Page 1

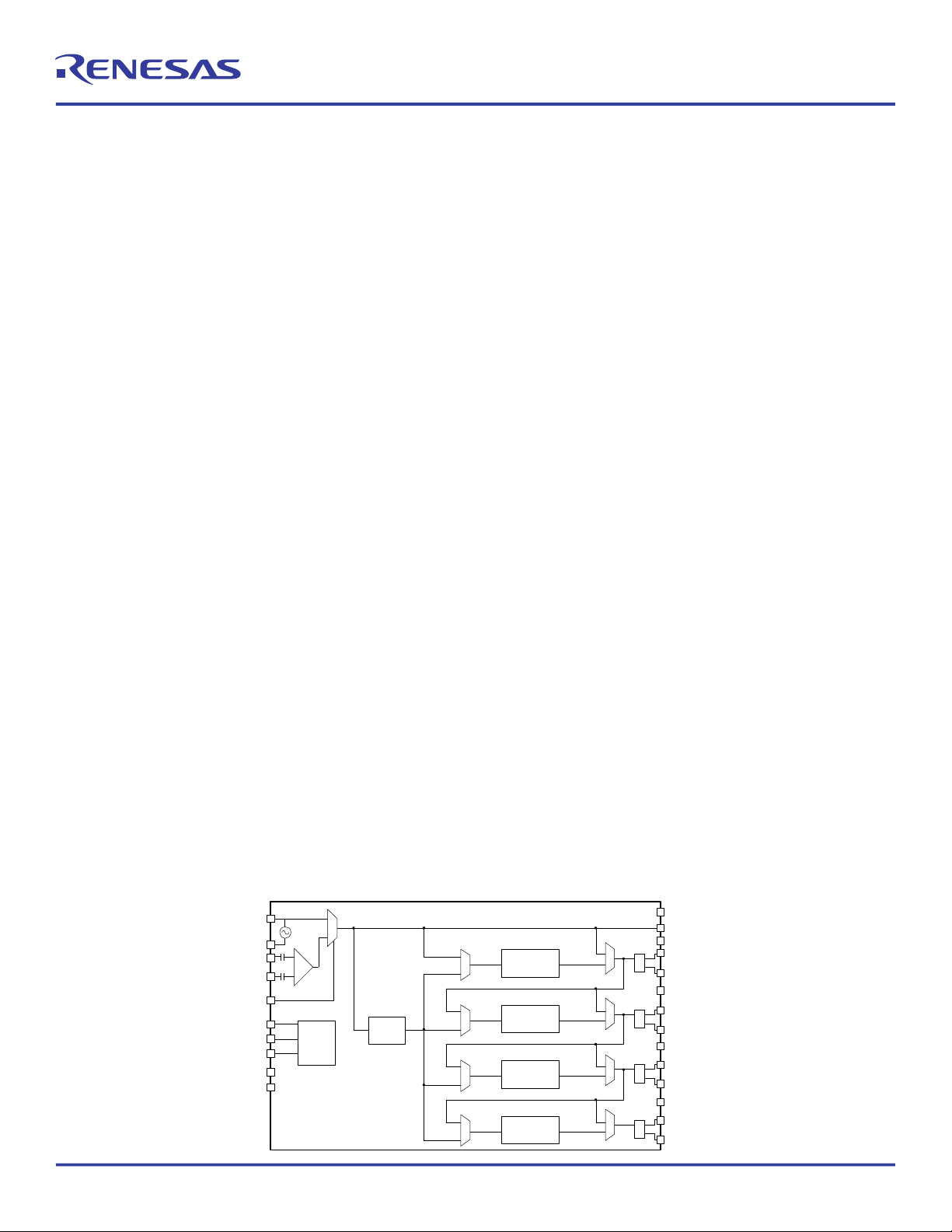

XIN/REF

XOUT

CLKIN

CLKINB

CLKSEL

SD/OE

SEL1/SDA

SEL0/S CL

V

DDA

V

DDD

V

DDO

0

OUT0 _SEL_I 2CB

V

DDO

1

OUT1

OUT1B

V

DDO

2

OUT2

OUT2B

V

DDO

3

OUT3

OUT3B

V

DDO

4

OUT4

OUT4B

FOD1

FOD2

FOD3

FOD4

PLL

OTP

and

Control

Logic

VersaClock® 6E Programmable

Clock Generator

5P49V6965

Datasheet

Description

The 5P49V6965 is a programmable clock generator intended for

high-performance consumer, networking, industrial, computing,

and data-communications applications. Configurations may be

stored in on-chip One-Time Programmable (OTP) memory or

changed using I

2

C interface. This is Renesas’ sixth generation of

programmable clock technology (VersaClock 6E).

The frequencies are generated from a single reference clock. The

reference clock can come from one of the two redundant clock

inputs. A glitchless manual switchover function allows one of the

redundant clocks to be selected during normal operation.

Two select pins allow up to four different configurations to be

programmed and accessible using processor GPIOs or

bootstrapping. The different selections may be used for different

operating modes (full function, partial function, partial

power-down), regional standards (US, Japan, Europe) or system

production margin testing. The device may be configured to use

one of two I

2

C addresses to allow multiple devices to be used in a

system.

Typical Applications

▪ Ethernet switch/router

▪ PCI Express 1.0 / 2.0 / 3.0 / 4.0 Spread Spectrum on

▪ PCI Express 1.0 / 2.0 / 3.0 / 4.0 / 5.0 Spread Spectrum off

▪ Broadcast video/audio timing

▪ Multi-function printer

▪ Processor and FPGA clocking

▪ Any-frequency clock conversion

▪ MSAN/DSLAM/PON

▪ Fiber Channel, SAN

▪ Telecom line cards

▪ Laser distance sensing

Features

▪ Flexible 1.8V, 2.5V, 3.3V power-rails

▪ High-performance, low phase noise PLL, < 0.5ps RMS typical

phase jitter on outputs

▪ Four banks of internal OTP memory

• In-system or factory programmable

• 2 select pins accessible with processor GPIOs or

bootstrapping

2

▪ I

C serial programming interface

• 0xD0 or 0xD4 I2C address options allows multiple devices

configured in a same system

▪ Reference LVCMOS output clock

▪ Four universal output pairs individually configurable:

• Differential (LVPECL, LVDS or HCSL)

• 2 single-ended (2 LVCMOS in-phase or 180 degrees out of

phase)

• I/O V

(LVDS and LVCMOS), 2.5V, or 3.3V

▪ Output frequency ranges:

• LVCMOS clock outputs: 1kHz to 200MHz

• LVDS, LVPECL, HCSL differential clock outputs: 1kHz to

350MHz

▪ Redundant clock inputs with manual switchover

▪ Programmable output enable or power-down mode

▪ Available in 4 × 4 mm 24-VFQFPN package

▪ -40° to +85°C industrial temperature operation

s can be mixed and matched, supporting 1.8V

DD

Block Diagram

1©2020 Renesas Electronics Corporation August 20, 2020

Page 2

5P49V6965 Datasheet

Contents

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pin Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Absolute Maximum Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Thermal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Recommended Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

I2C Bus Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Test Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Jitter Performance Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PCI Express Jitter Performance and Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Features and Functional Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Device Startup and Power-On-Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Reference Clock and Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Manual Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Internal Crystal Oscillator (XIN/REF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Programmable Loop Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fractional Output Dividers (FOD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Output Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SD/OE Pin Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

I2C Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Typical Application Circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Input – Driving the XIN/REF or CLKIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Output – Single-ended or Differential Clock Terminations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Package Outline Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Marking Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2©2020 Renesas Electronics Corporation August 20, 2020

