Remeha Gas 360 Eco Technical Information

Gas-fired boilers

GAS 360 S

EN

Installation and

Service Manual

300005180-001-C

Declaration of conformity 1

Declaration of conformity A.R. 8/1/2004 - BE

Manufacturer Remeha B. V.

Postbus 32

7300 AA APELDOORN

+31 55 5496969

*

+31 55 5496969

+

Issued by See end of notice

We hereby certify that the range of equipment specified below is in accordance with the format stated in the EC declaration of comformity,

that it is manufactured and distributed in accordance with the regulations and requirements in european directives and with the regulations

and requirements defined in the Royal Decree dated 8th January 2004.:

Product type Floor-standing gas boiler GAS 360 S

Models 8 - 10 - 12 - 14 sections

Standard applied - Royal Decree dated 8th January 2004

- 90/396/EEC Gas Appliance Directive

Reference Standard: EN 297 ; EN 656 ; EN 437

- 2006/95/EC Low Voltage Directive

Reference Standard: EN 60.335.1

- 2004/108/EC Electromagnetic Compatibility Directive

Reference Standard: EN 50.081.1 ; EN 50.082.1 ; EN 55.014

- 92/42/EEC Efficiency Directive

1

Low temperature gas boiler

Inspecting organisation GWI (D-Essen)

Measured values NOx: < 200 mg/kWh

CO: < 15 mg/kWh

Date: Signature

Technical Director

Mr. Bertrand Schaff

2

GAS 360 S 04/01/11 - 300005180-001-C

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Used symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.1 User country. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.3.2 Directive 97/23/EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2 Safety instructions and recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

3 Technical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

3.2 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.3 Main parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3.4 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1 Regulations governing installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.1 France . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.1.2 Other countries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.2 Package list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.3 Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.3.1 Position of the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.3.2 Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.3.3 Main dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.3.4 Assembling the appliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.4 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.4.1 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.4.2 Hydraulic connection of the heating circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.4.3 Hydraulic connection of the water circuit for domestic use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.4.4 Water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.5 Gas connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.6 Connection to a chimney . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4.7 Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.8 Skeleton Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

5 Start-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.1 Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.2 Check points before commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.3 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.4 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.4.1 Changing the burner injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.4.2 Changing the ignition burner injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

5.4.3 Setting the injector pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5.4.4 Setting the start up pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.4.5 Attaching the label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

5.4.6 Pressure setting and marking of calibrated injectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.5 Checks and adjustments after commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.6 Changing the settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6 Stopping the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.1 Precautions to take if there is a danger of frost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.2 Precautions to take in the event of prolonged shutdown (one year or more) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

04/01/11 - 300005180-001-C GAS 360 S

3

7 Checking and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.1 Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.1.1 Checking the ignition burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.1.2 Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.1.3 Water level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.1.4 Checking burner safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

7.1.5 Checking the safety thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

7.1.6 Checking the downdraught thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

7.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

7.2.1 Cleaning main burner and ignition burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

7.2.2 Cleaning of the heating body . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.2.3 Cleaning painted surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

7.3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.3.1 Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.3.2 Incidents and solutions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

8 Spare parts - GAS 360 S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8.1 Boiler body + Draught diverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2 Gas line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.2.1 8-10-12 sections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.2.2 14 sections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

8.3 Control panel K. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.4 Control panel K + Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.5 Metal casing for control panel K . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8.6 Boiler body insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8.7 Casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4

GAS 360 S 04/01/11 - 300005180-001-C

1Introduction

1.1 Used symbols

Caution danger

Risk of injury and damage to equipment. Attention must be

paid to the warnings on safety of persons and equipment.

Specific information

Information must be kept in mind to maintain comfort.

1.2 General

Congratulations on your choice of a high quality product. We

strongly advise you to read the following instructions in order to

guarantee the optimal operation of your appliance. We are sure

that it will be entirely to your satisfaction and will meet with all

of your expectations.

