Page 1

User’s Manual

(

)

E1/E20 Emulator

Additional Document for User’s Manual

Notes on Connection for RL78

Supported Devices:

RL78 Family

RL78/F12, RL78/G12, RL78/G13, RL78G14, RL78G1A,

RL78/I1A, RL78L12

All information contained in these materials, including products and product specifications,

represents information on the product at the time of publication and is subject to change by

Renesas Electronics Corp. without notice. Please review the latest information published by

Renesas Electronics Corp. through various means, including the Renesas Electronics Corp.

website (http://www.renesas.com).

www.renesas.com

Rev.1.00 April 2012

Page 2

Page 3

E1/E20 Emulator CONTENTS

CONTENTS

CHAPTER 1 OUTLINE....................................................................................................................................4

1.1. Features ...........................................................................................................................................4

1.2 Cautions on Using E20...................................................................................................................4

1.3 Configuration of Manuals...............................................................................................................4

CHAPTER 2 DESIGNING USER SYSTEM.....................................................................................................5

2.1 Connecting the Emulator with the User System..........................................................................5

2.2 Pin Assignments of the Connector on the User System ............................................................6

2.3 System Configuration.....................................................................................................................7

2.4 Recommend Circuit between Connector and MCU.....................................................................8

2.4.1 Recommend Circuit Connection (Except 20pin and 24pin of RL78/G12) .....................................8

2.4.2 Connection of reset pin.....................................................................................................................9

2.4.3 Recommend Circuit Connection (Only 20pin and 24pin of RL78/G12)....................................... 12

CHAPTER 3 SETTING OF SECURITY ID AND SETTING OF DEBUGGING RESOURCES .....................15

3.1 Setting of Security ID .....................................................................................................................15

3.2 Setting of On-chip debugging option byte...................................................................................16

3.3 Securing of area for debugging ....................................................................................................17

CHAPTER 4 SPECIFICATIONS ...................................................................................................................19

CHAPTER 5 NOTES ON USAGE.................................................................................................................20

5.1 Lists................................................................................................................................................20

5.2 Details.............................................................................................................................................21

APPENDIX EQUIVALENT CIRCUIT FOR E1/E20-RL78 CONNECTION....................................................23

R20UT1994EJ0100 Rev.1.00 Page 3 of 26

APR 20, 2012

Page 4

E1/E20 Emulator CHAPTER 1 OUTLINE

CHAPTER 1 OUTLINE

1.1. Features

E1/E20 Emulator (hereinafter referred to as E1/E20) is an on-chip debug emulator with flash programming function,

which is used for debugging and programming a program to be embedded in on-chip flash memor y microcontrollers. This

product can debug with the target microcontroller connected to the user system, and can write programs to the on-chip

flash memory of microcontrollers.

1.2 Cautions on Using E20

The functions used for debugging of the RL78 device by u sing the E20 are the sam e as in the E 1. Large trace function,

characteristic functions of the E20, cannot be used. The power supply function from the E20 is not supported.

1.3 Configuration of Manuals

Documentation for the E1/E20 emulator manual is in two parts: the E1/E20 Emulator User’s Manual and the E1/E20

Emulator Additional Document for User’s Manual (this manual). Be sure to read both of the manuals before using the

E1/E20 emulator.

(1) E1/E20 Emulator User’s Manual

The E1/E20 Emulator User’s Manual has the following contents:

Components of the emulators

Emulator hardware specificat ion

Connection to the emulator and the host computer and user system

(2) E1/E20 Emulator Additional Document for User’s Manual

The E1/E20 Emulator Additional Document for User’s Manual has the following contents:

For use in hardware d esign, an example of connection and the interface circuit required to connect the emulator.

Notes on using the emulator

Software specifications and so on for using each microcomputers

R20UT1994EJ0100 Rev.1.00 Page 4 of 26

Apr 20, 2012

Page 5

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

A

CHAPTER 2 DESIGNING USER SYSTEM

To connect the E1/E20 emulator, a connector for the user system interface cable must be mounted on the user system.

When designing the user system, read this section of this manual and the hardware manual for the MCUs.