Page 3

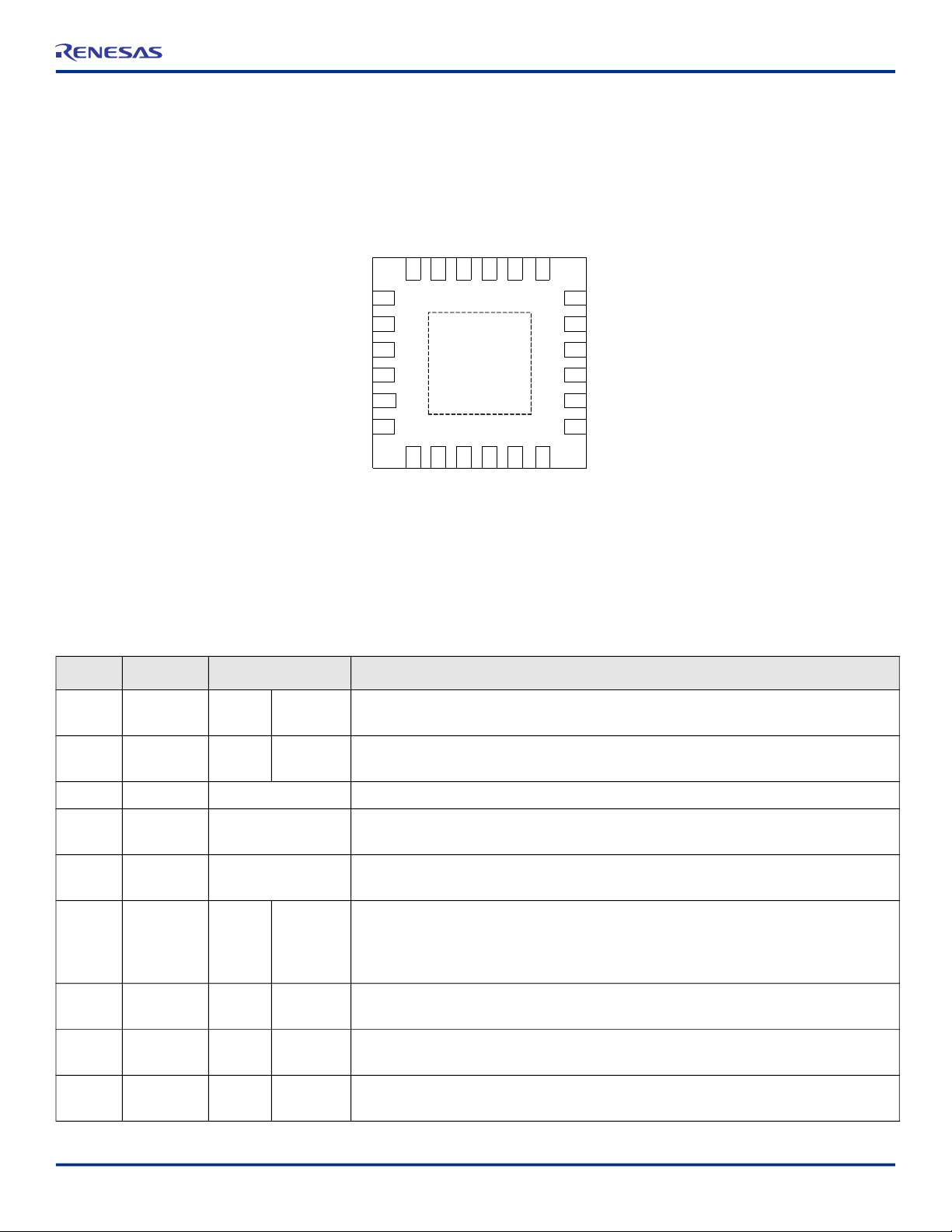

Pin Assignments

1

7

4 × 4 mm 24-VFQFPN

19

13

XOUT

XIN/REF

V

DDO

3

CLKIN

OUT3B

OUT2

CLKINB

CLKSEL

OUT3

OUT2B

V

DDO

2

V

DDA

SD/OE

SEL1/SDA

SEL0/SCL

V

DDO

4

OUT4

OUT4B

OUT1B

OUT1

V

DDO

1

V

DDD

V

DDO

0

OUT0_SEL_I2CB

EPAD

2

3

4

5

6

8

9101112

14

15

16

17

18

2021222324

Figure 1. Pin Assignments for 4 x 4 mm 24-VFQFPN Package – Top View

5P49V6965 Datasheet

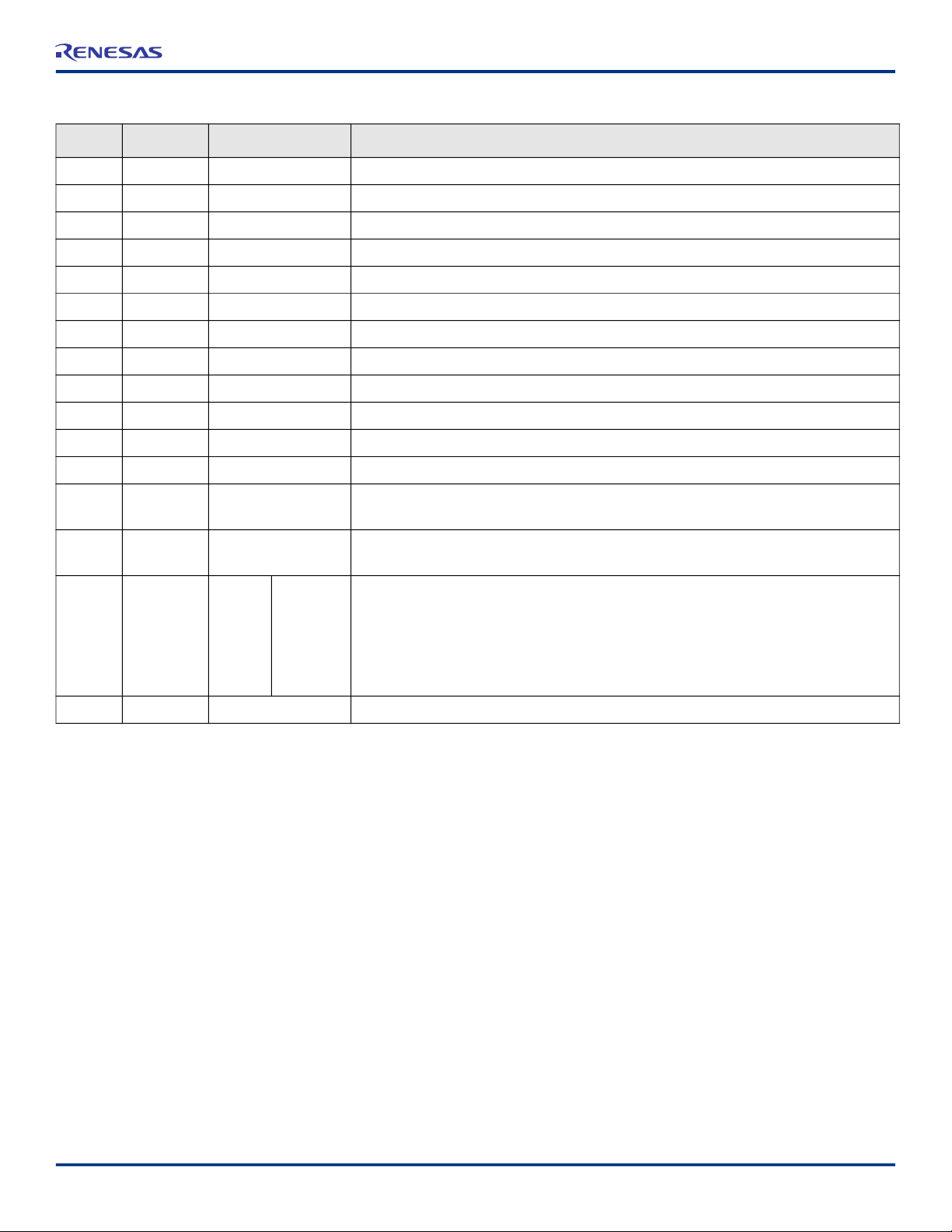

Pin Descriptions

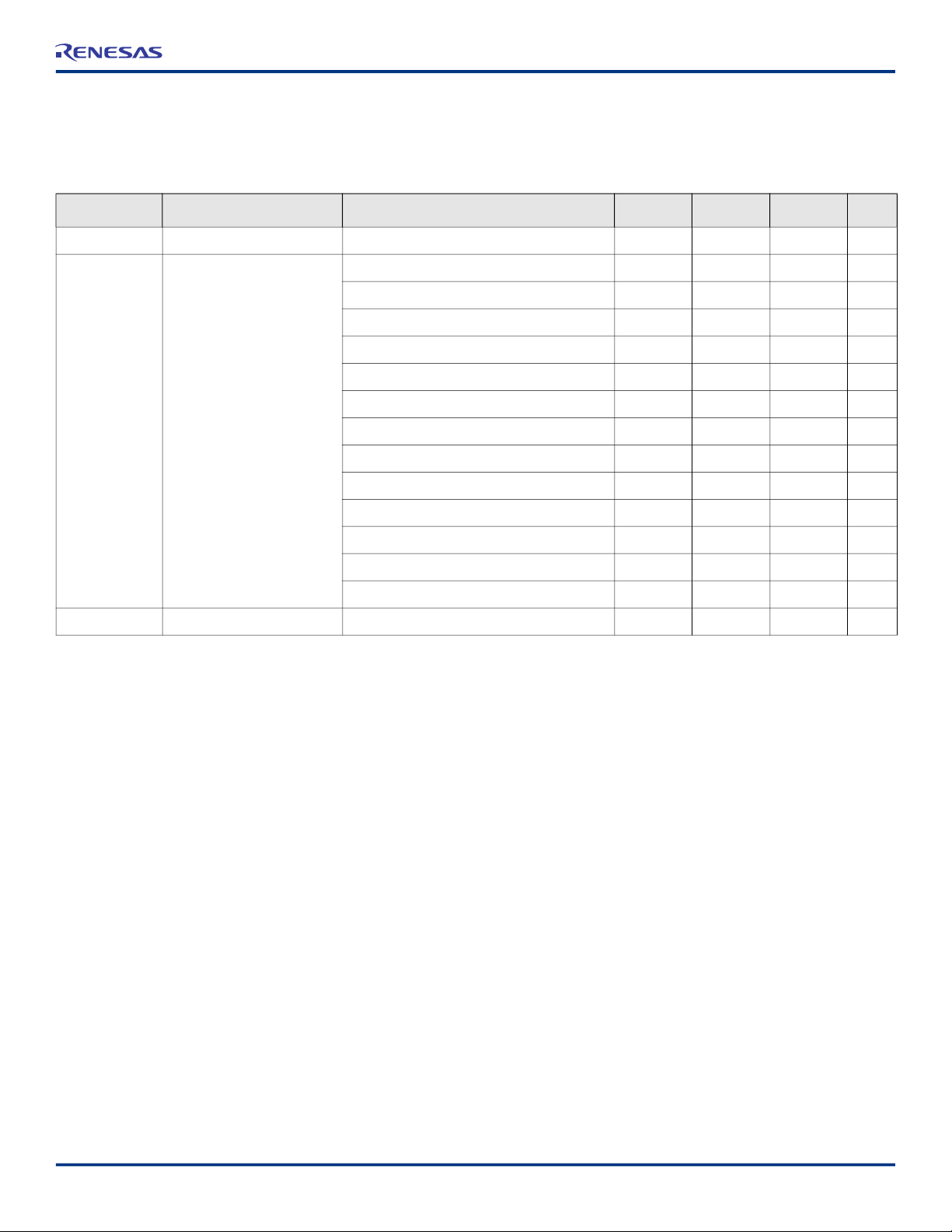

Table 1. Pin Descriptions

Number Name Type Description

Pull-down

Pull-down

Power

Pull-down

Pull-down

Pull-down

Pull-down

Internal

Internal

Internal

Internal

Internal

Internal

Differential clock input. Weak 100kΩ internal pull-down.

Complementary differential clock input. Weak 100kΩ internal pull-down.

Crystal oscillator interface input, or single-ended LVCMOS clock input. Input voltage needs

to be below 1.2V. Refer to the section Driving XIN/REF with a CMOS Driver.

Analog functions power supply pin. Connect to 1.8V to 3.3V. V

the same voltage applied.

Input clock select. Selects the active input reference source in manual switchover mode.

0 = XIN/REF, XOUT (default).

1 = CLKIN, CLKINB.

See Table 20. Input Clock Select for more details.

Enables/disables the outputs (OE) or powers down the chip (SD).

Configuration select pin, or I

2

C SDA input as selected by OUT0_SEL_I2CB. Weak internal

pull-down resistor.

2

Configuration select pin, or I

C SCL input as selected by OUT0_SEL_I2CB. Weak internal

pull-down resistor.

1 CLKIN Input

2 CLKINB Input

3 XOUT Output Crystal oscillator interface output.

4 XIN/REF Input

5 V

DDA

6 CLKSEL Input

7 SD/OE Input

8 SEL1/SDA Input

9 SEL0/SCL Input

DDA

and V

should have

DDD

3©2020 Renesas Electronics Corporation August 20, 2020

Page 4

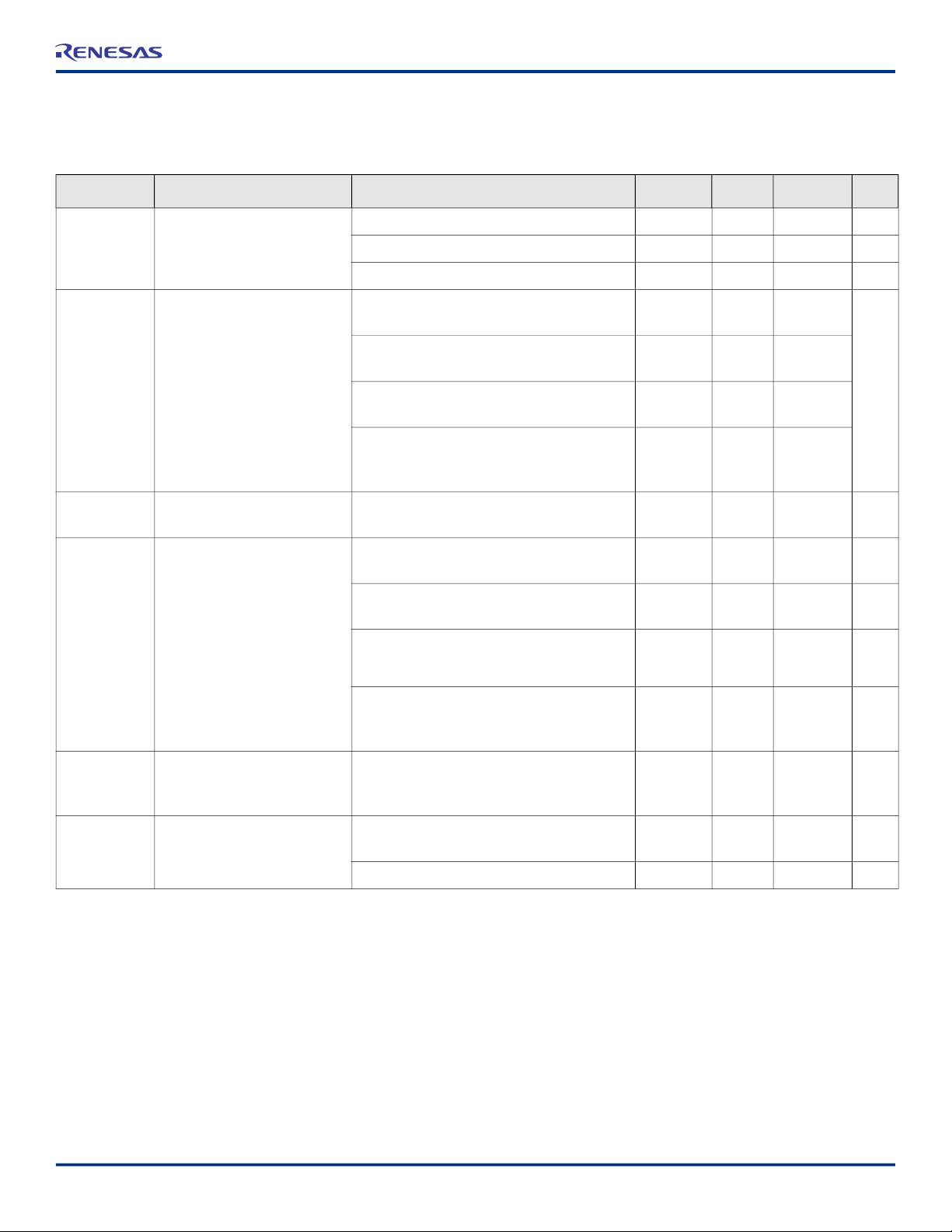

Table 1. Pin Descriptions (Cont.)

