REMEHA Gas 210 ECO Technical Information

Technical information

Remeha Gas 210 ECO

• High efficiency condensing

Remeha Gas 210 ECO

boiler with low NOX emission

• Ranges: 8-214 kW

1

INHOUD

Remeha Gas 210 ECO

Preface 4

1 SAFETY instructions 5

1.1 Symbols 5

2 General boiler description 6

3 construction 7

3.1 Boiler layout 7

3.2 Operation principle 8

4 Technical data and dimensions 9

4.1 Dimensions 9

4.2 Technical data 10

4.3 Quotation specifications 11

4.4 Optional Accessories 11

5 Efficiency information 12

5.1 Annual efficiency 12

5.2 Heat to water efficiency 12

5.3 Standing losses 12

6 Application information 12

7 Control and safety equipment 12

7.1 The instrument panel 12

7.1.1 General 12

7.1.2 Layout of the instrument panel 12

7.1.3 Indication LED’s 13

7.1.4 Manual override (hand/auto or

forced modes ‘high’ and ‘low’) 13

7.1.5 Display of values with more than

two digits 14

7.2 Flow diagram control system 14

7.3 Operating mode (x [[) 15

7.4 Shut-off mode (b XX) 16

7.5 Setting mode user level (X [[) 17

7.5.1 Flow temperature setpoint (!) 17

7.5.2 Pump run on time (@) 18

7.5.3 Boiler control setting (A) 18

7.6 Setting mode service level (only for the

qualified service engineer) (X [[) 18

7.6.1 Low fire start point ($) 19

7.6.2 Boiler output to indicate high

fire (%) 20

7.6.3 Maximum output (6) 20

7.6.4 Forced part load and running

time (& en *) 20

7.6.5 Cycling prevention delay-time (() 20

7.6.6 Start and end point for analog

signal (a and B) 20

7.6.7 PWM pump position (C and D) 20

7.6.8 dT from control stop point to start

point (E) 20

7.6.9 Maximum flue gas tempe/

rature (F) 20

7.6.10 High limit temperature

setpoint (G) 20

7.6.11 Modulation start point dT (H) 20

7.6.12 Minimum water pressure (I) 21

7.6.13 Adjustments options/

accessories (J) 21

7.6.14 Base point internal compen/

sation slope (L) 21

7.6.15 Boiler type (P) 21

7.7 Read-out mode (X [[) 21

7.8 Failure mode(X [[) (service level) 22

7.9 Counter mode (1, , and .)

(service level) 22

7.9.1 Hours Run 23

7.9.2 Successful ignition attempts 23

7.9.3 Total start attempts 23

8 Installation instructions 24

8.1 General 24

8.2 Delivery, positioning and support surface 24

8.3 Flue gas discharge and air supply 25

8.3.1 General 25

8.3.2 Classification due to discharging

flue gases 26

8.3.3 Material and installation 26

8.3.4 Single boiler conventional flue 26

8.3.5 Single boiler, room sealed flue 27

8.3.6 Different pressure zones 27

8.3.7 Cascade flue systems 28

8.4 Installation details 28

8.4.1 Condensate discharge 28

8.4.2 Water treatment 28

8.4.3 Safety valve 29

8.4.4 Water circulation 29

8.5 Multiple installation 29

9 Electrical installation 31

9.1 General 31

9.2 Electrical specifications 31

9.2.1 Power supply 31

9.2.2 Automatic Controls 31

9.2.3 Fuse specification 31

9.2.4 Boiler temperature control 31

9.2.5 Low water protection

(flow and content) 31

9.2.6 High limit protection 31

9.2.7 Differential air pressure

switch (LD2) 31

9.3 Electrical connections 31

9.4 Boiler control 33

9.5 Safety interlocks 34

9.5.1 Shutdown interlock 34

9.5.2 Lockout interlock 34

9.6 Remaining outputs 34

9.6.1 Analog output 34

9.6.2 Indicating module No.1 35

2

9.7 Options/accessories 35

9.7.1 Provision for thermostat pocket 35

9.7.2 Water pressure sensor 35

9.7.3 Differential pressure sensor 35

9.7.4 Gas valve proving (only for

120, 160 and 200 kW boilers) 35

9.7.5 Minimum gas pressure switch 36

9.7.6 Indicating module No.2 36

9.8 Remaining connections 36

9.8.1 System pump 36

9.8.2 Frost protection 36

10 Commissioning 37

10.1 Initial lighting 37

10.2 Shutdown 39

11 Fault-finding 40

11.1 General 40

11.2 Overview malfunctions (locking) 40

12 Inspection and maintenance instructions 43

12.1 General 43

12.2 Combustion control 43

12.2.1 Corrective maintenance 43

12.2.2 Cleaning the IMS 43

12.2.3 Fan cleaning 43

12.2.4 Heat exchanger cleaning (exterior) 44

12.2.5 Burner cleaning 44

12.3 Lubrication Integrated Mixing System (IMS) 44

12.4 Siphon cleaning 44

12.5 Ignition probe control 44

12.6 Leakage control 44

12.7 Hydraulic pressure control 44

3

PREFACE

Remeha Gas 210 ECO

Read these instructions carefully before putting the

boiler into operation, familiarise yourself with its control

functions, operation and strictly observe the instructions

given. Failure to do so may invalidate warranty or prevent the boiler from operating.

The installation and commissioning of the boiler must be

carried out by a competent Engineer, with the relevant

certification i.e.: CORGI, ACOPS, IEE regs. On completion a copy of the commissioning sheet should be

returned to Broag Ltd. for record purposes.

If you have any questions, or if you need more information about specific subjects relating to this boiler or its

installation please do not hesitate to contact us.

The data published in these technical instructions is

based on the latest information (at date of publication)

and may be subject to revisions.

We reserve the right to continuous development in both

design and manufacture, therefore any changes to the

technology employed may not be retrospective nor may

we be obliged to adjust earlier supplies accordingly.

