Remeha Gas 460 Eco Technical Information

Gas-fired boilers

GAS 460 S

EN

Installation and

Service Manual

300005247-001-E

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.1 Used symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.3 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 Safety instructions and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.2 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3.3 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.4 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.1 Regulations governing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.2 Package list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

4.3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4.4 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.5 Gas connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.6 Connection to a chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.7 Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.8 Skeleton Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

5 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.1 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.2 Check points before commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.3 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.4 Checks and adjustments after commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6 Stopping the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.1 Precautions to take if there is a danger of frost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.2 Precautions to take in the event of prolonged shutdown (one year or more) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

7 Checking and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7.1 Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

7.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

8 Spare parts Gas 460 S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.1 Boiler body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.2 Base frame + Draught diverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

8.3 Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.4 Control panel K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

8.5 Control panel K + Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

8.6 Metal casing for control panel K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

8.7 Gas line 20 mbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8.8 Circuit separation transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

8.9 Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2

GAS 460 S 04/01/11 - 300005247-001-E

1Introduction

1.1 Used symbols

Caution danger

Risk of injury and damage to equipment. Attention must be

paid to the warnings on safety of persons and equipment.

Specific information

Information must be kept in mind to maintain comfort.

1.2 General

Congratulations on your choice of a high quality product. We

strongly advise you to read the following instructions in order to

guarantee the optimal operation of your appliance. We are sure

that it will be entirely to your satisfaction and will meet with all

of your expectations.

` Keep these instructions in a safe place close to the appliance.

` For a proper operating of the boiler, follow carefully the

instructions.

` The manufacturer is not liable for any improper use of the

appliance or failure to maintain or install the unit correctly (the

user shall take care to ensure that the system is installed by a

qualified engineer).

` In the interest of customers, REMEHA are continuously

endeavouring to make improvements in product quality. All the

specifications stated in this document are therefore subject to

change without notice.

Reference

Z

Refer to another manual or other pages in this instruction

manual.

DHW: Domestic hot water

04/01/11 - 300005247-001-E GAS 460 S

3

1.3 Homologations

It is CE approved under the following number : 0085BL0187

The boilers are in compliance with the EC directives:

- Royal Decree dated 8th January 2004

- 90/396/EEC Gas Appliance Directive

- 2006/95/EC Low Voltage Directive

Reference Standard: EN 60.335.1

- 2004/108/EC Electromagnetic Compatibility Directive

Reference Standard: EN 50.081.1 ; EN 50.082.1 ; EN 55.014

- 92/42/EEC Efficiency Directive **

Low temperature gas boiler

1

,

1.3.1 Directive 97/23/EC

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 EC.

1.3.2 User country

User country ES, GB HU

Category I

Gas type G20 G20

Distribution pressure (mbar) 20 25

2H

I

2H

- Type B11 (B11

discharge control system).

France:

Performance class III boiler according to ATG B 84

recommendations.

Belgium:

The boilers comply with the specifications of the HR+ quality label.

The boilers should be fitted with a 160 VA circuit separation

transformer (delivered with the documentation package).

The boilers and hot water tanks are designed and manufactured in

accordance with the sound engineering practice, as requested in

article 3.3 of the directive 97/23/EC; it is certified by compliance with

the directives 90/396/EC, 92/42/EC, 2006/95/EC and 2004/108/EC.

if fitted with the optional combustion products

BS

The boilers leave the factory operating with H natural gas.

4

GAS 460 S 04/01/11 - 300005247-001-E

2 Safety instructions and recommendations

2.1 Safety instructions

Fire hazard

Do not stock products of an inflammable nature close to

the appliance.

If you smell gas, do not use a naked flame, do not smoke,

do not operate electrical contacts or switches (doorbell,

lights, motor, lift, etc.).

1.Isolate the gas supply

2.Open the windows

3.Extinguish all flames

4.Evacuate the premises

5.Contact a qualified professional

6.Inform the gas supplier

Risk of intoxication

Do not obstruct the air inlets in the room (even partially).

If you smell flue gases

1.Switch the appliance off

2.Open the windows

3.Evacuate the premises

4.Contact a qualified professional

Risk of being burnt

Avoid direct contact with the flame viewport.

Depending on the settings of the appliance:

- The temperature of the flue gas conduits may exceed 60°C

- The temperature of the radiators may reach 95°C

- The temperature of the domestic hot water may reach 65°C

Risk of damage

Do not stock chloride or fluoride compounds close to the

appliance.

Install the appliance in frost-free premises.

Do not neglect to service the appliance: Contact a qualified

professional or take out a maintenance contract for the annual

servicing of the appliance.

2.2 Recommendations

Only qualified professionals are authorised to work on the

appliance and the instalation.

Before any work, switch off the mains supply to the

appliance.

Check regularly that the installation contains water and is

pressurised.

Keep the appliance accessible at all times.

Avoid draining the installation.

