Page 1

Gas 310 ECO PRO Gas 610 ECO PRO

Great Britain

EN

Installation, User

and Service

Manual

125467-05

Page 2

EC declaration of conformity

The device complies with the standard type described in the EG

declaration of conformity. It was manufactured and commissioned in

accordance with European directives.

The original declaration of conformity is available from the

manufacturer.

Page 3

Contents

1 Introduction ................................................................................................6

1.1 Symbols used .......................................................6

1.2 Abbreviations ........................................................6

1.3 Liabilities ...............................................................7

1.3.1 Manufacturer’s liability .............................................7

1.3.2 Installer’s liability .....................................................7

1.3.3 User’s liability ..........................................................7

2 Safety instructions and recommendations ..............................................9

2.1 Safety instructions ...............................................9

2.2 Recommendations ................................................9

3 Technical description ..............................................................................11

3.1 General description ............................................11

3.2 Homologations ....................................................11

3.2.1 Certifications .........................................................11

3.2.2 Equipment categories ...........................................12

3.2.3 Type plate .............................................................12

3.2.4 Factory test ...........................................................12

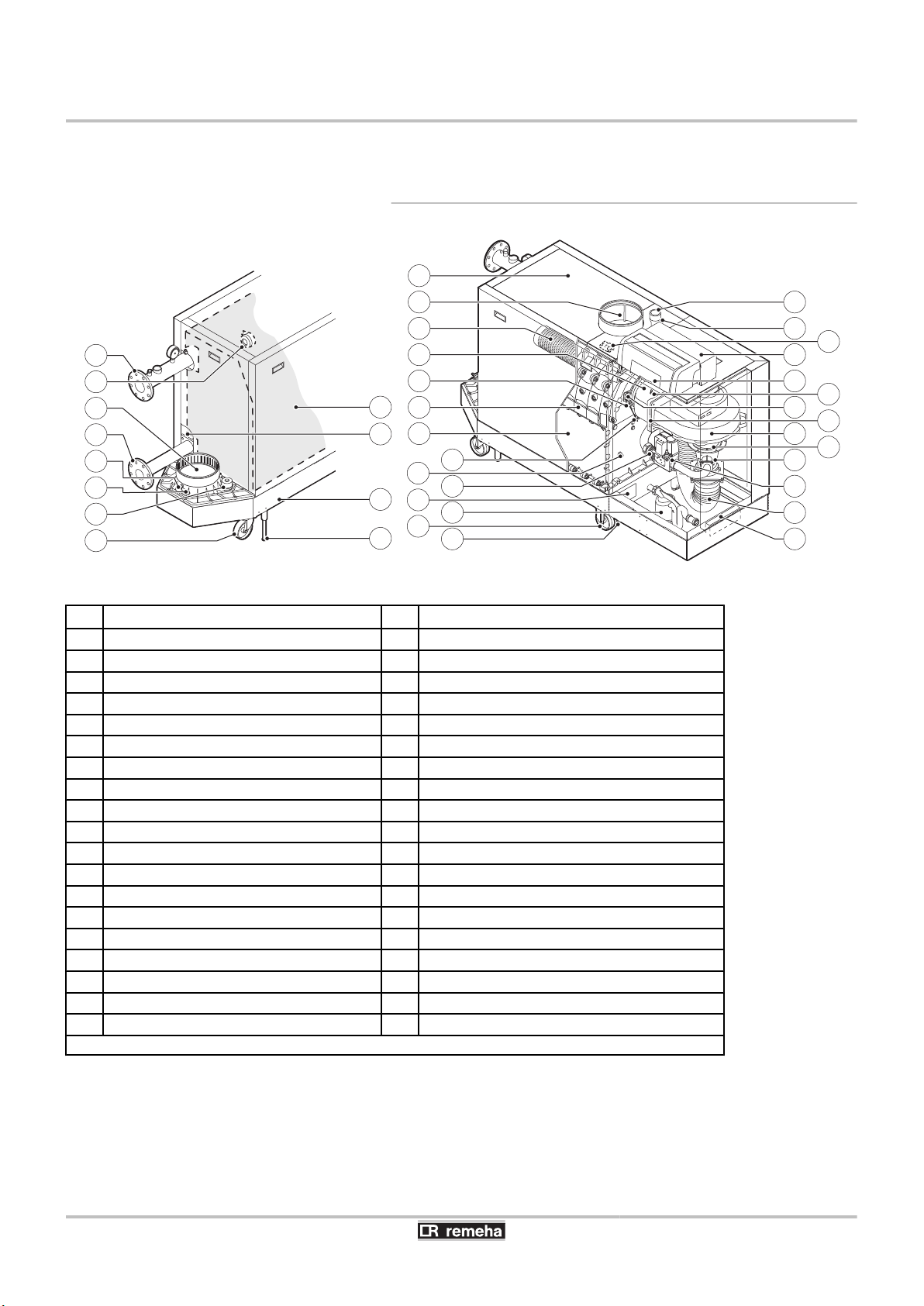

3.3 Main parts ............................................................13

3.3.1 Boiler type Gas 310 ECO PRO .............................13

3.3.2 Boiler type Gas 610 ECO PRO .............................14

3.3.3 System pump ........................................................14

3.3.4 Regulation of the water temperature .....................15

3.3.5 Protection against a shortage of water ..................15

3.3.6 Maximum temperature protection .........................15

3.3.7 Air differential pressure switch ..............................15

3.4 Technical specifications ....................................15

3.4.1 Boiler type Gas 310 ECO PRO .............................15

3.4.2 Boiler type Gas 610 ECO PRO .............................17

4 Installation ................................................................................................19

160514 - 125467-05

4.1 Regulations governing installation ...................19

4.2 Package list .........................................................19

4.2.1 Standard delivery ..................................................19

4.2.2 Accessories ...........................................................19

4.3 Installation options .............................................20

4.3.1 Transport ...............................................................20

1

Page 4

Contents

4.3.2 Location of the boiler .............................................21

4.3.3 Main dimensions ...................................................26

4.4 Hydraulic connections .......................................28

4.4.1 Flushing the system ..............................................28

4.4.2 Connection of the heating circuit ...........................28

4.4.3 Connecting the condensate discharge pipe ..........29

4.5 Gas connection ...................................................30

4.6 Connections for the air and exhaust

pipes ....................................................................30

4.6.1 Classification .........................................................31

4.6.2 Outlets ...................................................................31

4.6.3 Lengths of the air/flue gas pipes ...........................32

4.6.4 Additional Directives ..............................................35

4.6.5 Connection of the combustion gas exhaust

pipe .......................................................................35

4.6.6 Connection of the air intake pipe ...........................36

4.7 Electrical connections ........................................36

4.7.1 Control unit ............................................................37

4.7.2 Recommendations ................................................38

4.7.3 Standard control PCB ...........................................38

4.7.4 Connecting the on/off control ................................40

4.7.5 Connecting modulating controller .........................40

4.7.6 Shutdown input .....................................................40

4.7.7 Release input ........................................................41

4.7.8 System pump ........................................................41

4.7.9 PC/Laptop connection ...........................................41

4.7.10 Connection possibilities for the PCB (SCU-

S05) .......................................................................42

4.8 Electrical diagram ...............................................47

4.9 Filling the system ...............................................47

4.9.1 Water treatment ....................................................48

4.9.2 Filling the siphon ...................................................48

4.9.3 Filling the system ..................................................49

5 Commissioning ........................................................................................50

5.1 Control panel .......................................................50

5.1.1 Functions of the keys ............................................50

5.1.2 Meaning of the symbols on the display .................50

160514 - 125467-05

5.2 Check points before commissioning ................51

5.2.1 Preparing the boiler for commissioning .................51

5.2.2 Gas circuit .............................................................52

5.2.3 Hydraulic circuit .....................................................52

5.2.4 Connections for the air and exhaust pipes ............52

5.2.5 Electrical connections ...........................................52

5.3 Commissioning the boiler ..................................52

5.4 Gas settings ........................................................53

5.4.1 Setting the air/gas ratio (Full load) ........................54

2

Page 5

5.4.2 Setting the air/gas ratio (Part load) ......................55

5.5 Checks and adjustments after

commissioning ...................................................56

5.5.1 Finalizing work ......................................................56

5.6 Reading out measured values ...........................56

5.6.1 Reading the various current values .......................56

5.7 Changing the settings ........................................57

6 Switching off the boiler ............................................................................58

6.1 Installation shutdown .........................................58

6.2 Antifreeze protection ..........................................58

7 Checking and maintenance .....................................................................59

7.1 General ................................................................59

7.2 Standard checks .................................................59

7.2.1 Checking the hydraulic pressure ...........................60

7.2.2 Checking the ionization current .............................60

7.2.3 Check the water quality .........................................60

7.2.4 Checking the air supply connections and flue gas

discharge connections ..........................................60

7.2.5 Checking the gas filter for pollution .......................61

7.2.6 Checking combustion ............................................61

7.2.7 Check the air supply hose .....................................62

7.2.8 Check the dirt trap .................................................62

7.2.9 Check the air box ..................................................62

7.2.10 Check the air pressure differential switch PS ........63

7.2.11 Check the gas leakage control VPS ......................64

7.2.12 Check the minimum gas pressure switch

Gps ........................................................................66

7.3 Specific maintenance operations ......................66

7.3.1 Clean the fan and the venturi ................................67

7.3.2 Clean and inspect the non-return valve ................68

7.3.3 Replacing the ionization/ignition electrode ............68

7.3.4 Cleaning the gas filter ...........................................69

7.3.5 Cleaning the burner ...............................................70

7.3.6 Clean the burner area ...........................................70

7.3.7 Checking the heat exchanger ...............................71

7.3.8 Cleaning the condensate collector ........................72

7.3.9 Cleaning the siphon ..............................................72

7.3.10 Assembling the boiler ............................................73

7.3.11 Put the boiler back into operation ..........................73

8 Troubleshooting .......................................................................................74

8.1 Shutdowns and lock-outs ..................................74

8.1.1 General .................................................................74

8.1.2 Blocking .................................................................74

8.1.3 Lock out .................................................................74

160514 - 125467-05

3

Page 6

Contents

8.1.4 Error memory ........................................................75

9 Spare parts ................................................................................................76

9.1 General ................................................................76

10 Checklists .................................................................................................77

10.1 Checklist for commissioning .............................77

10.2 Checklist for periodic inspection and

maintenance ........................................................78

160514 - 125467-05

4

Page 7

160514 - 125467-05

5

Page 8

1. Introduction

1 Introduction

1.1 Symbols used

Gas 310 ECO PRO - Gas 610 ECO PRO

In these instructions, various danger levels are employed to draw the

user’s attention to particular information. In so doing, we wish to

safeguard the user’s safety, obviate hazards and guarantee correct

operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical

injury.

WARNING

Risk of a dangerous situation causing slight physical

injury.

1.2 Abbreviations

CAUTION

Risk of material damage.

Signals important information.

¼Signals a referral to other instructions or other pages in the

instructions.

4 3CE: Collective conduit for sealed boiler

4 Central heating: Central heating

4 PCU: Primary Control Unit - PCB for managing burner operation

4 SU: Safety Unit - Safety PCB

4 PSU: Parameter Storage Unit - Parameter storage for PCBs

PCU and SU

4 SCU: Secondary Control Unit - Extended control PCB

6

160514 - 125467-05

Page 9

Gas 310 ECO PRO - Gas 610 ECO PRO

1.3 Liabilities

1. Introduction

1.3.1. Manufacturer’s liability

Our products are manufactured in compliance with the requirements

of the various applicable European Directives. They are therefore

delivered with [ marking and all relevant documentation.

In the interest of customers, we are continuously endeavouring to

make improvements in product quality. All the specifications stated in

this document are therefore subject to change without notice.

Our liability as the manufacturer may not be invoked in the following

cases:

4 Failure to abide by the instructions on using the appliance.

4 Faulty or insufficient maintenance of the appliance.

4 Failure to abide by the instructions on installing the appliance.

1.3.2. Installer’s liability

The installer is responsible for the installation and inital start up of the

appliance. The installer must respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Carry out installation in compliance with the prevailing legislation

and standards.

4 Perform the initial start up and carry out any checks necessary.

4 Explain the installation to the user.

4 If a maintenance is necessary, warn the user of the obligation to

check the appliance and maintain it in good working order.

4 Give all the instruction manuals to the user.

1.3.3. User’s liability

To guarantee optimum operation of the appliance, the user must

respect the following instructions:

4 Read and follow the instructions given in the manuals provided

with the appliance.

4 Call on qualified professionals to carry out installation and initial

start up.

4 Get your installer to explain your installation to you.

4 Have the required checks and services done by a qualified

professional.

