查询M38030F1-XXXHP供应商

3803 Group (Spec.L)

SINGLE-CHIP 8-BIT CMOS MICROCOMPUTER

DESCRIPTION

The 3803 group (Spec.L) is the 8-bit microcomputer based on the

740 family core technology.

The 3803 group (Spec.L) is designed for household products,

office automation equipment, and controlling systems that

require analog signal processing, including the A/D converter

and D/A converters.

FEATURES

• Basic machine-language instructions ................................. 71

• Minimum instruction execution time .......................... 0.24 µs

(at 16.8 MHz oscillation frequency)

• Memory size

Mask ROM/Flash memory ............................ ........ 60 K bytes

RAM ...................................................................... 2048 bytes

• Programmable input/output ports ................ ....................... 56

• Software pull-up resistors............................................ Built-in

• Interrupts

21 sources, 16 vectors........................ .......................................

(external 8, internal 12, software 1)

• Timers .. ............................... ................................ ..... 16-bit × 1

8-bit × 4

(with 8-bit prescaler)

• Serial interface.........8-bit × 2 (UART or Clock-synchronized)

8-bit × 1 (Clock-synchronized)

• PWM ....................................... 8-bit × 1 (with 8-bit prescaler)

• A/D converter ........................................ 10-bit × 16 channels

(8-bit reading enabled)

• D/A converter ............................................ 8-bit × 2 channels

• Watchdog timer ...................................................... 16-bit × 1

• LED direct drive port..............................................................8

• Clock generating circuit ............................. Built-in 2 circuits

(connect to external ceramic resonator or quartz-crystal oscillator)

• Power source voltage (Mask ROM version)

[In high-speed mode]

At 16.8 MHz oscillation frequency ....................4.5 to 5.5 V

At 12.5 MHz oscillation frequency ....................4.0 to 5.5 V

At 8.4 MHz oscillation frequency ......................2.7 to 5.5 V

At 4.2 MHz oscillation frequency ......................2.2 to 5.5 V

At 2.1 MHz oscillation frequency ......................2.0 to 5.5 V

[In middle-speed mode]

At 16.8 MHz oscillation frequency ....................4.5 to 5.5 V

At 12.5 MHz oscillation frequency ....................2.7 to 5.5 V

At 8.4 MHz oscillation frequency ......................2.2 to 5.5 V

At 6.3 MHz oscillation frequency ......................1.8 to 5.5 V

[In low-speed mode]

At 32 kHz oscillation frequency.........................1.8 to 5.5 V

REJ03B0212-0100

Rev.1.00

Apr 2, 2007

• Power source voltage (Flash memory version)

[In high-speed mode]

At 16.8 MHz oscillation frequency....................4.5 to 5.5 V

At 12.5 MHz oscillation frequency............ ........4.0 to 5.5 V

At 8.4 MHz oscillation frequency......................2.7 to 5.5 V

[In middle-speed mode]

At 16.8 MHz oscillation frequency....................4.5 to 5.5 V

At 12.5 MHz oscillation frequency............ ........2.7 to 5.5 V

[In low-speed mode]

At 32 kHz oscillation frequency......................... 2.7 to 5.5 V

• Power dissipation (Mask ROM version)

In high-speed mode ........................................... 40 mW (typ.)

(at 16.8 MHz oscillation frequency, at 5 V power source voltage)

In low-speed mode ................... ......................... 45 µW (typ.)

(at 32 kHz oscillation frequency, at 3 V power source voltage)

• Power dissipation (Flash memory version)

In high-speed mode ........................................ 27.5 mW (typ.)

(at 16.8 MHz oscillation frequency, at 5 V power source voltage)

In low-speed mode ........................................ 1200 µW (typ.)

(at 32 kHz oscillation frequency, at 3 V power source voltage)

• Operating temperature range ............................. −20 to 85 °C

• Packages

SP...............PRDP0064BA-A (64P4B) (64-pin 750 mil SDIP)

......PLQP0064KB-A (64P6Q-A) (64-pin 10 × 10 mm LQFP)

HP

KP

......PLQP0064GA-A (64P6U-A) (64-pin 14 × 14 mm LQFP)

WG ........PTLG0064JA-A (64F0G) (64-pin 6 × 6 mm FLGA)

<Flash memory mode>

• Power source voltage .................. .............. V

• Program/Erase voltage ............................. VCC = 2.7 to 5.5 V

• Programming method .. ............. Programming in unit of byte

• Erasing method ................................................. Block erasing

• Program/Erase control by software command

• Number of times for programming/erasing ...................... 100

<Notes>

The flash memory version cannot be used for application

embedded in the MCU card.