The appliance should be on Summer or Antrifreeze mode rather than

switched off to guarantee the following functions:

- Frost protection

- Protection against corrosion on domestic hot water tanks fitted

with a titanium anode

04/01/11 - 300005247-001-E GAS 460 S

5

3 Technical description

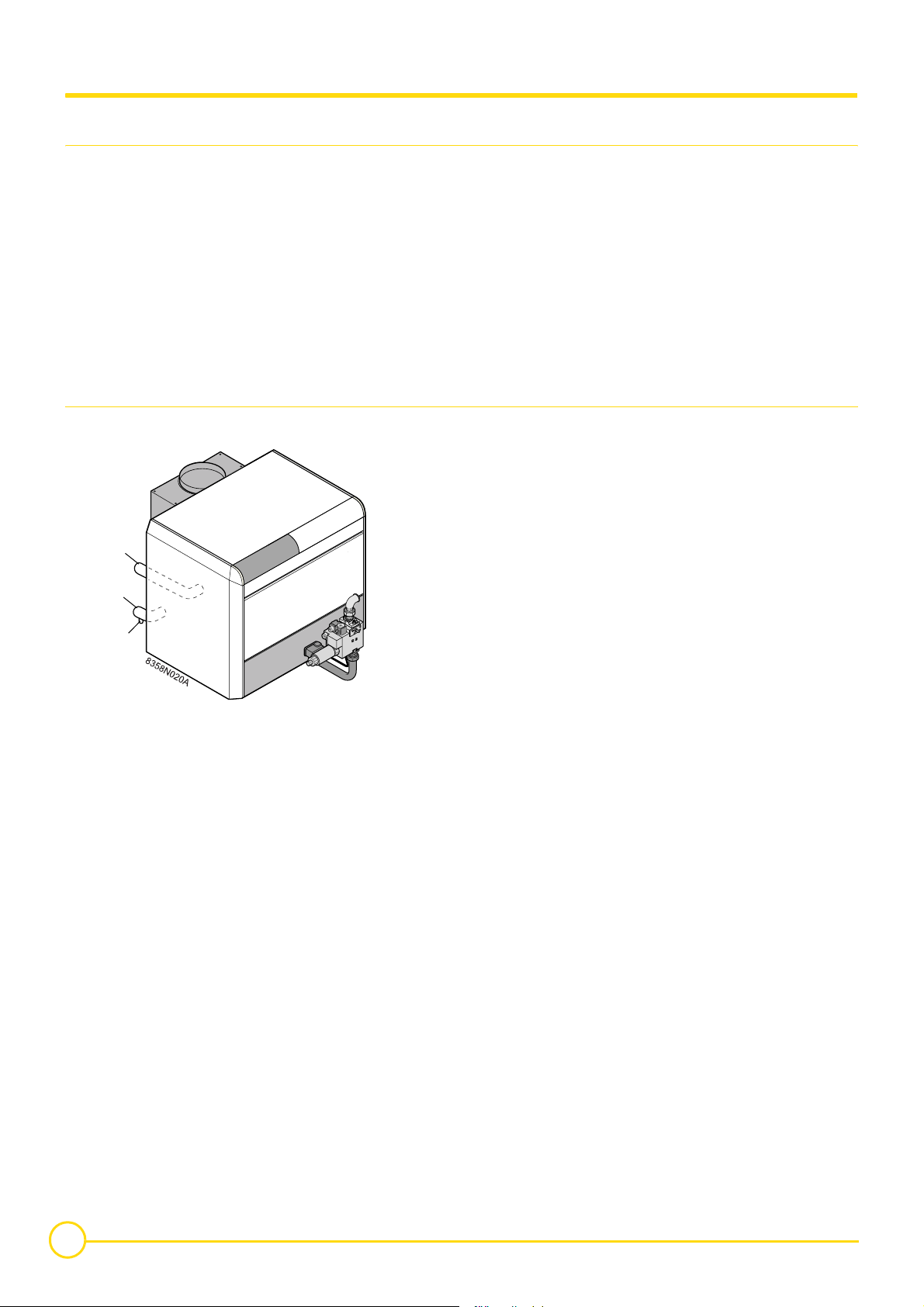

3.1 General description

Gas 460 S boilers are made of cast iron:

- with atmospheric gas burners

- with 2 operating stages

- with electronic ignition via the ignition burner for hot water central

heating

- with a useful output of between 119 and 380 kW

They are designed to be connected to a chimney.

The figure given after Gas 460 S indicates the number of sections

which make up the boiler.

Gas 460 S boilers are delivered with a K control panel. They can be

fitted with an optional RC4 and RC5 control unit (master-secondary

control unit options).

3.2 Technical characteristics

The boilers can operate on natural gases type H/L.

