

Vertical

Discharge

19-1/2

85-13/16 (2180)

Left Side View with Vertical Dischar

Plenum

Optional

Downturn

(495)

Curb Cap

39-3/16*

(995)

Cabinet

Curb Cap

4-3/32

(104)

e

3/4(19)

Front View with

Standard Horizontal Discharge

3/4(19)

D

B

C

A

38-1/8*

(968)

4-1/4

(108)

B

C

4-1/4

(108)

Front View with

Opt ional Vertical Discharge

(Downturn Plenum Option AQ5 or AQ8)

FIGURE 1C Dimensions, Outdoor/

Power-V ented Model

Series RPB

Model Size

150, 175

200, 225

(H)-RPB

125

250

300

350

400

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

inches

mm

AB

CD

28-5/8 17-3/8 25-7/8 15-1/4 1/2 1/2

727 441 657 387 13 13

34-1/8 22-7/8 31-3/8 20-3/4 1/2 1/2

867 581 797 527 13 13

39-5/8 28-3/8 36-7/8 26-1/4 1/2 1/2

1006 721 937 667 13 13

47-7/8 36-5/8 45-1/8 34-1/2 1/2 1/2

1216 930 1146 876 13 13

47-7/8 36-5/8 45-1/8 34-1/2 3/4 1/2

1216 930 1146 876 19 13

53-3/8 42-1/8 50-5/8 40 3/4 1/2

1362 1070 1286 1016 19 13

58-7/8 47-5/8 56-1/8 45-1/2 3/4 1/2

1470 1210 1426 1156 19 13

Gas Connection

Natural Propane

Air Openings: Dimensions

Standard Horizontal Air Inlet 19-1/2 (495) x B

Optional Return Air Opening (bottom) 19-1/2 (495) x B

Standard Horizontal Discharge Air Open ing 18 (457) x D

Optional Vertical Discharge Air Opening (with Option AQ5 or AQ8

Downtu rn P lenum****)

19-1/2 (495) x B

****for downturn plenum with cooling coil cabinet, see page 6.

4-5/8

(117)

31-11/32

(796)

43-17/32 (1106)

Screened

Outside

Air Hood -

Option AS2

NOTES:

*Height from top of

cabinet to top of curb

cap.

**Height from top of

cabinet to bottom of

cabinet side.

*** If system has a cooling

coil cabinet, add length

dimension on page 6 for full

system length.

**** The two-position

discharge dampers in

Option AQ8 fit in the

discharge air opening. The

damper motor fits inside

the downturn plenum

cabinet. For dimensions

with downturn plenum

cabinet with a cooling coil

cabinet, see page 6.

1-1/32 (26)

1-1/32

(26)

5 (127)

19-1/2

(495)

4-3/32

(104)

61-3/8 (1559)

Control Wiring

Entrance

5 (127)

19-1/2

(495)

Blower

Cabinet

Field Wiring

(line voltage)

61-7/8 (1572)

Left Side View with Horizontal Discharge

86-11/16 (2202)

Field Control

Wiring

Entrance

Blower

Cabinet

Optional

Return

Air Inlet

19-1/2

(495)

Furnace

Airflow

Gas

Field Wiring

(line voltage)

38-5/8 (981)

85-13/16 (2180)

Left Side View with Vertical Discharge

Furnace

Airflow

Gas

Optional

Vertical

Discharge

19-1/2

(495)

8-1/2(215)

3/4(19)

18

(457)

3/4(19)

11-1/4(286)

Curb Cap

Plenum

Cabinet

Downturn

A

39-3/16*

(995)

3/4(19)

Front View with

Standard Horizontal Discharge

3/4(19)

D

B

C

A

39-3/16*

(995)

Curb Cap

4-3/32

(104)

4-1/4

(108)

Opt ional Vertical Discharge

B

C

Front View with

(Downturn Plenum Option AQ5 or AQ8)

38-1/8**

(968)

38-1/8**

(968)

4-1/4

(108)

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 5

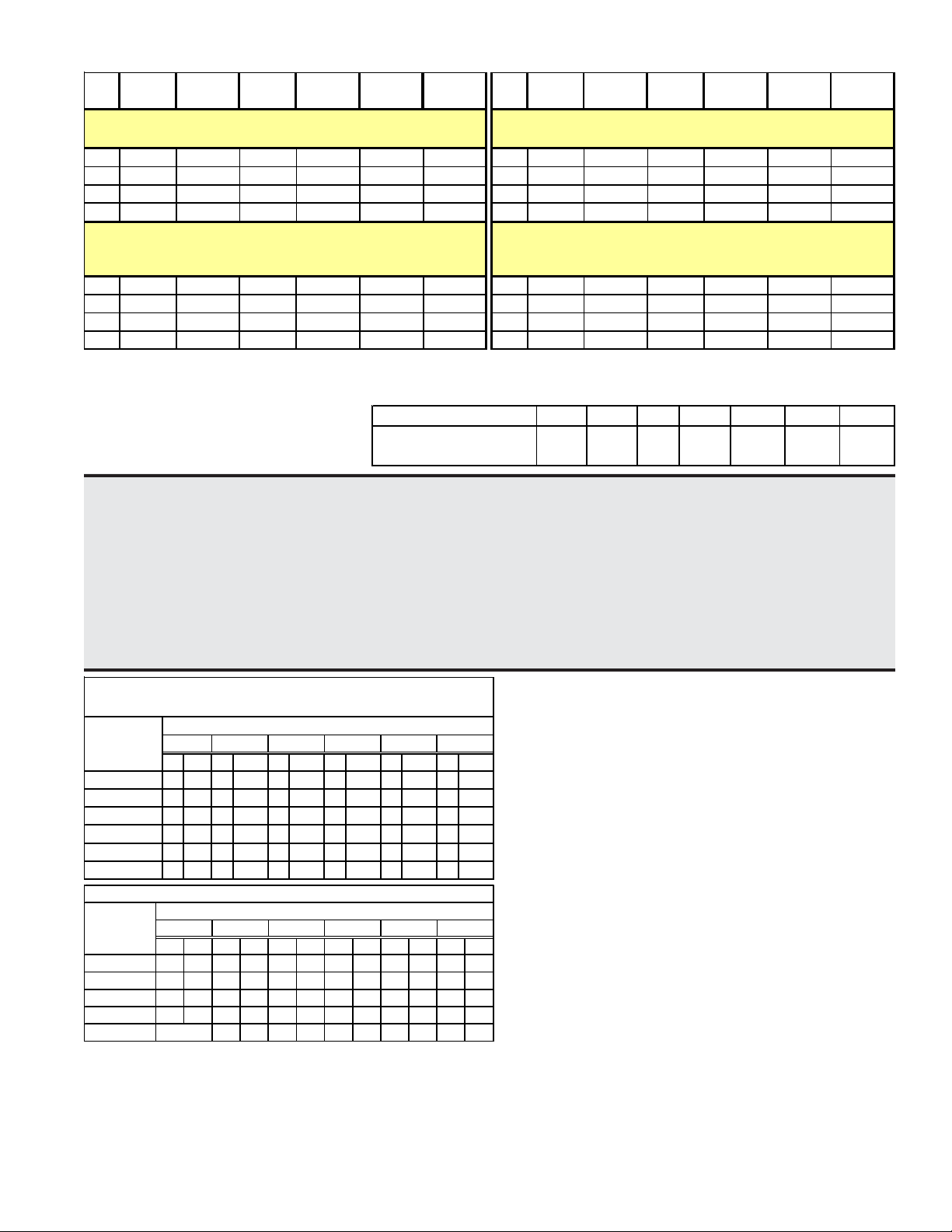

4. Dimensions (cont'd)

Refrigerant

R22 (DX)

Coil

Cabinet Options

AU3, AU13,

AU14

7/8 (22)

D

Side View

DX Coil

Cabinet

Drain Pan

Outlet

(1 FPVC)

2 (51)

Coil

Header

Housing

7/8 (22)

(7/8 or 1-3/8)

Suction Line

Connection

(1-5/8 or 2-1/8)

14-1/2

(368)

5-1/8 (130)

Liquid Line

Connections

12-1/2

(318)

16-1/4

(413)

8 (203)

3/4

(19)

(Option AU3)

A

B

Front View

DX Coil

Cabinet with

Horizontal

Discharge

3/4

(19)

18

(457)

11-1/4

(286)

3/4

(19)

44-1/4

(1124)

FIGURE 1D -

Optional Cooling

Coil Cabinets with

DX or Chilled

Water Coil, with

or without

Downturn Plenum

Cabinet (Applies

to Outdoor

Models)

F

(Inside of Curb Cap)

E

(Curb Cap Length)

Connection Knockouts

Liquid Line

(alternate locations)

Bottom View

DX Coil

Cabinet

G

2-3/8

(60)

3-1/2(89)

6-5/8

(168)

3-1/4(83)

Chilled W ater Cooling Coil Cabinet in Options AU2, AU1 1, AU12

Downturn Plenum Cabinet (factory attached to

either type of Cooling Coil Cabinet)

Side View

Side View

Optional

Optional

Downturn

Downturn

Plenum

Plenum

Cabinet

Cabinet

19-1/2 (495)

Discharge Air

4-1/4

(108)

Discharge Damper Note: Optional two-position discharge dampers

in Option AU12 or AU14 fit in the discharge air opening. The

damper motor fits inside the downturn cabinet. See field wiring

instructions in Paragraph 36.

