REMEHA Gas 310 ECO Technical Information

Supplied By www.heating spares.co Tel. 0161 620 6677

Technical Information

Remeha Gas 310 ECO

• High effi ciency condensing

Remeha Gas 310 ECO

boiler with low NOX emission

• Heat outputs: 51 - 573 kW

1

Supplied By www.heating spares.co Tel. 0161 620 6677

INHOUD

Preface 5

1 Safety instructions 6

1.1 Symbols 6

2 General description of boiler 7

3 Design 8

3.1 Boiler version 8

3.2 Operating principle 9

4 Technical data 10

4.1 Dimensions 10

4.2 Technical data 11

4.3 Quotation specification 12

4.4 Delivery options 12

4.5 Accessories 13

5 Efficiency information 14

5.1 Annual efficiency 14

5.2 Heat to water efficiency 14

5.3 Standing losses 14

6 Application data 14

7 Installation instructions for heating installer 15

7.1 General 15

7.2 Delivery and installation 15

7.3 Flue gas discharge and air supply 17

7.3.1 General 17

7.3.2 Classification due to discharging

flue gases 17

7.3.3 Connection options 17

7.3.4 Inlets/Outlets 17

7.3.5 Other requirements 17

7.3.6 Single boiler conventional flue 18

7.3.7 Single boiler, room sealed flue 18

7.3.8 Different pressure zones 20

7.3.9 Header flue systems 20

7.4 Installation details 20

7.4.1 Water pressure 20

7.4.2 Condensate discharge 20

7.4.3 Water treatment 20

7.4.4 Safety valve 21

7.4.5 Water circulation 21

7.4.6 Thermostat pocket 21

7.4.7 Noise production 21

7.5 Multiple boiler installation 21

8 Installation instructions for ELECTRICAL

installer 24

8.1 General 24

8.2 Electrical specifications 24

8.2.1 Mains voltage 24

8.2.2 Control unit 24

8.2.3 Power consumption 24

8.2.4 Fuse ratings 24

8.2.5 Temperature control 25

8.2.6 Low water level protection

(flow and content) 25

8.2.7 High limit protection 25

8.2.8 Air pressure differential

sensor (LDS) 25

8.3 Connections 26

8.4 Wiring diagram 27

8.5 Switch sequence diagram 27

8.6 Boiler control 27

8.6.1 Introduction 27

8.6.2 Modulating controls general

(two wire control) 28

8.6.3 BMS Analog control

(0-10 Volt DC) 28

8.6.4 On/ off control (1 x no volt

switched pair) 28

8.6.5 High/ low control (2 x no volt

switched pairs) 29

8.7 Other inputs 29

8.7.1 Shut down input 29

8.7.2 Lock-out input 29

8.7.3 External interlock 29

8.7.4 Other outputs 29

8.7.5 Analog output Depending on the

option settings in the service level

(see section 13.2.13), the analog

output signal is able to transmit

the following values: 29

8.7.6 Operation signal 29

8.7.7 Common alarm (lock-out) 29

8.7.8 External gas valve control 29

8.8 Options/ accessories 30

8.8.1 System pressure sensor 30

8.8.2 Gas valve leak proving system

(VPS) 30

8.8.3 Minimum gas pressure switch 30

8.8.4 Flue gas damper 30

8.8.5 Return butterfly valve (not Broag

supply) 30

8.9 Other connections 30

8.9.1 Boiler or System pump control 30

8.9.2 Frost protection 30

3

Supplied By www.heating spares.co Tel. 0161 620 6677

Remeha Gas 310 ECO

9 Installation instructions for gas installer 31

9.1 Gas connection 31

9.2 Gas pressures 31

9.3 Gas/ air ratio control 31

10 Commissioning 31

10.1 Initial lighting 31

10.2 Shutdown 33

11 control and safety equipment 34

11.1 General 34

11.1.1 Instrument panel layout 34

11.1.2 LED indicators 35

11.2 Switch function keys 35

11.2.1 Manual/automatic operation 35

11.2.2 Forced mode ‘high’ (h [[) 35

11.2.3 Forced mode ‘low’ (l [[) 35

11.3 Display of values 35

12 Operating mode 36

12.1 Operating mode (x [[) 36

12.2 Read-out mode (X [[) 36

12.3 Control strategy c 37

12.4 Shut-off (b xx) 37

12.4.1 Shut-off 37

12.4.2 Shut-off mode 37

12.5 Counter mode (1, , and .)

(service level) 38

12.5.1 General 38

12.5.2 Reading out counter mode 38

13 Setting mode 39

13.1 User level setting mode (X [[) 39

13.1.1 Flow temperature (!) 39

13.1.2 Pump run on time (@) 40

13.1.3 Boiler control (A) 40

13.2 Setting mode service level (only for

the qualified service engineer) (X [[) 40

13.2.1 Minimum fan speed ($ and 5) 42

13.2.2 Maximum fan speed (^ and 7) 42

13.2.3 Forced part load time (*) 42

13.2.4 Cycling prevention delay

time (() 42

13.2.5 Required flow temperature

at 0 - 10 volts (a and B) 42

13.2.6 High operation signal

switch point (C) 42

13.2.7 Shunt pump post-circulation

time (D) 42

13.2.8 dT from control stop point to

start point (E) 42

13.2.9 Maximum flue gas tempera ture (F) 42

13.2.10 Maximum temperature

setting (G) 42

13.2.11 Modulation start point at dT (H) 43

13.2.12 Minimum water pressure (I) 43

13.2.13 Adjustments options/ acces sories (J) 43

13.2.14 “Low” speed with H/L control (L) 43

13.2.15 Boiler type (P) 43

14 Fault-finding 44

14.1 General 44

14.2Failure mode (1 [[) (service level) 44

14.3 Cooling mode 44

14.4 Summary of failures (lock-out) 44

15 Inspection and maintenance instructions 48

15.1 General 48

15.2 Cooling mode 48

15.3 Annual Inspection 48

15.4 Maintenance 48

15.4.1 Inspection of air box and dirt trap 49

15.4.2 Cleaning the non return valve 49

15.4.3 Cleaning the venturi 49

15.4.4 Cleaning the fan 49

15.4.6 Cleaning the burner assembly 50

15.4.5 Cleaning the heat exchanger 50

15.4.7 Cleaning the condensate collector 50

15.4.8 Cleaning the syphon 50

15.4.10 Cleaning the inspection glass 51

15.4.9 Cleaning/Replacing the Ignition/

Ionisation electrode 51

15.5 Exploded view and spare parts list 52

16 appendices 55

16.1 Control menu 55

16.2 Shut-off codes 56

4

Supplied By www.heating spares.co Tel. 0161 620 6677

PREFACE

Read these instructions carefully before putting the

boiler into operation, familiarise yourself with its control

functions, operation and strictly observe the instructions

given. Failure to do so may invalidate warranty or prevent the boiler from operating.

The installation and commissioning of the boiler must be

carried out by a competent Engineer, with the relevant

certification i.e.: CORGI, ACOPS, IEE regs. On completion a copy of the commissioning sheet should be

returned to Broag Ltd. for record purposes.

If you have any questions, or if you need more information about specific subjects relating to this boiler or its

installation please do not hesitate to contact us.

The data published in these technical instructions is

based on the latest information (at date of publication)

and may be subject to revisions.