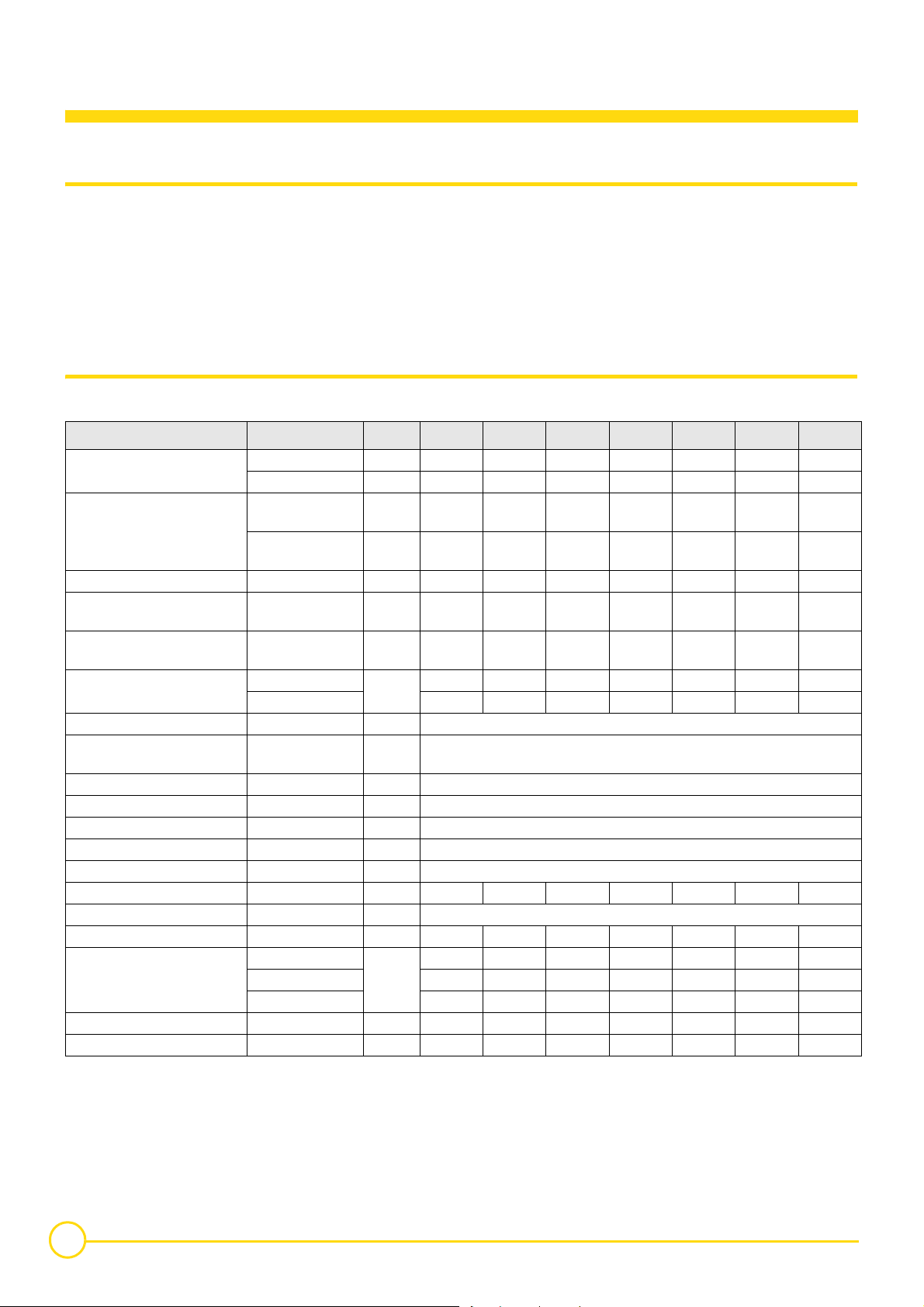

Boiler Gas 460 S / 8 10 12 14 16 18 20

Useful output

Power input

Number of sections Part 8 101214161820

Mass flue gas flow rate

Flue gas temperature Tf

Boiler temperature 80°C

CO

2

Ionization current µA 1.0

Required depressurisation at the

nozzle

Minimum outlet temperature °C 40

Maximum outlet temperature °C 90

Maximum operating pressure bar 6

Electrical connection V/Hz 230/50

Electrical power W 108 / 114 maximum

Gas connection 20 mbar inch 1" 1" 1" 1"1/4 1"1/4 1"1/4 1"1/2

Heating connection inch 2"

Internal diameter flue gas nozzle mm 250 300 300 350 350 350 400

Water resistance

Water content* l 61 76 91 106 122 137 154

Shipping weight kg 668 807 934 1096 1227 1364 1476

(1)

at 2nd stage

(1)

(1)