Fig. 01 Artist impression Gas 210 ECO

3D.AL.21H.000001

4

1 SAFETY INSTRUCTIONS

1.1 Symbols

The following symbols are used in this document to

emphasise certain instructions. This is in order to

increase your personal safety and to safeguard the technical reliability of the boiler.

g Instructions must be followed closely to avoid

personal injury or serious damage to the unit or the

environment.

g Important!! Instructions are of essential

importance for the correct functioning of the unit.

w Indicates possible danger of electric shock. Seri-

ous personal injury may occur.

i Instructions contain useful information.

Read and familiarise yourself with these instructions.

General Instructions

Keep unauthorised personnel away from the boiler. Do

not place objects on or against the boiler. Do not touch

hot water connections or the flue outlet when the boiler

is operating – burn hazard.

Casing panels should only be removed for maintenance and servicing purposes.

Refit all panels on completion of maintenance or servicing before putting the boiler back into service.

Instruction and warning labels on the boiler must

never be removed or covered and must be clearly legible throughout the entire service life of the boiler. Damaged or illegible instruction and warning labels must be

replaced immediately.

Generally applicable safety instructions related to accident prevention must be consulted in addition to the

information supplied in this technical documentation.

Boiler modifications and spare parts

The boiler must not be modified or non-Remeha spare

parts fitted without the express written approval of

Remeha.

w Danger

This boiler is connected to a 230v mains supply. An

improper installation or attempts to repair electrical components or controls may result in life threatening situations.

g Be aware of gas escapes

If you smell gas, close the (main) gas cock and contact

the emergency gas leak telephone number for your

area. DO NOT ISOLATE THE POWER SUPPLY TO

THE BOILER OR ANY OTHER APPLIANCE.

g Be aware of flue gas leaks

If you smell flue gas fumes, turn the boiler off and contact your service company or installer.

g Be aware of water leaks

If you see water leaking from the boiler, turn it off and

contact your Service Company or installer.

g Working on the boiler

Installation, commissioning, maintenance and repair

work must only be carried out by suitably qualified specialist. Engineer in accordance with all relevant national/

local standards and certifications.

Always disconnect the mains supply and close the main

gas cock before working on the boiler.

5

2 GENERAL BOILER DESCRIPTION

The Remeha Gas 210 ECO boiler is a pre-assembled,

free standing, gas fired, high efficiency condensing

boiler.

The sectional cast aluminium heat exchanger and other

major components are contained within a sealed air

box. This forms the main boiler casing with a removable

inspection hatch for maintenance purposes. All electrical

and electronic controls are contained within the instrument panel mounted on top of the boiler.

The flue gas outlet, combustion air inlet, flow, return and

gas connections are located on the top of the boiler with

a condensate connection at low level on the right hand

side.

The boiler is suitable for room sealed or open flue applications and has been designed for central heating and

indirect hot water production at working pressures not

exceeding 6 bar. It must be installed on a fully pumped

system and is suitable for use on both sealed and open

vented installations (minimum operating pressure open

vented 0.3 bar).

The pre-mix gas burner (NG only) with its gas/air ratio

control system ensures clean, trouble free operation

with higher than average efficiencies 109% (NCV) in

the condensing mode combined with ultra low NO

and

X

minimum CO emissions. The standard control package

allows actual and set values to be read and adjusted

on the built in digital display which also provides normal

operating and fault code indication.

An intelligent, advanced boiler control (‘abc

®

’) continuously monitors the boiler conditions, varying the heat

output to suit the system load. The control is able to

react to external “negative” influences in the rest of the

system (flow rates, air / gas supply problems) maintaining boiler output for as long as possible without resorting

to a lockout condition. At worst the boiler will reduce its

output and/or shutdown (shut off mode) awaiting the

“negative” conditions to return to normal before re-starting.

The ‘abc®’ control cannot override the standard flame

safety controls.

Every Remeha Gas 210 ECO is checked following

assembly by means of a test computer to ensure its

proper operation.

Remeha Gas 210 ECO

The boiler meets the requirements of the EC regulations

of the directives:

- Gas Appliances Directive, 90/ 396/ EEC

- Efficiency Directive, 92/ 42/ EEC

- E.M.C. Directive, 89/ 336/ EEC

- Electrical Low Voltage Directive, 73/23/EEC

- Pressure Equipment Directive, no. 97/ 23/ EEC, art.

3, item 3.

CE Reference number : 0063 BL 3264.

