Page 1

lum

■3800 © BY

RFVELL IN<

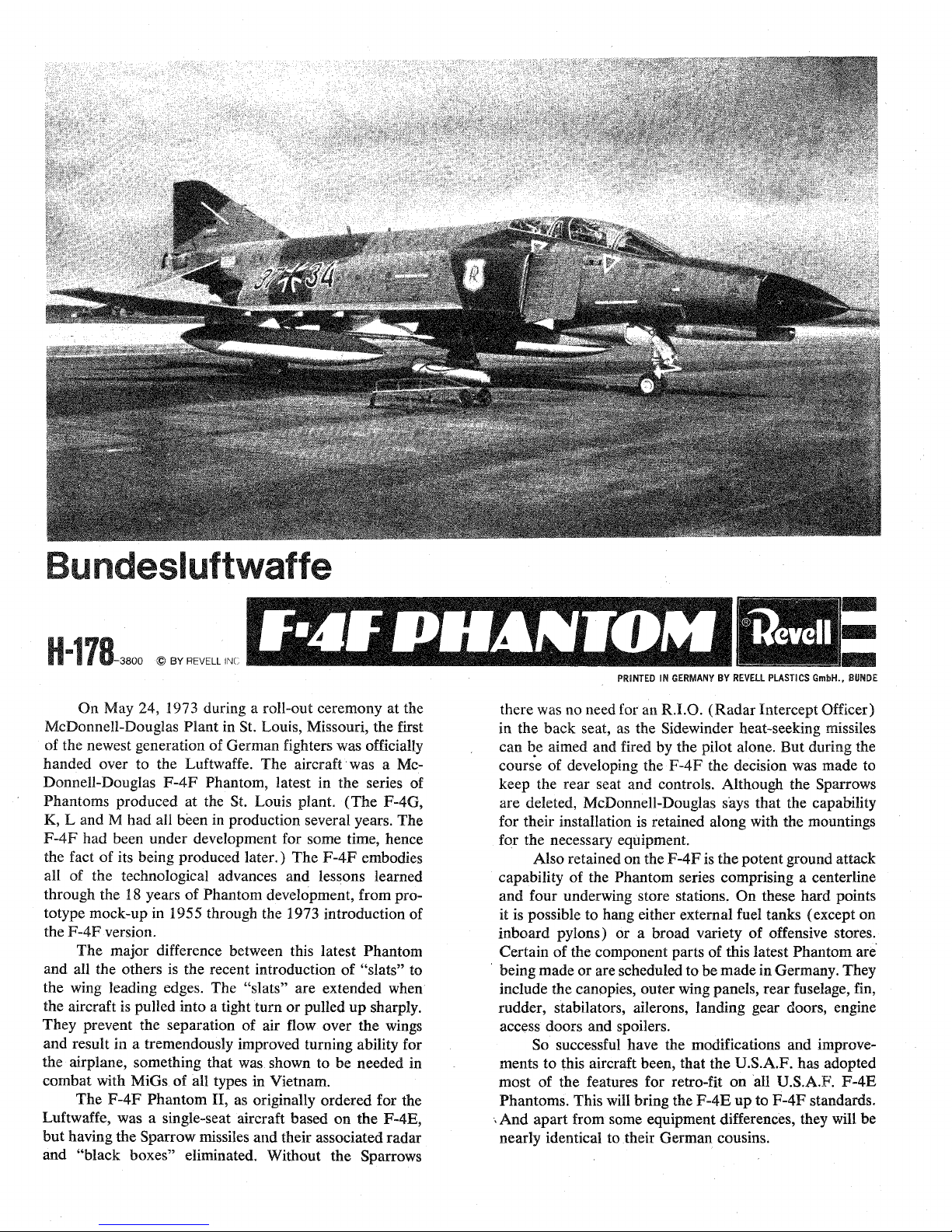

On

May

24,

1973 during a rollout ceremony at the

McDonnellDouglas

Plant in St. Louis, Missouri, the first

of the newest generation of German fighters was officially

handed over to the Luftwaffe. The aircraft was a Mc

DonnellDouglas

F4F

Phantom, latest in the series of

Phantoms

produced at the

St»

Louis plant, (The

F4G,

K9 L and M had all been in production several years. The

F4F

had been under development for some time, hence

the

fact

of its being produced later.) The

F4F

embodies

all of the technological advances and lessons learned

through the

18

years of Phantom development,

from

pro

totype mockup in 1955 through the 1973 introduction of

the

F4F

version.

The major difference between this latest Phantom

and all the others is the recent

introduction

of "slats" to

the wing leading edges. The "slats" are extended when

the aircraft is pulled into a tight turn or pulled up

sharply.

They prevent the separation of air flow over the wings

and result

ie

a tremendously improved turning ability for

the

airplane,

something that was shown to be needed in

combat

with MiGs of all types in Vietnam.

The

F4F

Phantom II, as originally ordered for the

Luftwaffe, was a

singleseat

aircraft based on the F-4E,

but having the Sparrow missiles and their associated radar

and "black

boxes"

eliminated. Without the Sparrows

PRINTED

IN

GERMANY BY

REVELL

PLASTICS GmbH.»

BÜWDE

there was no need for

an

R.I.O.

(Radar Intercept Officer)

in the back seat, as the Sidewinder

heatseeking missiles

can be aimed and fired by the pilot

alone»

Bet during the

course of developing the

F4F

the decision was made to

keep the rear seat and controls. Although the Sparrows

are deleted, McDonnellDouglas says that the capability

for their installation is retained along with the mountings

for the necessary equipment

Also retained on the

F4F

is the potent

ground

attack

capability of the

Phantom

series comprising a

centerfine

and four

enderwing

store

stations.

On these hard points

it is possible to hang either external fuel tanks (except on

inboard pylons) or a broad variety of offensive stores.

Certain of the component parts of this latest Phantom are

being made or are scheduled to be made in

Germany.

They

include the canopies, outer wing panels, rear fuselage, fin,

rudder,

stabilators,

ailerons,

landing gear doors, engine

access doors and spoilers.

So successful have the modifications and

improve

ments to this aircraft been, that the U.S.A.F. has adopted

most of the features for retrofit on all

U.S.A.F.

F4E

Phantoms. This will bring the

F4E

up to

F4F

standards.

.

And apart from some equipment differences, they will be

nearly identical to their German cousins.

Page 2

H-178-380-A

(GET YOUR TOOLS READY:

REMO¥E

PART

WHEW CALLED FOR

TO HOLD

PJ4HÏ8

k

TO

REMO¥E

AND

TRIM

PAiTS

HELPFUL MODELING HINTS

1.

Fit parts together before

cementing.

2.

Trim away excess plastic.

