Control panel Gas 360

Package RD 9

English

22/08/05

Technical

instructions

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1 Presentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1 Terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.1 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Installation with optional Rematic control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.1 Fitting the Rematic control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Connections optional REMATIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.3 Mouting of the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3 Connecting a third party control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

4 Connecting the harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

5 Connecting the low-water pressure switch alarm indicator (Only NL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

6 Connecting the safety thermostat alarm indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

7 Connecting one or two hour run meters (Package BG 40) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

8 Connecting the flue gas thermometer (Package BP 28) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

9 Connecting the burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Skeleton Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Starting up and operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

1 Control panel without Rematic control unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2 Control panel with optional Rematic control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Control panel RD 9 22/08/05 - 300005192-001-A

Introduction

The control panel is fitted to Remeha boilers in the Gas 360 ranges.

This product will be marketed in the following European Union

member states :

Version L: BE, ES

Version S: GB, HU, ES

Directive 97/23/EC

Gas and oil boilers with a maximum operating temperature of 110°C

and hot water tanks with a maximum operating pressure of 10 bar

pertain to article 3.3 of the directive, and therefore, cannot be CEmarked to certify compliance with the directive 97/23 ECThe boilers

and hot water tanks are designed and manufactured in accordance

with the sound engineering practice, as requested in article 3.3 of the

directive 97/23/EC; it is certified by compliance with the directives 90/

396/EC, 92/42/EC, 73/23 EC and 89/336/EC.

1 Presentation

The control panel is used to control boilers with 1 or 2-stage burners.

It may be fitted along with several optional features:

- Rematic control unit for 2-stage burners regulating the burner and

2 mixing valve, for heating only or for heating and domestic hot

water.

- Hour run meter/s (Package BG 40)

- Flue gas thermometer (Package BP 28)

Warning

The boiler shall be assembled and installed by a qualified

professional only.

For a proper operating of the boiler, follow carefully the instructions.

Z

Symbols used

Caution danger

Specific information Information must be kept in mind to maintain comfort

Reference Refer to another manual or other pages in this instruction manual

Risk of injury and damage to equipment. Attention must be paid to the warnings on