` Keep these instructions in a safe place close to the appliance.

` For a proper operating of the boiler, follow carefully the

instructions.

1.3 Homologations

CE identification no: CE-0085AU0115

8 sections: Type B11

10-14 sections: Type B11 boiler

BS

boiler

Reference

Z

Refer to another manual or other pages in this instruction

manual.

DHW: Domestic hot water

` The manufacturer is not liable for any improper use of the

appliance or failure to maintain or install the unit correctly (the

user shall take care to ensure that the system is installed by a

qualified engineer).

` In the interest of customers, De Dietrich Thermique SAS are

continuously endeavouring to make improvements in product

quality. All the specifications stated in this document are

therefore subject to change without notice.

France: Performance class III boiler according to ATG B 84

recommendations.

1.3.1 User country

User country

ES, GB

HU

Gas

category

II

2H3P

II

2H3P

Gas type

G20 20

G31 37

G20 25

G31 50

Connection

pressure (mbar)

1.3.2 Directive 97/23/EC

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 EC.

Compliance of Remeha boilers and DHW tanks with the codes of

practice, required by article 3.3 of directive 97/23/EEC, is certified by

the CE marking relative to directives 90/396/EEC, 92/42/EEC, 2006/

95/EC and 2004/108/EC.

Remeha Gas 360 S boilers are delivered preset for operation on

group H natural gases.

For operation on another gas group, see the chapter "Gas

Z

settings" (Page: 20).

04/01/11 - 300005180-001-C GAS 360 S

5

2 Safety instructions and recommendations

2.1 Safety instructions

Fire hazard

Do not stock products of an inflammable nature close to

the appliance.

If you smell gas, do not use a naked flame, do not smoke,

do not operate electrical contacts or switches (doorbell,

lights, motor, lift, etc.).

1.Isolate the gas supply

2.Open the windows

3.Extinguish all flames

4.Evacuate the premises

5.Contact a qualified professional

6.Inform the gas supplier

Risk of intoxication

Do not obstruct the air inlets in the room (even partially).

If you smell flue gases

1.Switch the appliance off

2.Open the windows

3.Evacuate the premises

4.Contact a qualified professional

Risk of being burnt

Avoid direct contact with the flame viewport.

Depending on the settings of the appliance:

- The temperature of the flue gas conduits may exceed 60°C

- The temperature of the radiators may reach 95°C

- The temperature of the domestic hot water may reach 65°C

Risk of damage

Do not stock chloride or fluoride compounds close to the

appliance.

Install the appliance in frost-free premises.

Do not neglect to service the appliance: Contact a qualified

professional or take out a maintenance contract for the annual

servicing of the appliance.

2.2 Recommendations

Only qualified professionals are authorised to work on the

appliance and the instalation.

Before any work, switch off the mains supply to the

appliance.

Check regularly that the installation contains water and is

pressurised.

Keep the appliance accessible at all times.

Avoid draining the installation.

The appliance should be on Summer or Antrifreeze mode rather than

switched off to guarantee the following functions:

- Frost protection

- Protection against corrosion on domestic hot water tanks fitted

with a titanium anode

6

GAS 360 S 04/01/11 - 300005180-001-C

3 Technical description

3.1 General description

Boilers in the GAS 360 S range have the following characteristics:

- Cast iron floor-standing gas boiler.

- Connecting to a chimney.

- Atmospheric burner (2 stages).

- Heating body in cast iron with overlapping studs making it possible

to obtain extremely high efficiency. Also, the baffling in the smoke

circuits limits the natural chimney effect and gives high

performance yields.

- Efficient insulation of the entire boiler unit for very low losses to the

ambient air.

The figure given after Remeha Gas 360 S indicates the number

of sections which make up the boiler.