1st stage kW 83-98 107-126 131-154 155-182 179-210 202-238 226-266

2nd stage kW 119-140 153-180 187-220 221-260 255-300 289-340 323-380

1st stage kW

2nd stage kW 131.1-153

kg per

sec

°C 125 123 130 126 133 140 126

1st stage

2nd stage 5.4-6.4 5.3-6.3 5.8-6.8 5.5-6.5 6.0-7.0 6.5-7.5 5.5-6.5

∆ T = 10K

∆ T = 15K 36 59 88 123 164 211 263

∆ T = 20K 20 33 50 69 92 118 148

%

daPa 0.7

mbar

93.1-

108.9

0.097 0.127 0.144 0.177 0.191 0.203 0.258

3.9-4.9 3.8-4.8 4.3-5.3 4.0-5.0 4.5-5.5 5.0-6.0 4.0-5.0

80 133 198 277 369 474 592

119.4-

139.7

168.2-

196.3

145.6-

170.4

205.2-

239.4

171.9-

201.1

242.2-

282.6

197.9-

231.8

278.8-

325.4

224-262.1

315.7-

368.4

250.1-

292.6

352.4-

411.3

1 mbar = 10 mmWG = 10 daPa = 100 Pa

6

GAS 460 S 04/01/11 - 300005247-001-E

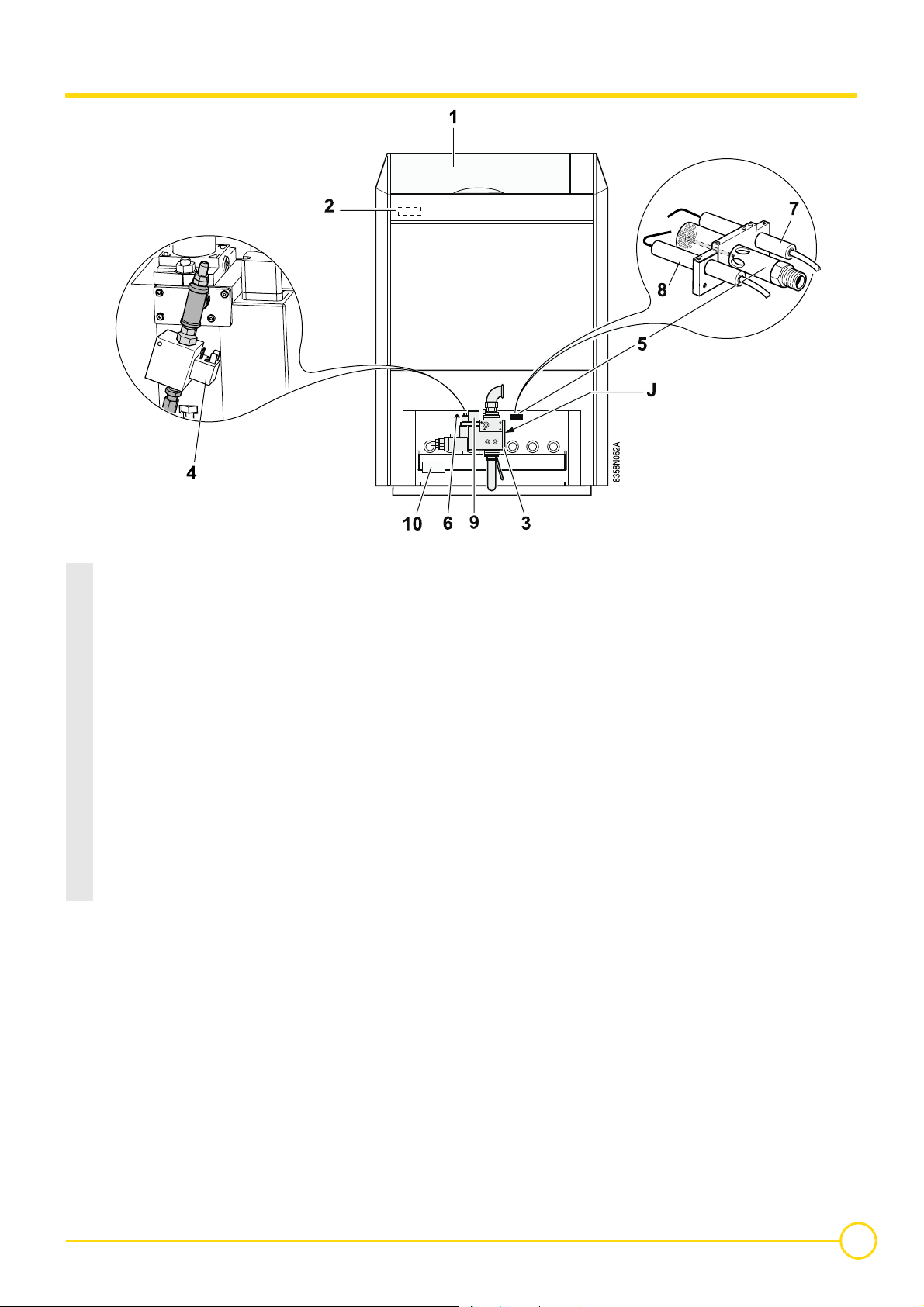

3.3 Main parts

1 Control panel

2 Safety box

The safety control box is fitted to the control panel and controls the

burner ignition, function and extinction sequences.