Width of Cabinets (not

Model

Series

CRGB and

RPB S ize

w/Chilled

Water Coil

inches mm inches mm inches mm inches m m

Cabinet

curb )

w/DX Coil

Cabinet

75, 100, 125 29-1/8 740 37-1/8 943 98-1/2 2502 121-5/8 3069

150, 175 34-5/8 879 42-5/8 1083 104 2642 127-1/2 3229

200, 225 40-1/8 1019 48-1/8 1222 109-1/2 2781 132-5/8 3369

250, 300 47-1/8 1197 55-1/8 1400 117-3/4 2991 140-7/8 3578

350 53-3/8 1356 61-3/8 1559 123-3/8 3134 146-1/2 3721

400 58-7/8 1495 66-7/8 1698 128-3/4 3270 151-7/8 3858

Form I-XE/CRGB/RPB, Page 6

Front View

Optional

Downturn

Plenum

Cabinet

4-1/4

J

(Discharge Air)

(108)

C

Length of All System

Cabinets (not curb)

w/Cooling

Coil Cabinet

only

4-1/4

(108)

w/Cooling

Coil Ca binet

w/Downturn

C

A

B

Front View

CW Coil

Cabinet with

Horizontal

Discharge

(Option AU2)

C

38-3/8

(975)

15-1/4

(387)

7/8 (22)

Side View

Chilled

Water Coil

Cabinet

Drain Pan

Connection

1 FPVC)

(Inside of Curb Cap)

F

E

(Curb Cap Length)

D

7/8 (22)

Return

Connection

2-1/2 NPT

Supply

Connection

2-1/2 NPT

G

Coil Vent

1/2 NPT

Coil Drain

Connection

1/2 NPT

6-5/8

(168)

Dimensions (inches ± 1/8; mm± 3)

Furnace Size 75, 100,

125

28-1/2 34 39-1/2 47-3/4 53-1/4 58-3/4

inches

mm 724 864 1003 1213 1353 1492

inches 15-1/4 20-3/4 26-1/4 34-1/2 40 45-1/2

mm 387 52 667 876 1016 1156

inches 25-7/8 31-3/8 36-7/8 45-1/8 50-5/8 56-1/8

mm 657 797 937 1146 1286 1426

inches 37-1/8 42-5/8 48-1/8 56-3/8 62 67-3/8

mm 943 1083 1222 1432 1575 1711

inches 40 45-5/8 51 59-3/8 64-7/8 70-3/8

mm 1016 1159 1295 1508 1648 1788

With

inches 64 69-5/8 75 83-3/8 88-7/8 94-3/8

mm 1626 1768 1905 2118 2257 2397

inches 38-1/8 43-5/8 49-1/8 57-3/8 63 68-3/8

mm 968 1108 1248 1457 1600 1737

With

inches 62-1/8 67-5/8 73-1/8 81-3/8 87 92-3/8

mm 1578 1718 1857 2067 2210 2346

inches 19-1/2 22-1/4 25 29-1/8 31-7/8 34-5/8

mm 495 565 635 740 810 879

inches 17-3/8 22-7/8 28-3/8 45-1/8 50-5/8 56-1/8

mm 441 581 721 1146 1286 1426

E

F

A

B

C

D

Without

Downturn

Downturn

Without

Downturn

Downturn

G

J

NOTE: For the length of a system with a cooling coil cabinet, see the

table on the left. Cooling coil cabinet is shipped separately and attached

in the field. See page 10 for roof curb dimensions.

150,

175

200,

225

250,

300

350 400

18

(457)

11-1/4

(286)

(19)

3/4

(19)

3/4

44-1/4

(1124)

5. Clearances

Provide clearance to combustibles as shown in the table. Clearance to

combustibles is defined as the minimum distance from the heater to a

surface or object that is necessary to ensure that a surface temperature

of 90°F above the surrounding ambient temperature is not exceeded.

Clearance is also required to sides of furnace for combustion air space

and for convenient installation and burner control system service.

REQUIRED CLEARANCES

Model Series

(H)XE

(H)RPB,

(H)CRGB

(H)CRGB

* When installed on a roof cu rb on a combustible roof, the roof area enclosed

within the curb must be either ventilated, left open, or covered with noncombustible material which has an "R" value at least 5. 0. See

Top

6"

(152mm )

36"

(915mm )

30' ( 9M) ra dius from center of vent ca p to obstructions

such as w a ll s, para pe t s or cupolas

Sides Bottom

Control Opposite

Width of

furnace

plus 6"

(152mm)

6"

(152mm )

6"

(152mm )

To

Combustibles

3" (76mm) 0

0 * 0

Combustibles

FIGURE 8

To Non-

, page 10.