We reserve the right to continuous development in both

design and manufacture, therefore any changes to the

technology employed may not be retrospective nor may

we be obliged to adjust earlier supplies accordingly.

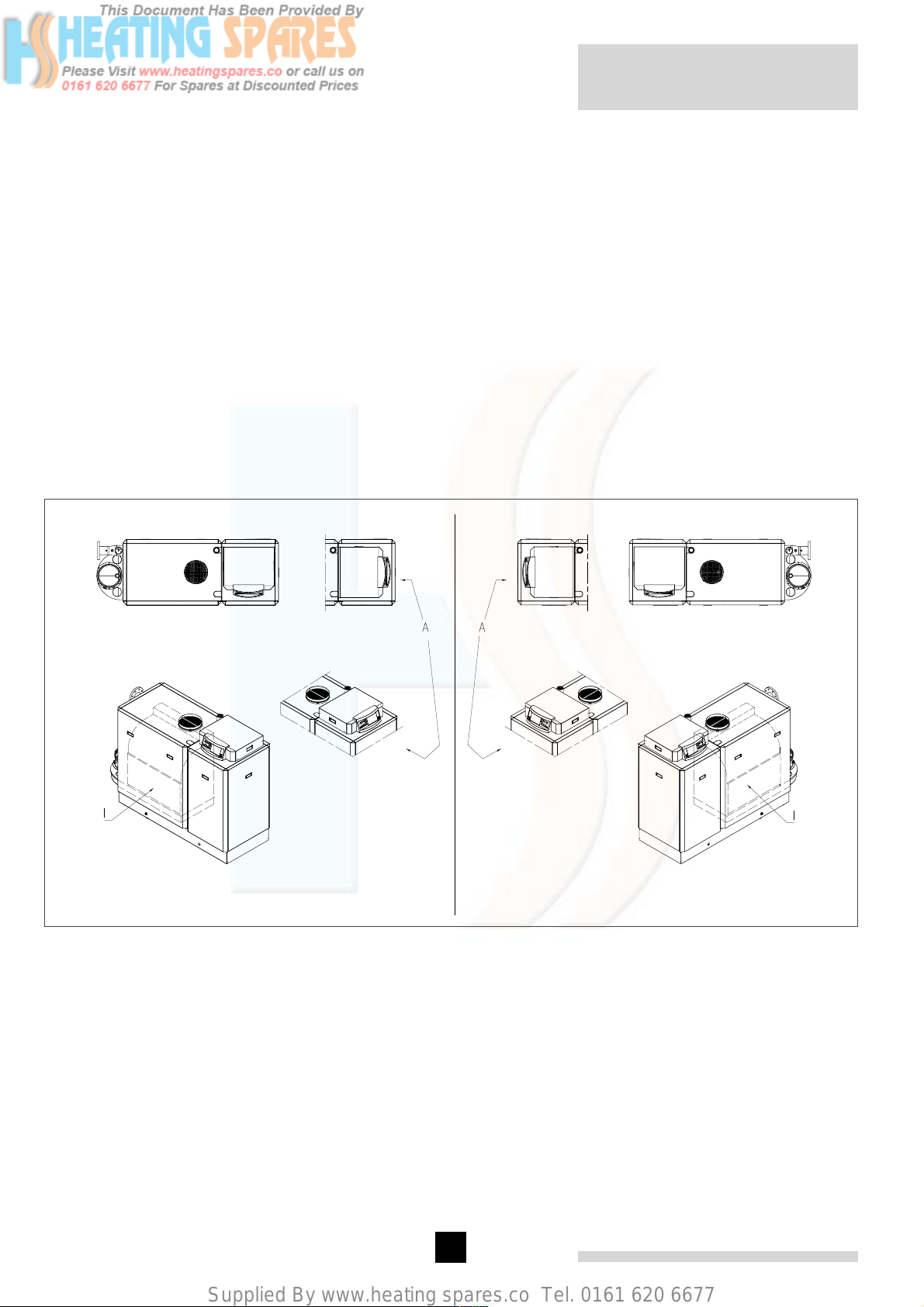

fig. 01 Artist impression Gas 310 ECO

3D.AL.31H.000.S.01

5

Supplied By www.heating spares.co Tel. 0161 620 6677

1 SAFETY INSTRUCTIONS

Remeha Gas 310 ECO

1.1 Symbols

The following symbols are used in this document to

emphasise certain instructions. This is in order to

increase your personal safety and to safeguard the technical reliability of the boiler.

g Instructions must be followed closely to avoid

personal injury or serious damage to the unit or the

environment.

g Important!! Instructions are of essential

importance for the correct functioning of the unit.

w Indicates possible danger of electric shock. Seri-

ous personal injury may occur.

i Instructions contain useful information.

Read and familiarise yourself with these instructions.

General Instructions

Keep unauthorised personnel away from the boiler. Do

not place objects on or against the boiler. Do not touch

hot water connections or the flue outlet when the boiler

is operating – burn hazard.

w Danger

This boiler is connected to a 230v mains supply. An

improper installation or attempts to repair electrical components or controls may result in life threatening situations.

g Be aware of gas escapes

If you smell gas, close the (main) gas cock and contact

the emergency gas leak telephone number for your

area. DO NOT ISOLATE THE POWER SUPPLY TO

THE BOILER OR ANY OTHER APPLIANCE.

g Be aware of flue gas leaks

If you smell flue gas fumes, turn the boiler off and contact your service company or installer.

g Be aware of water leaks

If you see water leaking from the boiler, turn it off and

contact your Service Company or installer.

g Working on the boiler

Installation, commissioning, maintenance and repair

work must only be carried out by suitably qualified specialist. Engineer in accordance with all relevant national/

local standards and certifications.

Always disconnect the mains supply and close the main

gas cock before working on the boiler.

Casing panels should only be removed for maintenance and servicing purposes.

Refit all panels on completion of maintenance or servicing before putting the boiler back into service.

Instruction and warning labels on the boiler must

never be removed or covered and must be clearly legible throughout the entire service life of the boiler. Damaged or illegible instruction and warning labels must be

replaced immediately.

Generally applicable safety instructions related to accident prevention must be consulted in addition to the

information supplied in this technical documentation.

Boiler modifications and spare parts

The boiler must not be modified or non-Remeha spare

parts fitted without the express written approval of

Remeha.

6

Supplied By www.heating spares.co Tel. 0161 620 6677

2 GENERAL DESCRIPTION OF BOILER

The Remeha Gas 310 ECO boiler is a fully assembled,

free standing, gas fired (Natural gas only), fully modulating high efficiency condensing boiler and is supplied

plastic wrapped, crated on a pallet.

The sectional cast aluminium heat exchanger and other

major components are contained within a rigid steel

frame with removable casing parts for maintenance

purposes. The Gas 310 ECO frame is fitted with a set

of casters to enable the assembled unit to be easily

manoeuvred into position within the plant room on site

with the minimum of effort. All major electrical and electronic controls are contained within the instrument panel

mounted on top of the boiler at the opposite end to the

connections facing to the front (long side) but can be

o

rotated 90

towards the short side to suit site location.

The boiler is available with flow and return connections

on the left or right hand end of the boiler (THIS MUST

BE DECIDED AT TIME OF ORDER), with the gas connection on the top of the boiler. The flue gas outlet c/w a

condensate connection will be at low level on the same

side as the connections. Combustion air inlet (for room

sealed operation) is located at the top of the boiler.