CC = 2.7 to 5.5 V

Rev.1.00 Apr 2, 2007 Page 1 of 117

REJ03B0212-0100

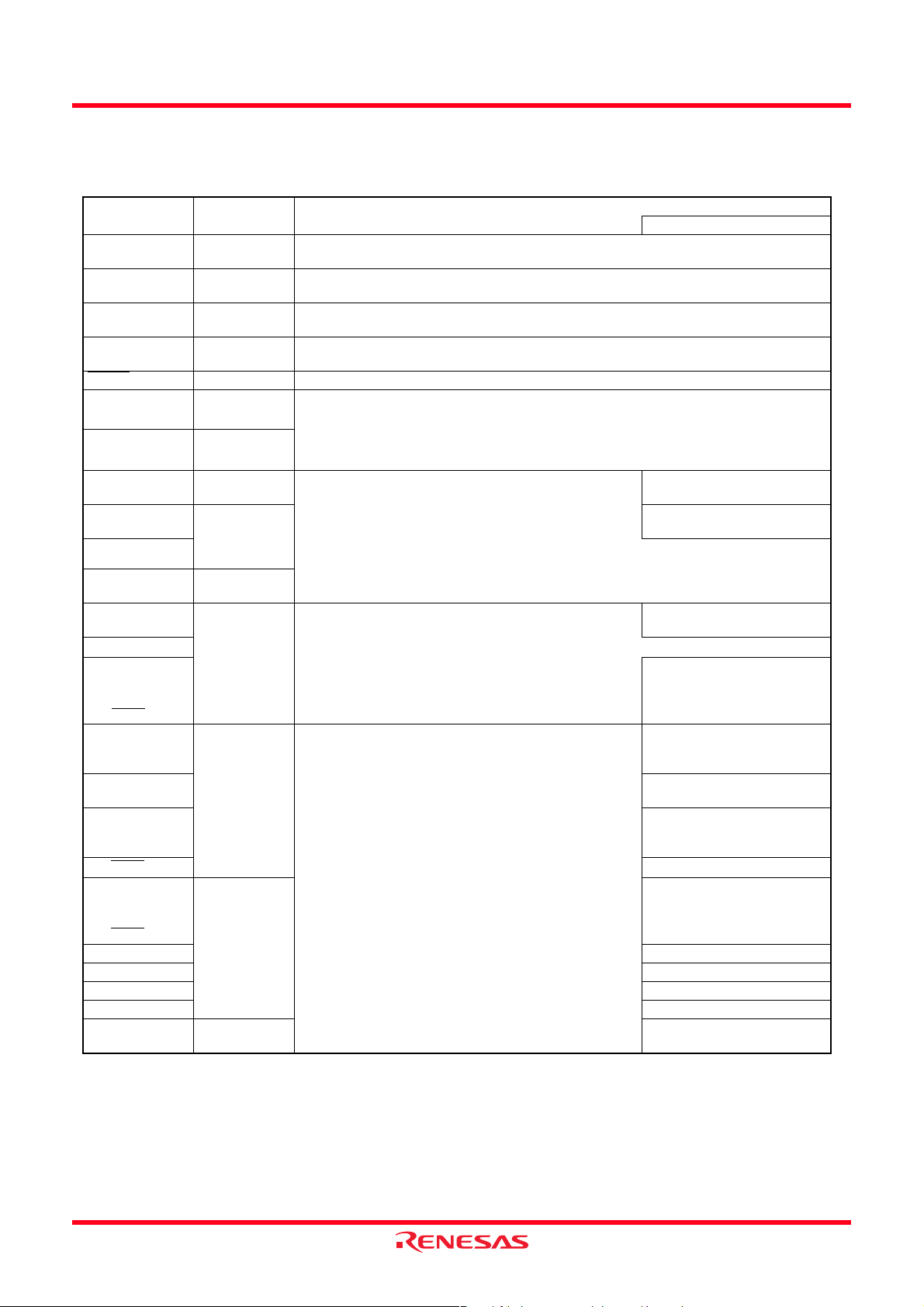

3803 Group (Spec.L)

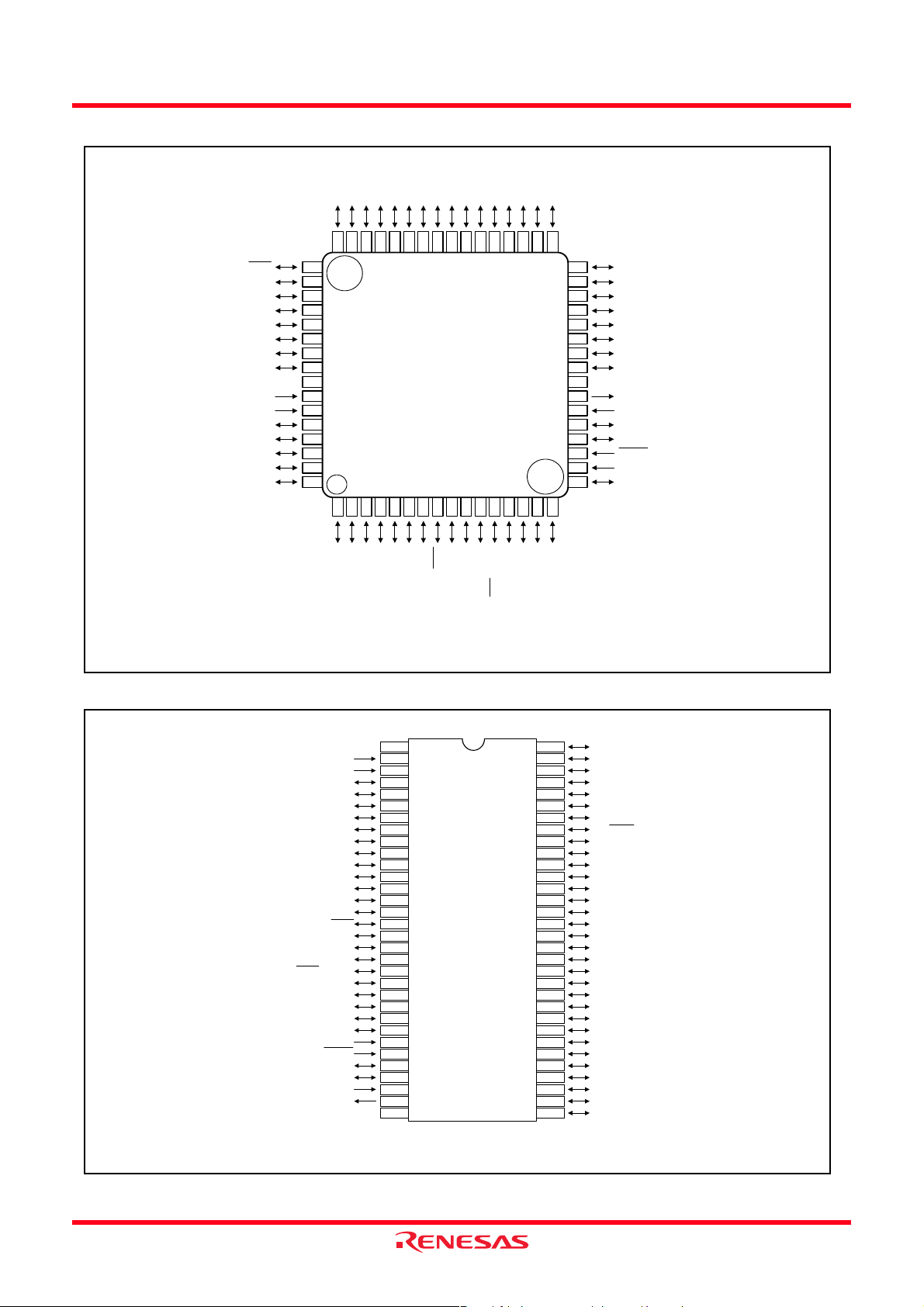

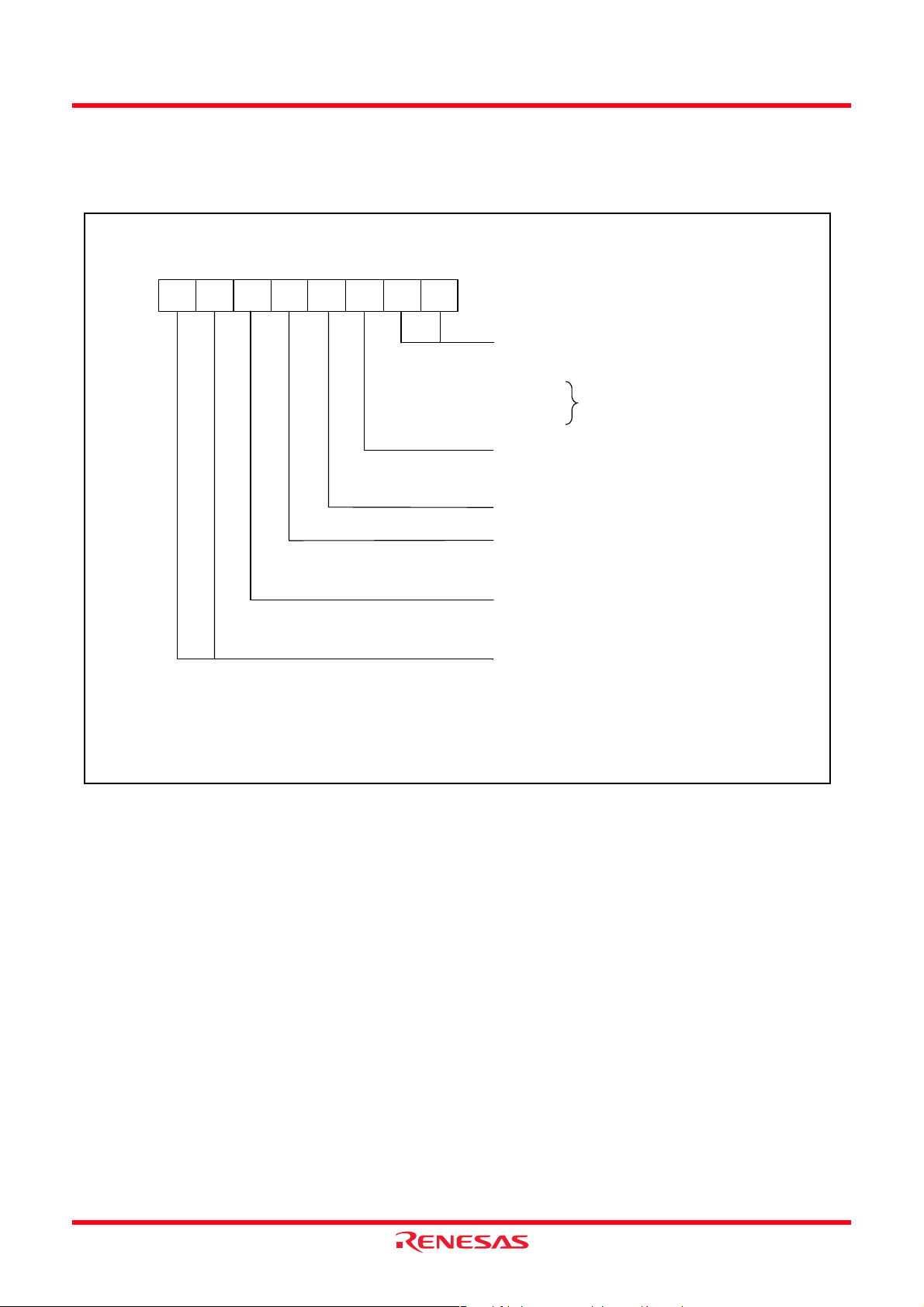

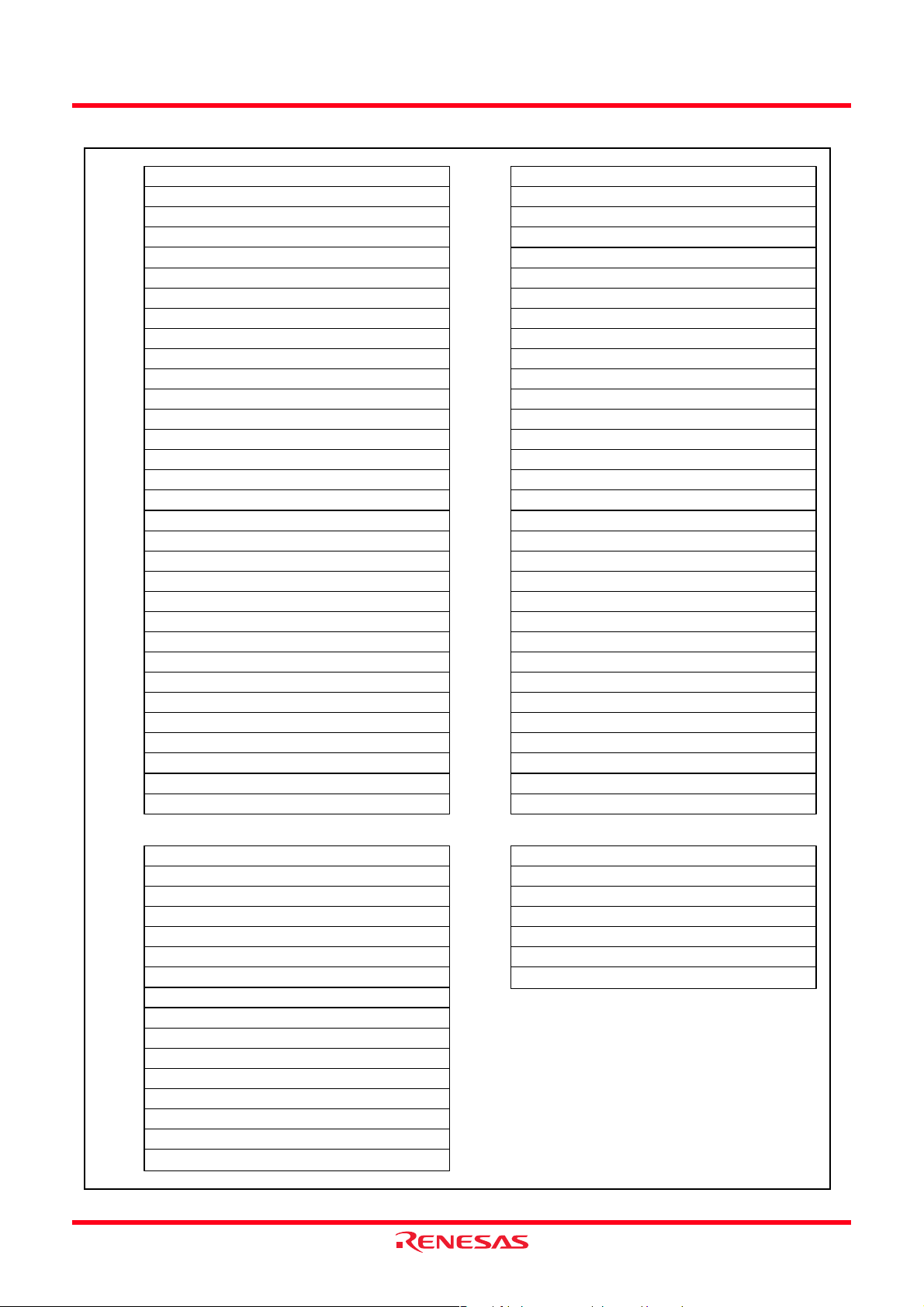

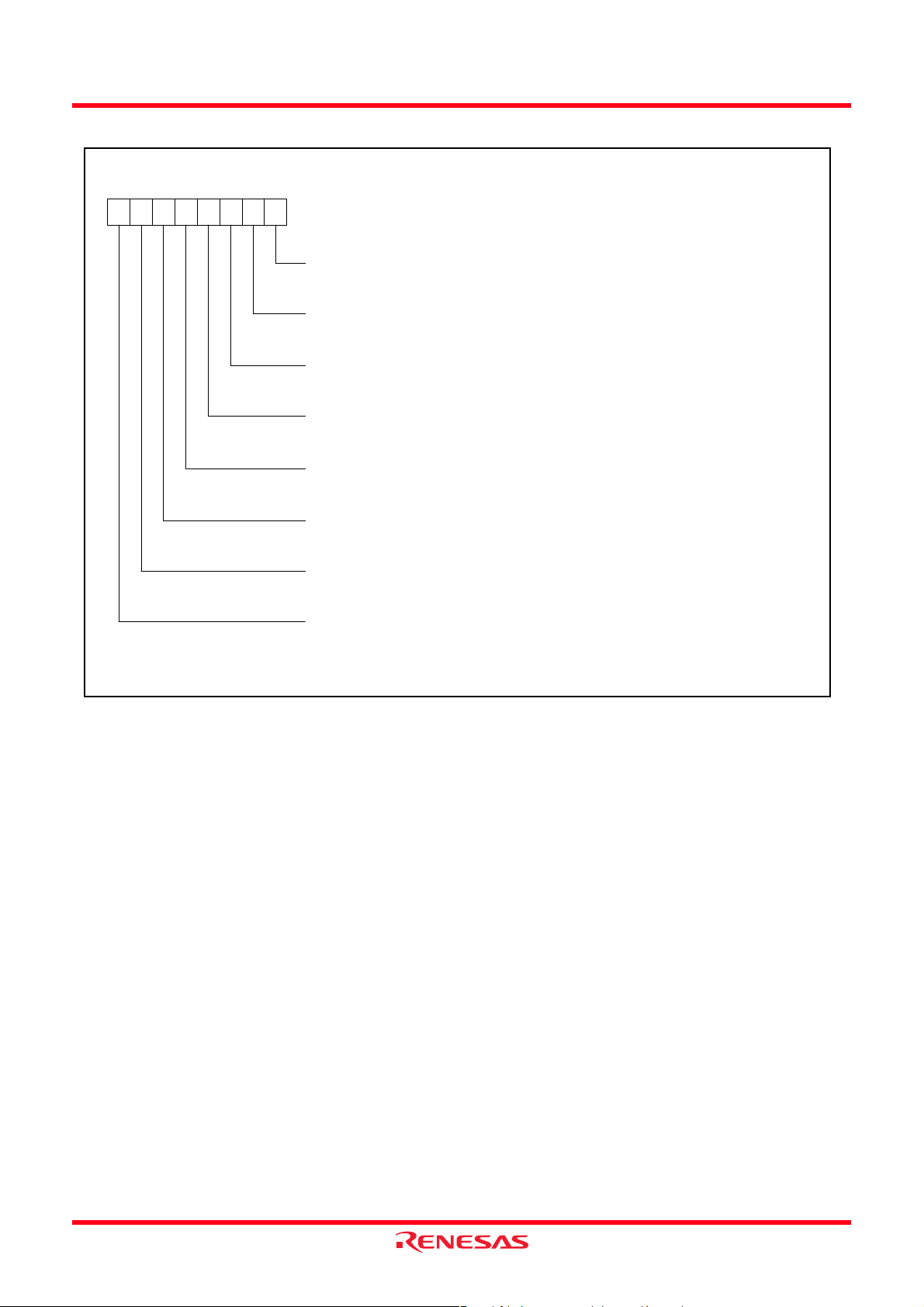

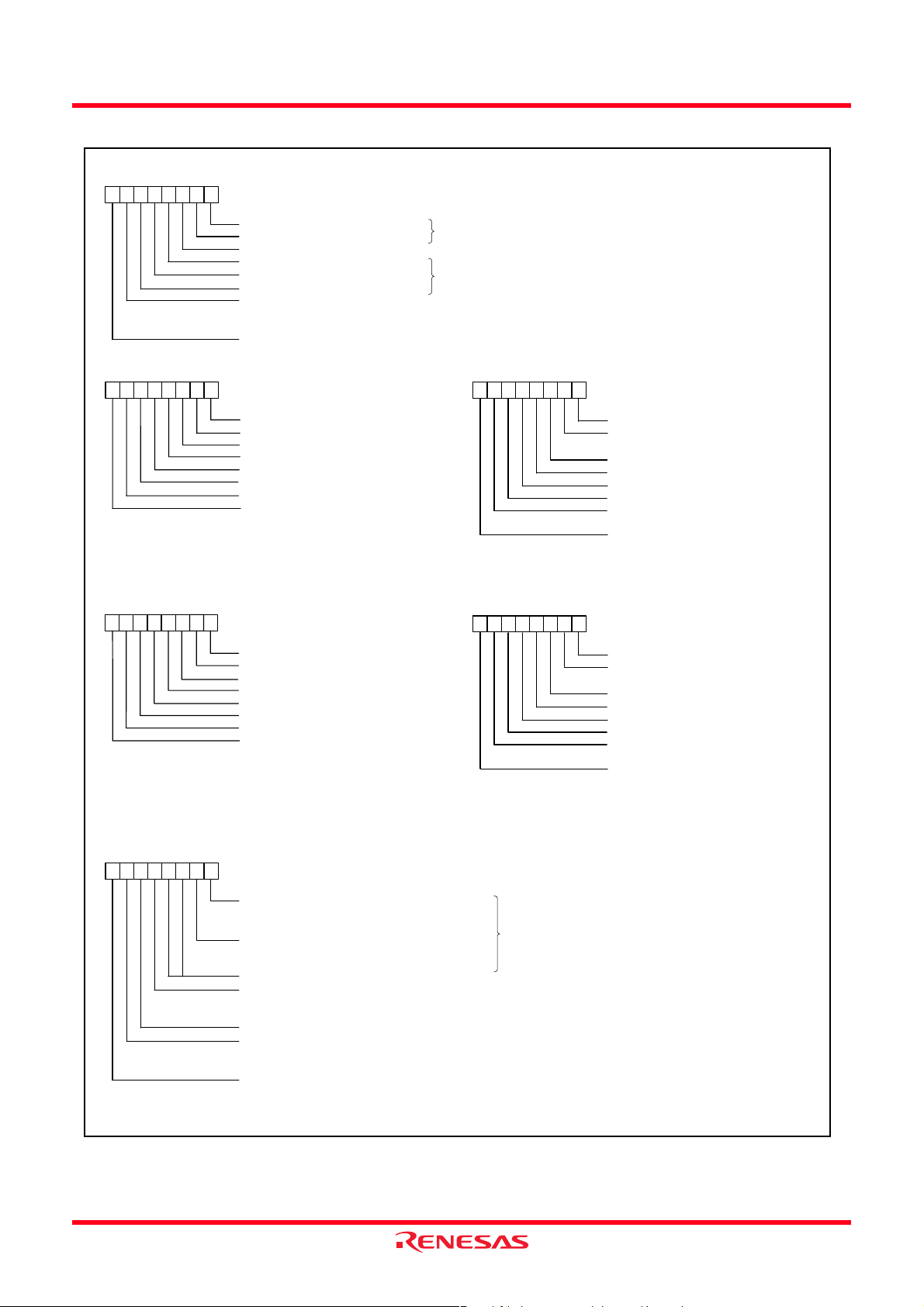

P37/SRDY3

P36/SCLK3

P35/TXD3

P34/RXD3

P33

P32

P31/DA2

P30/DA1

VCC

VREF

AVSS

P67/AN7

P66/AN6

P65/AN5

P64/AN4

P63/AN3

P00/AN8

P01/AN9

P02/AN10

48

474645444342414039383736353433

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

M38039MFL-XXXHP/KP

M38039FFLHP/KP

123456789

P03/AN11

P04/AN12

P05/AN13

P06/AN14

P07/AN15

P10/INT41

P11/INT01

P12

P13

P16

P14

P15

P17

32

P20(LED0)

31

P2

30

29

28

27

26

25

24

23

22

21

20

19

18

17

10111213141516

1(LED1)

P2

2(LED2)

3(LED3)

P2

4(LED4)

P2

P2

5(LED5)

P2

6(LED6)

P27(LED7)

VSS

XOUT

XIN

P40/INT40/XCOUT

P41/INT00/XCIN

RESET

SS

CNV

P42/INT1

P61/AN1

P60/AN0

P62/AN2

5/CNT R1

P57/INT3

P56/PWM

P54/CNT R0

P5

P50/SIN2

P52/SCLK2

P51/SOUT2

P53/SRDY2

P47/SRDY1/C NTR2

P43/INT2

P45/TXD1

P44/RXD1

P46/SCLK1

Package code : PLQP0064KB-A (64P6Q-A)/PLQP0064GA-A (64P6U-A)

Fig 1. Pin configuration (Top view) PLQP0064KB-A (64P6Q-A)/PLQP0064GA-A (64P6U-A)

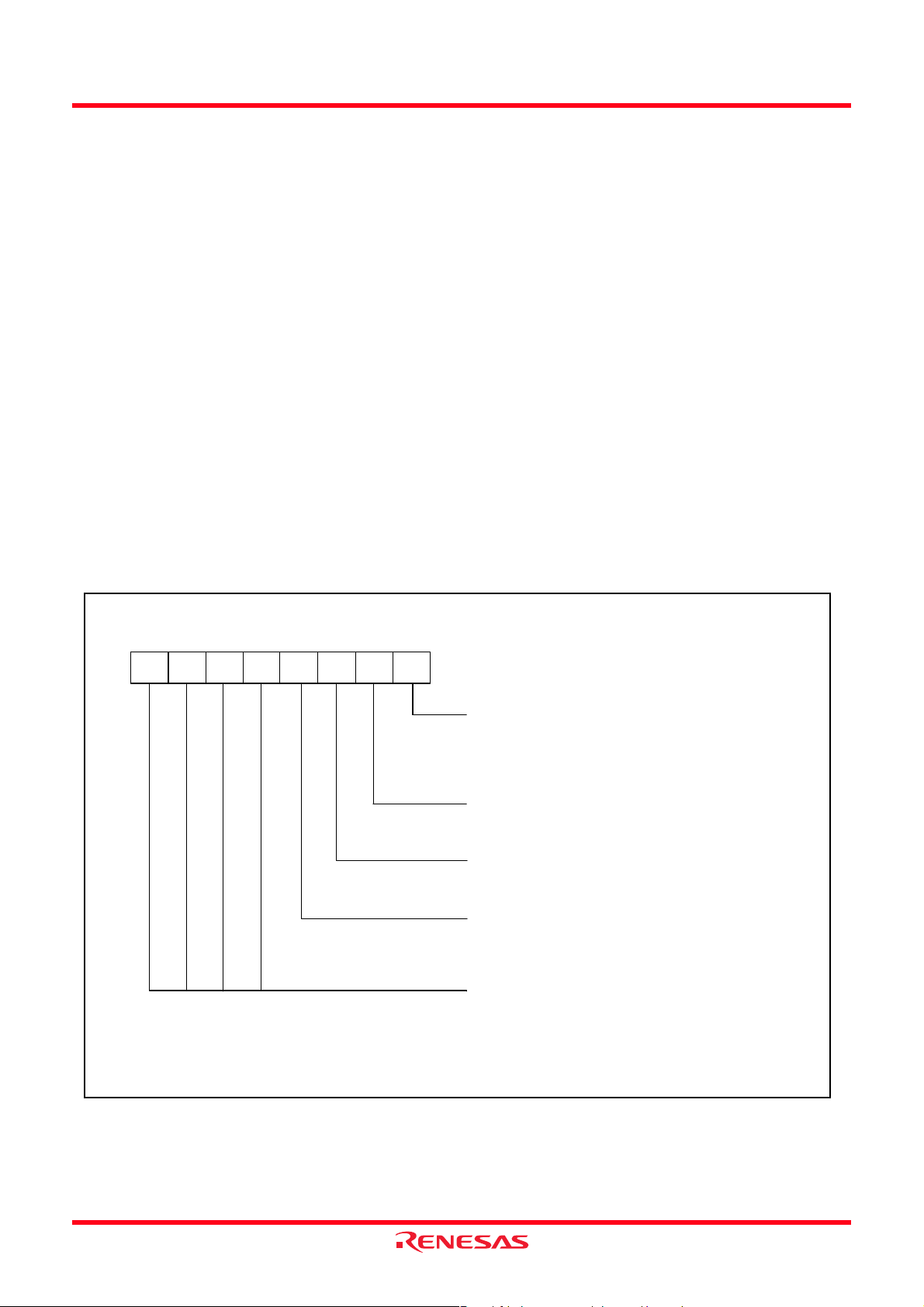

VREF

AVSS

P67/AN7

P66/AN6

P65/AN5

P64/AN4

P63/AN3

P62/AN2

P61/AN1

P60/AN0

P57/INT3

P56/PWM

5/CNTR1

P5

P54/CNTR0

P53/SRDY2

P52/SCLK2

P51/SOUT2

P50/SIN2

P47/SRDY1/CNTR2

P46/SCLK1

P45/TXD1

P44/RXD1

P43/INT2

P42/INT1

CNVSS

RESET

P4

1/INT00/XCIN

P40/INT40/XCOUT

XOUT

VCC

XIN

VSS

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

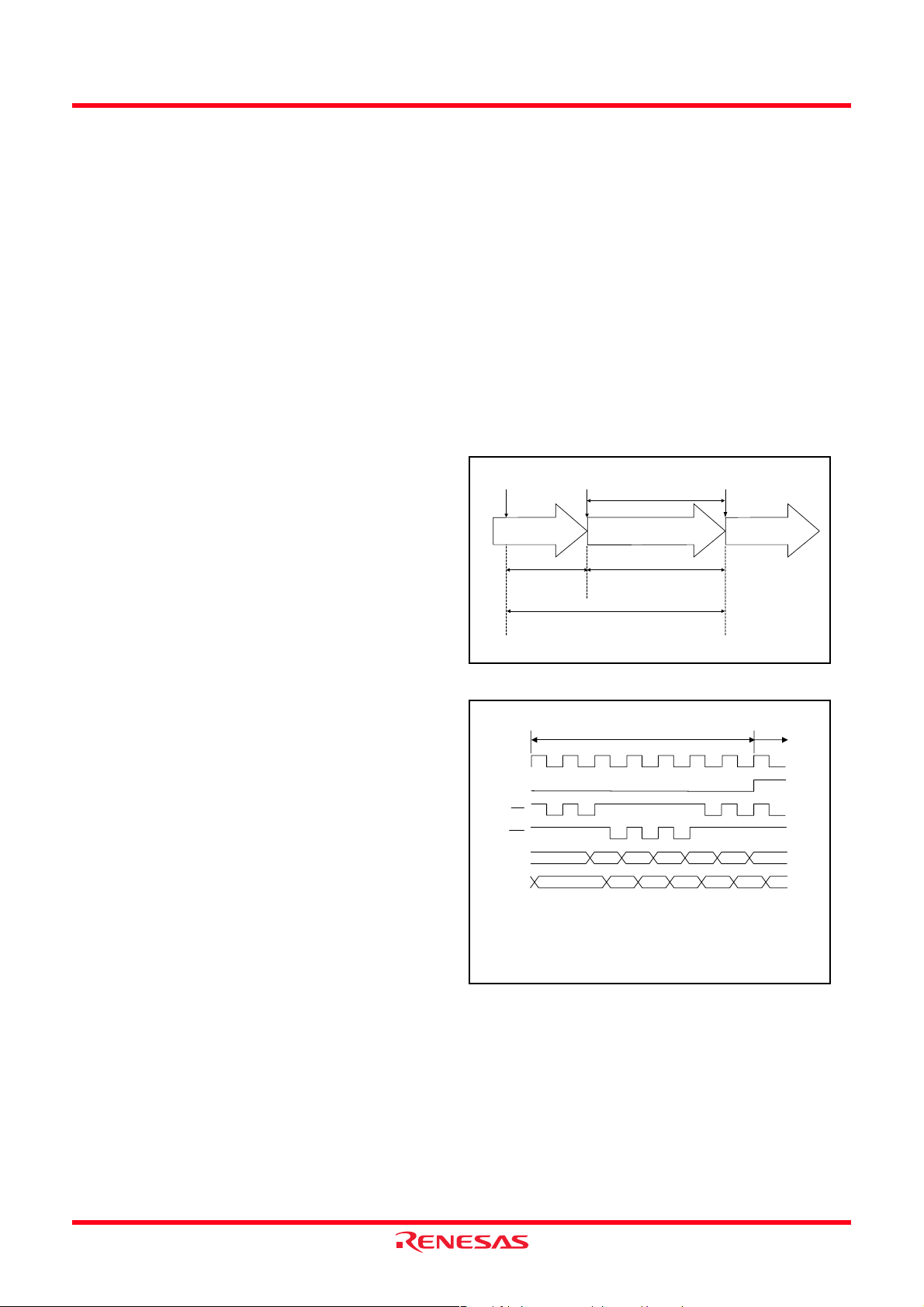

M38039MFL-XXXSP

M38039FFLSP

641

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

P30/DA1

P31/DA2

P32

P33

P34/RXD3

P35/TXD3

P36/SCLK3

P37/SRDY3

P00/AN8

P01/AN9

P02/AN10

P03/AN11

P04/AN12

P05/AN13

P06/AN14

P07/AN15

P10/INT41

P11/INT01

P1

2

P13

P14

P15

P16

P17

P20(LED0)

1(LED1)

P2

P2

2(LED2)

P23(LED3)

P2

4(LED4)

P2

5(LED5)

P2

6(LED6)

P27(LED7)

Package code : PRDP0064BA-A (64P4B)

Fig 2. Pin configuration (Top view) (PRDP0064BA-A (64P4B))

Rev.1.00 Apr 2, 2007 Page 2 of 117

REJ03B0212-0100

3803 Group (Spec.L)

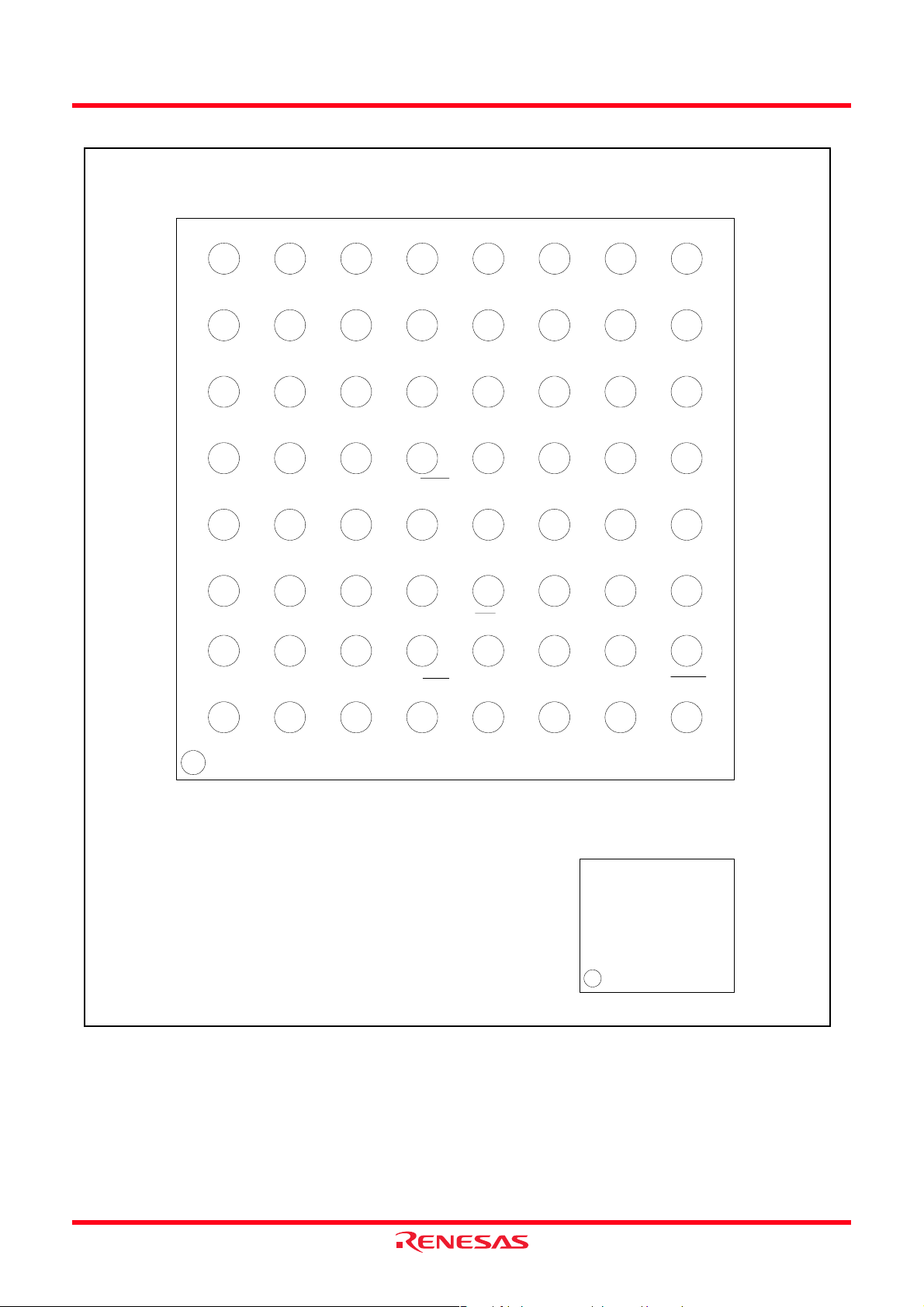

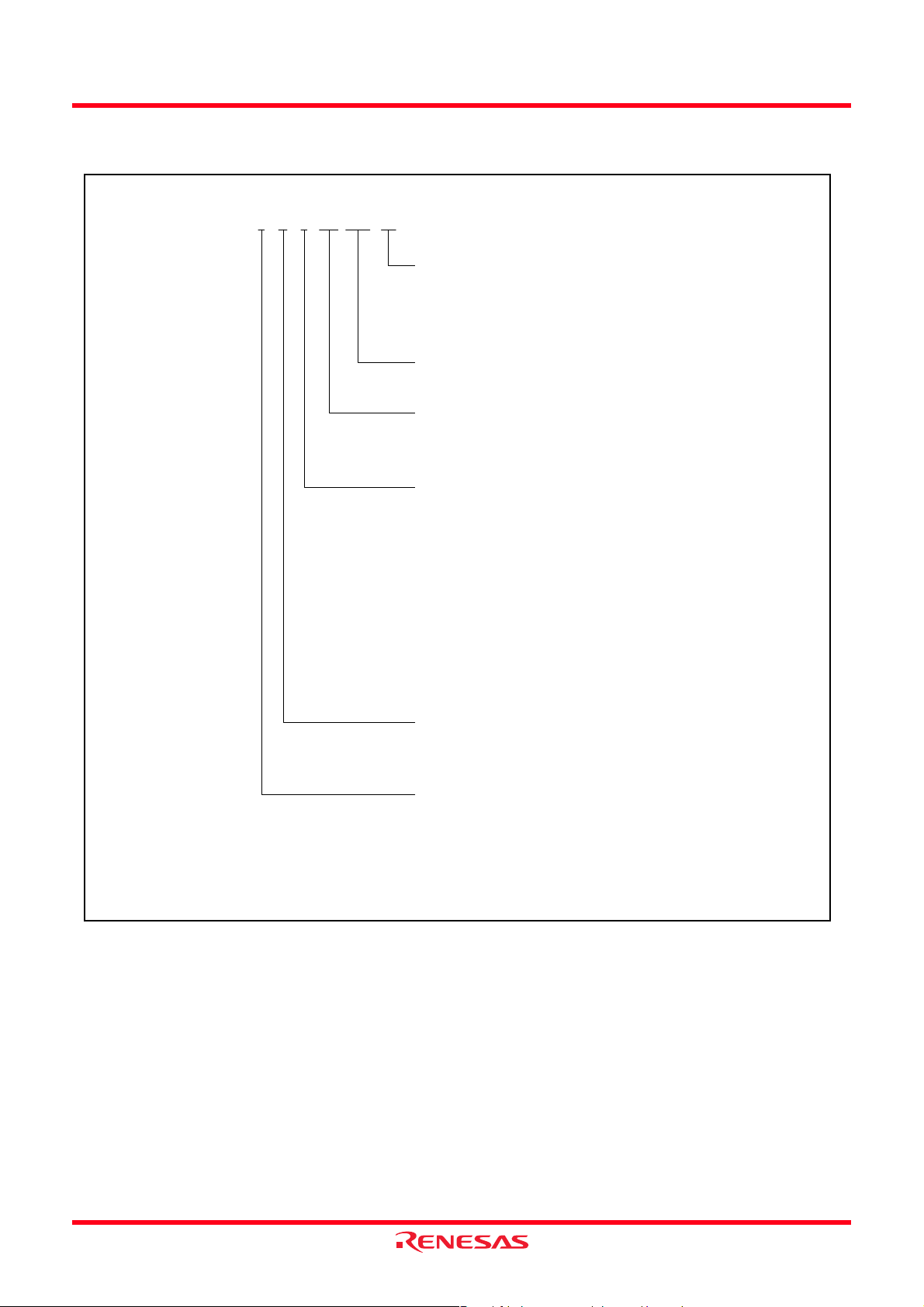

PIN CONFIGURATION (TOP VIEW)