4 Keep the instruction manuals in good condition close to the

appliance.

160514 - 125467-05

7

Page 10

1. Introduction Gas 310 ECO PRO - Gas 610 ECO PRO

This appliance is not intended to be used by persons (including

children) whose physcial, sensory or mental capacity is impaired or

persons with no experience or knowledge, unless they have the

benefit, through the intermediary of a person responsible for their

safety, of supervision or prior instructions regarding use of the

appliance. Care should be taken to ensure that children do not play

with the appliance.

If the mains lead is damaged it must be replaced by the original

manufacturer, the manufacturer’s dealer or another suitably skilled

person to prevent hazardous situations.

8

160514 - 125467-05

Page 11

Gas 310 ECO PRO - Gas 610 ECO PRO 2. Safety instructions and recommendations

2 Safety instructions and

recommendations

2.1 Safety instructions

DANGER

If you smell gas:

1. Do not use a naked flame, do not smoke, do not

operate electrical contacts or switches ( doorbell,

light, motor, lift, etc..).

2. Shut off the gas supply.

3. Open the windows.

4. Report any leaks immediately.

5. Trace possible leaks and seal them immediately.

6. If the gas leak is before the gas meter, contact the

gas supplier.

2.2 Recommendations

DANGER

If you smell flue gases:

1. Switch the appliance off.

2. Open the windows.

3. Report any leaks immediately.

4. Trace possible leaks and seal them immediately.

WARNING

4 Installation and maintenance of the boiler must be

carried out by a qualified professional in compliance

with prevailing local and national regulations.

4 When working on the boiler, always disconnect the

boiler from the mains and close the main gas inlet

valve.

4 After maintenance or repair work, check all

installations to ensure that there are no leaks.

160514 - 125467-05

CAUTION

The boiler must be installed in a frost-free environment.

Store this document in the document wallet on the inside

of the boiler casing (Underneath the instrument panel).

9

Page 12

2. Safety instructions and recommendations Gas 310 ECO PRO - Gas 610 ECO PRO

Casing components

Only remove the casing for maintenance and repair operations. Put

the casing back in place after maintenance and repair operations.

Instructions stickers

The instructions and warnings affixed to the appliance must never be

removed or covered and must remain legible during the entire lifespan

of the appliance. Immediately replace damaged or illegible

instructions and warning stickers.

Modifications

Modifications may only be made to the boiler after the written

permission of Remeha to do so.

10

160514 - 125467-05

Page 13

Gas 310 ECO PRO - Gas 610 ECO PRO 3. Technical description

3 Technical description

3.1 General description

Floor-standing high efficiency gas boiler

4 High efficiency heating.

4 Low pollutant emissions.

4 Heat exchanger made of cast aluminium sections.

4 Transport wheels as standard.

4 Left or right-hand version of the water and flue gas side

connections possible.

4 Separable for assembly in boiler room.

4 HMI Gas 310/610 ECO PRO control panel.

3.2 Homologations

Boiler type:

4 Type Gas 310 ECO PRO-285

4 Type Gas 310 ECO PRO-355

4 Type Gas 310 ECO PRO-430

4 Type Gas 310 ECO PRO-500

4 Type Gas 310 ECO PRO-575

4 Type Gas 310 ECO PRO-650

Boiler type:

4 Type Gas 610 ECO PRO-570

4 Type Gas 610 ECO PRO-710

4 Type Gas 610 ECO PRO-860

4 Type Gas 610 ECO PRO-1000

4 Type Gas 610 ECO PRO-1150

4 Type Gas 610 ECO PRO-1300

160514 - 125467-05

3.2.1. Certifications

CE identification no

NOx classification

Type of connection

(Flue gas outlet)

PIN 0063CL3613

5 (EN 15420)

B23, B

23P

, C33, C53, C63, C83, C

93

11

Page 14

T003475-F

3. Technical description Gas 310 ECO PRO - Gas 610 ECO PRO

3.2.2. Equipment categories

Gas category Gas type Connection pressure (mbar)

I

2H

Gas H (G20) 20

The boiler is preset in the factory to operate on natural gas G20 (Gas

H).

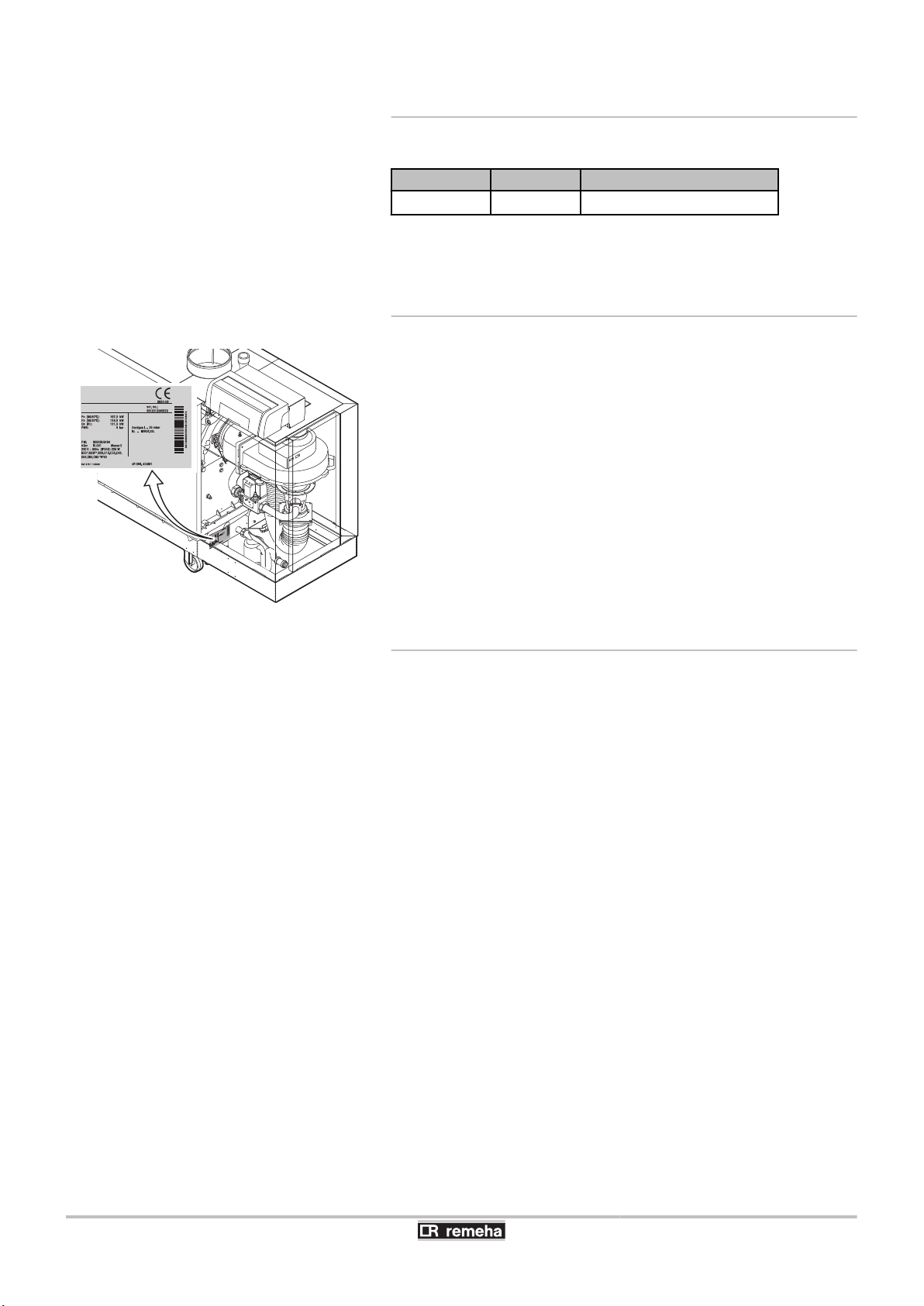

3.2.3. Type plate

The identification plate is located behind the boiler casing on the

frame, near the syphon connection. It contains the boiler serial

number and important boiler specifications, such as the model and

the gas category.

3.2.4. Factory test

Before leaving the factory, each boiler is set for optimum performance

and tested to check the following items:

4 Electrical safety

4 Adjustment (CO2)

4 Water tightness

4 Gas tightness

4 Parameter settings

12

160514 - 125467-05

Page 15

T004014-E

2

1

3

4

5

6

7

8

27

40

28

29

30

32

34

31

33

35

36

37

38

39

11

12

14

13

15

16

17

18

19

20

22

24

26

21

23

25

10

9

Gas 310 ECO PRO - Gas 610 ECO PRO 3. Technical description

3.3 Main parts

3.3.1. Boiler type Gas 310 ECO PRO

1

Flow connection

2

Air differential pressure switch

3

Flue gas discharge pipe

4

Return connection

5

Outlet for measuring combustion gases

6

Flue gas thermostat (Accessory)

7

Condensate collector sealant cap

8

Pivoting castor

9

Jacking bolt

10

Base frame

11

Second return connection (Accessory)

12

Heat exchanger insulation kit (Accessory)

13

Boiler casing

14

Air inlet

15

Burner

16

Adapter

17

Ignition/ionization electrode

18

Heat exchanger

19

Inspection hatch

20

Heat exchanger sensor

(1) ¼For more details about the devices in the flow pipe, please see "Connection of the heating circuit", page 28

160514 - 125467-05

(1)

21

Return sensor

22

Gas filter

23

Type plate

24

Siphon

25

Transport wheels

26

Jacking bolt

27

Gas connection

28

Gas pressure measurement point

29

Control panel

30

Location for optional features or a control unit

31

Pressure measurement point

32

Sight glass

33

Non-return valve

34

Fan

35

Extension piece

36

Venturi

37

Gas block

38

Air inlet hose

39

Document holder

40

Ignition transformer

13

Page 16

T004015-G

1

3

4

5

2

6

7

8

27

28

29

30

32

34

31

33

35

36

14

13

15

16

17

18

19

20

22

24

26

21

23

25

10

41

11

12

9

37

38

39

40

3. Technical description

Gas 310 ECO PRO - Gas 610 ECO PRO

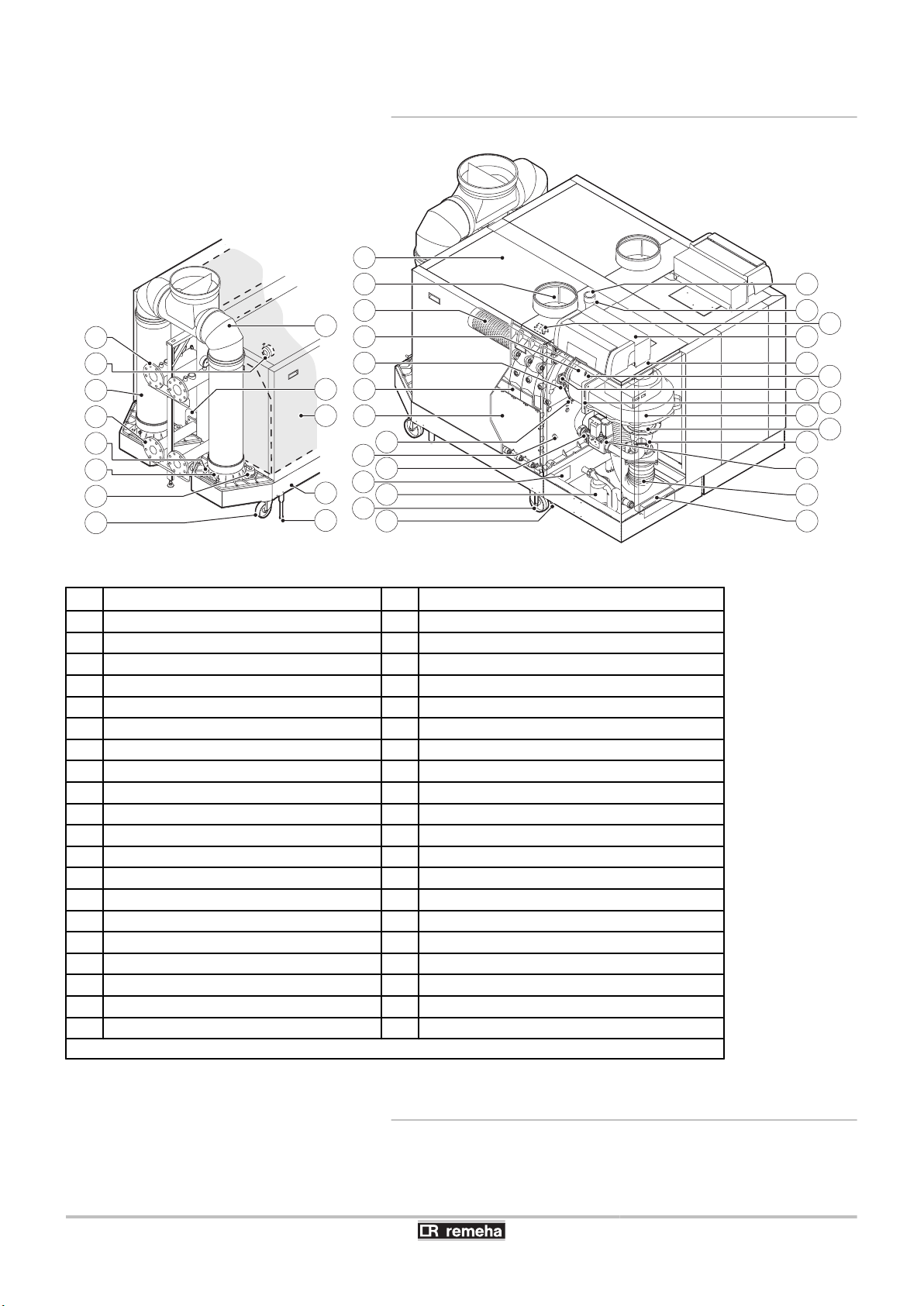

3.3.2. Boiler type Gas 610 ECO PRO

1

Flow connection

2

Air differential pressure switch

3

Flue gas discharge pipe

4

Return connection

5

Outlet for measuring combustion gases

6

Flue gas thermostat (Accessory)