safety of persons and equipment

22/08/05 - 300005192-001-A Control panel RD 9

3

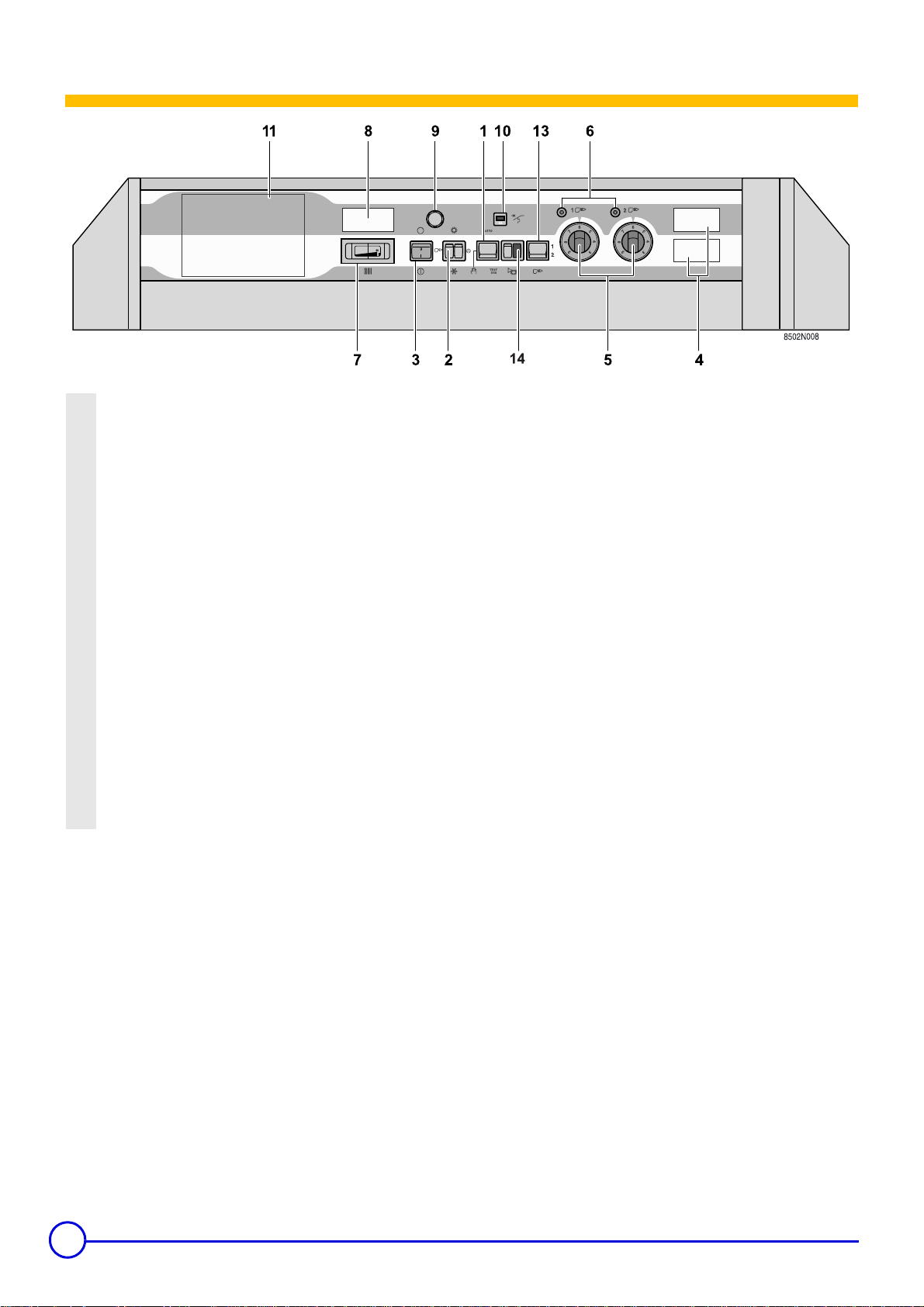

Description

13-position switch Auto / Manual ! / TEST STB

- The switch may be left on either position manual ! or automatic AUTO.

- STB TEST: temporary action to test the safety thermostat.

- Press the TEST STB switch and set pump shut-off switch (2) 9 to the “Summer” position %.

2 Switch Burner / Heating pump:

This button is used to control the burner and the heating pump.

Both buttons are in “Winter” . position: Heating and hot water production systems operate (if a hot water tank is included).

Both buttons are in “Summer” % position: The burner and the heating pump don't operate.

If the boiler is fitted with a control unit, both buttons must be left on the Winter . position.

3 Main ON/OFF switch

4 Location for hour run meter for the first and second stage (optional)

5 Boiler thermostat (30 to 90 °C):

A factory-set stop limits the maximum temperature to 75 °C. The stop may be moved if necessary.

6 Stage one or stage two indicators:

These only go on if the relevant thermostat or control unit require heating and if the safety contact is closed.

7 Boiler thermometer

8 Location for flue gas thermometer (optional)

9 Safety thermostat with manual reset (set to 110 °C).

10 10 A Circuit-breaker: with delayed action and manual reset.

11 Location for optional features or a RC4/RC5 control unit

13 Switch for selecting the number of burner stages

14 Burner alarm indicator + Reset button

4

Control panel RD 9 22/08/05 - 300005192-001-A

Operating principle

• Boiler regulation

The boiler may be regulated:

- either by the boiler thermostats,

- or by the Rematic control unit, if any (optional terminal strip present

in control panel)

- or by the Rematic control unit of the cascaded installation.

- or by a third party control unit with volt-free contacts for high-low

and on-off operation, if any (connection kit necessary).

If the boiler is fitted with a Rematic control unit, the boiler

temperature is modulated by the regulator, which controls the burner

and the motorised mixing valves depending upon the outside

temperature. With a third party control connected, the boiler

thermostats are set to the maximum position. Operating security is

provided by the safety thermostat with manual reset.

Electrical connections

As the electrical wiring has been carefuly checked in the

factory, the internal connections on the control panel must

not be changed in any way.