For example: Remeha Gas 360 S/8: 8 section boilers

04/01/11 - 300005180-001-C GAS 360 S

7

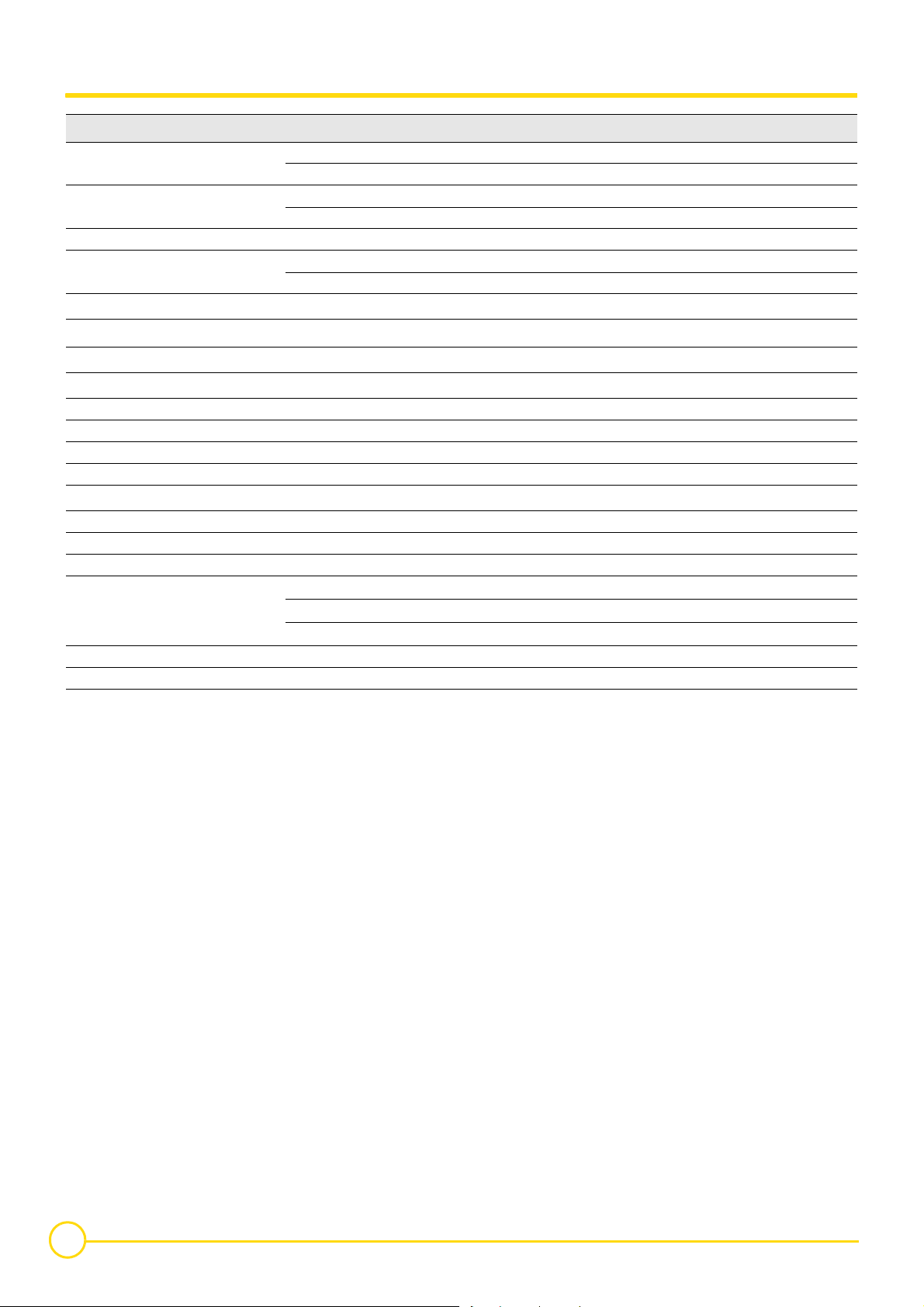

3.2 Technical characteristics

Models Gas 360 S/ 8 10 12 14

Useful output

Power input

Number of sections 8 10 12 14

Mass flue gas flow rate

Smoke temperature

CO

(Natural gas H)