3. Use cement sparingly; too much will damage your model.

SF

YOU

WISH

TO STOP AT ANY POINT DURING THE CONSTRUCTION OF YOUR MODEL,

DO SO AT THE END OF AN ASSEMBLY STEP

TO

APP»LY

TO HOLD

PAHTS

CEMENT

AFTEH

CEMENTING

4,

Suggested

painting

colors are indicated

byfT.

Paint small parts before detaching from runner.

J-

BECAt

#S4

MOLDED

IN

BASIC UPPER SURFACE - [MlTTEL^iRAU

IF

PAINTING:

USE

rMJ^ELGRAU^

SCHWARZMAT^

UNIFORM

-

HELLGRAU

^BSENFARBJG^X

[ILBER^

[HAUTF^RBE

DECAL

#5S

SEAT BACK

(2

Parts)

CONTROL

COUJJVIN

(2

Parts)

COCKPIT

FLOOi

PILOT'S INSTRUMENT

PANEEL

Umm

OPERATOR'S INSTRUMENT PANEL

CiEW

FIGURE - FRONT HALF

(2

Parts)

CREW FIGURE - BACK HALF

(2

Parts)

1.

2.

3.

4

B

5;

Cement

two Farts

(1)

and two Parts (2) to Part

(3).

Appif

DECALS to Parts (3), (4)

and'(§)

e

Cement (4) and

(5)

to Part (3).

Cement TWO Parts (6) to TWO Parts (7)

Cement CREW FIGURES to

SEATS.

§ VARYING SHADES

OF^fsiLiER^

8 LEFT ENGINE - LEFT HALF

9 LEFT ENGINE - RIGHT HALF

10 LEFT ENGINE INTAKE

11 ENGINE EXHAUST

CONE

VARYING

SHADES

OF - pEËS^

g

1.

Cement Part

(8)

to Part (9).

2.

Cement Parts

(10)

and

(11)

to Parts

(8)

and (9).

;

ARZM^rr

PAGE

2

(§)

1975

B¥

REVELL

INC.

Page 3

H-178-380-A

DO NOT LET CEMENT j

TOUCH

H1M6E

12

13

14

15

IS

Ï7

18

13

75

76

ÜEÏHOWE f LUSH

¥mom HOLES

i

IN

BOTH

WINES

DO

N@T

LET

CEDENT

TOUCH HINGE

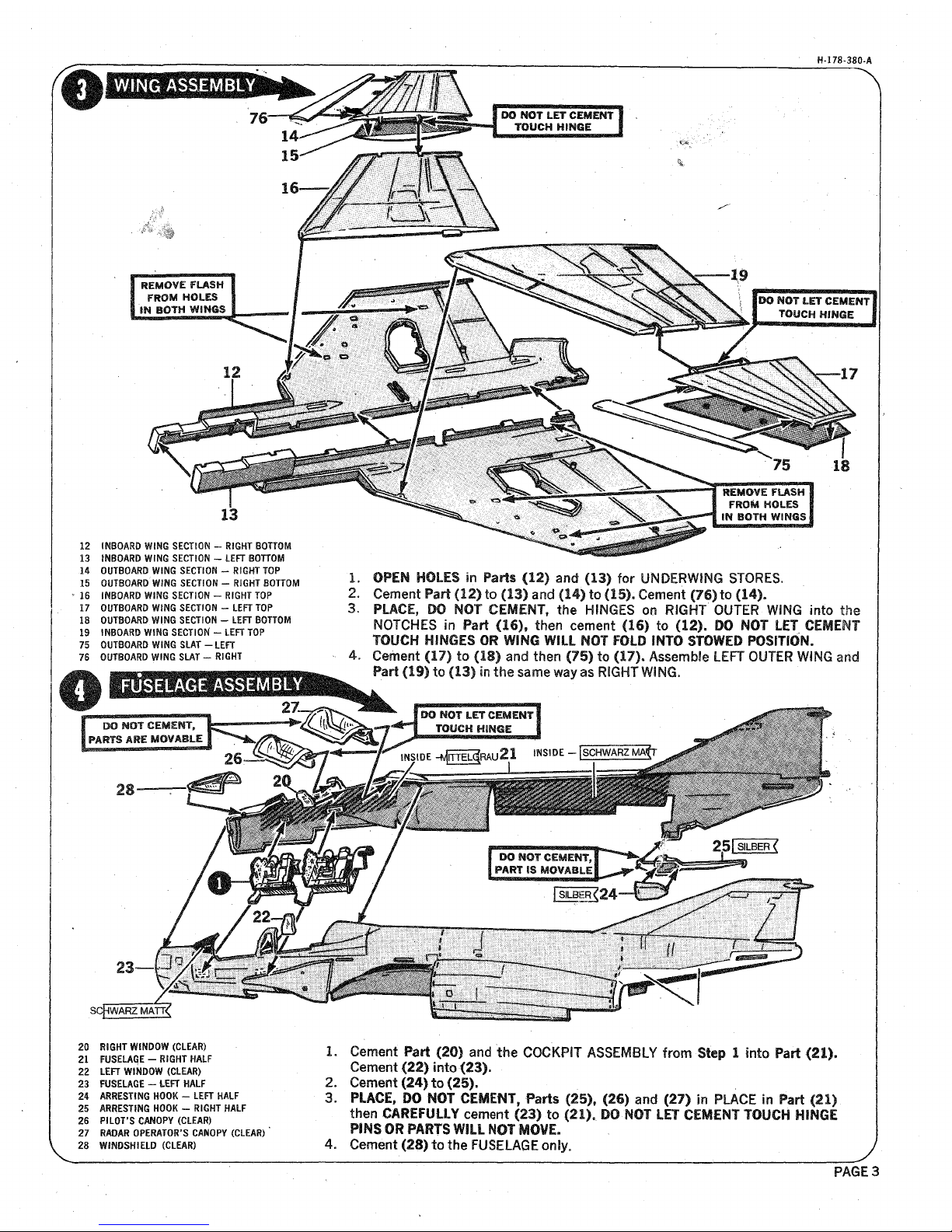

INBOARD WING SECTION - RIGHT BOTTOM

INBOARD WING SECTION - LEFT BOTTOM

OUTBOARD

WING SECTION - RIGHT TOP

oyieoAitp

WING

SECTION - RIGHT

BOTTOM

INBOARD WING SECTION - R1SHT

TOP

OUTBOAiD

WING

SECTION - LEFT TOP

OUTBOARD WING SECTION - LEFT BOTTOM

INBOARD

WING

SECTION' - LEFT TOP

OUTBOARD

WIWG

SLAT

-LEFT

OUTBOARD

WING

SLAT -

ilGHT

1.

3=

OPEN

HOLES

in

Parts

(12)

and (13) for

UNDERW1NG

STORES.

Cement

Part (12) to (13) and (14) to

(15).

Cement

(76) to (14).

