Technical information

Remeha Gas 3002 ECO

• High efficiency condensing

boiler with Low NOx

Remeha Gas 3002 ECO

emission

• Range 177 - 531 kW

• mbc 3.0

CONTENTS

Remeha

Gas 3002 ECO

Preface 3

1. Description of the boiler 4

2. Constructional data 5

2.1 General 5

2.2 Burners 5

3. Technical data and dimensions 6

4. Efficiency information 7

4.1 Combustion efficiency 7

4.2 Efficiency 7

4.3 Standing losses 7

4.4 Annual efficiency 7

5. Application data 8

5.1 Delivery and positioning 8

5.1.1 General 8

5.1.2 Location 8

5.1.3 Support 10

5.2 L.P.H.W. configuration 10

5.2.1 Water temperature 10

5.2.2 Water pressure 10

5.2.3 Water circulation 11

5.2.4 Water treatment 11

5.2.5 Noise levels 11

5.3 Hydraulic circuits with Low Loss Header 12

5.3.1 Single boiler installation 12

5.3.2 Modular boiler installation 12

5.4 Installation instructions 12

5.5 Condensate discharge 12

5.6 Flue gas discharge and air supply 13

5.6.1 General 13

5.6.2 Requirements 13

5.6.3 Conventional room ventilated 13

5.6.4 Room sealed operation 14

6. Principle of the boiler installation 16

7. Control and safety equipment 17

7.1 General 17

7.2 Instrument panel 17

7.2.1 General 17

7.2.2 Lay-out of the instrument panel 17

7.3 The control unit 17

7.3.1 General 17

7.3.2 User level 17

7.3.3 Service level 18

7.3.4 Overview of the different menus 20

7.4 Standard electronic gas train 21

7.4.1 Schematic construction 21

7.4.2 Specification 21

7.5 Functions 21

7.5.1 General 21

7.5.2 Flame protection (lock out) 21

7.5.3 Low-water protection 21

7.5.4 Temperature protection 21

7.5.5 Flue gas transport protection 21

8. Assembly guidelines and installation

instructions for the heating engineer 22

8.1 General 22

8.2 Water connections 22

8.3 Water pressure 22

8.4 Safety valve 22

8.5 Filling, refilling and venting of

the installation 22

8.6 Boiler draining 22

9. Gas supply 22

9.1 General 22

9.2 Pressure test of the gas installation 22

9.3 Gas pressures 22

10. Electrical supply 23

10.1 General 23

10.2 Electrical connections 23

10.3 Electrical data 23

10.4 Boiler control 23

10.4.1 General 23

10.4.2 Modulating 23

10.4.3 High/low control 24

10.5 Connections 24

10.5.1 Other inputs 24

10.5.2 Blocking inputs 24

10.5.3 Locking inputs 24

10.5.4 Gas leak check 24

10.6 Outputs 25

10.6.1 Alarm output 25

10.6.2 Operating message 25

10.6.3 External gas valve 25

10.6.4 Shunt pump connection 25

10.6.5 Extra 230V connection 25

10.7 Building Ma na ge ment System 25

10.8 Frequency changer 25

10.9 Electrical wiring diagram 26

11. Commissioning 28

11.1 Technical data 28

11.2 Initial lighting 28

11.3 Shut down the boiler 31

12. Fault-Finding 31

12.1 General 31

12.2 Faults 31

13. Inspection and servicing 35

13.1 General 35

13.2 Servicing 35

2

PREFACE

These technical instructions contain useful and important information for the correct operation and maintenance of the Remeha central heating boiler, model Gas

3002 ECO. Furthermore, important instructions are given

to prevent accidents and serious damage before commissioning and during operation of the boiler, to ensure

safe and trouble free boiler operation.

Read these instructions carefully before putting the boiler into operation, familiarize yourself with its operation

and control and strictly observe the instructions given.

If you have any questions, or if you need more information about specific subjects relating to this boiler, please

do not hesitate to contact us.

The data published in these technical instructions is

based on the latest information and is subject to revisions. We reserve the right to modify the design and/or

construction of our products at any moment, without

being obliged to adjust earlier supplies accordingly.

3

1. DESCRIPTION OF THE BOILER

Remeha

Gas 3002 ECO

The Remeha Gas 3002 ECO is a high efficiency condensing boiler with a very low NOx emission.

The boiler consists of two heat exchangers, the first

being made of cast iron and the second of aluminium.

