( Manual

3D-Printer Construction Kit RF1000

Item No. 1007507

3D-Printer RF1000

Item No. 1007508

Table of Contents

1. Introduction ................................................................................................................................................................................................... 3

2. Explanation of Symbols ...............................................................................................................................................................................

3. Intended Use .................................................................................................................................................................................................

4. Safety Information ........................................................................................................................................................................................

5. Features .....................................................................................................................................................................................................

6. Working Principle of the 3D Printer ..........................................................................................................................................................

7. Overview of the Most Important Parts .....................................................................................................................................................

8. Required Tools and Material ......................................................................................................................................................................

9. Assembly of the Mechanical Parts ...........................................................................................................................................................

a) General .................................................................................................................................................................................................... 8

b) Assembly of the Components .............................................................................................................................................................

10. Wiring of the Electrical Components ......................................................................................................................................................

a) General .................................................................................................................................................................................................. 40

b) Wiring of the Components ..................................................................................................................................................................

c) Installation of the PCBs ......................................................................................................................................................................

11. Final Work ....................................................................................................................................................................................................

12. Initial Commissioning .................................................................................................................................................................................

a) Assembly of the Filament Holder and the Filament Hose .............................................................................................................

b) Insertion of the Filament .....................................................................................................................................................................

c) Setup and Transport ............................................................................................................................................................................

d) Mains Connection and First Activation ............................................................................................................................................

e) Calibration ............................................................................................................................................................................................. 60

f) First Print of an Example Object from the SD Card ........................................................................................................................

13. Operation at the Printer .............................................................................................................................................................................

a) Menu Overview ....................................................................................................................................................................................

b) Functions of the Individual Menu Items ...........................................................................................................................................

14. General Notes on 3D Printing ...................................................................................................................................................................

15. Software “Repetier Host” .........................................................................................................................................................................

a) General Notes on Software ...............................................................................................................................................................

b) Installation ............................................................................................................................................................................................ 70

c) Connection of the Connected Printer ...............................................................................................................................................

d) Manual Operation via the Software .................................................................................................................................................

e) Placement of a printing Object in the Software .............................................................................................................................

f) Preparation for Print ............................................................................................................................................................................

g) Printing .................................................................................................................................................................................................. 78

h) More Detailed Description of the Slicer Functions ........................................................................................................................

16. Software “Cura” .........................................................................................................................................................................................

a) General Notes on Software ...............................................................................................................................................................

b) Installation ............................................................................................................................................................................................ 86

c) Setup of the Software .........................................................................................................................................................................

d) Use of the Software in the Quickprint Mode ...................................................................................................................................

e) Use of the Software in the Expert Mode ..........................................................................................................................................

17. Filament Change .........................................................................................................................................................................................

18. Firmware Update ........................................................................................................................................................................................

(

Page

40

41

49

54

57

57

58

59

59

63

65

65

67

69

70

70

71

73

74

76

80

86

86

87

91

92

94

95

4

4

4

6

6

7

8

8

9

2

Page

19. Maintenance ............................................................................................................................................................................................... 97

a) General .................................................................................................................................................................................................. 97

b) Cleaning ................................................................................................................................................................................................. 98

c) Fuse Replacement ...............................................................................................................................................................................

d) Checking the Belt Tension ..................................................................................................................................................................

e) Nozzle Change ....................................................................................................................................................................................

20. Handling ..................................................................................................................................................................................................... 101

21. Troubleshooting ........................................................................................................................................................................................ 102

22. Disposal ..................................................................................................................................................................................................... 104

23. Technical Data ..........................................................................................................................................................................................

24. Annex ......................................................................................................................................................................................................... 105

a) Wiring Plan of the Main PCB ...........................................................................................................................................................

b) Notes on the Print Files (GCODE Files) on the Enclosed SD Card .............................................................................................

c) Setting up the Printer Settings ........................................................................................................................................................

d) Explanation on the Configuration Files on the Enclosed SD Card .............................................................................................

e) Setting up the Slicer ..........................................................................................................................................................................

f) Recommended Tightening Torque of the Screws ........................................................................................................................

98

98

101

104

105

106

106

109

109

112

1. Introduction

Dear Customer,

thank you for purchasing this product.

This product complies with the statutory national and European specifications. To maintain this status and to ensure safe operati

on, you as the user must observe these operating instructions!

These operating instructions are part of this product. They contain important notes on commissioning and handling. Also

consider this if you pass on the product to any third party. Therefore, retain these operating instructions for reference!

If there are any technical questions, please contact:

International: www.conrad.com/contact

United Kingdom: www.conrad-electronic.co.uk/contact

-

3

2. Explanation of Symbols

The symbol with a lightning bolt in a triangle is used where there is a health hazard, e.g. from electric shock. The device

contains no parts that require servicing by the user. Therefore, never open the device.

The exclamation mark symbol indicates that the user must read these operating instructions before commissioning of

the device, and observe them during operation.

This symbol warns of hot surfaces the contact with which may cause injury.

This symbol warns of hand injury that may occur when reaching into the device in operation.

The symbol with the arrow indicates special advice and notes.

3. Intended Use

The 3D printer produces 3D-objects from suitable printing files. For this, suitable raw material (filament) is melted in the print head

and attached in the required position for the object.

This product is only approved for connection to 100-240 V/50/60 Hz alternating current and only for use in the private area.

It is intended for indoor operation only. Do not use it outdoors. Contact with moisture, e.g. in bathrooms, must be avoided under

all circumstances.

Any use other than that described above will damage this product and involves the risk of short circuit, fire, electric shock, etc.

This product complies with the statutory national and European requirements. All company names and product names are trade

marks of their respective owners. All rights reserved.

ATTENTION Mains voltage - the connection, installation and wiring of the electrical components must only be performed by an electrician who is familiar with the applicable safety provisions. Before commissioning, inspection according to the applicable safety provisions must be performed by an electrician.

Observe all safety and assembly notes in these operating instructions!

4. Safety Information

The guarantee/warranty will expire if damage is incurred resulting from non-compliance with these operating instruc-

tions. We do not assume liability for any consequential damage.

Nor do we assume any liability for damage to property or personal injury caused by improper use or failure to observe

the safety information. In such cases the warranty/guarantee is voided.

-

Dear Customer: The following safety information is intended not only for the protection of the device but also for the

protection of your health. Please read through the following attentively:

• For safety reasons, any unauthorized conversions and/or modifications to the product deviating from these operating

instructions are not permitted. Components may be damaged and thus impair the function or safety of the device.

• When setting up the 3D printer, observe that the mains switch at the rear of the device must be easy to reach so that

the device can be switched o quickly and easily in case of malfunction.

4

• Never reach into the 3D printer in operation. The mechanically moved parts within the printer pose a high risk of injury!

• The print head and the heating plate grow very hot in operation. Never touch these parts during or just after operation.

Let them cool down suciently first (approx. 60 minutes).

• The mains unit corresponds to the applicable CE provisions. Compliance with the applicable CE provisions for the

finished construction kit, whoever, is subject to the constructor of the construction kit and also essentially depends on

precise work during assembly.

• All persons who operate this product, mount, install, assemble it, put it into operation or service it must be trained and

qualified accordingly and must observe these operating instructions.

• Disconnect the device from the mains before maintenance work or modifications (unplug the mains plug) and let it

cool down.

• In operation, there will be noise and, depending on the filament material used, smells. Observe this when selecting

the site of setup and the filament material. Ensure sucient ventilation or install an extraction system. Do not inhale

arising vapours. When using any other than the recommended filament material, poisonous vapours or gases may

develop.

• The 3D printer is not suitable for persons with physical, sensor or metal limitations or for inexperienced or uninformed

persons.

• This product is not a toy and not suitable for children. Children cannot judge the dangers involved when handling

electrical devices.

• This device is a safety class 1 product. The only permissible voltage source is a properly grounded mains socket

(100-240 V/50/60 Hz) of the public mains.

• The devices must not be exposed to any extreme temperatures, strong vibrations, high moisture, such as rain or steam

or strong mechanical strain.

• Never place containers containing liquids, e.g. glasses, vases, etc. on the device or in its vicinity and do not pour any

liquids out over the device. Liquids may get into the housing and impair electrical safety. This also poses great danger

of fire or potentially fatal electric shock!

If this is the case, first power down the respective mains socket on all poles (e.g. switch o circuit breaker and FI

switch) and then pull the mains cable from the socket. Disconnect all lines from the device. Do not operate any part of

the product anymore afterwards, but take it to a specialist workshop.

• Never place any sources of open fire, such as lit candles, on or right next to the device.

• Do not touch the mains cable if it is damaged. First power down the respective mains socket on all poles (e.g. switch

o circuit breaker and FI switch) and then pull the mains cable from the socket. Never operate the product with a

damaged mains line.

• When setting up the product, make sure that the mains cable is not pinched or damaged by sharp edges.

• Never touch the mains line or the mains plug with wet or damp hands. There is a risk of potentially fatal electric

shock!

• The mechanical parts of the product are produced highly precisely. Never apply any mechanical force here. The

3D printer may be rendered useless by this.

• Never operate the device unattended.

• Only operate the device in moderate climates, never in tropical climates.

• Do not leave any packaging material unattended. It may become a dangerous toy for children.

• If you are not sure of the correct connection or if there are any questions that are not covered by the operating instruc

tions, do not hesitate to contact our technical support or another specialist.

• Also observe the additional safety information in the individual chapters of these instructions.

-

5

5. Features

• Large printing space of approx. 245 x 230 x 200 mm

• Play-free profile rail guides and ball-threaded drives for maximum precision

• Automatic printing plate measurement

• Ceramics heating plate with structural surface

• Highly precise extruder with replaceable printing nozzle

• Integrated long-lived industrial mains unit

• Display and key pad for the device operation right at the device

• Control via a computer (USB) or stand-alone operation (with SD or SDHC card) possible

• Manual control of the printing parameters possible even during operation

• Extremely stable by aluminium/steel mechanics

• Suitable for all common standard roll filament types

• Breaking and abrasion-free cable guides across energy guide chains

• Future-proof with optional accessories

6. Working Principle of the 3D Printer

For 3D print, first a file is needed that contains the three-dimensional data of the object to be printed (a common format of such a

file is, e.g., a .stl-file).

This file can be produced with the corresponding software or with a 3D-scanner. There are also many printing files already online

that can be downloaded to print an object as quickly as possible.

The actual printer software has the task to render the above three-dimensional file into a file that the printer can print. This is a

file in which the individual print layers, the print temperatures for printing head and heating bed, etc. are specified. The file has

the extension “.gcode”.

This GCODE printing file is sent to the 3D printer either via the USB interface by the computer, or an SD card with the printing file

is put into the card reader and the 3D printer is used in standalone operation.

The 3D printer then prints the print file layer for layer according to the FFF (Fused Filament Fabrication) / FDM (Fused Deposition

Modelling) procedure.

At the actual print, the filament material is transported from the filament roll to the print head (extruder).

In the extruder, the filament material is melted and then applied to the heating plate via a fine extruder nozzle layer by layer.

The heating plate moves in the Y and Z directions, the extruder moves in the X-direction. Thus, all prerequisites to produce a threedimensional object by horizontal application of the present layers are created.

A 3D printer is a highly complex device in which many parameters must be set depending on the printer, printed object

and filament material used.

Additionally, the adhesion of the printed object on the printing plate is influenced by printing plate temperature, fila

ment material, shape of the printed object and surface properties of the printing plate.

Ambience influences such as drafts, grease on the printing plate, etc. also play a role in the quality and adhesion of the

printed object.

For the above reasons, it is not possible to achieve high-quality print results at once and without previous experi

ments.

Change the adjustable parameters in small steps to achieve the best printing results for your application. The printing

examples enclosed on the SD-card provide references, but must be refined for perfect results depending on the above

parameters.

6

-

-

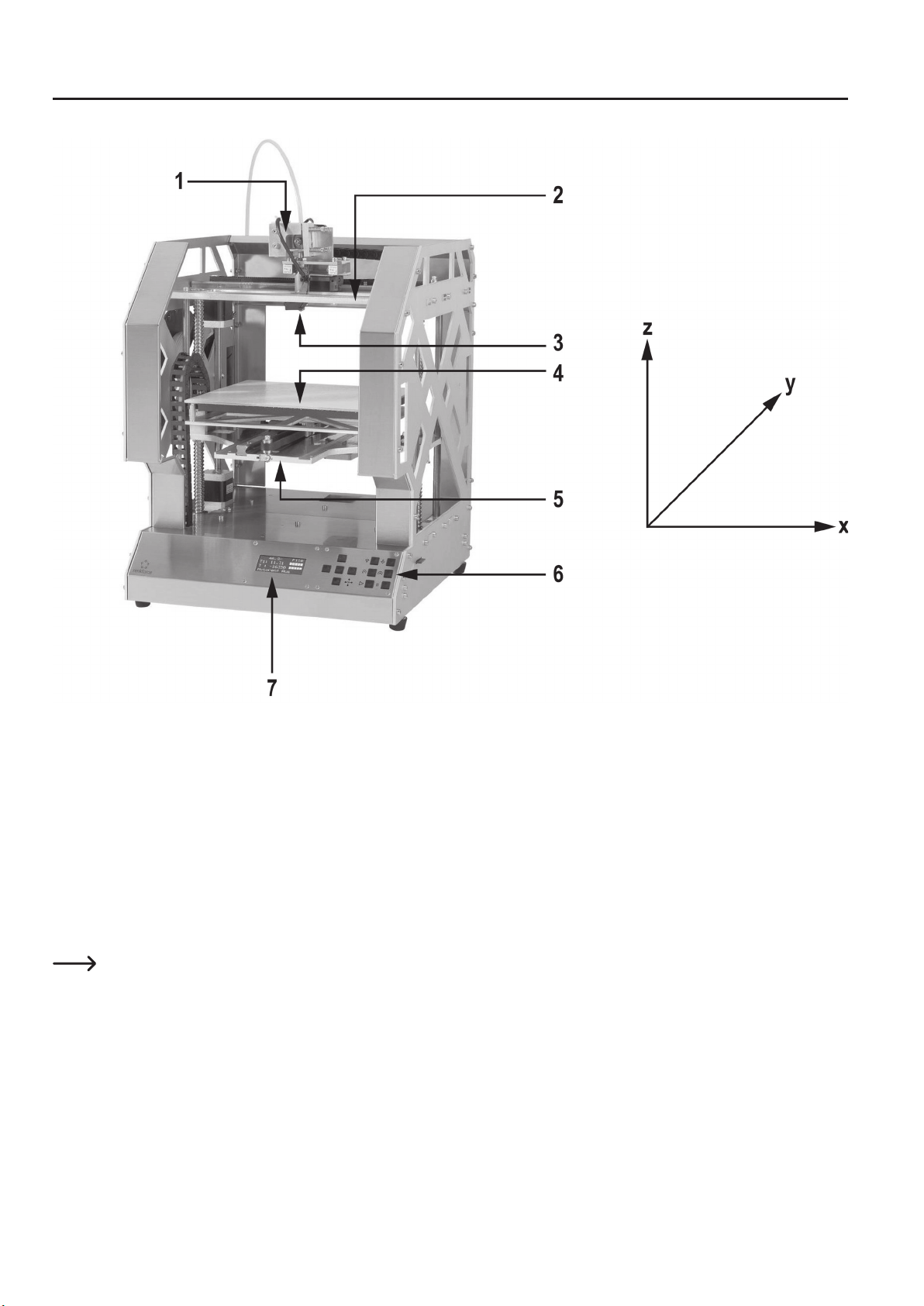

7. Overview of the Most Important Parts

(1) Extruder carriage

(2) X-plate

(3) Extruder

(4) Heating plate

(5) Y-plate

(6) Operating button field

(7) Display

To the right of the figure, the printing directions (x, y and z) are indicated.