ABCDEFGH

8

7

6

5

4

3

2

50 46 44 41 40 32 31 30

P3

6/SCLK3 P02/AN10 P04/AN12 P07/AN15 P10/INT41 P20(LED0)P21(LED1)P22(LED2)

51 47 45 42 39 27 29 28

P3

5/TXD3 P01/AN9 P03/AN11 P06/AN14 P11/INT01 P25(LED5)P23(LED3)P24(LED4)

53 52 48 43 38 37 26 25

P33 P34/RXD3 P00/AN8 P05/AN13 P12 P13 P26(LED6)P27(LED7)

56 55 54 49 33 36 35 34

P30/DA1 P31/DA2 P32 P37/SRDY3 P17 P14 P15 P16

1 64 58 59 57 24 22 23

2/AN2 P63/AN3 VREF AVSS VCC VSS XIN XOUT

P6

60 61 4 7 12 14 21 20

P67/AN7 P66/AN6 P57/INT3 P54/CNTR0

P4

7/SRDY1/CNTR2

P45/TXD1

P4

62 63 5 8 10 13 17 19

P65/AN5 P64/AN4 P56/PWM P53/SRDY2 P51/SOUT2 P46/SCLK1 P42/INT1 RESET

0/INT40/XCOUT

8

7

6

5

4

3

P41/INT00/XCIN

2

1

2 3 6 9 11 15 16 18

P61/AN1 P60/AN0 P55/CNTR1 P52/SCLK2 P50/SIN2 P44/RXD1 P43/INT2 CNVSS

ABCDEFGH

Package code : PTLG0064JA-A (64F0G)

Note : The numbers in circles corresponds with the number on the packages FP/HP/KP.

Fig 3. Pin configuration (Top view) (PTLG0064JA-A (64F0G))

1

M38039MFL

-XXXWG

M38039

FFLWG

Package (TOP VIEW)

Rev.1.00 Apr 2, 2007 Page 3 of 117

REJ03B0212-0100

3803 Group (Spec.L)

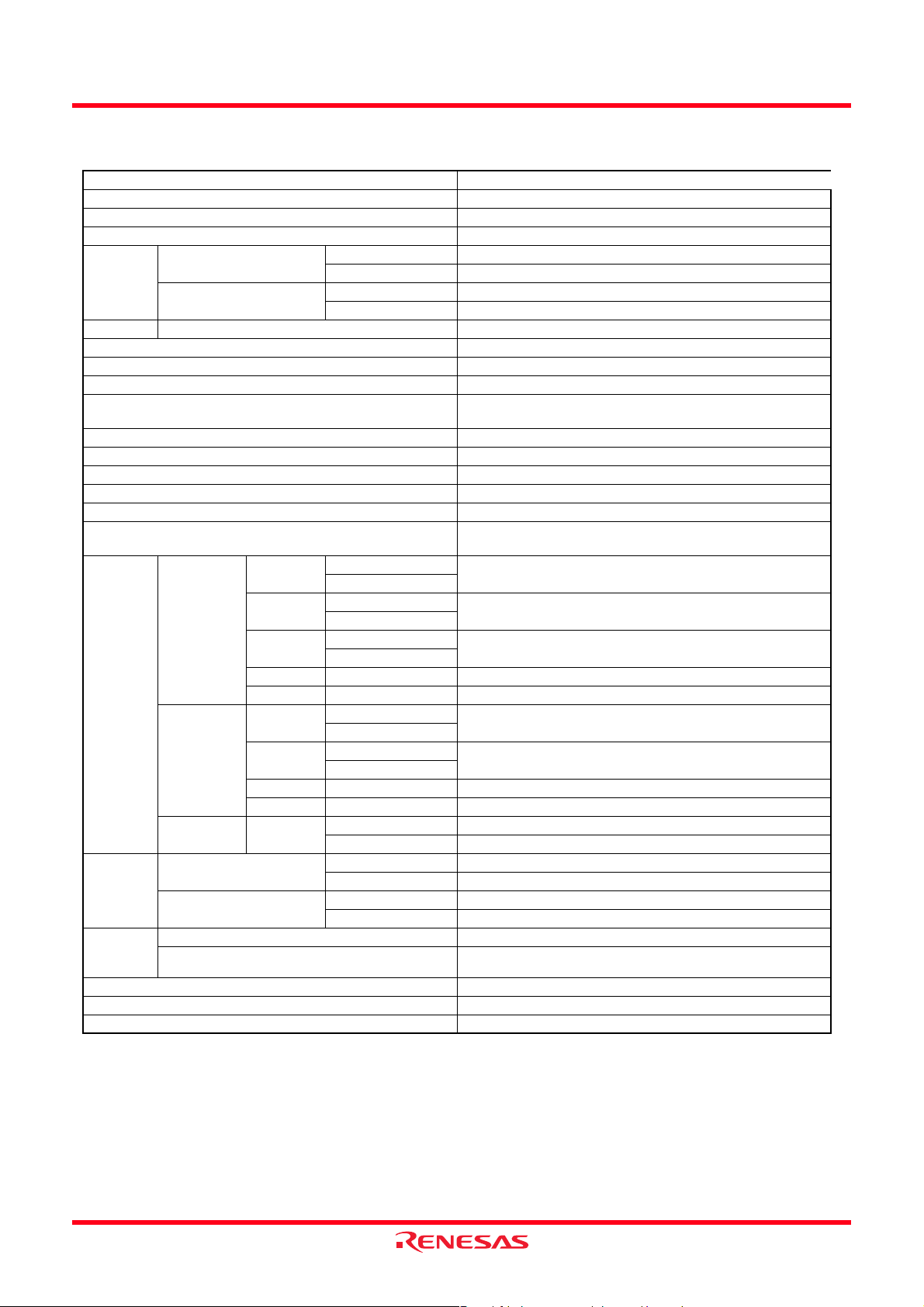

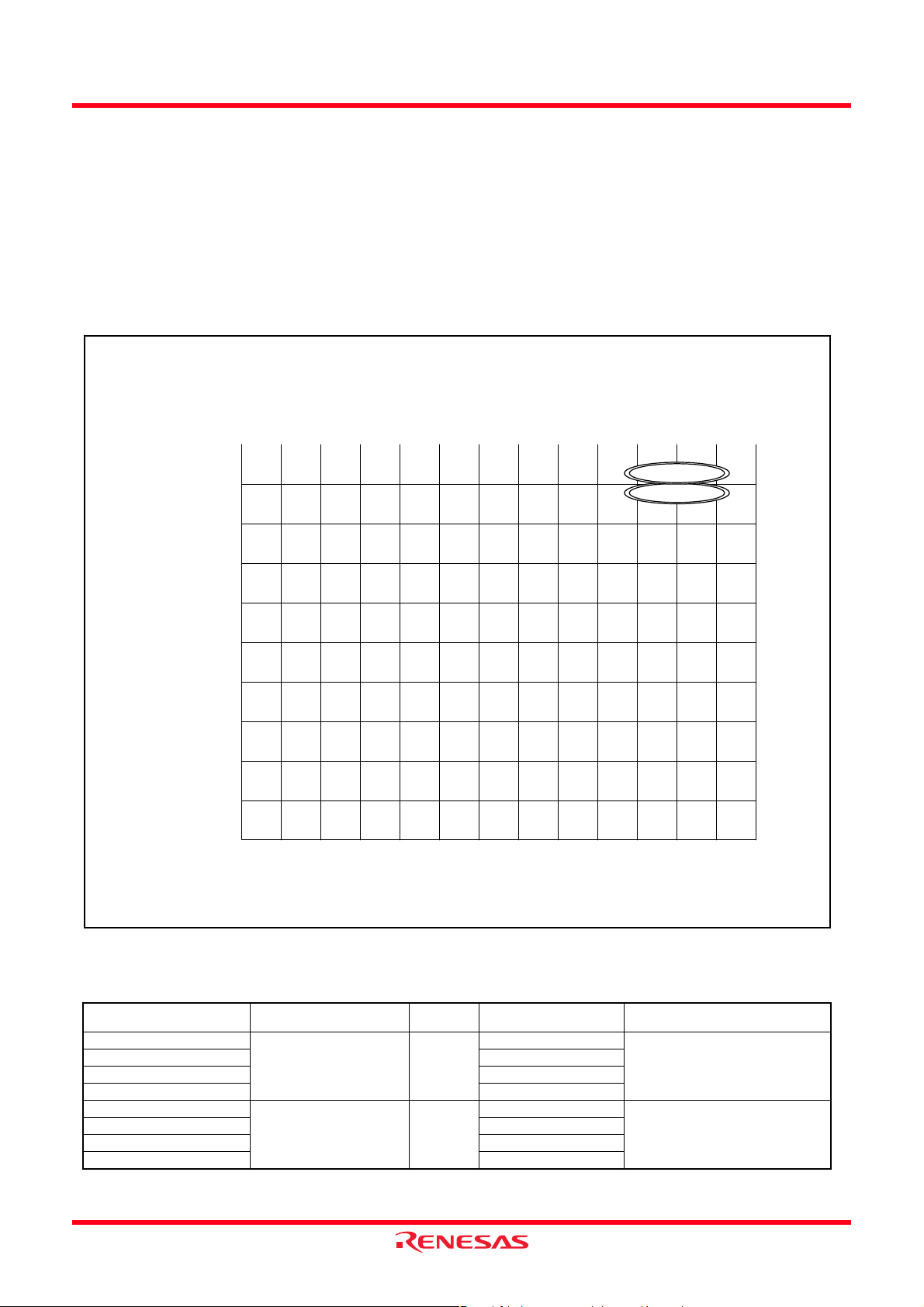

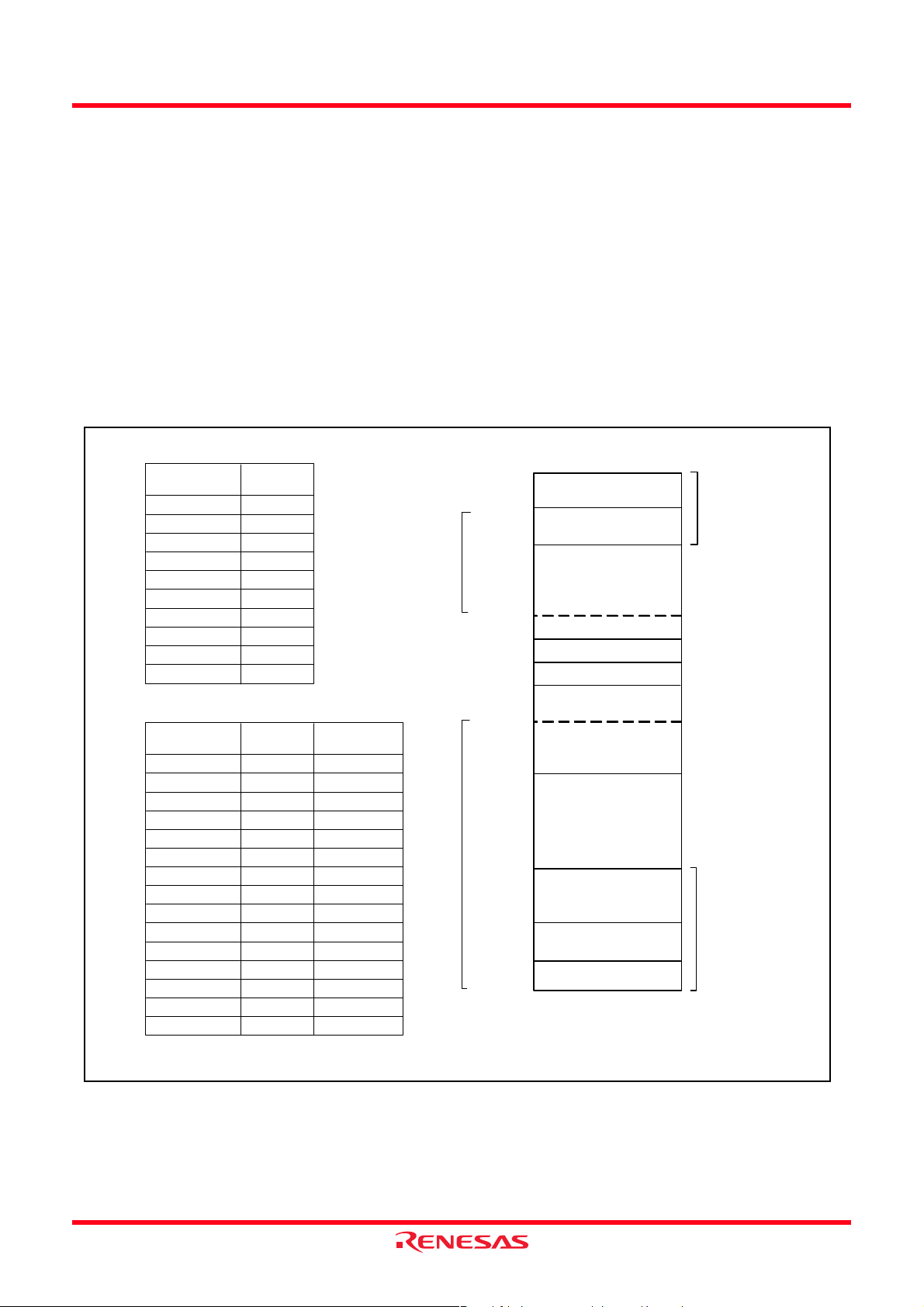

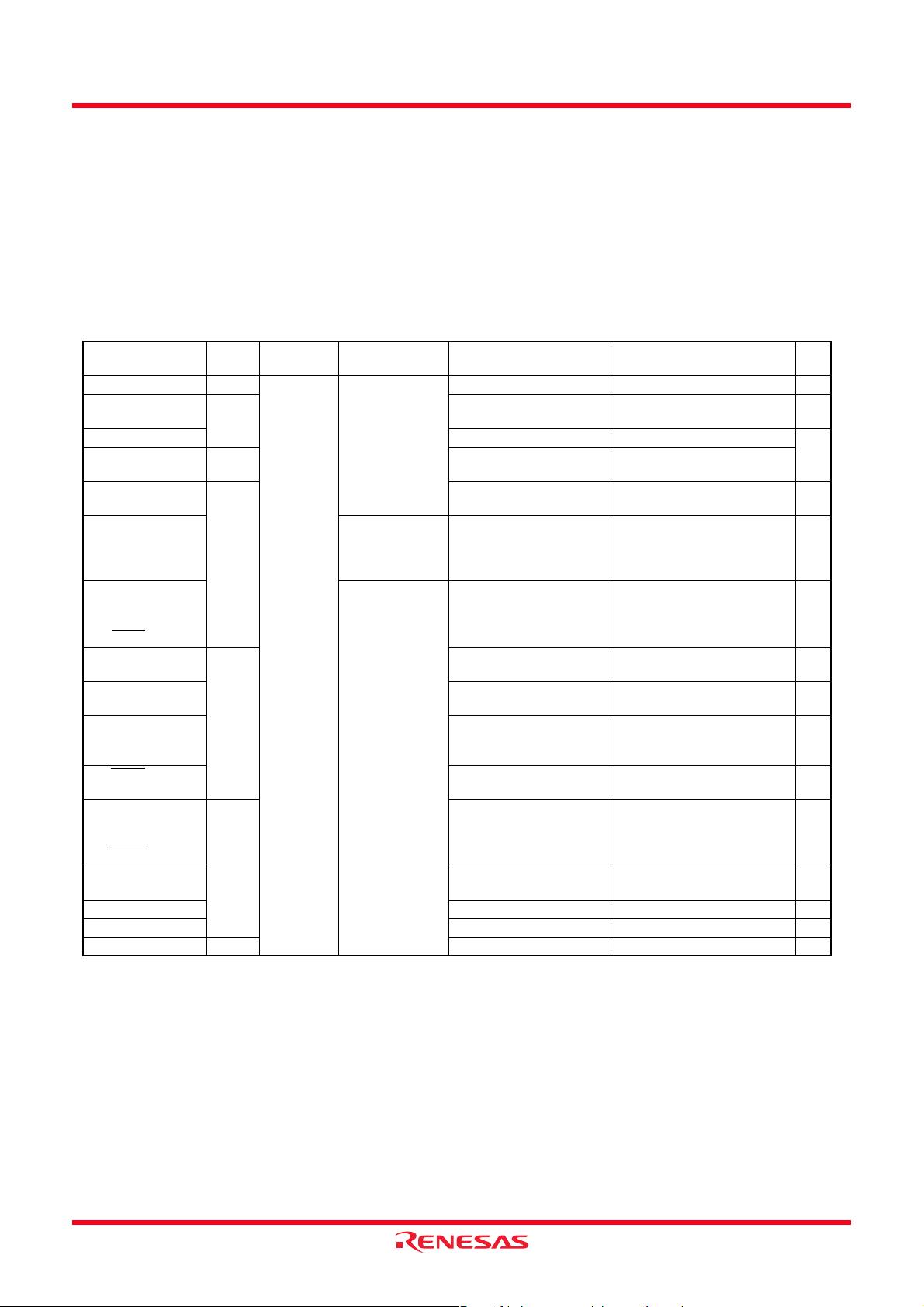

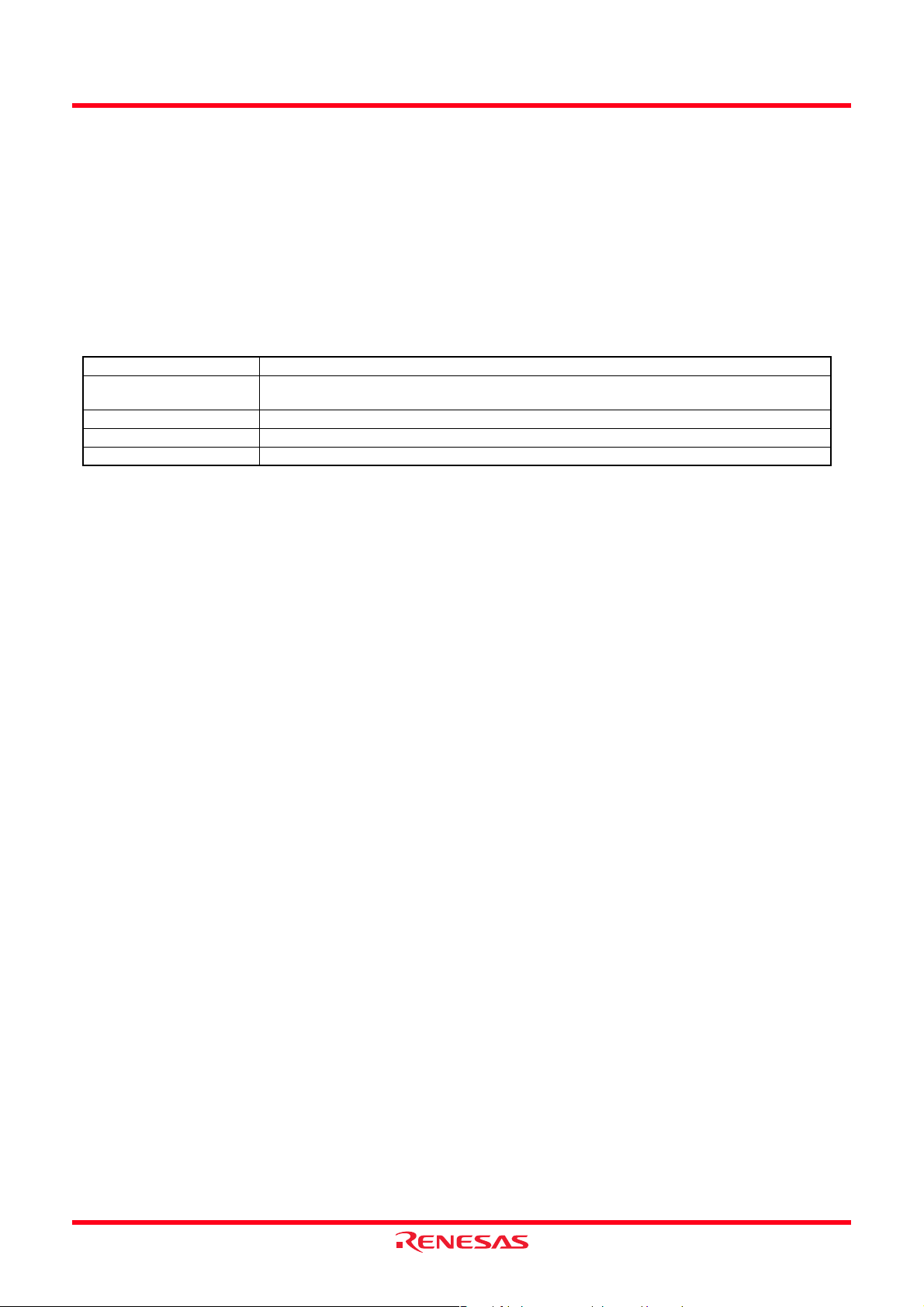

Table 1 Performance overview

Parameter Function

Number of basic instructions 71

Minimum instruction execution time 0.24 µs (Oscillation frequency 16.8 MHz)