The boiler is suitable for room sealed or open flue

applications and has been designed for central heating and indirect hot water production at working pressures not exceeding 6 bar. It must be installed on a fully

pumped system and is designed for operating pressures

between 0.8 and 6 bar.

The pre-mix gas burner (NG only) with its gas/ air ratio

control system ensures clean, trouble free operation

with higher than average efficiencies of up to 109% Hi

(NCV) in the condensing mode combined with ultra low

NOx and minimum CO emissions.

The standard control package allows for external On/

Off, High Low (volt free switch/s) or modulating control

(0-10V input). The built in digital display shows normal

operating/ fault code indication and allows actual and

set values to be read and adjusted.

The intelligent, advanced boiler control (‘abc®’) continuously monitors the boiler operating conditions, varying

the heat output to suit the system load. The control is

able to react to external “negative” influences in the

rest of the system (flow rates, air/ gas supply problems)

maintaining boiler output for as long as possible without resorting to a lock out condition. At worst the boiler

will reduce its output and/ or shut down (shut off mode)

awaiting the “negative” conditions to return to normal

before re-starting.

The ‘abc®’ control cannot override the standard flame

safety controls.

All Gas 310 boilers are live fired after assembly to

ensure the boiler and controls comply with our strict

quality policy.

The unit has been inspected for compliance with the

essential requirements of the following directives:

- Gas Appliances Directive, no. 90/ 396/ EEC

- Efficiency Directive, no. 92/ 42/ EEC

- EMC Directive, no. 89/ 336/ EEC

- Electrical Low Voltage Directive, no. 73/ 23/ EEC

- Pressure Equipment Directive, no. 97/ 23/ EEC,

art. 3, item 3

CE identification number (PIN) : 0063BP3474

NOX Class : 5

Type classification of flue gas discharg : B23, C33,

C43, C53, C63, C83

7

Supplied By www.heating spares.co Tel. 0161 620 6677

3 DESIGN

3.1 Boiler version

Remeha Gas 310 ECO

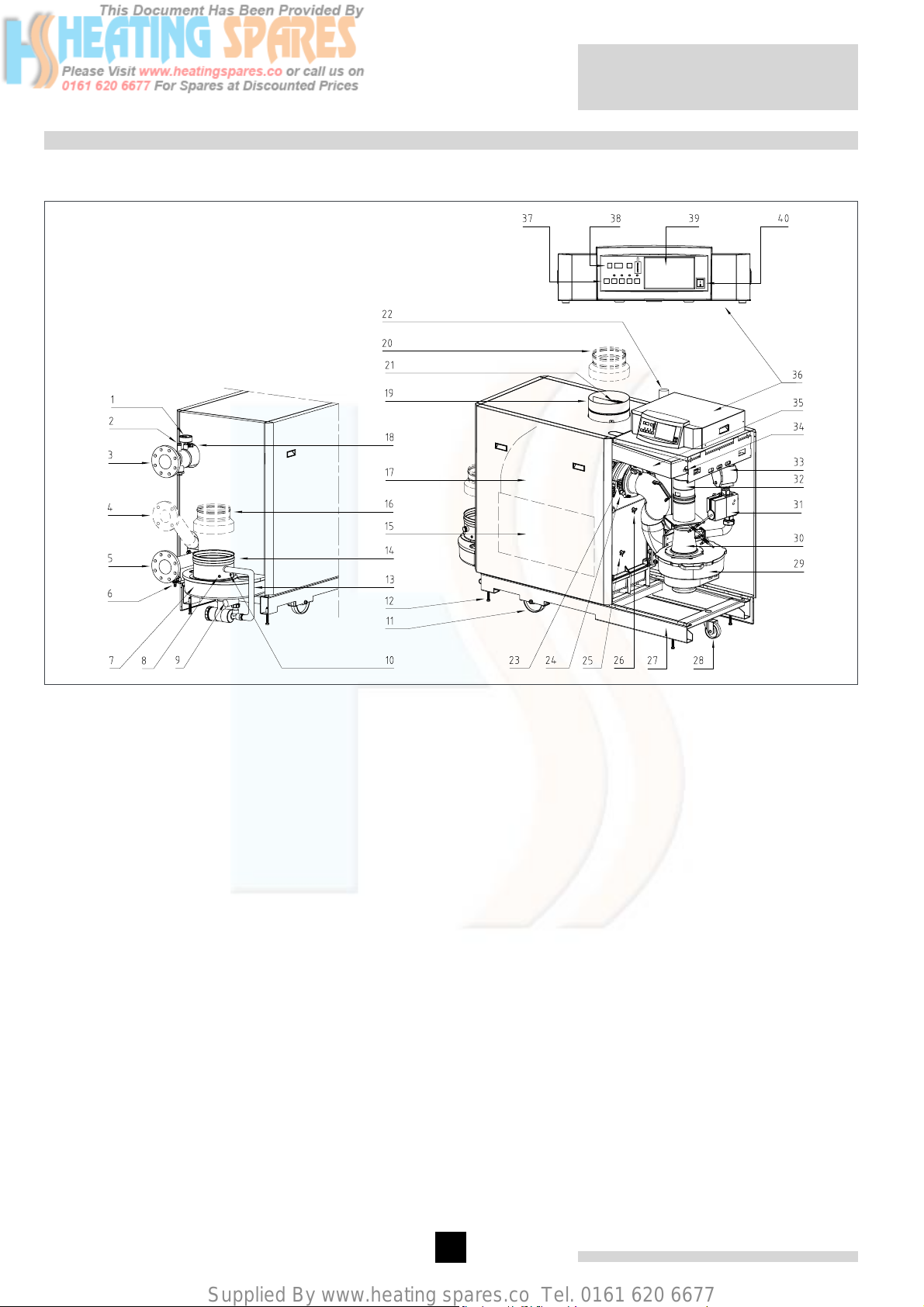

fig. 02 Cross-section Remeha Gas 310 ECO (Left

hand boiler illustrated)

00.31H.79.00002

The service side of the boiler (with the heat exchanger

inspection cover) is the front.

1. Pressure gauge

2. Pocket for external temperature sensor (7mm i/d

plain pocket)

3. Flow connection

4. 2nd Return connection (Optional)

5. Return connection

6. Filling/ drain cock

7. Condensate collector

8. Flue gas temperature sensor

9. Condensate drain

10. O2/ CO2 measuring point

11. Positioning wheels

12. Jacking bolts

13. Condensate drain hose

14. Flue gas discharge

15. Inspection hatch

16. Adapter ø 250/ ø 200 (optional)

17. Heat exchanger

18. Flow temperature sensor

19. Air supply

20. Adapter ø 200/ ø 250 (optional)

21. Air supply grille

22. Gas connection

23. Inspection glass

24. Ignition/ionisation electrode

25. Return temperature sensor

26. Boiler block temperature sensor

27. Frame

28. Steering castor

29. Fan

30. Venturi

31. Gas valve multiblock

32. Non return valve

33. Gas filter

34. Air pressure differential sensor (LDS)

35. Air box

36. Instrument panel

37. Control keys

38. Read-out window

39. Weather compensator installation (optional)

40. On/ off switch

8

Supplied By www.heating spares.co Tel. 0161 620 6677

3.2 Operating principle

Combustion air is drawn into the inlet connection from

the plant room (room ventilated version) or from outside

via the eccentric flue system (room sealed) by an air

supply fan.