PLACE,

DO

NOT

CESiEiT,

the HINGES

oo

RIGHT OUTER

WING

into

:he

NOTCHES in

Part

(16)f then cement (16) to

(11).

D©

NOT LET

CEMENT

TOUCH

HINGES

OR WING WILL

NOT FOLD INTO STOWED

POSITION.

Cement

(17) to (18) and

then

(75) to

(17).

Assemble LEFT OUTER WING

and

Part

(19) to (13)

in

the

same way as RIGHT

WING.

SCpWA^MATT^

20 RIGHT WINDOW (CLEAR)

21 FUSELAGE - RiSHT

HALF

22 LEFT

W1IDOW

(CLEAR)

23

FUSELAGE

- LEFT HALF

24

AÜEST1NG

HOOK - LEFT HALF

25

AiiESTING

HOOK - RIGHT HALF

26 PILOT'S CAiOPY (CLEAR)

2?

RADAR

OPERATOR'S CANOPY

(CLEAK)

*

28 WINDSHIELD (CLEAR)

1.

Cement Part (20) aod the COCKPIT ASSEMBLY from Step 1 Into Part (21).

Cement

(22)

Into

(23).

2.

Cement

(24) to (25).

3.

PLACE, TO NOT

CEi3ENTp Parts (25), (26) and (27) in PLACE in Part (21)

then €M£¥t3ltY

cement (23) to (21). DO NOT

LET CEMENT

TOUCH

HINGE

PINS OR PUTS WILL NOT

HOWE,

4.

Cement (28) to the

FUSELAGE

or%

B

PAGES

Page 4

H-178-380

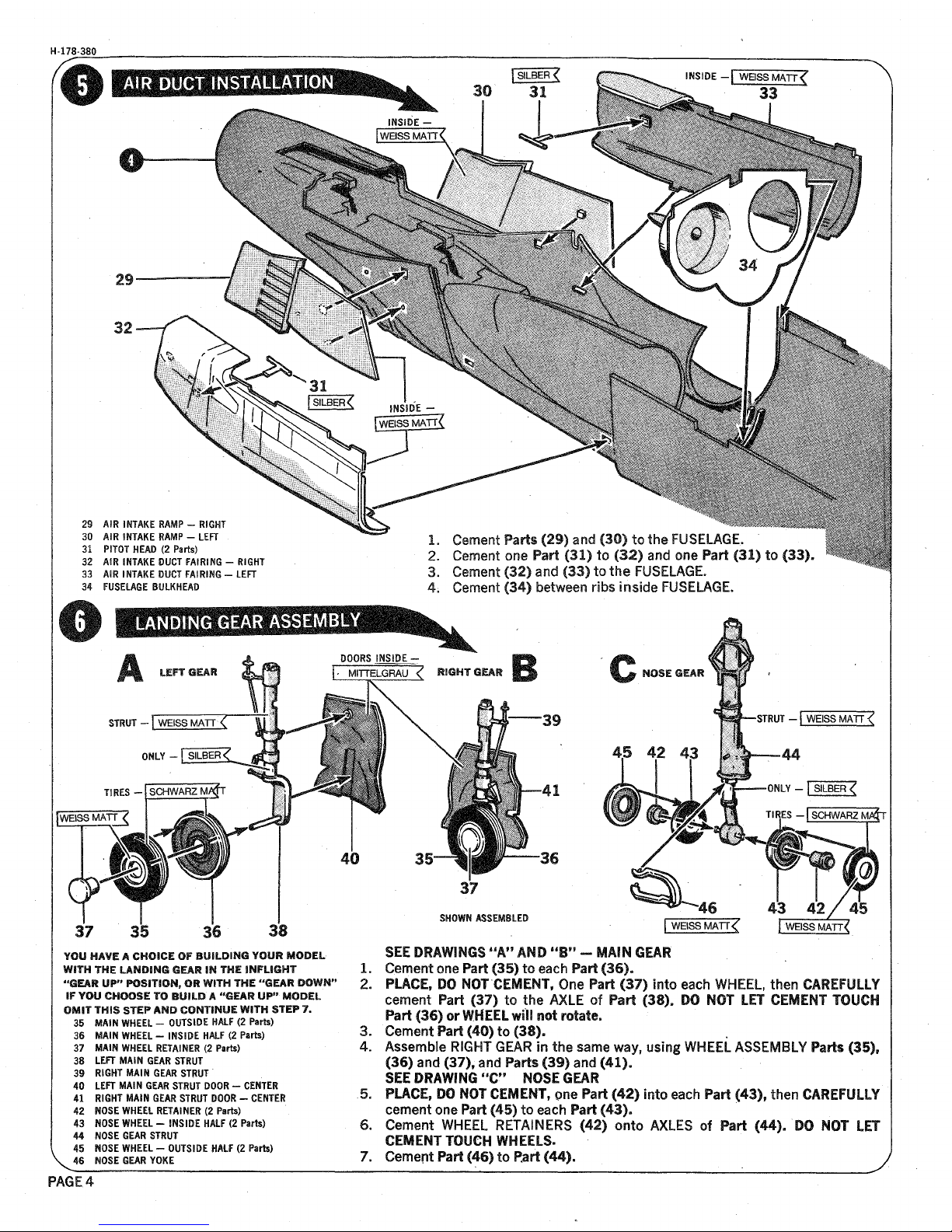

29 AIS INTAKE RAMP - RIGHT

30 AIR INTAKE RAMP - LEFT

31

P1TOT

HEAD (2 Parts)

32 AIR INTAKE DUCT PAIRING - RIGHT

33 AIR INTAKE DUCT FAIRING - LEFT

34 FUSELAGE BULKHEAD

1.

Cement

Parts (29) and

(30) to

the

FUSELAGE.

'

2.

Cement one Part (31) to (32) and one Part (31) to

(33).

3=

Cement (32) and (33) to the

FUSELAGE.

4.

Cement (34) between ribs inside FUSELAGE.

STOUT

-rwÜSM^T?"

ONLY - fsTLBER^

TliES -[JCHWARZM^T

STiUT _

fwElSSM^TT^

44

SHQWi

ASSEMBLED

BWTR

¥OU

MME A

CHOICE

OF

BUILDING

YOUR MODEL

WITH THE

mmmmm

©EAR

IN

THE INFLIGHT

"@EAR

UP" POSITION, OR

WITH

THE

"©EAR

DOWN"

IF

YOU

CH0OSE

TO BUILD.' A

"©EAR

UP"'

MODEL

OMIT f

HIS

STEP

HMD

CONTINUE

WITH Sf

EP 7.