Number Name Type Description

5P49V6965 Datasheet

10 V

4 Power Output power supply. Connect to 1.8 to 3.3V. Sets output voltage levels for OUT4/OUT4B.

DDO

11 OUT4 Output Output clock 4. Refer to the Output Drivers section for more details.

12 OUT4B Output Complementary output clock 4. Refer to the Output Drivers section for more details.

13 OUT3B Output Complementary output clock 3. Refer to the Output Drivers section for more details.

14 OUT3 Output Output clock 3. Refer to the Output Drivers section for more details.

15 V

3 Power Output power supply. Connect to 1.8 to 3.3V. Sets output voltage levels for OUT3/OUT3B.

DDO

16 OUT2B Output Complementary output clock 2. Refer to the Output Drivers section for more details.

17 OUT2 Output Output clock 2. Refer to the Output Drivers section for more details.

18 V

2 Power Output power supply. Connect to 1.8 to 3.3V. Sets output voltage levels for OUT2/OUT2B.

DDO

19 OUT1B Output Complementary output clock 1. Refer to the Output Drivers section for more details.

20 OUT1 Output Output clock 1. Refer to the Output Drivers section for more details.

21 V

22 V

23 V

1 Power Output power supply. Connect to 1.8 to 3.3V. Sets output voltage levels for OUT1/OUT1B.

DDO

DDD

0 Power

DDO

Power

Digital functions power supply pin. Connect to 1.8 to 3.3V. V

same voltage applied.

Power supply pin for OUT0_SEL_I2CB. Connect to 1.8 to 3.3V. Sets output voltage levels

for OUT0.

DDA

and V

should have the

DDD

Latched input/LVCMOS output. At power-up, the voltage at the pin OUT0_SEL_I2CB is

latched by the part and used to select the state of pins 8 and 9. If a weak pull-up (10kΩ) is

24

OUT0_SEL

_I2CB

Input/

Output

Internal

Pull-down

placed on OUT0_SEL_I2CB, pins 8 and 9 will be configured as hardware select pins, SEL1

and SEL0. If a weak pull-down (10kΩ) is placed on OUT0_SEL_I2CB or it is left floating,

pins 8 and 9 will act as the SDA and SCL pins of an I

2

C interface. After power-up, the pin

acts as an LVCMOS reference output.

25 GND GND Connect to ground pad.

4©2020 Renesas Electronics Corporation August 20, 2020

Page 5

5P49V6965 Datasheet

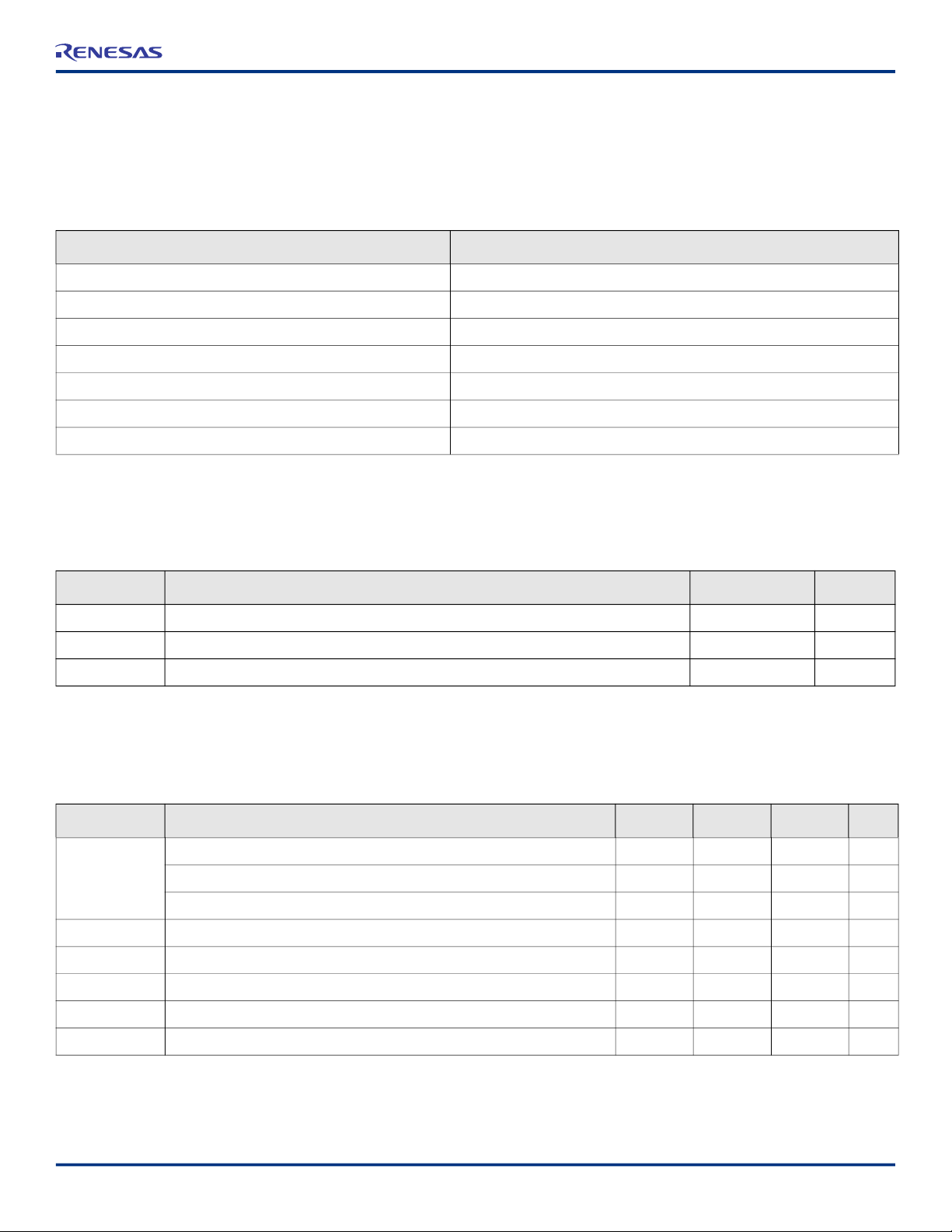

Absolute Maximum Ratings

The absolute maximum ratings are stress ratings only. Stresses greater than those listed below can cause permanent damage to the

device. Functional operation of the device at absolute maximum ratings is not implied. Exposure to absolute maximum rating conditions

may affect device reliability.

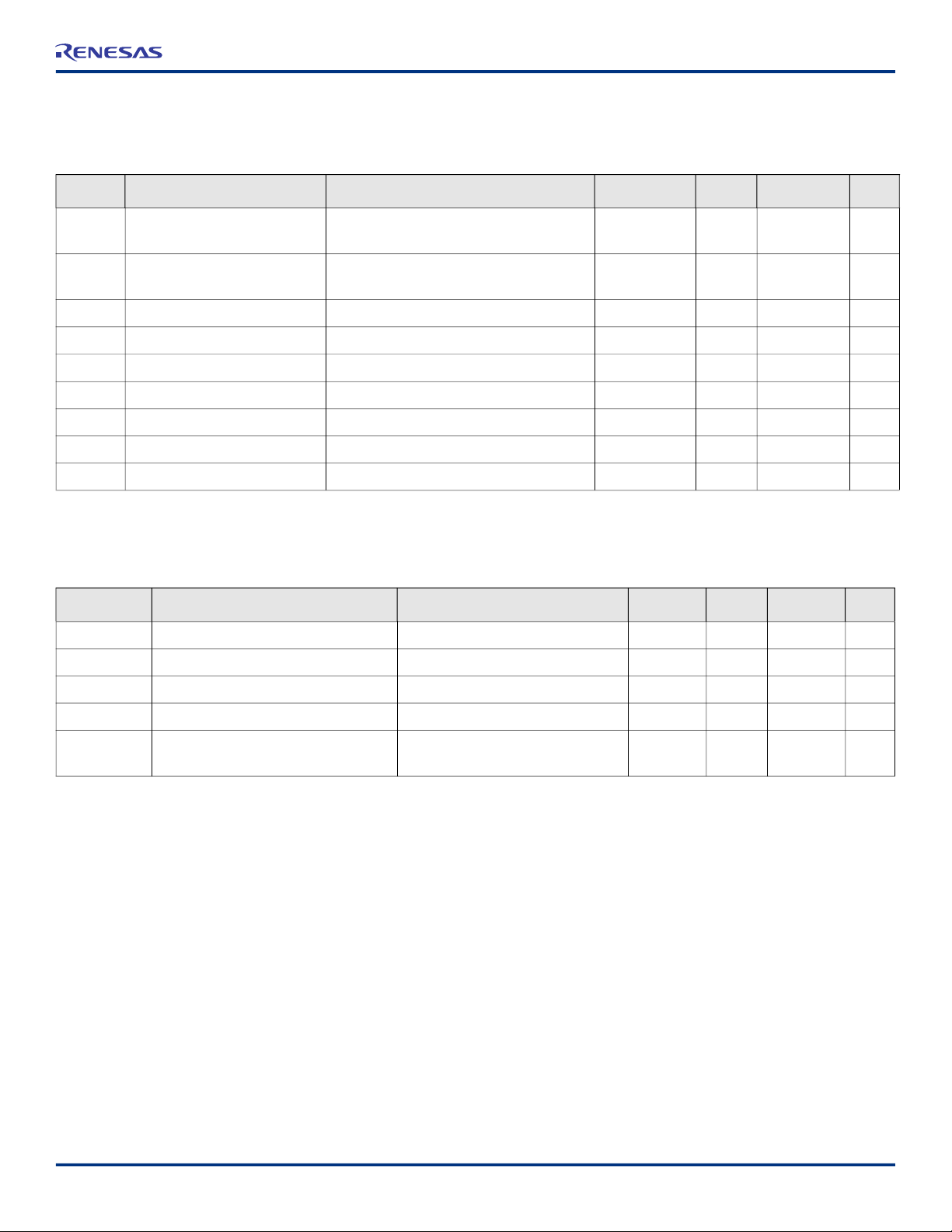

Table 2. Absolute Maximum Ratings

Item Rating

Supply Voltage, V

DDA

, V

DDD

, V

DDO

3.6V.

XIN/REF Input 1.2V.

CLKIN, CLKINB Input V

, 1.2V voltage swing.

DDO0

I2C Loading Current 10mA.

Storage Temperature, T

STG

-65°C to 150°C.

Junction Temperature 125°C

ESD Human Body Model 2000V.

