REMEHA Gas 220 Ace 220, Gas 220 Ace Series, Gas 220 Ace 160, Gas 220 Ace 250, Gas 220 Ace 300 Installation, User And Service Manual

United Kingdom

en

Installation, User and Service Manual

High-efficiency floor-standing gas boiler

Gas 220 Ace

160 - 200 - 250 - 300

HMI S-control

Dear Customer,

Thank you very much for buying this appliance.

Please read through the manual carefully before using the product, and keep it in a safe place for later reference. In order to

ensure continued safe and efficient operation we recommend that the product is serviced regularly. Our service and customer

service organisation can assist with this.

We hope you enjoy years of problem-free operation with the product.

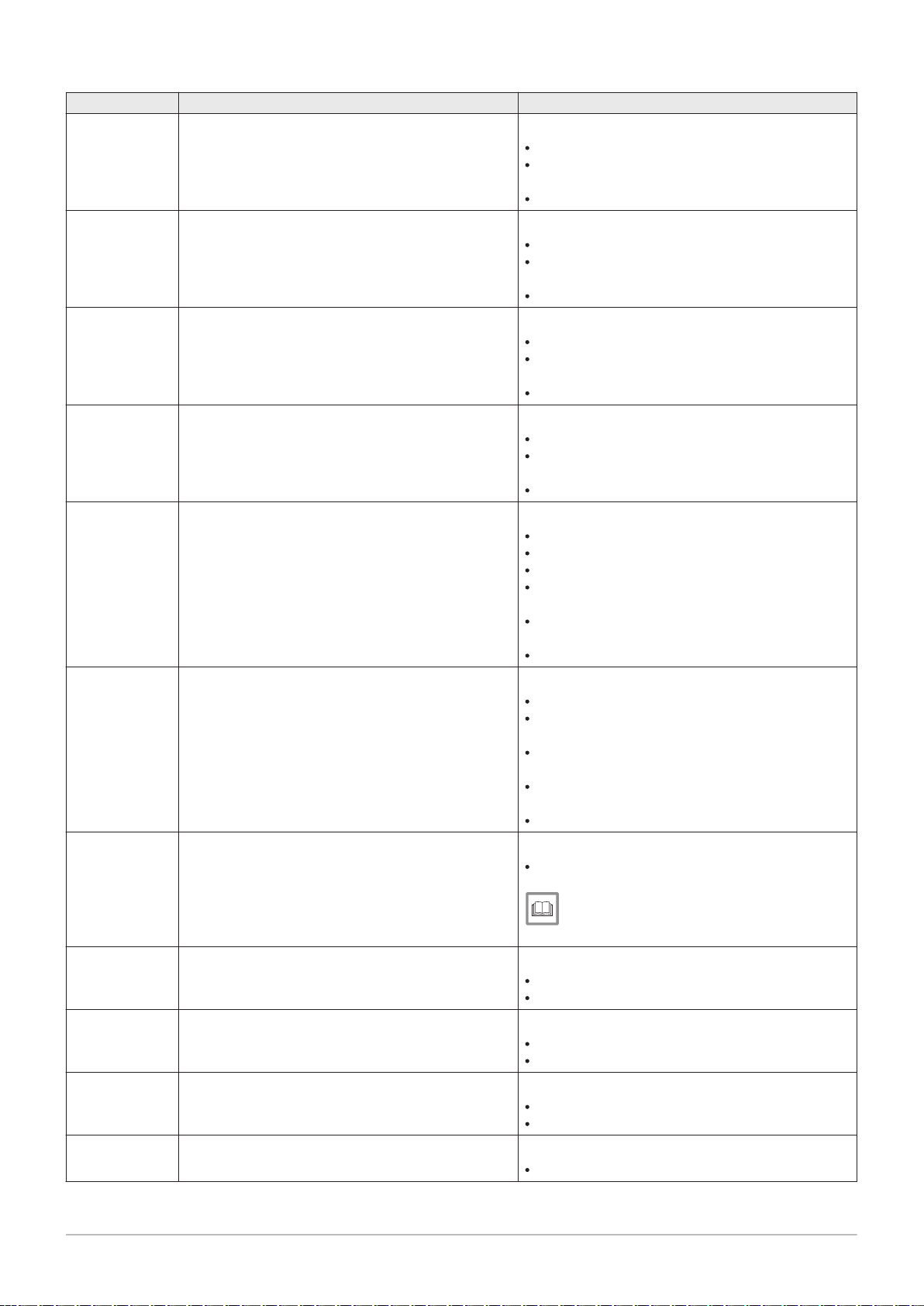

Contents

7665063 - v.05 - 18102018 3

Contents

1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3 Specific safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.3.1 Additional guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4 Liabilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.1 Manufacturer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.2 Installer's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.3 User's liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2 About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Additional documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Symbols used in the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Homologations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.1 Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Unit categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.1.3 Factory test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

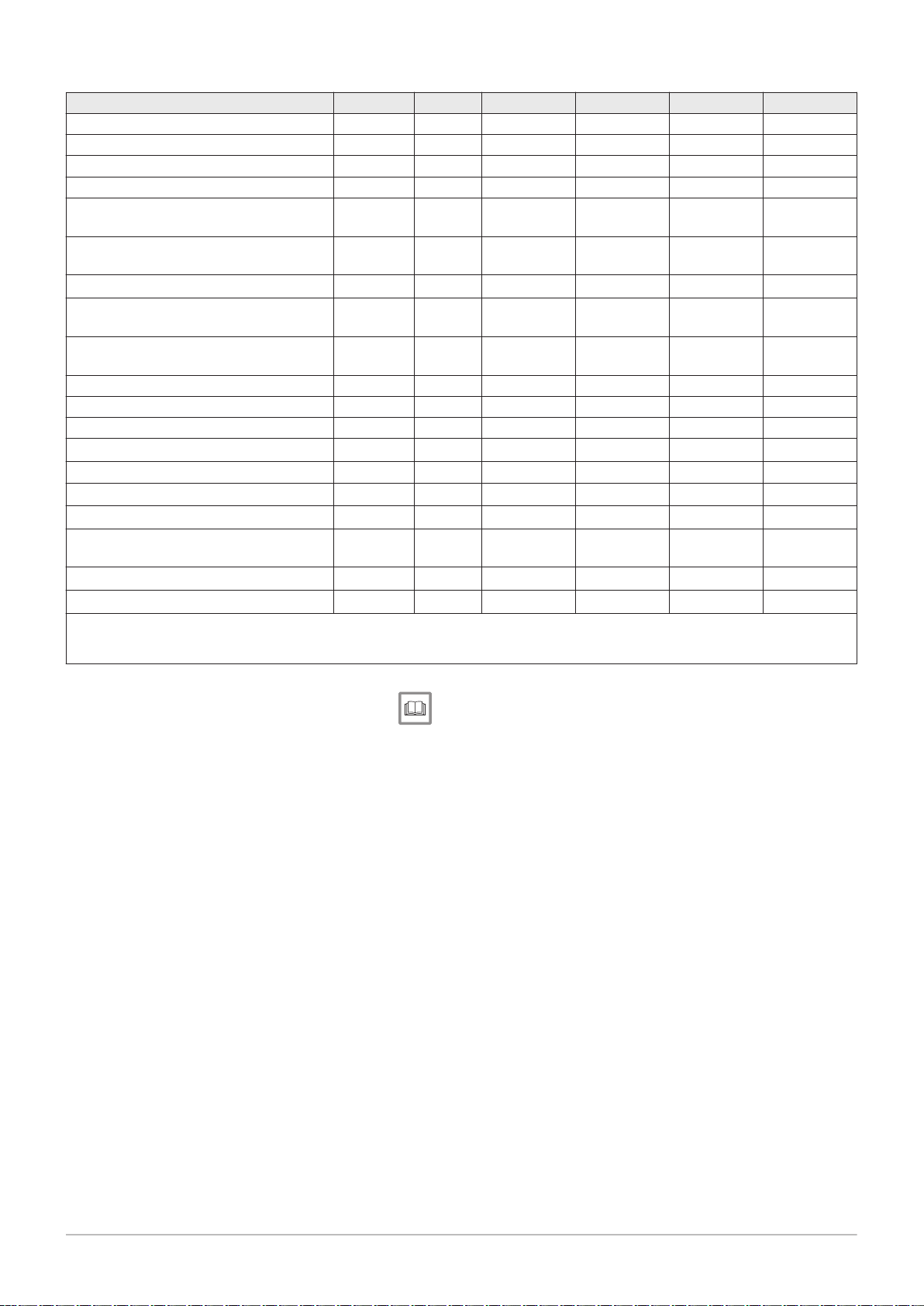

3.3 Dimensions and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

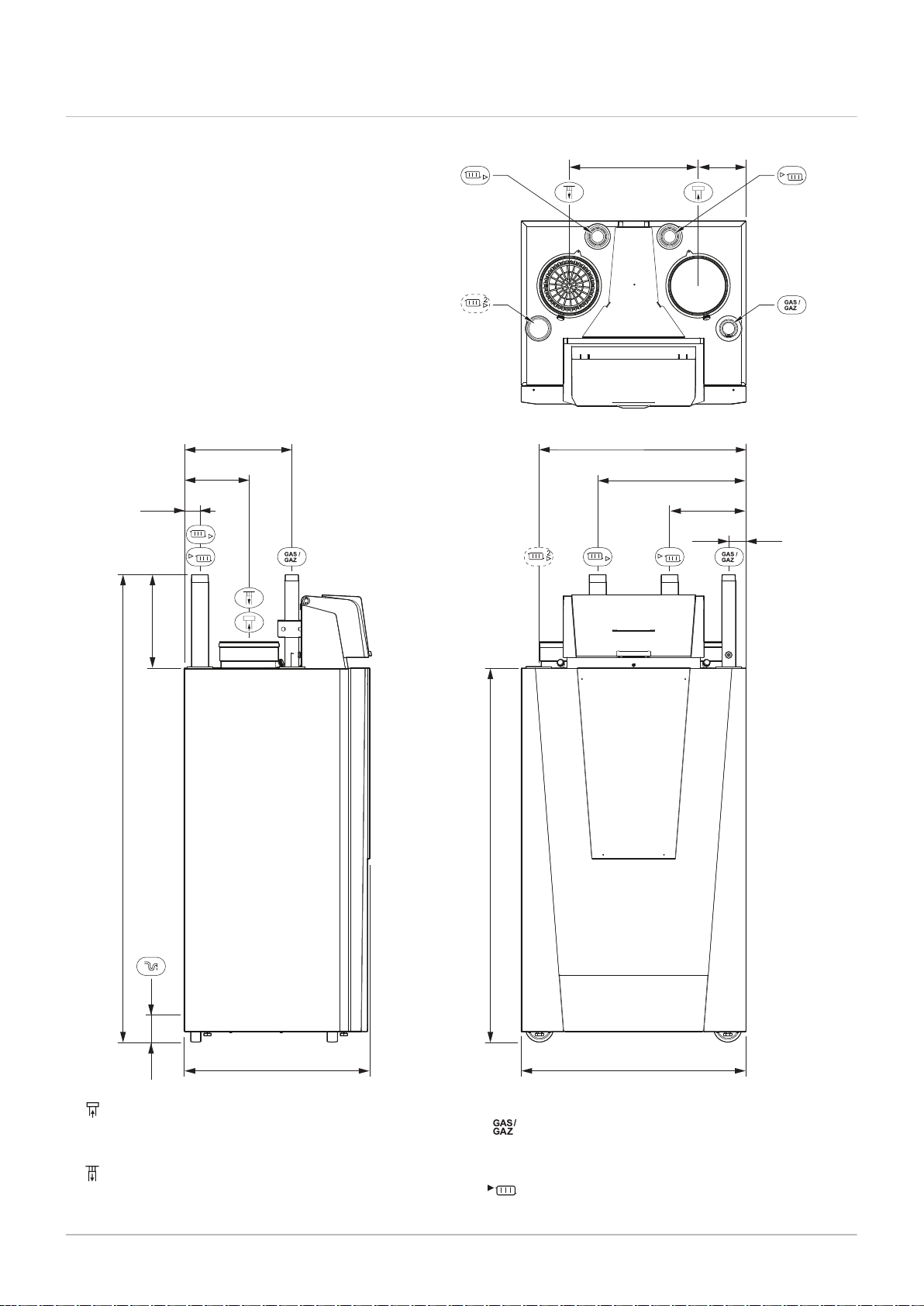

3.4 Electrical diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4 Description of the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.1 Gas/air regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.2 Combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.3 Control system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

4.1.4 Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.1.5 Regulating the water temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.6 Protection against shortage of water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.7 Water flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.8 Hydraulic pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.1.9 Air pressure differential switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4.1.10 Circulating pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.1.11 Calorifier connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

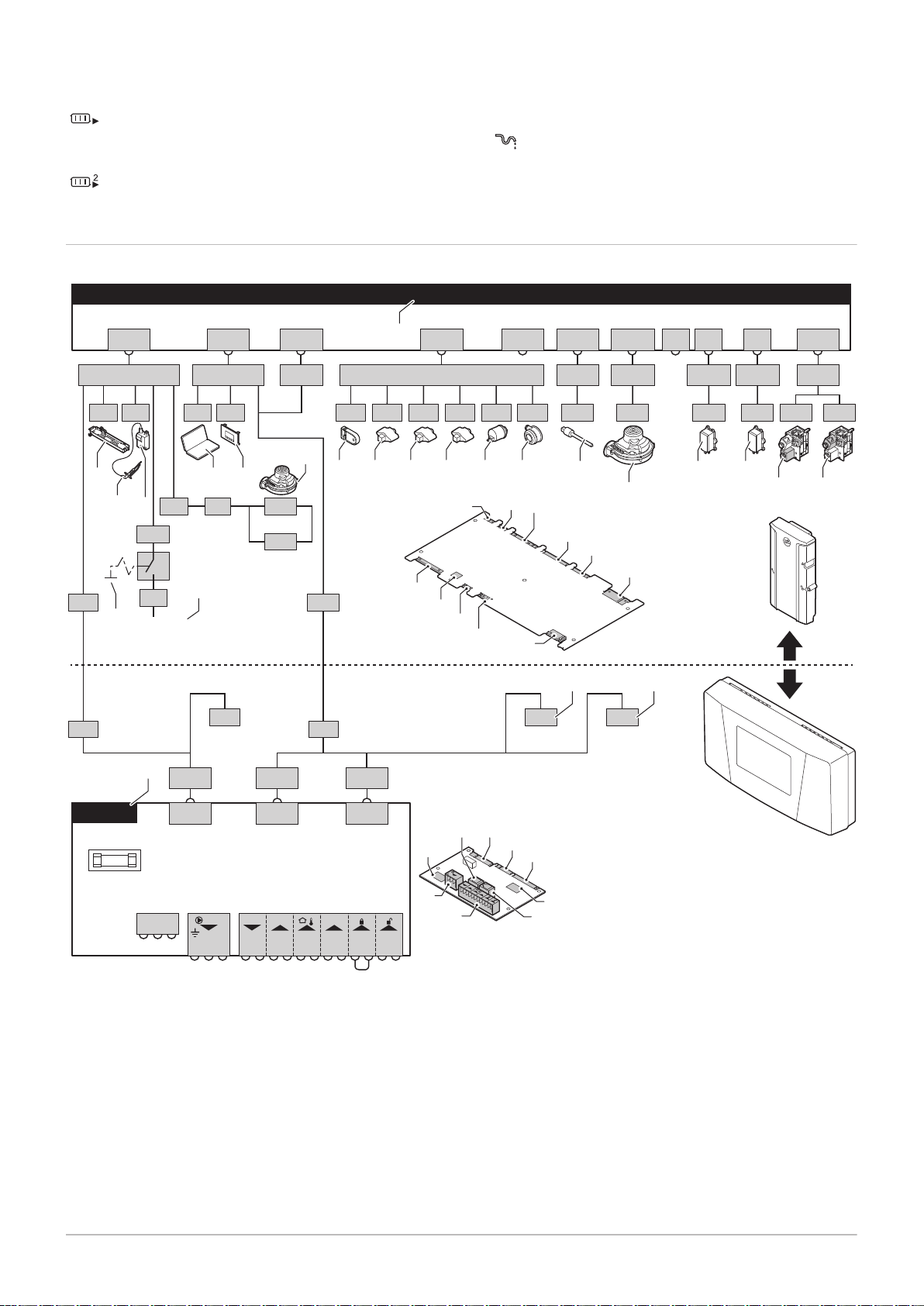

4.2 Main components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Control panel description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.1 What each key means . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.2 Meaning of the symbols on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.3.3 Browsing in the menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.4 Standard delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.5 Accessories and options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 Installation regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Choice of the location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2.1 Data plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2.2 Location of the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