2

Ionization current

(1) (2)

(1) (2)

(1)

(1)

Required depressurisation at the nozzle

Minimum output temperature °C 30 30 30 30

Maximum output temperature °C 90 90 90 90

Maximum operating pressure bar 6666

Electrical connection V/Hz 230/50 230/50 230/50 230/50

Electrical power

(1) (3)

Gas connection inch R1R1R1R1

Heating connection inch R1 1/2 R1 1/2 R1 1/2 R1 1/2

Internal diameter flue gas nozzle mm 180 200 200 225

Loss of load hydraulic circuit

(1)

Water content l 32.6 39.8 47 54.2

Net weight (without water) kg 257 305 357 408

(1) At nominal output (Stage2)

(2) Boiler temperature: 80 °C

(3) Electrical power of the boiler only with no accessories

Stage1 kW 36455454

Stage2 kW 63 81 99 117

Stage1 kW 39.4 49.1 58.8 58.8

Stage2 kW 68.9 88.4 107.8 127.2

Stage1 Kg/h 140 166 199 199

Stage2 Kg/h 138 177 216 255

°C 135 135 135 135

% 7.4 7.4 7.4 7.4

µA 3333

(1)

mbar 0.04 0.04 0.04 0.04

W 25252525

∆T= 10K mbar

∆T= 15K mbar

∆T= 20K mbar

56 120 216 320

25 53 96 142

14 30 54 80

Conditions of use:

- Max. safety temperature: 110 °C

- Max. operating pressure: 6 bar

- Thermostat adjustable from 30 to 90°C

- Safety thermostat: 110 °C

8

GAS 360 S 04/01/11 - 300005180-001-C

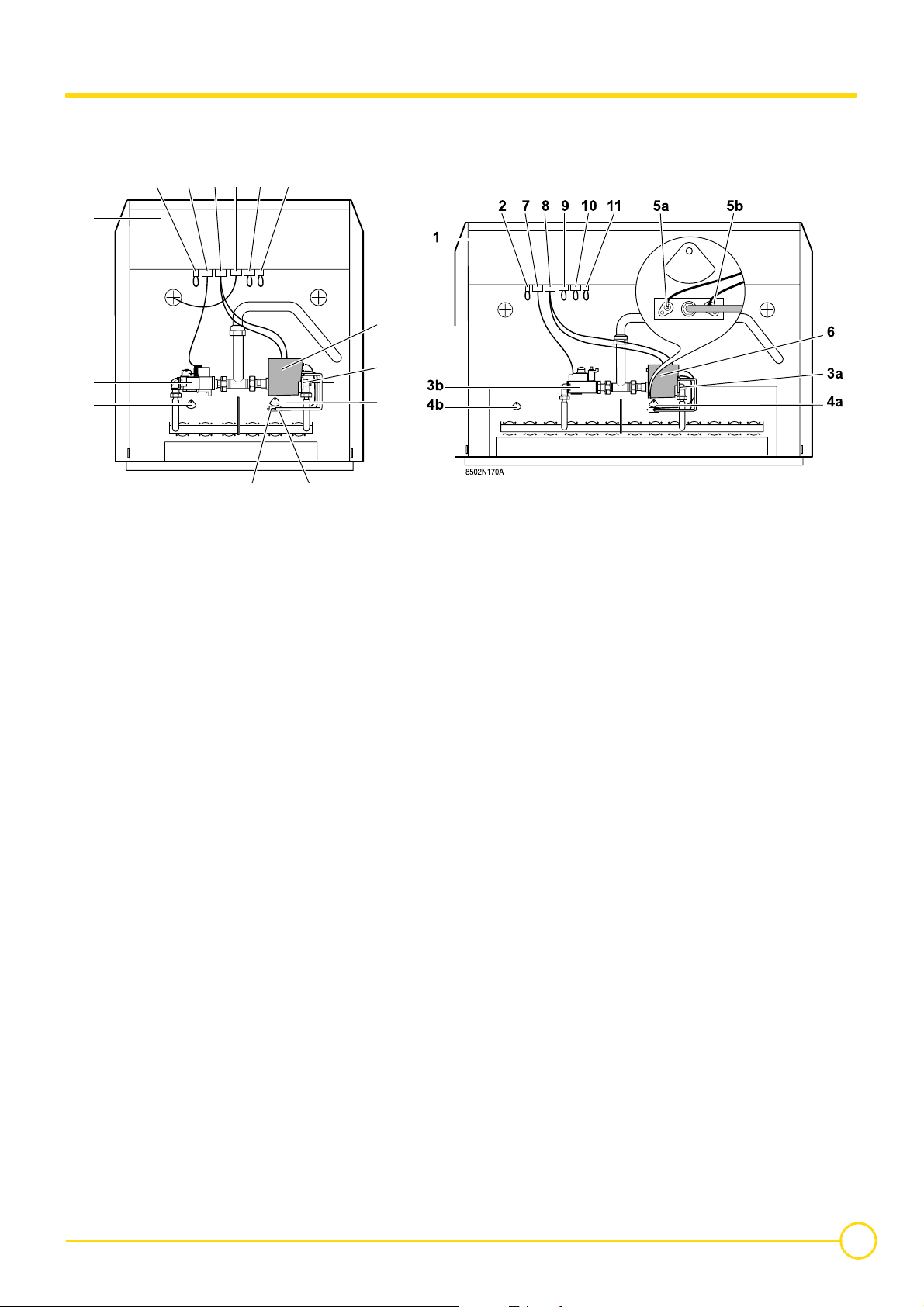

3.3 Main parts

8 sections 10-14 sections

7 8 9 10 11

2

1

6

3b

4b

8502N169A

5a 5b

1. Control panel

The control panel gives priority to producing domestic hot water

2. Factory fitted bridge

Connection for gas pressure switch

Natural gas: 12.5 mbar

Propane: 20 mbar

3. a: Gas valve - Stage1 - Type VK4100C1026

b: Gas valve - Stage2 - Type VK4105C1066 (8-12 sections) -

Type VR4605CB1033 (14 sections)

4. a: Flame inspection window - Stage1

b: Flame inspection window - Stage2

5. Complete ignition burner

a: Ignition electrode: This ensures ignition burner ignition using

a high voltage spark.

b: Ionization probe: This detects the presence of a burner

ignition flame through ionization.

3a

4a

11. Factory fitted bridge

Connection for cyclical tightness controller (Option - Package

RD18)

6. Safety box: The safety control box manages and checks the

boiler's ignition, operating and shutdown sequences.

Type Honeywell S 4565 BF 1161.

After resetting, the safety control box remains on standby for

around 1 minute.