The latter is suited for recovering both the sensible and

the latent (condensation) heat. Premix burners ensure a

very low NOx emission (< 25 ppm at O

mg/kWh at O2 = 3%) and low level noise production.

It is supplied disassembled and has a red and grey sheet

steel casing. Its compact construction and the fact that

the boiler is suitable for room sealed or room ventilated

operation, makes it suitable for an unprecedented range

of applications.

= 0%, or < 43

2

The boiler meets the requirements of the CE regulations

at the following directives:

- Gas appliance directive no. 90/396/EEC

- Efficiency directive no. 92/ 42/EEC

- Electrical low voltage directive no. 73/ 23/EEC

- Machinery directive no. 89/392/EEC

- E.M.C. directive no. 89/336/EEC.

Suitable for all qualities of natural gas

(category I 2 H 17 - 30 mbar).

Classification type for evacuation of the combustion

products: B23, C33, C53 or C63.

For further advice or information contact Broag Ltd.

4

2. CONSTRUCTIONAL DATA

2.1 General

- The first heat exchanger consists of cast iron sections

assembled with conical nipples.

- The second heat exchanger (economiser) is construc ted from finned tubes and made of aluminium.

- A fan supplies the combustion air and transports the

exhaust gases through the boiler and flue.

- The control and safety equipment is fitted behind the

casings.

- The boiler is entirely prewired.

- The casings are clear of the ground to avoid any corro sion as a result of moisture.

- The boiler is provided with an integrated instrument

®

panel in which a rematic

weather-compensated boiler

control can be incorporated.

- The boiler is available for either "room sealed" or con ventionally "room ventilated" operation.

- It is supplied disassembled, to facilitate transportation.

- A modulating or high/low load control by means of a

gas/air ratio control always ensures optimal combus

tion.

- Advanced menu-driven microprocessor boiler control,

with extensive operational and fault diagnostics.

- RS232-connection for a two-way connection to a

computer, modem or Building Management System.

2.2 Burners

The premix burners have a metal fibre cover and

guarantee low-noise operation and a very low NOx emission.