6

3 CONSTRUCTION

3.1 Boiler layout

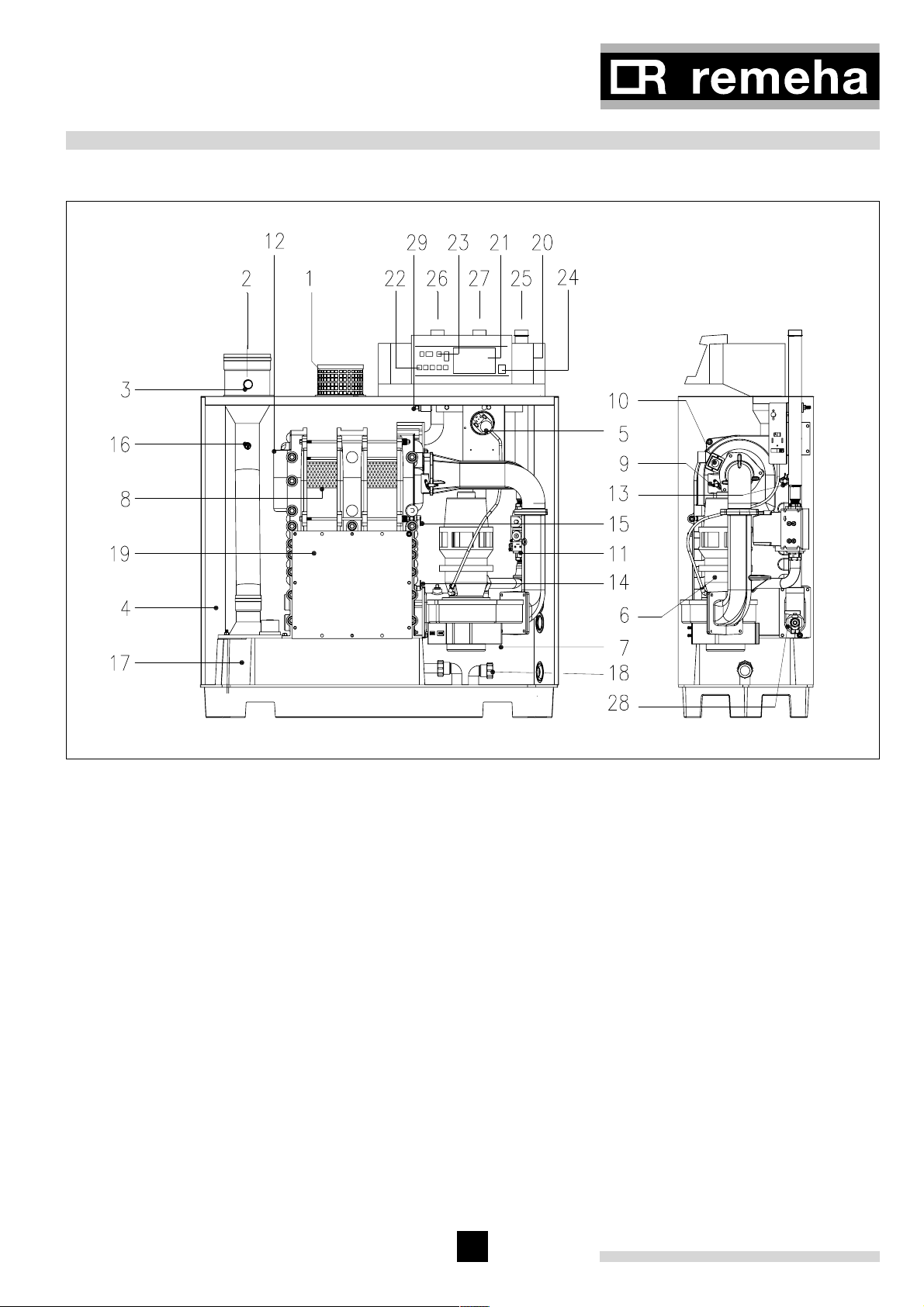

Fig. 02 Cut away view of Remeha Gas 210 ECO (160

kW model shown)

1. air supply

2. flue gas outlet

3. combustion test point (O

/CO2)

2

4. sealed air box

5. differential air pressure switch (LD2)

6. IMS gas-air ratio control

7. air supply fan

8. pre-mix, fibre faced burner

9. combined ignition/ionisation probe

10. sight glass

11. gas valve multiblock (with governor)

12. cast aluminium, sectional heat exchanger

13. temperature sensor - flow

14. temperature sensor - return

15. temperature sensor - heat exchanger

16. temperature sensor - flue gas

17. drain pan (condensate)

18. condensate connection

19. heat exchanger inspection hatch

20. instrument panel

21. facility for incorporating a rematic® weather

compensator (optional)

22. boiler setting keys

23. read-out display and reset key

24. on/off switch

25. gas connection

26. flow connection

27. return connection (standard)

28. drain cock and optional second return connection

(when fitted) or optional low level return connection

instead of standard return connection

29. connection for optional thermostat pocket (for use

with external sequence control).

7

3.2 Operation principle

Combustion air is drawn into the closed air box through

the air inlet from the plant room (open flued) or from

outside via the eccentric flue system (room sealed) by

an air supply fan.

On the inlet side of the fan is a specially designed IMS

(Integrated Mixing System) gas / air ratio control unit

which takes gas from the gas valve multiblock and

mixes it in the correct proportions with the incoming air.

The IMS-system includes regular auto-calibration (every

12 hours), which guarantees a constant air/gas ratio.

Therefore this mechanical mixing system ensures the

correct mixture is delivered to the pre-mix burner at all

times.

Depending on demand (under the dictates of flow/

return sensor and other external/internal control inputs)

the 'abc®' system determines the boiler output, which

directly controls the volume of mixed gas and air to the

premix burner. This mixture is initially ignited by the

combined ignition/ionisation probe, which monitors the

state of the flame. Should the flame be unstable or not

ignite within the pre-set safety time cycle the controls

will (after 5 attempts) shut the boiler down requiring

manual intervention to reset the boiler. The digital display will indicate a flashing fault code confirming the

reason for the failure.

The products of combustion in the form of hot flue gases

are forced through the heat exchanger transferring their

heat to the system water (the flue gas temperature is

reduced to approximately 5°C above the temperature of

the system return water). Then they are discharged via

the condensate collector, vertically through the 150 mm

connection to atmosphere.

Because of the low flue gas exit temperature there will

be a vapour cloud formed at the flue gas terminal - this

is not smoke, simply water vapour formed during the

combustion process.

If the controls allow the flow and therefore return temperature to fall below dew point (55°C) this water vapour

will begin to condense out in the boiler, transferring its

latent heat into the system water, increasing the output

of the boiler without increasing the gas consumption.

Condensation formed within the boiler and flue system

is discharged from the boiler to an external drain via the

drain pan / siphon supplied.

The boiler can be supplied, as an option with a

second (fixed temperature) return connection. This

additional connection enables the boiler to make full use

of its condensing ability whilst accepting both fixed and

variable temperature returns from the same system.