Electrical connections must match the electrical diagrams delivered

with the equipment and comply with the instructions in the manual.

The electrical connections shall comply with standards in force. The

equipment must have a power supply equipped with a omnipolar

switch with an opening distance above 3 mm.

The earth connections shall comply with local standards.

1 Terminal block

All connections are made with the terminal boxes designed for that

purpose on the back of the boiler's command board.

22/08/05 - 300005192-001-A Control panel RD 9

5

1.1 Electrical connections

9

5

4

4

1

85 2N1 7A08

5

4

6

3

7

8

9

5

4

6

3

7

8

9

3

2

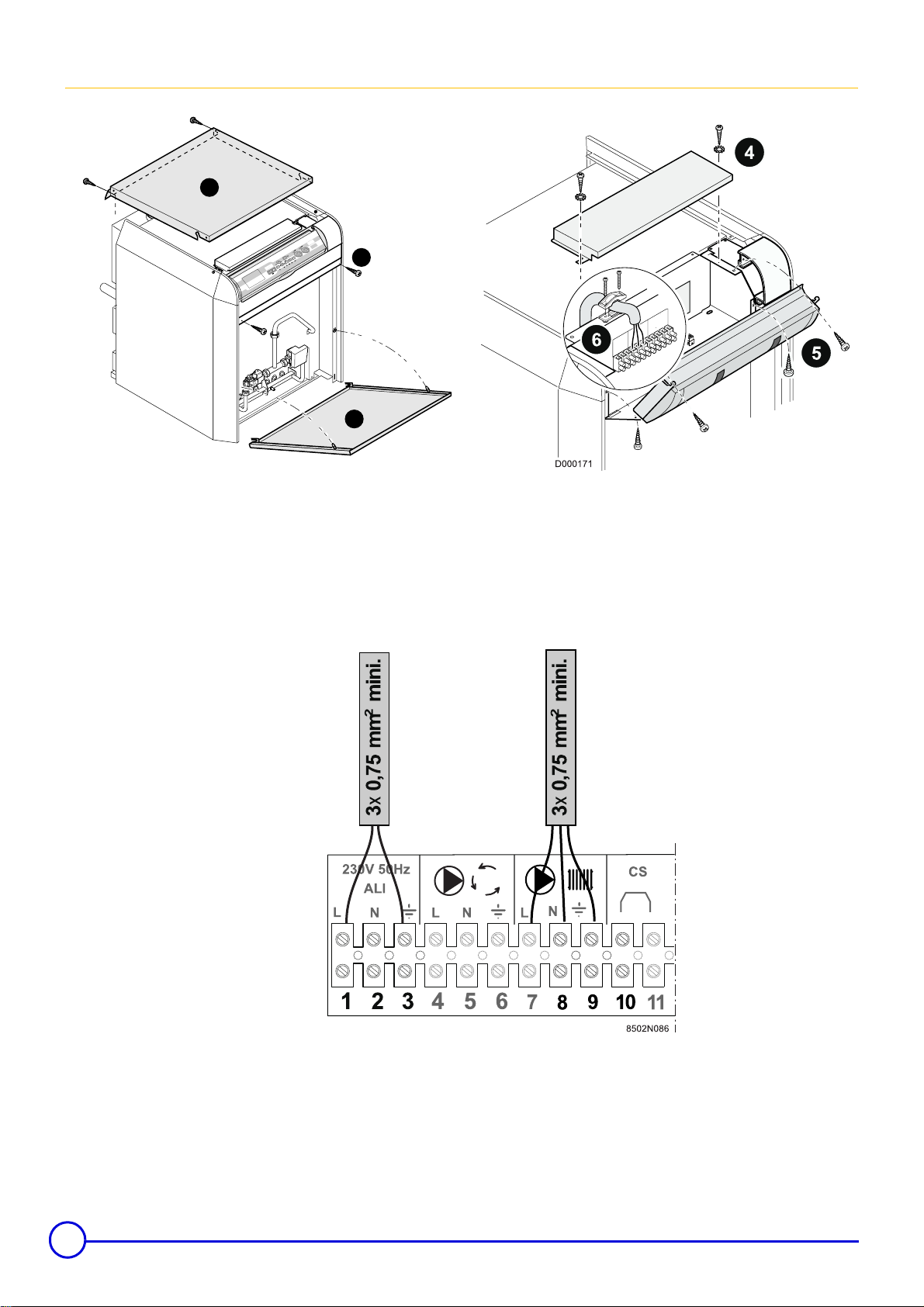

Proceed as follows to open the control panel:

Remove the upper casing of the boiler.