Fig. 01 Remeha Gas 3002 ECO

5

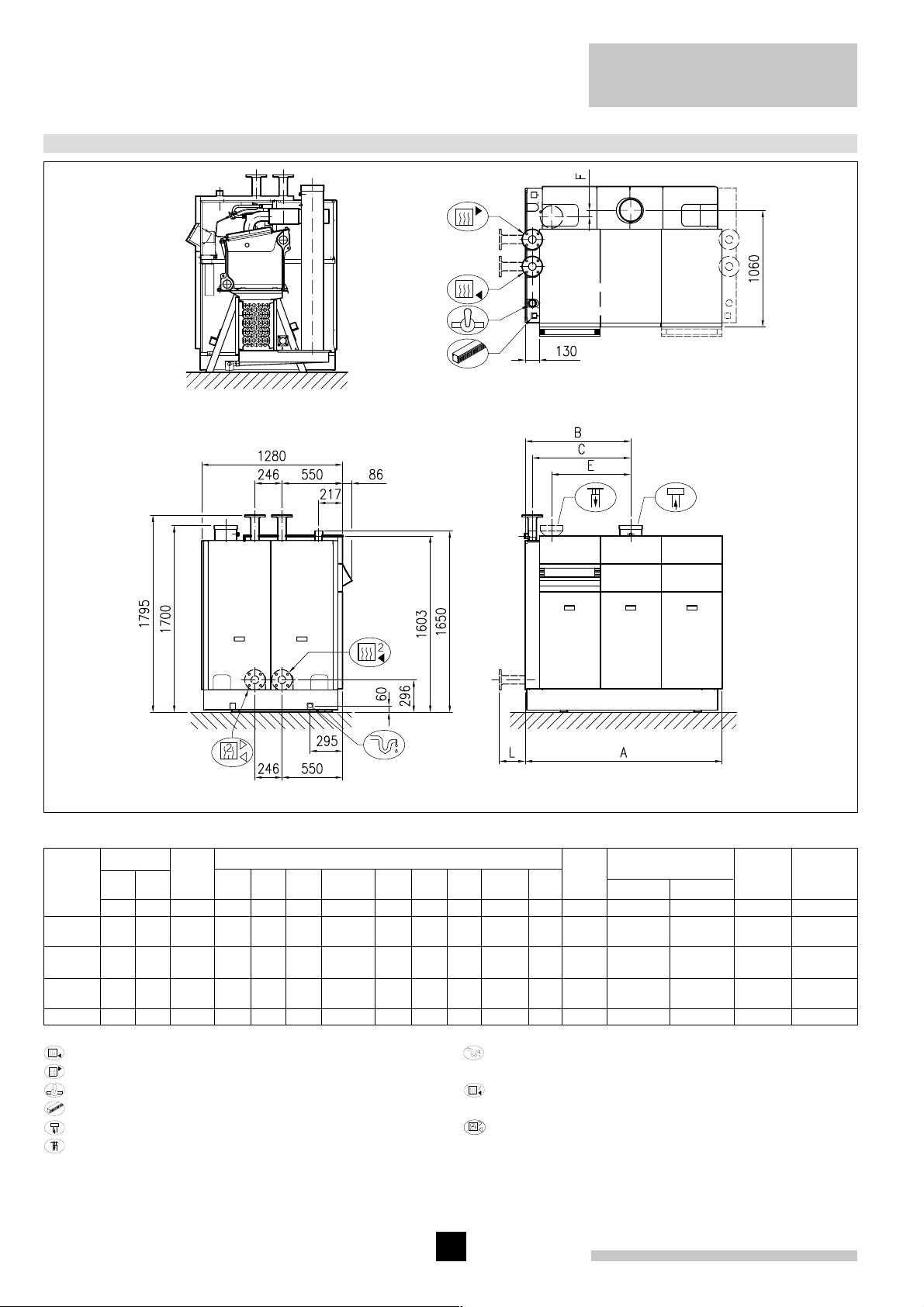

3. TECHNICAL DATA AND DIMENSIONS

Remeha

Gas 3002 ECO

Fig. 02 Dimensions

Number

of

sections

7

9

11

13

15

17

19

Output

80/60

˚C

kW

177

235

294

354

413

471

531

40/30

˚C

kW

193

256

320

382

445

507

570

Input

(Hs)

kW

201

268

335

402

469

536

603

Cross section

Left side view

Dimensions

1)

AB X

mm mm

683

1235

960

1790

960

1790

1083

2035

1238

2345

1360

2495

1483

2645

C

mm

618

895

895

1018

1173

1295

1418

ØD/Ød

mm

200

200

200

250

250

250

250

E

F

mm inch mbar

mm kg/h

20

20

60

60

60

60

60

1

1 1/

2

2

2

2

2

450

550

720

820

920

1060

1160

1

/

2

2

1)

2)

Y

NW 65

NW 65

NW 65

NW 80

NW 80

NW 80

NW 80

L

mm

313

235

235

312

156

233

110

Top view

Front view

Flue

gas

mass

∆ t = 20°C ∆ t = 10°C

320

427

535

641

747

853

961

80

95

119

145

177

220

285

Water

resistance

mbar

1140

320

380

476

580

708

880

Water

contents

ca.

ltr.

90

108

121

141

158

171

188

Assembly

weight

kg

893

1092

1228

1380

1520

1659

1799

Return NW Y

Flow NW Y

Gasconnection Rp X” int.

Cabel trough 40 x 40 mm

Flue gas connection Ø D int.

Air supply connection only for room sealed operation

(specify when ordering.

Knockouts in the right and left sides of the boiler for

condensate discharge, Ø 32 mm.

Return Eco NW 65, with option for seperate connec-

tions for second heat exchanger (ECO)

Flow Eco NW65, with option for seperate connec-

tions for second heat exchanger (ECO), or second

return with “second return” option.

1) 11/

connection for installation of a safety valve.

4

2) Flanges according to DIN 2576

6

4. EFFICIENCY INFORMATION

4.1 Combustion efficiency

Up to 98.5% at Hi (88.7% at Hs) at 80/60°C.

4.2 Efficiency

Up to 98% at Hi (88.3% at Hs) at 80/60°C and up to

108.1% at Hi (97.4% at Hs) at 40/30°C.

4.3 Standing losses

On average 0.38% at Hi (0.34% at Hs) at an

ave ra ge boiler water temperature of 45°C.

4.4 Annual efficiency

On average 108% at Hi (97.2% at Hs) at an

ave ra ge boiler water temperature of 35°C.

7

5. APPLICATION DATA

Remeha

Gas 3002 ECO

5.1 Delivery and positioning

5.1.1 General

All parts to be assembled on the site can be transported

using normal access doors.

The vulnerable parts are packed. If required, the casings

can be mounted after the boiler block has been connected on water side and after any temporary start-up (construction phase), without it being necessary to drain the

boiler block.