35

IAIN

WHEEL - OUTSIDE HALF (2 Parts)

38

MAIN

WHEEL - INSIDE HALF (2 Parts)

37 MAIN WHEEL RETAINER (2 Parts)

- 38 LEFT MAIN GEAR STRUT

39 RIGHT MAIN GEAR STRUT "

40 LEFT

MAIN GEAi

STMT

D00Ë

- CENTER

41 RIGHT MAIN GEAR STRUT POOH

- CENTEi

42 iOSE WHEEL

RETAINER

(2 Parts)

43

mm

WHEEL - INSIDE HALF

(2

Parts)

44 iOSE

6EA1 STiUT

45 iOSE WHEEL -

OyTSiDE

HALF

(2

Parts)

\

48 NOSE

6EJW

YOKE

PAGE,

4

3.

4.

SEE DRAWINGS "A"

AND

"B"

- MMM

GEAR

Cement

one Part (35) to each Part (36).

PLACE,

DO'NOT'CEMENT,

One Part (37) Into each WHEEL, then

CAiEFlJlLY

cement Part (37) to the AXLE of Part (38). DO NOT LET CEMENT TOUCH

Part (36) or WHEEL will not retate

a

'

Cement Part

(40)

to (38).

Assemble RIGHT GEAR In the same

way»

using WHEEL ASSEMBLY Parts

(35),

(36) and

(37),

and Parts (39) and (41).

SEE DRAWING

"C"

NOSE GEAI

PLACE,

DO NOT

€EifENIf gm

Part (42) into each Part

(43),

then

CAËEFULIY

cement one Part (45) to each Part (43).

Cement WHEEL RETAINERS (42) onto AXLES of Part

(44)B 'DO NOT LET

CEMENT

TOUCH

WHEELS-

Cement Part (46) to

Part

(44).

Page 5

H-178-380

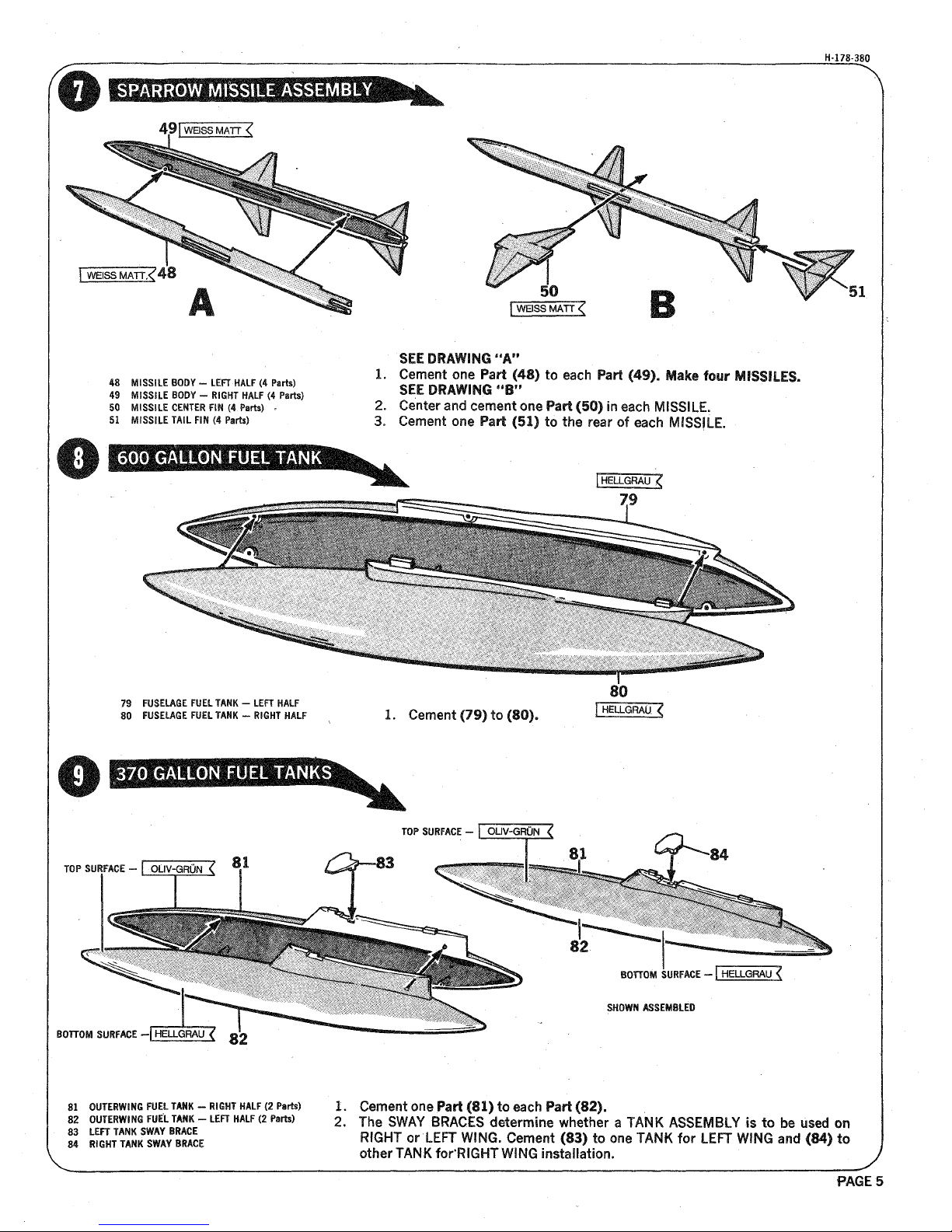

^niiËissMATf^

r^isy^^

4S MISSILE

BOPÏ -

LEFT-HALF (4 Parts)

49

MISSILE

iODÏ -

RIGHT HALF (4 Parts)

50

liSSiLE CENTEït FiN

(4. Parts)

.

51'

MISSILE TAIL

FIN (4 Parts)

'

'SEE

DRAWING

"A"

1.

Cement

one Part (48) to each Fart

(4§)0 ifaice

four MISSILES.

SEE DRAWING

"B"

2.

Center

and

cement

one

Part (50) in each MISSILE.

3. Cement one Part (51) to the rear of each MISSILE.

79

80

FUSELAGE FUEL TANK - LEFT HALF

FUSELAGE FUEL TANK -

R1ÊHT

HALF

1.

Cement (79) to (80).

[HELLGRALK

TOP

syitFüCE - röüv^Grti^

TOP

SURFACE - rOUV^RÓJT

SHOWN

ASSEMBLED

BOTTOM

SUftFACE

-[SLGMU^

81

OyiEiifiie

FUEL

TANK

- RIGHT HALF (2 Parts)

82

OyTEiifliG

FUEL TANK - LEFT HALF (2 Parts)

83 LEFT TANK SWAY BRACE

84 RIGHT TANK

SWAY

BRACE

1.

Cement one Part

(81)

to

each

Part

(82).

2.

The SWAY BRACES determine whether a TANK ASSEMBLY is to be

ysecf

on

RIGHT

or'LEFT

WING.