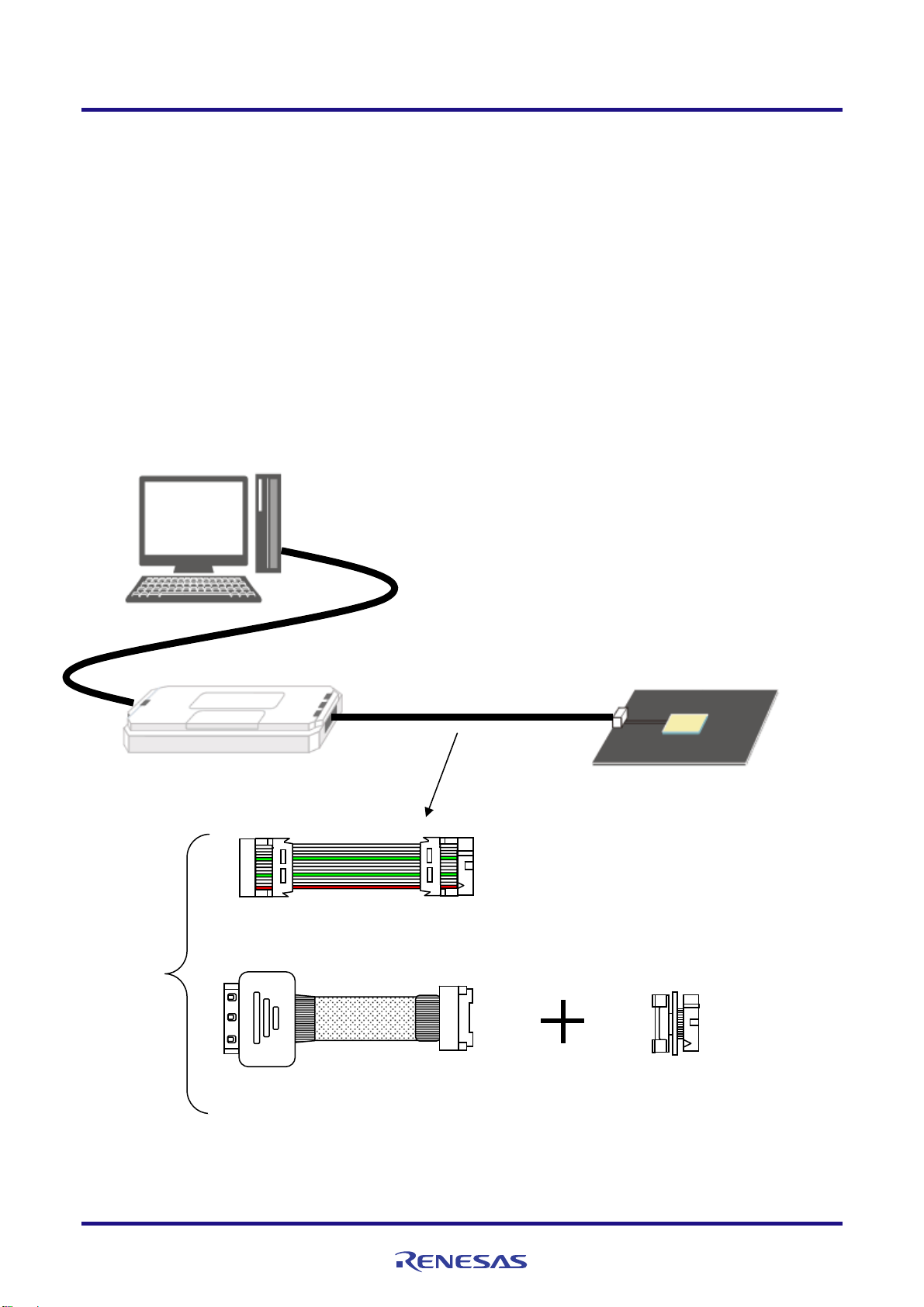

2.1 Connecting the Emulator with the User System

Table 2-1 shows the type numbers of the E1/E20 emulators

Table 2-1. Connector Type Numbers

Type Number Manufacturer Specification

14-pin

connector

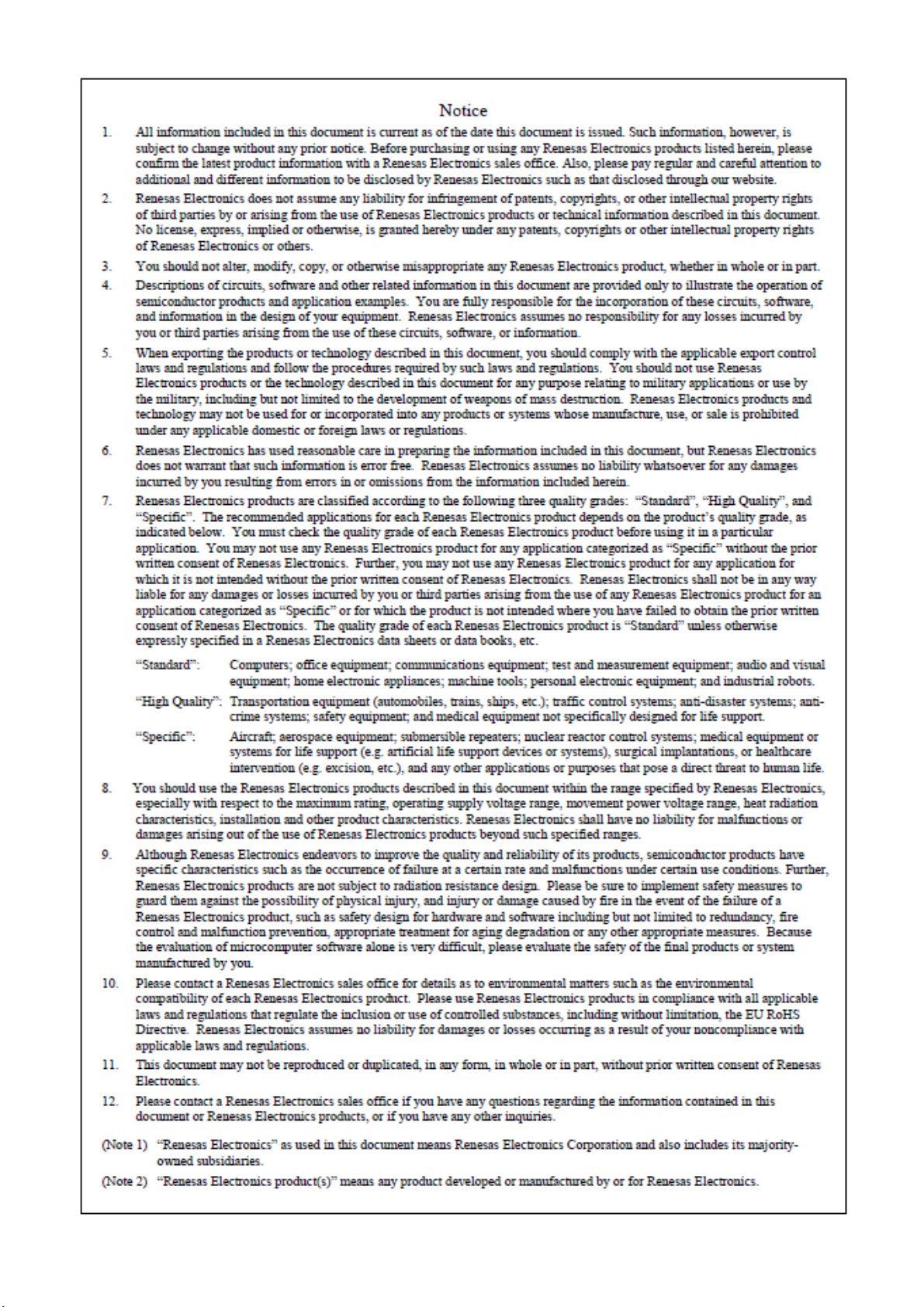

Figure 2-1 shows examples of the connection between a user system interface cable of the 14-pin type. Do not mount

other components with a height exceeding 10 mm within 5 mm of the connector on the user system. 38-pin of the E20

is not supported. To use the E20, use the 38-pin/14-pin conversion adapter [R0E00 0200CKA00] that comes with the

E20 for connection.