On the inlet side of the fan is a specially designed

chamber (venturi unit) which takes gas from the multiblock and mixes it in the correct proportions with the

incoming air. This mixing system ensures that the correct gas/ air ratio is delivered to the pre-mix burner at all

times.

Depending on demand (under the dictates of flow/return

sensor and other external/internal control inputs) the

®

’ system determines the required boiler output.

‘abc

The ‘abc®’ control then varies the speed of the air supply fan which alters the volume of air being drawn into

the venturi, this change in volume is measured using air

pressure differential which directly controls the volume

of gas also being delivered to the venturi. The resultant

controlled mixture is delivered to the premix burner.

This mixture is initially ignited by the combined ignition/

ionisation probe, which monitors the state of the flame.

Should the flame be unstable or not ignite within the

pre-set safety time cycle the controls will (after 5

attempts) shut the boiler down requiring manual intervention to reset the boiler. The digital display will indicate a flashing fault code confirming the reason for the

failure.

The products of combustion in the form of hot flue gases

are forced through the heat exchanger transferring their

heat to the system water, (the flue gas temperature is

reduced to approximately 5/ 8° above the temperature

of the system return water) then discharged via the condensate collector, to the flue gas outlet connection, to

atmosphere.

Because of the low flue gas exit temperature there will

be a vapour cloud formed at the flue gas terminal -this

is not smoke-, simply water vapour formed during the

combustion process.

If the flue gas temperature falls below dew point (55°),

water vapour (created during the combustion process)

will begin to condense out in the boiler, transferring its

latent heat into the system water, thereby increasing the

output of the boiler without increasing the gas consumption.

Condensation formed within the boiler and flue system

is discharged from the boiler to an external drain via the

drain pan and siphon supplied.

The boiler can be supplied, as an option with a

second (constant temperature) return connection. This

additional connection enables the boiler to make full use

of its condensing ability whilst accepting both fixed and

variable temperature returns from the same system.