3 Multivalve gas unit:

It includes a safety valve and a 2-stage principal valve with filter and

minimum gas pressure switch.

4 Ignition burner valve

5 Ignition burner

6 Flame inspection window

7 Ionization probe: It detects flame presence on the ignition burner by

flame ionization.

8 Ignition electrode: This ensures ignition burner ignition using a high

voltage spark.

9 Minimum gas pressure switch

(Minimum pressure: 12.5 mbar)

10 Ignition box

04/01/11 - 300005247-001-E GAS 460 S

7

3.4 Operating principle

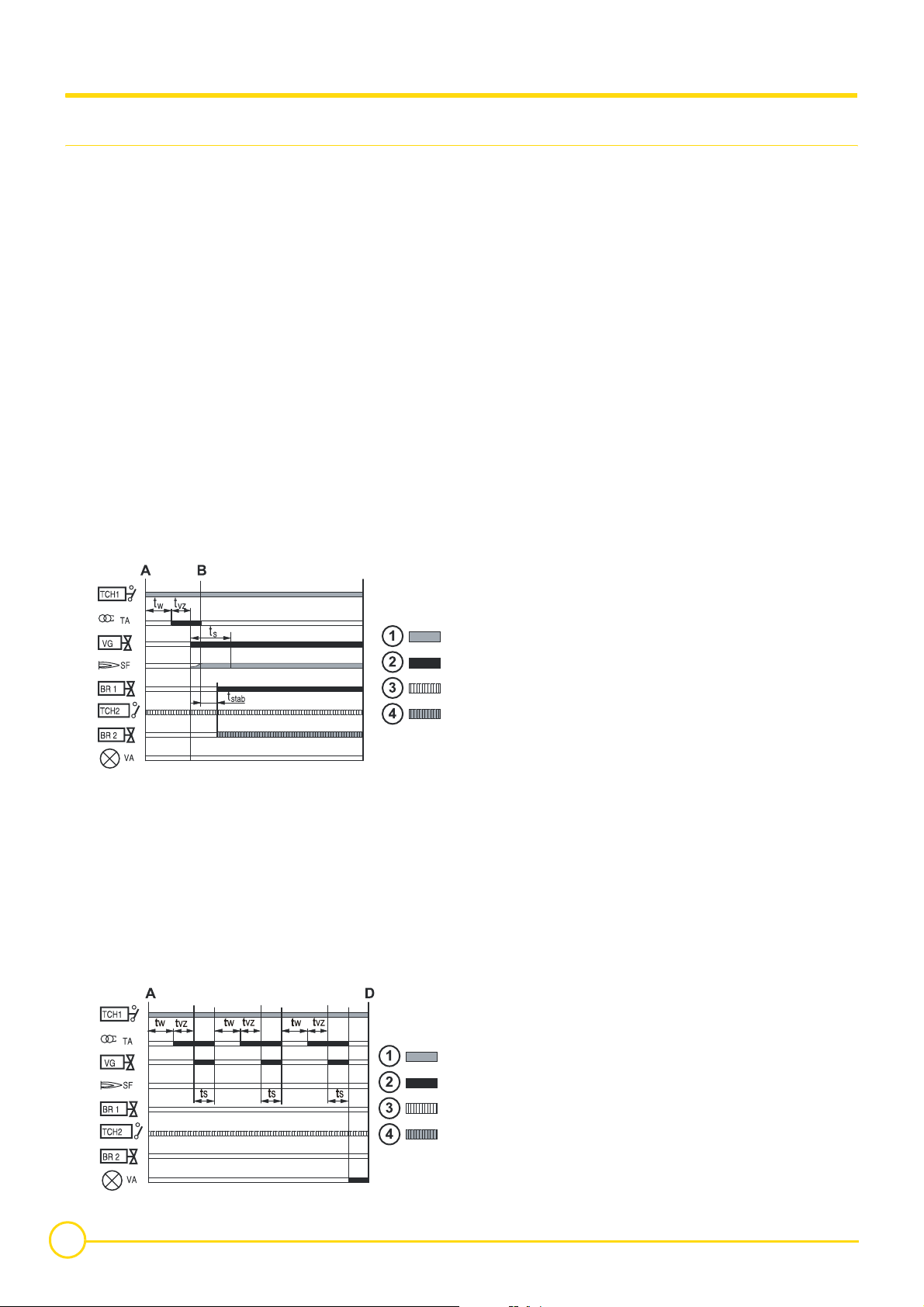

3.4.1 Furnace operation equipped with safety box RV 00 541 400 00

Operating principle

The boiler can operate at either 2nd stage or 1st stage depending on

the thermal needs of the installation.