7. Valve connector - Stage2

8. Safety control box and valve connector - Stage1

9. Downdraught thermostat: The downdraught thermostat

located in the draught diverter cuts off the gas supply and puts

the boiler into safety shutdown in the event of flue gas blow back

8 sections: Supplied

10-14 sections: Option (Factory fitted bridge) - Package RD19

10. Factory fitted bridge: Not used

04/01/11 - 300005180-001-C GAS 360 S

9

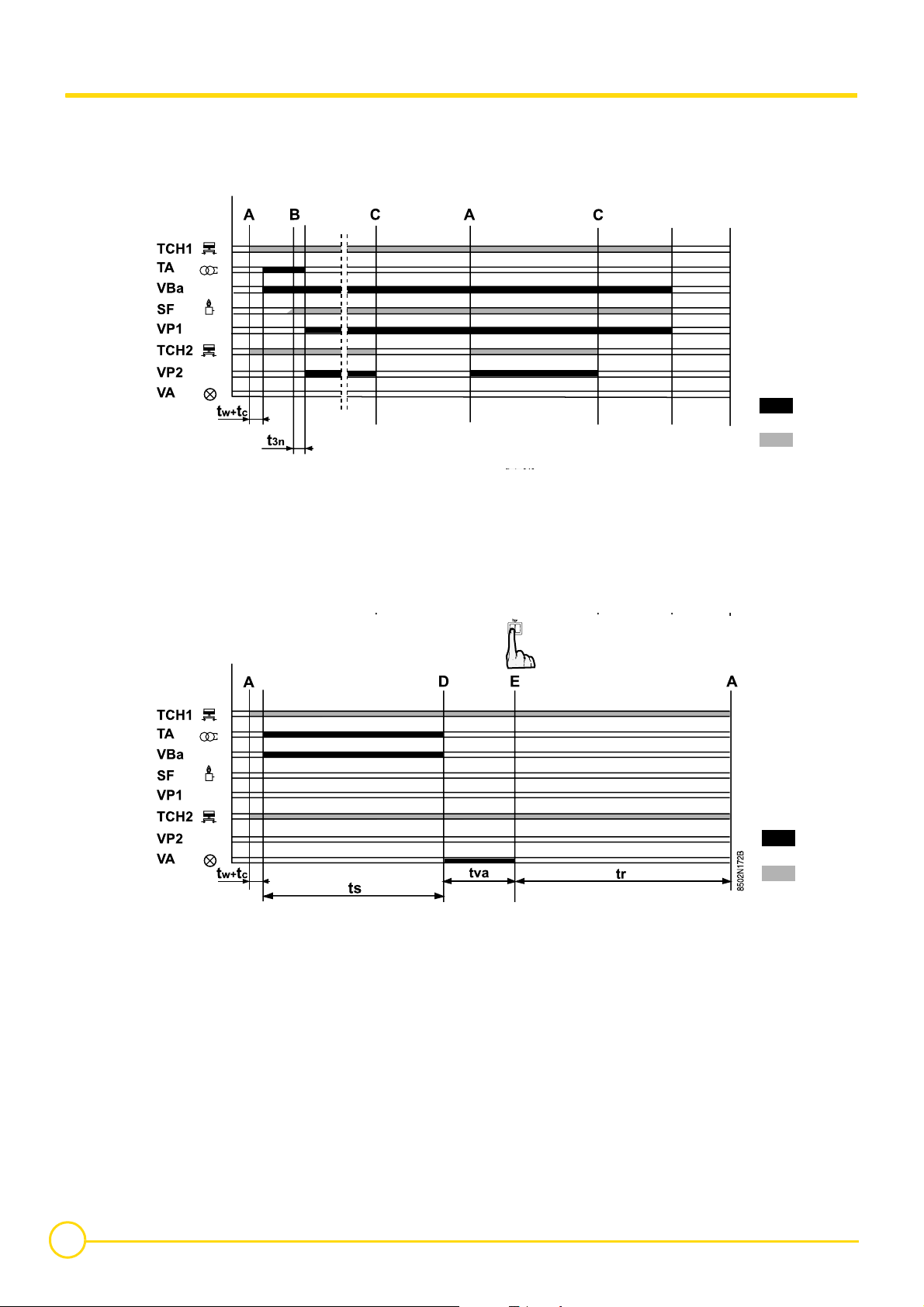

3.4 Operating principle

S4565 BF 1161 safety box The ignition and burner surveillance sequences are ensured by the

safety box.

Normal operating cycle

If heating is required, the boiler thermostat TCH 1 closes the contact.

The ignition transformer TA integrated into the safety control box and

the safety flap on the gas valve (supplying the ignition burner) are

switched on.