9

Supplied By www.heating spares.co Tel. 0161 620 6677

4 TECHNICAL DATA

4.1 Dimensions

Remeha Gas 310 ECO

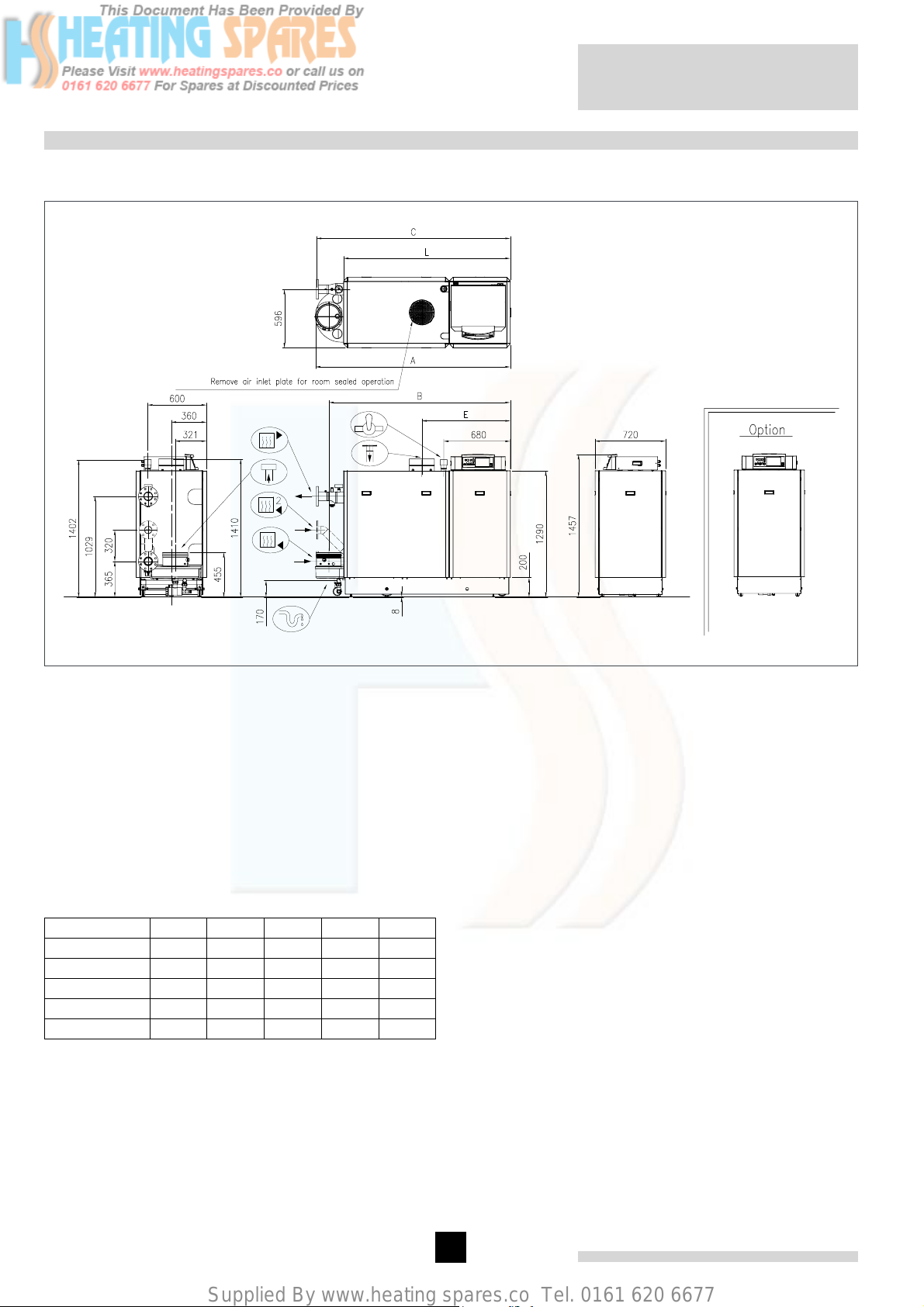

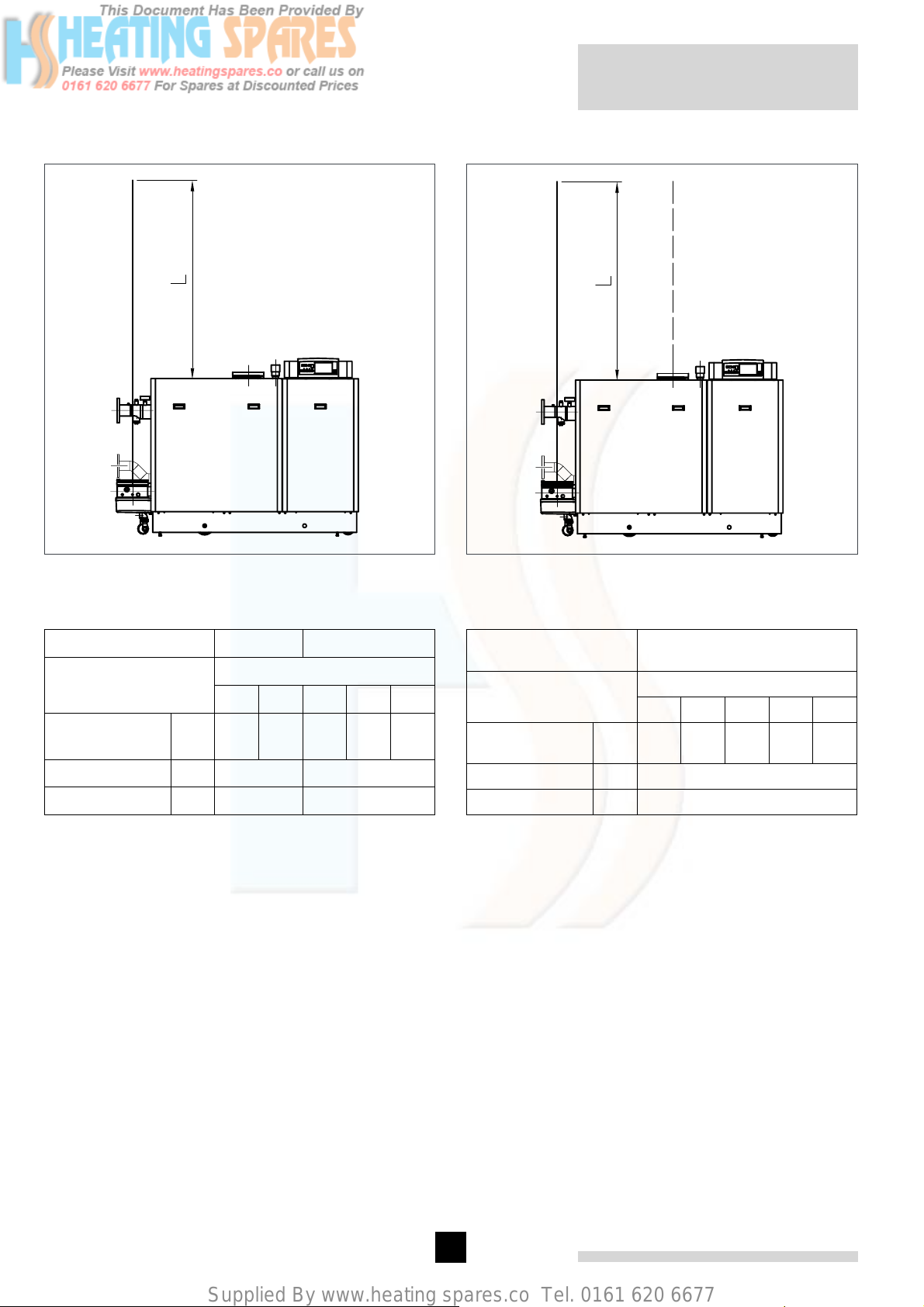

fig. 03 Elevation drawings (left-hand version shown)

04.31H.79.00002

É Flow connection NW 80, DIN 2576

Ê Return connection NW 80, DIN 2576

Ï Gas connection 2” BSP (F)

Ò Condensate drain 1 ¼” nb plastic waste

Ñ Flue gas discharge 250 mm i/d

Ð Combustion air supply 250 mm i/d

Ì Second return connection

(optional) NW 65, DIN 2576

Boiler type A B C E L

5 sections 1600 1463 1590 1004 1312

6 sections 1600 1463 1590 901 1312

7 sections 1990 1853 1980 1110 1702

8 sections 1990 1853 1980 1007 1702

9 sections 1990 1853 1980 904 1702

table 01 Dimensions in mm

10

Supplied By www.heating spares.co Tel. 0161 620 6677

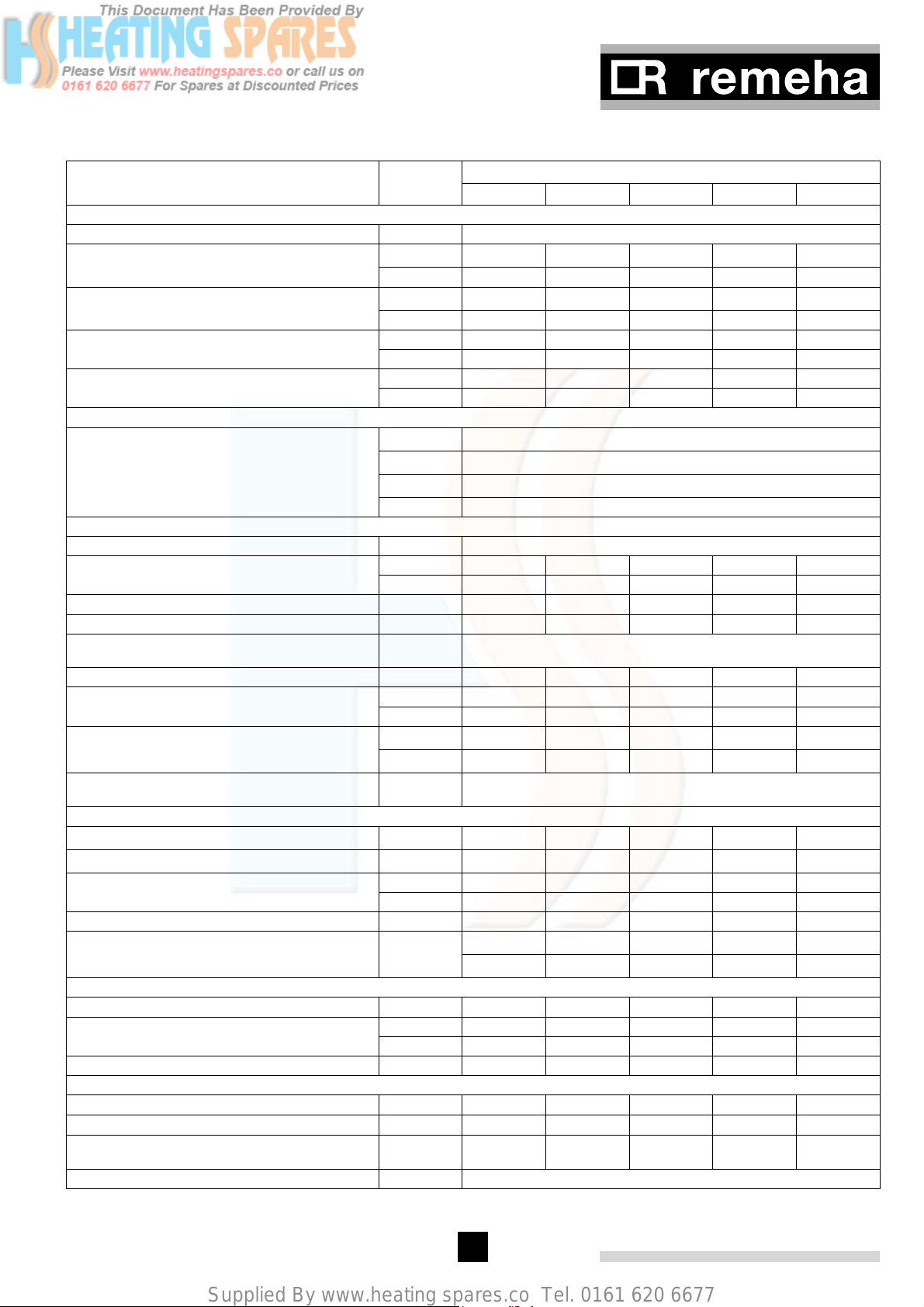

4.2 Technical data

Boiler type Unit

5 sections 6 sections 7 sections 8 sections 9 sections

Remeha Gas 310 ECO

General

Boiler control options - Modulating, high/ low or on/ off

Nominal output Pn (80/ 60°)

min kW 51 65 79 92 106

max kW 261 327 395 462 531

Nominal output Pn (50/ 30°)

min kW 56 71 84 98 113

max kW 282 353 427 499 573

Nominal input Qn (GCV/ Hs) min kW 60 75 91 105 121

max kW 298 372 448 523 598

Nominal input Qn (NCV/ Hi) min kW 54 68 82 95 109

max kW 269 336 404 471 539

Efficiency (Hi)