The ignition and burner surveillance sequences are ensured by the

safety box.

Behaviour in normal conditions

The box closes the TCH contact when there is a requirement for

heat1. The safety control box runs an auto-check of around 1

second(s).

After a waiting time tw, the ignition transformer TA produces a series

of sparks at the ignition electrode. After a pre-ignition period tvz, the

ignition burner valve VG and the safety valve VS open. Formation of

flame in ignition burner. The ionization sensor SF shows a flame

signal with a minimum ionization current of 1 µA and ignition is shut

down. After a period of stabilisation tstab, the principal burner ignites

at 1st stage BR1 (or at 2nd stage if the 2nd stage thermostat TCH2

is needed).

8358N016B

Resetting

The box is reset after going into safety by pressing the reset button.

If the reset button does not work, wait at least 15 seconds before

trying a second time. After activating the reset button, the warning

light goes out and the safety control box restarts after a waiting time

of around 1 minute.

Note 1: The box may be on safety on its first start up: press the reset

button to release it.

Note 2: If the reset button is pressed in normal operation, the gas

valves close and the box starts a new ignition sequence.

Required input signals

Box output signals

Thermostatic request at 2nd stage

Operation 2nd stage

A Start of operation

B Formation of flame in ignition burner

BR1 1st stage

BR2 2nd stage

SF Burner flame signal

TA Ignition transformer

TCH1 Boiler thermostat 1 stage

TCH2 Boiler thermostat 2 stage

VA Safety lockout warning light

VG Ignition burner valve + Safety valve VS

ts Safety time: maximum 10 seconds

tstab Flame stabilisation time: 5 seconds

tvz Pre-ignition time: 10 seconds

tw Waiting time: 0 seconds

Behaviour in abnormal conditions

- If a flame is not detected before the safety time ts, the box makes

2 more ignition attempts. If, at the end of the last attempt, there is

still no flame signal, the box goes into safety and the safety

indicator comes on. To restart the heater, press the reset button on

the safety box.

- If there is a loss of flame in normal operation, the box automatically

repeats the start up sequence.

8358N017C

8

GAS 460 S 04/01/11 - 300005247-001-E

4 Installation

4.1 Regulations governing installation

4.1.1 Other countries

Installation and maintenance of the boiler must be carried out by a

qualified professional in compliance with prevailing local and national

regulations.