Take out the heater door.

Remove the top front panel.

Pull out the connection board cover.

Open the side of the panel. Turn the panel.

Remove the 4 screws .

These cables will be fixed on to the control panel with cable clips

(supplied in a separate bag).

Make the connections, respecting the live (L), neutral (N) and

earth terminals.

6

Control panel RD 9 22/08/05 - 300005192-001-A

2 Installation with optional Rematic control unit

2.1 Fitting the Rematic control unit

The Rematic control unit is fitted on the left-hand side of the front of

the panel.

1. 2.

22/08/05 - 300005192-001-A Control panel RD 9

7

3. Installing the supplementary wiring

- Remove the "External Regulation" harness

- Fit the harnesses delivered with the REMATIC RC4/5 option

8

Control panel RD 9 22/08/05 - 300005192-001-A

2.2 Connections optional REMATIC

Connection block for Rematic sensors and controls.

See the instructions supplied with the control unit and any remote

control unit used.

Separate the extra low voltage sensor wires from 230 V

power wires in order to prevent electromagnetic

interference.

Inside the boiler:

- Boilers with one cable channel: Place the 230 V main supply

cables on one side of the cable channel and the sensor cables on

the other. The cables shall be held in place on either side using

plastic ties.

- Boilers with two cable channels: Place the 230 V main supply

cables in one cable channel and the sensor cables in the other.

The cables shall be held in place on either side using plastic ties.

Outside the boiler:

use 2 pipes or cable guides at least 10 cm apart.

Failure to comply with these instructions could lead to

interference and control unit malfunctioning or even

damage to the electronic circuitry.

22/08/05 - 300005192-001-A Control panel RD 9

9

2.3 Mouting of the control unit

1

2

1/4

1/4

4

Bring the blue connectors out through the opening in the control

panel.

Plug the connectors onto the back of the control unit.

10

Push the control unit into the front of the control panel and fix it

with the 2 plastic screws supplied (push and 1/4 turn, clockwise) on

the front of the control unit.

Close the control panel.

Control panel RD 9 22/08/05 - 300005192-001-A

3 Connecting a third party control unit

3x

Control of the first stage of the burner by volt-free contacts

Control of the second stage of the burner by volt-free contacts

4 Connecting the harness

Take out the shunt (bridge) CA

Connect the "External Regulation" harness to the control

panel harness.

22/08/05 - 300005192-001-A Control panel RD 9

11

5 Connecting the low-water pressure switch alarm indicator (Only NL)

1

2x 0, 5 mm 7

2

mi i.n

AL

N

L

Low-water pressure switch alarm indicator

6 Connecting the safety thermostat alarm indicator

Safety thermostat alarm indicator

12

Control panel RD 9 22/08/05 - 300005192-001-A

7 Connecting one or two hour run meters (Package BG 40)

One or two optional hour run meters (stage 1 and 2) may be fitted on the front of the control panel.

To do so:

- Cut the cover off with a cutter along the edges of the coloured rectangle.

- Pull out the *1 wires standing by in the control panel

- Connect the wires to the hour run meter (the wires are interchangeable):

- Brown and blue wires for stage 1

- Violet and blue wires for stage 2

- Clip the hour run meter into the control panel.

If the burner is a 1-stage burner, the counter displays the burner operating time.

If the burner has 2 stages, the first stage hour run meters displays the total burner operating time and the second hour run meter displays the

operating time of stage 2.

22/08/05 - 300005192-001-A Control panel RD 9

13

8 Connecting the flue gas thermometer (Package BP 28)

An optional flue gas thermometer may be fitted on the front of the control panel.