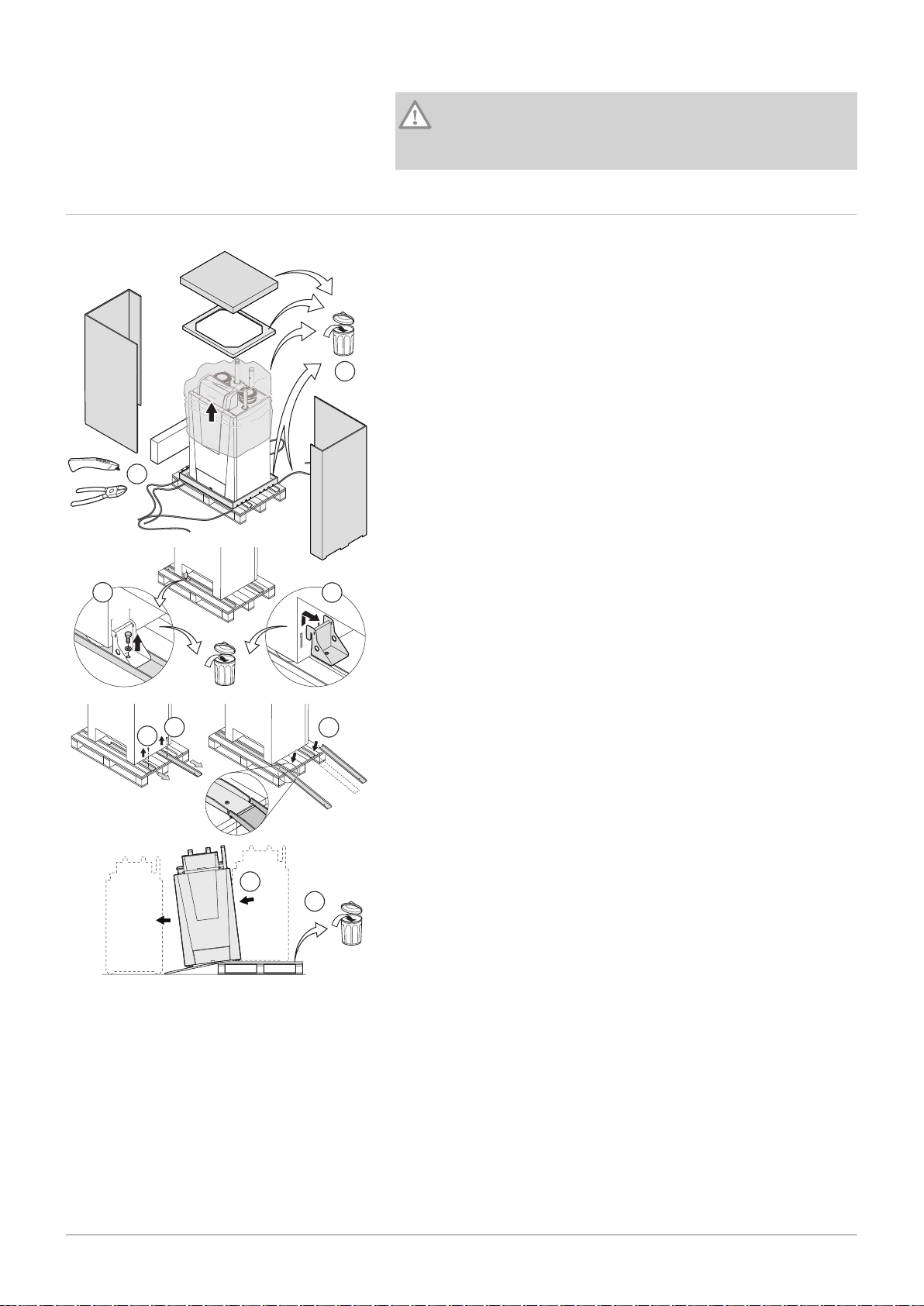

5.4 Unpacking & initial preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.1 Positioning the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3 Hydraulic connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.3.1 Rinsing the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3.2 Connecting the heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.3 Connecting the condensate drain pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 Gas connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 Air supply/flue gas outlet connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.5.1 Classification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Contents

4 7665063 - v.05 - 18102018

6.5.2 Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5.3 Dimensions of flue gas outlet pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.5.4 Length of the air and flue gas pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

6.5.5 Additional guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5.6 Connecting the flue gas outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5.7 Connecting the air supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.5.8 Specific air and flue gas applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.6 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.6.1 Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

6.6.2 Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.6.3 Assembly of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.6.4 Installation of the connection box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.6.5 Connection options for the standard PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.7 Filling the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.7.1 Water treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

6.7.2 Filling the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.7.3 Filling the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1 Checklist before commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.1 Preparing the boiler for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.2 Gas circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.3 Hydraulic circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.1.4 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.2 Commissioning procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3 Gas settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.1 Adjusting to a different gas type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

7.3.2 Checking/setting combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7.4 Final instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

8 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

8.1 Use of the control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.2 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8.3 Frost protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

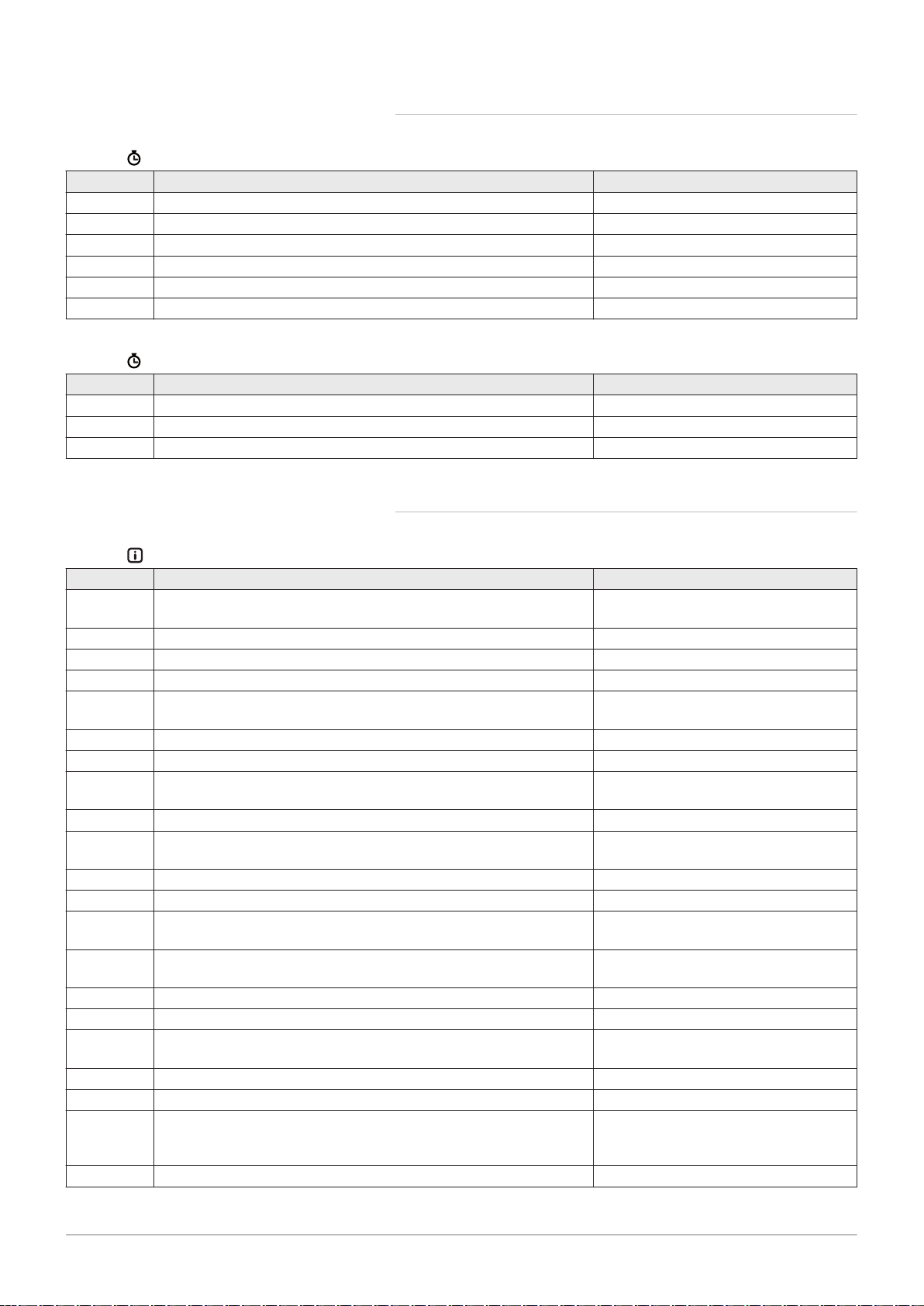

9 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.1 List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.1.1 Parameters - FSB-WHB-HE-150-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.2 Changing the parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.2.1 Configuring the installation parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.3 Reading out measured values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.3.1 Reading out counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

9.3.2 Reading out signals and software versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.3.3 Counters - FSB-WHB-HE-150-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.3.4 Signals - FSB-WHB-HE-150-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.3.5 Status and sub-status - FSB-WHB-HE-150-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.2 Maintenance message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.2.1 Resetting the service messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.2.2 Starting a new service interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

10.3 Standard inspection and maintenance operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.3.1 Checking the water pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.3.2 Checking the water quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

10.3.3 Checking the ionisation current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.3.4 Check the flue gas outlet/air supply connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

10.3.5 Checking the combustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.3.6 Checking the PS air pressure differential switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.3.7 Checking the VPS gas leakage control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.3.8 Checking the minimum gas pressure switch GPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

10.3.9 Checking the burner and cleaning the heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.3.10 Clean the condensate collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.3.11 Cleaning the siphon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.4 Specific maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.4.1 Replacing the ionisation/ignition electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Contents

7665063 - v.05 - 18102018 5

10.4.2 Checking the non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

10.4.3 Reassembling the boiler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

10.5 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.5.1 Removal/recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

11 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

11.1 Error codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.1.1 Warning - FSB-WHB-HE-150-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

11.1.2 Blocking - FSB-WHB-HE-150-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

11.1.3 Lock-out - FSB-WHB-HE-150-300 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

11.2 Error memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12 Removal/recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13.2 Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

14 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

14.1 ErP information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

14.1.1 Product fiche . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

14.2 EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

14.3 Checklist for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

14.4 Checklist for annual maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

1 Safety

6 7665063 - v.05 - 18102018

1 Safety

1.1 General safety instructions

For the installer:

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and

do not operate electrical contacts or switches

(doorbell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Trace possible leaks and seal them off

immediately.

5. If the leak is upstream of the gas meter, notify

the gas company.

Danger

If you smell flue gases:

1. Switch the boiler off.

2. Open the windows.

3. Trace possible leaks and seal them off

immediately.

Caution

After maintenance or repair work, check the

entire heating installation to ensure that there are

no leaks.

For the end user:

1 Safety

7665063 - v.05 - 18102018 7

Danger

If you smell gas:

1. Do not use naked flames, do not smoke and

do not operate electrical contacts or switches

(doorbell, lighting, motor, lift etc).

2. Shut off the gas supply.

3. Open the windows.

4. Report any leaks immediately.

5. Evacuate the property.

6. Contact a qualified installer.

Danger

If you smell flue gases:

1. Switch the boiler off.

2. Open the windows.

3. Report any leaks immediately.

4. Evacuate the property.

5. Contact a qualified installer.

Warning

Do not touch the flue gas pipes. Depending on

the boiler settings, the temperature of the flue gas

pipes can rise to over 60°C.

Warning

Do not touch radiators for long periods.

Depending on the boiler settings, the temperature

of the radiators can rise to over 60°C.

Warning

Be careful when using the domestic hot water.

Depending on the boiler settings, the temperature

of domestic hot water can rise to over 65°C.

Warning

The use of the boiler and the installation by you

as the end-user must be limited to the operations

described in this manual. All other actions may

only be undertaken by a qualified fitter/engineer.

Warning

The condensation drain must not be changed or

sealed. If a condensate neutralisation system is

used, the system must be cleaned regularly in

accordance with the instructions provided by the

manufacturer.

1 Safety

8 7665063 - v.05 - 18102018

1.2 Recommendations

Caution

Ensure that the boiler is regularly serviced.

Contact a qualified installer or arrange a

maintenance contract for the servicing of the

boiler.

Caution

Only genuine spare parts may be used.

Important

Regularly check for the presence of water and

pressure in the heating installation.

Danger

This appliance can be used by children aged

eight and above and people with a physical,

sensory or mental disability, or with a lack of

experience and knowledge, provided they are

supervised and instructed in how to use the

appliance in a safe manner and understand the

associated dangers. Children must not be

allowed to play with the appliance. Cleaning and

user maintenance should not be carried out by

children without adult supervision.

Warning

Installation and maintenance of the boiler must be

carried out by a qualified installer in accordance

with local and national regulations.

Warning

The installation and maintenance of the boiler

must be undertaken by a qualified installer in

accordance with the information in the supplied

manual, doing otherwise may result in dangerous

situations and/or bodily injury.

Warning

Removal and disposal of the boiler must be

carried out by a qualified installer in accordance

with local and national regulations.

Warning

If the mains lead is damaged, it must be replaced

by the original manufacturer, the manufacturer's

dealer or another suitably skilled person to

prevent hazardous situations from arising.

1 Safety

7665063 - v.05 - 18102018 9

Warning

Always disconnect the mains supply and close

the main gas tap when working on the boiler.

Warning

Check the entire system for leaks after

maintenance and servicing work.

Danger

For safety reasons, we recommend fitting smoke

and CO alarms at suitable places in your home.

Caution

Make sure the boiler can be reached at all

times.

The boiler must be installed in a frost-free area.

If the power cord is permanently connected, you

must always install a main bipolar switch with

an opening gap of at least 3 mm (BS EN

60335-1).

Drain the boiler and central heating system if

you are not going to use your home for a long

time and there is a chance of frost.

The frost protection does not work if the boiler is

out of operation.

The boiler protection only protects the boiler,

not the system.

Check the water pressure in the system

regularly. If the water pressure is lower than 0.8

bar, the system must be topped up

(recommended water pressure between 1.5 and

2 bar).

Important

Keep this document near to the boiler.

Important

Only remove the casing for maintenance and

repair operations. Refit all panels when

maintenance work and servicing are complete.

Important

Instruction and warning labels must never be

removed or covered and must be clearly legible

throughout the entire service life of the boiler.

Damaged or illegible instructions and warning

stickers must be replaced immediately.

Important

Modifications to the boiler require the written

approval of Remeha.

1 Safety

10 7665063 - v.05 - 18102018

1.3 Specific safety instructions

1.3.1 Additional guidelines

In addition to the legal requirements and guidelines, the

supplementary guidelines in this manual must also be

followed. Supplements or subsequent regulations and

guidelines that are valid at the time of installation shall

apply to all regulations and guidelines specified in this

manual.

1.4 Liabilities

1.4.1

Our products are manufactured in compliance with the

requirements of the various Directives applicable. They

are therefore delivered with the

documents necessary. In the interests of the quality of

our products, we strive constantly to improve them. We

therefore reserve the right to modify the specifications

given in this document.

Our liability as manufacturer may not be invoked in the

following cases:

Failure to abide by the instructions on installing and

maintaining the appliance.

Failure to abide by the instructions on using the

appliance.

Faulty or insufficient maintenance of the appliance.

1.4.2

The installer is responsible for the installation and initial

commissioning of the appliance. The installer must

observe the following instructions:

Manufacturer's liability

marking and any

Installer's liability

Read and follow the instructions given in the manuals

provided with the appliance.

Install the appliance in compliance with prevailing

legislation and standards.

Carry out initial commissioning and any checks

necessary.

Explain the installation to the user.

If maintenance is necessary, warn the user of the

obligation to check the appliance and keep it in good

working order.

Give all the instruction manuals to the user.

1 Safety

7665063 - v.05 - 18102018 11

1.4.3

User's liability

To guarantee optimum operation of the system, you

must abide by the following instructions:

Read and follow the instructions given in the manuals

provided with the appliance.

Call on a qualified professional to carry out installation

and initial commissioning.

Get your installer to explain your installation to you.

Have the required inspections and maintenance

carried out by a qualified installer.

Keep the instruction manuals in good condition close

to the appliance.

2 About this manual

12 7665063 - v.05 - 18102018

2 About this manual

2.1 General

This manual describes the installation, use and maintenance of the Gas

220 Ace boiler. This manual is part of all the documentation supplied with

the boiler.

2.2

2.3

Additional documentation

The following documentation is available in addition to this manual:

Installation and user manual for control panel

Water quality instructions

Symbols used in the manual

This manual uses various danger levels to draw attention to special

instructions. We do this to improve user safety, to prevent problems and to

guarantee correct operation of the appliance.