Fig. 01

Remeha Gas 210 ECO

8

4 TECHNICAL DATA AND DIMENSIONS

4.1 Dimensions

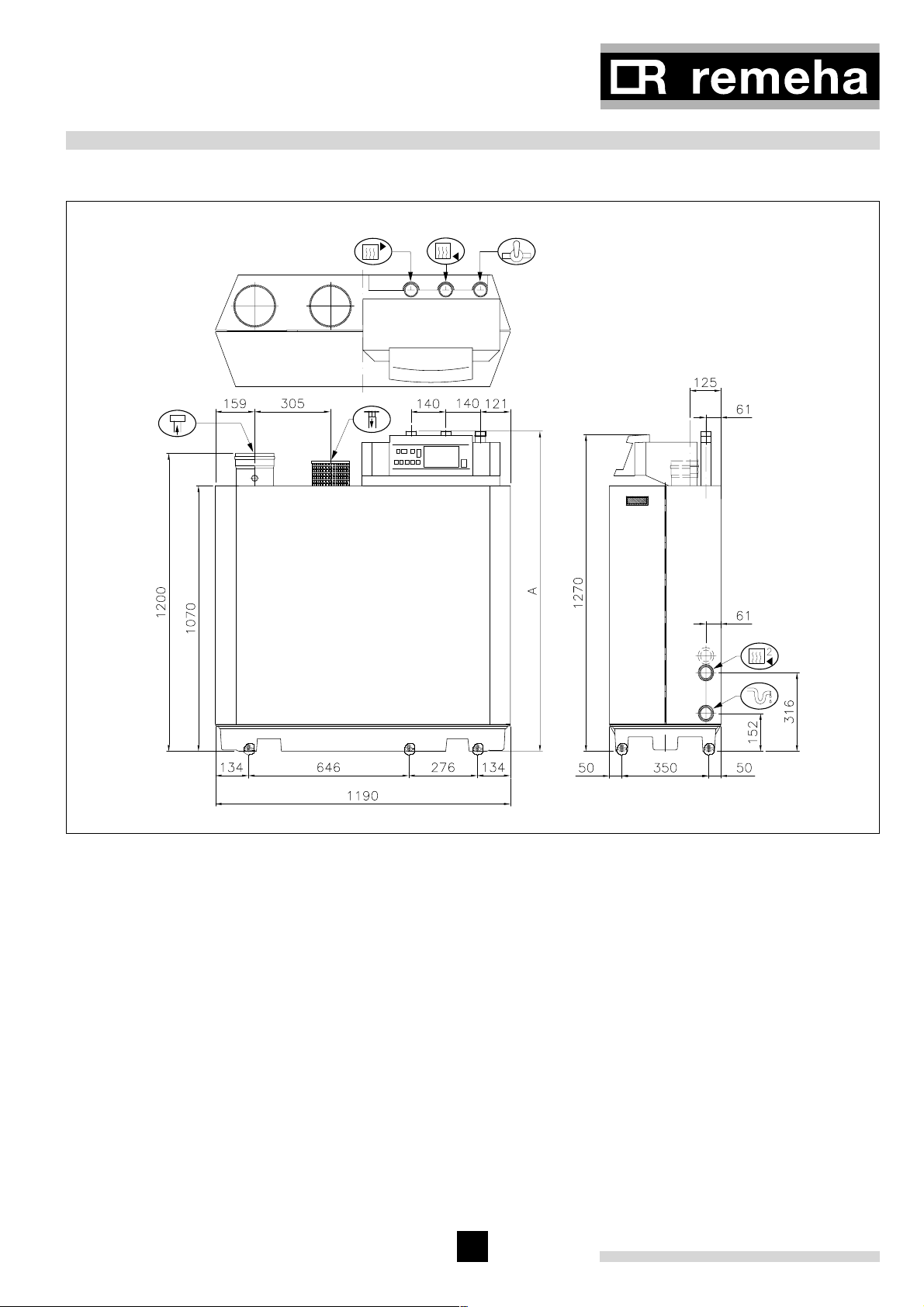

Fig. 03 View drawings

É Flow connection 80, 120 en 160 kW: 1¼" BSP (m) ; 200 kW: 1½” BSP (m)

Ê Return connection (standard) 80, 120 en 160 kW: 1¼" BSP (m) ; 200 kW: 1½” BSP (m)

Ï Gas connection 1¼" BSP (m)

Ò Condensate connection 32 mm o/d (plastic)

Ñ Flue gas connection 150 mm i/d

Ð Combustion air supply connection 150 mm i/d

Ì Second return connection* 1¼" BSP (m) (optional).