Combustion (Hi) at 80/ 60°

Heat to water (Hi) at 80/ 60°

Standing losses (T

average

= 45°)

% up to 99

% up to 98,5

% < 0.3

Annual efficiency (Hi) % 108,9

Gas and flue gas side

Gas category - Natural gas only

Inlet pressure gas (boiler running) min mbar 17

max mbar 100

3

Gas consumption m

emission (annual emissions) mg/ kWh < 60

NO

X

emission

NO

X

(annual emissions, O

= 0%, dry)

2

/ h 2936435057

0

ppm < 35

Residual fan duty Pa 150 150 150 150 150

Flue gas mass min kg/ h 91 114 138 160 183

max kg/ h 453 565 680 793 907

Flue gas temperature at 80/ 60°

Type classification due to discharging flue

gasses

min

°

max

°

- B23, C33, C43, C53, C63, C83

57

65

Water side

High limit temperature

Flow temperature operating

°

°

110

20 - 90

Operating pressure min bar 0.8

max PMS bar 6

Water contents litres 49 60 71 82 93

Water resistance at 11° dT

Water resistance at 20° dT

mbar (kPa) 374 (37.4) 364 (36.4) 397 (39.7) 364 (36.4) 413 (41.3)

mbar (kPa) 113 (11.3) 110 (11) 120 (12) 110 (11) 125 (12.5)

Electrical

Mains supply V/Hz 230/ 50

Power consumption min Watt 12 12 12 12 12

max Watt 303 340 470 600 858

Insulation class IP 20

Other

Weight dry kg 360 410 460 510 560

Floor area m

Noise level at a distance of 1 m from the

boiler (average)

2

1.2 1.2 1.4 1.4 1.4

dB(A) 60

Colour of casing RAL 2002 (red); 9023 (grey)

table 02 Technical data Remeha Gas 310 ECO

11

Supplied By www.heating spares.co Tel. 0161 620 6677

Remeha Gas 310 ECO

4.3 Quotation specification

- Cast aluminium - sectional pre-mix gas fired fully

condensing, modulating floor standing boiler

- Sectional heat exchanger manufactured from cast

aluminium

- Maximum operating pressure of 6 bar

- Maximum operating temperature of 90°C

- Ultra low NOx (max. 35 ppm at 0% O

)

2

- Pre-mix, fully modulating (20-100%) gas burner with

unique gas/ air ratio control for maximum efficiency

- Intelligent advanced boiler control ‘abc®’ c/w a compre-

hensive operating, service and fault diagnostic facility

- No minimum flow requirement (see section 7.4.5)

- Available as conventional flue or room sealed operation

- Capable of remote BMS control (0 -10V modulating,

on/ off or high/ low option)

- Socket for advanced service diagnostics (for PC/ PDA

connection)

- Supplied fully factory assembled and tested

- Powder coated enamel steel casing BS; RAL colour:

2002 (red); 9023 (grey)

- Rigid steel box frame

- Suitable for use with Natural gas only

- Supplied as standard with on/ off switch, temperature

indication, flow, return, heat exchanger block and flue

gas sensors

- Supplied as standard with indicating module No. 1

lock-out indication (Volt free), shut down indication

(Volt free), boiler on indication (24 Volt AC)

- Efficiencies up to 109% (NCV/ Hi)

- Manufactured to ISO 9001

- CE approved

4.4 Delivery options

Available in 5 section sizes, in “left-hand” or “right-hand”

versions each with 2 instrument panel positions:

Gas 310 ECO

Execution ‘left-hand’

fig. 04 Installation options

04.31H.79.00004

I = Front (service side)

A = Short side (alternative orientation of the instrument

panel)

The service side with the inspection cover on the heat

exchanger is considered to be the front of the boiler.

With a “left-hand” version, the flow, return and flue

connections are on the left of the boiler as you face

the front (service side). On a “right-hand” version, the

flow, return and flue connections are on the right of the

boiler as you face the front (service side). The boiler

instrument panel can be rotated to face the front or the

short side of the boiler (front will be standard unless

stated on the purchase order) (see fig. 04).

12

Gas 310 ECO

Execution ‘right-hand’

Supplied By www.heating spares.co Tel. 0161 620 6677

g Important!!

When ordering a Remeha Gas 310 ECO, it is essential

that the number of sections and whether a “left-hand”

or “right-hand” connection version is required as well

as the orientation of the instrument panel (short or front

side).

4.5 Accessories

- Modulating “OpenTherm” weather compensators,

‘’Open Therm’’ for single or rematic®’ for multi boiler

configurations

- Second return connection

- System pressure sensor

- Flue adapter 250mm to 200mm i/d (stainless steel)

- Air supply adapter 250mm to 200mm i/d (stainless

steel)

- Vertical room sealed terminal VRS 200/300 or VRS

250/350

- Condensate neutralisation box

- Condensate neutralisation granules

- Recom communication set with CD-ROM, interface

and wiring

- Interfaces for communication with various controllers

(see section 8.6)

- Gas leak proving control

- Minimum gas pressure switch

- Automatic flue gas damper for pressurised flue system

- Cleaning tools

13

Supplied By www.heating spares.co Tel. 0161 620 6677

5 EFFICIENCY INFORMATION

5.1 Annual efficiency

Up to 108.9% at Hi (up to 97% at Hs) at an average

water temperature of 40°C (50/ 30°C).

5.2 Heat to water efficiency

a. Up to 98.5% at Hi (88% at Hs) at an average water

temperature of 70°C (80/ 60ºC).

b. Up to 106.4% at Hi (98% at Hs) at an average water

temperature of 40° (50/ 30°).

5.3 Standing losses

Less then 0.3% at Hi (0.33% at Hs) at an average water

temperature of 45°C

Note: NCV = Hi, GCV = Hs

6 APPLICATION DATA

Remeha Gas 310 ECO

The Gas 310 ECO can be used on all new and refurbishment projects in both single and multiple configurations. Conventional and room sealed flue system

capability means that the boiler can be sited almost anywhere within a building.

The Remeha rematic® and “OpenTherm” weather compensators (option) are able to communicate directly with

the boiler/s controls to make full use of their fully modulating features, ensuring that the boiler closely matches

the system demand at all times.

External control systems (BMS) can be interfaced with

the boiler to provide on/ off - high/ low or modulating (0

-10V) control options.

14

Supplied By www.heating spares.co Tel. 0161 620 6677

7 INSTALLATION INSTRUCTIONS FOR HEATING INSTALLER

7.1 General

All gas appliances must, by law, be installed by competent persons (e.g. Corgi registered). Failure to install

appliances correctly could lead to prosecution.

It is in your own interest and that of safety to ensure that

the law is complied with.

The following instructions must be adhered to when the

Remeha Gas 310 ECO is installed:

- Gas Safety (Installation and Use) Regulations 1984

(as amended).