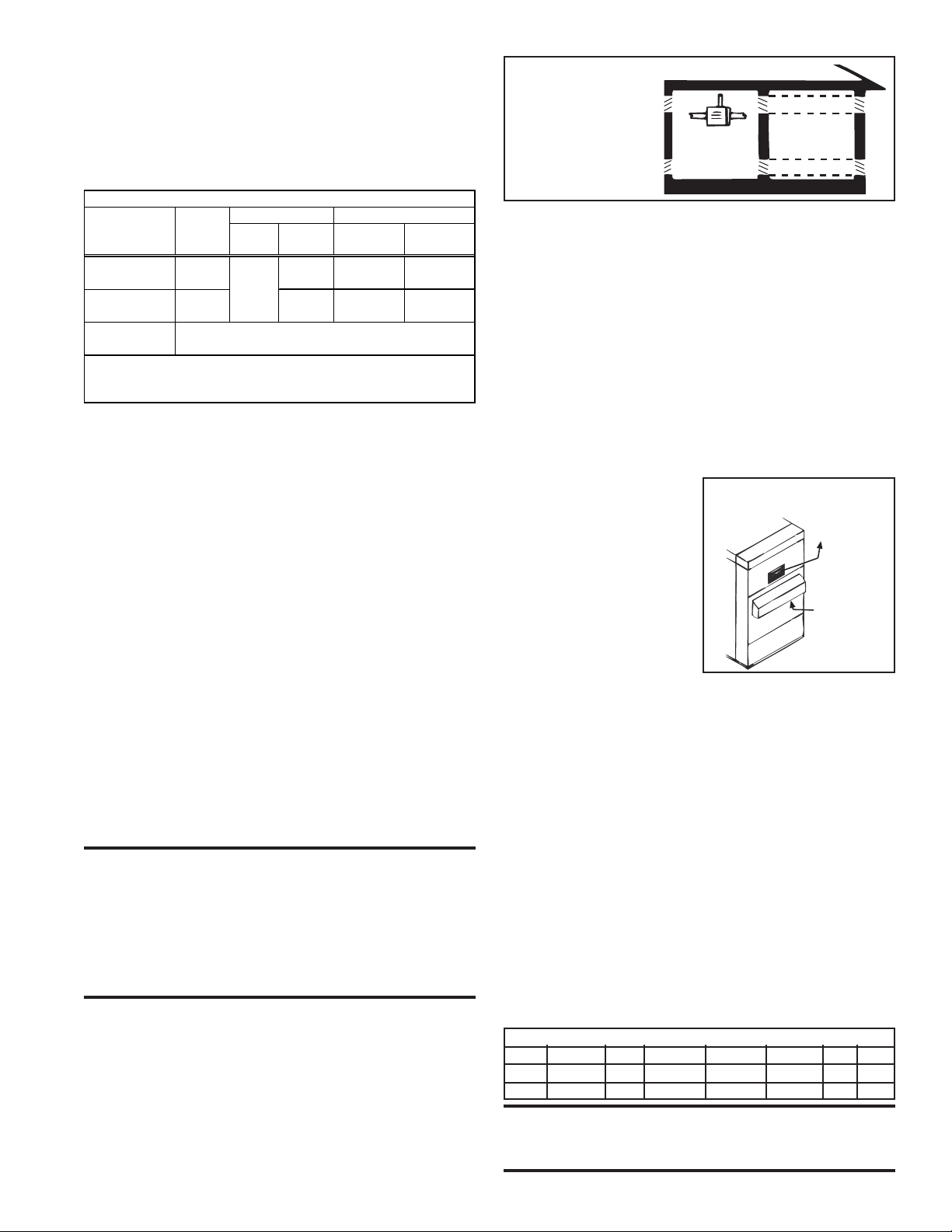

6. Combustion Air Requirements

6A. Indoor , Gravity-V ented Models XE/HXE

These furnaces are designed to take combustion air from the space in

which the furnace is installed. The air that enters into the combustion

process is vented to the outdoors. Sufficient air must enter the equipment location to replace the air exhausted through the vent system.

Modern construction methods involve the greater use of insulation,

improved vapor barriers and weather-stripping, with the result that

buildings generally are much tighter structurally than they have been in

the past. The combustion air supply for gas-fired equipment can be

affected by these construction conditions because infiltration that would

have existed in the past may not be adequate. Extensive use of exhaust

fans aggravates the situation. In the past the filtration of outside air

assumed in heat loss calculations (one air change per hour) was assumed

to be sufficient. However, current construction methods may now require the introduction of outside air through wall openings or ducts.

Requirements for combustion air and ventilation air depend upon whether

the unit is located in a confined or unconfined space. An "unconfined

space" is defined as a space whose volume is not less than 50 cubic feet

per 1000 BTUH of the installed appliance. Under all conditions, enough

air must be provided to ensure there will not be a negative pressure

condition within the equipment room or space. A positive seal must be

made in all return-air connections and ducts. Even a slight leak can create

a negative pressure condition in a confined space and affect combustion.

W ARNING: These gravity-vented, indoor furnaces

are designed to take combustion air from the space

in which the furnace is installed and are not designed

for connection to outside combustion air intake

ducts. Use of outside air ducts voids the warranty

and could cause hazardous operation. See Hazard

Levels, page 2.

Indoor , Gravity-V ented Furnace Located in a

Confined Space

Do not install a unit in a confined space without providing wall openings leading to and from the space. Provide openings near the floor and

ceiling for ventilation and air for combustion as shown in FIGURE 2,

depending on the combustion air source as noted in Items 1, 2 and 3.

Add total BTUH of all appliances in the confined space and divide by

figures below for square inch free area size of each (top and bottom)

opening.

FIGURE 2 Confined Space: A

space whose volume

(3)

(1)

(2)

is less than 50

(3)

Confined

Space

(1)

(2)

cubic feet per 1000

BTUH of the

installed appliance

input rating

1. Air fr om inside the building - openings 1 square inch free area per

1000 BTUH. Never less than 100 square inches free area for each opening. See (1) in FIGURE 2.

2. Air fr om outside through duct - openings 1 square inch free area per

2000 BTUH. See (2) in FIGURE 2.

3. Air direct from outside - openings 1 square inch free area per 4000

BTUH. See (3) in FIGURE 2.

NOTE: For further details on supplying combustion air to confined

space, see National Fuel Gas Code ANSI Z223.1a (latest edition) 5.3.3.

6B. Combustion Air for Gravity-V ented,

Outdoor Model Series CRGB

Combustion air enters through the screened air intakes located in the

furnace section access doors.

6C. Combustion Air for Power-V ented,

Outdoor Model

Series RPB

The combustion air and flue gas

openings are carefully designed

screened openings located on the

side of the unit just above the control access panel. Location of the

flue opening directly above the air

intake is designed to discourage recirculation of combustion products. See FIGURE 3.

FIGURE 3 - Combustion Air

Intake, Power-V ented

Models

Flue Products

Outlet

Combustion

Air Inlet

6D. Chlorine - All Models

The presence of chlorine vapors in the combustion air of gas-fired heating equipment presents a potential corrosion hazard. Chlorine will,

when exposed to flame, precipitate from the compound, usually freon

or degreaser vapors, and go into solution with any condensation that is

present in the heat exchanger or associated parts. The result is hydrochloric acid which readily attacks all metals including 300 grade stainless

steel.

Care should be taken to separate these vapors from the combustion

process. This may be done by wise location of the furnace with regard

to exhausters or prevailing wind direction. Remember, chlorine is heavier

than air. This fact should be kept in mind when determining installation

locations of heating equipment and building exhaust systems.

7. Suspending/Mounting

7A. Suspending/Mounting Indoor , Gravity-

Vented Models XE/HXE

Location - Before suspending the furnace, check the supporting structure to verify that it has sufficient load-carrying capacity to support the

weight of the unit.

Approximate Net Weight - Indoor Furnaces

Size 75-100 125 150-175 200-225 250-300 350 400

lbs 233 295 332 386 494 515 576

kg 106 134 151 175 224 234 261

W ARNING: A void installing a unit in an extremely

drafty area. Extreme drafts can shorten the life of

the heat exchanger and/or cause safety problems.

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 7

7A. Suspending/Mounting Indoor, Gravity-

Vented Models XE/HXE (cont'd)

WARNING: Unit must be level for proper

operation. Do not place or add additional weight to

a suspended unit. See Hazard Levels, page 2.