Height A 80, 120 en 160 kW: 1290 mm; 200 kW: 1305 mm

*or optional low level return connection instead of standard return connection

9

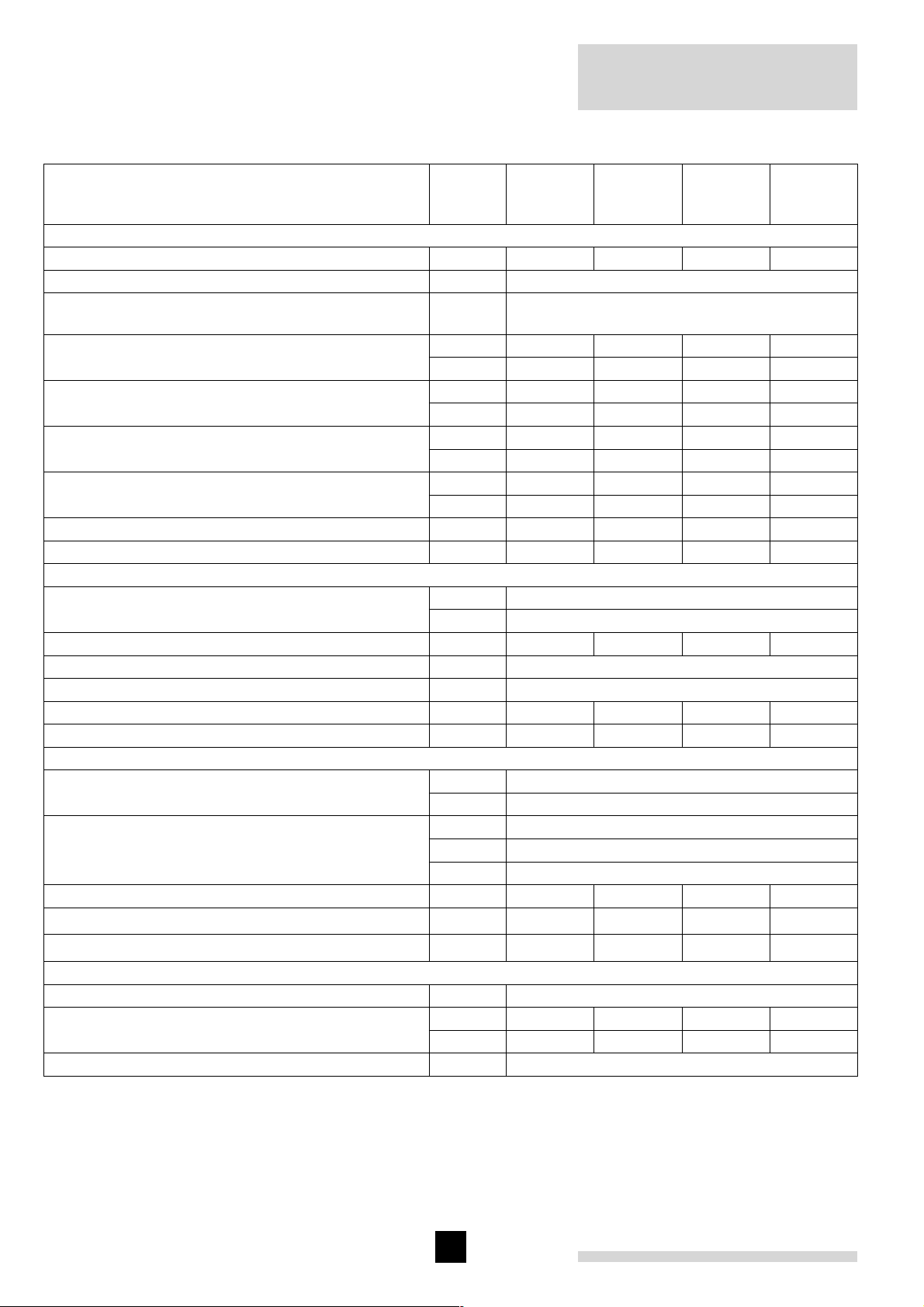

4.2 Technical data

Remeha Gas 210 ECO

Remeha

Boiler type

General

Number of sections qty. 3456

Casing Colour BS RAL 2002 (red) / 9023 (grey)

Boiler control options

(external input, two wire control)

Nominal output (80/60°C) Pn min. kW 8 12 16 20

max. kW 80 120 160 200

Nominal output (40/30°C) Pn min. kW 8.9 13.5 18.1 22.7

max. kW 86 129 171 214

Nominal input (GCV / Hs) Qn min. kW 9.3 14 18.7 23.3

max. kW 90.6 135.6 181.1 227

Nominal input (NCV / Hi) Qn min. kW 8.4 12.6 16.8 21

max. kW 81.5 122 163 204

Weight dry kg 130 150 170 200

Noise level at 1m from boiler, room sealed dBA ≤ 57 ≤ 59

Gas and Flue

Inlet pressure gas min. mbar 17

max. mbar 50

Gas consumption (natural gas) m3/h 8.6 12.9 17.2 21.6

NOX-emission mg/kWh < 35

NOX-emission (O2 = 0%, dry) ppm < 20

Residual fan duty Pa 115 100 100 140

Flue gas mass kg/h 137 205 274 343

Water side

Flow temperature max. °C 110

operating °C 20 - 90

Operating pressure - open vented min. bar 0.3

- closed min. bar 0.8

PMS max. bar 6

Water contents liter 12 16 20 24

Water resistance at 11°C dT

Water resistance at 20°C dT

Electrical

Main supply V / Hz 230 / 1 / 50

Power consumption min. Watt 68 58 69 75

max. Watt 92 84 110 160

Insulation class IP 20

Table 01 Technical data

mbar 496 446 536 720

mbar 150 135 162 180

Gas 210

ECO - 80

On/off, High/low, Analog 0-10V Communicating

Remeha

Gas 210

ECO - 120

Modulation

Remeha

Gas 210

ECO - 160

Remeha

Gas 210

ECO - 200

10

4.3 Quotation specifications

- Cast aluminium - sectional pre-mix gas fired boiler

- Sectional heat exchanger manufactured from cast

aluminium

- Maximum operating pressure of 6 bar

- Maximum operating temperature of 90°C

- Ultra low NO

(max. 20 ppm, O2= 0%, dry)

X

- Pre-mix, fully modulating (10-100%) gas burner with

unique IMS gas/air ratio control for maximum efficiency

- Intelligent advanced boiler control 'abc®' c/w a comprehensive operating, service and fault diagnostic

facility

- No minimum flow requirement

- Available as conventional flue or room sealed operation

- Capable of remote BMS control (0-10V modulating,

on/off and high/low option)

- Socket for advanced service diagnostics (for PC connection)

- Supplied fully factory assembled and tested

- Powder coated enamel steel casing BS RAL colour

2002 (red) / 9023 (grey)

- Sealed air box construction for maximum safety

- Suitable for use with Natural gas

- Supplied as standard with on/off switch, temperature

indication, flow, return, heat exchanger block and flue

gas sensors and hours run indication

- Supplied as standard with indicating module No. 1

lockout indication (Volt free), shutdown indication (Volt

free), boiler on indication (24 Volt AC)

- Efficiencies up to 109% (NCV / Hi)

- Manufactured to ISO 9001

- CE approved.

4.4 Optional Accessories

- Modulating weather-compensated / optimising boiler

controls for single and multiple installations

- Thermostat pocket

- Second return connection

- Water pressure sensor

- Air supply filter c/w air supply connecting piece (for

use during building construction)

- Vertical room sealed terminal c/w air supply connecting piece

- Indicating module No. 2 indicating operation, boiler on

and high fire (Volt free)

- Recom communication kit (includes CD-rom, interface

and wiring)

- Interface for communication with several boiler controls (see par. 9.4)

- Special cleaning tool

- Valve leak proving system

- Minimum gas pressure switch

- Low level return connection.

11

5 EFFICIENCY INFORMATION

Remeha Gas 210 ECO

5.1 Annual efficiency

Up to 108.2% at Hi (up to 97% at Hs) at an average

water temperature of 35°C (40/30°C).

5.2 Heat to water efficiency

a. Up to 98% at Hi (88% at Hs) at an average water

temperature of 70°C (80/60ºC).

b. Up to 109% at Hi (98% at Hs) at an average water

temperature of 35°C (40/30ºC).