5.1.2 Location

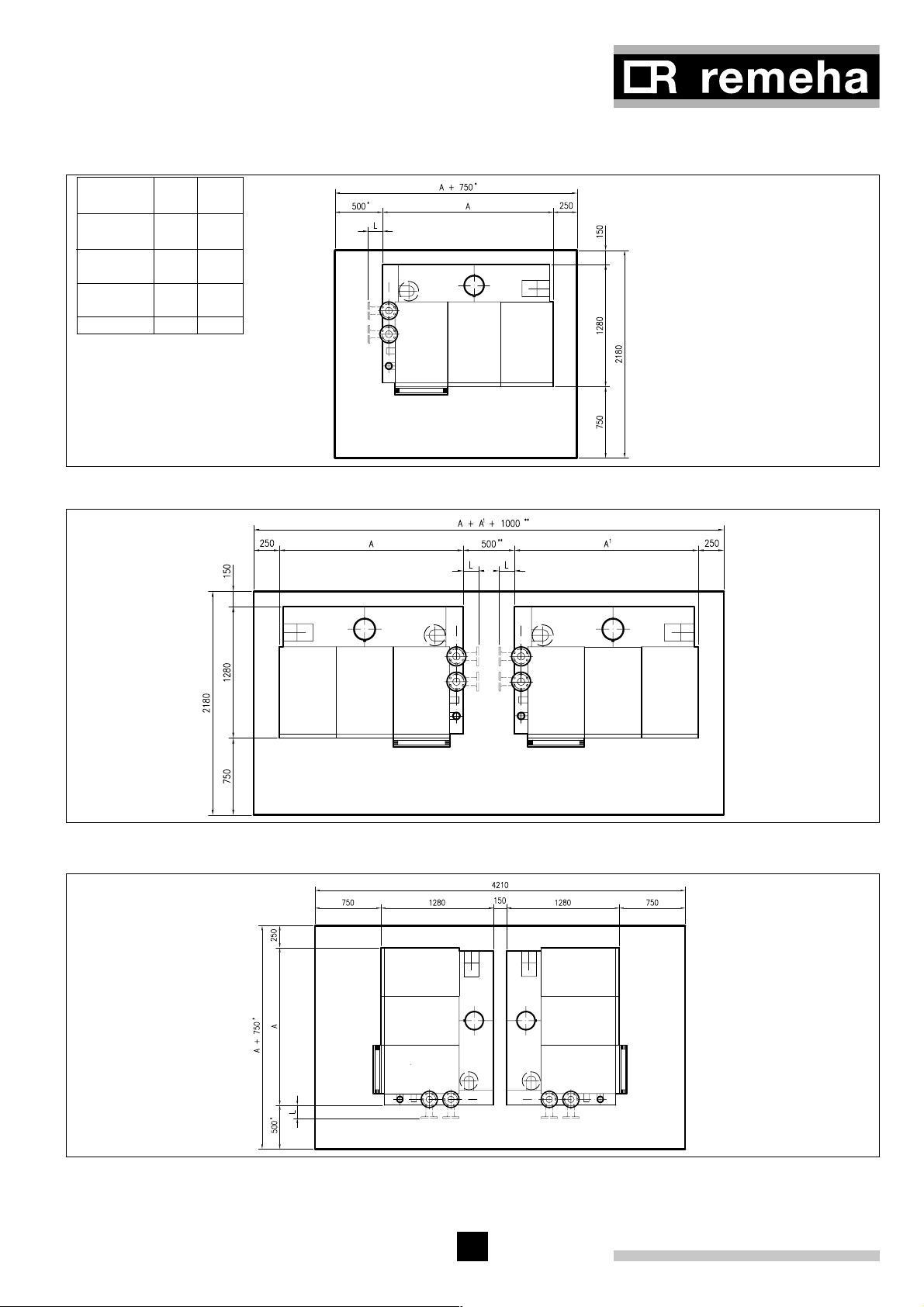

The drawings on the next page show a number of

possible arrangements with the required space all round.

The Remeha Gas 3002 ECO is supplied as standard

with connections at the top left side. If specified when

or de ring, it is possible to have the connections installed

top right.