7

8. Required Tools and Material

• Dierent screwdrivers (cross-head and slotted)

• Hexagon socket wrench 1.5 mm / 2 mm / 2.5 mm / 3 mm / 4 mm

• Hexagon wrench 4 mm / 5 mm / 5.5 mm / 7 mm / 13 mm (2x)

• Stop angle

• Calliper

• Wire cutter

• Small flat pliers and small long-nose pliers

• Threadlocker varnish, medium strength

• Hot-glue gun (optional)

9. Assembly of the Mechanical Parts

The following chapters refer to the assembly of the 3D printing construction kit, but are also interesting for owners of the readymade device as information for later accessory assembly.

If you have purchased the finished device, you can skip the following chapters and continue directly with the chapter “Initial

commissioning”.

a) General Information

Take enough time for the assembly. Hurrying often leads to mistakes that may damage components or ruin the time

benefit by elaborate rework.

The workplace should be suciently large and clean so that the dierent components and assemblies can be put down

and installed easily.

The stainless steel parts of the construction kit are very sensitive to dirt. Wash your hands before installing these parts

and use cotton gloves if necessary. Remove the protective film only directly before assembly.

Always observe the images during assembly. Here, the assembly locations and correct alignment of the components

are shown.

All mechanical components of the construction kit are produced extremely precisely. Never apply any force during as

sembly. All parts can be assembled without any great application of force. If this is not the case, rethink the assembly

step and reread the corresponding description in these instructions.

When tightening the screws, ensure that you do not tighten them too tightly. Many screws are turned into aluminium

For countersunk-head screws, the length (l) is measured with the screw head; for cylinder head screws, the length

threads and therefore must not be tightened as far as it would be possible, e.g., in steel threads. A table with the recommended tightening torques of the screws can be found in the appendix of these instructions.

Sort the screws by size before assembly. This facilitates assembly, since you do not have to look for individual screws.

measurement takes place without the screw head. The diameter (d) is always measured by the thread.

-

8

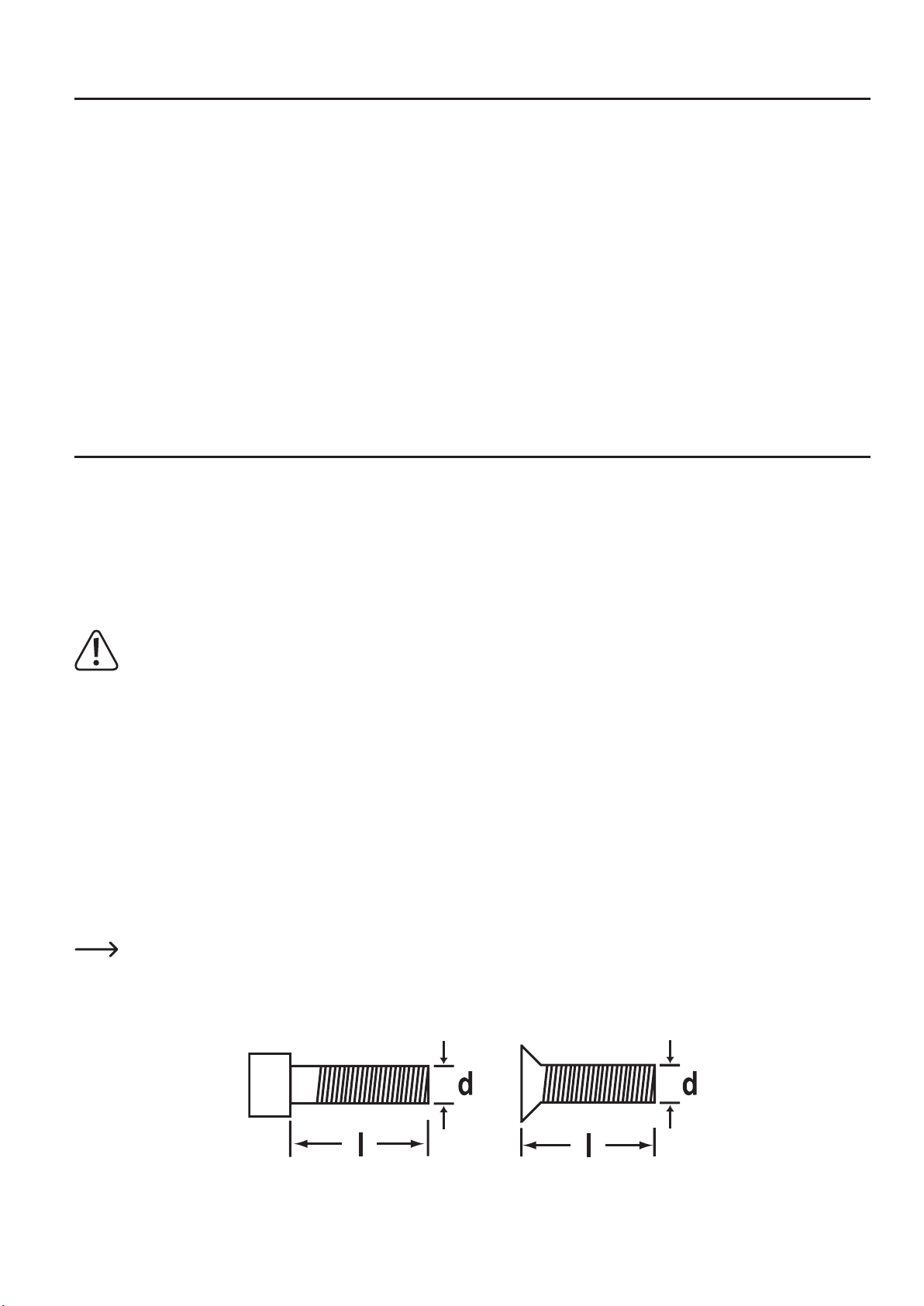

Application of the threadlocker varnish

In the following instruction, some screws must be secured with threadlocker varnish. This is indicated accordingly in the text.

Procedure:

Put a small drop of threadlocker varnish medium-strength onto the thread start. Observe that you must only use a small drop as

shown in the following screen.

b) Assembly of the Components

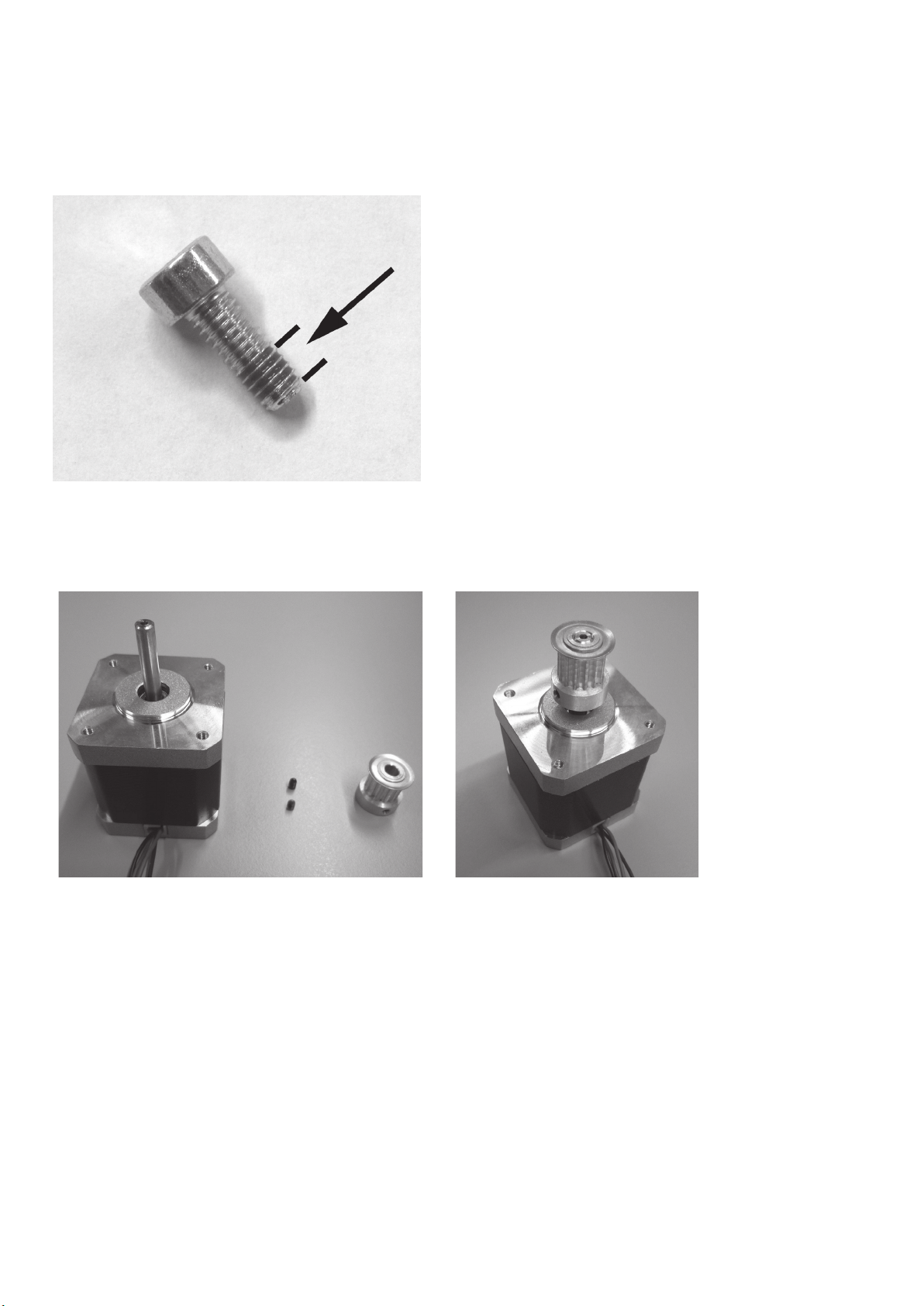

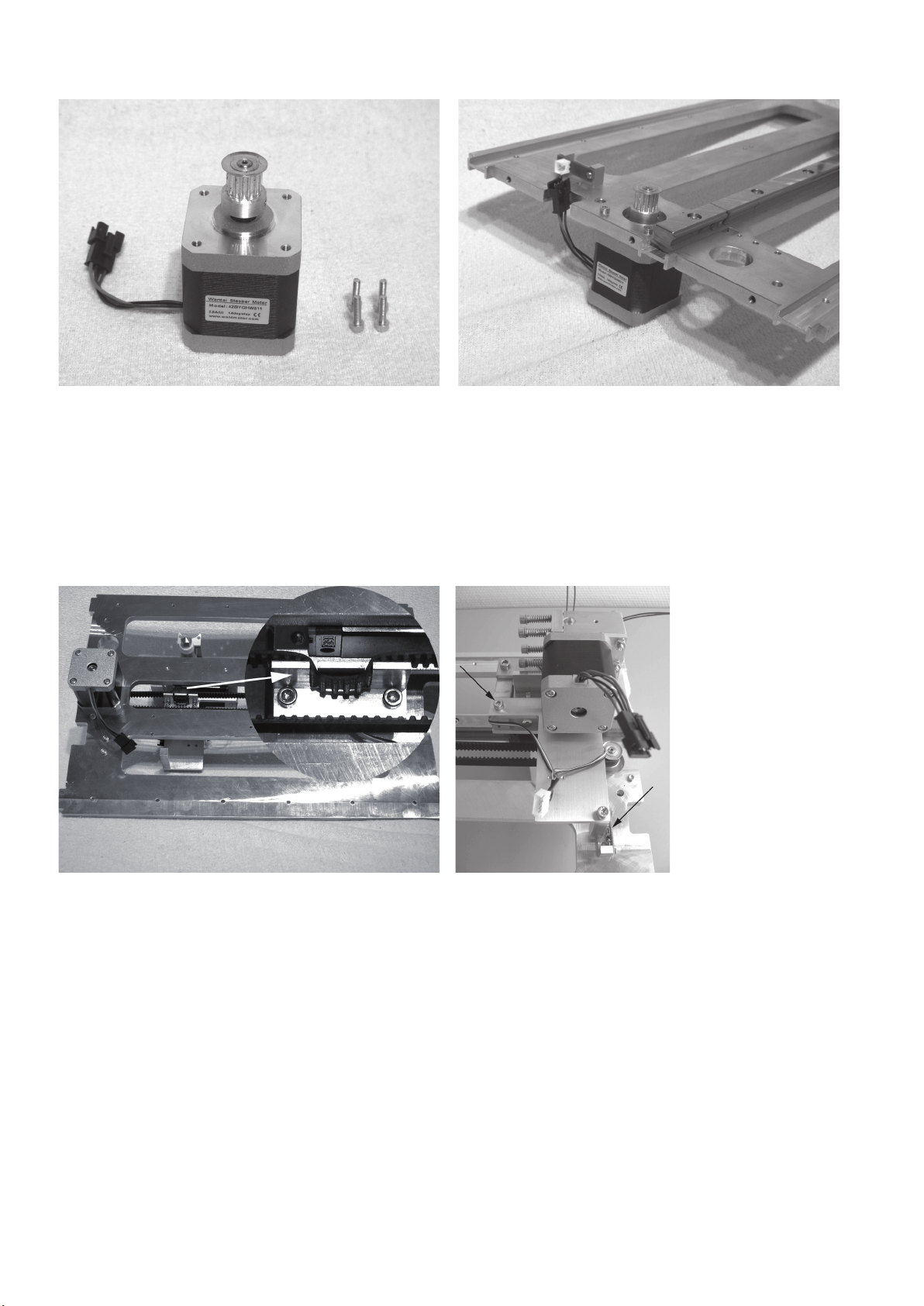

Attachment of the motor pinion to the actuators

3x actuator

3x sprocket 14Z (small pinion, outer dia. 16 mm)

6x threaded pin M3 x 5

Push sprockets onto axes of the actuators and attach them

with 2 threaded pins each. Apply threaded pins with thread

locker varnish.