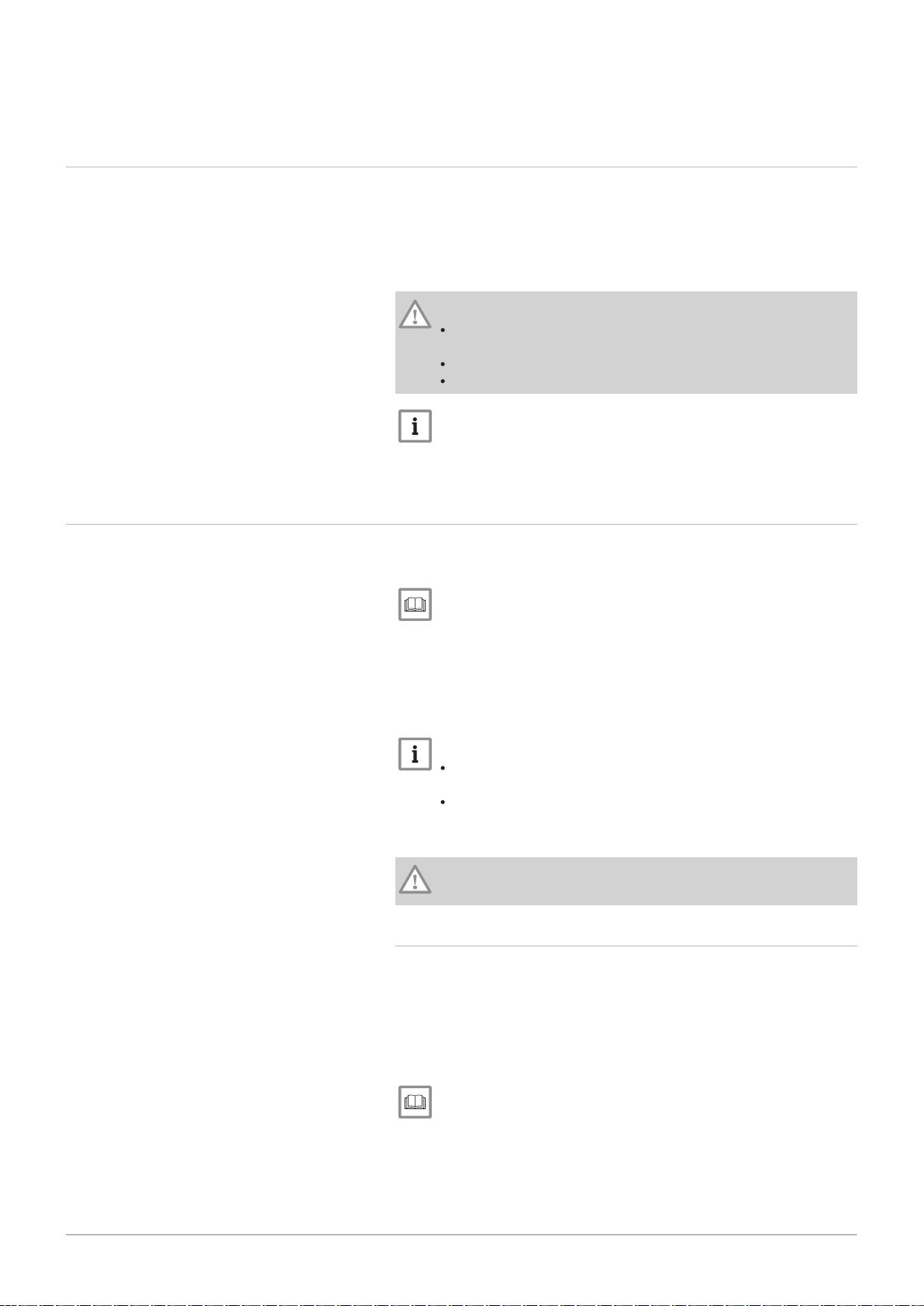

Danger

Risk of dangerous situations that may result in serious personal

injury.

Danger of electric shock

Risk of electric shock.

Warning

Risk of dangerous situations that may result in minor personal

injury.

Caution

Risk of material damage.

Important

Please note: important information.

See

Reference to other manuals or pages in this manual.

3 Technical specifications

7665063 - v.05 - 18102018 13

3.1 Homologations

3.1.1 Certifications

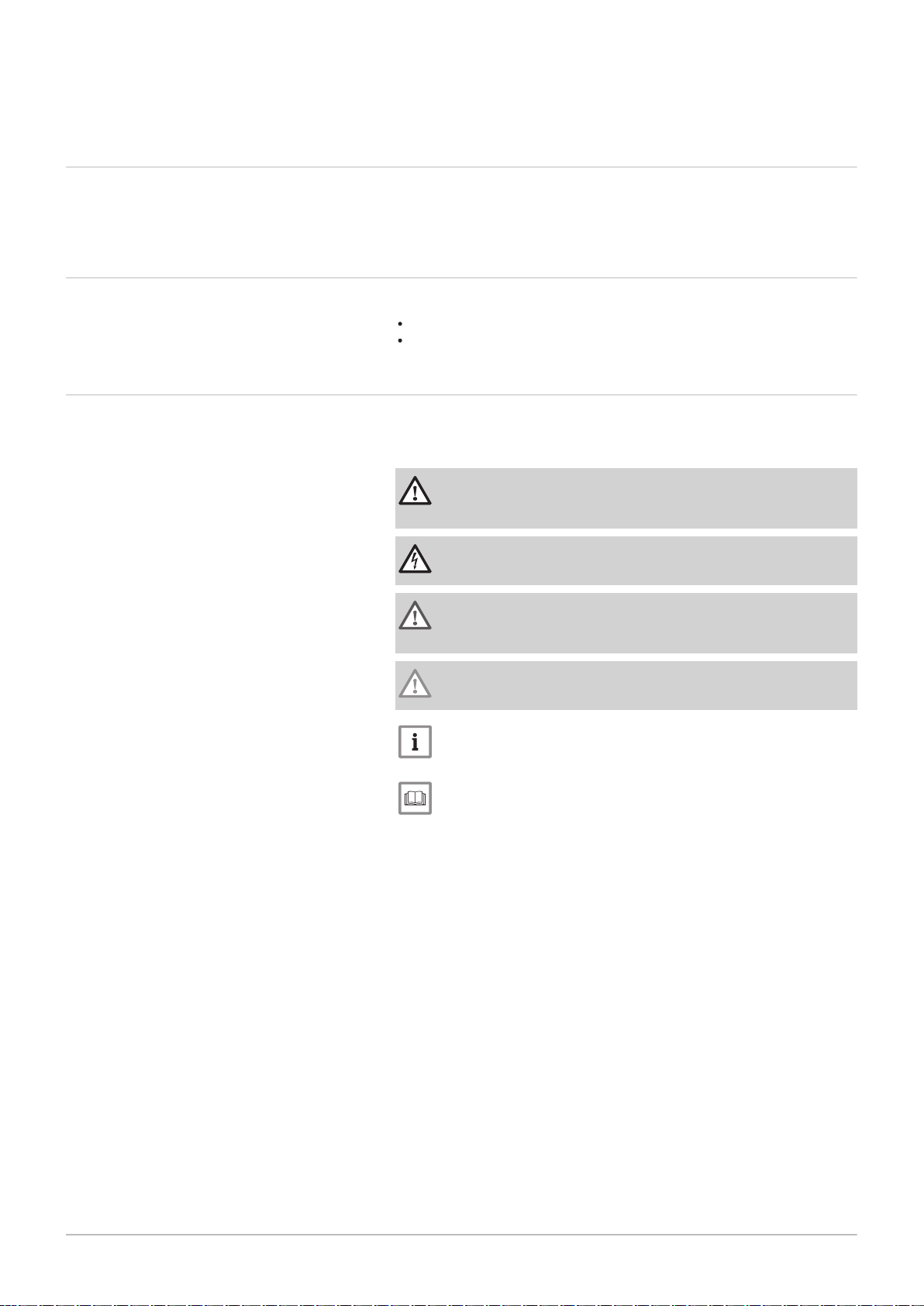

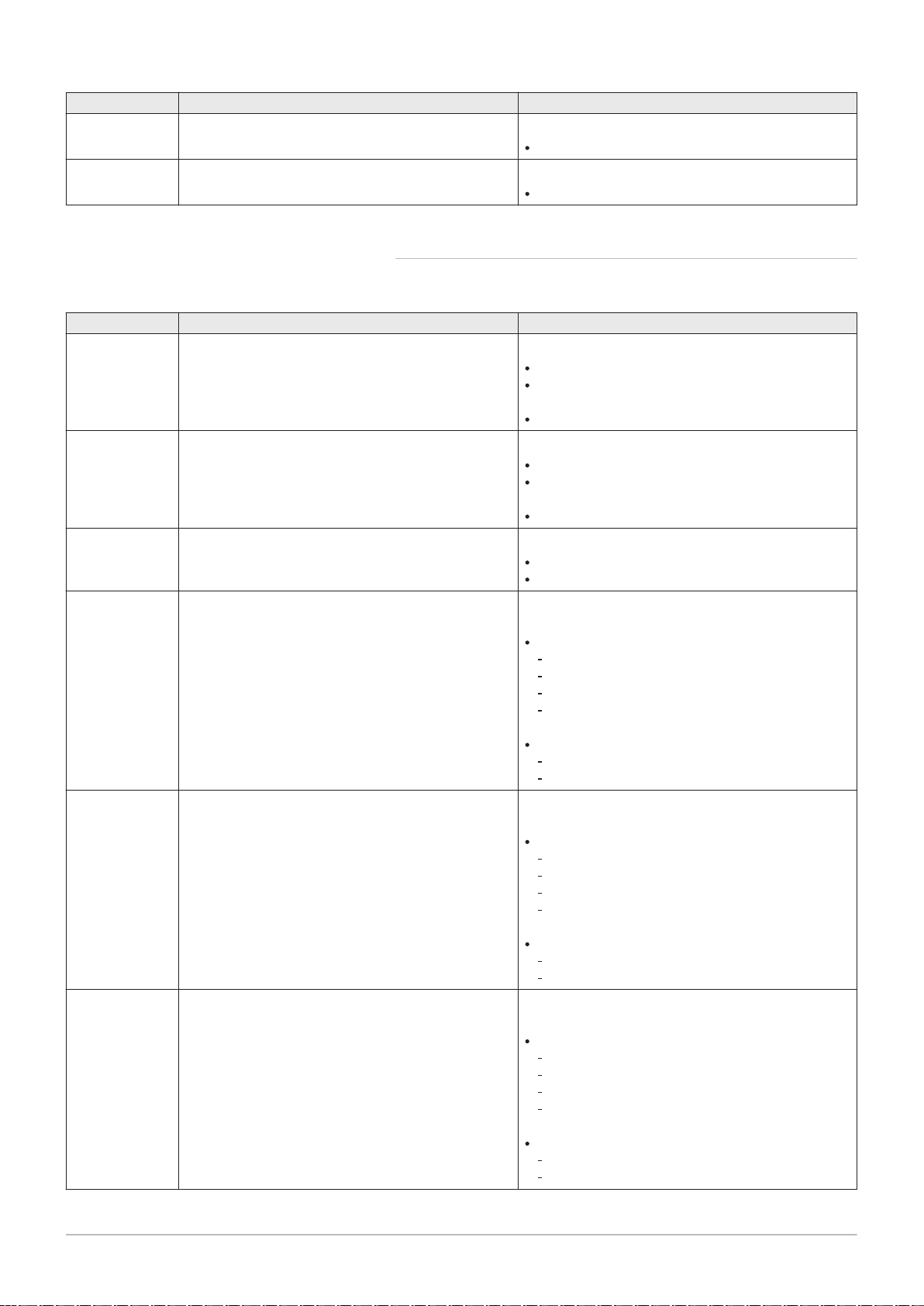

Tab.1 Certifications

CE identification number PIN 0063CQ3781

Class NOx

(1)

Type of flue gas connection

6

(2)

B

23P

C13, C33, C53, C63, C

(1) EN 15502–1

(2) When installing a boiler with connection type B

is lowered to

IP20.

3.1.2 Unit categories

3 Technical specifications

93

, the IP rating of the boiler

23P

Tab.2 Unit categories

Country Category Gas type Connection pressure (mbar)

Great Britain II

2H3B/P

G20 (H gas)

G30/G31 (butane/propane)

3.1.3

Factory test

20

30-50

Before leaving the factory, each boiler is optimally set and tested for:

Electrical safety.

Adjustment of (O2/CO2).

Water tightness.

Gas tightness.

Parameter setting.

3.2

Technical data

Tab.3 General

Gas 220 Ace 160 200 250 300

Nominal output (Pn)

Central heating operation (80/60°C)

Nominal output (Pn)

Central heating operation (50/30°C)

Nominal load (Qnh)

Central heating operation (Hi) G20 (H-

min. - max.

(1)

min. - max.

(1)

min. - max.

(1)

kW 31.5 - 152.1

152.1

kW 34.7 - 161.1

161.1

kW 32.0 - 156.0

156.0

39.4 - 194.4

194.4

43.2 - 209.8

209.8

40.0 - 200.0

200.0

49.2 - 243.3

243.3

54.1 - 261.0

261.0

50.0 - 250.0

250.0

59.0 - 290.9

290.9

65.0 - 310.7

310.7

60.0 - 299.0

299.0

gas)

Nominal load (Qnh)

min. - max. kW 40.0 - 156.0 40.0 - 200.0 50.0 - 250.0 70.0 - 299.0

CH operation (Hi) G31 (propane)

Nominal load (Qnh)

Central heating operation (Hs) G20 (H-

min. - max.

(1)

kW 35.6 - 173.3

173.3

44.4 - 222.2

222.2

55.6 - 277.8

277.8

66.7 - 332.2

332.2

gas)

Nominal load (Qnh)

min. - max. kW 43.5 - 169.6 43.5 - 217.4 54.3 - 271.7 76.1 - 325.0

Central heating operation (Hs) G31 (pro

pane)

Full load central heating efficiency (Hi)

% 97.5 97.2 97.3 97.3

(80/60 °C) (92/42/EEC)

3 Technical specifications

14 7665063 - v.05 - 18102018

Gas 220 Ace 160 200 250 300

Full load central heating efficiency (Hi)

% 103.6 104.9 104.4 103.9

(50°C/30°C) (EN15502)

Part load central heating efficiency (Hi)

% 98.4 98.4 98.4 98.4

(return temperature 60°C)

Part load central heating efficiency

% 108.5 108.0 108.2 108.4

(92/42/EEC) (return temperature 30°C)

(1) Factory setting.

Tab.4 Gas and flue gas data

Gas 220 Ace 160 200 250 300

Gas inlet pressure G20 (H gas) min. - max. mbar 17 - 25 17 - 25 17 - 25 17 - 25

Gas inlet pressure G31 (propane) min. - max. mbar 37 - 50 37 - 50 37 - 50 37 - 50

Gas consumption G20 (H gas) min. - max.

Gas consumption G31 (propane) min. - max.

BREEAM NO

X

Flue gas quantity

(1)