Cement (83) to one

TANK

for LEFT WING

and (14)

to

other TANK forRIGHT

WING

Installation.

PAGES

Page 6

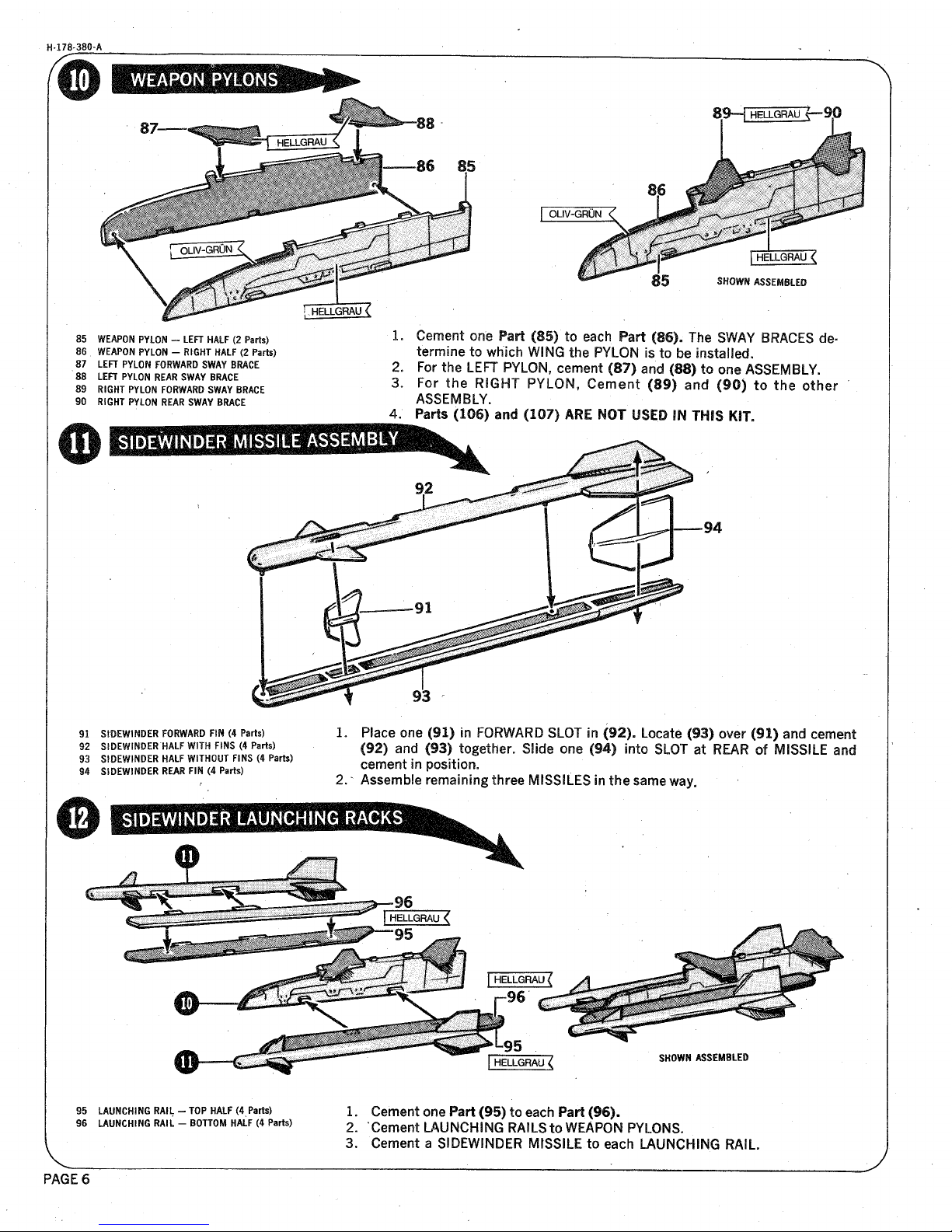

H-178-380-A

§9—^THELLGRAUl"§e

85

88

87

88

89

90

WEAPON PYLON - LEFT HALF (2 Parts)

WEAPÖi

PYLON - RIGHT HALF (2 Parts)

LEFT PYLON FORWARD

SWAY

BRACE

LEFT PYLON REAR SWAY

B1ACE

RIGHT PYLON FORWARD SWAY BRACE

RIGHT PYLON HEAR SWAY

BiACE

2.

3.

4.

SHOWi

ASSEMBLED

Cement one Part

(S§)

to each Part (86). The SWAY BRACES

de=

termine

to which

WING

the PYLON is to be

installed»

For the LEFT

PYLON,

cement

(B7)

and

(88)

to one ASSEMBLY.

For the RIGHT PYLON, Cement

(Si)

and (90) to the other

ASSEMBLY.

Parts (106) and (107)

ME STOT

USED

IN THIS

KIT.

91 SIDEWINDER FORWARD

FIN

(4 Parts)

92

SIOEWiNDEi

HALF

WITH

FINS (4 Parts)

93 SIDEWINDER HALF WITHOUT

FINS

(4 Parts)

94 SIDEWINDER

REAH

FIN

(4

Parts)

O

1.

Place one (§1) in FORWARD SLOT

in

(92). Locate (§3) over (91) and cement

(§2)

and

(93) together. Slide one (§4) into SLOT at REAR of MISSILE and

cement in

position,

2. * Assemble remaining three MISSILES in the same

way

e

HELLGRAU <

SHOWi

ASSEMBLED

95 LAUNCHING RAIL •

96 LAUNCHING

RAIL ■

- TOP HALF

(4

Parts)

- BOTTOM HALF (4 Parts)

1.

Cement

one Fart (95) to each Part (96).

2.

'Cement

LAUNCHING RAILS to WEAPON

PYLONS.

3. Cement a SIDEWINDER MISSILE to each LAUNCHING

RAIL.