The motor axes must end flush with the upper edges of the

sprockets.

-

9

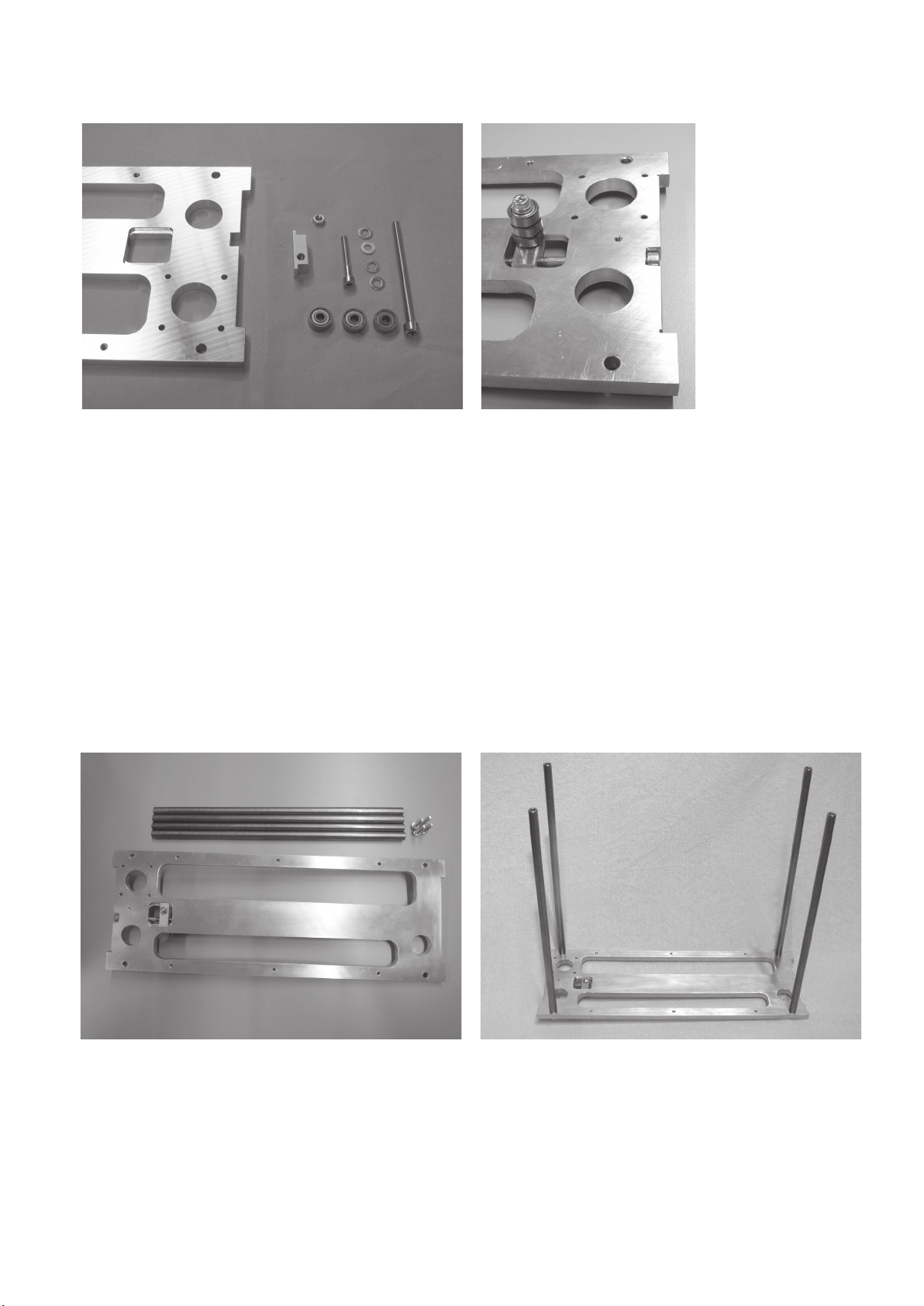

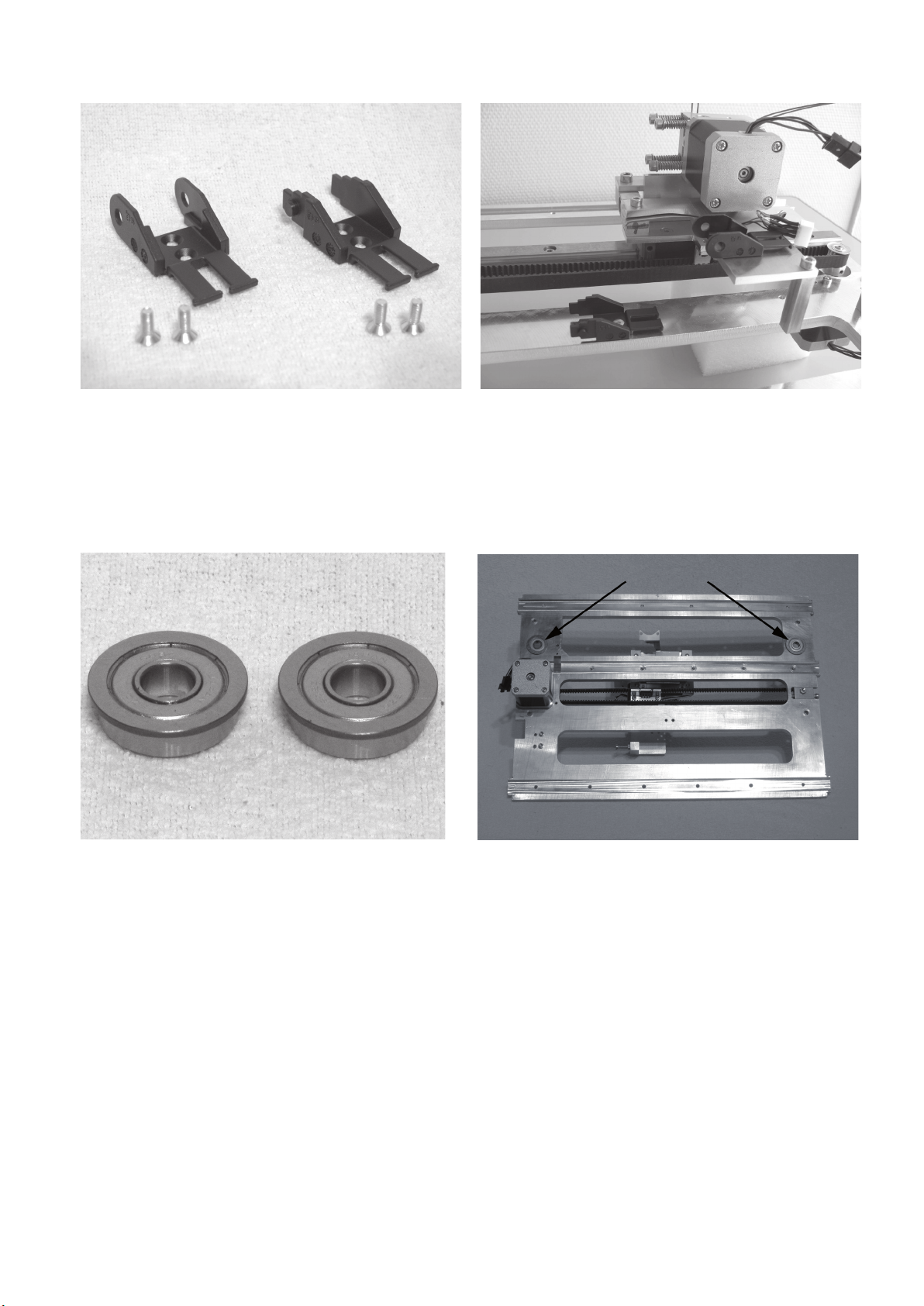

Assembly of the bottom plate

Assembly of the belt tensioner

1x bottom plate

1x belt tensioner basic body

3x ball bearing 624ZZ (diameter inside/outside (8.8/13 mm)

4x washer (diameter inside/outside 4.3/8.8 mm)

1x cylinder head screw M4x30

1x cylinder head screw M5x70

1x nut M4

Assembly of the Spacers

Insert belt tensioner basic body into the intended breakout of

the bottom plate. The cross-bore of the belt tensioner basic

body and the bore in the bottom plate must align.

Push washers onto the M4x30 screw alternatingly with the ball

bearings.

Screw the screw equipped in this manner, as shown in the figure, into the belt tensioner basic body and tighten it well.

Counter the screw with the nut at the belt tensioner basic body

(in the figure on the bottom of the bottom plate).

The screw head of the belt tensioner (on the right in the figure)

is supported against the housing side part to be installed later

so that the belt tensioner function is only present after assembly of the side part

4x spacers

1x bottom plate

4x cylinder head screw M5x16

10

Turn the bottom plate and attach the spacers to the top of the

bottom plate with the screws as shown.

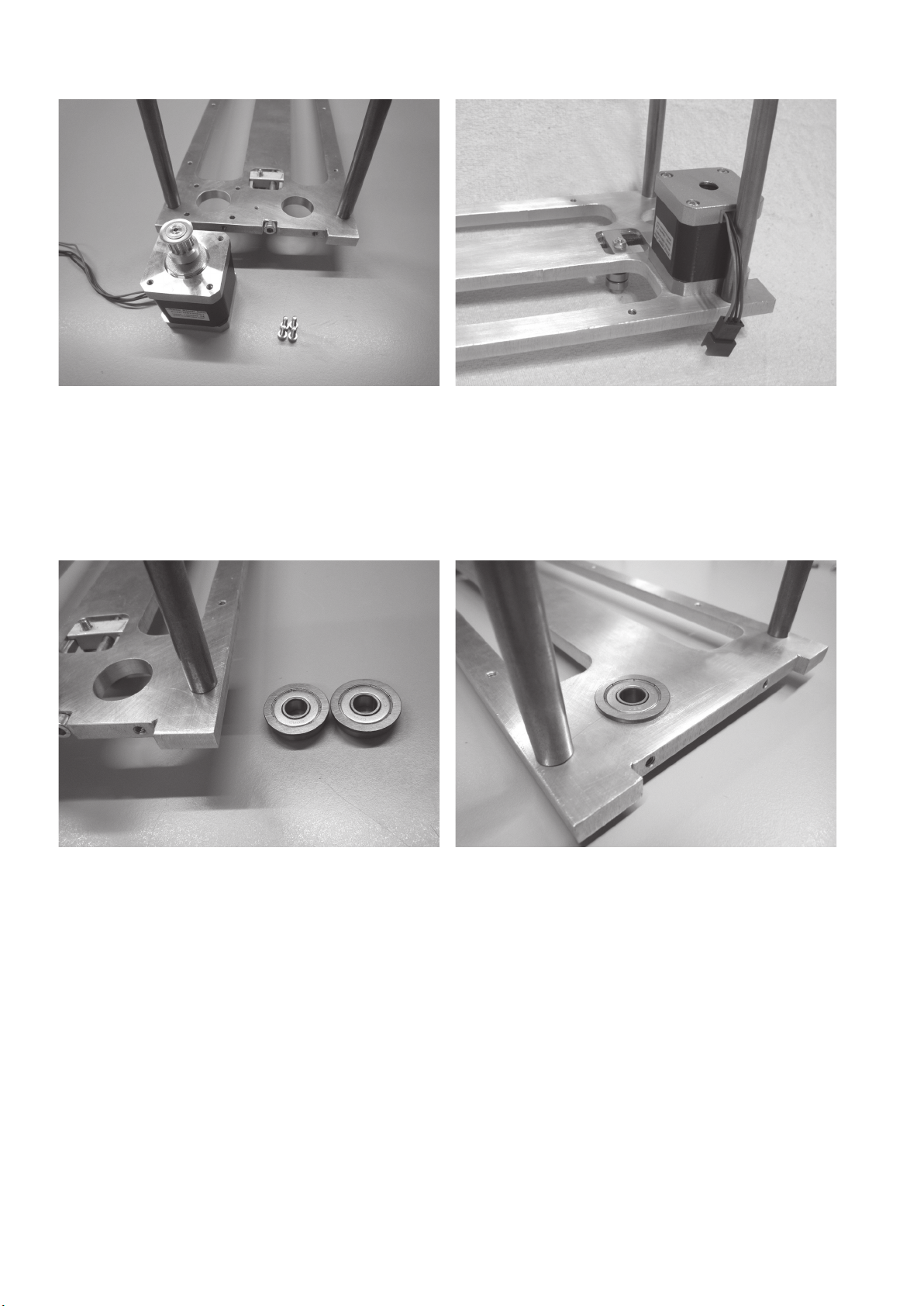

Assembly of the drive motor

1x actuator

1x bottom plate

4x cylinder head screw M3x12

Inserting the grooved ball bearings

Attach the actuator to the bottom plate with the 4 screws as

shown in the figure.

Apply screws with threadlocker varnish.

The cable exit of the actuator must point at the long side of the

plate as shown.

2x grooved ball bearings

1x bottom plate

Insert the grooved ball bearings into the corresponding bores

of the bottom plate from above.