mg/kWh 36 40 38 35

min. - max. kg/h

m3/h

m3/h

g/s

3.4 - 16.5 4.2 - 21.2 5.3 - 26.5 6.3 - 31.6

1.4 - 6.3 1.6 - 8.2 2.1 - 10.2 2.8 - 12.2

57 - 277

16 - 77

71 - 355

20 - 99

89 - 444

25 - 123

107 - 531

30 - 148

Flue gas temperature min. - max. °C 32 - 66 29 - 63 30 - 63 31 - 64

Maximum counter pressure Pa 200 150 150 150

(1) min = part load with Tr = 30 °C / max = full load with Tr = 60 °C

Tab.5 Central heating circuit data

Gas 220 Ace 160 200 250 300

Water content l 17.0 33.0 33.0 33.0

Water operating pressure min bar 0.8 0.8 0.8 0.8

Water operating pressure (PMS) max bar 5.0 6.0 6.0 6.0

Water temperature max °C 110.0 110.0 110.0 110.0

Operating temperature max °C 90.0 90.0 90.0 90.0

Hydraulic resistance (ΔT=20K) mbar 190 100 150 200

Tab.6 Electrical data

Gas 220 Ace 160 200 250 300

Supply voltage V~/Hz 230/50 230/50 230/50 230/50

Power consumption max W 275.0 204.0 323.0 343.0

Power consumption – part load min W 47.0 57.0 57.0 48.0

Power consumption – standby min W 5.3 11.0 11.0 9.0

Electrical protection index IP IPX1B IPX1B IPX1B IPX1B

Fuses Main

PCU

A 6.3

1.6

6.3

1.6

6.3

1.6

6.3

1.6

Tab.7 Other data

Gas 220 Ace 160 200 250 300

Total weight (including packaging) kg 235 275 275 275

Boiler weight kg 205 245 245 245

Average acoustic level at a distance of

dB(A) 58.7 59.7 63.8 63.8

one metre from the boiler

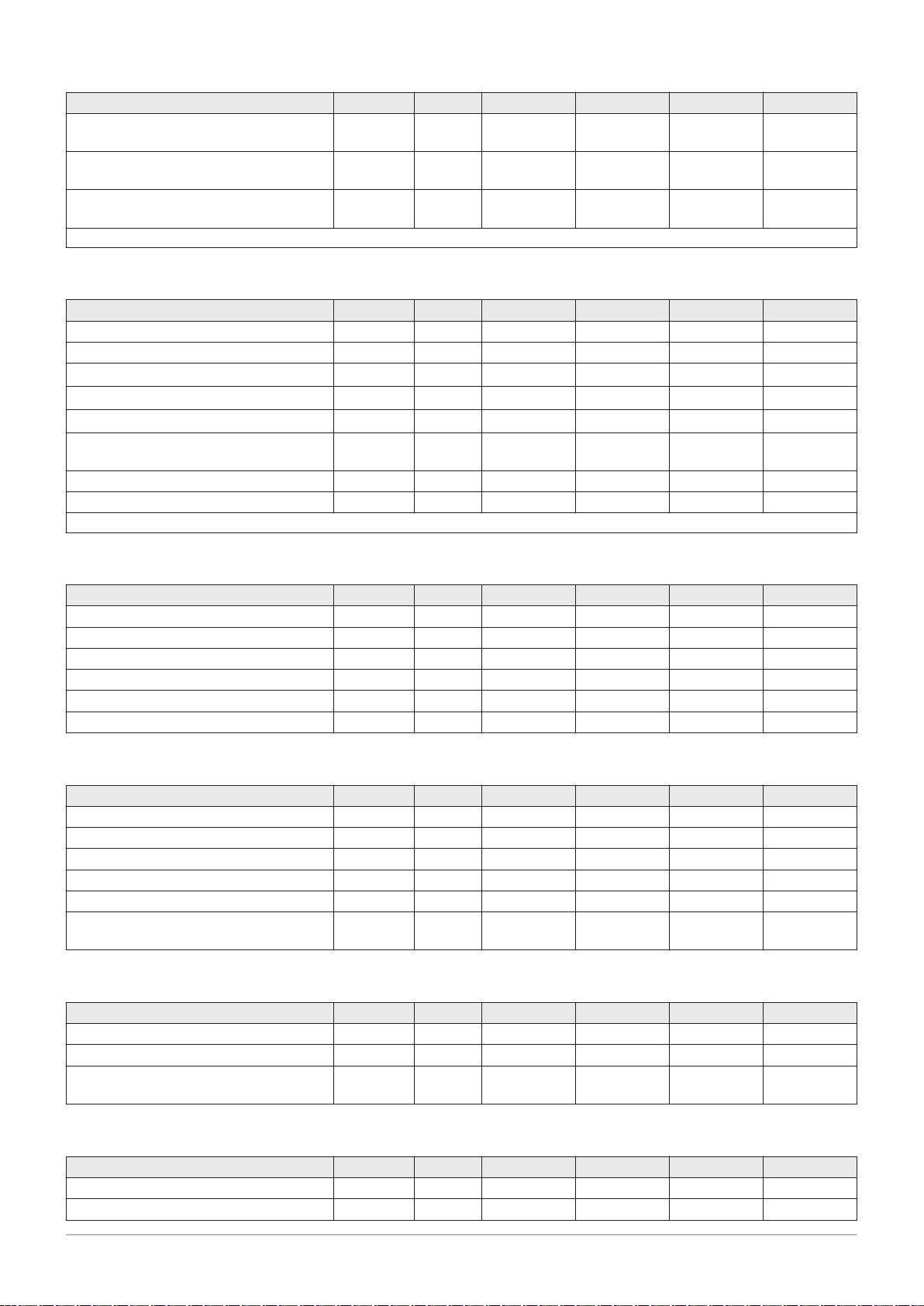

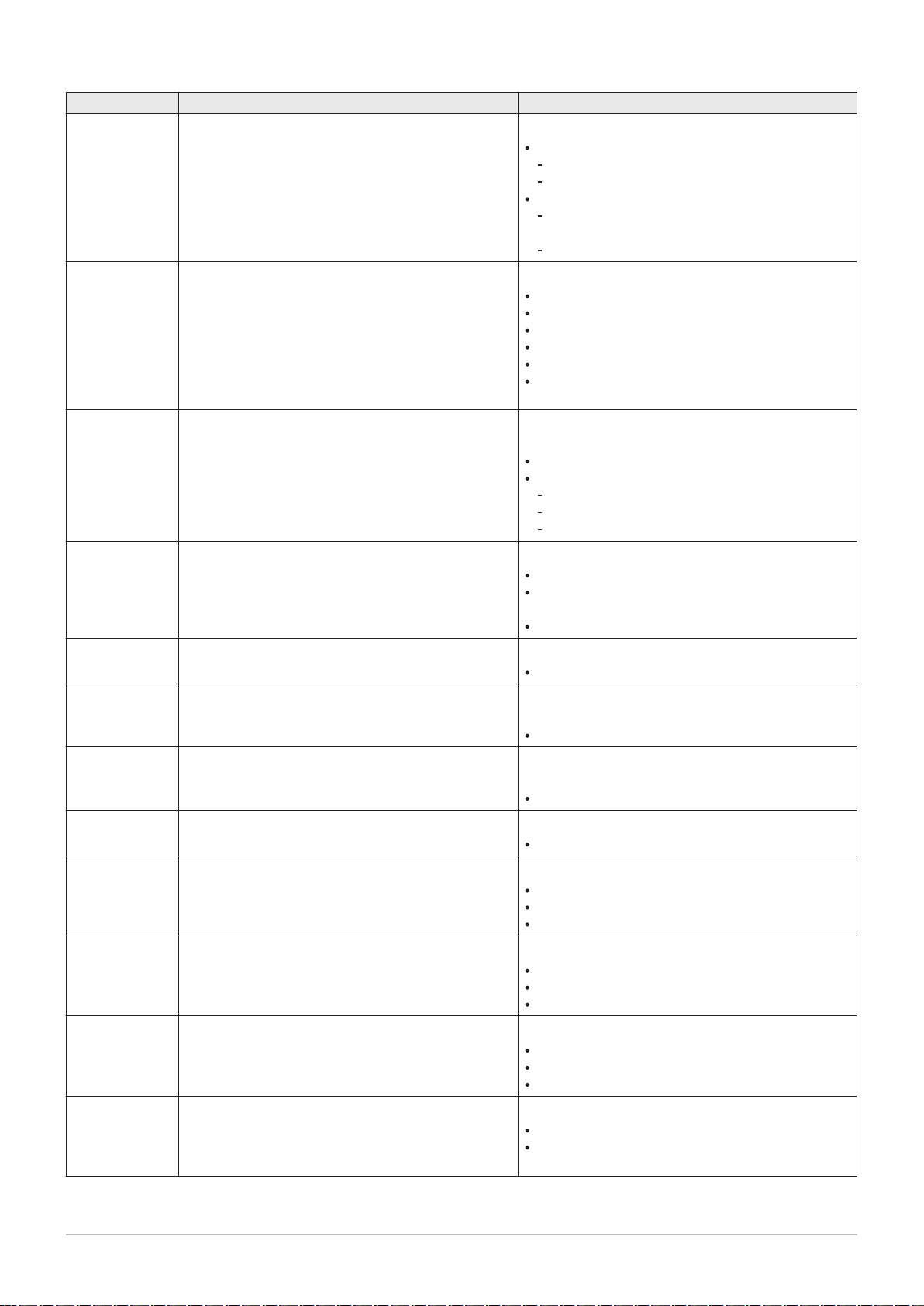

Tab.8 Technical parameters

Gas 220 Ace 160 200 250 300

Condensing boiler Yes Yes Yes Yes

Low-temperature boiler

(1)

No No No No

3 Technical specifications

7665063 - v.05 - 18102018 15

Gas 220 Ace 160 200 250 300

B1 boiler No No No No

Cogeneration space heater No No No No

Combination heater No No No No

Rated heat output

Useful heat output at nominal heat out

put and high temperature operation

Useful heat output at 30% of rated heat

output and low temperature regime

Seasonal space heating energy efficiency

Useful efficiency at rated heat output

and high temperature regime

(2)

Useful heat output at 30% of rated heat

output and low temperature regime

Prated

P

4

(2)

P

(2)

(2)

1

ƞ

s

ƞ

4

ƞ

1

kW 152 194 243 291

kW 152.1 194.4 243.3 290.9

kW 50.8 64.8 81.2 97.2

% - - - -

% 87.8 87.6 87.7 87.7

% 97.8 97.3 97.5 97.7

Auxiliary electricity consumption

Full load

Part load

Standby mode

elmax

elmin

P

SB

kW 0.275 0.204 0.323 0.343

kW 0.047 0.057 0.057 0.048

kW 0.005 0.011 0.011 0.009

Other items

Standby heat loss

Ignition burner power consumption

Annual energy consumption

P

stby

P

ign

Q

HE

kW 0.191 0.267 0.267 0.267

kW - - - -

kWh

- - - -

GJ

Sound power level, indoors

Emissions of nitrogen oxides NO

(1) Low temperature means 30 °C for condensing boilers, 37 °C for low temperature boilers and 50 °C (at heater inlet) for other heating

appliances.

(2) High temperature operation means 60 °C return temperature at heater inlet and 80 °C feed temperature at heater outlet.

L

WA

X

dB 67 68 72 72

mg/kWh 35 40 45 50

See

Refer to the back cover for contact details.

AD-3000809-01

528

62

272

738

657

800

458 171

1329

1662

332

56

383

231

84

3 Technical specifications

16 7665063 - v.05 - 18102018

3.3 Dimensions and connections

Fig.1 Dimensions

Connecting the flue gas outlet;

Gas 220 Ace 160; Ø 150 mm

Gas 220 Ace 200 - 250 - 300; Ø 200 mm

Connecting the air supply;

Gas 220 Ace ; Ø 150 mm

Gas 220 Ace 200 - 250 - 300; Ø 200 mm

Gas connection;

Gas 220 Ace ; R 1 inch male thread

Gas 220 Ace 200 - 250 - 300; R 1½ inch male thread

Flow connection;

Gas 220 Ace ; R 1¼ inch male thread

AD-0001189-01

X01

X02

X03

X04 / X05

X06

X07

X12

X11

X10

X09

X08

Pump

N

L

OT

On/off

0

+

0 - 10

0

+

PWM

BL

RL

Tout

X1

X8

X10

X4X9

X5

X6

X2

X3

X1

1 32

X2

1 32

Pump

N

L

X3

1 32 4 5 6 7 8 9 10 11 12

On/off

OT

PWM

0 +

0 - 10

0 +

Tout

BL RL

X4

1 7-

6.3 AT

F1

X019 X039 X036

X5

1 7-

X6

1 15-

CB-01

X018 X035

X020

230VAC

X038

Bus

CU-GH & HMI

X12

1 5-

X122X121

X11

1 - 4

X111

X10

1 - 4

X101

X09

1 - 4

X08

1 13-

X083

X07

1 4-

X071

X06

1 4-

X04 / X05

1 15-

X041 X051 X053 X054 X055 X081

X02

1 9-

X03

1 15-

X021X022

X031

X015

X01

1 7-

X0141

X014

230V, 50Hz

X011

X013X012

X20 X202

X201

EMC

X037

Bus

2323

22

21

20

18 19

17

16

151413121110

9

87

6

5

3 4

2

1

3 Technical specifications

7665063 - v.05 - 18102018 17

Gas 220 Ace 200 - 250 - 300;R 2 inch male thread

Central heating return connection;

Gas 220 Ace ; R 1¼ inch male thread

Gas 220 Ace 200 - 250 - 300; R 2 inch male thread

Second central heating return connection (option);

3.4 Electrical diagram

Fig.2 Electrical diagram

Gas 220 Ace ; R 1¼ inch male thread

Gas 220 Ace 200 - 250 - 300; R 2 inch male thread

Siphon connection

1

2

3

4

5

6

7

8

9

10

11

12

Boiler control unit

Lighting

Ionisation/ignition electrode (E)

Ignition transformer (IT)

On/Off switch (AU)

Power supply (P)

Service connector/computer connection (PC)

Control panel (HMI)

Fan supply (P)

Storage parameter (PSU)

Flow sensor (FTs)

Heat exchanger temperature sensor (HEs)

13

Return temperature sensor (RTs)

14

Hydraulic pressure sensor (WPs)

15

Air pressure differential switch (PS)

16

Flue gas sensor (FGs)

17

Fan control (PWM)

18

Gas leakage control VPS

19

Gas pressure switch GPS

20

Gas valve 1

21

Gas valve 2

22

Standard PCB

23

L-Bus connections for additional control PCBs

(depending on boiler model)

4 Description of the product

18 7665063 - v.05 - 18102018

4 Description of the product

The Gas 220 Ace boiler is delivered with a combination of the control

panel, control unit and extension PCB. The contents of this manual are

based on the following software and navigation information:

Tab.9 Software and navigation information

Name visible in display Software version

Boiler Gas 220 Ace FSB-WHB-HE-150-300 01.07

Control panel HMI S-control HMI 02.01

PCB SCB-01 SCB-01 00.02

4.1

Operating principle

4.1.1 Gas/air regulation

The boiler is equipped with a casing that also serves as an air box. The

fan draws in the combustion air. The gas is injected into the venturi and

mixed with the combustion air. The fan speed is controlled on the basis of

the settings, the heat demand and the prevailing temperatures measured

by the temperature sensors. The gas/air ratio control ensures an accurate

mixture of the required amounts of gas and air. This provides optimum

combustion over the entire heat input range. The gas/air mixture goes to

the burner, where it is ignited by the ignition electrode.

Important

The combustion air supply is checked before each burner start,

and at least once every 24 hours. During continuous operation

(e.g. supplying process water), please note that the boiler control

will reset every 24 hours.

4.1.2 Combustion

The burner heats the central heating water flowing through the heat

exchanger. If the temperature of the flue gases is lower than the dew point

(approx. 55°C), the water vapour condenses in the heat exchanger. The

heat released during this condensation process (referred to as the latent

or condensation heat) is also transferred to the central heating water. The

cooled flue gases are discharged through the flue gas discharge pipe. The

condensed water is discharged through a siphon.

4.1.3 Control system

The e-Smart electronic control system ensures that your heating system is

smart and reliable. This means that the boiler responds practically to

negative environmental influences (such as limited water flow and air flow

problems). In the event of such influences, the boiler will not go into

lockout mode, but in the first instance will modulate back. Depending on

the nature of the circumstances, a warning, blocking or lock-out may

occur. The boiler continues to supply heat provided the situation is not

dangerous. With this control system, your boiler is also equipped for

remote control and monitoring.

4.1.4 Control

On/off control

The heat input varies between the minimum and the maximum values

on the basis of the flow temperature set on the boiler. It is possible to

connect a 2-wire on/off thermostat or a power stealing thermostat to the

boiler.

Modulating control

The heat input varies between the minimum and the maximum values

on the basis of the flow temperature determined by the modulating

AD-0001329-02

100

150

300

0

0 2 41 3 5 8 9 10 11 12 13 14

6,7

15

250

50

190

4 Description of the product

7665063 - v.05 - 18102018 19

controller. The boiler output can be modulated with an appropriate

modulating controller.

Analogue control (0 - 10 V)

The heat input varies between the minimum and the maximum values

on the basis of the voltage present at the analogue input.

4.1.5 Regulating the water temperature

The boiler is fitted with an electronic temperature control with a flow and

return temperature sensor. The flow temperature can be adjusted between

20°C and 90°C. The boiler modulates back when the set flow temperature

is reached. The switch-off temperature is the set flow temperature + 5°C.

4.1.6 Protection against shortage of water

The boiler is fitted with low water level protection based on temperature

measurements. By modulating back when the water flow threatens to

become insufficient, the boiler remains operational as long as possible.

The boiler issues a warning in the event of no or too little water. With an

insufficient flow ΔT ≥ 25 K or too great an increase in the heat exchanger

temperature sensor, the boiler goes into blocking mode.

4.1.7 Water flow

The modulating control of the boiler limits the maximum difference

between the flow temperature and return temperature. In addition, a heat

exchanger temperature sensor is mounted to monitor the minimum water

flow. This limits the maximum increase in the heat exchanger temperature

and monitors the maximum temperature difference between the flow,

return and heat exchanger temperatures. As a result, the boiler is not

affected by low water flow.

4.1.8 Hydraulic pressure sensor

The hydraulic pressure sensor records the water pressure in the boiler.

Change the threshold value for the hydraulic pressure sensor using

parameter AP006.

4.1.9 Air pressure differential switch

The air pressure differential switch is a protection against a blocked trap or

blocked air supply/flue gas outlet.

Before start-up and when the boiler is in operation, the air pressure

differential switch APS measures the difference in pressure between the

measuring points on the condensate collector

p+ and the air box p-. If the

pressure difference is greater than 6 mbar, then the boiler will lock out.

After eliminating the cause of the breakdown, the boiler can be unlocked.