Operating cycle on safety (start up without flame signal)

Gas from the ignition burner is ignited by the ignition electrode and

within the time interval ts; a minimum current of 0.9 µA appears on

the ionization sensor SF and the gas valve regulation flap (supplying

the principal burner) opens.

If, moreover, TCH2 is required, the 2nd stage valve VP2 opens.

- If the flame is not detected before the end of the safety time ts, the

safety control box goes into safety lockout and the safety lockout

warning light comes on.

To restart the heater, press the reset button on the safety box.

- If there is a loss of flame in normal operation, the box automatically

repeats the start up sequence.

- If a flame is present before start-up, the safety control box remains

on standby.

10

GAS 360 S 04/01/11 - 300005180-001-C

Resetting

Legend

The box is reset after going into safety by pressing the reset button.

If the reset button does not work, wait at least 15 seconds before

trying a second time.

After activating the reset button, the warning light goes out and the

safety control box restarts after a waiting time of around 1 minute.

The box may be on safety on its first start up: press the reset

button to release it.

If the reset button is pressed in normal operation, the gas valves

close and the box starts a new ignition sequence.

A Heat demand - 1st/2nd stage

B Formation of flame in ignition burner

C Heat demand - 1st stage

D On safety through absence of flame signal

E Press the reset button

SF Burner flame signal

TA Ignition transformer

TCH1Stage 1 boiler thermostat

TCH2Stage 2 boiler thermostat

VA Safety lockout warning light

VBa Ignition burner valve

VP1 Main burner valve - 1st stage

VP2 Main burner valve - 2nd stage

t3n Flame stabilisation time: Wait 3 seconds

tr Restart waiting time: 1 minutes

ts Safety time: 55 s max

tva Alarm time: 15 seconds

tw Waiting time: 0 seconds

tc Auto-control time: 1.5 seconds

Box output signals

Required input signals

04/01/11 - 300005180-001-C GAS 360 S

11

4 Installation

4.1 Regulations governing installation

4.1.1 France

Residential buildings

Statutory terms and conditions of installation and maintenance:

The installation and maintenance of the appliance must be carried

out by a qualified professional in compliance with the statutory texts

of the codes of conduct in force, particularly:

- Order of 27 April 2009 amending the Order of 2 August 1977

Technical and safety rules applicable to combustible gas and

liquefied hydrocarbon installations situated inside residential

buildings and their annexes.

- NF P 45-204 standards

Gas installation, (formerly DTU 61-1, gas installations: April 1982,

addendum no 1: July 1984).

- Local Sanitary Regulations

For appliances connected to the electricity network:

- NF C 15-100 standards Low voltage electrical installation - Rules..

Establishments open to the public

Statutory terms and conditions of installation:

The installation and maintenance of the appliance must be carried

out in compliance with the statutory texts and rules of the codes of

conduct in force, particularly:

- Safety regulations against fire and panic in establishments open

to the public:

a. General regulations

For all appliances:

- Articles GZ - Installations operating on combustible gases and

liquefied hydrocarbons.

Then, depending on use:

- Articles CH-Heating, ventilation, refrigeration, air conditioning and

production of steam and domestic hot water.

b. Instructions specific to each type of establishment open to the

public (hospitals, stores, etc.).

Certificate of compliance

In application of Article 25 of the Order of 27 April 2009 amending the

Order of 2 August 1977 amended and Article 1 of the amended Order

of 05/02/1999, the installer is required to draw up certificates of

conformity approved by the Ministers responsible for construction

and gas safety:

- Different forms (forms 1, 2 or 3) for a new gas installation.

- "Model 4" in particular after replacing a furnace with a new one.

4.1.2 Other countries

Installation and maintenance of the boiler must be carried out by a

qualified professional in compliance with prevailing local and national

regulations.

4.2 Package list

Assembly Instructions

Z

12

GAS 360 S 04/01/11 - 300005180-001-C

Loading...

Loading...