Oscillation frequency Oscillation frequency 16.8 MHz(Maximum)

Memory

sizes

I/O port P0-P6 56 pins

Software pull-up resistors Built-in

Interrupt 21 sources, 16 vectors (8 external, 12 internal, 1 software)

Timer 8-bit × 4 (with 8-bit prescaler), 16-bit × 1

Serial interface 8-bit × 2 (UART or Clock-synchronized)

PWM 8-bit × 1 (with 8-bit prescaler)

A/D converter 10-bit × 16 channels (8-bit reading enabled)

D/A converter 8-bit × 2 channels

Watchdog timer 16-bit × 1

LED direct drive port

Clock generating circuits Built-in 2 circuits

Power

source

voltage

Power

dissipation

Input/Output

characteristics

Operating temperature range -20 to 85 °C

Device structure CMOS sillicon gate

Package 64-pin plastic molded SDIP/LQFP/FLGA

Mask ROM version ROM 60 Kbytes

RAM 2048 bytes

Flash memory version ROM 60 Kbytes

RAM 2048 bytes

8-bit × 1 (Clock-synchronized)

8 (average current: 15 mA, peak current: 30 mA, total current: 90 mA)

(connect to external ceramic rasonator or quartz-crystal oscillator)

In high-speed

mode

In middlespeed mode

In low-speed

mode

In high-speed mode Mask ROM version 40 mW

In low-speed mode Mask ROM version 45 µW

Input/Output withstand voltage VCC

Output current 10 mA

At 16.8 MHz

At 12.5 MHz

At 8.4 MHz

At 4.2 MHz Mask ROM version 2.2 to 5.5 V

At 2.1 MHz Mask ROM version 2.0 to 5.5 V

At 16.8 MHz

At 12.5 MHz

At 8.4 MHz Mask ROM version 2.2 to 5.5 V

At 6.3 MHz Mask ROM version 1.8 to 5.5 V

At 32 MHz

Mask ROM version

Flash memory version

Mask ROM version

Flash memory version

Mask ROM version

Flash memory version

Mask ROM version

Flash memory version

Mask ROM version

Flash memory version

Mask ROM version 1.8 to 5.5 V

Flash memory version 2.7 to 5.5 V

Flash memory version 27.5 mW

Flash memory version 1200 µW

4.5 to 5.5 V

4.0 to 5.5 V

2.7 to 5.5 V

4.5 to 5.5 V

2.7 to 5.5 V

Rev.1.00 Apr 2, 2007 Page 4 of 117

REJ03B0212-0100

3803 Group (Spec.L)

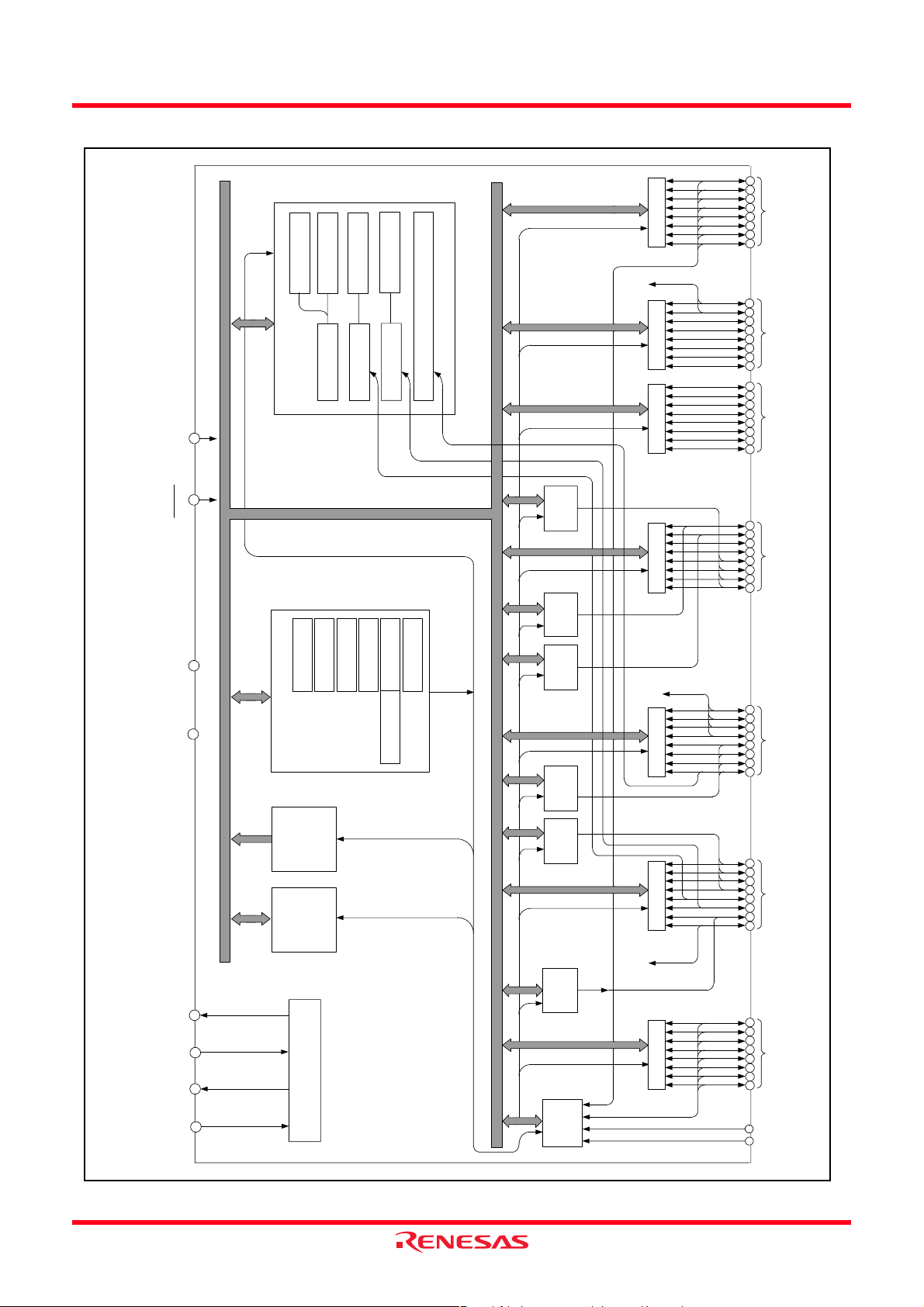

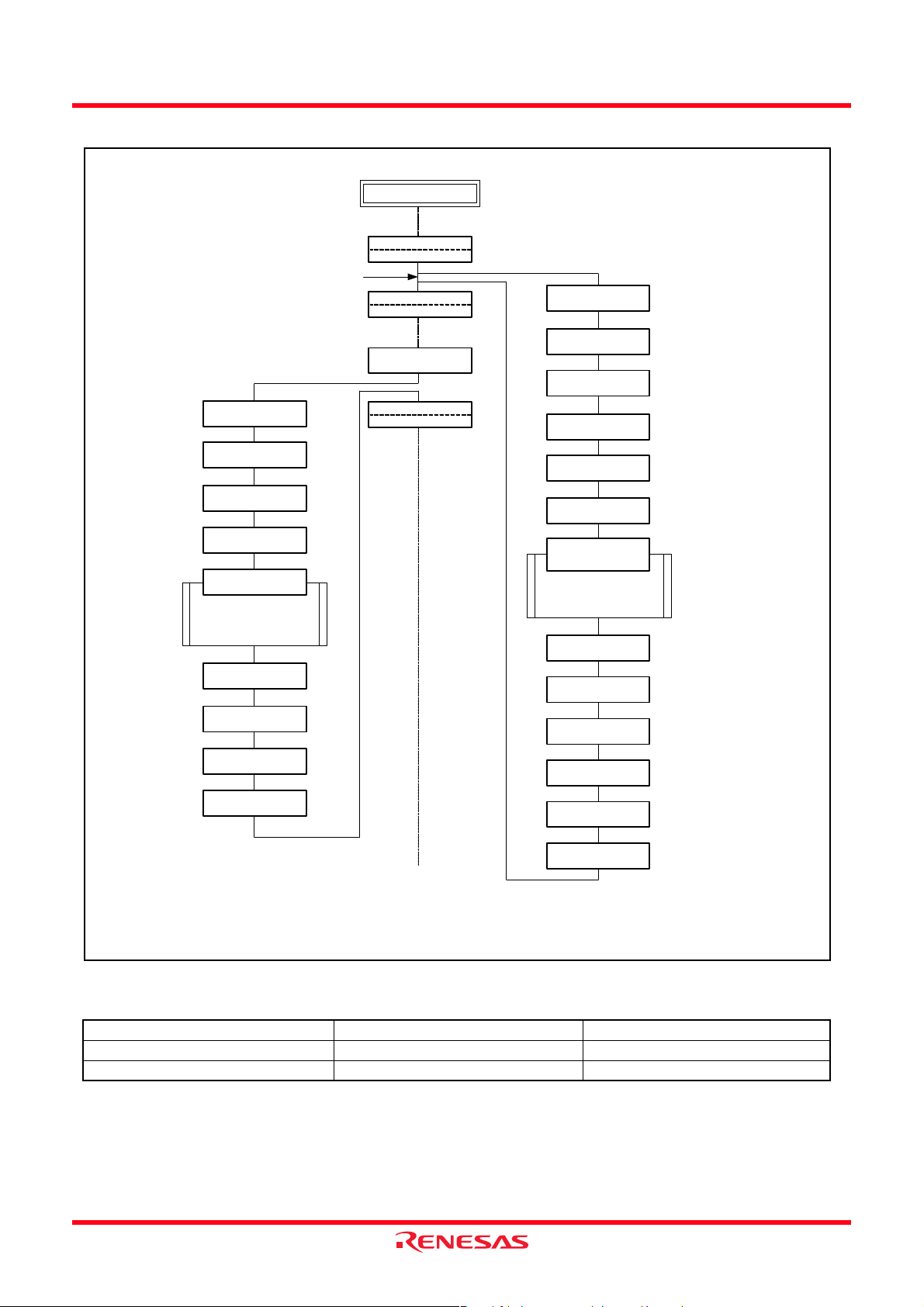

Reset in p ut

26

CNVSS

27

RESET

1

VCC

32

VSS

P0 (8)

Timer 1 (8 )

Timer 2 (8 )

Timer Y (8)

Timer X (8 )

INT01

INT41

Timer Z (16)

P1 (8)

Prescaler Y (8)

Prescaler X (8)

Prescaler 12 (8)

CNTR0

CNTR1

CNTR2

SI/O3 (8)

P2 (8)

P3 (8)

D/A

1 (8)

converter

A

X

Y

S

PS

PCLPCH

Data bus

D/A

2 (8)

converter

INT00

INT1

INT2

INT40

I/O port P0

49 50 51 52 5354 55 56

44 46 48

43 45 47

I/O port P1

42

41

I/O port P2

(LED drive)

33 35 37 3934 36 38 40

I/O port P3

58 6259 61 6360 6457

C P U

0

P4 (8)

I/O port P4

21 2522 24 2823 2920

R A M R O M

29

Sub-clock

output

28

XCIN XCOUT

Sub-clock

input

31

Main

clock

output

30

XIN XOUT

Main

clock

input

Clock generating circuit

FUNCTIONAL BLOCK DIAGRAM (Package: PRDP0064BA-A (64P4B))

Fig 4. Functional block diagram

Rev.1.00 Apr 2, 2007 Page 5 of 117

REJ03B0212-0100

SI/O2 (8) SI/O1 (8)

P5 (8)

INT3

PWM (8)

P6 (8)

A/D

(10)

converter

1912

13 1714 16 1815

4681057911

3

2

I/O port P5

I/O port P6

AVSS

VREF

3803 Group (Spec.L)

PIN DESCRIPTION

Table 2 P in des c r iption

Pin Name Functions

CC, VSS Power source • Apply voltage of 1.8 V − 5.5 V to VCC, and 0 V to VSS. In the flash memory version, apply

V

SS CNVSS input • This pin controls the operation mode of the chip.

CNV

REF Reference

V

voltage of 2.7 V − 5.5 V to V

• Normally connected to V

CC.

SS.

• Reference voltage input pin for A/D and D/A converters.

Function except a port function

voltage

SS Analog power

AV

source

RESET

IN Main clock input • Input and output pins for the clock generating circuit.

X

OUT Main clock

X

Reset input • Reset input pin for active “L”.

output

P0

P0

P1

0/AN8−

7/AN15

0/INT41

I/O port P0 • 8-bit CMOS I/O port.

I/O port P1 • Interrupt input pin

P11/INT01

2−P17

P1

P20(LED0)P2

7(LED7)

0/DA1

P3

I/O port P2

I/O port P3 • 8-bit CMOS I/O port.

P31/DA2

P3

2, P33

P34/RXD3

P35/TXD3

P36/SCLK3

P37/SRDY3

0/INT40/XCOUT

P4

I/O port P4 • 8-bit CMOS I/O port.

P41/INT00/XCIN

P4

2/INT1

P43/INT2

4/RXD1

P4

• Analog power source input pin for A/D and D/A converters.

• Connect to V

SS.

• Connect a ceramic resonator or quartz-crystal oscillator between the X

the oscillation frequency.

• When an external clock is used, connect the clock source to the X

IN pin and leave the XOUT pin

open.

• A/D converter input pin

• I/O direction register allows each pin to be individually

programmed as either input or output.

• CMOS compatible input level.

• CMOS 3-state output structure.

• Pull-up control is enabled in a bit unit.

•P2

0 − P27 (8 bits) are enabled to output large current for

LED drive.

• D/A converter input pin

• I/O direction register allows each pin to be individually

programmed as either input or output.

• CMOS compatible input level.

•P3

0, P31, P34 − P37 are CMOS 3-state output structure.

•P3

2, P33 are N-channel open-drain output structure.

• Pull-up control of P3

0, P31, P34 − P37 is enabled in a bit unit.

• Serial I/O3 function pin

• Interrupt input pin

• I/O direction register allows each pin to be individually

programmed as either input or output.

• CMOS compatible input level.

• Sub-clock generating I/O pin

(resonator connected)

• Interrupt input pin

• CMOS 3-state output structure.

• Pull-up control is enabled in a bit unit.

• Serial I/O1 function pin

IN and XOUT pins to set

P45/TXD1

P46/SCLK1

P4

7/SRDY1/CNTR2

0/SIN2

P5

I/O port P5 • Serial I/O2 function pin

• Serial I/O1, timer Z function pin

P51/SOUT2

P52/SCLK2

P53/SRDY2

4/CNTR0 • Timer X function pin

P5

5/CNTR1 • Timer Y function pin

P5

6/PWM • PWM output pin

P5

7/INT3 • Interrupt input pin

P5

P6

P6

0/AN0−

7/AN7

I/O port P6 • A/D converter input pin

Rev.1.00 Apr 2, 2007 Page 6 of 117

REJ03B0212-0100

3803 Group (Spec.L)

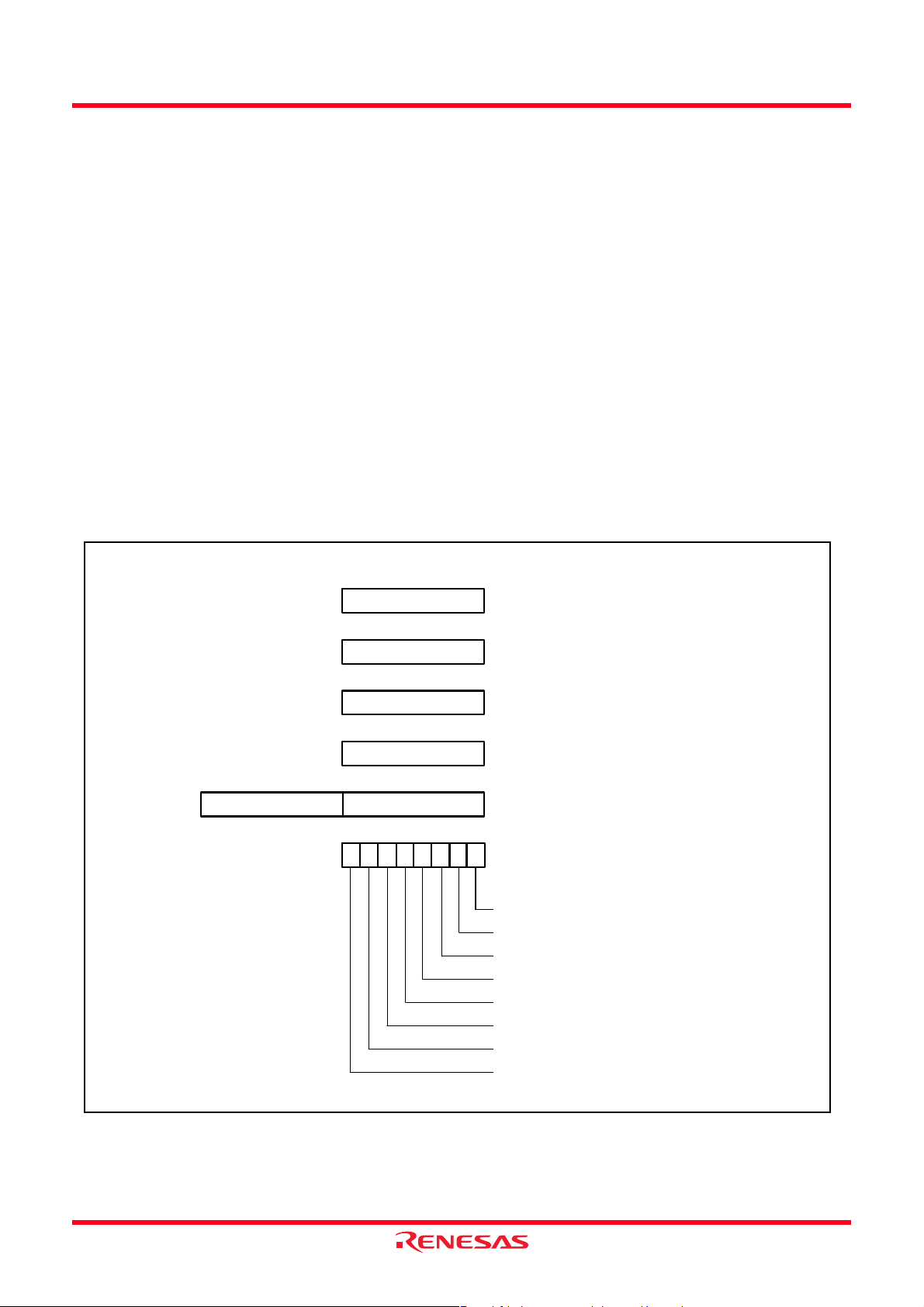

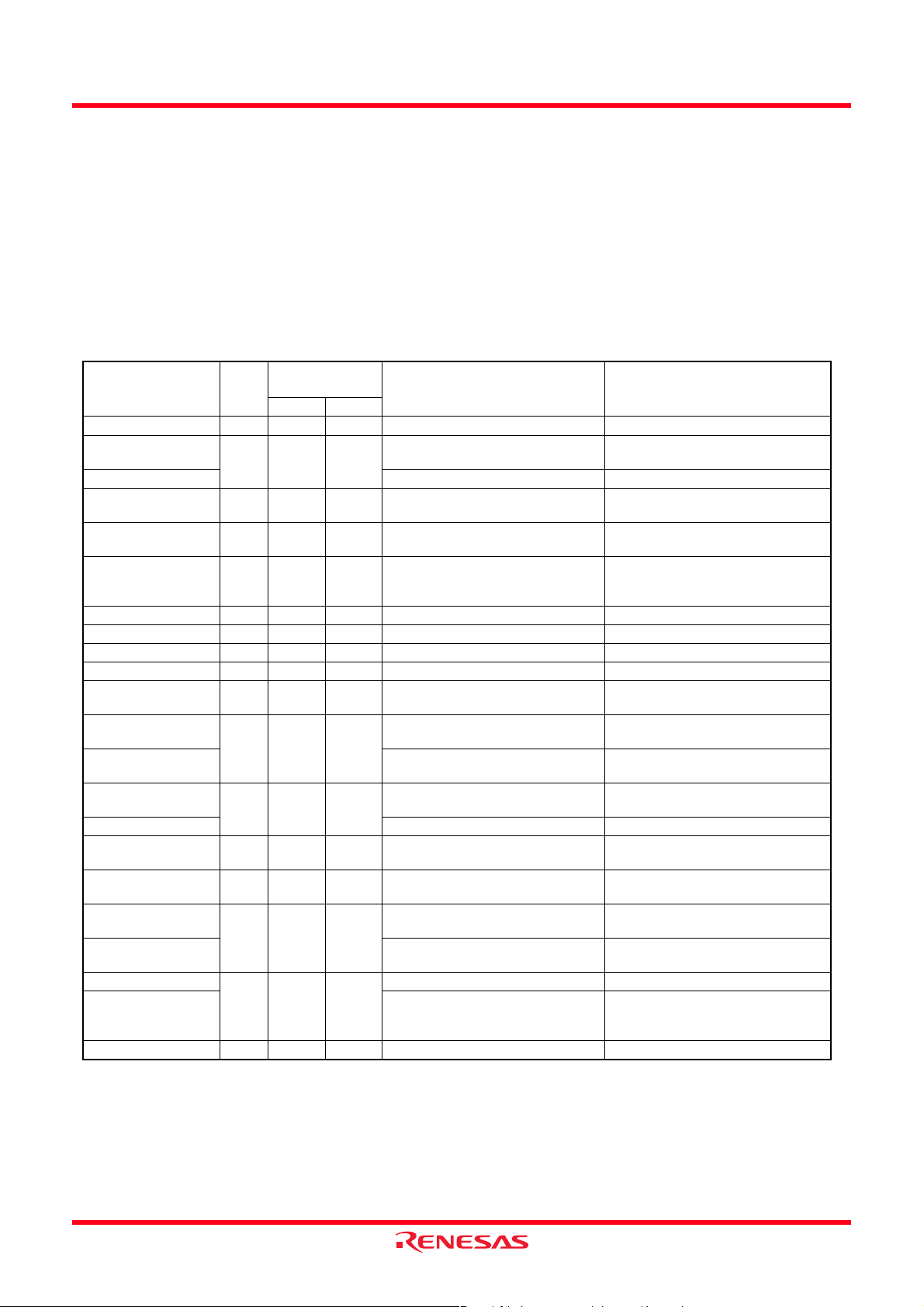

PART NUMBERING

Product name

M3803 9 M F

−

L

XXX SP

Package code

SP : PRDP0064BA-A (64P4B)

HP : PLQP0064KB-A (64P6Q-A)

KP : PLQP0064GA-A (64P6U-A)

WG : PTLG0064JA-A (64F0G)

ROM number

Omitted in the flash memory version.