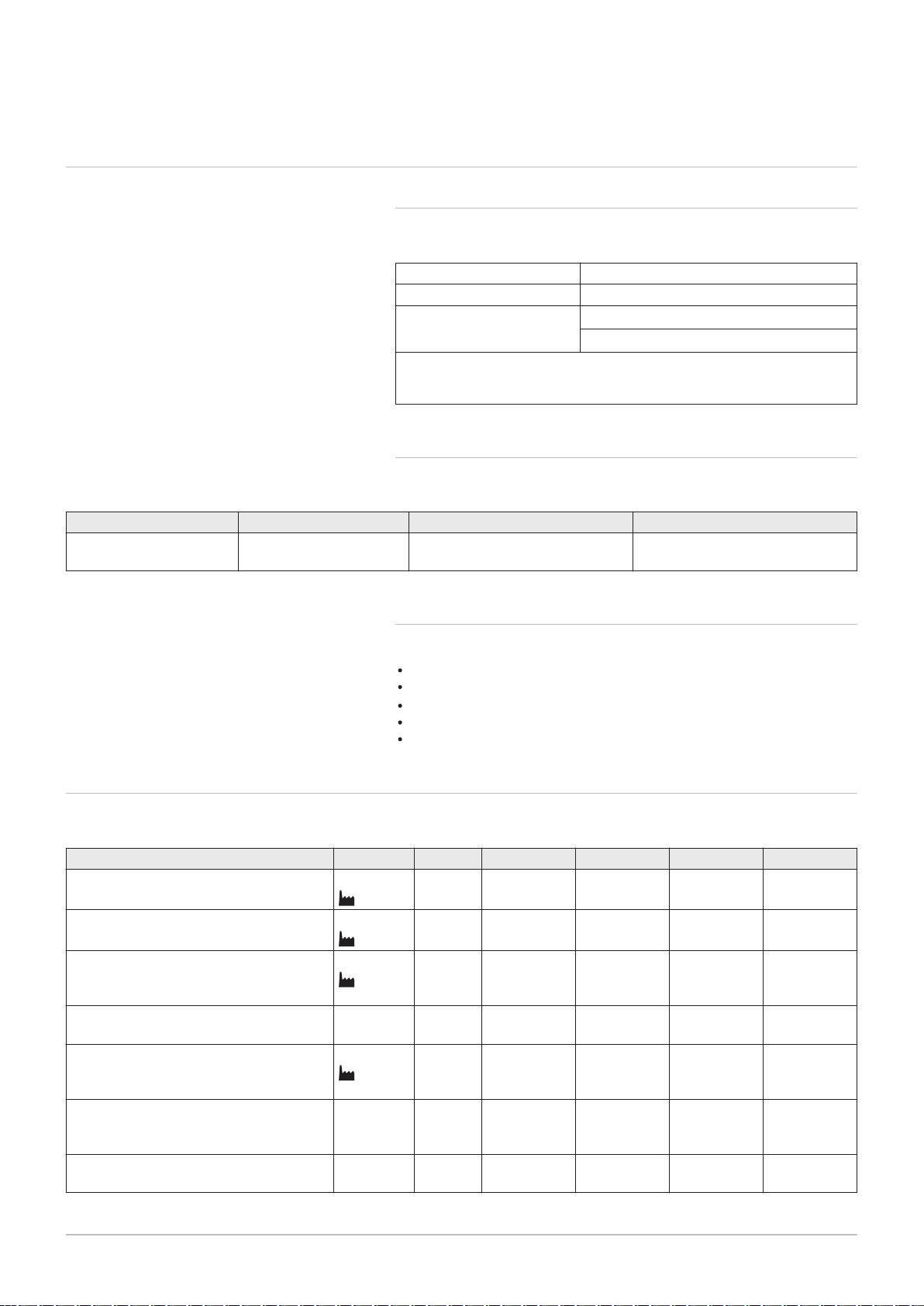

4.1.10 Circulating pump

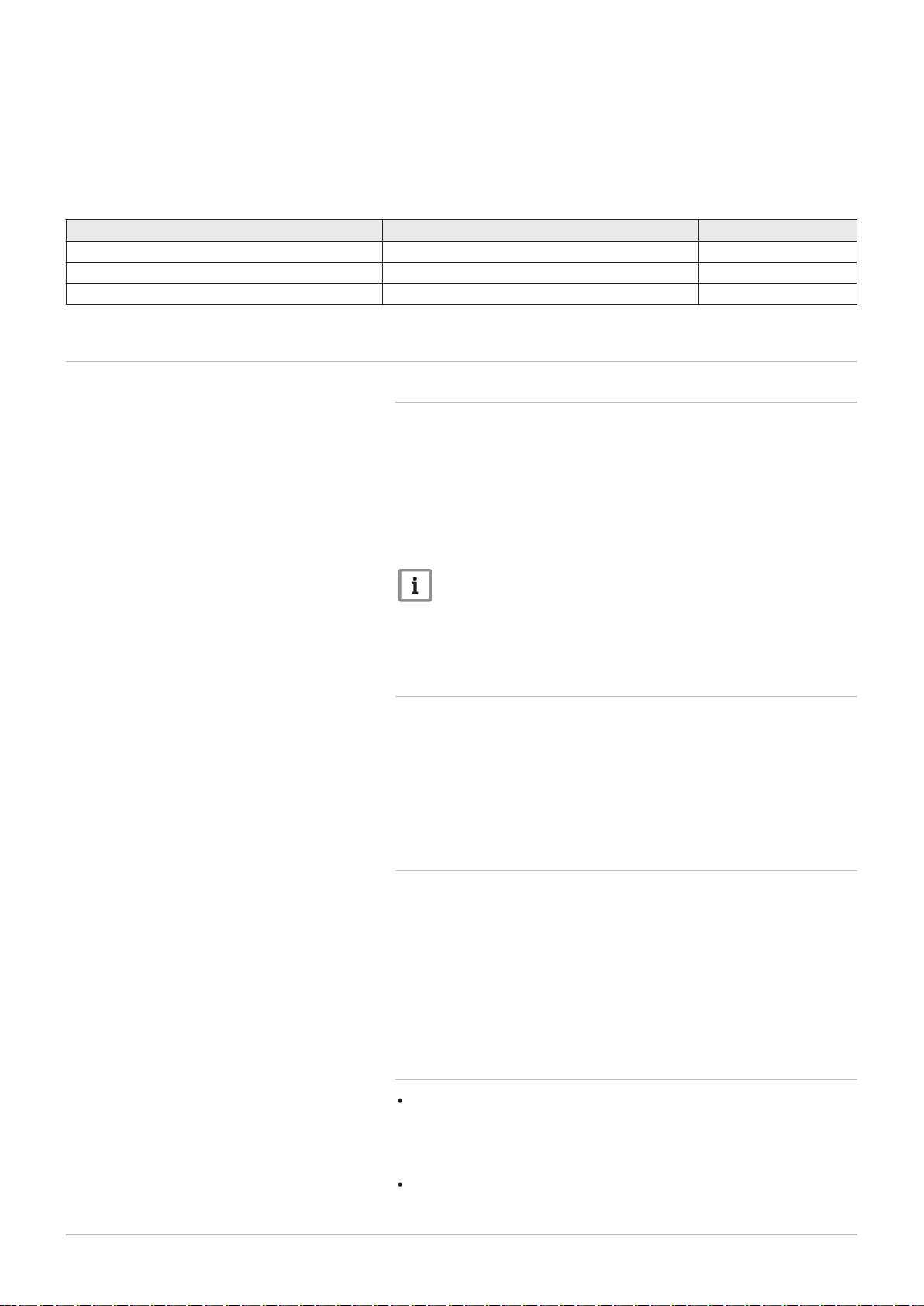

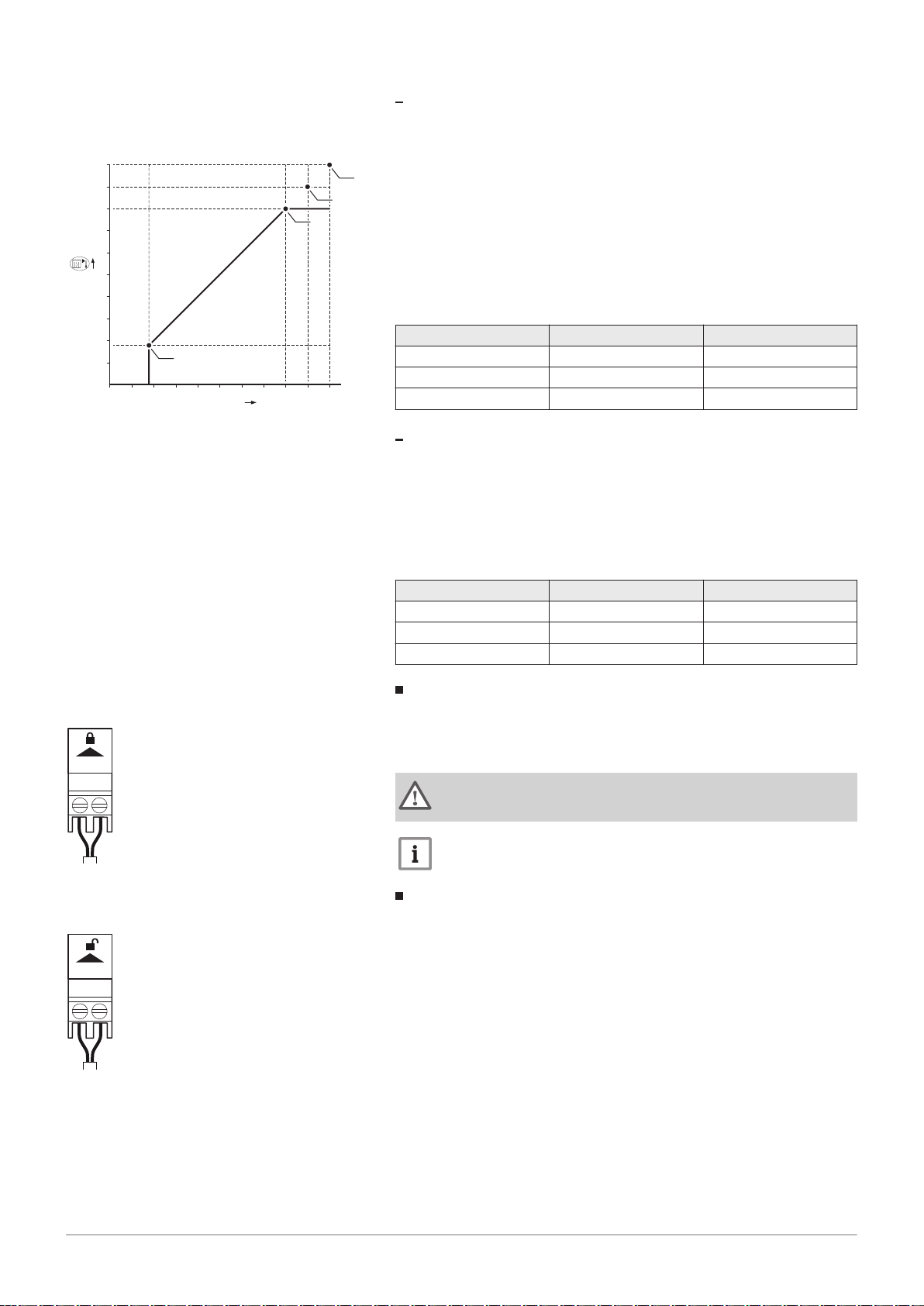

Fig.3 Hydraulic resistance Gas 220 Ace

160

ΔP

Boiler resistance (mbar)

Q

Flow rate (m3/h)

AD-0001328-01

100

200

150

300

0

0

[m3/h]

Q

2 4 6 141 3 5 7

8,6 10,8 12,5

15

250

50

300 kW

250 kW

200 kW

AD-0001160-01

1

38

37

35

36

24

27

28

26

25

31

30

29

32

34

23

33

22

21

3

8

9

2

7

6

4

5

13

10

19

14

15

16

18

17

12

11

20

4 Description of the product

20 7665063 - v.05 - 18102018

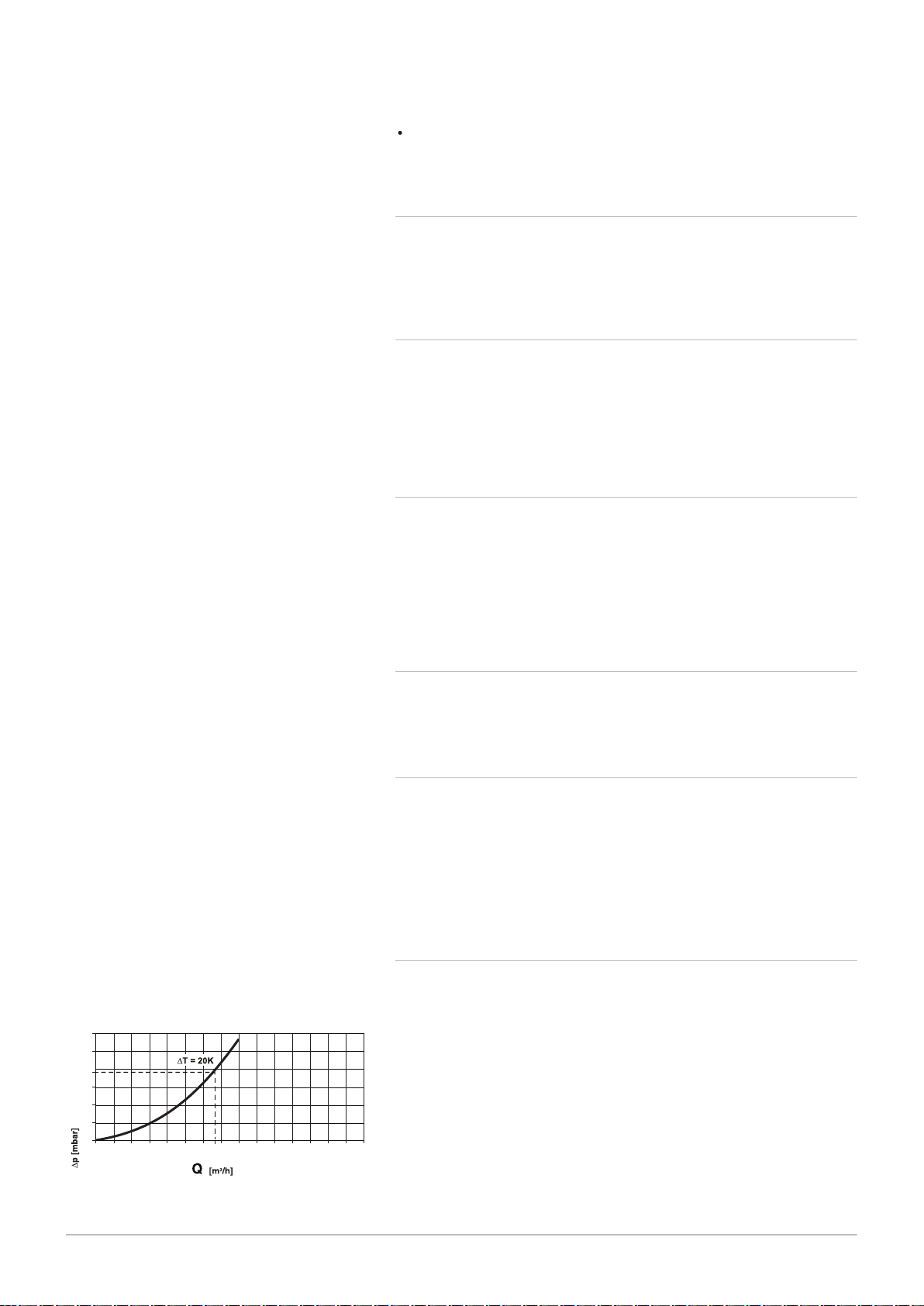

Fig.4 Hydraulic resistance Gas 220 Ace

200 - 250 - 300

ΔP

Boiler resistance (mbar)

Q

Flow rate (m3/h)

The boiler is supplied without a pump. Take the boiler resistance and

system resistance into account when selecting a pump.

Caution

Maximum power consumption may be 300 VA. Use an auxiliary

relay for a pump with greater power.

4.1.11

Calorifier connection

A calorifier can be connected to the boiler. Our range includes various

calorifiers.

Important

Contact us for more information.