Figure 2-1. Connecting the User System Interface Cable to the 14-pin Connector of the E1 Emulator

7614-6002 Sumitomo 3M Limited 14-pin straight type (Japan)

2514-6002 3M Limited 14-pin straight type (other countries)

14-pin user system interface cable

14-pin type connector

User system

rea with limit on mounted components

(heights must be no greater than 10 mm)

R20UT1994EJ0100 Rev.1.00 Page 5 of 26

Apr 20, 2012

Page 6

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

2.2 Pin Assignments of the Connector on the User System

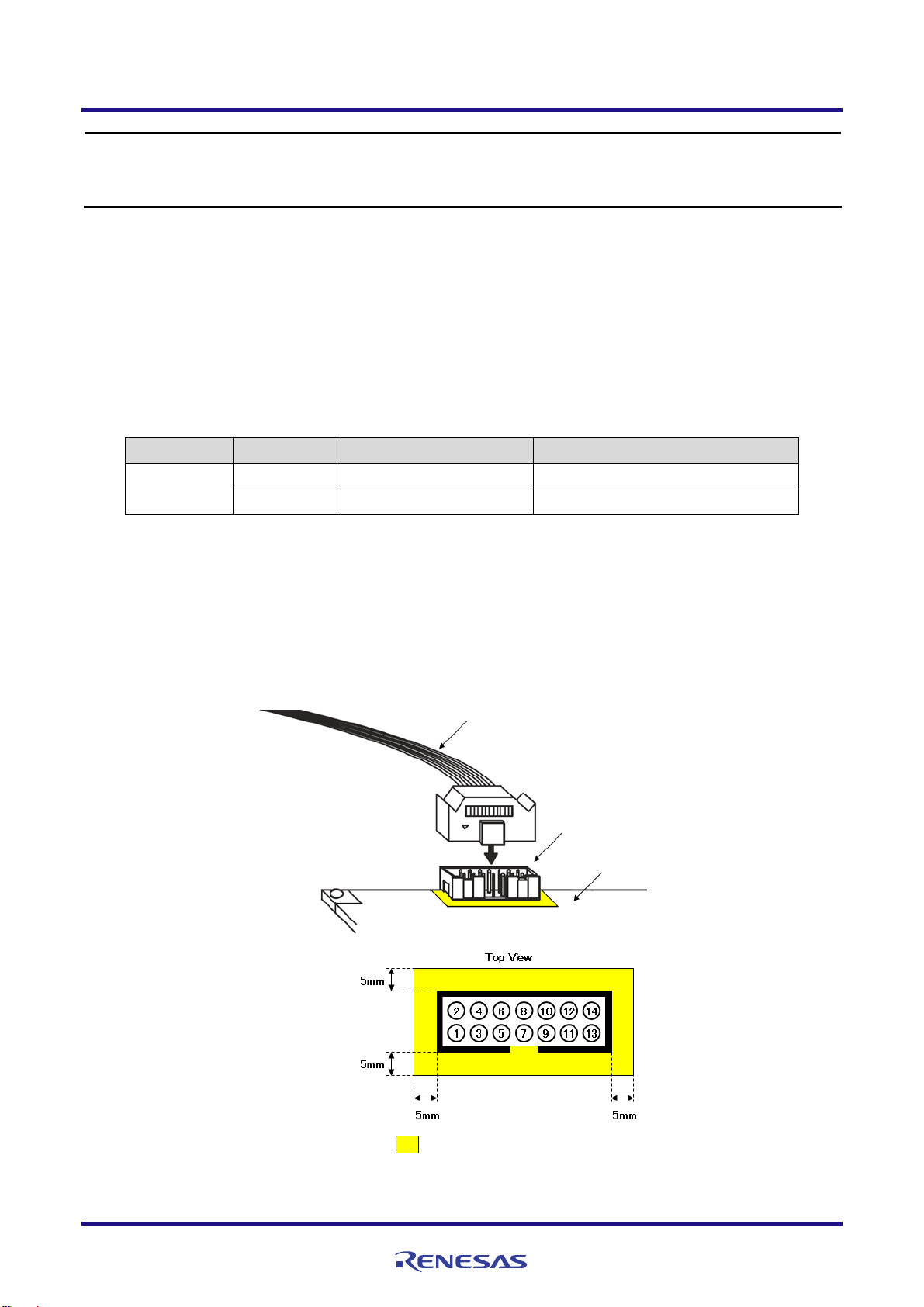

Table 2-2 shows the pin assignments of the 14-pin connector.

Table 2-2. Pin Assignments of the Connector on the User System (14-Pin)

Pin No. Pin Name Input/Output

Note 1

1 R.F.U Input

2 GND

Note 2

3 R.F.U 4 R.F.U / (RSTPU)

Note 4

- / (Output)

Note 4

5 TOOL0 Input/Output

6 RESET_IN Input

7 R.F.U 8 VDD 9 EMVDD 10 RESET_OUT

Note 3

Output

11 R.F.U 12 GND

13 RESET_OUT

14 GND

Note 2

-

Note 3

Output

Note 2

-

Notes 1. As seen from E1/E20.

2. Securely connect pins 2, 12, and 14 of the connector to GND of the user system. These pins are used for

electrical grounding as well as for monitoring of connection with the user system by the E1/E20.

3. Securely connect both pin 10 and pin 13. These pins are also used to monitor the user system.

4. RSTPU is used only when selecting the 20pin and 24pin of RL78/G12.

Table 2-2. Pin Functions

Pin Name Input/Output

Note

Description

RESET_IN Input Pin used to input reset signal from the user system

RESET_OUT Output Pin used to output reset signal to the target device

TOOL0 Output/Input Pin used to transmit command/data to the target device

R.F.U. – This pin is reserved. For the connection of the reserved pins, see each

circuit related to the pins.

RSTPU Output RSTPU is used only when selecting the 20pin and 24pin of RL78/G12.

This pin is used to pull up the reset line.

Note As seen from E1/E20.

R20UT1994EJ0100 Rev.1.00 Page 6 of 26

Apr 20, 2012

Page 7

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

2.3 System Configuration

Figure 2-2 shows the system configuration used for the E1/E20. For cautions on connection, refer to the E1/E20 User’s

Manual. As software used on the host machine, use the “CubeSuite+” when on-chip debugging is used, or use the

“Renesas Flash Programmer” for flash programming. For details, refer to the following URL’s.

Integrated development environment “CubeSuite+” website

http://www.renesas.com/cubesuite+

Flash writing tool “Renesas Flash Programmer” website

http://www.renesas.com/rfp

Figure 2-2. Connection Diagram of E1/E20

Host machine

E1 emulator

E20 emulator

or

User interface cable (E1)

User interface cable (E20)

Remark To use it with the E20, connect the 38-pin/14-pin conversion adapter to the user interface cable (E20).