7

Condensate collector sealant cap

8

Pivoting castor

9

Jacking bolt

10

Base frame

11

Heat exchanger insulation kit (Accessory)

12

Flue gas collector

13

Boiler casing

14

Air inlet

15

Burner

16

Adapter

17

Ignition/ionization electrode

18

Heat exchanger

19

Inspection hatch

20

Heat exchanger sensor

(1) ¼For more details about the devices in the flow pipe, please see "Connection of the heating circuit", page 28

14

(1)

21

Return sensor

22

Gas filter

23

Type plate

24

Siphon

25

Transport wheels

26

Jacking bolt

27

Gas connection

28

Gas pressure measurement point

29

Control panel

30

Location for optional features or a control unit

31

Pressure measurement point

32

Sight glass

33

Non-return valve

34

Fan

35

Extension piece

36

Venturi

37

Gas block

38

Air inlet hose

39

Document holder

40

Ignition transformer

41

Second return connection (Accessory)

3.3.3. System pump

The boiler does not have a built-in pump. A system pump can be

installed on the connector of the standard control PCB. This can be

an on/off pump or a modulating pump (with 0 - 10 V control).

160514 - 125467-05

Page 17

Gas 310 ECO PRO - Gas 610 ECO PRO

3. Technical description

¼For more information on controlling a modulating pump, See

paragraph: "Electrical connections", page 36.

Parameters p43 and p44 are used to modify the pump settings.

¼See the Installation and service manual HMI GAS 310/610 ECO

PRO for comprehensive operating instructions. This includes

information about changing and reading parameters, the meaning of

fault codes and deleting the failure memory.

3.3.4. Regulation of the water temperature

The boiler is equipped with electronic temperature control based on

flow, return, and boiler block temperature sensors. The flow

temperature can be set between 20°C and 90°C. The boiler reduces

its power when the set outlet-temperature is attained. The cutout

temperature is the set heating outlet-temperature + 5 °C.

3.3.5. Protection against a shortage of water

The boiler is fitted with a safety device to prevent the shortage of water

based on temperature measurements (Temperature difference

between flow and return). If ΔT = 25 K is reached (factory setting),

the boiler reduces its output by modulating to remain in operation as

long as possible. If ΔT ≥ 25 K the boiler goes into part load. If ΔT >

25 + 5 K the boiler goes into a normal control stop (blocking).

3.3.6. Maximum temperature protection

The maximum protection switches the boiler off if the water

temperature is too high (110°C) and locks it on the control box (Fixed

value, cannot be modified). Once the fault has been rectified, the

boiler can be reset by pressing the J button for 2 seconds.

3.3.7. Air differential pressure switch

Before a start and when the boiler is in operation, the air pressure

differential switch PS measures the difference in pressure between

the measuring points at the rear of the heat exchanger p+ and the air

box p-. If the pressure difference is greater than 6 mbar, then the boiler

will lock out. Once the fault has been rectified, the boiler can be reset

by pressing the J button for 2 seconds.

3.4 Technical specifications

160514 - 125467-05

3.4.1. Boiler type Gas 310 ECO PRO

15

Page 18

3. Technical description Gas 310 ECO PRO - Gas 610 ECO PRO

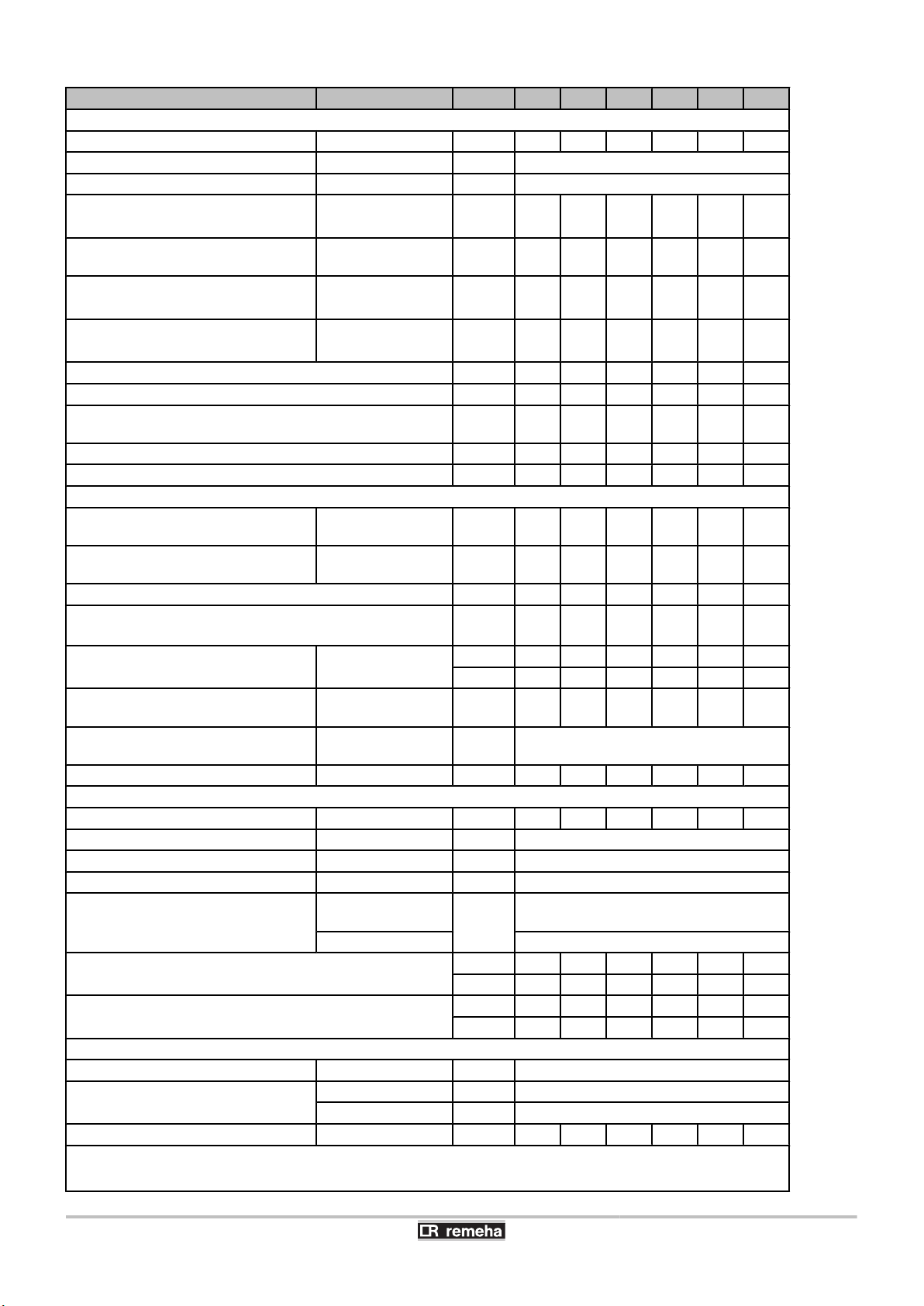

Boiler type GAS 310 ECO PRO Unit 285 355 430 500 575 650

General

Number of sections - - 5 6 7 8 9 10

EC indentification no. PIN

Input control Adjustable

Nominal output (Pn)

(80/60 °C)

Nominal output (Pn)

(50/30 °C)

Nominal input(Qn)

(Hs)

Nominal input (Qn)

(Hi)

minimum

maximum

maximum

minimum

maximum

minimum

maximum

(1)

(1)

(1)

(1)

kW

kW 279 350 425 497 574 651

kW

kW

Modulating, Start/Stop, 0 - 10 V

51

261653277939592461

60

2957536996445

54

266683338240295469

0063CL3613

105

520

106

530

121

598

109

539

119

601

135

677

122

610

Full load water efficiency (Hi) (80/60 °C) % 98.0 98.1 98.2 98.3 98.4 98.5

Full load water efficiency (Hi) (50/30 °C) % 104.8 105.2 105.6 106.0 106.4 106.8

Low load water efficiency (Hi)

(Tr = 60 °C)

% 94.7 95.3 95.8 96.3 96.8 97.3

Annual efficiency (DIN 4702, Part 8) % 109.6 109.5 109.4 109.3 109.2 109.1

Part load efficiency 92/42 EEG (Tr = 30 °C) % 109.2 109.0 108.8 108.6 108.3 108.1

Data on the gases and combustion gases

Gas consumption G20 (Gas H)

Gas inlet pressure G20 (Gas H)

minimum

maximum

minimum

maximum

m3/h

mbar

5.7

7.2

28.1

35.2

1730173017

8.7

10.1

42.5

49.6

11.5

57.0

12.9

64.6

10017100171001730

Flue gas losses % 2.3 2.3 2.3 2.3 2.3 2.3

NOx-Emission per year (BREEAM)

(EN 15420)

Maintenance consumption (EN15420)

(Without heat exchanger insulation kit)

Mass flue gas flow rate

Flue gas temperature

Maximum residual fan duty for flue gas

(∆T = 30 K)

minimum

maximum

minimum

maximum

(2)

mg/kWh 33 35 32 29 36 26

W 571 591 611 630 650 670

% 0.21 0.18 0.15 0.13 0.12 0.11

kg/h

°C

448

560

676

30

80

789

183

907

205

1026

91

114

138

160

Pa 130 120 130 150 150 150

Characteristics of the heating circuit

Water content - l 49 60 71 82 93 104

Water operating pressure minimum bar 0.8

Water operating pressure (PMS) maximum bar 7

Water temperature maximum °C 110

Operating temperature

minimum

maximum

°C

20

90

Factory setting 80

Water resistance (∆T = 20K)

Water resistance (∆T = 11K)

mbar 113 110 120 110 125 130

kPa 11.3 11 12 11 12.5 13.0

mbar 374 364 397 364 413 435

kPa 37.4 36.4 39.7 36.4 41.3 43.5

Electrical characteristics

Power supply voltage

Fuse (230 VAC)

F2 Circuit-breaker AT 10

F1 control PCB AT 2

VAC/Hz 230/50

Power consumption - Full load maximum W 279 334 426 543 763 723

(1) Factory setting

(2) ∆T = Boiler temp - Ambient temperature

(3) For a room sealed operation

16

160514 - 125467-05

Page 19

Gas 310 ECO PRO - Gas 610 ECO PRO 3. Technical description

Boiler type GAS 310 ECO PRO Unit 285 355 430 500 575 650

Power consumption - Part load maximum W 46 46 58 61 62 55

Power consumption - Standby maximum W 6 6 6 6 6 7

Electrical protection index IP

X1B

(3)