8

Installation 1

One boiler in the boiler room

Number of

sections

7

9

11

13

15

17

19

A

mmLmm

1235

1790

1790

2035

2345

2495

2645

313

235

235

312

156

233

110

Installation 2

Two boilers in the boiler room

Installation 3

Two boilers in the boiler room, back to back

Fig. 03 Typical boiler installations

** When using the seperate connections for the ECO,

this distance + 2 x L

* When using the seperate connections for the ECO,

this distance + L

9

Remeha

Gas 3002 ECO

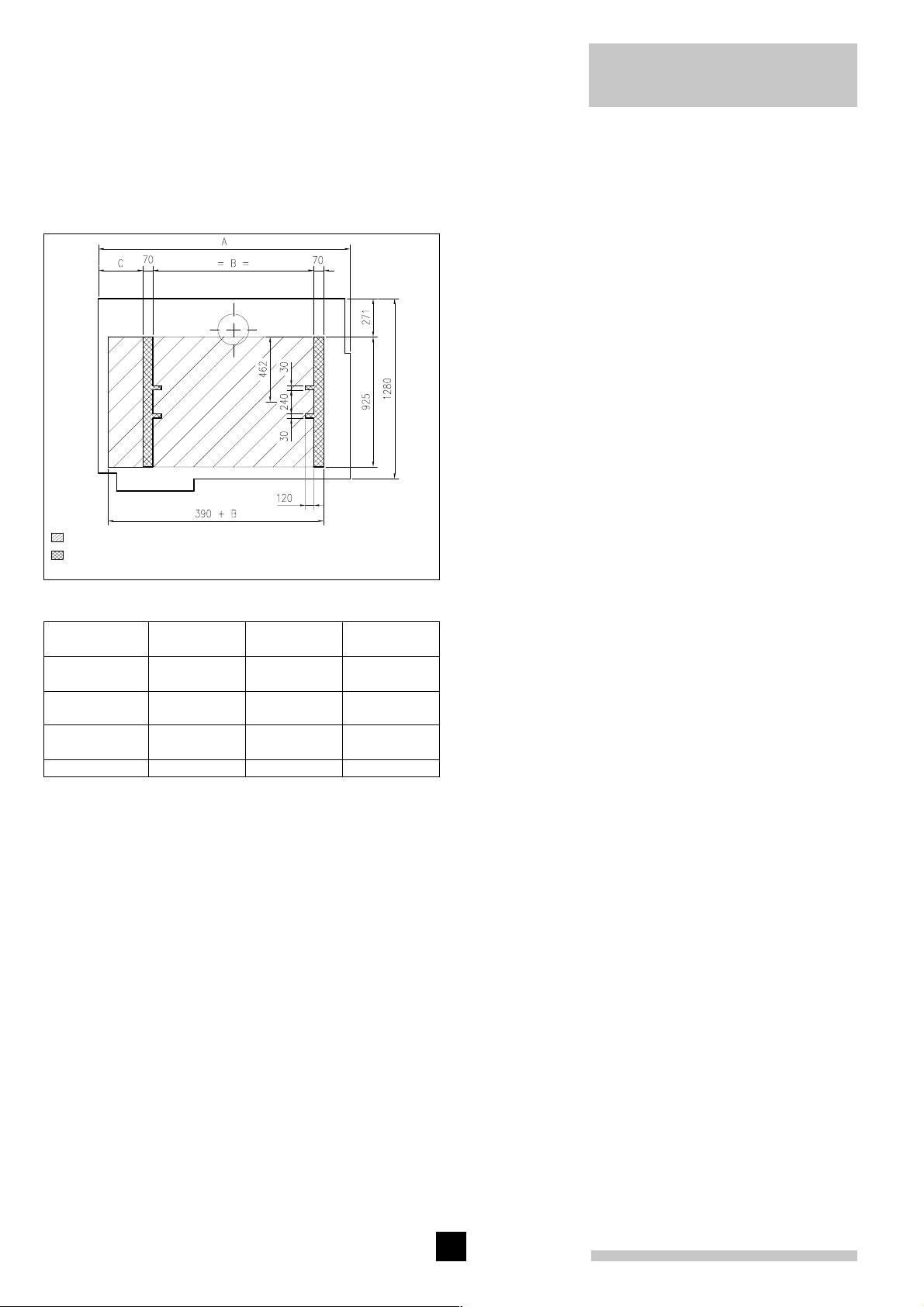

5.1.3 Support

The drawing below shows the support surface of the boiler with connections to the left (standard construction).

This drawing can be mirrored for the model with connections to the right (specify when ordering).

Minimum required floor surface

Support surface boiler

* Only for 7, 11, 15 and 19 sections.