38-pin is not supported.

USB Interface cable

User interface cable

User system

38-pin/14-pin conversion adapter

R20UT1994EJ0100 Rev.1.00 Page 7 of 26

Apr 20, 2012

Page 8

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

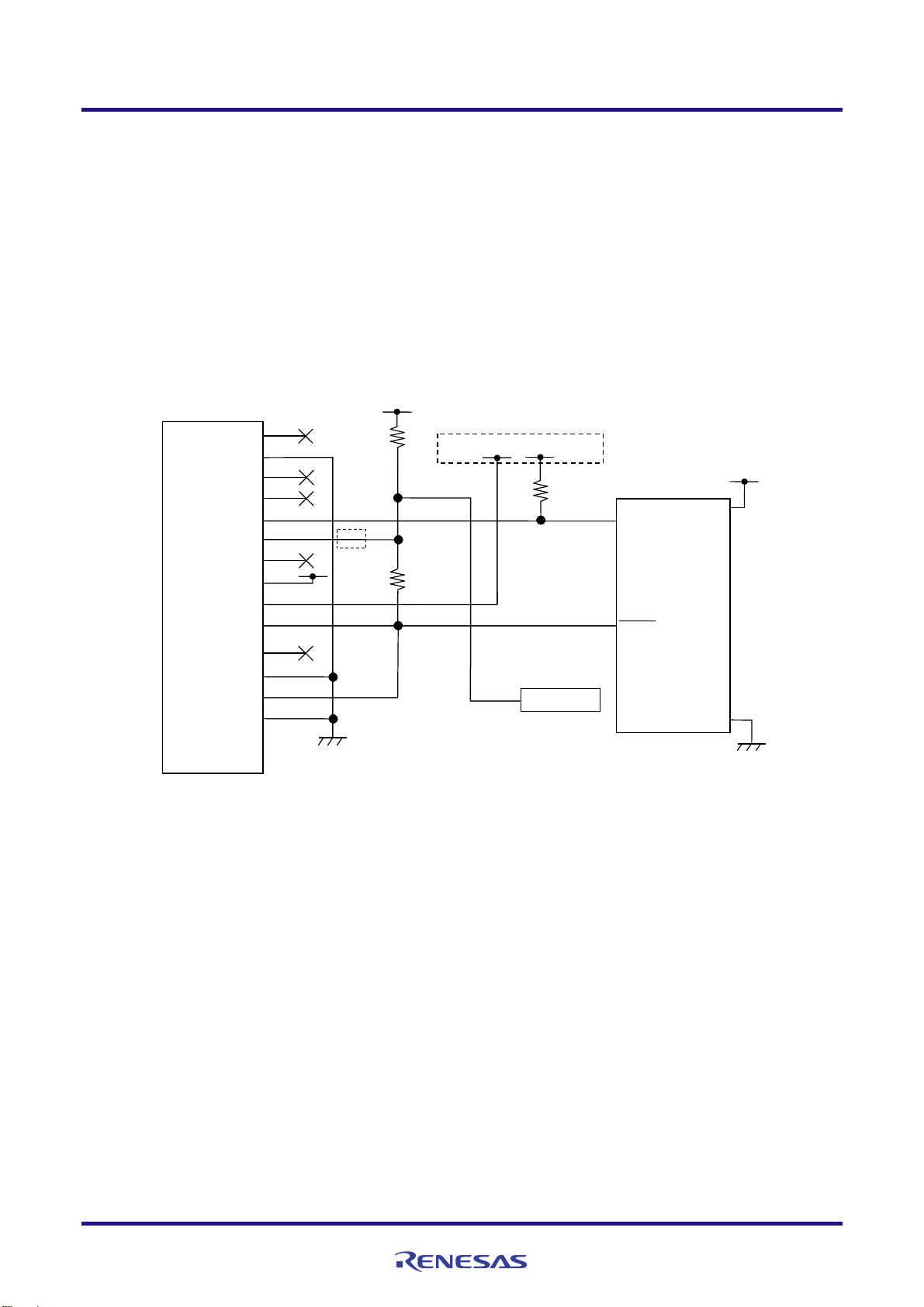

2.4 Recommend Circuit between Connector and MCU

2.4.1 Recommend Circuit Connection (Except 20pin and 24pin of

Refer to Figure 2-3 and design an appropriate circuit.

Be sure to take into consideration the specifications of the target device as well as measures to prevent noise when

designing your circuit.

Figure 2-3. Recommend Circuit Communication (Except 20pin and 24pin of RL78/G12)

V

Note1

DD

1 k

Operation voltage for TOOL0

10 k

Target Connecter

R.F.U.

GND

R.F.U.

R.F.U.

TOOL0

RESET_IN

R.F.U.

V

EMV

RESET_OUT

RESET OUT

Note2

R.F.U.

GND

Note2

GND

1

2

3

4

5

6

7

V

8

DD

9

DD

10

11

12

13

14

DD

RL78/G12)

1 k

Reset circuit

RESET signal

Note2

Note3

TOOL0

RESET

Target Device

V

DD

V

DD

V

SS

Notes 1. The circuit enclosed by a dashed line is not required when only flash programming is performed.

2. Refer to 2.4.2 connection of reset pin (1)

the pull-up resistor value of the reset circuit.

Automatically switching the reset signal via resistor about

3. The drive power supply of TOOL0 is different depending on devices. Defer to user’s manual of device.

Caution

The circuits and resistance values listed are recommended but not guaranteed. Determine the circuit desig n

and resistance values by taking into account the specifications of the target device and noise. For flash

programming for mass production, perform sufficient evaluation about whether the specifications of the target

device are satisfied.

For processing of pins not used by the E1/E20, refer to the user’s manual of the device.

Securely connect pins 2, 12, and 14 of the connection to GND of the user system. These pins are used for

electrical grounding as well as for monitoring of connection with the user system by the E1/E20.

Securely connect both pin 10 and pin 13. These pins are also used to monitor the user system.

R20UT1994EJ0100 Rev.1.00 Page 8 of 26

Apr 20, 2012

Page 9

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

2.4.2 Connection of reset pin

is section describes the connection of the reset pin, for which special attention must be paid, in circuit connection

Th

examples shown in the previous section.