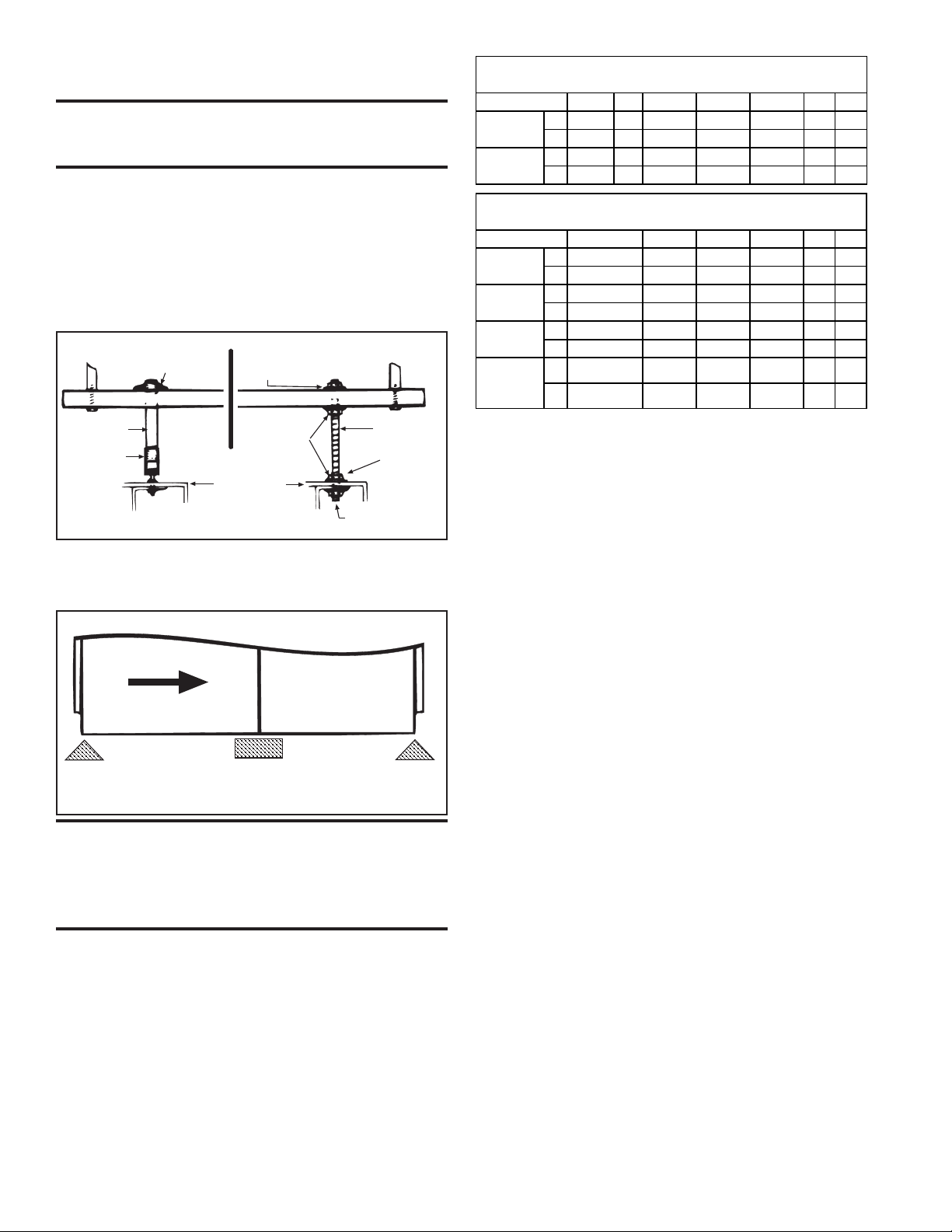

Suspending Furnaces

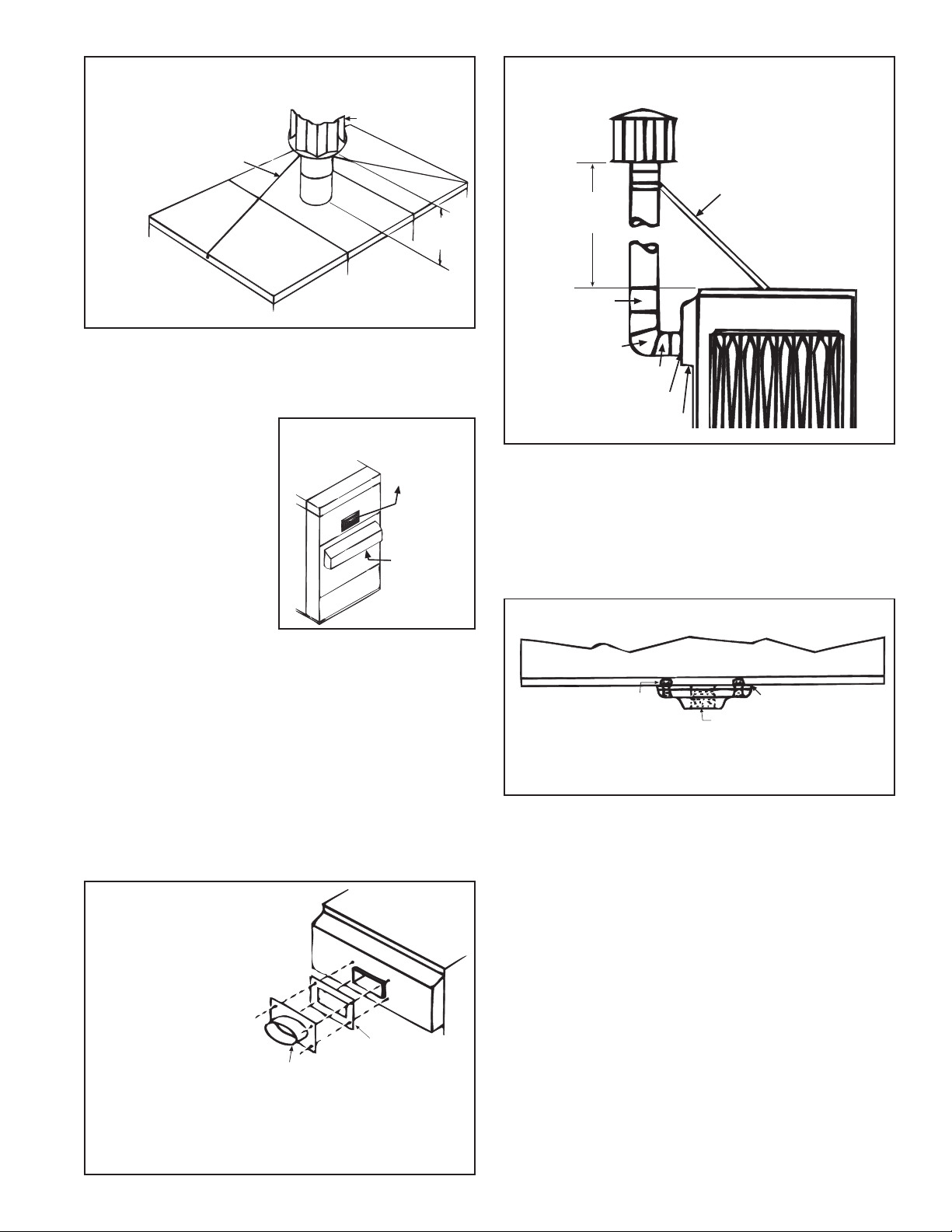

These indoor, packaged furnace/blower systems have four-point suspension. See hanger dimensions in Paragraph 4, FIGURE 1A. At each

suspension point, the unit is factory-equipped with a free-turning, female, 1" (NPT) pipe hanger. Suspend by connecting the pipe hanger to

a 1" threaded pipe. See the suspension method on the left in FIGURE 4.

As an alternative method, the factory-installed pipe hanger may be

removed and the heater suspended as illustrated on the right in FIG-

URE 4.

Standard Assembly

1 Pipe Flange

1 Pipe

Threaded

Socket

FIGURE 4 - Suspension Methods

Installer Replaced Assembly

Washer Nut Assembly

Washer Nut

Assembly

Heater Top

3/8 Rod

(Standard

Assembly

Removed)

Access through

the side panel

Approximate Net Weight (lbs/kg) - Outd oor Systems

(blower and furnace section s on ly)

Size 75, 100 125 150, 175 200, 225 250, 300 350 400

CRGB

Series

RPB

Series

Appro xim ate Net W eight ( lbs/kg) - Optional Coo l ing Co il Cabin et

Size 150, 175 200, 225 250, 300 350 400

DX w ith

Dow nturn

Chilled

Water

Chilled

Water w i t h

Dow nturn

Location - When selecting a location for an outdoor installation, posi-

tion the unit so that the air inlet will not be facing into the prevailing

wind.

When the unit is mounted on a roof over 20 ft (6 M) high, has parapet

walls or obstructions within 30 ft (9.1M), or is subject to winds over 25

mph, installation of a power-vented unit (Model Series RPB) is recommended.

lbs 439 472 510 529 573 624 655

kg 199 214 231 240 260 283 297

lbs -- 482 520 534 588 630 662

kg -- 219 236 242 267 286 300

(includes approximate weight of a coil with 12fpi)

75, 100, 125

lbs 464 551 661 753 848

DX

kg 269 250 300 342 385

lbs 593 689 813 914 1018

kg 269 313 369 415 462

lbs 457 544 654 746 841

kg 207 247 297 338 381

lbs 586 682 806 907 1011

kg 266 309 366 411 459

377

171

497

225

369

167

490

222

Mounting Indoor Furnaces

Indoor packaged systems require six support locations. See FIGURE 5.

All supports must be non-combustible.

FIGURE 5 - Support Locations for Indoor Systems

Airflow

Furnace

Blower Section

Support the unit at each end and where the blower cabinet and

furnace section join. Support at cabinet joint must extend

horizontally supporting both sections.

Section

WARNING: Do not support an indoor/gravityvented system with four corner support legs. The

system requires horizontal support at cabinet joint

as illustrated in FIGURE 5. Bottom clearance to

combustibles must be observed.

7B. Mounting Outdoor Model Series CRGB

and RPB

Rigging - Lifting holes are provided for rigging. Use spreader bars when

lifting to prevent chains or cables from damaging the unit. If the unit is

being mounted on a roof curb, apply caulking to the roof curb prior to

lifting the unit to the roof and setting it on the curb. See FIGURE 8, page

10.