Turn the grooved ball bearings slightly, when inserting them

into the bores. Do not apply any force. The flanges of the

grooved ball bearings must be cleanly aligned with the top of

the bottom plate.

11

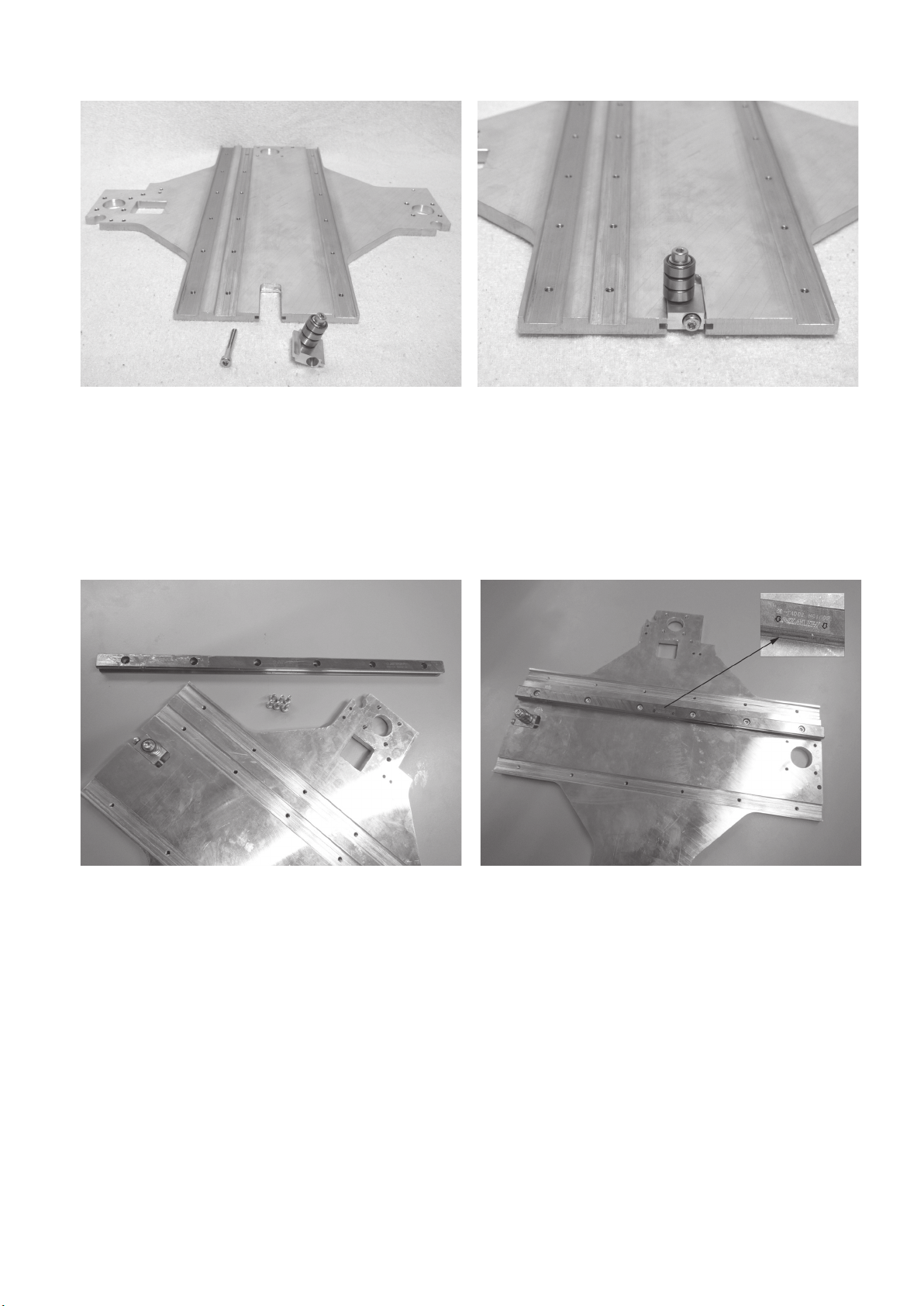

Assembly of the X plate

Assembly of belt tensioner

1x belt tensioner basic body

3x ball bearing 624ZZ (diameter inside/outside (8.8/13 mm)

4x washer (diameter inside/outside 4.3/8.8 mm)

1x cylinder head screw M4x30

1x nut M4

Attachment of belt tensioner to the X-plate

Push washers onto the screw with the ball bearings alternat

ingly.

Screw the screw into the belt tensioner basic body as shown

in the figure and tighten it well.

Counter the screw with a nut.

-

1x X-plate

1x assembly belt tensioner (see above)

1x cylinder head screw M4x30

12

Push the belt tensioner assembly into the intended section of

the X-plate and turn the screw into the belt tensioner.

Observe the position of the bore in the belt tensioner (must be

on the right as shown in the figure). The ball bearings must be

on the grooved side of the X-plate.

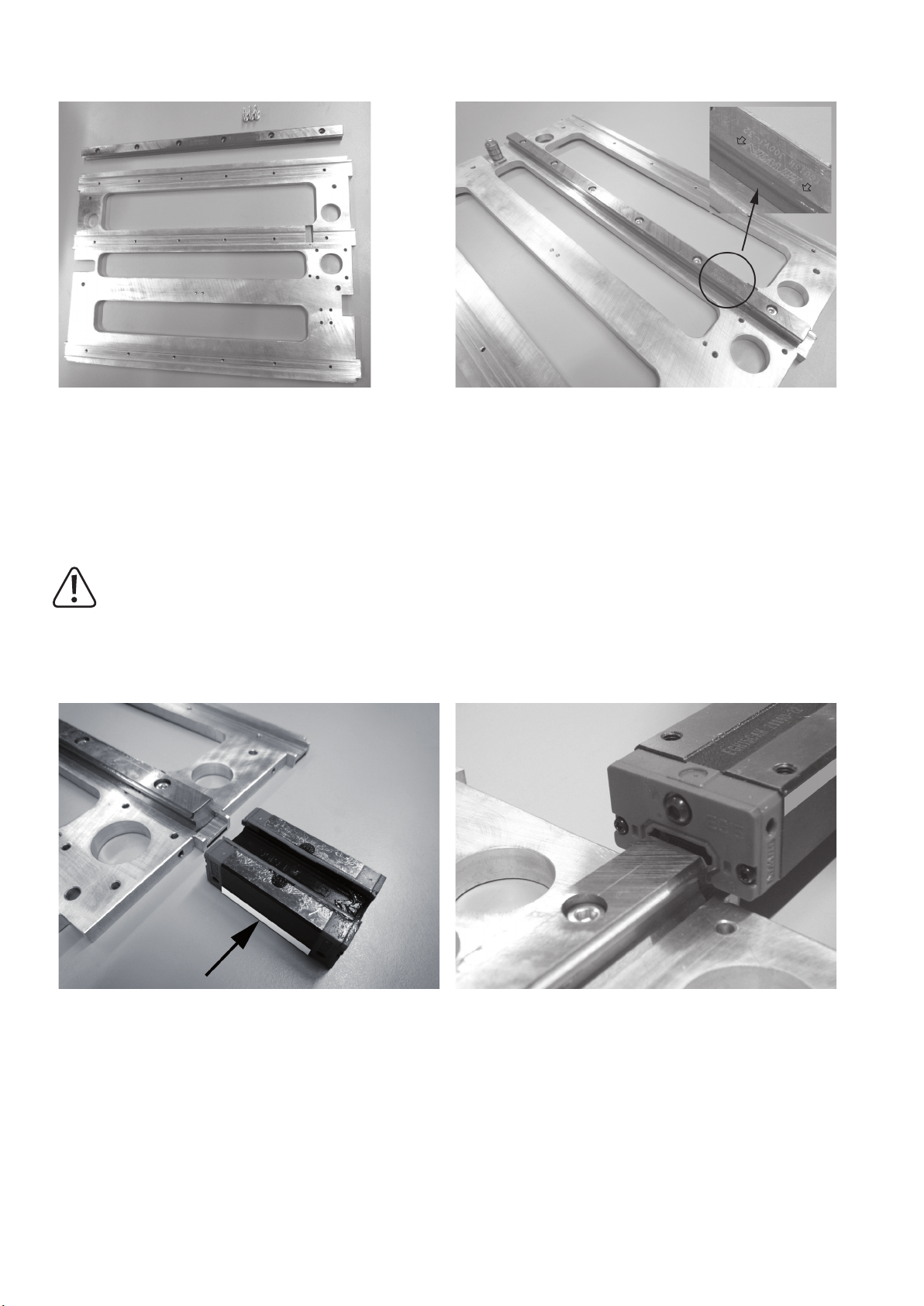

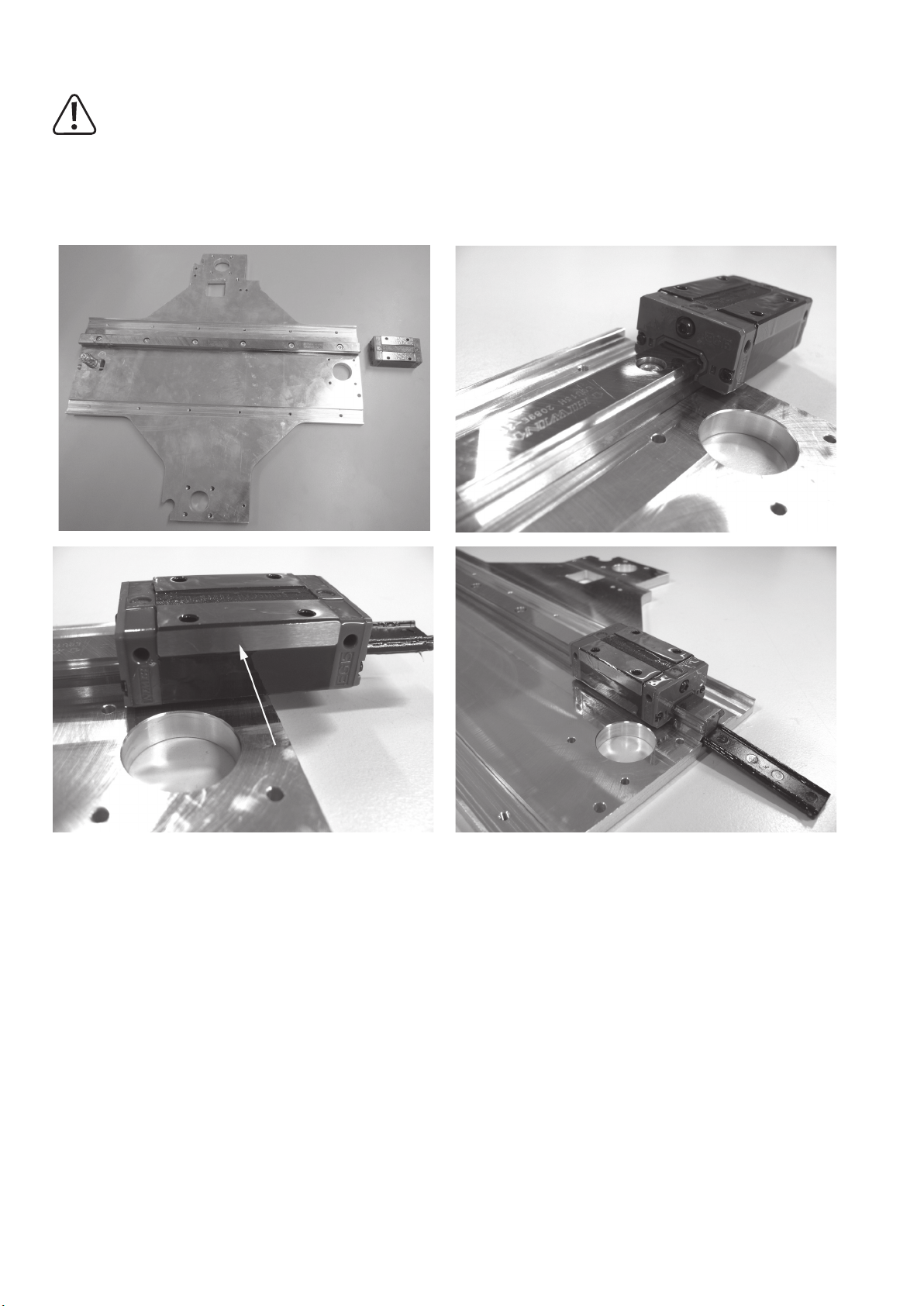

Attachment of the guide rail

1x X-plate

1x guide rails

6x cylinder head screws M4x12

Push the guide carriage onto the guide rail

The assembly aid (plastic part in the guide of the guide carriage) must never be removed before pushing on the guide

carriage, since the gearing balls will fall out of the carriage otherwise. This would be irreparable.

This also applies when the guide carriage is pushed from the guide rail after assembly. For reasons of safety, the guide

carriage should be secured, e.g. with adhesive tape before further installation.

The guide carriage has a polished area on one side (see arrow in the figure on the lower left). Turn the guide carriage

so that the arrows on the guide rails point towards the ground area of the guide carriage before pushing it on.

Insert the guide rail into the middle groove of the X-plate and

attach with the screws.

The imprinted arrows on the guide rail must point to the side of

the belt tensioner.