Other characteristics

Weight (empty) Total kg 364 398 433 495 531 568

Acoustic level at 1 metre

(3)

dB(A) 61 61 65 65 65 65

Ambient temperature maximum °C 40

(1) Factory setting

(2) ∆T = Boiler temp - Ambient temperature

(3) For a room sealed operation

3.4.2. Boiler type Gas 610 ECO PRO

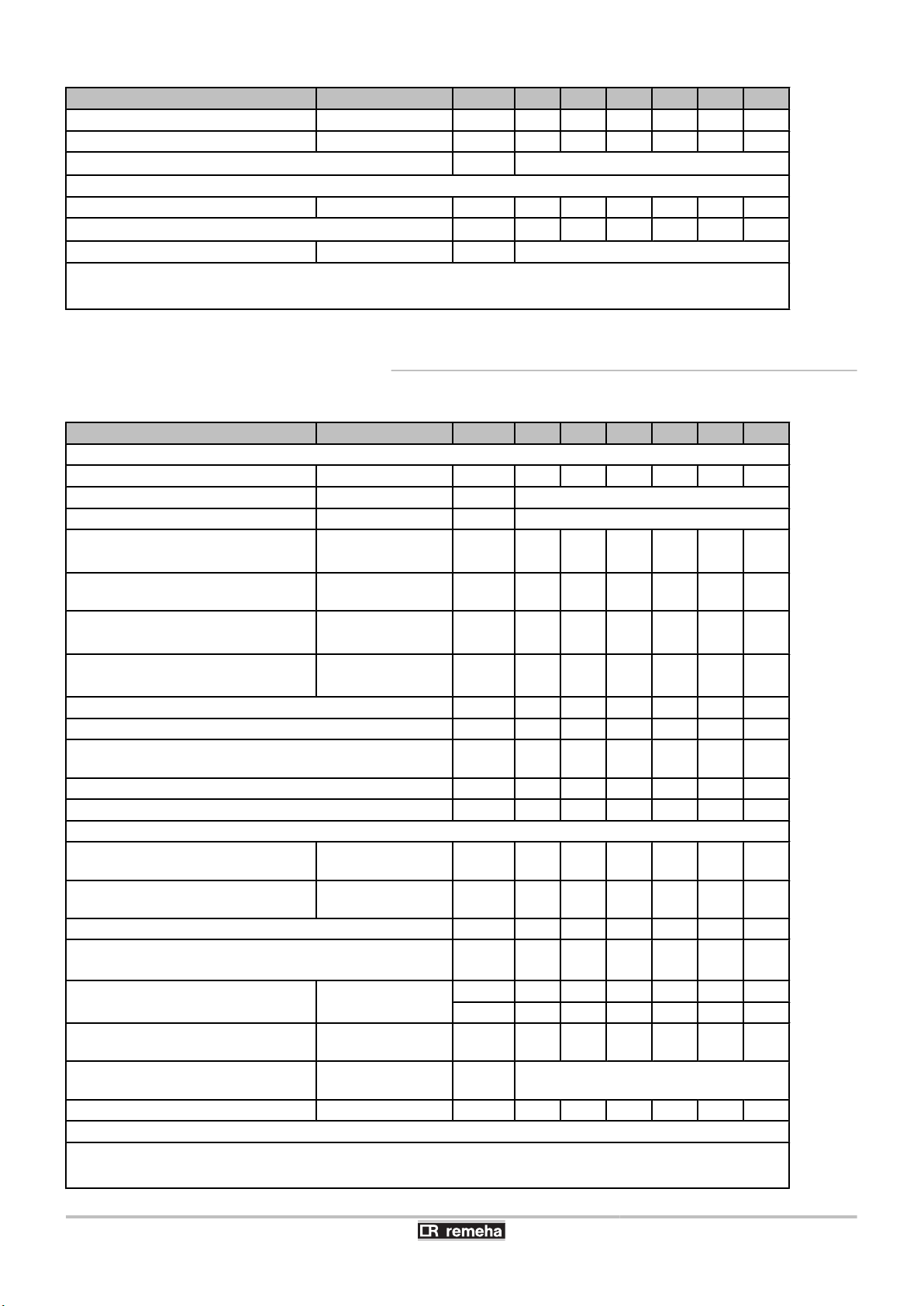

Boiler type

GAS 610 ECO PRO Unit 570 710 860 1000 1150 1300

General

Number of sections - - 2x5 2x6 2x7 2x8 2x9 2x10

EC indentification no. PIN

Input control Adjustable

Nominal output (Pn)

(80/60 °C)

Nominal output (Pn)

(50/30 °C)

Nominal input(Qn)

(Hs)

Nominal input (Qn)

(Hi)

minimum

maximum

maximum

minimum

maximum

minimum

maximum

(1)

(1)

(1)

(1)

kW

kW 558 700 850 994 1148 1303

kW

kW

Modulating, Start/Stop, 0 - 10 V

69

52287654

80

590

72

53291666

101

738

0063CL3613

123

122

790

922

142

141

890

1040

128

127

804

938

148

1060

170

1196

170

1078

158

1202

180

1354

162

1220

Full load water efficiency (Hi) (80/60 °C) % 98.0 98.1 98.2 98.3 98.4 98.5

Full load water efficiency (Hi) (50/30 °C) % 104.8 105.2 105.6 106.0 106.4 106.8

Low load water efficiency (Hi)

(Tr = 60 °C)

% 94.7 95.3 95.8 96.3 96.8 97.3

Annual efficiency (DIN 4702, Part 8) % 109.6 109.5 109.4 109.3 109.2 109.1

Part load efficiency 92/42 EEG (Tr = 30 °C) % 109.2 109.0 108.8 108.6 108.3 108.1

Data on the gases and combustion gases

Gas consumption G20 (Gas H)

Gas inlet pressure G20 (Gas H)

minimum

maximum

minimum

maximum

m3/h

mbar

7.6

9.6

56.2

70.4

1730173017

13.5

13.4

85.0

99.2

16.2

114.0

17.2

129.2

10017100171001730

Flue gas losses % 2.3 2.3 2.3 2.3 2.3 2.3

NOx-Emission per year (BREEAM)

(EN 15420)

Maintenance consumption (EN15420)

(Without heat exchanger insulation kit)

Mass flue gas flow rate

Flue gas temperature

Maximum residual fan duty for flue gas

(∆T = 30 K)

minimum

maximum

minimum

maximum

(2)

mg/kWh 33 35 32 29 36 26

W 1142 1182 1222 1260 1300 1340

% 0.21 0.18 0.15 0.13 0.12 0.11

kg/h

°C

896

1120

1352

30

80

1578

366

1814

410

2052

182

228

276

320

Pa 130 120 130 130 130 150

Characteristics of the heating circuit

(1) Factory setting

(2) ∆T = Boiler temp - Ambient temperature

(3) For a room sealed operation

160514 - 125467-05

17

Page 20

3. Technical description Gas 310 ECO PRO - Gas 610 ECO PRO

Boiler type GAS 610 ECO PRO Unit 570 710 860 1000 1150 1300

Water content - l 98 120 142 164 186 208

Water operating pressure minimum bar 0.8

Water operating pressure (PMS) maximum bar 7

Water temperature maximum °C 110

Operating temperature

minimum

maximum

°C

20

90

Factory setting 80

Water resistance (∆T = 20K)

Water resistance (∆T = 11K)

mbar 113 110 120 110 125 130

kPa 11.3 11 12 11 12.5 13

mbar 374 364 397 364 413 435

kPa 37.4 36.4 39.7 36.4 41.3 43.5

Electrical characteristics

Power supply voltage

Fuse (230 VAC)

F2 Circuit-breaker AT 10

F1 control PCB AT 2

VAC/Hz 230/50

Power consumption - Full load maximum W 558 668 852 1086 1526 1446

Power consumption - Part load maximum W 92 92 116 122 124 110

Power consumption - Standby maximum W 12 12 12 12 12 14

Electrical protection index IP

X1B

(3)

Other characteristics

Weight (empty) Total kg 707 771 837 957 1025 1095

Acoustic level at 1 metre

(3)

dB(A) 64 64 68 68 68 68

Ambient temperature maximum °C 40

(1) Factory setting

(2) ∆T = Boiler temp - Ambient temperature

(3) For a room sealed operation

18

160514 - 125467-05

Page 21

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

4 Installation

4.1 Regulations governing installation

WARNING

Installation of the appliance must be done by a qualified

engineer in accordance with prevailing local and national

regulations. The engineer must be Gas Safe registered

and have the correct ACS qualifications.

4.2 Package list

4.2.1. Standard delivery

4 The boiler

4 Complete siphon

4 Filling and drainage valve

4 Gas filter

4 Installation, User and Service Manual

4 Water quality instructions

4.2.2. Accessories

Only use the original or recommended accessories.

Description

Modulating cascade controller iSense Pro Gas valve leak proving system VPS

Modulating cascade controller Celcia MC4 Safety pressure sensitive switch

C-mix regulator Condensates neutralisation station

Modulating controller iSense Air supply collector (For a room sealed operation)

Outside temperature sensor (AF 60) Combined roof outlet 200/300 mm

Circulating pump replacement pipe Combined roof outlet 250/350 mm

Second return connection Parallel roof feed-through 350 mm

Heat exchanger insulation kit Air supply filter

Exchanger cleaning tool (lenghth 560 mm) Combustion air/flue gas adapter 250 - 200 mm

Gas main cock Combustion air/flue gas adapter Gas 310 ECO - Gas 310 ECO PRO

Recom communication kit Flue gas collector(250/350 mm) (base frame included)

Flue gas thermostat (Switch temperature 110ºC) Air supply filter box for closed configuration