If the system includes an outside air hood and/or a shipped-separate

cooling coil cabinet, attach them after the unit is in place.

If the system includes a cooling coil cabinet, the cooling coil cabinet

must be lifted to the roof separately, set on the roof curb or supports,

and attached to the furnace.

Form I-XE/CRGB/RPB, Page 8

Curb Cap Base

Outdoor systems are equipped with a load bearing curb cap which

forms an integral part of the unit. This curb cap has welded joints and

has a "skirt" which fits over a roof curb to provide a weatherproof

installation. Four holes are provided at the curb cap corners for lifting

the unit. These holes do not interfere with unit weatherproofing. The

curb cap is not designed to be placed directly on the roof surface.

The system may be mounted on an optional roof curb purchased with

the unit, a field-supplied roof curb, or field-supplied supports. If the

system has a downturn plenum and/or a bottom return air opening, a

roof curb is recommended to provide a weatherproof installation as well

as more workable clearances for ductwork. If the unit has an optional

cooling coil cabinet, the cabinet is shipped separately and attached in

the field. The cooling coil cabinet has a curb cap base that "matches and

extends" the length of the system base.

Mounting on Field-Supplied Supports (without a roof curb) - Prior

to installation, be sure that the method of support is in agreement with

all local building codes and is suited to the climate. If considering this

type of installation in snow areas, it is recommended that the 4x4 wooden

rails underneath the system be on cross-support structure at least 12"

higher than the roof surface (see support locations in FIGURE 6B).

Whether the supports are being mounted directly on the roof or being

placed "up" on additional structure, the horizontal length of the system

should be supported by two 4x4 treated wooden rails. Cut the rails to

the appropriate length (Dimension "A") in FIGURE 6A. (NOTE: Although dimensions are included for units with a downturn plenum cabinet, it is strongly recommended that a full roof curb be used on an

installation with a downturn plenum cabinet and/or a bottom return air

duct.)

Space the 4x4 wooden rails (See "B" Dimension, FIGURE 6A) so that

the curb cap "skirt" will fit over the edge of the boards with the rails

setting inside the horizontal length of the curb cap.

If the rails are being laid directly on the roof, position them as shown in

FIGURE 6A. Set the system on the rails, leaving the "ends" underneath

open for ventilation.

FIGURE 6A - Mounting Support Dimensions (inches/mm)

A

Leave both

ends open

for ventilation.

4x4 Treated Lumber

B

Bottom Duct Connections - The blower section and optional downturn plenum have duct flanges for connection to return air and supply

air ducts. Duct opening sizes and curb spacing shown in FIGURE 7 is

for currently manufactured curbs that are available from the system

manufacturer.

FIGURE 7 - Duct Opening Dimensions in Relation to Roof

Curb Option - inches (mm)

1-5/8 (41)

1-5/8 (41)

Standard

Heater

Blower

Package

Model Series CRGB

and RPB Sizes

75, 100,

150, 175 60-5/8" 84-9/16" 103-7/8" 127-7/8" 29-13/16"

200, 225 60-5/8" 84-9/16" 109-3/8" 133-3/8" 35-5/16"

250, 300 60-5/8" 84-9/16" 117-5/8" 141-5/8" 43-9/16"

75, 100,

150, 175 1540mm 2148mm 2638mm 3248mm 757mm

200, 225 1540mm 2148mm 2778mm 3388mm 897mm

250, 300 1540mm 2148mm 2988mm 3597mm 1106mm

60-5/8" 84-9/16" 98-3/8" 122-1/4" 24-5/16"

125

350 60-5/8" 84-9/16" 123-1/8" 147-1/8" 49-1/16"

400 60-5/8" 84-9/16" 128-5/8" 152-5/8" 54-1/2"

1540mm 2148mm 2499mm 3105mm 618mm

125

350 1540mm 2148mm 3127mm 3737mm 1246mm

400 1540mm 2148mm 3267mm 3877mm 1384mm

With Factory-

Installed

and

"A" "A" "A" "A" "B"

Downturn

Plenum

Cabinet

(Option AQ)

With

ShippedSeparate

Cool i n g

Coil

Cabinet

(O ption AU)

With Shipped-

Separate

Cooling Coil

Cabinet with

Downturn

Plenum

(Option AU)

All

Configurations

If the treated wooden rails are not being placed directly on the roof

surface, cross-supports should be placed underneath the rails at the

ends of the unit and at all cabinet "joints" (between the blower cabinet

and the furnace section; between the furnace and the optional downturn

plenum or coil cabinet; and between a coil cabinet and a downturn

plenum). See FIGURE 6B.

FIGURE 6B - Cross-Support Locations

Field

Supplied

Duct

4x4 Treated

Lumber

The field-supplied, weather-resistant cross-support structure must be

adequate for the weight of the system (including air conditioning coil if

applicable), and all cross-supports should run the entire width of the

system supporting the 4x4 wooden rails at the recommended locations.

Mounting on a Roof Curb - Whether using an optional roof curb

available with the system or a field-supplied curb, the curb must be

secure, square and level. The top surface of the roof curb must be

caulked with 1/4" x 1-1/4" sealant tape or two 1/4" beads of suitable

sealant. The unit must be sealed to the curb to prevent water leakage

into the curb area due to wind blown rain and capillary action. Except

for the curb assembly details which are specific to the optional roof

curb available with the system, the information and requirements in

this section apply to all curbs. See FIGURE 8, page 10, and the curb

installation instructions below.

Blower

Cabinet

Furnace

Section

= Cross Support Locations

Field

Supplied

Duct

1-5/8

(41)

1-5/8

(41)

19-1/2

(495)

Return

Duct

1-5/8 (41)

H

Roof Curb

19-1/2

H

(495)

G

Supply

Duct

1-5/8 (41)

1-5/8

(41)

1-5/8

(41)

• 1-5/8" (41mm) is the measurement from duct opening to

inside edge of roof curb.

• Duct openings should be 1" larger than the duct size for

installation clearance.

Model G

Series H With Downturn w/Cooling Coil Cabinet

CRGB and Plenum, Option w/Downturn, Options

RPB Sizes AQ5 or AQ8 AU 11, 12, 13, or 14

75, 100, 17-3/8" 38-5/8" 75-31/32"

125 441mm 981mm 1930mm

150, 175 22-7/8 38-5/8 81-15/32

581mm 981mm 2069mm

200, 225 28-3/8 38-5/8 86-31/32

721mm 981mm 2209mm

250, 300 36-5/8 38-5/8 95-1/4

930mm 981mm 2419mm

350 42-1/8 38-5/8 100-3/4

1070mm 981mm 2559mm

400 47-5/8 38-5/8 106-1/4

1210mm 981mm 2699mm

Roof Curb Assembly and Installation Instructions (Refer to

FIGURE 8, page 10)

Curbs are shipped unassembled. Field assembly and mounting on the

roof are the responsibility of the installer. All required hardware necessary to complete the assembly is supplied.

Before installing roof curb, verify that the size is correct for the

system being installed.

1. Position curb cross rails and curb side rails as illustrated in

FIGURE 8, page 10. If there are two side pieces to a side, fasten

them with splice plates and hardware as illustrated in the splicing

detail drawing. Join the corners as illustrated in the corner detail.

2. Check the assembly for squareness. Adjust the roof curb so that

the diagonal measurements are equal within a tolerance of + or 1/8" (3mm).

3. Level the roof curb. To ensure a good weather tight seal between

the curb cap and the roof curb, the roof curb must be leveled in

both directions with no twist end to end. Shim level as required

and secure curb to roof deck before proceeding with flashing.

4. Install field-supplied flashing.

5. Before placing the unit into position, apply furnished 1/4" x

1-1/4" foam sealant tape to top surface of curb, making good butt

joint at corners. The unit must be sealed to the curb to prevent

water leakage into the curb area due to blown rain and capillary

action.

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 9

7B. Mounting Outdoor Models on a Roof Curb (cont'd)

F

FIGURE 8 Optional Roof Curb

*Optional

Downturn Plenum

Splicing

Detail

Blower

Cabinet

Curb

Cap

A

1-7/8

(48mm)

Roof

Curb

materials, area within curb must be either ventilated, left open, or covered

with non-combustible material which has an "R" value of at least 5.0. If

area within curb is left open, higher radiated sound levels may result.