PAGES

Page 7

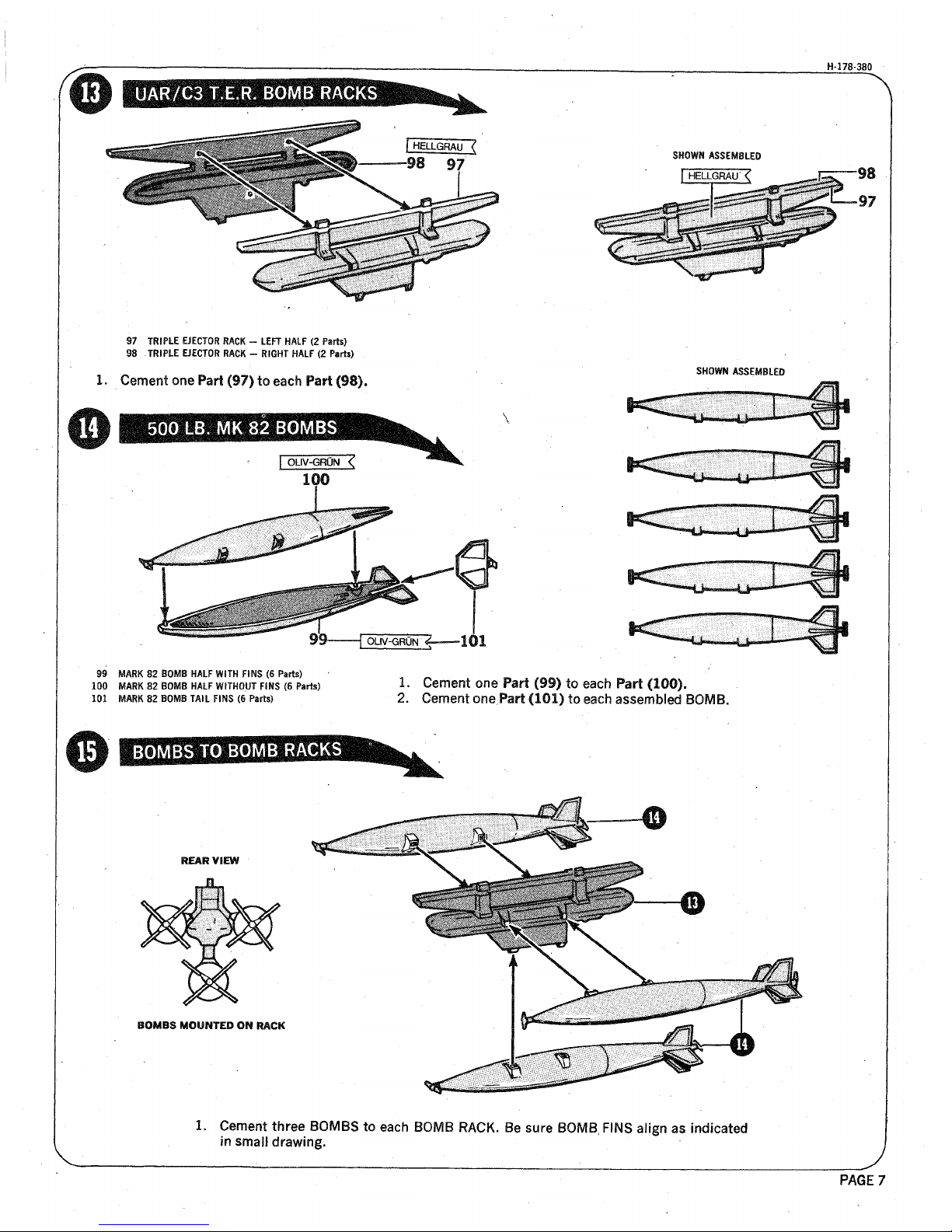

H-178-380

SHOWi

ASSEMBLED

97

TilPIE

EJECTOR

Mma

- LEFT HALF (2 Parts)

98 TUPLE

EJECTOR RACK - RIGHT HALF (2 Parts)

1.

Cement one Part (97) to each Part (98).

OÜ^GRÖN^

SHQifi

ASSEMBLED

99 MARK 82 BOMB HALF WITH

FINS

(6 Parts)

100

MAM

82 BOMB HALF WITHOUT

FINS

(S Parts)

101 MARK 82 BOMB TAIL

FINS

(8 Parts)

1.

Cement

one

Part

<

2.

Cement one Part (

99) to each Part (100).

,§1) to each assembled

BOME

BOMBS

MOUNTED OW RACK

1.

Cement three BOMBS to each BOMB RACK. Be sure

BOMB,

FINS

align as indicated

in small drawing. •

PAGE

7

Page 8

H-178-38Q

11 ENGINE EXHAUST CONE

40 LEFT MAIN

GEAi

STRUT DOOR - CENTER

41 RIGHT

IAIN

GEAR STiUT

DOOi

- CENTER

53

WGHT

MAIN GEAR DOOI - OUTBOARD

54 WGHT

MAIN

GEAR

DOOi -

INBOARD

56 LEFT MAIN GEAR DOOi - OUTBOARD

57 LEFT

IAIN

GEAR

DOOi

- INBOARD

77 SLAT ACTUATOR FAIRING INBOARD (2 Parts)

78 SLAT ACTUATOR FAIRING OUTBOARD (4 Parts)

L Slip the forward end of the WING ASSEMBLY (Step

3),

into

the-FUSELAGE

and slide it forward until the

WING

aligns with the FUSELAGE, then cement

Parts together.

2a .Cement Part (11) to WING

and FUSELAGE.

3. Cement two Parts (77) and four Parts (78) to

WING

as indicated.

FOR

A "GEAR

UP"

MODEL

ONLY, SEE DETAIL "A"

4.

Cement six LANDING GEAR DOORS Parts

(40), (41), (53),

(54), (56) and

(57) to

WING

in a closed position as shown.

82 ' RIGHT

IAIN

GEAR RETRACT STRUT

53 RIGHT

MAIN

GEAR

DOOi

- OUTBOARD

54

Ü6HT

MAIN GEAR DOOR - INBOARD

55 LEFT

IAIN

GEAR RETRACT STiUT

56 LEFT

IAIN

GEAR

DOOI

- OUTBOARD

57 LEFT

IAIN

BEAR DOOi - INBOARD

58 iOSE GEAi

SlETiACT

LOCK

59 NOSE GEAR RETRACT STRUT

60

NOSE GEAR'DOOR-REAR

HALF

1.

2„

3.

4.

5

D

6„

Per a

"GEAi

ÖP"

model,

skip

this

ASSEHiL¥ step and go on to Step

18» "

Cement the RIGHT MAIN GEAR into

WING.

.Cement

(52) to GEAR and

WINS.

Cement (53) and (54) to edges of GEAR OPENING in a

wertlcal

position.

Cement LEFT GEAR

and^Parts

(55), (56) and (5?) in place on LEFT

WING.

Cement (58) and NOSE GEAR into

WHEEL

WELL

Cement

(59)

to NOSE GEAR

and

WHEEL WELL LOCATOR.

Cement (60) to edge of WHEEL WELL in a vertical position.