4.2

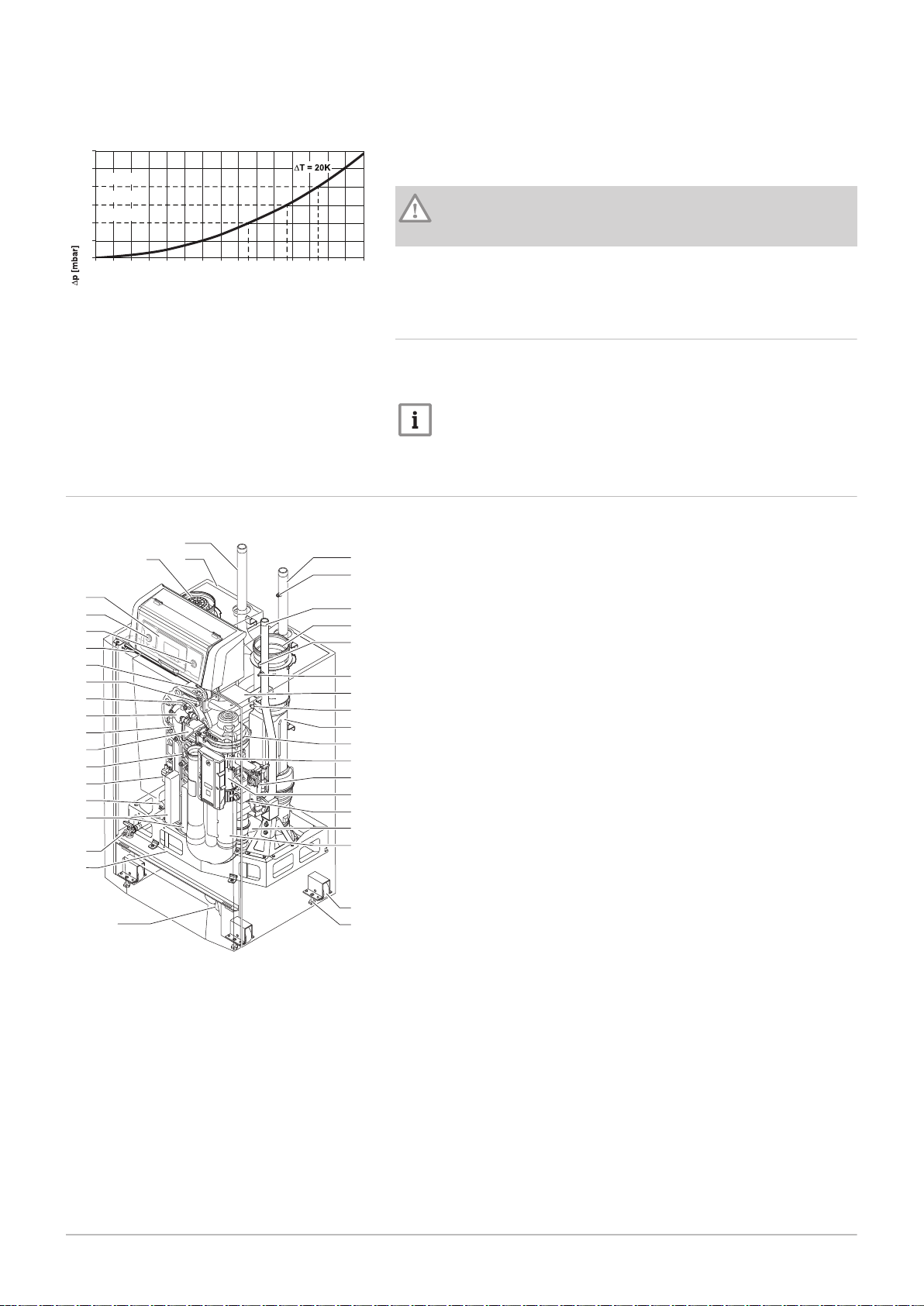

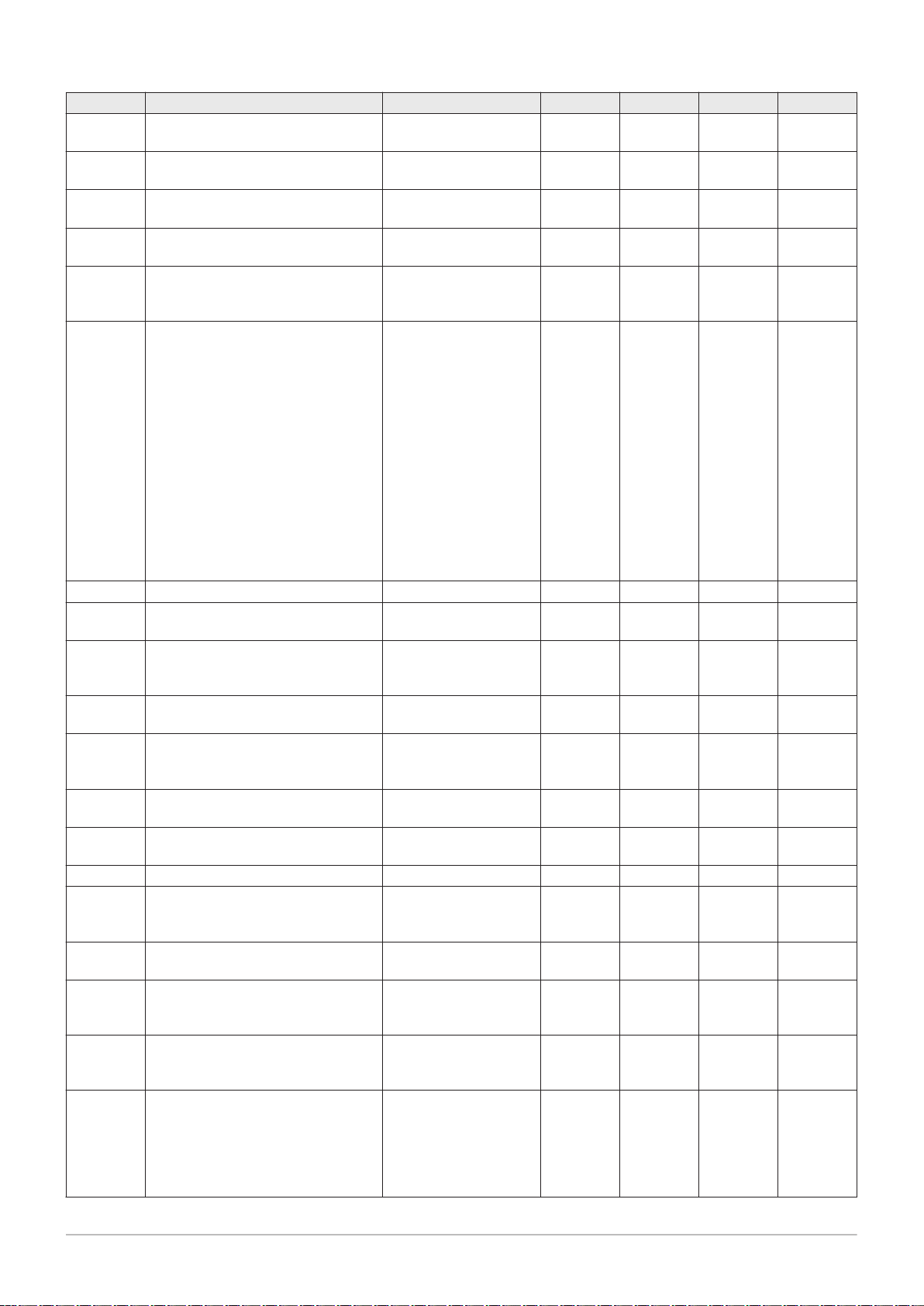

Fig.5 Main components

Main components

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Central heating return pipe

Casing/air box

Air supply

Control panel

On/off switch

Service connector (PC connection)

LED interior light

Air pressure differential switch

Flow sensor

Burner

Adapter

Heat exchanger

Non-return valve

Temperature sensor for heat exchanger

Ignition transformer

Hydraulic pressure sensor

Heat exchanger inspection hatch

Filling/drain valve

Frame

Siphon

Adjustment bolt

Transport wheel

Air intake silencer

Condensate collector

Gas pressure measuring point

Venturi

Gas valve unit

Control unit (CU-GH)

Fan

Flue gas connection pipe

Flue gas sensor

Support

Gas pressure measuring point

Flue gas measuring point

Flue gas outlet

Gas connection

Manual air vent

Central heating supply pipe

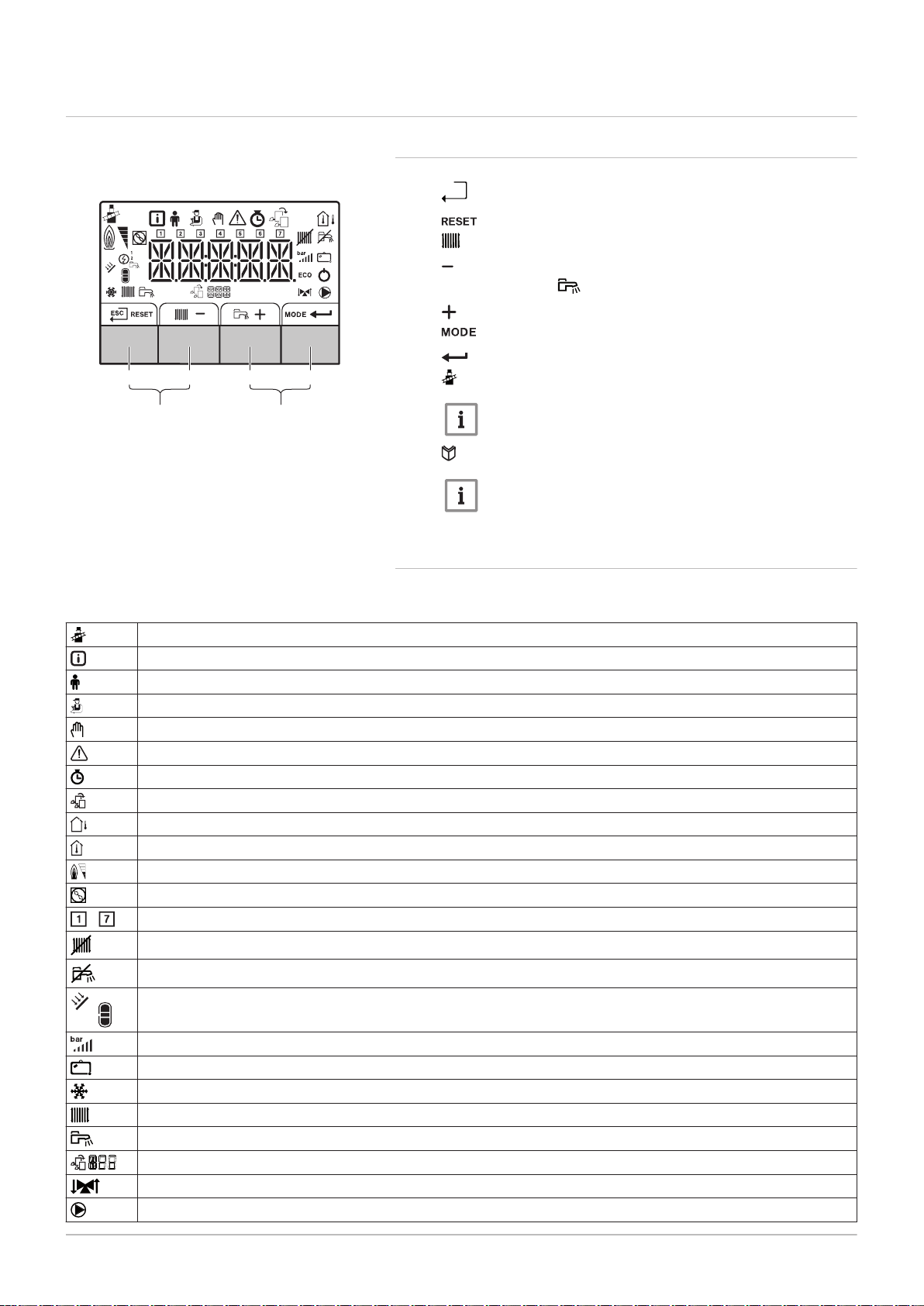

4.3 Control panel description

h

AD-3000833-01

1 2 3 4

5 6

7665063 - v.05 - 18102018 21

4 Description of the product

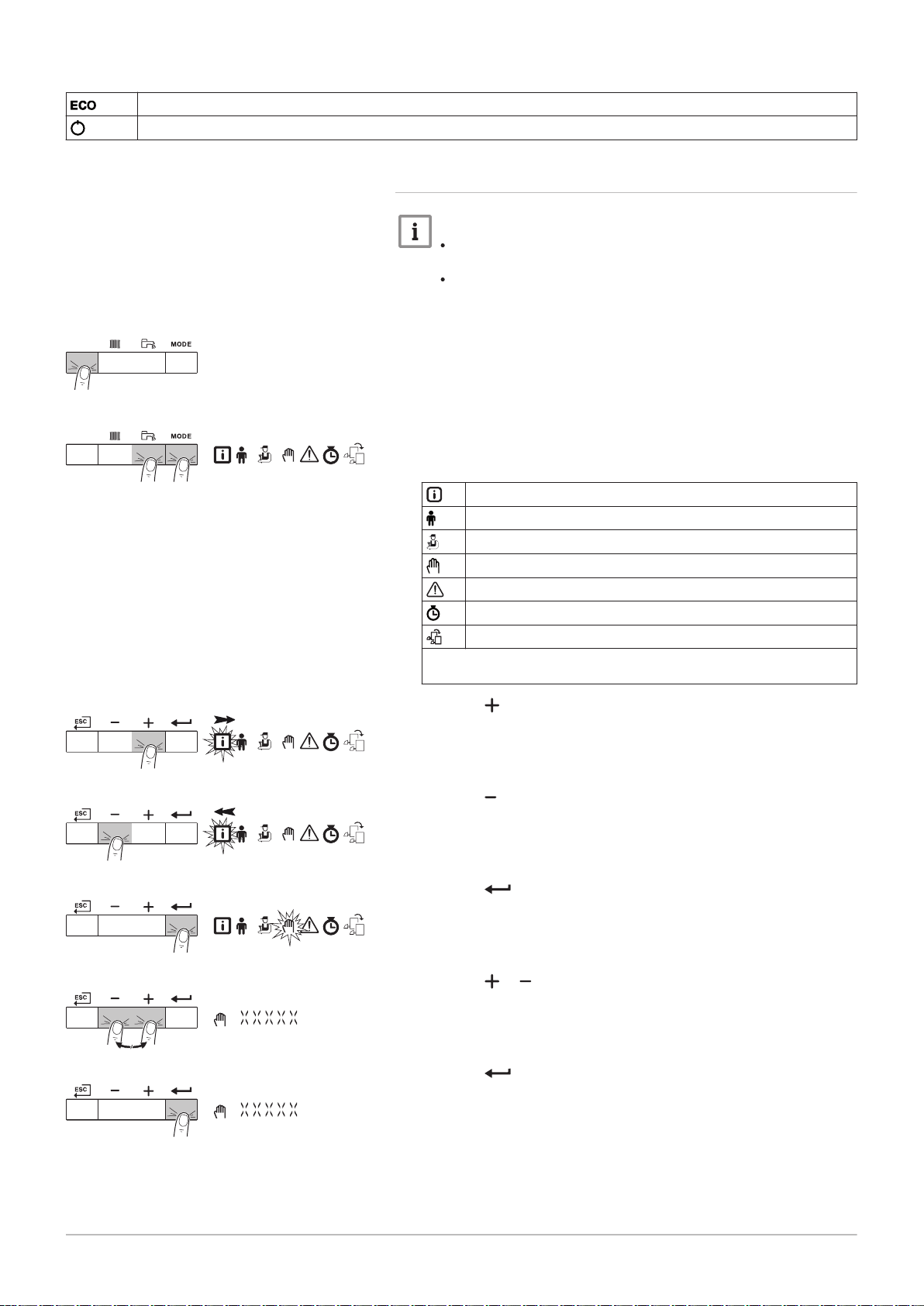

4.3.1 What each key means

Fig.6 Control panel

1

Escape: Back to the previous level.

Reset: Manual reset.

2

CH flow temperature Access to set temperature.

Min. key: Lowering the value.

3

DHW temperature: Access to set temperature.

Plus key: Raising the value.

4

5

6

CH/DHW function: Toggles function ON/OFF

Enter key: Confirms selection or value.

Chimney-sweeping keys

Important

Press the 1 and 2 keys simultaneously.

Menu keys

Important

Press the 3 and 4 keys simultaneously.

4.3.2 Meaning of the symbols on the display

Tab.10 Possible symbols in the display (depending on available devices or functions)

-

Chimney sweep mode is enabled (forced full load or part load for

Information menu: read out various current values.

User menu: user-level parameters can be configured.

Installer menu: installer level parameter can be configured.

Manual mode menu: manual mode can be configured.

Error menu: errors can be read out.

Hour counter/timer program/time display menu.

Control PCB menu: (optional) control PCBs can be read out.

The outside temperature sensor is connected.

The room temperature sensor is connected.

The burner output level (1 to 5 bars, with each bar representing 20% output)

The heat pump is switched on.

Day display

Central heating operation is switched off.

O2/CO2 measurement).

DHW operation is switched off.

The solar boiler is on and its heat level is displayed.

System water pressure display.

The holiday program is enabled.

Frost protection operation is enabled.

CH operation is enabled.

DHW operation is enabled.

Displaying the selected PCB.

The three-way valve is switched on.

The circulation pump is turning.

MW-3000377-02

MW-3000299-01

MW-3000300-02

MW-3000301-02

MW-3000302-01

MW-3000303-01

MW-3000304-01

4 Description of the product

22 7665063 - v.05 - 18102018

ECO mode operation is enabled.

Switch the appliance off then on again.

4.3.3 Browsing in the menus

Important

Depending on the devices or control PCBs connected, the

control panel shows selection options in some menus.

First, select a device, control PCB or zone to view or amend a

setting.

Fig.7

Step 1

Fig.8 Step 2

Fig.9 Step 3

1. Press any key to activate the controller from the stand-by screen.

2. Access the available menu options by pressing the two keys on the

right simultaneously.

Tab.11 Possible menu choices

Information Menu

User menu

Installer Menu

Manual mode menu

Failure Menu

Hour Run Meters / Timer Program / Clock menu

PCB menu

(1) The icon is displayed only if an optional control PCB has been instal

led.

(1)

3. Press the key to move the cursor to the right.

Fig.10 Step 4

Fig.11 Step 5

Fig.12 Step 6

Fig.13 Step 7

4. Press the key to move the cursor to the left.

5. Press the key to confirm selection of the required menu or

parameter.

6. Press the or key to modify the value.

7. Press the key to confirm the value.

MW-3000305-01

4 Description of the product

7665063 - v.05 - 18102018 23

Fig.14 Step 8

4.4 Standard delivery

8. Press the h key to go back to the main display.

Important

The screen will return to stand-by if no key is pressed for three

minutes.

The delivery includes 2 packages:

One package with:

The boiler, supplied with earthed mains plug

Documentation

Water quality instructions

One package with:

Siphon with condensate drain hose

Sticker: This central heating unit is set for...

The connection box

The control panel with a corresponding manual

Important

This manual only deals with the standard scope of supply. For the

installation or mounting of any accessories delivered with the

boiler, refer to the corresponding mounting instructions.

4.5 Accessories and options

Various accessories can be obtained for the boiler.

Important

Contact us for more information.