To do so:

- Cut the cover off with a cutter along the edges of the coloured rectangle.

- Clip the thermometer into the opening.

- Bring the sensor to the back of the boiler via the cable channel and insert it in the flue gas pipe.

14

Control panel RD 9 22/08/05 - 300005192-001-A

9 Connecting the burner

Gas pressostat (bridge factory-fitted)

1

Not used on a Gas 360

2a Gas valve 2nd stage

2b Safety box + Gas valve 1st stage

Anti-backflow thermostat Package RD19 (optional as of 10 section

3

models)

4 Flue damper (only version Gas 360 L, bridge plug factory-fitted)

5 Leak proofing system, Package RD18 (bridge factory-fitted)

22/08/05 - 300005192-001-A Control panel RD 9

15

3

1

11a

SCHEMA DE PRINCIPE - STROMLAUFPLAN - WIRING DIAGRAM - PRINCIPESCHEMA - GAS 360

11a

Skeleton Diagrams

8

1

ECS

1

6

RG

ZT

AUTO

å

STB

TEST

2

1

ZB2

1b

1a

TCH2

2

1

θ

2b2a

9 6

B2

SPL2

s

ECO

9 10

CO

ò

12

4

2

PSG

1

1

TAF

1

1a

BPR-VA

2b

2a

4

COM

NC NO

P

8

93 6 2 7

5

4

10 93178511 6 2

S 4565 ....