Thermal Characteristics

Table 3. Thermal Characteristics

Symbol Parameter Value Units

θ

JA

θ

JB

θ

JC

Theta JA. Junction to air thermal impedance (0mps). 42 °C/W

Theta JB. Junction to board thermal impedance (0mps). 2.35 °C/W

Theta JC. Junction to case thermal impedance (0mps). 41.8 °C/W

Recommended Operating Conditions

Table 4. Recommended Operating Conditions

Symbol Parameter Minimum Typical Maximum Units

Power supply voltage for supporting 1.8V outputs. 1.71 1.8 1.89 V

V

V

V

DDOX

DDD

DDA

T

PU

T

A

C

L

Power supply voltage for supporting 2.5V outputs. 2.375 2.5 2.625 V

Power supply voltage for supporting 3.3V outputs. 3.135 3.3 3.465 V

Power supply voltage for core logic functions. 1.71 3.465 V

Analog power supply voltage. Use filtered analog power supply. 1.71 3.465 V

Power ramp time for all VDDs to reach 90% of VDD. 0.05 50 ms

Operating temperature, ambient. -40 85 °C

Maximum load capacitance (3.3V LVCMOS only). 15 pF

5©2020 Renesas Electronics Corporation August 20, 2020

Page 6

5P49V6965 Datasheet

Electrical Characteristics

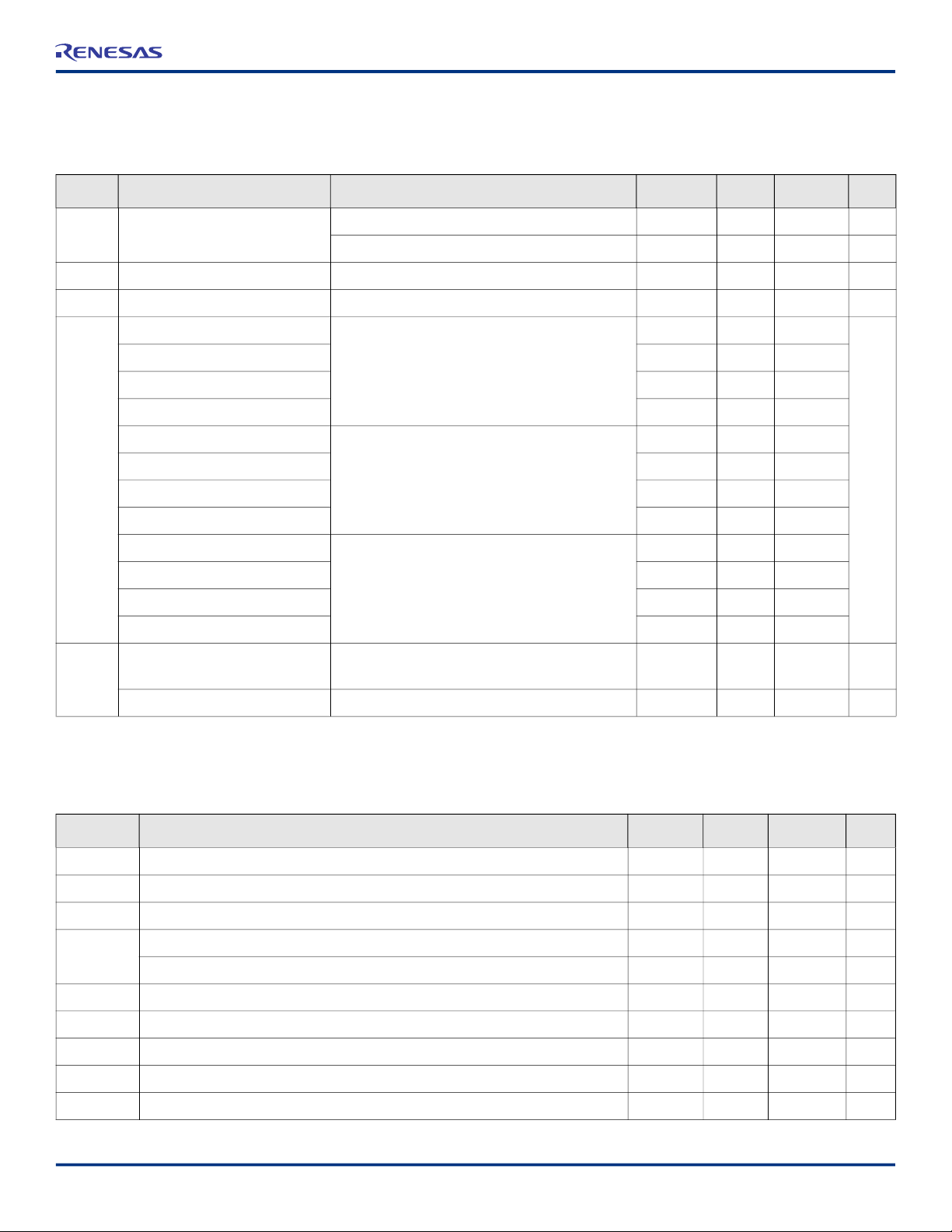

Table 5. Current Consumption

V

, V

DDD

, V

DDA

Symbol Parameter Conditions Minimum Typical Maximum Units

I

DDCORE

I

DDOx

I

DDPD

= 3.3V ±5%, 2.5V ±5%, 1.8V ±5%, TA = -40°C to +85°C.

DDO0

1

Core Supply Current 100MHz on all outputs, 25MHz REFCLK. 33 42 mA

Output Buffer Supply

Current

LVPECL, 350MHz, 3.3V V

LVPECL, 350MHz, 2.5V V

LVDS, 350MHz, 3.3V V

LVDS, 350MHz, 2.5V V

LVDS, 350MHz, 1.8V V

HCSL, 250MHz, 3.3V V

HCSL, 250MHz, 2.5V V

DDOx2.

DDOx2.

DDOx2.

DDOx 2.

DDOx 2.

LVCMOS, 50MHz, 3.3V, V

LVCMOS, 50MHz, 2.5V, V

LVCMOS, 50MHz, 1.8V, V

LVCMOS, 200MHz, 3.3V V

LVCMOS, 200MHz, 2.5V V

LVCMOS, 200MHz, 1.8V V

DDOx.2.

DDOx.2.

DDOx

DDOx

DDOx

DDOx

DDOx

DDOx

2,3

. 22 27 mA

2,3

. 20 24 mA

2,3

. 17 21 mA

2,3

. 43 56 mA

2,3

. 33 43 mA

2,3

. 24 31 mA

45 58 mA

36 47 mA

26 32 mA

25 30 mA

22 27 mA

39 48 mA

37 46 mA

Power Down Current SD asserted, I2C programming. 10 12 mA

1

I

2

Measured into a 5” 50Ω trace. See Test Loads section for more details.

3

Single CMOS driver active.

DDCORE

= I

DDA

+ I

DDD

.

6©2020 Renesas Electronics Corporation August 20, 2020

Page 7

5P49V6965 Datasheet

Table 6. AC Timing Characteristics

V

, V

DDA

DDD

, V

= 3.3V ±5%, 2.5V ±5%, 1.8V ±5%, TA = -40°C to +85°C unless stated otherwise.

DDO0

Symbol Parameter Conditions Minimum Typical Maximum Units

Input frequency limit (crystal). 8 40 MHz

1

F

IN

Input Frequency

Input frequency limit (CLKIN,CLKINB). 1 350 MHz

Input frequency limit (single-ended over XIN). 1 200 MHz

F

OUT

f

T

VCO

DC

2

Output Frequency

Single-ended clock output limit (LVCMOS),

individual FOD mode.

Differential clock output limit

(LVPECL/LVDS/HCSL), individual FOD mode.

Single-ended clock output limit (LVCMOS),

cascaded FOD mode, output 2–4.

1 200

1 350

MHz

0.001 200

Differential clock output limit

(LVPECL/LVDS/HCSL), cascaded FOD mode,

0.001 350

output 2–4.

VCO Operating Frequency

Range

Measured at V

reference output, V

Measured at V

reference output, V

3

Output Duty Cycle

Measured at V

/2, all outputs except

DD

DD

DD

= 2.5V or 3.3V.

DDOX

/2, all outputs except

= 1.8V

DDOX

/2, reference output OUT0

(5MHz–150.1MHz) with 50% duty cycle input.

Measured at V

/2, reference output OUT0

DD

(150.1MHz–200MHz) with 50% duty cycle

2500 2900 MHz

45 50 55 %

40 50 60 %

40 50 60 %

30 50 70 %

input.

Skew between the same frequencies, with

T

SKEW

Output Skew

outputs using the same driver format and

phase delay set to 0ns.

Measured after all VDDs have risen above

T

STARTUP

4,5

Startup Time

90% of their target value 6.

PLL lock time from shutdown mode. 3 4 ms

1

Practical lower frequency is determined by loop filter settings.

2

A slew rate of 2.75V/ns or greater should be selected for output frequencies of 100MHz or higher.

3

Duty cycle is only guaranteed at maximum slew rate settings.

4

Actual PLL lock time depends on the loop configuration.

5

Includes loading the configuration bits from EPROM to PLL registers. It does not include EPROM programming/write time.

6

Power-up with temperature calibration enabled; contact Renesas if shorter lock-time is required in system.

7©2020 Renesas Electronics Corporation August 20, 2020

75 ps

30 ms

Page 8

5P49V6965 Datasheet

Table 7. General Input Characteristics

V

, V

DDA

DDD

, V

= 3.3V ±5%, 2.5V ±5%, 1.8V ±5%, TA = -40°C to +85°C unless stated otherwise.

DDO0

Symbol Parameter Conditions Minimum Typical Maximum Units

CLKIN,CLKINB,CLKSEL,SD/OE,SEL1/SD

A, SEL0/SCL.

CLKSEL, SD/OE, SEL1/SDA, SEL0/SCL,

CLKIN, CLKINB, OUT0_SEL_I2CB.

3 7 pF

100 300 kΩ

V

DDD

+ 0.3 V

DDD

DDD

+ 0.3 V

DDO0

T

C

R

V

V

V

V

V

V

R/TF

Input Capacitance

IN

Pull-down Resistor

PD

Input High Voltage CLKSEL, SD/OE. 0.7 x V

IH

Input Low Voltage CLKSEL, SD/OE. GND - 0.3 0.3 x V

IL

Input High Voltage OUT0_SEL_I2CB. 1.7 V

IH

Input Low Voltage OUT0_SEL_I2CB. GND - 0.3 0.4 V

IL

Input High Voltage XIN/REF. 0.8 1.2 V

IH

Input Low Voltage XIN/REF. GND - 0.3 0.4 V

IL

Input Rise/Fall Time CLKSEL, SD/OE, SEL1/SDA, SEL0/SCL. 300 ns

Table 8. CLKIN Electrical Characteristics

V

, V

DDA

DDD

, V

= 3.3V ±5%, 2.5V ±5%, 1.8V ±5%, TA = -40°C to +85°C unless stated otherwise.

DDO0

Symbol Parameter Conditions Minimum Typical Maximum Units

V

SWING

Input Amplitude – CLKIN, CLKINB Peak to peak value, single-ended. 200 1200 mV

dv/dt Input Slew Rate – CLKIN, CLKINB Measured differentially. 0.4 8 V/ns

V

DC

I

IL

I

IH

IN

Input Leakage Low Current VIN = GND. -5 5 μA

Input Leakage High Current VIN = 1.7V. 20 μA

Input Duty Cycle

Measurement from differential

waveform.

45 55 %

8©2020 Renesas Electronics Corporation August 20, 2020

Page 9

5P49V6965 Datasheet

Table 9. Electrical Characteristics – CMOS Outputs

V

, V

DDA

DDD

, V

= 3.3V ±5%, 2.5V ±5%, 1.8V ±5%, TA = -40°C to +85°C unless stated otherwise.

DDO0

Symbol Parameter Conditions Minimum Typical Maximum Units

V

OH

V

OL

R

OUT

T

SR

I

OZDD

Output High Voltage

IOH = -15mA (3.3V), -12mA (2.5V). 0.7 x V

= -8mA (1.8V). 0.5 x V

I

OH

DDO

DDO

V

V

DDO

DDO

Output Low Voltage IOL = 15mA (3.3V), 12mA (2.5V), 8mA (1.8V). 0.45 V

Output Driver Impedance CMOS output driver. 17 Ω

Slew Rate, SLEW[1:0] = 00

Slew Rate, SLEW[1:0] = 01 1.2 2.3

Slew Rate, SLEW[1:0] = 10 1.3 2.4

Single-ended 3.3V LVCMOS output clock rise and

fall time, 20% to 80% of V

= 3.3V.