In addition to the above regulations, this boiler must be

installed in compliance with:

- Current I.E.E. Regulations for electrical installations

- Local building regulations

- The Building Standards (Scotland)

- (Consolidation) Regulations

- By-laws of the local water undertaking

- Health and Safety Document No 635 ‘The Electricity

at Work Regulations 1989’

It should also be in accordance with the relevant recommendations in the current edition of the following British

Standards and Codes of Practice, viz. BS 6644, BS5978

Part 1 & 2, BS 5449, BS 5446, BS 6798, BS 6891 and

BG DM2.

Important:

The Remeha Gas 310 ECO is a CE certified boiler and

must not be modified or installed in any way contrary to

these “Installation and Maintenance Instructions”.

Manufacturers Instructions must NOT be taken as overriding statutory obligations.

Once in position the boiler is fixed into position using the

fitted jacking bolts which both raise the wheels of the

ground and level the boiler. Technical documentation is

supplied with the boiler in a holder on the inside of the

boiler casing (beneath the instrument panel). A number

of small loose components, such as the 4 support pads

and the syphon for the boiler have been placed in the

flue gas discharge.

It is advisable (preferable) to install the Remeha Gas

310 ECO as follows:

- Place the crate c/w the boiler in the boiler room. Make

sure there is enough room at one end of the crate for

the boiler and ramp and clearance for the crate to be

removed (at least 3 M).

g Important!! Always transport the boiler in

the protective packaging wherever possible.

- Remove fixing strips, packaging lid and all other

packaging leaving the boiler on the pallet.

- Place the packaging lid on the end of the pallet (creating a ramp - secure with screw).

- Roll the boiler on its wheels off the pallet down the

ramp to the boiler room floor.

g WARNING! Use retaining straps to control

the rate of travel - Do not stand in front of the boiler!

- Manoeuvre the boiler to required final position.

i The pallet lid can be used as a rocking ramp to

convey the boiler over obstacles, such as thresholds

etc.

7.2 Delivery and installation

The Remeha Gas 310 ECO is supplied fully assembled

plastic wrapped and packed in a crate on a pallet.

The overall dimensions of the crate are 80 cm wide and

175 cm high with the length dependant on the number

of sections (5 & 6 sections: 170 cm, 7 to 9 sections:

209 cm). The base of the packaging is a 76-cm wide

pallet to enable it to be transported with a pallet truck,

forklift truck or 4-wheel transport boards.

Excluding the crate the boiler is 72-cm wide c/w casing panels and 70 cm without casing and will fit through

most standard doors (minimum door opening width 80

cm). The boiler itself has wheels so that, once the packaging has been removed, it can easily be moved around

on a smooth surface. The packaging lid includes a rocking ramp, which can be used to negotiate obstacles

such as doorsteps and small plinths.

g Important!! The wheels are designed for

transport purposes only and MUST NOT be used when

the boiler is in its final position!

- Place the 4 support pads under the adjustment bolts.

- Use the adjusting bolts to jack up the boiler lifting it

clear of the wheels and with the top of the condensate collector level.

- Fit the siphon assembly.

Use the plastic packaging to protect the boiler until

required for use.

g Important!! Additional protection may be

required if site conditions warrant it – overhead builders

working, insulation etc.

15

Supplied By www.heating spares.co Tel. 0161 620 6677

Remeha Gas 310 ECO

fig. 05 Layout in the boiler room

04.31H.79.00005

* Free space 800 mm, if instrument panel is facing the

short side.

Number of sections C in mm

5 1590

6 1590

7 1980

8 1980

9 1980

Clearance of at least 800mm is required at the front

(service side) of the boiler. However, we recommend a

clearance of 1 m. A clearance of at least 400mm above

the boiler, at least 300mm on both ends (800mm if the

instrument panel is rotated to face the short end).

fig. 06 shows the boiler’s support area including the

position of the support pads (shaded boxes) supplied.

fig. 06 Support area Remeha Gas 310 ECO

00.31H.79.00005

Number of sec-

tions

C in mm D in mm

5 1590 1118

6 1590 1118

7 1980 1508

8 1980 1508

9 1980 1508

table 03 longitudinal dimensions

16

Supplied By www.heating spares.co Tel. 0161 620 6677

7.3 Flue gas discharge and air supply

7.3.1 General

The Remeha Gas 310 ECO is suitable for both conventional room ventilated or eccentric room sealed operation. Room sealed terminals should comply with the

Gastec QA-requirements for vertical outlet constructions.

Any horizontal pipework in the flue gas discharge system should slope towards the boiler with a drain connection positioned approx. 300mm from the boiler connection. Horizontal pipework in the air supply system should

slope towards the supply opening and may require a

drain point at the low point.

Care should be taken when siting flue exit positions as

a vapour plume will be visible when the boiler is operational (flue gas temperature will be less than < 77°

resulting in the water vapour condensing out on contact

with the air).

7.3.2 Classification due to discharging flue gases

Classification according to CE:

Type B23: Conventional room ventilated appliance without draft diverter. Air supply from boiler room; flue gas

discharge on roof.

Type C33: Room sealed appliance, connected to combined roof outlet.

Type C43: Room sealed appliance in cascade configuration, connected via two ducts to a common duct system serving more than one appliance.

Type C53: Room sealed appliance, connected to separate ducts for the air supply and flue gas discharge, terminated in zones of different pressure.

Type C63: Room sealed appliance, supplied without the

terminal or the air supply and flue gas discharge ducts.

Type C83: Boiler with room sealed operation, connected

to separate air supply and flue gas discharge duct, with

flue gas discharge duct always in depression.

Note: The boilers can also be installed on a flue dilution system, but must incorporate a total flue break to

avoid boiler gas/air ratio controls being affected by the

flue dilution fan pressures. For full details please contact

Broag.

A table showing maximum air supply/ flue gas discharge

lengths for the room sealed version of the Remeha Gas

310 ECO can be found in section 7.3.7.

7.3.3 Connection options

The Remeha Gas 310 ECO is available in a room ventilated and a room sealed version. If the room-sealed version is used, the grille must be removed before installing

the air supply pipe.

7.3.4 Inlets/Outlets

For conventional flue systems the flue terminal exit point

should discharge vertically and be c/w a tapered cone

and bird guard. For room sealed options use the Broag

VRS terminals.

7.3.5 Other requirements

Flue gas discharge materials:

Single wall, rigid: stainless steel, thick-walled aluminium

(to comply with building regulations).

Flexible: stainless steel

(to comply with building regulations).

Flue gas discharge structure:

The flue gas discharge pipe must have airtight and

watertight joints and connections, or should be seamless. Horizontal sections in the flue gas discharge pipe

must slope down towards the boiler (at least 5-cm per

meter) and incorporate a drain point within 300mm of

the boiler connection.

Conventional flue or room ventilated installations:

A room-ventilated boiler takes the required combustion

air from the plant room. Combustion air for the boiler

must be provided to the room/ compartment in accordance with BS 6644. A table showing the maximum

discharge lengths for the room ventilated version of the

Remeha Gas 310 ECO can be found in section 7.3.6.

Room sealed installations:

It is unnecessary to provide separate combustion air to

the room/compartment as this is supplied direct to the

boiler via the eccentric flue and air inlet system to the

vertical terminal unit (see 0, VRS 200/250 options available from Broag).