4.2 Package list

Assembly Instructions

Z

04/01/11 - 300005247-001-E GAS 460 S

9

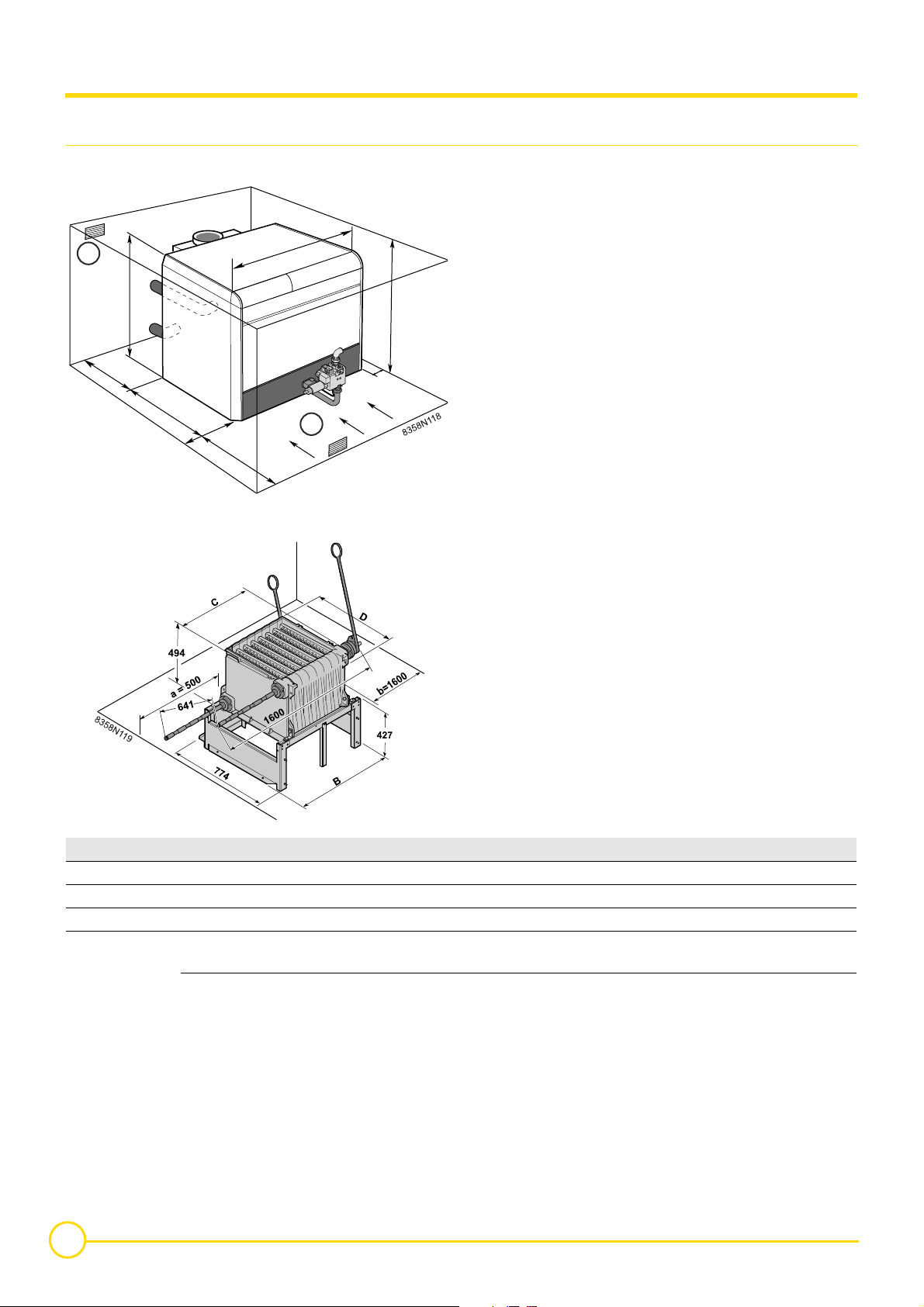

4.3 Mounting

4.3.1 Position of the boiler

1

1406

- The combustive air must reach the burner from the front.

- The dimensions (in mm) correspond to the minimum

recommended dimensions needed to ensure adequate

A

accessibility around the boiler.

- Dimensions a and b correspond to the dimensions to be respected

to ensure clearance of the assembly tool JD-TE Plus.

If a = 1400 mm , b = 500 mm

If a = 500 mm , b = 1400 mm

5

0

0

1006

* Water connection side

2002 mini

0

20

0*

0

4

10

0

0

2

It is forbidden to store inflammable products and materials

in the boiler room or close to the boiler, even temporarily.

A safety distance of at least 2 metres should be respected.

Gas 460 /... 8 10 12 14 16 18 20

A (mm) 970 1146 1322 1498 1674 1850 2026

B (mm) 938 1114 1290 1466 1642 1818 1994

(1)

C

(mm) 704 880 792 880 968 1056 1760

Side section

D

(mm)

Intermediate

section

704 704 704 704 704 704 704

720 720 720 720 720 720 720

(1) Thickness of a section

10

GAS 460 S 04/01/11 - 300005247-001-E

4.3.2 Ventilation

The location of air inlets in relation to the high ventilation openings

shall ensure that the air is renewed in the entire volume of the boiler

room.

Please refer to the prevailing regulations in your country.

` France:

Direct air inlet:

• Boiler with nominal output greater than 70 kW in accordance

with DTU 65.4 (NF P 52-221)