During on-chip debugging, a reset signal from the target system is input to E1/E20, masked, and then output to the

target device. Therefore, the reset signal connection varies depending on whether E1/E20 is connected.

For flash programming, the circuit must be designed so that the reset signals of the user system and E1/E20 do not

conflict.

Select one of the following methods and connect the reset signal in the circuit. The details of each method are

described on the following pages.

(1) Automatically switching the reset signal via resistor (recommended; described in recommended circuit connection

in the previous section)

(2) Manually switching the reset signal with jumper

(3) Resetting the target device by power-on clear (POC) only

R20UT1994EJ0100 Rev.1.00 Page 9 of 26

Apr 20, 2012

Page 10

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

(1) Automatically switching the reset signal via resistor

Figure 2-4 illustrates the reset pin connection described in 2.4.1 Circuit conn ection examples.

This connection is designed assuming that the reset circuit on the target system contains an N-ch open-drain

buffer (output resistance: 100 or less). The V

of E1/E20 is inverted, so observe the conditions described below in Remark.

Figure 2-4. Circuit Connection with Reset Circuit That Contains Buffer

DD or GND level may be unstable when the logic of RESET_IN/OUT

Target connector

RESET_OUT

RESET_IN

10, 13

6

R1

Target device

RESET

VDD

R2

Reset circuit

Buffer

V

DD

Remark Make the resistance of at least R1 ten times that of R2, R1 being 10 k or more.

Pull-up resistor R2 is not required if the buffer of the reset circuit consists of CMOS output.

The circuit enclosed by a dashed line is not required when only flash programming is performed.

Figure 2-5 illustrates the circuit connection for the case where the reset circuit on the target system contains no

buffers and the reset signal is only generated via resistors or capacitors. Design the circuit, observing the

conditions described below in Remark.

Figure 2-5. Circuit Connection with Reset Circuit That Contains No Buffers

Target connector

10, 13

RESET_OUT

R1

6

RESET_IN

Target device

RESET

Remark Make the resistance of at least R1 ten times that of R2, R1 being 10 k or more.

The circuit enclosed by a dashed line is not required when only flash programming is performed.

Reset circuit

VDD

R2

R20UT1994EJ0100 Rev.1.00 Page 10 of 26

Apr 20, 2012

Page 11

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

(2) Manually switching the reset sig nal with jumper

Figure 2-6 illustrates the circuit connection for the case where the reset signal is s witched using the jumper, with or

without E1/E20connected. This connection is simple, but the jumper must be set manually.

Figure 2-6. Circuit Connection for Switching Reset Signal with Jumper

Target connector

RESET_OUT

RESET_IN

10, 13

6

Jumper

1

2

3

Jumper setti n g

When E1/E20 is connected: 1-2 shorted

When E1/E20 is not connected: 2-3 shorted

Target device

RESET

Reset circuit

RESET signal

(3) Resetting the target device by power-on clear (POC) only

Figure 2-7 illustrates the circuit connection for the case where the target device is only reset via POC without using

the reset pin. RESET_OUT becomes active when power is applied to E1/E20.

Even if power supply to the target system is turned off during debugging, pseudo POC function emulation is

available because RESET_OUT becomes active.

Figure 2-7. Circuit Connection for the Case Where Target Device Is Only Reset via POC

Target connector

VDD

RESET_OUT

RESET_IN

1 k to 10 k

10, 13

6

Target device

RESET

R20UT1994EJ0100 Rev.1.00 Page 11 of 26

Apr 20, 2012

Page 12

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

2.4.3 Recommend Circuit Connection (Only 20pin and 24pin of RL78/G12)

(1) Circuit conn

etction with reset circuit.

Refer to Figure 2-8 and design an appropriate circuit.

Be sure to take into consideration the specifications of the target device as well as measures to prevent noise when

designing your circuit.

Figure 2-8. Recommend Circuit Communication (With RESET circuit)

Target connector

R.F.U.

GND

R.F.U.

RSTPU

TOOL0

RESET_IN

R.F.U.

V

DD

EMV

DD

RESET_OUT

R.F.U.

GND

RESET_OUT

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

VDD

Note1

Note1

1 k

470 to 570

V

DD

1 k

RESET circuit

RESET signal

Target device

TOOL0

RESET

VDD

V

DD

V

SS

Note 1. The circuit enclosed by a dashed line is not required when only flash programming is performed.

Caution

The circuits and resistance values listed are recommended but not guaranteed. Determine the circuit desig n

and resistance values by taking into account the specifications of the target device and noise. For flash

programming for mass production, perform sufficient evaluation about whether the specifications of the target

device are satisfied.

For processing of pins not used by the E1/E20, refer to the user’s manual of the device.

Securely connect pins 2, 12, and 14 of the connection to GND of the user system. These pins are used for

electrical grounding as well as for monitoring of connection with the user system by the E1/E20.

Securely connect both pin 10 and pin 13. These pins are also used to monitor the user system.

R20UT1994EJ0100 Rev.1.00 Page 12 of 26

Apr 20, 2012

Page 13

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

(2) Circuit connection without reset circuit

Refer to Figure 2-9 and design an appropriate circuit.

Be sure to take into consideration the specifications of the target device as well as measures to prevent noise when

designing your circuit.

Figure 2-9. Recommend Circuit Communication (Without RESET circuit)

V

Target connector

R.F.U.

GND

R.F.U.

RSTPU

TOOL0

RESET_IN

R.F.U.

V

DD

EMV

DD

RESET_OUT

R.F.U.

GND

RESET_OUT

GND

1

V

2

3

4

5

6

7

V

8

9

10

11

12

13

DD

DD

1 k

Target device

TOOL0

RESET

DD

V

DD

V

SS

Caution

The circuits and resistance values listed are recommended but not guaranteed. Determine the circuit desig n

and resistance values by taking into account the specifications of the target device and noise. For flash

programming for mass production, perform sufficient evaluation about whether the specifications of the target

device are satisfied.

For processing of pins not used by the E1/E20, refer to the user’s manual of the device.

Securely connect pins 2, 12, and 14 of the connection to GND of the user system. These pins are used for

electrical grounding as well as for monitoring of connection with the user system by the E1/E20.

Securely connect both pin 10 and pin 13. These pins are also used to monitor the user system.