−: standard

Omitted in the flash memory version.

−: Minner spec. change product

L

ROM/Flash memory size

1: 4096 bytes

2: 8192 bytes

3: 12288 bytes

4: 16384 bytes

5: 20480 bytes

6: 24576 bytes

7: 28672 bytes

8: 32768 bytes

The first 128 bytes and the last 2 bytes of ROM are reserved areas ; they

cannot be used as a user’s ROM area.

However, they can be programmed or erased in the flash memory version,

so that the users can use them.

9: 36864 bytes

A: 40960 bytes

B: 45056 bytes

C: 49152 bytes

D: 53248 bytes

E: 57344 bytes

F: 61440 bytes

Fig 5. Part numbering

Memory type

M:Mask ROM version

F: Flash memory version

RAM size

0: 192 bytes

1: 256 bytes

2: 384 bytes

3: 512 bytes

4: 640 bytes

5: 768 bytes

6: 896 bytes

7: 1024 bytes

8: 1536 bytes

9: 2048 bytes

Rev.1.00 Apr 2, 2007 Page 7 of 117

REJ03B0212-0100

3803 Group (Spec.L)

GROUP EXPANSION

Renesas plans to expand the 3803 group (Spec.L) as follows.

Memory Size

• Flash memory size .....................................................60 Kbytes

• Mask ROM size.........................................................60 Kbytes

• RAM size................................................................. 2048 bytes

Memory Expansion Plan

ROM size (bytes)

60 K

48 K

32 K

Packages

• PRDP0064BA-A (64P4B)

..............................................64-pin shrink plastic-molded DIP

• PLQP0064KB-A (64P6Q-A)

...........................................0.5 mm-pitch plast ic molded LQFP

• PLQP0064GA-A (64P6U-A)

...........................................0.8 mm-pitch plast ic molded LQFP

• PTLG0064JA-A (64F0G)

........................................0.65 mm-pitch plastic molded FLGA

M38039FFL

M38039MFL

28 K

24 K

20 K

16 K

12 K

8 K

512

384 768640

1024896 12801152 1408 20481536

RAM size (byte s)

Fig 6. Memory expansion plan

Table 3 S up port products

Part No.

M38039MFL-XXXSP

M38039MFL-XXXHP PLQP0064KB-A (64P6Q-A)

M38039MFL-XXXKP PLQP0064GA-A (64P6U-A)

M38039MFL-XXXWG PTLG0064JA-A (64F0G)

M38039FFLSP

M38039FFLHP PLQP0064KB-A (64P6Q-A)

M38039FFLKP PLQP0064GA-A (64P6U-A)

M38039FFLWG PTLG0064JA-A (64F0G)

ROM size (bytes)

ROM size for User in ( )

61440

(61310)

57344+4096 (NOTE) 2048

RAM size

(bytes)

2048

Package Remarks

PRDP0064BA-A (64P4B)

PRDP0064BA-A (64P4B)

NOTE:

1. ROM size includes the ID code area.

Mask ROM version

Flash memory version

VCC = 2.7 to 5.5 V

40323072

Rev.1.00 Apr 2, 2007 Page 8 of 117

REJ03B0212-0100

3803 Group (Spec.L)

FUNCTIONAL DESCRIPTION

CENTRAL PROCESSING UNIT (CPU)

The 3803 group (Spec.L) uses the standard 740 Family

instruction set. Refer to the table of 740 Family addressing

modes and machine instructions or the 740 Family Software

Manual for details on the instruction set.

Machine-resident 740 Family instructions are as follows:

The FST and SLW instructions cannot be used.

The STP, WIT, MUL, and DIV instructions can be used.

[Accumulator (A)]

The accumulator is an 8-bit register. Data operations such as data

transfer, etc. are executed mainly through the accumulator.

[Index Register X (X)]

The index register X is an 8-bit register. In the index addressing

modes, the value of the OPERAND is added to the contents of

register X and specifies the real address.

[Index Register Y (Y)]

The index register Y is an 8-bit register. In partial instruction, the

value of the OPERAND is added to the contents of register Y

and specifies the real address.

b7 b0

A

b7 b0

X

b7 b0

Y

b7 b0

S

[Stack Pointer (S)]

The stack pointer is an 8-bit register used during subroutine calls

and interrupts. This register indicates start address of stored area

(stack) for storing registers during subroutine calls and

interrupts.

The low-order 8 bits of the stack address are determined by the

contents of the stack pointer. The high-order 8 bits of the stack

address are determined by the stack page selection bit. If the

stack page selection bit is “0”, the high-order 8 bits becomes

“00

16”. If the stack page selection bit is “1”, the high-order 8 bits

becomes “01

The operations of pushing register contents onto the stack and

popping them from the stack are shown in Figure 8.

Store registers other than those described in Fi gure 7 with

program when the user needs them during interrupts or

subroutine calls (see Table 4).

[Program Counter (PC)]

The program counter is a 16-bit counter consisting of two 8-bit

registers PC

next instruction to be executed.

16”.

H and PCL. It is used to indicate the address of the

Accumulator

Index Register X

Index Register Y

Stack Pointer

b15

b7 b0

b7 b0

Fig 7. 740 Family CPU register structure

PC

LPCH

Program Counter

CZIDBTVN

Processor Status Register (PS)

Carry Flag

Zero Flag

Interrupt Disable Flag

Decimal Mode Flag

Break Flag

Index X Mode Flag

Overflow Flag

Negative Flag

Rev.1.00 Apr 2, 2007 Page 9 of 117

REJ03B0212-0100

3803 Group (Spec.L)

On-going Routine

Push Return

Address

on Stack

POP Return

Address from

Stack

Interrupt request

M(S)←(PCH)

(S)←(S) − 1

M(S)←(PCL)

(S)←(S) − 1

Subroutine

.....

Execute RTS

(S)←(S) + 1

(PCL)←M(S)

(1)

Execute JSR

M(S)←(PCH)

(S)←(S) − 1

M(S)←(PCL)

(S)←(S) − 1

M(S)←(PS)

(S)←(S) − 1

Interrupt

Service Routine

.....

Execute RTI

(S)←(S) + 1

(PS)←M(S)

(S)←(S) + 1

Push Return Address

on Stack

Push Contents of

Processor

Status Register on Stack

I Flag is Set from

“0” to “1”

Fetch the Jump

Vector

POP Contents of

Processor Status Register

from Stack

(S)←(S) + 1

(PCH)←M(S)

Note 1 : Condition for acceptance of an interrupt → Interrupt enable flag is “1”

Interrupt disable flag is “0”

(PCL)←M(S)

(S)←(S) + 1

(PCH)←M(S)

POP Return

Address from Stack

Fig 8. Register push and pop at interrupt generatio n and subroutine call

Table 4 Push and pop instructions of accumulator or processor status register

Push instruction to stack Pop instruction from stack

Accumulator PHA PLA

Processor status register PHP PLP

Rev.1.00 Apr 2, 2007 Page 10 of 117

REJ03B0212-0100

3803 Group (Spec.L)

[Processor status register (PS)]

The processor status register is an 8-bit register consisting of 5

flags which indicate the status of the processor after an

arithmetic operation and 3 flags which decide MCU operation.

Branch operations can be performed by testing the Carry (C)

flag, Zero (Z) flag, Overflow (V) flag, or the Negative (N) flag.

In decimal mode, the Z, V, N flags are not valid.

Bit 0: Carry flag (C)

The C flag contains a carry or borrow generated by the

arithmetic logic unit (ALU) immediately after an arithmetic

operation. It can also be changed by a sh ift or rotate

instruction.

Bit 1: Zero flag (Z)

The Z flag is set if the result of an immediate arithmetic

operation or a data transfer is “0”, and cleared if the result is

anything other than “0”.

Bit 2: Interrupt disable flag (I)

The I flag disables all interrupts except for the interrupt

generated by the BRK instruction.

Interrupts are disabled when the I flag is “1”.

Bit 3: Decimal mode flag (D)

The D flag determines whether additions and subtractions are

executed in binary or decimal. Binary arithmetic is executed

when this flag is “0”; decimal arithmetic is executed when it

is “1”.

Decimal correction is automatic in decimal mode. Only the

ADC and SBC instructions can execute decimal arithmetic.

Bit 4: Break flag (B)

The B flag is used to indicate that the current interrupt was

generated by the BRK instruction. The BRK flag in the

processor status register is always “0”. When the BRK

instruction is used to generate an interrupt, the processor

status register is pushed onto the stack with the break flag set

to “1”.

Bit 5: Index X mode flag (T)

When the T flag is “0”, arithmetic operations are performed

between accumulator and memory. When the T flag is “1”,

direct arithmetic operations and direct data transfers are

enabled between memory locations.

Bit 6: Overflow flag (V)

The V flag is used during the addition or subtraction of one

byte of signed data. It is set if the result exceeds +127 to −

128. When the BIT instruction is executed, bit 6 of the

memory location operated on by the BIT instruction is stored

in the overflow flag.

Bit 7: Negative flag (N)

The N flag is set if the result of an arithmetic operation or

data transfer is negative. When the BIT instruction is

executed, bit 7 of the memory location operated on by the

BIT instruction is stored in the negative flag.

Table 5 Set and clear instructions of each bit of processor status register

C flag Z flag I flag D flag B flag T flag V flag N flag

Set instruction SEC

Clear instruction CLC − CLI CLD − CLT CLV −

− SEI SED − SET −−

Rev.1.00 Apr 2, 2007 Page 11 of 117

REJ03B0212-0100

3803 Group (Spec.L)

[CPU Mode Register (CPUM)] 003B16

The CPU mode register contains the stack page selection bit, the

internal system clock control bits, etc.

The CPU mode register is allocated at address 003B16.

b7 b0

1

CPU mode register

(CPUM: address 003B

Processor mode bits

b1 b0

0 0 : Single-chip mode

01:

1 0 : Not available

11:

Stack page selection bit

0 : 0 page

1 : 1 page

Fix this bit to “1”.

Port XC switch bit

0 : I/O port function (stop oscillating)

CIN-XCOUT oscillating function

1:X

Main clock (X

0 : Oscillating

1 : Stopped

Main clock division ratio selection bits

b7 b6

00:φ = f(X

01:φ = f(X

10:φ = f(X

1 1 : Not available

IN-XOUT) stop bit

16)

IN)/2 (high-speed mode)

IN)/8 (middle-speed mode)

CIN)/2 (low-speed mode)

Fig 9. Structure of CPU mode register

Rev.1.00 Apr 2, 2007 Page 12 of 117

REJ03B0212-0100

3803 Group (Spec.L)

MISRG

(1) Bit 0 of address 0010

16: Oscillation stabilizing time

set after STP instruction released bit

When the MCU stops the clock oscillation by the STP instruction

and the STP instruction has been released by an external

interrupt source, usually, the fixed values of Timer 1 and

Prescaler 12 (Timer 1 = 0116, Prescaler 12 = FF16) are

automatically reloaded in order for the oscillation to stabilize.

The user can inhibit the automatic setting by setting “1” to bit 0

of MISRG (address 0010

16).

However, by setting this bit to “1”, the previous values, set just

before the STP instruction was executed, will remain in Timer 1

and Prescaler 12. Therefore, you will need to set an appropriate

value to each register, in accordance with the oscillation

stabilizing time, before executing the STP instruction.

Figure 10 shows the structure of MISRG.

(2) Bits 1, 2, 3 of address 0010

16: Middle-speed Mode

Automatic Switch Function

In order to switch the clock mode of an MCU which has a subclock, the following procedure is necessary:

set CPU mode register (003B

16) --> start main clock oscillation

--> wait for oscillation stabilization --> switch to middle-speed

mode (or high-speed mode).

However, the 3803 group (Spec.L) has the built-in function

which automatically switches from low to middle-spee d mode by

program.

• Middle-speed mode automatic switch by program

The middle-speed mode can also be automatically switche d by

program while operating in low-speed mode. By setting the

middle-speed automatic switch start bit (bit 3) of MISRG

(address 0010

16) to “1” in the condition that the middle-speed

mode automatic switch set bit is “1” while operating in lowspeed mode, the MCU will automatically switch to middle-speed

mode. In this case, the oscillation stabilizing time of the main

clock can be selected by the middle-speed automatic switch wait

time set bit (bit 2) of MISRG (address 0010

16).

b7 b0

Note 1 : When automatic switch to middle-speed mode from low-speed mode occurs,

the values of CPU mode register (3B

MISRG

(MISRG: address 0010

Oscillation stabilizing time set after STP instruction

released bit

0 : Automatically set “01

Prescaler 12

1 : Automatically set disabled

Middle-speed mode automatic switch set bit

0 : Not set automatically

1 : Au tomatic switching enabled

Middle-speed mode automatic switch wait time set bit

0 : 4.5 to 5.5 machine cycles

1 : 6.5 to 7.5 machine cycles

Middle-speed mode automatic switch start bit

(Depending on program)

0 : Invalid

1 : Automatic switch start

Not used (return “0” when read)

(Do not write “1” to this bit)

16) change.

16)

16” to Timer 1, “FF16” to

(1)

(1)

Fig 10. Structure of MISRG

Rev.1.00 Apr 2, 2007 Page 13 of 117

REJ03B0212-0100

3803 Group (Spec.L)

MEMORY

• Special Function Register (SFR) Area

The Special Function Register area in the zero page contains

control registers such as I/O ports and timers.

• RAM

The RAM is used for data storage and for stack area of

subroutine calls and interrupts.

•ROM

The first 128 bytes and the last 2 bytes of ROM are reserved for

device testing and the rest is a user area for storing programs.

The reserved ROM area can program/erase in the flash memory

version.

RAM area

RAM size

(bytes)

192

256

384

512

640

768

896

1024

1536

2048

Address

XXXX

00FF

16

013F16

01BF16

023F16

02BF16

033F16

03BF16

043F16

063F16

083F16

16

RAM

ROM area

ROM size

(bytes)

4096

8192

12288

16384

20480

24576

28672

32768

36864

40960

45056

49152

53248

57344

61440

Address

YYYY

F000

16

E00016

D00016

C00016

B00016

A00016

900016

800016

700016

600016

500016

400016

300016

200016

100016

Address

16

ZZZZ

16

F08016

E08016

D08016

C08016

B08016

A08016

ROM

908016

808016

708016

608016

508016

408016

308016

208016

108016

• Interrupt Vector Area

The interrupt vector area contains reset and interrupt vectors.

• Zero Page

Access to this area with only 2 bytes is possible in the zero page

addressing mode.

• Special Page

Access to this area with only 2 bytes is possible in the special

page addressing mode.

<Note>

Since the contents of RAM are undefined at reset, be sure to set

an initial value before use.

000016

004016

SFR area

Zero page

010016

XXXX16

0FE016

0FEF16

0FF016

0FFF

16

Not used

SFR area (Note 1)

SFR area

Not used

YYYY16

Reserved ROM area

(128 bytes)

ZZZZ16

FF0016

FFDC16

Special page

Interrupt vector area

FFFE16

FFFF16

Notes1: Only flash memory version has this SFR area.

2: The reserved ROM area can program/erase in

Reserved ROM area

the flash memory version. Note the difference of

the mask version.

Fig 11. Memory map diagram

Rev.1.00 Apr 2, 2007 Page 14 of 117

REJ03B0212-0100

3803 Group (Spec.L)

000016

000116

000216

000316

000416

000516

000616

000716

000816

000916

000A16

000B16

000C16

000D16

000E16

000F16

001016

001116

001216

001316

001416

001516

001616

001716

001816

001916

001A16

001B16

001C16

001D16

001E16

001F16

Port P0 (P0)

Port P0 direction register (P0D)

Port P1 (P1)

Port P1 direction register (P1D)

Port P2 (P2)

Port P2 direction register (P2D)

Port P3 (P3)

Port P3 direction register (P3D)

Port P4 (P4)

Port P4 direction register (P4D)

Port P5 (P5)

Port P5 direction register (P5D)

Port P6 (P6)

Port P6 direction register (P6D)

Timer 12, X count source selection register (T12XCSS)

Timer Y, Z count source selection register (TYZCSS)

MISRG

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Transmit/Receive buffer register 1 (TB1/RB1)

Serial I/O1 status register (SIO1 STS)

Serial I/O1 control register (SIO1CON)

UART1 control register (UART1CON)

Baud rate generator (BRG1)

Serial I/O2 control register (SIO2CON)

Watchdog timer control register (WDTCON)

Serial I/O2 register (SIO2)

002016

002116

002216

002316

002416

002516

002616

002716

002816

002916

002A16

002B16

002C16

002D16

002E16

002F16

003016

003116

003216

003316

003416

003516

003616

003716

003816

003916

003A16

003B16

003C16

003D16

003E16

003F16

Prescaler 12 (PRE12)

Timer 1 (T1)

Timer 2 (T2)

Timer XY mode register (TM)

Prescaler X (PREX)

Timer X (TX)

Prescaler Y (PREY)

Timer Y (TY)

Timer Z low-order (TZL)

Timer Z high-order (TZH)

Timer Z mode register (TZM)

PWM control register (PWMCON)

PWM prescaler (PREPWM)

PWM register (PWM)

Baud rate generator 3 (BRG3)

Transmit/Receive buffer register 3 (TB3/RB3)

Serial I/O3 status register (SIO3STS)

Serial I/O3 control regist er (SIO3CON)

UART3 control register (UART3CON)

AD/DA control register (ADCON)

AD conversion register 1 (AD1)

DA1 conversion register (DA1)

DA2 conversion register (DA2)

AD conversion register 2 (AD2)

Interrupt source selection register (INTSEL)

Interrupt edge selection register (INTEDGE)

CPU mode register (CPUM)

Interrupt request register 1 (IREQ1)

Interrupt request register 2 (IREQ2)

Interrupt control register 1 (ICON1)

Interrupt control register 2 (ICON2)

0FE016

0FE116

0FE216

0FE316

0FE416

0FE516

0FE616

0FE716

0FE816

0FE916

0FEA16

0FEB16

0FEC16

0FED16

0FEE16

0FEF16

Flash memory control register 0 (FMCR0)

Flash memory control register 1 (FMCR1)

Flash memory control register 2 (FMCR2)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Reserved (Note 1)

Fig 12. Memory map of special function register (SFR)

Rev.1.00 Apr 2, 2007 Page 15 of 117

REJ03B0212-0100

0FF016

0FF116

0FF216

0FF316

0FF416

0FF516

0FF616

Notes1: Do not write any data to these addresses, because these are

Port P0 pull-up control register (PULL0)

Port P1 pull-up control register (PULL1)

Port P2 pull-up control register (PULL2)

Port P3 pull-up control register (PULL3)

Port P4 pull-up control register (PULL4)

Port P5 pull-up control register (PULL5)

Port P6 pull-up control register (PULL6)

reserved area.

2: Do not access to the SFR area including nothing.

3803 Group (Spec.L)

I/O PORTS

The I/O ports have direction registers which determine the

input/output direction of each individual pin. Each bit in a

direction register corresponds to one pin, and each pin can be set

to be input port or output port.

When “0” is written to the bit corresponding to a pin, that pin

input are floating. If a pin set to input is written to, only the port

output latch is written to and the pin remains floating.

By setting the port P0 pull-up control register (address 0FF016)

to the port P6 pull-up control register (address 0FF6

16) ports can

control pull-up with a program. However, the contents of these

registers do not affect ports programmed as the output ports.

becomes an input pin. When “1” is written to that bit, that pin

becomes an output pin.

If data is read from a pin which is set to output, the value of the

port output latch is read, not the value of the pin itself. Pins set to

Table 6 I /O po rt function

Pin Name Input/

Output

0/AN8−P07/AN15 Port P0 Input/output,

P0

P10/INT

41

P11/INT

01

2−P17 (3)

P1

0(LED0)−

P2

7(LED7)

P2

0/DA1

P3

Port P1 External interrupt input Interrupt edge selection register (2)

Port P2

Port P3 D/A converter output AD/DA control register (4)

individual

bits

P31/DA2

2, P33 CMOS compatible

P3

P3

4/RXD3

P35/TXD3

P36/SCLK3

P37/SRDY3

P4

0/INT40/XCOUT

Port P4 External interrupt input

P41/INT00/XCIN

2/INT1

P4

P43/INT2

4/RXD1

P4

P45/TXD1

P46/SCLK1

P4

7/SRDY1/CNTR2

P5

0/SIN2

Port P5 Serial I/O2 function I/O Serial I/O2 control register (13)

P51/SOUT2

P52/SCLK2

P53/SRDY2

P5

4/CNTR0

P5

5/CNTR1

6/PWM PWM output PWM control register (18)

P5

7/INT3 External interrupt input Interrupt edge selection register (2)

P5

0/AN0−P67/AN7 Port P6 A/D converter input AD/DA control register (1)

P6

I/O Structure Non-Port Function Related SFRs Ref.

