Page 1

TB-690

Conveyor/Stacker

ASSEMBLY

&

OPERATIONS MANUAL

Revised: 7-14-14

Page 2

RENA Systems Inc. would like to Thank You for investing in our

quality built product s.

Please record the following information for future reference:

Model:

Serial Number:

Purchase Date:

Purchased From:

Dealer Name:

Contact Name:

Address:

Address:

Phone Number:

Please take this opportunity to register your product.

Use the following “Warranty Registration” link to register your product with Rena

Systems.

http://www.renausa.com/support_warranty_registration.html

Notes

Page 3

This manual is intended solely for the use and information of Neopost USA, its

designated agents, customers, and their employees. The information in this guide was

obtained from several different sources that are deemed reliable by all industry

standards. To the best of our knowledge, that information is accurate in all respects.

However, neither Neopost USA, Inc. nor any of its agents or employees shall be

responsible for any inaccuracies contained herein.

All rights reserved. No part of this book may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying, recording, or any information storage and retrieval system, without permission in

writing from the publisher

1

Page 4

CAUTION

DO NOT SWITCH DIRECTION OF

BREAKER WILL TRIP.

This conveyor can be used for Right Angle or Straight Thr ough operation. In addition it can be run in the Left-to-Right or Right-to-Left operating mode.

Setting up the Conveyor

1. First determine if the conveyor is to be used in the

Left-to-Right or Right-to-Left mode. A switch is

mounted under the conveyor near the front lefthand side of the conveyor on the motor mounting

plate.

BELTS WHEN MOTOR IS

RUNNING.

OVERLOAD MAY OCCUR AND

FUSES WILL BLOW AND/OR

2. Next mount the stacking tray to the appropriate

end of the conveyor using the three screws

supplied.

NOTE: THE STACKING TRAY CAN BE

MOUNTED TO EITHER END OF THE

CONVEYOR DETERMINED BY THE

DIRECTION THE BELTS TRAVEL.

3. If the conveyor is to be used in the straight

through mode the Right Angle Guide should be

removed. If the Right Angle Guide has to be

moved to the opposite end of the conveyor do the

following:

a) Remove the Right Angle Guide by first

removing the two screws that attach the

mounting bracket to the conveyor.

b) Then slide the guide assembly to the right

and lift it from the conveyor.

Note: The image, shown to the right, was taken

from the operator side of the conveyor. It shows the

Right Angle Guide’s finger and the corresponding

slot in the conveyor body.

2

Page 5

THE CONVEYOR IS VERY HEAVY.

INJURY DURING SETUP.

Installing the Conveyor

1. Roll the conveyor up to the machine that requires stacking of

its output.

2. Adjust the height of the conveyor to match the output end of

the machine by loosing (counterclockwise) the two large knobs

(one on each end), raising the conveyor to the proper height and

tightening (clockwise) the two knobs one at a time .

WARNING

IT IS RECOMMENDED THAT TWO

PEOPLE WORK TOGETHER TO

RAISE IT INTO THE PROPER

OPERATING HEIGHT. A BLOCK OF

WOOD UNDER THE CENTER OF

THE LEG WILL HELP PREVENT

Operating the Conveyor

1. Plug the conveyor into a properly grounded wall outlet using the

power cord supplied. Turn on the main power switch located

above the power receptacle.

CAUTION

THE CONVEYOR IS DESIGNED TO BE

PLUGGED INTO A GROUNDED OUTLET.

FOR YOUR SAFETY, DO NOT REMOVE THE

GROUND PIN FROM THE LINE CORD.

2. Adjust the speed control knob on the front of the conveyor to

obtain the proper speed. If the conveyor does not start check to

see that the Emergency Stop switch has been released.

NOTE: THE EMERGENCY STOP SWITCH IS

ACTIVATED BY PUSHING IN ON IT AND RELEASED

BY TURNING IT CLOCKWISE IN THE DIRECTION OF

THE ARROWS.

3. If you are using the conveyor in the right angle mode (conveyor is perpendicular to the machine feeding it)

then adjust the Right Angle Guide as follows:

a) With the conveyor belt stopped, loosen the two ball rack

locking levers [A]and raise the ball rack [B]. Place a piece

of media under the ball rack, then lower, and lock the

levers.

b) Loosen the locking screws [C] and move th e ball r ack

assembly in or out to center the media on the belt.