IMPORTANT: Top surface of curb MUST be sealed. See instructions above.

* Illustration is shown with an Option AQ5 or AQ8 downturn plenum. The system can have a

variety of configurations which affect installation.

• If the system does not have a downturn plenum, the discharge is horizontal.

• Downturn plenum Options AQ5 and AQ8 are factory installed to be lifted to the roof

and set on the roof curb as part of the packaged system.

• If the system has an Option AU2 or AU3 cooling coil cabinet, the discharge is horizontal. If

the system has an AU11, AU12, AU13, AU14 cooling coil cabinet, there is a downturn

plenum with vertical discharge. Options AU2, AU3, AU11, AU12, AU13, and AU14 are

not factory installed. Options AU2, AU3, AU11, AU12, AU13, and AU14 must be

lifted to the roof separately from the packaged system, set on the roof curb, and

attached to the furnace.

Return

Duct

Furnace

For top 4 holes (2 on

each side) at both joints,

Lift Holes

(4 corners)

from inside the curb insert

(4) 5/16 x 1 lag screws

and (4) 5/16 lockwashers.

1-1/2

(38mm)

1-7/8(48mm)

B

D

C

Supply

Duct

1-7/8

(48mm)

16 (406mm)

Curb Section

16

(406mm)

IMPORTANT: Area enclosed

by the roof curb must comply with

clearance to combustible materials.

If roof is constructed of combustible

4

(102mm)

(Inside

of Curb)

For bottom 4 holes (2 on each side) at both

joints, from outside of the curb insert (4)

5/16-18 x 3/4 long cap screws. Attach with

5/16 lockwashers and 5/16-18 hex nuts.

Corner Detail

1-7/8(48mm)

2 x 6 Wood Nailer

1-1/2 x 3 lb

Fiberglass

Flashed by the

installer (flashing must

be under lip of curb)

Typical

Lag Screw

Cabinet

Curb

Detail

Curb Cap Skirt

Counter Flashing

(by installer)

Cant Strip

(by installer)

Roofing Felts

(by others)

Weld, bolt, or lag screw curb to deck structure.

Curb Cap

Roof Curb

2 x 6

Wood

Nailer

Insulation

MUST be sealed

between curb cap

and roof curb

16

(406 mm)

Curb Height

Cap

Screws

Roof Curb Dimensions (inches)

75, 100,

Size

150, 175 200, 225 250, 300 350 400 Size

125

Option CJ1 - Roof Curb for (H)CRGB and (H)RPB

60-5/8 60-5/8 60-5/8 60-5/8 60-5/8 60-5/8

A

24-5/16 29-13/16 35-5/16 43-9/16 49-1/16 54-1/2

B

56-15/16 56-15/16 56-15/16 56-15/16 56-15/16 56-15/16

**

C

**

D

20-9/16 26-1/16 31-9/16 39-13/16 45-5/16 50-13/16

Option CJ2 - Roof Curb for (H)CRGB and (H)RPB with

Installed

84-9/16 84-9/16 84-9/16 84-9/16 84-9/16 84-9/16

A

24-5/16 29-13/16 35-5/16 43-9/16 49-1/16 54-1/2

B

80-13/16 80-13/16 80-13/16 80-13/16 80-13/16 80-13/16

**

C

20-9/16 26-1/16 31-9/16 39-13/16 45-5/16 50-13/16

**

D

** C and D are roof opening

dimensions.

Downturn Plenum Option AQ5 or AQ8

*** Field installed means that the cooling coil cabinet with or without the downturn is factory assembled

and shipped separately. The roof curb is sized to accommodate the complete length of the system. The

Factory-

shipped-separate cooling coil cabinet with or without a downturn must be lifted to the roof separately

from the packaged system, set on the roof curb, and attached to the furnace section (see instructions

beginning on page 38).

Form I-XE/CRGB/RPB, Page 10

75, 100,

125

150, 175 200, 225 250, 300 35 0 400

Option CJ4 - Roof Curb for (H)CRGB and (H)RPB with

Installed***

98-3/8 103-7/8 109-3/8 117-21/32 123-5/32 128-21/32

A

24-5/16 29-13/16 35-5/16 43-9/16 49-1/16 54-1/2

B

94-5/8 100-1/8 105-5/8 113-29/32 119-13/32 124-29/32

**

C

**

D

20-9/16 26-1/16 31-9/16 39-13/16 45-5/16 50-13/16

Cooling C oil Cabine t Option AU2 or AU3

Option CJ5 - Roof Curb for (H)CRGB and (H)RPB with

Installed***

Cooling Cabinet and Downturn Plenum Option AU11,

AU12, AU13, or AU14

122-3/8 127-7/8 133-3/8 141-21/32 147-5/ 32 152-21/32

A

24-5/16 29-13/16 35-5/16 43-9/16 49-1/16 54-1/2

B

118-5/8 124-1/8 129-5/8 137-29/32 143-13/32 148-29/32

**

C

20-9/16 26-1/16 31-9/16 39-13/16 45-5/16 50-13/16

**

D

Field-

ield-

Roof Curb Dimensions (mm)

F

75, 100,

Size

Option CJ1 - Roof Curb for (H)CRGB and (H)RPB

A

B

C

D

A

B

C

D

**, *** See Notes under chart on the bottom of previous page.

1540 1540 1540 1540 1540 1540

1446 1446 1446 1446 1446 1446

**

**

Option CJ2 - Roof Curb for (H)CRGB and (H)RPB with

2148 2148 2148 2148 2148 2148

2053 2053 2053 2053 2053 2053

**

**

150, 175 200, 225 250, 300 350 400 Size

125

618 757 897 1106 1246 1384

522 662 802 1011 1151 1291

Installed

618 757 897 1106 1246 1384

522 662 802 1011 1151 1291

Downturn Plenum Option AQ5 or AQ8

Factory-

75, 100,

125

Option CJ4 - Roof Curb for (H)CRGB and (H)RPB with

Installed***

2499 2638 2778 2988 3128 3267

A

B

C

D

Installed***

A

B

C

D

618 757 897 1106 1246 1384

2403 2543 2683 2893 3033 3173

**

**

522 662 802 1011 1151 1291

Option CJ5 - Roof Curb for (H)CRGB and (H)RPB with

3108 3248 3388 3598 3738 3877

618 757 897 1106 1246 1384

3013 3153 3292 3503 3643 3759

**

522 662 802 1011 1151 1291

**

150, 175 200, 225 250, 300 35 0 400

Cooling C oil Cabine t Option AU2 or AU3

Cooling Cabinet and Downturn Plenum Option AU11,

AU12, AU13, or AU14

Field-

ield-

8. Venting

8A. Gravity-Vented

Indoor Models

XE/HXE

DANGER: Failure to provide proper venting could result in death, serious injury, and/or pr operty damage. This

furnace must be installed with a vent connection and proper vent to the outside of the building. Install vent in

accordance with Part 7, V enting of Equipment, of the National Fuel Gas Code, ANSI Z223.1 (latest edition) or

applicable provision of national, state or local codes. A Canadian installation must be in accordance with the

CSA B149.1 and B149.2, Installation Code for Gas Burning Appliances and Equipment, and applicable local

codes. Also, follow venting recommendations listed below.

Safe operation of any gravity-vented gas-fired equipment requires a properly operating vent system, correct

provision for combustion air (See Paragraph 6), and regular maintenance and inspection. See Hazard Levels,

page 2.

TABLE 1 - Maximum Horizontal Run for Double-Wall Type B

Connector and Double-Wall Type B Vent

Verti cal

Height of

Vent

6' (1.8M )

8' (2.4M )

10' (3.0M)

15' (4.6M)

20' (6.1M)

30' (9.1M)

TABLE 2 - Maximum Horizontal Run for Single-Wall Metal Pipe

Vertical

Height of

Vent

6' ( 1.8M)

8' ( 2.4M)

10' (3.0M)

15' (4.6M)

20' (6.1M)

Venting Requirements - Indoor Models

1. Provide a minimum clearance of 18" (457mm) between the drafthood

relief opening and any obstruction. Do not expose the relief opening to

wind drafts from any source such as from an overhead door or adjacent

air handling equipment.