6 APPLICATION INFORMATION

The Gas 210 ECO can be used on all new and refurbishment projects in both single and multiple configurations. Conventional and room sealed flue system

capability means that the boiler can be sited almost anywhere within a building. The Remeha range of weather

compensators (options) are able to communicate

7 CONTROL AND SAFETY EQUIPMENT

5.3 Standing losses

< 0.3% at Hi (0.33% at Hs) at an average water temperature of 45°C.

i NCV = Hi, GCV = Hs

directly with the boiler controls to make full use of its

fully modulating feature, ensuring that the boiler closely

matches the system demand at all times. External control systems (BMS) can be interfaced with the boiler to

provide on/off - high/low or modulating (0-10V) control

options.

7.1 The instrument panel

7.1.1 General

The boiler is supplied with a standard set of defaults

pre-programmed for normal operation but can be

tailored by the Engineer to suit most site conditions.

These values are set and read using the built in control

panel or with a note book computer (with optional

software and interface).

For security the control has three levels of access:

1. User level - free access

2. Service level - access with service code by qualified

personnel

3. Factory level - access by PC with factory code

(Remeha only).

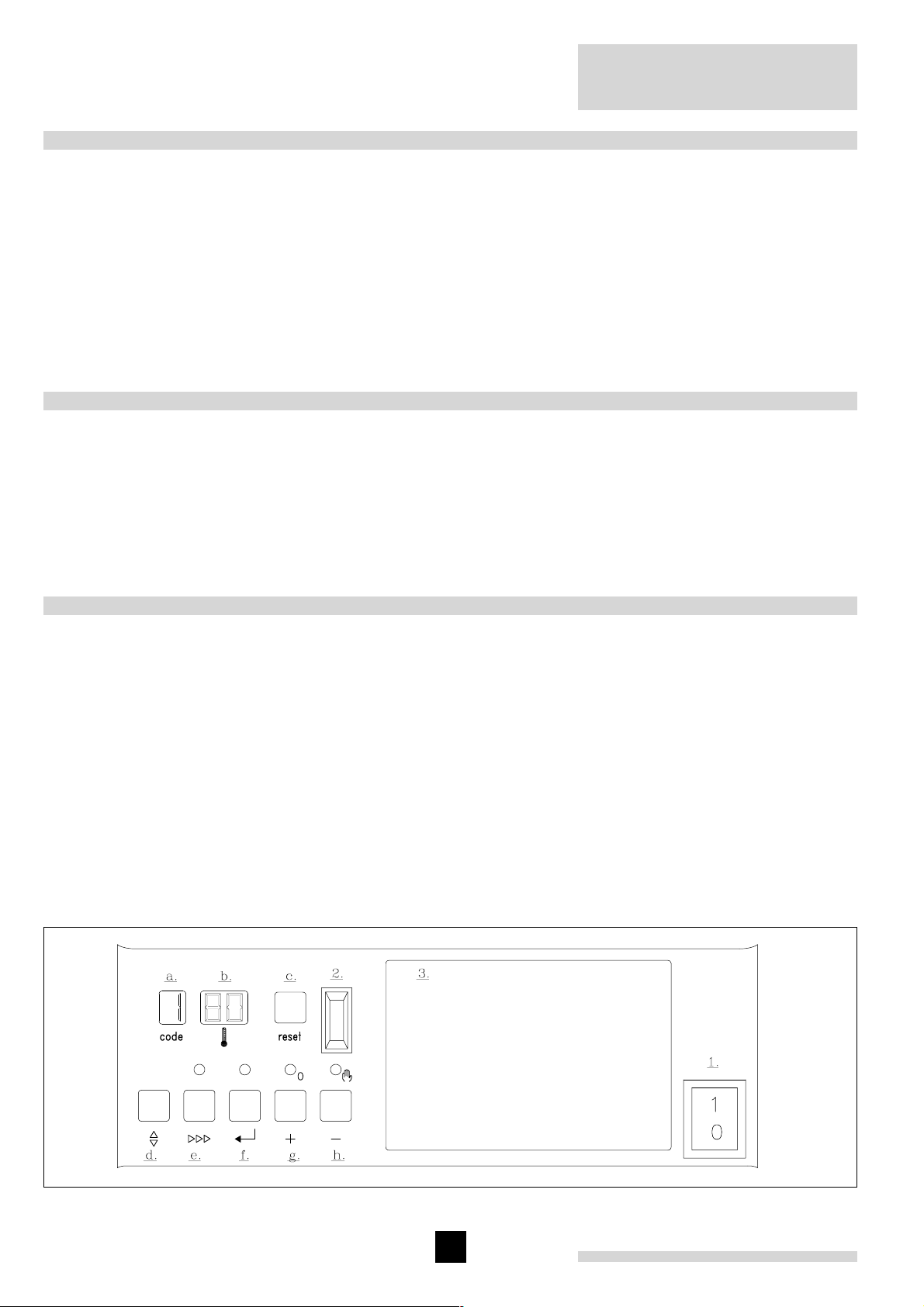

7.1.2 Layout of the instrument panel

The instrument panel consists of the following components (see Fig. 04 and Table 02):

1 Operation switch

2 PC/ PDA connection for Recom setting and

monitoring

3 Facility for incorporating an optimising / weather

compensator

The functions of keys and displays (letters a - h) are

explained in Table 02.

Fig. 04 Instrument panel

12

a. code-display

Indicates on user level:

Additional indication on service

level:

b. t-display

Indicates: temperatures

c. reset-key: to reset boiler after a lockout

d. m-key:

e. s-key:

f. e-key:

g. [+]-key: program function: to select a higher setting

h. [-]-key: program function: to select a lower setting

h. [-]-key held for 2 seconds switch function: manual override (hand/auto)

Table 02 Instrument panel functions

operating mode - 1 digit or letter

setting mode - ! digit or letter with dot

read-out mode - ! digit or letter with flashing dot

shut-off mode - letter b

forced full load - letter h

forced part load - letter l

test phase IMS - letter t

failure mode - 1 digit flashes

boiler run information mode - successively 1 + , + .

settings

shut-off codes

lockout codes

program function: key to select the required mode (mode-key)

program function: key to select the required program within the selected mode

(step-key)

program function: key to save the settings (store-key)

7.1.3 Indication LED's

The instrument panel has two indicating LED's.

1. The LED above the [-]-key (in the h-symbol) when

illuminated green confirms the boiler is in manual

override (see par. 7.1.4).