Upper and lower air vents compulsory

- Upper air vents

Cross section equal to half the total cross section of the flue gas

pipes with a minimum of 2.5 dm²

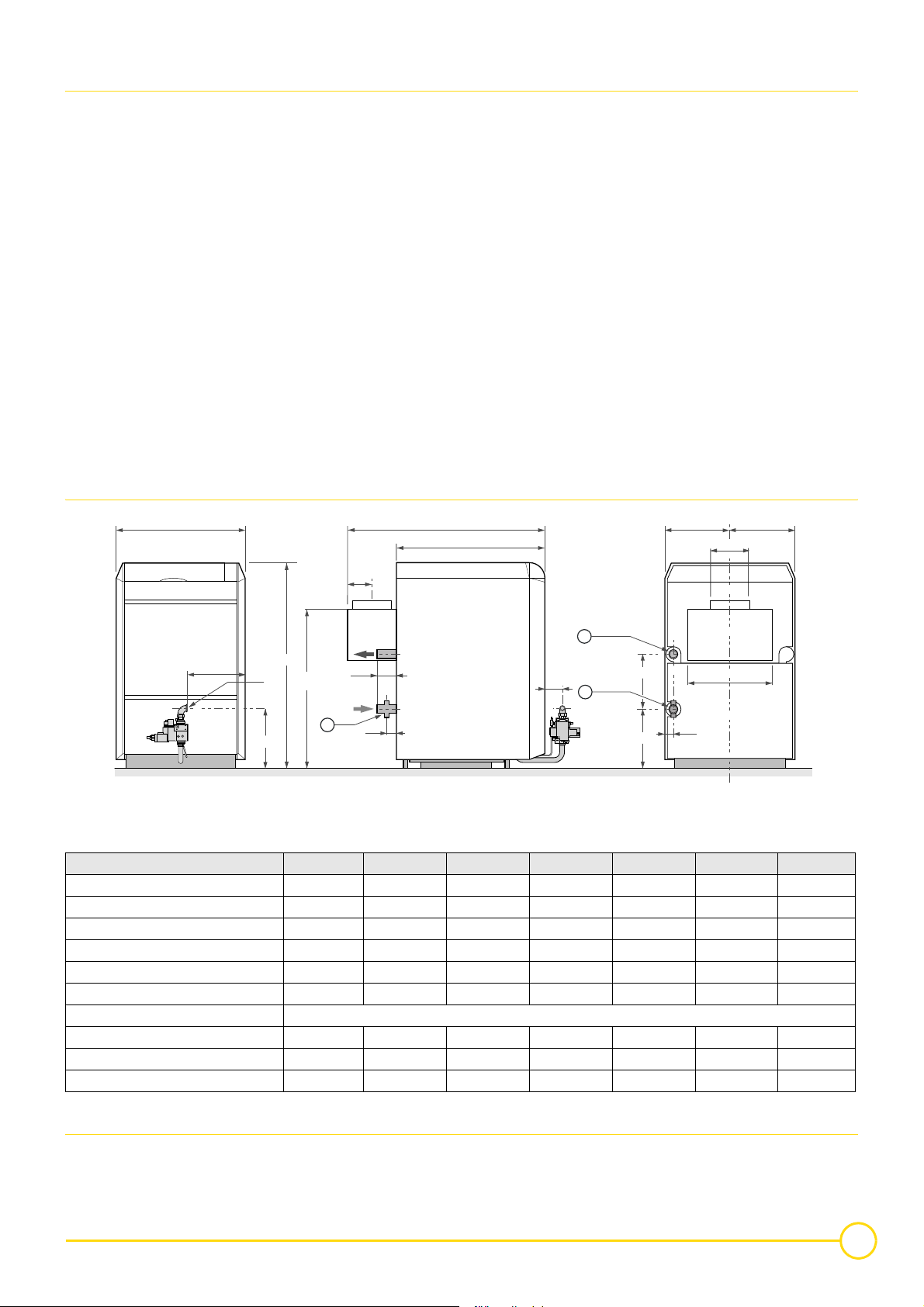

4.3.3 Main dimensions

B

- Lower air vents

Direct air inlet:

086P,

Sdm2()

≥

-------------20

P = Installed output in kW

Ensure a supply of air through the front of the burner but

avoid serious draughts.

Bottom aeration, even correctly dimensioned but positioned to the

rear of the boiler close to the draught diverter, may turn out to be

totally ineffective.

Incoming air is directly drawn in by the draught cut off without

reaching the burner.

An indirect air inlet through descending conduits presenting serious

airotic losses of load or input of meteorological conditions influencing

their draw should be avoided.

A

1006

= =

ø C

Heating outlet R 2

Heating return R 2

E

1

ø F

1406

J

H

130

3

60

130

2

Draining Rp 3/4

375

410

D

64

G

8358N061A

Boiler Gas 460 S /8 /10 /12 /14 /16 /18 /20

A (mm) 1362 1362 1362 1412 1412 1412 1462

B (mm) 970 1146 1322 1498 1674 1850 2026

Ø C (mm) 250 300 300 350 350 350 400

D (mm) 632 808 984 1160 1336 1512 1688

E (mm) 165 165 165 190 190 190 220

Ø F (mm) (20/25 mbar) Rp1 Rp1 Rp1 Rp1 1/4 Rp 1 1/4 Rp 1 1/4 Rp 1 1/2

Ø F (mm) (300 mbar) Rp 3/4

G 447 535 623 704 792 880 963

H 445 445 445 454 454 454 507

J 1094 1094 1094 1194 1194 1194 1194

4.3.4 Assembling the appliance

See assembly instructions

Z

04/01/11 - 300005247-001-E GAS 460 S

11

4.4 Hydraulic connections

4.4.1 Regulations

Installation must be carried out in accordance with the prevailing

regulations, the codes of practice and the recommendations in these

instructions.

Installing the boiler in new installations

(installations less than 6 months old)

- Clean the installation with a universal cleaner to eliminate debris

from the appliance (copper, flaxen thread, flux).

4.4.2 Hydraulic connection of the heating circuit

H

I

- Thoroughly flush the installation until the water runs clear and

shows no impurities.

Installing the boiler in existing installations

- Remove sludge from the installation.

- Flush the installation.

- Clean the installation with a universal cleaner to eliminate debris

from the appliance (copper, flaxen thread, flux).

- Thoroughly flush the installation until the water runs clear and

shows no impurities.

G

G Draining Rp 3/4

H Heating outlet R 2"

I Heating return R 2"

(1)

Welded connection possible after sawing off the threading.

The hydraulic connections must be made on the same side (either

right or left) but never in quincunx.

Install a sludge decanting pot on the return pipe, very close to the

boiler.

(1)

(1)

12

GAS 460 S 04/01/11 - 300005247-001-E

Loading...

Loading...