B1

CCE

13

A

4

6 7

2

CCE

15

9

14

CA

7

CA

SPL1

4

7 1 6

8

9

11

CO

11

4

2

ECS

2

1

1b1a

9

7

2

1

θ

SPL0

TCH1

TI

TI

DJ4A

1

RG

RG

ZT

1

STB

TEST

å

1b 1a

AUTO

6

ECS

CA

ZEH

12

CA

7

9

11

CA

1

5

8

4

RG

3

6

BA

CS

10

BA

θ

23

CCE

TS

3

ZEH

2

8

2b 2a

CA

ZG

CH2

h

1a

1b

VB2

8 5

CH1

B2

h

1b

VG

1a

ANTITERUGSLAG THERMOSTAATBLOCKED VENT SHUTOFF SYSTEMTAF

REGELINGREGULATORRG

KETELTHERMOSTAAT 1st TRAPBOILER THERMOSTAT 1st STAGETCH1

KETELTHERMOSTAAT 2de TRAPBOILER TH ERMOSTAT 2nd STAGETCH2

SCHEIDINGSTRAFOISOLATING TRANSFORMERTI

LAMPJE WERKING 1st TRAPON/OFF INDICATOR 1st STAGEVB1

VEILIG HEIDS THERMOSTAAT ALARM

LAMPJE

VEILIG HEIDS THERMOSTAATSAFETY THE RMOSTATTS

SAFETY THERMOSTAT ALARM INDICATORVA-TS

BRANDER 2DE TRAP SCHAKELAARBURNER SWITCH 2nd STAGEZB2

VEILIGHEIDSKLEPSAFETY VALVEVS

LAMPJE WERKING 2de TRAPON/OFF INDICATOR 2nd STAGEVB2

TEST SCHAKELAARTEST SWITCHZT

ALGEMENE SCHAKELAARMAIN SWITCHZG

ZOMMER-WINTER SCHAKELAAR

N° : 300005200-001-A

SUMMER-WINTER SWITCHZEH

VB1

VERWARMINGSPOMP KRING AHEATING PUMP CIRCUIT AÄ A

RECYCLAGE POMPSHUNT PUMPÄ Å

BRANDERBURNERB

DRUKKNOP HERBEWAPENING ALARM

LAMPJE

TRAPSGEWIJSCASCADE CONNECTIONCA

CYCLISCH DICHTINGSCONTROLE

CONTROLEUR

UURTELLER 1st TRAPHOUR RUN METER 1st STAGECH1

UURTELLER 2de TRAPHOUR RUN METER 2nd STA GECH2

AFSLUITKLEPFLUE DAMPERCO

VEILIGHEIDSCONTACT SAFETY CONTACTCS

THERMISCHE BEVEILIGINGCIRCUIT BREAKERDJ4A

SANITAIR WARM WATERDOMESTIC HOT WATERECS

FASEPHASEL

NULLEIDERNEUTRALN

GASPRESSIOSTAATGAS PRESSOSTATPSG

SPL3

2

CCE

BURNER RESET BUTTON AND ALARM

INDICATOR

52

1

E

C

O

s

14

BA

1

12

BA

7

BA

4

BA

A

15

KESSEL TEMPERATURREGLER 1.STUFETHERMOSTAT DE CHAUDIERE 1ere

ABGASÜBERWACHUNGSTHERMOSTATTHERMOSTAT ANTIREFOULEURTAF

REGELUNGREGULATIONRG

BA

VS

13

BA

VA-TS

ALLURE

4

TI

2

TI

Å

8

BA

A

Å

5

BA

P2

22a

TCH1

KESSELKREISPUMPE KREIS AACCELERATEUR CIRCUIT AÄ A

KESSELKREISPUMPEPOMPE DE RECYCLAGE CHAUDIEREÄ Å

BRENNERBRULEURB

BPR-VA

KESSEL TEMPERATURREGLER 2.STUFETHERMOSTAT DE CHAUDIERE 2eme

ALLURE

TCH2

BRENNERENTSTÖRUNGSTASTE UND

STÖRLEUCHTE

LEAK PROOFING SYSTEMCCE

TESTSCHALTERINTERRUPTEUR TESTZT

HAUPTSCHALTERINTERRUPTEUR GENERALZG

SOMMER-WINTERSCHALTERINTERRUPTEUR ETE-HIVERZEH

BRENNER SCHALTER 2.STUFEINTERRUPTEUR BRULEUR 2eme ALLUREZB2

MAGNETVENTILVANNE DE SECURITEVS

BETRIEBSLEUCHTE 2.STUFEVOYANT MARCHE 2eme ALLUREVB2

BETRIEBSLEUCHTE 1.STUFEVOYANT MARCHE 1ere ALLUREVB1

SICHERHEITSTEMPERATURBEGRENZER

ALARMLEUCHTE

SICHERHEITSTEMPERATURBEGRENZERTHERMOSTAT DE SECURITETS

TRENNTRAFOTRANSFORMATEUR D'ISOLEMENTTI

VOYANT ALARME THERMOSTAT DE

SECURITE

VA-TS

KASKADENSCHALTUNGCASCADECA

DRUCKDICHTHEITSKONTROLERCONTROLEUR CYCLIQUE D'ETANCHEITECCE

BETRIEBSSTUNDENZEHLER 1.STUFECOMPTEUR HORAIRE 1ere ALLURECH1

BETRIEBSSTUNDENZEHLER 2.STUFECOMPTEUR HORAIRE 2eme ALLURECH2

ABGASKLAPPECLAPET O BTURATEURCO

SICHERHEITSKONTAKTCONTACT DE SECURITECS

LEISTUNGSSCHALTERDISJONCTEURDJ4A

WARMWASSEREAU CHAUDE SANITAIREECS

PHASEPHASEL

NULLEITERNEUTREN

GASDRUCKWAECHTERPRESSOSTAT GAZPSG

ZG

16

NF

BOUTON REARMEMENT ET VOYANT

ALARME BRULEUR

1

BA

2

BA

BPR-VA

Control panel RD 9 22/08/05 - 300005192-001-A

1 Control panel without Rematic control unit

9

8

7

6

5

M000154

Starting up and operation

The first start-up is to be performed by your installation

engineer.

Before starting the boiler, check if the installation is filled with water.

Start the boiler in the following order:

• Boiler temperature regulation by means of the thermostats

Place the boiler thermostat 5 in the required position. If the burner

has 2 stages, the stage 2 thermostat must always be set to value

which is approximately 5°C less than that of the stage 1 thermostat.

If required, move the maximum temperature stop as instructed

below.

If there is no control unit, we advise you never to set the

boiler thermostat below mark 4 (approx. 40°C) in order to

avoid the risk of combustion products condensing on the

walls of the boiler.