Fig. 04 Support surface Remeha Gas 3002 ECO

5.2 L.P.H.W. configuration

5.2.1 Water temperature

The maximum water temperature is 110°C (sealed installation). The maximum operating temperature is 95°C.

The minimum return water temperature is 20°C with a

waterflow corresponding to a ∆t of 20°C at rated output.

With optimised installations the installation water temperature can drop below 20°C during the night or the weekend. In this situation, for heat supply to the installation

the return water temperature of the boiler must first be

restored to at least 25°C before releasing it to the rest

of the installation.

5.2.2 Water pressure

Each boiler section undergoes a test pressure of 12 bar.

The boiler can operate at an operating pressure from 0.8

up to 6 bar.

Number of

sections

7

9

11

13

15

17

19

A

1235

1790

1790

2035

2345

2495

2645

B

745

944

1143

1342

1541

1740

1939

C

240

418

318

341

397

420

443

10

5.2.3 Water circulation

The water flow through the boiler is limited to an amount

corresponding with a differential temperature across the

boiler of 45°C. If the differential temperature exceeds

45°C the boiler is turned off and blocked.

See also para. 7.5.3. As soon as the flow is again sufficient, the boiler will automatically restart.The minimum

water circulation in the boiler is determined by the

following formula:

Output boiler in (kW) = ..... m3/h

81

This circulation prevents, for example, activation of the

high limit thermostat when the mixing valves of the installation close when the boiler is in operation (to dissipate

residual heat).

The maximum water circulation in the boiler is

determined by the formula:

Output boiler in (kW) = ..... m3/h

9.3

5.2.4 Water treatment

The system should be filled with mains cold water (for the

UK this will usually have a pH of between 7 and 8).

Pressurised installations with a boiler/system content

ratio of 1:10 or less should not require water treatment,

provided that the following conditions apply:

1. The system is flushed thoroughly to remove all fluxes

and debris and filled completely once.

2. Make up water is limited to 5% per annum.

3. The hardness of the water does not exceed 360 ppm.

(200D).

All scale deposits will reduce the efficiency of the boiler

and should be prevented. However provided the above

is complied with any scale produced will not be too

detrimental to the boiler efficiency and will not reduce the

anticipated life expectancy of the boiler.

NOTE: Scale desposits in excess of 5mm will reduce

boiler efficiency and greatly increase the risk of

premature casting failure

As most systems contain a variety of metals wich can

react with each other to cause corrosion. It is considered

good practice to provide some form of water treatment

(especially in open vented systems) in order to prevent or

reduce the following.

a) Metallic corrosion

b) Formation of scale and sludge

c) Microbiological contamination

d) Chemical changes in the untreated system

water

Suitable chemicals and their use should be discussed

with a specialist water treatment company prior to

carrying out any work.

The specification of the system and manufacturers recommendations must be taken into account, along with

the age and codition of the system. New systems should

be flushed thoroughly to remove all traces of flux, debris,

grease and metal swarf generated during installation.

Care to be taken with old systems to ensure any black

metallic iron oxide sludge and other corrosive residues

are removed, again by thoroughly flushing, ensuring that

the system is drained completely from all low points.

NOTE: Please ensure that the new boiler plant is not in

circuit when the flushing takes place, especially if

cleansing chemicals are used to assist the proces.

Under no circumstances is the boiler to be operated

with cleaning chemicals in the system

To Summarise: Minimise water loss

Prevent pumping over in open vented

systems

Provide adequate air venting at all high

points

Maximum chlorine content of 200 mg/1

Take advice on suitability of inhibitors

for use with aluminium

MAX pH of 9 when using additives

If water treatment is used then we recommend that the

following products be used:

‘Copal’ manufactured by

Fernox Manufacturing Company Ltd.

Britannia Works

Clavering

Essex, CB1L 4QZ

Tel No: 0179 955 0811

Fax No: 0179 955 0853

or

Sentinal ‘X100’ manufactured by

BetzDearborn

Sentinal

Foundry Lane

Widnes

Cheshire WA8 8UD

Tel No: 051 495 5351

Fax No: 0151 420 5447

For the correct dosage and for further information on

water treatment or system cleaning we advise direct

contact either of the above companies.

5.2.5 Noise levels

The noise level in the boiler house, measured at a distance of 1 meter around the boiler, is approx. 60 dBA,

which means that it is usually not necessary to use

sound absorbent material.

11

Loading...

Loading...