V

DDOX

(output load = 5pF)

DDO

1.0 2.2

Slew Rate, SLEW[1:0] = 11 1.7 2.7

Slew Rate, SLEW[1:0] = 00

Slew Rate, SLEW[1:0] = 01 0.7 1.4

Slew Rate, SLEW[1:0] = 10 0.6 1.4

Single-ended 2.5V LVCMOS output clock rise and

fall time, 20% to 80% of V

= 2.5V.

V

DDOX

(output load = 5pF)

DDO

0.6 1.3

V/ns

Slew Rate, SLEW[1:0] = 11 1.0 1.7

Slew Rate, SLEW[1:0] = 00

Slew Rate, SLEW[1:0] = 01 0.4 0.8

Slew Rate, SLEW[1:0] = 10 0.4 0.9

Single-ended 1.8V LVCMOS output clock rise and

fall time, 20% to 80% of V

= 1.8V.

V

DD

(output load = 5pF)

DDO

0.3 0.7

Slew Rate, SLEW[1:0] = 11 0.7 1.2

Output Leakage Current

(OUT1–4)

Tri-state outputs. 5 μA

Output Leakage Current (OUT0) Tri-state outputs. 30 μA

V

V

Table 10. Electrical Characteristics – LVDS Outputs

V

, V

DDA

DDD

, V

= 3.3V ±5%, 2.5V ±5%, 1.8V ±5%, TA = -40°C to +85°C unless stated otherwise.

DDO0

Symbol Parameter Minimum Typical Maximum Units

(+) Differential Output Voltage for the TRUE Binary State 247 454 mV

V

OT

(-) Differential Output Voltage for the FALSE Binary State -454 -247 mV

V

OT

Change in VOT between Complimentary Output States 50 mV

ΔV

OT

Output Common Mode Voltage (Offset Voltage) at 3.3 V ±5%, 2.5V ±5% 1.125 1.25 1.375 V

V

ΔV

I

OS

I

OS

OSD

T

R

T

OS

F

Output Common Mode Voltage (Offset Voltage) at 1.8V ±5% 0.8 0.875 0.96 V

Change in VOS between Complimentary Output States 50 mV

Outputs Short Circuit Current, V

Differential Outputs Short Circuit Current, V

OUT

+ or V

- = 0V or V

OUT

+ = V

OUT

DDO

- 6 12 mA

OUT

9 24 mA

LVDS rise time 20%–80% 300 ps

LVDS fall time 80%–20% 300 ps

9©2020 Renesas Electronics Corporation August 20, 2020

Page 10

5P49V6965 Datasheet

Table 11. Electrical Characteristics – LVPECL Outputs

V

, V

DDA

DDD

, V

= 3.3V ±5%, 2.5V ±5%, TA = -40°C to +85°C unless stated otherwise.

DDO0

Symbol Parameter Minimum Typical Maximum Units

V

V

V

SWING

T

T

Output Voltage High, Terminated through 50Ω tied to V

OH

Output Voltage Low, Terminated through 50Ω tied to V

OL

Peak-to-Peak Differential Output Voltage Swing 1.1 2 V

LVPECL rise time 20%–80% 400 ps

R

LVPECL fall time 80%–20% 400 ps

F

Table 12. Electrical Characteristics – HCSL Outputs

V

, V

DDA

DDD

, V

= 3.3V ±5%, 2.5V ±5%, TA = -40°C to +85°C unless stated otherwise.

DDO0

- 2V V

DD

- 2V V

DD

1

- 1.19 V

DDO

- 1.94 V

DDO

- 0.69 V

DDO

- 1.4 V

DDO

Symbol Parameter Conditions Minimum Typical Maximum Units

2,3

dV/dt Slew Rate Scope averaging on

ΔdV/dt Slew Rate Matching Scope averaging on

V

MAX

V

MIN

V

SWING

V

CROSS

ΔV

CROSS

1

Guaranteed by design and characterization. Not 100% tested in production.

2

Measured from differential waveform.

3

Slew rate is measured through the V

4

V

CROSS

Maximum Voltage

Minimum Voltage -300 mV

Measurement on single-ended signal using absolute

value (scope averaging off).

Voltage Swing Scope averaging off

Crossing Voltage Value Scope averaging off

Crossing Voltage Variation Scope averaging off 5. 140 mV

voltage range centered around differential 0V. This results in a ±150mV window around differential 0V.

SWING

is defined as voltage where Clock = Clock# measured on a component test board and only applies to the differential rising edge (i.e. Clock

. 1 4 V/ns

2,3

. 20 %

1150 mV

2,6

. 300 mV

4,6

. 250 550 mV

rising and Clock# falling).

5

The total variation of all V

The intent is to limit V

6

Measured from single-ended waveform.

CROSS

measurements in any particular system. Note that this is a subset of V

CROSS

induced modulation by setting ΔV

to be smaller than V

CROSS

CROSS

CROSS

absolute.

min/max (V

absolute) allowed.

CROSS

Table 13. Spread Spectrum Generation Specifications

Symbol Parameter Conditions Minimum Typical Maximum Units

f

SSOUT

f

MOD

Spread Frequency Output frequency range for spread spectrum. 5 300 MHz

Mod Frequency Modulation frequency. 30 to 63 kHz

Amount of spread value (programmable)–center spread. ±0.1% to ±2.5%

f

SPREAD

Spread Value

Amount of spread value (programmable)–down spread. -0.2% to -5%

10©2020 Renesas Electronics Corporation August 20, 2020

%f

OUT

Page 11

I2C Bus Characteristics

5P49V6965 Datasheet

Table 14. I

2

C Bus (SCL/SDA) DC Characteristics

Symbol Parameter Conditions Minimum Typical Maximum Units

For SEL1/SDA pin and

SEL0/SCL pin.

For SEL1/SDA pin and

SEL0/SCL pin.

0.7 x V

DDD

DDD

0.3 x V

DDD

V

V

V

V

IH

IL

HYS

I

IN

OL

Input High Level

Input Low Level

Hysteresis of Inputs 0.05 x V

Input Leakage Current -1 36 μA

Output Low Voltage IOL = 3mA. 0.45 V

Table 15. I2C Bus (SCL/SDA) AC Characteristics

Symbol Parameter Conditions Minimum Typical Maximum Units

F

SCLK

t

BUF

t

SU:START

t

HD:START

t

SU:DATA

t

HD:DATA

t

OVD

C

B

t

R

t

F

t

HIGH

t

LOW

t

SU:STOP

1

A device must internally provide a hold time of at least 300ns for the SDA signal (referred to the V

Serial Clock Frequency (SCL) — 10 400 kHz

Bus Free Time between Stop and Start — 1.3 μs

Setup Time, Start — 0.6 μs

Hold Time, Start — 0.6 μs

Setup Time, Data Input (SDA) — 0.1 μs

Hold Time, Data Input (SDA)

1

— 0 μs

Output Data Valid from Clock — 0.9 μs

Capacitive Load for Each Bus Line — 400 pF

Rise Time, Data and Clock (SDA, SCL) — 20 + 0.1 x C

Fall Time, Data and Clock (SDA, SCL) — 20 + 0.1 x C

B

B

300 ns

300 ns

High Time, Clock (SCL) — 0.6 μs

Low Time, Clock (SCL) — 1.3 μs

Setup Time, Stop — 0.6 μs

of the SCL signal) to bridge the undefined

IH(MIN)

region of the falling edge of SCL.

2 I2

C inputs are 3.3V tolerant.

V

V

V

11©2020 Renesas Electronics Corporation August 20, 2020

Page 12

Test Loads

33 Ohm

5pF

Zo = 50 Ohm

Test

Point

Device

2pF

Differential

Zo = 100 Ohm

33 Ohm

Device

33 Ohm

50 Ohm

2pF

50 Ohm

Test

Points

Differential

Zo = 100 Ohm

100 Ohm

Test

Points

Device

2pF

2pF

Differential

Zo = 100 Ohm

Test

Points

Device

50Ohm 50 Ohm

R

2pF2pF

R = 50 Ohm for 3.3V LVPECL

R = 18 Ohm for 2.5V LVPECL

Figure 2. LVCMOS Test Load

Figure 3. HCSL Test Load

5P49V6965 Datasheet

Figure 4. LVDS Test Load

Figure 5. LVPECL Test Load

12©2020 Renesas Electronics Corporation August 20, 2020

Page 13

Jitter Performance Characteristics

Figure 6. Typical Phase Jitter Plot at 156.25MHz

5P49V6965 Datasheet

Note: Measured with OUT2 = 156.25MHz on, 39.625MHz input.

Table 16. Jitter Performance

1,2

Symbol Parameter Conditions Minimum Typical Maximum Units

LVCMOS 3.3V ±5%, -40°C–90°C. 5 30 ps

J

CY-CY

Cycle to Cycle Jitter

All differential outputs 3.3V ±5%, -40°C–90°C. 25 35 ps

LVCMOS 3.3V ±5%, -40°C–90°C. 28 40 ps

J

PK-PK

Period Jitter

All differential outputs 3.3V ±5%, -40°C–90°C. 4 30 ps

LVCMOS 3.3V ±5%, -40°C–90°C. 0.3 ps

J

1

Measured with 25MHz crystal input.

2

Configured with OUT0 = 25MHz–LVCMOS; OUT1 = 100MHz–HCSL; OUT2 = 125MHz–LVDS; OUT3 = 156.25MHz–LVPECL.

RMS Phase Jitter (12kHz–20MHz)

RMS

All differential outputs 3.3V ±5%, -40°C–90°C. 0.5 ps

13©2020 Renesas Electronics Corporation August 20, 2020

Page 14

5P49V6965 Datasheet

PCI Express Jitter Performance and Specification

Table 17. PCI Express Jitter Performance (Spread Spectrum = Off)

Parameter Symbol Conditions Minimum Typical Maximum Limit Units Notes

PCIe Phase Jitter

(Common Clocked

Architectures)

PCIe Phase Jitter

(SRNS Architectures)

t

jphPCIeG1-CC

t

jphPCIeG2-CC

t

jphPCIeG3-CC

t

jphPCIeG4-CC

t

jphPCIeG5-CC

t

jphPCIeG1-SRNS

t

jphPCIeG2-SRNS

t

jphPCIeG3-SRNS

t

jphPCIeG4-SRNS

PCIe Gen1 (2.5 GT/s)

SSC = OFF

PCIe Gen2 Lo Band (5.0 GT/s)

SSC = OFF

PCIe Gen2 Hi Band (5.0 GT/s)

SSC = OFF

PCIe Gen3 (8.0 GT/s)

SSC = OFF

PCIe Gen4 (16.0 GT/s)

SSC = OFF

PCIe Gen5 (32.0 GT/s)

SSC = OFF

PCIe Gen1 (2.5 GT/s)

SSC = OFF

PCIe Gen2 (5.0 GT/s)

SSC = OFF

PCIe Gen3 (8.0 GT/s)

SSC = OFF

PCIe Gen4 (16.0 GT/s)

SSC = OFF

4 86

0.05 3

0.22 3.1

0.12 1

0.12 0.5

0.05 0.15

0.3

0.26

0.07

N/A

0.07

ps

(p-p)

ps

(RMS)

ps

(RMS)

ps

(RMS)

ps

(RMS)

ps

(RMS)

ps

(p-p)

ps

(RMS)

ps

(RMS)

ps

(RMS)

1,2

1,2

1,2

1,2

1,2,3,4

1,2,3,5

1,2,6

1,2,6

1,2,6

1,2,6

t

jphPCIeG5-SRNS

1

The Refclk jitter is measured after applying the filter functions found in PCI Express Base Specification 5.0, Revision 1.0. See the Test Loads section

of the data sheet for the exact measurement setup. The worst case results for each data rate are summarized in this table.

2

Jitter measurements shall be made with a capture of at least 100,000 clock cycles captured by a real-time oscilloscope (RTO) with a sample rate

of 20GS/s or greater. Broadband oscilloscope noise must be minimized in the measurement. The measured PP jitter is used (no extrapolation) for

RTO measurements. Alternately, jitter measurements may be used with a Phase Noise Analyzer (PNA) extending (flat) and integrating and folding

the frequency content up to an offset from the carrier frequency of at least 200MHz (at 300MHz absolute frequency) below the Nyquist frequency.