13

1x X-plate

1x guide carriage complete with assembly aid

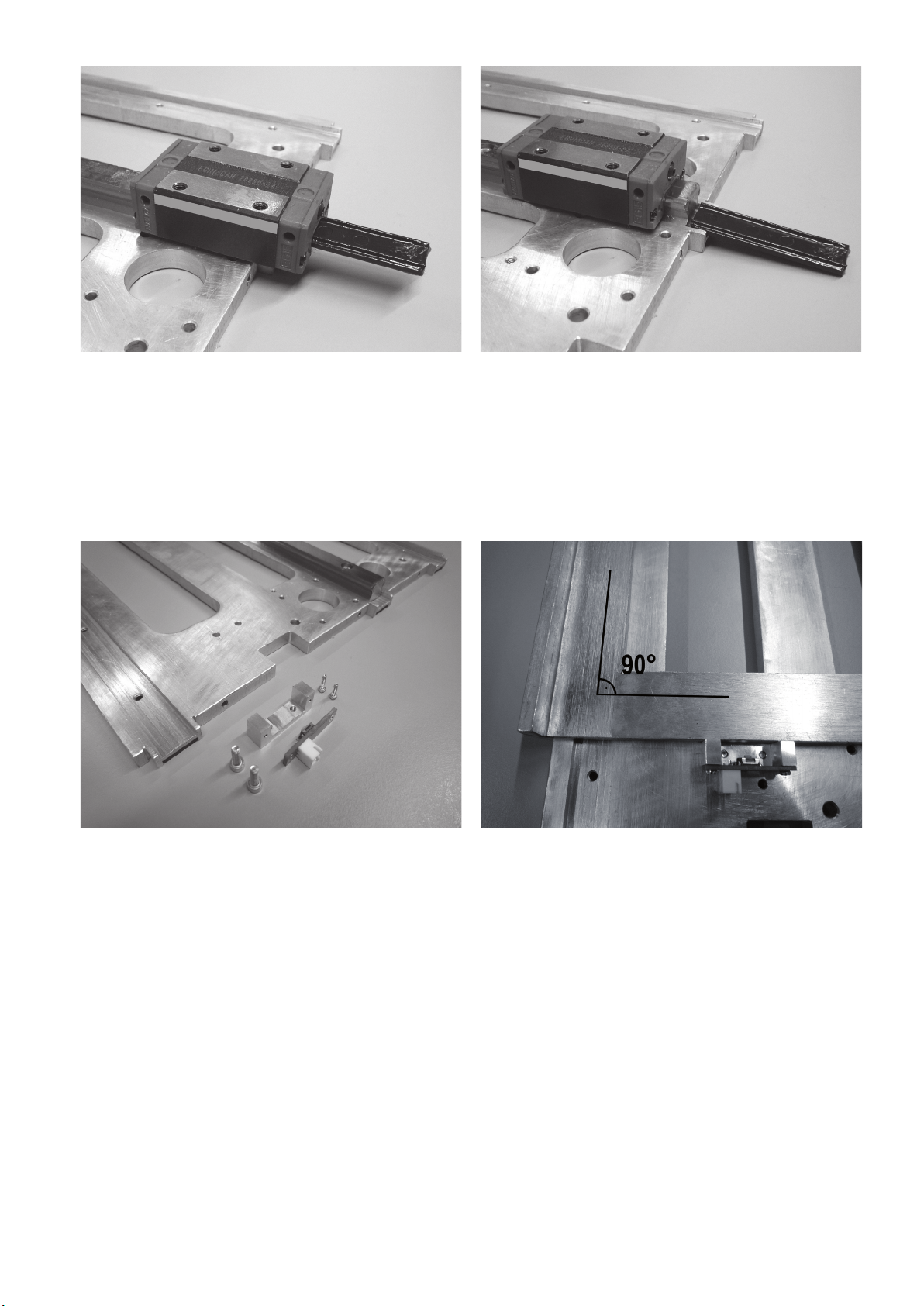

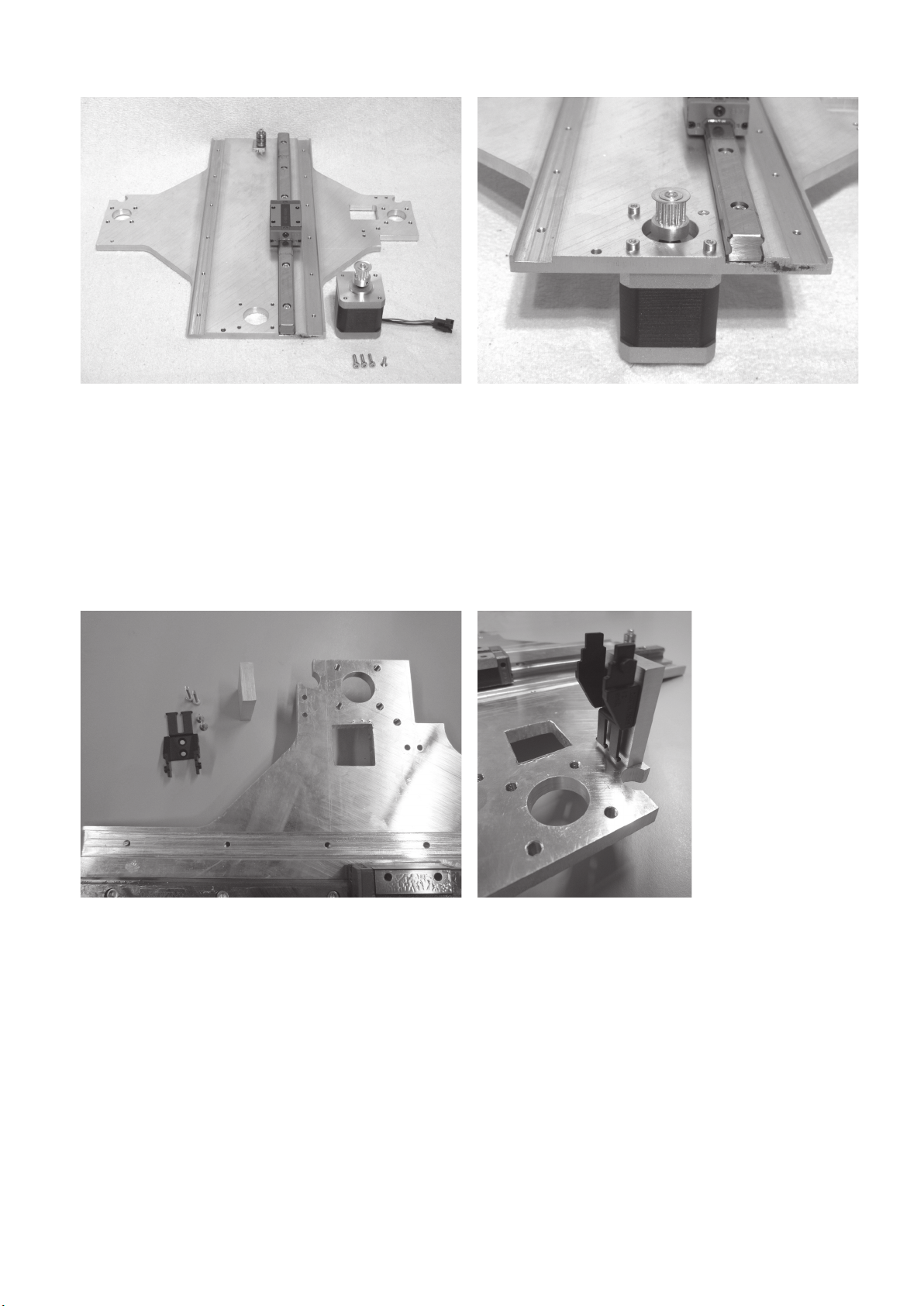

Attaching the limit switch for the X-direction

Carefully push the guide carriage onto the guide rail and push

the assembly aid (plastic part) from the guide carriage while

doing so.

1x X-plate

1x limit switch

1x holder for limit switch

2x cylinder head screw M2x6

2x cylinder head screw M3x10

14

Install the limit switch PCB with the M2x6-screws to its holder

so that the plug connector points away from the holder (see

figure).

Then align the limit switch with the holder with a stop angle at

a right angle to the X-plate and screw it onto the X-plate with

the M3x10 screws.

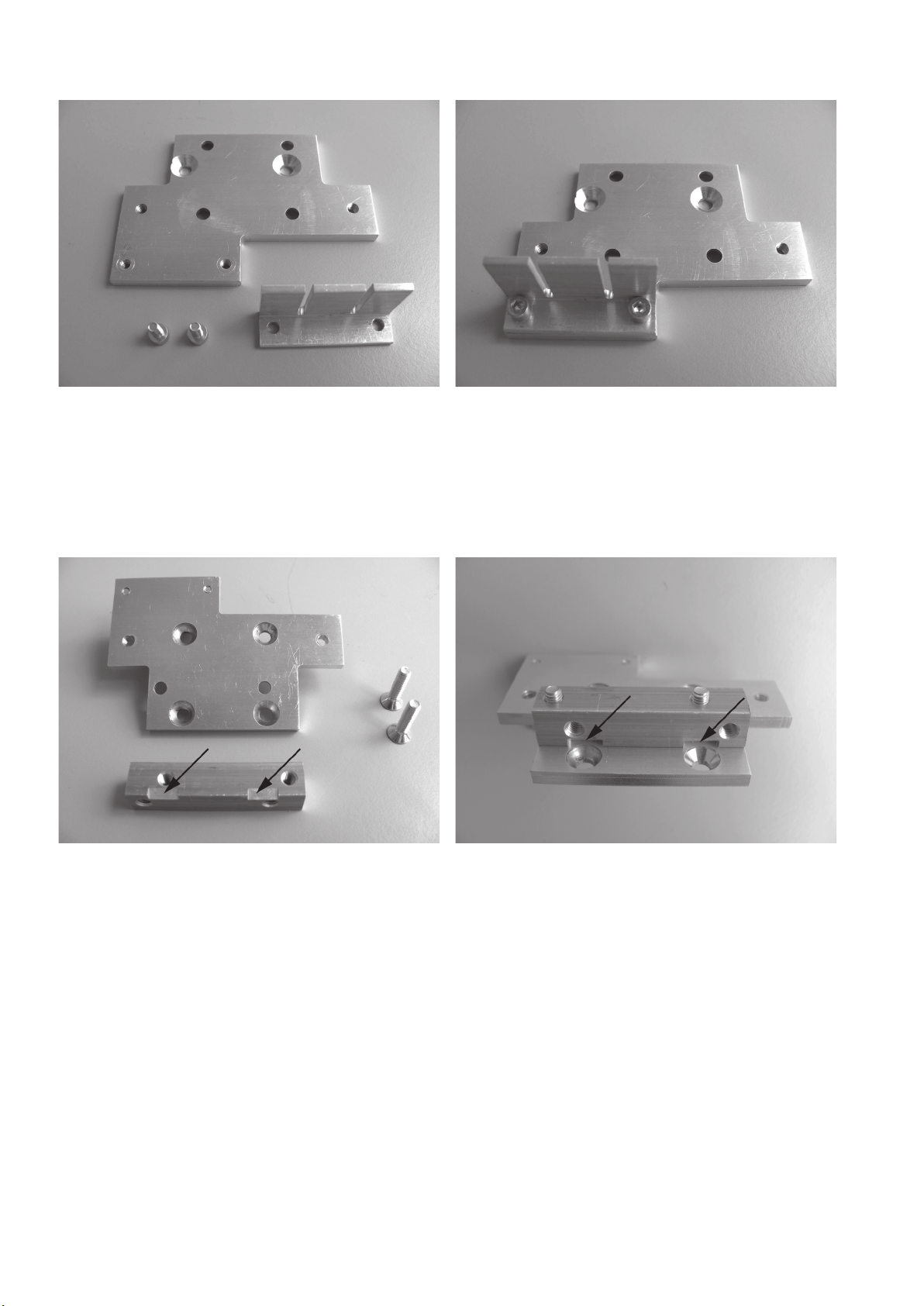

Attachment of the belt holder to the guide carriage plate

1x guide carriage plate

1x belt holder

2x cylinder head screw M3x6

Assembly of the infeed holder

Attach the belt holder at the bottom of the guide carriage plate

with the two screws as shown.

Apply screws with threadlocker varnish.

1x guide carriage plate

1x infeed holding block

4x countersunk head screw M4x10

2x countersunk head screw M4x16

Infeed holding block attached under the plate with the two

countersunk head screws M4x16. The two disconnections at

the infeed holding block must point to the recessed bores as

shown (see arrows). Tighten screws well, since the extruder

will acquire play later otherwise.

15

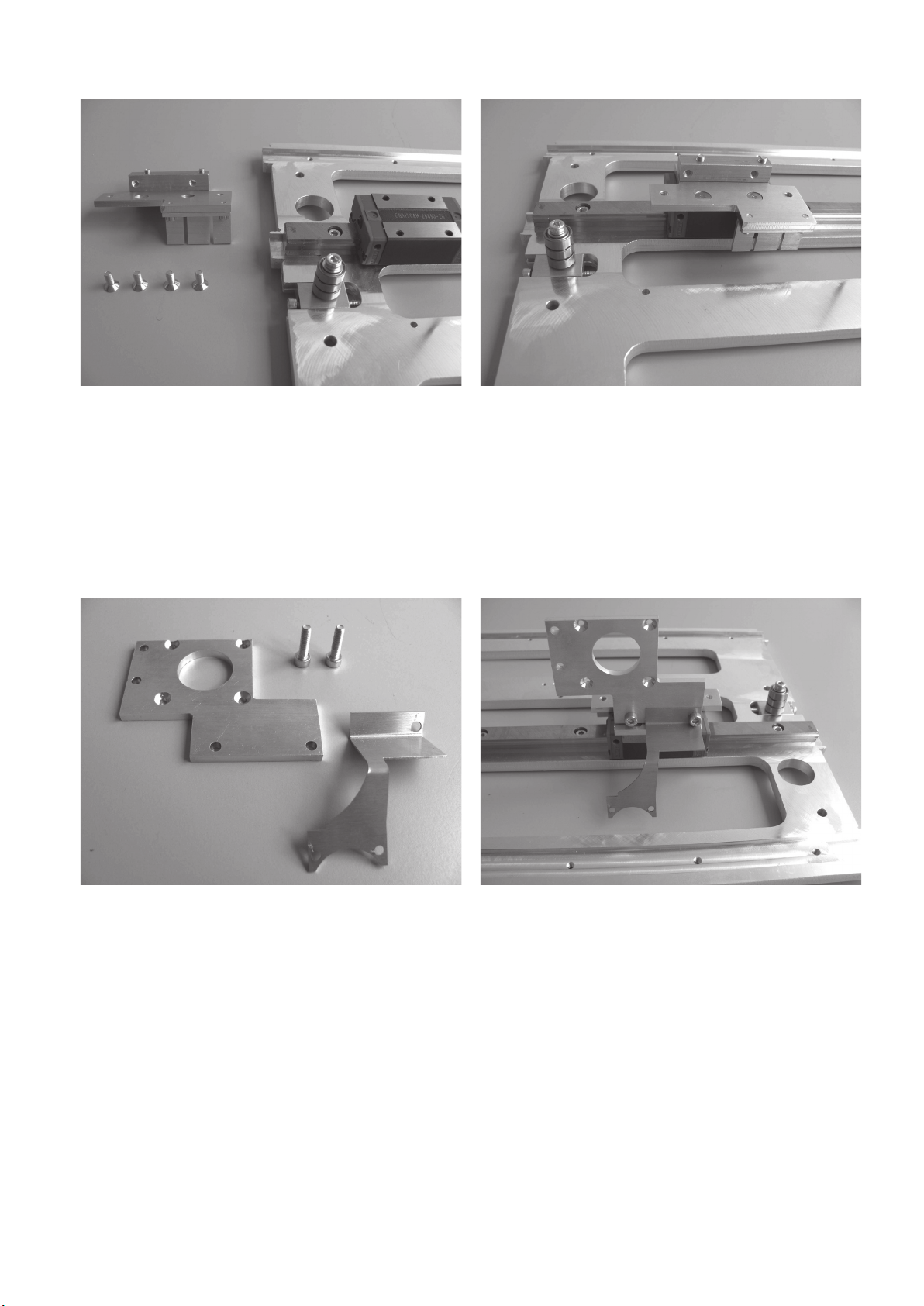

Assembly of the guide carriage plate on the guide carriage

1x guide carriage plate

1x X-plate

4x countersunk head screw M4x10

Attachment of motor holder and fan sheet

Attach the guide carriage plate to the guide carriage with the 4

countersunk head screws. First screw in the two screws at the

disconnections. Apply screws with threadlocker varnish. The

belt holders must be on the side with the previously installed

belt tensioner.