CMOS compatible

A/D converter input AD/DA control register (1)

input level

CMOS 3-state

output

input level

N-channel

open-drain output

CMOS compatible

input level

Serial I/O3 function I/O Serial I/O3 control register

UART3 control register

CMOS 3-state

output

Interrupt edge selection register

Sub-clock generating circuit

CPU mode register

External interrupt input Interrupt edge selection register (2)

Serial I/O1 function I/O Serial I/O1 control register

UART1 control register

Serial I/O1 function I/O

Timer Z function I/O

Serial I/O1 control register

Timer Z mode register

Timer X, Y function I/O Timer XY mode register (17)

NOTES:

1. Refer to the applicable sections how to use double-function ports as function I/O ports.

2. Make sure that the input level at each pin is either 0 V or VCC during execution of the STP instruction.

When an input level is at an intermediate potential, a current will flow from V

CC to VSS through the input-stage gate.

No.

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(6)

(7)

(8)

(12)

(14)

(15)

(16)

Rev.1.00 Apr 2, 2007 Page 16 of 117

REJ03B0212-0100

3803 Group (Spec.L)

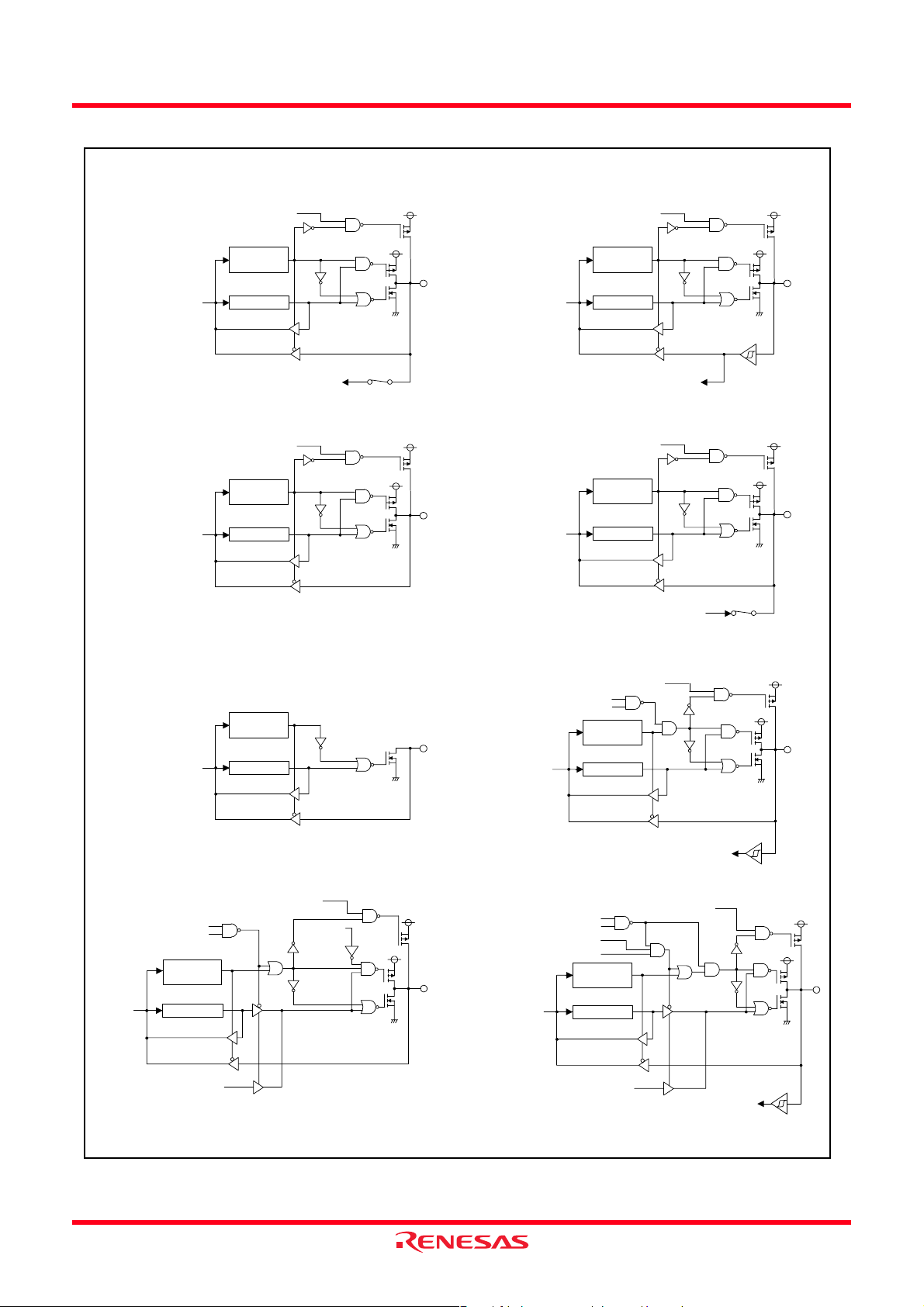

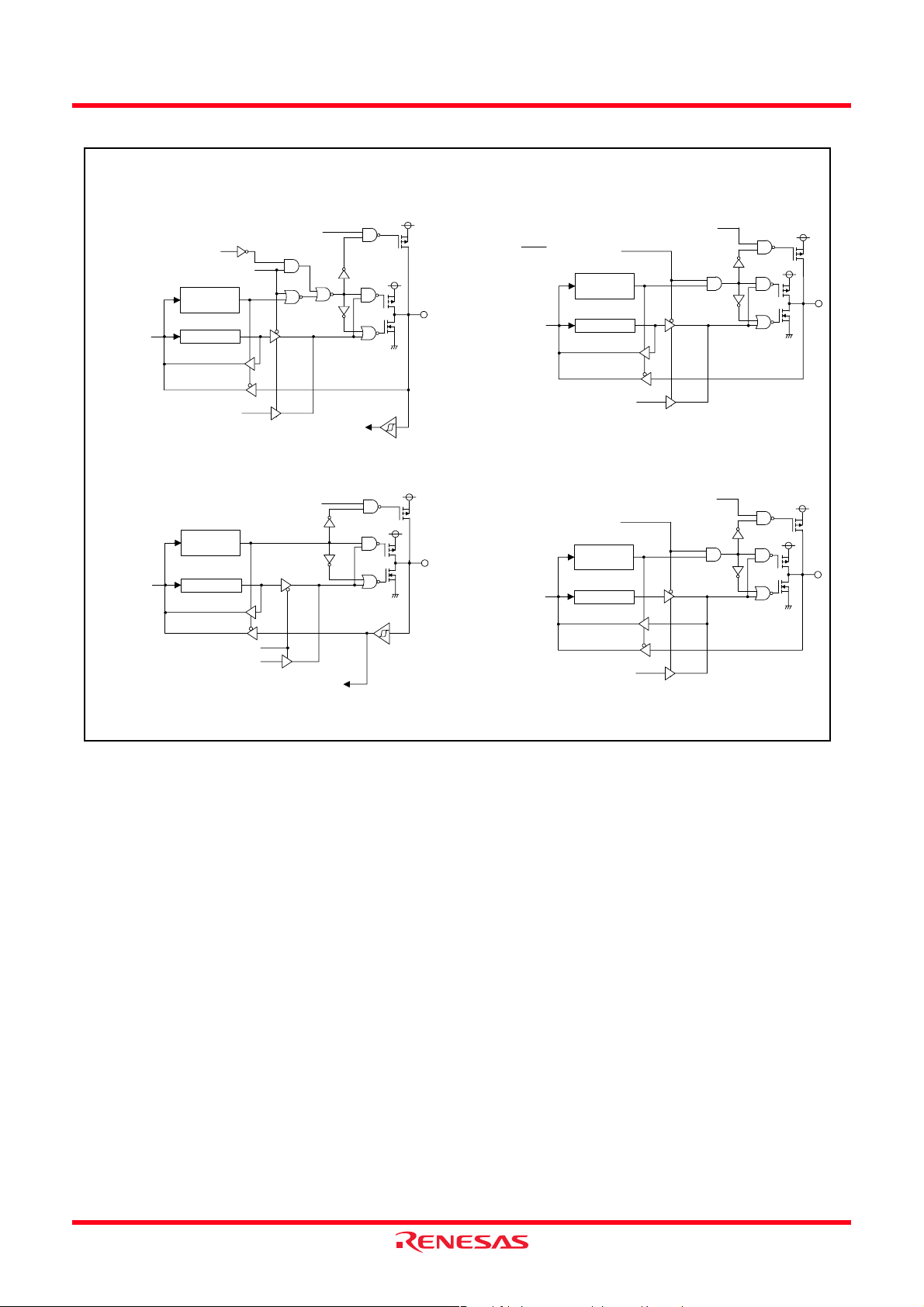

(1) Ports P0, P6

Data bus

(3) Ports P12 to P17, P2

Data bus

Pull-up control bit

Direction

register

Port latch

A/D converter input

Pull-up control bit

Direction

register

Port latch

Analog input pin

selection bit

(2) Ports P10, P11, P42, P43, P57

Pull-up control bit

Direction

register

Data bus

Port latch

(4) Ports P30, P31

Pull-up control bit

Direction

register

Data bus

Port latch

D/A converter output

Interrupt input

DA1 output enable bit (P30)

2 output enable bit (P31)

DA

(5) Ports P32, P33

Data bus

(7) Ports P35, P45

Serial I/O enable bit

Transmit enable bit

Direction

register

Data bus

Port latch

Serial I/O output

Direction

register

Port latch

Pull-up control bit

P-channel

output

disable bit

(6) Ports P34, P44

Serial I/O enable bit

Receive enable bit

Data bus

(8) Ports P36, P46

Serial I/O synchronous clock

Serial I/O mode selection bit

selection bit

Serial I/O enable bit

Serial I/O enable bit

Data bus

Serial I/O clock output

Pull-up control bit

Direction

register

Port latch

Direction

register

Port latch

Serial I/O external clock input

Serial I/O input

Pull-up control bit

Fig 13. Port block diagram (1)

Rev.1.00 Apr 2, 2007 Page 17 of 117

REJ03B0212-0100

3803 Group (Spec.L)

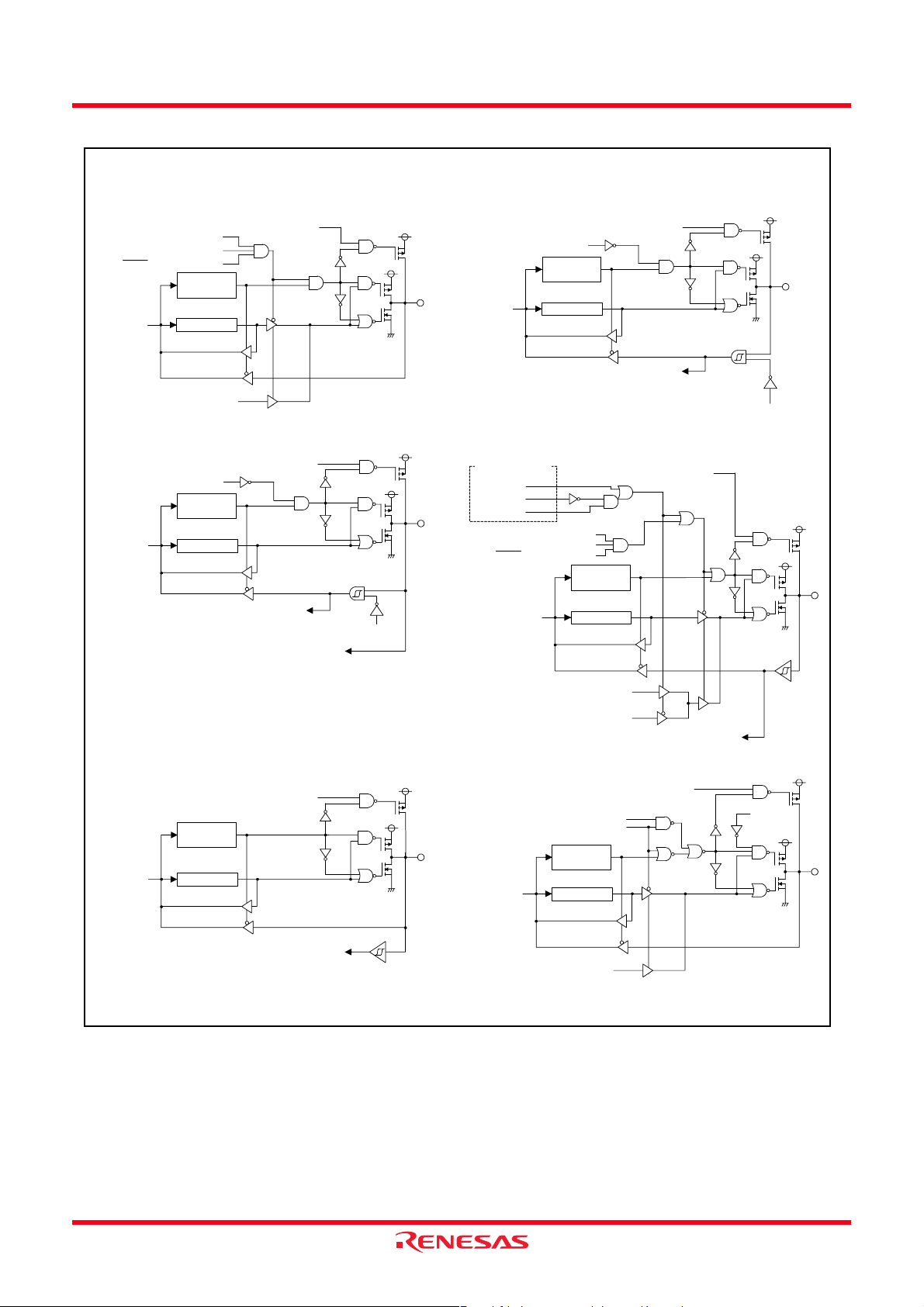

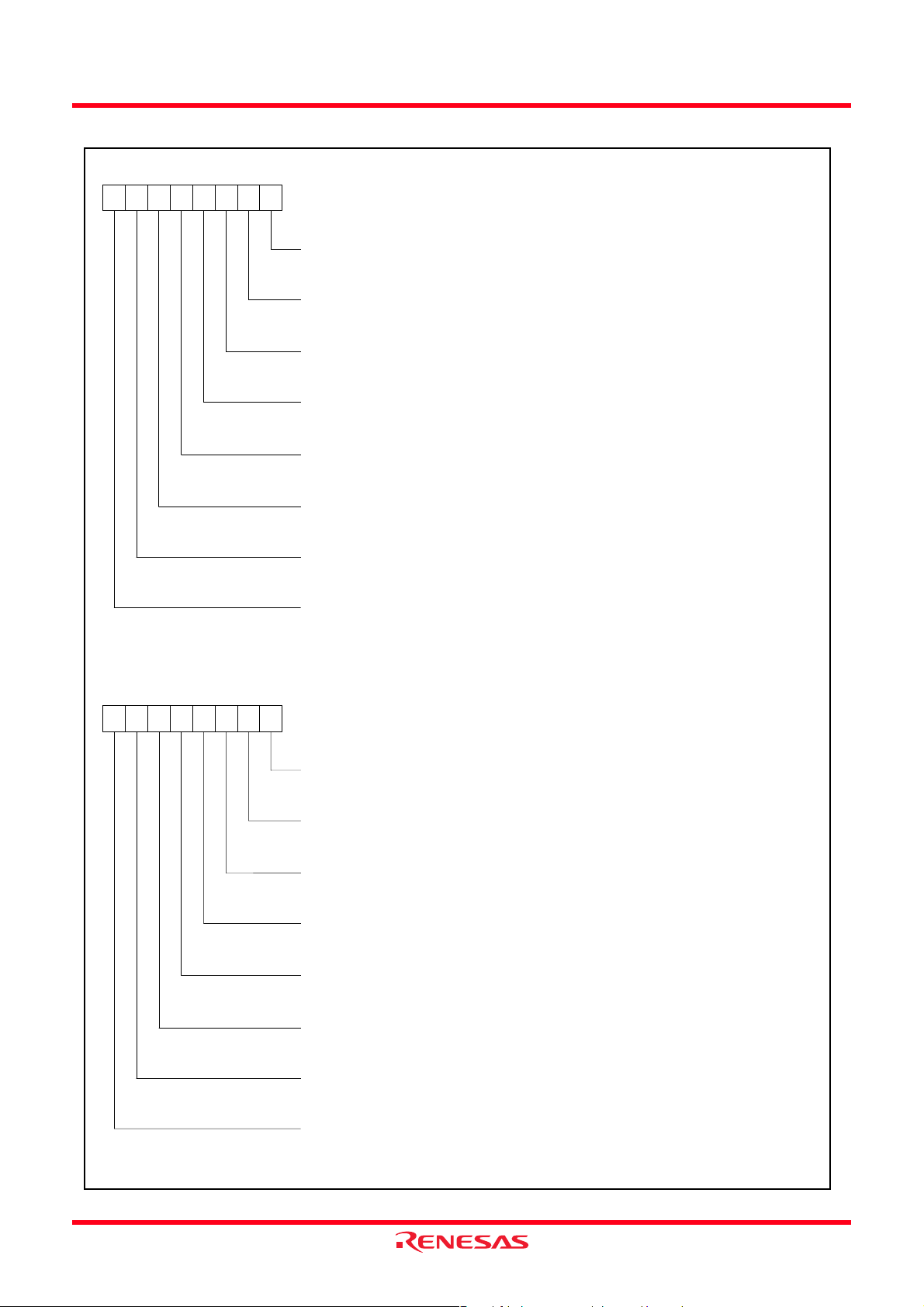

(9) Port P37

Serial I/O3 mode selection bit

Serial I/O3 enable bit

SRDY3 output enable bit

Direction

register

Data bus

Serial I/O3 ready output

Port latch

(11) Port P41

Port XC switch bit

Direction

register

Data bus

Port latch

Sub-clock generating circuit input

Pull-up control bit

Pull-up control bit

INT00 Interrupt input

Port XC

switch bit

(10) Port P40

Port XC switch bit

Direction

register

Data bus

Port latch

(12) Port P47

Timer Z operating

mode bits

Bit 2

Bit 1

Bit 0

Serial I/O1 mode selection bit

Serial I/O1 enable bit

SRDY1 output enable bit

Direction

register

Data bus

Port latch

Pull-up control bit

INT40 Interrupt input

Pull-up control bit

Port XC

switch bit

(13) Port P50

Pull-up control bit

Direction

register

Data bus

Port latch

Fig 14. Port block diagram (2)

Serial I/O2 input

Timer output

Serial I/O1 ready output

(14) Port P51

Serial I/O2 transmit completion signal

Serial I/O2 port selection bit

Direction

register

Data bus

Port latch

Serial I/O2 output

2 interrupt input

CNTR

Pull-up control bit

P-channel

output

disable bit

Rev.1.00 Apr 2, 2007 Page 18 of 117

REJ03B0212-0100

3803 Group (Spec.L)

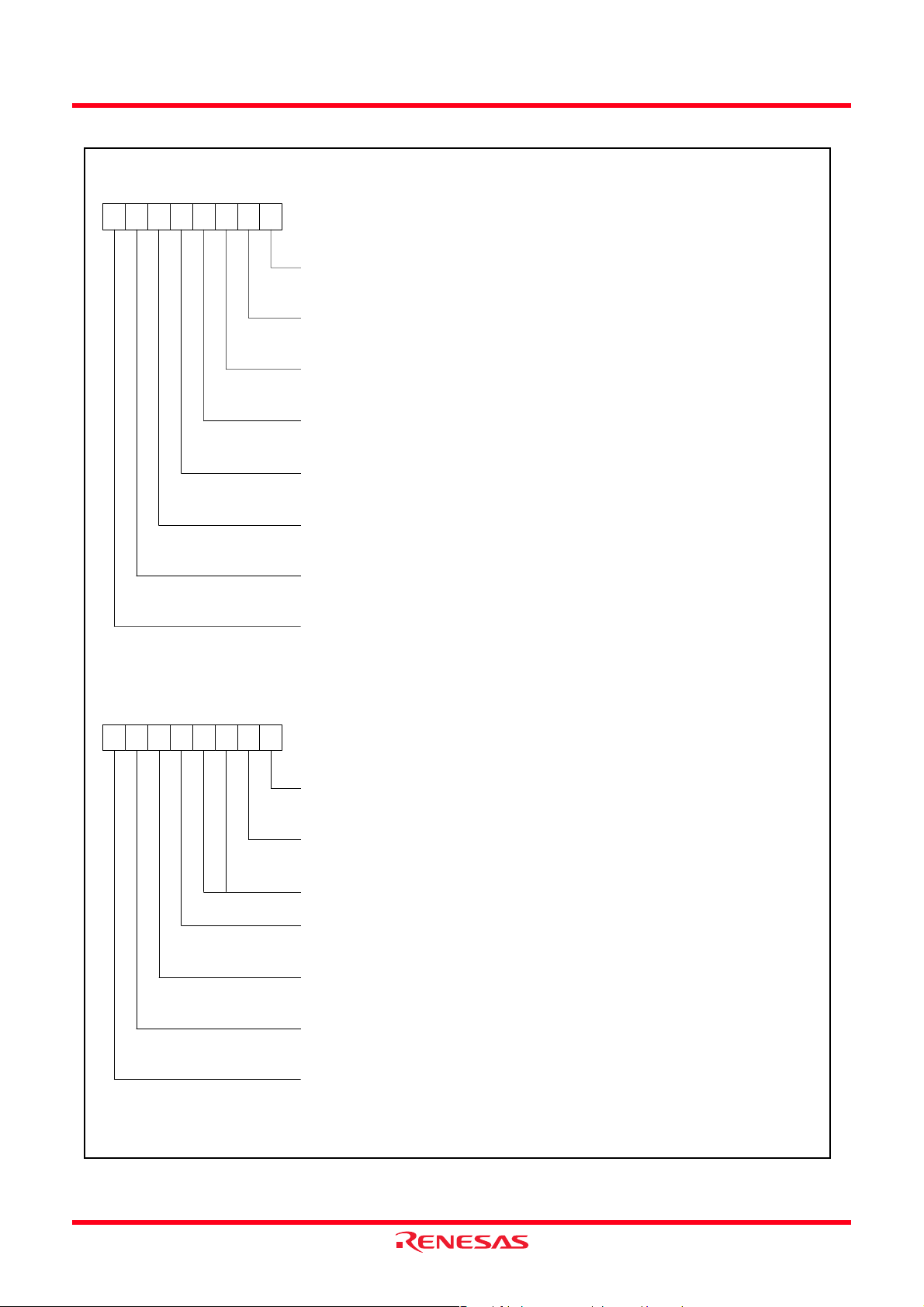

(15) Port P52

Serial I/O2 synchronous clock

Data bus

selection bit

Serial I/O2 port selection bit

Direction

register

Port latch

Serial I/O2 clock output

(17) Ports P54, P55

Direction

register

Data bus

Port latch

Pulse output mode

Timer output

Pull-up control bit

Serial I/O2 external clock input

Pull-up control bit

CNTR Interrupt input

(16) Port P53

SRDY2 output enable bit

Data bus

(18) Port P56

PWM function enable bit

Data bus

Direction

register

Port latch

Serial I/O2 ready output

Direction

register

Port latch

PWM output

Pull-up control bit

Pull-up control bit

Fig 15. Port block diagram (3)