For PNA measurements for the 2.5GT/s data rate, the RMS jitter is converted to peak to peak jitter using a multiplication factor of 8.83. In the case

where real-time oscilloscope and PNA measurements have both been done and produce different results, the RTO result must be used.

3

SSC spurs from the fundamental and harmonics are removed up to a cutoff frequency of 2MHz taking care to minimize removal of any non-SSC

content.

4

Note that 0.7ps RMS is to be used in channel simulations to account for additional noise in a real system.

5

Note that 0.25ps RMS is to be used in channel simulations to account for additional noise in a real system.

6

While the PCI Express Base Specification 5.0, Revision 1.0 provides the filters necessary to calculate SRIS jitter values, it does not provide

specification limits, hence the n/a in the Limit column. SRIS values are informative only. In general, a clock operating in an SRIS system must be

twice as good as a clock operating in a Common Clock system. For RMS values, twice as good is equivalent to dividing the CC value by Ö2.

PCIe Gen5 (32.0 GT/s)

SSC = OFF

0.07

ps

(RMS)

1,2,6

14©2020 Renesas Electronics Corporation August 20, 2020

Page 15

5P49V6965 Datasheet

Table 18. PCI Express Jitter Performance (Spread Spectrum = On)

Parameter Symbol Conditions Minimum Typical Maximum Limit Units Notes

PCIe Phase Jitter

(Common Clocked

Architectures)

PCIe Phase Jitter

(SRIS Architectures)

t

jphPCIeG1-CC

t

jphPCIeG2-CC

t

jphPCIeG3-CC

t

jphPCIeG4-CC

t

jphPCIeG5-CC

t

jphPCIeG1-SRIS

t

jphPCIeG2-SRIS

t

jphPCIeG3-SRIS

t

jphPCIeG4-SRIS

PCIe Gen 1 (2.5 GT/s)

-0.5%

SSC ≤

PCIe Gen 2 Lo Band (5.0 GT/s)

SSC ≤ -0.5%

PCIe Gen 2 Hi Band (5.0 GT/s)

SSC ≤ -0.5%

PCIe Gen 3 (8.0 GT/s)

SSC ≤ -0.5%

PCIe Gen 4 (16.0 GT/s)

SSC ≤ -0.5%

PCIe Gen 5 (32.0 GT/s)

SSC ≤ -0.5%

PCIe Gen 1 (2.5 GT/s)

SSC ≤ -0.3%

PCIe Gen 2 (5.0 GT/s)

SSC ≤ -0.3%

PCIe Gen 3 (8.0 GT/s)

SSC ≤ -0.3%

PCIe Gen 4 (16.0 GT/s)

SSC ≤ -0.3%

16 86

0.02 3

0.92 3.1

0.37 1

0.37 0.5

N/A 0.15

14

1.4

0.42

N/A

0.36

ps

(p-p)

ps

(RMS)

ps

(RMS)

ps

(RMS)

ps

(RMS)

ps

(RMS)

ps

(p-p)

ps

(RMS)

ps

(RMS)

ps

(RMS)

1,2

1,2

1,2

1,2

1,2,3,4

1,2,3,5

1,2,6

1,2,6

1,2,6

1,2,6

t

jphPCIeG5-SRIS

1

The Refclk jitter is measured after applying the filter functions found in PCI Express Base Specification 5.0, Revision 1.0. See the Test Loads section

of the data sheet for the exact measurement setup. The worst case results for each data rate are summarized in this table.

2

Jitter measurements shall be made with a capture of at least 100,000 clock cycles captured by a real-time oscilloscope (RTO) with a sample rate

of 20GS/s or greater. Broadband oscilloscope noise must be minimized in the measurement. The measured PP jitter is used (no extrapolation) for

RTO measurements. Alternately, jitter measurements may be used with a Phase Noise Analyzer (PNA) extending (flat) and integrating and folding

the frequency content up to an offset from the carrier frequency of at least 200MHz (at 300MHz absolute frequency) below the Nyquist frequency.

For PNA measurements for the 2.5GT/s data rate, the RMS jitter is converted to peak to peak jitter using a multiplication factor of 8.83. In the case

where real-time oscilloscope and PNA measurements have both been done and produce different results, the RTO result must be used.

3

SSC spurs from the fundamental and harmonics are removed up to a cutoff frequency of 2MHz taking care to minimize removal of any non-SSC

content.

4

Note that 0.7ps RMS is to be used in channel simulations to account for additional noise in a real system.

5

Note that 0.25ps RMS is to be used in channel simulations to account for additional noise in a real system.

6

While the PCI Express Base Specification 5.0, Revision 1.0 provides the filters necessary to calculate SRIS jitter values, it does not provide

specification limits, hence the n/a in the Limit column. SRIS values are informative only. In general, a clock operating in an SRIS system must be

twice as good as a clock operating in a Common Clock system. For RMS values, twice as good is equivalent to dividing the CC value by Ö2.

PCIe Gen 5 (32.0 GT/s)

SSC ≤ -0.3%

N/A

ps

(RMS)

1,2,6

15©2020 Renesas Electronics Corporation August 20, 2020

Page 16

Features and Functional Blocks

XIN/REF

XOUT

CLKIN

CLKINB

CLKSEL

OTP

and

Control

Logic

PRIMSRC

Reg 0x13[1]

5P49V6965 Datasheet

Device Startup and Power-On-Reset

The device has an internal power-up reset (POR) circuit. All VDDs

must be connected to desired supply voltage to trigger POR.

User can define specific default configurations through internal

One-Time-Programmable (OTP) memory. Either customer or

factory can program the default configuration. Please refer to

VersaClock 6E Family Register Descriptions and Programming

Guide for details or contact Renesas if a specific

factory-programmed default configuration is required.

Device will identity which of the 2 modes to operate in by the state

of OUT0_SEL_I2CB pin at POR. Both of the 2 modes default

configurations can be programmed as stated above.

1. Software Mode (I

2

C interface will be open to users for in-system programming,

I

overriding device default configurations at any time.

2. Hardware Select Mode: OUT0_SEL_I2CB is high at POR.

Device has been programmed to load OTP at power-up

(REG0[7]=1). The device will load internal registers according

to Table 19. Power-up Behavior.

Internal OTP memory can support up to 4 configurations,

selectable by SEL0/SEL1 pins.

At POR, logic levels at SEL0 and SEL1 pins must be settled,

resulting the selected configuration to be loaded at power up.

After the first 10ms of operation, the levels of the SELx pins

can be changed, either to low or to the same level as

V

DDD/VDDA

of < 300ns rise/fall time and only a single pin can be changed

at a time. After a pin level change, the device must not be

interrupted for at least 1ms so that the new values have time to

load and take effect.

2

C): OUT0_SEL_I2CB is low at POR.

. The SELx pins must be driven with a digital signal

Reference Clock and Selection

The device supports up to two clock inputs.

▪ Crystal input, can be driven by a single-ended clock.

▪ Clock input (CLKIN, CLKINB), a fully differential input that only

accepts a reference clock. A single-ended clock can also drive

it on CLKIN.

Figure 7. Clock Input Diagram, Internal Logic

Manual Switchover

The CLKSEL pin selects the input clock between either XTAL/REF

or (CLKIN, CLKINB).

CLKSEL polarity can be changed by I

0x13[1]) as shown in the table below.

0 = XIN/REF, XOUT (default); 1 = CLKIN, CLKINB.

Table 20. Input Clock Select

PRIMSRC CLKSEL Source

2

C programming (Byte

Table 19. Power-up Behavior

OUT0_SEL_I2CB

at POR SEL1 SEL0

1 0 0 No 0 0

1 0 1 No 0 1

1 1 0 No 0 2

1 1 1 No 0 3

0 X X Yes 1

0 X X Yes 0 0

I2C

Access REG0:7 Config

2

C

I

defaults

0 0 XIN/REF

0 1 CLKIN, CLKINB

1 0 CLKIN, CLKINB

1 1 XIN/REF

When SM[1:0] is “0x”, the redundant inputs are in manual

switchover mode. In this mode, CLKSEL pin is used to switch

between the primary and secondary clock sources. The PRIMSRC

bit determines the primary and secondary clock source setting.

During the switchover, no glitches will occur at the output of the

device, although there may be frequency and phase drift,

depending on the exact phase and frequency relationship

between the primary and secondary clocks.

16©2020 Renesas Electronics Corporation August 20, 2020

Page 17

5P49V6965 Datasheet

Internal Crystal Oscillator (XIN/REF)

Choosing Crystals

A crystal manufacturer will calibrate its crystals to the nominal

frequency with a certain load capacitance value. When the

oscillator load capacitance matches the crystal load capacitance,

the oscillation frequency will be accurate. When the oscillator load

capacitance is lower than the crystal load capacitance, the

oscillation frequency will be higher than nominal and vice versa so

for an accurate oscillation frequency you need to make sure to

match the oscillator load capacitance with the crystal load

capacitance.

Tuning the Crystal Load Capacitor

Ci1 and Ci2 are commonly programmed to be the same value.

Adjustment of the crystal tuning capacitors allows maximum

flexibility to accommodate crystals from various manufacturers.

The range of tuning capacitor values available are in accordance

with the following table.

Ci1/Ci2 starts at 9pF with setting 000000b and can be increased

up to 25pF with setting 111111b. The step per bit is 0.5pF.

Table 21. XTAL[5:0] Tuning Capacitor

Parameter Bits Step (pF) Minimum (pF) Maximum (pF)

XTAL 6 0.5 9 25

You can write the following equation for this capacitance:

Ci = 9pF + 0.5pF × XTAL[5:0]

C

= Ci1 + Cs1 + Ce1

XIN

C

= Ci2 + Cs2 + Ce2

XOUT

The final load capacitance of the crystal:

C

= C

XIN

× C

L

XOUT

/ (C

XIN

+ C

XOUT

)

It is recommended to set the same value for capacitors the same

at each crystal pin, meaning:

C

= C

XIN

XOUT

Example 1: The crystal load capacitance is specified as 8pF and

the stray capacitance at each crystal pin is Cs = 1.5pF. Assuming

equal capacitance value at XIN and XOUT, the equation is as

Cs1 and Cs2 are stray capacitances at each crystal pin and

follows:

typical values are between 1pF and 3pF.

8pF = (9pF + 0.5pF × XTAL[5:0] + 1.5pF) / 2

Ce1 and Ce2 are additional external capacitors, increasing the

So, XTAL[5:0] = 11 (decimal).

load capacitance reduces the oscillator gain so please consult the

factory when adding Ce1 and/or Ce2 to avoid crystal startup

issues. Ci1 and Ci2 are integrated programmable load capacitors,

one at XIN and one at XOUT. Ci1 and Ci2.

Example 2: The crystal load capacitance is specified as 12pF and

the stray capacitance Cs is unknown. Footprints for external

capacitors Ce are added and a worst case Cs of 5pF is used. For

now we use Cs + Ce = 5pF and the right value for Ce can be

The value of each capacitor is composed of a fixed capacitance

determined later to make 5pF together with Cs.

amount plus a variable capacitance amount set with the XTAL[5:0]

register.

12pF = (9pF + 0.5pF × XTAL[5:0] + 5pF) / 2

So, XTAL[5:0] = 20 (decimal).

Table 22. Recommended Crystal Characteristics

Parameter Minimum Typical Maximum Units

Mode of Oscillation Fundamental

Frequency 8 25 40 MHz

Equivalent Series Resistance (ESR) 10 100 Ω

Shunt Capacitance 7 pF

Load Capacitance (C

Load Capacitance (C

Maximum Crystal Drive Level 100 μW

) at < = 25MHz 6 8 12 pF

L

) > 25MHz to 40MHz 6 8 pF

L

17©2020 Renesas Electronics Corporation August 20, 2020

Page 18

5P49V6965 Datasheet

Programmable Loop Filter

The device PLL loop bandwidth range depends on the input

reference frequency (Fref).