AD-0001162-01

AD-0001163-01

800 100100

657 50

1100

1662 A

5 Before installation

24 7665063 - v.05 - 18102018

5 Before installation

5.1 Installation regulations

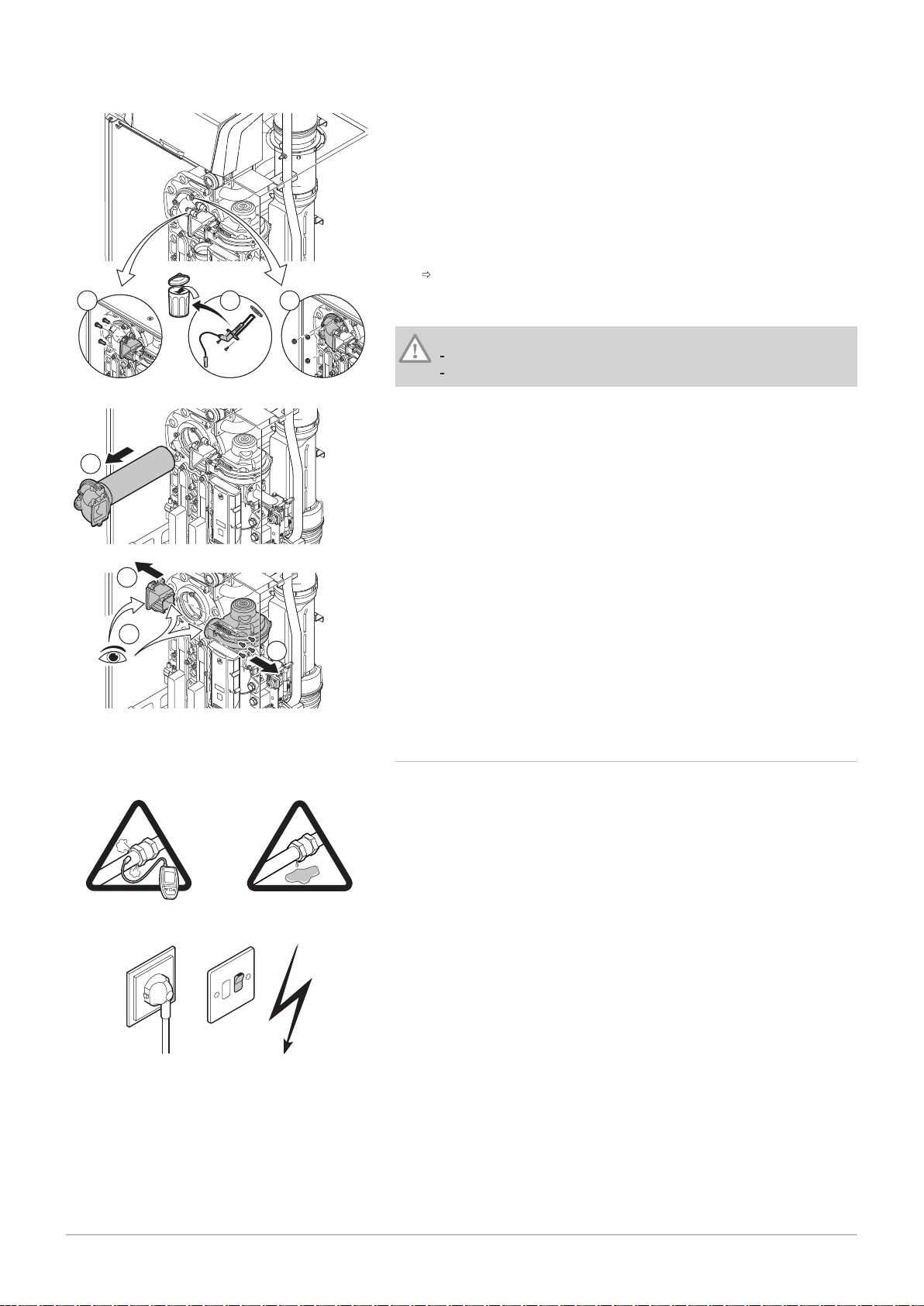

Warning

The installer must be registered with Gas Safe and have the

correct ACS qualifications.

Important

Practical guidelines - see the latest version.

5.2

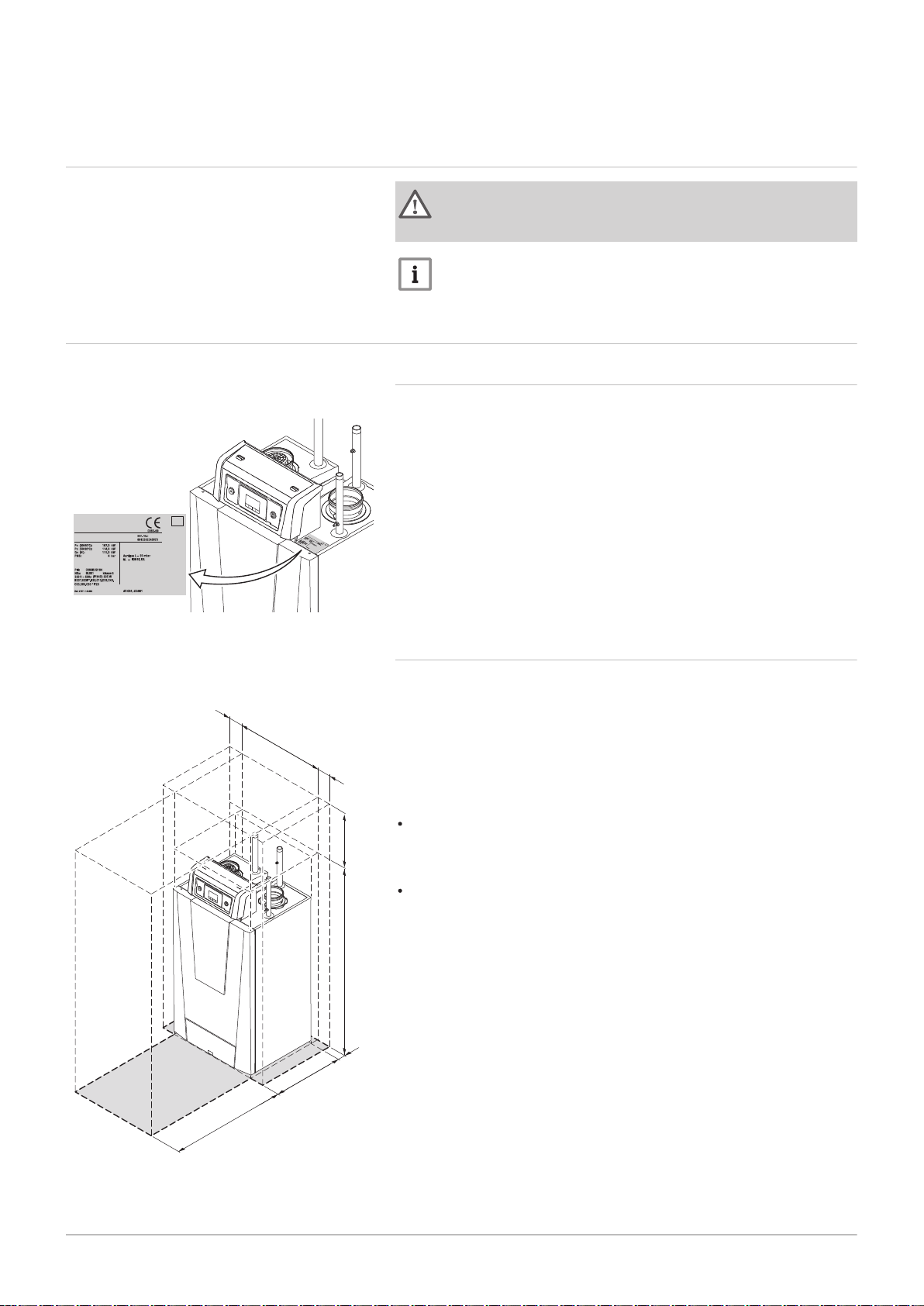

Fig.15

Fig.16 Clearance required

Choice of the location

Position of data plate

5.2.1 Data plate

The data plate on the boiler features the boiler serial number and

important boiler specifications, for example the model and unit category.

The factory setting codes CN 1 and CN 2 are also stated on the data

plate.

5.2.2 Location of the boiler

A

500 mm (if the air supply filter is used, there must be a clearance

of at least 650 mm)

The standard inspection and maintenance operations to the boiler are

carried out from the front. This is also where the inspection ports of the

heat exchanger are located. The hydraulic connections and the flue gas

outlet are located at the front of the boiler. The control panel housing is

also on the front of the boiler.

Use the guidelines and the required installation space as a basis for

determining the correct place to install the boiler.

When determining the correct installation space, take account of the

permitted position of the flue gas discharge and/or air supply outlet.

Ensure that there is sufficient space around the boiler for good access

and ease of maintenance.

AD-0001164-01

1200

1835

800

5 Before installation

7665063 - v.05 - 18102018 25

Danger

It is forbidden to store, even temporarily, combustible products

and substances in or near the boiler.

Caution

The boiler must be installed in a frost-free area.

The boiler must have an earthed electrical connection.

A connection to the drain must be present for the condensate

drain close to the boiler.

A technical clearance of at least 1100 mm is required at the

front (service side) of the boiler. We recommend a clearance of

at least 500 mm above the boiler.

Caution

If the power supply cable is permanently connected, you must

always install a main bipolar switch with an opening gap of at least

3 mm (BS EN 60335-1).

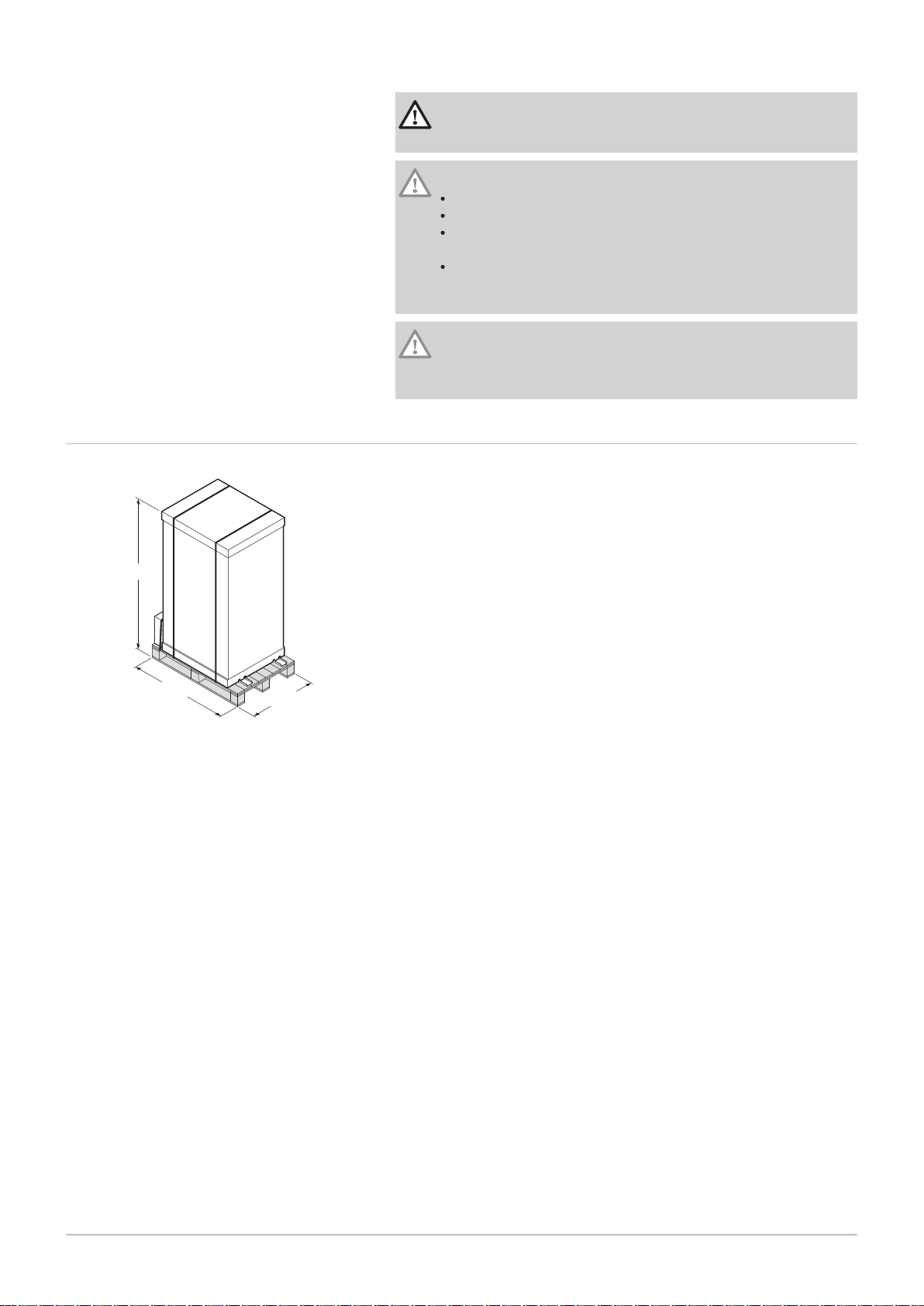

5.3

Fig.17

Transport

Boiler package

The boiler is supplied fully assembled and packaged on a pallet. Without

the packaging, the boiler will fit through all standard doorways.

The boiler is equipped with integrated transport wheels, meaning it can

easily be moved.

AD-0001165-01

8

7

6

5

5

3

4x

4

4x

1

2

5 Before installation

26 7665063 - v.05 - 18102018

5.4 Unpacking & initial preparation

Caution

The transport wheels under the boiler are designed for transport

purposes only and not for use when the boiler is in its final

position.

Fig.18 Unpacking the boiler

1. Cut the packaging straps and remove.

2. Remove the packaging.

3. Unscrew the boiler anchorage on the pallet.

4. Remove the boiler anchorage.

5. Unscrew the loading ramps on the pallet.

6. Fit the loading ramps in front of the pallet.

7. Move the boiler off the pallet.

8. Remove the pallet and the rest of the packaging.

The boiler can now be moved using the transport wheels.

6 Installation

AD-0001166-02

4x

4x

63 63

80

80

485

55

55

674

7665063 - v.05 - 18102018 27

6.1 General

6 Installation

Warning

The boiler must be installed by a qualified installer in accordance

with local and national regulations.

6.2

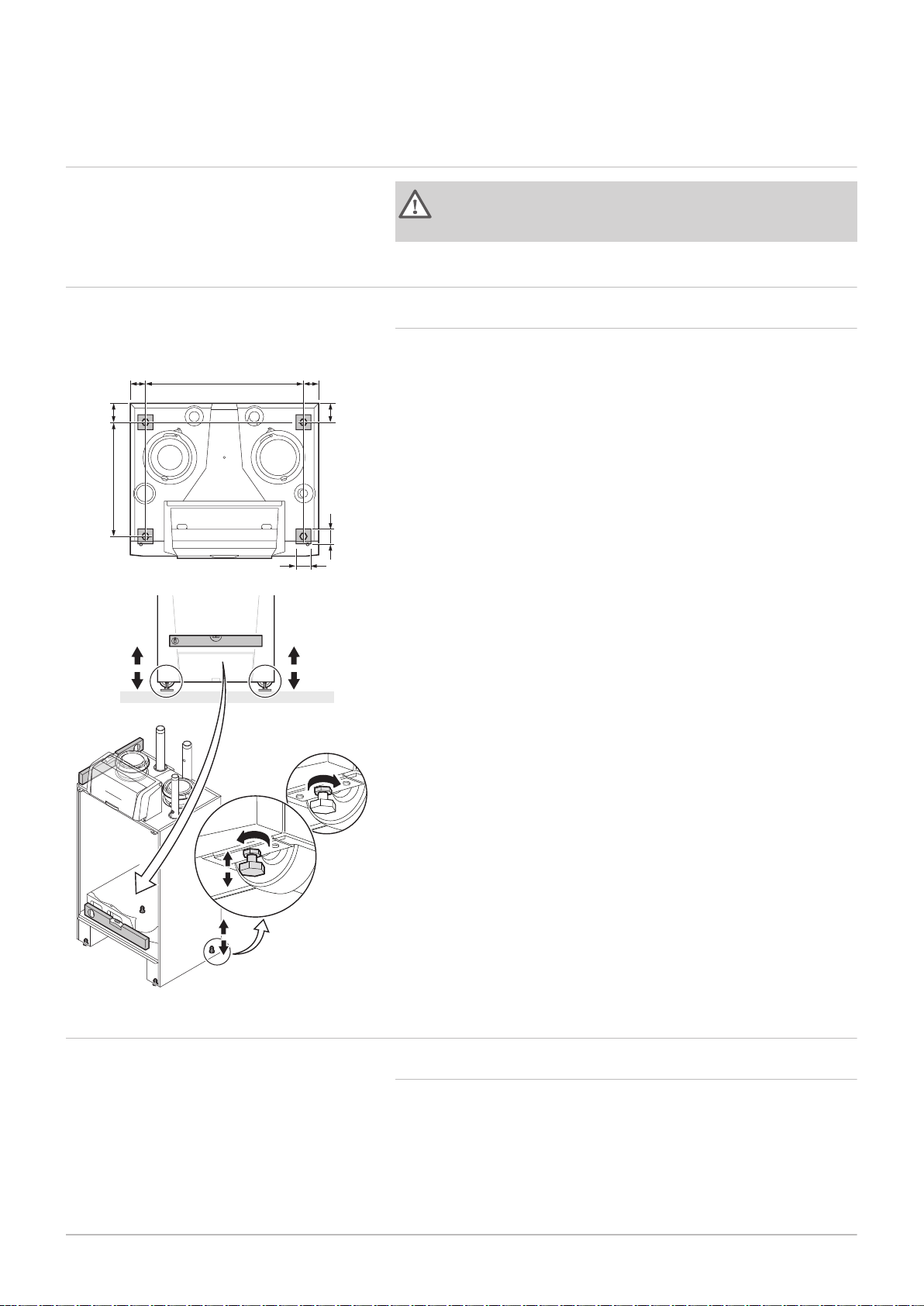

Fig.19 Position of the adjustment bolts

Preparation

6.2.1 Positioning the boiler

1. Place the boiler in the right position using the transport wheels.

2. Loosen the adjustment bolts and ensure that the boiler is completely

level.