PAGE'8

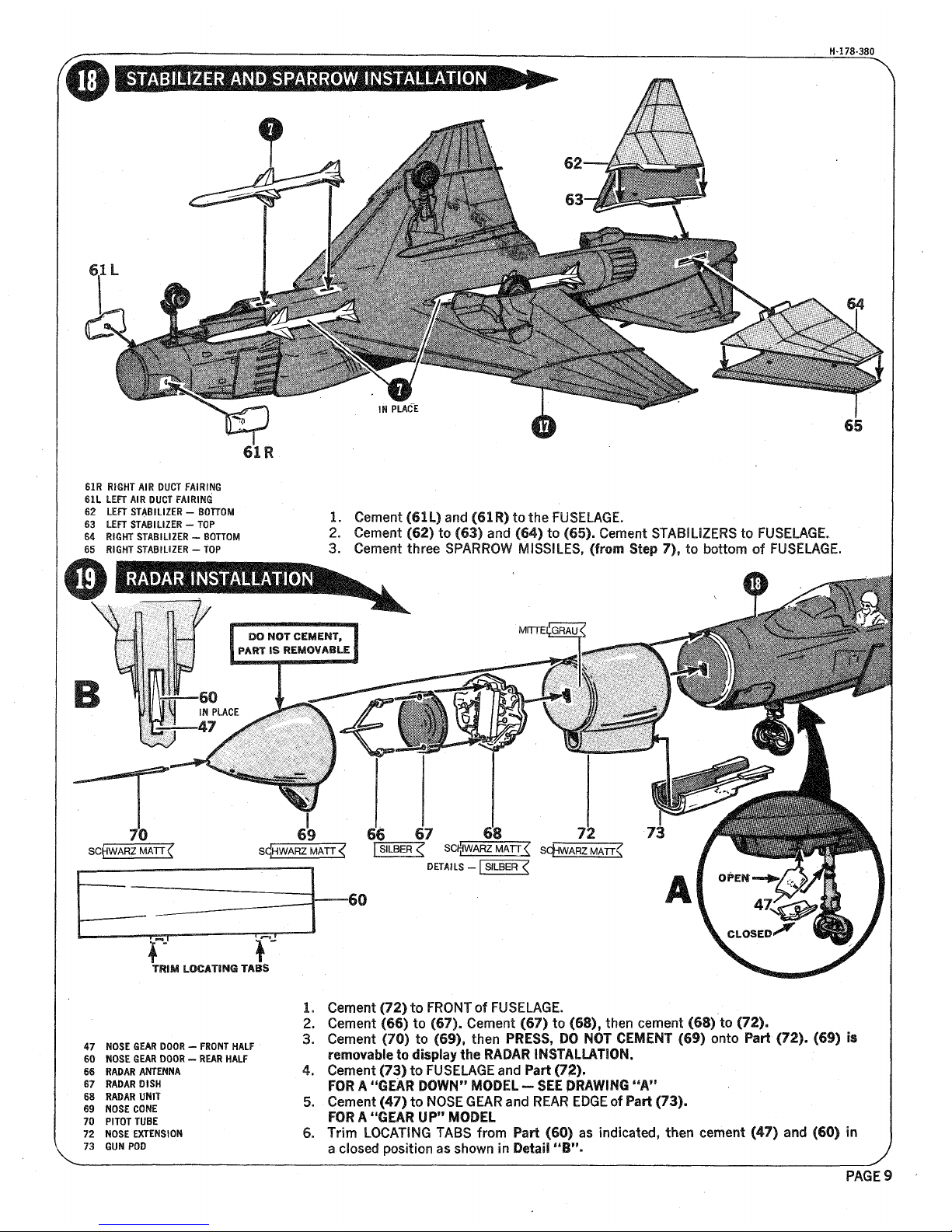

Page 9

H-178-380

i^L

61R

61R RIGHT AIR DUCT FAIRING

611

LEFT

AIR

DUCT FAIRING

62 LEFT STABILIZER -

POTTO!

S3 LEFT

STABILIZE!

- TOP

64 RIGHT STABILIZE! - BOTTOM

65

iiGHT

STABILIZER - TOP

1.

Cement

(61L)

and

(61R)

to the FUSELAGE.

2.

Cement

(62)

to (§3) and

(64)

to

(65).

Cement STABILIZERS to

FUSELAGE

8

3. Cement three SPARROW MISSILES, (from Step 7% to bottom of

FUSELAGE»

70

SCpVARZMATTlf

69 66 67 68 72 73

S^EARZMATT^

Pi? SGfWARZMATT? ScfJJJZMArR

DETAILS -

fSLBER^

A

f

v

TRIM LOCJITiN© TABS

47 NOSE

6EAR

DOOR

- FiöNT

HALF

60

iOSE

GEAR

DOOH -

REAR HALF

66 RADAR ANTENNA

67

MMU DISH

68 RADAR UNIT

69 iOSE

CONE

70

P1TOT

TUBE

72 NOSE EXTENSION

73

6tJN

POD

1.

3.

5»

Cement

(72)

to FRONT of FUSELAGE.

Cement (66) to (67).

Cement

(67) to

(§8),

then cement (68) to (72).

Cement (70) to

(69),

then

PiESSs DO

NOT CEMENT (69) onto

Part'

(72). (69) Is

removable to display the RADAR INSTALLATION.

Cement

(73)

to FUSELAGE

and

Part

(72),

FOR

k "mm

DOWN"

MODEL—'

SEE DRAWING "A"

Cement (47) to NOSE GEAR and REAR

EDGE

of Part

(73).

FOR

A "GEAR

UP"

MODEL

Trim LOCATING TABS from Part

(60)

as indicated, then cement (47) and

(60)

in

a closed position as shown in Detail

"B".