Additional ventilation will be required to the room/

compartment in accordance with BS 6644 (compartment ventilation). For installations where supply and discharge points are in two different pressure zones CLV

system please contact Broag Technical Dept. for further

details and advice.

Flue liners:

If flue liners are used they must be manufactured from

gas and water tight airtight, thick-walled rigid aluminium

or stainless steel (flexible plastic (with a continuous

operating temperature rating of 120°) and stainless

steel pipe liners are also acceptable provided they are

water and gas tight).

Air supply materials:

Single wall, rigid or flexible: aluminium, stainless steel.

Air supply structure:

The air supply pipe must also be airtight. Horizontal sections in the air supply must slope away from the boiler

towards the supply opening and incorporate a drain connection if the route rises from a lower point that could

flood.

17

Supplied By www.heating spares.co Tel. 0161 620 6677

Remeha Gas 310 ECO

7.3.6 Single boiler conventional flue

fig. 07 Flue gas discharge duct without bends, single

boiler, conventional flue.

00.31H.79.00011 (afb 1)

7.3.7 Single boiler, room sealed flue

fig. 08 Flue gas discharge duct without bends, single

boiler, room sealed application.

00.31H.79.00011 (nr 6)

Flue diameter 200 mm * 250 mm

sections

Model Gas 310 ECO

56789

max eq. length

L

m 103 65 145 105 78

bend 45°, R=D m 1.6 2

bend 90°, R=D m 2.8 3.5

table 04 Calculation data conventional flue

* When flue gas discharge pipes with a diameter of 200

mm are used, an optional adapter is required for connection to the Remeha Gas 310 ECO from ø 250 - ø

200 mm.

Example: Gas 310 ECO, 6 sections, total length 27 m,

diameter 200 mm, 2 bends 90°.

27 m + 2 x 2.8 = 32.6 < 65 m → flue OK.

Note: If the design parameters are outside the values shown in the above table or there is any doubt

over the flue system, please contact our technical

department for calculation to be undertaken.

Flue/ air inlet diameter

250/ 250 mm

sections

Model Gas 310 ECO

56789

max eq. length

L

m 172 108 71 49 34

bend 45°, R=D m 2

bend 90°, R=D m 3.5

table 05 Calculation data room sealed applications

Example:

Gas 310 ECO, 8 sections, total length flue and air inlet

each 32 m, each 2 bends 90°.

32 m + 2 x 3.5 = 39.0 < 49 m; flue and air inlet OK.

Note: If the design parameters are outside the values shown in the above table or there is any doubt

over the flue system, please contact our technical

department for calculation to be undertaken.

Combined vertical terminal sets, and roof sealing plates

for flat roofs, are available for the room-sealed version

with diameters of ø 200 and ø 250 in accordance with

the drawings below.

18

Supplied By www.heating spares.co Tel. 0161 620 6677

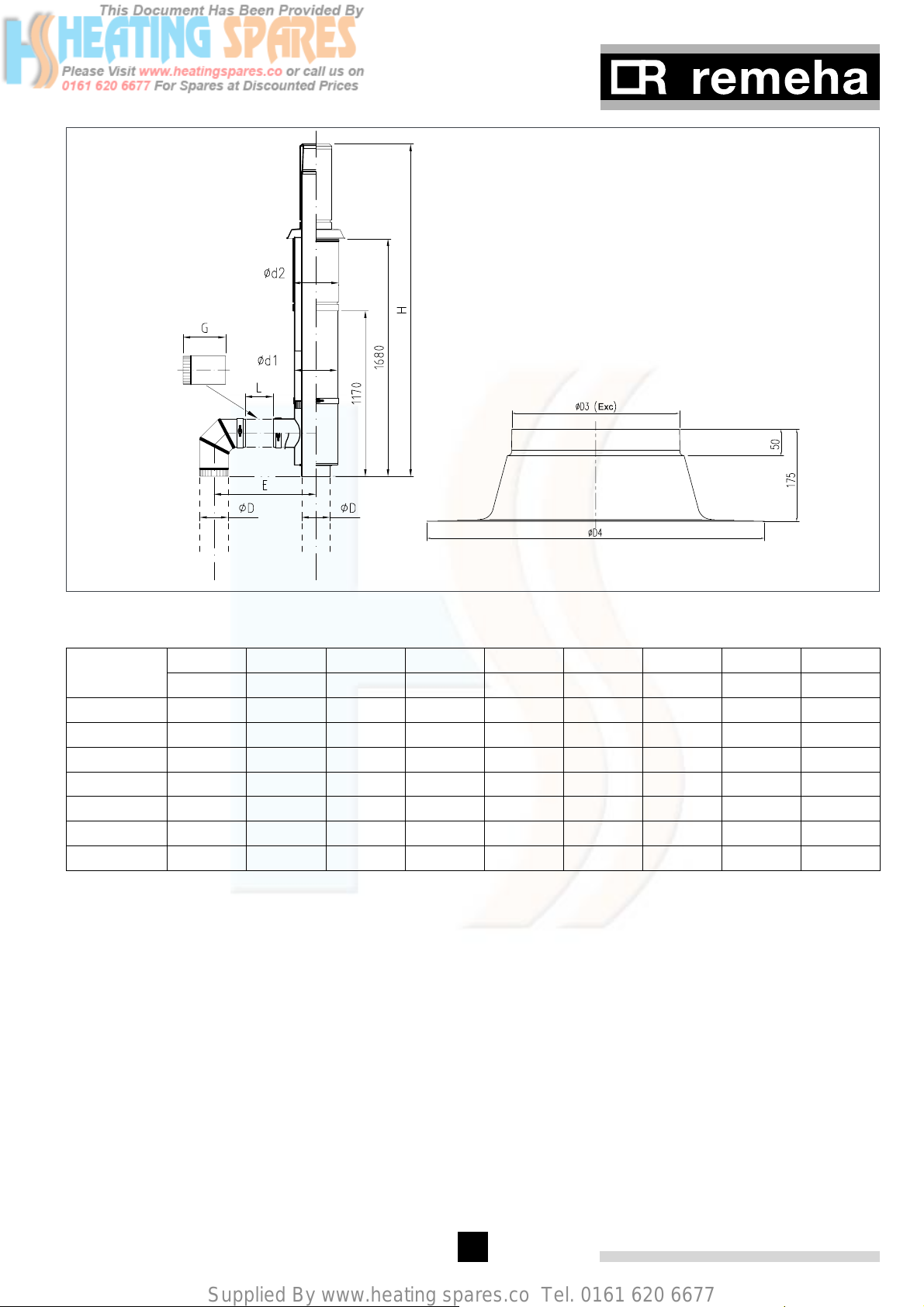

fig. 09 Vertical terminal for room sealed operation

pdf

Number of

sections

L E Ø D G* H Ød1 Ød2 ØD 3 ØD 4

mm mm mm mm mm mm mm mm mm

7 0 450 200 0 2350 300 320 318 640

9 30 550 200 130 2350 300 320 318 640

11 200 720 200 300 2350 300 320 318 640

13 260 820 250 360 2500 350 370 368 690

15 360 920 250 460 2500 350 370 368 690

17 500 1060 250 600 2500 350 370 368 690

19 600 1160 250 700 2500 350 370 368 690

* Correct lengths for 11 and 19 sections; for the 9, 13, 15 and 17 sections, the pipe supplied must be shortened.

This pipe is not suitable for the 7 section boiler.

19

Loading...

Loading...