The figure also shows the support surface of the boiler (this is the position

of the adjustment bolts).

6.3

Hydraulic connections

6.3.1 Rinsing the system

The installation must be cleaned and flushed in accordance with BS 7593

(2006) and BSRIA BG 33/2014.

Before a new boiler can be connected to an existing or new system, the

entire system must be thoroughly cleaned and flushed. This step is

absolutely crucial. The flushing helps to remove residue from the

installation process (weld slag, fixing products etc.) and accumulations of

dirt (silt, mud etc.)

AD-0001167-01

6 Installation

28 7665063 - v.05 - 18102018

Important

Flush the system with a volume of water equivalent to at least

three times the volume of the system.

Flush the DHW pipes with at least 20 times the volume of the

pipes.

Important

Due to the presence of an aluminium heat exchanger, suitable

chemicals and the correct use of these chemicals should be

discussed with specialist water treatment companies.

6.3.2 Connecting the heating circuit

Fig.20 Supply and return connections

1. Remove the dust cap on the central heating flow connection .

2. Remove the dust cap on the central heating return connection .

3. Fit the outlet pipe for CH water to the CH flow .

4. Fit the inlet pipe for CH water to the CH return .

5. In the supply directly above the boiler, establish a connection for a

overpressure valve of sufficient capacity.

6. Connect the pump to the boiler's return connection.

Always connect the boiler in a way that will guarantee the water flow

through the unit during operation. When the boiler is used in a system with

two return pipes, the return pipe must be used as a cold return. The

second return pipe is then used as a hot return. Contact us for more

information.

Caution

AD-0001168-02

6

1

7

3

54

2

AD-0001174-01

7665063 - v.05 - 18102018 29

If using plastic pipes, follow the manufacturer's (connection)

instructions.

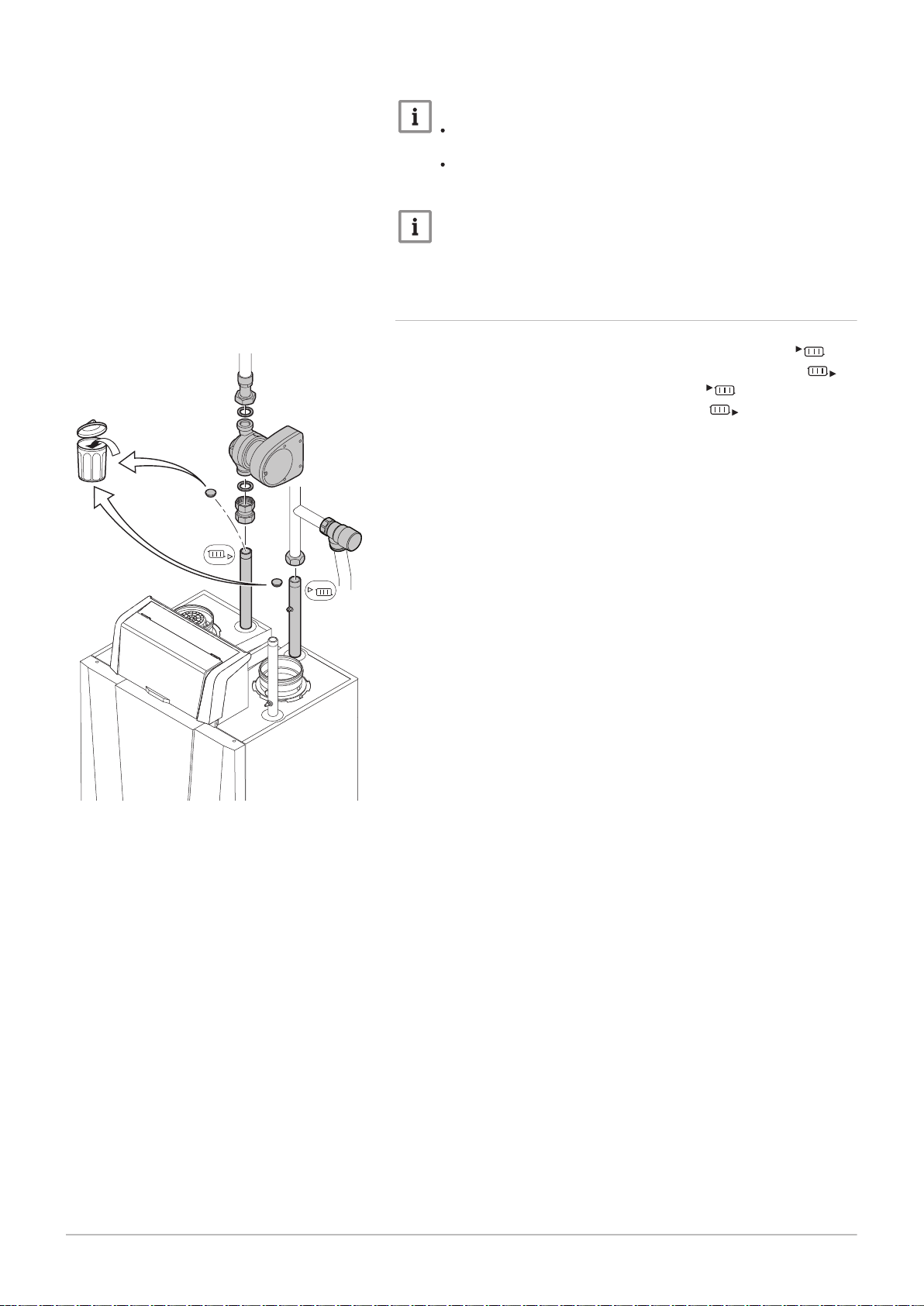

6.3.3 Connecting the condensate drain pipe

6 Installation

Fig.21 Connect the condensate drain pipe

The siphon is supplied separately with the boiler as standard (including a

flexible plastic siphon hose). .

1. Remove the dust cap from the siphon connection at the bottom of

the boiler

2. Pull the retainer clip of the siphon backwards.

3. Push the siphon firmly in the holder.

4. Push the retainer clip of the siphon forwards.

5. Check whether the siphon is firmly fitted in the boiler.

6. Attach the flexible siphon hose supplied to the output of the siphon

and insert the other end into the plastic drain pipe on the left

underneath the boiler.

7. Fit a plastic drain pipe of Ø 40 mm or larger to this, terminating in the

drain.

Important

The air opening on the siphon prevents siphoning when the drain

pipe is securely connected to the drain.

Danger

The siphon must always be filled with water. This prevents flue

gases from entering the room.

Caution

The drain pipe must slope down at least 30 mm per metre.

Condensed water must not be discharged into a gutter.

6.4 Gas connection

Fig.22 Gas connection

Warning

Before starting work on the gas pipes, turn off the main gas tap.

Before installing, check that the gas meter has sufficient

capacity. Take into account the consumption of all appliances.

Notify the local energy company if the gas meter has insufficient

capacity.

1. Remove the dust cap on the gas connection .

2. Fit the gas supply pipe.

Caution

Always perform welding work at a sufficient distance from the

boiler.

Remove dirt and dust from the gas pipe.

Important

We recommend installing a gas filter to prevent clogging of the

gas valve unit.

3. Also fit a gas isolation valve in this pipe, near the boiler.

AD-3001055-01

AD-3001056-01

AD-3001057-01

6 Installation

30 7665063 - v.05 - 18102018

6.5 Air supply/flue gas outlet connections

6.5.1 Classification

Important

The installer is responsible ensuring that the right type of flue

gas outlet system is used and that the diameter and length are

correct.

Always use connection materials, roof terminal and/or outside

wall terminal supplied by the same manufacturer. Consult the

manufacturer for compatibility details.

Tab.12 Type of flue gas connection: B

23P

Principle Description

Room-ventilated version

Without down-draught diverter.

Flue gas discharge via the roof.

Air from the installation area.

The IP rating of the boiler is lowered to IP20.

(1) The material must also satisfy the material property requirements from the relevant chapter.

Tab.13 Type of flue gas connection: C

13

Principle Description

Room-sealed version

Discharge in the outside wall.

Air supply opening is in the same pressure zone as the dis

charge (e.g. a combined outside wall terminal).

Parallel not permitted.

Permitted manufacturers

(1)

Connection material and roof

terminal:

Muelink & Grol

Permitted manufacturers

(1)

Outside wall terminal and con

nection material:

Remeha, combined with con

nection material from Muelink

& Grol

Muelink & Grol

(1) The material must also satisfy the material property requirements from the relevant chapter.

Tab.14 Type of flue gas connection: C

33

Principle Description

Room-sealed version

Flue gas discharge via the roof.

Air supply opening is in the same pressure zone as the dis

charge (e.g. a concentric roof terminal).

(1) The material must also satisfy the material property requirements from the relevant chapter.

Permitted manufacturers

(1)

Roof terminal and connection

material

Remeha, combined with con

nection material from Muelink

& Grol

Muelink & Grol

AD-3001058-02

AD-3001059-01

6 Installation

7665063 - v.05 - 18102018 31

Tab.15 Type of flue gas connection: C

53

Principle Description

Connection in different pressure zones

Closed unit.

Separate air supply duct.

Separate flue gas discharge duct.

Discharging into various pressure areas.

The air supply and the flue gas outlet must not be placed on

opposite walls.

(1) The material must also satisfy the material property requirements from the relevant chapter.

Tab.16 Type of flue gas connection: C

63

Principle Description

This type of unit is supplied by the manufacturer without an air

supply system and flue gas system.

(1) The material must also satisfy the material property requirements from the relevant chapter.

Permitted manufacturers

(1)

Connection material and roof

terminal:

Muelink & Grol

Permitted manufacturers

(1)

When selecting the material,

please note the following:

Condensed water must flow

back to the boiler.

The material must be resist

ant to the flue gas tempera

ture of this boiler.

Maximum permissible recir

culation of 10%.

The air supply and the flue

gas outlet must not be placed

on opposite walls.

Minimum permitted pressure

difference between the air

supply and the flue gas outlet

is -200 Pa (including -100 Pa

wind pressure).

Tab.17 Type of flue gas connection: C

Principle

(1)

Description

Room-sealed version

Air supply and flue gas discharge duct in shaft or ducted:

93

Concentric.

Permitted manufacturers

Connection material and roof

terminal:

Muelink & Grol

Air supply from existing duct.

Flue gas discharge via the roof.

Inlet opening for the air supply is in the same pressure zone

as the discharge.

(1) See table for shaft or duct requirements.

(2) The material must also satisfy the material property requirements from the relevant chapter.

Tab.18 Minimum dimensions of shaft or duct C

93

Version (D) Without air supply With air supply

Rigid 150 mm Ø 200 mm □ 200 x 200 mm Ø 220 mm □ 220 x 220 mm

Rigid 200 mm Ø 250 mm □ 250 x 250 mm Ø 280 mm □ 280 x 280 mm

Concentric 150/200 mm Ø 270 mm □ 270 x 270 mm - -

(2)

AD-3000330-03

□

D

Ø

D

AD-3001120-01

EN 14471 - T120 P1 W 1 O50 LI E U0

EN 1856-1 - T120 P1 W VxL40045 G(xx)

1

3

2

4

5

6 Installation

32 7665063 - v.05 - 18102018

Fig.23 Minimum dimensions of shaft or

duct C

93

Fig.24 Sample string

Important

The shaft must comply with the air density requirements of the

local regulations.

Important

Always clean shafts thoroughly when using lining pipes and/or

an air supply connection.

It must be possible to inspect the lining duct.

6.5.2 Material

Use the string on the flue gas outlet material to check whether it is suitable

for use on this appliance.

1

EN 14471 of EN 1856–1: The material is CE approved according to

this standard. For plastic this is EN 14471, For aluminium and

stainless steel this is EN 1856-1.

2

T120: The material has temperature class T120. A higher number

is also allowed, but not lower.

3

P1: The material falls into pressure class P1. H1 is also allowed.

4

W: The material is suitable for draining condensation water

(W=’wet’). D is not allowed (D=’dry’).

5

E: The material falls into fire resistance class E. Class A to D are

also allowed, F is not allowed. Only applicable to plastic.

Warning

The coupling and connection methods may vary depending on

the manufacturer. It is not permitted to combine pipes, coupling

and connection methods from different manufacturers. This also

applies to roof feed-throughs and common channels.

The materials used must comply with the prevailing regulations

and standards.

Please contact us to discuss using flexible flue gas outlet

material.

Tab.19 Overview of material properties

Version Flue gas outlet Air supply

Material Material properties Material Material properties

Single-wall, rigid

(1)

Plastic

Stainless steel

Thick-walled,

aluminium

(2)

With CE marking

(2)

Temperature class T120 or

higher

Condensate class W (wet)

Plastic

Stainless steel

Aluminium

Pressure class P1 or H1

Fire resistance class E or bet

(3)

ter

(1) according to EN 14471

(2) according to EN 1856

(3) according to EN 13501-1

With CE marking

Pressure class P1 or H1

Fire resistance class E or bet

(3)

ter

6.5.3 Dimensions of flue gas outlet pipe

AD-3001094-01

ød

1

AD-3000963-01

ød

1

øD

1

AD-0001169-01

L

=

7665063 - v.05 - 18102018 33

Warning

The pipes connected to the flue gas adapter must satisfy the

following dimension requirements.

6 Installation

Fig.25

Dimensions of open connection

Fig.26 Dimensions of parallel connection

d

External dimensions of flue gas outlet pipe

1

Tab.20 Dimensions of pipe

d1 (min-max)

150 mm 149 - 151 mm

200 mm 199 - 201 mm

d

External dimensions of flue gas outlet pipe

1

D

External dimensions of air supply pipe

1

Tab.21 Dimensions of pipe

d1 (min-max) D1 (min-max)

150/150 mm 149 - 151 mm 149 - 151 mm

6.5.4 Length of the air and flue gas pipes

Fig.27 Room-ventilated version

The maximum length of the flue gas outlet and air supply channel vary

depending on the appliance type; consult the relevant chapter for the

correct lengths.

Important

When using bends, the maximum chimney length (L) must be

shortened according to the reduction table.

For adaptation to another diameter use approved transitions

The boiler is also suitable for longer chimney lengths and

diameters other than those specified in the tables. Contact us

for more information.

Room-ventilated model (B

L

Length of the flue gas outlet channel to roof feed-through

23P

)

Flue gas outlet

Air supply

With a room-ventilated version, the air supply opening stays open; only the

flue gas outlet opening is connected. This will ensure that the boiler

obtains the necessary combustion air directly from the installation area.

Use adapters when using air supply and flue gas discharge pipes with

diameters other than the standard 150 or 200 mm.

AD-0001170-01

L =L

= +

6 Installation

34 7665063 - v.05 - 18102018

Caution

The air supply opening must stay open.

The installation area must be equipped with the necessary air

supply openings. These openings must not be obstructed or

shut off.

If the boiler, in room-ventilated operation, has been set up in a

(very) dusty room, use the air supply filter (accessory).

Use of the air inlet filter is compulsory when the boiler is

exposed to building dust.

Tab.22 Maximum chimney length (L)

Diameter 130 mm 150 mm 200 mm 250 mm

Gas 220 Ace 160 37 m

50 m

(1)

Gas 220 Ace 200 16 m 35 m

Gas 220 Ace 250 10 m 21 m

Gas 220 Ace 300 7 m 15 m

(1) With retention of the maximum flue length it is possible to apply an extra 5

times 90º or 10 times 45º elbows.

50 m

50 m

50 m

50 m

(1)

50 m

(1)

50 m

(1)

50 m

(1)

50 m

Room-sealed model (C13, C33, C63, C93)

(1)

(1)

(1)

(1)

Fig.28 Room-sealed version

L

Combined length of the flue gas outlet and air supply channel to

the roof feed-through

Flue gas outlet

Air supply

With a room-sealed version, both the flue gas outlet and the air supply

openings are connected (in parallel). Use adapters when using air supply

and flue gas discharge pipes with diameters other than the standard 150

or 200 mm.

Tab.23 Maximum chimney length (L)

Diameter 130 mm 150 mm 200 mm 250 mm

Gas 220 Ace 160 18 m 62 m

Gas 220 Ace 200 - 10 m

100 m

100 m

(1)

(1)

Gas 220 Ace 250 - - 74 m

Gas 220 Ace 300 - - 40 m

(1) With retention of the maximum flue length it is possible to apply an extra 5

times 90º or 10 times 45º elbows.

100 m

100 m

100 m

100 m

(1)

(1)

(1)

(1)

Connection in different pressure areas (C53)

AD-0001171-01

L

=

+

7665063 - v.05 - 18102018 35

6 Installation

Fig.29

Different pressure zones

L

Total length of the flue gas outlet and air supply duct

Connecting the flue gas outlet

Connecting the air supply

Combustion air supply and flue gas discharge are possible in different

pressure areas and semi-CLV systems, with the exception of the coastal

area. The maximum permitted height difference between the combustion