1x fan sheet

1x motor holder

2x cylinder head screw M4x16

16

Attach the motor holder to the guide carriage as shown togeth

er with the fan sheet.

-

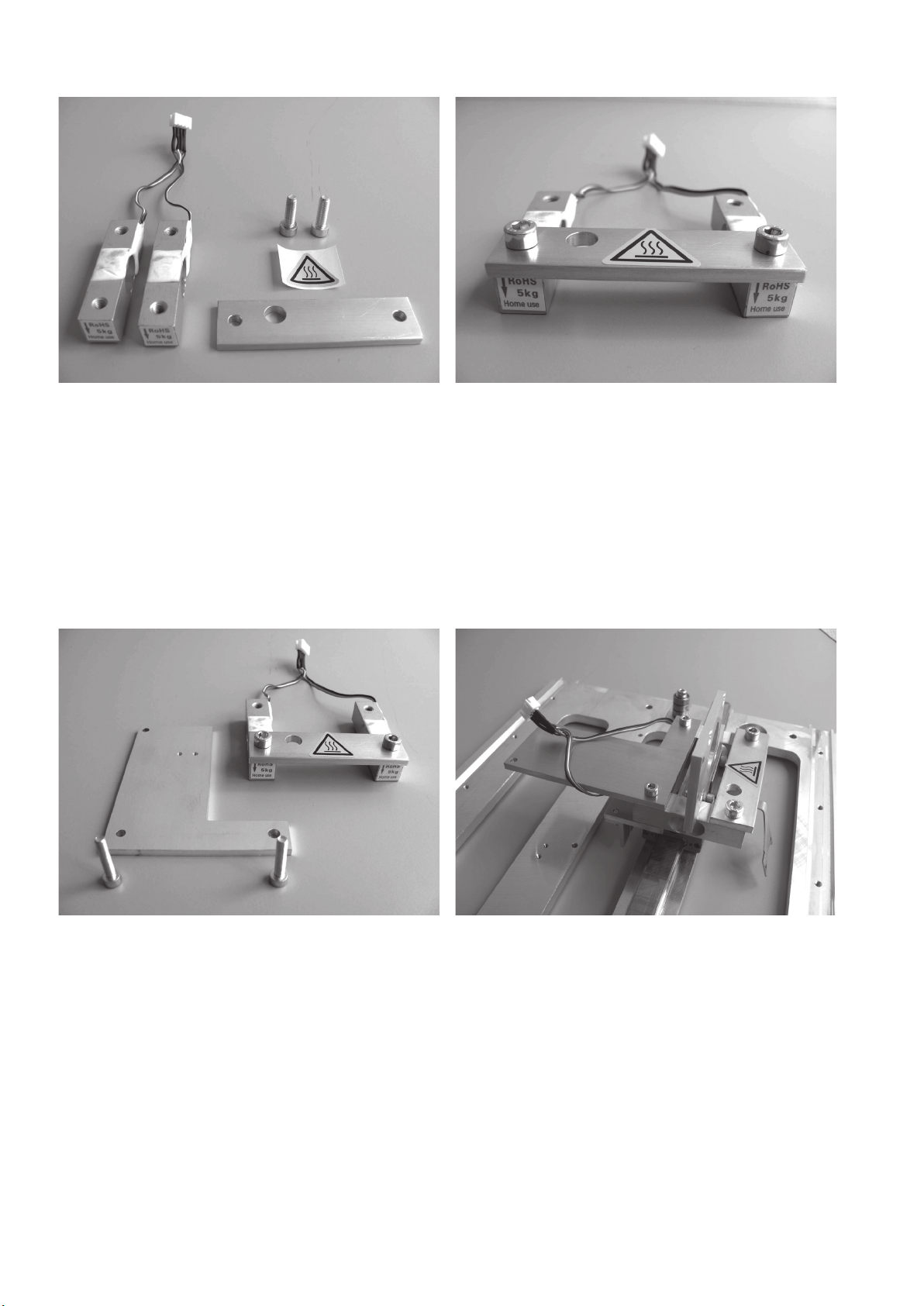

Assembly of the elongation measuring strips and the extruder holder

1x extruder holder

2x elongation measuring strips

2x cylinder head screw M5x16

1x sticker „Attention, hot surface“

Attach the extruder holder and elongation measuring strips

Attach extruder holder to the elongation measuring strips with

the two screws. For this, observe the position of the bores in

the extruder holder (see screen).

Apply screws with threadlocker varnish.

Do not tighten the screws yet though.

The arrows at the head sides of the

strips must point down.

Attach sticker to the extruder holder as shown.

elongation measuring

1x assembly extruder holder with elongation measuring strips

1x holding plate for end stop actuation

2x cylinder head screw M4x20

Attach the assembly from the previous construction section

together with the holding plate of the end stop actuation to the

guide carriage as shown.

Apply screws with threadlocker varnish.

Attention, the connection lines of the elongation measuring

strops must be placed above the holding plate (see figure).

Now tighten the two screws of the extruder holder as well.

17

Install the end stop actuation

1x end stop actuation

1x cylinder head screw M4x10

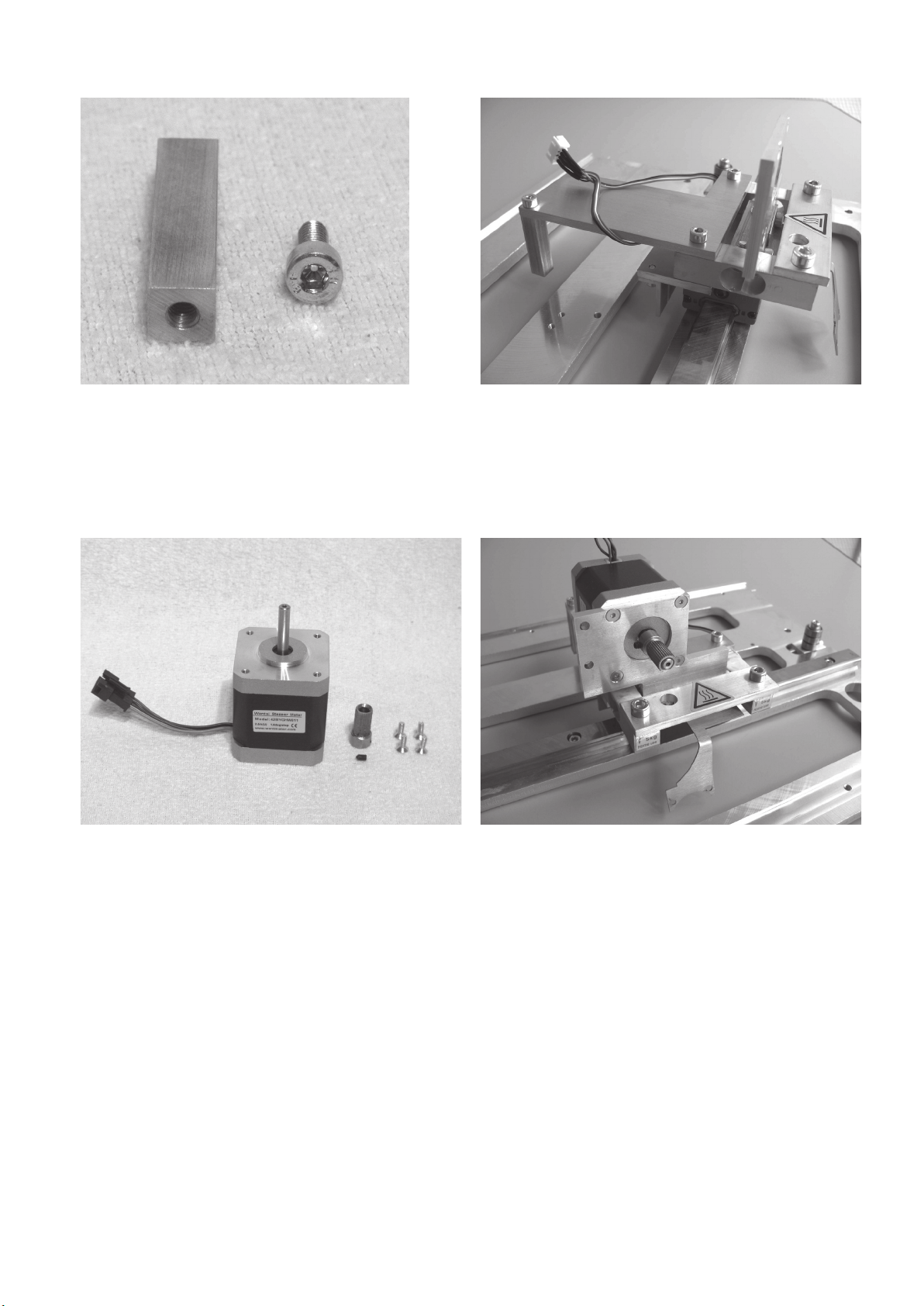

Assembly of the feed motor

1x actuator

1x feed knurl

1x threaded pin M3x5

4x countersunk head screw M3x8

Install the unit with the cylinder head screw as shown.

Push the feed knurl onto the axis of the actuator and attach

it with the threaded pin. Apply threaded pin with threadlocker

varnish.

The motor axis must end flush with the upper edge of the feed

knurl.

Push the motor through the motor holder from behind and attach it with the countersunk head screws. Apply screws with

threadlocker varnish.

The cable exit at the motor must point up as shown.

