REMEHA GAS 360/460

Gas

High-efficiency atmospheric

gas boilers with reduced

NOx emission

Outputs: Gas 360 54 - 117 kW

Gas 460 119 - 380 kW

GAS 360/460

360/460

ATMOSPHERIC

Atmospheric Range

TreadLightly

ON THE PLANET

Introduction

The Remeha Atmospheric

Range of boilers are high

efficiency atmospheric

gas boilers.

The burner bed consists of

stainless steel atmospheric

burners which guarantee low

noise operating levels.

Boiler description

The Remeha Atmospheric Range is a series of floor standing, cast

iron, sectional boilers with a powder coated enamel steel casing

complete with glass fibre insulation. The Gas 360/460 both come

with high/low atmospheric gas burners, suitable for natural gas

and LPG.

The boilers are pre-wired with site wiring connections and are

fitted to the instrument panel in the front casing.

All boilers are supplied with electronic ignition control via the pilot

burner for hot water central heating and are supplied with safety

equipment with ionisation flame detection.

The Remeha Atmospheric Range are designed to be connected to

most flue systems. All boilers have built in draught diverters.

The Gas 360 and Gas 460 boilers are delivered with a high/low

control panel.

Certifications

The Gas 360 and 460 boilers are in compliance with the

EC directives:

- 90/396/EEC Gas Appliance Directive

- EN 297; EN656 Ref Standard

- 73/23/EEC Low Voltage Directive

Reference Standard: EN 60.335.1

- 89/336/EEC Electromagnetic Compatibility Directive

Reference Standard: EN 50.081.1 ; EN 50.082.1 ; EN 55.014

Contents

Introduction 2

Boiler description 2

Certifications 2

Technical data Gas 360/Gas460 3

Typical boiler construction Gas 360 4

Typical boiler construction Gas 460 5

Dimensions Gas 360 6

Dimensions Gas 460 7

Typical boiler installation Gas 360 8

Typical boiler installation Gas 460 9

Instrument panels 10

External connections 10

Water treatment 11

page

- 92/42/EEC Efficiency Directive **

The Gas 360 is CE approved, No: 0085AU0115

The Gas 460 is CE approved, No: 0085BL0187

2

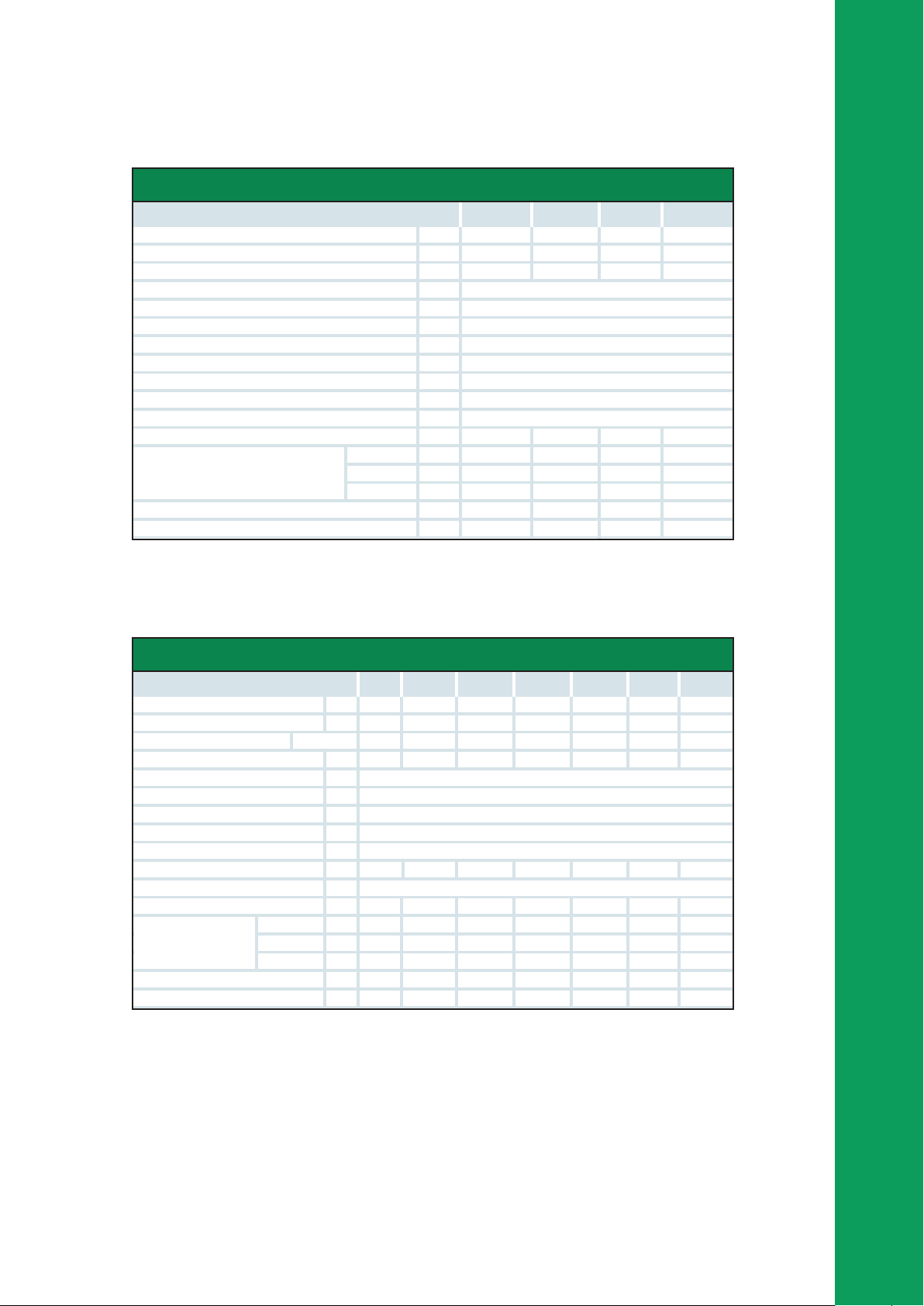

Technical data

Remeha Gas 360

Number of sections 8 10 12 14

Nominal heat output kW 36-63 45-81 54-99 54-117

Nominal heat input kW 39.4-68.9 49.1-88.4 58.8-107.8 58.8-127.2

Mass flue gas flow rate

E.F.G.T Flue gas temperature Tf

Minimum flow temperature °C 30

Maximum flow temperature °C 90

Maximum operating pressure bar 6

Electrical supply V/Hz 230/50

Power consumption

Gas connection BSP 1"

Flow & return connection BSP 1 1/2"

Internal diameter flue gas outlet mm 180 200 200 220

Water resistance

Water capacity litre 32.6 39.8 47 54.2

Dry weight kg 257 305 357 408

(1)

At nominal output (2nd stage)

(2)

Boiler temperature 80°C

(3)

Power consumption of the boiler only with no accessories

(1) (2)

(1) (2)

(3)

Kg/h 138 177 216 255

°C 135

W 25

Δ T = 10°C mbar 56 120 216 320

(1)

Δ T = 15°C mbar 25 53 96 142

Δ T = 20°C mbar 14 30 54 80

Conditions of use - Maximum safety temperature: 110°C

- Maximum operating pressure: 6 bar

- Thermostat adjustable from 30 to 90°C

- Safety thermostat: 110°C

REMEHA GAS 360/460

Remeha Gas 460

Number of sections 8 10 12 14 16 18 20

Nominal heat output kW

Nominal heat input

Mass flue gas flow rate

E.F.G.T Flue gas temperature Tf

(1)

Kg per sec

(2)

Minimum flow outlet temperature °C 40

Maximum flow outlet temperature °C 90

Maximum operating pressure bar 6

Electrical supply V/Hz 230/50

Power consumption W 108/114 maximum

Gas connection BSP 1" 1" 1" 1 1/4" 1 1/4" 1 1/4" 1 1/2"

Flow & return connection inch 2

Internal diameter flue gas outlet mm

Δ T = 10°C mbar

(1)

Water resistance

Δ T = 15°C mbar

Δ T = 20°C mbar

Water capacity litre

Dry weight kg

(1)

At 2nd stage 1 mbar = 10 mmCE = 10 daPa = 100 Pa

(2)

Boiler temperature 80°C

83-140 107-180 131-220 155-260 179-300 202-340 226-380

kW

93.1-153 119.4 -196.3 145.6-239.4 171.9-282.6 197.9-325.4 224-368.4 250.1-411.3

0.097 0.127 0.144 0.177 0.191 0.203 0.258

°C

125 123 130 126 133 140 126

250 300 300 350 350 350 400

80 133 198 277 369 484 592

36 59 88 123 164 211 263

20 33 50 69 92 118 148

61 76 91 106 122 137 154

668 807 934 1096 1227 1354 1476

3

Typical boiler construction

Remeha Gas 360

Upper insulation

Electrical connections area

Smoke nozzle

Draught diverter

with inspection trap

and motorised flap

Heating

flow

Closing

flap motor

DIEMATIC-m Delta

or K control panel

Eutectic

cast iron

boiler

body

Gas inlet

Heating return

with drain

Floor plate

Boiler body and

draught diverter +

combustion chamber

system insulation, in

glass wool, 100 mm

thick + glass fabric

Draught diverter

thermostat

-provided on DTG 220-7

and 8 Eco.NOx

-optional on other

models

Red painted

steel casing

1st stage gas valve

Pressure outlet

2nd stage gas valve

Auto-ignition

Wet combustion chamber

irrigated on three sides

2 stage atmospheric burner with full

premixing (pull-out drawer)

4

4

Loading...

Loading...