2. The LED above the [+]-key (in the 0-symbol) when

illuminated green confirms that the IMS system is

completely closed (rest position).

7.1.4 Manual override (hand/auto or forced modes

'high' and 'low')

Some of the keys on the instrument panel have a double function.

- Normal function - program input (see par. 7.5 and

7.6)

- Manual override - (during these modes as described

below the flow temperature cannot exceed its pre-set

maximum).

Hand/auto

When the [-]-key is pressed and held for 2 seconds the

boiler will run, even if external controls are not calling for

heat. The green LED above this key (in the h-symbol)

will illuminate indicating manual override.

By pressing and holding for 2 seconds the [-]-key, the

boiler will return to normal (auto control).

g Attention: A (system) pump that isn't

connected to the terminal strip of the boiler control

will not be activated!

Forced mode 'high' (h [[)

By pressing the m and [+]-key simultaneously in operating mode during 2 seconds, the boiler will run at

maximum power. The letter h will now appear on the

display.

By pressing the [+]- and [-]-keys simultaneously, the

boiler will return to operating mode.

Following a manual override the boiler will return to

normal (auto control) if no keys are used within a

15-minute period.

Forced mode 'low' (l [[)

By pressing the m and [-]-key simultaneously in operating mode, the boiler will run at minimum power. The

letter l will now appear on the display.

By pressing the [+]- and [-]-keys simultaneously, the

boiler will return to operating mode.

Following a manual override the boiler will return to normal (auto control) if no keys are used within a 15-minute

period.

13

Remeha Gas 210 ECO

7.1.5 Display of values with more than two digits

The display has only two digits available therefore values over this are displayed as follows:

- negative values will be indicated by a dot behind the

last digit e.g. 1) = -10

- values from 00 to 99 will be indicated without any

punctuation marks

- values from 100 to 199 will be indicated by a dot

between both digits e.g. )0 = 100, !0 = 110,

(9 = 199

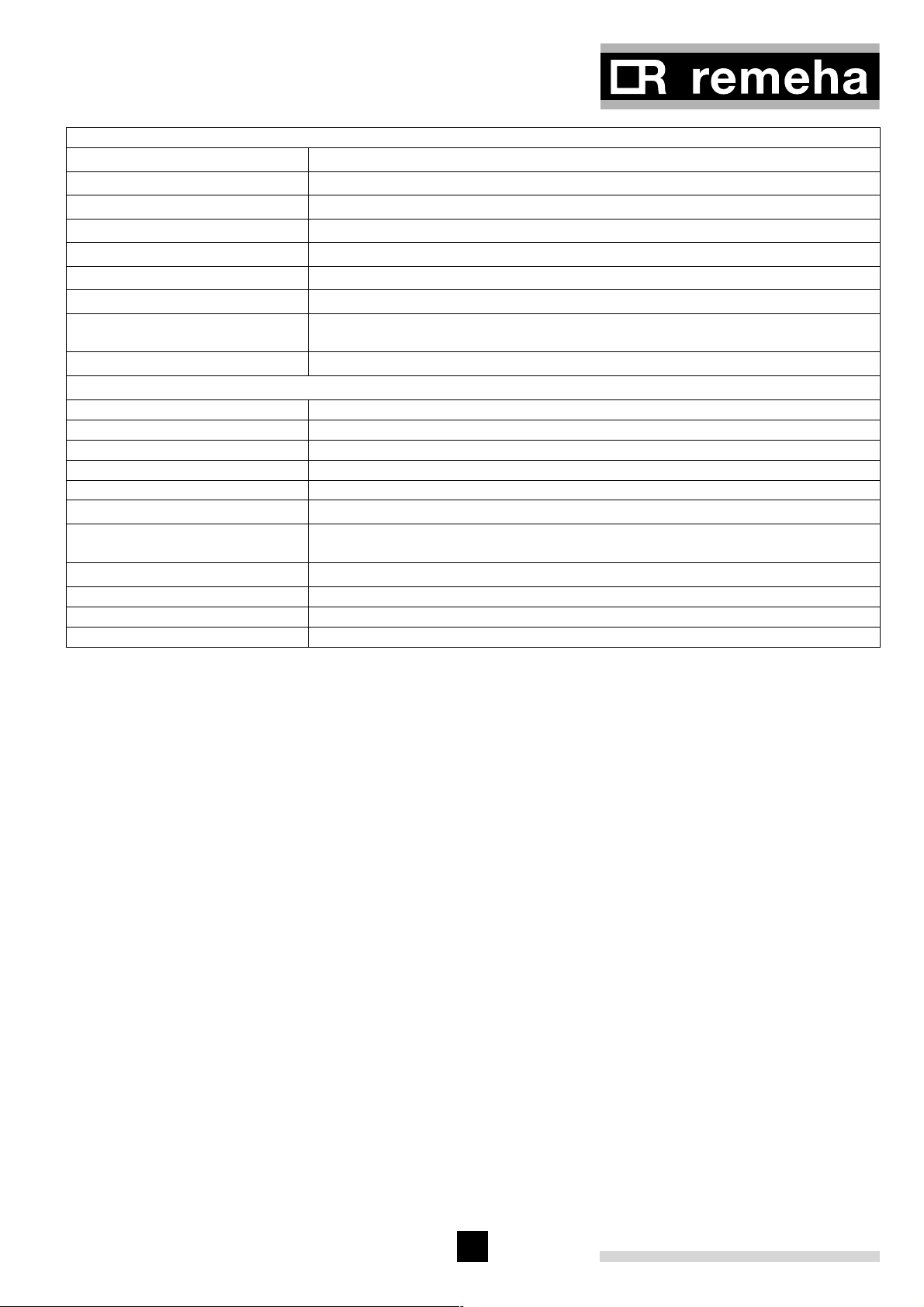

press the m-key press the s-key

Operating mode,

see par. 7.3

Setting mode,

see par. 7.5 and

7.6

code-display

only digit or letter

0 - 9, h, l, b, t

digit or letter with dot

!