18

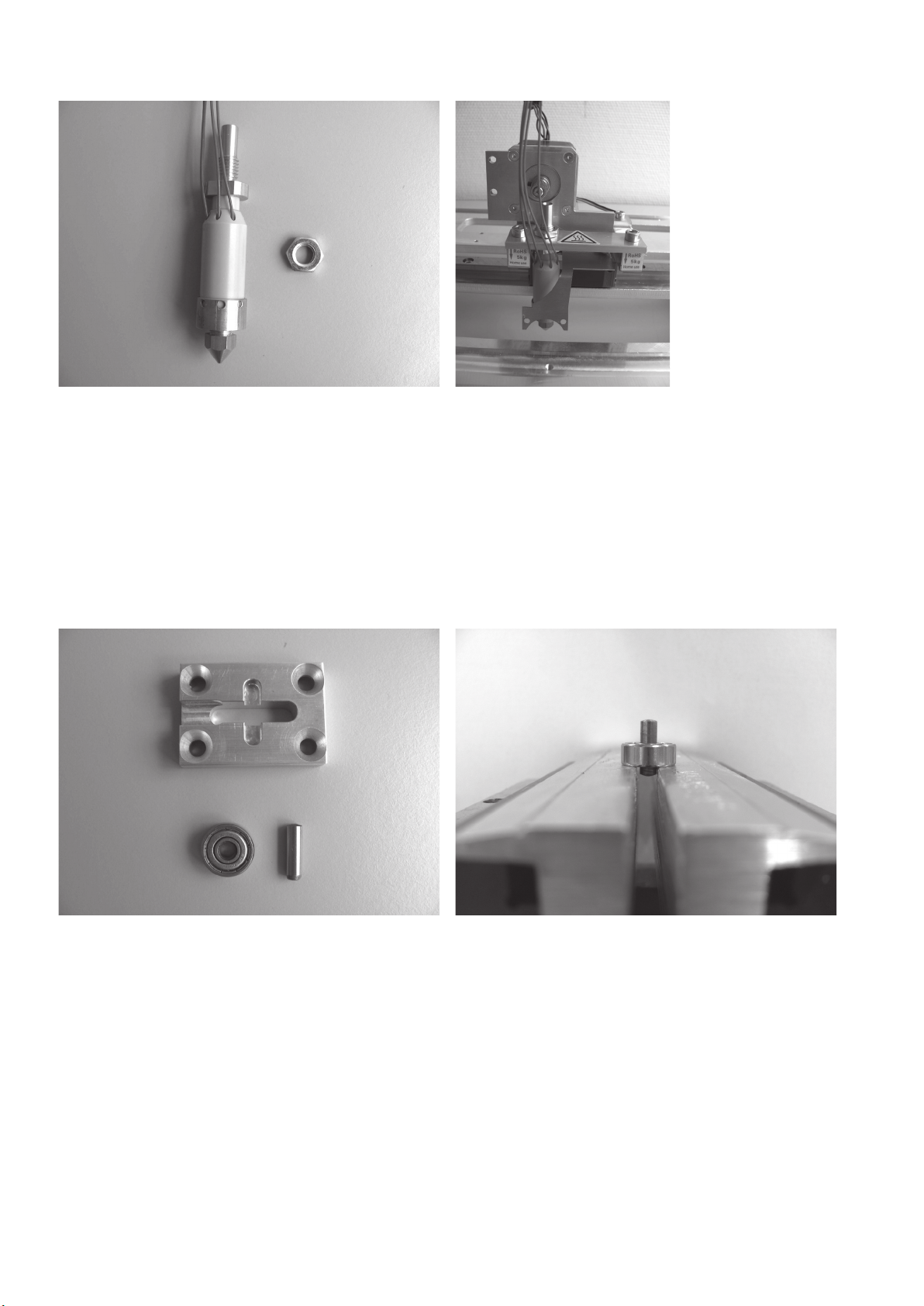

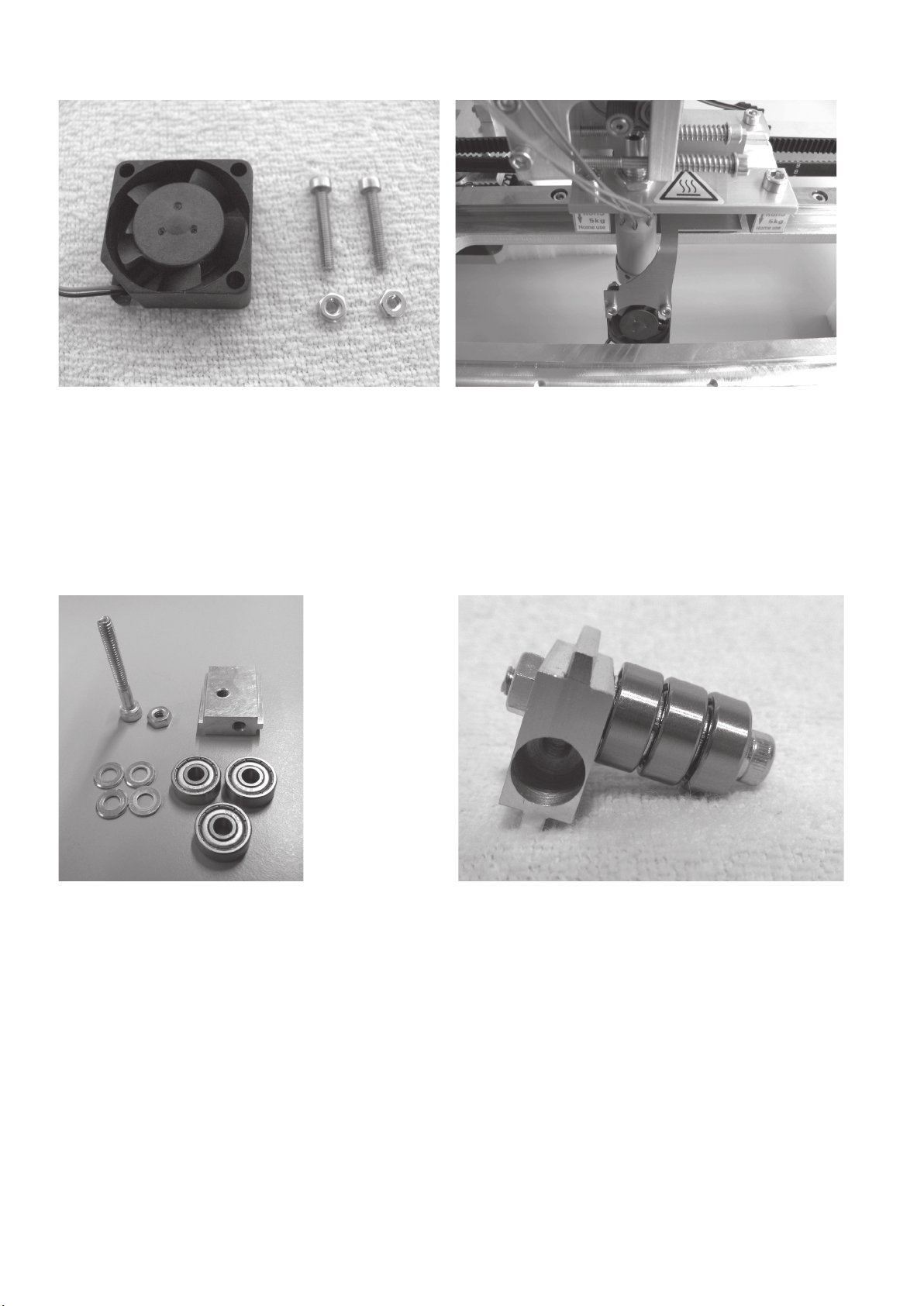

Install extruder.

1x extruder

1x flat nut M8

Assembly of the ball bearing holder

Push extruder through the extruder holder from below and at

tach it with the flat nut.

Align the extruder so that the filament material can be inserted

into the extruder bore straight from the top past the pinion of

the actuator.

During assembly, observe that the connection lines of the extruder are not caught or damaged.

-

1x ball bearing 624ZZ (diameter outside 13 mm)

1x cylinder pin 4x14 mm

1x ball bearing holder

Carefully drive the cylinder pin into the ball bearing with a hammer until it is centred in the ball bearing. For this, support the

ball bearing, e.g. on a vice and open the vice slightly so that the

cylinder pin can be driven through the ball bearing.

19

Insert the ball bearing with cylinder pin into the groove of the

ball bearing after assembly.

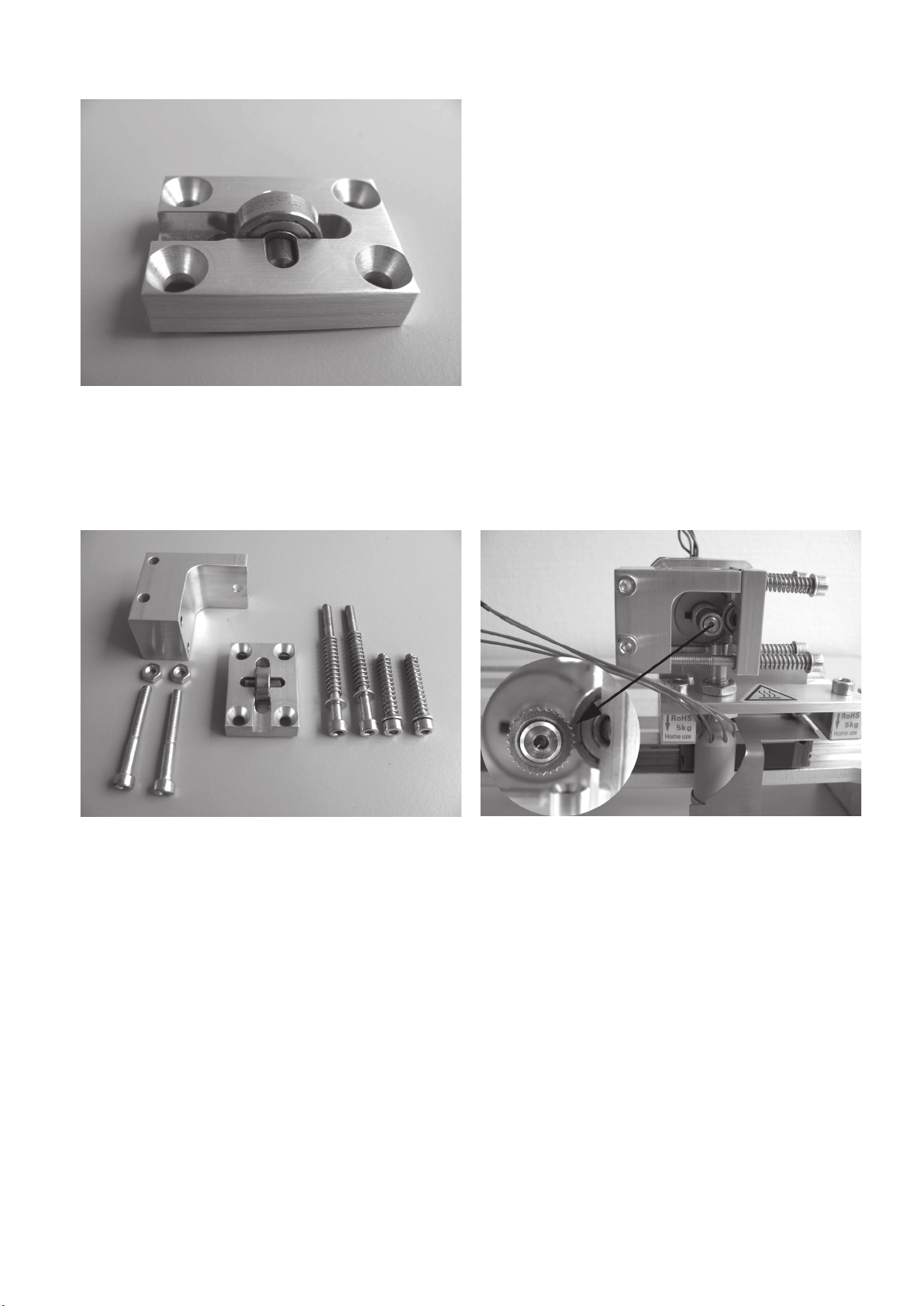

Assembly of the filament infeed unit

1x ball bearing holder with ball bearing unit

4x springs

1x feed basic part

2x cylinder head screw M4x25

2x cylinder head screw M4x35

2x cylinder head screw M4x45

2x nut M4

4x fitted discs 4/8 (diameter inside/outside 4/8 mm)

20

Attach feed basic part to the motor holder from the front with 2

cylinder head screws M4x35 and 2 nuts M4.

Push one spring each onto 2 cylinder head screws M4x25 and

2 cylinder head screws M4x45. Enclose the fitted discs 4/8 at

the screwheads.

Attach the ball bearing holder to the feed basic part with the

screws equipped with springs and washers from the right (top

M4x25, bottom M4x45). Observe that the ball bearing does not

fall from the holder or cant.

The ball bearing must be supported on the feed knurl of the

feed motor after assembly.

Install motor

1x actuator

4x cylinder head screw M3x12

Attach toothed belt

Attach the actuator to the X-plate with the 4 screws as shown

in the figure.

Apply screws with threadlocker varnish.

The cable exit of the actuator must point at the rear of the plate

as shown.

1x toothed belt 675 mm

Caution:

The toothed belt must not be tensioned too strongly. If the belt

tensioner bends, the belt tension must be reduced under all

circumstances.

A method for more precise setting of the belt tension is found

in the chapter „Maintenance“.

Relieve belt tensioners entirely.

Insert the toothed belt on the motor pinion and then into the

belt holders as shown in the first figure.

Then put the toothed belt across the belt tensioner.

Caution: For the above steps, always observe that the guide

carriage does not leave the guide rail.

Tension toothed belt by turning the belt tensioner screw until it

can still easily be turned by 180° with two fingers.

After the belt has been installed, move the extruder carriage to

check whether the limit switch (arrow in the right of the figure)

is tripped by slight pressure from the end stop actuation (trig

gering leads to a slight click).

If the limit switch is not actuated, loosen the screw again (arrow to the left on the screen) and twist the holding plate for the

end stop actuation a little until the limit switch can be actuated.

21

-

Assembly of the drag chain end pieces

1x drag chain end piece with hole

1x drag chain end piece with nipple

4x countersunk head screw M3x8

Inserting the grooved ball bearings

Install the drag chain end pieces as shown in the figure.

Drag chain end piece with hole = extruder carriage

Drag chain end piece with nipple = X-plate

2x grooved ball bearings Insert the grooved ball bearings into the corresponding bores

of the X-plate from below.

Turn the grooved ball bearings slightly, when inserting them

into the bores. Do not apply any force. The flanges of the

grooved ball bearings must be cleanly aligned with the bottom

of the X-plate.

22

Assembly of the fan

1x fan

2x cylinder head screw M2.5x16

2x nut M2.5

Assembly of the Y-plate

Assembly of belt tensioner

Install the fan at the fan sheet as shown with both screws. Ap

ply screws with threadlocker varnish.

Observe that the blowing direction (marked by an arrow on the

fan) points towards the extruder.

-

1x belt tensioner basic body

3x ball bearing 624ZZ (diameter inside/outside (8.8/13 mm)

4x washer (diameter inside/outside 4.3/8.8 mm)

1x cylinder head screw M4x30

1x nut M4

Push washers onto the screw with the ball bearings alternat

ingly.

Screw the screw into the belt tensioner basic body as shown

in the figure and tighten it well.

Counter the screw with a nut.

23

-

Attachment of belt tensioner to the Y-plate

1x Y-plate

1x assembly belt tensioner (previous construction step)

1x cylinder head screw M4x30

Attachment of the guide rail

Push the belt tensioner assembly into the intended section of

the Y-plate and turn the screw into the belt tensioner.

The ball bearings must point to the grooved side of the Y-plate

and the bore in the belt tensioner must be on the right (see

figure).

1x Y-plate

1x guide rails

6x cylinder head screws M4x12

24

Insert the guide rail into the middle groove of the Y-plate and

attach it with the screws.

The imprinted arrows on the guide rail must point to the plate

centre.

Push the guide carriage onto the guide rail

The assembly aid (plastic part in the guide of the guide carriage) must never be removed before pushing on the guide

carriage, since the gearing balls will fall out of the carriage otherwise. This would be irreparable.

This also applies when the guide carriage is pushed from the guide rail after assembly. For reasons of safety, the guide

carriage should be secured, e.g. with adhesive tape before further installation.

The guide carriage has a polished area on one side (see arrow in the figure on the lower left). Turn the guide carriage

so that the arrows on the guide rails point towards the ground area of the guide carriage before pushing it on.

1x Y-plate

1x guide carriage complete with assembly aid

Carefully push the guide carriage onto the guide rail and push

the assembly aid (plastic part) from the guide carriage while

doing so.

25

Assembly of the drive motor

1x actuator

1x Y-plate

3x cylinder head screw M3x12

1x countersunk screw M3x12

Assembly of the drag chain end piece top

Attach the actuator to the Y-plate with the 3 cylinder head

screws and the countersunk screw as shown in the figure.

Use the countersunk screw for the countersunk bore.

Apply screws with threadlocker varnish.

The cable exit at the motor must point to the middle of the Y-

plate (i.e. in the figure backwards).

1x drag chain end piece with nipple

1x holding block for guide rail

2x cylinder head screw M3x16

2x countersunk screw M3x8

26

Attach the drag chain end piece with the countersunk screws

at the holding block.

Attach the holding block with the cylinder head screws as

shown in the figure on the grooved side of the Y-plate.

Assembly of the drag chain end piece bottom

1x drag chain end piece with hole

2x countersunk screw M3x8

Install the holder of the under-table plate

Attach the drag chain end piece with the countersunk screws

as shown in the figure on the ungrooved side of the Y-plate.