• Set switch 1 to the manual ! position.

• Control unit in boiler room electrical cabinet

See the instructions supplied with the control unit and any

remote control unit used.

• Check that safety thermostat 9 is properly set. To do so,

unscrew the hexagonal cap and press the reset button with a

screwdriver.

• Set the burner and heating pump buttons 2 to the Winter .

position.

• Set main On/Off switch 3 to 8.

Moving the thermostat stop:

A factory-set stop limits the maximum temperature to 75 °C. To move

the stop, proceed as follows:

- Pull the thermostat button out carefully (use pliers and a cloth).

- Remove the stop with the pliers.

- Put the stop in the hole of the desired higher temperature

(maximum 90°C).

22/08/05 - 300005192-001-A Control panel RD 9

17

2 Control panel with optional Rematic control unit

The first start-up is to be performed by your installation

engineer.

Before starting the boiler, check if the installation is filled with water.

Start the boiler in the following order:

• Set the boiler thermostats 5 on maximum position.

If required, move the maximum temperature stop as instructed

on the preceding page.

Set the Rematic control unit 12. To do so, operate

according to the control instructions supplied with the

unit.

• Set switch 1 to the AUTO position.

• Check that safety thermostat 9 is properly set. To do so,

unscrew the hexagonal cap and press the reset button with a

screwdriver.

• Set the burner and heating pump buttons 2 to the Winter .

position.

• Set main On/Off switch 3 to 8.

18

Control panel RD 9 22/08/05 - 300005192-001-A

Control panel RD 9 22/08/05 - 300005192-001-A

NL Remeha B.V.

Postbus 32

7300 AA APELDOORN

Tel: +31 55 5496969

Fax: +31 55 5496496

Internet: nl.remeha.com

E-mail: remeha@remeha.com

GB Broag Ltd.

Remeha House

Molly Millars Lane

RG41 2QP WOKINGHAM, Berks.

Tel: +44 118 9783434

Fax: +44 118 9786977

Internet: uk.remeha.com

E-mail: boilers@broag-remeha.com

B J.L. Mampaey BVBA

Uitbreidingstraat 54

2600 ANTWERPEN

Tel: +32 3 2307106

Fax: +32 3 2301153

Internet: www.mampaey.be

E-mail: info@mampaey.be

B Thema S.A.

6, Avenue de l'expansion

4460 GRACE-HOLLOGNE

Tel: +32 4 2469575

Fax: +32 4 2469576

Internet: www.thema-sa.be

E-mail: info@thema-sa.be

E D.A.C. S.A.

Tomás A. Edison 29

Poligono Cogullada

50014 ZARAGOZA

Tel: +34 76 464076

Fax: +34 76 471311

Internet: www.dac.es

E-mail: dac@dac.es

E Norte Comercial Organización S.A.

Bereteage Bidea, 19

48180 LOIU (Vizcaya)

Tel: +34 94 471 03 33

Fax: +34 94 471 11 52

E-mail: nco@nco.es

IRL Euro Gas Ltd.

Unit 38, Southern Cross Business Park

Boghall Road, Bray, Co

WICKLOW

Tel: +353 12868244

Fax: +353 12861729

Internet: www.eurogas.ie

E-mail: sales@eurogas.ie

H Marketbau - Remeha Kft.

Gyár u. 2.

Ipari Park

2040 BUDAÖRS

Tel: +36 23 503 980

Fax: +36 23 503 981

Internet: www.remeha.hu

E-mail: remeha@remeha.hu

E Termibarna S.A.

C. Zamora 55-59

08005 BARCELONA

Tel: +34 3 3000204

Fax: +34 3 3009558

E Cuatrocesa S.A.

c) Sor Angela de La Cruz, 10

- 1º Oficina C

28020 MADRID

Tel: +34 91 658 18 88

Fax: +34 91 658 30 77

© Copyright

All technical and technological information contained in these technical instructions, as well as any

drawings and technical descriptions supplied, remain our property and shall not be multiplied without

our prior consent in writing..

Ours is a policy of continuous development. We reserve the right to alter specifications without prior

notification

.

Subject to alterations

Loading...

Loading...