@

A

service engineer level only:

$

%

^

&

*

(

a

B

C

D

E

F

G

H

I

J

L

P

t-display

Flow temperature, shut-off code

Flow temperature setpoint

Pump run on time

Boiler control setting

Low fire start point as percentage

Boiler output as % to indicate high fire*

Maximum output

Forced part load

Forced part load running time

Cycling prevention delay-time

Start point for 0 Volt analogue signal

End point for 10 Volt analogue signal

n/a

n/a

dT from control stop point to start point

n/a

High limit temperature setpoint

Modulation start point dT

Minimum water pressure*

Adjustments options/accessories

n/a

Boiler type, factory set

- values from 200 to 299 will be indicated by a dot

behind every digit e.g. )) = for 200, !) = 210,

(( = 299

- values over 300 will be indicated by showing the

thousands, hundreds, tens and units in separate alternating pairs.

7.2 Flow diagram control system

Read-out mode,

see par. 7.7

digit or letter with flashing dot

!

@

Actual flow temperature

Actual return temperature

14

#

$

%

^

&

*

(

A

B

C

D

E

F

G

H

Actual flue gas temperature

Actual outdoor temperature (with outside temperature sensor)

Actual heat exchanger temperature

Flow temperature (setpoint)

Actual heat demand status and differential air pressure switch

position

Actual open to close time IMS

Requested output

Calculated or actual output

Status IMS

Actual valve position IMS

Actual water pressure*

Actual ∆p over burner and heat exchanger*

Actual fan speed

Actual ionisation level

Minimum position IMS

Failure mode,

see par. 7.8

Counter mode,

see par. 7.9

* Note: Only active when optional module / sensor is fitted.

Table 03 Flow diagram control system

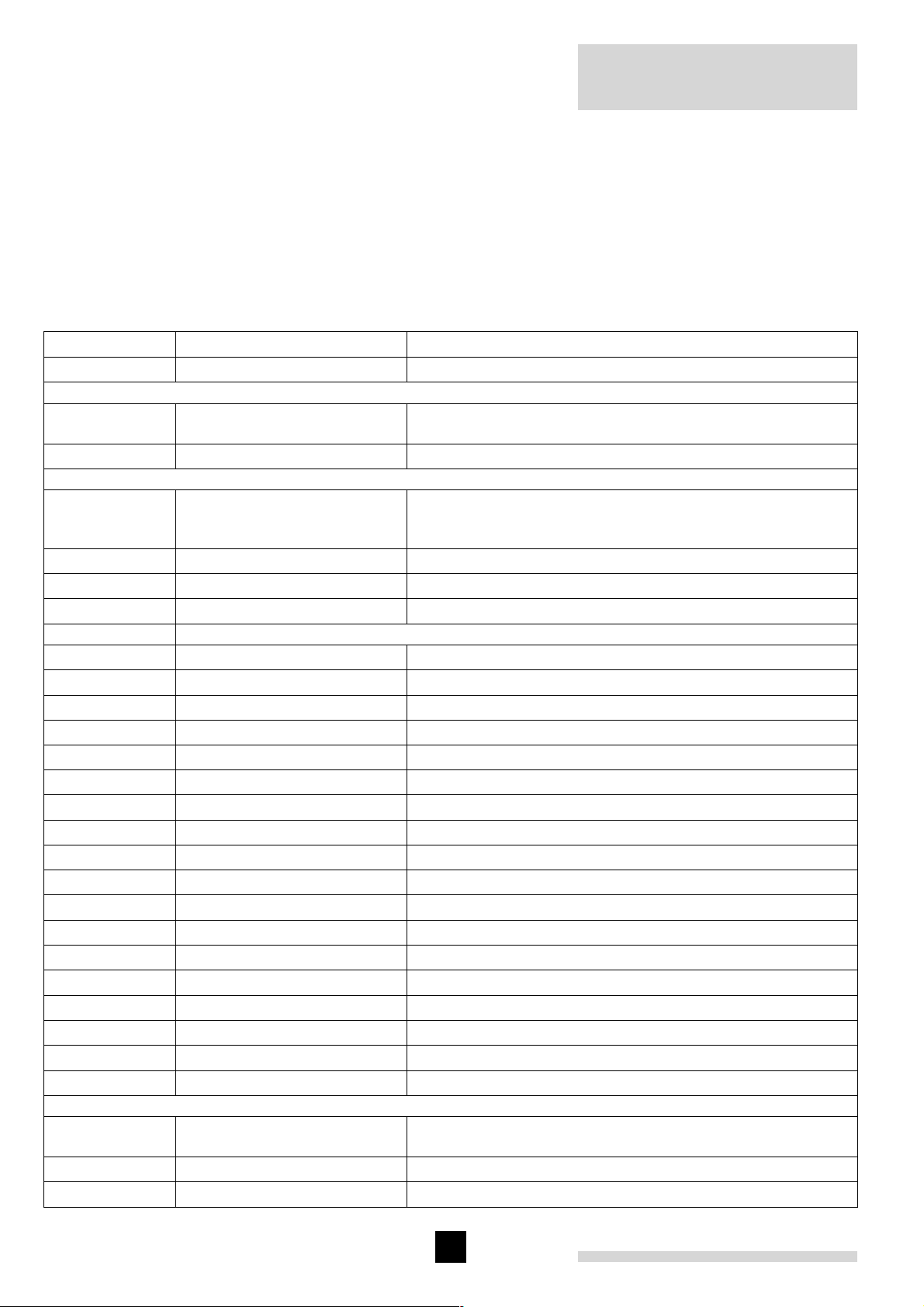

7.3 Operating mode (x [[)

During normal operation the code-display shows the

status (position in cycle) of the boiler, with the t-dis-

play indicating the actual flow temperature.

digit flashes digits flash

1

2

3

4

5

6

digit + , + .

1, ,, .

2, ,, .

3, ,, .

Failure code (chapter 11)

Operating mode during failure (par. 7.3)

Flow temperature during failure

Return temperature during failure

Flue gas temperature during failure

Position of IMS during failure

digits flash

Number of operating hours burner

Number of successful ignition attempts

Total number of start attempts

The digits or letters in the code-display have the following meaning:

15

Loading...

Loading...