PAGEf

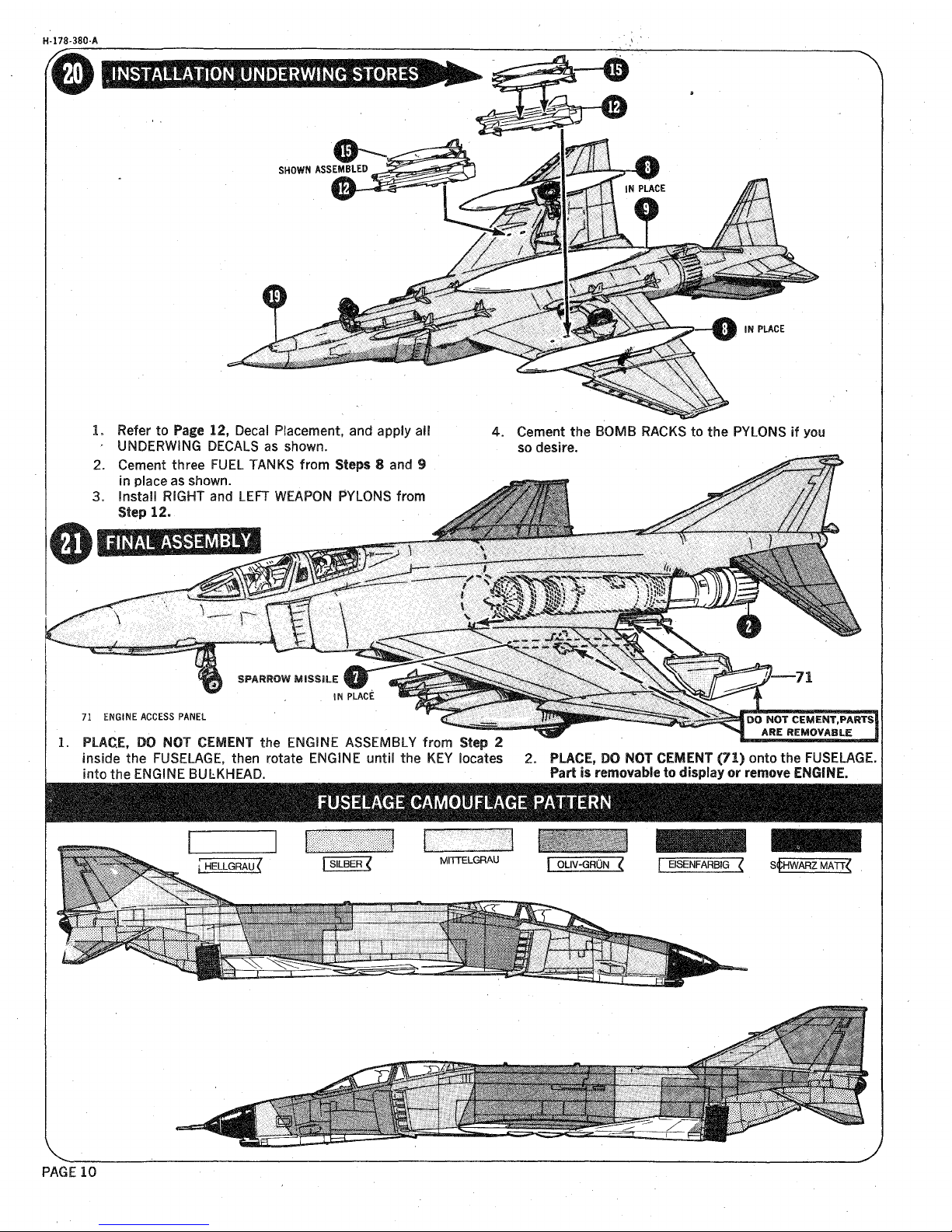

Page 10

H-178-380-A

SHOWN

ASSEliLED

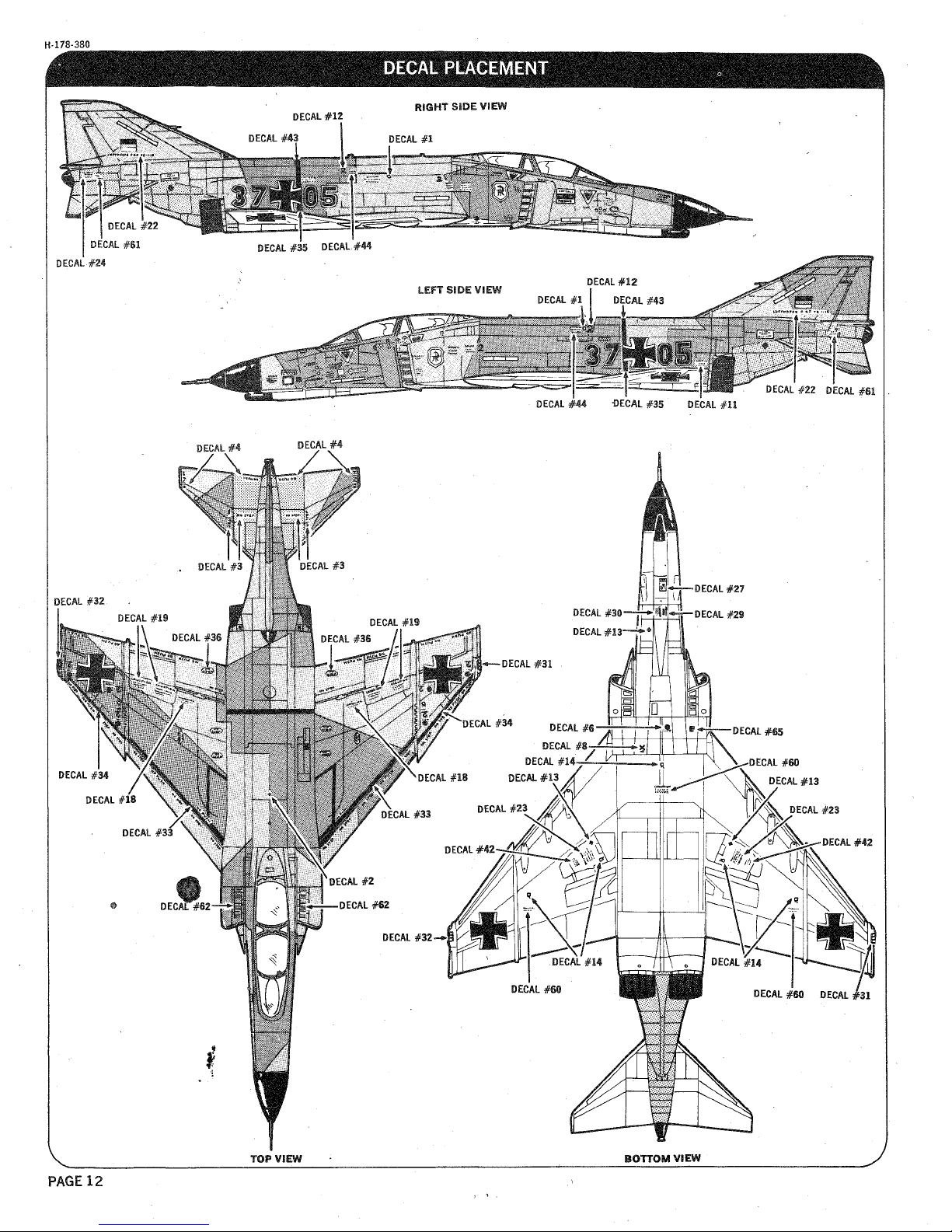

Refer to Page 12, Decal Placement, and apply all

UNDERWJNG

DECALS as

shown.

Cement three FUEL TANKS from Steps 8 and §

in place as shown.

Install

RIGHT and LEFT WEAPON PYLONS from

Step

12.

4.

Cement the BOMB RACKS to the PYLONS if you

so desire.

I

71

ENGINE ACCESS PANEL

I

2.

PLACE,

PO

WOT CEMENT the ENGINE ASSEMBLY from Step 2

i inside the FUSELAGE, then rotate ENGINE

until

the KEY locates 2.

PLACE,

DO NOT CEMENT (71) onto the

FUSELAGE.

i into the ENGINE BULKHEAD. Part

Ss

removable to display or

remowe

ENGINE.

■:.-;:<yT';f:-t ;<"

PAGE 10

Page 11

H-178-380

PAGE

11

Page 12

H-178-380

TOP

WiEW

BOTTOM WiEU

PAGE

12

Loading...

Loading...