2. The unit is equipped with a built-in draft diverter, consequently an

external draft diverter MUST NOT be installed in the vent connector or

5" 6" 7" 8"

ft M ft M ft M ft M ft M ft M

6 1.8 6 1.8 6 1.8 6 1.8 6 1.8 6 1.8

8 2.4 8 2.4 16 4.9 16 4.9 16 4.9 16 4.9

10 3.0 16 4.9 20 6.1 20 6.1 20 6.1 20 6.1

16 4.9 16 4.9 30 9.1 30 9.1 30 9.1 30 9.1

20 6.1 30 9.1 30 9.1 30 9.1 30 9.1 30 9.1

20 6.1 40 12.2 40 12.2 40 12.2 40 12.2 40 12.2

5" 6" 7" 8"

ft M ft M ft M ft M ft M ft M

20.620.620.620.620.620.6

5 1.5 5 1.5 10 3.0 10 3.0 10 3.0 10 3.0

5 1.5 10 3.0 15 4.6 15 4.6 15 4.6 15 4.6

5 1.5 10 3.0 15 4.6 20 6.1 20 6.1 20 6.1

N.R. 10 3.0 15 4.6 20 6.1 20 6.1 20 6.1

Furnaces have

the following

vent outlet sizes:

Vent Diameter

Vent Diameter

Model S ize

Flue Collar

Diameter/Configurati on

10" 12"

10" 12"

75 100 125 150, 175 200, 225 250, 300 350, 400

5"

Round

any internal alterations made. Do not install a manual damper or

other fixed restriction in the vent connector.

3. Vent pipe should be a minimum of 26-gauge galvanized steel or

other noncorrosive material. Double-wall, T ype B vent is recommended. Where it is necessary to run the vent pipe through an

exterior wall of combustible materials, a suitable thimble must be

used. The vent pipe shall have a clearance of at least six inches

(152mm) from combustible materials, or as is specified by the

double-wall vent pipe manufacturer.

4. The horizontal vent pipe run should have a uniform rise of at

least 1/4" per foot (6.3mm per 305mm) of horizontal run in the

direction of discharge. The length of the lateral run must not

exceed lengths in the vent tables of the National Fuel Gas Code or

the Canadian Installation Code for Gas Burning Appliances. See

TABLES 1 and 2 on the right.

5. Lateral runs should be supported every six feet (1.8M) using a

non-combustible material, such as strap steel or chain. Do not

rely on the drafthood or heater for support of either horizontal or

vertical vent pipe.

6. Vent connectors serving Category I heaters (heater with non-

positive vent pressure and with a vent gas temperature at least

140°F above its dewpoint) shall not be connected into any portion of a mechanical draft system operating under positive pressure.

7. Where it is necessary to use a long run of vent pipe, or where the

vent pipe is exposed to cold air, condensation within the pipe

may occur. There are two ways to overcome or eliminate this

problem.

(a) Prevent condensation by insulating the pipe so that the temperature of the flue products never drops below 250°F.

6"

Round

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 11

7"

Oval

8"

Oval

8"

Round

10"

Oval

12"

Oval

)

8A. Gravity-Vented Models XE/HXE (cont'd)

Venting Requirements - Indoor Models (cont'd)

(b) Use double-wall, T ype B vent pipe which is recommended for the

reduction or elimination of condensate problems. Where extreme conditions are present and condensate is anticipated, install a trap for collecting condensate.

8. The vent connection may be made into a suitable permanent chimney

or into a gas vent. The effective area of the vent con-nector, gas vent, or

chimney when connected to a single appliance shall not be less than the

area of the appliance drafthood outlet or in accordance with approved

venting methods. The effective area of the gas vent or chimney when

connected to more than one appliance shall not be less than the area of

the largest vent connector plus 50% of the areas of additional vent

connectors or in accordance with approved venting methods.

Minimum permissible height of the vertical vent is five feet (1.5M)

providing no horizontal vent pipe connector is used. If a horizontal

vent connector is necessary, consult TABLES 1 or 2 or the National

Fuel Gas Code or the Canadian Installation Code for Gas Burning

Appliances, for the maximum permissible length of a horizontal pipe

run (vent connector) for a given vertical height of gas vent.

The gas vent or chimney should extend at least three feet (.9M) above

the highest point where it passes through a roof of a building and at

least two feet (.6M) higher than any portion of a building or obstruction within a horizontal distance of ten feet (3M). A suitable weather

cap should be installed on the end of the vent pipe to prevent rain or

snow from entering the open end.

9. If the heater is installed in a space served by a large exhaust fan, be sure

that the exhaust fan does not affect the operation of the heater or the

satisfactory venting of its products of combustion.

If a negative pressure exists, as evidenced by a downdraft, a factory-

designed mechanical motor driven venter (Option CA) should be installed. In severe negative pressure conditions, makeup air equipment

may be necessary.

Optional Power V enting (Option CA)

To install a gravity-vented furnace in an area where horizontal venting is

required or where negative building pressure inhibits gravity venting, install an optional power venter (Option CA). Use only a power venter

provided by the furnace manufacturer and carefully follow the instructions included in the optional venter package. Use the venter adapter

supplied to connect the power venter to the heater. Do not install the

power venter without the venter adapter.

With an Option CA power venter installed, the furnace may be vented

either horizontally or vertically. Do not exceed the maximum vent lengths

shown in the table below. Minimum vent length is 5 ft (1.5M).

Vent Pipe

Diameter

* Reduce the vent pipe lengths as follows for each item: 45° Elbow - 7ft

(2.1M); 90° Elbow - 15ft (4.6M); Reznor® or Breidert Vent Cap - 10ft (3M).

** If the venter outlet is 4", connect a taper-type "enlarger" to the vent

outlet when installing 6" vent pipe.

Maximum* Vent Length (ft or M) for Furnace with Optional

Power Venter (Option CA)

75, 100, 125, 150 175 200 225 250 300 350 400

ft 100 75 50 35 30 15

4"

M30 23151194.6

ft 100** 100** 100 92

6"