Pressure switch minimum GPS

160514 - 125467-05

19

Page 22

T003980-C

1789

800

L

T003676-B

1107

1000

700

L

1000

4. Installation

4.3 Installation options

Gas 310 ECO PRO - Gas 610 ECO PRO

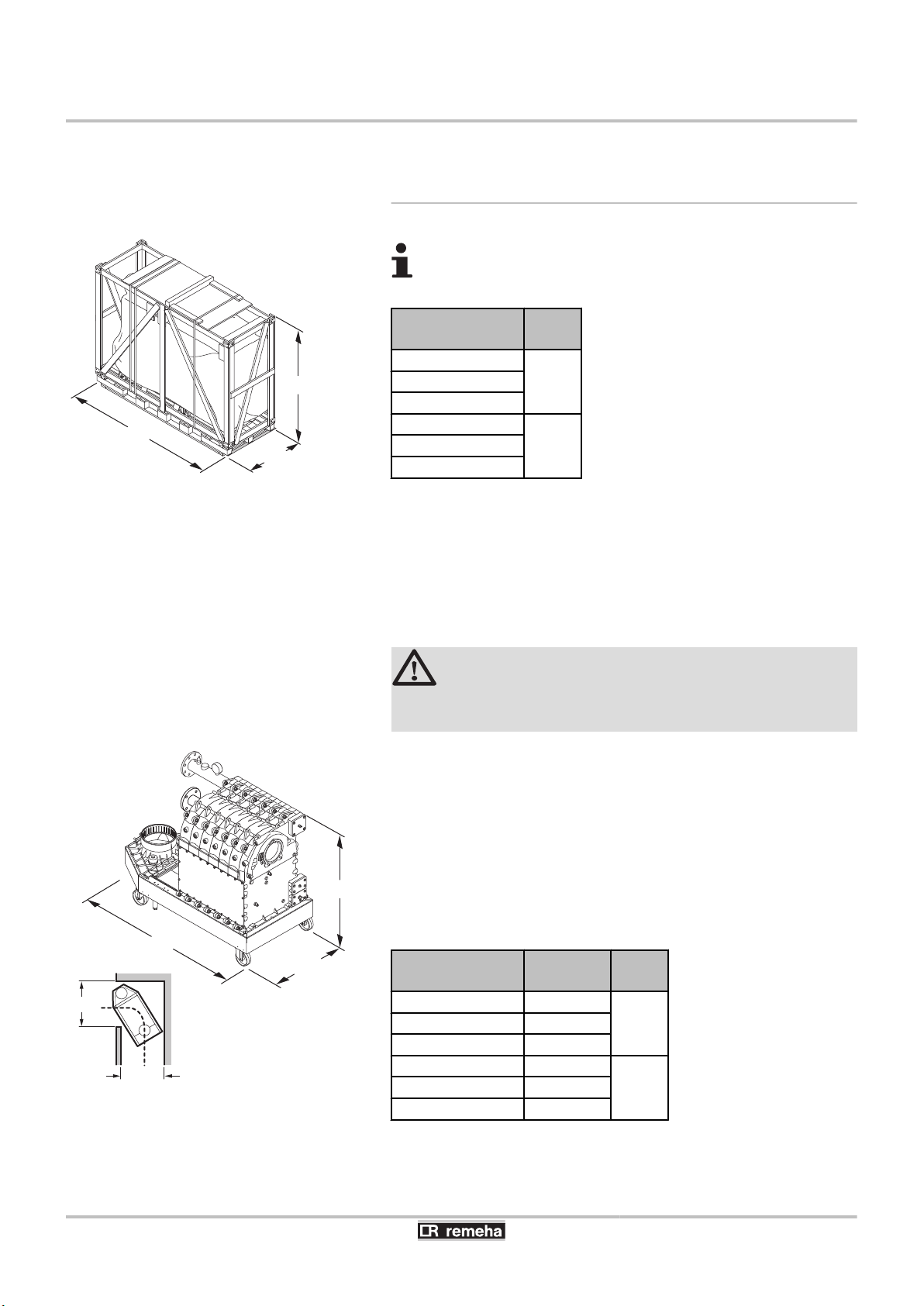

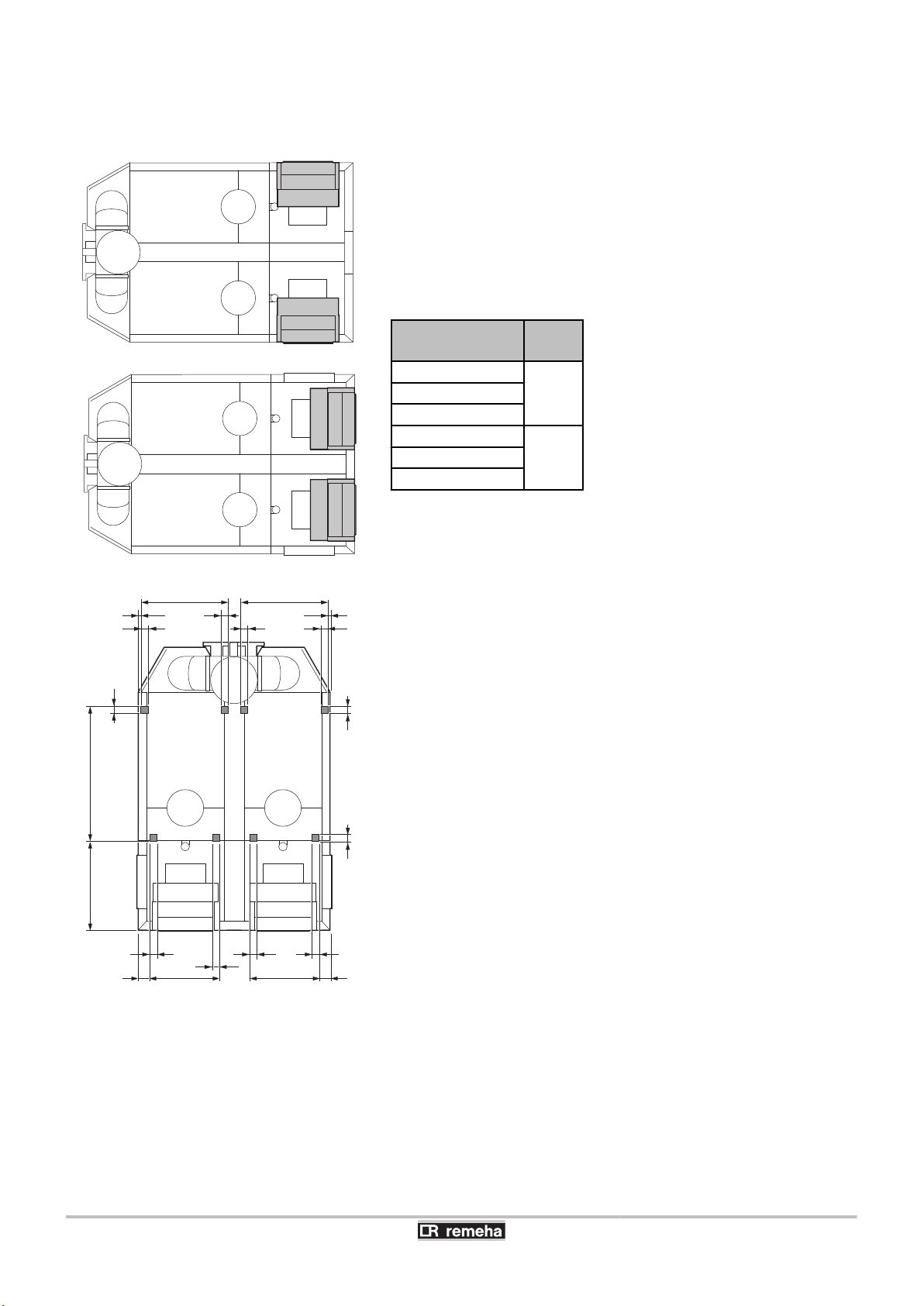

4.3.1. Transport

For Gas 610 ECO PRO boilers: The features and

instructions described are for each boiler module.

Boiler type

Gas 310 ECO PRO

285

430

500

650

L (mm)

1920355

2230575

The boiler is supplied fully assembled on a pallet. See the diagram

and table for the dimensions. The base of the packaging is a pallet

80 cm wide. This means that the crate can be transported with a pallet

truck or four-wheel transport boards. Without the packaging, the

boiler is 720 mm wide (700 mm without casing) and the boiler will fit

through standard doors. The boiler has integrated wheels, so that it

can easily be moved around once the packaging has been

removed.

CAUTION

The wheels are designed for transport purposes only and

not for use when the boiler is in its final position.

If required for internal transport, the boiler can be dismantled into

smaller parts for transport. The boiler can be stripped of:

20

4 Casing components

4 Gas/air components

4 The frame section on the instrument panel side

See the diagram and table for the dimensions of the largest remaining

transport part (Frame section with heat exchanger and water

connections).

Boiler type

Gas 310 ECO PRO

285 249

430 317

500 356

¼For information on fitting the parts, refer to the assembly

instructions delivered with the boiler.

650 424

Weight (kg) L (mm)

1160355 283

1469575 390

160514 - 125467-05

Page 23

T003785-C

L

R

I

I

T003474-B

55 55

55 55

663 21,5

531 87,5

673

55

A

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

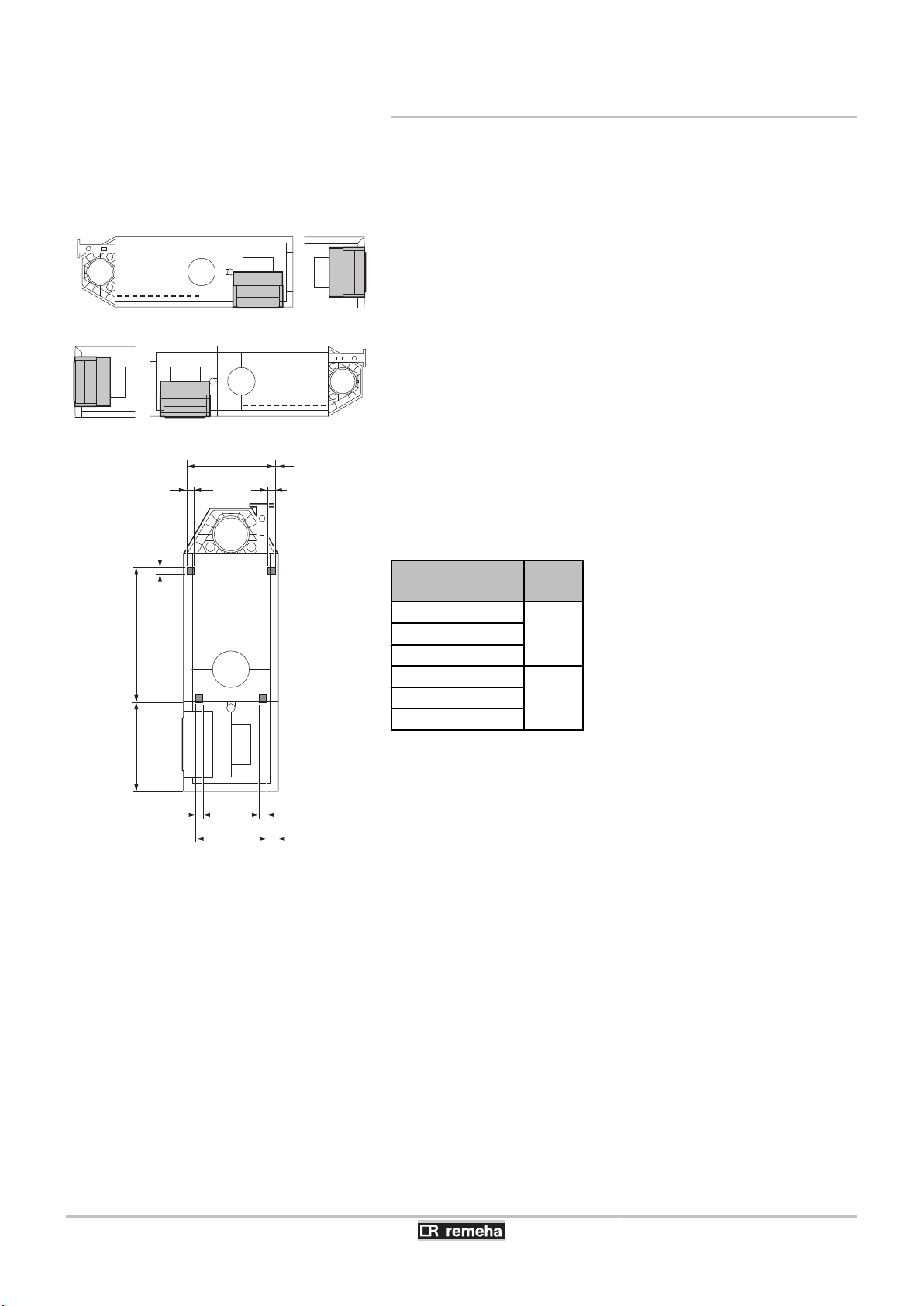

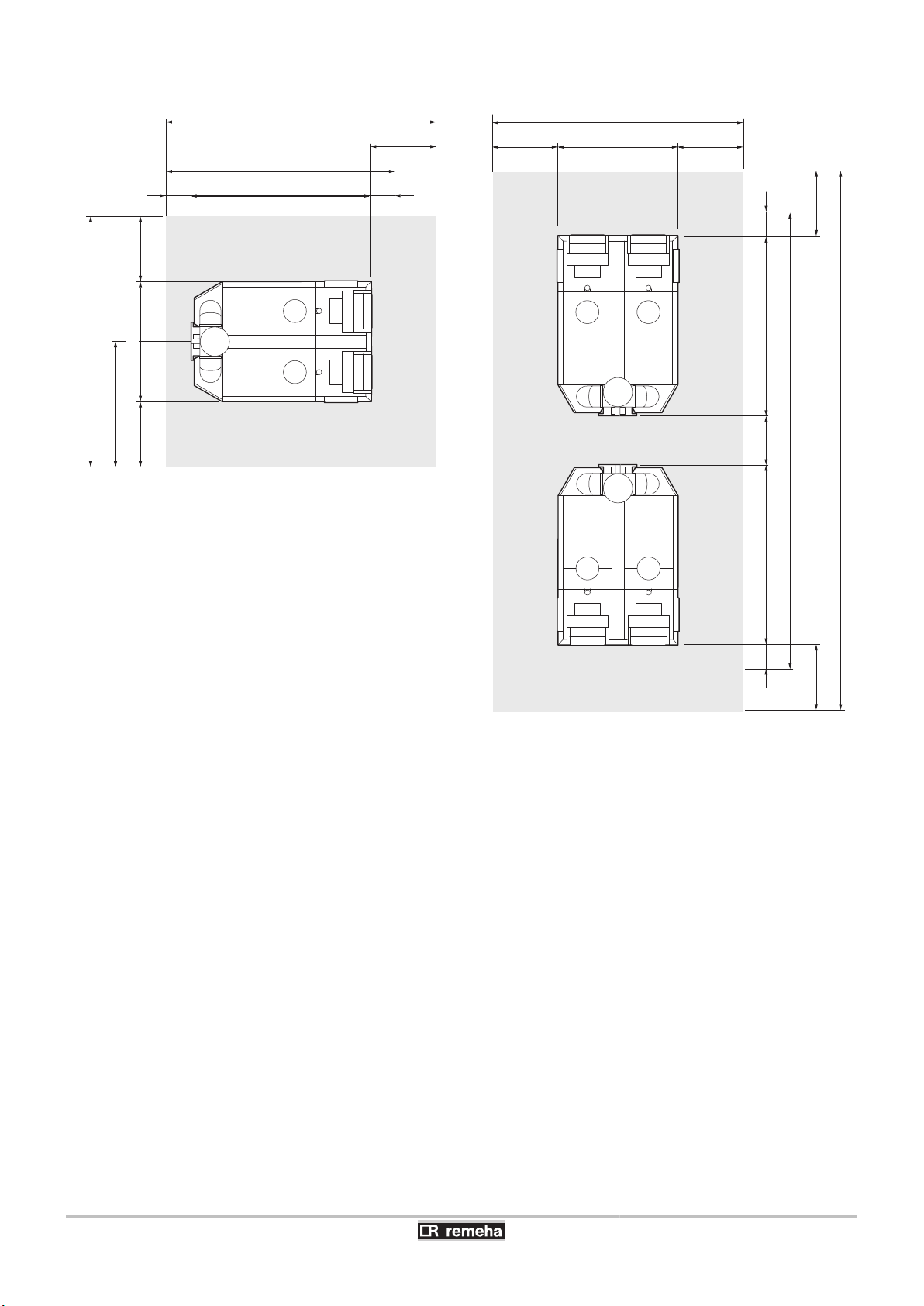

4.3.2. Location of the boiler

Boiler type Gas 310 ECO PRO

n

L

R

I

Left version

Right version

Inspection hatch (Service side)

The service side with the inspection hatch on the heat exchanger is

considered to be the front of the boiler. The boiler is available in both

a ’left-hand’ and ’right-hand’ version. This means that the hydraulic

connections and the flue gas discharge are situated on either the left

or the right-hand side of the boiler. The control panel is on the front

as standard, but can easily be rotated so that it is on the short side.