R20UT1994EJ0100 Rev.1.00 Page 13 of 26

Apr 20, 2012

Page 14

E1/E20 Emulator CHAPTER 2 DESIGNING USER SYSTEM

(3) Circuit connection for using RESET pin as P125/KR1/SIO1.

Refer to Figure 2-10 and design an appropriate circuit.

Be sure to take into consideration the specifications of the target device as well as measures to prevent noise when

designing your circuit.

Figure 2-10. Recommend Circuit Communication (Using RESET pin as P125/KR1/SIO1)

Target connector

R.F.U.

GND

R.F.U.

RSTPU

TOOL0

RESET_IN

R.F.U.

V

DD

EMV

DD

RESET_OUT

RESET_OUT

Note2

R.F.U.

GND

Note2

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

V

DD

1 k

V

DD

1 k

Taget device

TOOL0

P125/KR1/SIO1

External circuit

V

DD

V

SS

Caution

The circuits and resistance values listed are recommended but not guaranteed. Determine the circuit desig n

and resistance values by taking into account the specifications of the target device and noise. For flash

programming for mass production, perform sufficient evaluation about whether the specifications of the target

device are satisfied.

For processing of pins not used by the E1/E20, refer to the user’s manual of the device.

Securely connect pins 2, 12, and 14 of the connection to GND of the user system. These pins are used for

electrical grounding as well as for monitoring of connection with the user system by the E1/E20.

Securely connect both pin 10 and pin 13. These pins are also used to monitor the user system.

R20UT1994EJ0100 Rev.1.00 Page 14 of 26

Apr 20, 2012

Page 15

E1/E20 Emulator CHAPTER 3 SETTING OF SECURITY ID AND SETTING OF DEBUGGING RESOURCES

CHAPTER 3 SETTING OF SECURITY ID AND SETTING OF DEBUGGING RESOURCES

The user must prepare the following to perform communication between E1/E20 emulator and the tar get device and

implement each debug function. Refer to the descriptions on the following sections and set these items in the user

program or using the build tool property.

When C-SPY manufactured by IAR Systems is used, read also the following material.

- IAR C-SPY Hardware Debugger Systems User Guide issued by IAR Systems

3.1 Setting of Security ID

This setting is required to prevent the memory from being read by an unauthorized person. Embed a security ID at

addresses 0xC4 to 0xCD in the internal flash memory. The debugger starts only when the security ID that is set during

debugger startup and the security ID set at addresses 0xC4 to 0xCD match. If the ID codes do not match, the debugger

manipulates the target device in accordance with the value set to the on-chip debug option byte area (refer to Table

3-2).

If the user has forgotten the security ID to enable debugging, erase the flash memory and set the security ID again.

[How to set security ID]

A setting method of the security ID is following. When both (a) and (b) methods are done at a time, method (b) has a

priority.

(a) Embed the security ID at addresses 0xC4 to 0xCD in the user program.

(b) Setting of the security ID by build tool common options. (In case of CubeSuite+)

(a) Embed a security ID at addresses 0xC4 to 0xCD in the user program.

For example If the security ID is embedded as follows, the security ID set by the debugger

is ″0123456789ABCDEF1234″ (not case-sensitive).

Table 3-1 Security ID

Address Value

0xC4 0x01

0xC5 0x23

0xC6 0x45

0xC7 0x67

0xC8 0x89

0xC9 0xAB

0xCA 0xCD

0xCB 0xEF

0xCC 0x12

0xCD 0x34

R20UT1994EJ0100 Rev.1.00 Page 15 of 26

Apr 20, 2012

Page 16

E1/E20 Emulator CHAPTER 3 SETTING OF SECURITY ID AND SETTING OF DEBUGGING RESOURCES

(b) Setting of the security ID by build tool common options. (In case of CubeSuite+)

Set in “device” in the common options tab as figure 3-1.

[How to authenticate the security ID at debugger startup]

When connecting a debugger to the device set the security ID, it is necessary to specify the security ID by connection

settings in debug tool property. (Default security ID is set in build tool property.)

Set in “Flash” in the connect settings tab as figure 3-2.

3.2 Setting of On-chip debugging option byte

This is the area for the security setting to prevent the flash memory from being read by an unauthorized person. The

debugger manipulates the target device in accordance with the set value, as shown below.

Table 3-2 On-Chip Debug Option Byte Setting and Operation

Set Value Description Remark

This setting is available only for

0x04 Debugging is disabled

flash programming and self

programming.

The on-chip flash memory is not erased no

0x85

matter how many times the security ID code

authentication fails.

0x84

All on-chip flash memory areas are erased if

the security ID code authentication fails.

Other than above Setting prohibited

[How to secure areas]

A setting method of On-chip debug option byte is following. When setting each other, priority is (b).

(a) Embed the On-chip debug option byte at addresses 0xC3 in the user program.

(b) Set the On-chip debug option byte by build tool link options. (In case of CubeSuite+)

(a) Embed the On-chip debug option byte at addresses 0xC3 in the user program

Embed the On-chip debug option byte at addresses 0xC3 in the user program

(b) Set the On-chip debug option byte by build tool link options. (In case of CubeSuite+)

Set in “device” in the link options tab as figure 3-3.

Figure 3-1 Examples for Setting the On-chip debug option by

te

-

-

-

R20UT1994EJ0100 Rev.1.00 Page 16 of 26

Apr 20, 2012

Page 17

E1/E20 Emulator CHAPTER 3 SETTING OF SECURITY ID AND SETTING OF DEBUGGING RESOURCES

3.3 Securing of area for debugging

The yellow portions in Figure 3-4 are the areas reserved for placing the debug monitor program, so user programs or

data cannot be allocated in these spaces. These spaces must be secured so as not to be used by the user program.

Moreover, this area must not be rewritten by the user program.

Secure the resources for debugging with the contents explained by (a) and (b).

Figure 3-2 Memory Spaces Where Debug Monitor Programs Are Allocated

R20UT1994EJ0100 Rev.1.00 Page 17 of 26

Apr 20, 2012

Page 18

E1/E20 Emulator CHAPTER 3 SETTING OF SECURITY ID AND SETTING OF DEBUGGING RESOURCES

(a) Securing of debug monitor area

This is the area to which the debug monitor program is to be allocated. The monitor program performs initialization

processing for debug communication interface and RUN or break processing for the CPU.