M 30** 30** 30

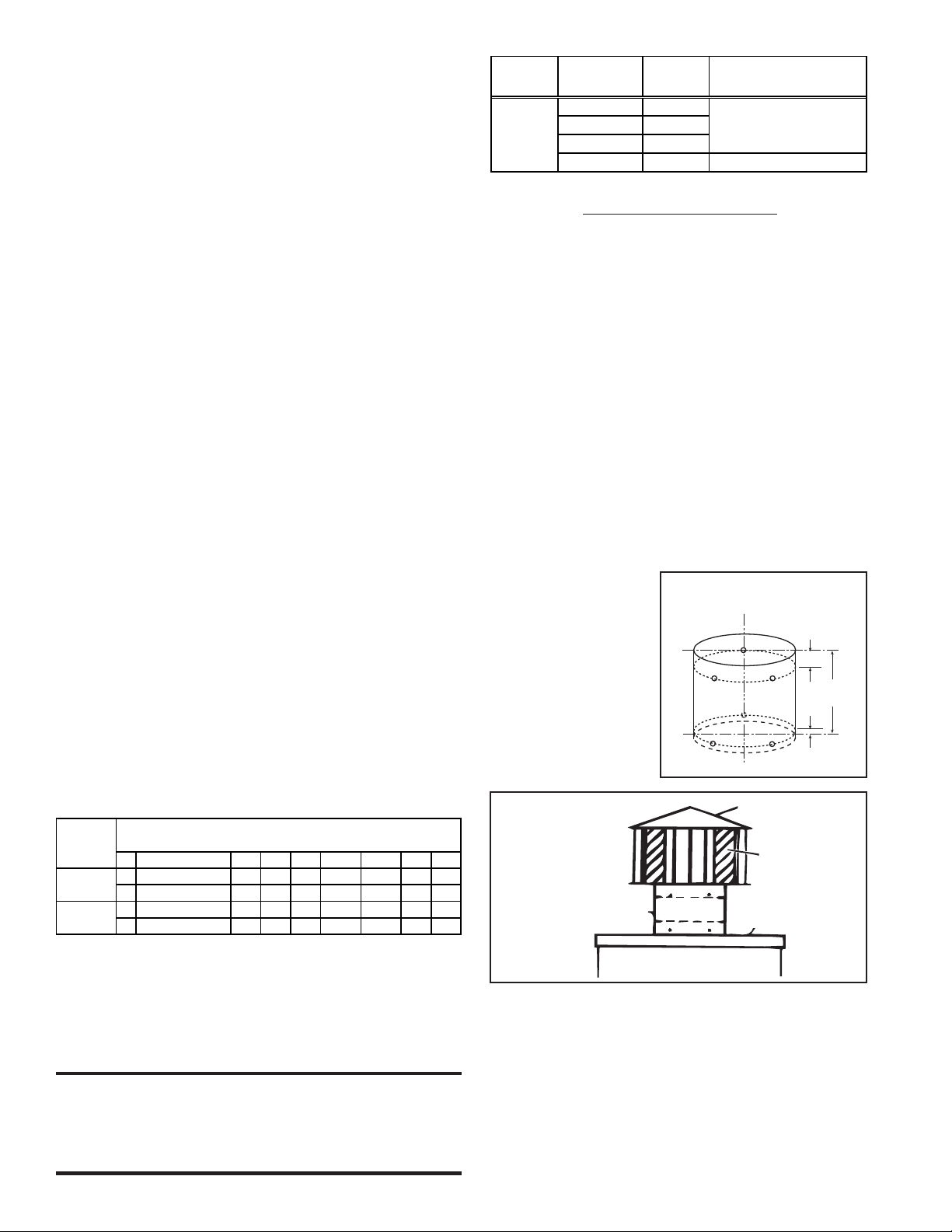

8B. Venting - Gravity-V ented, Out door Model

Series CRGB

The appropriate size of gravity vent cap is supplied with the furnace. The

gravity vent cap requires field installation.

WARNING: This gravity-vented furnace should be

located on a roof or slab with at least 30-foot (9M)

radius between the center of the vent cap and

obstructions such as walls, parapets or cupolas. See

Hazard Levels, page 2.

Form I-XE/CRGB/RPB, Page 12

Model Size

Vent Cap

Size

Extension Required

75, 100 6"

(H)CRGB

125, 175 8" No

225, 250, 300 10"

350, 400 12" Yes (packed inside cap)

Vent Cap Installation Instructions:

IMPORTANT REQUIREMENT

For proper operation of the gravity vent cap, position the

holes so that the solid side panel of the cap will face the

control compartment access panel side of the furnace. See

FIGURE 9B.

1) Furnaces that do not require a Vent Cap Extension

(H)CRGB Sizes 75- 300, align holes and attach the vent cap to the

furnace flue collar with sheetmetal screws. (See Important Requirement above.)

2) Furnaces that require a Vent Cap Extension (packed inside

the vent cap) - See FIGURES 9A and 9B

(H)CRGB Sizes 350 and 400 require a 12" extension to raise the

vent cap above the top of the furnace.

a) Remove the extension from the inside of the cap.

b) Attach the extension to the furnace flue collar --

1) With 3/8" centerline clearance holes at the bottom, wrap

extension around flue collar on the top of the furnace.

2) Align holes in the extension with holes in the flue collar .

3) Secure with #10 1/2" sheetmetal screws.

c) Attach the vent cap to

the extension --

1) Position vent cap into

top of extension.

(See Important

Requirement

above)

2) Align holes and push

cap into extension.

3) Secure with 1/2"

sheetmetal screws.

FIGURE 9B - V ent

FIGURE 9A - V ent Cap

Extension, P/N 20524

Top

Bottom

Vent Cap

2 (51mm)

12

(305mm

3/8

(10mm)

Cap Installation

Vent Opening

Vent Cap

Extension

Control Compartment

Access Panel

Furnace Top

Optional 4-foot (1.2M) Stack Extension for

Outdoor, Gravity Vent Models (Option ZZ)

Outdoor, gravity-vented furnaces that are factory-built with Option

ZZ are designed to release flue gases four feet (1.2M) above the top

of the furnace. A field-provided 4-ft (1.2M) vent extension must be

installed between the top of the furnace and the bottom of the vent

cap. (See FIGURE 9C). Furnaces with Option ZZ (factory-installed

restrictor plus field-provided 4-ft stack) may be installed adjacent to

fresh air inlet(s) when local code requires that release of flue gases be

above an adjacent fresh air inlet that is not part of the furnace.

FIGURE 9C - Optional Stack Extension applies only to

5 Vent Cap,

P/N 110052

5 dia Flue Pipe

4

(1.2M)

5 dia

90° Elbow

18 (457mm) Straight Pipe

Oval Adapter Assy

Combustion Air Intake

Support angles for flue pipe.

Recommended size is

1/2x1/2, 20 gauge

Furnaces with Suffix "Z" in their Model No.

FIGURE 11B - Installation of the V ent Cap (included in the

option package) and the field-supplied Piping and Supports

Three guy wires, spaced 120°

apart, fastened to the vent

cap collar and furnace top

with sheetmetal screws.

Gravity Vent Cap

4 ft

(1.2M)

8C. Venting - Power Vented, Outdoor Models

Locate power-vented furnaces so that flue discharge is not directed at

fresh air inlets.

Flue Gas and

Combustion Air

Openings

These screened openings are located on the side of the furnace

just above the control access

panel. See FIGURE 10. The position of these openings discourages recirculation of combustion

products and provides for furnace operation in all normal

weather conditions.

FIGURE 10 - Flue Outlet,

Power-V ented Furnaces

Flue Products

Outlet

Combustion

Air Inlet

9. Condensate Drain

9A. Indoor Models XE/HXE

Condensate can form in the heat exchanger of furnaces installed as makeup

air units or when installed downstream from a cooling coil. Under these

conditions, a drain flange, Option CS1, may be installed on the furnace

bottom as shown in FIGURE 12. When using Option CS1, seal all

corners and the four square holes in the bottom pan edge.

FIGURE 12 - Condensate Drain, Option CS1 (P/N 31765)

Optional Vertical Flue Discharge (Option CC3)

These power vented furnaces are certified with four feet (1.2M) of

vertical pipe attached as shown in FIGURES 11A and 11B. The dis-

tance is measured from the top of the unit to the bottom of the vent cap.

The option package includes the 5" vent cap, the adapter assembly and

the seal plate. The vent pipe and supports are field supplied. The

straight pipe connecting the furnace to the 90° elbow must be at

least 18" (457mm) in length.

Optional vertical vent piping provides compliance with local codes

that require either 10-ft (3M) horizontal or 4-ft (1.2M) vertical clearance between the flue outlet and fresh air intake of the heating system

and/or the building.

1) Remove and discard

the louvered

discharge grill.

2) Using venter seal

plate as a template,

drill holes. Attach

venter seal plate and

oval adapter

assembly with 3/8"10 sheetmetal

screws.

FIGURE 11A - Installation of Adapter for Optional Vertical

Flue Discharge (Option CC3, P/N 45021)

Oval Adapter Assy,

PN/ 103025

Venter Seal Plate,

P/N 43446

Bottom of the Furnace Casing

#10 x 1-1/4 Bolt and Nut

3/4 Pipe Waste Nut

Seal holes in bottom pan. Terminate drain outside of

building. Periodic cleaning of the condensate collector and

disposal system is required.

Gasket

9B. Outdoor Model Series CRGB and RPB

A hole is provided in all four corners of the furnace bottom to drain off

condensation to the outside of the curb cap to the roof.

10. Duct Connections

Requirements and Suggestions for Connecting

and Installing Ducts

• Type of Ductwork - The type of duct installation to be used de-

pends in part on the type of construction of the roof (whether wood

joist, steelbar joist, steel truss, pre-cast concrete) and the ceiling

(whether hung, flush, etc.).

• Ductwork Material - Rectangular duct should be constructed of

not lighter than No. 26 U.S. gauge galvanized iron or No. 24 B & S

gauge aluminum.

• Ductwork Structure - All duct sections 24 inches or wider, and

over 48 inches in length, should be cross broken on top and bottom

and should have standing seams or angle-iron braces. Joints should

be S and drive strip, or locked.

Form I-XE/CRGB/RPB, P/N 131782 Rev 5, Page 13

Loading...

Loading...