To make the boiler level and to raise the wheels off the floor, the

adjustment bolts must be used. Turn the adjustment bolts out as soon

as the boiler is placed in the correct position. The picture shows the

support surface of the boiler (This is the position of the adjustment

bolts).

Boiler type

Gas 310 ECO PRO

285

430

500

650

A (mm)

723355

1032575

160514 - 125467-05

21

Page 24

T003499-C

C1 C300 300

C

C + 600

800*

C + 1100*

300300

600

C + C1 + 2200*

C + C1 + 1200

800* 800*

720

1670

800 150

720 720

3190

800 800150

720

1670

800 150

C

C + 600

800*

C + 1100*

300300

4. Installation

Gas 310 ECO PRO - Gas 610 ECO PRO

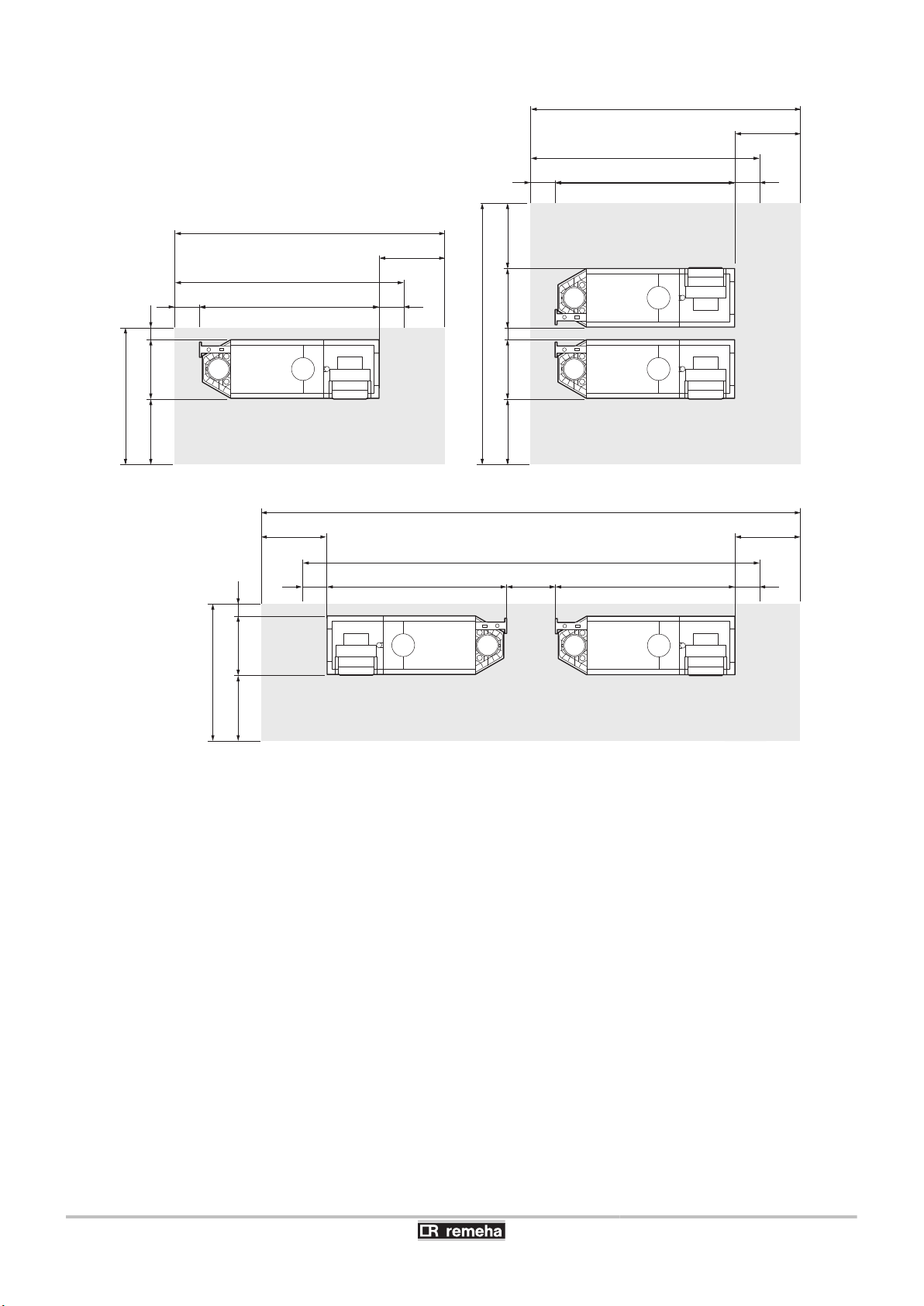

* =

Spacing required if this is operating side.

¼For the dimensions of C/C1, see paragraph: "Main

dimensions", page 26

A technical clearance of at least 80 cm is required at the front (service

side) of the boiler. However, we recommend that the clearance is at

least 100 cm. We recommend a clearance of at least 40 cm above

the boiler (If the air supply filter is used, there must be a clearance of

at least 65 cm). A minimum of 30 cm is required on the side of the

flue gas discharge, and a minimum of 30 cm is also required on the

other side (or 80 cm, if this is operating side).

22

160514 - 125467-05

Page 25

T003784-C

T003767-D

5555

55

55

21,5

21,5

87,5531

663663

53187,5

673

A

55

55

55

55

55

55

55

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

Boiler type Gas 610 ECO PRO

n

The boiler is not available with a choice between ’left-hand’ and ’righthand’ versions. The control panel is on the front as standard, but can

easily be rotated so that it is on the short side.

To make the boiler level and to raise the wheels off the floor, the

adjustment bolts must be used. Turn the adjustment bolts out as soon

as the boiler is placed in the correct position. The picture shows the

support surface of the boiler (This is the position of the adjustment

bolts).

Boiler type

Gas 610 ECO PRO

570

860

1000

1300

A (mm)

723710

10321150

160514 - 125467-05

23

Page 26

T003768-F

C

C

300

300

C

C + 600

800

C + 1100

300300

600

E

D

800

800

1450

1525

3050

800 800

1450

3050

800 800

4. Installation

Gas 310 ECO PRO - Gas 610 ECO PRO

¼For the dimensions of C, see paragraph: "Main dimensions",

page 26.

A technical clearance of at least 80 cm is required at the front (service

side) of the boiler. However, we recommend that the clearance is at

least 100 cm. We recommend a clearance of at least 40 cm above

the boiler (If the air supply filter is used, there must be a clearance of

at least 65 cm). A minimum of 30 cm is required on the side of the

flue gas discharge, and a minimum of 30 cm is also required on the

other side (or 80 cm, if this is operating side).

24

160514 - 125467-05

Page 27

T004028-E

3 2x

4

90º

5

6

72x

8

9

1

2

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

Rotate instrument panel

n

The control panel is on the front as standard, but can easily be rotated

so that it is on the short side.

1. Unscrew the 4 lateral holding screws in the control panel.

2. Remove the protective cover.

3. Unscrew the 2 bottom plate screws.

4. Lift up the instrument panel with the bottom plate.

5. Turn the instrument panel and the bottom plate into position on the

short side.

6. Slide the lips of the bottom plate into the appropriate slots.

7. Tighten the 2 bottom plate screws.

8. Refit the protective cover.

9. Screw the 4 lateral holding screws back in.

160514 - 125467-05

25

Page 28

T003472-H

1500

1023

130

366

320

1477

447

1293

310

706

592

716

155

2

Ø 250

C

L

920

B

A

Ø 250

1310

353

2 2

4. Installation Gas 310 ECO PRO - Gas 610 ECO PRO

4.3.3. Main dimensions

Boiler type Gas 310 ECO PRO

n

Gas 310 ECO PRO A (mm) B (mm) C (mm) L (mm) Symbol Fittings

285 1833 1635 1862 1490

355 1833 1635 1862 1490

430 1833 1635 1862 1490

500 2142 1944 2172 1800

575 2142 1944 2172 1800

650 2142 1944 2172 1800

{

z

Gas / Gaz

j

i

h

d

Heating circuit flow, Flange NW 80 (DIN 2576)

Heating circuit return, Flange NW 80 (DIN 2576)

Gas connection, G2" (Female thread)

Condensates discharge, Ø 32 mm (Internal)

Condensates discharge, 1¼" (Internal)

Flue gas discharge pipe, Ø 250 mm

Air intake, Ø 250 mm

Second return (optional), Flange NW 65 (DIN 2576))

26

160514 - 125467-05

Page 29

T003766-J

B

920

869

A

641

L

C

592592

366 320

2 2

1023

1760

1477

1293

310

155

1500

130

1726

1310

8

8353353

722

1460

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

Boiler type Gas 610 ECO PRO

n

Gas 610 ECO PRO A (mm) B (mm) C (mm) L (mm) Symbol Fittings

570 1833 1582 1862 1490

710 1833 1582 1862 1490

860 1833 1582 1862 1490

1000 2142 1892 2172 1800

1150 2142 1892 2172 1800

1300 2142 1892 2172 1800

{

z

Gas / Gaz

j

i

h

d

Heating circuit flow, Flange NW 80 (DIN 2576)

Heating circuit return, Flange NW 80 (DIN 2576)

Gas connection, G2" (Female thread)

Condensates discharge, Ø 32 mm (Internal)

Condensates discharge, 1¼" (Internal)

Flue gas discharge pipe, Ø 350 mm

Air intake, Ø 250 mm

Air supply collector (Option), Ø 350 mm

Second return (optional), Flange NW 65 (DIN 2576)

160514 - 125467-05

27

Page 30

4. Installation

4.4 Hydraulic connections

Gas 310 ECO PRO - Gas 610 ECO PRO

4.4.1. Flushing the system

The installation must be cleaned and flushed according to BS 7593

(2006).

Installing the boiler in new installations (installations less than

6 months old)

4 Clean the installation with a universal cleaner to eliminate debris

from the system (copper, hemp, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

Installing the boiler in existing installations

4 Remove sludge from the installation.

4 Flush the installation.

4 Clean the installation with a universal cleaner to eliminate debris

from the system (copper, hemp, flux).

4 Thoroughly flush the installation until the water runs clear and

shows no impurities.

Suitable chemicals and their use should be discussed with

specialist water treatment companies in respect to

aluminium heat exchangers.

4.4.2. Connection of the heating circuit

For the connection(s) of the boiler Gas 610 ECO PRO: The

features and instructions described are for each boiler

module.

CAUTION

The heating pipe must be mounted in accordance with

prevailing provisions.

1. Remove the dust cap on the central heating flow connection

.

Ù

2. Remove the dust cap on the central heating return connection

.

Ú

3.

Connect the heating water outlet pipe to the connection Ù.

4.

Connect the heating water return pipe to the connection Ú.

5. Connect a safety valve to the boiler’s flow connection.

6. Connect the pump to the boiler’s return connection.

28

Always connect the boiler in a way that will guarantee the water flow

through the unit during operation. When the boiler is used in a system

with two return pipes, the return pipe must be used as a lowest

temperature return. The second return pipe (accessory) is then used

as a higher temperature return. Refer to the instructions supplied with

the product. Please contact us for further information.

160514 - 125467-05

Page 31

T003476-C

1

3

2

6

4

5

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

The flow pipe is fitted with the following components:

1

Tube pocket for a temperature sensor for an external

control (½").

2

3

4

5

6

Vent device (⅛").

Connection for safety valve (1½").

Pressure gauge (½").

Flow sensor (M6).

High-limit thermostat (M4).

4.4.3. Connecting the condensate discharge pipe

For the connection(s) of the boiler Gas 610 ECO PRO: The

features and instructions described are for each boiler

module.

Discharge the condensed water directly into the drain using a

syphon. In view of the acidity level (pH 2 to 5), only use plastic material

for the discharge pipe.