This user programs or data must not be placed in an area of 22 bytes near the on-chip debug option b yte, and an

area of 1024 bytes

allocated to a monitor program.

Note It is an area of 88 bytes when the pseudo RRM/DMM function is not used during debugging in 2 -wire mode.

If the internal ROM end address is 0x3FFFF, a monitor program of 88 bytes is allocated to the area from

0x3FFA8 to 0x3FFFF.

[How to secure areas]

It is not necessarily required to secure this area if the user program does not use this area.

However To avoid problems that may occur during the debugger startup, it is recommended to secure this area in

advance, using the compiler. Figure 3-5 shows example for securing the area, using the CubeSuite+. Set in “device” in

link options tab as figure 3-5.

(b) Securing of stack area for debugging

This area requires 6 bytes as the stack area for debugging

stack area, the address of this area varies depending on the stack increase and decrease. That is, 6 extra bytes are

consumed for the stack area used.

Figure 3-6 illustrates the case where the stack area is increased when the internal high-speed RAM start s from

0xFCF00.

Note When the self programming is executed, it will be 12 bytes.

Note

before the internal ROM end address. In addition, reset vector is rewritten to address

Note

. Since this area is allocated immediately before the

Figure 3-3 Variation of Address of Stack Area for Debugging

[How to secure areas]

Set the stack pointer by estimating the stack area consumed by the user program + 6 bytes. Make sure that the stack

pointer does not extend beyond the internal high-speed RAM start address.

Remark Refer to the self programming manual for how to secure the stack area for self programming.

R20UT1994EJ0100 Rev.1.00 Page 18 of 26

Apr 20, 2012

Page 19

E1/E20 Emulator CHAPTER 4 SPECIFICATIONS

CHAPTER 4 SPECIFICATIONS

Specifications are below table.

Table 4-1. E1/E20 Specification List

Large Item Middle Item Small Item

Hardware

Common

Related

debugging

Target host machine Computer equipped with a USB port

User system interface 14-pin connector

Host machine interface USB2.0 (Full speed/High speed)

Connection to the user system Connection by the provided

Power supply function 3.3 V or 5.0 V, set in software tool,

Power supply for the emulator No need (the host computer supplies

Break

Event

Trace Unavailable

Performance measurement

Pseudo realtime RAM monitor (RRM) Available (CPU is used when

Dynamic memory modification (DMM) Available (CPU is used when

Hot plug-in Unavailable

Security 10-byte ID code authentication

Software break 2000 points

Hardware break 1 point (commonly used by

Forced break Available

Number of events 1 point (commonly used by

Available function Hardware break only

Measurement item From run to break

Performance Resolution 100 s, Max.

Specification

E1 E20

OS depends on the software.

user-system interface cable

can be supplied to the user system

(with current up to 200 mA)

power through the USB)

execution and access)

execution and access)

measurement time 100 hours

monitoring)

changing)

Cannot supply

power.

Related

programming

Clock supply Clock mounted on the user system

can be used

Security flag setting Available

Standalone operation Unavailable (must be connected to

host machine)

R20UT1994EJ0100 Rev.1.00 Page 19 of 26

Apr 20, 2012

Page 20

E1/E20 Emulator CHAPTER 5 NOTES ON USAGE

CHAPTER 5 NOTES ON USAGE

This section describes cautions on use of the E1/E20 emulator. To use the E1/E20 properly, read the cautions

thoroughly.

5.1 Lists

Table 5-1. List of Notes on Usage

No. Item

1 Handling the device used for debugging

2 Flash self programming

3 Operation after a reset

4 Checking operation of a device after debugging

5 Current consumption of On-chip debugging

6 On-chip debugging option byte setting (address C3H)

7 Operation at voltage with which flash memory cannot be written

8 Pseudo real-time RAM monitor function

9 Relation between Standby function and Break function

10 Cautions on using step-in (step execution)

11 Step-in (step execution) of Division operation

( target :device with multiplier and divider/multiply-accmulator)

12 Emulation of flash memory CRC accumulator function

R20UT1994EJ0100 Rev.1.00 Page 20 of 26

Apr 20, 2012

Page 21

E1/E20 Emulator CHAPTER 5 NOTES ON USAGE

5.2 Details

No.1 Handling of device that was used for debugging

Do not mount a device that was used for debugging on a mass-produce d product. (Because the flash memory

was rewritten during debugging and the number of rewrites of the flash memory cannot be guara nteed.) Do not

embed the monitor program for debugging in a mass-produced product.

No.2 Flash self programming

If a space where the debug monitor program is allocated is rewritten by flash self programming, the debugger

can no longer operate normally. This caution also applies to boot swapping for such an area.

No.3 Operation after a res et

After an external pin reset or internal reset, the monitor program performs debug initialization processing.

Consequently, the time from reset occurrence until user program execution differs from that in the actual device

operation. If “No” is selected in Permit flash programming in property of the debug tool, the time until the user

program is executed compared with the time when “Yes” is selected is delayed several 100 ms.

No.4 Checking operation of a device after debugging

After downloading a load module file to the device to for on-chip debugging, do not check the operation of this

device without E1/E20.

A device after debugging contains the specific program for on-chip debugging, so it is different from actual

operation.

No.5 Current consumption when On-chip debugging

On-chip debugging circuit in the device operates during on-chip debugging.

Therefore current consumption of the device increases.

When evaluations current consumption of device, please do not connect a debugger.

No.6 On-chip d eb ugging option byte setting (address C3H)

The on-chip debugging option byte setting is rewritten arbitrarily by the debugger.

No.7 Operation at voltage with which flash memory cannot be written

If the following debugger operations are executed at voltage with which flash memory cannot be written, the

debugger outputs an error and the operation is ignored. Because these operations are included flash memory

rewriting.

<1> Writing to internal flash memory

<2> Setting or canceling of software breakpoint

<3> Starting execution at the set software breakpoint position

<4> Step execution at the set software breakpoint position

<5> Step-over execution, Return Out execution

<6> Come Here

<7> Setting, changing, or canceling of hardware breaks

<8> Masking/unmasking of internal reset

<9> Switching of peripheral breaks

R20UT1994EJ0100 Rev.1.00 Page 21 of 26

Apr 20, 2012

Page 22

E1/E20 Emulator CHAPTER 5 NOTES ON USAGE

No.8 Pseudo real-time RAM monitor function

Note the following points when using the pseudo real-time RAM monitor function.