Table 23. Loop Filter Settings

Input Reference

Frequency (MHz)

1 40 126

350 300 1000

Loop Bandwidth

Minimum (kHz)

Loop Bandwidth

Maximum (kHz)

Fractional Output Dividers (FOD)

The device has 4 fractional output dividers (FOD). Each of the

FODs are comprised of a 12-bit integer counter, and a 24-bit

fractional counter. The output divider can operate in integer divide

only mode for improved performance, or utilize the fractional

counters to generate a clock frequency accurate to 50ppb.

FOD has the following features:

Individual Spread Spectrum Modulation

The output clock frequencies can be modulated to spread energy

across a broader range of frequencies, lowering system EMI.

When device is at hardware select mode outputs will be

automatically aligned at POR. The same synchronization reset is

also triggered when switching between configurations with the

SEL0/1 pins. This ensures that the outputs remain aligned in

every configuration.

When using software mode I

during operation, alignment can be lost. Alignment can be

restored by manually triggering the reset through I

The outputs are aligned on the falling edges of each output by

default. Rising edge alignment can also be achieved by utilizing

the programmable skew feature to delay the faster clock by 180

degrees. The programmable skew feature also allows for fine

tuning of the alignment.

Programmable Skew

The device has the ability to skew outputs by quadrature values.

The skew on each output can be adjusted from 0 to 360 degrees.

Skew is adjusted in units equal to 1/32 of the VCO period. So, for

100MHz output and a 2800MHz VCO, you can select how many

11.161ps units you want added to your skew (resulting in units of

0.402 degrees). For example, 0, 0.402, 0.804, 1.206, 1.408, and

so on. The granularity of the skew adjustment is always

dependent on the VCO period and the output period.

2

C to reprogram an output divider

2

C.

Each divider has individual spread ability. Spread modulation

independent of output frequency, a triangle wave modulation

between 30 and 63kHz.

Spread spectrum can be applied to any output clock, any clock

frequency, and any spread amount from ±0.25% to ±2.5%

center-spread and -0.5% to -5% down-spread.

Bypass Mode

Bypass mode (divide by 1) to allow the output to behave as a

buffered copy from the input or another FOD.

Cascaded Mode

As shown in the block diagram, FODs can be cascaded for lower

output frequency.

For example, user currently has OUT1 running at 12.288MHz and

needs another 48kHz output. The user can cascade FOD2 by

taking input from OUT1, with a divide ratio of 256. In this way,

OUT 2 is running at 48kHz while in alignment with 12.288MHz on

OUT1.

Dividers Alignment

Each output divider block has a synchronizing pulse to provide

startup alignment between outputs dividers. This allows alignment

of outputs for low skew performance.

Output Drivers

The device output drivers support the following features

individually:

▪ 2.5V or 3.3V voltage level for HCSL/LVPECL operation

▪ 1.8V, 2.5V or 3.3V voltage levels for CMOS/LVDS operation

▪ CMOS supports 4 operating modes:

• CMOSD: OUTx and OUTxB 180 degrees out of phase

• CMOSX2: OUTx and OUTxB phase-aligned

• CMOS1: only OUTx pin is on

• CMOS2: only OUTxB pin is on

When a given output is configured to at CMOSD or CMOSX2, then

all previously described configuration and control apply equally to

both pins.

▪ Independent output enable/disabled by register bits. When

disabled, an output can be either in a logic 1 state or Hi-Z.

The following options are used to disable outputs:

1. Output turned off by I

2. Output turned off by SD/OE pin.

3. Output unused, which means is turned off regardless of OE pin

status.

2

C.

18©2020 Renesas Electronics Corporation August 20, 2020

Page 19

5P49V6965 Datasheet

SD/OE Pin Function

SD/OE pin can be programmed as following functions:

1. OE output enable (low active).

2. OE output enable (high active).

3. Global shutdown (low active).

4. Global shutdown (high active).

Output behavior when disabled is also programmable. User will

have the option to choose output driver behavior when it's off:

1. OUTx pin high, OUTxB pin low. (Controlled by SD/OE pin).

2. OUTx/OUTxB Hi-Z (Controlled by SD/OE pin).

3. OUTx pin high, OUTxB pin low. (Configured through I

4. OUTx/OUTxB Hi-Z (Configured by I

2

C).

The user has the option to disable the output with either I

SD/OE pin. Refer to VersaClock 6E Family Register Descriptions

and Programming Guide for details.

Figure 8. I2C R/W Sequence

2

C).

2

C or

I2C Operation

The device acts as a slave device on the I2C bus using one of the

2

two I

C addresses (0xD0 or 0xD4) to allow multiple devices to be

used in the system. The interface accepts byte-oriented block

write and block read operations.

Address bytes(2 bytes) specify the register address of the byte

position of the first register to write or read.

Data bytes (registers) are accessed in sequential order from the

lowest to the highest byte (most significant bit first).

Read and write block transfers can be stopped after any complete

byte transfer. During a write operation, data will not be moved into

the registers until the STOP bit is received, at which point, all data

received in the block write will be written simultaneously.

For full electrical I

SDATA and SCLK.

2

C compliance, use external pull-up resistors for

19©2020 Renesas Electronics Corporation August 20, 2020

Page 20

Typical Application Circuits

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

Layout notes:

1. Separate Xout and Xin Traces by 3 x the trace width

2. Do not share crystal load capacitor ground via with

other components.

3. Route power from bead through bulk capacitor pad

then through 0.1uF capacitor pad then to clock chip

Vdd pad.

4. Do not share ground vias. One ground pin one ground

via.

Revision history

0.1 11/30/16 first publication

Manufacture Part Number Z@100MHz PkgSz DC res. Current(Ma)

Fair-Rite 2504021217Y0 120 0402 0.5 200

muRata BLM15AG221SN1 220 0402 0.35 300

muRata BLM15BB121SN1 120 0402 0.35 300

TDK MMZ1005S241A 240 0402 0.18 200

TECSTAR TB4532153121 120 0402 0.3 300

NOTE:FERRITE BEAD FB1 =

PLACE NEAR

I2C CONTROLLER

IF USED

LVDS TERMINATION

3.3V LVPECL TERMINATION

2.5V and 3.3V HCSL TERMINATION

CONFIGURATION

PULL-UP FOR

HARDWARE

CONTROL

REMOVE FOR I2C

LVCMOS TERMINATION

FOR LVDS, LVPECL USE

TERMINATION ON RIGHT BEFORE

AC COUPLING

following pins have

weak internal

pull down resistors:

6, 7, 8, 9 and 24

for pins#: 22,23,21,18,15,10

pin# 5

FG_X1

OUT_0_SEL-I2C

V1P8VC

V1P8VC

OUTR0

CLKIN

CLKINB V1P8VC

OUTR1

CLKSEL OUTRB1

SDA V1P8VC

SCL OUTR2

OUTRB2

SD/OE

SDA

SCL CLKIN

CLKINB

OUT_0_SEL-I2C

FG_X2

V1P8VC V1P8VCA

V1P8VCA

OUTR3

OUTRB3

V1P8VC

OUTR4

OUTRB4

V1P8VC

VCC1P8

V3P3

V1P8VC

Size

Document Number Re v

Date: Sheet

of

0.1

Integrated Device Technology

A

11Wednesday, November 30, 2016

5P49V6965_SCH

San Jose, CA

Size

Document Number Re v

Date: Sheet

of

0.1

Integrated Device Technology

A

11Wednesday, November 30, 2016

5P49V6965_SCH

San Jose, CA

Size

Document Number Re v

Date: Sheet

of

0.1

Integrated Device Technology

A

11Wednesday, November 30, 2016

5P49V6965_SCH

San Jose, CA

R3 100

1 2

R2

2.2

1 2

C14

.1uF

12

C11

.1uF

12

FB1

SIGNAL_BEAD

1 2

U2

RECEIVER

1

2

R12 50

1 2

R9

10K

1 2

C5

.1uF

12

C8

.1uF

12

R5

49.9

1%

1 2

U4

RECEIVER

1

2

R14 33

1 2

C4

.1uF

12

C13 .1uF

1 2

R11 50

1 2

R10 50

1 2

R8

10K

1 2

C15

.1uF

12

R6 33

1 2

R4

49.9

1%

1 2

C3

.1uF

12

R15 33

1 2

C1

10uF

12

C7

NP

12

U5

5P49V6965A

XOUT3XIN/REF4CLKIN1CLKINB2CLKSEL6SEL1/SDA

8

SEL0/SCL9SD/OE

7

VDDA

5

VDDD

22

VDDO0

23

OUT0_SEL_I2CB

24

VDDO1

21

OUT1

20

OUT1B

19

VDDO2

18

OUT2

17

OUT2B

16

VDDO3

15

OUT3

14

OUT3B

13

VDDO4

10

OUT4

11

OUT4B

12

EPAD

25

EPAD

26

EPAD

27

EPAD

28

EPAD

29

EPAD

30

EPAD

31

EPAD

32

EPAD

33

R13 33

1 2

GNDGND

Y1

25.000 MHz

CL = 8pF

4

1

2

3

U3

RECEIVER

1

2

C12 .1uF

1 2

C6

NP

12

R7

10K

1 2

C2

1uF

12

Figure 9. Application Circuit Example

5P49V6965 Datasheet

20©2020 Renesas Electronics Corporation August 20, 2020

Page 21

5P49V6965 Datasheet

XO U T

XIN / REF

1 nF

Zo = 50 Ohm

Ro + Rs = 50 ohm

LVCMOS

VDD

Rs

Ro

R1

C3

R2

V_XIN

XOU T

XIN / REF

1 nF

5050

50

Zo = 50 Ohm

+3.3V LVPECL Driver

Zo = 50 Ohm

R2

R1

R3

C1

Input – Driving the XIN/REF or CLKIN

Driving XIN/REF with a CMOS Driver

In some cases, it is encouraged to have XIN/REF driven by a clock input for reasons like better SNR, multiple input select with device

CLKIN, etc. The XIN/REF pin is able to take an input when its amplitude is between 500mV and 1.2V and the slew rate more than

0.2V/ns.

The XIN/REF input can be overdriven by an LVCMOS driver or by one side of a differential driver through an AC coupling capacitor. The

XOUT pin can be left floating.

Figure 10. Overdriving XIN with a CMOS Driver

Table 24. Nominal Voltage Divider Values for Overdriving XIN with Single-ended Driver

LVCMOS Diver V

DD

Ro + Rs R1 R2 V_XIN (peak) Ro+Rs+R1+R2

3.3 50.0 130 75 0.97 255

2.5 50.0 100 100 1.00 250

1.8 50.0 62 130 0.97 242

Driving XIN with an LVPECL Driver

Figure 11 shows an example of the interface diagram for a +3.3V LVPECL driver. This is a standard LVPECL termination with one side of

the driver feeding the XIN/REF input. It is recommended that all components in the schematics be placed in the layout; though some

components might not be used, they can be utilized for debugging purposes. The datasheet specifications are characterized and

guaranteed by using a quartz crystal as the input. If the driver is 2.5V LVPECL, the only change necessary is to use the appropriate value

of R3.

Figure 11. Overdriving XIN with an LVPECL Driver

21©2020 Renesas Electronics Corporation August 20, 2020

Page 22

5P49V6965 Datasheet

R1

R2

Vrx

V er s aCloc k 5 Rec eive r

CLKI N

CLKI NB

LV CMOS

VDD

Zo = 50 Ohm

Ro + Rs = 5 0

Rs

Ro

Zo=50ohm

Zo=50ohm

CLKIN

CLKINB

VersaClock 6 Receiver

Q

nQ

Wiring the CLKIN Pin to Accept Single-ended Inputs

CLKIN cannot take a signal larger than 1.2V pk-pk due to the 1.2V regulated input inside. However, it is internally AC coupled so it is able

to accept both LVDS and LVPECL input signals.