1. Install a plastic drain pipe on the syphon (dia. 32 mm or larger,

connected to a drain).

CAUTION

Do not make a fixed connection in order to prevent an

overpressure in the siphon.

4 The condensate drain must be connected openly to

the drain.

4 Set the discharge pipe at a gradient of at least 5 -

10 mm per metre, maximum horizontal length 5

metres.

4 Do not drain condensation water into a roof gutter at

any time.

4 Connect the condensate discharge pipe in

accordance with prevailing standards.

160514 - 125467-05

29

Page 32

4. Installation

4.5 Gas connection

Gas 310 ECO PRO - Gas 610 ECO PRO

For the connection(s) of the boiler Gas 610 ECO PRO: The

features and instructions described are for each boiler

module.

WARNING

4 Close the main gas valve before starting work on the

gas pipes.

4 Also fit a gas cock near the boiler.

4 Eliminate debris and dust from the gas pipes.

The boiler is fitted with a gas filter as standard.

1.

Remove the dust cap on the gas connection ß.

2. Connect the gas inlet pipe (Please refer to local rules).

4.6 Connections for the air and exhaust pipes

¼The boiler is suitable for the following types of flue gas

connections. See chapter: "Certifications", page 11.

Follow applicable local guidelines when connecting the flue gas

discharge and air supply pipes to the boiler. The diameters of the

pipes must be defined in accordance with the standards in force in

your country. The total resistance of the flue gas discharge and air

supply must not exceed the maximum acceptable resistance.

¼To determine the maximum length of the air pipes and flue gas

pipes. See chapter: "Lengths of the air/flue gas pipes", page 32.

With room sealed operation, make sure the dirt trap in the

boiler air supply remains accessible. For example, fit a T

piece with an inspection hatch in the air supply pipe directly

above the boiler.

With a flue gas connection of two or more Gas 310 ECO

PRO boilers, certain fan speeds need to be changed.

Change the values of parameters p18, p19 and

p20 for each boiler in the flue gas connection. Set them

to the values as specified in the parameter table for the

Gas 610 ECO PRO boiler.

30

¼See the Installation and service manual HMI GAS 310/610 ECO

PRO for comprehensive operating instructions. This includes

information about changing and reading parameters, the meaning of

fault codes and deleting the failure memory.

160514 - 125467-05

Page 33

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

4.6.1. Classification

The table specifies this classification in detail according to [.

Type Execution Description

B23

B23P

B33 Open flue

C33 Room sealed flue

C53 Room sealed flue

C63 Room sealed flue

C83

C93

(1) Including the pressure classification P1

(2) An under pressure of 4 mbar is possible

(3) Ask your supplier for minimum dimensions of duct or sleeve

Open flue

(1)

(2)

Room sealed flue

(3)

Room sealed flue

4 Without fire-stop approval.

4 Exhaust of combustion gases above the roof.

4 Air in the installation room.

4 Without fire-stop approval.

4 Common exhaust of combustion gases above the roof.

4 Common exhaust of combustion gases mixed in the air, air in the installation room (special

construction).

4 Exhaust of combustion gases above the roof.

4 The opening for the air-supply inlet is located in the same pressure zone as the vent (For

example, a concentric passage to the roof).

4 Closed equipment.

4 Separate channelling for the air-supply.

4 Separate channelling for the combustion gases.

4 Air-supply inlet and flue gas outlet are located in different pressure zones.

4 The manufacturer delivers this type of equipment without a supply or exhaust system.

4 The equipment can be connected on a so-called semi-CLV system (with common combustion

gas exhaust).

4 Channel for the air-supply and exhaust fumes in a duct or surrounded by a sleeve:

- Concentric.

- Eccentric; Air supply from the shaft.

- Exhaust of combustion gases above the roof.

- The opening for the air-supply inlet is located in the same pressure zone as the vent.

4.6.2. Outlets

The boilers can be used in room-ventilated or room-sealed

operation. The air supply connection kit must be used for closed

configurations (This is available as an accessory).

When exhausting combustion gases of type C6, the material of the

exhaust must conform with Gastec QA and/or be provided with CE

marking.

The flue gas pipes must be calculated conforming to EN 13384 (parts

1 & 2).

For open exhaust of combustion gases above the roof, the

vent must always be provided with a suitable stainless steel

wire grill.

160514 - 125467-05

31

Page 34

R000363-A

L =

4. Installation Gas 310 ECO PRO - Gas 610 ECO PRO

4.6.3. Lengths of the air/flue gas pipes

4 To define the maximum final length, you must deduct

the pipe length in accordance with the reduction table.

4 The boiler is also suitable for longer chimney lengths

with diameters other than those indicated in the

table. Please contact us for further information.

Open flue (B23, B23P)

n

"If using an open flue version, the air supply opening remains open;

only the combustion gas opening is connected". The boiler then takes

in the combustion air required directly from the premises in which it

is installed. For the application of air discharge and combustion gas

discharge piping with a diameter other than 250 mm, a reducer should

be used.

CAUTION

4 If the boiler, in room ventilated operation, has been

set up in a (very) dusty room, use the air supply

filter (Accessory).

4 Use of the air supply filter is compulsory when the

boiler is exposed to building dust.

CAUTION

4 The air supply opening must remain open.

4 The premises in which the appliance is installed must

be fitted with the necessary air supply openings.

They must not be reduced or closed.

Gas 310

ECO PRO

Boiler type

285 20 m 50 m 50 m 50 m

355 11 m 30 m 50 m 50 m

430 8 m 22 m 39 m 50 m

500 7 m 18 m 32 m 50 m

575 5 m 13 m 24 m 50 m

650 5 m 12 m 21 m 50 m

(1) Calculated with rigid pipe and Outlet without hood (open ’free’)

Chimney length for the open flue version

(1)

with a Ø of

200 mm

with a Ø of

150 mm

Maximum length (L)

with a Ø of

180 mm

with a Ø of

250 mm

32

160514 - 125467-05

Page 35

R000361-A

L =

R000358-A

L = +

R000362-A

L = +

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

Gas 610 ECO

Chimney length for the open flue version

PRO

(1)

Boiler type

Maximum length (L)

with a Ø of 250mmwith a Ø of 300mmwith a Ø of 350

mm

570 50 m 50 m 50 m

710 31 m 50 m 50 m

860 20 m 50 m 50 m

1000 11 m 39 m 50 m

1150 5 m 26 m 50 m

1300 3 m 19 m 50 m

(1) Calculated with rigid pipe and Outlet without hood (open ’free’)

Room sealed flue (C33, C63, C93)

n

If using a room sealed version, it is necessary to connect both the

combustion gas exhaust and the air-supply opening (parallel). For the

application of air discharge and combustion gas discharge piping with

a diameter other than 250 mm, a reducer should be used.

Gas 310 ECO

PRO

Boiler type

285 42 m 50 m 50 m

355 21 m 50 m 50 m

430 13 m 50 m 50 m

500 10 m 50 m 50 m

575 5 m 34 m 50 m

650 4 m 30 m 50 m

(1) Calculated with rigid pipe and Outlet without hood (open ’free’)

Chimney length for room sealed operation

Maximum length (L)

(1)

with a Ø of 200mmwith a Ø of 250mmwith a Ø of 300

mm

160514 - 125467-05

Gas 610 ECO

Chimney length for room sealed operation

PRO

(1)

Boiler type

Maximum length (L)

with a Ø of 300mmwith a Ø of 350mmwith a Ø of 400

mm

570 50 m 50 m 50 m

710 43 m 50 m 50 m

860 26 m 50 m 50 m

1000 13 m 35 m 50 m

1150 5 m 16 m 24 m

1300 - 10 m 12 m

(1) Calculated with rigid pipe and Parallel roof feed-through 350 mm (Accessory)

33

Page 36

R000359-A

L = +

R000360-A

L = +

4. Installation Gas 310 ECO PRO - Gas 610 ECO PRO

Connection in areas of different pressure ( C53, C83)

n

Combustion air supply and combustion gas discharge are possible in

various pressure zones, semi-CLV systems. The maximum

permissible difference in height between the combustion air supply

and the combustion gas discharge is 36 m.

Gas 310 ECO PRO Chimney length in the various pressure zones

Boiler type

Maximum length (L)

with a Ø of 250 mm

285 50 m

355 50 m

430 50 m

500 50 m

575 49 m

650 40 m

(1) Calculated with rigid pipe and Elbow 90º and Outlet without hood (open ’free’)

Gas 610 ECO PRO Chimney length in the various pressure zones

Boiler type

with a Ø of 350 mm with a Ø of 400 mm

Maximum length (L)

570 50 m 50 m

710 50 m 50 m

860 50 m 50 m

1000 33 m 50 m

1150 - 22 m

1300 - -

(1) Calculated with rigid pipe and Elbow 90º and Outlet without hood (open ’free’)

(1)

(1)

Reduction table

n

Pipe reductions per element used

Diameter

Elbow 45° Elbow 90°

Pipe reduction Pipe reduction

150 mm 1,2 m 2,1 m

180 mm 1,4 m 2,5 m

200 mm 1,6 m 2,8 m

250 mm 2,0 m 3,5 m

300 mm 2,4 m 4,2 m

350 mm 2,8 m 4,9 m

400 mm 3,2 m 5,6 m

34

160514 - 125467-05

Page 37

Gas 310 ECO PRO - Gas 610 ECO PRO

4. Installation

4.6.4. Additional Directives

4 Please refer to the manufacturer’s instructions for the material in

question when installing the flue gas discharge and air supply

materials. If the flue gas discharge and air supply materials are not

installed according to the instructions (e.g. they are not leakproof,

not clamped in place etc.), this may cause hazardous situations

and/or result in bodily injury. After assembly, check at least all flue

gas and air–carrying parts for tightness.

4 Connection of the combustion gas exhaust directly to the buildings

brick chimneys or flues is forbidden for condensation reasons.

4 Always clean the ducts thoroughly in cases where lining pipes are

used and/or a connection of the air-supply.

4 It must be possible to inspect the flue or chimney.

4 In cases where condensate coming from the stainless steel or

plastic sections of the flue gas pipe can be driven back towards

the aluminium section, this condensate must be removed using a

collecting device before the aluminium section is reached.

4 For long, aluminium, combustion-gas exhaust pipes it is initially

necessary to consider the relatively high quantity of corrosive

products which are brought together with the condensate from the

exhaust pipe. The siphon on the equipment requires regular

cleaning or, preferably, an additional condensate collector can be

installed above the equipment.

4 The combusted gas discharge pipe must be sufficiently inclined

towards the boiler (at least 50 mm per metre) and an adequate

condensate collection tank and discharge system constructed (at

least 1 m before the boiler opening). The elbows fitted must be at

more than 90° to guarantee the provision of an adequate gradient

and tightness on the lip rings.

Please contact us for further information.

4.6.5. Connection of the combustion gas exhaust

pipe

The boiler is equipped with a mechanical flue gas non-return valve as

standard. This prevents flue gas travelling back up into the boiler

when it is not in operation. (E.g. for cascade systems).

Mounting

1. Fit the combustion product discharge conduit.

160514 - 125467-05

35

Page 38

4. Installation Gas 310 ECO PRO - Gas 610 ECO PRO

2. Fit together the combustion gas exhaust pipes, without welding.

4 The pipes must allow no leakage of flue gases and be

resistant to corrosion.

4 Connect the pipes together without stress between

the sections.

4 Maximum bracket distance from vertical pipes is 2 m.

4 Maximum tilt of vertical pipes is 20 mm/m.

4 The pipes must not rest on the boiler or flue gas

adapter.

4 The horizontal sections need to be constructed with a

gradient of 50 mm per metre: Back to the boiler.

4 Use a bracket at each connection from horizontal

pipes.

4.6.6. Connection of the air intake pipe

Mounting

1. Fit the air-intake conduit.

2. Fit the air-intake conduits together without welding.

4

The pipes must be airtight and corrosion-resistant.

4 Connect the pipes together without stress between

the sections.

4 Maximum bracket distance from vertical pipes is 2 m.

4 Maximum tilt of vertical pipes is 20 mm/m.

4 The pipes must not rest on the boiler or air supply

adapter.

4 The horizontal sections need to be constructed with a

gradient: Downwards in the direction of the supply

opening.

4 Use a bracket at each connection from horizontal

pipes.

Material

Single wall, rigid

Flexible

(1) The materials used must comply with the prevailing regulations and standards

aluminium/Stainless steel

(1)

4.7 Electrical connections

36

For the connection(s) of the boiler Gas 610 ECO PRO: The

features and instructions described are for each boiler

module.