3

Page 6

4. Feed stock through the machine and onto the conveyor to check operation.

Troubleshooting

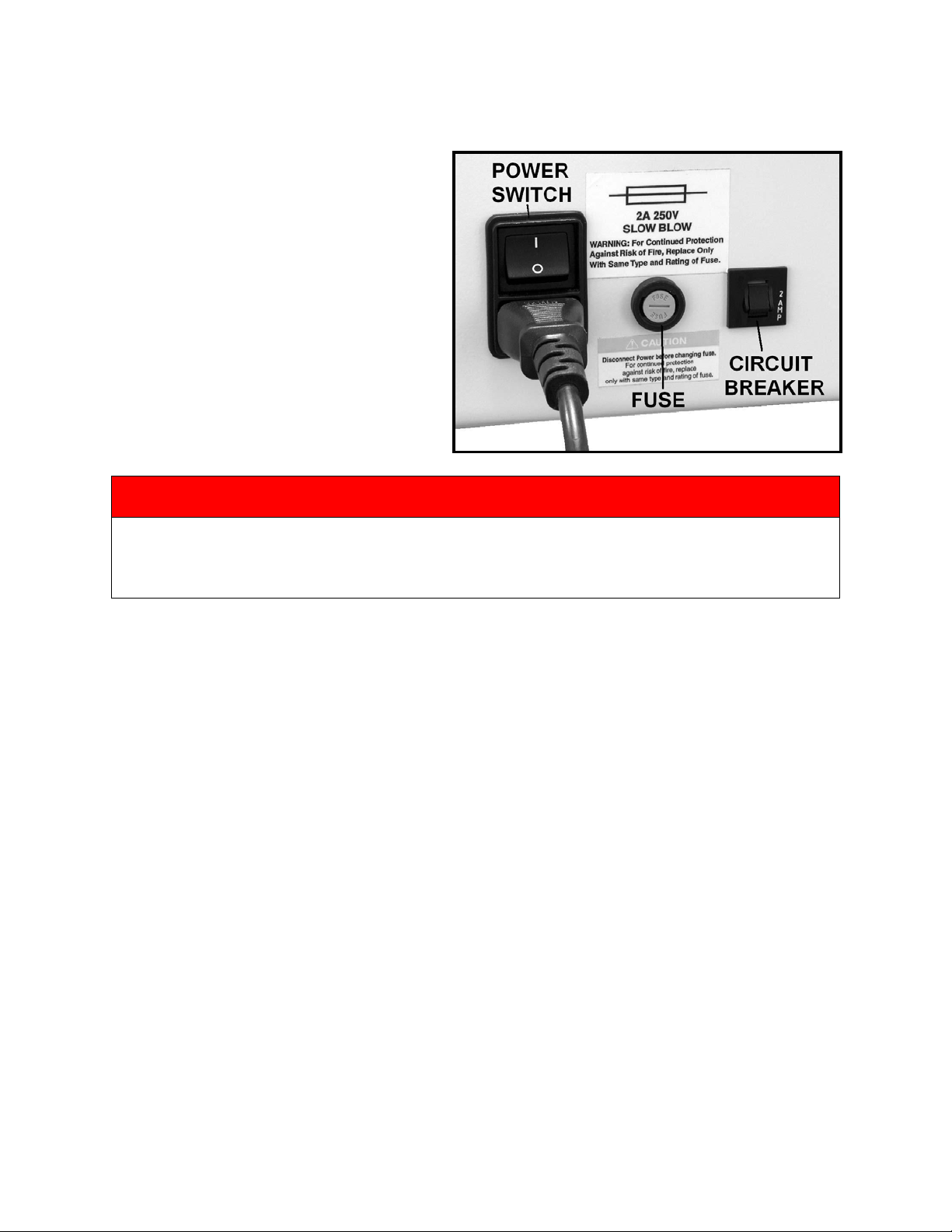

If the conveyor should fail to run, check for

jammed paper between the belt and roller.

Also, check the fuse and motor circuit breaker

and replace or reset if necessary. The fuse

holders and circuit breaker are located on the

rear of the conveyor, next to the power inlet.

WARNING

DISCONNECT THE POWER CORD WHEN CHECKING OR REPLACING FUSE!

ALWAYS REPLACE THE FUSE WITH THE SAME TYPE. FAILURE TO DO SO MAY DAMAGE THE

ELECTRONIC CIRCUIT BOARD.

4

Page 7

Drop Tray Kit Installation Instructions

(Part # Drop Tray-TB)

NOTE: This optional drop tray was designed for conveyors that are set for Left to Right transport.

1. Remove the three screws attaching the Stacking Tray to the

conveyor. Remove the Stacking Tray and discard.

2. Install the Drop Tray Mounting Plate to the Right-Hand end of

the Conveyor using the five screws supplied.

3. Assemble the Drop Tray as shown and install it on the

Mounting Plate as shown.

4. Install the Guide Rollers to the side frames of the Conveyor

Body using the screws provided.

5

Page 8

Copyright © 2014 NEOPOST USA

Optional Accessories:

Part # Description

IR1K ~1000 Watt Dryer

IR2K ~2000 Watt Dryer

Drop Tray-TB Drop Tray for the TB-690 Conveyors (for Left to Right use only)

Specifications

Length: 72”

Width 18”

Height 30” to 36” (Adjustable)

Belt Speed: 15 to 250 feet per minute

Power: 115 VAC/ 60Hz

Shipping Weight: 100 lbs

Specifications are subject to change without notice.

The TB-690 belt direction and stacking tray may be reversed to su it the application.

6

Loading...

Loading...