Occasionally, it is desired to have CLKIN to take CMOS levels. Below is an example showing how this can be achieved.

This configuration has three properties:

1. Total output impedance of Ro and Rs matches the 50Ω transmission line impedance.

2. Vrx voltage is generated at the CLKIN which maintains the LVCMOS driver voltage level across the transmission line for best S/N.

3. R1–R2 voltage divider values ensure that Vrx p-p at CLKIN is less than the maximum value of 1.2V.

Figure 12. Recommended Schematic for Driving CLKIN with LVCMOS Driver

VersaClock 6 Receiver

Table 25 shows resistor values that ensure the maximum drive level for the CLKIN port is not exceeded for all combinations of 5%

tolerance on the driver V

DD

, V

and 5% resistor tolerances. The values of the resistors can be adjusted to reduce the loading for

DDO0

slower and weaker LVCMOS driver by increasing the impedance of the R1–R2 divider. To better assist this assessment, the total load

(Ro + Rs + R1 + R2) on the driver is included in the table.

Table 25. Nominal Voltage Divider Values for Overdriving CLKIN with Single-ended Driver

LVCMOS Diver V

DD

Ro + Rs R1 R2 Vrx (peak) Ro+Rs+R1+R2

3.3 50.0 130 75 0.97 255

2.5 50.0 100 100 1.00 250

1.8 50.0 62 130 0.97 242

Driving CLKIN with Differential Clock

CLKIN/CLKINB will accept DC coupled HCSL/LVPECL/LVDS signals.

Figure 13. CLKIN, CLKINB Input Driven by an HCSL Driver

22©2020 Renesas Electronics Corporation August 20, 2020

Page 23

5P49V6965 Datasheet

Output – Single-ended or Differential Clock Terminations

LVDS Termination

For a general LVDS interface, the recommended value for the termination impedance (ZT) is between 90Ω and 132Ω. The actual value

should be selected to match the differential impedance (Zo) of your transmission line. A typical point-to-point LVDS design uses a 100Ω

parallel resistor at the receiver and a 100Ω. differential transmission-line environment. In order to avoid any transmission-line reflection

issues, the components should be surface mounted and must be placed as close to the receiver as possible. The standard termination

schematic as shown in figure Standard Termination or the termination of figure Optional Termination can be used, which uses a center tap

capacitance to help filter common mode noise. The capacitor value should be approximately 50pF. In addition, since these outputs are

LVDS compatible, the input receiver's amplitude and common-mode input range should be verified for compatibility with the Renesas

LVDS output. If using a non-standard termination, it is recommended to contact Renesas and confirm that the termination will function as

intended. For example, the LVDS outputs can be AC coupled by placing capacitors between the LVDS outputs and the 100Ω shunt load.

This is a common practice with receiver with internal self-bias circuitry. If using a non-standard termination, it is recommended to contact

Renesas and confirm that the termination will function as intended.

Figure 14. Standard and Optional Terminations

Standard Termination

Z

LVDS

Driver

Z

O

T

Z

T

LVDS

Receiver

LVDS

Driver

Optional Termination

ZO Z

T

Z

T

2

Z

C

T

LVDS

Receiver

2

23©2020 Renesas Electronics Corporation August 20, 2020

Page 24

5P49V6965 Datasheet

LVPECL

Zo = 50 Ohm

Zo = 50 Ohm

3.3V

R1 R2

3.3V

50 Ohm

50 Ohm

RTT

50 Ohm

Input

+

-

LVPECL

Zo = 50 Ohm

Zo = 50 Ohm

3.3V

+

-

Input

R1 R2

3.3V

84 Ohm

84 Ohm

3.3V

R3 R4

125 Ohm

125 Ohm

2.5V LVPECL

Driver

Zo = 50 Ohm

Zo = 50 Ohm

2.5V

+

-

R2 R4

V

DDO

= 2.5V

62.5 Ohm

62.5 Ohm

2.5V

R1 R3

250 Ohm

250 Ohm

2.5V LVPECL

Driver

Zo = 50 Ohm

Zo = 50 Ohm

2.5V

+

-

R1 R2

V

DDO

= 2.5V

50 Ohm

50 Ohm

2.5V LVPECL

Driver

Zo = 50 Ohm

Zo = 50 Ohm

2.5V

+

-

R1 R2

V

DDO

= 2.5V

50 Ohm

50 Ohm

R3

18 Ohm

LVPECL Termination

The clock layout topology shown below is a typical termination for LVPECL outputs.

The differential outputs generate ECL/LVPECL compatible outputs. Therefore, terminating resistors (DC current path to ground) or

current sources must be used for functionality. These outputs are designed to drive 50Ω transmission lines. Matched impedance

techniques should be used to maximize operating frequency and minimize signal distortion.

For V

= 2.5V, the V

DDO

- 2V is very close to ground level. The R3 in 2.5V LVPECL output termination can be eliminated and the

DDO

termination is shown in Figure 17, 2.5V LVPECL Output Termination.

Figure 15. 3.3V LVPECL Output Termination (1)

Figure 16. 3.3V LVPECL Output Termination (2)

Figure 17. 2.5V LVPECL Output Termination

Figure 18. 2.5V LVPECL Driver Termination (1)

Figure 19. 2.5V LVPECL Driver Termination (2)

24©2020 Renesas Electronics Corporation August 20, 2020

Page 25

HCSL Termination

50 Ohm

HCSL

Zo = 50 Ohm

Zo = 50 Ohm

+

-

50 Ohm

VersaClock 6E Output

Driver

Receiver

33 Ohm

33 Ohm

HCSL

+

-

VersaClock 6E Output

Driver

Receiver

Zo = 50 Ohm

Zo = 50 Ohm

50 Ohm

50 Ohm

33 Ohm

33 Ohm

CMOSD

+

-

VersaClock 6E Output

Driver

Receiver

Zo = 50 Ohm

Zo = 50 Ohm

33 Ohm

33 Ohm

5P49V6965 Datasheet

HCSL termination scheme applies to both 3.3V and 2.5V V

Figure 20. HCSL Receiver Terminated

Figure 21. HCSL Source Terminated

DDO

.

LVCMOS Termination

Each output pair can be configured as a standalone CMOS or dual-CMOS output driver. CMOSD driver termination example is shown

below.

Figure 22. LVCMOS Termination

CMOS1 - Single CMOS active on OUTx pin.

CMOS2 - Single CMOS active on OUTxB pin.

CMOSD - Dual CMOS outputs active on both OUTx and OUTxB pins, 180 degrees out of phase.

CMOSX2 - Dual CMOS outputs active on both OUTx and OUTxB pins, in-phase.

25©2020 Renesas Electronics Corporation August 20, 2020

Page 26

5P49V6965 Datasheet

6965A

ddd

YWW**$

Package Outline Drawings

The package outline drawings are appended at the end of this document and are accessible from the link below. The package information

is the most current data available.

www.idt.com/us/en/document/psc/24-vfqfpn-package-outline-drawing-40-x-40-x-09-mm-body-05mm-pitch-epad-280-x-280-mm-nlg24p2

Marking Diagram

▪ Line 1: truncated part number.

▪ Line 2: “ddd” denotes dash code.

▪ Line 3:

• “YWW” is the last digit of the year and week that the part was assembled.

• “**” denotes sequential lot number.

• “$” denotes mark code.

Ordering Information

Orderable Part Number Package Carrier Type Temperature

5P49V6965AdddNLGI 4 × 4 mm, 0.5mm pitch 24-VFQFPN Tray -40° to +85°C

5P49V6965AdddNLGI8 4 × 4 mm, 0.5mm pitch 24-VFQFPN Tape and Reel -40° to +85°C

5P49V6965A000NLGI 4 × 4 mm, 0.5mm pitch 24-VFQFPN Tray -40° to +85°C

5P49V6965A000NLGI8 4 × 4 mm, 0.5mm pitch 24-VFQFPN Tape and Reel -40° to +85°C

1

“ddd” denotes factory programmed configurations based on required settings. Contact factory for factory programming.

2

“000” denotes un-programmed parts for user customization.

26©2020 Renesas Electronics Corporation August 20, 2020

Page 27

Revision History

Revision Date Description of Change

August 20, 2020 Updated the slew rate terminology in section Driving XIN/REF with a CMOS Driver.

5P49V6965 Datasheet

September 18, 2019

▪ Updated Absolute Maximum Ratings table.

▪ Updated PCI Express Jitter Performance tables (Table 17 and Table 18).

▪ Updated Electrical Characteristics tables (Table 9, Table 11, and Table 14).

June 19, 2019

▪ PCIe specification updated.

▪ Added recommended power ramp time.

▪ Expanded spread spectrum value range.

▪ I2C tolerant voltage footnote changed to 3.3V.

▪ LVDS Termination section allows AC-coupling for LVDS signals.

August 31, 2018 Updated schematics for Driving XIN/REF with a CMOS Driver and Driving XIN with an LVPECL Driver.

March 15, 2018

▪ Updated absolute maximum ratings for supply voltage to 3.6V.

▪ Updated typical and maximum values in Current Consumption table.

▪ Minor updates to AC Timing Characteristics, Electrical Characteristics – CMOS Outputs, and Electrical

Characteristics – LVDS Outputs tables.

November 6, 2017 Initial release.

27©2020 Renesas Electronics Corporation August 20, 2020

Page 28

© Integrated Device Technology, Inc.

24-VFQFPN, Package Outline Drawing

4.0 x 4.0 x 0.90 mm Body,0.50mm Pitch,Epad 2.80 x 2.80 mm

NLG24P2, PSC-4192-02, Rev 02, Page 1

Page 29

© Integrated Device Technology, Inc.

24-VFQFPN, Package Outline Drawing

4.0 x 4.0 x 0.90 mm Body,0.50mm Pitch,Epad 2.80 x 2.80 mm

NLG24P2, PSC-4192-02, Rev 02, Page 2

Package Revision History

Rev No.Date Created

Description

Rev 01

Add Chamfer

Oct 12, 2016

Rev 02

New Format, Recalculate Land Pattern

Nov 2, 2018

Page 30

IMPORTANT NOTICE AND DISCLAIMER

RENESAS ELECTRONICS CORPORATION AND ITS SUBSIDIARIES (“RENESAS”) PROVIDES TECHNICAL

SPECIFICATIONS AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING

REFERENCE DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND

OTHER RESOURCES “AS IS” AND WITH ALL FAULTS, AND DISCL AIMS ALL WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, OR NON-INFRINGEMENT OF THIRD PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for developers skilled in the art designing with Renesas products. You are solely responsible

for (1) selecting the appropriate products for your application, (2) designing, validating, and testing your application, and (3)

ensuring your application meets applicable standards , and any other safety, security, or other requirements. These

resources are subject to change without notice. Renesas grants you permission to use these resources only for

development of an application that uses Renesas products. Other reproduction or use of these resources is strictly

prohibited. No license is granted to any other Renesas intellectual property or to any third party intellectual property.

Renesas disclaims responsibility for, and you will fully indemnify Renesas and its representatives against, any claims,

damages, costs, losses , or liabilities arising out of your use of these resources. Renesas' products are provided only subject

to Renesas' Terms and Conditions of Sale or other applicable terms agreed to in writing. No use of any Renesas resources

expands or otherwise alters any applicable warranties or warranty disclaimers for these products.

Corporate Headquarters

TOYOSU FORESIA, 3-2-24 Toyosu,

Koto-ku, Tokyo 135-0061, Japan

www.renesas .com

Trademarks

Renesas and the Renesas logo are trademarks of Renesas

Electronics Corporation. All trad emarks and registered

trademarks are the property of their respective owners.

(Rev.1.0 Mar 2020)

Contact Information

For further information on a product, technology, the most

up-to-date version of a document, or your nearest sales

office, please visit:

www.renesas .com/contact/

© 2020 Renesas Electronics Corporation. All rights reserved.

Loading...

Loading...