<1> Standby mode (HALT or STOP) may be cancelled during monitoring.

<2> The pseudo real-time RAM monitor function does not operate while the CPU operating clock is sto pped.

<3> When the number of monitoring point are numerous, the response of the debugger becomes slow.

Influence to the debugger response becomes small by using a watch panel instead of a memory panel.

No.9 Relation between Standby function and Break function

The break is interrupt function of CPU. The standby mode is released by the break for using the following debug

function.

<1> Stops execution of the user program.

<2> Step execution of the standby instruction (Stops user program after execution instruction)

<3> Pseudo real-time RAM monitor function (Break When Readout)

<4> Pseudo Dynamic Memory Modification (Break When Write)

<5> Breakpoint setting executing of the user program.

No.10 Cautions on using step-in (step execution)

The value of some SFRs (special function registers) might remain unchanged while stepping into code. If the

value of the SFRs does not change while stepping into code, operate the microcontroller by continuously

executing the instructions instead of executing them in steps.

Stepping into code: Instructions in the user-created program are executed one by one.

Continuous execution: The user-created program is executed from the current PC value.

No.11 Step-in (step e x ecution) of Division operation

( target :device with multiplier and divider/multiply-accmulator)

When the instruction which sets (1) the bit 0 (DIVST) of Multiplication/Division control r egister (MDUC) is stepped,

the division operation is not finished.

The step execution of the division operation of C source file is not relevant.

No.12 Emulation of flash memory CRC accumulator function

<1> High-speed CRC (code flash : all area)

The operation result of CRC is different from actual result. Because monitor program is arranged and reset

vector is rewritten by on-chip debugging.

Please check the operation of high-speed CRC by using IECUBE or using device without E1/E20.

<2> General-purpose CRC(code flash : specification area)

The operation result of CRC at following areas is different from actual result. Because monitor program is

arranged and reset vector is rewritten by on-chip debugging.

- reset vector area

- debugging monitor area

- on-chip debugging option byte area

- software break setting area

R20UT1994EJ0100 Rev.1.00 Page 22 of 26

Apr 20, 2012

Page 23

E1/E20 Emulator APPENDIX EQUIVALENT CIRCUIT FOR E1/E20-RL78 CONNECTION

APPENDIX EQUIVALENT CIRCUIT FOR E1/E20-RL78 CONNECTION

The internal equivalent circuit related to the communication interface between the E1/E20 and user system is shown

below. An example of circuit connection for the user system is shown in this document. Please use it as a reference

when determining parameters in board design.

Figure A-1. E1/E20 Equivalent Circuit

Inside the E1/E20

22 Ω

RD74LVC125B

100 kΩ

EMV

DD

Target system side

(Pin numbers of the taget connector)

4

100 kΩ

RD74LVC125B

22 Ω

5

SN74LVC2T45

SN74LVC8T245

VDD

100 kΩ

22 Ω

6

VDD

100 kΩ

22 Ω

10

RD74LVC125B

VDD

SN74LVC8T245

100 kΩ

22 Ω

13

DTC124EE

R20UT1994EJ0100 Rev.1.00 Page 23 of 26

Apr 20, 2012

Page 24

E1/E20 Emulator

Additional Document for User’s Manual

(Notes on Connection for RL78)

Publication Date: April 20, 2012 Rev.1.00

Published by: Renesas Electronics Corporation

Page 25

SALES OFFICES

Refer to "http://www.renesas.com/" for the latest and detailed information.

Renesas Electronics America Inc.

2880 Scott Boulevard Santa Clara, CA 95050-2554, U.S.A.

Tel: +1-408-588-6000, Fax: +1-408-588-6130

Renesas Electronics Canada Limited

1101 Nicholson Road, Newmarket, Ontario L3Y 9C3, Canada

Tel: +1-905-898-5441, Fax: +1-905-898-3220

Renesas Electronics Europe Limited

Dukes Meadow, Millboard Road, Bourne End, Buckinghamshire, SL8 5FH, U.K

Tel: +44-1628-585-100, Fax: +44-1628-585-900

Renesas Electronics Europe GmbH

Arcadiastrasse 10, 40472 Düsseldorf, Germany

Tel: +49-211-65030, Fax: +49-211-6503-1327

Renesas Electronics (China) Co., Ltd.

7th Floor, Quantum Plaza, No.27 ZhiChunLu Haidian District, Beijing 100083, P.R.China

Tel: +86-10-8235-1155, Fax: +86-10-8235-7679

Renesas Electronics (Shanghai) Co., Ltd.

Unit 204, 205, AZIA Center, No.1233 Lujiazui Ring Rd., Pudong District, Shanghai 200120, China

Tel: +86-21-5877-1818, Fax: +86-21-6887-7858 / -7898

Renesas Electronics Hong Kong Limited

Unit 1601-1613, 16/F., Tower 2, Grand Century Place, 193 Prince Edward Road West, Mongkok, Kowloon, Hong Kong

Tel: +852-2886-9318, Fax: +852 2886-9022/9044

Renesas Electronics Taiwan Co., Ltd.

13F, No. 363, Fu Shing North Road, Taipei, Taiwan

Tel: +886-2-8175-9600, Fax: +886 2-8175-9670

Renesas Electronics Singapore Pte. Ltd.

1 harbourFront Avenue, #06-10, keppel Bay Tower, Singapore 098632

Tel: +65-6213-0200, Fax: +65-6278-8001

Renesas Electronics Malaysia Sdn.Bhd.

Unit 906, Block B, Menara Amcorp, Amcorp Trade Centre, No. 18, Jln Persiaran Barat, 46050 Petaling Jaya, Selangor Darul Ehsan, Malaysia

Tel: +60-3-7955-9390, Fax: +60-3-7955-9510

Renesas Electronics Korea Co., Ltd.

11F., Samik Lavied' or Bldg., 720-2 Yeoksam-Dong, Kangnam-Ku, Seoul 135-080, Korea

Tel: +82-2-558-3737, Fax: +82-2-558-5141

http://www.renesas.com

© 2012 Renesas Electronics Corporation. All rights reserved.

Colophon 1.1

Page 26

E1/E20 Emulator

Additional Document for User’s Manual

(Notes on Connection for RL78)

R20UT1994EJ0100

Loading...

Loading...