Rev.1.00 Apr 2, 2007 Page 19 of 117

REJ03B0212-0100

3803 Group (Spec.L)

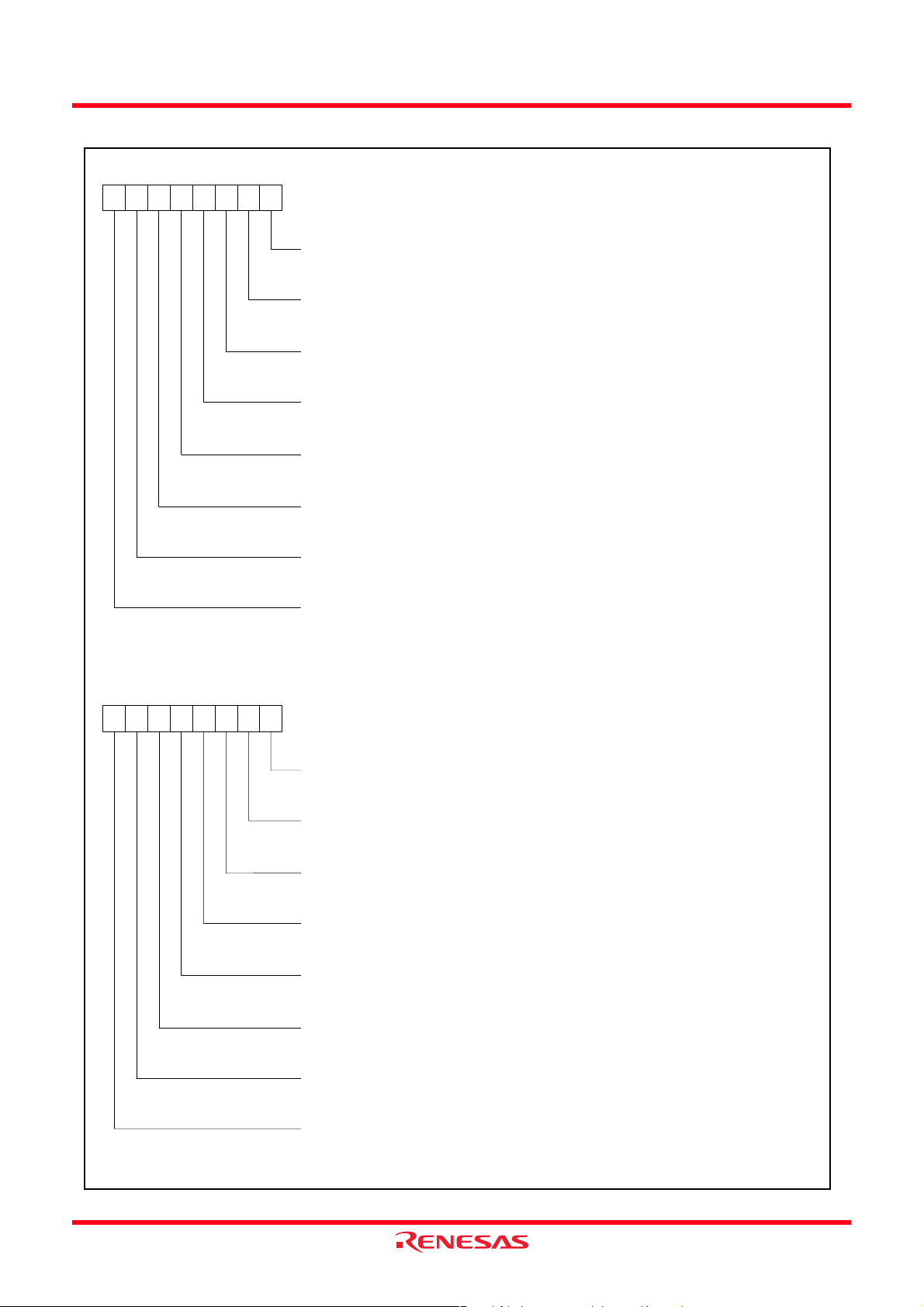

b7 b0

Port P0 pull-up control register

(PULL0: address 0FF0

0 pull-up control bit

P0

16)

0: No pull-up

1: Pull-up

P0

1 pull-up control bit

0: No pull-up

1: Pull-up

2 pull-up control bit

P0

0: No pull-up

1: Pull-up

P0

3 pull-up control bit

0: No pull-up

1: Pull-up

4 pull-up control bit

P0

0: No pull-up

1: Pull-up

P0

5 pull-up control bit

0: No pull-up

1: Pull-up

6 pull-up control bit

P0

0: No pull-up

1: Pull-up

7 pull-up control bit

P0

0: No pull-up

1: Pull-up

Note: Pull-up control is valid when the corresponding

bit of the port direction register is “0” (input).

When that bit is “1” (output), pull-up cannot be

set to the port of which pull-up is selected.

b7 b0

Port P1 pull-up control register

(PULL1: address 0FF1

0 pull-up control bit

P1

16)

0: No pull-up

1: Pull-up

P1

1 pull-up control bit

0: No pull-up

1: Pull-up

2 pull-up control bit

P1

0: No pull-up

1: Pull-up

P1

3 pull-up control bit

0: No pull-up

1: Pull-up

4 pull-up control bit

P1

0: No pull-up

1: Pull-up

P1

5 pull-up control bit

0: No pull-up

1: Pull-up

P1

6 pull-up control bit

0: No pull-up

1: Pull-up

7 pull-up control bit

P1

0: No pull-up

1: Pull-up

Note: Pull-up control is valid when the corresponding

bit of the port direction register is “0” (input).

When that bit is “1” (output), pull-up cann ot be

set to the port of which pull-up is selected.

Fig 16. Structure of port pull-up control register (1)

Rev.1.00 Apr 2, 2007 Page 20 of 117

REJ03B0212-0100

3803 Group (Spec.L)

b7 b0

Port P2 pull-up control register

(PULL2: address 0FF2

0 pull-up control bit

P2

16)

0: No pull-up

1: Pull-up

1 pull-up control bit

P2

0: No pull-up

1: Pull-up

P2

2 pull-up control bit

0: No pull-up

1: Pull-up

P2

3 pull-up control bit

0: No pull-up

1: Pull-up

4 pull-up control bit

P2

0: No pull-up

1: Pull-up

P2

5 pull-up control bit

0: No pull-up

1: Pull-up

6 pull-up control bit

P2

0: No pull-up

1: Pull-up

P2

7 pull-up control bit

0: No pull-up

1: Pull-up

Note: Pull-up control is valid when the corresponding

bit of the port direction register is “0” (input).

When that bit is “1” (output), pull-up cannot be

set to the port of which pull-up is selected.

b7 b0

Port P3 pull-up control register

(PULL3: address 0FF3

0 pull-up control bit

P3

16)

0: No pull-up

1: Pull-up

1 pull-up control bit

P3

0: No pull-up

1: Pull-up

Not used

(return “0” when read)

P3

4 pull-up control bit

0: No pull-up

1: Pull-up

5 pull-up control bit

P3

0: No pull-up

1: Pull-up

P3

6 pull-up control bit

0: No pull-up

1: Pull-up

7 pull-up control bit

P3

0: No pull-up

1: Pull-up

Note: Pull-up control is valid when the corresponding

bit of the port direction register is “0” (input).

When that bit is “1” (output), pull-up cann ot be

set to the port of which pull-up is selected.

Fig 17. Structure of port pull-up control register (2)

Rev.1.00 Apr 2, 2007 Page 21 of 117

REJ03B0212-0100

3803 Group (Spec.L)

b7 b0

Port P4 pull-up control register

(PULL4: address 0FF4

0 pull-up control bit

P4

16)

0: No pull-up

1: Pull-up

P4

1 pull-up control bit

0: No pull-up

1: Pull-up

2 pull-up control bit

P4

0: No pull-up

1: Pull-up

P4

3 pull-up control bit

0: No pull-up

1: Pull-up

4 pull-up control bit

P4

0: No pull-up

1: Pull-up

P4

5 pull-up control bit

0: No pull-up

1: Pull-up

6 pull-up control bit

P4

0: No pull-up

1: Pull-up

7 pull-up control bit

P4

0: No pull-up

1: Pull-up

Note: Pull-up control is valid when the corresponding

bit of the port direction register is “0” (input).

When that bit is “1” (output), pull-up cannot be

set to the port of which pull-up is selected.

b7 b0

Port P5 pull-up control register

(PULL5: address 0FF5

0 pull-up control bit

P5

16)

0: No pull-up

1: Pull-up

P5

1 pull-up control bit

0: No pull-up

1: Pull-up

2 pull-up control bit

P5

0: No pull-up

1: Pull-up

P5

3 pull-up control bit

0: No pull-up

1: Pull-up

4 pull-up control bit

P5

0: No pull-up

1: Pull-up

P5

5 pull-up control bit

0: No pull-up

1: Pull-up

P5

6 pull-up control bit

0: No pull-up

1: Pull-up

7 pull-up control bit

P5

0: No pull-up

1: Pull-up

Note: Pull-up control is valid when the corresponding

bit of the port direction register is “0” (input).

When that bit is “1” (output), pull-up cann ot be

set to the port of which pull-up is selected.

Fig 18. Structure of port pull-up control register (3)

Rev.1.00 Apr 2, 2007 Page 22 of 117

REJ03B0212-0100

3803 Group (Spec.L)

b7 b0

Port P6 pull-up control register

(PULL6: address 0FF6

0 pull-up control bit

P6

16)

0: No pull-up

1: Pull-up

1 pull-up control bit

P6

0: No pull-up

1: Pull-up

2 pull-up control bit

P6

0: No pull-up

1: Pull-up

P6

3 pull-up control bit

0: No pull-up

1: Pull-up

P6

4 pull-up control bit

0: No pull-up

1: Pull-up

5 pull-up control bit

P6

0: No pull-up

1: Pull-up

6 pull-up control bit

P6

0: No pull-up

1: Pull-up

7 pull-up control bit

P6

0: No pull-up

1: Pull-up

Note: Pull-up control is valid when the corresponding

bit of the port direction register is “0” (input).

When that bit is “1” (output), pull-up cannot be

set to the port of which pull-up is selected.

Fig 19. Structure of port pull-up control register (4)

Rev.1.00 Apr 2, 2007 Page 23 of 117

REJ03B0212-0100

3803 Group (Spec.L)

Termination of unused pins

• Termination of common pins

I/O ports: Select an input port or an output port and follow

each processing method.

In addition, it is recommended that related

registers be overwritten periodically to prevent

malfunctions, etc.

Output ports: Open.

Input ports: If the input level become unstable, through current

flow to an input circuit, and the power supply

current may increase.

Table 7 Termination of unused pins

Pins Termination

P0, P1, P2, P3, P4, P5, P6 • Set to the input mode and connect each to V

REF Connect to VCC or VSS (GND).

V

SS Connect to VCC or VSS (GND).

AV

OUT Open (only when using external clock)

X

• Set to the output mode and open at “L” or “H” output state.

Especially, when expecting low consumption

current (at STP or WIT instruction execution etc.),

pull-up or pull-down input ports to prevent

through current (builtin resistor can be used).

We recommend processing unused pins through a

resistor which can secure I

OH(avg) or IOL(avg).

Because, when an I/O port or a pin which have an

output function is selected as an input port, it may

operate as an output port by incorrect operation

etc.

CC or VSS through a resistor of 1 kΩ to 10 kΩ.

Rev.1.00 Apr 2, 2007 Page 24 of 117

REJ03B0212-0100

3803 Group (Spec.L)

INTERRUPTS

The 3803 group (Spec.L) interrupts are vector interrupts with a

fixed priority scheme, and generated by 16 sources among 21

sources: 8 external, 12 internal, and 1 software.

(1)

The interrupt sources, vector addresses

, and interrupt priority

are shown in Table 8.

An interrupt requests is accepted when all of the following

conditions are satisfied:

• Interrupt disable flag ................................ .“0”

• Interrupt request bit...................................“1”

• Interrupt enable bit............. .......................“1”

Though the interrupt priority is determined by hardware, priority

processing can be performed by software using the above bits

Each interrupt except the BRK instruction interrupt has the

and flag.

interrupt request bit and the interrupt enable bit. These bits and

the interrupt disable flag (I flag) control the acceptance of

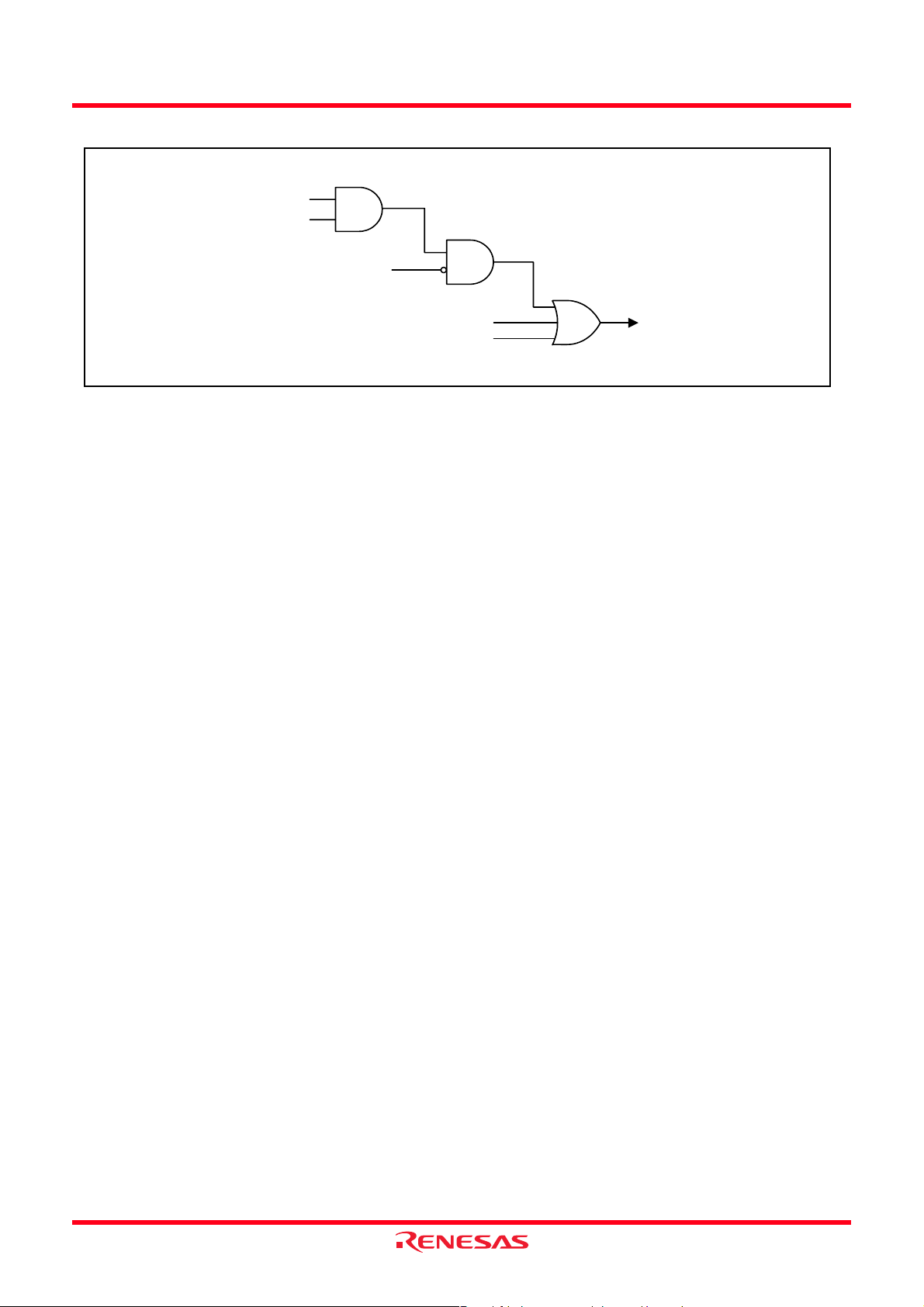

interrupt requests. Figure 20 shows an interrupt control diagram.

Table 8 Interrupt vector addresses and priority

Vector

Interrupt Source Priority

Addresses

(1)

High Low

(2)

Reset

INT

0 2FFFB16 FFFA16 At detection of either rising or falling

1FFFD16 FFFC16 At reset Non-maskable

Timer Z At timer Z underflow

1 3 FFF916 FFF816 At detection of either rising or falling

INT

Serial I/O1 reception 4 FFF7

Serial I/O1

5 FFF5

16 FFF616 At completion of serial I/O1 data

16 FFF416 At completion of serial I/O1

transmission

Timer X 6 FFF3

Timer Y 7 FFF1

Timer 1 8 FFEF

Timer 2 9 FFED

0 10 FFEB16 FFEA16 At detection of either rising or falling

CNTR

1 11 FFE916 FFE816 At detection of either rising or falling

CNTR

16 FFF216 At timer X underflow

16 FFF016 At timer Y underflow

16 FFEE16 At timer 1 underflow STP release timer underflow

16 FFEC16 At timer 2 underflow

Serial I/O3 reception At completion of serial I/O3 data

Serial I/O2 12 FFE7

16 FFE616 At completion of serial I/O2 data

Timer Z At timer Z underflow

2 13 FFE516 FFE416 At detection of either rising or falling

INT

3 14 FFE316 FFE216 At detection of either rising or falling

INT

4 15 FFE116 FFE016 At detection of either rising or falling

INT

2 At detection of either rising or falling

CNTR

A/D conversion 16 FFDF

16 FFDE16 At completion of A/D conversion

Serial I/O3

transmission

BRK instruction 17 FFDD

NOTES:

1. Vector addresses contain interrupt jump destination addresses.

2. Reset function in the same way as an interrupt with the highest priority.

16 FFDC16 At BRK instruction execution Non-maskable software interrupt

Interrupt Request Generating

Conditions

edge of INT

edge of INT

0 input

1 input

reception

transmission shift or when

transmission buffer is empty

edge of CNTR

edge of CNTR

0 input

1 input

reception

transmission or reception

edge of INT

edge of INT

edge of INT

edge of CNTR

2 input

3 input

4 input

2 input

At completion of serial I/O3

transmission shift or when

transmission buffer is empty

Remarks

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

Valid when serial I/O1 is selected

Valid when serial I/O1 is selected

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

Valid when serial I/O3 is selected

Valid when serial I/O2 is selected

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

External interrupt

(active edge selectable)

Valid when serial I/O3 is selected

Rev.1.00 Apr 2, 2007 Page 25 of 117

REJ03B0212-0100

3803 Group (Spec.L)

Interrupt request bit

Interrupt enable bit

Interrupt disable flag (I)

BRK instruction

Fig 20. Interrupt control diagram

• Interrupt Disable Flag

The interrupt disable flag is assigned to bit 2 of the processor

status register. This flag controls the acceptance of all interrupt

requests except for the BRK instruction. When this flag is set to

“1”, the acceptance of interrupt requests is disabled. When it is

set to “0”, acceptance of interrupt requests is enabled. This flag is

set to “1” with the SET instruction and set to “0” with the CLI

instruction.

When an interrupt request is accepted, the contents of the

processor status register are pushed onto the stack while the

interrupt disable flag remaines set to “0”. Subsequently, this flag

is automatically set to “1” and multiple interrupts are disabled.

To use multiple interrupts, set this flag to “0” with the CLI

instruction within the interrupt processing routine.

The contents of the processor status register are popped off the

stack with the RTI instruction.

• Interrupt Request Bits

Once an interrupt request is generated, the corresponding

interrupt request bit is set to “1” and remaines “1” until the

request is accepted. When the request is accepted, this bit is

automatically set to “0”.

Each interrupt request bit can be set to “0”, but cannot be set to

“1”, by software.

Reset

Interrupt request

• Interrupt Source Selection

Any of the following combinations can be selected by the

interrupt source selection register (0039

1. INT

0 or timer Z

16).

2. CNTR1 or Serial I/O3 reception

3. Serial I/O2 or timer Z

4 or CNTR2

4. INT

5. A/D conversion or serial I/O3 transmission

• External Interrupt Pin Selection

For external interrupts INT

0 and INT4, the INT0, INT4 interrupt

switch bit in the interrupt edge selection register (bit 6 of address

003A16) can be used to select INT00 and INT40 pin input or

INT

01 and INT41 pin input.