160514 - 125467-05

Page 39

N L

Mains

F1

N L

PUMP

ON/OFF

OT BL

F2

PW

M

T003486-E

Gas 310 ECO PRO - Gas 610 ECO PRO

4. Installation

4.7.1. Control unit

PW

M

Pre-wired in the boiler

Three wired power cord

The boiler has a detection phase. The boiler is fully pre-wired. The

boiler is suitable for a 230 V / 50 Hz power supply with live/neutral/

earth. Other connection values are only acceptable if an isolating

transformer is installed. Connect the wires of the mains lead to the

appropriate terminal block. This can be found to the left underneath

the connector MAINS. (The mains lead is not supplied).

CAUTION

4 In the case of a fixed connection to the power cord,

you must always install a main bipolar switch with an

opening gap of at least 3 mm.

4 When connecting the mains lead to the plug, the

earth wire must be longer than the electrical wires.

The main characteristics of the control unit are described in the table

below.

Power supply voltage 230 VAC/50Hz

Rating of the main fuse F2 (230 VAC) 10 AT

Fuse rating F1 (230 VAC) 2 AT

Maximum power consumption of the pump 300 VA

WARNING

The following boiler components are at a voltage of

230V:

4 Electrical connection of the heating pump (Central

heating) (if used).

4 Electrical connection of the combined gas valve unit.

4 Fan.

4 The majority of components in the control panel.

4 Ignition transformer.

4 Connection of the power supply cable.

The boiler has a unique boiler code. This, together with

other data, incl. boiler type, counter readings, etc. is stored

in a (PSU) that belongs with the boiler. If the control unit is

replaced, the counter readings remain stored in it.

It is possible to connect various control, safety and regulation systems

to the boiler. The heat output of the boiler can be controlled as follows:

4 Adjustable control: The output varies between the minimum and

maximum value on the basis of the value determined by the

controller.

4 Analogue setting: Where the heat output or the temperature is

controlled by a 0-10V signal.

160514 - 125467-05

37

Page 40

4. Installation Gas 310 ECO PRO - Gas 610 ECO PRO

4 On/Off setting: where the heat output modulates between the

minimum and maximum value based on the flow temperature set

in the boiler.

¼The standard control PCB (PCU-06) can be extended with the

following, for example: "Accessories", page 19

4.7.2. Recommendations

WARNING

4 Only qualified professionals may carry out electrical

connections, always with the power off.

4 The boiler is entirely pre-wired. Do not modify the

connections inside the control panel.

4 Earth the appliance before making any electrical

connections.

Make the electrical connections of the boiler according to:

4 The instructions of the prevailing standards.

4 The instructions on the electrical diagrams provided with the

boiler.

4 The recommendations in the instructions.

CAUTION

Separate the sensor cables from the 230 V cables.

4.7.3. Standard control PCB

The protection PCB SU, which protects the boiler, is connected to the

standard control PCB PCU-06.

Various thermostats and controllers can be connected to the standard

control PCB (PCU-06). The possible connections on the standard

control PCB are described in the following paragraphs.

38

160514 - 125467-05

Page 41

T003477-D

N L

Mains

N L

PUMP

ON/OFF

OT RLBL

T004637-B

54 +

4

14x

2

3

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

A clearance of 20 cm is required above the instrument

panel to allow the front cover to open fully. Bear this in mind

when installing cable ducts.

Access to the connector block:

1. Unscrew the 4 lateral holding screws in the control panel.

2. Remove the protective cover.

3. The detachable screw connectors are now accessible.

4. Secure cable(s) using the traction clip and the cable clamps (The

cable clamps are supplied separately).

5. Firmly retighten the cable clamps and close the control panel.

Accessing the PCBs behind the control panel:

1. Unscrew the 4 lateral holding screws in the control panel.

2. Remove the protective cover.

3. Open the front cover.

4. Use both thumbs to press the top of the control panel downwards

a little.

5. While maintaining some of the pressure you are applying to the

top of the control panel, use both hands to tip the casing forwards

and upwards.

160514 - 125467-05

39

Page 42

N L

Mains

N L

PUMP

ON/OFF

OT RLBL

T003482-A

N L

Mains

N L

PUMP

ON/OFF

OT RLBL

T003482-A

N L

Mains

N L

PUMP

ON/OFF

OT RLBL

T003483-B

4. Installation

Gas 310 ECO PRO - Gas 610 ECO PRO

4.7.4. Connecting the on/off control

The boiler can be controlled with an on/off controller. Connect the

controller to the ON/OFF-OT connector. (It does not matter which wire

is connected to which cable clamp).

4.7.5. Connecting modulating controller

The boiler is fitted with a OpenTherm connection as standard. As a

result, modulating OpenTherm room controllers can be connected

without any further adjustments. Connect the two-wire cable to

terminals ON/OFF-OT of the connector (It does not matter which wire

is connected to which cable clamp).

4.7.6. Shutdown input

The boiler has a shutdown input (Normally closed contact). If this

contact is opened, the boiler will go into shutdown or be locked out.

This input can be used for example in combination with the flue gas

thermostat (Accessory). This input is on the BL terminals of the

connector.

CAUTION

Only suitable for potential-free contacts.

Remove the bridge before using the input

The behaviour of the input can be changed using parameter

p35.

40

160514 - 125467-05

Page 43

N L

Mains

N L

PUMP

ON/OFF

OT RLBL

T003484-B

N L

Mains

N L

PUMP

ON/OFF

OT RLBL

T003485-B

T003492-E

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

4.7.7. Release input

The boiler has a release input (Normally open contact). If this contact

is closed when there is a heat demand, the burner will go into

shutdown after a waiting time. This input can be used in combination

with the limit switches on flue gas dampers, hydraulic shutter valves,

etc.. This input is on the RL terminals of the connector.

CAUTION

Only suitable for potential-free contacts.

The waiting time of the input can be changed using parameter

p32.

4.7.8. System pump

An external central heating pump can be connected to the Pump

terminals of the connector. The maximum input power is 300 VA.

¼For more information on controlling a modulating pump See

paragraph: "Connection possibilities for the PCB (SCU-S05)", page

42

4.7.9. PC/Laptop connection

A PC can be connected to the RS 232 input using an USB cable.

Using the Recom PC/Laptop service software, you can enter, change

and read out various boiler settings.

160514 - 125467-05

41

Page 44

T003684-C

X2

SCU-S05

X1

X3

X7X6X4 X5

N L

N

L

EgV

N L

EgV

N L

HdV

N L

HdV

N L

FgV

FgV

X9

X8

+0 S

+0

Wps

S

Gps

Gps

VPS

VPS+0

+0

+0

+0

Ctrl0-10

Pump

N L

N

Pump

L

NoNc C

NoNc C

Status

NoNc C

NoNc C

Status

Tout

Tout

R000303-A

N L

N L

FgV

FgV

R000304-A

HdV

N L

HdV

N L

R000305-A

EgV

N L

EgV

N L

4. Installation

Gas 310 ECO PRO - Gas 610 ECO PRO

4.7.10. Connection possibilities for the PCB (SCU-

S05)

¼To set the parameter selected: See the Installation and service

manual HMI Gas 310/610 ECO PRO for comprehensive operating

instructions.

CAUTION

On removing this PCB, the boiler will show fault code

e[38. To prevent this fault, an auto-detect must be

carried out after removing this PCB.

Flue gas damper control (FgV)

n

Not applicable.

Hydraulic valve control (HdV)

n

In a cascade configuration, a hydraulic valve prevents heat loss when

the boiler is not running. Connect the hydraulic valve to the HdV

terminals of the terminal strip. The running time of the hydraulic valve

must be programmed with parameter p30.

Control of external gas valve (EgV)

n

42

If there is a heat demand, an alternating voltage of 230 VAC, 1 A

(maximum) becomes available on the EgV terminals of the connector

to control an external gas valve.

160514 - 125467-05

Page 45

R000306-A

Pump

N L

N

Pump

L

R000307-B

NoNc C

NoNc C

Status

NoNc C

NoNc C

Status

R000308-B

+0

+0

Ctrl

max

min

Off

1 2 3

4 5 6 7 8 9 10

T003802-B

U

R

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

Connecting a shunt pump (Pump)

n

If required, a shunt pump may also be installed on the terminals

Pump of the connector. Only an on/off pump can be controlled. The

pump is activated during lock outs 5t:9 (5v:4,5 and 6). The

maximum input power is 300 VA.

Operation signal and failure signal (Status)

n

The alarm or operation signal is selected using parameter p26

(Connector X4).

The alarm or operation signal is selected using parameter p27

(Connector X5).

4 If the boiler is operating, the operation signal can be switched via

a potential-free contact (maximum 230 VAC, 1 A) on the No and

C terminals of the connector.

4 If the boiler locks out, the alarm can be transmitted via a potential-

free contact (maximum 230 VAC, 1 A) on the Nc and C terminals

of the connector.

Analogue output (Ctrl)

n

The function of the analogue output can be set using parameter

p36.

An outgoing 0-10 V signal can be used either to report the supplied

heat output or the supplied temperature.

The speed of the system pump can be controlled with an outgoing

0-10 V signal. (Only possible if the pump is suitable for this).

Control of 0-10V Wilo system pump

R

min

max

Off

U

Output signal (V) Description

Pump regime

Minimum pump speed

Maximum pump speed

The pump is off

Output signal (V)

<1 Pump off

1 - 2 Hysteresis

2 - 3 Pump on (Minimum pump speed)

3 - 10 Pump modulates (Linear)

160514 - 125467-05

43

Page 46

max

Sp

min

R

1 2 3

4 5 6 7 8 9 10

T003803-B

U

R000309-A

+0

+0

0-10

4. Installation

Gas 310 ECO PRO - Gas 610 ECO PRO

Control of 0 - 10 V Grundfos system pump

R

min

max

Sp

U

Output signal (V) Description

Pump regime

Minimum pump speed

Maximum pump speed

Nominal set-point

Output signal (V)

<0,5 Pump on (Minimum pump speed)

>0,5 Pump modulates (Linear)

Control of PWM system pump

In this case, the 0-10 V signal controls the system pump linear.

Message about the supplied temperature

Output signal (V)

0,5 - Lock out

1 - 10 10 - 100 Delivered temperature

Temperature °C Description

Message about the supplied heat output

Output signal (V)

0 0 Boiler off

0,5 - Lock out

2,0 - 10

(1) Dependent on the minimum modulation depth (set speeds, standard 20%)

Analogue input (0-10 V)

n

(1)

Heat output (%) Description

20 - 100 Heat output supplied

The function of the analogue input can be set using parameter

p37.

This control can be based on temperature or heat output. If this input

is used for 0-10 V control, then the boiler OT communication is

ignored.

Analogue temperature-based control (°C)

The 0 - 10 V signal controls the boiler flow temperature. This control

modulates on the basis of flow temperature, whereby the heat output

varies between the minimum and maximum values on the basis of

the flow temperature set point calculated by the controller.

Input signal (V)

0 - 1,5 0 - 15 Boiler off

1,5 - 1,8 15 - 18 Hysteresis

1,8 - 10 18 - 100 Temperature required

Analogue heat output-based control (%)

Temperature °C Description

44

160514 - 125467-05

Page 47

R000310-A

+0 S

+0

Wps

S

R000311-A

Tout

Tout

T003800-A

0 10 20

-20

-10

10

30

70

50

90

F

R000312-A

Gps

Gps

Gas 310 ECO PRO - Gas 610 ECO PRO 4. Installation

The 0 - 10 V signal controls the boiler output. The minimum and

maximum values are limited. The minimum output is linked to the

boiler’s modulation depth. The output varies between the minimum

and maximum value on the basis of the value determined by the

controller.

Input signal (V) Heat output (%) Description

(1)

0 - 2,0

2,0 - 2,2

2,0 - 10

(1) Dependent on the minimum modulation depth (set speeds, standard 20%)

Hydraulic pressure sensor (Wps)

n

(1)

(1)

0 - 20 Boiler off

20 - 22 Hysteresis

20 - 100 Heat output requested

The hydraulic pressure sensor registers the water pressure and can

shut the boiler down when the minimum water pressure is reached.

To activate this blocking option, a minimum pressure must be set with

parameter p"8. Connect the hydraulic pressure sensor to the

Wps terminals of the terminal strip.

0 = Earth or neutral of the power supply

S = Signal or output from the sensor

+ = Supply voltage

Connecting the (Tout) outside temperature sensor

n

An outside sensor can be connected to the Tout terminals of the

connector (Accessory). Where there is an on/off thermostat controller,

the boiler will control the temperature with the set point of the internal

heating curve.

If an outside temperature sensor is connected, it is possible to adapt

the heating curve. The setting can be modified using parameters

p1, p"2, p"3 and p"4.

A OpenTherm controller can also use this outside

sensor. The heating curve required must then be set on the

controller.

Pressure switch minimum (Gps)

n