1x undertable holder

1x limit switch holder

1x limit switch PCB

1x belt tappet angle

2x cylinder head screw M3x6

2x cylinder head screw M3x8

2x cylinder head screw M2x6

Attach limit switch holder to the undertable plate with screws

M3x8.

Attach the limit switch PCB to the limit switch holder with

screws M2x6.

Install the belt tappet angles with screws M3x6 as shown in

the figure.

Apply screws of the belt tappet angle with threadlocker varnish.

27

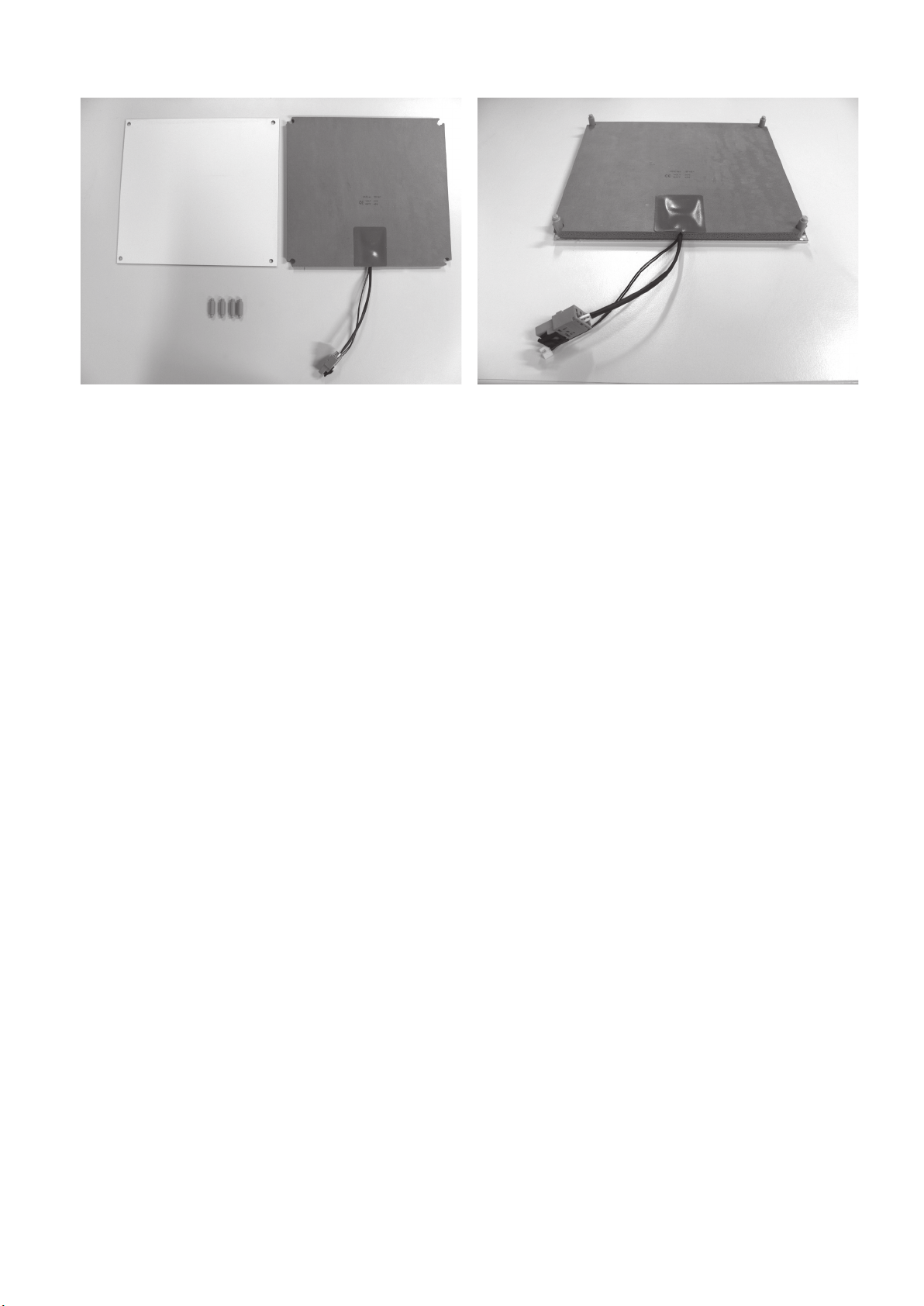

Glue connection of the heating plate.

1x ceramics plate

1x heating

4x spacer bolts

Plug the spacer bolts with the thread bores to the bottom of

the ceramics plate (side with tissue structure) and provision

ally fasten with 4 screws.

Caution: Only tighten the screws slightly since there is the

danger that the ceramics plate will break otherwise.

Check the alignment of the heating by pushing the heating

across the spacer bolts. The heating must then be supported

fold-free with the side with the protection foil against the bottom of the ceramics plate and must not protrude at the edges.

Clear the bottom of the ceramics plate of dust and grease with

a rag and solvent.

Then remove the protective foil from the heating and finally

glue the heating to the bottom of the ceramics plate without

blisters.

-

28

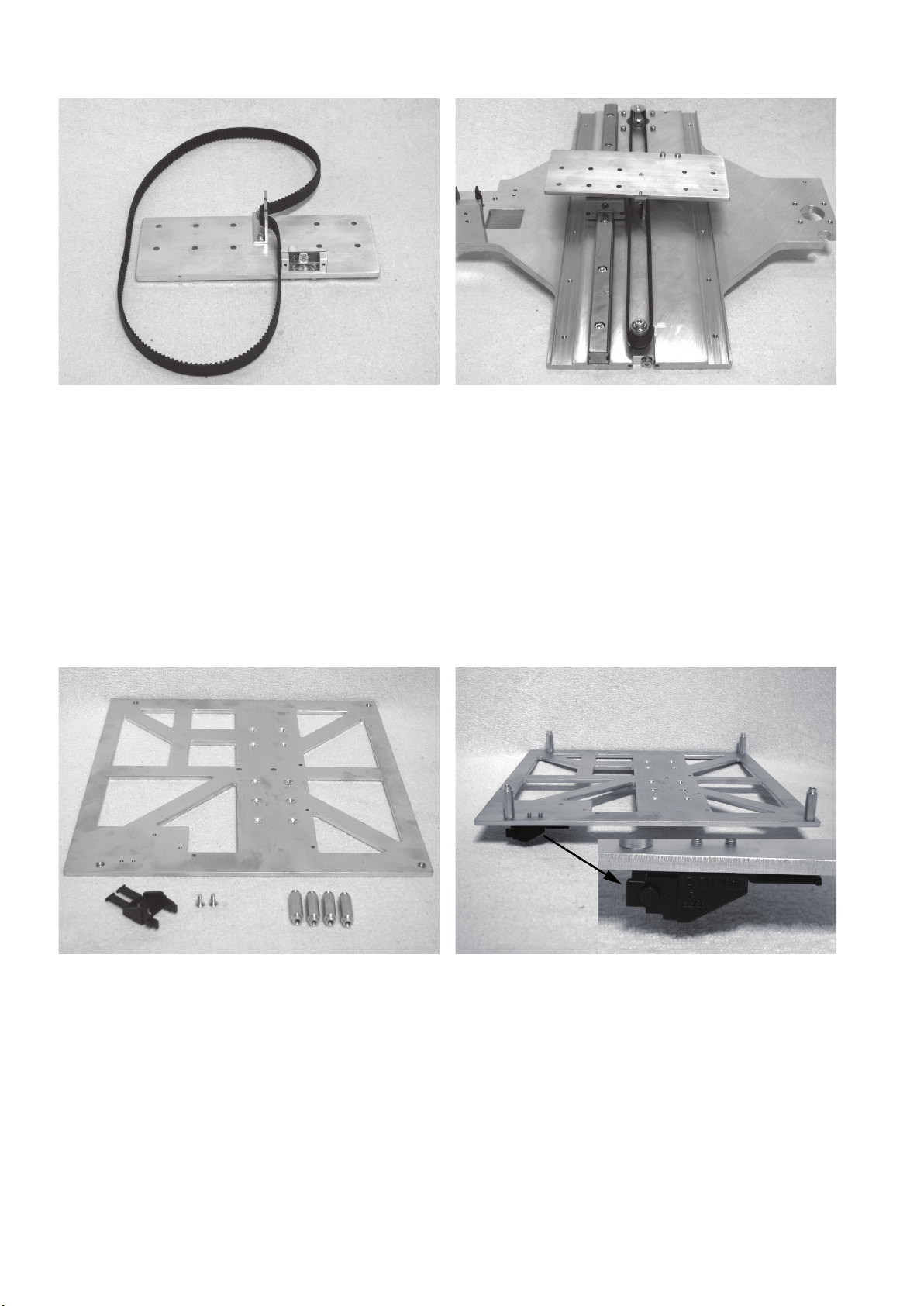

Application of the toothed belt

1x undertable holder from the previous step

1x toothed belt 675 mm

Caution:

The toothed belt must not be tensioned too strongly. If the belt

tensioner bends, the belt tension must be reduced under all

circumstances.

A method for more precise setting of the belt tension is found

in the chapter „Maintenance“.

Assembly of the undertable

Insert toothed belt into the belt tappet angle as shown on the

left.

Relieve belt tensioners entirely.

Turn the undertable holder and put the toothed belt onto pinion

and belt tensioner as shown.

The undertable holder is only placed on the guide carriage

here (do not screw on yet).

Tension toothed belt by turning the belt tensioner screw until it

can still easily be turned by 180° with two fingers.

1x undertable

1x drag chain end piece with nipple

4x spacer bolts

2x countersunk screw M3x8

Screw in spacer bolts into the top of the undertable (side with

recessed bores).

Install the drag chain end piece on the underside of the undert

able.

29

-

Assembly of the undertable

1x undertable

1x Y-plate

4x countersunk head screw M4x12

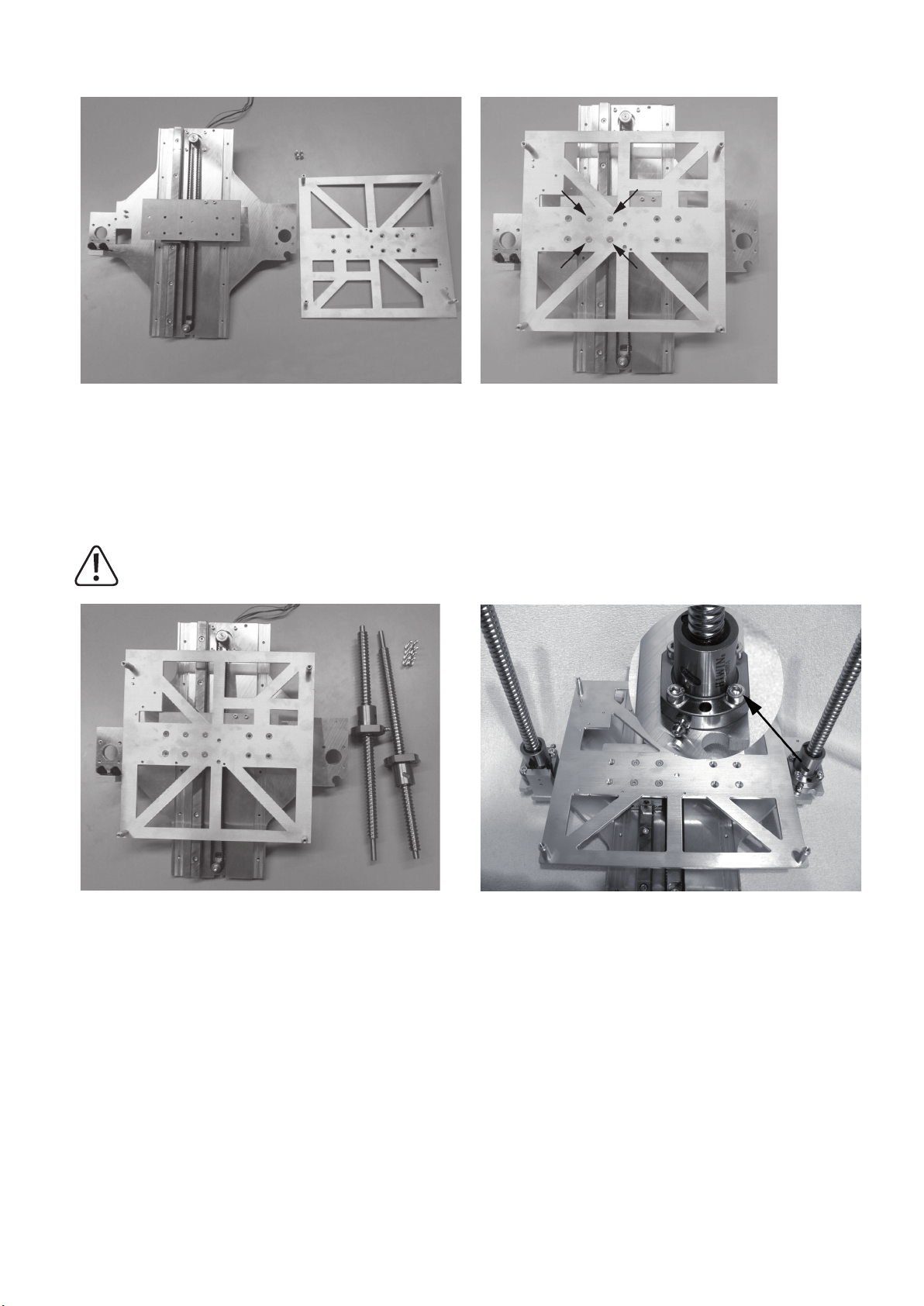

Assembly of the thread circulation spindles

The nuts on the threaded circulation spindles must never be removed from the threaded circulation spindles, since the

bearing balls would fall out otherwise. This would be irreparable.

Attach the undertable with the 4 countersunk head screws to

the undertable holder as shown.

Apply screws with threadlocker varnish.

2x threaded circulation spindle

1x Y-plate

8x cylinder head screw M5x16

30

Attach threaded circulation spindles to the Y plate as shown

with 4 screws each.

Observe the position of the lubrication nipples. They must both

point to the inside of the device.

The flattened sides of the attachments must end flush with the

outer edge of the Y-plate.

Loading...

Loading...