• Interrupt Enable Bits

The interrupt enable bits control the acceptance of t he

corresponding interrupt requests. When an interrupt enable bit is

set to “0”, the acceptance of the corresponding interrupt request

is disabled. If an interrupt request occurs in this condition, the

corresponding interrupt request bit is set to “1”, but the interrupt

request is not accepted. When an interrupt enable bit is set to “1”,

acceptance of the corresponding interrupt request is enabled.

Each interrupt enable bit can be set to “0” or “1” by software.

The interrupt enable bit for an unused interrupt should be set to

“0”.

Rev.1.00 Apr 2, 2007 Page 26 of 117

REJ03B0212-0100

3803 Group (Spec.L)

b7 b0

b7 b0

0 : No interrupt request issued

1 : Interrupt request issued

b7 b0

Interrupt edge selection register

(INTEDGE : address 003A

0 interrupt edge selection bit

INT

1 interrupt edge selection bit

INT

16)

Not used (returns “0” when read)

INT

2 interrupt edge selection bit

INT

3 interrupt edge selection bit

INT

4 interrupt edge selection bit

INT

0, INT4 interrupt switch bit

00, INT40 interrupt

0 : INT

01, INT41 interrupt

1 : INT

Not used (returns “0” when read)

Interrupt request register 1

(IREQ1 : address 003C

INT

0/Timer Z interrupt request bit

1 interrupt request bit

INT

Serial I/O1 receive interrupt request bit

Serial I/O1 transmit interrupt request bit

16)

Timer X interrupt request bit

Timer Y interrupt request bit

Timer 1 interrupt request bit

Timer 2 interrupt request bit

Interrupt control register 1

(ICON1 : address 003E

16)

0 : Falling edge active

1 : Rising edge active

0 : Falling edge active

1 : Rising edge active

b7 b0

0 : No interrupt request issued

1 : Interrupt request issued

b7 b0

Interrupt request register 2

(IREQ2 : address 003D

0 interrupt request bit

CNTR

1/Serial I/O3 receive interrupt

CNTR

16)

request bit

Serial I/O2/Timer Z interrupt request bit

INT

2 interrupt request bit

INT

3 interrupt request bit

4/CNTR2 interrupt request bit

INT

AD converter/Serial I/O3 transmit

interrupt request bit

Not used (returns “0” when read)

Interrupt control register 2

(ICON2 : address 003F

16)

0 : Interrupts disabled

1 : Interrupts enabled

b7 b0

INT

0/Timer Z interrupt enable bit

1 interrupt enable bit

INT

Serial I/O1 receive interrupt enable bit

Serial I/O1 transmit interrupt enable bit

Timer X interrupt enable bit

Timer Y interrupt enable bit

Timer 1 interrupt enable bit

Timer 2 interrupt enable bit

Interrupt source selection register

(INTSEL : address 0039

0/Timer Z interrupt source selection bit

INT

0 interrupt

0 : INT

1 : Timer Z interrupt

Serial I/O2/Timer Z interrupt source selection bit

16)

(Do not write “1” to these bits simultaneously.)

0 : Serial I/O2 interrupt

1 : Timer Z interrupt

Not used (Do not write “1”.)

INT

4/CNTR2 interrupt source selection bit

0 : INT

4 interrupt

1 : CNTR

2 interrupt

Not used (Do not write “1”.)

1/Serial I/O3 receive interrupt source selection bit

CNTR

0 : CNTR

1 interrupt

1 : Serial I/O3 receive interrupt

AD converter/Serial I/O3 transmit interrupt source selection bit

0 : A/D converter interrupt

1 : Serial I/O3 transmit interrupt

CNTR0 interrupt enable bit

CNTR

enable bit

Serial I/O2/Timer Z interrupt enable bit

INT

2 interrupt enable bit

INT

3 interrupt enable bit

4/CNTR2 interrupt enable bit

INT

AD converter/Serial I/O3 transmit

interrupt enable bit

Not used (returns “0” when read)

(Do not write “1”.)

0 : Interrupts disabled

1 : Interrupts enabled

1/Serial I/O3 receive interrupt

Fig 21. Structure of interrupt-related registers

Rev.1.00 Apr 2, 2007 Page 27 of 117

REJ03B0212-0100

3803 Group (Spec.L)

• Interrupt Request Generation, Acceptance, and Handling

Interrupts have the following three phases.

(i) Interrupt Request Generation

An interrupt request is generated by an interrupt source

(external interrupt signal input, timer underflow, etc.) and

the corresponding request bit is set to “1”.

(ii) Interrupt Request Acceptance

Based on the interrupt acceptance timing in each instruction

cycle, the interrupt control circuit determines acceptance

conditions (interrupt request bit, interrupt enable bit, and

interrupt disable flag) and interrupt priority levels for

accepting interrupt requests. When two or more interrupt

requests are generated simultaneo usly, the highest priority

interrupt is accepted. The value of interrupt request bit for

an unaccepted interrupt remains the same and acceptance is

determined at the next interrupt acceptance timing point.

(iii) Handling of Accepted Interrupt Request

The accepted interrupt request is processed.

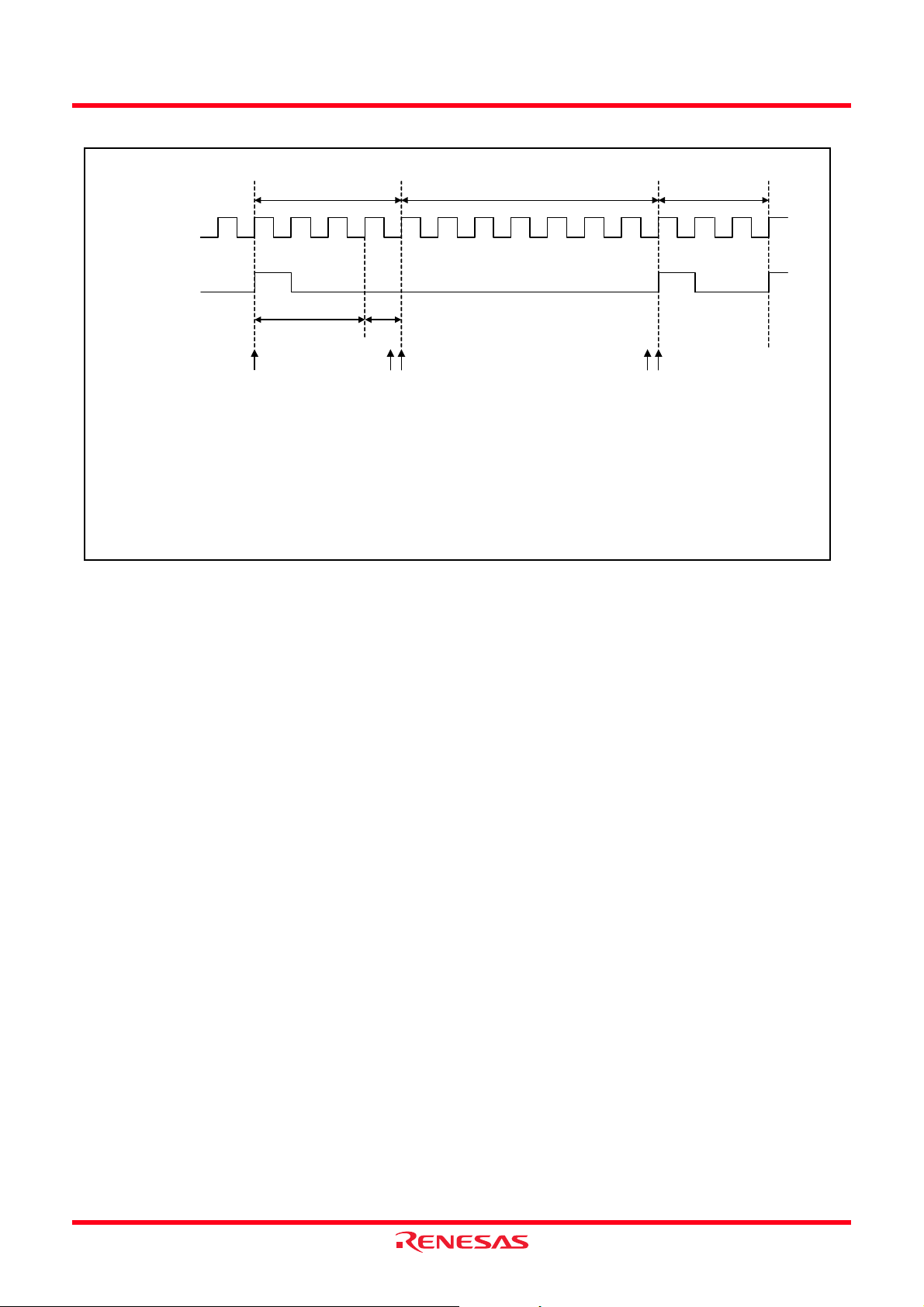

Figure 22 shows the time up to execution in the interrupt

processing routine, and Figure 23 shows the interrupt sequence.

Figure 24 shows the timing of interrupt request generation,

interrupt request bit, and interrupt request acceptance.

• Interrupt Handling Execution

When interrupt handling is executed, the following operations

are performed automatically.

(1) Once the currently executing instruction is completed, an

interrupt request is accepted.

(2) The contents of the program counters and the processor

status register at this point are pushed onto the stack area in

order from 1 to 3.

1. High-order bits of program counter (PCH)

2. Low-order bits of program counter (PCL)

3. Processor status register (PS)

(3) Concurrently with the push operation, the jump address of

the corresponding interrupt (the start address of the interrupt

processing routine) is transferred from the interrupt vector to

the program counter.

(4) The interrupt request bit for the corresponding interrupt is

set to “0”. Also, the interrupt disable flag is set to “1” and

multiple interrupts are disabled.

(5) The interrupt routine is executed.

(6) When the RTI instruction is executed, the contents of the

registers pushed onto the stack area are popped off in the

order from 3 to 1. Then, the routine that was before running

interrupt processing resumes.

As described above, it is necessary to set the stack pointer and

the jump address in the vector area corresponding to each

interrupt to execute the interrupt processing routine.

<Notes>

The interrupt request bit may be set to “1” in the following cases.

• When setting the external interrupt active edge

Related registers:Interrupt edge selection register

(address 003A

16)

Timer XY mode register (address 002316)

Timer Z mode register (address 002A

16)

• When switching the interrupt sources of an interrupt vector

address where two or more interrupt sources are assigned

Related registers:Interrupt source selection register

(address 0039

16)

If it is not necessary to generate an interrupt synchronized with

these settings, take the following sequence.

(1) Set the corresponding enable bit to “0” (disabled).

(2) Set the interrupt edge selection bit (the active edge switch

bit) or the interrupt source bit.

(3) Set the corresponding interrupt request bit to “0” after one

or more instructions have been executed.

(4) Set the corresponding interrupt enable bit to “1” (enabled).

Interrupt request

generated

Main routine

* When executing DIV instruction

*

0 to 16 cycles

Interrupt request

acceptance

7 to 23 cycles

Interrupt sequence

Stack push and

Vector fetch

7 cycles

Interrupt routine

starts

Interrupt handling

routine

Fig 22. Time up to execution in interrupt routine

Push onto stack

Vector fetch

φ

SYNC

RD

WR

Address bus

Data bus

SYNC : CPU operation code fetch cycle

(This is an internal signal that cannot be observed from the external unit.)

BL, BH: Vector address of each interrupt

AL, AH: Jump destination address of each interrupt

16” or “0116”

SPS : “00

([SPS] is a page selected by the stack page selection bit of CPU mode register.)

S,SPS S-1,SPS S-2,SPS

PC

Not used PCH PCL PS AL AH

BL BH AL,AH

Execute interrupt

routine

Rev.1.00 Apr 2, 2007 Page 28 of 117

REJ03B0212-0100

Fig 23. Interrupt sequence

3803 Group (Spec.L)

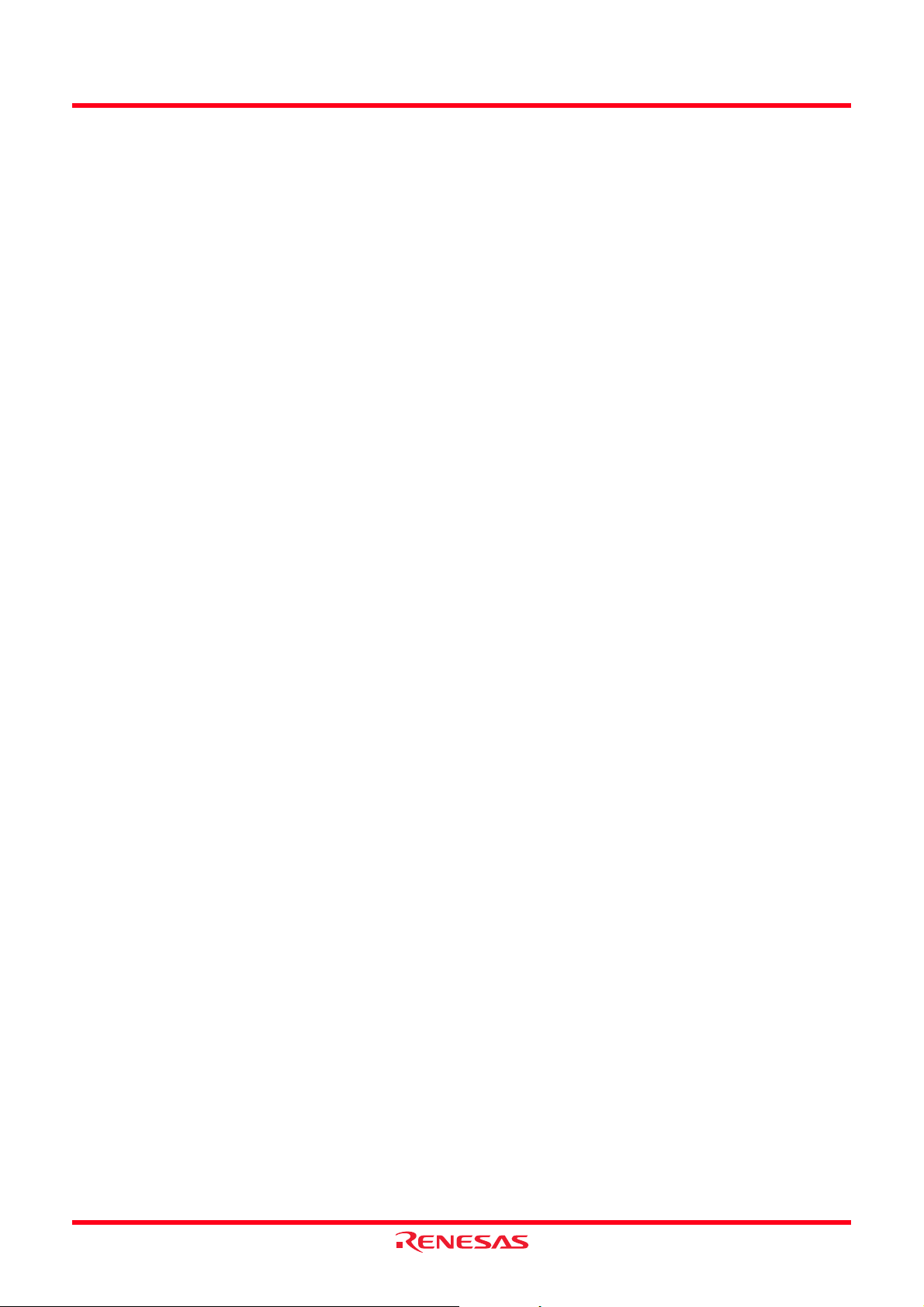

Push onto stack

Vector fetch

Instruction cycle

IR2T3

Internal clock φ

SYNC

Instruction cycle

12

T1

T1 T2 T3 : Interrupt acceptance timing points

IR1 IR2 : Timings points at which the interrupt request bit is set to “1”.

Note : Period 2 indicates the last φ cycle during one instruction cycle.

(1) The interrupt request bit for an interrupt request generated during period 1 is set to “1” at timing point IR1.

(2) The interrupt request bit for an interrupt request generated during period 2 is set to “1” at timing point IR1 or IR2.

The timing point at which the bit is set to “1” varies depending on conditions. When two or more interrupt

requests are generated during the period 2, each request bit may be set to “1” at timing point IR1 or IR2

separately.

IR1T2

Fig 24. Timing of interrupt request generation, interrupt request bit, and interrupt acceptance

Rev.1.00 Apr 2, 2007 Page 29 of 117

REJ03B0212-0100

3803 Group (Spec.L)

TIMERS

•8-bit Timers

The 3803 group (Spec.L) has four 8-bit timers: timer 1, timer 2 ,

timer X, and timer Y.

The timer 1 and timer 2 use one prescaler in common, and the

timer X and timer Y use each prescaler. Those are 8-bit

prescalers. Each of the timers and prescalers has a timer latch or

a prescaler latch.

The division ratio of each timer or prescaler is given by 1/(n + 1),

where n is the value in the corresponding timer or prescaler latch.

All timers are down-counters. When the timer reaches “00

16”, an

underflow occurs at the next count pulse and the contents of the

corresponding timer latch are reloaded into the timer and the

count is continued. When the timer underflows, the interrupt

request bit corresponding to that timer is set to “1”.

• Timer divider

The divider count source is switched by the main clock division

ratio selection bits of CPU mode register (bits 7 and 6 at address

003B

16). When these bits are “00” (high-speed mode) or “01”

(middle-speed mode), X

(low-speed mode), X

IN is selected. When these bits are “10”

CIN is selected.

• Prescaler 12

The prescaler 12 counts the output of the timer divider. The

count source is selected by the timer 12, X count source selection

register among 1/2, 1/4, 1/8, 1/16, 1/32, 1/64, 1/128, 1/256,

1/512, 1/1024 of f(XIN) or f(XCIN).

• Timer 1 and Timer 2

The timer 1 and timer 2 counts the output of prescaler 12 and

periodically set the interrupt request bit.

• Prescaler X and prescaler Y

The prescaler X and prescaler Y count the output of the timer

divider or f(X

X count source selection register (address 000E

Y, Z count source selection register (address 000F

CIN). The count source is selected by the timer 12,

16) and the timer

16) among 1/2,

1/4, 1/8, 1/16, 1/32, 1/64, 1/128, 1/256, 1/512, and 1/1024 of

f(XIN) or f(XCIN); and f(XCIN).

(1) Timer mode

• Mode selection

This mode can be selected by setting “00” to the timer X

operating mode bits (bits 1 and 0) and the timer Y operating

mode bits (bits 5 and 4) of the t imer XY mode re gister (add ress

0023

16).

• Explanation of operation

The timer count operation is started by setting “0” to the timer X

count stop bit (bit 3) and the timer Y count stop bit (bit 7) of the

timer XY mode register (address 0023

When the timer reaches “00

16”, an underflow occurs at the next

16).

count pulse and the contents of timer latch are reloaded into the

timer and the count is continued.

(2) Pulse Output Mode

• Mode selection

This mode can be selected by setting “01” to the timer X

operating mode bits (bits 1 and 0) and the timer Y operating

mode bits (bits 5 and 4) of the t imer XY mode re gister (add ress

16).

0023

• Explanation of operation

The operation is the same as the timer mode’s. Moreover the

pulse which is inverted each time the timer underflows is output

from CNTR

not the output of CNTR

0/CNTR1 pin. Regardless of the timer counting or

0/CNTR1 pin is initialized to the level of

specified by their active edge switch bits when writing to the

timer. When the CNTR0 active edge switch bit (bit 2) and the

CNTR

1 active edge switch bit (bit 6) of the timer XY mode

register (address 0023

16) is “0”, the output starts with “H” level.

When it is “1”, the output starts with “L” level.

Switching the CNTR

reverse the output level of the corresponding CNTR

0 or CNTR1 active edge switch bit will

0 or CNTR1

pin.

• Precautions

Set the double-function port of CNTR

4/P55 to output in this mode.

P5

0/CNTR1 pin and port

• Timer X and Timer Y

The timer X and timer Y can each select one of four operating

modes by setting the timer XY mode register (address 0023

16).

(3) Event Counter Mode

• Mode selection

This mode can be selected by setting “10” to the timer X

operating mode bits (bits 1 and 0) and the timer Y operating

mode bits (bits 5 and 4) of the t imer XY mode re gister (add ress

0023

16).

• Explanation of operation

The operation is the same as the timer mode’s except that the

timer counts signals input from the CNTR

valid edge for the count operation depends on the CNTR

edge switch bit (bit 2) or the CNTR

of the timer XY mode register (address 0023

0 or CNTR1 pin. The

0 active

1 active edge switch bit (bit 6)

16). When it is “0”,

the rising edge is valid. When it is “1”, the falling edge is valid.

• Precautions

Set the double-function port of CNTR

P5

4/P55 to input in this mode.

0/CNTR1 pin and port

Rev.1.00 Apr 2, 2007 Page 30 of 117

REJ03B0212-0100

3803 Group (Spec.L)

(4) Pulse Width Measurement Mode

• Mode selection

This mode can be selected by setting “11” to the timer X

operating mode bits (bits 1 and 0) and the timer Y operating

mode bits (bits 5 and 4) of the timer XY mode register (address

002316).

• Explanation of operation

When the CNTR

active edge switch bit (bit 6) of the timer XY mode register

(address 0023

falling edge of CNTR

edge of input (“L” term). When it is “0”, the timer counts during

the term of one rising edge input until the next falling edge input

(“H” term).

• Precautions

Set the double-function port of CNTR

P5

4/P55 to input in this mode.

The count operation can be stopped by setting “1” to the timer X

count stop bit (bit 3) and the timer Y count stop bit (bit 7) of the

timer XY mode register (address 0023

bit is set to “1” each time the timer underflows.

• Precautions when switching count source